Page 1

BA327F/00/en/03.05

No. 52027874

Valid as of software version

V 01.02.04 (amplifier)

V 01.02.04 (communication)

Operating Instructions

Levelflex M FMP40 and FMP45

Guided Level-Radar for interface measurement according to

MVTFN0341

HART/4...20 mA

6

Page 2

Brief overview Levelflex M FMP40 and FMP45

2

Brief overview

For quick and simple commissioning:

Safety Instructions → Page 4 ff.

Explanation of the warning symbols

You can find special instructions at the appropriate position in the chapter in

question. The positions are indicated with the icons Warning #, Caution " and

Note !.

Æ

Installation → Page 14 ff.

The steps for installing the device and installation conditions (e.g. dimensions)

can be found here.

Æ

Wiring → Page 23 ff.

The device is virtually completely wired on delivery.

Æ

Display and Operating Elements → Page 29 ff.

An overview of the position of the display and operating elements can be found

here.

Æ

Commissioning via Display VU 331 Page 33 ff.

The set-up is supported by a special FieldCare DTM, which is delivered with

the device. Do not use the display VU 331 for set-up.

Æ

Commissioning via Operating Software FieldCare → Page 29 ff.

In the "Commissioning" section, you learn how to switch on the device and

check the functioning.

Æ

Fault Tracking / Trouble Shooting → Page 58 ff.

If faults occur during operation, use the checklist to localise the cause.

Here you can find measures you can take yourself to take remedial action

against the fault.

Æ

Index → Page 77 ff.

You can find important terms and keywords on the individual sections here.

Use the keyword index to find quickly and efficiently the information you need.

Page 3

Levelflex M FMP40 and FMP45 Table of contents

3

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning and operation . . . . . . . . 4

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Notes on safety conventions and icons . . . . . . . . . . . 5

2 Identification . . . . . . . . . . . . . . . . . . . . 6

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3 Certificates and approvals . . . . . . . . . . . . . . . . . . . 13

2.4 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . 13

3 Installation . . . . . . . . . . . . . . . . . . . . . 14

3.1 Quick installation guide . . . . . . . . . . . . . . . . . . . . . 14

3.2 Incoming acceptance, transport, storage . . . . . . . . . 15

3.3 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 16

3.4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5 Turn housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.6 Post-installation check . . . . . . . . . . . . . . . . . . . . . . 22

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 Quick wiring guide . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 Connecting the measuring unit . . . . . . . . . . . . . . . 25

4.3 Recommended connection . . . . . . . . . . . . . . . . . . 28

4.4 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 28

4.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . . 28

5 Operation . . . . . . . . . . . . . . . . . . . . . . 29

5.1 Display and operating elements . . . . . . . . . . . . . . . 29

5.2 Display and acknowledging error messages . . . . . . 31

6 Commissioning. . . . . . . . . . . . . . . . . . 32

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2 Switching on the measuring device . . . . . . . . . . . . 32

6.3 Basic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 Description of Instrument Functions . 39

7.1 Function group "basic setup" . . . . . . . . . . . . . . . . . 39

7.2 Function group "safety settings" . . . . . . . . . . . . . . . 41

7.3 Function group "length adjustment" . . . . . . . . . . . . 46

7.4 Function group "extended calibr." . . . . . . . . . . . . . 46

7.5 Function group "output" . . . . . . . . . . . . . . . . . . . . 47

7.6 Function group "display" . . . . . . . . . . . . . . . . . . . . 50

7.7 Function group "diagnostics" . . . . . . . . . . . . . . . . . 52

7.8 Function group "system parameters" . . . . . . . . . . . 54

7.9 Function group "service" . . . . . . . . . . . . . . . . . . . . 54

8 Maintenance . . . . . . . . . . . . . . . . . . . . 55

9 Accessories . . . . . . . . . . . . . . . . . . . . . 56

10 Trouble-shooting . . . . . . . . . . . . . . . . . 58

10.1 Trouble-shooting instructions . . . . . . . . . . . . . . . . . 58

10.2 System error messages . . . . . . . . . . . . . . . . . . . . . . 59

10.3 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.5 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.6 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.7 Contact addresses of Endress+Hauser . . . . . . . . . . . 64

11 Technical data . . . . . . . . . . . . . . . . . . . 65

11.1 Additional technical data . . . . . . . . . . . . . . . . . . . . 65

12 Appendix. . . . . . . . . . . . . . . . . . . . . . . 74

12.1 Function and system design . . . . . . . . . . . . . . . . . . 74

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Page 4

Safety instructions Levelflex M FMP40 and FMP45

4

1 Safety instructions

1.1 Designated use

The Levelflex M FMP40 and FMP45 is a compact level transmitter for the continuous measurement

of the interface level in liquids, measuring prinziple: Guided Level Radar / TDR:

Time Domain Reflectometry.

1.2 Installation, commissioning and operation

The Levelflex M has been designed to operate safely in accordance with current technical, safety

and EU standards. If installed incorrectly or used for applications for which it is not intended,

however, it is possible that application-related dangers may arise, e.g. product overflow due to

incorrect installation or calibration. For this reason, the instrument must be installed, connected,

operated and maintained according to the instructions in this manual: personnel must be authorised

and suitably qualified. The manual must have been read and understood, and the instructions

followed. Modifications and repairs to the device are permissible only when they are expressly

approved in the manual.

1.3 Operational safety

Hazardous areas

Measuring systems for use in hazardous environments are accompanied by separate "Ex

documentation", which is an integral part of this Operating Manual. Strict compliance with the

installation instructions and ratings as stated in this supplementary documentation is mandatory.

• Ensure that all personnel are suitably qualified.

• Observe the specifications in the certificate as well as national and local regulations.

Page 5

Levelflex M FMP40 and FMP45 Safety instructions

5

1.4 Notes on safety conventions and icons

In order to highlight safety-relevant or alternative operating procedures in the manual, the following

conventions have been used, each indicated by a corresponding symbol in the margin.

Safety conventions

#

Warning!

A warning highlights actions or procedures which, if not performed correctly, will lead to personal

injury, a safety hazard or destruction of the instrument

"

Caution!

Caution highlights actions or procedures which, if not performed correctly, may lead to personal

injury or incorrect functioning of the instrument

!

Note!

A note highlights actions or procedures which, if not performed correctly, may indirectly affect

operation or may lead to an instrument response which is not planned

Explosion protection

0

Device certified for use in explosion hazardous area

If the device has this symbol embossed on its name plate it can be installed in an explosion hazardous

area

-

Explosion hazardous area

Symbol used in drawings to indicate explosion hazardous areas. Devices located in and wiring

entering areas with the designation “explosion hazardous areas” must conform with the stated type

of protection.

.

Safe area (non-explosion hazardous area)

Symbol used in drawings to indicate, if necessary, non-explosion hazardous areas. Devices located in

safe areas still require a certificate if their outputs run into explosion hazardous areas

Electrical symbols

%

Direct voltage

A terminal to which or from which a direct current or voltage may be applied or supplied

&

Alternating voltage

A terminal to which or from which an alternating (sine-wave) current or voltage may be applied or

supplied

)

Grounded terminal

A grounded terminal, which as far as the operator is concerned, is already grounded by means of an

earth grounding system

*

Protective grounding (earth) terminal

A terminal which must be connected to earth ground prior to making any other connection to the

equipment

+

Equipotential connection (earth bonding)

A connection made to the plant grounding system which may be of type e.g. neutral star or

equipotential line according to national or company practice

Temperature resistance of the connection cables

States, that the connection calbes must be resistant to a temperature of at least 85 °C.

t >85°C

Page 6

Identification Levelflex M FMP40 and FMP45

6

2 Identification

2.1 Device designation

2.1.1 Nameplate

The following technical data are given on the instrument nameplate:

L00-FMP4xxxx-18-00-00-en-001

Fig. 1: Information on the nameplate of the Levelflex M (example)

2.1.2 Ordering structure

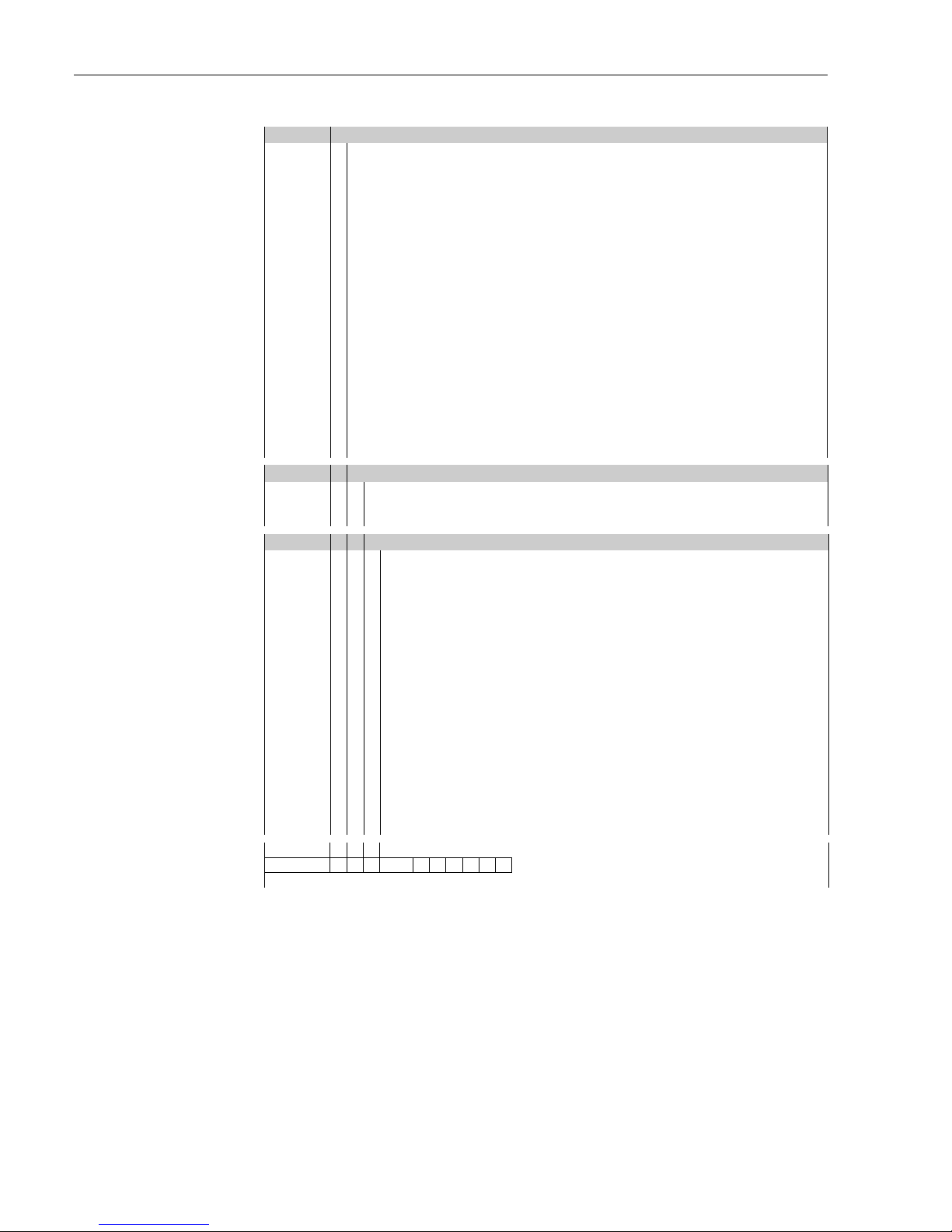

Ordering structure Levelflex M FMP40

Made in Germany

D-79689 Maulburg

Dat./Insp.:

Order Code:

IP68 / NEMA 6P

Ser.-No.:

4-wire

ENDRESS+HAUSER

t >85°C

TA > 70°C:

D01301-A

if modification

see sep. label

X=

Patents

LEVELFLEX-M

90 … 253 V AC 3,5VA

10,5 … 32 V DC 1W

16 … 3 V DC 0,8W

Profibus PA

Foundation Fieldbus

LN= PN=

4 … 20 mA HART 2-wire

Order No

(see Order Information)

Communication

variant and

supply voltage

Serial number

Reference to additional

safety-relevant documentation

Designation according to Directive 94/9/EC

and designation of protection

10 Approval:

A Non-hazardous area

F Non-hazardous area, WHG

1 ATEX II 1/2G EEx ia IIC T6

2 ATEX II 1/2D, Alu blind cover

3 ATEX II 2G EEx em (ia) IIC T6

4 ATEX II 1/3D

5 ATEX II 1/2G EEx ia IIC T6, ATEX II 1/3D

6 ATEX II 1/2G EEx ia IIC T6, WHG

7 ATEX II 1/2G EEx d (ia) IIC T6

8 ATEX II 1/2G EEx ia IIC T6, ATEX II 1/3D, WHG

M FM DIP Cl.II Div.1 Gr.E-G N.I.

S FM IS Cl.I,II,III Div.1 Gr.A-G N.I.

T FM XP Cl.I,II,III Div.1 Gr.A-G

N CSA General Purpose

P CSA DIP Cl.II Div.1 Gr.G + coal dust, N.I.

U CSA IS Cl.I,II,III Div.1 Gr.A-D,G + coal dust, N.I.

V CSA IS Cl.I,II,III Div.1 Gr.A-D,G + coal dust, N.I.

K *TIIS Ex ia IIC T4

L *TIIS Ex d (ia) IIC T5

D AUS Ex DIP A20/A21

YSpecial version

FMP40- Product designation (part 1)

Page 7

Levelflex M FMP40 and FMP45 Identification

7

Ordering structure Levelflex M FMP40 (continued)

20 Probe:

A Rope 4mm / 1/6", mainly solid

B Rope 6mm / 1/4", solid

H Rope 6mm / 1/4", PA > steel, solid

P Rod 6mm, liquid

1 Rod 12mm, liquid

K Rod 16mm, mainly liquid

L Coax, liquid

YSpecial version

30 Probe length:

Rope probes:

Options A, B, E, D, F:

1000mm-35000mm/40in-1378in

Option C:

35in-1378in

The price is based on 1000mm

A ..... mm, rope 4mm, 316

B ..... mm, rope 6mm, 316

E ..... mm, rope 6mm, PA > steel

The price is based on inch

C ..... inch rope 1/6", 316

D ..... inch, rope 1/4", 316

F ..... inch, rope 1/4", PA > steel

Rod probes:

Options K, L, 1, 2, M, N:

300mm-4000mm/12in-157in

Options P, R, 3, 4:

300mm-2000mm/12in-80in

The price is based on 100mm

K ..... mm, rod 16mm, 316L

L ..... mm, coax, 316L

P ..... mm, rod 6mm, 316L

The price is based on inch

M ..... inch, rod 16mm, 316L

N ..... inch, coax, 316L

R ..... inch, rod 6mm, 316L

YSpecial version

40 O-ring Material:

2Viton

3EPDM

4Kalrez

9 Special version

FMP40- Product designation (part 2)

Page 8

Identification Levelflex M FMP40 and FMP45

8

Ordering structure Levelflex M FMP40 (continued)

50 Process connection:

Threaded boss

CRJ Thread ISO228 G3/4, 316L

GRJ Thread ISO228 G1-1/2, 316L

CNJ Thread ANSI NPT3/4, 316L

GNJ Thread ANSI NPT1-1/2, 316L

EN-Flanges

CFJ DN40 PN25/40 B1, 316L

CGJ DN50 PN25/40 B1, 316L

CMJ DN80 PN10/16 B1, 316L

CSJ DN80 PN25/40 B1, 316L

CQJ DN100 PN10/16 B1, 316L

CTJ DN100 PN25/40 B1, 316L

CWJ DN150 PN10/16 B1, 316L

CXJ DN200 PN16 B1, 316L

ANSI-Flanges

ACJ 1-1/2" 150lbs RF, 316/316L

ADJ 1-1/2" 300lbs RF, 316/316L

AEJ 2" 150lbs RF, 316/316L

AFJ 2" 300lbs RF, 316/316L

ALJ 3" 150lbs RF, 316/316L

AMJ 3" 300lbs RF, 316/316L

APJ 4" 150lbs RF, 316/316L

AQJ 4" 300lbs RF, 316/316L

AWJ 6" 150lbs RF, 316/316L

A3J 8" 150lbs RF, 316/316L

JIS-Flanges

KDJ 10K 40A RF, 316L

KEJ 10K 50A RF, 316L

KLJ 10K 80A RF, 316L

KPJ 10K 100A RF, 316L

YY9 Special version

60 Power supply; Output:

Y Special version according MVTFN0341, HART 2-wire

70 Operation:

1 w/o display, via communication

2 4-line display VU331

3 Prepared for FHX40, remote display (Accessory)

9Special version

80 Remote electronics:

1 Compact, basic version

2 Temp. separator, 400mm

3 Remote, cable 3m

9 Special version

FMP40- Product designation (part 3)

Page 9

Levelflex M FMP40 and FMP45 Identification

9

Ordering structure Levelflex M FMP40 (continued)

90 Housing; Cable entry:

A F12 Alu, coated IP68; Gland M20

B F12 Alu, coated IP68; Thread G1/2

C F12 Alu, coated IP68; Thread NPT1/2

D F12 Alu, coated IP68; Plug M12

E F12 Alu, coated IP68; Plug 7/8"

G T12 Alu, coated IP68; Gland M20

H T12 Alu, coated IP68; Thread G1/2

J T12 Alu, coated IP68; Thread NPT1/2

K T12 Alu, coated IP68; Plug M12

L T12 Alu, coated IP68; Plug 7/8"

M T12 Alu, coated IP68; Gland M20 + OVP

OVP = overvoltage protection

N T12 Alu, coated IP68; Thread G1/2 + OVP

OVP = overvoltage protection

P T12 Alu, coated IP68; Thread NPT1/2+OVP

OVP = overvoltage protection

Q T12 Alu, coated IP68; Plug M12 + OVP

OVP = overvoltage protection

R T12 Alu, coated IP68; Plug 7/8" + OVP

OVP = overvoltage protection

1 F23 316L IP68; Gland M20

2 F23 316L IP68; Thread G1/2

3 F23 316L IP68; Thread NPT1/2

4 F23 316L IP66; Plug M12

5 F23 316L IP68; Plug 7/8"

9Special version

100 Additional option:

A Basic version

B EN10204-3.1B (316L wetted parts)

Inspection certificate

N EN10204-3.1B, NACE MR0175

(316L wetted parts)

Inspection certificate

S GL/ABS marine certificate

YSpecial version

FMP40- complete product designation

⇓

Please enter probe length in mm or inch / 0.1 inch

mm

inch / 0.1 inch

probe length LN see Page 18

Page 10

Identification Levelflex M FMP40 and FMP45

10

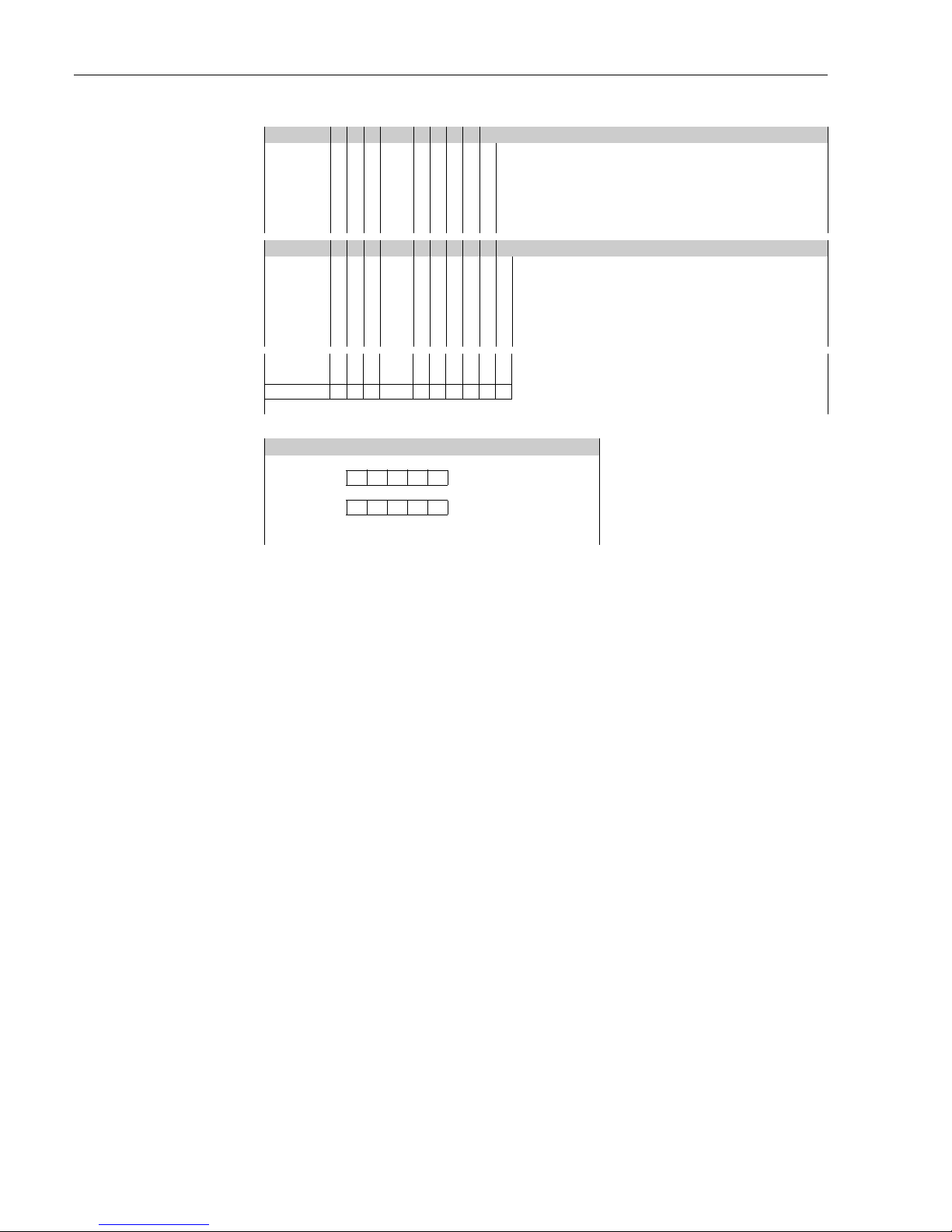

Ordering structure Levelflex M FMP45

10 Approval:

A Non-hazardous area

F *Non-hazardous area, WHG

1 ATEX II 1/2G EEx ia IIC T6

6 *ATEX II 1/2G EEx ia IIC T6, WHG

7 ATEX II 1/2G EEx d (ia) IIC T6

5 ATEX II 1/2G EEx ia IIC T6,ATEX II 1/3D

8*ATEX II 1/2G EEx ia IIC T6

ATEX II 1/3D, WHG

3 ATEX II 2G EEx em (ia) IIC T6

2 ATEX II 1/2D, Alu blind cover

4 ATEX II 1/3D

M *FM DIP Cl.II Div.1 Gr.E-G N.I.

S *FM IS Cl.I,II,III Div.1 Gr.A-G N.I.

T *FM XP Cl.I,II,III Div.1 Gr.A-G

N *CSA General Purpose

P *CSA DIP Cl.II Div.1 Gr.G + coal dust, N.I.

U *CSA IS Cl.I,II,III Div.1 Gr.A-D,G + coal dust, N.I.

V *CSA XP Cl.I,II,III Div.1 Gr.A-D,G + coal dust, N.I.

K *TIIS Ex ia IIC T4

L *TIIS Ex d (ia) IIC T5

YSpecial version

20 Process temperature:

A -200...+280 °C/-328...+536 °F (XT)

B -200...+400 °C/-328...+752 °F (HT)

YSpecial version

30 Probe:

Rod probe:

300mm-4000mm/12in-157in

The price is based on 100mm

K ..... mm, rod 16mm, PTFE > 316L

The price is based on inch

M ..... inch, rod 16mm, 316L

Rope probe:

1000mm-35000mm/40in-1378in

The price is based on 1000mm

A ..... mm, rope 4mm, 316

The price is based on inch

C ..... inch, rope 1/6", 316

Coax probe:

300mm-4000mm/12in-157in

The price is based on 100mm

L ..... mm, coax, 316L

The price is based on inch

N ..... inch, coax, 316L

YSpecial version

FMP45- Product designation (part 1)

Page 11

Levelflex M FMP40 and FMP45 Identification

11

Ordering structure Levelflex M FMP45 (continued)

40 Process connection:

Threaded boss

GGJ Thread ISO228 G1-1/2, 200bar, 316L

GJJ Thread ISO228 G1-1/2, 400bar, 316L, high pressure test

RGJ Thread ANSI NPT1-1/2, 200bar, 316L

RJJ *Thread ANSI NPT1-1/2, 400bar, 316L, high pressure test

EN-Flanges

CRJ DN50 PN10-40 B1, 316L

C1J DN50 PN64 B1, 316L

C2J DN50 PN100 B1, 316L

CSJ DN80 PN10-40 B1, 316L

C3J DN80 PN63 B1, 316L

C4J DN80 PN100 B1, 316L

CHJ DN100 PN10/16 B1, 316L

CTJ DN100 PN25/40 B1, 316L

C5J DN100 PN63 B1, 316L

C6J DN100 PN100 B1, 316L

ANSI-Flanges

AFJ 2" 150lbs RF, 316/316L

ARJ 2" 300/600lbs RF, 316/316L

A1J 2" 1500lbs RF, 316/316L

AGJ 3" 150lbs RF, 316/316L

ASJ 3" 300/600lbs RF, 316/316L

A2J 3" 1500lbs RF, 316/316L

AHJ 4" 150lbs RF, 316/316L

ATJ 4" 300lbs RF, 316/316L

A3J 4" 600lbs RF, 316/316L

A4J 4" 900lbs RF, 316/316L

A5J 4" 1500lbs RF, 316/316L

JIS-Flanges

KFJ 10K 50A RF, 316L

KGJ 10K 80A RF, 316L

KHJ 10K 100A RF, 316L

K3J 63K 50A RF, 316L

K4J 63K 80A RF, 316L

K5J 63K 100A RF, 316L

YSpecial version

50 Power supply; Output:

Y Special version according to MVTFN0341, HART 2-wire

60 Operation:

1 w/o display, via communication

2 4-line display VU331

3 Prepared for FHX40, remote display (Accessory)

9Special version

70 Remote electronics:

1 Compact, basic version

3 Remote, cable 3m

9Special version

80 Housing:

A F12 Alu, coated IP68 NEMA6P

C T12 Alu, coated IP68 NEMA6P, separate conn. compartment

B F23 316L IP68 NEMA6P

D *T12 Alu, coated IP68 NEMA6P + OVP, separate conn. compartment,

OVP = overvoltage protection

YSpecial version

FMP45- Product designation (part 2)

Page 12

Identification Levelflex M FMP40 and FMP45

12

Ordering structure Levelflex M FMP45 (continued)

90 Cable entry:

2Gland M20

3Thread G1/2

4Thread NPT1/2

5Plug M12

6 Plug 7/8"

9Special version

100 Additional option:

A Basic version

B EN10204-3.1B (316L wetted parts)

Inspection certificate

N *EN10204-3.1B, NACE MR0175 (316L wetted parts)

Inspection certificate

Y Special version

FMP45- Complete product designation

⇓

Please enter probe length in mm or inch / 0.1 inch

mm

inch / 0.1 inch

probe length LN see Page 18

Page 13

Levelflex M FMP40 and FMP45 Identification

13

2.2 Scope of delivery

"

Caution!

It is essential to follow the instructions concerning the unpacking, transport and storage of

measuring instruments given in the chapter "Incoming acceptance, transport, storage" on Page 15!

The scope of delivery consists of:

• Assembled instrument

• FieldCare CD-ROM

• FMP4x HART Interface, DTM CD-ROM

• Accessories (→ Chap. 9).

Accompanying documentation:

• Operating manual (this manual)

• Approval documentation: if this is not included in the operating manual.

2.3 Certificates and approvals

CE mark, declaration of conformity

The instrument is designed to meet state-of-the-art safety requirements, has been tested and left the

factory in a condition in which it is safe to operate. The instrument complies with the applicable

standards and regulations as listed in the EC declaration of conformity and thus complies with the

statutory requirements of the EG directives. Endress+Hauser confirms the successful testing of the

instrument by affixing to it the CE mark.

For further information see → Chap. 11.1.7 on Page 71 ff.

2.4 Registered trademarks

KALREZ®, VITON®, TEFLON

®

Registered trademark of the company, E.I. Du Pont de Nemours & Co., Wilmington, USA

TRI-CLAMP

®

Registered trademark of the company, Ladish & Co., Inc., Kenosha, USA

HART

®

Registered trademark of HART Communication Foundation, Austin, USA

ToF

®

Registered trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

PulseMaster

®

Registered trademark of the company Endress+Hauser GmbH+Co. KG, Maulburg, Germany

FieldCare

®

Registered trademark of the company Endress+Hauser Process Solutions AG.

Page 14

Installation Levelflex M FMP40 and FMP45

14

3 Installation

3.1 Quick installation guide

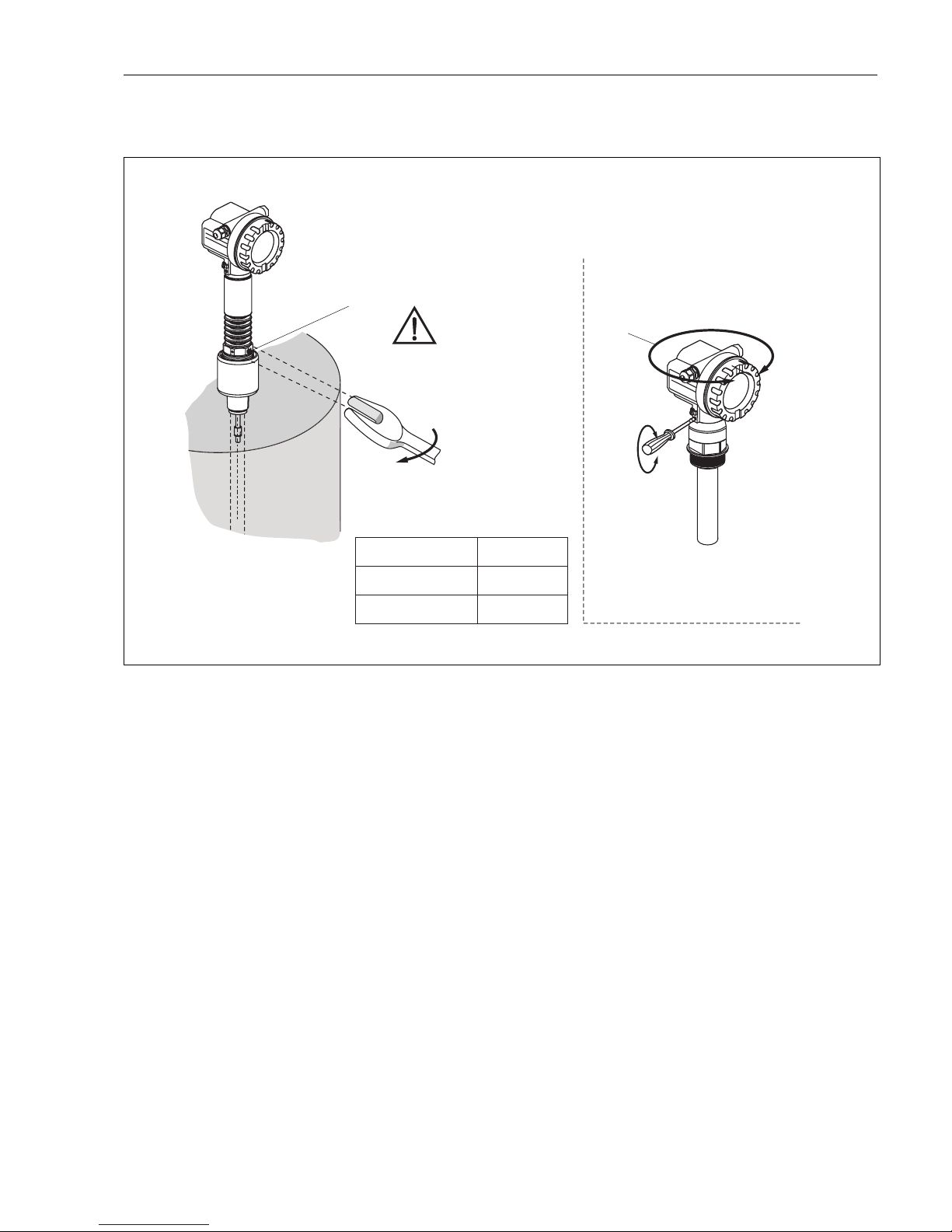

3.1.1 FMP40

L00-FMP4xxxx-17-00-00-en-029

3

1

3

1

2

2

60

50

1½"

¾"

F12/F23 housing

T12 housing

Turn housing

The housing can be turned 350°

in order to simplify access to the

display and the terminal compartment

Allen key

4 mm / 0.1"

AF 60

AF 50

max. torque

20 Nm

max. torque

5 Nm

Caution!

Use only the

threaded boss

F12/F23 or T12 housing

F12/F23 or T12 housing

Page 15

Levelflex M FMP40 and FMP45 Installation

15

3.1.2 FMP45

L00-FMP45xxx-17-00-00-e n-003

3.2 Incoming acceptance, transport, storage

3.2.1 Incoming acceptance

Check the packing and contents for any signs of damage.

Check the shipment, make sure nothing is missing and that the scope of supply matches your order.

3.2.2 Transport

"

Caution!

Follow the safety instructions and transport conditions for instruments of more than

18 kg.

Do not lift the measuring instrument by its probe rod in order to transport it.

3.2.3 Storage

Pack the measuring instrument so that is protected against impacts for storage and transport. The

original packing material provides the optimum protection for this.

The permissible storage temperature is -40 °C…+80 °C.

3

1

2

60

1"

½

F12 housing

Turn housing

The housing can be turned 350°

in order to simplify access to the

display and the terminal compartment

AF 60

max. torque

see table

Caution!

Use only the

threaded boss ???

F12 or T12 housing

torqueProcess temperature

max. 280 °C 450 Nm

max. 400 °C 400 Nm

Page 16

Installation Levelflex M FMP40 and FMP45

16

3.3 Installation conditions

3.3.1 Dimensions

Housing dimensions

Dimensions for the process connection and the probe type see Page 18.

L00-F12xxxx-06-00-00-en-001

L00-T12xxxx-06-00-00-en-001

L00-F23xxxx-06-00-00-en-001

ENDRESS+HAUSER

65

78

max. 110

85

150

Ø 129

(Aluminium)

F12 housing

ENDRESS+HAUSER

78

85

65

162

max. 100 94

Ø 129

(Aluminium)

T12 housing

max. 94

104

Ø 129

150

40

(316L)

F23 housing

Page 17

Levelflex M FMP40 and FMP45 Installation

17

Levelflex M FMP40 - process connection, probe type

Housing dimensions see Page 16

L00-FMP4xxxx-06-00-00-en-007

Fig. 2: Dimensions Levelflex M FMP40

88

88

400

123

2765

112

270...310

Ø 76

Ø 76

SW 50

SW 60

4 x Ø 8,5

110

110

Ø 60

Ø 67,8

150

20

Ø 60,3

25

25

Threaded connection

G ¾ (¾ BSP)

or ¾ NPT

Threaded connection

G 1 ½ (1 ½BSP)

or 1 ½ NPT

Flange DN 40…200

or equivalent

reference point of

measurement

option:

distance sleeve

option:

remote electronic

68

rope:

Ø 4 mm/or0.16”

Ø 6 mm/0.24”

or

Ø 8 mm/0.32”, coated PA

rope probe rod probe coax probe

Ø 6/0.24” (on ¾” thread)

Ø 16/0.63” (on 1½” thread

or flange)

Ø 21,3/0.84” (on ¾” thread)

Ø 42,4/1.67” (on 1½” thread

or flange)

Ø 22/0.87” (on 4 mm/ rope)0.16”

Ø 30/1.18” (on 6 mm/0.24” rope)

internal thread:

M14 on 4 mm/0.16” rope

M20 on 6 mm/0.24” rope

probe length LN

Probe rods in Alloy C22

consist of 1 piece

(can not be dismantled)

F12 / T12 / F23 housing

Page 18

Installation Levelflex M FMP40 and FMP45

18

Levelflex M FMP45 - process connection, type of probe

Housing dimensions see Page 16.

L00-FMP45xxx-06-00-00-en-001

88

88

123

2765

112

Ø 76

4 x Ø 8,5

150

HT 400 °C

XT 280 °C

Threaded connection

G 1 ½ (1 ½BSP)

or 1 ½ NPT

Threaded connection

G 1 ½ (1 ½BSP)

or 1 ½ NPT

Flange DN 50…100

or equivalent

Flange DN 50…100

or equivalent

reference point of

measurement

option:

remote electronic

rope:

Ø 4 mm/0.16”

rope probe rod probe coax probe

Ø 16/0.63”

Ø 42,4/1.67”

Ø 22/0.87”

probe length LN

F12 / T12 / F23 housing

SW 60 SW 60

262

159

159

338

25

25

Ø 90

Ø 90

Ø 90

Ø 90

Ø 60

Ø 60

Ø 60

Ø 60

132

235

311

132

Page 19

Levelflex M FMP40 and FMP45 Installation

19

3.4 Installation

3.4.1 General instructions for interface measurement

For the measurement of the interface level, the coaxial probe, the rod or rope probe may be used.

However, rope and rod probes may be used in bypass resp. stilling well only. Rope probes should be

used in exceptions only, e.g. if the measurement range extends for more than 4 meters or the

available space above the tank is too limited to introduce rod probes.

The following constraints for the Levelflex Interface Version have to be considered:

• The overall level has to be constant.

• The dielectric constant of the upper prodcut level has to be smaller than 10.

• The difference between the dielectric values of the two product levels should be 10 or bigger.

• The minimum product level of each product is 100mm.

!

Note!

If one of these conditions is not met, the interface level measurement is not possible!

3.4.2 Installation

• Coaxial probes may be mounted directly into the tank.

• Rope and Rod probes have to be mounted into a bypass or stilling well

• For the use of any probes into stilling wells it has to be made sure that the stilling well or bypass

is perforated in a way which allows the product level in the inner part of the stilling well to adjust

to the outer level.

• The diameter of the stilling well / bypass should not exceed DN150 / 6” and not be smaller than

DN 50 / 2”

For a bypass, the dimensions of the following diagram should be kept:

L00-FMP4xxxx-17-00-00-en-062

100 %

0%

recommendation min.

200 mm / 8

”

recommendation min.

200 mm / 8

”

50mm / 2” DN 150 mm / 6”<<

Page 20

Installation Levelflex M FMP40 and FMP45

20

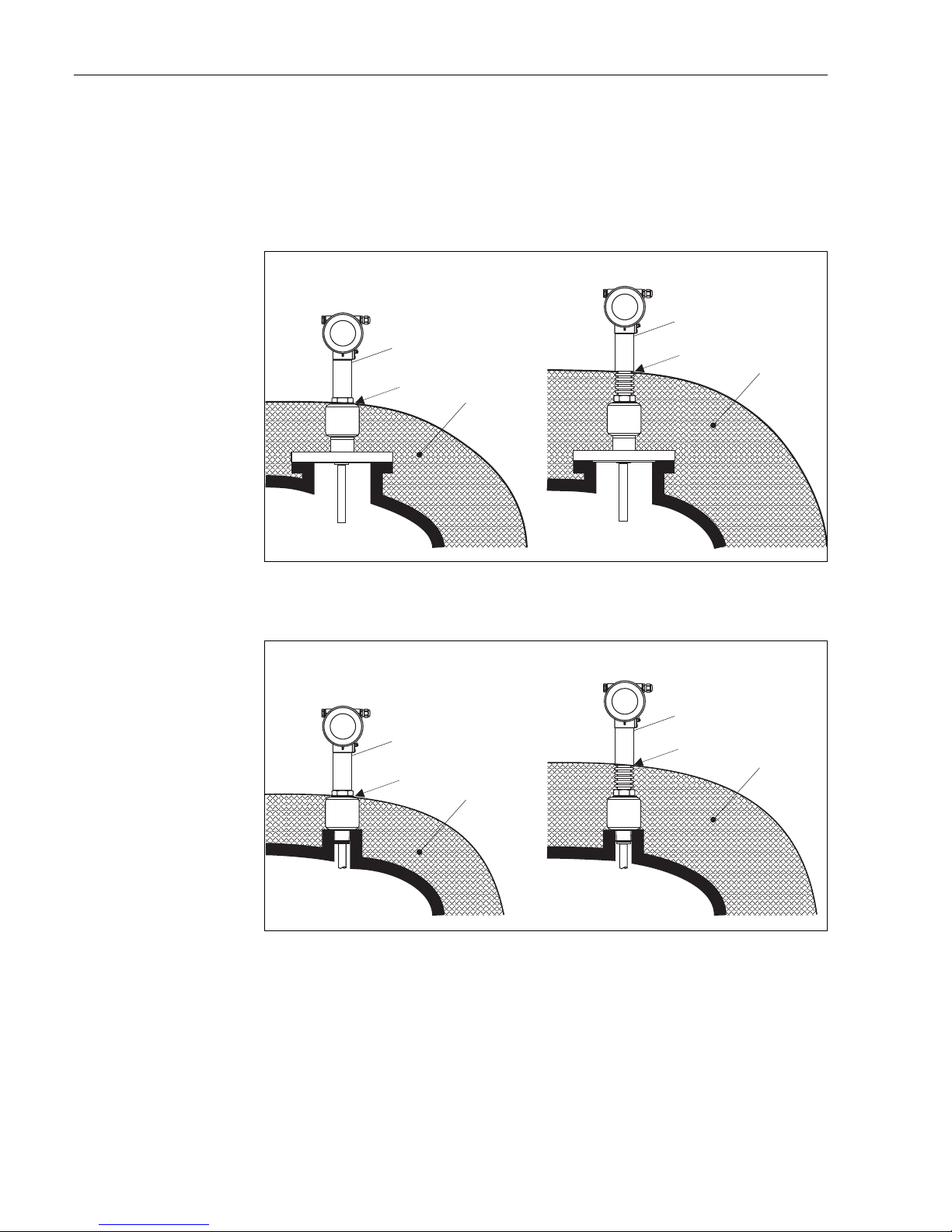

FMP45: Installing with heat insulation

• If process temperatures are high (≥ 200 °C), FMP45 must be included in normal tank insulation

to prevent the electronics heating up as a result of heat radiation or convection.

• The insulation may not exceed beyond the points labelled "MAX" in the drawing.

Process connection with flange DN50...DN100

L00-FMP45xxx-17-00-00-en-001

Process connection with adapter G 1½" and 1½" NPT

L00-FMP45xxx-17-00-00-en-002

MAX

MAX

HT 400 °C

XT 280 °C

max. 400° C (752° F)max. 280° C (536° F)

tank insulation

tank insulation

high temperature version

(type of probe B)

extended temperature version

(type of probe A)

MAX

MAX

HT 400 °C

XT 280 °C

max. 400° C (752° F)max. 280° C (536° F)

tank insulation

tank insulation

high temperature version

(type of probe B)

extended temperature version

(type of probe A)

Page 21

Levelflex M FMP40 and FMP45 Installation

21

3.4.3 Installation for difficult to access process connections

Installation with remote electronic

• Follow installation instructions on Page 19 ff.

• Mount the housing on the wall or pipe (in vertical or horizontal position as required) as shown in

the diagram.

L00-FMP4xxxx-17-00-00-en-015

!

Note!

The connection tube cannot be disassembled at these points (1).

With remote electronics, for FMP40 temperatures up to 150 °C (302 °F) and for FMP45

temperatures up to 280 °C (536 °F) or 400 °C (752 °F) are permitted at the process connection

depending on the instrument version.

The ambient temperature for the connecting line (2) between the probe and electronics can be max.

105 °C.

The version with remote electronics consists of the probe, a connecting tube and the housing. If

they are ordered as a set, they are assembled on delivery.

150

ENDRESS+HAUSER

Levelflex M

65 78

Ø 129

85

150

ENDRESS+HAUSER

Levelflex M

65 78

Ø 129

85

52

52

150

max. 80

min. 30

96

94

94

88

88

123

2765

112

190

≥75

Ø 76

1

1

4 x Ø 8,5

1

2

pipe

wall

Note min.

bend radius!

Page 22

Installation Levelflex M FMP40 and FMP45

22

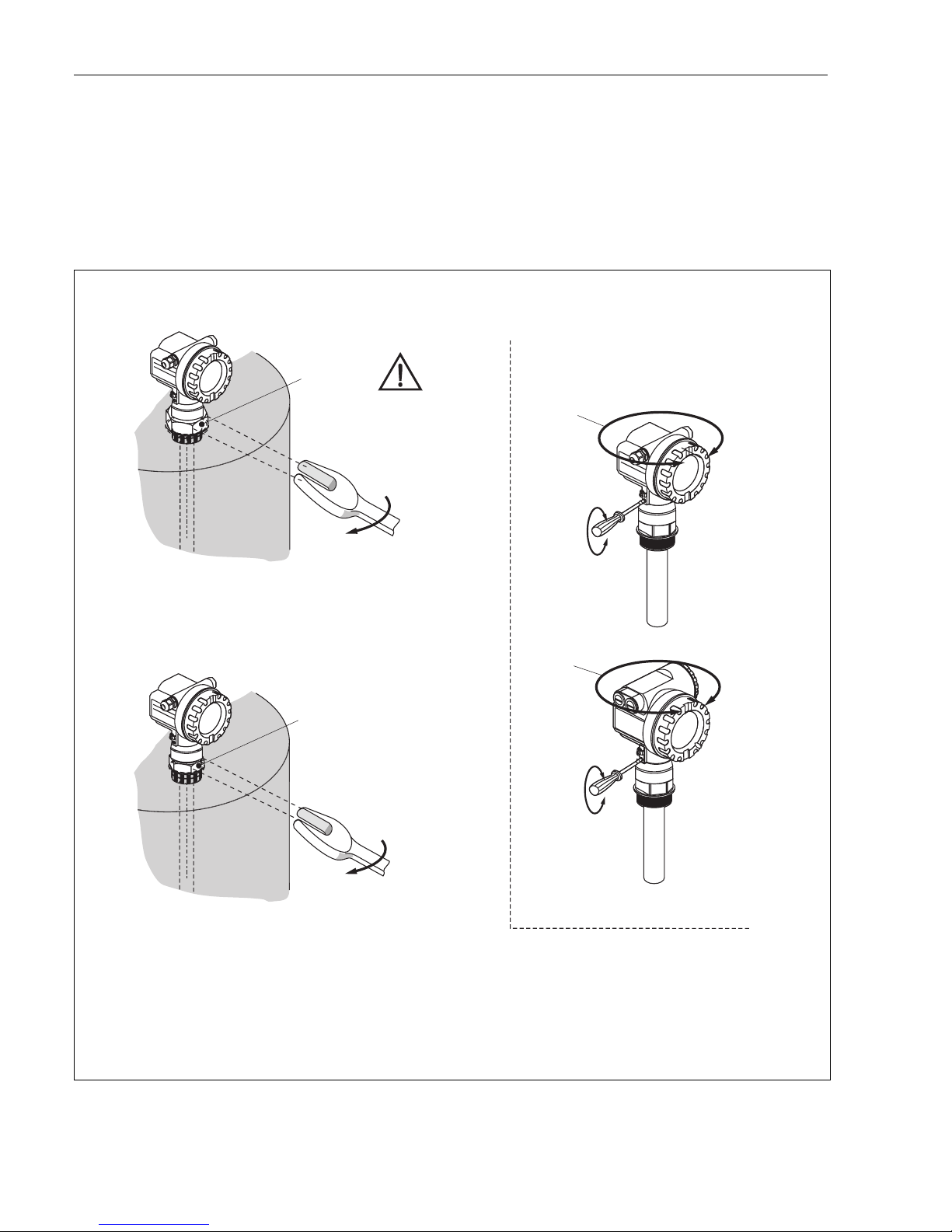

3.5 Turn housing

After mounting, the housing can be turned 350° in order to simplify access to the display and the

terminal compartment. Proceed as follows to turn the housing to the required position:

•Undo the fixing screws (1)

• Turn the housing (2) in the required direction

• Tighten up the fixing screws (1).

L00-FMP41Cxx-17-00-00-de-002

3.6 Post-installation check

After the measuring instrument has been installed, perform the following checks:

• Is the measuring instrument damaged (visual check)?

• Does the measuring instrument correspond to the measuring point specifications such as process

temperature/pressure, ambient temperature, measuring range, etc.?

• Are the measuring point number and labeling correct (visual check)?

• Is the measuring instrument adequately protected against rain and direct sunlight (see

Page 56 ff.)?

90°90°

90°90°

90°90°

1

1

2

2

F12/F23 housing T12 housing

allen key

4 mm/0.1”

Page 23

Levelflex M FMP40 and FMP45 Wiring

23

4 Wiring

4.1 Quick wiring guide

Wiring in F12/F23 housing

L00-FMP41Cxx-04-00-00-en-001

Made in Germany

D-79689 Maulburg

Dat./Insp.:

Order Code:

IP68 / NEMA 6P

Ser.-No.:

4-wire

ENDRESS+HAUSER

t>85°C

TA > 70°C:

D01301-A

if modification

see sep. label

X=

Patents

LEVELFLEX-M

90 … 253 V AC 1VA

10,5 … 32VDC 1W

16 … 3 VDC 0,8W

Profibus PA

Foundation Fieldbus

LN= PN=

4 … 20 mA HART 2-wire

1234

#

4

5

6

2

3

7

7

1

7

8

-

-

"

56

I+ I-

1

2

L-

L+

12

L1/L+ N/L-

3

4

I+

I-

EN

DRESS+H

A

USER

ENDRESS+HAUSER

Sealed terminal

compartment

Before connection please note the following:

The power supply must be identical to the data on the

nameplate (1).

Switch off power supply before connecting up the device.

Connect Equipotential bonding to transmitter

ground terminal (7) before connecting up the device.

Tighten the locking screw (8):

It forms the connection between the probe and the housing

ground potential.

●

●

●

●

When you use the measuring system in hazardous areas, make sure you comply with

national standards and the specifications in the safety instructions (XA’s).

Make sure you use the specific cable gland.

On devices supplied with a certificate, the explosion protection

is designed as follows:

Housing F12/F23 - EEx ia:

Power supply must be intrinsically safe (not for dust-Ex).

The electronics and the current output are galvanically

separated from the probe circuit.

●

●

Connect up the Levelflex M as follows:

Unscrew housing cover (2).

Remove any display (3) if fitted.

Remove cover plate from terminal compartment (4).

Pull out terminal module slightly using "pulling loop" (only 2-wire).

Only ground screening of the line (7) on sensor side.

Make connection (see pin assignment).

Re-insert terminal module.

Tighten cable gland (6). Max. torque 10...12 Nm!

Tighten screws on cover plate (4).

Insert display if fitted.

Screw on housing cover (2).

(on dust-Ex torque 40 Nm).

Switch on power supply.

●

●

●

●

●

●

●

●

●

●

●

●

≈

Insert cable (5) through gland (6).

A standard installation cable is sufficient if only the analogue signal is

used. Use a screened cable when working with a superimposed

communications signal (HART).

Unplug display connector!

Caution!

Note!

plant

ground

test sockets

(output current)

power power

display unit,

recorder, PCS

2-wire-version 4-wire-version

If 4-wire for dust-Ex-applications is used,

the current output is .intrinsically save

AC / DCDC

plant

ground

0...20mA

Page 24

Wiring Levelflex M FMP40 and FMP45

24

Wiring in T12 housing

L00-FMP41Cxx-04-00-00-en-002

Made in Germany

D-79689 Maulburg

Dat./Insp.:

Order Code:

IP68 / NEMA 6P

Ser.-No.:

4-wire

ENDRESS+HAUSER

t>85°C

TA > 70°C:

D01301-A

if modification

see sep. label

X=

Patents

LEVELFLEX-M

90 … 253 V AC 1VA

10,5 … 32VDC 1W

16 … 3 V DC 0,8W

Profibus PA

Foundation Fieldbus

LN= PN=

4 … 20 mA HART 2-wire

2

-

-

1234

4

3

1

5

1

2

L-

L+

7

8

3

4

I+

I-

Caution!

"

Before connection please note the following:

The power supply must be identical to the data on the

nameplate (1).

Switch off power supply before connecting up the device.

Connect Equipotential bonding to transmitter

ground terminal (7) before connecting up the device.

Tighten the locking screw (8):

It forms the connection between the probe and the housing

ground potential.

●

●

●

●

When you use the measuring system in hazardous areas, make sure you comply with

national standards and the specifications in the safety instructions (XA’s).

Make sure you use the specific cable gland.

Connect up the Levelflex M as follows:

Before unscrew housing cover (2) at seperate connection room

turn off the power supply!

Insert cable (3) through gland (4).

Only ground screening of the line (5) on sensor side.

Make connection (see pin assignment).

Tighten cable gland (4). Max. torque 10...12 Nm!

Screw on housing cover (2)

(on dust-Ex torque 40 Nm).

Switch on power supply.

●

●

●

●

●

≈

A standard installation cable is sufficient if only the analogue signal is

used. Use a screened cable when working with a superimposed

communications signal (HART).

plant

ground

test sockets

(output current)

power

2-wire-version

Page 25

Levelflex M FMP40 and FMP45 Wiring

25

4.2 Connecting the measuring unit

Terminal compartment

Three housings are available:

• Aluminium housing F12 with additionally sealed terminal compartment for:

–standard,

–EEx ia.

• Aluminium housing T12 with separate terminal compartment for:

–standard,

–EEx e,

–EEx d

– EEX ia (with overvoltage protection).

• Stainless steel 316L housing F23 for:

–standard,

–EEx ia.

After mounting, the housing can be turned 350° in order to simplify access to the display and the

terminal compartment.

L00-FMR2xxxx-04-00-00-en-019

The instrument data are given on the nameplate together with important information regarding the

analog output and voltage supply. Housing orientation regarding the wiring see "Turn housing" on

Page 22.

Load HART

Minimum load for Hart communication: 250 Ω

Cable entry

Cable gland: M20x1.5

Cable entry: G ½ or ½ NPT

Supply voltage

HART, 2-wire

The following values are the voltages across the terminals directly at the instrument:

1 1

2 2

3 3

4 4

1

2

3

4

sealed terminal

compartment

F12 housing F23 housing

T12 housing

Page 26

Wiring Levelflex M FMP40 and FMP45

26

HART residual ripple, 2-wire: Uss ≤ 200 mV

HART, 4-wire active

Power consumption

min. 60 mW, max. 900 mW

Current consumption

Overvoltage protection

If there is the risk of differences in potential forming when installing the Levelflex M to measure the

level of flammable liquids, the device can be fitted with a T12 housing and integrated overvoltage

protection (600 V gas tube surge arrester), see Ordering structure on Page 6. This overvoltage

protection meets the requirements of DIN EN 60079-14, test standard 60060-1, and also protects

the device (10 kA, impulse 8/20 µs).

Communication

Current

consumption

Terminal voltage

minimal maximal

HART

standard

4mA 16V 36V

20 mA 7.5 V 36 V

EEx ia

4mA 16V 30V

20 mA 7.5 V 30 V

EEx em

EEx d

4mA 16V 30V

20 mA 11 V 30 V

Fixed current, adjustable

e.g. for solar power

operation (measured

value transferred at

HART)

standard 11 mA 10 V 36 V

EEx ia 11 mA 10 V 30 V

Fixed current for HART

Multidrop mode

standard 4 mA

1)

1) Start up current 11 mA.

16 V 36 V

EEx ia 4 mA

1)

16 V 30 V

Version Voltage Max. load

DC 10.5...32 V 600 Ω

AC 85...250 V 600 Ω

Communication

Current

consumption

Current

consumption

Power consumption

HART, 2-wire 3.6…22 mA —

HART, 4-wire (90...250 V

AC

) 2.4...22 mA ~ 3...6 mA / ~ 3.5 VA

HART, 4-wire (10,5...32 V

DC

) 2.4...22 mA ~ 100 mA / ~ 1 W

PROFIBUS-PA max. 11 mA —

Foundation Fieldbus (FF) max. 15 mA —

Page 27

Levelflex M FMP40 and FMP45 Wiring

27

4.2.1 HART connection with E+H RMA 422 / RN 221 N

L00-FMP4xxxx-04-00-00-yy-001

4.2.2 HART connection with other supplies

L00-FMP4xxxx-04-00-00-en-002

"

Caution!

If the HART communication resistor is not built into the supply unit and the HART interface is to

be used, it is necessary to insert a communication resistor of 250 Ω into the 2-wire line.

4...20 mA

1

234

ENDRESS + HAUSER

RMA 422

Commubox

FXA191

RMA422

RN221N

- FieldCare

1

234

- FieldCare

Commubox

FXA191

³W250

PLC

DC power supply

unit

or

4...20 mA

Page 28

Wiring Levelflex M FMP40 and FMP45

28

4.3 Recommended connection

4.3.1 Equipotential bonding

Connect the Equipotential bonding to the external ground terminal (1) of the transmitter.

L00-FMP41Cxx-17-00-00-en-003

4.3.2 Wiring screened cable

"

Caution!

In Ex applications, the instrument must only be grounded on the sensor side. Further safety

instructions are given in the separate documentation for applications in explosion hazardous areas.

4.4 Degree of protection

• housing: IP 68, NEMA 6P (open housing: IP20, NEMA 1)

• probe: IP 68 (NEMA 6P)

4.5 Post-connection check

After wiring the measuring instrument, perform the following checks:

• Is the terminal allocation correct (see Page 23 ff. and Page 24)?

• Is the cable gland tight?

• Is the housing cover screwed tight?

• If auxiliary power is available:

Is the instrument ready for operation and is the liquid crystal display visible?

1

1

F12/F23 housing T12 housing

Page 29

Levelflex M FMP40 and FMP45 Operation

29

5Operation

5.1 Display and operating elements

L00-FMxxxxxx-07-00-00-en-001

Fig. 3: Layout of the display and operating elements

"

Caution!

For the Interface version of Levelflex FMP4x, the display unit VU 331 is inteded to show the

measurement values only; The set-up should be done using the special FieldCare DTM which

comes with the device.

5.1.1 Display symbols

The following table describes the symbols that appear on the liquid crystal display:

5.1.2 Key assignment

The operating elements are located inside the housing and are accessible for operation by opening

the lid of the housing.

ENDRESS + HAUSER

E

+

–

E

N

D

R

E

S

S

+

H

A

U

S

E

R

M

I

C

R

O

P

I

L

O

T

I

I

EN

DR

E

SS+HA

USE

R

MICROPILOT II

I

P

6

5

I

P 65

O

r

d

e

r

C

o

d

e

:

S

e

r

.

N

o

.

:

O

r

de

r

Code:

Ser.-No.:

M

e

s

s

b

e

r

e

i

c

h

M

e

a

s

u

r

i

n

g

r

a

n

g

e

Messber

e

ich

Measuring ra

n

ge

U

1

6

.

.

.

3

6

V

D

C

4

.

.

.

2

0

m

A

U

1

6

...36

V DC

4...20

mA

m

a

x

.

2

0

m

max.20 m

Made in Germany Maulburg

Made in Germany Maulburg

T

>

7

0

°

C

:

A

t

>

8

5

°

C

T

>7

0°C :

A

t

>85°C

LCD

(liquid crystal display)

Symbols

3 keys

Sybmols Meaning

ALARM_SYMBOL

This alarm symbol appears when the instrument is in an alarm state. If the symbol

flashes, this indicates a warning.

LOCK_SYMBOL

This lock symbol appears when the instrument is locked, i.e. if no input is possible.

COM_SYMBOL

This communication symbol appears when a data transmission via e.g. HART,

PFOFIBUS-PA or Foundation Fieldbus is in progress.

Page 30

Operation Levelflex M FMP40 and FMP45

30

Function of the keys

"

Caution!

For the Interface version of Levelflex FMP4x, the display unit VU 331 is inteded to show the

measurement values only; The set-up should be done using the special FieldCare DTM which

comes with the device.

Key(s) Meaning

O

or

V

Navigate upwards in the selection list

Edit numeric value within a function

S

or

W

Navigate downwards in the selection list

Edit numeric value within a function

X

or

Z

Navigate to the left within a function group

F

or

M

Navigate to the right within a function group, confirmation.

O

and

F

or

S

and

F

Contrast settings of the LCD

O

and S and

F

Hardware lock / unlock

After a hardware lock, an operation of the instrument via display or

communication is not possible!

The hardware can only be unlocked via the display. An unlock parameter must

be entered to do so.

Page 31

Levelflex M FMP40 and FMP45 Operation

31

5.2 Display and acknowledging error messages

Type of error

Errors that occur during commissioning or measuring are displayed immediately on the local

display. If two or more system or process errors occur, the error with the highest priority is the one

shown on the display.

The measuring system distinguishes between two types of error:

• A (Alarm):

Instrument goes into a defined state (e.g. MAX 22 mA)

Indicated by a constant symbol.

(For a description of the codes see Page 59)

• W (Warning):

Instrument continue measuring, error message is displayed.

Indicated by a flashing symbol.

(For a description of the codes see Page 59)

• E (Alarm / Warning):

Configurable (e.g. loss of echo, level within the safety distance)

Indicated by a constant/flashing symbol.

(For a description of the codes see Page 59)

Error messages

Error messages appear as four lines of plain text on the display. In addition, a unique error code is

also output. A description of the error codes is given on Page 59.

•The "diagnostics" (0A) function group can display current errors as well as the last errors that

occurred.

• If several current errors occur, use

O

or S to page through the error messages.

• The last occurring error can be deleted in the "diagnostics" (0A) function group

with the function "clear last error" (0A2).

⇒

ENDRESS + HAUSER

E

+

–

Page 32

Commissioning Levelflex M FMP40 and FMP45

32

6 Commissioning

6.1 Function check

Make sure that all final checks have been completed before you start up your measuring point:

• Checklist “Post-installation check” (see Page 22 ff.).

• Checklist “Post-connection check” (see Page 22 ff.).

6.2 Switching on the measuring device

When the instrument is switched on for the first time, the following messages appear on the display:

"

Caution!

For the Interface version of Levelflex FMP4x, the display unit VU 331 is inteded to show the

measurement values only; The set-up should be done using the special FieldCare DTM which

comes with the device.

⇒

⇓

After 5 s, the following message appears

⇓

After 5 s, the following message appears (e.g. on HART

devices)

⇓

After 5 s or after you have pressed F the following

message appears

Select the language

(this message appears the first time the instrument is

switched on)

⇓

Select the basic unit

(this message appears the first time the instrument is

switched on)

⇓

The current measured value is displayed

ENDRESS + HAUSER

E

+

–

Page 33

Levelflex M FMP40 and FMP45 Commissioning

33

6.3 Basic Setup

The Basic Setup of the device has to be performed with a special FieldCare DTM which is delivered

with the device. The setup is not inteded to be made via the display VU 331 or via any other digital

communication!

In order to perform the basic calibration via FieldCare, please proceed as follows:

• connect the FXA191 (HART Commubox) with the device

• start FieldCare and define a new project.

• Add a HART Comm DTM to the project.

• Add the FMP4x Interface HART DTM.

• Extablish an on-line communication to the device by pressing .

• Start the parametrization by opening th "on-line parametrization".

L00-FMP4xxxx-19-00-00-de-002

On the screen, the following picture will appear:

L00-FMP4xxxx-19-00-00-de-004

Please use the flash buttoms to go through the basic calibration step by step.

Page 34

Commissioning Levelflex M FMP40 and FMP45

34

Basic Setup step 1/4:

• The TAG of the measurement point can be edited.

• Additional information are displayed:

protocol and SW number

device name

order code

L00-FMP4xxxx-19-00-00-de-006

!

Note!

Each changed parameter has to be entered / confirmed by the Return key.

Basic Setup step 2/4:

• Enter the application parameters:

– Dielectric const.

– Dist. total level

l00-L00-FMP4xxxx-19-00-00-de-007

Page 35

Levelflex M FMP40 and FMP45 Commissioning

35

Function "Dielectric. const."

By this function the medium property of the upper product layer is defined. The dielectric value can

be defined also by clicking the tank smbol and by this opening the table book of dielectric values.

By entering the dielectic value, the threshold (noise level elimination) of the device is configured. If

it is necessary to adjust this threshold manually, this can be done in step 4.

l00-L00-FMP4xxxx-19-00-00-de-008

!

Note!

The table value of the dielectic constant may be different from the real product dielectric value.

Function "Dist. total level"

By this function, the distance to the overall level is defined. It is used to compensate the gas layer

above the product.

!

Note!

After entering the function “Dist. total level”, the parameter “upper blocking dist.” is adjusted to

the same value!

Page 36

Commissioning Levelflex M FMP40 and FMP45

36

Basic Setup step 3/4:

• Enter the length calibration:

– Function "probe length"

l00-fmp4xxxx-20-00-00-de-004

Function "probe length"

By this function it is defined if the probe length has been changed after factory calibration. Any

adjustment is necessary only if the probe length has been changed!

Selection:

• Not changed

• Changed

L00-FMP4xxxx-19-00-00-de-009

In case the function "probe length " "changed" has been selected, in the following steps the new,

actual probe length can be entered.

Page 37

Levelflex M FMP40 and FMP45 Commissioning

37

Function "probe length"

By this function the probe length is entered.

Basic Setup step 4/4:

• Entering the application parameters:

– Empty calibr.

– Full calibr.

L00-FMP4xxxx-19-00-00-de-012

Function "Empty calibr."

By this function the distance from the flange (reference point of the measurement) to the minimum

level (zero point) is entered.

L00-FMP4xxxx-19-00-00-de-013

Page 38

Commissioning Levelflex M FMP40 and FMP45

38

Function "Full calibr."

By this function the distance from the minimum level to the maximum overall level (Span) is

entered.

The 100% Point should not be higher than the overall (total) level!

L00-FMP4xxxx-19-00-00-de-013

"

Achtung!

The usable measurement range is situated between the overall level and the probe length. Especially

for products / media of the upper layer with a dielectric value bigger than 4, the measurement range

can be diminished by adjusting the upper blocking distance.

More information about this topic please refer to function “upper blocking dist.” see page 47.

Page 39

Levelflex M FMP40 and FMP45 7 Description of Instrument Functions

Endress+Hauser 39

7 Description of Instrument Functions

7.1 Function group "basic setup"

7.1.1 Function "measured value"

This function displays the current measured value in the selected unit. The number of places after

decimal point can be selected in the "no.of decimals" function.

7.1.2 Function "Dielectric const."

By this function the dielectric product property of the upper product phase is defined. The value of

the dielectric constant can be identified also by activating the table of dielectric values by clicking

on the tank drawing.

!

Note!

The value of the dielectric constant can be identified also by activating the table of dielectric values

by clicking on the tank drawing. The listed dielectric values may vary from the real dielectric values

of the product.

7.1.3 Function "Dist. total level"

The total level is entered by this function. It is needed to compensate gaseous phase which might

be present.

!

Note!

After entereing the "Dist. total level" function, the "upper blocking dist." function is automatically set to the same value!

Page 40

7 Description of Instrument Functions Levelflex M FMP40 and FMP45

40 Endress+ Hauser

7.1.4 Function "empty calibr."

This function is used to enter the distance from the flange (reference point of the measurement) to

the minimum level (=zero).

7.1.5 Function "full calibr."

This function is used to enter the distance from the minimum level to the maximum level (=span).

The 100% point should not be defined at a higher level than the overall level

Page 41

Levelflex M FMP40 and FMP45 7 Description of Instrument Functions

Endress+Hauser 41

!

Note!

The usable measurement range extends between the overall level and the probe length.

For media of the upper product phase with a dielectric value > 4, the measurement range may have

to be restricted by increasing the upper blocking distance. The upper blocking distance is used to

eliminate the overall level echo.

Further Informations to the "blocking distance" see function "upper blocking dist." on page 47.

7.2 Function group "safety settings"

7.2.1 Function "output on alarm"

This function is used to select the reaction of output on an alarm.

Selection:

• MIN (<= 3.6mA)

• MAX (22mA)

• hold

• user specific

MIN (<= 3.6mA)

If the instrument is in alarm state, the output changes as follows:

• HART: MIN-Alarm 3.6 mA

MAX 110% 22mA

Page 42

7 Description of Instrument Functions Levelflex M FMP40 and FMP45

42 Endress+ Hauser

If the instrument is in alarm state, the output changes as follows:

• HART: MAX-Alarm 22 mA

hold

If the instrument is in alarm state, the last measured value is held.

user specific

If the instrument is in alarm state, the output is set to the value configured in "output on alarm"

(x mA).

"

Caution!

This selection is available for HART devices only!

7.2.2 Function "output on alarm", HART only

On alarm, the output current is in mA. This function is active when you selected "user specific"

in the "output on alarm" function.

"

Caution!

This function is available for HART devices only!

Page 43

Levelflex M FMP40 and FMP45 7 Description of Instrument Functions

Endress+Hauser 43

7.2.3 Function "outp. echo loss"

Use this function to set the output response on echo loss.

Selection:

•alarm

•hold

•ramp %/min

alarm

On echo loss, the instrument switches to alarm state after an adjustable "delay time". The output

response depends on the configuration set in "output on alarm".

hold

On echo loss, a warning is generated after a definable "delay time". Output is held.

Page 44

7 Description of Instrument Functions Levelflex M FMP40 and FMP45

44 Endress+ Hauser

ramp %/min

On echo loss, a warning is generated after a definable "delay time". The output is changed towards

0% or 100% depending on the slope defined in "ramp %span/min".

7.2.4 Function "ramp %span/min"

Ramp slope which defines the output value on echo loss. This value is used if "ramp %span/min"

is selected in "outp. echo loss". The slope is given in % of the measuring range per minute.

7.2.5 Function "delay time"

Use this function to enter the delay time (Default = 30 s) after which a warning is generated on echo

loss, or after which the instrument switches to alarm state.

7.2.6 Function "safety distance"

A configurable safety distance is placed before the "blocking dist.". This distance warns you that

any further level increase would make the measurement invalid.

Enter the size of the safety distance here. The default value is: 0.1 m.

Page 45

Levelflex M FMP40 and FMP45 7 Description of Instrument Functions

Endress+Hauser 45

7.2.7 Function "in safety dist."

This function defines the response when the level enters the safety distance .

Selection:

•alarm

• warning

alarm

Instrument enters the defined alarm state ("output on alarm"). The alarm message E651 -

"level in safety distance - risk of overspill" is displayed.

If the level drops out of the safety distance, the alarm warning disappears and the instrument starts

to measure again.

warning

Instrument displays a warning E651 -"level in safety distance - risk of overspill", but conti-

nues to measure. If the level leaves the safety distance, the warning disappears.

Page 46

7 Description of Instrument Functions Levelflex M FMP40 and FMP45

46 Endress+ Hauser

7.3 Function group "length adjustment"

7.3.1 Function "probe length"

Use this function to select whether the probe length was changed after factory calibration. Only then

is it necessary to enter or correct the probe length.

Selection:

• modified

•not modified

!

Note!

If "modified" was selected in the "probe length" function, the probe length is defined in the next

step.

7.3.2 Function "probe length"

Use this function to enter the probe length.

7.4 Function group "extended calibr."

7.4.1 Function "echo quality"

The echo quality is the benchmark for measurement reliability. It describes the amount of reflected

energy and depends primarily on the following conditions:

• Dielectric constant of the medium

•probe type

• Distance between sensor and product

Low values increase the probability that the echo is lost through a change in measurement conditions, e.g. emulsion or high dampening of the upper product phase.

7.4.2 Function "offset"

This function corrects the measured level by a constant value. The entered value is added to the

measured level.

Page 47

Levelflex M FMP40 and FMP45 7 Description of Instrument Functions

Endress+Hauser 47

7.4.3 Function "output damping"

Influences the time an output requires to react to a sudden level jump (63% of steady state). A high

value attenuates, for example, the influences of rapid changes on the measured variable.

User input:

0...255 s

The default value depends on the selected application parameter "process cond.".

7.4.4 Function "upper blocking dist."

In case of strong reflections of the upper (overall) level, the echo signal of the overall level has to be

eliminated by the blocking distance. It is advised to enter the “distance overall level” + 100mm.

!

Note!

The available measuring range is decreased by the value entered.

7.5 Function group "output"

7.5.1 Function "commun. address", HART only

Enter the communication address for the instrument with this function.

•Standard: 0

• Multidrop: 1-15

In multidrop mode, the standard output current is 4 mA. This can be changed in the "fixed cur.

value" function.

"

Caution!

This function is available for HART devices only!

7.5.2 Function "no. of preambels", HART only

Enter the number of preambles for the HART protocol with this function.

An increase in the value is advisable for "bad" lines with communications problems.

"

Caution!

This user input is available for HART devices only!

Page 48

7 Description of Instrument Functions Levelflex M FMP40 and FMP45

48 Endress+ Hauser

7.5.3 Function "low output limit", HART only

The output of negative level values can be suppressed with this function.

Selection:

• off minimum output -10% (3.8 mA for HART)

• on minimum output 0% (4 mA for HART)

"

Caution!

This user input is available for HART devices only!

7.5.4 Function "curr. output mode", HART only

Use this function to specify the current output mode for HART devices.

Selection:

• standard

• curr. turn down

• fixed current

standard

This selection displays the complete measuring range (0...100%) across the full current interval

(4...20 mA).

curr. turn down

This selection only displays a part of the measuring range across the full current interval (4...20 mA).

This range is specified using the "4mA value" and "20mA Value" functions.

fixed current

Selecting this outputs a fixed current. The measured value is only transmitted using the HART signal. The current output value is set using the "fixed cur. value" function.

"

Caution!

This selection is available for HART devices only!

Page 49

Levelflex M FMP40 and FMP45 7 Description of Instrument Functions

Endress+Hauser 49

7.5.5 Function "fixed cur. value", HART only

Set the fixed current value with this function. This data is necessary if you have selected the "fixed

current" option in the "curr. output mode" function.

User input:

3,8...20,5 mA

"

Caution!

This user input is available for HART devices only!

7.5.6 Function "simulation"

If necessary, linearisation, the output signal and the current output can be tested with the simulation

function. You have the following simulation options:

Selection:

• sim. off

• sim. volume

• sim. current (HART only)

sim. off

Simulation is switched off.

Page 50

7 Description of Instrument Functions Levelflex M FMP40 and FMP45

50 Endress+ Hauser

sim. level

Enter the level value in "simulation value".

The functions

•measuredvalue

• measured level

• output current" - only with HART instruments!

follow the entered values.

sim. volume

Enter the volume value in "simulation value".

The functions

•measuredvalue

• output current" - only with HART instruments!

follow the entered values.

sim. current (HART only)

Enter the current value in "simulation value".

The function

• output current" - only with HART instruments!

follows the entered values.

7.5.7 Function "simulation value"

7.5.8 Function "output current", HART only

Displays the output current in mA.

"

Caution!

This function is available for HART devices only!

7.5.9 Function "4mA value", HART only

In this function, enter the level (or volume, weight) at which the output current should be 4 mA.

This entry is only required if you selected the

"

current turn down" option in the "curr. output

mode

"

function.

7.5.10 Function "20mA value", HART only

In this function, enter the level (or volume, weight) at which the output current should be 20 mA.

This entry is only required if you have selected the

"

current turn down" option in the "curr. output mode" function.

7.6 Function group "display"

7.6.1 Function "language"

Selects the display language.

Selection:

•English

•Deutsch

• Français

•Español

• Italiano

• Nederlands

• Katakana (japanese)

Page 51

Levelflex M FMP40 and FMP45 7 Description of Instrument Functions

Endress+Hauser 51

Dependence

All texts are changed.

"

Caution!

This function is not visualised in Commuwin II!

7.6.2 Function "back to home"

If no entry is made using the display during the specified time period, the display returns to the

measured value display.

9999 s means that there is no return.

User input:

3...9999 s

7.6.3 Function "format display"

Selects the display format.

Selection:

•decimal

•ft-in-1/16"

decimal

The measured value is given in decimal form in the display (e.g. 10.70%).

ft-in-1/16"

The measured value is given in the display in this format (e.g 5'05-14/16").

This option is only possible for "distance unit"-"ft" and "in"!

7.6.4 Function "no.of decimals"

Selection:

•x

•x.x

•x.xx

•x.xxx

7.6.5 Function "sep. character"

Selection:

•.

•,

.

The decimal place is separated by a point.

,

The decimal place is separated by a comma.

7.6.6 Function "display test"

All display pixels are switched on. If the whole LCD is dark, it is working correctly.

Page 52

7 Description of Instrument Functions Levelflex M FMP40 and FMP45

52 Endress+ Hauser

7.7 Function group "diagnostics"

In the "diagnostics" function group, you can display and confirm error messages.

Type of error

Errors that occur during commissioning or measuring are displayed immediately on the local display. If two or more system or process errors occur, the error with the highest priority is the one

shown on the display.

The measuring system distinguishes between two types of error:

• A (Alarm):

Instrument goes into a defined state (e.g. MAX)

Indicated by a constant symbol.

(For a description of the codes see system error messages)

• W (Warning):

Instrument continue measuring, error message is displayed.

Indicated by a flashing symbol.

(For a description of the codes, see system error messages)

• E (Alarm / Warning):

Configurable (e.g. loss of echo, level within the safety distance)

Indicated by a constant/flashing symbol.

(For a description of the codes, see system error messages)

Error messages

Error messages appear as four lines of plain text on the display. In addition, a unique error code is

also output. A description of the error codes is given by system error messages.

•The "diagnostics" function group can display current errors as well as the last errors that occur-

red.

• If several current errors occur, use

O

or S to page through the error messages.

The last occurring error can be deleted in the "diagnostics" function group with the function "clear

last error".

7.7.1 Function "present error"

The present error is shown using this function.

7.7.2 Function "previous error"

The last error presented is shown with this function.

7.7.3 Function "clear last error"

Selection:

•keep

•erase

7.7.4 Function "reset"

"

Caution!

Generally, no reset is necessary.

Page 53

Levelflex M FMP40 and FMP45 7 Description of Instrument Functions

Endress+Hauser 53

7.7.5 Function "unlock parameter"

Set-up can be locked and unlocked with this function. Levelflex M for interface measurements is

delivered in locked status (access code = 99). The access code has to be entered before the device

commissioning. It is advised to lock the device again after installation and commissioning.

7.7.6 Locking of the configuration mode

The Levelflex can be protected in two ways against unauthorised changing of instrument data,

numerical values or factory settings:

"unlock parameter":

A value

<>

100 for HART (e.g. 99) must be entered in "unlock parameter" in the "diagnostics"

function group. The lock is shown on the display by the symbol and can be released again either

via the display or by communication.

7.7.7 Unlocking of configuration mode

If an attempt is made to change parameters when the instrument is locked, the user is automatically

requested to unlock the instrument:

"unlock parameter":

By entering the unlock parameter (on the display or via communication)

100 = for HART devices

the Levelflex is released for operation.

"

Caution!

Changing certain parameters such as all sensor characteristics, for example, influences numerous

functions of the entire measuring system, particularly measuring accuracy. There is no need to

change these parameters under normal circumstances and consequently, they are protected by a

special code known only to the E+H service organization. Please contact Endress+Hauser if you

have any questions.

7.7.8 Function "measured dist."

Display of measured distance in the selected "distance unit".

7.7.9 Function "measured level"

Display of measured level in the selected "distance unit".

7.7.10 Function "application par."

If, for example, the "output damping" is changed, the "application par."shows"modified".

Selection:

•not modified

• modified

Page 54

7 Description of Instrument Functions Levelflex M FMP40 and FMP45

54 Endress+ Hauser

7.8 Function group "system parameters"

7.8.1 Function "tag no."

You can define the tag number with this function.

User input:

• 16 alphanumeric characters for HART instruments (8 using the HART universal command)

7.8.2 Function "protocol+sw-no."

This function shows the protocol and the hardware and software version: Vxx.yy.zz.prot.

Display:

xx: hw-version

yy: sw-version

zz: sw-revision

prot: protocoll type (e.g. HART)

7.8.3 Function "serial no."

This function displays the instrument serial number.

7.8.4 Function "distance unit"

You can select the basic distance unit with this function.

Selection:

•m

•ft

•mm

•inch

Dependence

m, mm: "format display" can only be "decimal".

The units are changed for the following parameters:

• empty calibr.

• full calibr.

•safetydistance

• offset

•measureddist.

• measured level

7.8.5 Function "download mode"

!

Note!

The parameter up- / download are not possible with the Levelflex M interface version.

7.9 Function group "service"

Parameters in the function group service are for use of the E+H Service only!

7.9.1 System error messages

See Chapter 10.2.

Page 55

Levelflex M FMP40 and FMP45 Maintenance

55

8Maintenance

The Levelflex M measuring instrument requires no special maintenance.

Exterior cleaning

When cleaning the Levelflex M, always use cleaning agents that do not attack the surface of the

housing and the seals.

Repairs

The Endress+Hauser repair concept assumes that the measuring devices have a modular design and

that customers are able to undertake repairs themselves. Spare parts are contained in suitable kits.

They contain the related replacement instructions. All the spare parts kits which you can order from

Endress+Hauser for repairs to the Levelflex M are listed with their order numbers on Page 60 ff.*.

* Excepted from this is the exchange of an electronics according to MVTFN0341. Please contact

Endress+Hauser Service for further information on service and spare parts.

Repairs to Ex-approved devices

When carrying out repairs to Ex-approved devices, please note the following:

• Repairs to Ex-approved devices may only be carried out by trained personnel or by

Endress+Hauser Service.

• Comply with the prevailing standards, national Ex-area regulations, safety instructions (XA) and

certificates.

• Only use original spare parts from Endress+Hauser.

• When ordering a spare part, please note the device designation on the nameplate. Only replace

parts with identical parts.

• Carry out repairs according to the instructions. On completion of repairs, carry our the specified

routine test on the device.

• Only Endress+Hauser Service may convert a certified device into a different certified variant.

• Document all repair work and conversions.

Replacement electronics module

After a complete electronic module has been replaced, the parameters can be downloaded into the

instrument not again via the communication interface.

After a probe or electronic has been replaced, a new basic setup must be performed by the

Endress+Hauser service.

Page 56

Accessories Levelflex M FMP40 and FMP45

56

9Accessories

Various accessories, which can be ordered separately from Endress+Hauser, are available for the

Levelflex M.

Weather protection cover

A Weather protection cover made of stainless steel is available for outdoor mounting (order code:

543199-0001). The shipment includes the protective cover and tension clamp.

L00-FMR2xxxx-00-00-06-en-001

Commubox FXA 191 HART

For intrinsically safe communication via the RS 232C interface using FieldCare.

ENDRESS+HAUSER

MICROPILOT II

ENDRESS+HAUSER

MICROPILOT II

IP 65

O

r

d

e

r

C

o

d

e

:

S

e

r

.-

N

o

.:

Order Code:

Ser.-No.:

M

e

s

s

b

e

r

e

ic

h

M

e

a

s

u

r

in

g

r

a

n

g

e

Messbereich

Measuring range

U

1

6

.

..

3

6

V

D

C

4

..

.2

0

m

A

U 16...36V DC

4...20 mA

m

a

x

.

2

0

m

max.20 m

Made in Germany Maulburg

Made in Germany Maulburg

T>

7

0

°

C

:

A

t

>

8

5

°

C

T >70°C :

A

t >85°C

F12 / F23 / T12 housing

Page 57

Levelflex M FMP40 and FMP45 Accessories

57

Remote display FHX40

Dimensions

L00-FMxxxxxx-00-00-06-en-003

Technical data (cable and housing) and product structure:

ENDRESS+HAUSER

ENDRESS+HAUSER

IP 65

O

rder Code:

Ser.-No.:

Order Code:

Ser.-No.:

Messbereich