Endress+Hauser Micropilot FMR50 Brief Operating Instructions

KA01099F/00/EN/05.18

71394693

2018-04-12

Products Solutions Services

Brief Operating Instructions

Micropilot FMR50

HART

Free space radar

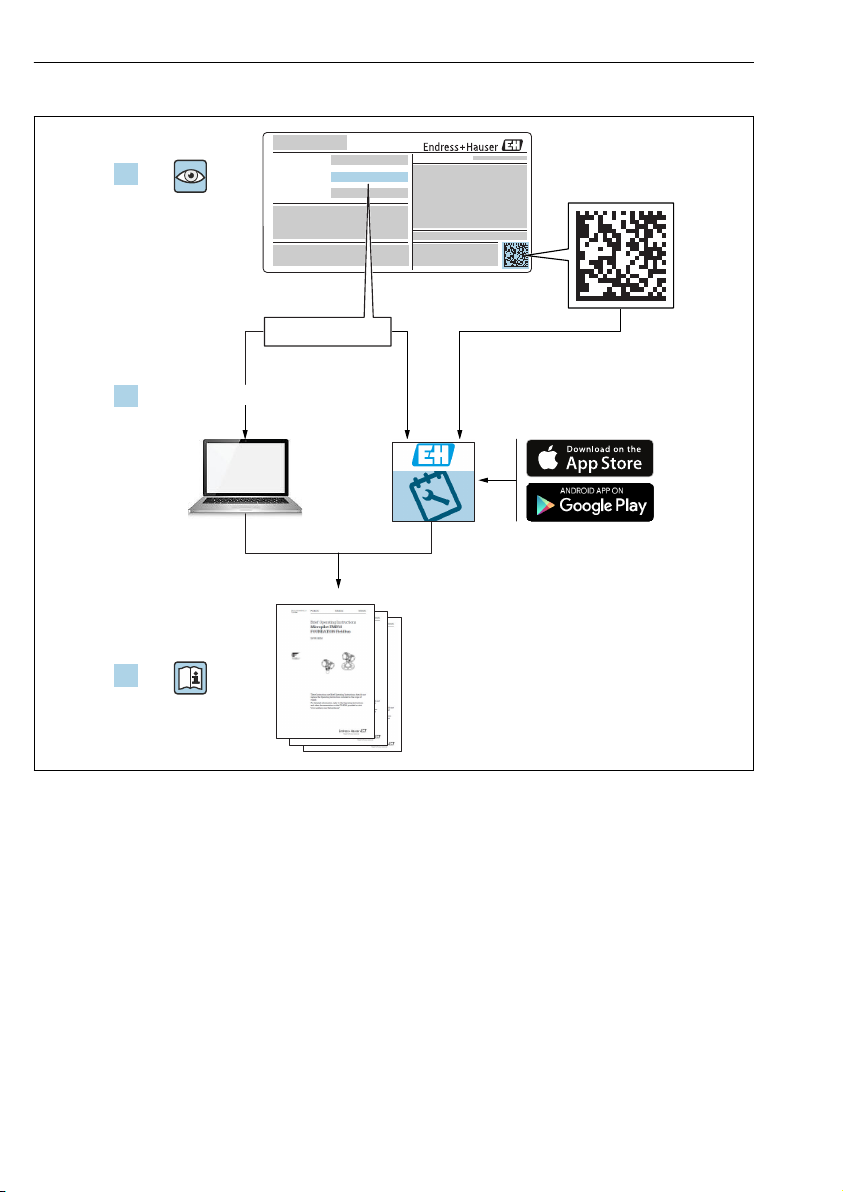

These Instructions are Brief Operating Instructions; they are

not a substitute for the Operating Instructions pertaining to

the device.

Detailed information about the device can be found in the

Operating Instructions and the other documentation:

Available for all device versions via:

– Internet: www.endress.com/deviceviewer

– Smart phone/tablet: Endress+Hauser Operations App

Micropilot FMR50 HART

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

1.

3.

2.

2 Endress+Hauser

A0023555

Micropilot FMR50 HART Table of contents

Table of contents

1 Wichtige Hinweise zum Dokument ................................................ 4

1.1 Symbols ............................................................................. 4

1.2 Terms and abbreviations ................................................................. 6

1.3 Registered trademarks .................................................................. 7

2 Basic safety instructions .......................................................... 8

2.1 Requirements for the personnel ............................................................ 8

2.2 Designated use ........................................................................ 8

2.3 Workplace safety ...................................................................... 9

2.4 Operational safety ......................................................................9

2.5 Product safety ......................................................................... 9

3 Product description .............................................................. 11

3.1 Product design ....................................................................... 11

4 Incoming acceptance and product identification ................................. 11

4.1 Incoming acceptance ................................................................... 11

4.2 Product identification .................................................................. 12

5 Storage, Transport ............................................................... 13

5.1 Storage conditions .................................................................... 13

5.2 Transport product to the measuring point ................................................... 13

6 Installation ...................................................................... 14

6.1 Installation conditions .................................................................. 14

6.2 Measuring conditions .................................................................. 19

6.3 Installation in vessel (free space) .......................................................... 20

6.4 Installation in stilling well ............................................................... 25

6.5 Installation in bypass .................................................................. 26

6.6 Container with heat insulation ........................................................... 27

6.7 Turning the transmitter housing .......................................................... 27

6.8 Turning the display .................................................................... 28

6.9 Post-installation check ................................................................. 30

7 Electrical connection ............................................................ 31

7.1 Connection conditions .................................................................. 31

7.2 Connecting the measuring device ......................................................... 45

7.3 Post-connection check ..................................................................49

8 Commissioning via SmartBlue (app) ............................................. 49

8.1 Requirements ........................................................................ 49

8.2 Commissioning ....................................................................... 50

9 Commissioning via wizard ....................................................... 54

10 Commissioning (via operating menu) ............................................ 55

10.1 Display and operating module ............................................................ 55

10.2 Operating menu ...................................................................... 58

10.3 Unlock the device ..................................................................... 59

10.4 Setting the operating language ........................................................... 59

10.5 Configuration of a level measurement ...................................................... 60

10.6 User-specific applications ............................................................... 61

Endress+Hauser 3

Wichtige Hinweise zum Dokument Micropilot FMR50 HART

DANGER

WARNING

CAUTION

NOTICE

1 Wichtige Hinweise zum Dokument

1.1 Symbols

1.1.1 Safety symbols

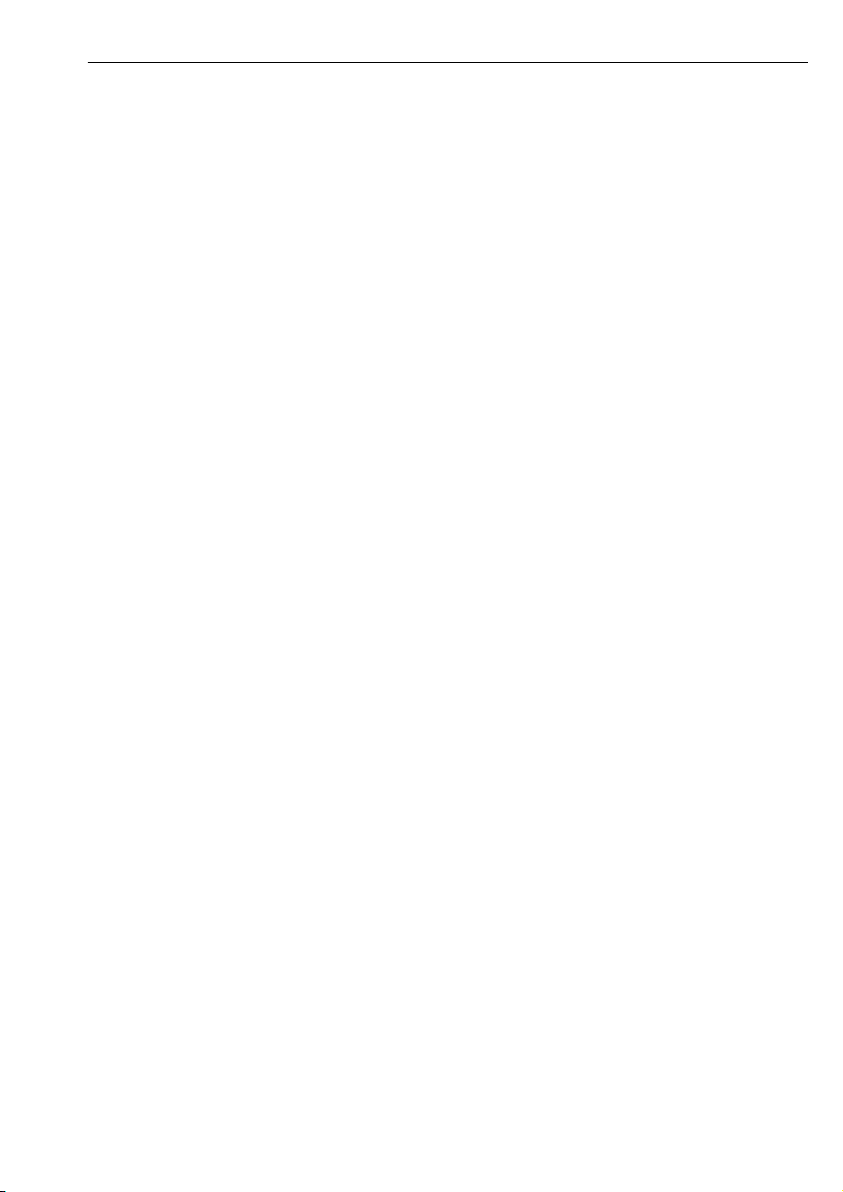

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.1.2 Electrical symbols

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

Symbol Meaning

Protective Earth (PE)

A terminal which must be connected to ground prior to establishing any other connections.

The ground terminals are situated inside and outside the device:

• Inner ground terminal: Connects the protectiv earth to the mains supply.

• Outer ground terminal: Connects the device to the plant grounding system.

A grounded terminal which, as far as

the operator is concerned, is grounded

via a grounding system.

1.1.3 Tool symbols

Flat blade

screwdriver

A0011220

A0013442 A0011221

Torx screwdriver Allen key Hexagon wrench

A0011219

Cross-head

screwdriver

4 Endress+Hauser

A0011222

Micropilot FMR50 HART Wichtige Hinweise zum Dokument

A

1.

1.

-

.

1.1.4 Symbols for certain types of information

Symbol Meaning Symbol Meaning

Permitted

Procedures, processes or actions that

are permitted.

Forbidden

Procedures, processes or actions that

are forbidden.

Reference to documentation.

Preferred

Procedures, processes or actions that

are preferred.

Tip

Indicates additional information.

Reference to page.

Reference to graphic.

Result of a step. Visual inspection.

1.1.5 Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

, 2., 3.… Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

Hazardous area

Indicates a hazardous area.

Safe area (non-hazardous area)

Indicates the non-hazardous area.

1.1.6 Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

Temperature resistance of the connection cables

Specifies the minimum value of the temperature resistance of the connection cables.

, 2., 3.… Series of steps.

Endress+Hauser 5

Wichtige Hinweise zum Dokument Micropilot FMR50 HART

1.2 Terms and abbreviations

Term/abbreviation Explanation

BA Document type "Operating Instructions"

KA Document type "Brief Operating Instructions"

TI Document type "Technical Information"

SD Document type "Special Documentation"

XA Document type "Safety Instructions"

PN Nominal pressure

MWP Maximum Working Pressure

ToF Time of Flight

FieldCare Scalable software tool for device configuration and integrated plant asset management solutions

DeviceCare Universal configuration software for Endress+Hauser HART, PROFIBUS, FOUNDATION Fieldbus

DTM Device Type Manager

DD Device Description for HART communication protocol

εr (DC value) Relative dielectric constant

Operating tool The term "operating tool" is used in place of the following operating software:

BD Blocking Distance; no signals are analyzed within the BD.

PLC Programmable Logic Controller

CDI Common Data Interface

PFS Pulse Frequence Status (Switching output)

The MWP can also be found on the nameplate.

and Ethernet field devices

• FieldCare / DeviceCare, for operation via HART communication and PC

• SmartBlue (app), for operation using an Android or iOS smartphone or tablet.

6 Endress+Hauser

Micropilot FMR50 HART Wichtige Hinweise zum Dokument

1.3 Registered trademarks

®

HART

Registered trademark of the FieldComm Group, Austin, USA

Bluetooth®

The Bluetooth® word mark and logos are registered trademarks owned by the Bluetooth SIG,

Inc. and any use of such marks by Endress+Hauser is under license. Other trademarks and

trade names are those of their respective owners.

Apple®

Apple, the Apple logo, iPhone, and iPod touch are trademarks of Apple Inc., registered in the

U.S.and other countries. App Store is a service mark of Apple Inc.

Android®

Android, Google Play and the Google Play logo are trademarks of Google Inc.

KALREZ®, VITON

Registered trademark of DuPont Performance Elastomers L.L.C., Wilmington, USA

TEFLON

®

Registered trademark of E.I. DuPont de Nemours & Co., Wilmington, USA

TRI CLAMP

Registered trademark of Alfa Laval Inc., Kenosha, USA

®

®

Endress+Hauser 7

Basic safety instructions Micropilot FMR50 HART

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel must fulfill the following requirements for its tasks:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task.

Are authorized by the plant owner/operator.

‣

Are familiar with federal/national regulations.

‣

Before starting work, read and understand the instructions in the manual and

‣

supplementary documentation as well as the certificates (depending on the application).

Follow instructions and comply with basic conditions.

‣

2.2 Designated use

Application and measured materials

The measuring device described in these Operating Instructions is intended for the

continuous, contactless level measurement of liquids, pastes and sludge. The device can also

be freely mounted outside closed metal vessels (e.g. above basins, open channels or open

piles) because of its operating frequency of about 26 GHz, a maximum radiated pulsed power

of 5.7 mW and an average power output of 0.015 mW (for the version with advanced

dynamics: maximum pulse power: 23.3 mW; average power: 0.076 mW). Operation is

completely harmless to humans and animals.

Observing the limit values specified in the "Technical data" and listed in the Operating

Instructions and supplementary documentation, the measuring device may be used for the

following measurements only:

Measured process variables: level, distance, signal strength

‣

Calculated process variables: Volume or mass in arbitrarily shaped vessels; flow through

‣

measuring weirs or flumes (calculated from the level by the linearization functionality)

To ensure that the measuring device remains in proper condition for the operation time:

Use the measuring device only for measured materials against which the process-wetted

‣

materials are adequately resistant.

Observe the limit values in "Technical data".

‣

Incorrect use

The manufacturer is not liable for damage caused by improper or non-designated use.

Verification for borderline cases:

For special measured materials and cleaning agents, Endress+Hauser is glad to provide

‣

assistance in verifying the corrosion resistance of wetted materials, but does not accept any

warranty or liability.

Residual risk

The electronics housing and its built-in components such as display module, main electronics

module and I/O electronics module may heat to 80 °C (176 °F) during operation through heat

transfer from the process as well as power dissipation within the electronics. During operation

the sensor may assume a temperature near the temperature of the measured material.

8 Endress+Hauser

Micropilot FMR50 HART Basic safety instructions

Danger of burns due to heated surfaces!

For high process temperatures: Install protection against contact in order to prevent burns.

‣

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

2.4 Operational safety

Risk of injury.

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with the manufacturer.

‣

Repair

To ensure continued operational safety and reliability,

Carry out repairs on the device only if they are expressly permitted.

‣

Observe federal/national regulations pertaining to repair of an electrical device.

‣

Use original spare parts and accessories from the manufacturer only.

‣

Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the hazardous

area (e.g. explosion protection, pressure vessel safety):

Based on the nameplate, check whether the ordered device is permitted for the intended

‣

use in the hazardous area.

Observe the specifications in the separate supplementary documentation that is an integral

‣

part of these Instructions.

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet stateof-the-art safety requirements, has been tested, and left the factory in a condition in which it

is safe to operate. It meets general safety standards and legal requirements.

NOTICE

Loss of degree of protection by opening of the device in humid environments

If the device is opened in a humid environment, the degree of protection indicated on the

‣

nameplate is no longer valid. This may also impair the safe operation of the device.

2.5.1 CE mark

The measuring system meets the legal requirements of the applicable EC guidelines. These are

listed in the corresponding EC Declaration of Conformity together with the standards applied.

Endress+Hauser 9

Basic safety instructions Micropilot FMR50 HART

Endress+Hauser confirms successful testing of the device by affixing to it the CE mark.

2.5.2 EAC conformity

The measuring system meets the legal requirements of the applicable EAC guidelines. These

are listed in the corresponding EAC Declaration of Conformity together with the standards

applied.

Endress+Hauser confirms successful testing of the device by affixing to it the EAC mark.

10 Endress+Hauser

Micropilot FMR50 HART Product description

1 1 6

1

2 4 4

3 5

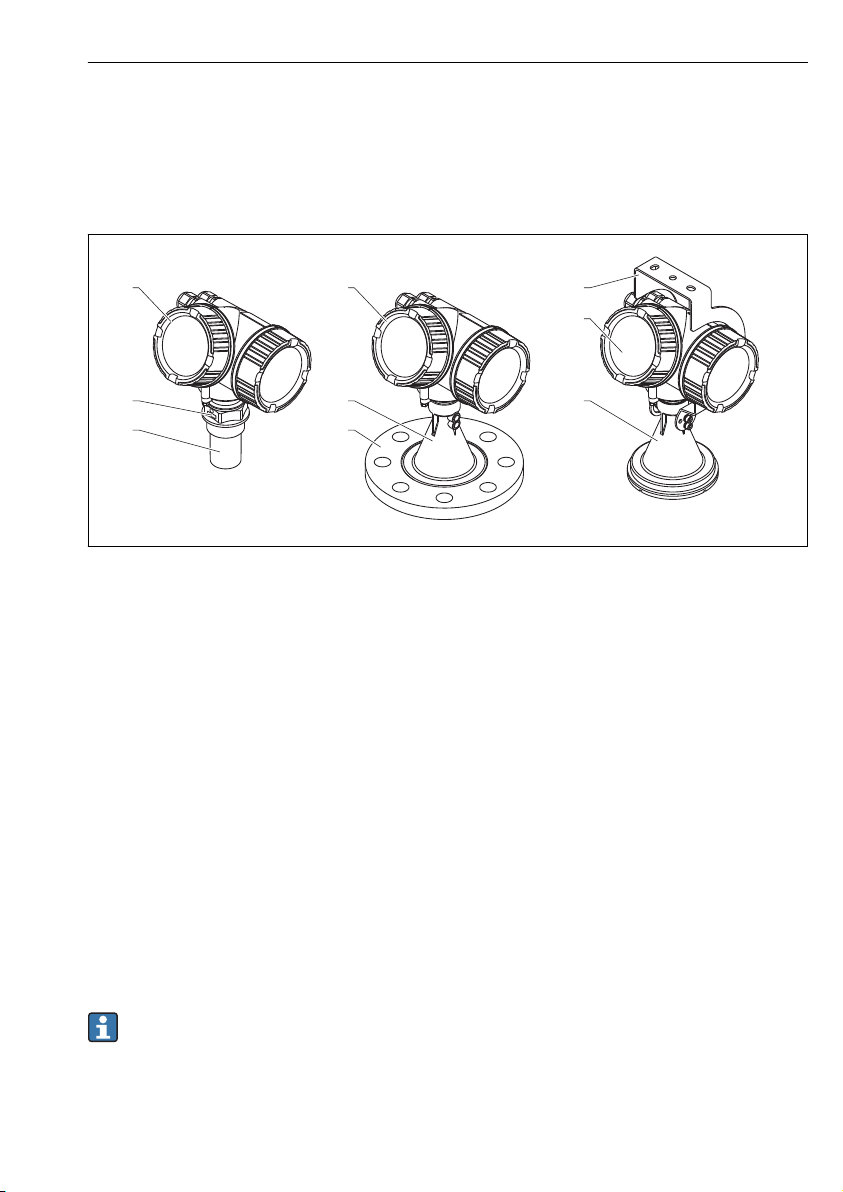

3 Product description

3.1 Product design

3.1.1 Micropilot FMR50

A0016784

1 Design of the Micropilot FMR50 (26 GHz)

1 Electronics housing

2 Process connection (Thread)

3 Horn antenna 40 mm (1-1/2 in), PVDF encapsulated

4 Horn antenna 80mm/100 mm (3in/4 in), PP cladded

5 Slip-on flange

6 Mounting bracket

4 Incoming acceptance and product identification

4.1 Incoming acceptance

Upon receipt of the goods check the following:

• Are the order codes on the delivery note and the product sticker identical?

• Are the goods undamaged?

• Do the nameplate data match the ordering information on the delivery note?

• Is the DVD with the operating tool present?

If required (see nameplate): Are the Safety Instructions (XA) present?

If one of these conditions is not satisfied, contact your Endress+Hauser Sales Center.

Endress+Hauser 11

Incoming acceptance and product identification Micropilot FMR50 HART

Order code:

Ext. ord. cd.:

Ser. no.:

Order code:

Ext. ord. cd.:

Ser. no.:

1

2

3

4

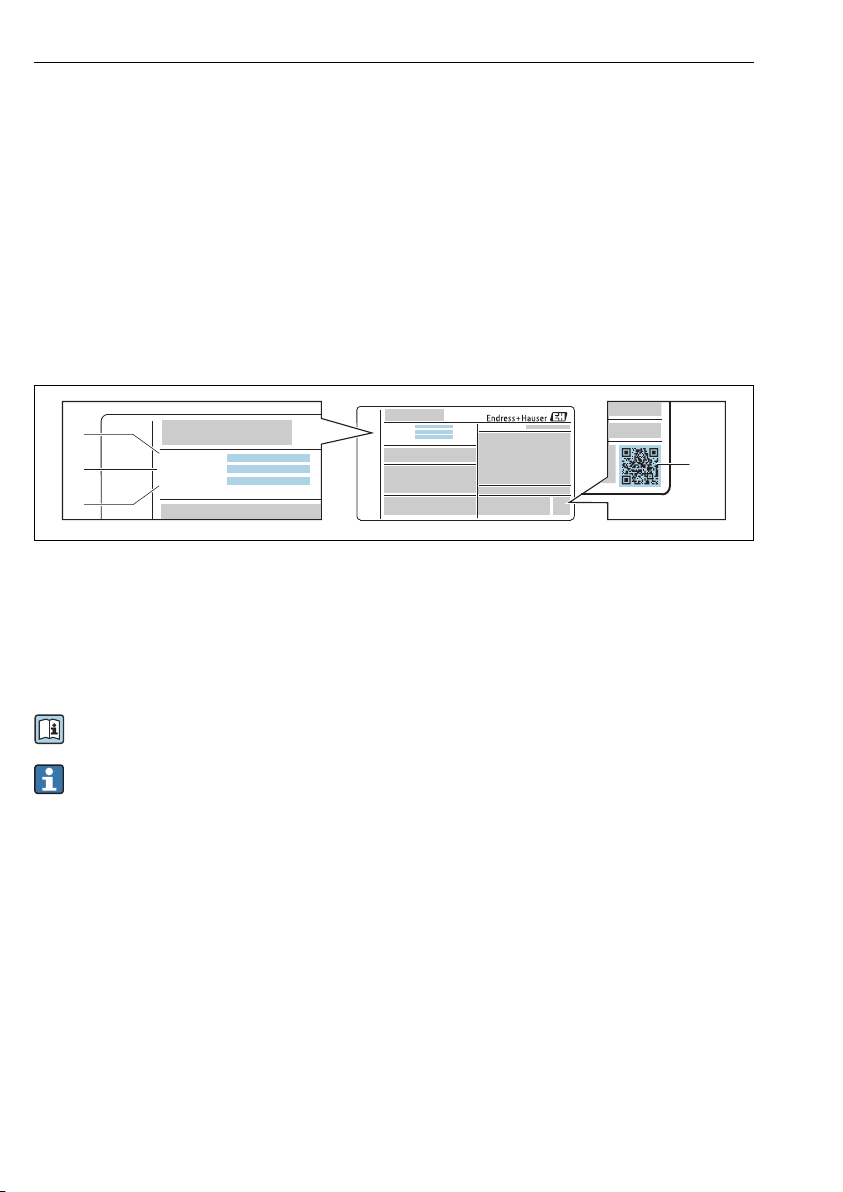

4.2 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Extended order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

( www.endress.com/deviceviewer ): All information about the measuring device is

displayed.

• Enter the serial number from the nameplates into the Endress+Hauser Operations App or

scan the 2-D matrix code (QR code) on the nameplate with the Endress+Hauser Operations

App: all the information for the measuring device is displayed.

4.2.1 Nameplate

A0030196

2 Example of a nameplate

1 Order code

2 Serial number (Ser. no.)

3 Extended order code (Ext. ord. cd.)

4 2-D matrix code (QR code)

For detailed information about interpreting the nameplate specifications, refer to the

Operating Instructions for the device.

Only 33 digits of the extended order code can be indicated on the nameplate. If the

extended order code exceeds 33 digits, the rest will not be shown. However, the complete

extended order code can be viewed in the operating menu of the device: Extended order

code 1 to 3 parameter

12 Endress+Hauser

Micropilot FMR50 HART Storage, Transport

5 Storage, Transport

5.1 Storage conditions

• Permitted storage temperature: –40 to +80 °C (–40 to +176 °F)

• Use the original packaging.

5.2 Transport product to the measuring point

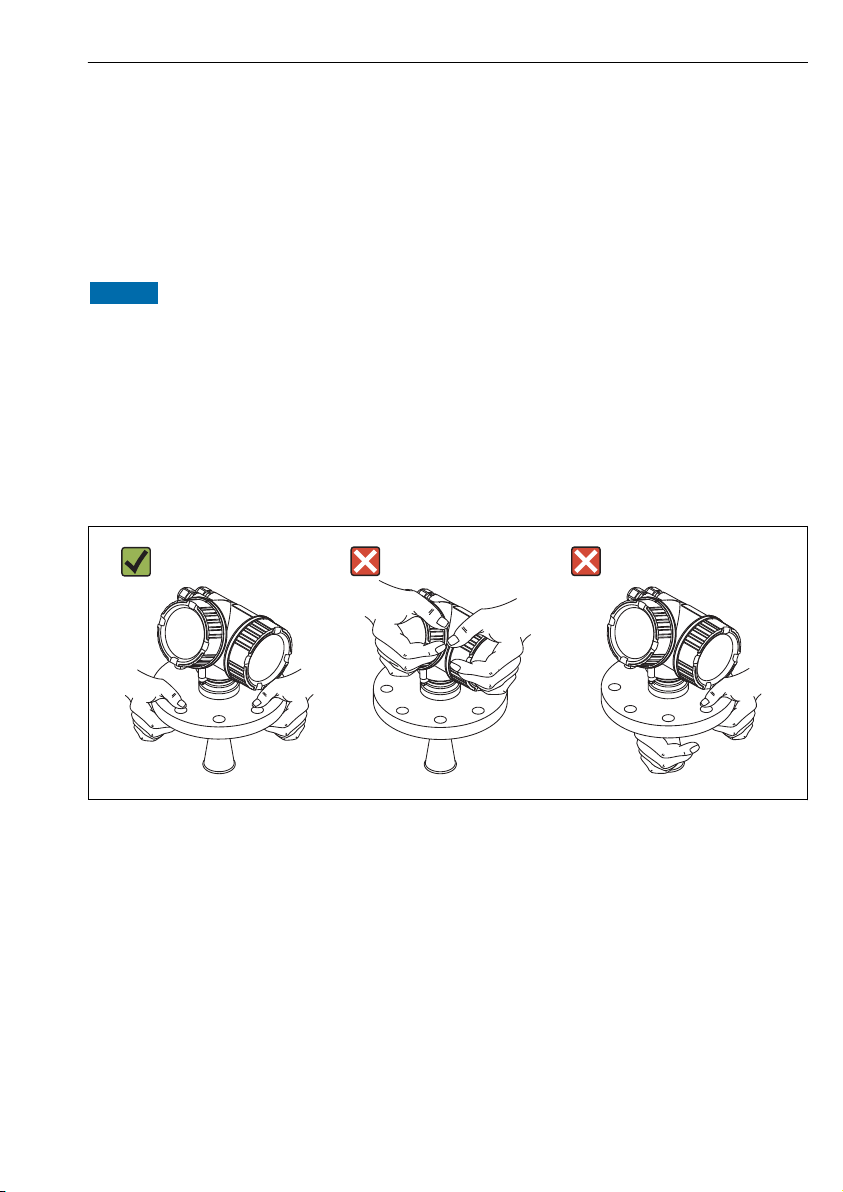

NOTICE

Housing or antenna horn may be damaged or break away.

Risk of injury!

Transport the measuring device to the measuring point in its original packaging or at the

‣

process connection.

Do not fasten lifting devices (hoisting slings, lifting eyes etc.) at the housing or the antenna

‣

horn but at the process connection. Take into account the mass center of the device in

order to avoid unintended tilting.

Comply with the safety instructions, transport conditions for devices over 18kg (39.6lbs)

‣

(IEC61010).

A0016875

Endress+Hauser 13

Installation Micropilot FMR50 HART

A

1 2 3

6 Installation

6.1 Installation conditions

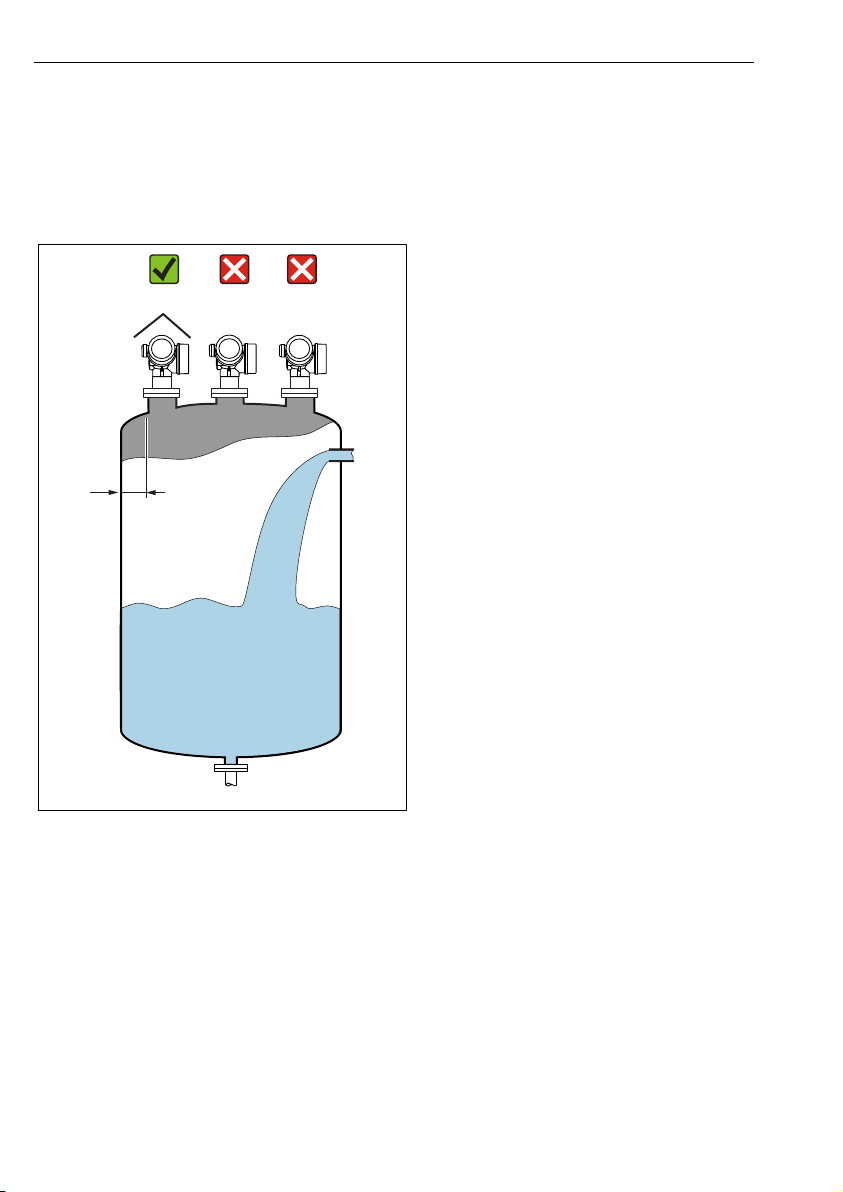

6.1.1 Mounting position

• Recommended distance A from wall

to outer edge of nozzle: ~ 1/6 of tank

diameter.

Nevertheless the device should not be

installed closer than 15 cm (5.91 in)

to the tank wall.

• Not in the center (2), as interference

can cause signal loss.

• Not above the fill stream (3).

• It is recommended to us a weather

protection cover (1) in order to protect

the device from direct sun or rain.

A0016882

14 Endress+Hauser

Micropilot FMR50 HART Installation

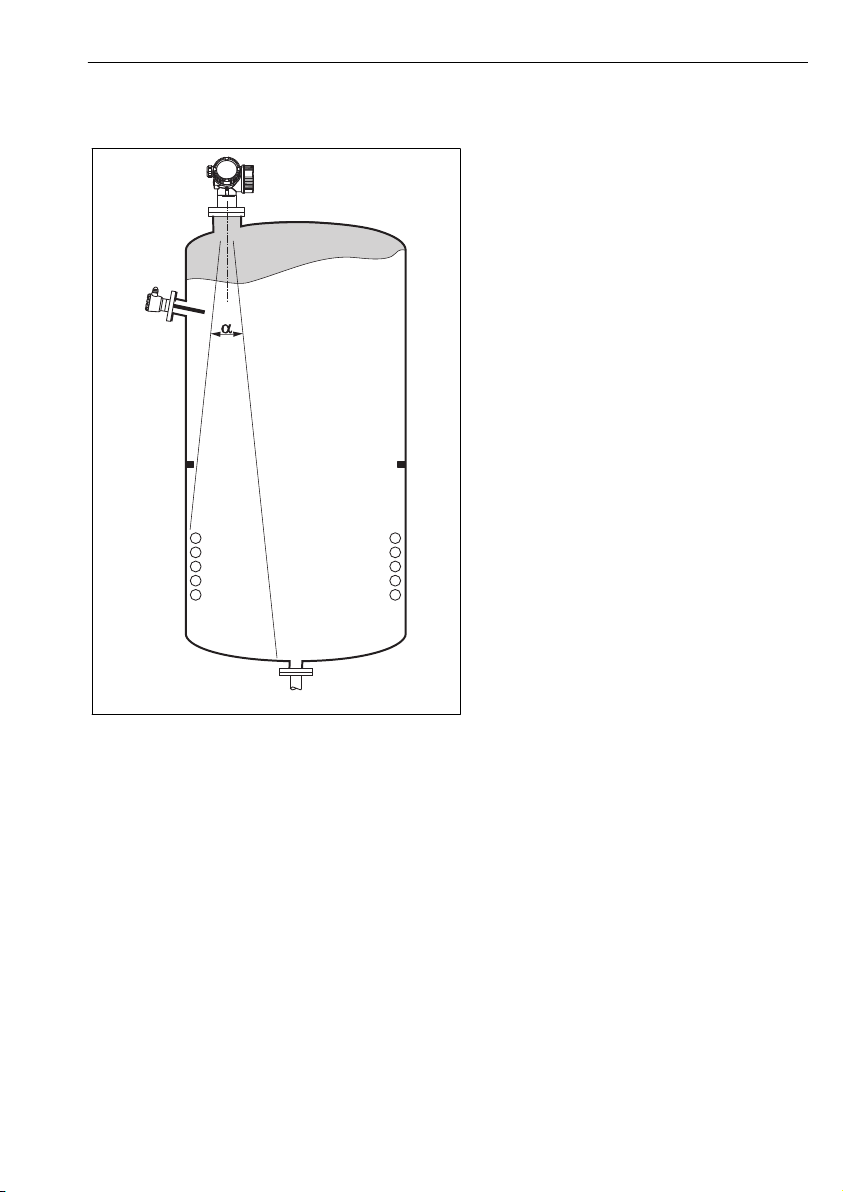

6.1.2 Vessel installations

Avoid any installations (point level

switches, temperature sensors, braces,

vacuum rings, heating coils, baffles etc.)

inside the signal beam. Take into

account the beam angle → 18.

A0018944

Endress+Hauser 15

Installation Micropilot FMR50 HART

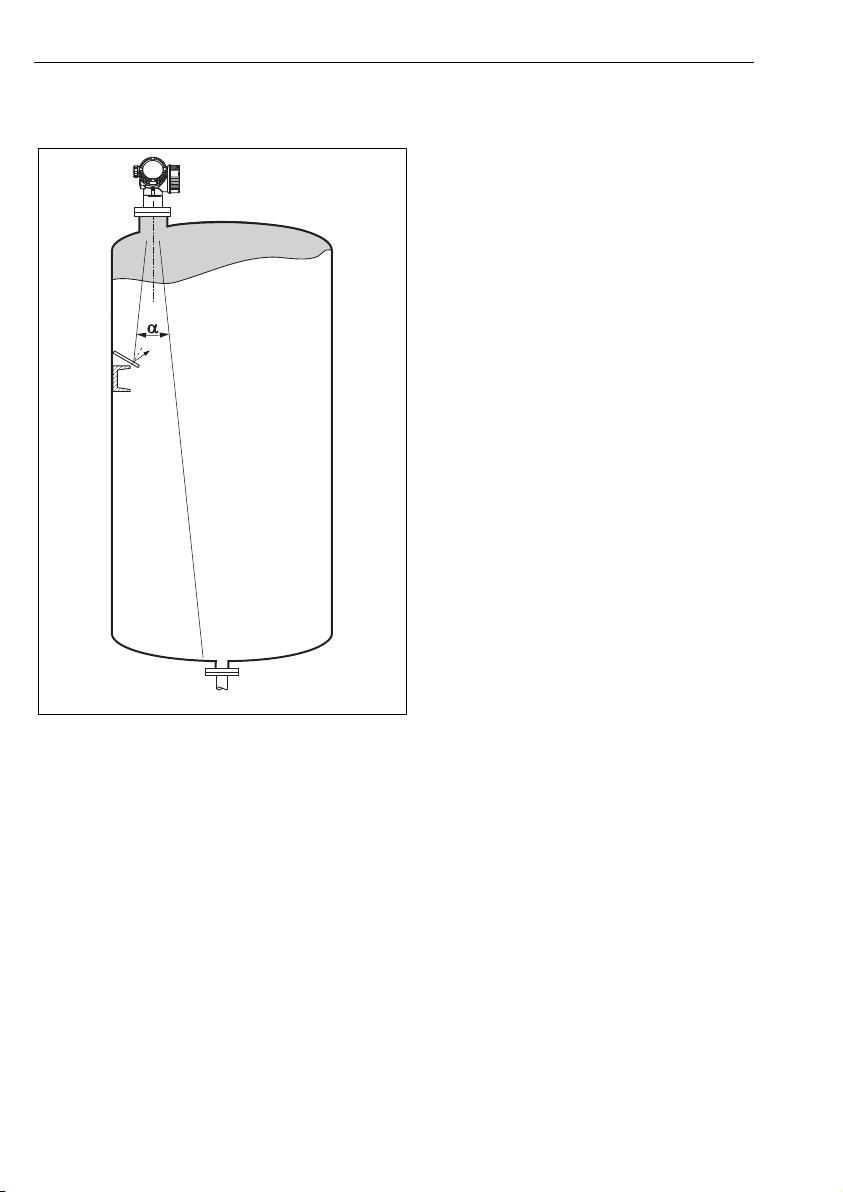

6.1.3 Reduction of interference echoes

Metallic screens mounted at a slope

spread the radar signal and can,

therefore, reduce interference echoes.

A0016890

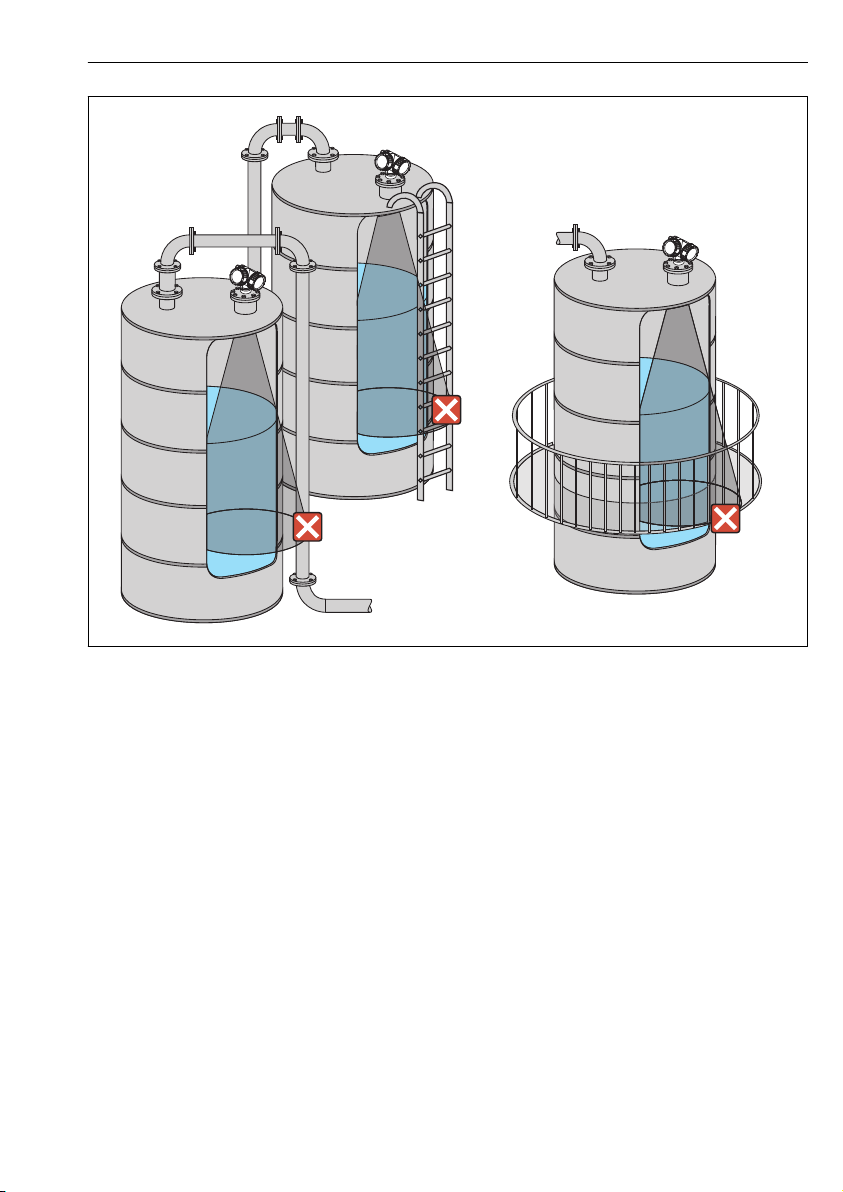

6.1.4 Measurement in a plastic vessel

If the outer wall of the vessel is made of a non-conductive material (e.g. GRP), microwaves can

also be reflected off interfering installations outside the vessel (e.g. metallic pipes (1), ladders

(2), grates (3), ...). Therefore, there should be no such interfering installations in the signal

beam. Please contact Endress+Hauser for further information.

16 Endress+Hauser

Micropilot FMR50 HART Installation

2

3

1

A0017123

6.1.5 Optimization options

• Antenna size

The bigger the antenna, the smaller the beam angle α and the fewer interference echoes

→ 18.

• Mapping

The measurement can be optimized by means of electronic suppression of interference

echoes.

• Antenna alignment

Take into account the marker on the flange or threaded connection → 20 → 22.

• Stilling well

A stilling well can be applied to avoid interferences → 25.

• Metallic screens mounted at a slope

They spread the radar signals and can, therefore, reduce interference echoes.

Endress+Hauser 17

Installation Micropilot FMR50 HART

a

D

W

a

D

_

=

2

2

. .

tan

W

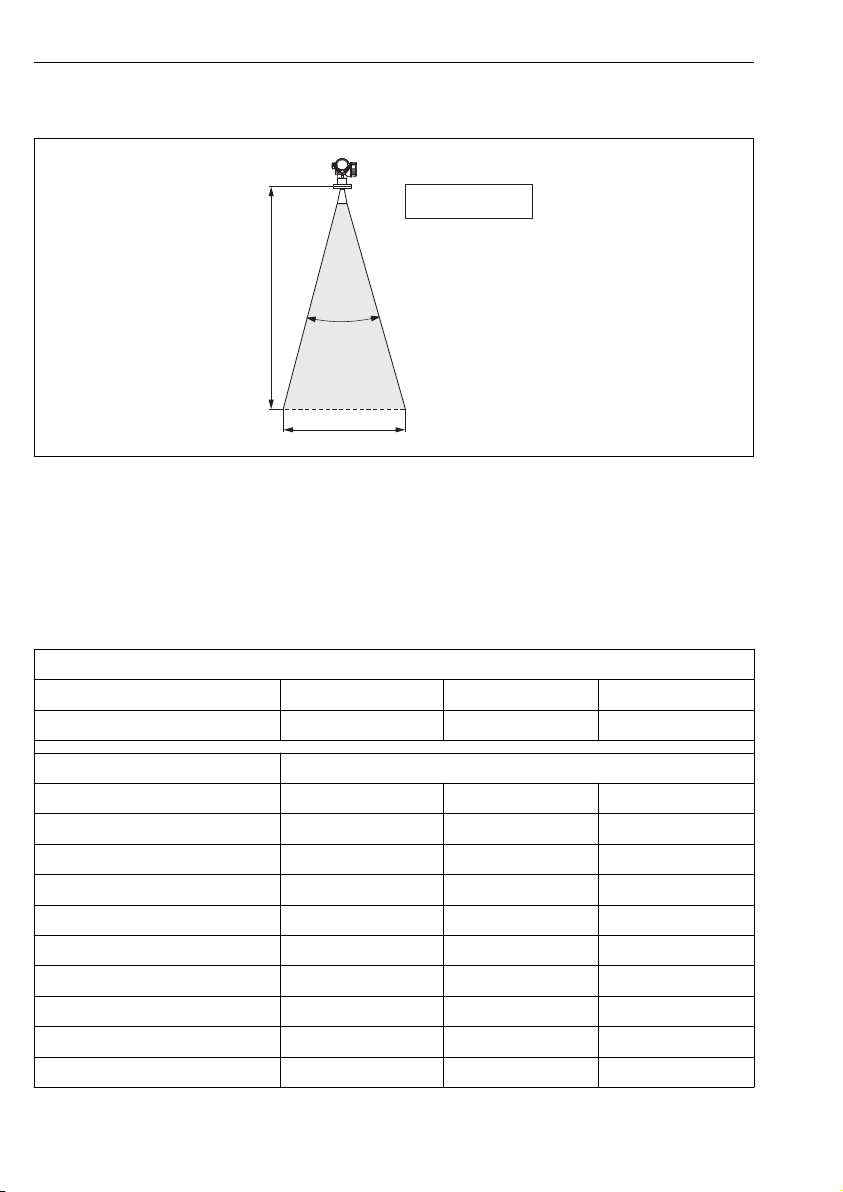

6.1.6 Beam angle

A0016891

3 Relationship between beam angle α, distance D and beamwidth diameter W

The beam angle is defined as the angle α where the energy density of the radar waves reaches

half the value of the maximum energy density (3-dB-width). Microwaves are also emitted

outside the signal beam and can be reflected off interfering installations.

Beam diameter W as a function of beam angle α and measuring distance D:

FMR50

Antenna size 40 mm (1½ in) 80 mm (3 in) 100 mm (4 in)

Beam angle α 23° 10° 8°

Measuring distance (D) Beamwidth diameter W

3 m (9.8 ft) 1.22 m (4 ft) 0.53 m (1.7 ft) 0.42 m (1.4 ft)

6 m (20 ft) 2.44 m (8 ft) 1.05 m (3.4 ft) 0.84 m (2.8 ft)

9 m (30 ft) 3.66 m (12 ft) 1.58 m (5.2 ft) 1.26 m (4.1 ft)

12 m (39 ft) 4.88 m (16 ft) 2.1 m (6.9 ft) 1.68 m (5.5 ft)

15 m (49 ft) 6.1 m (20 ft) 2.63 m (8.6 ft) 2.10 m (6.9 ft)

20 m (66 ft) 8.14 m (27 ft) 3.50 m (11 ft) 2.80 m (9.2 ft)

25 m (82 ft) 10.17 m (33 ft) 4.37 m (14 ft) 3.50 m (11 ft)

30 m (98 ft) - 5.25 m (17 ft) 4.20 m (14 ft)

18 Endress+Hauser

35 m (115 ft) - 6.12 m (20 ft) 4.89 m (16 ft)

40 m (131 ft) - 7.00 m (23 ft) 5.59 m (18 ft)

Micropilot FMR50 HART Installation

6.2 Measuring conditions

• In case of boiling surfaces, bubbling or tendency for foaming use FMR53 or FMR54.

Depending on its consistence, foam can either absorb microwaves or reflect them off the

foam surface. Measurement is possible under certain conditions. For FMR50, FMR51 and

FMR52, the additional option "Advanced dynamics" is recommended in these cases (feature

540: "Application Package", option EM).

• In case of heavy steam development or condensate, the maximum measuring range of

FMR50, FMR51 and FMR52 may decrease depending on density, temperature and

composition of the steam → use FMR53 or FMR54.

• For the measurement of absorbing gases such as ammonia NH3 or some fluorocarbons

please use Levelflex or Micropilot FMR54 in a stilling well.

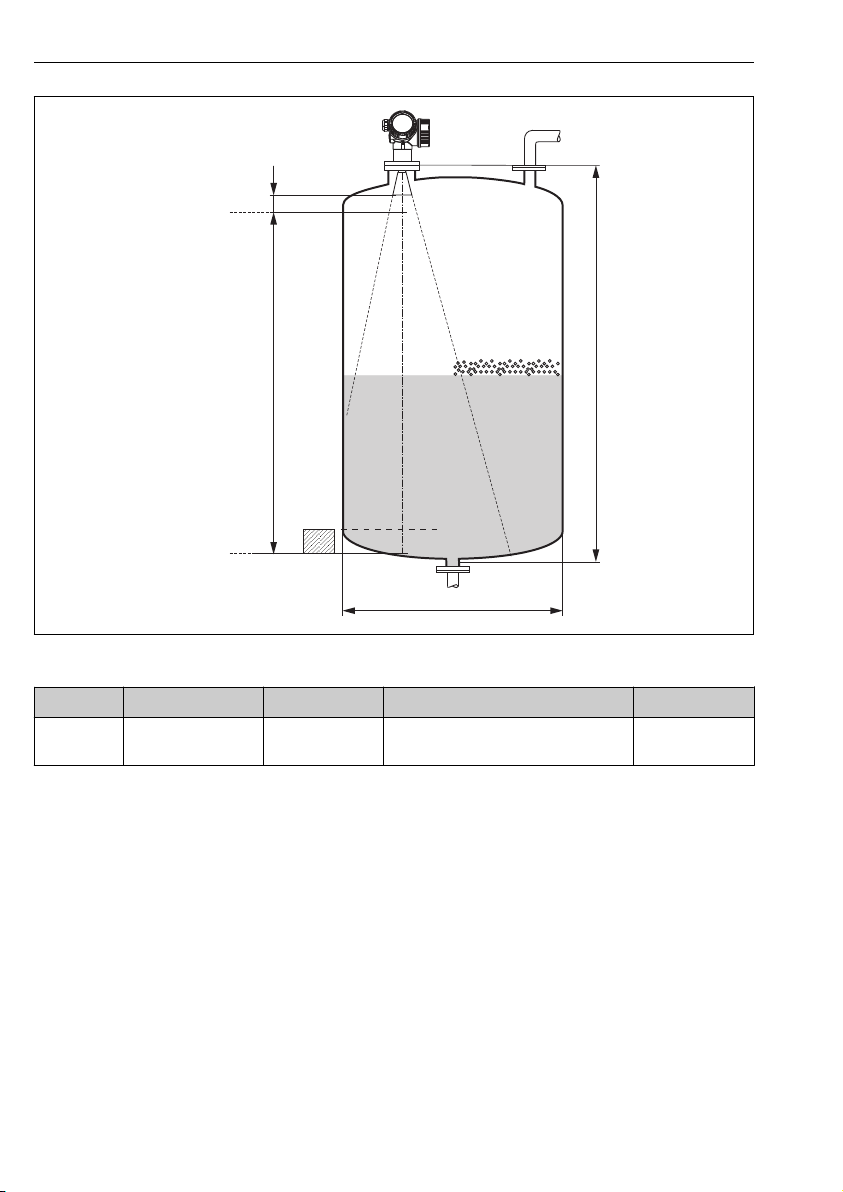

• The measuring range begins, where the beam hits the tank bottom. Particularly with dish

bottoms or conical outlets the level cannot be detected below this point.

• In stilling well applications, the electromagnetic waves do not propagate completely outside

the tube. It must be taken into account that the accuracy may be reduced in the area C. In

order to guarantee the required accuracy in these cases, it is recommended to position the

zero-point at a distance C above the end of the tube (see figure).

• In case of media with a low dielectric constant (εr = 1.5 to 4)

2)

the tank bottom can be

visible through the medium at low levels (low height C). Reduced accuracy has to be

expected in this range. If this is not acceptable, we recommend positioning the zero point at

a distance C (see figure) above the tank bottom in these applications.

• In principle it is possible to measure up to the tip of the antenna with FMR51, FMR53 and

FMR54. However, due to considerations regarding corrosion and build-up, the end of the

measuring range should not be chosen any closer than A (see figure) to the tip of the

antenna.

• When using FMR54 with planar antenna, especially for media with low dielectric constants,

the end of the measuring range should not be closer than A: 1 m (3.28 ft) to the flange.

• The smallest possible measuring range B depends on the antenna version (see figure).

• The tank height should be at least H (see table).

1)

,

1) Affected compounds are e.g. R134a, R227, Dymel 152a.

2) Dielectric constants of important media commonly used in various industries are summarized in the DC manual

(CP01076F) and in the Endress+Hauser "DC Values App" (available for Android and iOS).

Endress+Hauser 19

Installation Micropilot FMR50 HART

100%

0%

B

A

C

H

øD

Device A [mm (in)] B [m (ft)] C [mm (in)] H [m (ft)]

FMR50 150 (

5.91)

> 0.2 (0.7) 50 to 250 (1.97 to 9.84) > 0.3 (1.0)

6.3 Installation in vessel (free space)

6.3.1 Horn antenna encapsulated (FMR50)

Alignment

• Align the antenna vertically to the product surface.

• A marking at the threaded connection enables alignment of the antenna. This marking

must be aligned towards the tank wall as well as possible.

20 Endress+Hauser

A0018872

Loading...

Loading...