Page 1

TI00424F/00/EN/15.12

71198463

Technical Information

Levelflex M FMP43

Guided Level-Radar

Continuous Level Transmitter for continuous level measurement

in liquids in hygienic applications.

Application

The Levelflex M FMP43 is used for continuous level

measurement of liquids in applications with special

hygienic requirements:

Materials

• All wetted components are FDA-listed and tested in

accordance with USP Cl. VI.

• Choice of mechanically polished or electropolished

metal surfaces up to 0.38 μm and low Δ ferrite

content.

Design

• The design is flush-mounted and gap-free and meets

ASME BPE requirements.

• The probe is completely dismountable; the probe rod,

process connection and seals are replaceable.

• Aseptic process connections from DN25 (1") are

available.

• The probe is autoclavable and suitable for CIP, SIP.

Approvals (hygiene)

• Approvals according to 3A and EHEDG

• Certificate of Compliance (CoC)

The following interfaces are available for system

integration:

• HART (standard) with 4 to 20 mA analog;

PROFIBUS PA, FOUNDATION Fieldbus

Your benefits

• Measurement independent of product properties

such as:

–density,

– dielectric constant,

– conductivity.

• Measurement possible despite very turbulent

surfaces or foam.

• Easy menu-guided onsite operation via four-line plain

text display.

• Convenient remote operation, diagnosis and

documentation of the measuring point via the

FieldCare operating program which is provided free of

charge.

• Optional remote display and operation.

• Envelope curve presentation onsite on the display for

easy diagnosis.

• Electronics can be replaced without opening the tank.

• Application in safety related systems (Overfill

prevention) with requirements for functional safety up

to SIL 2 in accordance to IEC 61508/IEC 61511-1.

• Approvals:

– Europe: ATEX

– North America: FM, CSA

– China: NEPSI (in preparation)

Page 2

Levelflex M FMP43

2 Endress+Hauser

Table of contents

Function and system design. . . . . . . . . . . . . . . . . . . . . 3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Measuring range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Blocking distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Used frequency spectrum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Linearization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Data of the FOUNDATION

Fieldbus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Auxiliary energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ground connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cable gland . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Terminal assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Load HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cable entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

FISCO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Overvoltage protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Performance characteristics. . . . . . . . . . . . . . . . . . . . 16

Reference operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Maximum measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Reaction time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Influence of ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . 17

Operating conditions: Installation . . . . . . . . . . . . . . . 18

General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cleaning of the probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Special instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Notes on special installation situations . . . . . . . . . . . . . . . . . . . . 21

Installation for difficult to access process connections . . . . . . . . . 22

Operating conditions: Environment . . . . . . . . . . . . . . 23

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Ambient temperature limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning of the probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electromagnetic compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . 23

Operating conditions: Process . . . . . . . . . . . . . . . . . . 24

Process temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Process pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Dielectric constant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . 25

Design, dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

General information on

flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Tolerance of probe length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Material

(not in contact with process) . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Material

(in contact with process) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Process connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Operation concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Display elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Onsite operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Remote operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . 40

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Suitability for hygenic processes . . . . . . . . . . . . . . . . . . . . . . . . 41

Pharma (CoC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Overfill prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Telecommunications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

External standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . 41

Ordering information. . . . . . . . . . . . . . . . . . . . . . . . . 42

Levelflex M FMP43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Weather protection cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Weld-in adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Remote display FHX40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Commubox FXA195 HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Commubox FXA291 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

ToF Adapter FXA291 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Protective cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Calibration kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Additional documentation . . . . . . . . . . . . . . . . . . . . . 49

Fields of activities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Competence brochure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Page 3

Levelflex M FMP43

Endress+Hauser 3

Function and system design

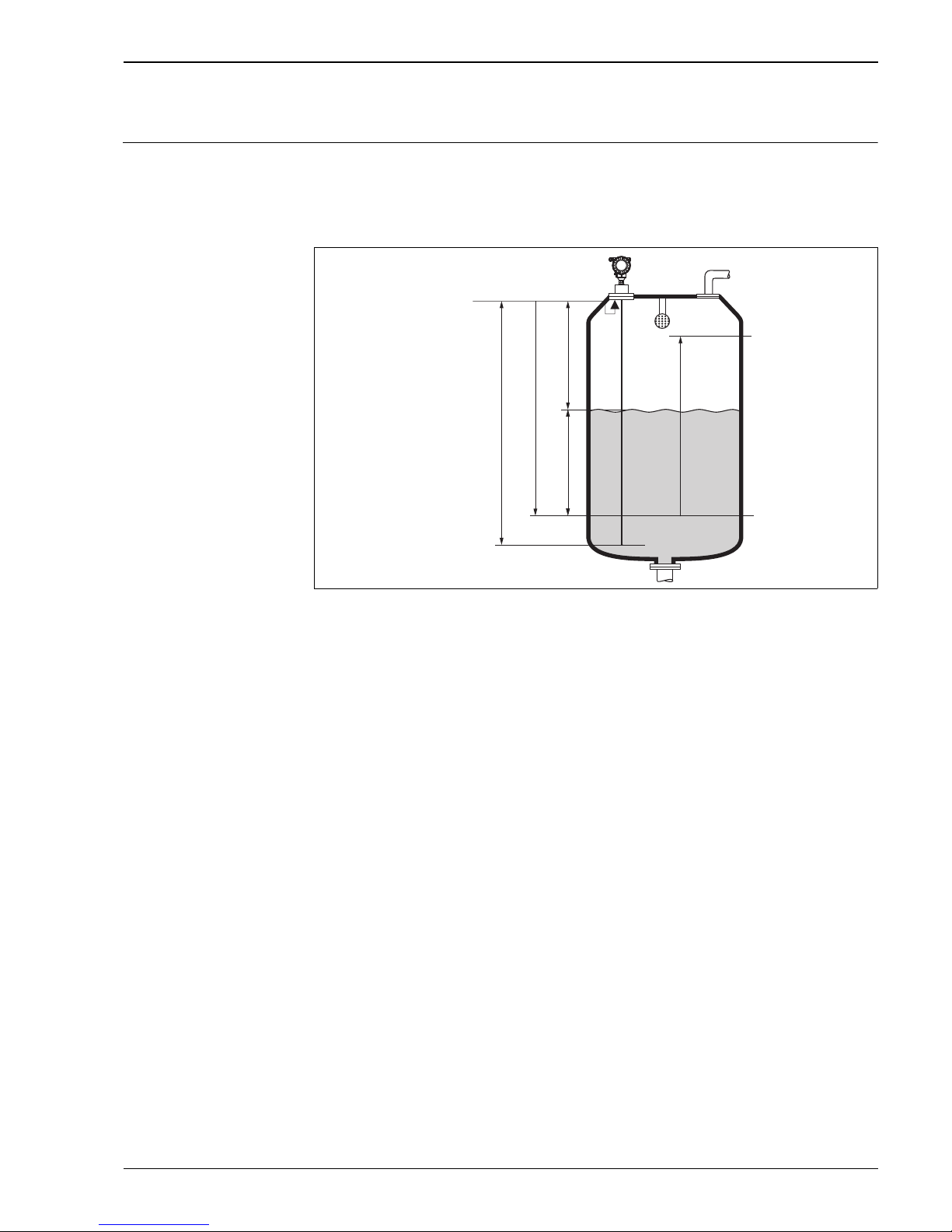

Measuring principle The Levelflex is a "downward-looking" measuring system that functions according to the ToF method (ToF =

Time of Flight). The distance from the reference point (process connection of the measuring device, → ä 26)

to the product surface is measured. High-frequency pulses are injected to a probe and led along the probe. The

pulses are reflected by the product surface, received by the electronic evaluation unit and converted into level

information. This method is also known as TDR (Time Domain Reflectometry).

L00-FMP43xxx-15-00-00-en -001

Reference point of measurement, details → ä 26

Dielectric constant

The dielectric constant (DC) of the medium has a direct impact on the degree of reflection of the highfrequency pulses. In the case of large DC values, such as for water or ammonia, there is strong pulse reflection

while, with low DC values, such as for hydrocarbons, weak pulse reflection is experienced.

Input

The reflected pulses are transmitted from the probe to the electronics. There, a microprocessor analyses the

signals and identifies the level echo, which was generated by the reflection of the high-frequency pulses at the

product surface. This clear signal finding benefits from the more than 30 years of experience with pulse timeof-flight procedures that have been integrated into the development of the PulseMaster® Software.

The distance "D" to the product surface is proportional to the time of flight "t" of the pulse:

D = c · t/2,

with "c" being the speed of light.

Based on the known empty distance "E", the level "L" is calculated:

L = E – D

Reference point for "E" see above diagram.

The Levelflex possesses functions for the interference echo suppression that can be activated by the user.

They guarantee that interference echoes from e.g. internals and struts are not interpreted as level echoes.

DD

LL

20 mA

100%

4mA

0%

F

EE

Probe length LN

loweredgeoftheprocessconnection:

referencepointof

measurement

Page 4

Levelflex M FMP43

4 Endress+Hauser

Output

The Levelflex is initially adjusted at the factory to the probe length ordered, so that in most cases only the

application parameters, that automatically adapt the device to the measuring conditions, need to be entered.

For models with current output, the factory adjustment for zero point "E" and span is "F" 4 mA and 20 mA.

For digital outputs and the display module, the factory adjustment for zero point "E" and span "F" is 0 % and

100 %. A linearization function with max. 32 points, that is based on a manually or semi-automatically input

table, can be activated onsite or via remote operation. This function enables, for example, the conversion of

the level into units of volume or weight.

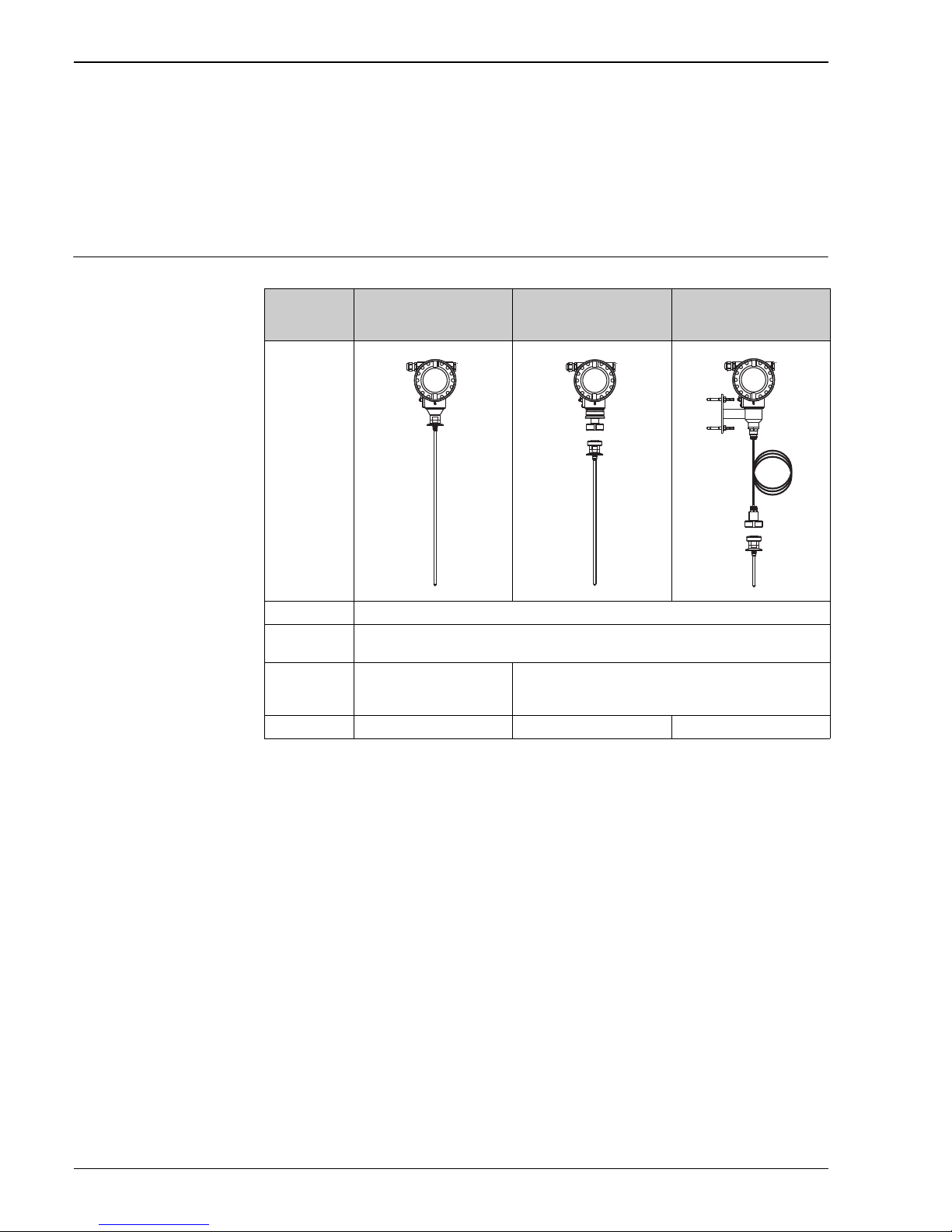

Equipment architecture Probe selection

Probe type: Rod probe, compact

Standard version

Rod probe, compact

Slotted nut for separation

from housing

Rod probe, remote

Slotted nut for separation

from housing

Probe length: 0.3 to 4 m

Sideways

capacity:

• 10 Nm with 316L (1.4435)

• 16 Nm with Hastelloy C22 (on request)

Options: • Reference probe can be connected (Calibration kit FMP43 -

order number: 71041382)

• Autoclavable (Protective cover FMP43 - order no.: 71041379)

Feature 70 Option "1" Option "5" Option "6, 7"

Page 5

Levelflex M FMP43

Endress+Hauser 5

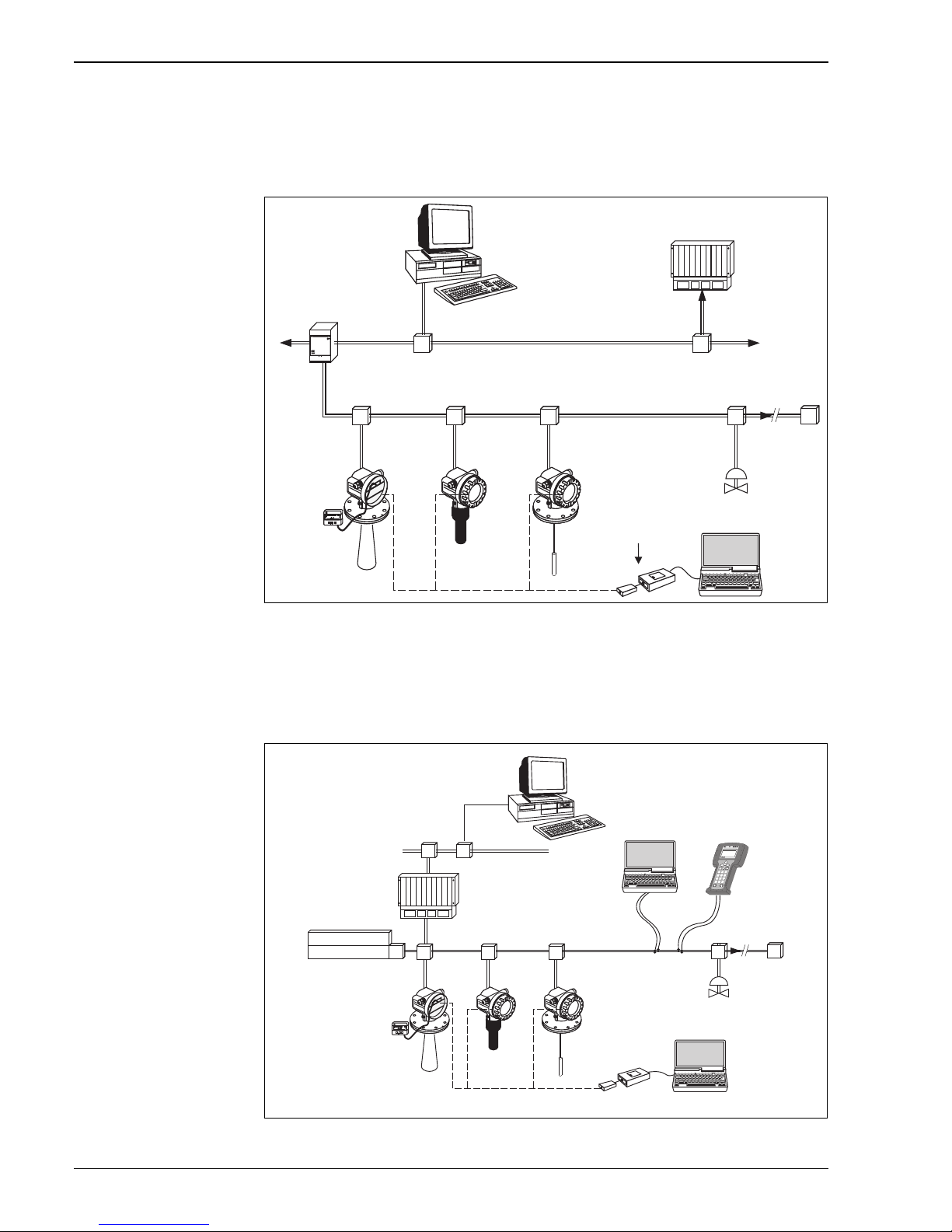

Stand-alone

• Power supply directly from power line (4-wire) or from transmitter power supply unit (2-wire).

• Operation by onsite display or remote operation via HART protocol.

L00-FMxxxxxx-14-00-06-en-008

ENDRESS + HAUSER

E

+–

%

ENDRESS + HAUSER

RMA 422

1

# % &

Copy

G H I

P Q R S

, ( )‘

A B C

Paste

Page

On

Page

Up

DeleteBksp

Insert

J K L

T UV

_ < >

D E F

Hot Key

+ Hot Key

M N O

W XY Z

+ * /

4

7

.

2

5

8

0

375

FIELD COMMUNICATOR

3

6

9

-

9

6

DELTABAR:* * * * * * * *

ONLINE

1 QUICK SETUP

2 OPERATING MENU

4 SV 0 °C

3 PV 352 mbar

HELP SAVE

dsdmdm

df das.

asdas fa

asas la.

1

# % &

Copy

G H I

P Q R S

, ( )‘

A B C

Paste

Page

On

Page

Up

DeleteBksp

Insert

J K L

T UV

_ < >

D E F

Hot Key

+ Hot Key

M N O

W XY Z

+ * /

4

7

.

2

5

8

0

375

FIELD COMMUNICATOR

3

6

9

-

9

6

DELTABAR:* * * * * * * *

ONLINE

1 QUICK SETUP

2 OPERATING MENU

4 SV 0 °C

3 PV 352 mbar

HELP SAVE

dsdmdm

df das.

asdas fa

asas la.

FieldCare

FieldCare

Commubox

FXA195

Field Communicator

375, 475

FXA195

or Field Communicator

375, 475

transmitter power

supply unit

RMA422

or RN221N

(communication resistor

included)

PLC

operating and

display module

Power supply

(for 4-wire)

CommuboxFXA291 with

ToF Adapter FXA291

Page 6

Levelflex M FMP43

6 Endress+Hauser

System integration via PROFIBUS PA

Maximum 32 transmitters (depending on the segment coupler, 10 in the Ex ia IIC hazardous area according

to the FISCO Model) can be connected to the bus. The Bus voltage is supplied by the segment coupler. Both

onsite as well as remote operation are possible.

L00-FMxxxxxx-14-00-06-en-001

System integration via FOUNDATION Fieldbus

Max. 32 transmitters (standard, Ex em or Ex d) can be connected to the bus. For protection type Ex ia IIC, the

max. number of transmitters depends on the relevant regulations and standards for the interconnection of

intrinsically safe circuits (EN 60079-14, verification of intrinsic safety). Both onsite as well as remote operation

are possible. The complete measuring system comprises:

L00-FMxxxxxx-14-00-06-en-003

ENDRESS + HAUSER

Micropilot M

Prosonic M

Levelflex M

ENDRESS + HAUSER

E

+–

%

T

PROFIBUS DP

PROFIBUS PA

FieldCare

personal computer with

FieldCare and

Profibard resp. Proficard

segment coupler

PLC

operating and

display module

More

Functions

(valves etc)

CommuboxFXA291 with

ToFAdapter FXA291

T

T

ENDRESS + HAUSER

E

+–

%

1

# % &

Copy

G H I

P Q R S

, ( )‘

A B C

Paste

Page

On

Page

Up

DeleteBksp

Insert

J K L

T UV

_ < >

D E F

Hot Key

+ Hot Key

M N O

W XY Z

+ * /

4

7

.

2

5

8

0

375

FIELD COMMUNICATOR

3

6

9

-

9

6

DELTABAR:* * * * * * * *

ONLINE

1 QUICK SETUP

2 OPERATING MENU

4 SV 0 °C

3 PV 352 mbar

HELP SAVE

dsdmdm

df das.

asdas fa

asas la.

1

# % &

Copy

G H I

P Q R S

, ( )‘

A B C

Paste

Page

On

Page

Up

DeleteBksp

Insert

J K L

T UV

_ < >

D E F

Hot Key

+ Hot Key

M N O

W XY Z

+ * /

4

7

.

2

5

8

0

375

FIELD COMMUNICATOR

3

6

9

-

9

6

DELTABAR:* * * * * * * *

ONLINE

1 QUICK SETUP

2 OPERATING MENU

4 SV 0 °C

3 PV 352 mbar

HELP SAVE

dsdmdm

df das.

asdas fa

asas la.

Ethernet

SPS

PLC

API

FF link

FOUNDATION Fieldbus

Micropilot M

Prosonic M

Levelflex M

Field Communicator

375, 475

FieldCare

ControlCare

DeltaV

...

power supply

power conditioner

Commubox FXA291 with

ToFAdapter FXA291

operating and

display module

additional

functions

(valves etc.)

e.g.

NI-FBUS

configurator

Page 7

Levelflex M FMP43

Endress+Hauser 7

System integration via Fieldgate

Vendor Managed Inventory

By using Fieldgates to interrogate tank or silo levels remotely, suppliers of raw materials can provide their

regular customers with information about the current supplies at any time and, for example, account for them

in their own production planning. For their part, the Fieldgates monitor the configured level limits and, if

required, automatically activate the next supply. The spectrum of options here ranges from a simple purchasing

requisition via e-mail through to fully automatic order administration by coupling XML data into the planning

systems on both sides.

Remote maintenance of measuring equipment

Fieldgates not only transfer the current measured values, they also alert the responsible standby personnel, if

required, via e-mail or SMS. In the event of an alarm or also when performing routine checks, service

technicians can diagnose and configure connected HART devices remotely. All that is required for this is the

corresponding HART operating software (e.g. FieldCare) for the connected device. Fieldgate passes on the

information transparently, so that all options for the respective operating software are available remotely. Some

onsite service operations can be avoided by using remote diagnosis and remote configuration and all others can

at least be better planned and prepared.

L00-FXA520xx-14-00-06-en-009

Note!

The number of devices which can be connected in multidrop mode can be calculated by the "FieldNetCalc"

program. A description of this program can be found in Technical Information TI00400F/00/EN (Multidrop

Connector FXN520). The program is available from your Endress+Hauser sales organization or in the internet

at: www.endress.com → select your country → download → search: Fieldnetcalc.

-

Fieldgate

FXA520

ENDRESS+HAUSER

RN 221N

ENDRESS+HAUSER

RN 221N

.

Fieldgate

FXA520

20...45 V

DC

FXN520

FXN520

Multidrop-Connector

FXN520

HTTP script

Web browser

…

Analogue

Ethernet

GSM

e.g. 2 xRN221N-B …

Channel 1 Channel 2

via HART Client:

-FieldCare

...

Remote monitoring

Remote configuration/diagnostics

Page 8

Levelflex M FMP43

8 Endress+Hauser

Input

Measured variable The measured variable is the distance between the reference point (see Fig, → ä 26) and the product surface.

Subject to the input zero point empty distance "E" (see Fig., → ä 3) the level is calculated.

Alternatively, the level can be converted by means of linearization (32 points) into other variables (volume,

mass).

Measuring range The measuring range spans the entire probe. The upper blocking distance set in the delivery status can be

adapted as required (see recommendations in the "Blocking distance" chapter). The specified accuracy of the

probe is reduced in the upper and lower range of the probe (table, → ä 16), especially when using media with

a smaller dielectric constant (DC < 7).

Blocking distance The upper blocking distance (= UB) is the minimum distance from the reference point of the measurement

(lower edge of process connection) to the maximum level. At the lowest part of the probe an exact

measurement is not possible, see "Performance characteristics", → ä 16.

L00-FMP43xxx-17-00-00-en-001

Reference point of measurement, details → ä 26

The blocking distance is preset to 0.2 m when using rod probes. The blocking distance can be reduced when

the probe is installed flush with a wall or in a nozzle with a max. height of 50 mm.

When using a spray ball the blocking distance may not be smaller than 50 mm.

Used frequency spectrum 100 MHz to 1.5 GHz

100%

0%

F

UB

D

L

E

referencepointof

measurement

max. 20 m /67 ft

remote display

FHX40

F=measuring span

E = emptydistance(=zero)

UB = upperblockingdistance

LN =probelength

probe length LN

Page 9

Levelflex M FMP43

Endress+Hauser 9

Output

Output signal • 4 to 20 mA (invertible) with HART protocol

• PROFIBUS PA:

– signal coding: Manchester Bus Powered (MBP)

– data transmission rate: 31.25 KBit/s, voltage mode

• FOUNDATION Fieldbus (H1):

– signal coding: Manchester Bus Powered (MBP)

– data transmission rate: 31.25 KBit/s, voltage mode

Signal on alarm Error information can be accessed via the following interfaces:

• Local display:

– Error symbol

– Plain text display

• Current output, signal on error can be selected (e.g. according to NAMUR recommendation NE43)

• Digital interface

Linearization The linearization function of the Levelflex M allows the conversion of the measured value into any unit of

length or volume and mass or %. Linearization tables for calculating the volume in cylindrical tanks are

preprogrammed. Other tables of up to 32 value pairs can be entered manually or semi-automatically.

The creation of a linearization table with FieldCare is particularly convenient.

Data of the FOUNDATION

Fieldbus interface

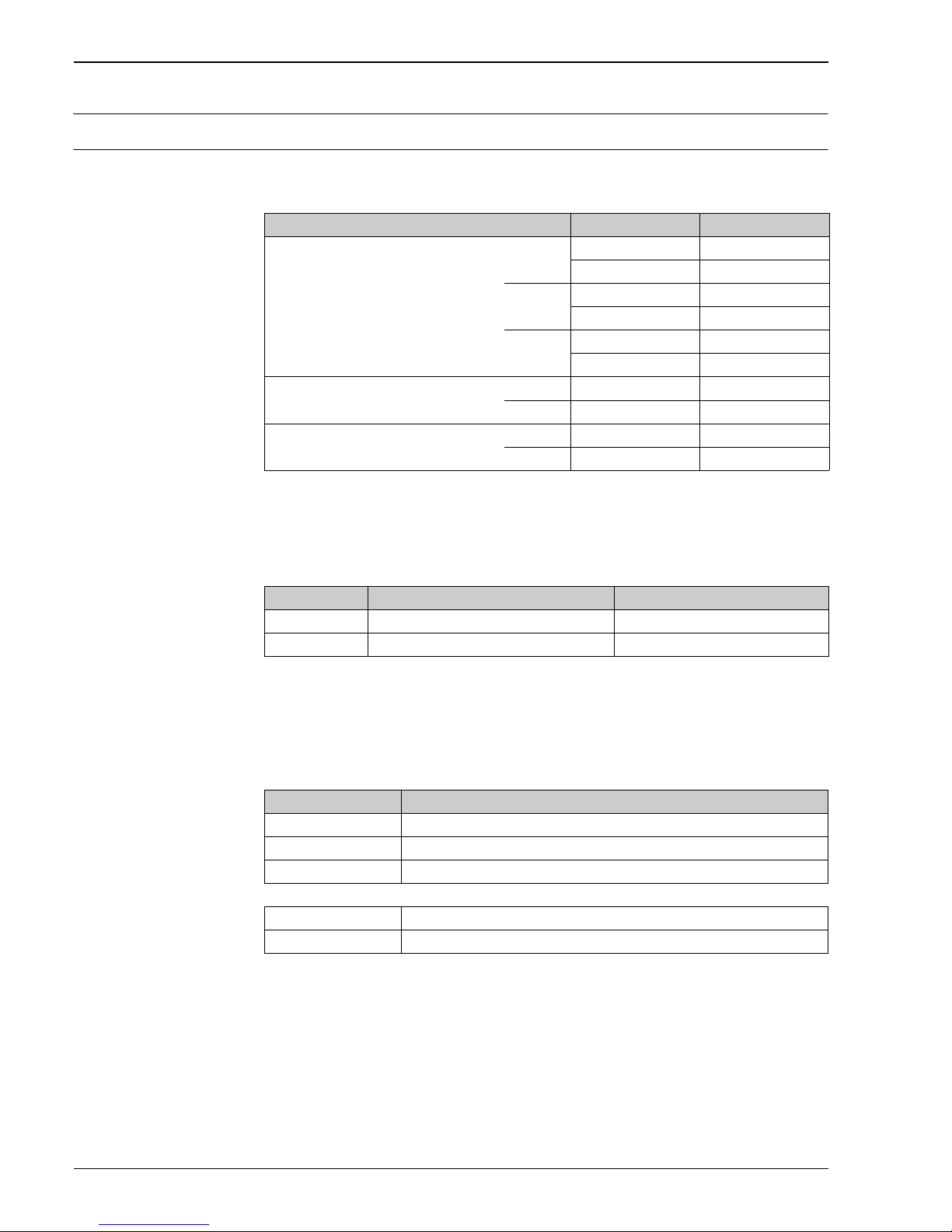

Basic Data

Virtual communication references (VCRs)

Link Settings

Device Type 1012 (hex)

Device Revision 04 (hex)

DD Revision 02 (hex)

CFF Revision 02 (hex)

ITK Version 4.61

ITK-Certification Driver-No. www.endress.com / www.fieldbus.org

Link-Master (LAS) cabable yes

Link Master / Basic Device selectable yes; Default: Basic Devce

Number VCRs 24

Number of Link-Objects in VFD 24

Permanent Entries 1

Client VCRs 0

Server VCRs 24

Source VCRs 23

Sink VCRs 0

Subscriber VCRs 23

Publisher VCRs 23

Slot time 4

Min. Inter PDU delay 6

Max. response delay 10

Page 10

Levelflex M FMP43

10 Endress+Hauser

Transducer Blocks

Function Blocks

Block Content Output values

Sensor Block contains all parameters related to the measurement • level or volume1) (channel 1)

• distance (channel 2)

1) Depending on the configuration of the sensor-block.

Diagnsotic Block contains diagnostiv information no output values

Display Block contains parameters to configure the local display no output values

Block Content Execution time Functionality

Resource Block The Resource Block contains all the data that uniquely

identifies the field device. It is an electronic version of a

nameplate of the device.

enhanced

Analog Input

Block 1

Analog Input

Block 2

The AI block takes the manufacturer's input data,

selected by channel number, and makes it available to other

function blocks at its output.

30 ms standard

PID Block The PID block serves as proportional-integral-derivative

controller and is used almost universally to do closed-loopcontrol in the field including cascade and feedforward.

80 ms standard

Arithmetic Block This block is designed to permit simple use of popular

measurement math functions. The user does not have to

know how to write equations. The math algorithm is

selected by name, chosen by the user for the function to

be done.

50 ms standard

Input Selector

Block

The input selector block provides selection of up to four

inputs and generates an output based on the configured

action. This block normally receives its inputs from AI

blocks. The block performs maximum, minimum, middle,

average and ‘first good’ signal selection.

30 ms standard

Signal Characterizer Block

The signal characterizer block has two sections, each

with an output that is a non-linear function of the

respective input. The non-linear function is determined by a

single look-up table with 21 arbitrary x-y pairs.

40 ms standard

Integrator Block The Integrator Function Block integrates a variable as a

function of the time or accumulates the counts from a

Pulse Input block. The block may be used as a totalizer

that counts up until reset or as a batch totalizer that has a

setpoint, where the integrated or accumulated value is

compared to pre-trip and trip settings, generating discrete

signals when these settings are reached.

60 ms standard

Page 11

Levelflex M FMP43

Endress+Hauser 11

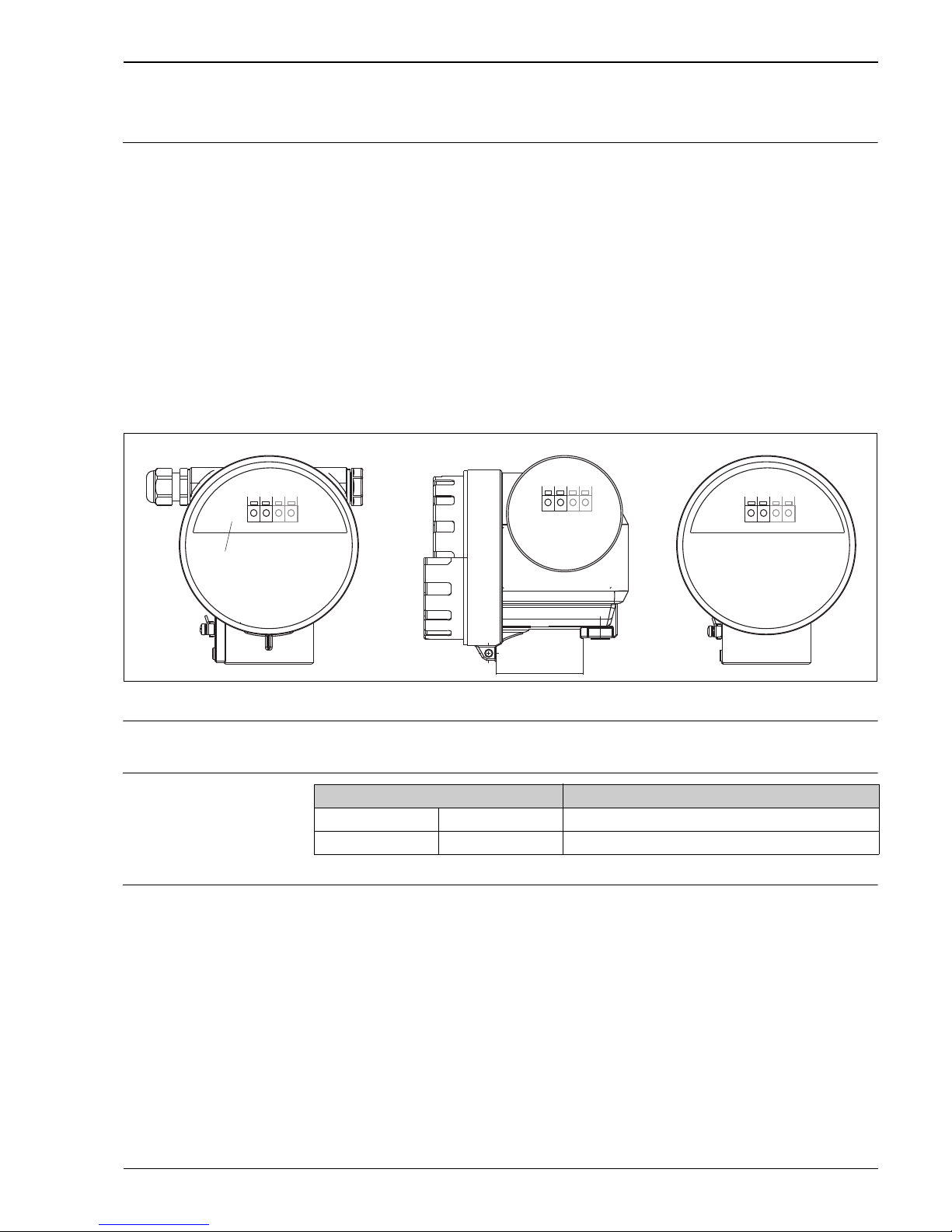

Auxiliary energy

Electrical connection Terminal compartment

Three housings are available:

• Aluminum housing F12 with additionally sealed terminal compartment for:

– standard,

– Ex ia.

• Aluminum housing T12 with separate terminal compartment for:

– standard,

–Ex e,

– Ex d

– Ex ia (with overvoltage protection).

• Stainless steel 316L (1.4435) housing F23 for:

– standard,

– Ex ia.

After mounting, the housing can be turned 350° in order to simplify access to the display and the terminal

compartment.

L00-FMR2xxxx-04-00-00-en-019

Ground connection It is necessary to make a good ground connection to the ground terminal on the outside of the housing, in order

to achieve EMC security.

Cable gland

Terminals For wire cross-sections of 0.5 to 2.5 mm

2

.

1 1

2 2

3 3

4 4

1

2

3

4

sealed terminal

compartment

F12 housing F23 housing

T12 housing

Type Clamping area

Standard, Ex ia, IS Plastic M20x1.5 5 to 10 mm

Ex em, Ex nA Metal M20x1.5 7 to 10.5 mm

Page 12

Levelflex M FMP43

12 Endress+Hauser

Terminal assignment

Note!

If 4-wire for dust-Ex-applications is used, the current output is intrinsically save.

Connect the connecting line to the screw terminals in the terminal compartment.

Cable specifications:

A standard installation cable is sufficient if only the analog signal is used. Use a shielded cable when working

with a superimposed communications signal (HART).

Note!

Protective circuitry against reverse polarity, RFI and over-voltage peaks is built into the device (see also

TI00241F/00/EN "EMC Test Procedures").

2-wire, 4 to 20 mA with HART 4-wire, 4 to 20 mA active with HART

L00-FMxxxxxx-04-00-00-en-015 L00-FMxxxxxx-04-00-00-en-011

CommuboxFXA195

Field Communicator 375, 475

power

56

I+ I-

12

L1/L+ N/L-

4...

20mA

Commubox FXA195

Field Communicator

375, 475

AC / DCDC

alternatively

power

display unit,

recorder, PCS

plant

ground

PROFIBUS PA

The digital communication signal is transmitted to the

bus via a 2-wire connection. The bus also provides the

auxiliary energy. For further information on the

network structure and grounding and for further bus

system components such as bus cables, see the

relevant documentation, e.g. Operating Instructions

BA034S/04/EN "Guidelines for planning and

commissioning PROFIBUS DP/PA" and the PNO

Guideline.

Cable specifications:

Use a twisted, shielded two-wire cable, preferably

cable type A.

L00-FMxxxxxx-04-00-00-en-022

Note!

For further information on the cable specifications, see Operating Instructions BA034S/04/EN

Guidelines for planning and commissioning PROFIBUS DP/PA", PNO Guideline 2.092 "

PROFIBUS PA User and Installation Guideline" and IEC 61158-2 (MBP).

3

4

1

2

+–

plant

ground

Page 13

Levelflex M FMP43

Endress+Hauser 13

Connector For the versions with a connector M12 or 7/8", the housing does not have to be opened for connecting the

signal line.

PIN assignment for M12 connector

PIN assignment for 7/8" connector

FOUNDATION Fieldbus

The digital communication signal is transmitted to the

bus via a 2-wire connection. The bus also provides the

auxiliary energy. For further information on the

network structure and grounding and for further bus

system components such as bus cables, see the

relevant documentation, e.g. Operating Instructions

BA013S/04/EN "FOUNDATION Fieldbus

Overview" and the FOUNDATION Fieldbus

Guideline.

Cable specifications:

Use a twisted, shielded two-wire cable, preferably

cable type A.

L00-FMxxxxxx-04-00-00-en-022

Note!

For further information on the cable specifications, see Operating Instructions BA013S/04/EN

"FOUNDATION Fieldbus Overview", FOUNDATION Fieldbus Guideline and IEC 61158-2 (MBP).

3

4

1

2

+–

plant

ground

A0011175

PIN Meaning

1 Signal +

2 Not assigned

3 Signal –

4Earth

A0011176

PIN Meaning

1 Signal –

2 Signal +

3Shield

4 Not assigned

21

3

4

+

–

nc

2

1

4

3

Page 14

Levelflex M FMP43

14 Endress+Hauser

Load HART Minimum load for HART communication: 250 Ω

Supply voltage HART, 2-wire

The following values are the voltages across the terminals directly at the device:

HART residual ripple, 2-wire: U

ss

≤ 200 mV

HART, 4-wire active

HART residual ripple, 4-wire, DC version: Uss ≤ 2 V, voltage incl.

ripple within the permitted voltage (10.5 to 32 V).

PROFIBUS PA and FOUNDATION Fieldbus

The following values are the voltages across the terminals directly at the device:

Communication Current consumption Terminal voltage

HART

standard

4mA 16V to 36V

20 mA 7.5 V to 36 V

Ex ia

4mA 16V to 30V

20 mA 7.5 V to 30 V

Ex em

Ex d

4mA 16V to 30V

20 mA 11 V to 30 V

Fixed current, adjustable e.g. for solar power

operation (measured value transferred at HART)

standard 11 mA 10 V to 36 V

Ex ia 11 mA 10 V to 30 V

Fixed current for HART Multidrop mode

standard 4 mA

1))

1) Start up current 11 mA.

16 V to 36 V

Ex ia 4 mA

1)

16 V to 30 V

Version Voltage max. load

DC 10.5 to 32 V 600 Ω

AC, 50/60 Hz 90 to 253 V 600 Ω

Version Terminal voltage

Standard 9 V to 32 V

Ex ia (FISCO model) 9 V to 17.5 V

Ex ia (Entity concept) 9 V to 24 V

Supply voltage 9 V to 32 V

1)

1) There may be additional restrictions for devices with an explosion protection certificate. Refer to the notes in the

appropriate safety instructions (XA).

Lift-off voltage 9 V

Page 15

Levelflex M FMP43

Endress+Hauser 15

Cable entry • Cable gland: M20x1.5 (only cable entry for Ex d)

• Cable entry: G½ or ½NPT

• PROFIBUS PA M12 plug

• FOUNDATION Fieldbus 7/8" plug

Power consumption Min. 60 mW, max. 900 mW.

Current consumption HART

PROFIBUS PA

Max. 11 mA.

FOUNDATION Fieldbus

FISCO

Overvoltage protector If the measuring device is used for the level measurement in flammable liquids which requires the use of an

overvoltage protection according to EN/IEC 60079-14 or EN/IEC 60060-1 (10 kA, pulse 8/20 μs) it has to

be ensured that

• the measuring device with integrated overvoltage protection with 600 V gas discharge tubes within the T12-

enclosure is used, refer to "Ordering information", → ä 42

or

• this protection is achieved by the use of other appropriate measures (external protection devices e.g.

HAW562Z).

Communication Output current Current consumption Power consumption

HART, 2-wire 3.6 to 22 mA

1)

1) For HART-Multidrop: start up current is 11 mA.

— min. 60 mW,

max. 900 mW

HART, 4-wire (90 to 250 V

AC

) 2.4 to 22 mA ~ 3 to 6 mA ~ 3,5 VA

HART, 4-wire (10.5 to 32 V

DC

) 2.4 to 22 mA ~ 100 mA ~ 1 W

Nominal current 15 mA

Starting current ≤ 15 mA

Error current 0 mA

FISCO/FNICO conformal Compliant

Polarity sensitive No

U

i

17,5 V

I

i

500 mA; with overvoltage protection 273 mA

P

i

5,5 W; with overvoltage protection 1,2 W

C

i

5 nF

L

i

0,01 mH

Page 16

Levelflex M FMP43

16 Endress+Hauser

Performance characteristics

Reference operating

conditions

• Temperature = +20 °C ±5 °C

• Pressure = 1013 mbar abs. ±20 mbar

• Relative humidity (air) = 65 % ±20 %

• Metallic tank, no internals, distance to tank wall > 500 mm

• Medium: water (DC > 7), respectively oil (DC = 2)

• Probe length > 500 mm

Maximum measured error Typical statements for reference conditions:

DIN EN 61298-2, percentage of the span.

If the reference conditions are not met, the offset/zero arising from the installation setup may be up to

±12 mm. This additional offset/zero can be compensated for by entering a correction (function "offset"

(057)) during commissioning.

Differing from this, the following measuring error is present in the vicinity of the upper and lower

probe end:

Output: Digital Analog

sum of non-linearity,

non-repeatability and hysteresis

±3 mm ±0.06 %

Offset / Zero ±4 mm ±0.03 %

L00-FMP43xxx-05-00-00-en-001

3 mm

0mm

- 3 mm

100 mm 200 mm 80 mm200 mm 40 mm 20 mm

10 mm

-10mm

20 mm

-20mm

30mm

- 30mm

40 mm

-40mm

50mm

- 50mm

DK > 7

DK > 7

60mm

- 60mm

DK=2

DK=2

reference point of measurement

probe end

maximummeasured error

probe end

(water-based

medium)

(water-based

medium)

(oilsandsolvents)

()oilsandsolvents

Page 17

Levelflex M FMP43

Endress+Hauser 17

Resolution • Digital: 1 mm

• Analog: 0.03 % of measuring range

Reaction time The reaction time depends on the configuration.

Shortest time:

• 2-wire electronics: 1 s

• 4-wire electronics: 0.7 s

Influence of ambient

temperature

The measurements are carried out in accordance with EN 61298-3:

• digital output (HART, PROFIBUS PA, FOUNDATION Fieldbus):

–average T

K

: 0.6 mm/10 K, max. ±3.5 mm over the entire temperature range -40 °C to +80 °C

2-wire

• Current output (additional error, in reference to the span of 16 mA):

– Zero point (4 mA)

average T

K

: 0.032 %/10 K, max. 0.35 % over the entire temperature range -40 °C to +80 °C

– Span (20 mA)

average TK: 0.05 %/10 K, max. 0.5 % over the entire temperature range -40 °C to +80 °C

4-wire

• Current output (additional error, in reference to the span of 16 mA):

– Zero point (4 mA)

average T

K

: 0.02 %/10 K, max. 0.29 % over the entire temperature range -40 °C to +80 °C

– Span (20 mA)

average T

K

: 0.06 %/10 K, max. 0.89 % over the entire temperature range -40 °C to +80 °C

Page 18

Levelflex M FMP43

18 Endress+Hauser

Operating conditions: Installation

General instructions Probe selection (→ ä 4)

Note!

You must ensure that the probe does not come into contact with the container wall, container bottom and tank

internals.

Mounting location

• Do not mount the probe in the filling curtain (2).

• Mount the probe at such a distance away from the

wall (B) that, in the event of buildup on the wall,

there is still a minimum distance of 100 mm

between the probe and the buildup.

• Mount the probe as far away as possible from

internals.

• Minimum distance from the probe end to the tank

floor is 10 mm.

• When installing outdoors, it is recommended that

you use a weather protection cover (1)

("Accessories", → ä 45).

L00-FMP43xxx-17-00-00-xx-001

B

12

C

Tank internals

• If the distance to the internals is < 300 mm,

"mapping" must be carried out, and the

measurement capability may be restricted.

• During operation, the probe must not touch any

internals within the measuring range.

Optimization options

• Interference echo suppression: measurement can

be optimized by electronically tuning out

interference echoes.

L00-FMP43xxx-17-00-00-xx-002

Page 19

Levelflex M FMP43

Endress+Hauser 19

Cleaning of the probe Installation close to tank wall

By installing the probe close to the tank wall, the

cleaning effect is improved in cases where a spray ball

is used. The cleaning jet is deflected against the tank

wall and onto the probe. This means that those parts

of the probe are cleaned which would normally not be

reached by the spray ball jet. If the probe is positioned

in this way, only one spray ball is needed.

L00-FMP43xxx-17-00-00-xx-003

Installation in the center of the tank

If the probe is mounted in the center of the tank, it

may be necessary to use a second spray ball. The spray

balls should then be mounted to the left and right of

the probe.

L00-FMP43xxx-17-00-00-xx-004

Page 20

Levelflex M FMP43

20 Endress+Hauser

Special instructions When installing in tanks with agitator, observe the lateral loading capacity of rod probes:

• 10 Nm with 316L (1.4435)

• 16 Nm with Hasteloy C22 (on request).

The formula for calculating the bending torque M impacting on the probe:

with

cw : Friction factor

ρ [kg/m

3

]: Density of the medium

v [m/s]: Velocity of the medium perpendicular to the probe rod

d [m]: Diameter of the probe rod (8 mm)

L [m]: Level

L

N

[m]: Probe length

L00-FMP43xxx-16-00-00-de-004

Calculation example

L00-FMP43xxx-16-00-00-xx-003

Friction factor [c

w]

0.9 (on the assumption of a turbulent

current (high Reynolds number ))

Density [ρ] in kg/m

3

1000 (e.g. water)

Probe diameter [d] in m 0.008

L = L

N

(worst case)

M = c ··v · d ·L·(L−0.5 ·L)

W N

2

r

2

v

L

N

L

d

Bending torque[M]onrodprobes

Probe length [ ] in meters

L

N

v=0.5m/s

v=0.7m/s

v=1.0m/s

max. bending torque

0.4 0.8 1.2 1.6 2 2.4 2.8 3.2 3.6 4

0.0

2.0

4.0

6.0

8.0

10.0

12.0

14.0

16.0

18.0

20.0

Bending [Nm]

torque

Page 21

Levelflex M FMP43

Endress+Hauser 21

Notes on special installation

situations

When installing in stirring tanks, observe lateral loadbearing capacity of rod probes.

Possibly check whether a non-contact process,

Ultrasonic or Level-Radar would not be better suited,

above all if the stirrer generates large mechanical

loads on the probe.

L00-FMP43xxx-17-00-00-xx-005

Installation at an angle

• For mechanical reasons, the probe should be

installed as vertically as possible.

• With inclined installations the probe length has to

be adjusted in dependence to the installation angle.

– up to 1 m = 30°

– up to 2 m = 10°

– up to 4 m = 5°.

L00-FMP4xIxx-17-00-00-en-048

rope probe

mounting angle

Page 22

Levelflex M FMP43

22 Endress+Hauser

Installation for difficult to

access process connections

Installation with separate housing

• The Wall and pipe bracket is contained in the scope of delivery and is already mounted.

• Mount the housing on the wall or pipe (vertically or horizontally, as required) as shown in the diagram.

• The wall bracket can also be used for mounting in display panels. For the cutout, please observe the

dimensions, → ä 25.

L00-FMP43xxx-17-00-00-en-002

Note!

The cable can not be disassembled at these points (1). The cable must not be kinked.

The ambient temperature for the connecting line (2) between the probe and electronics can be max. 105 °C.

The version with remote electronics consists of the probe, a connecting cable and the housing. If they are

ordered as a set, they are assembled on delivery.

150

ENDRESS+HAUSER

Levelflex M

65 78

Ø 129

85

150

ENDRESS+HAUSER

Levelflex M

65 78

Ø 129

150

max. 80

min.30

96

146

94

88

88

123

1

4xØ8,5

1

1

2

85

99

Ø54

Ø5

R50

≥

17

pipe

wall

display plate

Probe lengthLN

Page 23

Levelflex M FMP43

Endress+Hauser 23

Operating conditions: Environment

Ambient temperature range Ambient temperature for electronics: -40 °C to +80 °C. The functionality of the LCD display may be limited

for temperatures T

a

< -20 °C and Ta> +60 °C. A weather protection cover should be used for outdoor

operation if the device is exposed to direct sunlight.

Ambient temperature limits If the temperature (T

2

) at the process connection is above 80 °C, the permitted ambient temperature (T1)

decreases as per the following diagram (temperature derating):

L00-FMP43xxx-05-00-00-en -002

Storage temperature -20 °C to +80 °C

Climate class DIN EN 60068-2-38 (test Z/AD)

Degree of protection • with closed housing tested according to:

– all housings:

– IP68, NEMA6P (24 h at 1,83 m under water)

– IP66, NEMA4X

– F23 housing: additionally IP69K in connection with M20, G½" and NPT½" cable entries.

• with open housing: IP20, NEMA1 also ingress protection of the display)

Note!

Degree of protection IP68 NEMA6P applies for M12 PROFIBUS PA plugs only when the PROFIBUS cable is

plugged in.

Vibration resistance DIN EN 60068-2-64 / IEC 68-2-64: 20 to 2000 Hz, 1 (m/s

2)2

/Hz

Cleaning of the probe Depending on the application, contamination or build-up can accumulate on the probe. A thin, even layer only

influences measurements slightly. Thick layers can dampen the signal and then reduce the measuring range.

Severe, uneven build-up, adhesion e.g. through crystallization, can lead to incorrect measurement. In this case,

we recommend that you use a non-contact measuring principle, or check the probe regularly for soiling.

Electromagnetic compatibility

(EMC)

Electromagnetic compatibility to EN 61326 and NAMUR Recommendation EMC (NE21). Details are provided

in the Declaration of Conformity. A standard installation cable is sufficient if only the analog signal is used.

Use a shielded cable when working with a superimposed communications signal (HART).

When installing the probes in metal and concrete tanks and when using a coax probe:

• Interference emission to EN 61326 - x series, electrical equipment Class B.

• Interference immunity to EN 61326 - x series, requirements for industrial areas and NAMUR

Recommendation NE21 (EMC)

The measured value can be affected by strong electromagnetic fields when installing rod and rope probes

without a shielding/metallic wall, e.g. plastic, and in wooden silos.

• Interference emission to EN 61326 - x series, electrical equipment Class A.

• Interference Immunity: the measured value can be affected by strong electromagnetic fields.

T

2

[°C]

T

1

[°C]

-40 0

-40

0

40

60

80

100 150

80

T

2

T

1

max. process connection temperature

max. ambient temperature

80 °C with separate

housing

62 °C compact:

F23 housing

70 °C

F12 housing

T12 housing

compact:

Page 24

Levelflex M FMP43

24 Endress+Hauser

Operating conditions: Process

Process temperature range The maximum permitted temperature at the process connection (see figure measuring point) is determined by

the O-ring material ordered:

Process pressure Pmax = 16 bar.

The specified range may be reduced by the selection of process connection (→ ä 27).

The pressure rating (PN) specified on the flanges refers to a reference temperatur of 20 °C, for ASME flanges

100 °F. Observe pressure-temperature dependency.

Please refer to the following standards for the pressure values permitted for higher temperatures:

• EN 1092-1 : 2001 Tab.18

With regard to their temperature stability properties, the materials 1.4404 and 1.4435 are grouped under

13E0 in EN 1092-1 Tab.18. The chemical composition of the two materials can be identical.

• ASME B 16.5a - 1998 Tab. 2-2.2 F316

• ASME B 16.5a - 1998 Tab. 2.3.8 N10276

• JIS B 2220

Dielectric constant

ε

r ≥ 1.6

O-ring material Min. temperature Max. temperature

FFKM (Kalrez) -20°C +150°C

EPDM -20°C +130°C

measured

here

Page 25

Levelflex M FMP43

Endress+Hauser 25

Mechanical construction

Design, dimensions Housing dimensions

L00-F12xxxx-06-00-00-en-001

L00-T12xxxx-06-00-00-en-001

L00-F23xxxx-06-00-00-en-001

ENDRESS+HAUSER

65 (2.56)

78 (3.07)

max. 110 (4.33)

mm (in)

85 (3.35)

150 (5.91)

ø129 (ø5.08)

(Aluminium)

F12 housing

ENDRESS+HAUSER

78 (3.07)

85 (3.35)

65 (2.56)

162 (6.38)

max. 100 (4.33) 94 (3.7)

mm (in)

ø129 (ø5.08)

(Aluminium)

T12 housing

max. 94 (3.7)

mm (in)

93 (3.66)

ø129 (ø5.08)

150 (5.91)

40 (1.57)

(316L)

F23 housing

Page 26

Levelflex M FMP43

26 Endress+Hauser

Probes - Dimensions and materials

L00-FMP43xxx-06-00-00-en-001

88

88

103

99

17

Ø 54

4 x Ø 8,5

R50≥

Ø 5

55

69

17

17

F12 / T12 / F23 housing

option “6/7”:

remote electronic

option “1”:

compact

Probe length LN

Probe length LN

Probe length LN

Probe length LN

option “5”:

compact, detachable

reference point of

measurement

➀

Insulator

Material Approval

Ketron PEEK LSG FDA, 3A,

USP Cl. VI

➁

O-ring (see Feature 30 in "Ordering information"

Material Approval Temperature range Option

EPDM Freudenberg 70 EPDM 291

FDA, 3A,

USP Cl. VI

-20 °C to +130 °C (functional)

-20 °C to +121 °C (3A Class. II, USP Cl. VI)

5

FFKM DuPont Kalrez 6221 -20 °C to +150 °C (functional)

-20 °C to +149 °C (3A Class. I, USP Cl. VI)

6

➂

Probe (see Feature 20 in "Ordering information)

Material Version Option

316L (1.4435)

0.76 μm mechanically polished K, M

0.38 μm electropolished S, T

Hastelloy C22 Special version available on request Y

➀

➁

➂

process

connection

(example)

M24 x 1.5

Page 27

Levelflex M FMP43

Endress+Hauser 27

Process connections - Dimensions and materials

Endress+Hauser supplies DIN/EN flanges made of stainless steel according to AISI 316L (DIN/EN material

number 1.4404 or 1.4435). With regard to their temperature stability properties, the materials 1.4404 and

1.4435 are grouped under 13EO in EN 1092-1 Tab. 18. The chemical composition of the two materials can

be identical.

Process connection Designation Versions Approvals Option

Tri-clamp ISO2852

DN25-38 (1 to 1-½")*

P

max

= 16 bar

Material: 316L (1.4435)

•0.76 μm

•0.38 μm

electropolished

• 5

•EHEDG

• ASME-BPE

compliant

TCJ

Tri-clamp ISO2852

DN40-51 (2")*

P

max

= 16 bar

Material: 316L (1.4435)

TDJ

Tri-clamp ISO2852

DN70-76.1 (3")

P

max

= 10 bar

Material: 316L (1.4435)

TFJ

SMS 1-½" PN25

with slotted nut*

P

max

= 16 bar

Material:

A= 1.4307

B= 316L (1.4435)

•0.76 μm • EHEDG

T7J

SMS 2" PN25

with slotted nut*

P

max

= 16 bar

Material:

A= 1.4307

B= 316L (1.4435)

TXJ

ø50,4

ø43,4

ø63,9

ø56,4

ø90,9

ø83,4

ø74

A

B

25

ø54,85

26

ø84

ø63,9

ø56,4

A

B

Page 28

Levelflex M FMP43

28 Endress+Hauser

DIN11851 DN40 PN40

with slotted nut F40*

P

max

= 16 bar

Material:

A= 1.4307

B= 316L (1.4435)

•0.76 μm

•EHEDG

MQJ

DIN11851 DN50 PN40

with slotted nut F50*

P

max

= 16 bar

Material:

A= 1.4307

B= 316L (1.4435)

MRJ

DIN11864-1 A DN25

Pipe DIN11850

with slotted nut F25*

P

max

= 16 bar

Material:

A= 1.4307

B= 316L (1.4435)

•0.76 μm

•0.38 μm

electropolished

MAJ

NEUMO BioControl

DN25 PN16*

P

max

= 16 bar

Material: 316L (1.4435)

S1J

1-1/2" 150lbs RF

Flange ANSI B16.5*

P

max

= 16 bar

Material: 316L

•0.76 μm

AEJ

2" 150lbs RF

Flange ANSI B16.5*

P

max

= 16 bar

Material: 316L

AFJ

Process connection Designation Versions Approvals Option

21

ø78

ø39

ø56

A

B

22

ø92

ø51

ø68

A

B

21

ø63

ø42,9

A

B

ø30,4

ø64

1717

2020

ø127

17,5

ø152,4

19,1

Page 29

Levelflex M FMP43

Endress+Hauser 29

General information on

flanges

The surface roufhness of the surface in contact with the medium, including the sealing surface of the flanges

(all standards) made of Hastelloy C, Monel or Tantas, is Rz 3.2.

Lower surface roughness levels are available on request.

Tolerance of probe length

Weight

Thread M24 x 1.5 U1J

You need the following weld-in adapter:

Weld-in adapter

order number: 71041381

P

max

= 16 bar

Material: 316L (1.4435)

Accessory:

weld-in adapter

•0.76 μm

Process connection Designation Versions Approvals Option

M24x1.5M24x1.5

ø31ø31

ø65

8.58.5

1717

Tolerance Rod length

+0 / -3 mm < 1000 mm

+0 / -5 mm 1000 to < 4000 mm

Part Weight

Housing T12 approx. 2.7 kg

Housing F12 approx. 1.8 kg

Housing F23 approx. 5 kg

Probe compact approx. 0.7 kg

Probe compact, detachable approx. 0.8 kg

Probe remote approx. 2.1 kg

Probe rod approx. 0.4 kg/m

Page 30

Levelflex M FMP43

30 Endress+Hauser

Material

(not in contact with process)

T12 and F12 housing (seawater-resistant*, powder-coated)

L00-x12xxxx-16-00-00-en-001

* Seawater-resistant on request (complete in 316L (1.4404)).

Pos. Part Material

1 T12 and F12 housing AlSi10Mg

2

Cover (Display) AlSi10Mg

Sealing Fa. SHS: EPDM 70pW FKN

Window ESG-K-Glass (Toughened safety glass)

Sealing of the glass Silicone sealing compound Gomastit 402

3

Sealing Fa. SHS: EPDM 70 pW FKN Trelleborg: EPDM E7502

Cable gland Polyamid (PA), CuZn nickel-plated

Plug

PBT-GF30 1.0718 galvanized

PE 3.1655

Adapter 316L (1.4435) AlMgSiPb (anodized)

4

Cover (Connection compartment) AlSi10Mg

Sealing Fa. SHS: EPDM 70pW FKN Trelleborg: EPDM E7502/E7515

Clamp Screws: A4; Clamp: Ms nickel-plated; Spring washer: A4

5 Sealing ring Fa. SHS: EPDM 70pW FKN Trelleborg: EPDM E7502/E7515

6

Tag VA

Rope VA

Crimp sleeve Aluminium

7

Nameplate* 304 (1.4301)

Groove pin* A2

8 Ground terminal*

Screws: A2; Spring washer: A4; Clamp: 304 (1.4301);

Holder: 301 (1.4310)

9Screws* A2-70

(Aluminium) (Aluminium)

ENDRESS+HAUSER

IP 65

Order Code:

Ser.-No.:

Messbereich

Measur

ing r

ange

U 16...36

V DC

4...20 mA

max.

20 m

Made in Ger

manyMaulburgMade in Germany Maulburg

T>70°C :

A

t >85°C

Made in Germany MaulburgMade in Germany Maulburg

ENDRESS+HAUSER

IP 65

Order Code:

Ser

.-No

.:

Messbereich

Measur

ing r

ange

U 16...36

V DC

4...20 mA

max.

20 m

Made in Germany MaulburgMade in Germany Maulburg

T>70°C :

A

t >85°C

F12 housing

T12 housing

987

5

6

98

56

3

2

1

4

2

1

3

3

7

Page 31

Levelflex M FMP43

Endress+Hauser 31

F23 housing (seawater-resistant*, corrosion-resistant)

L00-x12xxxx-16-00-00-en-001

* Seawater-resistant on request (complete in 316L (1.4404)).

Pos. Part Material

1 F23 housing

Housing body: 316L (1.4404); Sensor neck: 316L (1.4435);

earth connection block: 316L (1.4435)

2

Cover 316L (1.4404)

Sealing Fa. SHS: EPDM 70pW FKN

Window ESG-K-Glass (Toughened safety glass)

Sealing of the glass Silicone sealing compound Gomastit 402

3

Sealing Fa. SHS: EPDM 70pW FKN Trelleborg: EPDM E7502

Cable gland Polyamid (PA), CuZn nickel-plated

Plug

PBT-GF30 1.0718 galvanized

PE 3.1655

Adapter 316L (1.4435)

4 Sealing ring Fa. SHS: EPDM 70pW FKN Trelleborg: EPDM E7502

5 Nameplate* 304 (1.4301)

6 Grounding terminal*

Screws: A2; Spring washer: A4; Clamp: 304 (1.4301);

Holder: 301 (1.4310)

7Screw* A2-70

8

Tag VA

Rope VA

Crimp sleeve Aluminium

316L (1.4404/1.4435)

F23 housing

67

48

1

3

5

2

Page 32

Levelflex M FMP43

32 Endress+Hauser

Wall and pipe bracket

L00-FMP4xxxx-16-00-00-xx-002

Connecting parts

L00-FMP4xxxx-16-00-00-xx-002

Pos. Part Material

1 Bracket 304 (1.4301)

2 Disc 304 (1.4301)

3

Screw nut A4

Washer A2

4 Bar 304 (1.4301)

5 Housing adapter 316L (1.4435)

6 Thread adapter 304 (1.4301)

7 Cable gland CuZn nickel-plated

Pos. Part Material

1 Adapter (compact) 304 (1.4301)

2 Adapter (separable) 304 (1.4301)

3Cable FEP

4 Cable gland CuZn nickel-plated

5 Counter nut 304 (1.4301)

21

3

54

6

7

2

5

2

4

2

5

2

3

1

Page 33

Levelflex M FMP43

Endress+Hauser 33

Material

(in contact with process)

L00-FMP43xxx-16-00-00-xx-004

Process connection See "Ordering information", → ä 42.

Probe See "Ordering information", → ä 42.

Note!

The modular structure of the probe makes a simple possible exchanges of the process seals, the probe rod and

the process coupling ring.

Pos. Part Material

1 Probe 316L (1.4435)

2

O-Ring

EPDM Freudenberg 70 EPDM 291

FFKM DuPont Kalrez 6221

Isulator Ketron PEEK LSG

1

22 2

11

Page 34

Levelflex M FMP43

34 Endress+Hauser

Human interface

Operation concept The display of the process value and the configuration of the Levelflex occur locally by means of a large 4-line

alphanumeric display with plain text information. The guided menu system with integrated help texts ensures

a quick and safe commissioning.

To access the display the cover of the electronic compartment may be removed even in hazardous area (IS and

XP).

Remote commissioning, including documentation of the measuring point and in-depth analysis functions, is

supported via FieldCare, the graphical operating software for Endress+Hauser time-of-flight systems.

Display elements Liquid crystal display (LCD):

Four lines with 20 characters each. Display contrast adjustable through key combination.

L00-FMxxxxxx-07-00-00-en-001

The VU331 LCD display can be removed to ease operation by simply pressing the snap-fit (see graphic above).

It is connected to the device by means of a 500 mm cable.

The following table describes the symbols that appear on the liquid crystal display:

ENDRESS + HAUSER

E

+

–

E

N

D

RE

S

S

+H

A

U

S

E

R

M

IC

R

O

P

IL

O

T

II

ENDRESS+HAUSER

MICROPILOTII

IP6

5IP65

OrderCode:

Ser.-No.:

Order

Code:

Ser.-No.:

Messbereich

Measuringrange

Messbereich

Measuring

range

U16...36VDC

4...20mA

U

16...36

V

DC

4...20

mA

max.20mmax.

20

m

MadeinGermany MaulburgMadeinGermany Maulburg

T>70°C:

A

t

>

8

5

°

C

T>70°C

:

A

t

>85°C

LCD

(liquid crystal display)

Symbols

3 keys

snap-fit

Symbol Meaning

ALARM_SYMBOL

This alarm symbol appears when the device is in an alarm state. If the symbol flashes, this indicates a

warning.

LOCK_SYMBOL

This lock symbol appears when the device is locked, i.e. if no input is possible.

COM_SYMBOL

This communication symbol appears when a data transmission via e.g. HART, PROFIBUS PA or

FOUNDATION Fieldbus is in progress.

SIMULATION_SWITCH_ENABLE

This communication symbol appears when simulation in FOUNDATION Fieldbus is enabled via the DIP

switch.

Page 35

Levelflex M FMP43

Endress+Hauser 35

Operating elements The operating elements are located inside the housing and are accessible for operation by opening the lid of the

housing.

Function of the keys

Key(s) Meaning

O

or

V

Navigate upwards in the selection list.

Edit numeric value within a function.

S

or

W

Navigate downwards in the selection list.

Edit numeric value within a function.

X

or

Z

Navigate to the left within a function group.

F

Navigate to the right within a function group, confirmation.

O

and

F

or

S

and

F

Contrast settings of the LCD.

O

and S and

F

Hardware lock / unlock

After a hardware lock, an operation of the device via display or communication is not

possible! The hardware can only be unlocked via the display. An unlock parameter must be

entered to do so.

Page 36

Levelflex M FMP43

36 Endress+Hauser

Onsite operation Operation with VU331

The LC-Display VU331 allows configuration via 3 keys directly at the device. All device functions can be set

through a menu system. The menu consists of function groups and functions. Within a function, application

parameters can be read or adjusted. The user is guided through a complete configuration procedure.

L00-FMRxxxxx-07-00-00-en-002

X

X

X

X

S

S

O

O

FF

F

F

HOME

FG00

F000 F001 F002 F003 F004 ...

FG01

FG02

FG03

FG04

FG05

FG06

FG07

...

ENDRESS + HAUSER

E

+

–

Headline Position indicator

Main value

Unit

Symbol

Selection list

Function groups -> Functions

Help text

Envelope

curve

Bargraph

Page 37

Levelflex M FMP43

Endress+Hauser 37

Remote operation The Levelflex M can be remotely operated via HART, PROFIBUS PA and FOUNDATION Fieldbus. Onsite

adjustments are also possible.

Operation with FieldCare

FieldCare is an Endress+Hauser Plant Asset Management Tool based on FDT technology. You can use FieldCare to configure all your Endress+Hauser devices, as well as devices from other manufacturers that support

the FDT standard. Hardware and software requirements you can find on the internet:

www.endress.com → select your country → search: FieldCare → FieldCare → Technical Data.

FieldCare supports the following functions:

• Online configuration of transmitters

• Signal analysis via envelope curve

• Tank linearization

• Loading and saving of device data (upload/download)

• Documentation of the measuring point

Connection options:

• HART via Commubox FXA195 and the USB port of a computer

• PROFIBUS PA via segment coupler and PROFIBUS interface card

• Commubox FXA291 with ToF Adapter FXA291 via service interface

Menu-guided commissioning

L00-FMP4xxxx-20-00-00-en-001

Page 38

Levelflex M FMP43

38 Endress+Hauser

Signal analysis via envelope curve

Tank linearization

L00-FMP4xxxx-20-00-00-en-007

L00-fmp-Ixxx-20-00-00-en-041

Page 39

Levelflex M FMP43

Endress+Hauser 39

Operation with NI-FBUS Configurator (only FOUNDATION Fieldbus)

The NI-FBUS Configurator is an easy-to-use graphical environment for creating linkages, loops, and a schedule

based on the FOUNDATION fieldbus concepts.

You can use the NI-FBUS Configurator to configure a fieldbus network as follows:

• Set block and device tags

• Set device addresses

• Create and edit function block control strategies (function block applications)

• Configure vendor-defined function and transducer blocks

• Create and edit schedules

• Read and write to function block control strategies (function block applications)

• Invoke Device Description (DD) methods

• Display DD menus

• Download a configuration

• Verify a configuration and compare it to a saved configuration

• Monitor a downloaded configuration

• Replace devices

• Save and print a configuration

Operation with the Field Communicator 375, 475

With the Field Communicator 375, 475, you can configure all the device functions via menu operation.

Note!

Further information on the HART handheld unit is given in the respective operating manual included in the

transport bag of the Field Communicator 375, 475.

L00-FMP4xxxx-20-00-00-de-011

Page 40

Levelflex M FMP43

40 Endress+Hauser

Certificates and approvals

CE mark The measuring system meets the legal requirements of the applicable EC guidelines. These are listed in the

corresponding EC Declaration of Conformity together with the standards applied. Endress+Hauser confirms

successful testing of the device by affixing to it the CE mark.

Ex approval The devices are certified for use in hazardous areas. The safety instructions to be observed are enclosed and

referenced on the nameplate:

• Europe: EC type-examination certificate, Safety Instructions XA

• USA: FM Approval, Control Drawing

• Canada: CSA Certificate of Compliance, Control Drawing

• China: NEPSI Explosion Protection Certificate of Conformity, Safety Instructions XA

• Japan: TIIS Certificate for Ex-apparatus

Correlation of the certificates (XA, ZD) to the device:

1) Housing F12/F23/T12-OVP: In combination with electronics B, D or F supply intrinsically safe.

* in preparation

XA410F

X

X

X

X

X

XA411F

X

X

X

X

X

X

XA412F

X

X

X

X

X

XA413F

X

X

X

X

X

XA414F

X

X

X

X

X

XA415F

X

X

X

X

X

X

X

X

X

XA416F

X

X

X

X

X

X

XA378F

X

X

XA379F

X

X

X

ZD080F

X

X

X

ZD081F

X

X

X

X

ZD082F

X

X

X

X

X

ZD083F

X

X

X

X

ZD113F

X

X

X

ZD114F

X

X

X

X

ZD116F

X

X

X

ZD117F

X

X

X

X

ZD075F

X

X

X

ZD076F

X

X

X

X

ZD077F

X

X

X

X

X

ZD078F

X

X

X

X

ZD106F

X

X

X

ZD107F

X

X

X

X

ZD109F

X

X

X

ZD110F

X

X

X

X

ZD021F

X

X

X

X

X

X

Variant

A

I

K

M

N

P

S

T

U

V

1

2

3

4

5

7

B

D

F

G

H

A

B

C

D

Non-hazardous area

*NEPSI Ex ia IIC T6

*TIIS Ex ia IIC T4

FM DIP Cl.II Div.1 Gr. E-G, N.I.

CSA General Purpose

CSA DIP Cl.II Div.1 Gr. G + coal dust

FM IS Cl.I,II,III Div.1 Gr. A-G, N.I., zone 0, 1, 2

FM XP Cl.I,II,III Div.1 Gr. A-G, zone 1, 2

CSA IS Cl.I,II,III Div.1 Gr. A-D, G + coal dust, N.I., zone 0, 1, 2

CSA XP Cl.I,II,III Div.1 Gr. A-D, G + coal dust, N.I., zone 1, 2

ATEX II 1/2G Ex ia IIC T6

ATEX II 1/2D, Alu blind cover

1)

ATEX II 2G Ex e mb (ia) IIC T6

ATEX II 1/3D

1)

ATEX II 1/2G Ex ia IIC T6,ATEX II 1/3D

ATEX II 1/2G Ex d (ia) IIC T6

2-wire 4-20mA SIL HART

2-wire PROFIBUS PA

2-wire FOUNDATION Fieldbus

4-wire 90-250VAC 4-20mA SIL HART

4-wire 10.5-32VDC 4-20mA SIL HART

F12 Alu, coated IP68 NEMA6P

F23 316L IP68 NEMA6P

T12 Alu, coated IP68 NEMA6P

T12 Alu, coated IP68 NEMA6P + OVP

Feature

10

Approval:

50

Power

supply

Output:

80

Housing:

Page 41

Levelflex M FMP43

Endress+Hauser 41

Suitability for hygenic

processes

Note!

The gap-free connections can be cleaned without residue using the usual cleaning methods.

Many versions of the Levelflex M meet the requirements of 3A-Sanitary Standard No. 74. Endress+Hauser

confirms this by attaching the 3A symbol.

Pharma (CoC) Certificate of Compliance (CoC)

• See "Ordering information", → ä 42, feature 100 "Additional Option:", option"P".

• Materials in Contact with process made of 316L with Δ ferrite < 3%

• Surface roughness Ra < 0,38 μm/15 μin

• Information on ASME BPE Conformity

Overfill prevention SIL 2, for 4 to 20 mA output signal (see SD00174F/00/EN "Functional Safety Manual").

Telecommunications Complies with "Part 15" of the FCC rules for an "Unintentional Radiator". All probes meet the requirements

for a "Class A Digital Device".

In addition, all probes in metallic tanks meet the requirements for a "Class B Digital Device".

External standards and

guidelines

The European directives and standards applied can be taken from the associated EC Declarations of

Conformity. In addition, the following also applied for Levelflex M:

EN 60529

Protection class of housing (IP-code)

NAMUR - international user association of automation technology in process industries.

•NE21

Electromagnetic compatibility (EMC) of industrial process and laboratory control equipment.

•NE43

Standardization of the signal level for the failure information of digital transmitters.

Overview of permitted process connections, → ä 27.

74 -74-

Page 42

Levelflex M FMP43

42 Endress+Hauser

Ordering information

Levelflex M FMP43 Device selection

L00-FMP43xxx-16-00-00-en-002

Note!

For orders with a display, the housing cover is delivered with an inspection glass. For orders without a display,

a dummy cover is delivered.

Exception: For orders with the ATEX II 1/2 D dust ignition-proof certificate, a dummy cover is always

delivered, even for orders with a built-in display.

F12+F23* F12+F23*T12 T12 T12

PA PA PA PA

FF FF FF FF

Ex em Ex d

XP

1 ½”

Clamp

2”

Clamp

3”

Clamp

Ex ia

IS

20

30

Ex-free

area

2 Wire

4-20 mA/

HART

2 Wire

4-20 mA/

HART

2 Wire

4-20 mA/

HART

2 Wire

4-20 mA/

HART

4 Wire

4-20 mA/

HART

* Instead of the F12 housing from aluminium also the F23 housing from stailness steel can be supplied to all 2-wire electronics.

10

Approval

40

Process

connection

20

Probe

30

O-ring

Material

50

Power Supply/

Output

60

Operation

70

Type of probe

80

Housing

90

Cable entry

Option “6/7”:

Remote, detachable

Option “1”:

compact

Option “5”:

compact,detachable

Endress+Hauser

weld-in

adapter

Adapter

SMS 2”

Adapter

SMS 1 ”

½

Milk pipe

gland

DN50

Milk pipe

gland

DN40

Flange adapter

Neumo Bio

Control D25

ASME flange

1

½”or2”

Slotted nut

DIN 11851

F40

Slotted nut

DIN 11851 F25

Slotted nut

DIN 11851

F50

Slotted nut

SMS 2”

Slotted nut

SMS 1 ”

½

Aseptic

11864-1

form A /DN25

Page 43

Levelflex M FMP43

Endress+Hauser 43

Ordering information Levelflex M FMP43

10 Approval:

A Non-hazardous area

1 ATEX II 1/2 G Ex ia IIC T6

7 ATEX II 1/2 G Ex d (ia) IIC T6

5 ATEX II 1/2 G Ex ia IIC T6, ATEX II 1/3 D

3 ATEX II 2G Ex e mb (ia) IIC T6

2 ATEX II 1/2 D, Alu blind cover

4 ATEX II 1/3 D

M FM DIP Cl. II Div. 1 Gr. E-G N.I.

S FM IS Cl. I, II, III Div. 1 Gr. A-G N.I., zone 0, 1, 2

T FM XP Cl. I, II, III Div. 1 Gr. A-G, zone 1, 2

N CSA General Purpose

P CSA DIP Cl. II Div. 1 Gr. G + coal dust, N. I.

U CSA IS Cl. I, II, III Div. 1 Gr. A-D, G + coal dust, N.I., zone 0, 1, 2

V CSA XP Cl .I, II, III Div. 1 Gr. A-D, G + coal dust, N.I., zone 1, 2

K TIIS Ex ia IIC T4 (in preparation)

I NEPSI Ex ia IIC T6 (in preparation)

Y Special version, TSP-No. to be spec.

20 Probe:

300 mm - 4000 mm/12 in - 157 in

K ..... mm, rod 8 mm, 316L, Ra < 0.76 μm/30 μin

M ..... in, rod 8 mm 316L, Ra < 0.76 μm/30 μin

S ..... mm, rod 8 mm, 316L, electropolished Ra < 0.38 μm/15 μin

T ..... in, rod 8 mm 316L, electropolished Ra < 0.38 μm/15 μin

Y Special version, TSP-No. to be spec.

30 O-ring Material; Temperature:

5 EPDM, FDA, USP Cl. VI; - 20 °C to 130 °C

6 Kalrez, FDA, USP Cl. VI; - 20 °C to 150 °C

9 Special version, TSP-No. to be spec.

40 Process Connection:

-- Threaded boss --

U1J Thread M24, 316L, install > accessory weld-in adapter

-- Clamp connections --

TCJ Tri-clamp ISO2852 DN25-38 (1 to 1-1/2"), 316L, 3A, EHEDG

TDJ Tri-clamp ISO2852 DN40-51 (2"), 316L, 3A, EHEDG

TFJ Tri-clamp ISO2852 DN70-76.1 (3"), 316L, 3A, EHEDG

-- Hygienic connections --

T7J SMS 1-1/2" PN25, 316L, EHEDG

TXJ SMS 2" PN25, 316L, EHEDG

MAJ DIN11864-1 A DN25 tube DIN11850, 316L, slotted-nut, EHEDG

MQJ DIN11851 DN40 PN40, slotted-nut, 316L, EHEDG

MRJ DIN11851 DN50 PN40, slotted-nut, 316L, EHEDG

S1J NEUMO BioControl DN25 PN16, 316L, EHEDG

-- ANSI flanges --

AEJ 1-1/2" 150 lbs RF, 316L flange ANSI B16.5

AFJ 2" 150 lbs RF, 316L flange ANSI B16.5

YY9 Special version, TSP-No. to be spec.

50 Power Supply; Output:

B 2-wire ; 4-20mA SIL HART

D2-wire; PROFIBUS PA

F 2-wire; FOUNDATION Fieldbus

G 4-wire 90-250 VAC; 4-20mA SIL HART

H 4-wire 10.5-32 VDC; 4-20mA SIL HART

Y Special version, TSP-No. to be spec.

60 Operation:

1 W/o display, via communication

2 4-line display VU331

3 Prepared for FHX40

9 Special version, TSP-No. to be spec.

70 Type of Probe:

1 Compact, basic version

5 Compact, detachable

6 Remote, cable 3 m, detachable

7 Remote, cable 6 m, detachable

9 Special version, TSP-No. to be spec.

Page 44

Levelflex M FMP43

44 Endress+Hauser

1)

OVP = overvoltage protection

80 Housing:

A F12 Alu, coated IP68 NEMA6P

B F23, 316L, IP68, NEMA6P

C T12 Alu, coated IP68 NEMA6P, separate conn. compartment

D T12 Alu, coated IP68 NEMA6P + OVP

1)

, seperate terminal compartment

Y Special version, TSP-No. to be spec.

90 Cable Entry:

2 Gland M20 (EEx d > thread M20)

3 Thread G 1/2

4 Thread NPT 1/2

5Plug M12

6 Plug 7/8"

9 Special version, TSP-No. to be spec.

100 Additional Option:

A Basic version

B EN10204-3.1 material (316L wetted parts) inspection certificate