Endress+Hauser Proservo NMS83 Brief Operating Instructions

KA01206G/00/EN/02.17

71364766

Products Solutions Services

Brief Operating Instructions

Proservo NMS83

Tank Gauging

These Instructions are Brief Operating Instructions; they are

not a substitute for the Operating Instructions pertaining to

the device.

Detailed information about the device can be found in the

Operating Instructions and the other documentation:

Available for all device versions via:

– Internet: www.endress.com/deviceviewer

– Smart phone/tablet: Endress+Hauser Operations App

Proservo NMS83

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

1.

3.

2.

2 Endress+Hauser

A0023555

Proservo NMS83 Table of contents

Table of contents

1 About this document ..............................................................4

1.1 Symbols ............................................................................. 4

2 Basic safety instructions .......................................................... 6

2.1 Requirements for the personnel ............................................................ 6

2.2 Designated use ........................................................................ 6

2.3 Workplace safety ...................................................................... 6

2.4 Operational safety ......................................................................7

2.5 Product safety ......................................................................... 7

3 Product description ............................................................... 8

3.1 Product design ........................................................................ 8

4 Incoming acceptance and product identification ................................... 9

4.1 Incoming acceptance ................................................................... 9

4.2 Product identification ................................................................... 9

4.3 Storage and transport ................................................................... 9

5 Installation ...................................................................... 11

5.1 Requirements ........................................................................ 11

5.2 Mounting of the device ................................................................. 13

6 Electrical connection ............................................................ 20

6.1 Terminal assignment .................................................................. 20

6.2 Connecting requirements ............................................................... 33

6.3 Ensuring the degree of protection ......................................................... 34

7 Commissioning .................................................................. 35

7.1 Operating methods .................................................................... 35

7.2 Terms related to tank measurement ....................................................... 38

7.3 Setting the display language ............................................................. 39

7.4 Calibration .......................................................................... 40

7.5 Configuration of the inputs .............................................................. 48

7.6 Linking measured values to tank variables ................................................... 56

7.7 Configuration of the limit evaluation ....................................................... 57

7.8 Configuration of the signal output ......................................................... 59

Endress+Hauser 3

About this document Proservo NMS83

DANGER

WARNING

CAUTION

NOTICE

1 About this document

1.1 Symbols

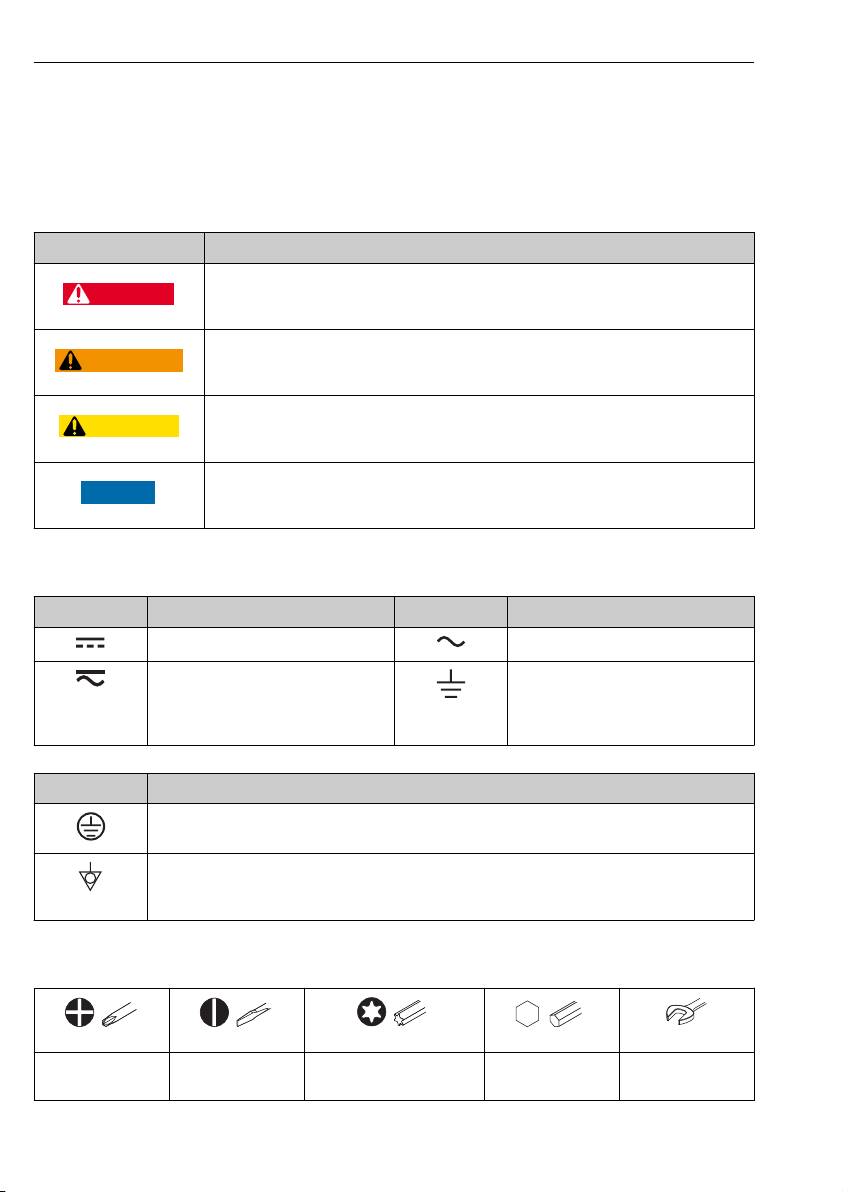

1.1.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.1.2 Electrical symbols

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

Symbol Meaning

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a potential

equalization line or a star grounding system depending on national or company codes of practice.

A grounded terminal which, as far as

the operator is concerned, is grounded

via a grounding system.

1.1.3 Tool symbols

Flat blade

screwdriver

A0011220

A0013442 A0011221

Torx screwdriver Allen key Hexagon wrench

A0011219

Cross-head

screwdriver

4 Endress+Hauser

A0011222

Proservo NMS83 About this document

A

1.

1.

-

.

1.1.4 Symbols for certain types of information

Symbol Meaning Symbol Meaning

Permitted

Procedures, processes or actions that

are permitted.

Forbidden

Procedures, processes or actions that

are forbidden.

Reference to documentation

Preferred

Procedures, processes or actions that

are preferred.

Tip

Indicates additional information.

Reference to page

Reference to graphic

Result of a step Visual inspection

1.1.5 Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

, 2., 3.… Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Hazardous area

Indicates a hazardous area.

Safe area (non-hazardous area)

Indicates the non-hazardous area.

1.1.6 Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

Temperature resistance of the connection cables

Specifies the minimum value of the temperature resistance of the connection cables.

, 2., 3.… Series of steps

Endress+Hauser 5

Basic safety instructions Proservo NMS83

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel must fulfill the following requirements for its tasks:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task.

Are authorized by the plant owner/operator.

‣

Are familiar with federal/national regulations.

‣

Before starting work, read and understand the instructions in the manual and

‣

supplementary documentation as well as the certificates (depending on the application).

Follow instructions and comply with basic conditions.

‣

2.2 Designated use

Application and measured materials

Depending on the version ordered, the measuring device can also measure potentially

explosive, flammable, poisonous and oxidizing media.

Measuring devices for use in hazardous areas, in hygienic applications or in applications

where there is an increased risk due to process pressure, are labeled accordingly on the

nameplate.

To ensure that the measuring device remains in proper condition for the operation time:

Only use the measuring device in full compliance with the data on the nameplate and the

‣

general conditions listed in the Operating Instructions and supplementary documentation.

Check the nameplate to verify if the device ordered can be put to its intended use in the

‣

approval-related area (e.g. explosion protection, pressure vessel safety).

Use the measuring device only for media against which the process-wetted materials are

‣

adequately resistant.

If the measuring device is not operated at atmospheric temperature, compliance with the

‣

relevant basic conditions specified in the associated device documentation is absolutely

essential.

Protect the measuring device permanently against corrosion from environmental

‣

influences.

Observe the limit values in the "Technical Information".

‣

The manufacturer is not liable for damage caused by improper or non-designated use.

Residual risk

During operation the sensor may assume a temperature near the temperature of the

measured material.

Danger of burns due to heated surfaces!

For high process temperatures: Install protection against contact in order to prevent burns.

‣

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

6 Endress+Hauser

Proservo NMS83 Basic safety instructions

2.4 Operational safety

Risk of injury.

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with the manufacturer.

‣

Repair

To ensure continued operational safety and reliability,

Carry out repairs on the device only if they are expressly permitted.

‣

Observe federal/national regulations pertaining to repair of an electrical device.

‣

Use original spare parts and accessories from the manufacturer only.

‣

Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the hazardous

area (e.g. explosion protection, pressure vessel safety):

Based on the nameplate, check whether the ordered device is permitted for the intended

‣

use in the hazardous area.

Observe the specifications in the separate supplementary documentation that is an integral

‣

part of these Instructions.

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet stateof-the-art safety requirements, has been tested, and left the factory in a condition in which it

is safe to operate. It meets general safety standards and legal requirements.

2.5.1 CE mark

The measuring system meets the legal requirements of the applicable EC guidelines. These are

listed in the corresponding EC Declaration of Conformity together with the standards applied.

Endress+Hauser confirms successful testing of the device by affixing to it the CE mark.

Endress+Hauser 7

Product description Proservo NMS83

5

6

7

8

2

3

4

9

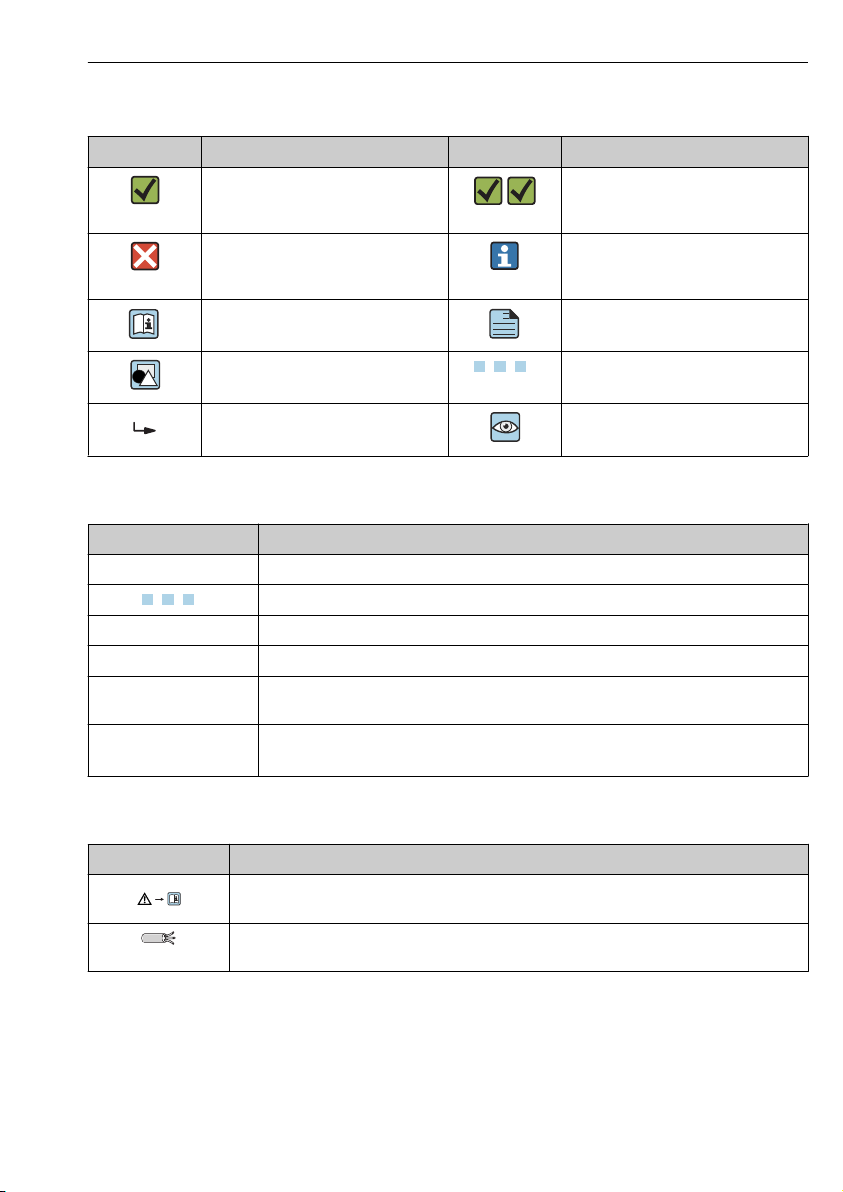

3 Product description

3.1 Product design

A0028873

1 Configuration of NMS83

1 Front cover

2 Display

3 Modules

4 Sensor unit

5 Housing

6 Wire drum

7 Bracket

8 Housing cover

9 Displacer

8 Endress+Hauser

Proservo NMS83 Incoming acceptance and product identification

4 Incoming acceptance and product identification

4.1 Incoming acceptance

Upon receipt of the goods check the following:

• Are the order codes on the delivery note and the product sticker identical?

• Are the goods undamaged?

• Do the nameplate data match the ordering information on the delivery note?

• If required (see nameplate): Are the Safety Instructions (XA) enclosed?

If one of these conditions is not satisfied, contact your Endress+Hauser Sales Center.

4.2 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Extended order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

( www.endress.com/deviceviewer ): All information about the measuring device is

displayed.

• Enter the serial number from the nameplates into the Endress+Hauser Operations App or

scan the 2-D matrix code (QR code) on the nameplate with the Endress+Hauser Operations

App: all the information for the measuring device is displayed.

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• The W@M Device Viewer: Enter the serial number from the nameplate

(www.endress.com/deviceviewer)

• The Endress+Hauser Operations App: Enter the serial number from the nameplate or scan

the 2-D matrix code (QR code) on the nameplate.

4.2.1 Manufacturer address

Endress+Hauser GmbH+Co. KG

Hauptstraße 1

79689 Maulburg, Germany

Address of the manufacturing plant: See nameplate.

4.3 Storage and transport

4.3.1 Storage conditions

• Storage temperature: –50 to +80 °C (–58 to +176 °F)

• Store the device in its original packaging.

Endress+Hauser 9

Incoming acceptance and product identification Proservo NMS83

4.3.2 Transport

NOTICE

Risk of injury

Transport the measuring device to the measuring point in its original packaging.

‣

Take into account the mass center of the device in order to avoid unintended tilting.

‣

Comply with the safety instructions, transport conditions for devices over 18kg (39.6lbs)

‣

(IEC61010).

10 Endress+Hauser

Proservo NMS83 Installation

+1°

-1°

1

5 Installation

5.1 Requirements

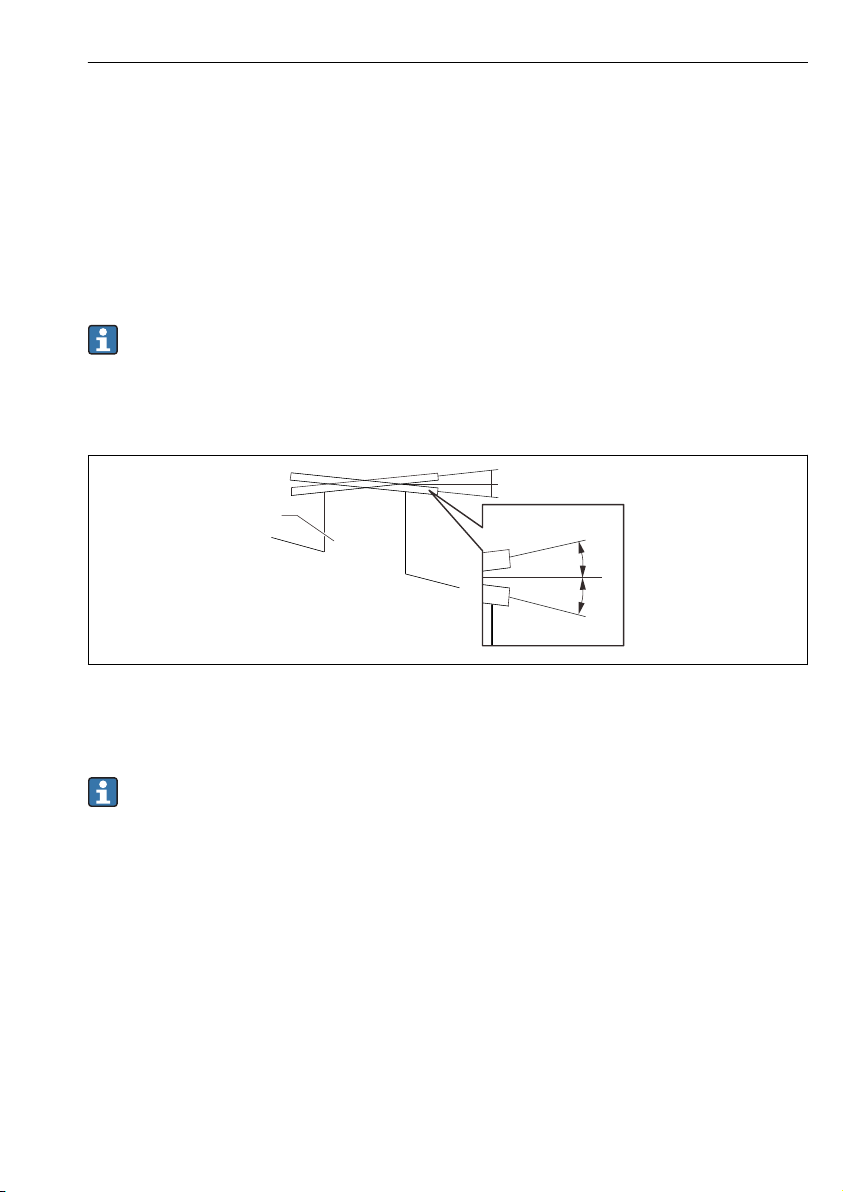

5.1.1 Alignment of NMS8x

Flange

Confirm that the size of the nozzle and the flange is matched prior to mounting NMS8x on

the tank. The flange size and the rating of NMS8x vary depending on the customer’s

specifications.

• Check the flange size of NMS8x.

• Mount the flange on the top of the tank. The deviation of the flange from the

horizontal plane should not exceed +/- 1 degree.

• When mounting NMS8x on a long nozzle, make sure that the displacer does not touch

the inner wall of the nozzle.

A0026889

2 Allowable inclination of mounting flange

1 Nozzle

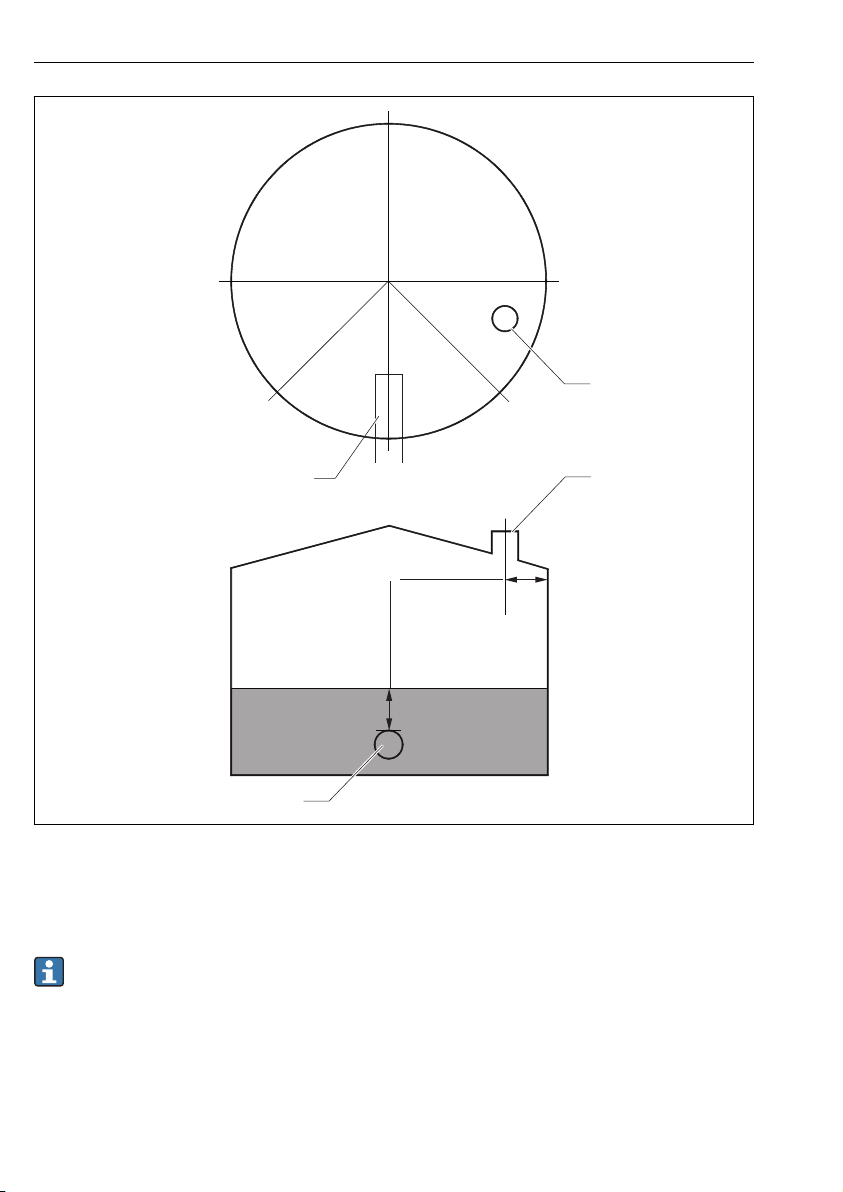

When NMS8x is installed without a guide system, follow the recommendations below:

• Confirm the mounting nozzle is in the sector between 45 and 90 degrees (or -45 and

-90 degrees)away from the inlet pipe of the tank. This prevents heavy swinging of the

displacer caused by waves or turbulence from the inlet liquid.

• Confirm the mounting nozzle is 500 mm (19.69 in) or more away from the tank wall.

• Confirm the minimum measuring level is at 500 mm (19.69 in) or more above the top

of the inlet pipe by setting the low stop (for details of low stop setting, refer to

"Commissioning" in the separate BA (Instruction Manual)). This protects the displacer

from direct flow of the inlet liquid.

• If a stilling well cannot be mounted in the tank due to the shape or condition of the

tank, attaching a guide system is recommended. Consult E+H services for further

information.

Endress+Hauser 11

Installation Proservo NMS83

≥500 (19.69)

90°-90°

0°

45°-45°

1

1

≥500 (19.69)

2

2

3 Recommended position for mounting NMS8x and minimum measuring level; dimensions mm (in)

1 Inlet pipe

2 Tank nozzle

• Before pouring liquid into the tank, confirm that liquid flowing through the inlet of the

A0026890

pipe will not contact the displacer directly.

• When discharging liquid out of the tank, ensure that the displacer will not get caught

in the liquid current and sucked into the outlet pipe.

12 Endress+Hauser

Proservo NMS83 Installation

5.1.2 Electrostatic charge

When liquid measured by NMS8x has a conductivity of 1 uS/m or less, it is quasinonconductive. In this case, using a stilling well or guide wire is recommended. This releases

the electrostatic charge on the liquid surface.

5.2 Mounting of the device

When NMS8x is delivered, the displacer is always shipped separately and there are two

methods to install displacer as follows.

• Installation for displacer shipped separately method

• Installation through the calibration window

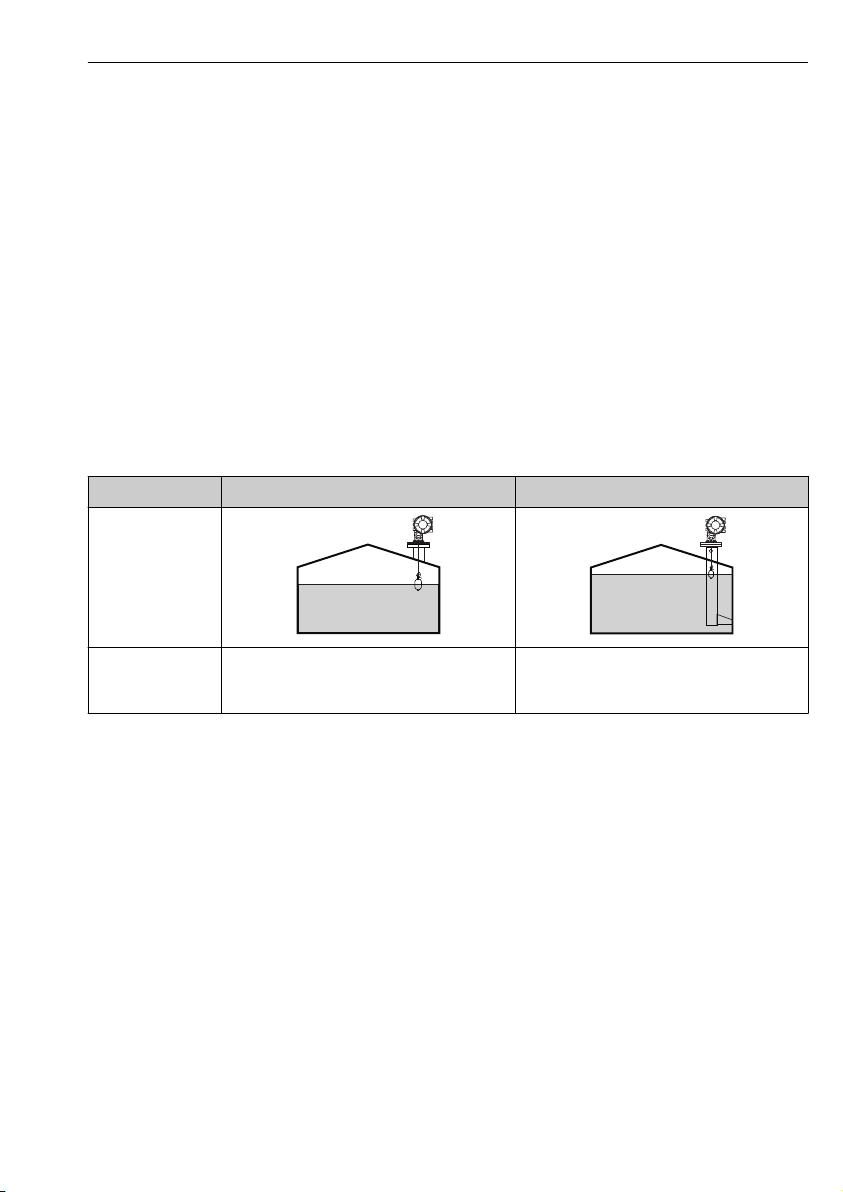

5.2.1 Available installations

The following installation procedures are available for NMS8x.

• Mounting without guide system

• Mounting with stilling well

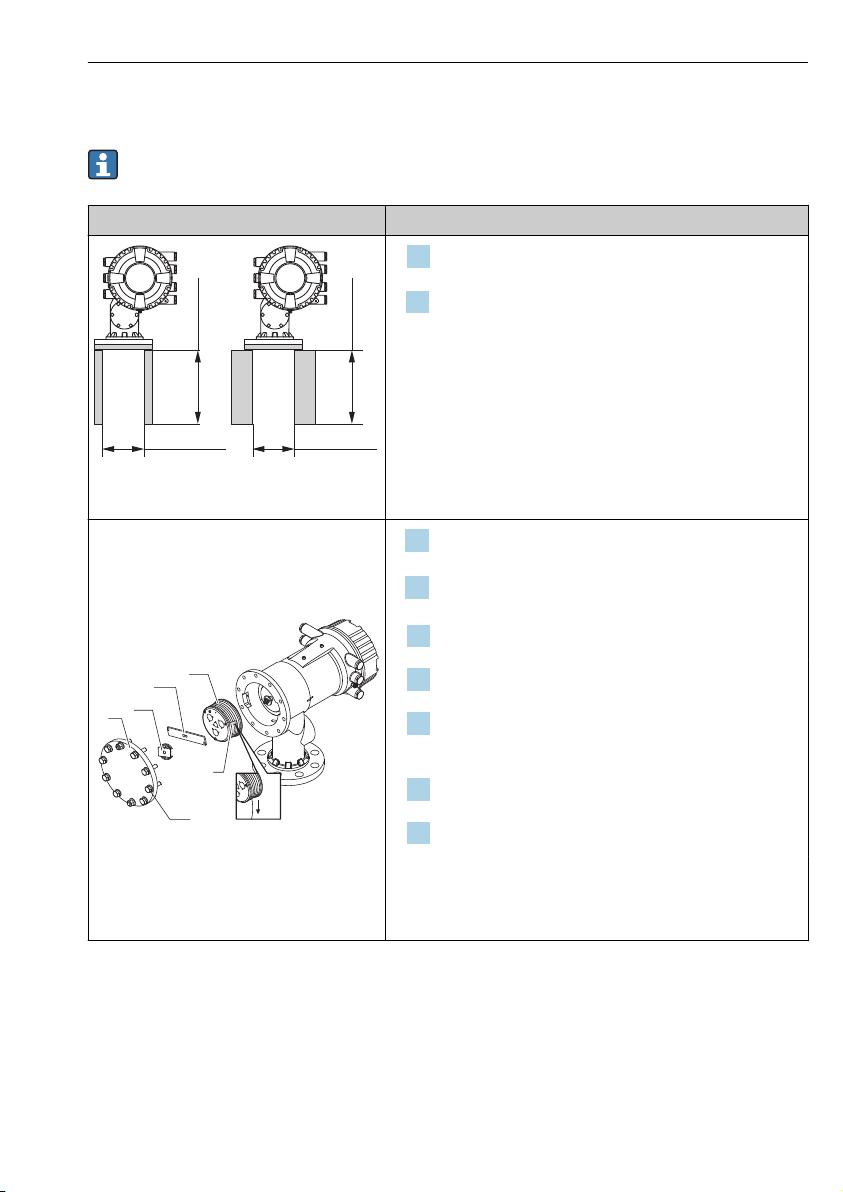

Mounting options Free-space mounting With stilling well

Type of tanks

Type of installations • Displacer shipped separately

• Displacer installation through calibration

window

Endress+Hauser 13

• Displacer shipped separately

• Displacer installation through calibration

window

Installation Proservo NMS83

316L

50

ml

70.8

ml

141.6

g

256.6

Ø

B

V

D

V

D

m

NMS8

Displacer

12345678901

Ser.no.:

mm

302.xxx

Cir.

NMS8

Wiredrum

98765432109

Ser.no.:

712xxxxx

Spare part-no.:

HNBR

O-Ring

28m

Range

NMS8

98765432109

Ser. no.:

3

1.

2.

Spare part-no.: 712xxxxx

12345678901

712xxxxx

m 256.6g

D

V 141.6mL

D

V 70.8mL

B

!50 316L

Ø

0.15

HNBR

m

28

WireDia.

O-Ring

Range

Spare part-no.: 712xxxxx

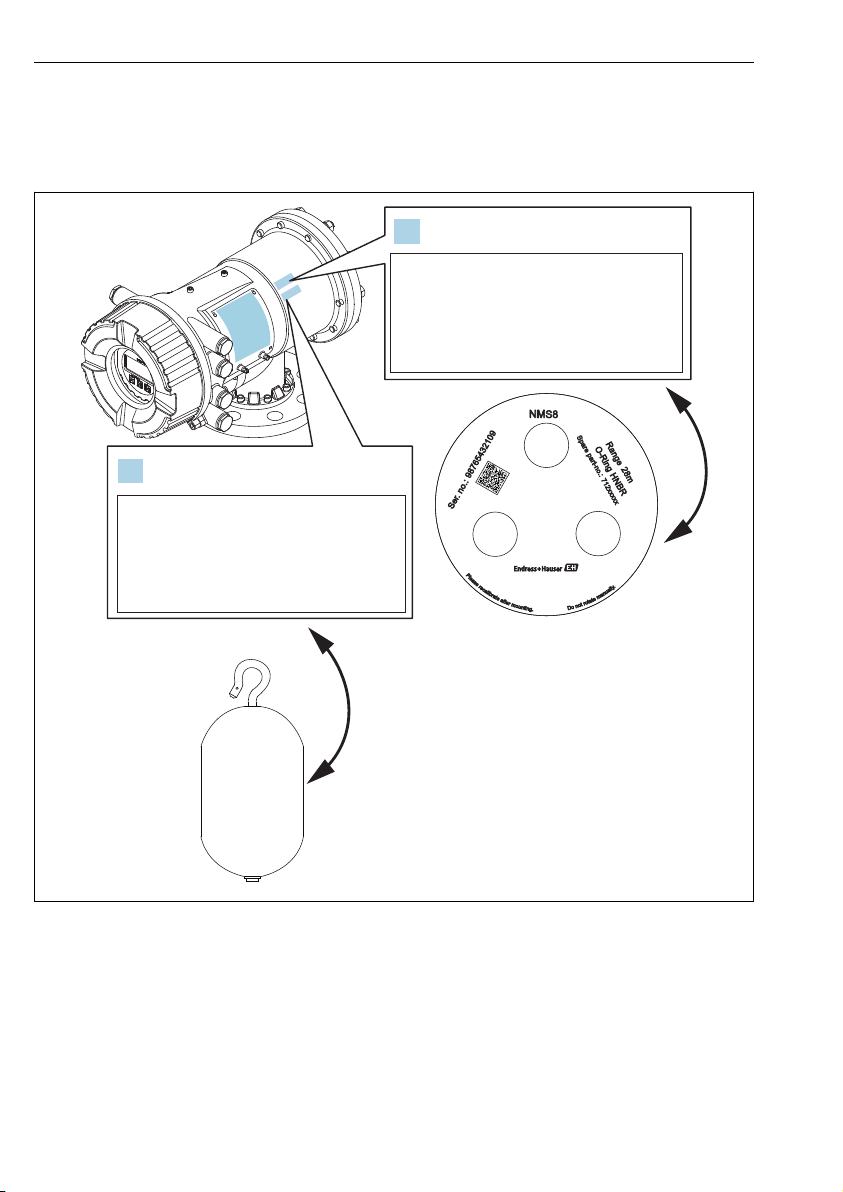

5.2.2 Verification of displacer and wire drum

Prior to installation of NMS8x, confirm that the serial numbers of displacer and the wire drum

match with those printed to the label attached on the housing.

A0028025

4 Verification of displacer and wire drum

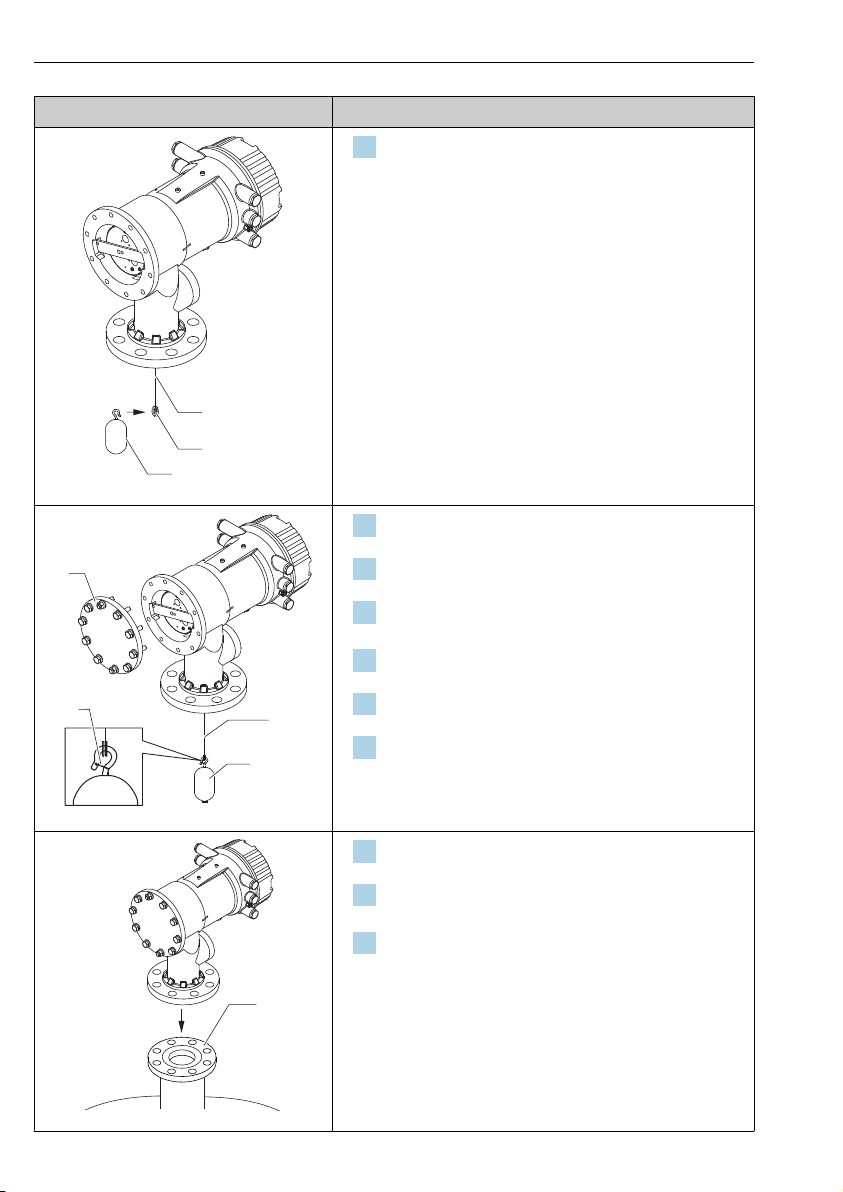

5.2.3 Installation for displacer shipped separately method

It is necessary to remove the wire drum from NMS8x, remove the tape on the wire drum,

mount the wire drum in the drum housing, and install the displacer on the measuring wire.

14 Endress+Hauser

Proservo NMS83 Installation

200 (7.87)

200 (7.87)

130 (5.12) 130 (5.12)

1.

2.

3

1

2

6

4

3.

4.

5.

6.

7.

8.

9.

Use blocks or a pedestal to secure NMS8x and provide an environment where electrical power

can be supplied to NMS8x.

The following procedure uses NMS81 figures for an example.

Figures Procedures

Secure NMS8x on the blocks or pedestal.

Confirm that there is enough space under NMS8x.

Be careful not to drop NMS8x.

A0032442

Dimensions mm (in)

Remove screws and M6 bolts [6] (M10 bolts for stainless

steel housing).

Remove the wire drum cover [5], wire drum stopper [4], and

the bracket [2].

Remove the wire drum [1] from the drum housing.

Endress+Hauser 15

A0028876

Remove the tape [3] on the wire drum.

Unwind the measuring wire approximately

250 mm (9.84 in) so that the wire ring is positioned under

the flange.

Mount the wire drum on NMS8x.

Mount the bracket.

• Take special care to not hit the wire drum against the

housing due to strong magnet force.

• Handle the measuring wire with care. It may kink.

• Be sure that the wire is wound correctly in the grooves.

Installation Proservo NMS83

1

3

2

10.

2

3

4

1

11.

12.

13.

14.

15.

16.

1

17.

18.

19.

Figures Procedures

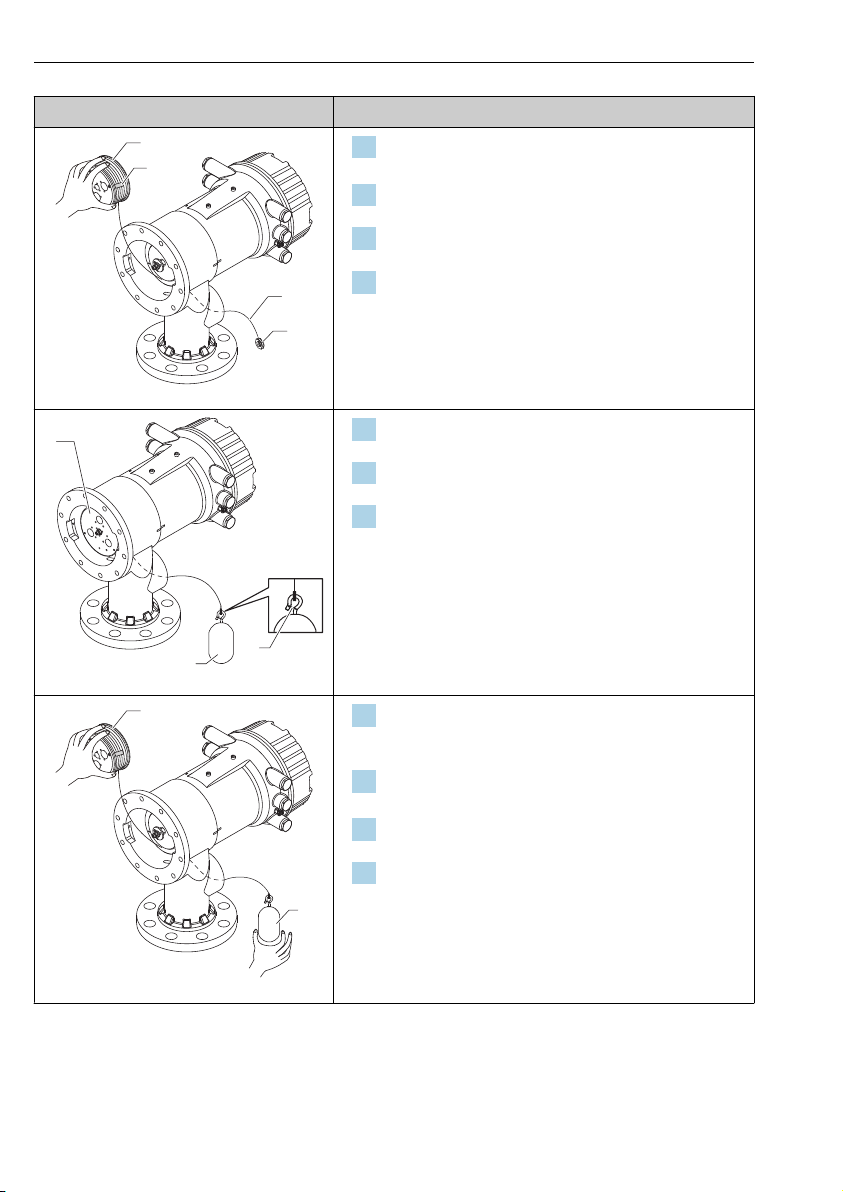

Hook the displacer [3] on the ring [2].

• Be sure that the wire is wound correctly in the grooves.

• If not, remove the displacer and the wire drum, and repeat

step 7.

A0029116

Turn on the power of NMS8x.

Perform sensor calibration

Secure the displacer [2] to the measuring wire [1] using the

securing wire [3].

Perform reference calibration.

Turn off the power.

Mount the wire drum cover [4].

• For sensor calibration, → 43

A0027017

• For reference calibration, → 45.

Mount NMS8x on the tank nozzle [1].

Confirm that the displacer does not touch the inner wall of

the nozzle.

Turn on the power.

16 Endress+Hauser

A0028877

Proservo NMS83 Installation

20.

1

1.

2

1

3

4

6

2.

3.

4.

5.

Figures Procedures

Perform drum calibration.

For drum calibration, → 46

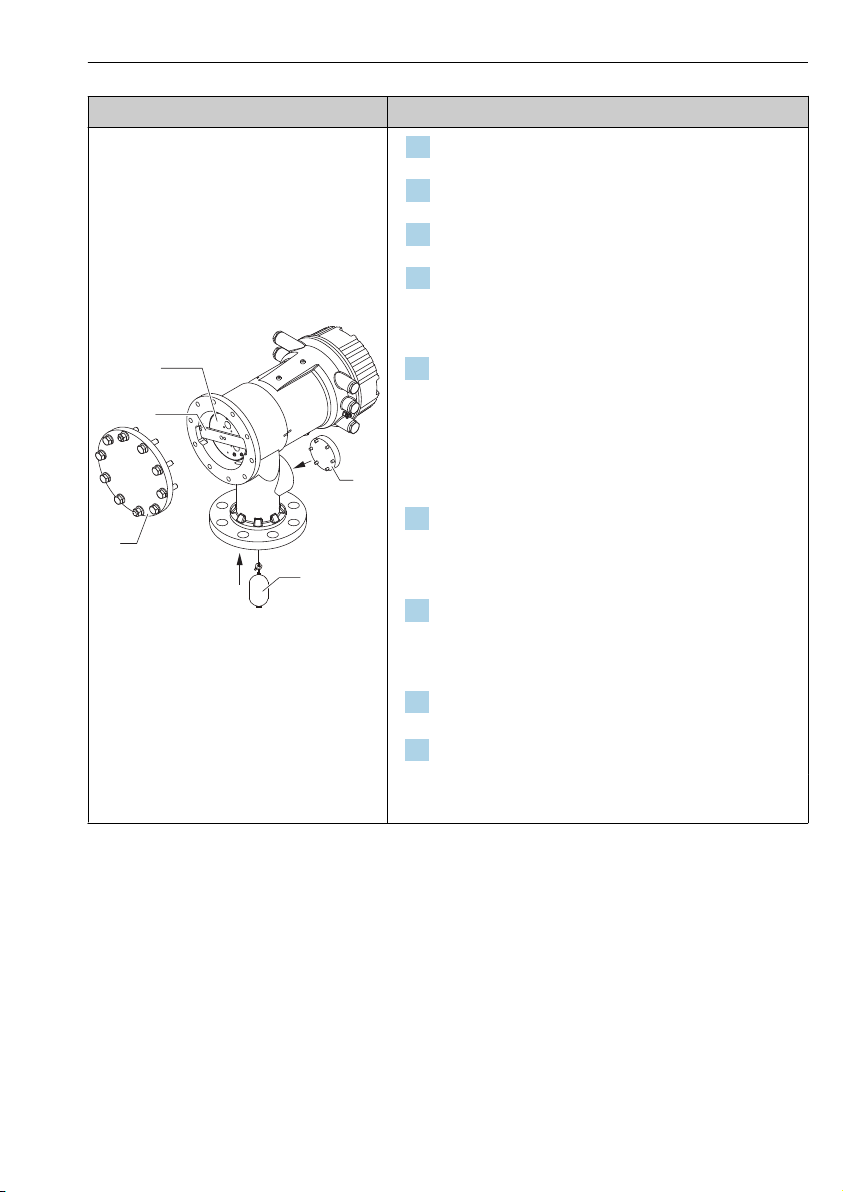

5.2.4 Installation through the calibration window

In the case of a 50 mm (1.97 in) diameter displacer, the displacer can be installed through the

calibration window.

It is only possible to install the following displacers through the calibration window:

50 mm SUS, 50 mm alloy C, 50 mm PTFE

The following procedure uses NMS81 figures for an example.

Figures Procedures

Remove the calibration window cover [1].

A0032443

Remove M6 bolts and screws [6] (M10 bolts for stainless

steel housing).

Remove the cover [5], wire drum stopper [4], and the

bracket [3].

Remove the wire drum [1] from the drum housing.

Remove the tape [2] that is securing the wire.

Handle the measuring wire with care. It may kink.

Endress+Hauser 17

A0029118

Installation Proservo NMS83

3

4

2

1

6.

7.

8.

9.

1

2

3

10.

11.

12.

2

1

13.

14.

15.

16.

Figures Procedures

Holding the wire drum [1] with one hand, unwind the

measuring wire [3] approximately 500 mm (19.69 in).

Secure the wire [3] temporarily with the tape [2].

Insert the wire ring [4] into the drum housing.

Pull the wire ring out through the calibration window.

• Take special care to not hit the wire drum against the

housing due to strong magnet force.

• Handle the measuring wire with care.

A0028879

Insert the wire drum [3] temporarily into the drum housing.

Hook the displacer [2] on the wire ring.

Secure the displacer to the measuring wire using the

securing wire [1].

Handle the measuring wire with care. It may kink.

A0027984

Remove the wire drum from the drum housing and unwind

the measuring wire down approximately

500 mm (19.69 in).

Hold the wire drum [1] up and place the displacer [2] into

the calibration window.

Hold the displacer at the center of the calibration window.

Hold the other hand (wire drum) up to add tension to the

measuring wire in order not to drop the displacer rapidly.

A0027986

18 Endress+Hauser

Proservo NMS83 Installation

3

4

5

2

1

17.

18.

19.

20.

21.

22.

23.

24.

25.

Figures Procedures

Let go of the displacer [2].

Remove the tape from the wire drum [5].

Insert the wire drum into the drum housing.

Mount the bracket [4].

Be sure that the wire is wrapped correctly in grooves.

Turn on the power of NMS8x and move the displacer up

using the Move displacer wizard→ 41 until the wire

ring can be seen in the calibration window.

• Confirm that there are no kinks or other defects in the

measuring wire.

• Confirm that the displacer does not touch the inner wall of

the nozzle.

Perform sensor calibration.

For sensor calibration, → 43

A0032444

Perform reference calibration.

For reference calibration, → 45.

Mount the drum housing cover [5] and the calibration

window cover [1].

Perform drum calibration.

For drum calibration, → 46

Endress+Hauser 19

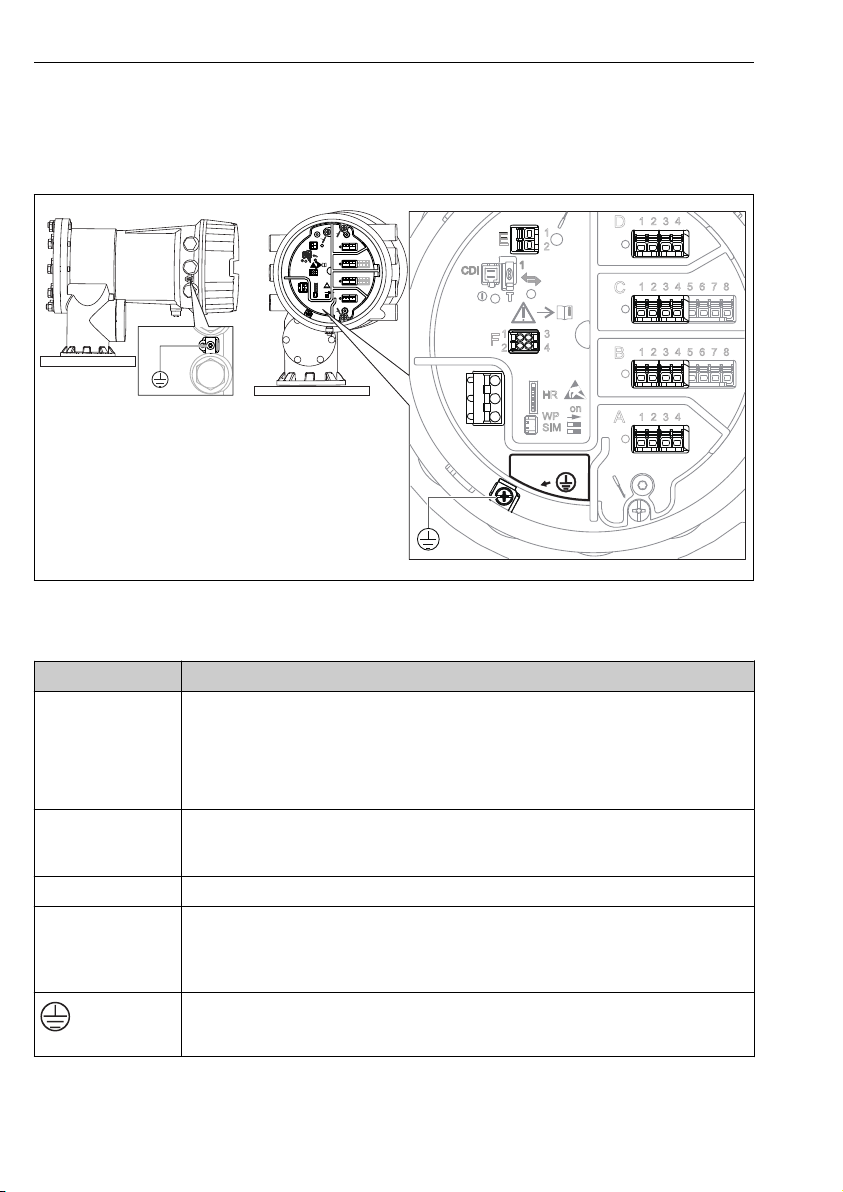

Electrical connection Proservo NMS83

D

E

G

F

C

B

A

1

1

1

1

1 3

2

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

POWER

i

D

E

F

C

B

A

1

1

1

1 3

2

2 4

1

HR

CDI

WP

on

SIM

22334

4

112233445566778

8

i

G

1

3

2

POWER

G1 N

G3 L

AC 85...264 V

6 Electrical connection

6.1 Terminal assignment

A0032445

5 Terminal compartment (typical example) and ground terminals

Terminal area Module

Up to four I/O modules, depending on the order code

A/B/C/D

(slots for I/O modules)

• Modules with four terminals can be in any of these slots.

• Modules with eight terminals can be in slot B or C.

The exact assignment of the modules to the slots is dependent on the device version

→ 23.

E HART Ex i/IS interface

• E1: H+

• E2: H-

F Remote display (in preparation)

Power supply: 85 to 264 V

G

• G1: N

• G2: not connected

AC

• G3: L

Protective ground connection

A0018339

20 Endress+Hauser

Loading...

Loading...