Page 1

TI01180R/09/EN/03.18

71400849

2018-04-30

Products

Solutions Services

Technical Information

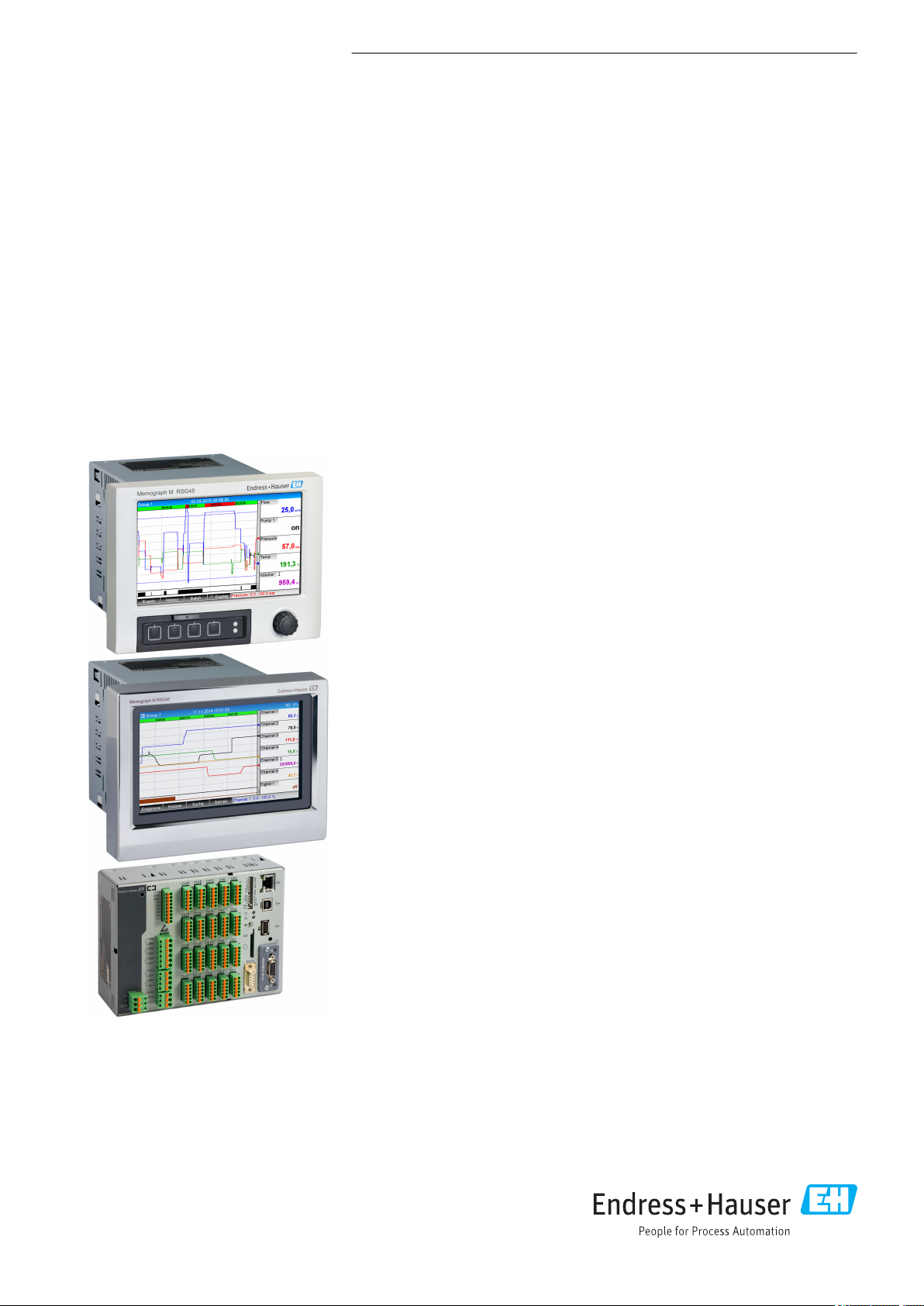

Memograph M, RSG45

Advanced Data Manager

Records, visualizes, analyzes and communicates

Application

The Advanced Data Manager Memograph M is a flexible and powerful system for

organizing process values. Thanks to its intuitive operation, the Memograph M

adapts quickly and easily to the respective application. The measured process values

are clearly presented on the display and logged safely, monitored against limit

values, and analyzed. Via common communication protocols, the measured and

calculated values can be easily communicated to higher-level systems and individual

plant modules can be interconnected.

Your benefits

• High data security: tamper-proof data storage and personalized access

authorization with electronic signature (FDA 21 CFR 11)

• 7" TFT display for the clear presentation of measured values

• Stainless steel front with touch operation: trouble-free operation in demanding

environments such as hygienic or hazardous areas

• HART® input card: HART® sensors directly connected provide accurate process

values for calculation and logging

• HART® gateway: time-saving direct access to HART® sensors in the field with

FieldCare using Memograph M without interrupting the measuring loop

• Integrated Web server: remote access to device operation and visualization for

lower maintenance costs

• WebDAV: data saved on SD card transmitted directly to a PC via HTTP without any

additional software

• Future-oriented: simple device upgrade to up to 20 universal/HART® and 14

digital inputs or 12 relay outputs

• System capability: supports common fieldbuses (Modbus, Profibus DP, PROFINET,

EtherNet/IP) for fast integration into different systems

• Standard interfaces: can connect a USB keyboard or mouse for faster data entry

Page 2

Function and system design

Memograph M, RSG45

Measuring principle

Measuring system

Electronic acquisition, display, recording, analysis, remote transmission and archiving of analog and

digital input signals as well as calculated values.

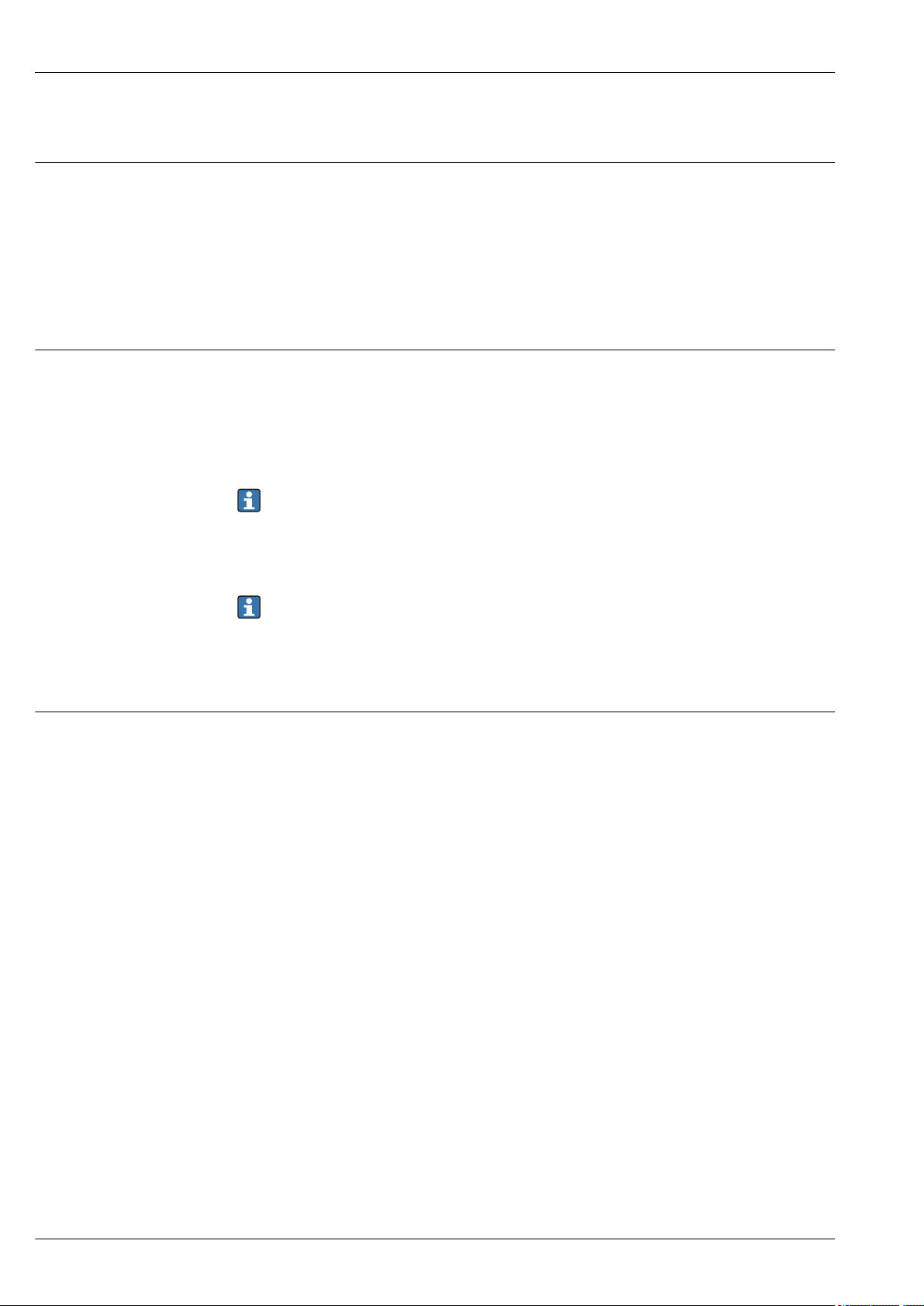

Panel version: Device with display and operating keys for installation in a panel or control cabinet

door. There is also the option of operating it in a desktop housing or field housing.

Panel version with stainless steel front: Device with touch screen (no operating keys) for

installation in a panel or a cabinet door. There is also the option of operating it in a desktop housing

or field housing.

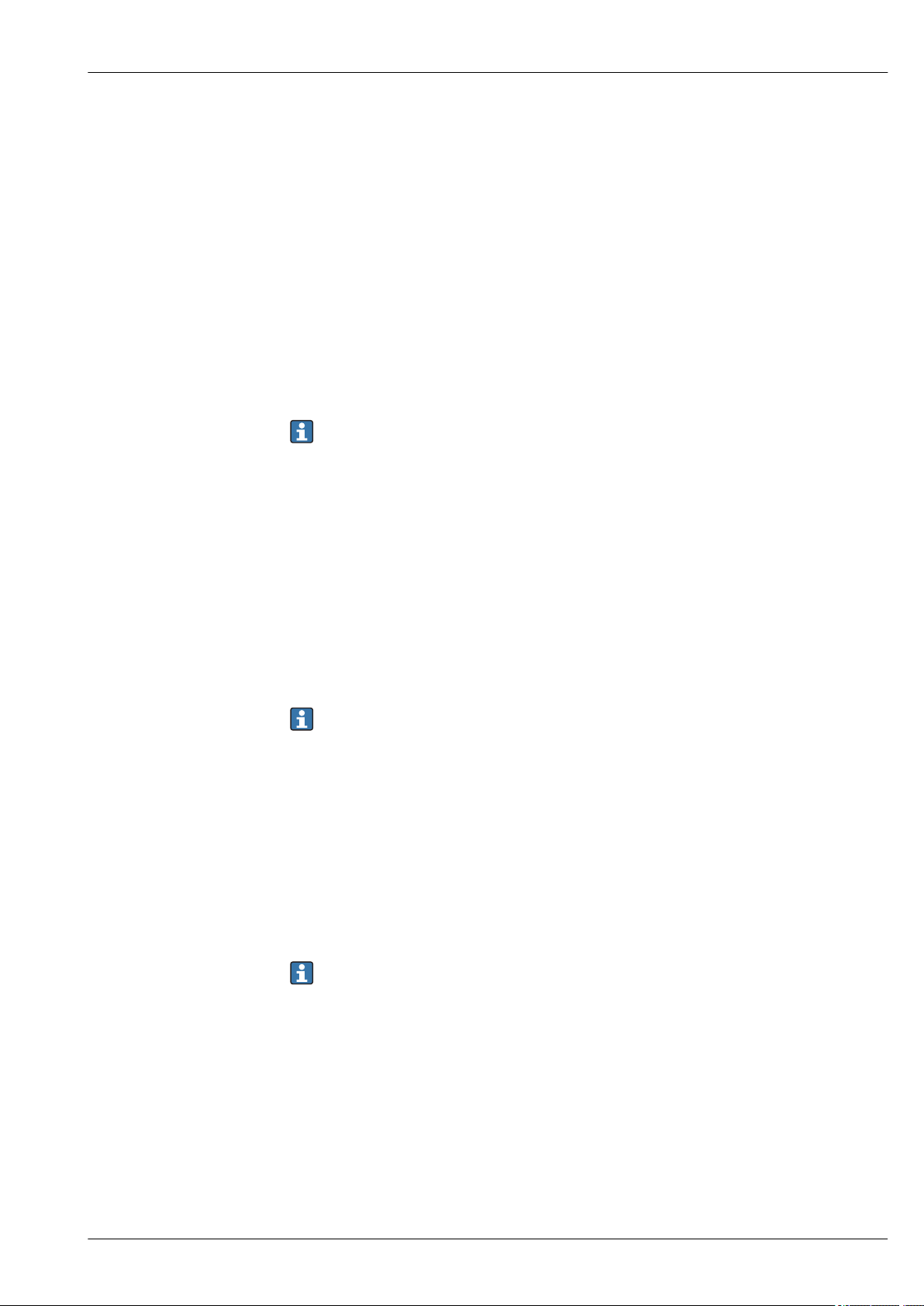

DIN rail version: Device without a display or operating keys for mounting on a DIN rail.

Multichannel data recording system with multicolor TFT display (order option, 178 mm (7 in) screen

size), internal memory, external memory (SD card and USB stick), galvanically isolated universal

inputs (U, I, TC, RTD, pulse, frequency), HART® inputs, digital inputs, transmitter power supply, limit

relays, digital and analog outputs, communication interfaces (USB, Ethernet, RS232/485), optionally

available with Modbus, Profibus DP or PROFINET I/O or EtherNet/IP.

An Essential Version of the Field Data Manager (FDM) software is included for SQL-supported data

analysis at the PC.

The number of inputs available in the basic device can be individually increased using a

maximum of 5 plug-in cards. The device supplies power directly to connected two-wire

transmitters. The device is configured and operated via the navigator (jog/shuttle dial) or by

touchscreen (optional) using the integrated Web server and a PC, an external USB keyboard or

mouse or with the FieldCare / DeviceCare configuration software. Online help supports the user

during local operation.

Ex version:

• The hazardous area version (Ex version) is only available in conjunction with the stainless

steel front and touch control.

• In this version, the SD card is integrated in the device and cannot be removed. The card can

be read out using the Field Data Manager (FDM) software supplied via USB or Ethernet or via

WebDAV.

Application packages / software options

In the standard version, the Advanced Data Manager has a variety of functions, including an end-toend safety concept to meet the requirements of FDA 21 CFR Part 11. The following application

packages are available to help users meet the requirements of their applications and save time:

• Mathematics

• Telealarm

• Batch management

• Wastewater + RSB (rain spillway basin)

• Energy calculation

The application packages contain the standard functions and the specific package functions. The

individual packages can be largely combined as the user requires. The application packages can also

be activated retroactively by entering the activation code.

Standard functions

• Signal analysis: external, 1 min to 12 h, day, week, month, year

• Web server

• User administration compliant with FDA 21 CFR Part 11

• Event log/audit trail

• Process screen

• Operation time counter

• Text entry/comments

• Change language

• Time synchronization

• Linearization

• Access protection through release code

• E-mail notification in event of alarms and limit violation

• Encrypted e-mail transmission via SSL (TLS)

• Operation via external USB keyboard and mouse

• External USB or network printer

2 Endress+Hauser

Page 3

Memograph M, RSG45

Mathematics

With the mathematics package, measured values of the inputs or the results of other math channels

can be linked mathematically. A formula with up to 200 characters can be created using a formula

editor. Once entered, the user can then check the plausibility of the formula.

Functions:

• 12 math channels

• Mathematics functions via formula editor

• Basic arithmetic operations, relational operators, logic operations and functions

Telealarm software

The Telealarm software facilitates user mobility, allowing users to respond to events while they are

on the road. E-mails or SMS messages triggered by process alarms or other important process events

can be sent to several recipients simultaneously or automatically forwarded to a recipient/

destination. Messages can be confirmed, relays controlled remotely and current values queried by

cellular phone. The Advanced Data Manager with GSM (GPRS) or Ethernet is ideal both for

environmental applications to monitor unstaffed outstations, and for tank monitoring applications.

The Telealarm software contains the mathematics package.

Functions:

• Advanced SMS/e-mail notification in the event of an alarm

• Instantaneous values queried by cellular phone

• Remote relay switching

• Alarm confirmation by SMS

Batch software

Batch management allows users to reliably record and visualize discontinuous processes. Userdefinable or externally controlled analysis intervals are possible for up to four batches

simultaneously. Batches are assigned batch-specific values and the measured data, the start, end and

duration of every batch, along with the current batch status, are displayed on the device and in the

Field Data Manager software. At the end of the batch, batch information is automatically printed out

directly at the device (USB or network printer) or is printed out via a PC with the Field Data Manager

software.

The batch software contains the mathematics package.

Functions:

• Batch report for 4 batches simultaneously

• USB barcode reader

• Automatic batch printout

• Preset counter

Wastewater + RSB (rain spillway basin)

The water/wastewater software supports operations monitoring of the water/wastewater sewage

network to obtain information about the quality and efficiency of the plant. The daily, weekly,

monthly and yearly maximum and minimum value is determined per quantity channel. Infiltration

water recording and the monitoring of rain spillway basins for reservoir and overflow events are also

functions of this software option.

The water/wastewater software contains the mathematics package and the telealarm software.

Functions:

• Rain spillway basin (reservoir/overflow)

• Highest and lowest values for quantities

• Highest and lowest values from ¼-hourly averages

• Determination of infiltration water

Energy package (water + steam)

The energy package allows users to calculate the mass and energy flow in water and steam

applications on the basis of the flow, pressure and temperature (or temperature differential).

Furthermore, energy calculations are also possible using glycol-based refrigerant media.

By balancing the results against one another or by linking the results to other input variables (e.g.

gas flow, electr. energy), users can calculate overall balances, efficiency levels etc. These values are

Endress+Hauser 3

Page 4

Memograph M, RSG45

important indicators for the quality of the process and form the basis for process optimization and

maintenance.

The internationally recognized standard IAPWS-IF 97 is used to calculate the thermodynamic state

variables of water and steam.

In the energy software, it is also possible to compensate differential pressure flow measurement

("DP-Flow"). The calculation of flow based on the differential pressure method is a special form of

flow measurement. Volumes or mass flow rates that are determined using the DP method require

specific correction. By solving the calculation equations listed in the standard in an iterative manner,

highly accurate results for DP flow measurements can be achieved. The measurement (orifice plate,

nozzle, Venturi pipe) is performed in accordance with ISO5167. Flow measurement based on the

dynamic pressure method uses the interrelation between differential pressure and flow.

The energy package contains the mathematics package.

Additional functions:

• 12 math channels

(Channels 1-8: energy-specific formulas and formula editor, channels 9-12: formula editor)

• Heat quantity + mass calculation for water and steam applications

• Efficiency calculation

TrustSens Calibration Monitoring

Available in conjunction with iTHERM TrustSens TM371 / TM372.

Application package :

• Up to 20 iTHERM TrustSens TM371 / TM372 can be monitored via the HART interface

• Self-calibration data displayed on screen or via the Web server

• Generation of a calibration history

• Creation of a calibration protocol as an RTF file directly at the RSG45

• Evaluation, analysis and further processing of the calibration data using "Field Data Manager"

(FDM) analysis software

Dependability Reliability

Depending on the device version, the mean time between failures (MTBF) is between 52 years and

16 years (calculated based on SN29500 standard at 40°C)

Maintainability

Battery-backed time and data memory. It is advisable to have the backup battery replaced by a

service technician after 10 years.

Real time clock (RTC)

• Automatic or manual summer time changeover

• Battery buffer. It is advisable to have the backup battery replaced by a service technician after 10

years.

• Drift: <10 min./year.

• Time synchronization possible via SNTP or via digital input.

Standard diagnostic functions as per Namur NE 107

The diagnostic code is made up of the error category as per Namur NE 107 and the message number.

• Cable open circuit, short-circuit

• Incorrect wiring

• Internal device errors

• Overrange/underrange detection

• Ambient temperature out-of-range detection

Device error/alarm relay

One relay can be used as an alarm relay. If the device detects a system error (e.g. hardware defect) or

a fault (e.g. cable open circuit), the selected relay switches.

This "alarm relay" switches if the device status is "F" (Failure). If the device status is "M" (Maintenance

required), the alarm relay does not switch.

4 Endress+Hauser

Page 5

Memograph M, RSG45

Safety

Recorded data are saved in a tamper-proof format and can be exported and archived with

manipulation protection using the Field Data Manager software.

IT security

The manufacturer only provides a warranty if the device is installed and used as described in the

Operating Instructions. The device is equipped with security mechanisms to protect it against any

inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide additional

protection for the device and device data transfer must be implemented by the operators themselves.

Input

Measured variables Analog universal inputs

Standard version without universal inputs. Optional multifunction cards (slot 1-5) with 4 universal

inputs (4/8/12/16/20) each.

You are free to choose between the following measured variables for each universal input: U, I, RTD,

TC, pulse input or frequency input.

Integration of input variable for totalization e.g. flow (m3/h) in quantity (m3).

HART® inputs

Standard version without HART® inputs. Optional HART® input cards (slot 1-5) with 4 inputs

(4/8/12/16/20) each.

Both the digital HART® values and the 4 to 20 mA signal can be evaluated at every input.

The 4 HART® values (PV, SV, TV, QV) of a sensor can be evaluated and the analog HART® value (PV)

can be measured via the digital HART® signal. Up to 40 digital HART® values can be recorded in

total. It is possible to access the HART® sensor in the field from a PC tool (e.g. FieldCare). In this way,

the sensor can be configured from the control room and the status information of the sensor can be

analyzed/displayed. The Memograph M acts as a HART® Gateway.

Access to the connected sensors is only possible if the device is connected by Ethernet.

Port 5094 must be open in the firewall.

Digital inputs

Standard version: 6 digital inputs

Optional digital card (slot 5): 8 additional digital inputs, 6 additional relays and 2 analog outputs

Math channels

12 math channels (optional). Mathematics functions can be freely edited via a formula editor.

Integration of calculated values e.g. for totalization.

Limit values

60 limit values (individual channel assignment)

Calculated values

The values of the universal and HART® inputs can be used to perform calculations in the math

channels.

The results of the math channels can also be used for calculations in other math channels.

Endress+Hauser 5

Page 6

Memograph M, RSG45

Measuring range

According to IEC 60873-1: An additional display error of ±1 digit is permitted for every measured

value.

User-definable measuring ranges per universal input of the multifunction card:

Measured

variable

Current (I) 0 to 20 mA; 0 to 20 mA quadratic

Voltage (U)

>1 V

Voltage (U)

≤1 V

Resistance

thermometer

(RTD)

Thermocoupl

es (TC)

Pulse input

1)

(I)

Frequency

input (I)

Measuring range Maximum measured error of

0 to 5 mA

4 to 20 mA; 4 to 20 mA quadratic

±20 mA

Overrange: up to 22 mA or -22 mA

0 to 10 V; 0 to 10 V quadratic

0 to 5 V

1 to 5 V; 1 to 5 V quadratic

±10 V

±30 V

0 to 1 V; 0 to 1 V quadratic

±1 V

±150 mV

Pt100: -200 to 850 °C (-328 to 1562 °F) (IEC 60751:2008, α=0.00385)

Pt100: -200 to 510 °C (-328 to 950 °F) (JIS C 1604:1984, α=0.003916)

Pt100: -200 to 850 °C (-328 to 1562 °F) (GOST 6651-94, α=0.00391)

Pt500: -200 to 850 °C (-328 to 1562 °F) (IEC 60751:2008, α=0.00385)

Pt500: -200 to 510 °C (-328 to 950 °F) (JIS C 1604:1984, α=0.003916)

Pt1000: -200 to 600 °C (-328 to 1112 °F) (IEC 60751:2008, α=0.00385)

Pt1000: -200 to 510 °C (-328 to 950 °F) (JIS C 1604:1984, α=0.003916)

Cu50: -50 to 200 °C (-58 to 392 °F) (GOST 6651-94, α=4260)

Cu50: -200 to 200 °C (-328 to 392 °F) (GOST 6651-94, α=4280)

Pt50: -200 to 1100 °C (-328 to 2012 °F) (GOST 6651-94, α=0.00391)

Cu100: -200 to 200 °C (-328 to 392 °F) (GOST 6651-94, α=4280)

Pt46: -200 to 1100 °C (-328 to 2012 °F) (GOST 6651-94, α=0.00391)

Cu53: -200 to 200 °C (-328 to 392 °F) (GOST 6651-94, α=4280)

Type J (Fe-CuNi): -210 to 1200 °C (-346 to 2192 °F) (IEC 60584:2013)

Type K (NiCr-Ni): -270 to 1300 °C (-454 to 2372 °F) (IEC 60584:2013)

Type L (NiCr-CuNi): -200 to 800 °C (-328 to 1472 °F) (GOST R8.585:2001)

Type L (Fe-CuNi): -200 to 900 °C (-328 to 1652 °F) (DIN 43710-1985)

Type N (NiCrSi-NiSi): -270 to 1300 °C (-454 to 2372 °F) (IEC 60584:2013)

Type T (Cu-CuNi): -270 to 400 °C (-454 to 752 °F) (IEC 60584:2013)

Type A (W5Re-W20Re): 0 to 2500 °C (32 to 4532 °F) (ASTME 988-96)

Type B (Pt30Rh-Pt6Rh): 42 to 1820 °C (107.6 to 3308 °F) (IEC 60584:2013)

Type C (W5Re-W26Re): 0 to 2315 °C (32 to 4199 °F) (ASTME 988-96)

Type D (W3Re-W25Re): 0 to 2315 °C (32 to 4199 °F) (ASTME 988-96)

Type R (Pt13Rh-Pt): -50 to 1768 °C (-58 to 3214 °F) (IEC 60584:2013)

Type S (Pt10Rh-Pt): -50 to 1768 °C (-58 to 3214 °F) (IEC 60584:2013)

Min. Pulse length 40 μs, max. 12.5 kHz; 0 to 7 mA = LOW; 13 to 20 mA = HIGH Load: 50 Ω

0 to 10 kHz, overrange: up to 12.5 kHz; 0 to 7 mA = LOW; 13 to 20 mA = HIGH ±0.02% @ f <100 Hz of reading

1)

measuring range (oMR),

temperature drift

±0.1% oMR

Temperature drift: ±0.01%/K oMR

±0.1% oMR

Temperature drift: ±0.01%/K oMR

±0.1% oMR

Temperature drift: ±0.01%/K oMR

4-wire: ±0.1% oMR

3-wire: ±(0.1% oMR + 0.8 K)

2-wire: ±(0.1% oMR + 1.5 K)

Temperature drift: ±0.01%/K oMR

4-wire: ±0.2% oMR

3-wire: ±(0.2% oMR + 0.8 K)

2-wire: ±(0.2% oMR + 1.5 K)

Temperature drift: ±0.02%/K oMR

4-wire: ±0.3% oMR

3-wire: ±(0.3% oMR + 0.8 K)

2-wire: ±(0.3% oMR + 1.5 K)

Temperature drift: ±0.02%/K oMR

±0.1% oMR from -100 °C (-148 °F)

±0.1% oMR from -130 °C (-202 °F)

±0.1% oMR from -100 °C (-148 °F)

±0.1% oMR from -100 °C (-148 °F)

±0.1% oMR from -100 °C (-148 °F)

±0.1% oMR from -200 °C (-328 °F)

Temperature drift: ±0.01%/K oMR

±0.15% oMR from 500 °C (932 °F)

±0.15% oMR from 600 °C (1112 °F)

±0.15% oMR from 500 °C (932 °F)

±0.15% oMR from 500 °C (932 °F)

±0.15% oMR from 100 °C (212 °F)

±0.15% oMR from 100 °C (212 °F)

Temperature drift: ±0.01%/K oMR

±0.01% @ f ≥100 Hz of reading

Temperature drift: 0.01% of

measured value over the entire

temperature range

Input

resistance

Load: 50 Ω

±1 Ω

≥1 MΩ

≥2.5 MΩ

≥1 MΩ

≥1 MΩ

±1 Ω

1) If a universal input is used as a frequency or pulse input, a series resistor must be used in series connection with the voltage source. Example: 1.2

kΩ series resistor at 24 V

6 Endress+Hauser

Page 7

Memograph M, RSG45

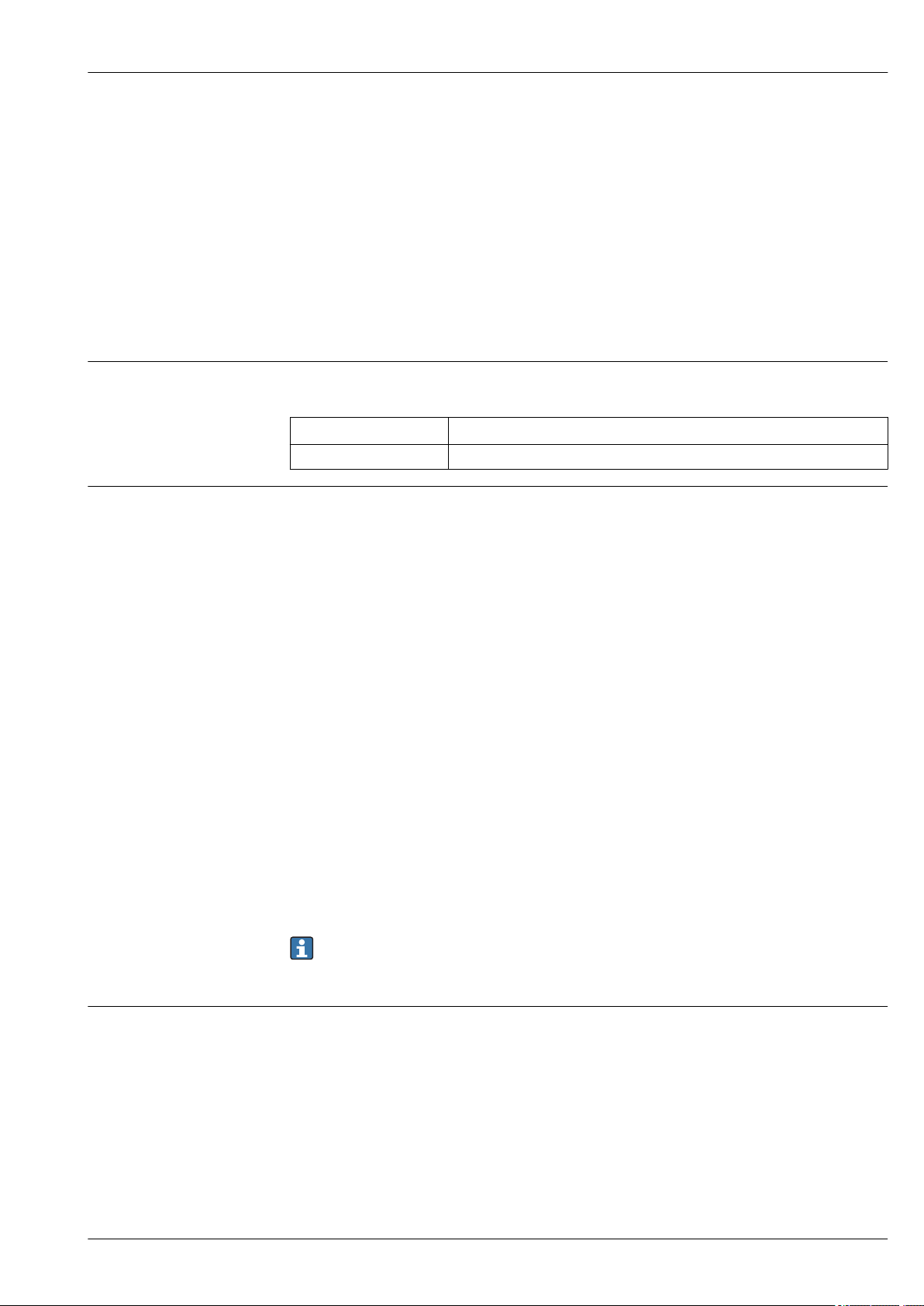

Current measuring range of the HART® card:

Measured

variable

Current (I) 4 to 20 mA

Measuring range Maximum measured error of

measuring range (oMR),

temperature drift

±0.1% oMR

Overrange: up to 22 mA

Temperature drift: ±0.01%/K oMR

Maximum load and additional input parameters of the multifunction cards

Limit values for input voltage and current as well as cable open circuit detection/line influence/temperature compensation:

Measured variable Limit values (steady-state, without

destroying input)

Current (I) Maximum permitted input voltage: 2.5 V

Maximum permitted input current: 50 mA

Pulse, frequency (I) Maximum permitted input voltage: 2.5 V

Maximum permitted input current: 50 mA

Voltage (U) >1 V Maximum permitted input voltage: 35 V 1 to 5 V range with disengageable cable open circuit monitoring:

Voltage (U) ≤1 V Maximum permitted input voltage: 24 V

Resistance

thermometer (RTD)

Thermocouples (TC) Maximum permitted input voltage: 24 V Influence of line resistance: <0.001%/Ω

Measuring current: ≤1 mA Maximum barrier resistance (or line resistance):

Cable open circuit detection/line influence/temperature compensation

4 to 20 mA range with disengageable cable open circuit monitoring to NAMUR

NE43. The following error ranges apply when NAMUR NE43 monitoring is

switched on:

≤3.8 mA: underrange

≥20.5 mA: overrange

≤ 3.6 mA or ≥ 21.0 mA: open circuit (display shows: – – – –)

No cable open circuit monitoring

<0.8 V or >5.2 V: cable open circuit (display shows: - - - -)

4-wire: max. 200 Ω; 3-wire: max. 40 Ω

Maximum influence of barrier resistance (or line resistance) for Pt100, Pt500

and Pt1000: 4-wire: 2 ppm/Ω, 3-wire: 20 ppm/Ω

Maximum influence of barrier resistance (or line resistance) for Pt46, Pt50,

Cu50, Cu53, Cu100 and Cu500: 4-wire: 6 ppm/Ω, 3-wire: 60 ppm/Ω

Cable open circuit monitoring if any connection is interrupted.

Error, internal temperature compensation: ≤ 2 K

Input

impedance

Load: 10 Ω

±1 Ω

Maximum load and additional input parameters of the HART® cards

Limit values for input voltage and current as well as cable open circuit detection:

Measured variable Limit values (steady-state, without

destroying input)

Current (I) Maximum permitted input voltage: 0.5 V

Maximum permitted input current: 50 mA

Cable open circuit detection

4 to 20 mA range with disengageable cable open circuit monitoring to NAMUR

NE43. The following error ranges apply when NAMUR NE43 monitoring is

switched on:

≤3.8 mA: underrange

≥20.5 mA: overrange

≤ 3.6 mA or ≥ 21.0 mA: open circuit (display shows: – – – –)

Scan rate

Current/voltage/pulse/frequency input: 100 ms per channel

Thermocouples and resistance temperature detector: 1 s per channel

Data storage / memory cycle

Choose from the following for the memory cycle: off / 100 ms / 1s / 2s / 3s / 4s / 5s / 10s / 15s /

20s / 30s / 1min / 2min / 3min / 4min / 5min / 10min / 15min / 30min / 1h

Highspeed storage (100 ms) can be selected for up to 8 channels in Group 1 only.

Highspeed storage is not available in the energy package (option).

Endress+Hauser 7

Page 8

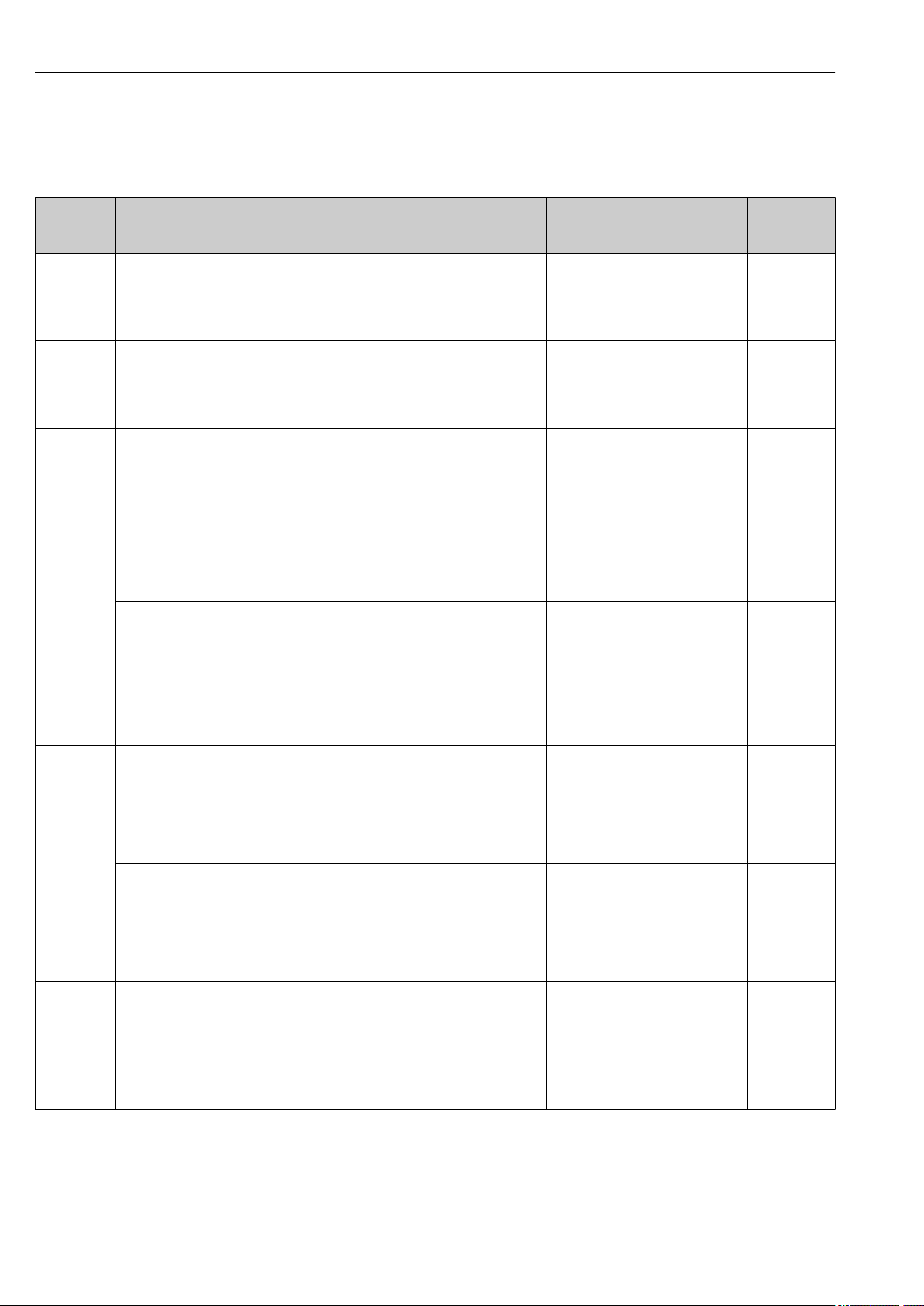

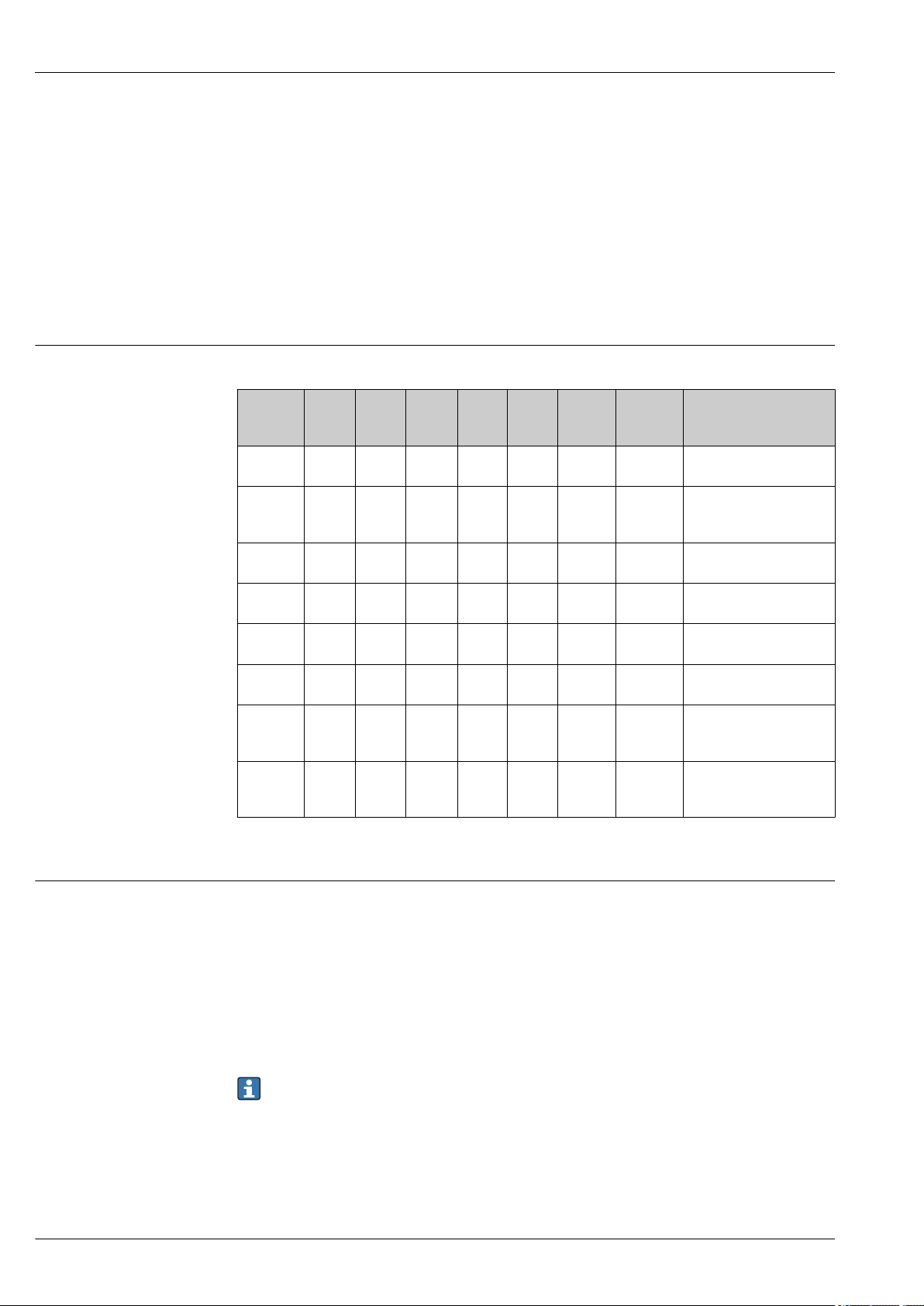

256 MB internal memory:

Memograph M, RSG45

Typical recording length

Prerequisites for following tables:

• No limit value violation / integration

• Digital input not used

• Signal analysis 1: off, 2: day, 3: month, 4: year

• No active math channels

Frequent entries in the event log reduce the memory availability!

Analog

inputs

1 1/0/0/0/0/0/0/0/0/0 1796, 6, 13 362, 5, 17 181, 4, 9 60, 4, 3 6, 0, 10

4 4/0/0/0/0/0/0/0/0/0 1319, 2, 23 267, 5, 17 134, 1, 2 44, 5, 10 4, 3, 8

8 4/4/0/0/0/0/0/0/0/0 661, 4, 3 133, 6, 21 67, 0, 16 22, 2, 17 2, 1, 16

12 4/4/4/0/0/0/0/0/0/0 441, 3, 8 89, 2, 9 44, 5, 3 14, 6, 11 1, 3, 10

20 4/4/4/4/4/0/0/0/0/0 265, 0, 15 53, 4, 7 26, 5, 21 8, 6, 16 0, 6, 6

40 4/4/4/4/4/4/4/4/4/4 132, 4, 8 26, 5, 16 13, 2, 23 4, 3, 8 0, 3, 3

Channels in groups Storage cycle (weeks, days, hours)

5 min 1 min 30 s 10 s 1 s

External memory, 1 GB SD card:

Analog

inputs

1 1/0/0/0/0/0/0/0/0/0 12825, 5, 20 2580, 4, 18 1291, 2, 5 430, 4, 14 43, 0, 12

4 4/0/0/0/0/0/0/0/0/0 8672, 5, 12 1749, 6, 13 875, 6, 13 292, 1, 8 29, 1, 14

8 4/4/0/0/0/0/0/0/0/0 4343, 1, 1 875, 1, 17 438, 0, 6 146, 0, 17 14, 4, 7

12 4/4/4/0/0/0/0/0/0/0 2896, 6, 13 583, 3, 21 292, 0, 6 97, 2, 20 9, 5, 4

20 4/4/4/4/4/0/0/0/0/0 1738, 6, 4 350, 1, 3 175, 1, 14 58, 3, 2 5, 5, 22

40 4/4/4/4/4/4/4/4/4/4 869, 5, 0 175, 0, 15 87, 4, 7 29, 1, 13 2, 6, 11

Channels in groups Storage cycle (weeks, days, hours)

5 min 1 min 30 s 10 s 1 s

Digital inputs

Converter resolution

24 bit

Totalization

The interim value, daily value, weekly value, monthly value, annual value and overall value can be

determined (13-digit, 64 bit).

Analysis

Recording of quantity/operating time (standard function), also a min/max/median analysis within

the set time frame.

Input level Logical "0" (corresponds to –3 to +5 V), activation with logical "1" (corresponds to

+12 to +30 V)

Input frequency max. 25 Hz

Pulse length Min. 20 ms (pulse counter)

Pulse length Min. 100 ms (control input, messages, operating time)

Input current max. 2 mA

Input voltage Max. 30 V

8 Endress+Hauser

Page 9

Memograph M, RSG45

Selectable functions

• Functions of the digital input: control input, ON/OFF message, pulse counter (13-digit, 64-bit),

operating time, message+operating time, quantity from time, Profibus DP, EtherNet/IP,

PROFINET.

• Functions of the control input: start recording, screensaver on, lock setup, time synchronization,

change group, limit value monitoring on/off, individual LV on/off, block keyboard/navigator,

start/stop analysis.

Additionally for the batch software option: reset batch number, batch limit values on/off.

Output

Auxiliary voltage output

Analog and pulse outputs Number

The auxiliary voltage output can be used for loop power supply or to control the digital inputs. The

auxiliary voltage is short-circuit proof and galvanically isolated.

Output voltage 24 VDC ±15%

Output current Max. 250 mA

Optional digital card (slot 5): 2 analog outputs which can be operated as current or pulse outputs.

Analog output (current output)

Output current: 0/4 to 20 mA with 10% overrange

Max. output voltage: approx. 16 V

Accuracy: ≤0.1% of end of range value

Temperature drift: ≤0.015%/K of end of range value

Resolution: 13 Bit

Load: 0 to 500 Ω

Error signal as per NAMUR NE43: 3.6 mA or 21 mA can be configured

Digital output (pulse output)

Output voltage:

≤5 V corresponds to LOW

≥12 V corresponds to HIGH

Short-circuit proof (maximum 25 mA)

Speed: max. 1000 pulses/s

Pulse width: 0.5 to 1000 ms

The pulse pause is at least as long as the pulse width.

Load: ≥1 kΩ

Relay outputs

A mix of low voltage (230 V) and safety extra low voltage (SELV circuits) is not permitted at the

connections of the relay contacts.

Alarm relay

1 alarm relay with changeover contact.

Standard relay

5 relays with NO contact, e.g. for limit value messages (can be configured as NC contact).

Endress+Hauser 9

Page 10

Memograph M, RSG45

Optional relays

Optional digital card (slot 5): 6 additional relays with NO contact e.g. for limit value alarms (can be

configured as an NC contact).

Relay switching capacity

• Max. relay switching capacity: 3 A @ 30 V DC

• Max. relay switching capacity: 3 A @ 250 V AC

• Min. switching load: 300 mW

Switching cycles

5

>10

Galvanic isolation

All inputs and outputs are galvanically isolated from each other and designed for the following test

voltages:

Relay DigitalinAnalog

Relay 500

V

2 kVDC2 kVDC2 kVDC2 kVDC2 kV

DC

Digital in 2 kVDC500

V

DC

but:

Analog

in/HART®

Analog

out

2 kVDC500

V

DC

2 kVDC500

V

DC

Ethernet 2 kVDC500

V

DC

RS232/

RS485

2 kVDC500

V

DC

USB 2 kVDC500

V

DC

Auxiliary

voltage

2 kVDC500

V

DC

output

in/

HART®

500

V

1)

500

V

500

V

500

V

500

V

500

V

500

V

Analog

out

500

V

DC

500

V

DC

500

V

DC

500

V

DC

500

V

DC

500

V

DC

EthernetRS232/

500

V

DC

DC

500

V

DC

DC

500

V

DC

DC

- 500 VDC500 V

DC

500

V

DC

DC

500

V

DC

DC

USB Auxiliary voltage output

RS485

2 kV

DC

500 VDC500 V

500 VDC500 V

500 VDC500 V

- 500 V

DC

DC

DC

DC

DC

DC

500 VDCGalvanicall

y

2 kV

500 V

500 V

500 V

500 V

500 V

500 V

DC

DC

DC

DC

DC

DC

DC

connected

500

V

DC

500

V

DC

DC

500 VDC500 V

-

DC

1) Test voltage applies between inputs on power unit (terminals D11 to D61) to inputs on optional digital

card (terminals D71 to DE1). The inputs are galvanically connected on the same plug-in connector.

Cable specification Cable specification, spring terminals

All connections on the rear of the device are designed as pluggable screw or spring terminal blocks

with reverse polarity protection. This makes the connection very quick and easy. The spring

terminals are unlocked with a slotted screwdriver (size 0).

Please note the following when connecting:

• Wire cross-section, auxiliary voltage output, digital I/O and analog I/O: max. 1.5 mm2 (14 AWG)

(spring terminals)

• Wire cross-section, mains: max. 2.5 mm2 (13 AWG) (screw terminals)

• Wire cross-section, relays: max. 2.5 mm2 (13 AWG) (spring terminals)

• Stripping length: 10 mm (0.39 in)

No ferrules must be used when connecting flexible wires to spring terminals.

Shielding and grounding

Optimum electromagnetic compatibility (EMC) can only be guaranteed if the system components

and, in particular, the lines - both sensor lines and communication lines - are shielded and the shield

forms as complete a cover as possible. A shielded line must be used for sensor lines that are longer

than 30 m. A shield coverage of 90% is ideal. In addition, make sure not to cross sensor lines and

10 Endress+Hauser

Page 11

Memograph M, RSG45

0

1

2

3

4

5

6

O15

O16

O25

O26

D71

D81

D91

DA1

DB1

DC1

DD1

DE1

GND2

GND2

RA

RB

RC

RD

RE

RF

RG

RH

RI

RJ

RK

RL

Ethernet

USB

RS 232 / RS 485

Bus Interface

Ch1

Ch2

Ch3

41

…

.

.

…

46

Ch4

31

…

.

.

…

36

21

…

.

.

…

26

11

…

.

.

…

16

Ch5

Ch6

Ch7

81

…

.

.

…

86

Ch8

71

…

.

.

…

76

61

…

.

.

…

66

51

…

.

.

…

56

Ch9

Ch10

Ch11

C1

…

.

.

…

C6

Ch12

B1

…

.

.

…

B6

A1

…

.

.

…

A6

91

…

.

.

…

96

G1

…

.

.

…

G6

F1

…

.

.

…

F6

E1

…

.

.

…

E6

D1

…

.

.

…

D6

L/+

N/-

PE

24V

Out

R11

R12

R13

R41

R42

R51

R52

R61

R62

D11

D21

D31

D41

D51

D61

GND1

R21

R22

R31

R32

+

Ch13

Ch14

Ch15

Ch16

-

0123456

communication lines when routing them. Connect the shield as often as possible to the reference

ground to ensure optimum EMC protection for the different communication protocols and the

connected sensors.

To comply with requirements, three different types of shielding are possible:

• Shielding at both ends

• Shielding at one end on the supply side with capacitance termination at the device

• Shielding at one end on the supply side

Experience shows that the best results with regard to EMC are achieved in most cases in installations

with one-sided shielding on the supply side (without capacitance termination at the device).

Appropriate internal device wiring measures must be taken to allow unrestricted operation when

EMC interference is present. These measures have been taken into account for this device. Operation

in the event of disturbance variables as per NAMUR NE21 is thus guaranteed.

Where applicable, national installation regulations and guidelines must be observed during the

installation! Where there are large differences in potential between the individual grounding points,

only one point of the shielding is connected directly with the reference ground.

If the shielding of the cable is grounded at more than one point in systems without potential

matching, mains frequency equalizing currents can occur. These can damage the signal cable or

significantly impact signal transmission. In such cases the shielding of the signal cable is to be

grounded on one side only, i.e. it may not be connected to the ground terminal of the housing.

The shield that is not connected should be insulated!

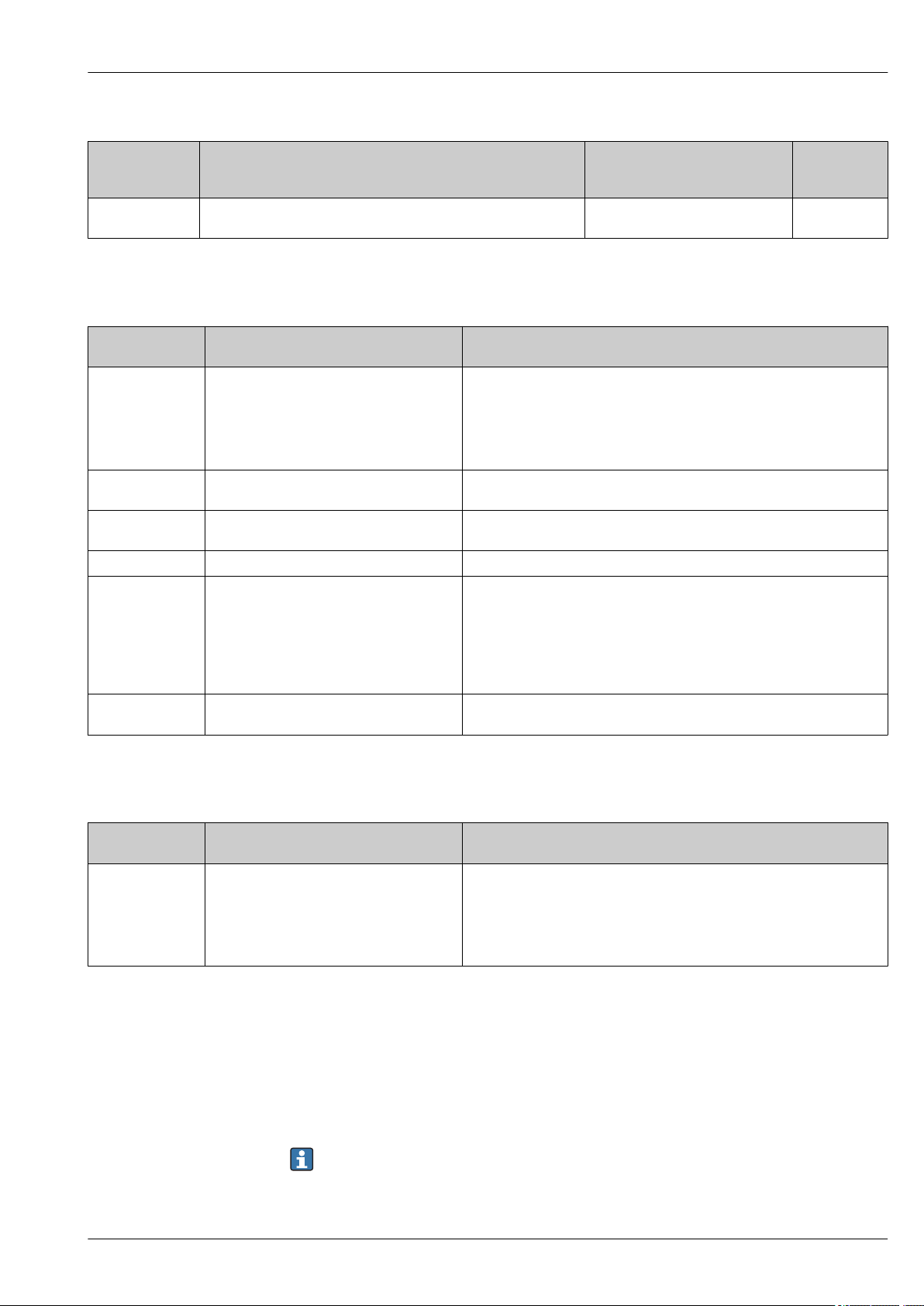

Connections

Power supply

A0024605

1 Connections: back of device, panel version (left), DIN rail version (right)

6 Slot 6: Power supply with relays

5 Slot 5: Multifunction card or HART® card (channels 17-20) or digital card

4 Slot 4: Multifunction card or HART® card (channels 13-16)

3 Slot 3: Multifunction card or HART® card (channels 9-12)

2 Slot 2: Multifunction card or HART® card (channels 5-8)

1 Slot 1: Multifunction card or HART® card (channels 1-4)

0 Slot 0: CPU card with interfaces

Supply voltage

Power consumption

Endress+Hauser 11

• Extra-low voltage power supply unit ±24 V AC/DC (-10% / +15%) 50/60Hz

• Low voltage power supply unit 100 to 230 V AC (±10%) 50/60Hz

Overcurrent protection (rated current ≤ 10 A) must be installed for the power cable.

• 100 to 230 V: max. 47 VA

• 24 V: max. 30 VA

Page 12

Memograph M, RSG45

The power actually consumed depends on the individual operating state and the device version (LPS,

USB, brightness of screen, number of channels, etc). The active power here is approx. 3 W to 25 W.

Power supply failure

Electrical connection, terminal assignment

Battery-backed time and data memory. The device starts automatically following a power failure.

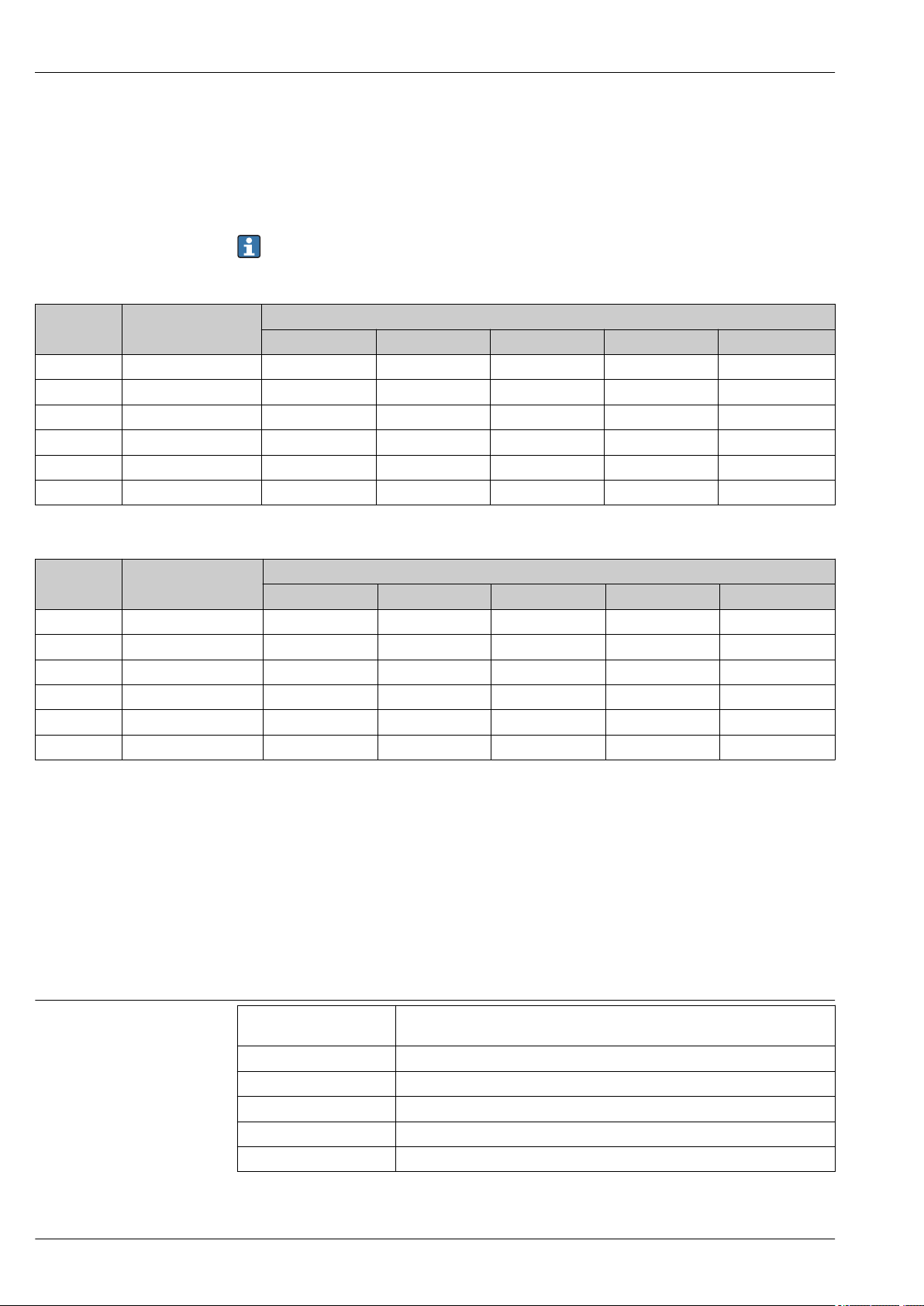

All connection examples are illustrated using the panel version. The connections on the DIN rail

version are identical.

12 Endress+Hauser

Page 13

Memograph M, RSG45

-

+

b) 1 V≤

a) >1 V

Rel. max. 250 V / 3 A

a) 0...5 V, 1...5 V, 0...10 V, ±10 V, ±30 V

b) 0...1 V, ±150 mV, ±1 V

L+

N-

PE

100-230 VAC

(±10%)

50 / 60 Hz

12-24 VDC

>5 mA

+

+

_

RTD

I

U

TC

0...20 mA, 4...20 mA, 0...5 mA, ±20 mA

A, B, C, D, J, K, L, N, T, R, S

+

_

12-24 VDC

24 V AC/DC

(-10%; +15%)

50 / 60 Hz

24V Out: max. 250 mA

Dx1

LOW = 0...7 mA

HIGH = 13...20 mA

15

69

>40 µs

>20 ms

RS 232

22335

5

1

1

5

5

6

6

9

9

RS 485

RxD/TxD(+)

R

L

RxD/TxD(-)

R=

8

9

8 9

8 9

8 9

x2x1 x3 x4x5x6

x2x1 x3 x4x5x6

Dx1

GNDx

24 V +

Dx1

GNDx

24 V -

-

GNDx

Dx1

GNDx

10k

O15

O16

O25

O26

+ - + -

1 2

0...20 mA;

4...20 mA

+ - + -

1 2

Pt46, Pt50, Pt100,

Pt500, Pt1000,

Cu50, Cu53, Cu100

x2x1 x3 x4x5x6 x2x1 x3 x4x5x6

24 V

x2x1 x3 x4x5x6

R=1.2 k

Ethernet

USB

RS 232 / RS 485

Bus Interface

Ch1

Ch2

Ch3

41

…

…

…

…

46

Ch4

31

…

…

…

…

36

21

…

…

…

…

26

11

…

…

…

…

16

Ch5

Ch6

Ch7

81

…

…

…

…

86

Ch8

71

…

…

…

…

76

61

…

…

…

…

66

51

…

…

…

…

56

Ch9

Ch10

Ch11

C1

…

…

…

…

C6

Ch12

B1

…

…

…

…

B6

A1

…

…

…

…

A6

91

…

…

…

…

96

Ch13

Ch14

Ch15

G1

…

…

…

…

G6

Ch16

F1

…

…

…

…

F6

E1

…

…

…

…

E6

D1

…

…

…

…

D6

L/+

N/-

PE

24V

Out

O15

O16

O25

O26

D71

D81

D91

DA1

DB1

DC1

DD1

DE1

GND2

GND2

R11

R12

R13

R41

R42

R51

R52

R61

R62

D11

D21

D31

D41

D51

D61

GND1

+

R21

R22

R31

R32

-

RARBRCRDRERFRGRHRIRJRK

RL

+

-

+

-

+

-

+

-

+

-

U

I

(Volt drop 1 V, Ri50 Ohm)≤ ≤

Further units

Termination

resistor

(typical 120 )Ω

Power supply

Digital in (D)

To PC: Cable with

9 pol. Sub-D plug

RxD - 3 GND - 5

TxD - 2

To modem: Cable with

9 pol. Sub-D socket

Analog inputs

LED

yellow

LED

green

Pulse/

frequency

Slot 6: Power upply lots s ( tandard)s

Slot 5: analog input d o17-20 or igital-I/O ( ption)/ HART

Slot 4: 13-16 ( ption)analog input o/ HART

Slot 3: analog input o9-12 ( ption)/ HART

Slot 2: 5-8 ( ption)analog input o/ HART

Slot 1: )analog input o1-4 ( ption/ HART

Slot 0: CPU ( tandard)s

Analog

outputs (O)

(Selectable in unit setup)

Pulse

Circuit diagram

A0026669-EN

2 For connection examples of the HART® inputs (optional), see the Operating Instructions

Endress+Hauser 13

Page 14

Memograph M, RSG45

Supply voltage (power unit, slot 6)

Power unit type Terminal

100-230 VAC L+ N- PE

Phase L Zero conductor N Ground

24 V AC/DC L+ N- PE

Phase L or + Zero conductor N or - Ground

Relay (power unit, slot 6)

Type Terminal (max. 250 V, 3 A)

A0019103

Alarm relay 1 R11 R12 R13

Changeover

contact

Normally

closed contact

1)

(NC)

Normally open

contact (NO)

2)

Relay 2 to 6 Rx1 Rx2

Switching contact Normally open

contact (NO

1) NC = normally closed (breaker)

2) NO = normally open (maker)

The open or close function (= activation or deactivation of the relay coil) in a limit event can be

configured in the setup: "Setup -> Advanced setup -> Outputs -> Relay -> Relay x". However, in

the event of a power failure, the relay adopts its quiescent switch state regardless of the setting

programmed.

Digital inputs; auxiliary voltage output (power unit, slot 6)

Type Terminal

A0019103

2)

)

A0019103

Digital input

1 to 6

D11 to D61 GND1

Digital input 1 to 6 (+) Ground (-) for digital

inputs 1 to 6

14 Endress+Hauser

Page 15

Memograph M, RSG45

Chx

x1

x2

x3

x4

x5

x6

Type Terminal

Auxiliary

voltage

output, not

stabilized,

max. 250 mA

24V Out - 24V Out +

- Ground + 24V (±15%)

If the auxiliary voltage is to be used for the digital inputs, the 24 V out - terminal of the

auxiliary voltage output must be connected with the GND1 terminal.

Analog inputs (slot 1-5)

The first digit (x) of the two-digit terminal number corresponds to the associated channel:

Type Terminal

A0019103

A0019303

x1 x2 x3 x4 x5 x6

Current/pulse/frequency

1)

input

Voltage > 1V (+) (-)

Voltage ≤1V (+) (-)

Resistance thermometer

RTD (2-wire)

Resistance thermometer

RTD (3-wire)

Resistance thermometer

RTD (4-wire)

Thermocouples TC (+) (-)

1) If a universal input is used as a frequency or pulse input, a series resistor must be used in series connection

with the voltage source. Example: 1.2 kΩ series resistor at 24 V

(A) (B)

(A) b (sense) (B)

(A) a (sense) b (sense) (B)

(+) (-)

Endress+Hauser 15

Page 16

Memograph M, RSG45

Chx

x1

x2

x3

x4

x5

x6

250Ω 10Ω

x1

x2

x3

x4

x5

x6

Modem

O15

O16

O25

O26

D71

D81

D91

DA1

DB1

DC1

DD1

DE1

GND2

GND2

RA

RB

RC

RD

RE

RF

RG

RH

RI

RJ

RK

RL

O15

O16

O25

O26

D71

D81

D91

DA1

DB1

DC1

DD1

DE1

GND2

GND2

RA

RB

RC

RD

RE

RF

RG

RH

RI

RJ

RK

RL

HART® inputs (slot 1-5)

The first digit (x) of the two-digit terminal number corresponds to the associated channel:

Type Terminal

x1 x2 x3 x4 x5 x6

HART® (4 to 20 mA) SHD H_1 H_2 R

com

• A 250 Ω communication resistor (load) is installed on the device side between terminals x4

and x5.

• A 10 Ω resistor (shunt) is installed on the device side at the current input between terminals

x5 and x6.

• Terminals x2 and x3 (H_1 and H_2) are jumpered internally.

• The internal HART® modem is located between terminals x2/x3 and x6.

Relay extension (digital card, slot 5)

I+ I-

A0024862

Type Terminal (max. 250 V, 3 A)

Relay 7, 8 RA RB RC RD

Relay 9, 10 RE RF RG RH

Relay 11, 12 RI RJ RK RL

Switching contact Normally open

contact (

1)

)

Switching contact Normally open contact

2)

(

)

1) NO)

2) NO)

The open or close function (= activation or deactivation of the relay coil) in a limit event can be

configured in the setup: "Setup -> Advanced setup -> Outputs -> Relay -> Relay x". However, in

the event of a power failure, the relay adopts its quiescent switch state regardless of the setting

programmed.

Analog outputs (digital card, slot 5)

Type Terminal

A0024736

Analog

output 1-2

16 Endress+Hauser

O15 O16 O25 O26

Analog output 1 (+) Ground, analog output

Analog output 2 (+) Ground, analog output

1 (-)

2 (-)

A0024736

Page 17

Memograph M, RSG45

O15

O16

O25

O26

D71

D81

D91

DA1

DB1

DC1

DD1

DE1

GND2

GND2

RA

RB

RC

RD

RE

RF

RG

RH

RI

RJ

RK

RL

Extension of digital inputs (digital card, slot 5)

Type Terminal

Digital input 7 to14D71 to DE1 GND2 GND2

Digital input 7 to 14 (+) Ground (-) for digital inputs 7

to 14

Ground (-) for digital inputs 7

to 14

If the auxiliary voltage is to be used for the digital inputs, the 24 V out - terminal of the

auxiliary voltage output (power unit, slot 6) must be connected with the GND2 terminal.

A0024736

Connector

Overvoltage protection

Connection data interface, communication

• Panel-mounted device/DIN rail version: connected to mains via plug-in screw terminals with

reverse polarity protection

• Desktop version (option): connected to mains via IEC connector

To avoid high-energy transients on long signal cables, connect a suitable surge arrester upstream

(e.g. E+H HAW562) in series upstream.

USB interfaces:

1 x USB port type A (host) on the front of device (only for version with navigator and front interfaces)

A USB 2.0 port is available on a shielded USB A socket at the front of the device. A USB stick as a

memory medium, for example, can be connected to this port. An external keyboard/mouse for device

operation, a USB hub, a barcode reader or a printer (PCL5c or higher) may also be connected.

1 x USB port type B (function) on the front of device (only for version with navigator and front

interfaces)

A USB 2.0 port is available on a shielded USB B socket at the front of the device. This can be used to

connect the device for communication with a laptop, for example.

2 x USB port type A (host) on the rear of the device (standard)

Two USB 2.0 ports are available on shielded USB A sockets at the rear of the device. A USB stick as a

memory medium, for example, can be connected to these ports. An external keyboard/mouse for

device operation, a USB hub, a barcode reader or a printer (PCL5c or higher) may also be connected.

• USB-2.0 is compatible with USB-1.1 or USB-3.0, i.e. communication is possible.

• The assignment of the USB interfaces complies with the standard such that shielded standard

cables with a maximum length of 3 meters (9.8 ft) can be used here.

• The USB devices are detected by the "plug-and-play" function. If several devices of the same

type are connected, only the USB device that was connected first is available.

• A maximum of 8 external USB devices (incl. USB hub) can be connected if they do not exceed

the maximum load of 500 mA. If overloaded, the corresponding USB devices are

automatically disabled. An active USB hub can be used for higher power ratings.

Reference list for USB printers:

HP Color LaserJet CP1515n, HP Color LaserJet Pro CP1525n, ECOSYS P6021cdn.

The printer must support PCL5c (or higher). GDI printers are not supported!

Reference list for USB barcode readers:

Datalogic Gryphon D230; Metrologic MS5100 Eclipse Series; Symbol LS2208, Datalogic Quickscan 1,

Godex GS220, Honeywell Voyager 9590.

Ethernet interface (standard):

Ethernet interface on back, 10/100 Base-T, plug type RJ45. The Ethernet interface can be used to

integrate the device via a hub or switch into a PC network (TCP/ IP Ethernet). A standard patch cable

(e.g. CAT5E) can be used for the connection. Using DHCP, the device can be fully integrated into an

existing network without the need for additional configuration. The device can be accessed from

Endress+Hauser 17

Page 18

Memograph M, RSG45

every PC in the network. Normally only the automatic assignment of the IP address must be

configured at the client. When the device is started, it can automatically retrieve the IP address,

subnet mask and gateway from a DHCP server. If DHCP is not used (depending on the specific

network) these settings must be made directly in the device. Two Ethernet function LEDs are located

on the rear of the device.

The following functions are implemented:

• Data communication with PC software (analysis software, configuration software, OPC server)

• Web server

• WebDAV (Web-based Distributed Authoring and Versioning) is an open standard for the

provisioning of files via the HTTP protocol. The data saved on the device's SD card can be read out

using a PC. A Web browser or dedicated WebDAV client can be selected as the network drive on

the PC for this purpose.

Requirements with regard to a network printer:

Network printer reference list:

HP Color LaserJet CP1515n, HP Color LaserJet Pro CP1525n, ECOSYS P6021cdn.

The printer must support PCL5c (or higher). GDI printers are not supported!

Ethernet Modbus TCP master (option):

As a Modbus master, the device can interrogate other Modbus slaves via Ethernet. The Modbus TCP

master can be operated in parallel with the Profibus DP slave, Modbus RTU/TCP slave or PROFINET

I/O Device.

Up to 40 analog inputs can be transmitted via Modbus and stored in the device.

Ethernet Modbus TCP slave (option):

Connection to SCADA systems (Modbus master).

Up to 40 analog inputs and 20 (14 real + 6 virtual) digital inputs can be transmitted via Modbus and

stored in the device.

Serial RS232/RS485 interface:

A combined RS232/RS485 connection is available on a shielded SUB D9 socket at the rear of the

device. This can be used for data transfer and to connect a modem. For communication via modem,

we recommend an industrial modem with a watchdog function.

• The following baud rates are supported: 9600, 19200, 38400, 57600, 115200

• Max. cable length with a shielded cable: 2 m (6.6 ft) (RS232), or 1000 m (3281 ft) (RS485)

Only one interface can be used at any one time (RS232 or RS485).

Modbus RTU master (option):

As a Modbus master, the device can interrogate other Modbus slaves via RS485. The Modbus RTU

master can be operated in parallel with the Profibus-DP slave, PROFINET I/O Device or Modbus TCP

slave.

Up to 40 analog inputs can be transmitted via Modbus and stored in the device.

Modbus RTU slave (option):

The device can be interrogated as a Modbus slave by another Modbus master via RS485.

Up to 40 analog inputs and 20 (14 real + 6 virtual) digital inputs can be transmitted via Modbus and

stored in the device.

A Modbus RTU master and RTU slave cannot be operated in parallel.

Remote interrogation with analog or GSM/GPRS wireless modem:

Analog modem:

An analog modem for industrial use (e.g. Devolo or WESTERMO), which is connected to the RS232

interface with a special modem cable (see Accessories → 29), is recommended.

18 Endress+Hauser

Page 19

Memograph M, RSG45

GSM/GPRS wireless modem:

A GSM/GPRS wireless modem (e.g. Cinterion, INSYS or WESTERMO, incl. antenna and power unit)

for industrial use, which is connected to the RS232 interface with a special modem cable (see

Accessories → 29), is recommended.

Important: the wireless modem needs a SIM card and data transfer subscription. In addition, it must

be possible to deactivate the PIN prompt.

If the Web server is operated via a wireless modem, this may result in high provider costs as

data are transmitted continuously.

AnyBus® interface (CPU card, slot 0, optional)

PROFIBUS–DP slave:

The device can be integrated into a fieldbus system as per the PROFIBUS–DP standard by means of

the PROFIBUS-DP interface. Up to 40 analog inputs and 20 (14 real + 6 virtual) digital inputs can be

transmitted via PROFIBUS-DP and stored in the device. Bidirectional communication with cyclic data

transfer is possible. Connection via Sub-D socket.

Baud rate: maximum 12 Mbit/s.

EtherNet/IP adapter (slave):

Up to 40 analog inputs and 20 (14 real + 6 virtual) digital inputs can be transmitted via EtherNet/IP

and stored in the device. The built-in module corresponds to I/O server category (Level 2). It has an

integrated 2-port switch, thereby supporting EtherNet/IP communication in line or ring topologies.

Connection via 2 RJ45 standard sockets.

Response time

PROFINET I/O device:

Up to 40 analog inputs and 20 (14 real + 6 virtual) digital inputs can be transmitted via PROFINET

IO and stored in the device. The 2-port module for PROFINET IO meets compliance class B. The

integrated switch enables communication in line or ring topologies without an additional external

switch. Connection via 2 RJ45 standard sockets.

Performance characteristics

Input Output Time [ms]

Current, voltage, pulse Relays, OC, analog output ≤ 550

RTD Relays, OC, analog output ≤ 1150

1)

TC

Cable open circuit detection, current input Relays, OC, analog output ≤ 1150

Sensor error RTD, TC Relays, OC, analog output ≤ 5000

Digital input Relays, OC, analog output ≤ 350

HART® input Relays, OC, analog output Non-deterministic

1) If internal measuring point temperature compensation is used, otherwise values as for voltage

Relays, OC, analog output ≤ 1550

Reference operating conditions

Hysteresis

Long-term drift

Reference temperature 25 °C (77 °F) ±5 K

Warm-up period 120 min.

Humidity 20 to 60 % rel. humidity

Can be configured for limit values in the setup

As per IEC 61298-2: max. ±0.1%/year (of measuring range)

Endress+Hauser 19

Page 20

Installation

27

(1.06)

149.2 (5.87)

195.2 (7.69)

37.1

141.2 (5.56)

158.5 (6.24)

(1.46)

150 (5.91)

196 (7.72)

31.4 (1.24)

141.2 (5.56)

158.5 (6.24)

138

(5.43 )

+1

+0.04

138

(5.43 )

+1

+0.04

A

B

C

138

(5.43)

138 (5.43)

70

162 (6.38)

(2.76)

24 (0.94)

208 (8.19)

Memograph M, RSG45

Panel mounting: mounting location and installation dimensions

The device with a display is designed for use in a panel.

The device must be installed in a pressurized enclosure system for operation in the hazardous

area. To ensure safe installation, it is essential to follow the installation instructions for the

cabinet and the installation instructions in the Ex-related Safety Instructions (XA).

3 Panel mounting and dimensions in mm (in).

A Version with navigator and front interfaces

B Version with stainless steel front and touchscreen

C Grid dimensions of panel cutouts for multiple devices

A0024610

Installation dimensions

• Installation depth (excluding terminal cover): approx. 159 mm (6.26 in) for device incl. terminals

and fastening clips.

• Installation depth including terminal cover (option): approx.198 mm (7.8 in)

• Panel cutout: 138 to 139 mm (5.43 to 5.47 in) x 138 to 139 mm (5.43 to 5.47 in)

• Panel thickness: 2 to 40 mm (0.08 to 1.58 in)

• viewing angle range: 50˚ in all directions from the display central axis

20 Endress+Hauser

Page 21

Memograph M, RSG45

89.9 (3.54)

72.7 (2.86)

17.2 (0.68)

181 (7.13)

136 (5.35)

• A minimum distance of 12 mm (0.47 in) between the devices must be observed if aligning the

devices vertically above one another or horizontally beside one another.

• The grid dimension of the panel cutouts for multiple devices must be at least 208 mm (8.19 in)

horizontally and at least 162 mm (6.38 in) vertically (tolerance not considered).

• Securing to DIN 43 834

Mounting location and installation dimensions for the DIN rail version

The device without a display is designed for DIN rail mounting.

The DIN rail device is not approved for operation in the hazardous area.

Field housing assembly and design (optional)

Desktop housing assembly and design (optional)

Ambient temperature range

Storage temperature

A0036528

4 DIN rail version, dimensions in mm (in).

Installation dimensions

• Installation depth: approx. 90 mm (3.54 in) for device incl. terminals.

• Mounting on DIN rail as per IEC 60715

• The devices can be arranged horizontally beside one another without clearance between the

devices.

As an option, the panel-mounted device can be ordered ready-mounted in a field housing with IP65.

Dimensions (B x H x D) approx.: 320 mm (12.6 in) x 320 mm (12.6 in) x 254 mm (10 in)

As an option, the panel-mounted device can be ordered ready-mounted in a desktop housing.

Dimensions (B x H x D) approx.: 293 mm (11.5 in) x 188 mm (7.4 in) x 213 mm (8.39 in)

(dimensions with bracket, feet and installed device)

Environment

–10 to +50 °C (14 to 122 °F)

–20 to +60 °C (–4 to +140 °F)

Humidity

5 to 85 %, non-condensing

Endress+Hauser 21

Page 22

Memograph M, RSG45

Climate class

Electrical safety

Altitude

Degree of protection

Electromagnetic compatibility

To IEC 60654-1: Class B2

Class I equipment, overvoltage category II

Pollution level 2

< 2 000 m (6 561 ft) over MSL

Front of panel-mounted

device

Back of panel-mounted

device (terminal side)

DIN rail version IP20 (overall device)

IP65 / NEMA 4 (not assessed by UL)

IP20

EMC in accordance with all relevant requirements of the IEC/EN 61326 series and NAMUR NE21.

For details, refer to the Declaration of Conformity.

• Interference immunity: as per IEC/EN 61326 series (industrial environment) / NAMUR NE21

Maximum measured error <1% of measuring range

• Interference emissions: as per IEC 61326-1 Class A

Mechanical construction

Design, dimensions

Weight

Materials

Information about design and dimensions → 20

• Panel-mounted device with navigator and front interfaces (with maximum configuration): approx.

2.7 kg (5.9 lbs)

• Panel-mounted device with stainless steel front and touchscreen (with maximum configuration):

approx. 3.2 kg (7 lbs)

• DIN rail version: approx. 1.8 kg (3.97 lbs)

• Desktop housing (excluding device): approx. 2.3 kg (5 lbs)

• Field housing (excluding device): approx. 4 kg (8.8 lbs)

Panel-mounted device with navigator and front

interfaces

Front frame Zinc die cast GD-Z410, powder-coated

Display glass Transparent Makrolon® plastic (FR clear 099) UL94-V2

Flap; jog/shuttle dial ("Navigator") Plastic ABS UL94-V2

Membrane keypad Polyester membrane PC-ABS UL94-V2

Intermediate frame (front towards control panel) Plastic PA6-GF20 UL94-V2

Seal towards panel wall; seal in flap; seal towards

navigator

Casing; rear panel Galvanized sheet steel St 12 ZE

Panel-mounted device with stainless steel front and

touchscreen

Front frame AISI 316L

Display glass 6 mm single-pane safety glass (soda-lime glass)

Intermediate frame (front towards control panel) Plastic PA6-GF20 UL94-V2

Seal towards control panel wall Rubber EPDM 70 Shore A

Window seal between front frame and glass Rubber EPDM 60 Shore A

Casing; rear panel Galvanized sheet steel St 12 ZE

Rubber EPDM 70 Shore A

22 Endress+Hauser

Page 23

Memograph M, RSG45

DIN rail version

Retaining bracket EN AW 6060 T66 / AlMgSi0.5 F22

Casing; front Galvanized sheet steel St 12 ZE

Designation Short form Properties

AISI 316L (corresponds to

1.4404 or 1.4435)

X2CrNiMo17-13-2,

X2CrNiMo18-14-3

Austenitic, stainless steel

High corrosion resistance in general

All materials are silicone-free.

Materials of desktop housing

• Housing half-panels: sheet steel, electrolytically plated (powder-coated)

• Side sections: aluminum extruded section (powder-coated)

• Section ends: colored polyamide

• Feet: colored polyamide, fiber-glass reinforced

Field housing materials

• Housing (front frame, door, base frame, side parts): thermoplastic polycarbonate PC

• Front panel and wall mounting: chrome-nickel stainless steel 1.4301 V2A

Display and operating elements

Operating concept

Local operation Display elements on panel-mounted device

The description for local operation does not apply for the DIN rail version, as this has neither a

display screen nor operating elements. The description for remote configuration applies for all

versions.

The device can be operated directly onsite, or via remote configuration with the PC via interfaces and

operating tools (Web server, configuration software).

Web server

A Web server is integrated into the device. The Web server offers the following range of functions:

• Easy configuration without additional installed software

• Instantaneous value display and diagnostics information

• Display of current measured value curves via Web browser (remote control)

• Display of historical measured data in numerical format or as a curve

• Display of events and logbook entries

• Loading/saving of device configuration

• Device firmware update

• Printout of device configuration

Integrated operating instructions

The device's simple operating concept enables you to perform commissioning for many applications

without the need for hardcopy operating instructions. The device has an integrated help function

and displays operating instructions directly on screen.

Type

Wide-screen TFT color graphic display (optionally with touch control)

Size (diagonal screen measurement)

178 mm (7")

Resolution

Wide VGA 384,000 pixels (800 x 480 pixels)

Endress+Hauser 23

Page 24

Memograph M, RSG45

5

9

8

4

3

d

c b a

1

2

6

7

10

5

9

8

4

6 7

10

Backlight

50,000 h half value time (= half brightness)

Number of colors

262,000 viewable colors, 256 colors used

Viewing angle

Max. viewing angle range: 50˚ in all directions from the display central axis

Screen display

• Users can choose between black or white for the background color

• Active channels can be assigned to up to 10 groups. These groups can be given a name e.g. "Temp.

boiler 1" or "Daily averages" so that they can be uniquely identified.

• Scales linear or logarithmic

• Measured value history: quick retrieval of historic data with zoom function

• Pre-formatted display formats, such as horizontal or vertical curves, instrument display, circular

chart, process screen, bargraph or digital display.

Measured value display and operating elements

Measured value display and operating elements on panel-mounted device

5 Device front (left: version with navigator and front interfaces; right: version with stainless steel front and

touchscreen)

Item

No.

a Slot for SD card

b USB B socket "Function" e.g. to connect to PC or laptop

c USB A socket "Host" e.g. for USB memory stick, external keyboard, barcode reader or printer

d LED at SD slot. Yellow LED lit or flashing when the device writes to the SD card or reads it.

Operating function (display mode = display of measured values)

(Setup mode = operation in the Setup menu)

Do not remove the SD card if the LED is lit or flashing! Risk of data loss!

24 Endress+Hauser

A0024709

Page 25

Memograph M, RSG45

7

4

8

1

5

6

3

2

9

10

Item

No.

1 "Navigator": jog/shuttle dial for operating with additional press/hold function.

2 Functions of LED indicators (according to NAMUR NE44:)

3 Variable "soft keys" 1-4 (from left to right)

4 Function indicator of "soft keys"

5 In display mode: current group name, type of analysis;

6 In display mode: displays current date/time

7 In display mode: user ID (if function is active)

8 In display mode: alternating display indicating the percentage space on the SD card or USB stick that

9 In display mode: window for measured value display (e.g. curve display).

9 In setup mode: display of operating menu

10 In display mode: alternating status display (e.g. set zoom range) of the analog or digital inputs in the

Operating function (display mode = display of measured values)

(Setup mode = operation in the Setup menu)

In display mode: turn the dial to switch between the various signal groups. Press the dial to display the

main menu.

In setup mode or in a selection menu: turn the dial anticlockwise to move the bar or the cursor

upwards or to the left, changes the parameter. Turning clockwise moves the bar or cursor down or to

the right, changes the parameter. Press = select highlighted function, start parameter change (ENTER

key).

• Green LED (top) lit: power supply OK

• Red LED (bottom) flashing: maintenance required, caused by external factor (e.g. cable open circuit

etc.) or a message/notification requiring acknowledgment is pending, calibration is running.

In setup mode: name of the current operating item (dialog title)

In setup mode: --

In setup mode: --

has already been used.

Status symbols are also displayed in alternation with the memory information (e.g. simulation mode,

data storage active, operation lock, batch active)

In setup mode: the current "direct access" operating code is displayed

Display of current measured values and the status in the event of an error/alarm condition. In the case

of counters, the type of counter is displayed as a symbol.

If a measuring point has limit value status, the corresponding channel identifier is highlighted

in red (quick detection of limit value violations). During a limit value violation and device

operation, the acquisition of measured values continues uninterrupted.

appropriate color of the channel.

In setup mode: different information is displayed here depending on the display type.

Operating elements of the DIN rail version

A0036811

6 Device front of the DIN rail version

Endress+Hauser 25

Page 26

Memograph M, RSG45

1

2

3

4

5

6

7

8

9

10

11

12

OFF ON

Item

Operating function

No.

1 DIP switches

The behavior of the Ethernet interface is configured via DIP switches (left =

OFF, right = ON).

The DIN rail version is supplied with the following Ethernet settings:

IP address: 192.168.1.212; subnet mask: 255.255.255.0; gateway:

0.0.0.0

2 Ethernet interface

3 USB B socket "Function" e.g. to connect to PC or laptop

4 Functions of LED indicators (according to NAMUR NE44:)

• Green LED (top) lit: power supply OK

• Red LED (bottom) flashing: maintenance required, caused by external factor (e.g. cable open circuit

etc.) or a message/notification requiring acknowledgment is pending, calibration is running.

5 Cyclic storage is completed via the "Remove SD card safely" button, the LED (d) goes out. The SD card

can now be removed.

If the SD card is not removed within 5 minutes, the write cycles start again.

6 USB A socket "Host" e.g. for USB memory stick or printer

If a USB stick is inserted, data that have not yet been saved are copied to the stick automatically. The

red LED on the USB socket flashes while the data are being copied to the stick.

Do not remove the USB stick when the red LED is flashing! Risk of data loss!

If an error occurs (e.g. USB stick full or defective), the red LED is lit constantly. Remove the USB stick

and replace it.

7 LED at SD slot. Yellow LED lit or flashing when the device writes to the SD card or reads it.

Do not remove the SD card if the LED is lit or flashing! Risk of data loss!

A0036815

8 Slot for SD card

9 Anybus® interface (option)

10 Serial RS232/RS485 interface

Languages

The following languages can be selected in the operating menu: German, English, Spanish, French,

Italian, Dutch, Swedish, Polish, Portuguese, Czech, Russian, Japanese, Chinese (Traditional), Chinese

(Simplified)

Remote operation Device access via operating tools

Device configuration and measured value retrieval can also be done via interfaces. The following

operating tools are available for this purpose:

Operating tool Functions Access via

"Field Data Manager

(FDM)" analysis

software, SQL

database support

(included in the

delivery)

Web server

(integrated into the

device; access via

browser)

• Export of saved data (measured values, analyses, event log)

• Visualization and processing of saved data (measured

values, analyses, event log)

• Safe archiving of exported data in a SQL database

• Display of current and historical data and measured value

curves via the Web browser

• Easy configuration without additional installed software

• Remote access to device and diagnostic information

RS232/RS485, USB,

Ethernet

Ethernet, or Ethernet via

USB

26 Endress+Hauser

Page 27

Memograph M, RSG45

CE mark

Ex approval

UL approval

OPC server

(optional)

"FieldCare /

DeviceCare"

configuration

software

The following momentary values can be provided:

• Analog channels

• Digital channels

• Mathematics

• Totalizer

• Device configuration

• Loading and saving of device configurations (upload/

download)

• Documentation of the measuring point

RS232/RS485, USB,

Ethernet

USB, Ethernet

Certificates and approvals

The product meets the requirements of the harmonized European standards. As such, it complies

with the legal specifications of the EC directives. The manufacturer confirms successful testing of the

product by affixing to it the CE-mark.

ATEX/IECEx

The following hazardous area versions are currently available (not for DIN rail version):

• ATEX II2G Ex px IIC Gb

• ATEX II2D Ex pD IIIC Db

UL recognized component (see www.ul.com/database, search for Keyword "E225237")

Electronic recording/ electronic signature

Certifications

Other standards and guidelines

Ordering information

FDA 21 CFR Part 11

The device meets the requirements of the "Food and Drug Administration" for electronic recording/

electronic signature.

• HART® certification (HCF)

• PROFINET certification

• EtherNet/IP certification

• IEC 60529:

Degree of protection provided by housing (IP code)

• IEC/EN 61010-1:

Safety requirements for electrical equipment for measurement, control and laboratory use

• IEC/EN 61326 Series:

Electromagnetic compatibility (EMC requirements)

Ordering information

The hazardous area version (Ex version) is only available in conjunction with the stainless steel

front and touch control.

Detailed ordering information is available from the following sources:

• In the Product Configurator on the Endress+Hauser website: www.endress.com -> Click "Corporate"

-> Select your country -> Click "Products" -> Select the product using the filters and search field ->

Open product page -> The "Configure" button to the right of the product image opens the Product

Configurator.

• From your Endress+Hauser Sales Center: www.addresses.endress.com

Product Configurator - the tool for individual product configuration

• Up-to-the-minute configuration data

• Depending on the device: Direct input of measuring point-specific information such as

measuring range or operating language

• Automatic verification of exclusion criteria

• Automatic creation of the order code and its breakdown in PDF or Excel output format

• Ability to order directly in the Endress+Hauser Online Shop

Endress+Hauser 27

Page 28

Memograph M, RSG45

Scope of delivery

The scope of delivery of the device comprises:

• Device (with terminals, as per order)

• Panel-mounted device: 2 screw fastening clips

• Version with navigator and front interfaces or DIN rail version: USB cable

• Panel-mounted device: sealing rubber towards the panel wall

• "Industrial Grade" SD card, industry standard:

Panel-mounted device with navigator and front interfaces: card is located in the SD slot behind the

flap on the front of the device (optional).

Panel-mounted device with stainless steel front and touchscreen: card is located in the device and

cannot be replaced or retrofitted.

DIN rail version: card is located in the SD slot (optional).

• "Field Data Manager (FDM)" analysis software on DVD (Essential, Demo or Professional version,

depending on order)

• Delivery note

• Multilanguage Brief Operating Instructions, hard copy

• Ex Safety Instructions, hard copy (optional)

28 Endress+Hauser

Page 29

Memograph M, RSG45

320 (12.6)

320 (12.6)

254 (10)

Accessories

Various accessories, which can be ordered with the device or subsequently from Endress+Hauser, are

available for the device. Detailed information on the order code in question is available from your

local Endress+Hauser sales center or on the product page of the Endress+Hauser website:

www.endress.com.

Device-specific accessories

Description Order No.

"Industrial Grade" SD card, industry standard, 1GB 71213190

Field Data Manager analysis software with SQL database support (1 x workstation

license, Professional version)

OPC server software (full version on CD) RXO20-11

Description Order No.

Accessories for RXU10 data manager RXU10- _ _

Designation:

Cable set RS232 for connection to PC or modem

USB - RS232 converter

Cable USB-A - USB-B, 1.8 m (5.9 ft)

Configuration software "FieldCare Device Setup" + USB cable

Description Order No.

Field housing IP65 (for panel-mounted device)

MS20-A1

RXU10-B _

RXU10-E _

RXU10-F _

RXU10-G _

RXU10-H _

A0024766

7 Dimensions in mm (in)

Endress+Hauser 29

Page 30

Memograph M, RSG45

293.4 (11.6)

236 (9.29)

173 (6.81)

188 (7.4)

173 (6.81)

212.6 (8.37)

184 (7.24)

293.4 (11.6)

236 (9.29)

Description Order No.

Desktop housing (for panel-mounted device), cable with Schuko plug

Desktop housing (for panel-mounted device), cable with US plug

Desktop housing (for panel-mounted device), cable with Swiss plug

RXU10-I _

RXU10-J _

RXU10-K _

A0024767

8 Dimensions in mm (in)

Version:

Standard

Neutral

Description Order No.

Terminal cover can be sealed (for panel-mounted device)

An optional terminal cover is available to prevent tampering at the device terminals

and terminal temperature measurement.

RXU10- _ 1

RXU10- _ 2

XPR0011-A5

A0029023

30 Endress+Hauser

Page 31

Memograph M, RSG45

Supplementary documentation

Standard documentation

• Technical Information for Memograph M RSG45: TI01180R

• Operating Instructions for Memograph M RSG45: BA01338R

• Brief Operating Instructions for Memograph M RSG45: KA01177R

• System components and data manager - solutions to complete your measuring point: FA00016K

Supplementary device-dependent documentation

• Competence brochure PROFIBUS® - process automation with digital fieldbus technology:

CP00005S

• Operating Instructions for Memograph M RSG45 with telealarm: BA01387R

• Operating Instructions for Memograph M RSG45 with Modbus RTU / TCP slave: BA01388R

• Operating Instructions for Memograph M RSG45 with Modbus RTU / TCP master: BA01390R

• Operating Instructions for Memograph M RSG45 with wastewater + RSB (rain spillway basin)

option: BA01337R

• Operating Instructions for Memograph M RSG45 with batch software: BA01411R

• Operating Instructions for Memograph M RSG45 with energy option: BA01412R

• Operating Instructions for Memograph M RSG45 with EtherNet/IP® adapter: BA01413R

• Operating Instructions for Memograph M RSG45 with PROFIBUS® DP slave: BA01414R

• Operating Instructions for Memograph M RSG45 with PROFINET: BA01415R

• Operating Instructions for Memograph M RSG45 with TrustSens Calibration Monitoring:

BA01887R

• Ex-related additional documentation: