Endress+Hauser micropilot M FMR 230, micropilot M FMR 240, micropilot M FMR 231 Technical Information

Technical Information

TI 345F/00/en

Level-Radar

micropilot M

FMR 230/231/240

Smart Transmitter for continuous and

non-contact level measurement

Cost-effective 4…20 mA 2-wire technology

Suitable for hazardous locations

Features and benefits

• 2-wire technology, low price:

A real alternative to differential

pressure, floats and displacers.

2-wire technology reduces wiring costs

and allows easy implementation into

existing systems.

• Non-contact measurement:

Measurement is almost independent

from product properties.

• Easy on-site operation via menu-driven

alphanumeric display.

• Easy commissioning, documentation

and diagnostics via operating software

(ToF Tool).

• 2 frequency ranges – approx. 6 and

26 GHz:

No compromises, the right frequency

for every application.

• HART or PROFIBUS-PA respectively

Foundation Fieldbus protocol.

• High temperatures:

Suitable for process temperatures up to

+200 °C (392 °F), up to 400 °C (752 °F)

with high-temperature antenna.

• Rod antenna with inactive length:

Reliable measurement in narrow

nozzles, with condensation and

build-up in the nozzle.

Application

The Micropilot M is used for continuous,

non-contact level measurement of

liquids, pastes, and slurries.

The measurement is not affected by

changing media, temperature changes,

gas blankets or vapours.

• The FMR 230 is especially suited for

measurement in buffer and process

tanks.

• The FMR 231 has its strengths

wherever high chemical compatibility is

required.

• The FMR 240 with the small (1½") horn

antenna is ideally suited for small

vessels. Additionally, it provides an

accuracy of ±3 mm.

FMR 231

FMR 230

FMR 240

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Micropilot M

2 Endress+Hauser

Function and system design

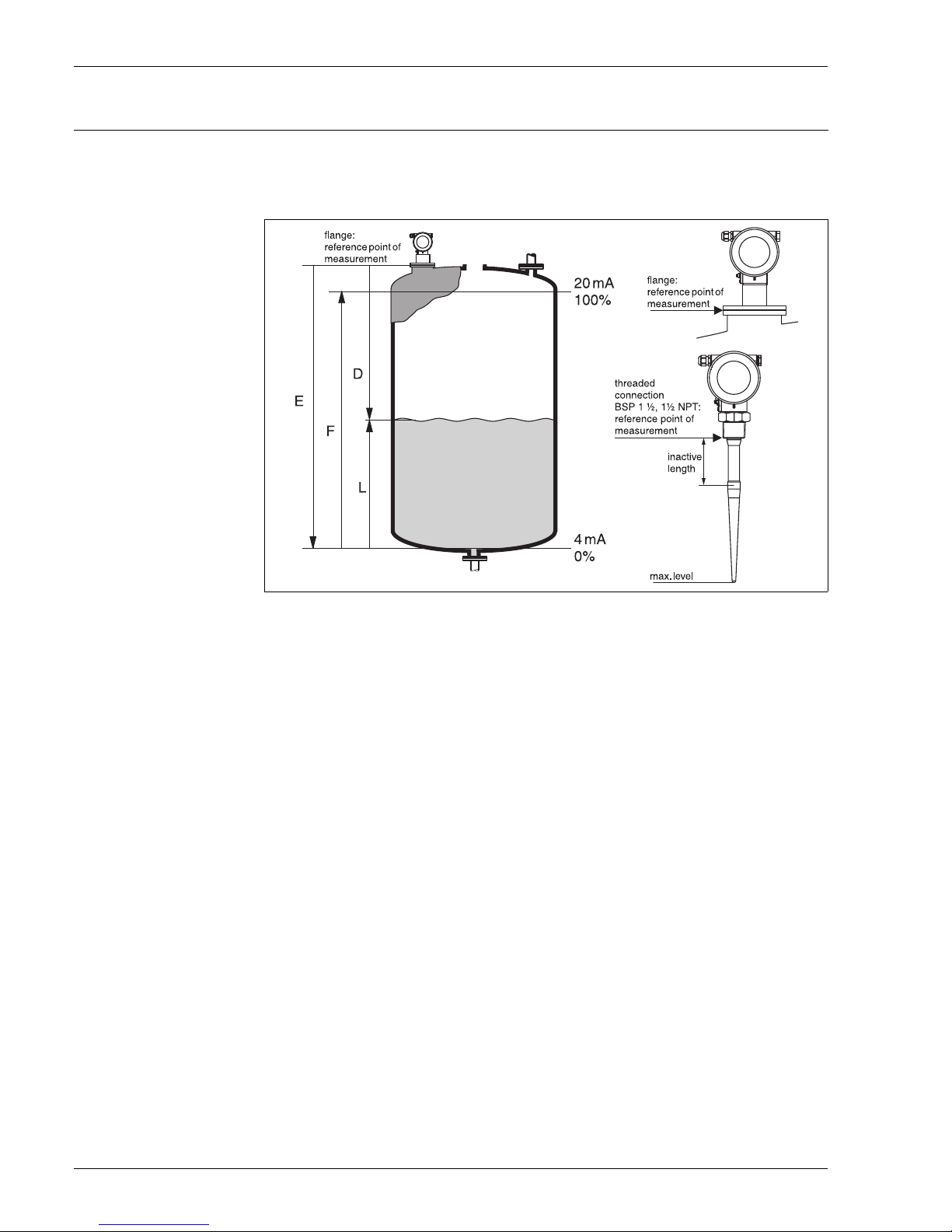

Measuring principle The Micropilot is a "downward-looking" measuring system, operating based on the time-of-flight

method. It measures the distance from the reference point (process connection) to the product

surface. Radar impulses are emitted by an antenna, reflected off the product surface and

received again by the radar system.

Input

The reflected radar impulses are received by the antenna and transmitted into the electronics.

A microprocessor evaluates the signal and identifies the level echo caused by the reflection of the

radar impulse at the product surface. The unambiguous signal identification is accomplished by

the PulseMaster software, based on many years of experience with time-of-flight technology.

The mm-accuracy of the Micropilot S could be achieved with the patented algorithms of the

PhaseMaster software.

The distance D to the product surface is proportional to the time of flight t of the impulse:

D = c · t/2,

with c being the speed of light.

Based on the known empty distance E, the level L is calculated:

L = E – D

Refer to the above figure for the reference point for "E".

The Micropilot is equipped with functions to suppress interference echoes. The user can activate

these functions. They ensure that interference echoes (i.e. from edges and weld seams) are not

interpreted as level echo.

Output

The Micropilot is commissioned by entering an empty distance E (=zero), a full distance F (=span)

and an application parameter. The application parameter automatically adapts the instrument to

the measuring conditions. The data points “E” and “F” correspond with 4mA and 20mA for

instruments with current output. They correspond with 0 % and 100 % for digital outputs and the

display module.

A linearization, based on a table entered either manually or semi-automatically, can be activated

locally or remotely. This function provides a measurement in engineering units and a linear output

signal for spheres, horizontal cylindrical tanks and vessels with conical outlet.

L00-FMR2xxxx-15-00-00-en-001

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Micropilot M

Endress+Hauser 3

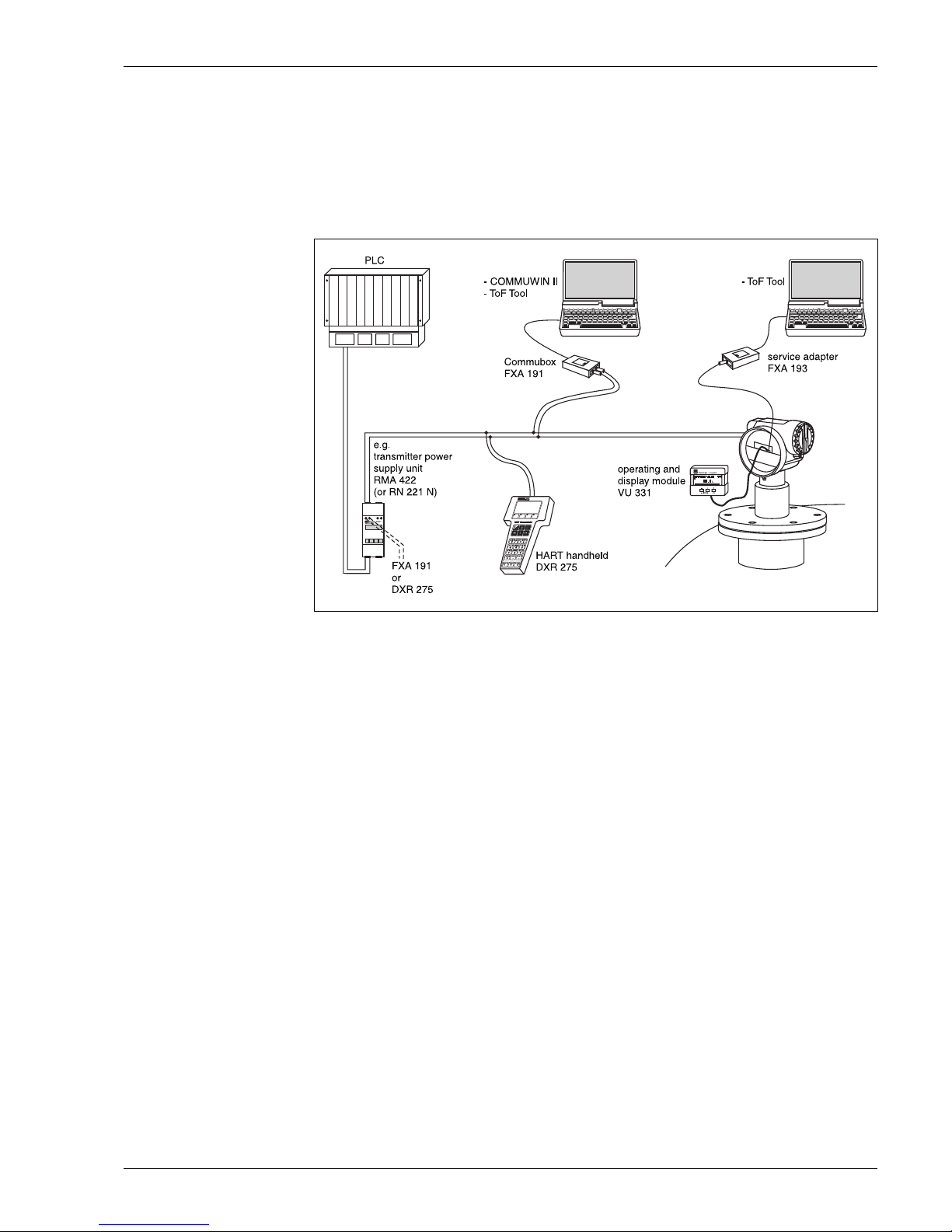

Equipment architecture Stand-alone

The Micropilot M can be used for measurement in a stilling well / bypass as well as in free space.

The instrument provides a 4…20 mA output with HART protocol, or PROFIBUS-PA respectively

Foundation Fieldbus communication.

4…20 mA output with HART protocol.

The complete measuring system consists of:

On-site operation:

• with display and operating module VU 331,

• with a Personal Computer, FXA 193 and the operating software ToF Tool.

The ToF Tool is a graphical operating software for instruments from Endress+Hauser that

operate based on the time-of-flight principle (radar, ultrasonic, guided micro-impulse). It assists

with commissioning, securing data, signal analysis and documentation of the measuring point.

Remote operation:

• with HART handheld DXR 275,

• with a Personal Computer, Commubox FXA 191 and the operating software COMMUWIN II

respectively ToF Tool.

L00-FMR2xxxx-14-00-06-en-001

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Micropilot M

4 Endress+Hauser

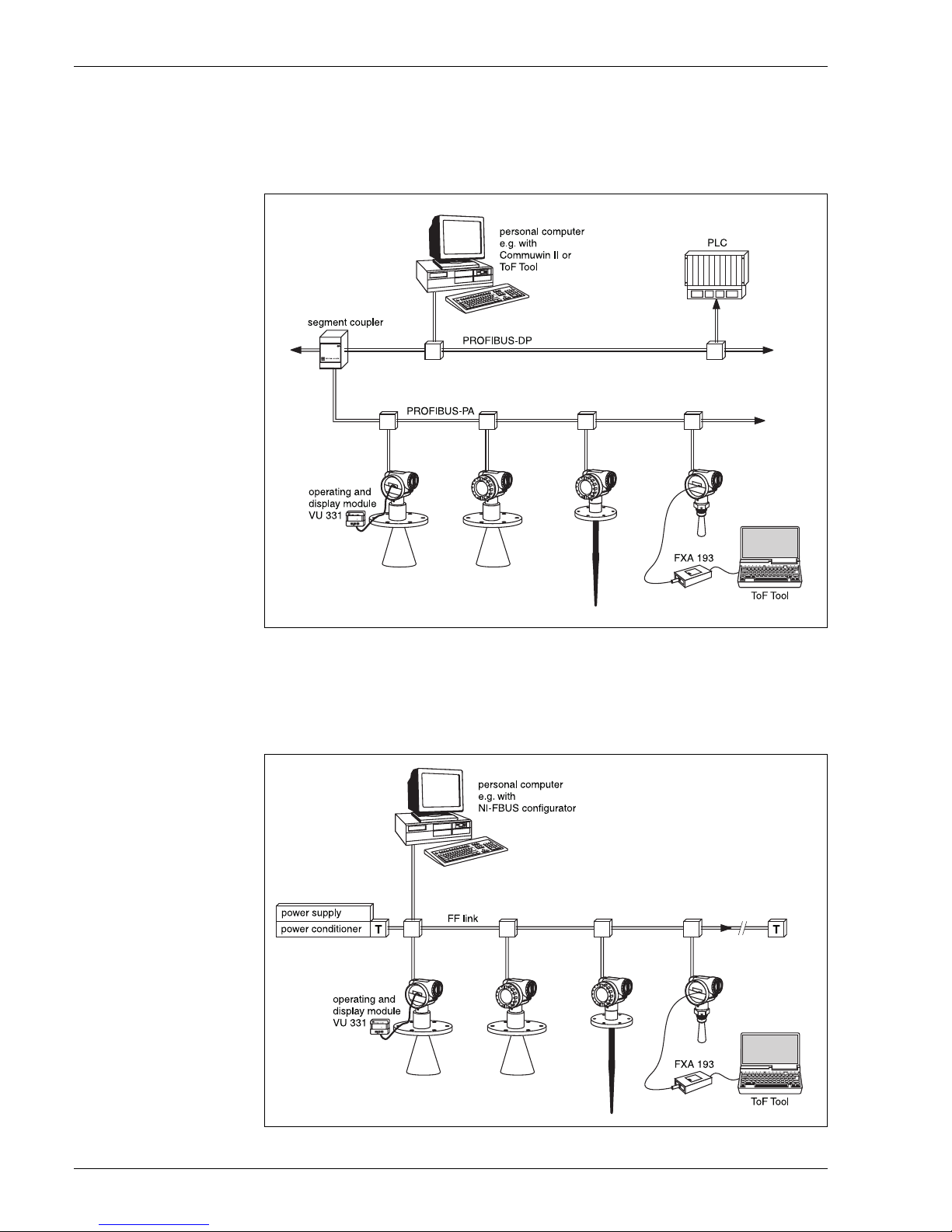

System integration via PROFIBUS-PA

A maximum of 32 transmitters (8 if mounted in an explosion hazardous location EEx ia IIC

according to FISCO-model) can be connected to the bus. The segment coupler provides the

operating voltage to the bus. Both on-site as well as remote operation are possible.

The complete measuring system consists of:

System integration via Foundation Fieldbus

A maximum of 32 transmitters (standard, EEx em or EEx d) can be connected to the bus. For

protection class EEx ia IIC: the max. number of transmitters depends on the established rules and

standards for intrinsically safe circuits (EN 60070-14), proof of intrinsically safety. Both on-site as

well as remote operation are possible. The complete measuring system consists of:

L00-FMR2xxxx-14-00-06-en-002

L00-FMR2xxxx-14-00-06-en-003

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Micropilot M

Endress+Hauser 5

System integration via Rackbus

Multiple transmitters Micropilot M (or other instruments) can be connected to a higher-level bus

system via a Gateway ZA:

• Every HART transmitter via one interface module FXN 672 each.

• Gateways are available for MODBUS, FIP, PROFIBUS, INTERBUS etc.

• Both on-site as well as remote operation are possible.

L00-FMR2xxxx-14-00-06-en-006

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Micropilot M

6 Endress+Hauser

Input

Measured variable The measured variable is the distance between a reference point (refer to fig. on page 2) and a

reflective surface (i.e. medium surface).

The level is calculated based on the tank height entered.

The level can be converted into other units (volume, mass) by means of a linearization.

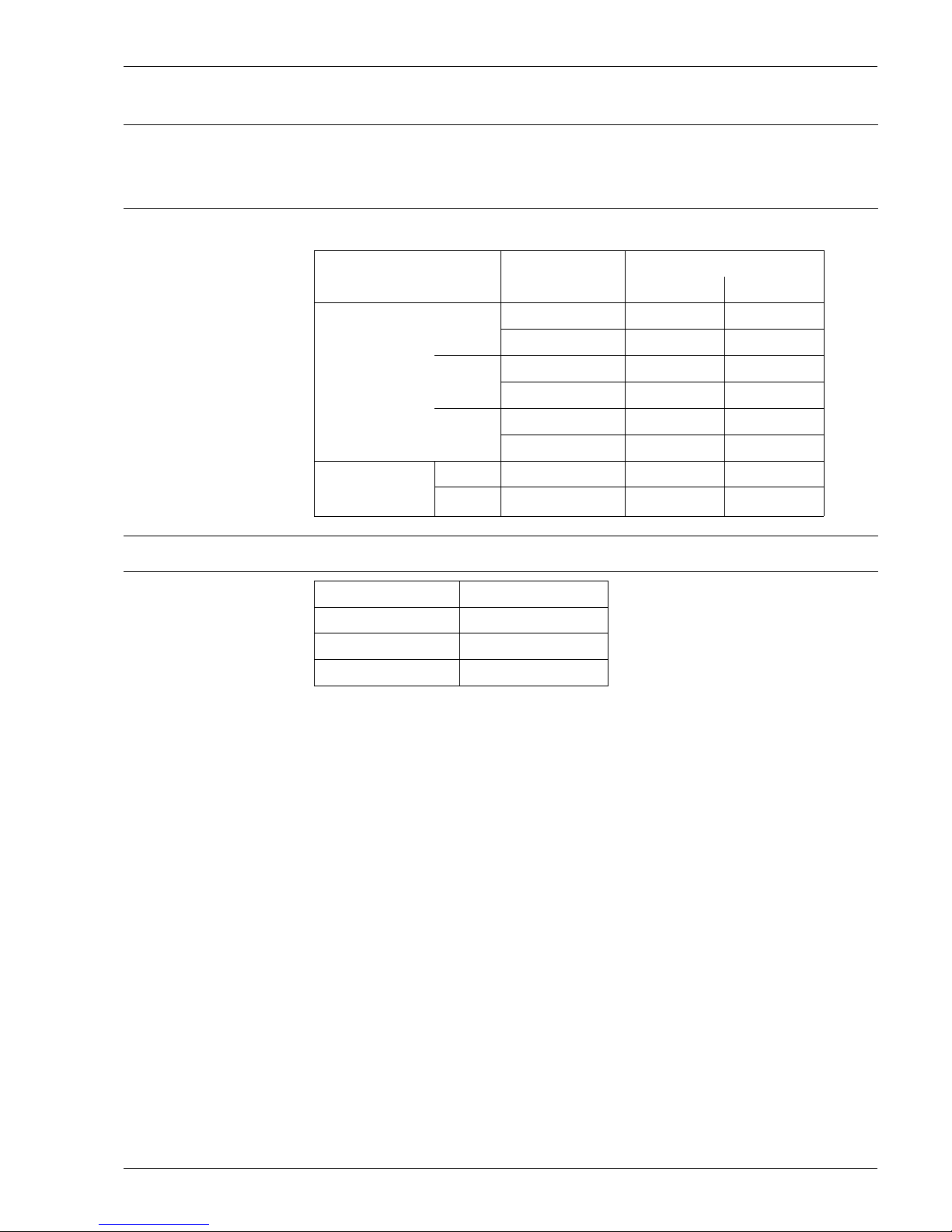

Measuring range The usable measuring range depends on the size of the antenna, the reflectivity of the medium,

the mounting location and eventual interference reflections.

The following tables describe the groups of media as well as the achievable measuring range as

a function of application and media group. If the dielectric constant of a medium is unknown, it is

recommended to assume media group B to ensure a reliable measurement.

1) Treat Ammonia NH3 as a medium of group A, i.e. always use a stilling well.

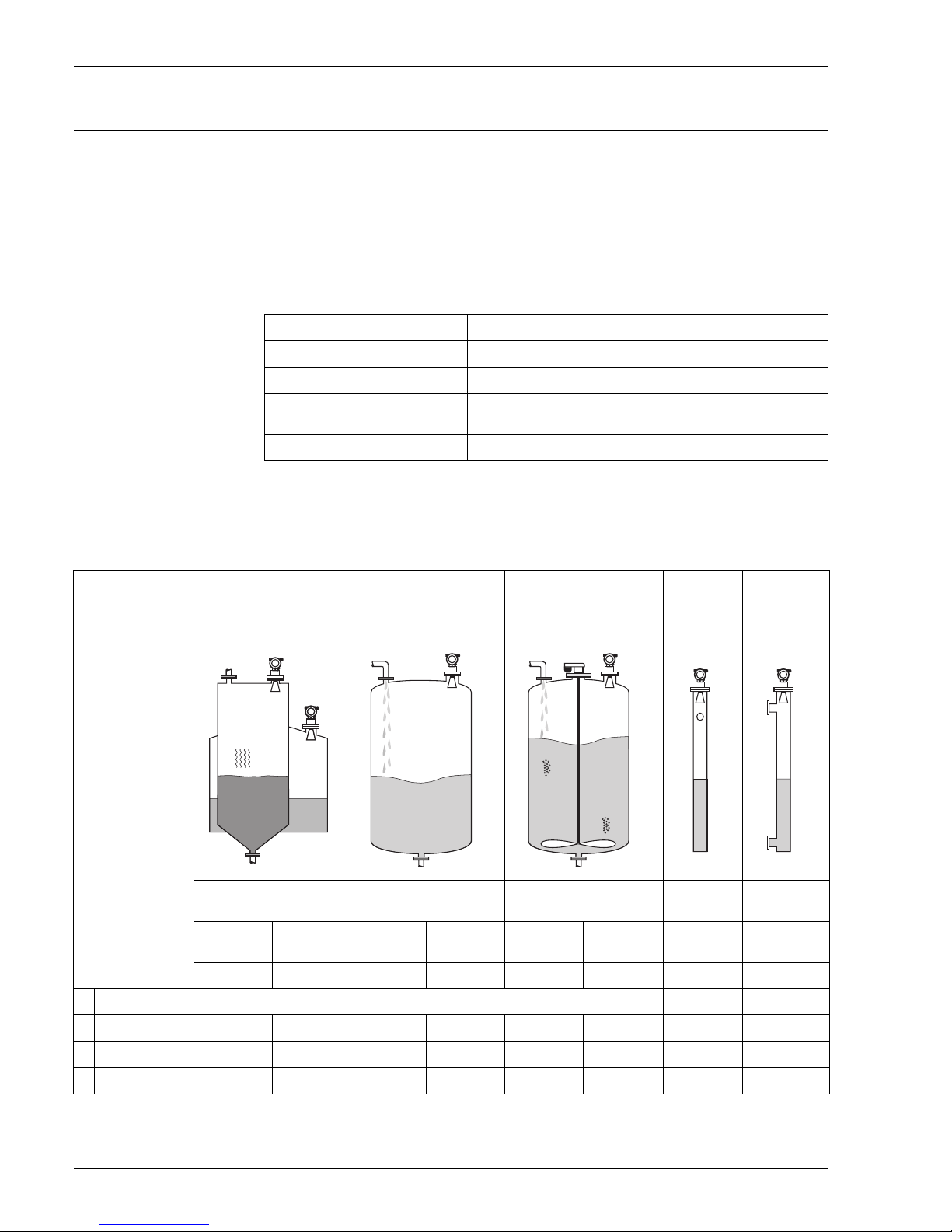

Measuring range depending on vessel type, conditions and product for Micropilot M

FMR 230 and FMR 231:

2) possible, i.e. with stilling well in bypass.

Product class DK (

εr) Examples

A 1.4 … 1.9 non-conducting liquids, e.g. liquefied gas

1)

B 1.9 … 4 non-conducting liquids, e.g. benzene, oil, toluene, …

C 4 … 10 e.g. concentrated acids, organic solvents, esters, aniline, alcohol,

acetone, …

D > 10 conducting liquids, e.g. aqueous solutions, dilute acids and alkalis

Product class Storage tank

(scarce

draining/filling)

Buffer tank

(continuous

draining / filling)

Tank with single stage

propeller agitator

Stilling well Bypass

Measuring range Measuring range Measuring range

Measuring

range

Measuring

range

FMR 230:

DN1506"DN200/250

8" / 10"

DN1506"DN200/250

8" / 10"

DN150

6"

DN200/250

8" / 10"

DN80…250

3"…10"

DN80…150

3"…6"

FMR 231: Rod antenna — Rod antenna — Rod antenna — — —

A DK(

εr)=1.4…1.9 to use the stilling well (20 m / 67 ft) 20 m/67 ft

2)

B DK(εr)=1.9…4 10 m/33 ft 15 m/50 ft 5 m/16 ft 7.5 m/24 ft 4 m/13 ft 6 m/20 ft 20 m/67 ft

2)

C DK(εr)=4…10 15 m/50 ft 20 m/67 ft 7.5 m/24 ft 10 m/33 ft 6 m/20 ft 8 m/27 ft 20 m/67 ft 20 m/67 ft

D DK(

εr)>10 20 m/67 ft 20 m/67 ft 10 m/33 ft 12.5 m/42 ft 8 m/27 ft 10 m/33 ft 20 m/67 ft 20 m/67 ft

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Micropilot M

Endress+Hauser 7

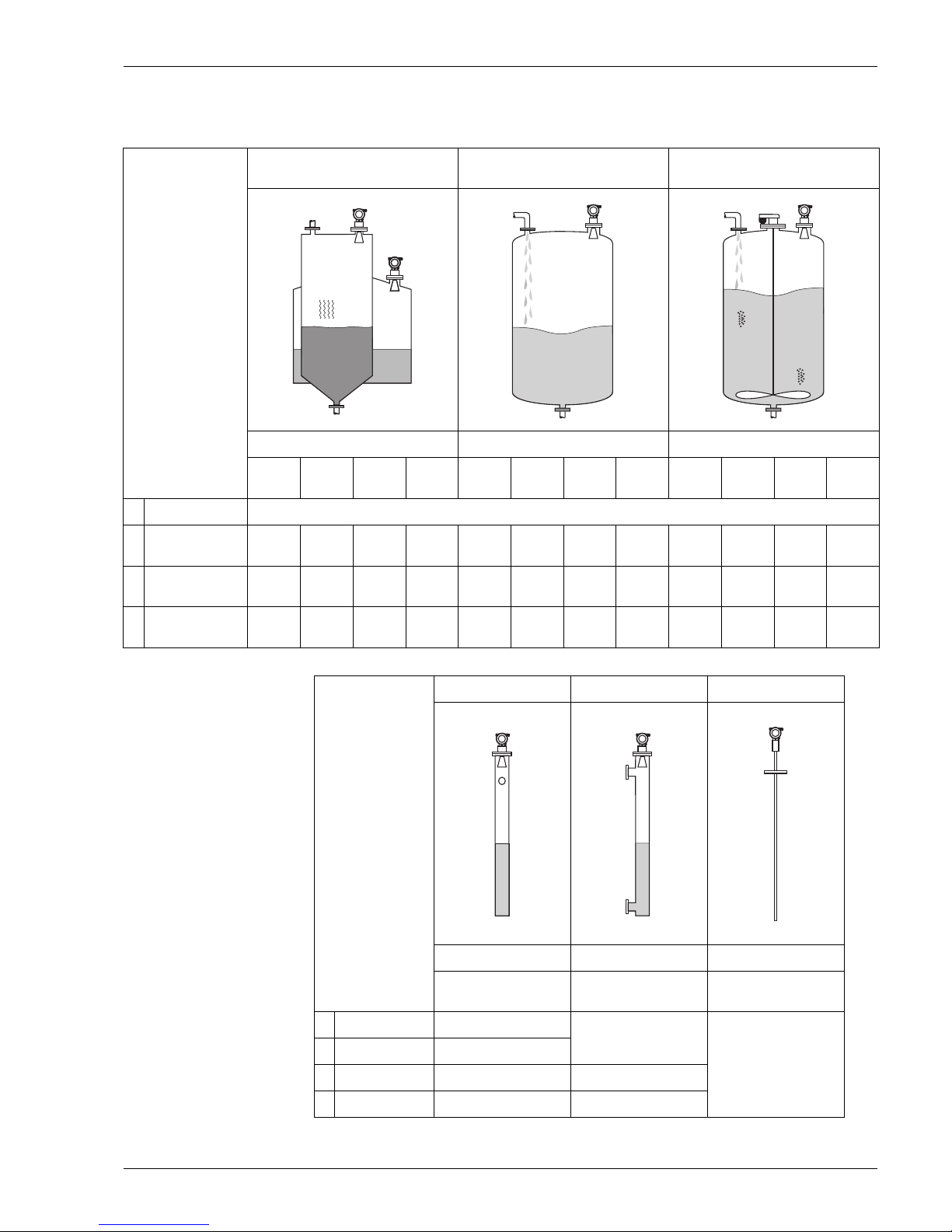

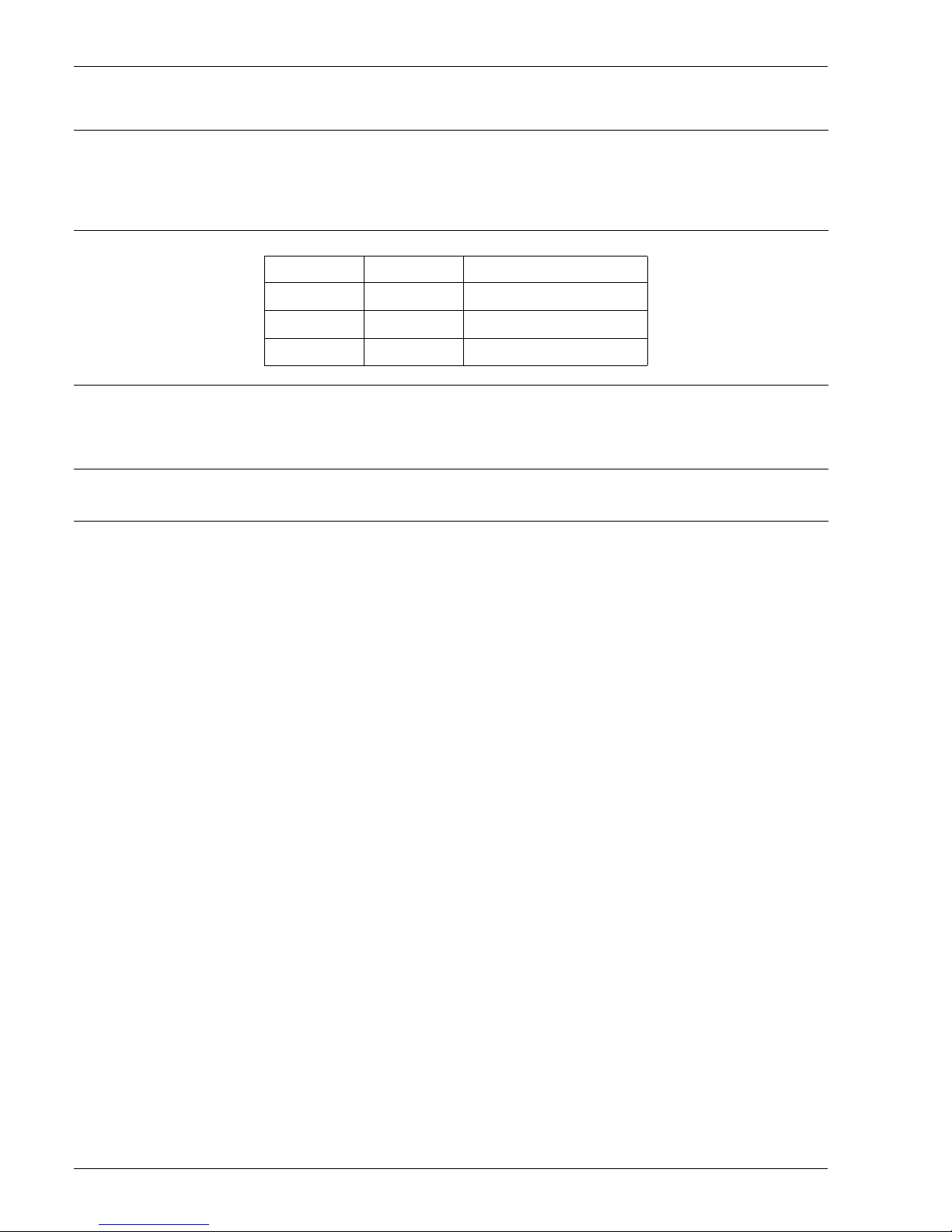

Measuring range depending on vessel type, conditions, and product for Micropilot M

FMR 240:

Product class Storage tank

(scarce draining/filling)

Buffer tank

(continuous draining / filling)

Tank with single stage propeller

agitator

Measuring range Measuring range Measuring range

FMR 240:

1½"

40mm

DN502"DN803"DN1004"1½"

40mm

DN502"DN803"DN1004"1½"

40mm

DN502"DN803"DN100

4"

A DK(

εr)=1.4…1.9 to use the stilling well (20 m / 67 ft)

B DK(

εr)=1.9…4

3 m /

10 ft

5 m /

16 ft

10 m /

33 ft

15 m /

50 ft

2 m /

7ft

2.5 m /

8ft

5 m /

16 ft

7.5 m /

25 ft

1 m /

3ft

1 m /

3ft

2 m /

7ft

3 m /

10 ft

C DK(

εr)=4…10

6 m /

20 ft

10 m /

33 ft

15 m /

50 ft

20 m /

67 ft

3 m /

10 ft

5 m /

16 ft

7.5 m /

25 ft

10 m /

33 ft

1.5 m /

5ft

2 m /

7ft

3 m /

10 ft

5 m /

16 ft

D DK(

εr)>10

9 m /

30 ft

15 m /

50 ft

20 m /

67 ft

20 m /

67 ft

5 m /

16 ft

7.5 m /

25 ft

10 m /

33 ft

12.5 m

/ 42 ft

2 m /

7ft

3 m /

10 ft

5 m /

16 ft

7 m /

23 ft

Product class Stilling well Bypass Wave Guide antenna

Measuring range Measuring range Measuring range

FMR 240:

1½" / 40mm … DN100

1½"…4"

DN50…100

2"…4"

Wave Guide antenna

A DK(

εr)=1.4…1.9 20 m/ 67 ft

see pipe antenna

depending

on pipe length,

max. 2.8 m (9.2 ft)

B DK(

εr)=1.9…4 20 m/ 67 ft

C DK(

εr)=4…10 20 m/ 67 ft 20 m/ 67 ft

D DK(

εr)>10 20 m/ 67 ft 20 m/ 67 ft

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Micropilot M

8 Endress+Hauser

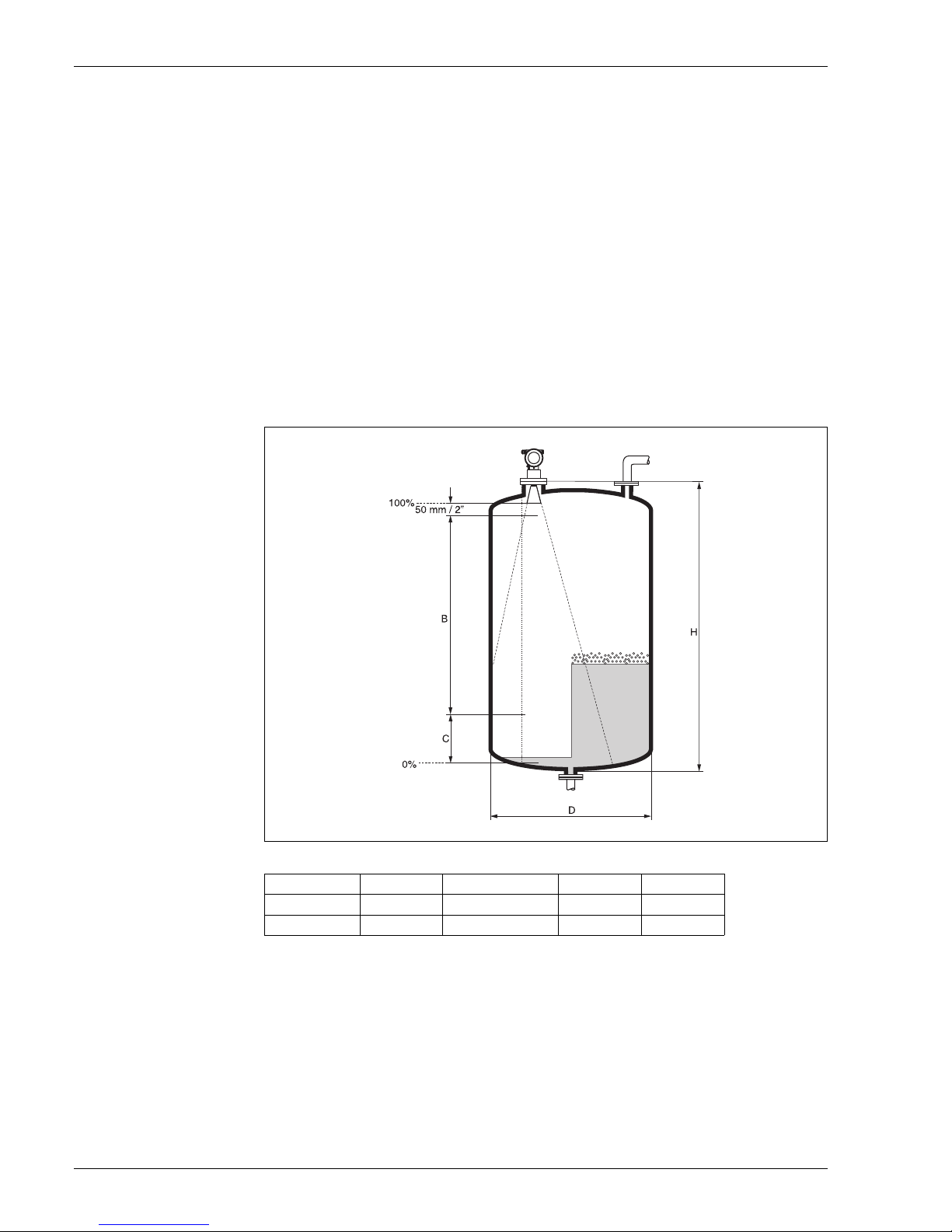

Measuring conditions Note!

Please use FMR 230 respectively FMR 231 for boiling surfaces or in case of a tendency for

foaming.

The maximum measuring range of the FMR240 may decrease in case of heavy steam

development, depending on density, temperature and composition of the steam (-> please

use FMR 230 respectively FMR 231). Please use FMR 230 in stilling well for the

measurement of ammonia NH

3

.

• The measuring range begins, where the beam hits the tank bottom. Particularly with dish

bottoms or conical outlets the level cannot be detected below this point.

• In case of media with a low dielectric constant (groups A and B), the tank bottom can be visible

through the medium at low levels. In order to guarantee the required accuracy in these cases,

it is recommended to position the zero-point at a distance (C) above the tank bottom

• In principle it is possible to measure up to the tip of the antenna. However, due to considerations

regarding corrosion and build-up, the end of the measuring range should not be chosen any

closer than 50 mm (2”) to the tip of the antenna.

• The smallest possible measuring range (B) depends on the antenna version.

• The tank diameter should be greater than (D), the tank height at least (H).

• Depending on its consistence, foam can either absorb microwaves or reflect them off the foam

surface. Measurement is possible under certain conditions.

B [m / inch] C [mm / inch] D [m / inch] H [m / ft]

FMR 230 / 231 > 0.5 / > 20 150…300 / 6…12 > 1 / > 40 > 1.5 / > 5

FMR 240 > 0.2 / > 8 50…150 / 2…6 > 0.2 / > 8 > 0.3 / > 1

L00-FMR2xxxx-17-00-00-en-005

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Micropilot M

Endress+Hauser 9

Output

Output signal • 4…20 mA with HART protocol

• PROFIBUS-PA

• Foundation Fieldbus (FF)

Signal on alarm Error information can be accessed via the following interfaces:

• Local display:

– Error symbol (see page 27)

– Plain text display

• Current output

• Digital interface

Auxiliary energy

Electrical connection Terminal compartment

Two housings are available:

• Housing F 12 with additionally sealed terminal compartment for standard or EEx ia

• Housing T 12 with separate terminal compartment for standard, EEx e or EEx d.

L00-FMR2xxxx-04-00-00-en-001

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Micropilot M

10 Endress+Hauser

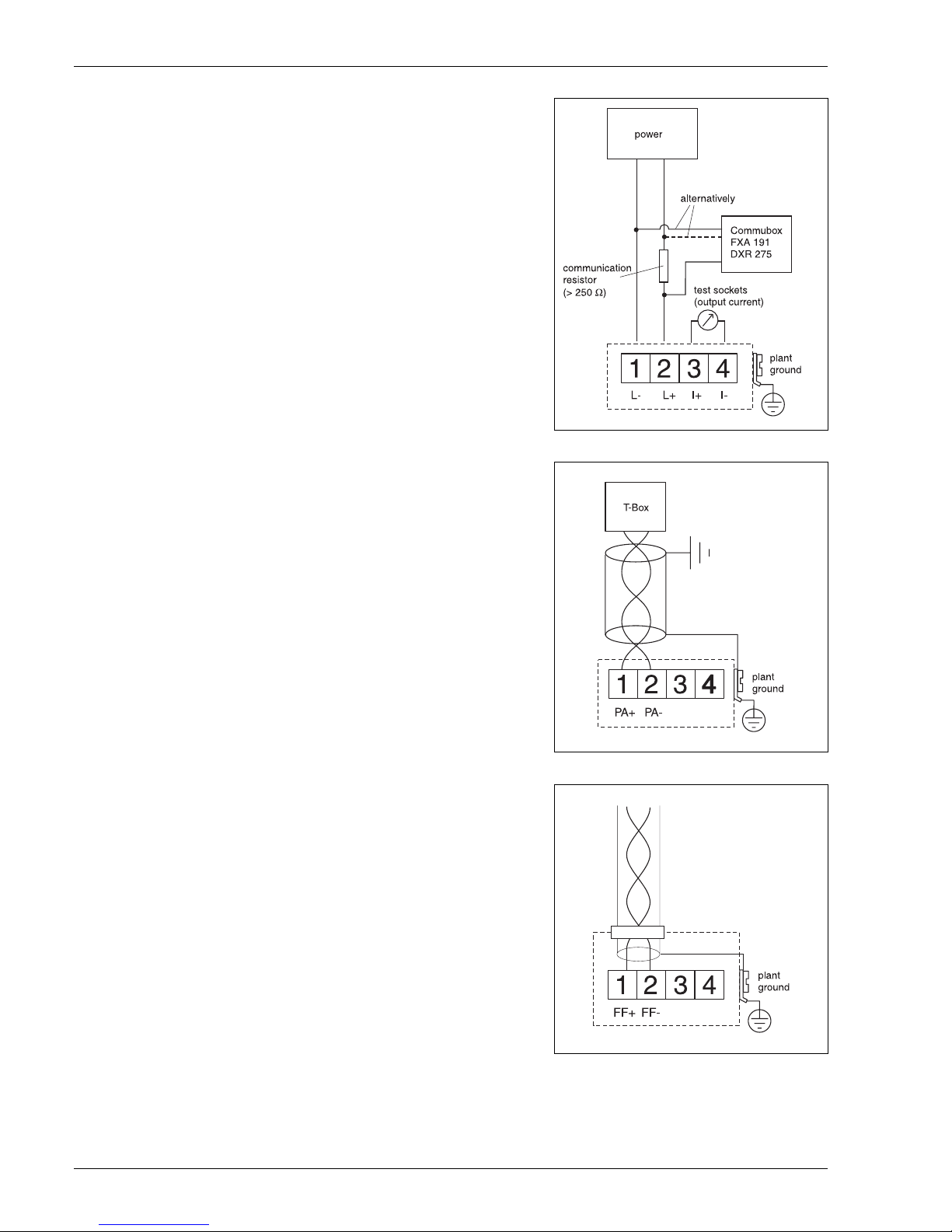

Terminal assignment 4…20 mA with HART

The 2-wire cable is connected to the screw

terminals (wire diameter 0.5…2.5mm) in the

terminal compartment.

Use 2-wire twisted pair cable with screen for

the connection.

Protective circuitry against reverse polarity,

RFI, and over-voltage peaks is built into the

device (refer to TI 241F »basics for EMCtests«).

Terminal assignment PROFIBUS-PA

The digital communication signal is transmitted

to the bus via a 2-wire connection. The bus also

provides the auxiliary energy.

Please use 2-wire twisted pair cable with

screen.

Hints regarding architecture and grounding of

the network can be found in BA 198F

»projecting hints PROFIBUS-PA« and the

specification for PROFIBUS-PA.

Terminal assignment Foundation Fieldbus

The digital communication signal is transmitted

to the bus via a 2-wire connection. The bus

also provides the auxiliary energy.

Please use 2-wire twisted pair cable with

screen. Further cable specifications can be

found in the FF specification or the

IEC 61158-2.

Further hints regarding architecture and

grounding of the network can be found at the

Internet address »http://www.fieldbus.org«.

L00-FMR2xxxx-04-00-00-en-002L00-FMR2xxxx-04-00-00-en-003L00-FMR2xxxx-04-00-00-en-007

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Micropilot M

Endress+Hauser 11

Load HART Minimum load for HART communication: 250 Ω

Cable entry Cable gland: M20x1.5 or Pg13.5

Cable entry: G ½ or ½ NPT

PROFIBUS-PA M12 plug

Fieldbus Foundation 7/8" plug

Supply voltage The following values are the voltages across the terminals directly at the instrument:

.

Power consumption Normal operation: min. 60 mW, max. 900 mW

Current consumption .

Communication

Current

consumption

Terminal voltage

minimal maximal

HART

standard

4 mA 16 V 36 V

20 mA 7.5 V 36 V

EEx ia

4 mA 16 V 30 V

20 mA 7.5 V 30 V

EEx em

EEx d

4 mA 16 V 30 V

20 mA 11 V 30 V

Fixed current

(measured value

transferred at HART)

standard 11 mA 10 V 36 V

EEx ia 11 mA 10 V 30 V

Communication Current consumption

HART 3.6…22 mA

PROFIBUS-PA ca. 13 mA

Foundation Fieldbus (FF) ca. 15 mA

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Micropilot M

12 Endress+Hauser

Performance characteristics

Reference operating

conditions

• temperature = +20 °C (68 °F) ±5 °C (9 °F)

• pressure = 1013 mbar abs. (14.7 psia) ±20 mbar (0.3 psi)

• relative humidity (air) = 65 % ±20%

• ideal reflector

• no major interference reflections inside the signal beam

Maximum measured error Typical statements for reference conditions, include linearity, repeatability, and hysteresis:

.

Resolution Digital / analog in % 4…20 mA

• FMR 230: 1mm / 0.1 % of measuring range

• FMR 231: 1mm / 0.1 % of measuring range

• FMR 240: 1mm / 0.1 % of measuring range

Reaction time The reaction time depends on the parameter settings (min. 1 s). In case of fast level changes, the

instrument needs the reaction time to indicate the new value.

Influence of ambiente

temperature

0.006% / 10 K referring to max. measuring range

Type of device to 10 m ex 10 m

FMR 230

±10 mm ±0.1% of measuring range

FMR 231

±10 mm ±0.1% of measuring range

FMR 240

±3 mm ±0.03% of measuring range

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Micropilot M

Endress+Hauser 13

Operating conditions / Installation

Installation instructions

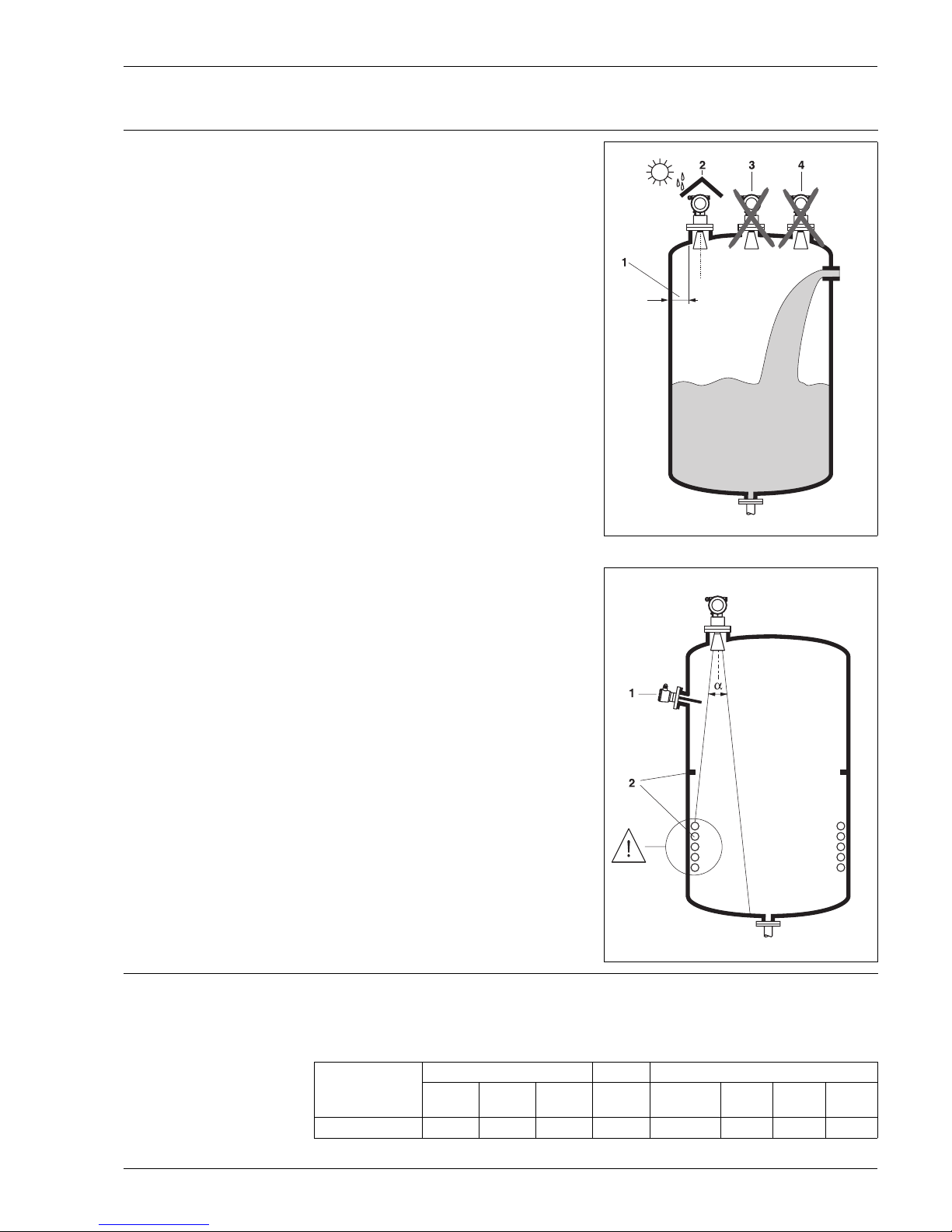

Beam angle The beam angle is defined as the angle α where the energy density of the radar waves reaches

half the value of the maximum energy density (3dB-width). Microwaves are also emitted outside

the signal beam and can be reflected off interfering installations.

Beam angle in dependence of antenna type (diameter).

Orientation

• Recommended distance (1) wall – outer

edge of nozzle: ~1/6 of tank diameter

(FMR 230/231: min. 30 cm (12“),

FMR 240: min. 15 cm (6“)).

• Not in the centre (3), interference can cause

signal loss.

• Not above the fill stream (4).

• It is recommended to use a weather

protection cover (2) in order to protect the

transmitter from direct sun or rain. Assembly

and disassembly is simply done by means of

a tension clamp (see »Accessories« on

page 39).

Tank installations

• Avoid any installations (1), like limit switches,

temperature sensors, etc., inside the signal

beam (refer to beam angle).

• Symmetrical installations (2), i.e. vacuum

rings, heating coils, baffles, etc., can also

interfere with the measurement.

Optimization options

• Antenna size: the bigger the antenna, the

smaller the beam angle, the less interference

echoes.

• Mapping: the measurement can be

optimized by means of electronic

suppression of interference echoes.

• Antenna alignment: refer to "optimum

mounting position"

• Stilling well: a stilling well respectively a

Wave Guide antenna can always be used to

avoid interference.

Please contact Endress+Hauser for further

information.

L00-FMR2xxxx-17-00-00-xx-001

L00-FMR2xxxx-17-00-00-xx-002

Antenna size FMR 230 FMR 231 FMR 240

DN1506"DN2008"DN250

10"

Rod 1½" / 40 mm DN502"DN803"DN100

4"

Beam angle

α 23° 19° 15° 30° 23° 18° 10° 8°

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Micropilot M

14 Endress+Hauser

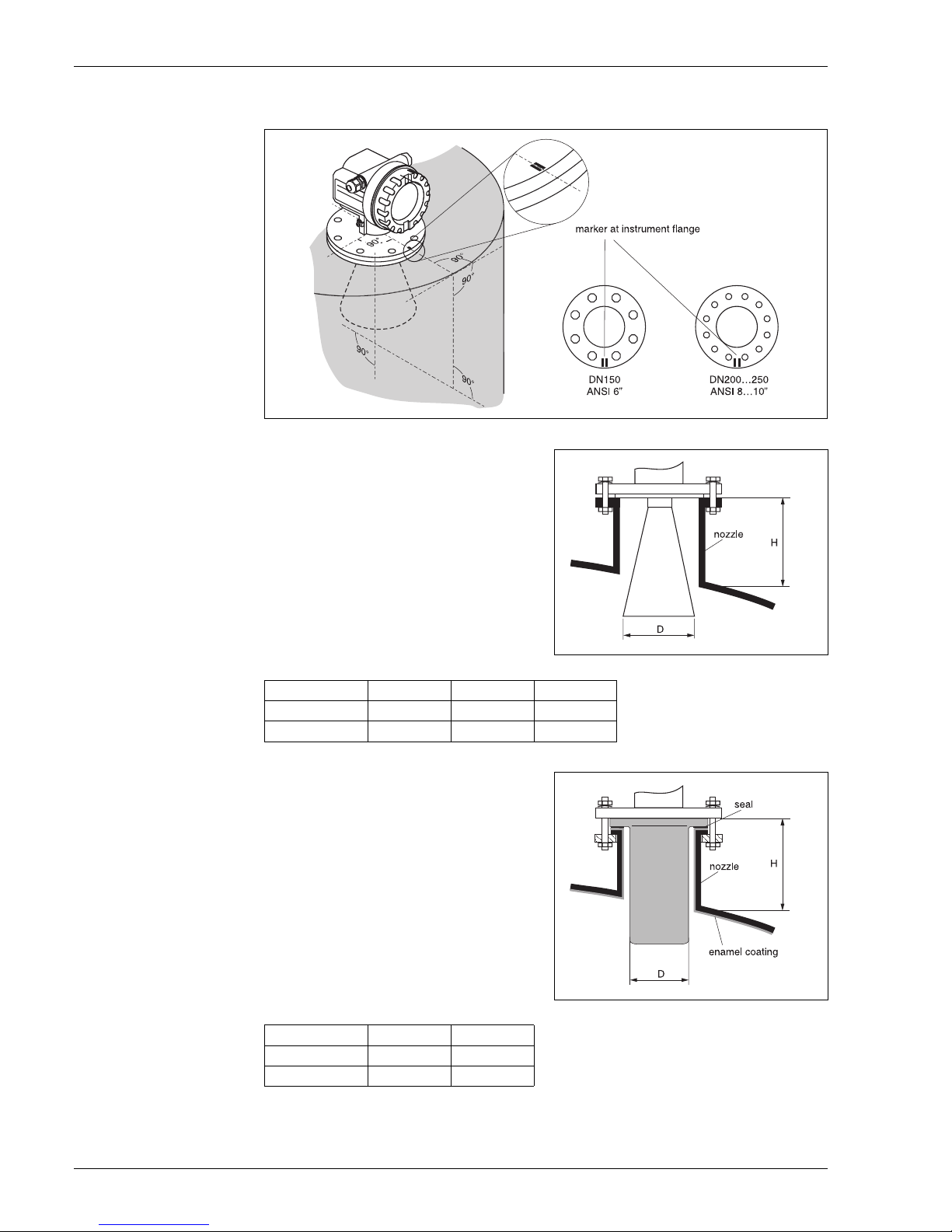

Installation in tank

(free space) FMR 230

Optimum mounting position

Standard installation

• Observe installation instructions on page 13.

• Marker is aligned towards tank wall.

• The marker is always exactly in the middle

between two bolt-holes in the flange.

• After mounting, the housing can be turned

350° in order to simplify access to the display

and the terminal compartment.

• The horn antenna must extend below the

nozzle, otherwise use antenna extension

FAR10.

• Align horn antenna vertically.

Antenna size 150 mm / 6" 200 mm / 8" 250 mm / 10"

D [mm / inch] 146 / 5.8 191 / 7.5 241 / 9.5

H [mm / inch] < 205 / < 8.1 < 290 / < 11.5 < 380 / <15

Installation instructions for enamelled

antenna

• Refer to standard installation.

• Attention!

Do not hit or chip the enamelled antenna,

the coating can be damaged.

Antenna size 150 mm / 6" 200 mm / 8"

D [mm / inch] 140 / 5.5 158 / 6.2

H [mm / inch] < 219 / 8.6 < 269 / 10.6

L00-FMR230xx-17-00-00-en-001

L00-FMR230xx-17-00-00-en-002L00-FMR230xx-17-00-00-en-008

www.aotewell.com

www.fa-market.com

info@aotewell.com

AoteWell International.inc

sales@aotewell.com

Tel: +852-6563-2160

Loading...

Loading...