Page 1

TI00150R/09/EN/05.16

71315973

Products Solutions Services

Technical Information

RMA42

Process transmitter with control unit

Digital process transmitter for monitoring and

visualizing analog measured values

Application

• Plant and apparatus engineering and construction

• Control rooms and cabinets

• Laboratories

• Process recording and supervision

• Process control

• Signal adjustment and signal conversion

• WHG compliant limit signal transmitter

Your benefits

• 5-digit, 7-segment backlit LC display

• User-configurable dot matrix display range for bar graph, units and tag name

• 1 or 2 universal inputs

• 2 relays (optional)

• Min./max. value saved

• 1 or 2 calculated values

• One linearization table with 32 points for each calculated value

• 1 or 2 analog outputs

• Digital status output (open collector)

• Operation using 3 keys

• Configuration via interface and FieldCare or DeviceCare software

Page 2

Measuring principle

Analog in 1

Analog in 2

RMA42

Function and system design

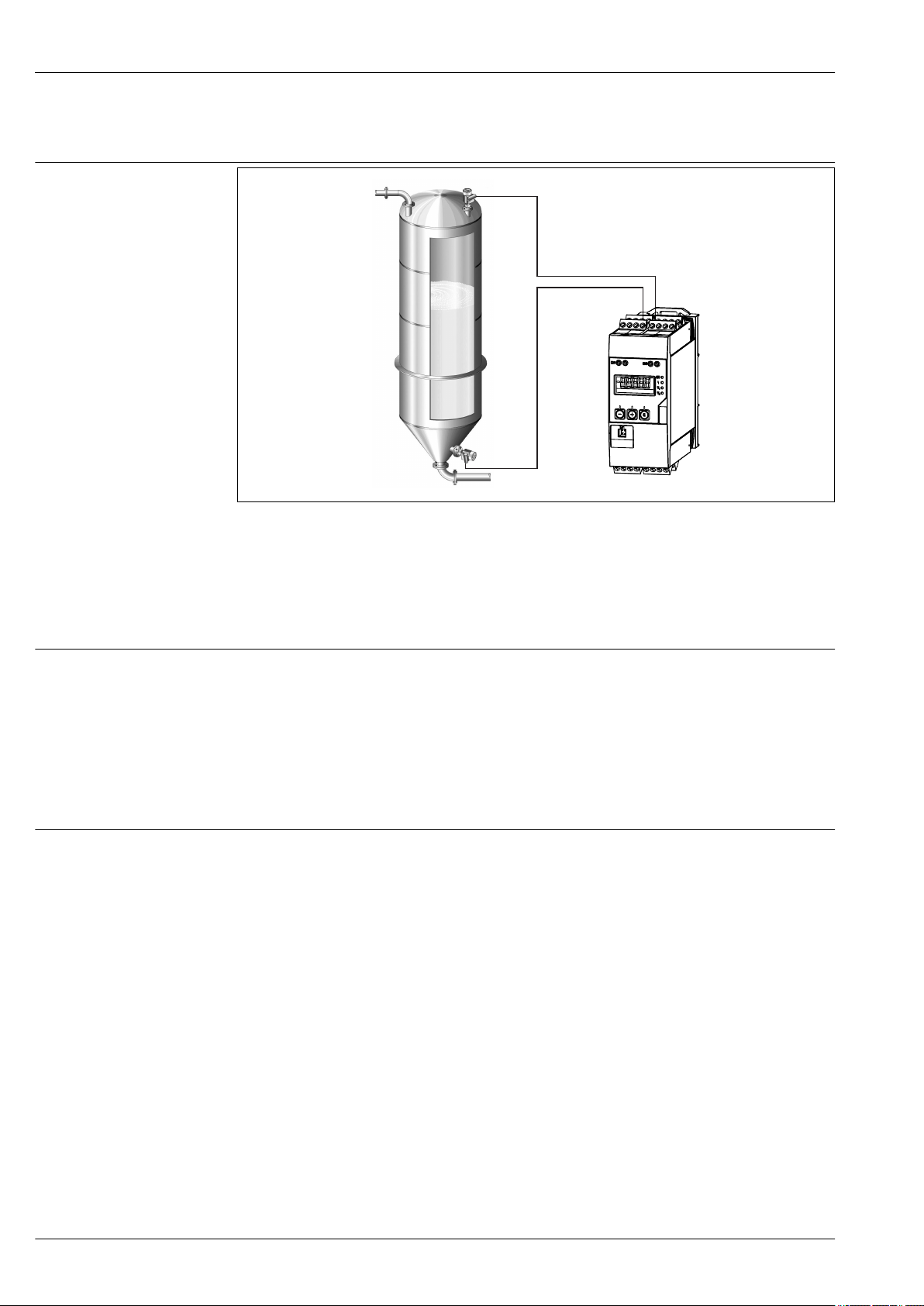

A0011762

1 Example for "differential pressure" application

Measuring system

Mathematics functions

The RMA42 process transmitter powers the transmitter and processes analog signals from

transmitters, particularly from the area of process instrumentation. These signals are monitored,

evaluated, calculated, saved, separated, linked, converted and displayed. The signals, intermediate

values and the results of calculations and analysis are transmitted by digital or analog means.

The RMA42 is a process transmitter, which is controlled by a microcontroller, and exhibits a display,

analog inputs for process and status signals, analog and digital outputs, as well as an interface for

configuration.

Connected sensors (e.g. temperature, pressure) can be powered by the integrated transmitter power

supply system. The signals to be measured are converted from analog to digital signals, processed

digitally in the device, and then converted from digital to analog signals and made available to the

various outputs. All measured values, and values calculated in any way, are available as a signal

source for the display, all outputs, relays and the interface. It is possible to make multiple use of the

signals and results (e.g. a signal source as an analog output signal and limit value for a relay).

The following mathematics functions are available in RMA42:

• Sum

• Difference

• Multiplication

• Mean

• Linearization

Linearization function

Up to 32 user-definable points are available in the device per calculated value to linearize the input,

e.g. for tank linearization. In the case of the two-channel device (option), mathematics channel M2

can be used to linearize mathematics channel M1.

Linearization is also available in the FieldCare configuration software.

2 Endress+Hauser

Page 3

RMA42

Input

Measured variable

Measuring ranges

Current, voltage, resistance, resistance thermometer, thermocouples

Current:

• 0/4 to 20 mA +10% overrange

• Short-circuit current: max. 150 mA

• Load: 10 Ω

Voltage:

• 0 to 10 V, 2 to 10 V, 0 to 5 V, 0 to 1 V, 1 to 5 V, ±1 V, ±10 V, ±30 V, ±100 mV

• Max. permitted input voltage:

Voltage ≥ 1 V: ±35 V

Voltage < 1 V: ±12 V

• Input impedance: > 1 000 kΩ

Resistance:

30 to 3 000 Ω

Resistance thermometer:

• Pt100 as per IEC60751, GOST, JIS1604

• Pt500 and Pt1000 as per IEC60751

• Cu100, Cu50, Pt50, Pt46, Cu53 as per GOST

• Ni100, Ni1000 as per DIN 43760

Thermocouple types:

• Typ J, K, T, N, B, S, R as per IEC60584

• Typ U as per DIN 43710

• Typ L as per DIN 43710, GOST

• Typ C, D as per ASTM E998

Number of inputs

Update time

Galvanic isolation

One or two universal inputs

200 ms

Towards all other circuits

Endress+Hauser 3

Page 4

Output

RMA42

Output signal

Loop power supply

Switching output

One or two analog outputs, galvanically isolated

Current/voltage output

Current output:

• 0/4 to 20 mA

• Overrange up to 22 mA

Voltage:

• 0 to 10 V, 2 to 10 V, 0 to 5 V, 1 to 5 V

• Overrange: up to 11 V, short-circuit proof, I

< 25 mA

max

HART®

HART® signals are not affected

• Open-circuit voltage: 24 VDC (+15% /-5%)

Ex version: > 14 V at 22 mA

Non-hazardous operation: > 16 V at 22 mA

• Maximum 30 mA short-circuit-proof and overload-proof

• Galvanically isolated from system and outputs

Open Collector for monitoring of the device state and alarm notification. The OC output is closed in

normal state. In error state, the OC output is opened.

• I

= 200 mA

max

• U

= 28 V

max

• U

= 2 V at 200 mA

on/max

Galvanic isolation towards all other circuits; test voltage 500 V

Relay output

Relay output for limit function

Relay contact Changeover

Maximum contact burden DC 30 V / 3 A (permanent state, without destruction of the input)

Maximum contact burden AC 250 V / 3 A (permanent state, without destruction of the input)

Minimum contact load 500 mW (12 V/10 mA)

Galvanic isolation towards all other circuits Test voltage 1 500 V

Switching cycles > 1 million

AC

4 Endress+Hauser

Page 5

RMA42

Terminal assignment

Power supply

2 Terminal assignment of the process transmitter (relays (terminals Rx1-Rx3) and channel 2 (terminals

21-28 and O25/O26) optional)

Supply voltage

Power consumption

Connection data interface Commubox FXA291 PC USB interface

Wide-area power supply unit 24 to 230 V AC/DC (-20 % / +10 %) 50/60 Hz

Max. 21.5 VA / 6.9 W

• Connection: 4-pin connector

• Transmission protocol: FieldCare

• Transmission rate: 38,400 Baud

Interface cable TXU10-AC PC USB interface

• Connection: 4-pin connection

• Transmission protocol: FieldCare

• Delivery scope: Interface cable incl. FieldCare Device Setup DVD with all Comm DTMs and Device

DTMs

A0011798

Endress+Hauser 5

Page 6

Performance characteristics

RMA42

Reference operating conditions

Power supply: 230 VAC, 50/60 Hz

Ambient temperature: 25 °C (77 °F) ± 5 °C (9 °F)

Humidity: 20 %...60 % rel. humidity

Maximum measured error Universal input:

Accuracy Input: Range: Maximum measured error of

measuring range (oMR):

Current 0 to 20 mA, 0 to 5 mA, 4 to 20 mA; Overrange: up to

22 mA

Voltage ≥ 1 V 0 to 10 V, 2 to 10 V, 0 to 5 V, 1 to 5 V, 0 to 1 V, ±1 V,

±10 V, ±30 V

Voltage < 1 V ±100 mV ±0.05%

Resistance measurement 30 to 3 000 Ω 4-wire: ± (0.10% oMR + 0.8 Ω)

RTD Pt100, –200 to 850 °C (–328 to 1 562 °F) (IEC60751,

α=0.00385)

Pt100, –200 to 850 °C (–328 to 1 562 °F) (JIS1604,

w=1.391)

Pt100, –200 to 649 °C (–328 to 1 200 °F) (GOST,

α=0.003916)

Pt500, –200 to 850 °C (–328 to 1 562 °F) (IEC60751,

α=0.00385)

Pt1000, –200 to 600 °C (–328 to 1 112 °F) (IEC60751,

α=0.00385)

Cu100, –200 to 200 °C (–328 to 392 °F) (GOST,

w=1.428)

Cu50, –200 to 200 °C (–328 to 392 °F) (GOST, w=1.428)

Pt50, –200 to 1 100 °C (–328 to 2 012 °F) (GOST,

w=1.391)

Pt46, –200 to 850 °C (–328 to 1 562 °F) (GOST,

w=1.391)

Ni100, –60 to 250 °C (–76 to 482 °F) (DIN43760,

α=0.00617)

Ni1000, –60 to 250 °C (–76 to 482 °F) (DIN43760,

α=0.00617)

Cu53, –50 to 200 °C (–58 to 392 °F) (GOST, w=1.426) 4-wire: ± (0.10% oMR + 0.3 K (0.54 °F))

Thermocouples Typ J (Fe-CuNi), –210 to 1 200 °C (–346 to 2 192 °F)

(IEC60584)

Typ K (NiCr-Ni), –200 to 1 372 °C (–328 to 2 502 °F)

(IEC60584)

Typ T (Cu-CuNi), –270 to 400 °C (–454 to 752 °F)

(IEC60584)

Typ N (NiCrSi-NiSi), –270 to 1 300 °C (–454 to 2 372 °F)

(IEC60584)

Typ L (Fe-CuNi), –200 to 900 °C (–328 to 1 652 °F)

(DIN43710, GOST)

Typ D (W3Re/W25Re), 0 to 2 495 °C (32 to 4 523 °F)

(ASTME998)

Typ C (W5Re/W26Re), 0 to 2 320 °C (32 to 4 208 °F)

(ASTME998)

Typ B (Pt30Rh-Pt6Rh), 0 to 1 820 °C (32 to 3 308 °F)

(IEC60584)

±0.05%

±0.1%

3-wire: ± (0.10% oMR + 1.6 Ω)

2-wire: ± (0.10% oMR + 3 Ω)

4-wire: ± (0.10% oMR + 0.3 K (0.54 °F))

3-wire: ± (0.10% oMR + 0.8 K (1.44 °F))

2-wire: ± (0.10% oMR + 1.5 K (2.7 °F))

4-wire: ± (0.10% oMR + 0.3 K (0.54 °F))

3-wire: ± (0.10% oMR + 0.8 K (1.44 °F))

2-wire: ± (0.10% oMR + 1.5 K (2.7 °F))

3-wire: ± (0.10% oMR + 0.8 K (1.44 °F))

2-wire: ± (0.10% oMR + 1.5 K (2.7 °F))

± (0.10% oMR +0.5 K (0.9 °F))

from –100 °C (–148 °F)

± (0.10% oMR +0.5 K (0.9 °F))

from –130 °C (–202 °F)

± (0.10% oMR +0.5 K (0.9 °F))

from –200 °C (–328 °F)

± (0.10% oMR +0.5 K (0.9 °F))

from –100 °C (–148 °F)

± (0.10% oMR +0.5 K (0.9 °F))

from –100 °C (–148 °F)

± (0.15% oMR +1.5 K (2.7 °F))

from 500 °C (932 °F)

± (0.15% oMR +1.5 K (2.7 °F))

from 500 °C (932 °F)

± (0.15% oMR +1.5 K (2.7 °F))

from 600 °C (1 112 °F)

6 Endress+Hauser

Page 7

RMA42

Accuracy Input: Range: Maximum measured error of

measuring range (oMR):

Typ S (Pt10Rh-Pt), –50 to 1 768 °C (–58 to 3 214 °F)

(IEC60584)

Typ U (Cu-CuNi), –200 to 600 °C (–328 to 1 112 °F) (DIN

43710)

AD converter resolution 16 bit

Temperature drift Temperature drift: ≤ 0.01%/K (0.1%/18 °F) oMR

≤ 0.02%/ K (0.2%/18 °F) oMR for Cu100, Cu50, Cu53, Pt50 and Pt46

Analog output:

Current 0/4 to 20 mA, overrange bis 22 mA ±0.05% of measuring range

Max. load 500 Ω

Max. inductivity 10 mH

Max. capacity 10 µF

Max. ripple 10 mVpp at 500 Ω, frequency < 50 kHz

Voltage 0 to 10 V, 2 to 10 V

0 to 5 V, 1 to 5 V

Overrange: up to 11 V, shortcircuit proof, I

Max. ripple 10 mVpp at 1 000 Ω, frequency < 50 kHz

Resolution 13 bit

Temperature drift ≤ 0.01%/K (0.1%/18 °F) of measuring range

Galvanic isolation Testing voltage of 500 V towards all other circuits

< 25 mA

max

±0.05% of measuring range

±0.1 % of measuring range

± (0.15% oMR +3.5 K (6.3 °F))

für –50 to 100 °C (–58 to 212 °F)

± (0.15% oMR +1.5 K (2.7 °F))

from 100 °C (212 °F)

± (0.15% oMR +1.5 K (2.7 °F))

from 100 °C (212 °F)

Installation

Mounting location

Orientation

Mounting on top-hat rail as per IEC 60715.

Vertical or horizontal.

NOTICE

Heat accumulation when installing several devices on a vertically mounted top-hat rail

Keep sufficient gaps between the individual devices.

‣

Environment

Ambient temperature range NOTICE

The life-time of the display is shortened when operated in the upper temperature range.

To avoid heat accumulation, always make sure the device is sufficiently cooled.

‣

Non-Ex/Ex devices: –20 to 60 °C (–4 to 140 °F)

UL devices: –20 to 50 °C (–4 to 122 °F)

Storage temperature

Operating height

–40 to 85 °C (–40 to 185 °F)

< 2 000 m (6 560 ft) above MSL

Endress+Hauser 7

Page 8

RMA42

115 (4.53)

45 (1.77) 118 (4.65)

Climate class

Degree of protection

Electrical safety

Condensation

Electromagnetic compatibility (EMC)

Design, dimensions

As per IEC 60654-1, Klasse B2

Top-hat rail housing IP 20

Protection class II, overvoltage category II, pollution degree 2

Not permitted

• Interference immunity:

To IEC 61326 industrial environments / NAMUR NE 21

• Interference emissions:

To IEC 61326 Class A

Mechanical construction

3 Dimensions of the process transmitter in mm (in)

Weight

Material

Terminals

Approximately 300 g (10.6 oz)

Housing: plastic PC-GF10

Screw terminals, plug-in, 2.5 mm2 (14 AWG), 0.1 to 4 mm2 (30 to 12 AWG), torque

0.5 to 0.6 Nm (0.37 to 0.44 lbf ft)

A0011792

8 Endress+Hauser

Page 9

RMA42

1

2

3

4

5

6

7

8

3

5

4

6

2

1

Local operation

Operability

A0011767

4 Display and operating elements of the process transmitter

1 HART® connection sockets

2 Display

3 Operating keys

4 PC interface connection port

5 Green LED; on = supply voltage applied

6 Red LED; on = error/alarm

7 Yellow LED; on = relay 1 energized

8 Yellow LED; on = relay 2 energized

A0011765

5 Display of the process transmitter

1 Channel display: 1: analog input 1; 2: analog input 2; 1M: calculated value 1; 2M: calculated value 2

2 Measured value display

3 Dot matrix display for TAG, bar graph and unit

4 Limit value indicators in the bar graph

5 "Operation locked" indicator

6 Minimum/maximum value indicator

• Display

5-digit, 7-segment backlit LC display

Dot matrix for text/bar graph

• Display range

-99999 to +99999 for measured values

• Signaling

– Setup security locking (lock)

– Measuring range overshoot/undershoot

– 2 x status relay (only if relay option was selected)

Operating elements

3 keys: -, +, E

Remote operation Configuration

The device can be configured with the PC software or on site using the operating keys. FieldCare

Device Setup is delivered together with the Commubox FXA291 or TXU10-AC (see ’Accessories’) or

can be downloaded free of charge from www.endress.com.

Endress+Hauser 9

Page 10

RMA42

Interface

4-pin socket for the connection with a PC via Commubox FXA291 or TXU10-AC interface cable (see

'Accessories')

Certificates and approvals

CE mark

EAC mark

Ex approval

Overfill prevention

Functional safety

Marine approvals

UL

CSA

Power station

Other standards and guidelines

The measuring system meets the legal requirements of the applicable EC guidelines. These are listed

in the corresponding EC Declaration of Conformity together with the standards applied. Endress

+Hauser confirms successful testing of the device by affixing to it the CE mark.

The product meets the legal requirements of the EEU guidelines. The manufacturer confirms the

successful testing of the product by affixing the EAC mark.

Information about currently available Ex versions (ATEX, FM, CSA, etc.) can be supplied by your E+H

Sales Center on request. All explosion protection data are given in a separate documentation which

is available upon request.

WHG-compliant limit signal transmitter (optional)

SIL2 (optional)

German Lloyd (GL, optional)

UL recognized component (see www.ul.com/database, search by keyword "E225237")

CSA General Purpose (CSA GP)

Seismic test according to KTA3505 (optional)

• IEC 60529:

Degrees of protection provided by enclosures (IP code)

• IEC 61010-1:

Safety Requirements for Electrical Equipment for Measurement, Control and Laboratory Use

• EN 60079-11:

Explosive atmospheres - Part 11: Equipment protection by intrinsic safety "I" (optional)

Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser website: www.endress.com -> Click "Corporate"

-> Select your country -> Click "Products" -> Select the product using the filters and search field ->

Open product page -> The "Configure" button to the right of the product image opens the Product

Configurator.

• From your Endress+Hauser Sales Center: www.addresses.endress.com

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

10 Endress+Hauser

Page 11

RMA42

Accessories

Various accessories, which can be ordered with the device or subsequently from Endress+Hauser, are

available for the device. Detailed information on the order code in question is available from your

local Endress+Hauser sales center or on the product page of the Endress+Hauser website:

www.endress.com.

Communication-specific accessories

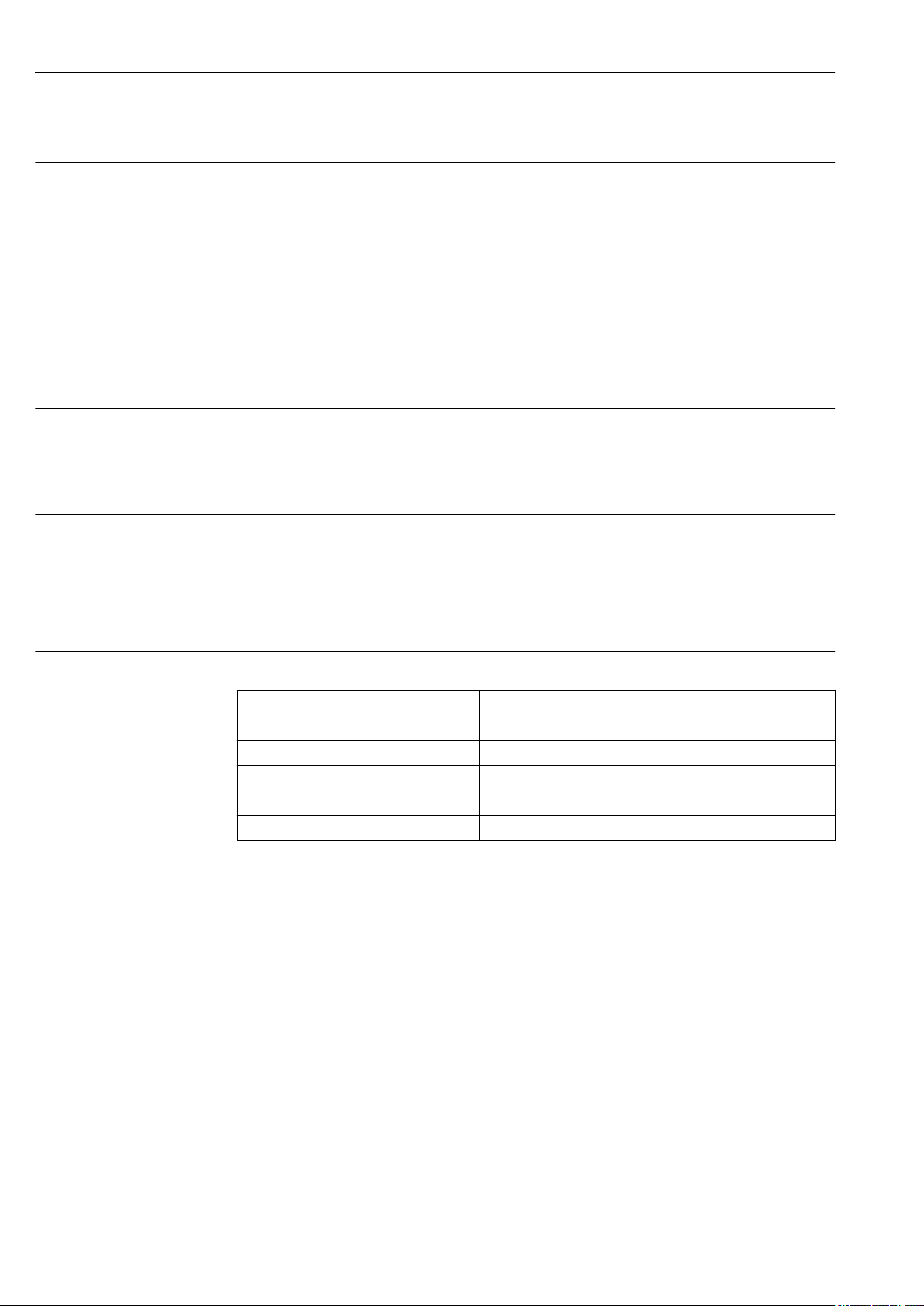

Designation

Interface cable

Commubox TXU10 incl. FieldCare Device Setup and DTM Library

Commubox FXA291 incl. FieldCare Device Setup and DTM Library

Supplementary documentation

• System components and data manager - solutions to complete your measuring point:

FA00016K/09

• Operating Instructions for process transmitter RMA42: BA00287R/09

• Ex-related additional documentation:

ATEX II (1)G [Ex ia] IIC, ATEX II (1)D [Ex ia] IIIC: XA00095R/09

• SIL Safety Manual:

SD00025R/09

Endress+Hauser 11

Page 12

www.addresses.endress.com

Loading...

Loading...