Page 1

BA01009F/00/EN/15.16

71344082

01.01.zz (Device firmware)

Products Solutions Services

Operating Instructions

Levelflex FMP56, FMP57

PROFIBUS PA

Guided wave radar

Page 2

Order code:

Ext. ord. cd.:

Ser. no.:

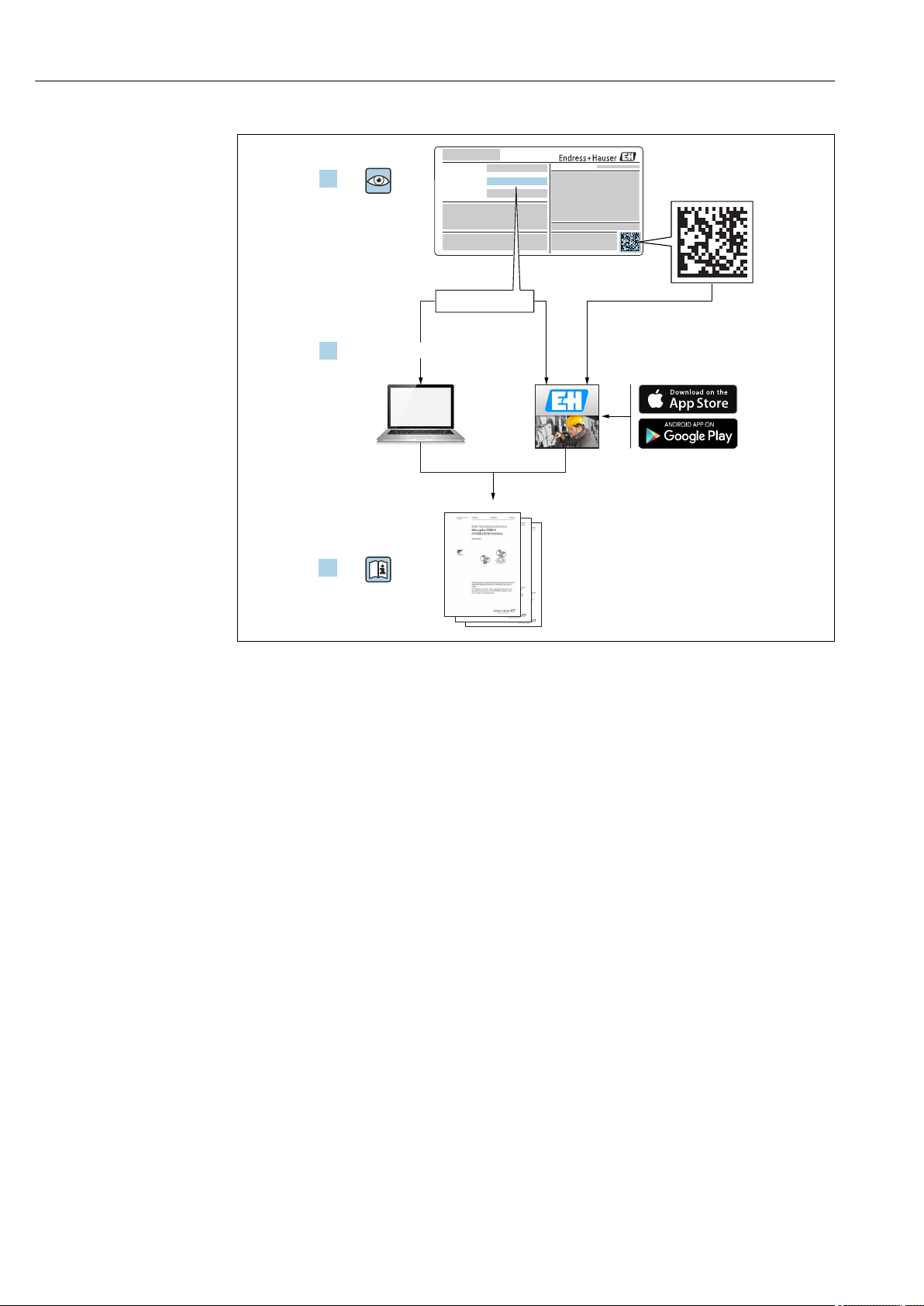

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

1.

3.

2.

A0023555

2 Endress+Hauser

Page 3

Table of contents

Table of contents

1 Important document information .... 5

1.1 Document function ..................... 5

1.2 Symbols .............................. 5

1.2.1 Safety symbols .................. 5

1.2.2 Electrical symbols ................ 5

1.2.3 Tool symbols .................... 6

1.2.4 Symbols for certain types of

information .................... 6

1.2.5 Symbols in graphics ............... 6

1.2.6 Symbols at the device ............. 7

1.3 Supplementary documentation ............. 8

1.3.1 Safety Instructions (XA) ............ 9

2 Basic safety instructions ........... 12

2.1 Requirements for the personnel ........... 12

2.2 Designated use ....................... 12

2.3 Workplace safety ...................... 13

2.4 Operational safety ..................... 13

2.5 Product safety ........................ 13

2.5.1 CE mark ...................... 13

2.5.2 EAC conformity ................. 13

3 Product description ................ 14

3.1 Product design ........................ 14

3.1.1 Levelflex FMP56/FMP57 ......... 14

3.1.2 Electronics housing .............. 15

3.2 Registered trademarks .................. 16

4 Incoming acceptance and product

identification ..................... 17

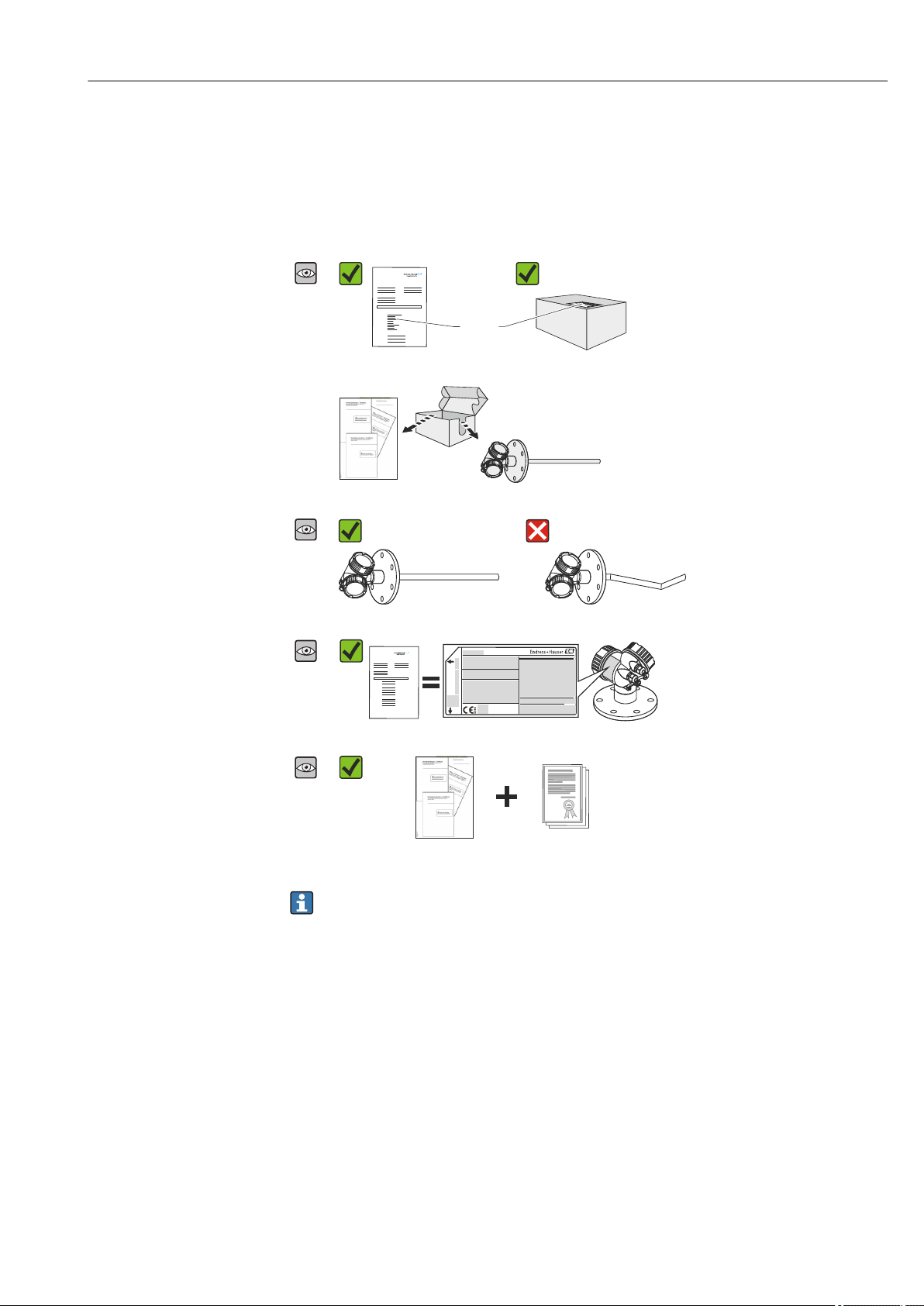

4.1 Incoming acceptance ................... 17

4.2 Product identification .................. 17

4.2.1 Nameplate .................... 18

5 Storage, Transport ................ 19

5.1 Storage conditions ..................... 19

5.2 Transport product to the measuring point .... 19

6 Mounting ......................... 20

6.1 Mounting requirements ................. 20

6.1.1 Suitable mounting position ........ 20

6.1.2 Applications with restricted

mounting space ................. 22

6.1.3 Notes on the mechanical load of the

probe ........................ 23

6.1.4 Notes on the process connection .... 27

6.1.5 Securing the probe .............. 31

6.1.6 Special mounting conditions ....... 33

6.2 Mounting the device ................... 37

6.2.1 Required mounting tools .......... 37

6.2.2 Shortening the probe ............. 37

6.2.3 Mounting the device ............. 39

6.2.4 Mounting the "Sensor remote"

version ....................... 40

6.2.5 Turning the transmitter housing .... 42

6.2.6 Turning the display module ........ 42

6.3 Post-installation check .................. 43

7 Electrical connection .............. 44

7.1 Connection conditions .................. 44

7.1.1 Terminal assignment ............. 44

7.1.2 Cable specification ............... 45

7.1.3 Device plug connectors ........... 46

7.1.4 Power supply .................. 47

7.1.5 Overvoltage protection ........... 47

7.2 Connecting the device .................. 48

7.2.1 Pluggable spring-force terminals .... 49

7.3 Post-connection check .................. 49

8 Operation options ................. 51

8.1 Overview ............................ 51

8.1.1 Local operation ................. 51

8.1.2 Operation with remote display and

operating module FHX50 .......... 52

8.1.3 Remote operation ............... 52

8.2 Structure and function of the operating

menu .............................. 54

8.2.1 Structure of the operating menu .... 54

8.2.2 User roles and related access

authorization .................. 56

8.2.3 Write protection via access code ..... 57

8.2.4 Disabling write protection via access

code ......................... 58

8.2.5 Deactivation of the write protection

via access code ................. 58

8.2.6 Write protection via write protection

switch ........................ 59

8.2.7 Enabling and disabling the keypad

lock ......................... 61

8.3 Display and operating module ............ 62

8.3.1 Display appearance .............. 62

8.3.2 Operating elements .............. 65

8.3.3 Entering numbers and text ........ 66

8.3.4 Opening the context menu ......... 68

8.3.5 Envelope curve on the display and

operating module ............... 69

9 Integration into a PROFIBUS

network .......................... 70

9.1 Overview of the device database files (GSD) .. 70

9.2 Set device address ..................... 70

9.2.1 Hardware adressing ............. 70

9.2.2 Software addressing ............. 70

Endress+Hauser 3

Page 4

Table of contents

10 Commissioning via wizard ......... 72

11 Commissioning via operating

menu ............................. 73

11.1 Installation and function check ............ 73

11.2 Setting the operating language ............ 73

11.3 Configuration of a level measurement ...... 74

11.4 Recording the reference curve ............ 76

11.5 Configuration of the on-site display ........ 77

11.5.1 Factory settings of the on-site

display for level measurements ..... 77

11.5.2 Adjustment of the on-site display ... 77

11.6 Configuration management .............. 78

11.7 Protection of the settings against

unauthorized changes .................. 79

12 Diagnostics and troubleshooting ... 80

12.1 General trouble shooting ................ 80

12.1.1 General errors .................. 80

12.1.2 Parametrization errors ........... 81

12.2 Diagnostic information on local display ...... 82

12.2.1 Diagnostic message .............. 82

12.2.2 Calling up remedial measures ...... 84

12.3 Diagnostic event in the operating tool ....... 85

12.4 Diagnostic list ........................ 85

12.5 List of diagnostic events ................. 86

12.6 Event logbook ........................ 87

12.6.1 Event history ................... 87

12.6.2 Filtering the event logbook ........ 88

12.6.3 Overview of information events ..... 88

12.7 Firmware history ...................... 90

15.2 Communication-specific accessories ....... 100

15.3 Service-specific accessories .............. 100

15.4 System components ................... 100

16 Operating menu .................. 101

16.1 Overview of the operating menu (display

module) ........................... 101

16.2 Overview of the operating menu (operating

tool) .............................. 108

16.3 "Setup" menu ........................ 114

16.3.1 "Mapping" wizard ............... 121

16.3.2 "Analog input 1 to 6" submenu ..... 122

16.3.3 "Advanced setup" submenu ........ 124

16.4 "Diagnostics" menu .................... 167

16.4.1 "Diagnostic list" submenu ......... 169

16.4.2 "Event logbook" submenu ......... 170

16.4.3 "Device information" submenu ..... 171

16.4.4 "Measured values" submenu ....... 173

16.4.5 "Analog input 1 to 6" submenu ..... 175

16.4.6 "Data logging" submenu .......... 177

16.4.7 "Simulation" submenu ........... 180

16.4.8 "Device check" submenu .......... 185

16.4.9 "Heartbeat" submenu ............ 187

Index ................................. 188

13 Maintenance ...................... 91

13.1 Exterior cleaning ...................... 91

14 Repairs ........................... 92

14.1 General information on repairs ............ 92

14.1.1 Repair concept ................. 92

14.1.2 Repairs to Ex-approved devices ..... 92

14.1.3 Replacement of an electronics

module ....................... 92

14.1.4 Replacement of a device .......... 92

14.2 Spare parts .......................... 93

14.3 Return .............................. 93

14.4 Disposal ............................ 93

15 Accessories ....................... 94

15.1 Device-specific accessories ............... 94

15.1.1 Weather protection cover ......... 94

15.1.2 Mounting bracket for the electronics

housing ...................... 95

15.1.3 Extension rod / centering HMP40 ... 96

15.1.4 Mounting kit, isolated ............ 97

15.1.5 Remote display FHX50 ........... 98

15.1.6 Overvoltage protection ........... 99

4 Endress+Hauser

Page 5

Levelflex FMP56, FMP57 PROFIBUS PA Important document information

DANGER

WARNING

CAUTION

NOTICE

1 Important document information

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

1.2 Symbols

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other

connections.

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a

potential equalization line or a star grounding system depending on national or

company codes of practice.

Endress+Hauser 5

Page 6

Important document information Levelflex FMP56, FMP57 PROFIBUS PA

A

1.

1.

1.2.3 Tool symbols

Symbol Meaning

Torx screwdriver

A0013442

Flat blade screwdriver

A0011220

Cross-head screwdriver

A0011219

Allen key

A0011221

Hexagon wrench

A0011222

1.2.4 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Notice or individual step to be observed

, 2., 3.… Series of steps

Result of a step

Help in the event of a problem

Visual inspection

1.2.5 Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

, 2., 3.… Series of steps

A, B, C, ... Views

A-A, B-B, C-C, ... Sections

6 Endress+Hauser

Page 7

Levelflex FMP56, FMP57 PROFIBUS PA Important document information

-

.

Symbol Meaning

Hazardous area

Indicates a hazardous area.

Safe area (non-hazardous area)

Indicates the non-hazardous area.

1.2.6 Symbols at the device

Symbol Meaning

Safety instructions

Observe the safety instructions contained in the associated Operating Instructions.

Temperature resistance of the connection cables

Specifies the minimum value of the temperature resistance of the connection cables.

Endress+Hauser 7

Page 8

Important document information Levelflex FMP56, FMP57 PROFIBUS PA

1.3 Supplementary documentation

Document Purpose and content of the document

Technical Information

TI01004F (FMP56, FMP57)

Brief Operating Instructions

KA01073F (FMP56/FMP57,

PROFIBUS PA)

Description of Device Parameters

GP01001F (FMP5x, PROFIBUS PA)

Special documentation

SD00326F

Special documentation

SD01872F

Planning aid for your device

The document contains all the technical data on the device and provides

an overview of the accessories and other products that can be ordered for

the device.

Guide that takes you quickly to the 1st measured value

The Brief Operating Instructions contain all the essential information

from incoming acceptance to initial commissioning.

Reference for your parameters

The document provides a detailed explanation of each individual

parameter in the operating menu. The description is aimed at those who

work with the device over the entire life cycle and perform specific

configurations.

Functional Safety Manual

The document is part of the Operating Instructions and serves as a

reference for application-specific parameters and notes.

Manual for Heartbeat Verification and Heartbeat Monitoring

The document contains descriptions of the additonal parameters and

technical data which are available with the Heartbeat Verification and

Heartbeat Monitoring application packages.

For an overview of the scope of the associated Technical Documentation, refer to the

following:

• The W@M Device Viewer : Enter the serial number from the nameplate

(www.endress.com/deviceviewer)

• The Endress+Hauser Operations App: Enter the serial number from the nameplate

or scan the 2-D matrix code (QR code) on the nameplate.

8 Endress+Hauser

Page 9

Levelflex FMP56, FMP57 PROFIBUS PA Important document information

1.3.1 Safety Instructions (XA)

Depending on the approval, the following Safety Instructions (XA) are supplied with the

device. They are an integral part of the Operating Instructions.

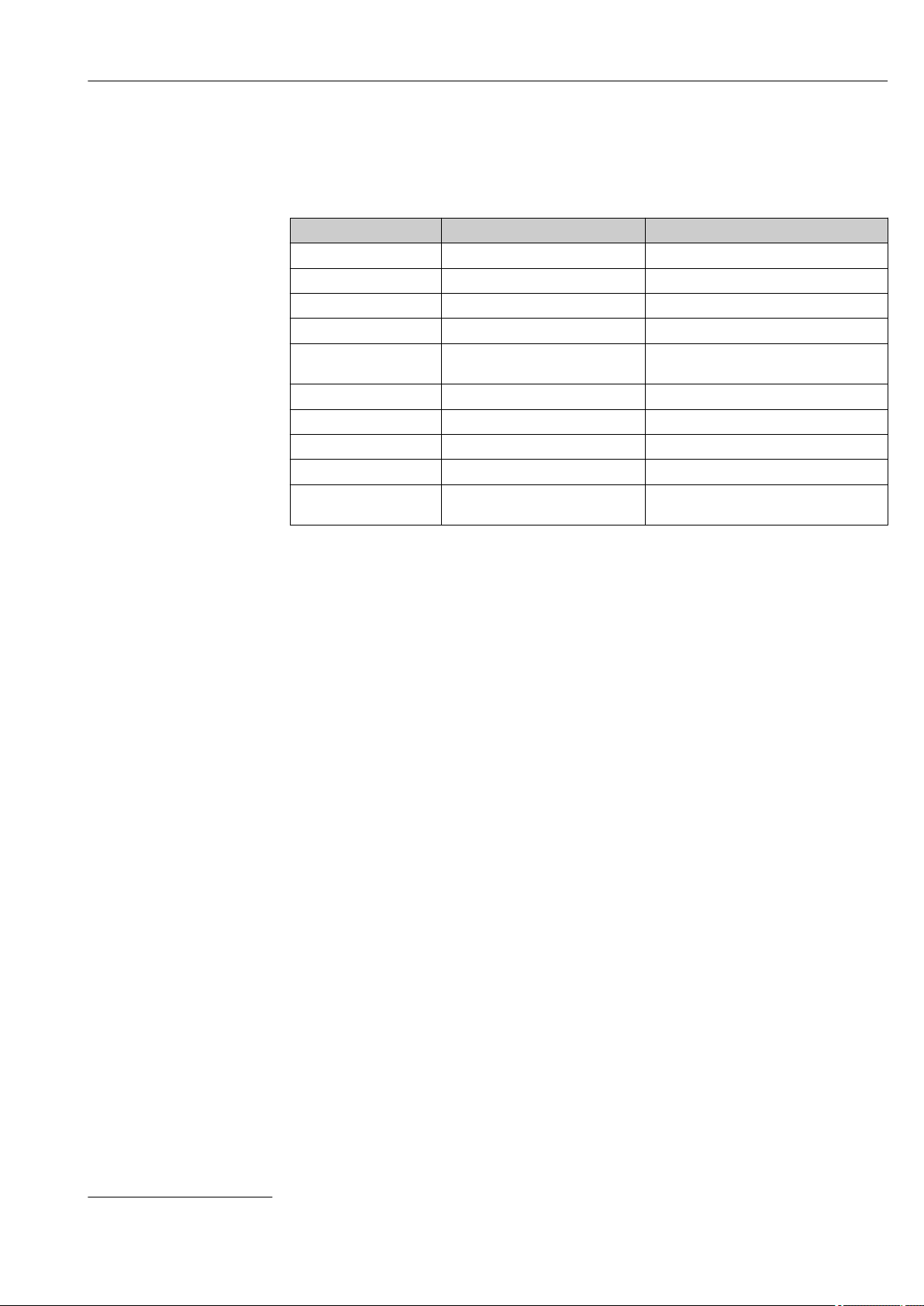

Feature 010 Approval Available for Feature 020: "Power Supply; Output"

BA ATEX II 1G Ex ia IIC T6 Ga • FMP56

• FMP57

BB ATEX II 1/2G Ex ia IIC T6 Ga/Gb • FMP56

• FMP57

BE ATEX II 1D Ex t IIIC Da • FMP56

• FMP57

BF ATEX II 1/2D Ex t IIIC Da/Db • FMP56

• FMP57

BG ATEX II 3G Ex nA IIC T6 Gc • FMP56

• FMP57

BH ATEX II 3G Ex ic IIC T6 Gc • FMP56

• FMP57

B2 ATEX II 1/2G Ex ia IIC T6 Ga/Gb, 1/2D Ex ia IIIC Da/Db • FMP56

• FMP57

B3 ATEX II 1/2G Ex d[ia] IIC T6 Ga/Gb, 1/2 D Ex t IIIC

Da/Db

CD CSA C/US DIP Cl.II,III Div.1 Gr.E-G • FMP56

C2 CSA C/US IS Cl.I,II,III Div.1 Gr.A-G, NI Cl.1 Div.2, Ex ia • FMP56

C3 CSA C/US XP Cl.I,II,III Div.1 Gr.A-G, NI Cl.1 Div.2, Ex d • FMP56

FB FM IS Cl.I,II,III Div.1 Gr.A-G, AEx ia, NI Cl.1 Div.2 • FMP56

FD FM XP Cl.I,II,III Div.1 Gr.A-G, AEx d, NI Cl.1 Div.2 • FMP56

FE FM DIP Cl.II,III Div.1 Gr.E-G • FMP56

GA EAC Ex ia IIC T6 Ga • FMP56

GB EAC Ex ia IIC T6 Ga/Gb • FMP56

IA IEC Ex ia IIC T6 Ga • FMP56

IB IEC Ex ia IIC T6 Ga/Gb • FMP56

IE IEC Ex t IIIC Da • FMP56

IF IEC Ex t IIIC Da/Db • FMP56

IG IEC Ex nA IIC T6 Gc • FMP56

IH IEC Ex ic IIC T6 Gc • FMP56

I2 IEC Ex ia IIC T6 Ga/Gb, Ex ia IIIC Da/Db • FMP56

• FMP56

• FMP57

• FMP57

• FMP57

• FMP57

• FMP57

• FMP57

• FMP57

• FMP57

• FMP57

• FMP57

• FMP57

• FMP57

• FMP57

• FMP57

• FMP57

• FMP57

1)

A

XA00496F XA01125F XA01126F XA00516F -

XA00496F XA01125F XA01126F XA00516F -

XA00501F XA00501F XA00501F XA00521F XA00501F

XA00501F XA00501F XA00501F XA00521F XA00501F

XA00498F XA01130F XA01131F XA00518F XA01132F

XA00498F XA01130F XA01131F XA00518F -

XA00502F XA00502F XA00502F XA00522F -

XA00503F XA00503F XA00503F XA00523F XA01136F

XA00529F XA00529F XA00529F XA00570F XA00529F

XA00530F XA00530F XA00530F XA00571F XA00530F

XA00529F XA00529F XA00529F XA00570F XA00529F

XA00531F XA00531F XA00531F XA00573F XA00531F

XA00532F XA00532F XA00532F XA00572F XA00532F

XA00532F XA00532F XA00532F XA00572F XA00532F

XA01380F XA01380F XA01380F XA01381F XA01380F

XA01380F XA01380F XA01380F XA01381F XA01380F

XA00496F XA01125F XA01126F XA00516F -

XA00496F XA01125F XA01126F XA00516F -

XA00501F XA00501F XA00501F XA00521F XA00501F

XA00501F XA00501F XA00501F XA00521F XA00501F

XA00498F XA01130F XA01131F XA00518F XA01132F

XA00498F XA01130F XA01131F XA00518F -

XA00502F XA00502F XA00502F XA00522F -

2)

B

3)

C

4)/G 5)

E

6)/L 7)

K

Endress+Hauser 9

Page 10

Important document information Levelflex FMP56, FMP57 PROFIBUS PA

Feature 010 Approval Available for Feature 020: "Power Supply; Output"

I3 IEC Ex d [ia] IIC T6 Ga/Gb, Ex t IIIC Da/Db • FMP56

• FMP57

KA KC Ex ia IIC T6 Ga • FMP56

• FMP57

KB KC Ex ia IIC T6 Ga/Gb • FMP56

• FMP57

MA INMETRO Ex ia IIC T6 Ga • FMP56

• FMP57

ME INMETRO Ex t IIIC Da • FMP56

• FMP57

MH INMETRO Ex ic IIC T6 Gc • FMP56

• FMP57

NA NEPSI Ex ia IIC T6 Ga • FMP56

• FMP57

NB NEPSI Ex ia IIC T6 Ga/Gb • FMP56

• FMP57

NF NEPSI DIP A20/21 T85…90oC IP66 • FMP56

• FMP57

NG NEPSI Ex nA II T6 Gc • FMP56

• FMP57

NH NEPSI Ex ic IIC T6 Gc • FMP56

• FMP57

N2 NEPSI Ex ia IIC T6 Ga/Gb, Ex iaD 20/21 T85…90°C • FMP56

• FMP57

N3 NEPSI Ex d[ia] IIC T6 Ga/Gb, DIP A20/21 T85…90°C

IP66

• FMP56

• FMP57

8A FM/CSA IS+XP Cl.I,II,III Div.1 Gr.A-G • FMP56

• FMP57

1)

A

XA00503F XA00503F XA00503F XA00523F XA01136F

XA01169F - XA01169F - -

XA01169F - XA01169F - -

XA01038F XA01038F XA01038F - XA01038F

XA01043F XA01043F XA01043F - XA01043F

XA01040F XA01040F XA01040F - XA01040F

XA00634F XA00634F XA00634F XA00640F XA00634F

XA00634F XA00634F XA00634F XA00640F XA00634F

XA00637F XA00637F XA00637F XA00643F XA00637F

XA00635F XA00635F XA00635F XA00641F XA00635F

XA00635F XA00635F XA00635F XA00641F XA00635F

XA00638F XA00638F XA00638F XA00644F XA00638F

XA00639F XA00639F XA00639F XA00645F XA00639F

XA00531F

XA00532F

2)

B

XA00531F

XA00532F

3)

C

XA00531F

XA00532F

4)/G 5)

E

XA00572F

XA00573F

6)/L 7)

K

XA00531F

XA00532F

1) A: 2-wire; 4-20mA HART

2) B: 2-wire; 4-20mA HART, switch output

3) C: 2-wire; 4-20mA HART, 4-20mA

4) E: 2-wire; FOUNDATION Fieldbus, switch output

5) G: 2-wire; PROFIBUS PA, switch output

6) K: 4-wire 90-253VAC; 4-20mA HART

7) L: 4-wire 10,4-48VDC; 4-20mA HART

For certified devices the relevant Safety Instructions (XA) are indicated on the

nameplate.

10 Endress+Hauser

Page 11

Levelflex FMP56, FMP57 PROFIBUS PA Important document information

Ex-marking in case of connected FHX50 remote display

If the device is prepared for the remote display FHX50 (product structure: feature 030:

Display, Operation", option L or M), the Ex marking of some certificates changes according

to the following table

Feature 010 ("Approval") Feature 030 ("Display, Operation") Ex-marking

BE L or M ATEX II 1D Ex ta [ia] IIIC T

BF L or M ATEX II 1/2 D Ex ta [ia Db] IIIC Txx°C Da/Db

BG L or M ATEX II 3G Ex nA [ia Ga] IIC T6 Gc

BH L or M ATEX II 3G Ex ic [ia Ga] IIC T6 Gc

B3 L or M ATEX II 1/2G Ex d [ia] IIC T6 Ga/Gb,

IE L or M IECEx Ex ta [ia] IIIC T500 xx°C Da

IF L or M IECEx ta [ia Db] IIIC Txx°C Da/Db

IG L or M IECEx Ex nA [ia Ga] IIC T6 Gc

IH L or M IECEx Ex ic [ia Ga] IIC T6 Gc

I3 L or M IECEx Ex d [ia] IIC T6 Ga/Gb,

1)

:

xx°C Da

500

ATEX II 1/2D Ex ta [ia Db] IIIC Txx°C Da/Db

IECEx Ex ta [ia Db] IIIC Txx°C Da/Db

1) The marking of certificates not mentioned in this table are not affected by the FHX50.

Endress+Hauser 11

Page 12

Basic safety instructions Levelflex FMP56, FMP57 PROFIBUS PA

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task.

Are authorized by the plant owner/operator.

‣

Are familiar with federal/national regulations.

‣

Before starting work, read and understand the instructions in the manual and

‣

supplementary documentation as well as the certificates (depending on the

application).

Follow instructions and comply with basic conditions.

‣

The operating personnel must fulfill the following requirements:

Are instructed and authorized according to the requirements of the task by the facility's

‣

owner-operator.

Follow the instructions in this manual.

‣

2.2 Designated use

Application and measured materials

The measuring device described in these Operating Instructions is intended only for level

measurement of bulk solids. Depending on the version ordered the device can also

measure potentially explosive, flammable, poisonous and oxidizing materials.

Observing the limit values specified in the "Technical data" and listed in the Operating

Instructions and supplementary documentation, the measuring device may be used for the

following measurements only:

Measured process variables: level

‣

Calculated process variables: Volume or mass in arbitrarily shaped vessels (calculated

‣

from the level by the linearization functionality)

To ensure that the measuring device remains in proper condition for the operation time:

Use the measuring device only for measured materials against which the process-

‣

wetted materials are adequately resistant.

Observe the limit values in "Technical data".

‣

Incorrect use

The manufacturer is not liable for damage caused by improper or non-designated use.

Verification for borderline cases:

For special measured materials and cleaning agents, Endress+Hauser is glad to provide

‣

assistance in verifying the corrosion resistance of wetted materials, but does not accept

any warranty or liability.

Residual risk

The electronics housing and its built-in components such as display module, main

electronics module and I/O electronics module may heat to 80 °C (176 °F) during operation

through heat transfer from the process as well as power dissipation within the electronics.

During operation the sensor may assume a temperature near the temperature of the

measured material.

Danger of burns due to heated surfaces!

For high process temperatures: Install protection against contact in order to prevent

‣

burns.

12 Endress+Hauser

Page 13

Levelflex FMP56, FMP57 PROFIBUS PA Basic safety instructions

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

2.4 Operational safety

Risk of injury.

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with the manufacturer.

‣

Repair

To ensure continued operational safety and reliability,

Carry out repairs on the device only if they are expressly permitted.

‣

Observe federal/national regulations pertaining to repair of an electrical device.

‣

Use original spare parts and accessories from the manufacturer only.

‣

Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the

hazardous area (e.g. explosion protection, pressure vessel safety):

Based on the nameplate, check whether the ordered device is permitted for the

‣

intended use in the hazardous area.

Observe the specifications in the separate supplementary documentation that is an

‣

integral part of these Instructions.

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate. It meets general safety standards and legal requirements.

2.5.1 CE mark

The measuring system meets the legal requirements of the applicable EC guidelines. These

are listed in the corresponding EC Declaration of Conformity together with the standards

applied.

Endress+Hauser confirms successful testing of the device by affixing to it the CE mark.

2.5.2 EAC conformity

The measuring system meets the legal requirements of the applicable EAC guidelines.

These are listed in the corresponding EAC Declaration of Conformity together with the

standards applied.

Endress+Hauser confirms successful testing of the device by affixing to it the EAC mark.

Endress+Hauser 13

Page 14

Product description Levelflex FMP56, FMP57 PROFIBUS PA

1

2

5

3

4

3 Product description

3.1 Product design

3.1.1 Levelflex FMP56/FMP57

A0012470

1 Design of the Levelflex

1 Electronics housing

2 Process connection (here as an example: flange)

3 Rope probe

4 End-of-probe weight

5 Rod probe

14 Endress+Hauser

Page 15

Levelflex FMP56, FMP57 PROFIBUS PA Product description

Esc

–

+

E

1

2

3

4

5

6

9

7

8

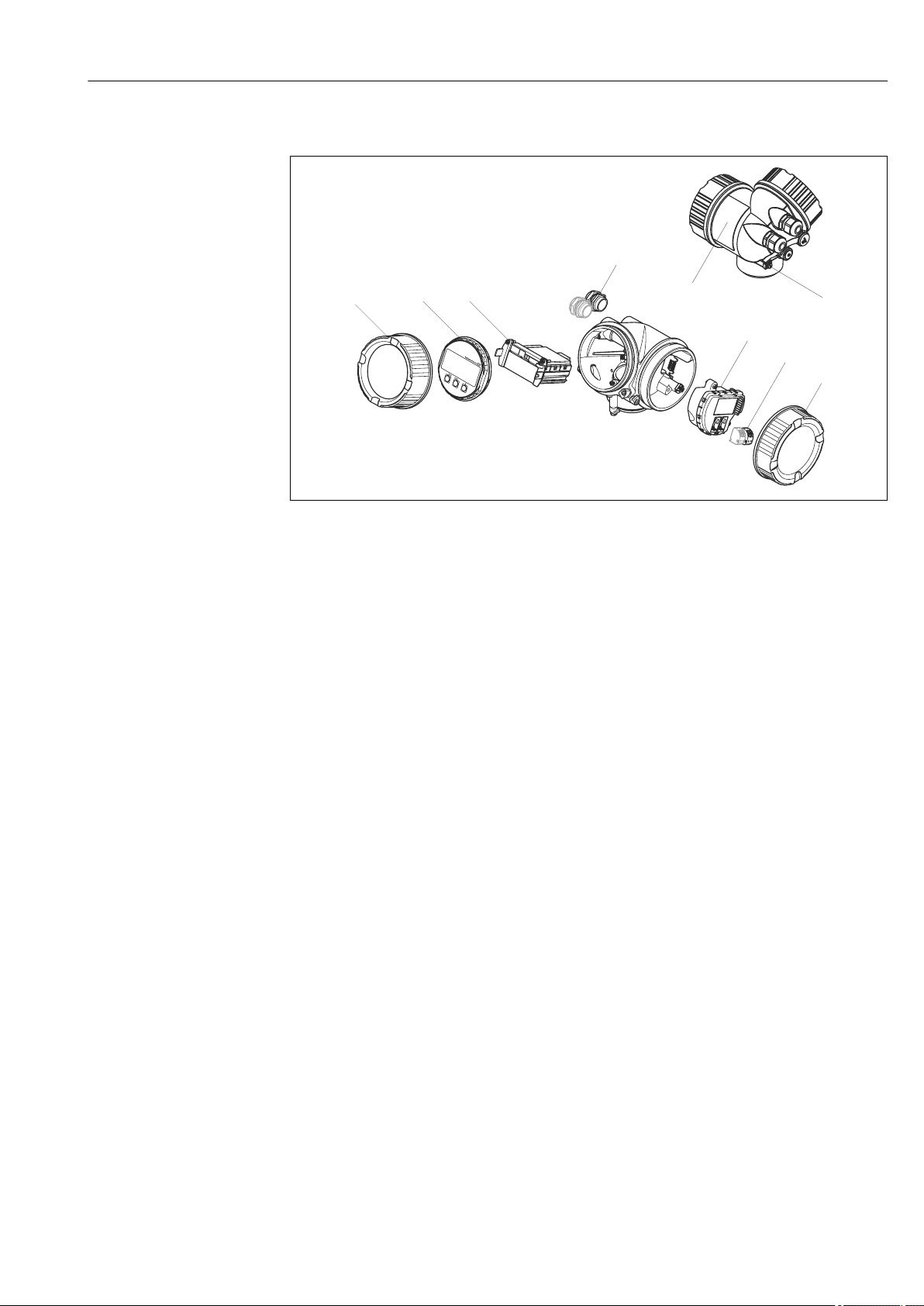

3.1.2 Electronics housing

A0012422

2 Design of the electronics housing

1 Electronics compartment cover

2 Display module

3 Main electronics module

4 Cable glands (1 or 2, depending on instrument version)

5 Nameplate

6 I/O electronics module

7 Terminals (pluggable spring terminals)

8 Connection compartment cover

9 Grounding terminal

Endress+Hauser 15

Page 16

Product description Levelflex FMP56, FMP57 PROFIBUS PA

3.2 Registered trademarks

PROFIBUS

Registered trademark of the PROFIBUS User Organization, Karlsruhe, Germany

KALREZ®, VITON

Registered trademark of DuPont Performance Elastomers L.L.C., Wilmington, USA

TEFLON

Registered trademark of E.I. DuPont de Nemours & Co., Wilmington, USA

TRI CLAMP

Registered trademark of Alfa Laval Inc., Kenosha, USA

®

®

®

®

16 Endress+Hauser

Page 17

Levelflex FMP56, FMP57 PROFIBUS PA Incoming acceptance and product identification

DELIVERYNOTE

1 = 2

DELIVERYNOTE

Madein Germany, 79689 Maulburg

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

Is the order code on the delivery

A0015502

A0022480

A0022486

note (1) identical to the order

code on the product sticker (2)?

Are the goods undamaged?

A0015502

A0022489

Do the nameplate data match the

A0015502

A0022491

ordering information on the

delivery note?

Is the DVD (operating tool)

A0015502

present?

If required (see nameplate): Are

the Safety Instructions (XA)

present?

A0022494

If one of the conditions does not comply, contact your Endress+Hauser distributor.

4.2 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

( www.endress.com/deviceviewer ): All information about the measuring device is

displayed.

• Enter the serial number from the nameplates into the Endress+Hauser Operations App

or scan the 2-D matrix code (QR code) on the nameplate with the Endress+Hauser

Operations App: all the information for the measuring device is displayed.

Endress+Hauser 17

Page 18

Incoming acceptance and product identification Levelflex FMP56, FMP57 PROFIBUS PA

20

21

22

24

25

23

26

1

2

3

4

5

6

7

8

9

10

19

18

17

16

15

14

Ext. ord. cd.:

Order code:

Ser. no.:

LN =

Lref =

Mat.:

Date:

FW:

Dev.Rev.:

DeviceID:

Ta:

if modification

see sep. label

X =

MWP:

12

11

47 (1.85)

92 (3.62)

mm (in)

13

4.2.1 Nameplate

A0010725

3 Nameplate of the Levelflex

1 Device name

2 Address of manufacturer

3 Order code

4 Serial number (Ser. no.)

5 Extended order code (Ext. ord. cd.)

6 Process pressure

7 Gas phase compensation: reference distance

8 Certificate symbol

9 Certificate and approval relevant data

10 Degree of protection: e.g. IP, NEMA

11 Document number of the Safety Instructions: e.g. XA, ZD, ZE

12 2-D matrix code (QR code)

13 Modification mark

14 Manufacturing date: year-month

15 Permitted temperature range for cable

16 Geräterevision (Dev.Rev.)

17 Additional information about the device version (certificates, approvals, communication): e.g. SIL, PROFIBUS

18 Firmware version (FW)

19 CE mark, C-Tick

20 DeviceID

21 Material in contact with process

22 Permitted ambient temperature (Ta)

23 Size of the thread of the cable glands

24 Length of probe

25 Signal outputs

26 Operating voltage

Only 33 digits of the extended order code can be indicated on the nameplate. If the

extended order code exceeds 33 digits, the rest will not be shown. However, the

complete extended order code can be viewed in the operating menu of the device in

the Extended order code 1 to 3 parameter.

18 Endress+Hauser

Page 19

Levelflex FMP56, FMP57 PROFIBUS PA Storage, Transport

5 Storage, Transport

5.1 Storage conditions

• Permitted storage temperature: –40 to +80 °C (–40 to +176 °F)

• Use the original packaging.

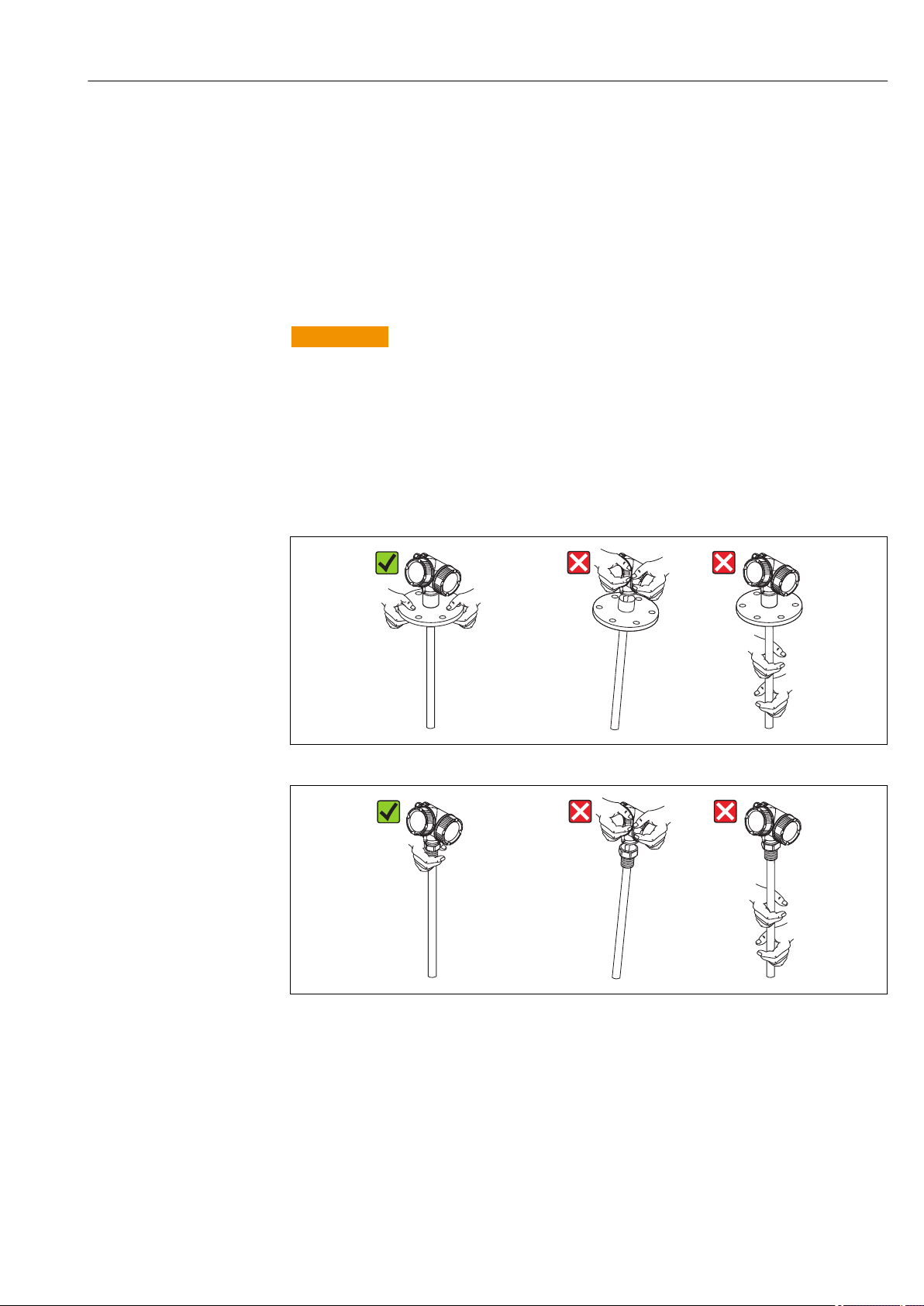

5.2 Transport product to the measuring point

WARNING

L

Housing or probe may be damaged or break away.

Risk of injury!

Transport the measuring device to the measuring point in its original packaging or at

‣

the process connection.

Do not fasten lifting devices (hoisting slings, lifting eyes etc.) at the housing or the

‣

probe but at the process connection. Take into account the mass center of the device in

order to avoid unintended tilting.

Comply with the safety instructions, transport conditions for devices over 18kg

‣

(39.6lbs) (IEC61010).

A0013920

A0014264

Endress+Hauser 19

Page 20

Mounting Levelflex FMP56, FMP57 PROFIBUS PA

A

C

1 32

4

B

6 Mounting

6.1 Mounting requirements

6.1.1 Suitable mounting position

A0021468

4 Mounting requirements for Levelflex

Mounting distances

• Distance (A) between wall and rod or rope probe:

– for smooth metallic walls: > 50 mm (2 in)

– for plastic walls: > 300 mm (12 in) to metallic parts outside the vessel

– for concrete walls: > 500 mm (20 in), otherwise the available measuring range may be

reduced.

• Distance (B) between rod or rope probe and internal fittings in the vessel: >

300 mm (12 in)

• When using more than one Levelflex:

Minimum distance between the sensor axes: 100 mm (3.94 in)

• Distance (C) from end of probe to bottom of the vessel:

– Rope probe: > 150 mm (6 in)

– Rod probe: > 10 mm (0.4 in)

20 Endress+Hauser

Page 21

Levelflex FMP56, FMP57 PROFIBUS PA Mounting

Additional conditions

• When mounting in the open, a weather protection cover (1) may be installed to protect

the device against extreme weather conditions.

• In metallic vessels: Preferably do not mount the probe in the center of the vessel (2), as

this would lead to increased interference echoes.

If a central mounting position can not be avoided, it is crucial to perform an interference

echo suppresion(mapping) after the commissioning of the device.

• Do not mount the probe in the filling curtain (3).

• Avoid buckling the rope probe during installation or operation (e.g. through product

movement against silo wall) by selecting a suitable mounting location.

• Check the probe regularly for defects.

With suspended rope probes (probe end not fixed at the bottom) the distance

between the probe rope and internal fittings in the tank must not fall below 300 mm

(12") during the entire process. A sporadic contact between the probe weight and the

cone of the vessel, however, does not influence the measurement as long as the

dielectric constant of the medium is at least DC = 1.8.

When mounting the electronics housing into a recess (e.g. in a concrete ceiling),

observe a minimum distance of 100 mm (4 inch) between the cover of the terminal

compartment / electronics compartment and the wall. Otherwise the connection

compartment / electronics compartment is not accessible after installation.

Endress+Hauser 21

Page 22

Mounting Levelflex FMP56, FMP57 PROFIBUS PA

A

B

C

C

r = 100 (4)

min

r = 100 (4)

min

6 Nm

(4.42 lbf ft)

6 Nm

(4.42 lbf ft)

6 Nm

(4.42 lbf ft)

6 Nm

(4.42 lbf ft)

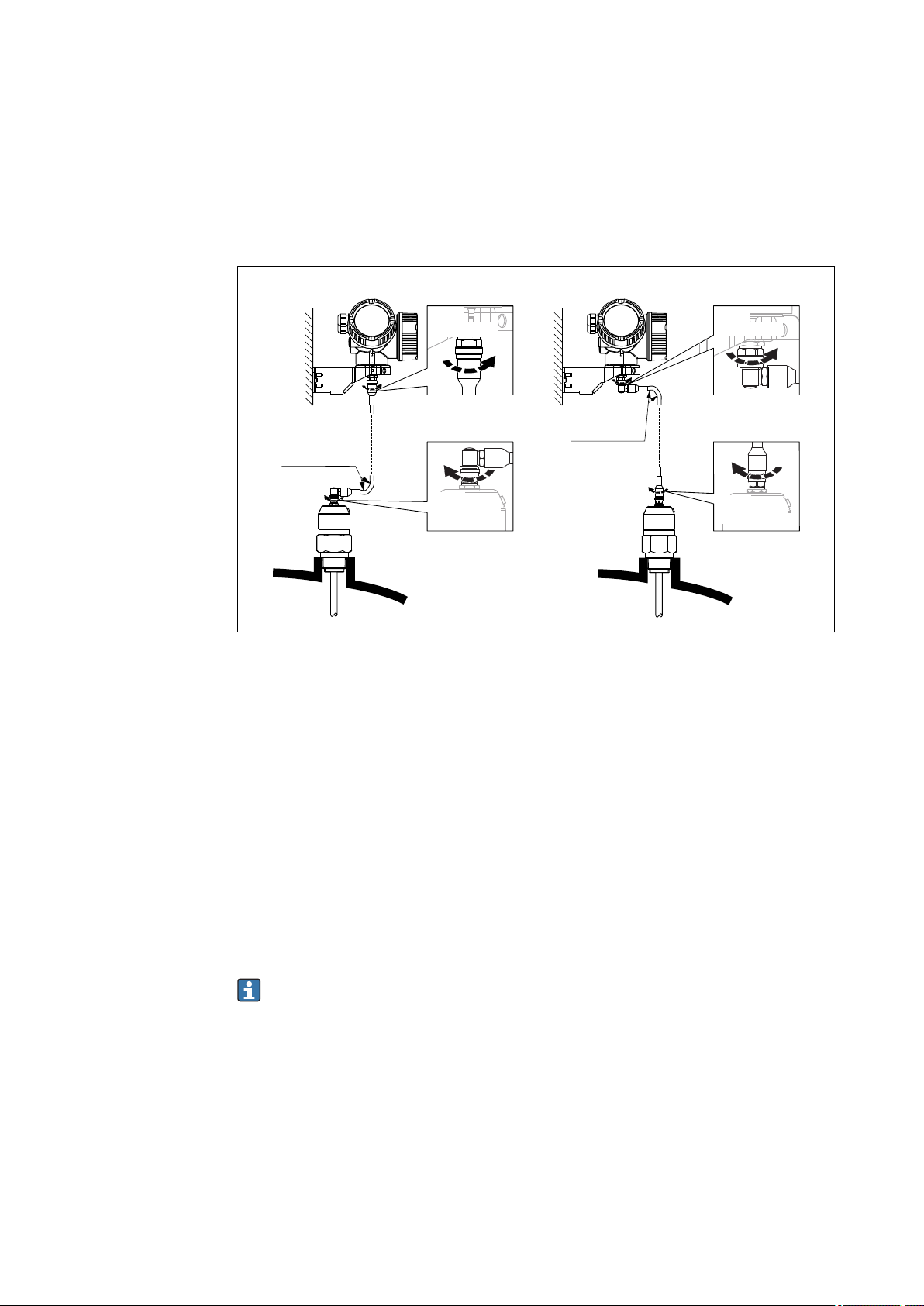

6.1.2 Applications with restricted mounting space

Mounting with remote sensor

The device version with a remote sensor is suited for applications with restricted mounting

space. In this case the electronics housing is mounted at a separate position from which it

is easier accessible.

A0014794

A Angled plug at the probe

B Angled plug at the electronics housing

C Length of the remote cable as ordered

• Product structure, feature 600 "Probe Design":

– Option MB "Sensor remote, 3m/9ft cable"

– Option MC "Sensor remote, 6m/18ft cable"

– Option MB "Sensor remote, 9m/27ft cable"

• The remote cable is supplied with these device versions

Minimum bending radius: 100 mm (4 inch)

• A mounting bracket for the electronics housing is supplied with these device versions.

Mounting options:

– Wall mounting

– Pipe mounting; diameter: 42 to 60 mm (1-1/4 to 2 inch)

• The connection cable has got one straight and one angled plug (90°). Depending on the

local conditions the angled plug can be connected at the probe or at the electronics

housing.

Probe, electronics and connection cable are adjusted to match each other. They are

marked by a common serial number. Only components with the same serial number

shall be connected to each other.

22 Endress+Hauser

Page 23

Levelflex FMP56, FMP57 PROFIBUS PA Mounting

6.1.3 Notes on the mechanical load of the probe

Tensile load limit of rope probes

Sensor Feature 060 Probe Tensile load limit [kN] Max. rupture load [kN]

FMP56 LA, LB Rope 4mm (1/6") 316 12 20

NB, NE Rope 6mm (1/4") PA>Steel 12 20

FMP57 LA, LB Rope 4mm (1/6") 316 12 20

LC, LD Rope 6mm (1/4") 316 30 42

NB, NE Rope 6mm (1/4") PA>Steel 12 20

NC, NF Rope 8mm (1/3") PA>Steel 30 42

1) The ceiling of the silo must be designed to withstand this load.

1)

Tensile load

Bulk solids exert tensile forces on rope probes whose height increases with:

• the length of the probe, i.e. max. cover

• the bulk density of the product,

• the silo diameter and

• the diameter of the probe rope

Since the tensile forces are also heavily dependent on the viscosity of the product, a higher

safety factor is necessary for highly viscous products and if there is a risk of cornice

buildup. In critical cases it is better to use a 6 mm rope instead of a 4 mm one.

The same forces also act on the silo cover. On a fixed rope, the tensile forces are definitely

greater, but this can not be calculated. Observe the tensile strength of the probes.

Options for reducing the tensile forces:

• Shorten the probe.

• If the maximum tensile load is exceeded, check whether it would be possible to use a

non-contact Ultrasonic or Level-Radar device.

The following diagrams show typical loads for frequently occurring bulk solids as reference

values. The calculation is performed for the following conditions:

• Calculation according to DIN 1055, Part 6 for the cylindrical part of the silo.

• Suspended probe (probe end not fixed at the bottom)

• Free-flowing bulk solid, i.e. mass flow. A calculation for core flow is not possible. In the

event of collapsing cornices, considerably higher loads can occur.

• The specification for tensile forces contains the safety factor 2 (in addition to the safety

factors already taken into account by DIN 1055), which compensates for the normal

fluctuation range in pourable bulk solids.

Endress+Hauser 23

Page 24

Mounting Levelflex FMP56, FMP57 PROFIBUS PA

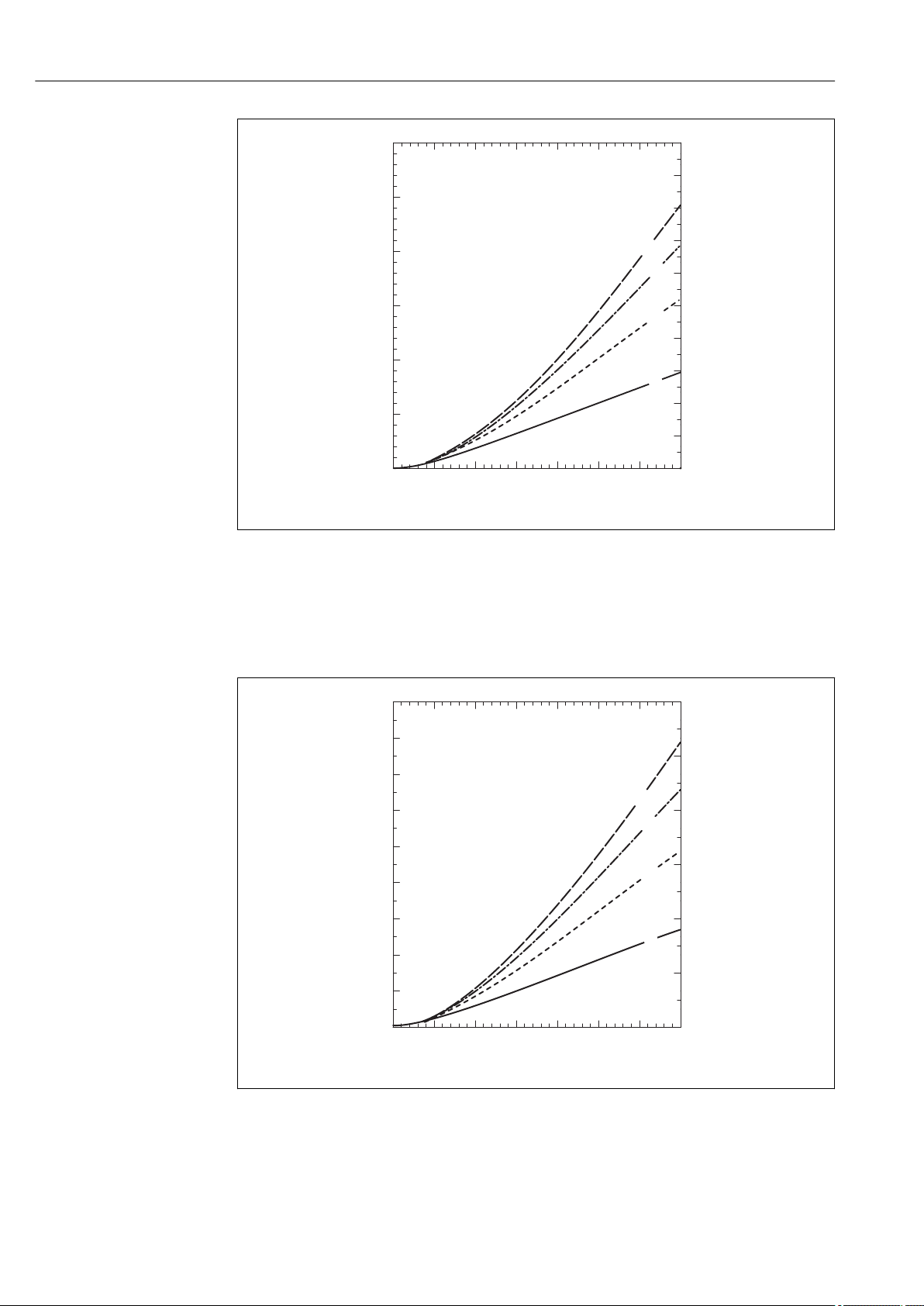

0 5 10 15 20 25 30 35

0

10

20

30

40

50

60

F [kN]

6 mm

L [m]

F [kN]

4 mm

0

4

8

12

16

20

24

28

32

36

40

A

B

C

D

F [kN]

6 mm

L [m]

F [kN]

4 mm

0 5 10 15 20 25 30 35

A

B

C

0

2

4

6

8

10

12

14

16

18

0

2

4

6

8

10

12

D

A0017170

5 Silica sand in silo with smooth metallic walls; tensile load as a function of level L for rope diameters 6mm

(0,24 in) and 4mm (0,16 in)

A Silo diameter 12 m (40 ft)

B Silo diameter 9 m (30 ft)

C Silo diameter 6 m (20 ft)

D Silo diameter 3 m (10 ft)

6 Polyethylene pellets in silo with smooth metallic walls; tensile load as a function of level L for rope

diameters 6mm (0,24 in) and 4mm (0,16 in)

A Silo diameter 12 m (40 ft)

B Silo diameter 9 m (30 ft)

C Silo diameter 6 m (20 ft)

D Silo diameter 3 m (10 ft)

A0017171

24 Endress+Hauser

Page 25

Levelflex FMP56, FMP57 PROFIBUS PA Mounting

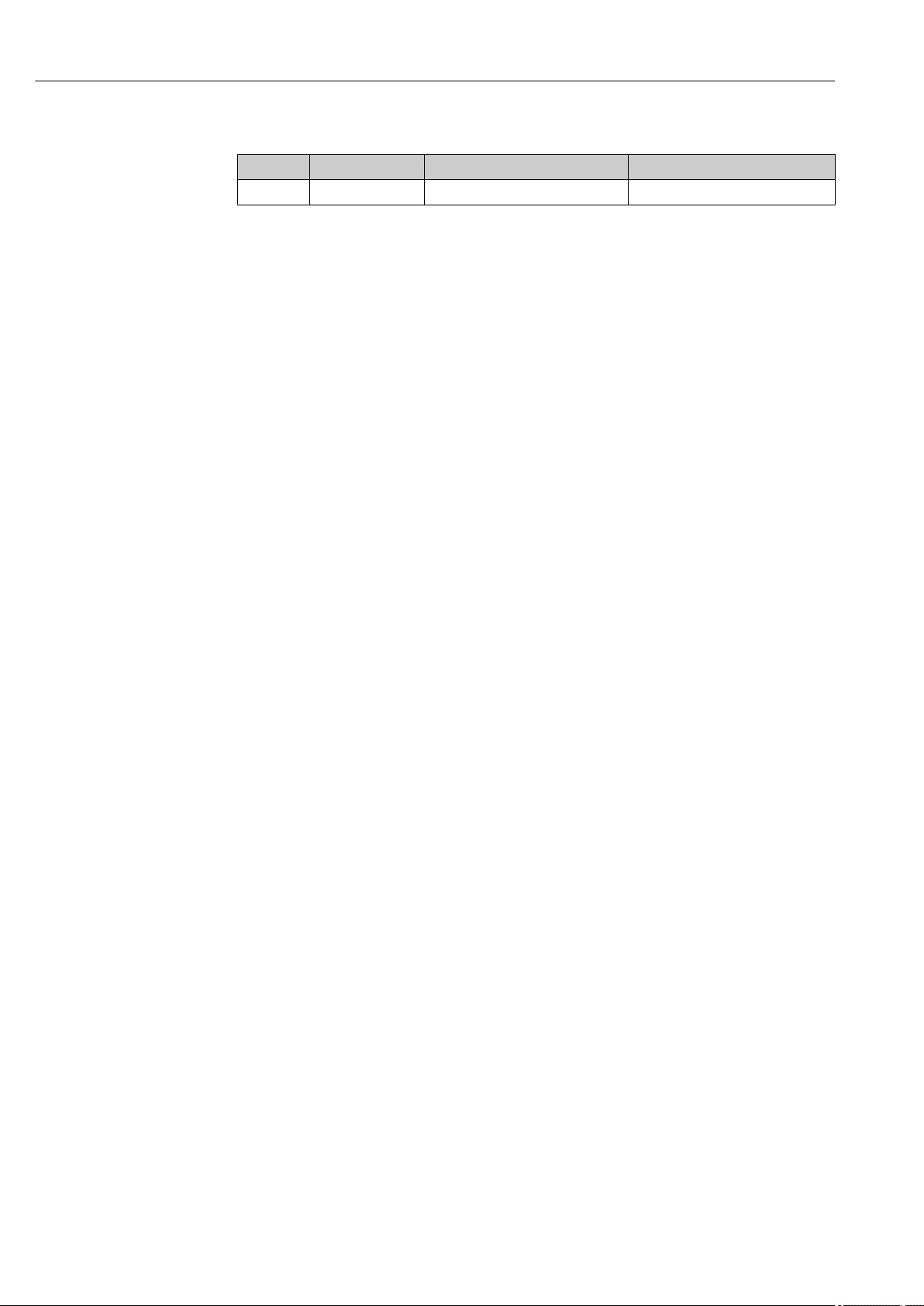

F [kN]

6 mm

L [m]

F [kN]

4 mm

A

B

C

D

0 5 10 15 20 25 30 35

0

4

8

12

16

20

24

28

32

36

0

4

8

12

16

20

24

F [kN]

6 mm

L [m]

F [kN]

4 mm

A

B

C

D

0 5 10 15 20 25 30 35

0

10

20

30

40

50

60

0

4

8

12

16

20

24

28

32

36

40

A0017172

7 Wheat in silo with smooth metallic walls; tensile load as a function of level L for rope diameters 6mm

(0,24 in) and 4mm (0,16 in)

A Silo diameter 12 m (40 ft)

B Silo diameter 9 m (30 ft)

C Silo diameter 6 m (20 ft)

D Silo diameter 3 m (10 ft)

8 Cement in silo with smooth metallic walls; tensile load as a function of level L for rope diameters 6mm

A Tank diameter 12 m (40 ft)

B Tank diameter 9 m (30 ft)

C Tank diameter 6 m (20 ft)

D Tank diameter 3 m (10 ft)

(0,24 in) and 4mm (0,16 in)

A0017173

Endress+Hauser 25

Page 26

Mounting Levelflex FMP56, FMP57 PROFIBUS PA

Bending strength of rod probes

Sensor Feature 060 Probe Bending strength [Nm]

FMP57 AE, AF Rod 16mm (0.63") 316L 30

26 Endress+Hauser

Page 27

Levelflex FMP56, FMP57 PROFIBUS PA Mounting

6.1.4 Notes on the process connection

Probes are mounted to the process connection with threaded connections or flanges. If

during this installation there is the danger that the probe end moves so much that it

touches the tank floor or cone at times, the probe must, if necessary, be shortened and

fixed down → 31.

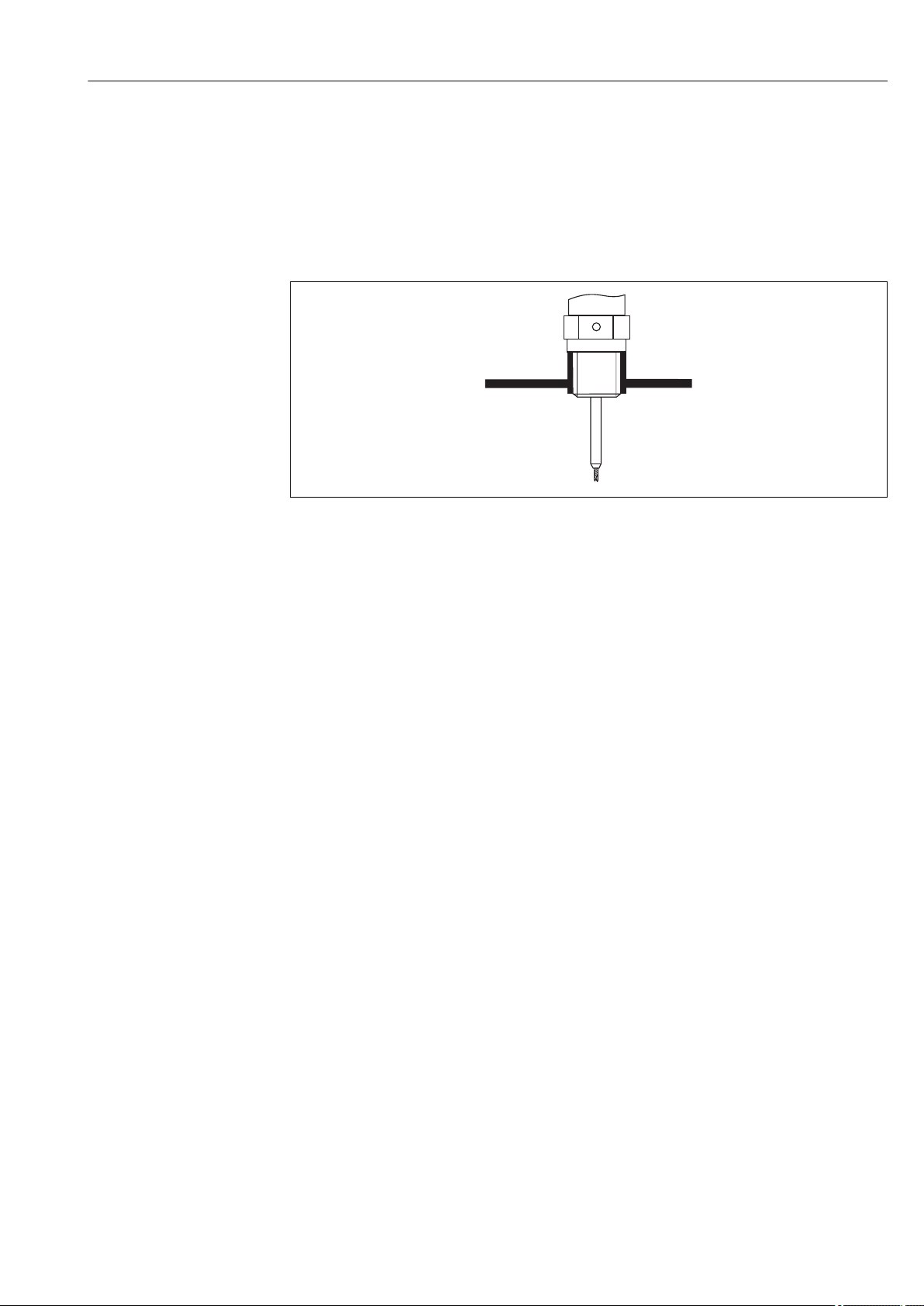

Threaded connection

A0015121

9 Mounting with threaded connection; flush with the container ceiling

Seal

The thread as well as the type of seal comply to DIN 3852 Part 1, screwed plug form A.

They can be sealed with the following types of sealing rings:

• Thread G3/4": According to DIN 7603 with the dimensions 27 x 32 mm

• Thread G1-1/2": According to DIN 7603 with the dimensions 48 x 55 mm

Please use a sealing ring according to this standard in the form A, C or D and of a material

that is resistant to the application.

Endress+Hauser 27

Page 28

Mounting Levelflex FMP56, FMP57 PROFIBUS PA

£150 (6)

H

ø 150 (6)£

Nozzle mounting

A0015122

Length H of the rigid part of the rope probe

Probe H

FMP56, rope 4 mm (0.16 in) 94 mm (3.7 in)

FMP57, rope 4 mm (0.16 in) 120 mm (4.7 in)

FMP57, rope 6 mm (0.24 in) 135 mm (5.3 in)

• Permissible nozzle diameter: ≤ 150 mm (6 in).

For larger diameters the near range measuring capability may be reduced.

For nozzles ≥ DN300: → 30.

• Permissible nozzle height

2)

: ≤ 150 mm (6 in).

For a larger height the near range measuring capability may be reduced.

Larger nozzle heights may be possible in special cases (see section "Rod extension/

centering HMP40 for FMP57").

• The end of the nozzle should be flush with the tank ceiling in order to avoid ringing

effects.

With thermally insulated vessels the nozzle should also be insulated in order to

prevent condensate formation.

2) Larger nozzle heights on request

28 Endress+Hauser

Page 29

Levelflex FMP56, FMP57 PROFIBUS PA Mounting

Rod extension/centering HMP40 for FMP57

For FMP57 with rope probes the rod extension/centering HMP 40 is available as an

accessory → 96. It has to be used if otherwise the probe rope comes into contact with

the lower edge of the nozzle.

For FMP57 with rope probes the rod extension/centering HMP 40 is available as an

accessory. It has to be used if otherwise the probe rope comes into contact with the lower

edge of the nozzle.

This accessory consists of the extension rod corresponding to the nozzle height, on

which a centering disk is also mounted if the nozzles are narrow or when working in

bulk solids. This component is delivered separately from the device. Please order the

probe length correspondingly shorter.

Centering disks with small diameters (DN40 and DN50) may only be used if there is

no significant build-up in the nozzle above the disk. The nozzle must not become

clogged by the product.

Endress+Hauser 29

Page 30

Mounting Levelflex FMP56, FMP57 PROFIBUS PA

1

2

3

4

Installation in nozzles ≥ DN300

If installation in ≥ 300mm/12" nozzles is unavoidable, installation must be carried out in

accordance with the following sketch.

A0014199

1 Lower edge of the nozzle

2 Approx. flush with the lower edge of the nozzle (± 50 mm/2")

3 Plate

4 Pipe 150 to 180 mm (6 to 7 inch)

Nozzle diameter Plate diameter

300 mm (12") 280 mm (11")

≥ 400 mm (16") ≥ 350 mm (14")

30 Endress+Hauser

Page 31

Levelflex FMP56, FMP57 PROFIBUS PA Mounting

1

A

C

B

2

6.1.5 Securing the probe

Securing rope probes

A0012609

A Sag of the rope: ≥ 1 cm per 1m of the probe length (0.12 inch per 1 ft of the probe length)

B Reliably grounded end of probe

C Reliably isolated end of probe

1: Mounting and contact with a bolt

2 Mounting kit isolated

• The end of the probe needs to be secured under the following conditions:

– if otherwise the probe sporadically comes into contact with the wall of the vessel, the

outlet cone, internal fittings or other parts of the installation.

– if otherwise the probe sporadically gets close to a concrete wall (minimum distance 0.5

m / 20 inch).

• The end of probe can be secured at its internal thread

– rope 4 mm (1/6"), 316: M 14

– rope 6 mm (1/4"), 316: M 20

– rope 6mm (1/4"), PA>steel: M14

– rope 8mm (1/3"), PA>steel: M20

• Preferably use the 6 mm (1/4") rope probe due to the higher tensile strength when

fixing a rope probe.

• The fixing must be either reliably grounded or reliably insulated. If it is not possible to

mount the probe weight with a reliably insulated connection, it can be secured using an

isolated eyelet, which is available as an accessory.

• In the case of a grounded fixing the search for a positive end-of-probe signal must be

activated. Otherwise an automatic probe length correction is impossible.

Navigation: Expert → Sensor → EOP evaluation → EOP search mode

Setting: Positive EOP option

• In order to prevent an extremely high tensile load (e.g. due to thermal expansion) and

the risk of rope crack, the rope has to be slack. Make the rope longer than the required

measuring range such that there is a sag in the middle of the rope that is ≥ 1cm/(1 m

rope length) [0.12 inch/(1 ft rope length)].

Tensile load limit of rope probes: → 23

Endress+Hauser 31

Page 32

Mounting Levelflex FMP56, FMP57 PROFIBUS PA

mm (in)

ø a

ø b

»50 (1.97)

1

2

3

»50 (1.97)

4

5

6

ø<25 (1.0)

3 (0.12)»

Securing rod probes

• For WHG approvals: For probe lengths ≥ 3 m (10 ft) a support is required.

• In general, rod probes must be supported if there is a horizontal flow (e.g. from an

agitator) or in the case of strong vibrations.

• Rod probes may only be supported at the end of the probe.

1 Probe rod, uncoated

2 Sleeve bored tight to ensure electrical contact between the rod and sleeve!

3 Short metal pipe, e.g. welded in place

4 Probe rod, coated

5 Plastic sleeve, e.g. PTFE, PEEK or PPS

6 Short metal pipe, e.g. welded in place

NOTICE

Poor grounding of the end of probe may cause measuring errors.

Apply a narrow sleeve which has good electrical contact to the probe.

‣

NOTICE

Welding may damage the main electronics module.

‣

Before welding: Ground the probe and dismount electronics.

A0012607

32 Endress+Hauser

Page 33

Levelflex FMP56, FMP57 PROFIBUS PA Mounting

≥≥100

4

≥≥100

4

mm(in)

ø80...150

(ø3.2...6)

1

3

2

6.1.6 Special mounting conditions

Concrete silos

Installation, for example, into a thick concrete ceiling should be made flush with the lower

edge. Alternatively, the probe can also be installed into a pipe that must not protrude over

the lower edge of the silo ceiling. The pipe should be kept at a minimum length.

Installation suggestions see diagram.

A0014138

1 Metal sheet

2 Metal tube

3 Extension rod / Centering HMP40 (see "Accessories")

Note for installations with rod extension/center washer (accessories): Strong dust

generation can lead to build-up behind the center washer. This can cause an interference

signal. For other installation possibilities please contact Endress+Hauser.

Endress+Hauser 33

Page 34

Mounting Levelflex FMP56, FMP57 PROFIBUS PA

Ø16

(Ø0.63)

Ø16.5(0.65)

Ø<26

(Ø<1.02)

mm(in)

Installation from the side

A0014140

• If installation from above is not possible, the Levelflex can also be mounted from the

side.

• In this case, always fix the rope probe → 31 .

• Support rod probe if the lateral loadbearing capacity is exceeded → 26. Only fix rod

probes at the probe end → 31.

34 Endress+Hauser

Page 35

Levelflex FMP56, FMP57 PROFIBUS PA Mounting

1

2

Non-metallic vessels

A0012527

1 Non-metallic vessel

2 Metal sheet or metal flange

To ensure reliable measurements in non-metallic vessels:

• Select an instrument version with metal flange (minimum size DN50/2").

• Or: mount a metal sheet with a diameter of at least 200 mm (8 in) to the probe at the

process connection. Its orientation must be perpendicular to the probe.

Endress+Hauser 35

Page 36

Mounting Levelflex FMP56, FMP57 PROFIBUS PA

MAX

1

3

MAX

2

40(1.57)

40(1.57)

MAX

mm(in)

MAX

1

3

2

Vessels with heat insulation

If process temperatures are high, the device must be included in normal tank

insulation to prevent the electronics heating up as a result of heat radiation or

convection. The insulation may not exceed beyond the points labeled "MAX" in the

drawings.

A0014653

10 Process connection with thread - FMP56, FMP57

1 Tank insulation

2 Compact device

3 Sensor remote (feature 600)

11 Process connection with flange - FMP57

1 Tank insulation

2 Compact device

3 Sensor remote (feature 600)

36 Endress+Hauser

A0014654

Page 37

Levelflex FMP56, FMP57 PROFIBUS PA Mounting

6.2 Mounting the device

6.2.1 Required mounting tools

• For mounting thread 3/4": Hexagonal wrench 36 mm

• For mounting thread 1-1/2": Hexagonal wrench 55 mm

• To shorten rod or coax probes: Saw

• To shorten rope probes:

– Allen key AF 3 mm (for 4mm ropes) or AF 4 mm (for 6 mm ropes)

– Saw or bolt cutter

• For flanges and other process connections: appropriate mounting tools

• To turn the housing: Hexagonal wrench 8 mm

6.2.2 Shortening the probe

When shortening the probe: Enter the new length of probe into the Quick Setup

which can be found in the electronics housing behind the display module.

A0014241

Shortening rod probes

Rod probes must be shortened if the distance to the container floor or outlet cone is less

than 10 mm (0.4 in). The rods of a rod probe are shortened by sawing at the bottom end.

Rod probes of FMP52 can not be shortened as they are coated.

Shortening rope probes

Rope probes must be shortened if the distance to the container floor or outlet cone is less

than 150 mm (6 in).

Endress+Hauser 37

Page 38

Mounting Levelflex FMP56, FMP57 PROFIBUS PA

B

A

C

A0021693

Rope material A B C Torque for set screws

316 4 mm (0.16 in) 40 mm (1.6 in) 3 mm 5 Nm (3.69 lbf ft)

316 6 mm (0.24 in) 55 mm (2.2 in) 4 mm 15 Nm (11.06 lbf ft)

PA > steel 6 mm (0.24 in) 40 mm (1.6 in) 3 mm 5 Nm (3.69 lbf ft)

PA > steel 8 mm (0.31 in) 55 mm (2.2 in) 4 mm 15 Nm (11.06 lbf ft)

1. Using an Allen key, loosen the set screws at the end-of-probe weight. Note: The set

screws have got a clamping coating in order to prevent accidental loosening. Thus an

increased torque might be necessary to loosen them.

2. Remove released rope from the weight.

3. Measure off new rope length.

4. Wrap adhesive tape around the rope at the point to be shortened to prevent it from

fanning out.

5. Saw off the rope at a right angle or cut it off with a bolt cutter.

6. Insert the rope completely into the weight.

7. Screw the set screws into place. Due to the clamping coating of the setscrews

application of a screw locking fluid is not necessary.

38 Endress+Hauser

Page 39

Levelflex FMP56, FMP57 PROFIBUS PA Mounting

6.2.3 Mounting the device

Mounting devices with thread

A0012528

Devices with mounting thread are screwed into a welding boss or a flange and are usually

also secured with these.

• Tighten with the hexagonal nut only:

– Thread 3/4": Hexagonal wrench 36 mm

– Thread 1-1/2": Hexagonal wrench 55 mm

• Maximum permissible torque:

– Thread 3/4": 45 Nm

– Thread 1-1/2": 450 Nm

• Recommended torque when using the supplied aramid fibre seal and a process

pressure of 40 bar (580 psi):

– Thread 3/4": 25 Nm

– Thread 1-1/2": 140 Nm

• When installing in metal containers, take care to ensure good metallic contact

between the process connection and container.

Flange mounting

If a seal is used, be sure to use unpainted metal bolts to ensure good electrical contact

between probe flange and process flange.

Mounting rope probes

NOTICE

Electrostatic discharges may damage the electronics.

Earth the housing before lowering the rope into the vessel.

‣

Endress+Hauser 39

Page 40

Mounting Levelflex FMP56, FMP57 PROFIBUS PA

*

*

A0012529

When lowering the rope probe into the vessel, observe the following:

• Uncoil rope and lower it slowly and carefully into the vessel.

• Do not kink the rope.

• Avoid any backlash, since this might damage the probe or the vessel fittings.

Mounting rope probes in a partially full silo

It is not always possible to empty a silo which is already in operation. If a minimum of

2/3 of the silo is empty, it is possible to install the probe into the partially filled silo. If

possible, make a visual check after the installation to see that the rope has not

tangled or is lying such that it can knot when the level falls. Before full accuracy is

obtained the probe rope must hang fully extended.

6.2.4 Mounting the "Sensor remote" version

This section is only valid for devices of the version "Probe Design" = "Sensor remote"

(feature 600, option MB/MC/MD).

For the version "Probe design" = "Sensor remote" the following is supplied:

• The probe with the process connection

• The electronics housing

• The mounting bracket for wall or pipe mounting of the electronics housing

• The connection cable (length as ordered). The cable has got one straight and one angled

plug (90°). Depending on the local conditions the angled plug can be connected at the

probe or at the electronics housing.

CAUTION

L

The plugs of the connection cable may be damaged by mechanical stress.

Mount the probe and the electronics housing tightly before connecting the cable.

‣

Lay the cable such that it is not exposed to mechanical stress. Minimum bending

‣

radius: 100 mm (4").

When connecting the cable: Connect the straight plug before the angled one. Torque

‣

for both coupling nuts: 6 Nm.

Probe, electronics and connection cable are adjusted to match each other. They are

marked by a common serial number. Only components with the same serial number

shall be connected to each other.

If the measuring point is exposed to strong vibrations, an additional locking

compound (e.g. Loctite 243) can be applied at the plug connectors.

40 Endress+Hauser

Page 41

Levelflex FMP56, FMP57 PROFIBUS PA Mounting

122 (4.8)

52 (2)

86

(3.4)

70

(2.8)

140 (5.5)

158 (6.2)

175 (6.9)

A B

ø42...60

(1.65...2.36)

A

B

C

C

r = 100 (4)

min

r = 100 (4)

min

6 Nm

(4.42 lbf ft)

6 Nm

(4.42 lbf ft)

6 Nm

(4.42 lbf ft)

6 Nm

(4.42 lbf ft)

Mounting the electronics housing

A0014793

12 Mounting the electronics housing using the mounting bracket; dimensions: mm (in)

A Wall mounting

B Pipe mounting

Connecting the cable

Required tools:

Open-end wrench 18AF

13 Connecting the cable. There are the following possibilities:

A Angled plug at the probe

B Angled plug at the electronics housing

C Length of the remote cable as ordered

A0014794

Endress+Hauser 41

Page 42

Mounting Levelflex FMP56, FMP57 PROFIBUS PA

max.350°

8mm

8mm

+

E

–

1

3mm

6.2.5 Turning the transmitter housing

To provide easier access to the connection compartment or display module, the transmitter

housing can be turned:

A0013713

1. Unscrew the securing screw using an open-ended wrench.

2. Rotate the housing in the desired direction.

3. Tighten the securing screw (1,5 Nm for plastics housing; 2,5 Nm for aluminium or

stainless steel housing).

6.2.6 Turning the display module

1. If present: Loosen the screw of the securing clamp of the electronics compartment

cover using an Allen key and turn the clamp 90° conterclockwise.

2. Unscrew cover of the electronics compartment from the transmitter housing.

3. Pull out the display module with a gentle rotation movement.

4. Rotate the display module into the desired position: Max. 8 × 45 ° in each direction.

5. Feed the spiral cable into the gap between the housing and main electronics module

and plug the display module into the electronics compartment until it engages.

6. Screw the cover of the electronics compartment firmly back onto the transmitter

housing.

7. Tighten the securing clamp again using the Allen key (Torque: 2.5 Nm).

A0013905

42 Endress+Hauser

Page 43

Levelflex FMP56, FMP57 PROFIBUS PA Mounting

6.3 Post-installation check

Is the device undamaged (visual inspection)?

m

Does the device conform to the measuring point specifications?

For example:

• Process temperature

m

• Process pressure (refer to the chapter on "Material load curves" of the "Technical Information"

document)

• Ambient temperature range

• Measuring range

Are the measuring point identification and labeling correct (visual inspection)?

m

Is the device adequately protected from precipitation and direct sunlight?

m

Are the securing screw and securing clamp tightened securely?

m

Endress+Hauser 43

Page 44

Electrical connection Levelflex FMP56, FMP57 PROFIBUS PA

1

3

+

+

2

4

FIELDBUS

2-channel overvoltage protection

-

-

[17]

4-20mA/

4-20mA/

B

1

1

+

+

2

2

FIELDBUS

Spare part

71023457

PA/FF

[06/07]

FIELDBUS

-

-

1

3

+

+

2

4

PA/FF

10 mm

Spare part

71108xxx

2- wire level

4-20 mA PFS

FIELDBUS

[26/27]

open

-

-

A

4

1

1

2

3

6

5

3+

3+

4-

4-

!

7 Electrical connection

7.1 Connection conditions

7.1.1 Terminal assignment

PROFIBUS PA / FOUNDATION Fieldbus

14 Terminal assignment PROFIBUS PA / FOUNDATION Fieldbus

A Without integrated overvoltage protection

B With integrated overvoltage protection

1 Cable screen: Observe cable specifications

2 Switch output (open collector): Terminals 3 and 4

3 PROFIBUS PA / FOUNDATION Fieldbus: Terminals 1 and 2

4 Terminal for potential equalization line

5 Cable entries

6 Overvoltage protection module

44 Endress+Hauser

A0011341

Page 45

Levelflex FMP56, FMP57 PROFIBUS PA Electrical connection

3+

+

-

4-

3+

2

1

+

4-

Connection examples for the switch output

A0015909

15 Connection of a relay

Suitable relays (examples):

• Solid-state relay: Phoenix Contact OV-24DC/480AC/5 with mounting

rail connector UMK-1 OM-R/AMS

• Electromechanical relay: Phoenix Contact PLC-RSC-12DC/21

16 Connection of a digital input

1 Pull-up resistor

2 Digital input

A0015910

For optimum interference immunity we recommend to connect an external resistor

(internal resistance of the relay or Pull-up resistor) of < 1 000 Ω.

7.1.2 Cable specification

• Devices without integrated overvoltage protection

Pluggable spring-force terminals for wire cross-sections 0.5 to 2.5 mm2 (20 to 14 AWG)

• Devices with integrated overvoltage protection

Screw terminals for wire cross-sections 0.2 to 2.5 mm2 (24 to 14 AWG)

• For ambient temperature TU≥60 °C (140 °F): use cable for temperature TU +20 K.

PROFIBUS

Use a twisted, screened two-wire cable, preferably cable type A.

For further information on the cable specifications, see Operating Instructions

BA00034S "PROFIBUS DP/PA: Guidelines for planning and commissioning",

PNO Guideline 2.092 "PROFIBUS PA User and Installation Guideline" and

IEC 61158-2 (MBP).

Endress+Hauser 45

Page 46

Electrical connection Levelflex FMP56, FMP57 PROFIBUS PA

2

1

3

4

4

2

3

1

7.1.3 Device plug connectors

For the versions with fieldbus plug connector (M12 or 7/8"), the signal line can be

connected without opening the housing.

Pin assignment of the M12 plug connector

Pin Meaning

1 Signal +

2 not connected

3 Signal -

4 Ground

A0011175

Pin assignment of the 7/8" plug connector

Pin Meaning

1 Signal -

2 Signal +

3 Not connected

4 Screen

A0011176

46 Endress+Hauser

Page 47

Levelflex FMP56, FMP57 PROFIBUS PA Electrical connection

7.1.4 Power supply

PROFIBUS PA, FOUNDATION Fieldbus

"Power supply; Output"

E: 2-wire; FOUNDATION Fieldbus, switch output

G: 2-wire; PROFIBUS PA, switch output

1) Feature 020 of the product structure

2) Feature 010 of the product structure

3) Input voltages up to 35 V will not spoil the device.

Polarity sensitive No

FISCO/FNICO compliant

according to IEC 60079-27

1)

Yes

"Approval"

• Non-Ex

• Ex nA

• Ex nA[ia]

• Ex ic

• Ex ic[ia]

• Ex d[ia] / XP

• Ex ta / DIP

• CSA GP

• Ex ia / IS

• Ex ia + Ex d[ia] / IS + XP

2)

Terminal voltage

9 to 32 V

9 to 30 V

3)

7.1.5 Overvoltage protection

If the measuring device is used for level measurement in flammable liquids which requires

the use of overvoltage protection according to DIN EN 60079-14, standard for

test procedures 60060-1 (10 kA, pulse 8/20 μs), overvoltage protection has to be ensured

by an integrated or external overvoltage protection module.

Integrated overvoltage protection

An integrated overvoltage protection module is available for 2-wire HART as well as

PROFIBUS PA and FOUNDATION Fieldbus devices.

Product structure: Feature 610 "Accessory mounted", option NA "Overvoltage protection".

Technical data

Resistance per channel 2 × 0.5 Ω max.

Threshold DC voltage 400 to 700 V

Threshold impulse voltage < 800 V

Capacitance at 1 MHz < 1.5 pF

Nominal arrest impulse voltage (8/20 μs) 10 kA

External overvoltage protection

HAW562 or HAW569 from Endress+Hauser are suited as external overvoltage protection.

For detailed information please refer to the following documents:

• HAW562: TI01012K

• HAW569: TI01013K

Endress+Hauser 47

Page 48

Electrical connection Levelflex FMP56, FMP57 PROFIBUS PA

1.

2.

3.

10 (0.4)

10 (0.4)

mm (in)

4.

5.

5.

7.2 Connecting the device

WARNING

L

Explosion hazard!

Comply with the relevant national standards.

‣

Observe the specifications in the Safety Instructions (XA).

‣

Only use the specified cable glands.

‣

Check whether the supply voltage matches the specifications on the nameplate.

‣

Before connecting the device: Switch the supply voltage off.

‣

Before switching on the supply voltage: Connect the potential bonding line to the

‣

exterior ground terminal.

Required tools and accessories:

• For instruments with safety pin for the lid: AF 3 Allen key

• Wire stripping pliers

• When using stranded wires: Wire end sleeves.

A0012619

1. Loosen the screw of the securing clamp of the connection compartment cover and

turn the clamp 90° counterclockwise.

2. Unscrew the connection compartment cover.

3. Push the cable through the cable entry. To ensure tight sealing, do not remove the

sealing ring from the cable entry.

4. Strip the cable.

5. Strip the cable ends 10 mm (0.4 in). For stranded cables, also attach wire end

ferrules.

6. Firmly tighten the cable glands.

48 Endress+Hauser

Page 49

Levelflex FMP56, FMP57 PROFIBUS PA Electrical connection

2

1

4

3

mm(in)

≤ 3(0.12)

7.

A0013837

Connect the cable in accordance with the terminal assignment → 44.

8. When using screened cable: Connect the cable screen to the ground terminal.

9. Screw the cover onto the connection compartment.

10. For instruments with safety pin for the lid: Adjust the safety pin so that its edge is

over the edge of the display lid. Tighten the safety pin.

7.2.1 Pluggable spring-force terminals

Instruments without integrated overvoltage protection have pluggable spring-force

terminals. Rigid conductors or flexible conductors with cable sleeve can directly be inserted

and are contacted automatically.

To remove cables from the terminal: Press on the groove between the terminals using a

flat-tip screwdriver ≤ 3 mm (0.12 inch) while pulling the cables out of the terminals.

A0013661

7.3 Post-connection check

Are cables or the device undamaged (visual inspection)?

m

Do the cables comply with the requirements?

m

Do the cables have adequate strain relief?

m

Are all cable glands installed, firmly tightened and correctly sealed?

m

Does the supply voltage match the specifications on the transmitter nameplate?

m

Is the terminal assignment correct → 44?

m

Endress+Hauser 49

Page 50

Electrical connection Levelflex FMP56, FMP57 PROFIBUS PA

If required: Is the protective earth connected correctly ?

m

If supply voltage is present: Is the device ready for operation and do values appear on the display

m

module?

Are all housing covers installed and firmly tightened?

m

Is the securing clamp tightened correctly?

m

50 Endress+Hauser

Page 51

Levelflex FMP56, FMP57 PROFIBUS PA Operation options

8 Operation options

8.1 Overview

8.1.1 Local operation

Operation

with

Order code for

"Display;

Operation"

Display

elements

Operating

elements

Additional

functionality

Pushbuttons Touch Control

Option C "SD02" Option E "SD

A0032219 A0032221

4-line display 4-line display

white background lighting; switches to red in

event of device error

Format for displaying measured variables and status variables can be individually configured

Permitted ambient temperature for the display: –20 to +70 °C (–4 to +158 °F)

The readability of the display may be impaired at temperatures outside the temperature

range.

local operation with 3 push buttons (, ,)external operation via touch control; 3 optical

keys: , ,

Operating elements also accessible in various hazardous areas

Data backup function

The device configuration can be saved in the display module.

Data comparison function

The device configuration saved in the display module can be compared to the current device

configuration.

Data transfer function

The transmitter configuration can be transmitted to another device using the display module.

Endress+Hauser 51

Page 52

Operation options Levelflex FMP56, FMP57 PROFIBUS PA

3

2

1

ENDRESS + HAUSER

T

PROFIBUS DP

PROFIBUS PA

1

2

3

5

4 4 4

8.1.2 Operation with remote display and operating module FHX50

A0013137

17 FHX50 operating options

1 Housing of the remote display and operating module FHX50

2 Display and operating module SD02, push buttons; cover must be removed

3 Display and operating module SD03, optical keys; can be operated through the glass of the cover

8.1.3 Remote operation

Via PROFIBUS PA protocol

A0015775

1 Segment coupler

2 Computer with Profiboard/Proficard and operating tool (e.g. FieldCare)

3 PLC (Progrommable Logic Controller)

4 Transmitter

5 Additional functions (valves etc.)

52 Endress+Hauser

Page 53

Levelflex FMP56, FMP57 PROFIBUS PA Operation options

+

E

–

12

3

Via service interface (CDI)

A0014019

1 Service interface (CDI) of the measuring device (= Endress+Hauser Common Data Interface)

2 Commubox FXA291

3 Computer with "FieldCare" operating tool

Endress+Hauser 53

Page 54

Operation options Levelflex FMP56, FMP57 PROFIBUS PA

8.2 Structure and function of the operating menu

8.2.1 Structure of the operating menu

Menu Submenu /

parameter

Language

Commissioning

Setup Parameter 1

Diagnostics Diagnostic list Contains up to 5 currently active error

5)

Expert

Contains all parameters of the device

(including those which are already contained

in one of the above submenus). This menu is

organized according to the function blocks of

the device.

The parameter of the Expert menu are

described in:

GP01018F (PROFIBUS PA)

2)

...

Parameter N

Advanced setup Contains further submenus and

Event logbook

Device information Contains information needed to identify

Measured values Contains all current measured values.

Data logging Contains the history of the individual

Simulation Used to simulate measured values or

Device check Contains all parameters needed to check

Heartbeat

System Contains all general device parameters

Sensor Contains all parameters needed to

Output Contains all parameters neeed to

1)

4)

Meaning

Defines the operating language of the

on-site display.

Opens the interactive wizard for a guided

commissioning of the device.

As a rule, no additional settings in the

other menus are required after the

completion of the wizard.

When all these parameters have been

assigned appropriate values, the

measured should be completely

configured in a standard application.

parameters:

• to adapt the device to special

measuring conditions.

• to process the measured value (scaling,

linearization).

• to configure the signal output.

messages.

3)

Contains the last 20 messages (which are

no longer active).

the device.

measuring values.

output values.

the measurement capability of the

device.

Contains all wizards for the Heartbeat

Verification and Heartbeat Monitoring

application packages.

which do not affect the measurement or

the communication interface.

configure the measurement.

configure the switch output (PFS).

54 Endress+Hauser

Page 55

Levelflex FMP56, FMP57 PROFIBUS PA Operation options

Menu Submenu /

parameter

Communication Contains all parameters needed to

Diagnostics Contains all parameters needed to detect

1) In case of operation via operating tools (e.g. FieldCare), the "Language" parameter is located at "Setup →

Advanced setup → Display"

2) only for operation via a FDT/DTM system

3) only available with local operation

4) only available for operation via DeviceCare or FieldCare

5) On entering the "Expert" menu, an access code is always requested. If a customer specific access code has

not been defined, "0000" has to be entered.

Meaning

configure the digital communication

interface.

and analyze operational errors.

Endress+Hauser 55

Page 56

Operation options Levelflex FMP56, FMP57 PROFIBUS PA

8.2.2 User roles and related access authorization

The two user roles Operator and Maintenance have different write access to the

parameters if a device-specific access code has been defined. This protects the device

configuration via the local display from unauthorized access → 57.

Access authorization to parameters

User role Read access Write access

Without access

code

(from the factory)

Operator --

Maintenance

If an incorrect access code is entered, the user obtains the access rights of the Operator

role.

The user role with which the user is currently logged on is indicated by the Access

status display parameter (for display operation) or Access status tooling parameter

(for tool operation).

With access code Without access

code

(from the factory)

With access code

56 Endress+Hauser

Page 57

Levelflex FMP56, FMP57 PROFIBUS PA Operation options

8.2.3 Write protection via access code

Using the device-specific access code, the parameters for the measuring device

configuration are write-protected and their values can no longer be changed via local

operation.

Define access code via local display

1. Navigate to: Setup → Advanced setup → Administration → Define access code

→ Define access code

2. Define a max. 4-digit numeric code as an access code.

3. Repeat the same code in Confirm access code parameter.

The -symbol appears in front of all write-protected parameters.

Define access code via operating tool (e.g. FieldCare)

1. Navigate to: Setup → Advanced setup → Administration → Define access code

2. Define a max. 4-digit numeric code as an access code.

Write protection is active.

Parameters that can always be changed

The write protection does not include certain parameters that do not affect the

measurement. Despite the defined access code, they can always be modified, even if the

other parameters are locked.

If no key is pressed for 10 minutes in the navigation and editing mode, the device

automatically locks the write-protected parameters. If the user goes from the navigation

and editing mode back to the measured value display mode, the device automatically locks

the write-protected parameters after 60 s.

• If write access is activated via access code, it can be also be deactivated only via the

access code → 58.

• In the "Description of Device Parameters" documents, each write-protected

parameter is identified with the -symbol.

Endress+Hauser 57

Page 58

Operation options Levelflex FMP56, FMP57 PROFIBUS PA

8.2.4 Disabling write protection via access code

If the

write-protected by a device-specific access code and its value cannot be changed at the

moment using the local display → 57.

The locking of the write access via local operation can be disabled by entering the devicespecific access code.

-symbol appears on the local display in front of a parameter, the parameter is

1. After you press , the input prompt for the access code appears.

2. Enter the access code.

The -symbol in front of the parameters disappears; all previously write-

protected parameters are now re-enabled.