Page 1

TI00264T/02/EN/15.19

71443142

Products Solutions Services

Technical Information

Thermowell

Omnigrad M TW13

Pipe thermowell

Flanged process connection

Application

TW13 is designed for use in the fine chemical s industry but can also be used for generic

applications.

Modular configuration according to DIN 43772 (form 2F/3F) enable a use in all

industrial processes with severe thermal and mechanical stresses.

Your benefits

• TW13 is a pipe thermowell.

• The process connection is flanged.

• Extension, immersion length and total length can be chosen according to process

requirements.

• A wide choice of dimensions, materials and process connections is available.

•Special versions can be manufactured according to customer requirements.

Page 2

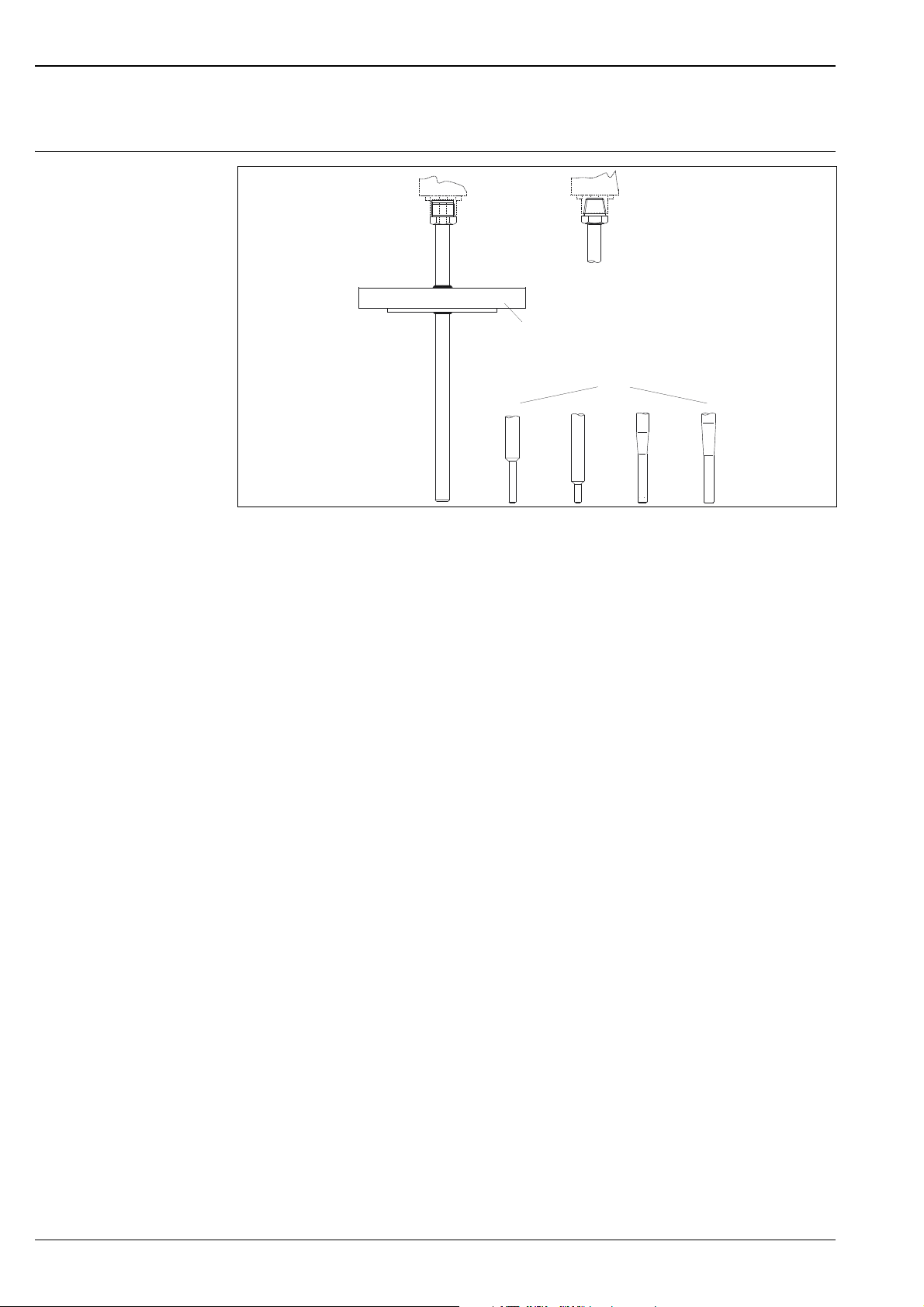

Equipment architecture

TW13

Function and system design

1

4

5

Equipment architecture of the Omnigrad M TW13

1 Thread M24x1.5

2 Thread 1/2" NPT

3 Various tip shapes - detailed information see chapter "Tip shape"

4 Process connection: flange

5 Jacket (protective sheath)

2

3

A0020843

The Omnigrad M TW13 thermowells are designed according to DIN 43772 and can therefore

guarantee a good level of resistance to the most typical and common industrial processes. The

thermowell is made from a pipe with a diameter of 9, 11, 12, 14 or 15 mm (0.35, 0.43, 0.47, 0.55 or

0.59 in). The end of the thermowell can be straight, tapered or reduced (stepped). An oversheath in

plastic can be supplied for thermowells with straight tip. The Omnigrad M TW13 thermowells can be

fitted on the plant (pipe or vessel) using a flanged process connection, which can be chosen from the

most common models.

2 Endress+Hauser

Page 3

TW13

Performance characteristics

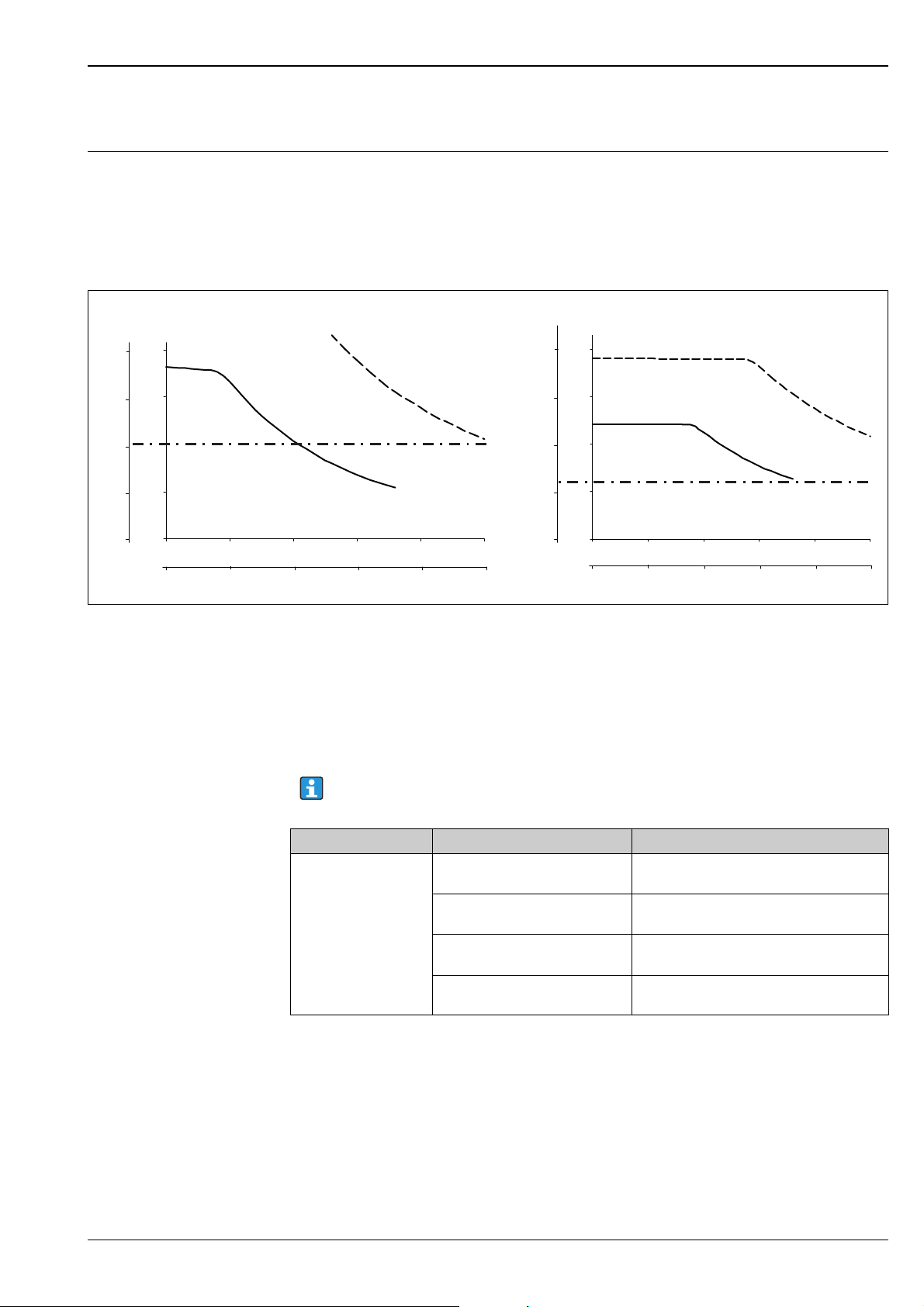

Operating conditions Process pressure

The pressure values to which the thermowell can be subjected at the various temperatures and

maximum permitted flow velocity are illustrated by the figure below. Occasionally, the pressure

loading capacity of the process connection can be considerably lower. The maximum allowable process

pressure for a specific thermometer is derived from the lower pressure value of the thermowell and

process connection.

P (PSI)

2900

2100

1400

700

P (bar)

200

150

P ~ PN100

max.

100

50

0

0

150 200 250 300 350 400

L (mm)

L (in)

8

10 12 14 16

Maximum permitted process pressure for tube diameter

A Medium water at T = 50 °C (122 °F)

B Medium superheated steam at T = 400 °C (752 °F)

LImmersion length

P Process pressure

___ Thermowell diameter 9 x 1 mm (0.35 in)

- - - Thermowell diameter 12 x 12.5 mm (0.47 in)

P (PSI)

2900

2100

1400

700

P (bar)

200

150

100

P ~ PN60

max.

50

0

0

150 200 250 300 350 400

L (mm)

L (in)

6

8

10 12

BA

14 166

A0013494

Note the limitation of the maximum process pressure to the flange pressure ratings indicated

in the following table.

Process connection Standard Max. process pressure

Flange EN1092-1 or ISO 7005-1 Depending on the flange pressure rating PNxx:

ANSI B16.5 Depending on the flange pressure rating 150

JIS B 2220 Depending on the flange pressure rating

DIN2526/7 Depending on the flange pressure rating

20, 40, 50 or 100 bar at 20 °C (68 °F)

or 300 psi at 20 °C (68 °F)

20K, 25K or 40K

PN40 at 20 °C (68 °F)

Endress+Hauser 3

Page 4

TW13

100 200 300 400 500

v (m/s)

A

100 200 300 400 500

v (m/s)

B

4

8

12 16 20

4

8

12 16

v (ft/s)

v (ft/s)

L (mm)

0

10

20

30

40

50

60

70

80

90

L (in)

20

0

30

65

100

130

165

200

230

260

295

0

5

10

15

20

25

30

35

40

45

0

15

30

50

65

80

100

115

130

145

L (mm)

L (in)

50

2

50

2

Maximum flow velocity

The highest flow velocity tolerated by the thermowell diminishes with increasing immersion length

exposed to the stream of the fluid. Detailed information may be taken from the figure below.

Flow velocity depending on the immersion length

A Medium water at T = 50 °C (122 °F)

B Medium superheated steam at T = 400 °C (752 °F)

LImmersion length

v Flow velocity

___ Thermowell diameter 9 x 1 mm (0.35 in)

- - - Thermowell diameter 12 x 12.5 mm (0.47 in)

A0008605

4 Endress+Hauser

Page 5

TW13

Material Thermowell and process connections.

The temperatures for continuous operation specified in the following table are only intended as

reference values for use of the various materials in air and without any significant compressive load.

The maximum operation temperatures are reduced considerably in some cases where abnormal

conditions such as high mechanical load occur or in aggressive media.

Material name Short form Recommended

max. temperature

for continuous use

in air

AISI 316L/1.4404

1.4435

AISI 316Ti/1.4571 X6CrNiMoTi17-12-2 700 °C (1292 °F)

Hastelloy

2.4819

Inconel600/2.4816 NiCr15Fe 1100 °C (2012 °F) • A nickel/chromium alloy with very good resistance to aggressive, oxidizing and

PTFE (Teflon) Polytetrafluorethylen 100 °C (212 °F) • Resistant to almost all chemicals

PVDF Polyvinylidene fluoride 80 °C (176 °F) • High stability

Tantalum - 250 °C (482 °F) • With the exception of hydrofluoric acid, fluorine and fluorides, tantalum

®

C276/

X2CrNiMo17-12-2

X2CrNiMo18-14-3

NiMo16Cr15 W 1100 °C (2012 °F) • A nickel-based alloy with good resistance to oxidizing and reducing

650 °C (1202 °F)

Properties

1)

• Austenitic, stainless steel

• High corrosion resistance in general

• Particularly high corrosion resistance in chlorine-based and acidic, nonoxidizing atmospheres through the addition of molybdenum (e.g. phosphoric

and sulfuric acids, acetic and tartaric acids with a low concentration)

• Increased resistance to intergranular corrosion and pitting

• Compared to 1.4404, 1.4435 has even higher corrosion resistance and a lower

delta ferrite content

1)

• Properties comparable to AISI316L

• Addition of titanium means increased resistance to intergranular corrosion

even after welding

• Broad range of uses in the chemical, petrochemical and oil industries as well as

in coal chemistry

• Can only be polished to a limited extent, titanium streaks can form

atmospheres, even at high temperatures

• Particularly resistant to chlorine gas and chloride as well as to many oxidizing

mineral and organic acids

reducing atmospheres, even at high temperatures

• Resistant to corrosion caused by chlorine gas and chlorinated media as well as

many oxidizing mineral and organic acids, sea water etc.

• Corrosion from ultrapure water

• Not to be used in a sulfur-containing atmosphere

• High temperature stability

• Max. operating pressure: <2 bar (29 psi)

• A high creepage stability under continuous demand

• Good cold properties

exhibits excellent resistance to most mineral acids and saline solutions

• Prone to oxidation and embrittlement at higher temperatures in air

1) Can be used to a limited extent up to 800 °C (1472 °F) for low compressive loads and in non-corrosive media.

Please contact your Endress+Hauser sales team for further information.

Endress+Hauser 5

Page 6

Components

M24x1.5

½“ NPT

L

E

1 2

Design, dimensions All dimensions in mm (in).

TW13

A0020855

Dimensions of the Omnigrad M TW13

1 M24x1.5 connection; sliding on the neck L Immersion length

2 ½" NPT connection; welded, not sliding on the neck ⌀D Diameter

ENeck tube length

The standard lengths of the neck are 80 or 145 mm (3.15 or 5.71 in). In accordance with standard DIN 43772, in the case of a thermowell with a diameter of ⌀12 mm (0.47 in) and a tapered tip (form 3F), the extension neck will respectively be 82 or 147 mm (3.23 or 5.79 in).

6 Endress+Hauser

Page 7

TW13

40 (1.6)

35 (1.34)

50 (1.97)

20 (0.8)

40 (1.6)

20

(0.8)

4

3

2

5

5 (0.2)

3.2

(0.13)

3 (0.12)

~3.5

(0.14)

6.1 (0.24)

3

(0.12)

3.2 (0.13)

3

(0.12)

7 (0.28)

1-2.5 (0.04-0.1)

9 (0.35)

(0.35)

(0.35)

2

(0.47)

6.5 (0.26)

1-2.5 (0.04-0.1)

7 (0.28)

1-2.5 (0.04-0.1)

11 (0.43)

1-2.5 (0.04-0.1)

10 (0.39)

1-2.5 (0.04-0.1)

6

1

L

D

K

d

b

f

Tip shape

Available thermowell tips (reduced, straight or tapered). Maximum surface roughness Ra ≤ 1.6 μm (62.9 μin)

Pos. No. Tip shape Insert diameter

1 Straight 6 mm (0.24 in)

2 Reduced, L ≥ 50 mm (1,97 in) 3 mm (0.12 in)

3 Reduced, L ≥ 30 mm (1,18 in)

4Tapered, L ≥ 70 mm (2.76 in)

5 Tapered DIN 43772-3F, L ≥ 90 m (3.54 in)

1)

1)

1)

3 mm (0.12 in)

3 mm (0.12 in)

6 mm (0.24 in)

6 Welded tip, weld quality according to EN ISO 5817 - quality class B

1) not with material Hastelloy® C276/2.4819 and Inconel600

Weight From 1.5 to 4.0 kg (3.3 to 8.8 lbs) for standard options.

Process connection Standard connections are available as weld-in connection (without flange) or with flange.

The following figure shows the basic dimensions of the available flanges.

A0019347

Endress+Hauser 7

Basic dimensions of the flange process connections

For detailed information on the flange dimensions refer to the following flange standards:

•ANSI/ASME B16.5

• ISO 7005-1

A0010471

Page 8

• EN 1092-1

L

1

L

2

3

4

h

• JIS B 2220 : 2004

• DIN 2526/7

The flange material should be the same as of the stem of the thermowell. For this reason, connections

are available both in SS 316L/1.4404 and in SS 316Ti/1.4571. Models in Hastelloy® C have flanges in

basic material SS 316L and a disc in Hastelloy® C on the surface in contact with the process media.

Installation conditions

Orientation No restrictions.

Installation instructions

TW13

A0020859

Installation examples

1 - 2: In pipes with a small cross section the sensor tip should reach or extend slightly past the center line of the pipe (= L)

3 - 4: Tilted installation

The immersion length of the thermometer influences the accuracy. If the immersion length is too small

then errors in the measurement are caused by heat conduction via the process connection and the

container wall. If installing into a pipe then the immersion length should be half of the pipe diameter,

if possible (see 1 and 2). A further solution could be an angled (tilted) installation (see 3 and 4). When

determining the immersion length all thermometer parameters and the process to be measured must

be taken into account (e.g. flow velocity, process pressure).

• Installation possibilities: Pipes, tanks or other plant components

• Recommended minimum immersion length = 80 to 100 mm (3.15 to 3.94 in)

The immersion length should correspond to at least 8 times of the thermowell diameter.

Example: Thermowell diameter 12 mm (0.47 in) x 8 = 96 mm (3.8 in). A standard immersion length

of 120 mm (4.72 in) is recommended.

• ATEX certification: Always take note of the installation regulations!

8 Endress+Hauser

Page 9

TW13

Certificates and approvals

CE mark The device meets the legal requirements of the EC directives if applicable. Endress+Hauser confirms

that the device has been successfully tested by applying the CE mark.

PED approval The thermowell complies with paragraph 3.3 of the Pressure Equipment Directive (97/23/CE) and is

not marked separately.

Material certification The material certificate 3.1 (according to standard EN 10204) can be directly selected from the sales

structure of the product and refers to the parts of the sensor in contact with the process fluid. Other

types of certificates related to materials can be requested separately. The "short form" certificate

includes a simplified declaration with no enclosures of documents related to the materials used in the

construction of the single sensor and guarantees the traceability of the materials through the

identification number of the thermometer. The data related to the origin of the materials can

subsequently be requested by the client if necessary.

Test on thermowell Thermowell pressure tests are carried out in accordance with the specifications in the DIN 43772

standard. With regards to thermowells with tapered or reduced tips that do not comply with this

standard these are tested using the pressure of corresponding straight thermowells. Sensors certified

for use in Ex Zones, are always tested to pressures according to the same criteria. Tests according to

other specifications can be carried out on request. Dye penetration tests verify the absence of cracks on

the thermowell welding.

Ordering information

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser website:

www.endress.com → Select country → Instruments → Select device → Product page function:

Configure this product

• From your Endress+Hauser Sales Center:

www.endress.com/worldwide

Product Configurator - the tool for individual product configuration:

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

Endress+Hauser 9

Page 10

www.addresses.endress.com

Loading...

Loading...