Page 1

Products Solutions Services

Operating Instructions

RIA15

Loop-powered 4 to 20 mA process display unit

with HART® communication

BA01170K/09/EN/05.15

71300896

Valid as of FW version:

01.04.xx

Page 2

Page 3

Table of contents

Endress+Hauser 3

Table of contents

1 Document information .............. 4

1.1 Document function ..................... 4

1.2 Document conventions ................... 4

1.3 Registered trademarks ................... 6

2 Safety instructions .................. 7

2.1 Requirements for the personnel ............ 7

2.2 Designated use ........................ 7

2.3 Workplace safety ....................... 7

2.4 Operational safety ...................... 7

2.5 Product safety ......................... 8

3 Product description ................. 9

3.1 Function ............................. 9

3.2 Operating modes ....................... 9

3.3 Input channels ........................ 12

4 Identification ..................... 13

4.1 Nameplate ........................... 13

4.2 Scope of delivery ...................... 13

4.3 Certificates and approvals ............... 13

4.4 HART® protocol certification ............. 14

5 Installation ....................... 15

5.1 Incoming acceptance, transport, storage ..... 15

5.2 Installation conditions .................. 15

5.3 Installation instructions ................. 15

5.4 Post-installation check .................. 19

6 Wiring ............................ 21

6.1 Quick wiring guide ..................... 21

6.2 Connection in 4 to 20 mA mode ........... 22

6.3 Connection in HART mode ............... 22

6.4 Wiring with switchable backlighting ........ 27

6.5 Inserting the cable, field housing .......... 29

6.6 Shielding and grounding ................ 29

6.7 Connecting to functional grounding ........ 30

6.8 Degree of protection ................... 31

6.9 Post-connection check .................. 31

7 Operation ......................... 32

7.1 Operating functions .................... 32

8 Commissioning .................... 34

8.1 Post-installation check and switching on the

device .............................. 34

8.2 Operating matrix ...................... 34

8.3 Operating matrix in conjunction with the

Micropilot FMR20 ..................... 39

9 Troubleshooting .................. 41

9.1 Error limits as per NAMUR NE 43 ......... 41

9.2 Diagnostic messages ................... 41

9.3 Spare parts .......................... 44

9.4 Software history and overview of

compatibility ......................... 44

10 Maintenance ...................... 46

11 Return ............................ 47

12 Disposal .......................... 48

13 Accessories ....................... 49

13.1 Device-specific accessories ............... 49

13.2 Service-specific accessories ............... 50

14 Technical data .................... 51

15

HART® communication ............ 55

15.1

HART® protocol command classes .......... 55

15.2

HART® commands used ................. 56

15.3 Field device status ..................... 56

15.4 Supported units ....................... 57

15.5

HART® protocol connection types .......... 61

15.6 Device variables for multivariable devices .... 62

Index .................................. 63

Page 4

Document information RIA15

4 Endress+Hauser

1 Document information

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

1.2 Document conventions

1.2.1 Safety symbols

Symbol Meaning

DANGER

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTICE

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning

A0011197

Direct current

A terminal to which DC voltage is applied or through which direct current flows.

A0011198

Alternating current

A terminal to which alternating voltage is applied or through which alternating current flows.

A0017381

Direct current and alternating current

• A terminal to which alternating voltage or DC voltage is applied.

• A terminal through which alternating current or direct current flows.

A0011200

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a grounding

system.

A0011199

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

A0011201

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a potential

equalization line or a star grounding system depending on national or company codes of practice.

A0012751

ESD - Electrostatic discharge

Protect the terminals against electrostatic discharge. Failure to comply with this instruction can

result in the destruction of parts or malffunction of the electronics.

Page 5

RIA15 Document information

Endress+Hauser 5

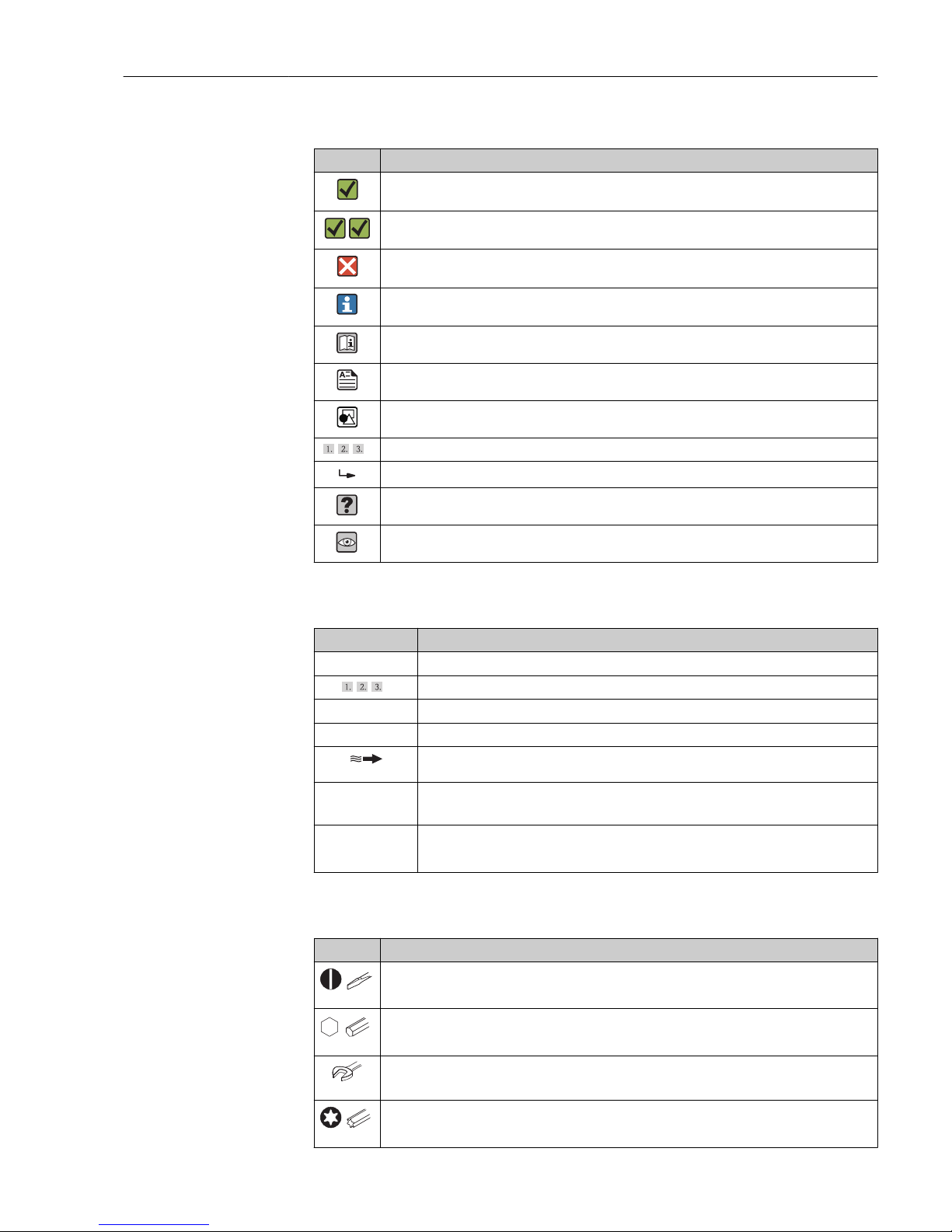

1.2.3 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

,…,

Series of steps

Result of a step

Help in the event of a problem

Visual inspection

1.2.4 Symbols in graphics

Symbol Meaning

1, 2, 3,... Item numbers

,…,

Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

A0013441

Flow direction

-

A0011187

Hazardous area

Indicates a hazardous area.

.

A0011188

Safe area (non-hazardous area)

Indicates a non-hazardous area.

1.2.5 Tool symbols

Symbol Meaning

A0011220

Flat blade screwdriver

A0011221

Allen key

A0011222

Open-ended wrench

A0013442

Torx screwdriver

Page 6

Document information RIA15

6 Endress+Hauser

1.3 Registered trademarks

HART®

Registered trademark of the HART® Communication Foundation

Page 7

RIA15 Safety instructions

Endress+Hauser 7

2 Safety instructions

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

‣

Trained, qualified specialists must have a relevant qualification for this specific function

and task

‣

Are authorized by the plant owner/operator

‣

Are familiar with federal/national regulations

‣

Before beginning work, the specialist staff must have read and understood the

instructions in the Operating Instructions and supplementary documentation as well as

in the certificates (depending on the application)

‣

Following instructions and basic conditions

The operating personnel must fulfill the following requirements:

‣

Being instructed and authorized according to the requirements of the task by the

facility's owner-operator

‣

Following the instructions in these Operating Instructions

2.2 Designated use

The process display unit displays analog process variables or HART ® process variables on

its screen.

The device is powered via the 4 to 20 mA current loop and does not require an additional

power supply.

• The manufacturer accepts no liability for damages resulting from incorrect use or use

other than that designated. It is not permitted to convert or modify the device in any

way.

• Panel-mounted device

The device is designed for installation in a panel and must only be operated in an

installed state.

• Field device:

The device is designed for installation in the field.

• The device may only be operated under the permitted ambient conditions → 52.

2.3 Workplace safety

For work on and with the device:

‣

Wear the required personal protective equipment according to federal/national

regulations.

2.4 Operational safety

Risk of injury.

‣

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

‣

If, despite this, modifications are required, consult with Endress+Hauser.

Page 8

Safety instructions RIA15

8 Endress+Hauser

Repair

To ensure continued operational safety and reliability,

‣

Carry out repairs on the device only if they are expressly permitted.

‣

Observe federal/national regulations pertaining to repair of an electrical device.

‣

Use original spare parts and accessories from Endress+Hauser only.

Environmental requirements

If a plastic transmitter housing is permanently exposed to certain steam and air mixtures,

this can damage the housing.

‣

If you are unsure, please contact your Endress+Hauser Sales Center for clarification.

‣

If used in an approval-related area, observe the information on the nameplate.

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EC

directives listed in the device-specific EC Declaration of Conformity. Endress+Hauser

confirms this by affixing the CE mark to the device.

Page 9

RIA15 Product description

Endress+Hauser 9

3 Product description

3.1 Function

Process display unit RIA15 is integrated in the 4 to 20 mA/HART® loop and transmits the

measuring signal in digital form. The process display unit does not require an external

power supply. It is powered directly from the current loop.

In connection with the radar level sensor Micropilot FMR20, the RIA15 can be used to

make the basic settings for the Micropilot FMR20. As a prerequisite the RIA15 must be

ordered with the respective option for the FMR20 basic setting.

The device meets the requirements of the HART® Communication Protocol Specifications

and can be used with devices with HART® Revision ≥ 5.0.

3.2 Operating modes

The process display unit can be used in two different operating modes:

4 to 20 mA mode:

In this operating mode, the process display unit is incorporated into the 4 to 20 mA

current loop and measures the transmitted current. The variable calculated based on the

current value and range limits is displayed in digital form on the 5-digit LCD. In addition,

the associated unit and a bar graph can be displayed.

HART mode:

The device functions as a display unit even when operating with a HART® sensor/actuator.

In this case, the display is also powered from the current loop.

The process display unit can choose to function as a primary master or secondary master

(default) in the HART® loop. When it functions as a master, the device can read process

values from the measuring device and display them. HART® communication operates on

the principle of master/slave. As a general rule, the sensor/actuator is a slave and only

transmits information if a request has been made by the master.

A HART® loop can have a maximum of two HART® masters at any one time. A distinction

is made between primary (e.g. the control system) and secondary master (e.g. handheld

terminal for on-site operation of the measuring devices) for these HART® masters. The

two masters in the loop/in the network cannot be masters of the same type, e.g. they

cannot be two "secondary masters".

If a third HART® master is added to the network, one of the other masters must be

disabled; otherwise a collision occurs in the network.

If the process display unit is operating as "secondary master" and another "secondary

master", e.g. a handheld device, is added to the network, the device interrupts HART®

communication as soon as it detects that there is another "secondary master". The display

alternates between error message C970 "Multi master collision" and "- - -". A measured

value is not displayed in this case. The device leaves the HART® loop for 30 seconds and

tries to re-establish HART® communication once again. Once the additional "secondary

master" is removed from the network, the device continues communication and displays

the measured values of the sensor/actuator once more.

Please note that if two process display units are to be used in a multidrop connection,

one device must be configured as "primary master" and the other as "secondary master"

to prevent a master collision.

In HART mode, the process display unit can show up to four device variables of a

multivariable measuring device. These variables are referred to as the Primary Variable

(PV), Secondary Variable (SV), Tertiary Variable (TV) and Quaternary Variable (QV). These

variables are placeholders for measured values that can be called up using HART®

communication.

Page 10

Product description RIA15

10 Endress+Hauser

For a flowmeter, such as the Promass, these four values can be as follows:

• Primary process variable (PV) →Mass flow

• Secondary process variable (SV) → Totalizer 1

• Third process variable (TV) → Density

• Fourth process variable (QV) → Temperature

The HART® section at the end of these Operating Instructions provides examples of these

four device variables for multivariable measuring devices → 62.

Please refer to the Operating Instructions for each device for details on the variables

that are set as default on the sensor/actuator and how they can be changed.

The process display unit can show each of these values. The individual values must be

activated in the SETUP – HART1 to HART4 menu for this purpose. The individual

parameters are assigned to fixed process variables in the device in this case:

HART1 = PV

HART2 = SV

HART3 = TV

HART4 = QV

For example, if the PV and TV are to be displayed on the process display unit, HART1 and

HART3 must be activated.

The values can either be shown alternately on the process display unit or one value is

displayed continuously and the other values are only shown by pressing '+' or '–'. The

switching time can be configured in the "EXPRT" – "SYSTM" – "TOGTM" menu.

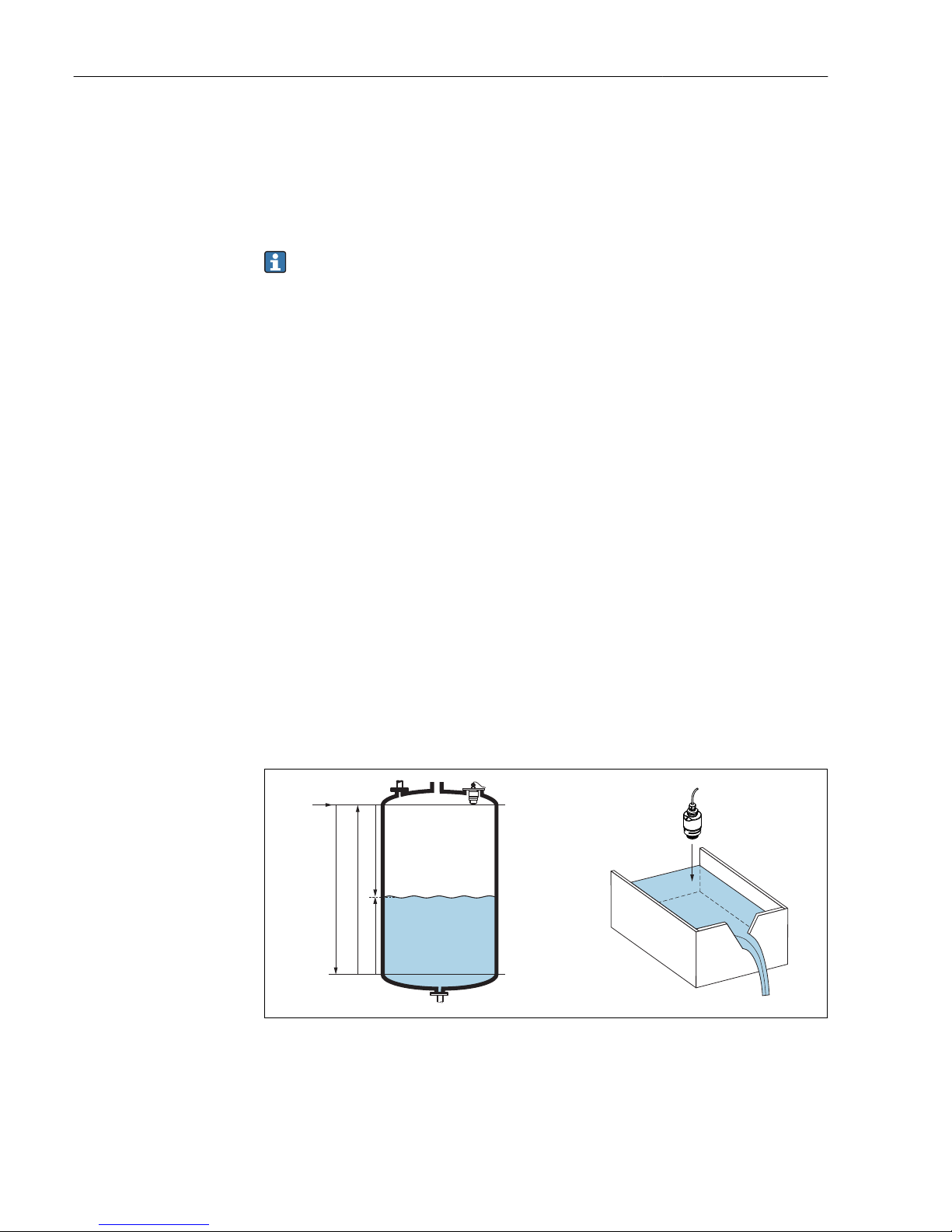

3.2.1 RIA15 as a remote display and for operation of the Micropilot

FMR20

The Micropilot is a "downward-looking" measuring system, operating based on the time-offlight method (ToF). It measures the distance from the reference point (process

connection) to the product surface. Radar impulses are emitted by an antenna, reflected

off the product surface and received again by the radar system.

The FMR20 can be adjusted under the "SETUP → LEVEL" menu (see operating matrix). The

measured value displayed corresponds to the distance measured or, if linearization is

enabled, to a percentage value.

D

Q

R

100%

0%

D

L

F

E

A0028409

1 Setup parameters of the Micropilot

E Empty calibration (= zero)

F Full calibration (= span)

D Measured distance

L Level (L = E - D)

Q Flow rate at measuring weirs or channels (calculated from the level using linearization)

Page 11

RIA15 Product description

Endress+Hauser 11

Input

The reflected radar impulses are received by the antenna and transmitted into the

electronics. A microprocessor evaluates the signal and identifies the level echo caused by

the reflection of the radar impulse at the product surface. This clear signal detection

system benefits from over 30 years' experience with time-of-flight procedures.

The distance D to the product surface is proportional to the time of flight t of the impulse:

D = c · t/2,

where c is the speed of light.

Based on the known empty distance E, the level L is calculated:

L = E – D

Output

The Micropilot is adjusted by entering the empty distance E (= zero point) and the

full distance F (= span).

• Current output: 4 to 20 mA

• Digital output (HART, SmartBlue): 0 to 10 m (0 to 33 ft) or 0 to 20 m (0 to 66 ft)

depending on antenna version

The RIA15 can be used as a local display unit and for the basic configuration of the

Micropilot FMR20 radar level sensor via HART®.

1

4

5

2

3

A0030964

2 Remote operation of the FMR20 via the RIA15

1 PLC

2 Transmitter power supply, e.g. RN221N (with communication resistance)

3 Connection for Commubox FXA195 and Field Communicator 375, 475

4 RIA15 loop-powered process display unit

5 Transmitter

For this, the RIA15 can either be ordered together with the FMR20 via the FMR20 product

structure, or the RIA15 must be ordered separately with option 3 "4 to 20 mA current

signal + HART + FMR20 basic configuration" in feature 030 "Input".

FMR20 product structure, feature 620 "Accessory enclosed":

• Option R4: "Remote display RIA15, non-hazardous"

• Option R5: "Remote display RIA15, hazardous"

RIA15 product structure, feature 030 "Input":

Option 3: "4 to 20 mA current signal + HART + FMR20 basic setting"

The following parameters can then be configured at the FMR20 via the 3 operating keys

on the front of the RIA15:

• Unit

• Empty and full calibration

• Mapping area if the measured distance does not match the actual distance

Further information on the operating parameters → 39

Page 12

Product description RIA15

12 Endress+Hauser

3.3 Input channels

The process display unit has one analog 4 to 20 mA input. In "HART" operating mode, this

channel can be used for measuring and displaying HART® values for a connected sensor/

actuator. In this case, a HART® device can be directly connected to the process display unit

in a point-to-point connection or the process display unit can be incorporated in a HART®

multidrop network.

The RIA15 can be used as a local display unit and for the basic configuration of the

Micropilot FMR20 radar level sensor via HART®.

Page 13

RIA15 Identification

Endress+Hauser 13

4 Identification

4.1 Nameplate

The nameplate is located on the right-hand side of the housing in the case of the field

device, and on the rear of the housing in the case of the panel-mounted device.

Ord. cd.: XXXXXXXX

Ser. no.: XXXXXXXXXXXXXXXXX

Ext. ord. cd.: RIA15-XXXXXXX

Ta= -40...+60°C

Front IP67 Type 4X Encl.

Loop powered 4...20 mA

RIA15

Made in Germany 2012

D-87484 Nesselwang

1

2

4

5

6

7

Class2 circuit or SELV circuit

3

9

8

A0019608

3 Nameplate of the process display unit (example)

1 Order code of the device 6 Device designation

2 Serial number of the device 7 Approvals (optional)

3 Extended order code of the device 8 Input signal

4 Manufacturer's address 9 Housing degree of protection

5 Ambient temperature range

4.2 Scope of delivery

The scope of delivery of the device comprises:

• Panel-mounted device

– Process display unit

– Brief Operating Instructions

– Ex Safety Instructions (optional)

– Fastening fixtures

– HART® communication resistance module (optional)

• Field device

– Process display unit

– Brief Operating Instructions

– Ex Safety Instructions (optional)

– Fastening fixtures for wall/pipe mounting (optional)

– HART® communication resistance module (optional)

– Weather protection cover (optional)

4.3 Certificates and approvals

An overview of all available approvals is provided in the "Technical data" section.

→ 54.

4.3.1 CE mark

The measuring system meets the legal requirements of the applicable EC guidelines. These

are listed in the corresponding EC Declaration of Conformity together with the standards

applied. Endress+Hauser confirms successful testing of the device by affixing to it the CE

mark.

Page 14

Identification RIA15

14 Endress+Hauser

4.3.2 EAC mark

The product meets the legal requirements of the EEU guidelines. The manufacturer

confirms the successful testing of the product by affixing the EAC mark.

4.4 HART® protocol certification

The RIA15 is registered by the HART® Communication Foundation. The device fulfills the

requirements of HCF Specification, Revision 7.1. This version is downwards compatible

with all sensors/actuators with HART® versions ≥ 5.0.

Page 15

RIA15 Installation

Endress+Hauser 15

5 Installation

5.1 Incoming acceptance, transport, storage

Compliance with the permitted environmental and storage conditions is mandatory.

Precise specifications for this are provided in the "Technical data" .

5.1.1 Incoming acceptance

On receipt of the goods, check the following points:

• Is the packaging or the content damaged?

• Is the delivery complete? Compare the scope of delivery against the information on your

order form.

5.1.2 Transport and storage

Please note the following:

• Pack the device so that is protected against impact for storage and transport. The

original packaging provides optimum protection.

• The permitted storage temperature is –40 to +85 °C (–40 to +185 °F); it is possible to

store the device at borderline temperatures for a limited period (48 hours maximum).

5.2 Installation conditions

At temperatures below –25 °C (–13 °F) the readability of the display can no longer be

guaranteed.

5.2.1 Display unit in the panel-mount housing

Permitted ambient temperature range –40 to 60 °C (–40 to 140 °F), horizontal orientation.

IP65 protection at front, IP20 at rear

See "Technical data" section .

5.2.2 Display unit in the field housing

Permitted ambient temperature range –40 to 60 °C (–40 to 140 °F). IP67 protection,

NEMA 4x (aluminum housing).

See "Technical data" section .

5.3 Installation instructions

For the dimensions of the device, see "Technical data" → 53.

Page 16

Installation RIA15

16 Endress+Hauser

5.3.1 Panel housing

1.

2.

A0017762

4 Installation instructions for the panel housing

Installation in a panel with a panel cutout 92x45 mm (3.62x1.77 in), max. panel thickness

13 mm (0.51 in).

1. Slot the device into the panel cutout from the front.

2. Fit the mounting clips on the side of the housing and tighten the threaded rods.

5.3.2 Field housing

Pipe mounting (with optional mounting kit)

The device can be mounted on a pipe with a diameter of up to 50.8 mm (2 in) with the

mounting kit (optionally available).

Page 17

RIA15 Installation

Endress+Hauser 17

2

1

5mm

4mm

1.

2.

3.

4.

TX20

A0017789

5 Mounting the process display unit on a pipe

1 Mounting plate for pipe/wall mounting

2 Weather protection cover (optional)

1. Release the 4 housing screws

2. Open the housing

3. Secure the mounting plate to the rear of the device with 4 screws supplied. The

optional weather protection cover can be secured between the device and the

mounting plate.

4. Guide the two gripper clamps through the mounting plate, fit them around the pipe

and tighten.

Wall mounting

With optionally available mounting kit.

Page 18

Installation RIA15

18 Endress+Hauser

1.

2.

3.

A0017803

6 Mounting the process display unit on a wall

1. Use the mounting plate as a stencil for 2 6 mm (0.24 in) bore holes, 82 mm (3.23 in)

apart, and secure the plate on the wall with 2 screws (not supplied).

2. Open the housing.

3. Secure the display unit on the mounting plate with the 4 screws supplied.

4. Close the cover and tighten the screws.

Without a mounting kit.

1. Open the housing.

2. Use the device as a stencil for 4 6 mm (0.24 in) bore holes, 99 mm (3.9 in) apart on

the horizontal plane, 66 mm (2.6 in) apart on the vertical plane.

3. Secure the display unit on the wall with 4 screws.

4. Close the cover and tighten the housing screws.

5.3.3

Mounting the optional HART® communication resistance

module

Panel housing

The HART® communication resistance module is available as an accessory, see section

Accessories → 49.

Page 19

RIA15 Installation

Endress+Hauser 19

A0020785

7

Mounting the optional HART® communication resistance module

1. Unplug the pluggable terminal block.

2.

Plug terminal block into the suitable plug-in position on the HART® communication

resistance module.

3.

Plug the HART® communication resistance module into the plug-in position on the

housing.

Field housing

The HART® communication resistance module is available as an accessory, see section

Accessories → 49.

A0020844

8

Mounting the optional HART® communication resistance module

1. Unplug the pluggable terminal block.

2.

Plug terminal block into the suitable plug-in position on the HART® communication

resistance module.

3.

Plug the HART® communication resistance module into the plug-in position in the

housing.

5.4 Post-installation check

5.4.1 Display unit in the panel-mount housing

• Is the seal undamaged?

• Are the mounting clips securely fastened on the housing of the device?

• Are the threaded rods properly tightened?

• Is the device located in the center of the panel cutout?

Page 20

Installation RIA15

20 Endress+Hauser

5.4.2 Display unit in the field housing

• Is the seal undamaged?

• Is the housing firmly screwed to the mounting plate?

• Is the mounting bracket firmly secured on the wall/pipe?

• Are the housing screws firmly tightened?

Page 21

RIA15 Wiring

Endress+Hauser 21

6 Wiring

L

WARNING

Danger! Electric voltage!

‣

The entire connection of the device must take place while the device is de-energized.

Only certified devices (optionally available) may be connected in the hazardous area

‣

Observe corresponding notes and wiring diagrams in the Ex-specific supplement to

these Operating Instructions. If you have any questions, please do not hesitate to

contact your E+H representative.

NOTICE

SELV/Class 2 device

‣

The device may only be powered by a power unit with an energy-limited circuit in

accordance with IEC 61010-1: 'SELV or Class 2 circuit'.

Device destroyed if current too high

‣

Do not operate the device at a voltage source without a current limiter. Instead, operate

the device only in the current loop with a transmitter.

• Panel housing:

The terminals are located on the rear of the housing.

• Field housing:

The terminals are located inside the housing. The device has two M16 cable entries. The

housing must be opened for wiring purposes.

Operation of the spring terminals

A0020848

9 Operation of the spring terminals

1. When using rigid cables with a ferrule, just plug the cable into the terminal. No tools

required. With flexible wires the spring mechanism of the terminal must be operated

as shown in step 2.

2. In order to loosen the cable, push the spring mechanism in completely using a

screwdriver or other suitable tool and pull out the cable.

6.1 Quick wiring guide

Terminal Description

+ Positive connection, current measurement

- Negative connection, current measurement (without backlighting)

LED Negative connection, current measurement (with backlighting)

Auxiliary terminals (electrically connected internally)

Functional grounding:

• Panel-mounted device:

Terminal on the rear of the housing

• Field device:

Terminal in the housing

Page 22

Wiring RIA15

22 Endress+Hauser

6.2 Connection in 4 to 20 mA mode

The following diagrams show how the process display unit is connected in 4 to 20 mA

mode.

Connection without backlighting Connection with backlighting

Connection with transmitter power supply

and transmitter

LED

-

+

-

-

+

+

I

Y

1

A0017704

1 Transmitter power supply

+

+

I

Y

1

-

-

LED

-

+

A0017705

1 Transmitter power supply

Connection with transmitter power supply

and transmitter using the auxiliary

terminal

-

-

+

+

I

Y

1

LED

-

+

A0017706

1 Transmitter power supply

+

+

I

Y

1

-

-

LED

-

+

A0017707

1 Transmitter power supply

Connection with PLC and transmitter

-

-

+

+

I

Y

1

LED

-

+

A0019720

1 PLC

-

-

+

+

I

Y

1

LED

-

+

A0019721

1 PLC

Connection without transmitter power

supply directly in the 4 to 20 mA circuit

+

2

-

I

Y

LED

-

+

A0017708

2 4 to 20 mA power source

+

2

-

I

Y

LED

-

+

A0017709

2 4 to 20 mA power source

6.3 Connection in HART mode

The following diagrams show how the process display unit is connected in HART mode.

6.3.1

HART® connection

NOTICE

Undefined behavior due to incorrect wiring of an actuator

‣

When installing the process display unit together with an actuator, the Operating

Instructions for the actuator must be followed!

The HART® communication resistance of 230 Ω in the signal line is always necessary

in the case of a low-impedance power supply. It must be installed between the power

supply and the display unit.

Page 23

RIA15 Wiring

Endress+Hauser 23

Circuit diagram / Description

2-wire sensor with

process display unit

and transmitter power

supply, without

backlighting

Y

I

R

s

DC

1

2

3

LED

-

+

A0019567

1 Sensor

2 Power supply

3

HART® resistance

2-wire sensor with

process display unit

and transmitter power

supply, with

backlighting

Y

I

R

s

DC

1

2

3

LED

-

+

A0019568

1 Sensor

2 Power supply

3

HART® resistance

4-wire sensor with

process display unit

and transmitter power

supply, without

backlighting

1

3

Y

I

2

4

LED

-

+

A0019570

1

HART® resistance

2 Current measuring device (optional)

3 Sensor

4 Power supply 4-wire device

4-wire sensor with

process display unit

and transmitter power

supply, with

backlighting

1

3

Y

I

2

4

LED

-

+

A0019571

1

HART® resistance

2 Current measuring device (optional)

3 Sensor

4 Power supply 4-wire device

Page 24

Wiring RIA15

24 Endress+Hauser

Circuit diagram / Description

Current output with

process display unit

and actuator (e.g.

actuator valve),

without backlighting

1

3

2

LED

-

+

A0019573

1 Actuator

2 Power supply 4-wire device

3 Current output

Current output with

process display unit

and actuator (e.g.

actuator valve), with

backlighting

1

3

2

LED

-

+

A0019574

1 Actuator

2 Power supply 4-wire device

3 Current output

Multi-drop 2-wire

sensors with process

display unit and

transmitter power

supply

R

s

DC

1

2

3

Y

I

LED

-

+

Y

I

Y

I

A0019575

1 Sensors

2 Power supply

3

HART® resistance

Multi-drop 2-wire

sensors with process

display unit and

transmitter power

supply, with

backlighting

R

s

DC

1

2

3

I

Y

Y

I

Y

I

LED

-

+

A0019722

1 Sensors

2 Power supply

3

HART® resistance

Page 25

RIA15 Wiring

Endress+Hauser 25

Circuit diagram / Description

2-wire sensor with

process display unit

and active barrier

RN221N as

transmitter power

supply

Y

I

1

2

3

O+

O-

RN221N

R

s

R

LED

-

+

A0019576

1 Sensor

2

HART® primary master

3

HART® resistance

Optional HART® communication resistance module

A HART® communication resistance module is available as an accessory, see the

"Accessories" section → 49.

Please refer to the section on installation when mounting the HART® communication

resistance module → 18

Wiring

Circuit diagram / Description

2-wire sensor with

process display unit

and transmitter power

supply, without

backlighting

1

LED

-

+

3

2

Y

I

R

s

DC

A0020839

1

HART® communication resistance module

2 Sensor

3 Power supply

2-wire sensor with

process display unit

and transmitter power

supply, with

backlighting

1

3

2

Y

I

R

s

DC

LED

-

+

A0020840

1

HART® communication resistance module

2 Sensor

3 Power supply

Page 26

Wiring RIA15

26 Endress+Hauser

Circuit diagram / Description

4-wire sensor with

process display unit

and transmitter power

supply, without

backlighting

1

3

Y

I

2

LED

-

+

A0020837

1

HART® communication resistance module

2 Power supply 4-wire device

3 Sensor

4-wire sensor with

process display unit

and transmitter power

supply, with

backlighting

1

3

Y

I

2

LED

-

+

A0020838

1

HART® communication resistance module

2 Power supply 4-wire device

3 Sensor

Configuration of HART® devices

The process display unit cannot be used to configure connected HART® devices.

Configuration is done using the Field Xpert SFX100 device configurator, for example.

1

2

3

5

4

A0019580

10

Configuration of HART® devices; example TMT162

1

HART® primary master (e.g. PLC)

2

HART® resistance

3 RIA15 process display unit

4

HART® handheld, e.g. Field Xpert SFX100

5

Sensor with HART® transmitter, e.g. TMT162

Page 27

RIA15 Wiring

Endress+Hauser 27

6.4 Wiring with switchable backlighting

An additional current-limited current source is required to implement switchable

backlighting, e.g. active barrier RN221N. This current source is used to supply the LED

backlighting of up to 7 RIA15 process display units without causing an additional voltage

drop in the measurement loop. The backlighting can be switched on and off using an

external switch.

The following shows connection examples for the hazardous area. Wiring is similar

for the non-hazardous area; however, it is not necessary to use Ex-certified devices.

6.4.1 Connection diagram for one process display unit

LED

-

+

-

+

I

Y

1

+

-

O-

LNPE

O+

7

6

5

+

-

O-

LNPE

O+

8

4

2

3

9

10

A0028248

1 Process display unit RIA15

2 3-wire connector, e.g. WAGO 221 series

3 2-wire sensor

4 Terminal block on top-hat rail

5 Active barrier, e.g. RN221N

6 4 to 20 mA output to the control unit

7 Power supply

8 Current source, e.g. RN221N

9 Switch to activate backlighting

10 Power supply

Page 28

Wiring RIA15

28 Endress+Hauser

6.4.2 Connection diagram for multiple process display units

LED

-

+

-

+

I

Y

1

+

-

O-

LNPE

O+

7

6

5

+

-

O-

LNPE

O+

9

8

10

4

2

3

LED

-

+

-

+

I

Y

LED

-

+

-

+

I

Y

+

-

O-

LNPE

O+

+

-

O-

LNPE

O+

11

A0028249

1 Process display unit RIA15

2 3-wire connector, e.g. WAGO 221 series

3 2-wire sensor

4 Terminal block on top-hat rail

5 Active barrier, e.g. RN221N

6 4 to 20 mA output to the control unit

7 Power supply

8 Current source, e.g. RN221N

9 Switch to activate backlighting

10 Power supply

11 Can be extended to 7 devices

Page 29

RIA15 Wiring

Endress+Hauser 29

6.5 Inserting the cable, field housing

TX20

2.

3.

4.

1.

A0017830

11 Inserting the cable, field housing

Inserting the cable, field housing, connection without transmitter power supply (example)

1. Release the housing screws

2. Open the housing

3. Open the cable gland (M16) and insert the cable

4. Connect the cable incl. functional grounding and close the cable gland

6.6 Shielding and grounding

Optimum electromagnetic compatibility (EMC) can only be guaranteed if the system

components and, in particular, the lines are shielded and the shield forms as complete a

cover as possible. A shield coverage of 90% is ideal.

• To ensure an optimum EMC protective effect when communicating with HART®, connect

the shield as often as possible to the reference ground.

• For reasons of explosion protection, you should refrain from grounding however.

To comply with both requirements, three different types of shielding are possible when

communicating with HART®:

• Shielding at both ends

• Shielding at one end on the feed side with capacitance termination at the field device

• Shielding at one end on the feed side

Experience shows that the best results with regard to EMC are achieved in most cases in

installations with one-sided shielding on the feed side (without capacitance termination at

the field device). Appropriate measures with regard to input wiring must be taken to allow

unrestricted operation when EMC interference is present. These measures have been

taken into account for this device. Operation in the event of disturbance variables as per

NAMUR NE21 is thus guaranteed. Where applicable, national installation regulations and

guidelines must be observed during the installation! Where there are large differences in

potential between the individual grounding points, only one point of the shielding is

connected directly with the reference ground. In systems without potential equalization,

Page 30

Wiring RIA15

30 Endress+Hauser

therefore, cable shielding of fieldbus systems should only be grounded on one side, for

example at the supply unit or at safety barriers.

NOTICE

If the shielding of the cable is grounded at more than one point in systems without

potential matching, power supply frequency equalizing currents can occur that

damage the signal cable or have a serious effect on signal transmission.

‣

In such cases the shielding of the signal cable is to be grounded on one side only, i.e. it

must not be connected to the ground terminal of the housing. The shield that is not

connected should be insulated!

6.7 Connecting to functional grounding

6.7.1 Panel-mounted device

For EMC reasons, the functional grounding should always be connected. When the device

is used in the hazardous area (with optional Ex approval) the connection is obligatory.

1

A0018894

12 Functional grounding terminal on panel-mounted device

6.7.2 Field device

For EMC reasons, the functional grounding should always be connected. When used in the

hazardous area (with optional Ex approval), the connection is obligatory and the field

housing must be grounded via a grounding screw fitted on the outside of the housing.

TX20

A0018895

13 Functional grounding terminal in field housing

Page 31

RIA15 Wiring

Endress+Hauser 31

TX20

A0018908

14 Ground terminal on field housing

6.8 Degree of protection

6.8.1 Field housing

The devices meet all the requirements of IP67. It is absolutely essential to comply with the

following points to ensure this protection is guaranteed after mounting or servicing the

device:

• The housing seal must be clean and undamaged when inserted into the groove. The seal

must be cleaned, dried or replaced if necessary.

• The cables used for connection must be of the specified outside diameter (e.g. M16 x

1.5, cable diameter 5 to 10 mm (0.2 to 0.39 in)).

• Mount the measuring device in such a way that the cable entries point downwards.

• Replace unused cable entries with dummy plugs.

• The housing cover and the cable entries must be firmly tightened.

6.8.2 Panel housing

The front of the device meets the requirements of IP65. It is absolutely essential to comply

with the following points to ensure this protection is guaranteed after mounting or

servicing the device:

• The seal between the front of the housing and the panel must be clean and undamaged.

The seal must be cleaned, dried or replaced if necessary.

• The threaded rods of the panel mounting clips must be firmly tightened.

6.9 Post-connection check

Device condition and specifications Notes

Are cables or the device damaged? Visual inspection

Electrical connection Notes

Does the supply current match the specifications on the nameplate? -

Are the cables, incl. functional grounding, connected correctly and strain-relieved? -

Field housing: Are the cable glands securely closed? -

Page 32

Operation RIA15

32 Endress+Hauser

7 Operation

1

2

3

4

5

6

7

8

A0017719

15 Display and operating elements of the process display unit

1 Symbol: operating menu disabled

2 Symbol: error

3 Symbol: warning

4

Symbol: HART® communication active

5 Operating keys "-", "+", "E"

6 14-segment display for unit/TAG

7 Bar graph with indicators for under range and over range

8 5-digit 7-segment display for measured value, digit height 17 mm (0.67 in)

The device is operated using three operating keys on the front of the housing. The device

setup can be disabled with a 4-digit user code. If the setup is disabled, a padlock symbol

appears on the display when an operating parameter is selected.

A0017716

Enter key; calling up the operating menu, confirming the option/setting parameters in the

operating menu

A0017714

Selecting and setting/changing values in the operating menu; pressing the '-' and '+' keys

simultaneously takes the user back up a menu level. The configured value is not saved.

A0017715

7.1 Operating functions

The operating functions of the process display unit are divided into the following menus.

The individual parameters and settings are described in the "Commissioning" section.

If the operating menu is disabled by means of a user code, the individual menus and

parameters can be displayed but not changed. To change a parameter, the user code

must be entered. As the display unit can only display digits in the 7-segment display

and not alphanumeric characters, the procedure for number parameters is different to

that for text parameters.

If the operating position contains only numbers as parameters, the operating position

is displayed in the 14-segment display and the configured parameter is displayed in

the 7-segment display. To edit, press the 'E'-button followed by the user code.

If the operating position contains text parameters, only the operating position is

initially displayed in the 14-segment display. If the 'E' button is pressed again, the

configured parameter is displayed in the 14-segment display. To edit, press the '+'

button followed by the user code.

Page 33

RIA15 Operation

Endress+Hauser 33

Setup

(SETUP)

Basic device settings

Diagnostics

(DIAG)

Device information, display of error messages

Expert

(EXPRT)

Expert settings for the device setup → 37

The Expert menu is protected from editing by an access code (default 0000).

Page 34

Commissioning RIA15

34 Endress+Hauser

8 Commissioning

8.1 Post-installation check and switching on the device

Perform the final checks before commissioning the device:

• Checklist for "post-installation check" → 19.

• Checklist for "post-connection check" → 31.

The device starts after being connected to the 4 to 20 mA/HART® circuit. The firmware

version appears on the display during the start-up phase.

When the device is being commissioned for the first time, program the setup in accordance

with the descriptions in the Operating Instructions.

If you are commissioning a device that is already configured or preset, the device

immediately starts measuring the current or making a HART® request as defined in the

settings. The values of the currently activated process variables appear in the display.

Devices with the "Level" option for the FMR20 are preconfigured as follows at the factory:

• Operating mode: HART mode

• Decimal point HART: 2 decimal places

• Display HART3: Off

• Display HART4: Off

Remove the protective film from the display as this would otherwise affect the

readability of the display.

8.2 Operating matrix

Setup menu (SETUP)

Parameters Values visible at Description

LEVEL FMR20

option

This menu contains the parameters for configuring the

FMR20 level transmitter.

The individual parameters are described in the section

"Operating matrix in conjunction with the Micropilot

FMR20" → 39.

MODE 4-20

HART

Select the operating mode for the display unit

4-20: The circuit's 4 to 20 mA signal is displayed

HART: Up to four HART® variables (PV, SV, TV, QV) of a

sensor/actuator in the loop can be displayed.

For the "Level" option for FMR20: default = HART

DECIM 0 DEC

1 DEC

2 DEC

3 DEC

4 DEC

MODE =

4-20

Number of decimal places for display

For the "Level" option for FMR20: default = 2 DEC

SC__4 Numerical value

–19 999 to 99 999

Default: 0.0

MODE =

4-20

5-digit value (number of decimal places as configured

under DECIM) for scaling the measured value at 4 mA

Example: SC__4 = 0.0 Þ 0.0 displayed at 4 mA

measuring current

The unit selected under UNIT is used to display the value.

SC_20 Numerical value

–19 999 to 99 999

Default: 100.0

MODE =

4-20

5-digit value (number of decimal places as configured

under DECIM) for scaling the measured value at 20 mA

Example: SC_20 = 100.0 Þ 100.0 displayed at 20 mA

measuring current

The unit selected under UNIT is used to display the value.

Page 35

RIA15 Commissioning

Endress+Hauser 35

Setup menu (SETUP)

Parameters Values visible at Description

UNIT %

°C

°F

K

USER

MODE =

4-20

Use this function to select the unit for displaying the

value. If "USER" is selected, a user-defined unit can be

entered in the TEXT parameter.

TEXT Customized text,

5-digit

MODE =

4-20

User-defined unit, only visible if the "USER" option has

been selected under UNIT.

SCAN NO

YES

MODE =

HART

Select "YES" to start scanning. All addresses are then

automatically scanned once in a HART® application until

a sensor/actor is found. Scanning runs from 0 to 63. Only

addresses up to 15 are permitted for HART 5. Once the

address of the sensor/actor whose values are to be

displayed is found, the address must be confirmed by

pressing the 'E' key. This address is adopted and is used

even after a device restart.

By pressing the '+' or '–' key, it is possible to search for

other addresses.

Pressing '+'- and '-' simultaneously will cancel scanning.

If "NO" is selected, scanning is not active. The address of

the sensor/actor, whose values are to be displayed on the

process display unit, must be configured manually using

the operating keys.

ADDR Numerical value

0 to 63

Default: 0

MODE =

HART

Use this function to enter manually the address of the

HART® sensor/actor whose values are to be displayed.

If the address of the HART® slave is changed, it

must also be changed on the process display unit.

To do this, either enter the address manually or

search using SCAN mode.

MTYPE PRIM

SEC

MODE =

HART

Use this function to select the HART® master type:

PRIM = Primary master

SEC = Secondary master

HART1-HART4 MODE =

HART

Use this function to select which HART® value of a

sensor/actor (PV, SV, TV, QV) should be activated and

configured:

HART1 = PV

HART2 = SV

HART3 = TV

HART4 = QV

Press the E key to open the configuration submenu.

DISP1 –DISP4 OFF

MAN

AUTO

MODE =

HART

Use this function to select how or whether the value

should be displayed.

OFF: Value is not displayed

MAN: You can manually scroll through activated HART®

values by pressing '+' or '–'. Otherwise the values are not

displayed. If all four HART® values (HART1 to HART4)

are set to "MAN", HART1 (PV) is displayed if you do not

scroll manually through the values.

AUTO: Activated HART® values are shown alternately

(switching time can be configured in the EXPRT menu

under "TOGTM"). If one value is set to AUTO, this value is

displayed continuously on the device.

For the "Level" option for FMR20: default for DISP3 and

DISP4 = OFF

DEC1 – DEC4 0 DEC

1 DEC

2 DEC

3 DEC

4 DEC

MODE =

HART

Number of decimal places

Page 36

Commissioning RIA15

36 Endress+Hauser

Setup menu (SETUP)

Parameters Values visible at Description

BGLO1BGLO4

Numerical value

–19 999 to 99 999

Default: 0.0

MODE =

HART

5-digit value (number of decimal places as configured

under DEC1-DEC4) for scaling the lower range of the bar

graph for HART1 - HART4.

The bar graph is disabled if BGLOx and BGHIx are set to

"0.0".

BGHI1-BGHI4 Numerical value

–19 999 to 99 999

Default: 0.0

MODE =

HART

5-digit value (number of decimal places as configured

under DEC1-DEC4) for scaling the upper range of the bar

graph for HART1 - HART4.

The bar graph is disabled if BGLOx and BGHIx are set to

"0.0".

UNIT1-UNIT4 HART

%

°C

°F

K

USER

MODE =

HART

Use this function to select the unit for displaying the

HART® value.

If "HART" is selected, the unit configured on the sensor/

actor is automatically adopted for the relevant HART®

value. Only units with a maximum of 5 characters can be

shown. Longer units are displayed as unit code "UCxxx".

The table in the HART® communication section at the

end of these Operating Instructions provides an overview

of the units that can be displayed.

If "USER" is selected, a user-defined unit can be entered in

the TEXT1-TEXT4 parameter.

TEXT1-TEXT4 Customized text,

5-digit

MODE =

HART

User-defined unit. Only visible if the "USER" option has

been selected under UNIT

Diagnostics menu (DIAG)

Parameters Values Description

AERR Read only The current diagnostic message appears on the display. If two or more

messages occur simultaneously, the message with the highest priority

is shown on the display.

LERR Read only The last diagnostic message with the highest priority appears on the

display.

FWVER Read only The firmware version appears on the display.

TERR

1)

Read only Displays the diagnostic code/error code pending at Endress+Hauser

HART® transmitters/sensors. Please refer to the Operating

Instructions of the relevant Endress+Hauser transmitter/sensor for

additional information about the meaning of the diagnostic number

and the remedial measures.

1) For Endress+Hauser transmitters/sensors with HART® communication, the diagnostic code/error code

currently pending can be queried via Endress+Hauser command #231. This command is only supported by

Endress+Hauser transmitters/sensors. Therefore, the TERR parameter is not visible if third-party devices

are connected to the RIA15.

Page 37

RIA15 Commissioning

Endress+Hauser 37

Expert menu (EXPRT); a code must be entered

In addition to all the parameters in the Setup menu, the Expert menu also contains the parameters

described in this table. If you call up the Expert menu, you will be asked to enter the user code (UCODE,

default: 0000).

Parameters Values visible at Description

LEVEL MODE =

HART

This menu contains the parameters for

configuring the FMR20 level transmitter.

The Level menu and all the related submenus

are only visible if the RIA15 has been ordered

with the "FMR20 basic configuration" option. The

basic settings can be made at the Micropilot

FMR20 radar level sensor via the RIA15 using

this menu. Description of the individual

parameters → 40

SYSTM

UCODE Numerical value 0000

to 9999

Default: 0000

4-digit user code

With the user code it is possible to protect the

device setup from unauthorized modifications. If

the setup is disabled, a padlock symbol appears

on the display when an operating parameter is

selected.

The user code is not active with the default

setting "0000". This means that setup parameters

can be changed without entering the code. The

code must always be entered for the Expert

menu, even for the default setting.

FRSET NO

YES

Resets the device setup. The values are reset to

the preset values for preconfigured devices, and

to the default values for all other devices. Select

"YES" and press "E" by way of confirmation to

reset the device.

TOGTM 5

10

15

20

MODE =

HART

Use this function to select the switching time in

seconds between HART® values if "AUTO" was

selected in the DISP1-DISP4 menu.

INPUT The following parameters are available in

addition to the parameters from the Setup menu.

Page 38

Commissioning RIA15

38 Endress+Hauser

Expert menu (EXPRT); a code must be entered

In addition to all the parameters in the Setup menu, the Expert menu also contains the parameters

described in this table. If you call up the Expert menu, you will be asked to enter the user code (UCODE,

default: 0000).

Parameters Values visible at Description

CURV LINAR

SQRT

Use this to select the calculation function for

the process value (for MODE = 4-20)

LINAR (scaling with SC__4 and SC_20):

Process value = (mA value - 4)/16 * (SC_20 SC__4) + SC__4 + OFFST

SQRT (square root extraction and scaling):

Process value = Square root((mA value - 4)/16)

* (SC_20 - SC__4) + SC__4 + OFFST

Negative values when calculating the square root

are set to 0.

Use this to select the calculation function for

the HART1 value (PV) (for MODE = HART)

LINAR:

HART1 value (PV) = "exported PV value" * FACT1

+ OFFS1

SQRT (square root extraction and scaling with

BGLO1 and BGHI1):

HART1 value (PV) = (square root("exported

percentage PV value" / 100) * (BGHI1 - BGLO1)

+ BGLO1) * FACT1 + OFFS1

Negative values when calculating the square root

are set to 0.

Example for SQRT:

• exported percentage PV value = 50

• BGLO1 = 100.0

• BGHI1 = 200.0

• FACT1 = 1

• OFFS1 = 0.0

HART1 value (PV) = (square root(50/100) *

(200 - 100) + 100) * 1 + 0 = 170.7

NAMUR NO

YES

MODE =

4-20

Use this function to define the error limits in

accordance with standard NAMUR NE 43

→ 41

RNGLO Numerical value NAMUR =NOLower range limit. An error message is displayed

if the measured current falls below this limit.

RNGHI Numerical value NAMUR =NOUpper range limit. An error message is displayed

if the measured current exceeds this limit.

OFFST Numerical value

–19 999 to 99 999

MODE =

4-20

Use this function to enter an offset value to

display the measured value.

FACT1-FACT4 1E-6

1E-5

1E-4

1E-3

1E-2

1E-1

1

1E1

1E2

1E3

1E4

1E5

1E6

MODE =

HART

As the display is limited to 5 characters, the

measured value must be multiplied by a factor if

necessary.

For example: conductivity 0.00003 S multiplied

by factor 1E6 Þ 30.000 µS.

If a factor is used, it is recommended to set

the unit under UNIT1-4 to "UNIT" and to

enter user-defined text because the unit

automatically delivered via HART® no

longer matches the displayed value.

OFFS1-OFFS4 Numerical value

–19 999 to 99 999

MODE =

HART

Use this function to enter an offset value to

display the HART1-HART4 measured value.

If a factor is used, the offset is added to the

multiplied value (displayed value = measured

value*factor + offset)

Page 39

RIA15 Commissioning

Endress+Hauser 39

Expert menu (EXPRT); a code must be entered

In addition to all the parameters in the Setup menu, the Expert menu also contains the parameters

described in this table. If you call up the Expert menu, you will be asked to enter the user code (UCODE,

default: 0000).

Parameters Values visible at Description

EXP1-EXP4 YES

NO

MODE =

HART

Measured value display for measured values

greater than 99999.

• YES: If the display overruns, the measured

value is displayed in exponential notation.

• NO: Values with more than 5 digits are not

displayed if the display overruns. Value is

displayed with leading zeros.

Example: Measured value: 130002.4

YES => 1.30E5

NO => 0002.4

DIAG

CNTHI Read only MODE =

HART

Counter for the number of values transmitted via

HART® , 5 top positions. The counter goes back

to 0 after a device restart or scan.

CNTLO Read only MODE =

HART

Counter for the number of values transmitted via

HART® , 5 bottom positions. The counter goes

back to 0 after a device restart or scan.

RETRY Read only MODE =

HART

Counter for the number of retries to establish

HART® communication. The counter goes back

to 0 after a device restart or scan.

FAIL Read only MODE =

HART

Counter for the number of failed attempts to

establish HART® communication. The counter

goes back to 0 after a device restart or scan.

HLEVL

Tx mV Read only MODE =

HART

Value of the peak-to-peak level of the

transmission signal in mV

Rx mV Read only MODE =

HART

Value of the peak-to-peak level of the received

signal in mV

NOISE Read only MODE =

HART

Displays the level of the interference signal

LO = low interference signal

MED = medium interference signal

HI = high interference signal

Rc Ω Read only MODE =

HART

Value of the total resistance in the HART® loop

in Ohm

8.3 Operating matrix in conjunction with the Micropilot

FMR20

In the HART mode, it is possible to use the RIA15 with the option for the FMR20 for the

basic setting of the Micropilot FMR20 radar level sensor.

Further information on the FMR20, see corresponding Operating Instructions

→ BA01578F.

FMR20 basic setting

The RIA15 must be in the HART mode (MODE = HART) to make the basic settings. The

LEVEL menu is not visible in the analog mode (MODE = 4-20).

1. Press the key.

The Setup menu opens.

2. Press the key.

The LEVEL submenu opens.

Page 40

Commissioning RIA15

40 Endress+Hauser

3. Set the desired parameters. For parameter descriptions, see the following table.

Setup -> Level (LEVEL) menu

The Level menu is only visible if the RIA15 has been ordered with the "FMR20 basic setting" option and

the display unit is operated in the HART mode (MODE = HART). The basic settings can be made at the

Micropilot FMR20 radar level sensor via the RIA15 using this menu.

Parameters Values visible at Description

Level MODE =

HART

This menu contains the parameters for configuring the

FMR20 level transmitter.

The Level menu and all the related submenus are only

visible if the RIA15 has been ordered with the "FMR20

basic configuration" option. The basic settings can be

made at the Micropilot FMR20 radar level sensor via the

RIA15 using this menu.

UNIT m

ft

Select the displayed unit

EMPTY Numerical value

0 to 100 m

Default 2 m

Empty calibration using keys -,+,E.

Enter distance from process connection to min. level

FULL Numerical value

–19 999 to 99 999

Full calibration using keys -,+,E.

Enter span from max. level to min. level

DIST Measured value Measured value (measured distance)

MAP

DI OK To be selected if the distance displayed matches the

actual distance. The device then records a mapping.

MAN To be selected if the range of mapping is to be defined

manually in the 'Mapping end point' parameter. A

comparison between the distance displayed and the

actual distance is not necessary in this case. Mapping

becomes active after approx. 20 s.

DI UN To be selected if the actual distance is unknown. No

mapping is recorded.

FACT To be selected if the present mapping curve (if one

exists) is to be deleted. The device returns to the "Confirm

distance" parameter and a new mapping can be recorded.

Page 41

RIA15 Troubleshooting

Endress+Hauser 41

9 Troubleshooting

9.1 Error limits as per NAMUR NE 43

In Mode=4-20, the device can be configured for error limits as per NAMUR NE 43

→ 37.

The device displays an error message if a value is outside these limits.

Current value Error Diagnostic code

≤ 3.6 mA Under range F100

3.6 mA < x ≤ 3.8 mA Unpermitted measured value S901

20.5 mA ≤ x < 21.0 mA Unpermitted measured value S902

> 21.0 mA Over range F100

9.2 Diagnostic messages

If several errors are pending simultaneously, the device always displays the error with

the highest priority.

1 = Highest priority

Diagnostic

number

Short text Corrective measure Status signal Diagnostic

behavior

Priority

Diagnostics for the sensor

F100 Sensor error • Check electrical wiring

• Check sensor

• Check sensor settings

F Alarm 6

S901 Input signal

too small

• Check transmitter output for defect and conformity error

• Check transmitter for incorrect configuration

S Warning 4

S902 Input signal

too large

S Warning 5

Diagnostics for the electronics

F261 Electronics

module

Replace electronics F Alarm 1

F283 Memory

content

• Restart device

• Reset device

• Replace electronics

F Alarm 2

F431 Factory

calibration

Replace electronics F Alarm 3

Diagnostics for the configuration

M561 Display

overshoot

Check scaling M Warning 7

9.2.1 HART® diagnostic messages

If several errors are pending simultaneously, the device always displays the error with

the highest priority.

1 = Highest priority

Page 42

Troubleshooting RIA15

42 Endress+Hauser

Diagnostic

number

Short text Corrective measure Status signal Diagnostic

behavior

Priority

F960 HART®

communication (slave

not responding)

• Verify HART slave address

• Check electrical wiring (HART®)

• Check HART® function sensor/actor

F Alarm 8

C970 Multi-master collision • Check additional master in the HART® network

(e.g. handheld).

• Check master setting (secondary/primary)

C Check 9

F911 HART® slave device

error (HART® Field

Device Status)

Check sensor/actor configuration or check for defects F Alarm 10

S913 HART® slave current

output saturated

(HART® Field Device

Status)

• Commissioning: Check sensor/actor for incorrect

configuration, check sensor/actor configuration

• Operation: Process parameter outside valid range

S Warning 11

S915 HART® slave variable

outside limits of range

(HART® Field Device

Status)

S Warning 12

9.2.2 Other diagnostics in the HART® mode

The process display unit has an integrated HART® diagnostics function. This function can

be used to estimate the HART® signal level, the applicable communication resistance, and

the noise of the network.

The display unit can measure and display the following values:

Parameters Description Display

Tx mV Process display unit signal level mV Peak-to-peak level of the

transmission signal

Rx mV Slave signal level mV Peak-to-peak level of the received

signal

NOISE Weighting of the interference

signal

LO / MED / HI Categorization of the interference

into low, medium or high

Rc Ω Effective communication resistance Ω Resistance in Ohm

The values can be called up in the EXPRT – DIAG – HLEVL menu.

Measuring the transmission signal level "Tx":

The Tx measurement can be used to assess the signal level of the transmission signal.

Ideally this should be between 200 mV and 800 mV . The following values are displayed:

Tx < 120 mV 120 to 200 mV 200 to 800 mV 800 to 850 mV > 850 mV

Display LO Level in mV HI

Bargraph < < 0 to 100 % > >

Measuring the received signal level "Rx":

The Rx measurement can be used to assess the signal level of the received signal. Ideally

this should be between 200 mV and 800 mV .

The Rx signal value that is displayed is a filtered signal level as assessed by the process

display unit. In this way, the value measured externally and the displayed value can differ

from one another, for example in the case of a trapezoidal received signal.

Page 43

RIA15 Troubleshooting

Endress+Hauser 43

The following values are displayed:

Rx < 120 mV 120 to 200 mV 200 to 800 mV 800 to 850 mV > 850 mV

Display LO Level in mV HI

Bargraph < < 0 to 100 % > >

Measuring the "NOISE" interference signal:

When the interference signal level is measured, the interference signal determined is

divided into three categories:

LO = low

MED = medium

HIGH = high

The noise measurement is also a filtered signal level as assessed by the process display

unit. The value measured externally and the displayed value can therefore differ from one

another, depending on the frequency and the form of the signal.

With low wanted signal levels (Rx, Tx), transmission errors can occur even if the

interference signal level is low ("LO" displayed).

Measuring the communication resistance "Rc":

The "Rc" measurement can be used to determine the network resistance of the HART®

network. Ideally this should be between 230 Ω and 600 Ω .

The network resistance is the sum of the HART® communication resistance, the

device's input resistance, the transmission line resistance and line capacitance.

The following values are displayed:

Rc < 100 Ω 100 to 230 Ω 230 to 600 Ω 600 to 1 000 Ω > 1 000 Ω

Display LO Resistance in Ω HI

Bargraph < < 0 to 100 % > >

9.2.3 Error messages via HART® response codes

The transmitter responds with a response code for HART® commands #194 and #195. If

the response code does not equal 0, the process display unit shows the response code

briefly in the format rc xx.

The meaning of the response codes is explained in the following table.

For the response to the Endress+Hauser-specific HART® command #231, see the

"Commissioning" section, "Diagnostics" menu → 36.

Code Class Description Solution

0 Success No command-specific

error

-

2 Error Invalid selection Check HART® settings and

firmware in the FMR20

3 Error Value too large Check basic settings → 40

4 Error Value too small Check basic settings → 40

5 Error Not enough data bytes

received

Check HART® settings and

firmware in the FMR20

6 Error Device-specific

command error

Check HART® settings and

firmware in the FMR20

Page 44

Troubleshooting RIA15

44 Endress+Hauser

Code Class Description Solution

7 Error In the write-protected

mode

Check write protection in the

FMR20

14 Error Span too small Check basic settings → 40

16 Error Access restricted Check HART® settings and

firmware in the FMR20

29 Error Invalid span Check basic settings → 40

32 Error Busy Try again

9.3 Spare parts

1

4

4 444

2

4

2

1

3

3 3

3

A0018882

16 Spare parts of the process display unit

Item No. Description Order number

1 Mainboard HART® XPR0005-ABA

2 LCD module XPR0006-A1

3 Small parts set for panel-mount housing (5-pin plug-in

terminal, seal on front frame, 2x fastening clip)

XPR0006-A2

4 Small parts set for field housing (5-pin plug-in terminal, seal

on cover, 2x cover hinge, grounding connection on bottom,

cover screws, grounding lug)

XPR0006-A3

9.4 Software history and overview of compatibility

Release

The firmware version on the nameplate and in the Operating Instructions indicates the

device release: XX.YY.ZZ (example 1.02.01).

XX Change to main version.

No longer compatible. The device and Operating Instructions change.

YY Change to functions and operation.

Compatible. The Operating Instructions change.

ZZ Fixes and internal changes.

No changes to the Operating Instructions.

Page 45

RIA15 Troubleshooting

Endress+Hauser 45

Date Firmware

Version

Software changes Documentation

11/2012 1.00.01 Original software Analog: BA01073K/09/EN/02.13

03/2013 1.01.00 HART® option, only relevant for HART®

version

Analog: BA01073K/09/EN/03.13

HART: BA01170K/09/EN/02.13

07/2013 1.02.00 HART® level measurement, only relevant for

HART® version

Analog: BA01073K/09/EN/04.13

HART: BA01170K/09/EN/03.13

11/2014 1.03.00 New EXP1-EXP4 parameter for HART® option,

only relevant for HART® version

Analog: BA01073K/09/EN/05.14

HART: BA01170K/09/EN/04.14

05/2016 1.04.00 New menus and parameters for "FMR20 basic

configuration", only relevant for HART®

version

Analog: BA01073K/09/EN/06.15

HART: BA01170K/09/EN/05.15

Page 46

Maintenance RIA15

46 Endress+Hauser

10 Maintenance

No special maintenance work is required on the device.

Page 47

RIA15 Return

Endress+Hauser 47

11 Return

The measuring device must be returned if it is need of repair or a factory calibration, or if

the wrong measuring device has been delivered or ordered. Legal specifications require

Endress+Hauser, as an ISO-certified company, to follow certain procedures when handling

products that are in contact with the medium.

To ensure safe, swift and professional device returns, please refer to the procedure and

conditions for returning devices provided on the Endress+Hauser website at

http://www.endress.com/support/return-material

Page 48

Disposal RIA15

48 Endress+Hauser

12 Disposal

The device contains electronic components and must therefore be disposed of as electronic

waste. Comply with local disposal regulations.

Page 49

RIA15 Accessories

Endress+Hauser 49

13 Accessories

Various accessories, which can be ordered with the device or subsequently from Endress

+Hauser, are available for the device. Detailed information on the order code in question is

available from your local Endress+Hauser sales center or on the product page of the

Endress+Hauser website: www.endress.com.

13.1 Device-specific accessories

Protective cover

298 (11.73)201 (7.91)

63

(2.48)

205 (8.07)

A0017731

17 Dimensions of protective cover, engineering unit mm (in)

Mounting kit for wall/

pipe mounting

11.5

(0.45)

82 (3.23)

80 (3.15)

115 (4.53)

A0017801

18 Dimensions of mounting bracket, engineering unit mm (in)

HART® communication

resistance module

54 (2.13)

31 (1.22)

24 (0.94)

22 (0.87)

8.1 (0.32)

A0020858

19 Dimensions of communication resistance module, engineering unit mm(in)

Active barrier RN221N

96 (3.78)

110 (4.33)

112 (4.41)

22.5

(0.89)

A0028251

20 Dimensions of active barrier, engineering unit mm (in)

For further information, see TI00073R/09/