Page 1

BA00430C/07/EN/14.19

71453974

2019-01-07

Products Solutions Services

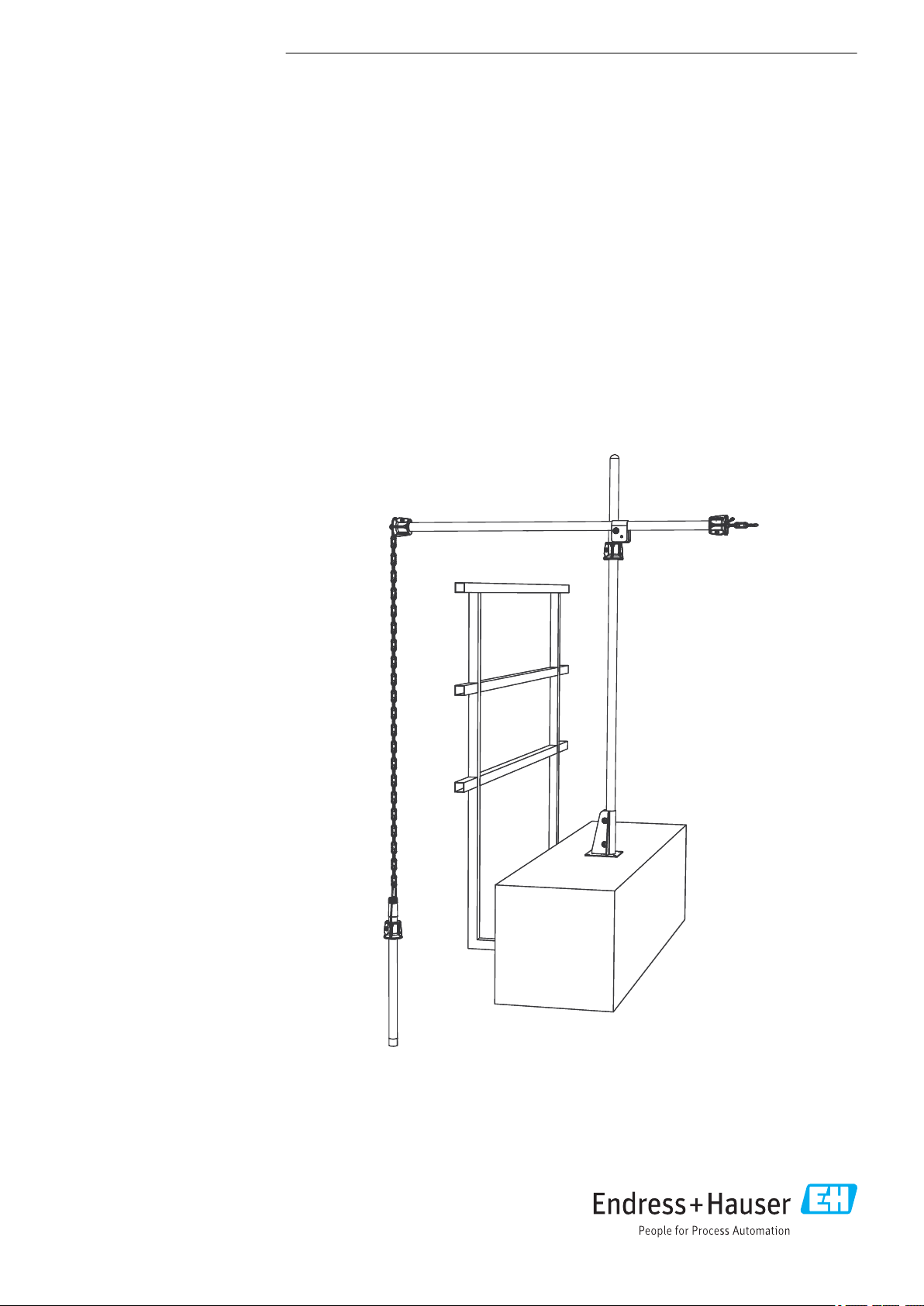

Operating Instructions

Flexdip CYH112

Holder for water and wastewater assemblies

Page 2

Page 3

Flexdip CYH112 Table of contents

Table of contents

1 About this document ................ 4

1.1 Warnings ............................ 4

1.2 Symbols used .......................... 4

2 Basic safety instructions ............ 5

2.1 Requirements for the personnel ............ 5

2.2 Designated use ........................ 5

2.3 Workplace safety ....................... 5

2.4 Operational safety ...................... 6

2.5 Product safety ......................... 6

3 Product description ................. 7

3.1 Product design ......................... 7

4 Incoming acceptance and product

identification ....................... 9

4.1 Incoming acceptance .................... 9

4.2 Product identification ................... 10

4.3 Scope of delivery ...................... 10

4.4 Certificates and approvals ............... 11

5 Installation ....................... 12

5.1 Installation conditions .................. 12

5.2 Mounting the holder ................... 13

5.3 Mounting options ..................... 25

5.4 Post-installation check .................. 29

6 Operation options ................. 30

6.1 Operating the pendulum holder ........... 30

7 Maintenance ...................... 31

7.1 Maintenance tasks ..................... 31

8 Repair ............................ 34

8.1 Return .............................. 34

8.2 Disposal ............................ 34

9 Accessories ....................... 35

10 Technical data .................... 40

10.1 Environment ......................... 40

10.2 Mechanical construction ................ 40

Index .................................. 44

Endress+Hauser 3

Page 4

About this document Flexdip CYH112

1 About this document

1.1 Warnings

Structure of information Meaning

DANGER

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

NOTICE

Cause/situation

If necessary, Consequences of

non-compliance (if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to

property.

1.2 Symbols used

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

1.2.1 Symbols on the device

Symbol Meaning

Reference to device documentation

4 Endress+Hauser

Page 5

Flexdip CYH112 Basic safety instructions

2 Basic safety instructions

2.1 Requirements for the personnel

• Installation, commissioning, operation and maintenance of the measuring system may

be carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the

specified activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions

and must follow the instructions contained therein.

• Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

The assembly holder has been developed for use in the wastewater sector. CYH112 is

designed as a modular holder system for sensors and assemblies in open basins, channels

and tanks.

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

NOTICE

Applications outside specifications!

Incorrect measurements, malfunctions and even measuring point failure could result

Use the product only in accordance with the specifications.

‣

Pay attention to the technical data on the nameplate.

‣

2.3 Workplace safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

• Regulations for explosion protection

Endress+Hauser 5

Page 6

Basic safety instructions Flexdip CYH112

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

During operation:

If faults cannot be rectified:

‣

products must be taken out of service and protected against unintentional operation.

2.5 Product safety

2.5.1 State-of-the-art technology

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

international standards have been observed.

6 Endress+Hauser

Page 7

Flexdip CYH112 Product description

1

2

3

4

5

6

3 Product description

3.1 Product design

A0037898

1 Example of mounted CYH112 holder

1 Base

2 Main pipe

3 Multifunctional clamp ring

4 Transverse pipe

5 Cross clamp

6 Immersion pipe of the CYA112 assembly

Endress+Hauser 7

Page 8

Product description Flexdip CYH112

1

2

3

4

4

5

6

7

A0037909

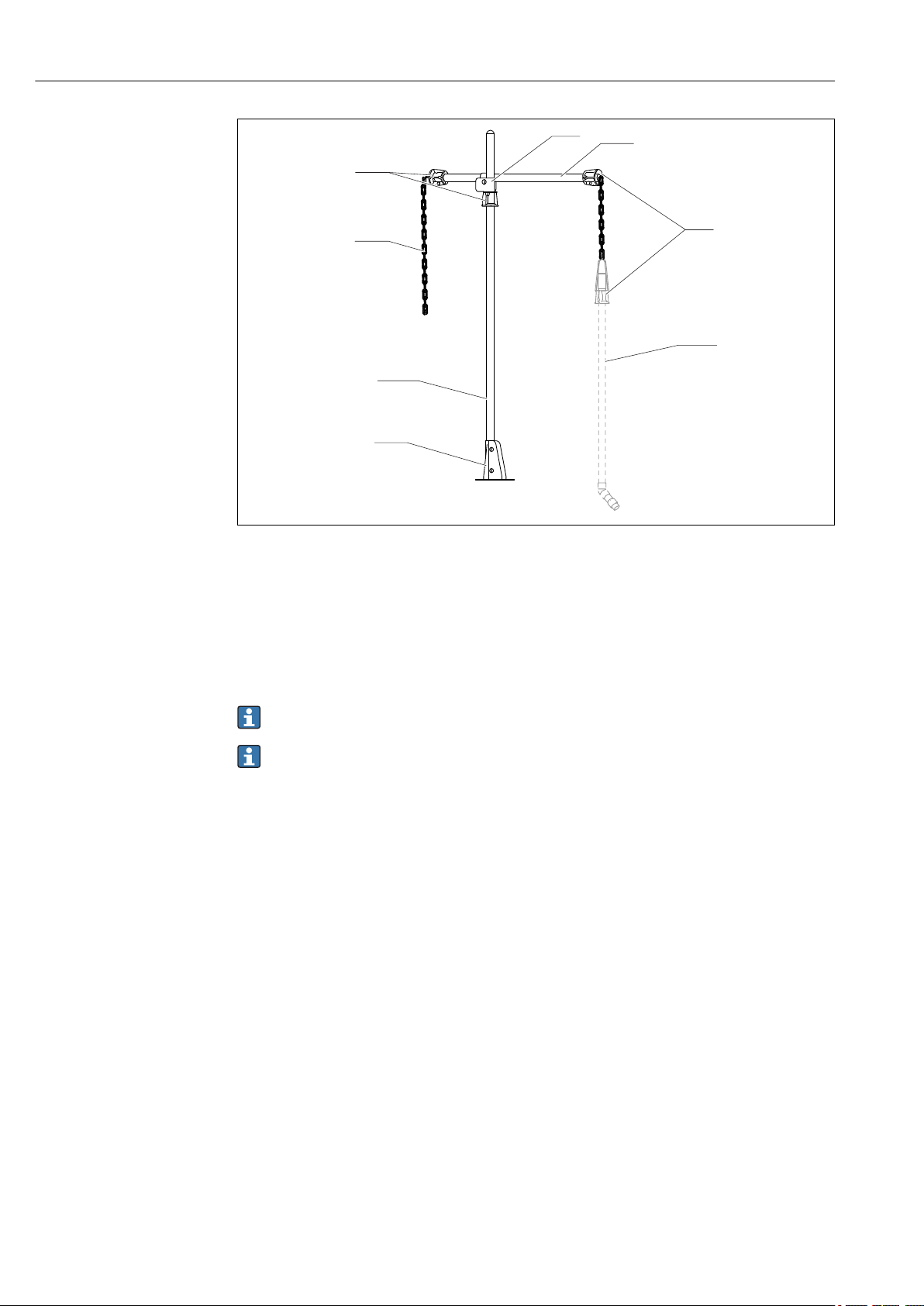

2 Example of mounted CYH112 holder with chain

1 Base

2 Main pipe

3 Chain

4 Multifunctional clamp ring

5 Cross clamp

6 Transverse pipe

7 Immersion pipe of the CYA112 assembly

Always hook the bracket of the assembly through the last link in the chain.

Attach the holder depending on the ambient conditions.

8 Endress+Hauser

Page 9

Flexdip CYH112 Incoming acceptance and product identification

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify the supplier of any damage to the packaging.

Keep the damaged packaging until the issue has been resolved.

2. Verify that the contents are undamaged.

Notify the supplier of any damage to the delivery contents.

Keep the damaged goods until the issue has been resolved.

3. Check that the delivery is complete and nothing is missing.

Compare the shipping documents with your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

Make sure to comply with the permitted ambient conditions.

If you have any questions, please contact your supplier or your local Sales Center.

Endress+Hauser 9

Page 10

Incoming acceptance and product identification Flexdip CYH112

4.2 Product identification

4.2.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Order code

• Extended order code

• Serial number

• Ambient and process conditions

• Safety information and warnings

Compare the information on the nameplate with the order.

‣

4.2.2 Identifying the product

Product page

www.endress.com/cyh112

Interpreting the order code

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Go to www.endress.com.

2. Call up the site search (magnifying glass).

3. Enter a valid serial number.

4. Search.

The product structure is displayed in a popup window.

5. Click on the product image in the popup window.

A new window (Device Viewer) opens. All of the information relating to your

device is displayed in this window as well as the product documentation.

4.2.3 Manufacturer's address

Endress+Hauser Conducta GmbH+Co. KG

Dieselstraße 24

D-70839 Gerlingen

4.3 Scope of delivery

The delivery comprises:

• Ordered version of assembly holder

• Operating Instructions

If you have any queries:

‣

Please contact your supplier or local sales center.

10 Endress+Hauser

Page 11

Flexdip CYH112 Incoming acceptance and product identification

4.4 Certificates and approvals

Explosion protection

The CYH112 holder may also be used in hazardous areas in Zone 1 and 2.

The holder does not fall within the scope of ATEX Directive 2014/34/EU as it does not

have a potential source of ignition of its own. Consequently, the holder does not bear

ATEX identification marking. Potential equalization must be implemented as described in

the "Installation conditions" section.

Endress+Hauser 11

Page 12

Installation Flexdip CYH112

kg

10

1200

1000

lbs

22

39.4

47.2

5

4

0

11

8.8

mm

inch

500

19.7

0

6.5

14.3

750

29.5

5 Installation

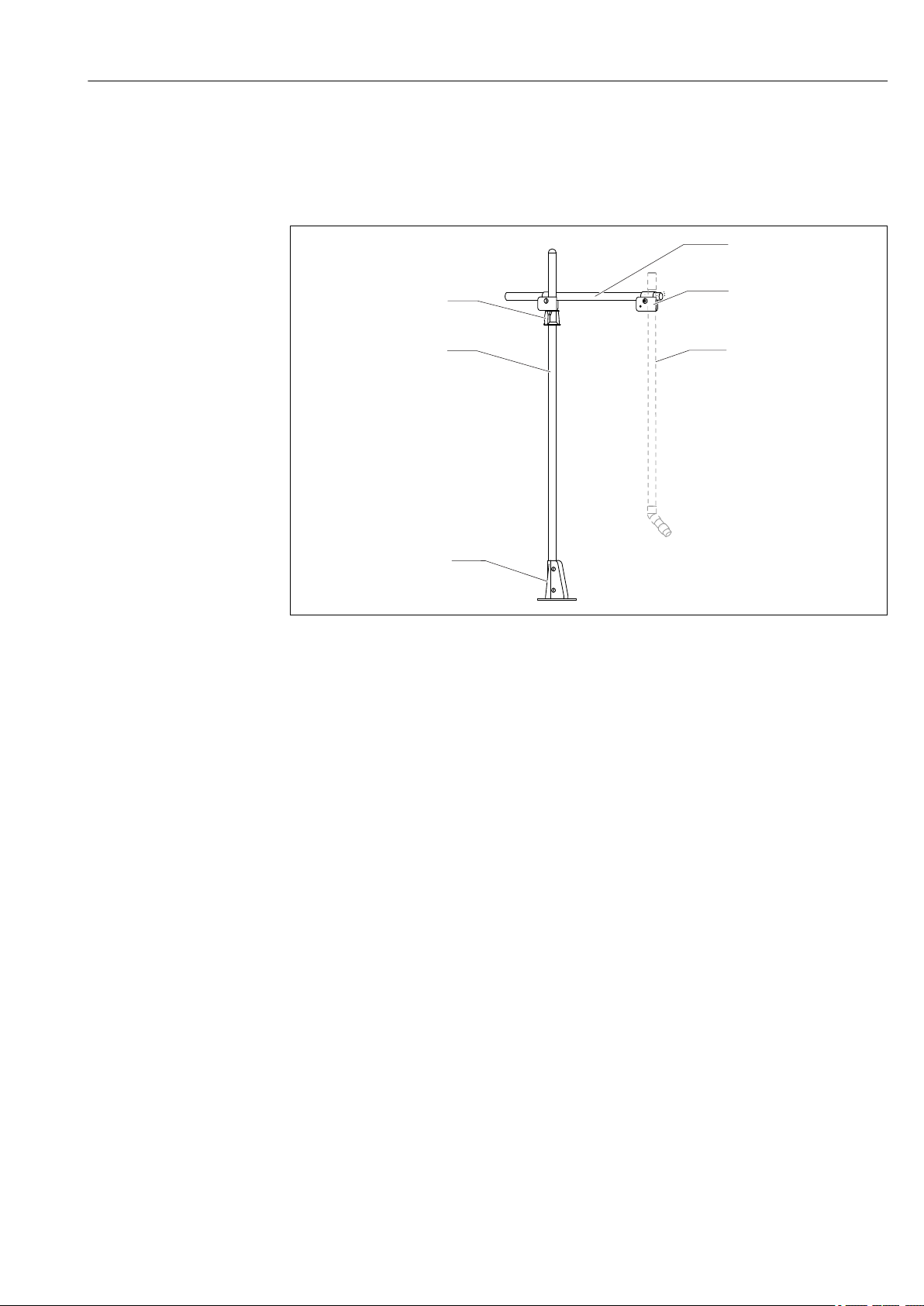

5.1 Installation conditions

5.1.1 Mounting instructions

The maximum extension depends on the suspended load (weight of immersion pipe,

assembly and cable). See the following diagram for this purpose:

A0010837

3 Extension as a function of the suspended load

The maximum permitted load when mounting on a rail and using a pendulum holder with

a pendulum adapter is 5 kg (11 lb). Potential equalization must be implemented at the

place of installation. All electrically conductive parts must be interconnected.

Cable

The cable to the sensor is routed outside along the pipe. Hook-and-loop cable ties can be

ordered as accessories to secure the cable.

Cable routing for the power supply must be implemented by the customer onsite.

12 Endress+Hauser

Page 13

Flexdip CYH112 Installation

1200 (47.2)

1200 (47.2)

5.1.2 Dimensions

A0010838

4 Dimensions with maximum extension. Dimensions: mm (in)

The values indicated are valid for floor, wall and rail mounting.

5.2 Mounting the holder

For more information on mounting the assembly with the holder, see Operating

Instructions BA00432

5.2.1 Measuring system

A complete measuring system consists of:

• CYH112 holder

• Assembly, e.g. CYA112

• Transmitter, e.g. Liquiline CM44

• Sensor, e.g. CUS71D

Endress+Hauser 13

Page 14

Installation Flexdip CYH112

1

2

3

4

6

7

5

A0010865

5 Measuring system with CYH112 holder

1 Main pipe secured to floor

2 Transmitter

3 Protective cover

4 Transverse pipe with fastening elements

5 Hook-and-loop cable ties

6 Chain

7 CPA111 assembly

5.2.2 Mounting the base

Use the M10 chemical anchor to mount the base on a concrete floor.

1. Set the base in position (the open part faces the basin rim).

The minimum distance between the bores and the basin rim is 40 mm (1.57 in).

2. Mark the securing holes for the base on the floor.

3. Drill the securing holes with a 12 mm drill.

4. Install the 4 chemical anchors.

5. Firmly screw down the base.

6. Ground the base with a ground cable (≥ 4 mm² (≥ 12 AWG)).

14 Endress+Hauser

Page 15

Flexdip CYH112 Installation

1

2

1

2

3

5.2.3 Mounting the main pipe

A0038457

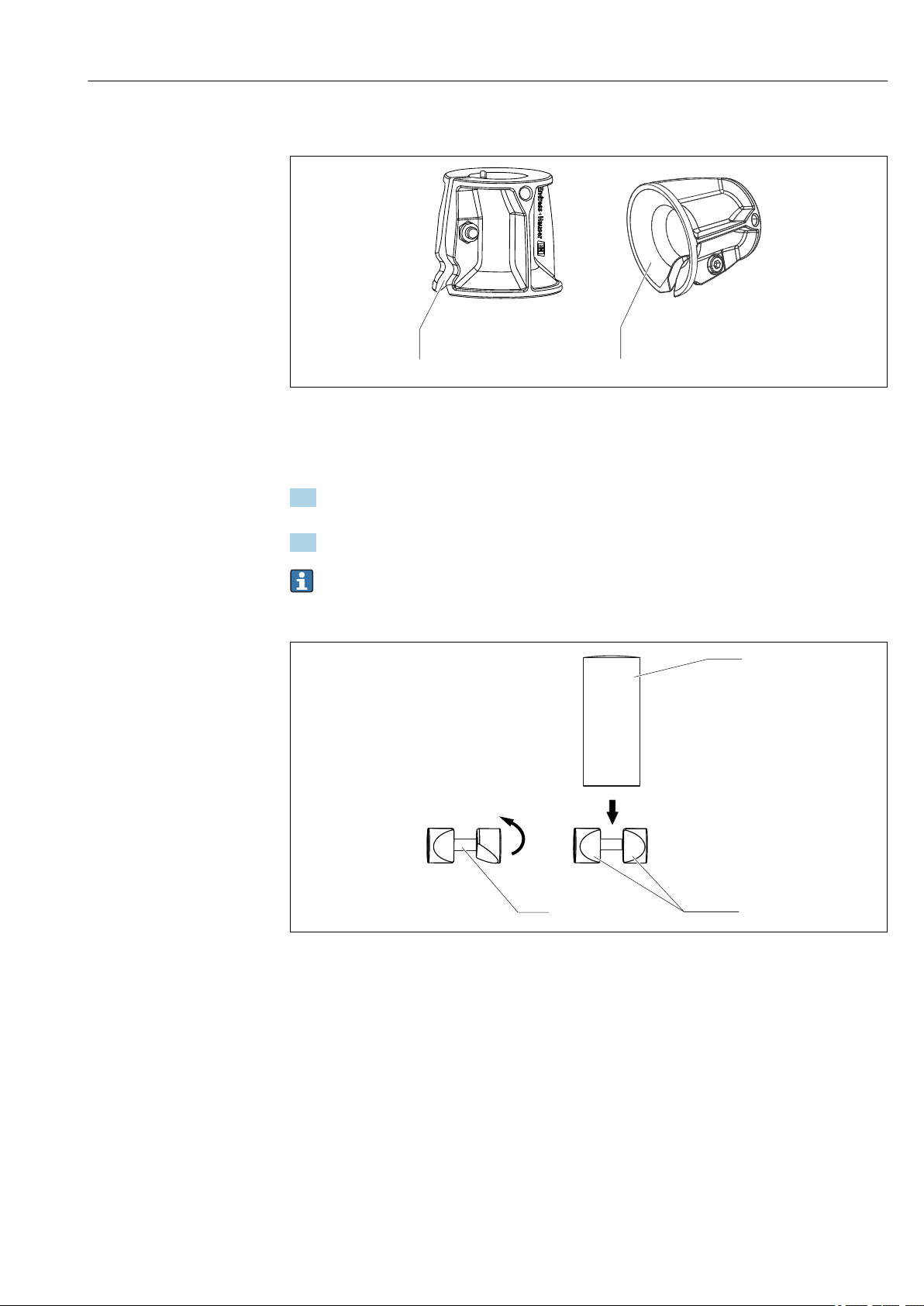

6 Multifunctional clamp ring

1 Slot in the multifunctional clamp ring

2 Multifunctional clamp ring, funnel-shaped side

1. Attach the multifunctional clamp ring to the main pipe, with the funnel-shaped side

pointing downwards.

2. Firmly tighten the multifunctional clamp ring.

The distance between the upper edge of the multifunctional clamp ring and the base

plate may not exceed 1 100 mm (43.3 in). The multifunctional clamp ring acts as an

anti-slip lock here.

7 Adjusting the clamps

1 Pipe

2 Clamps

3 Clamp screw

A0038382

Endress+Hauser 15

Page 16

Installation Flexdip CYH112

1

2

3

4

3

4

A0038385

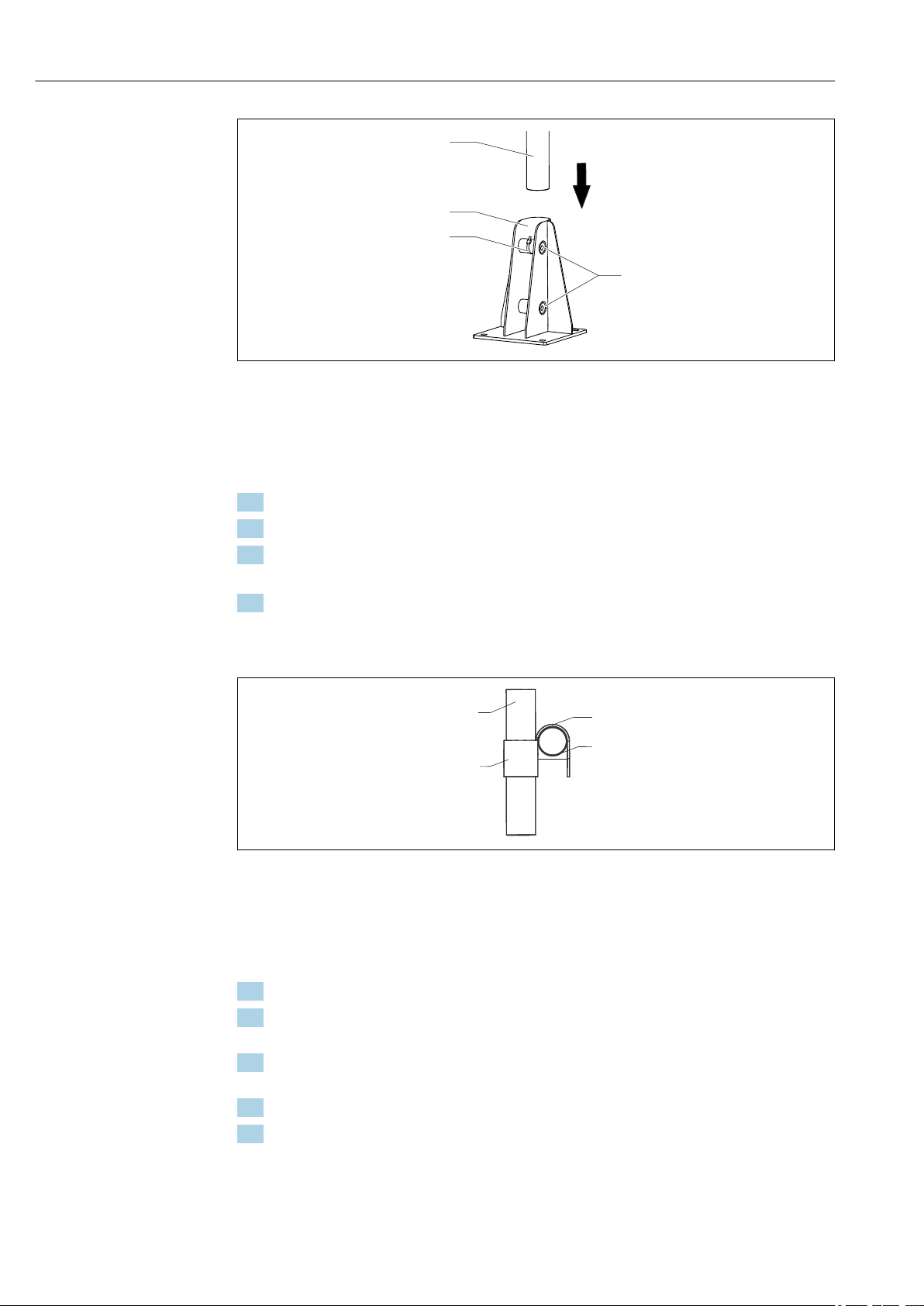

8 Base with main pipe

1 Main pipe

2 Base

3 Hook-and-loop cable ties

4 Clamps with clamp screws

1. Set the clamps in the base in position → 7, 15.

2. Insert the main pipe into the base → 8, 16.

3. Lift the main pipe approx. 5 mm (0.2 in) and fasten it.

No backwater can form in the main pipe.

4. Fit the protection cap on the top end of the main pipe.

5.2.4 Mounting the transverse pipe for fixed-installation assemblies

A0011292

9 Mounting the cross clamp

1 Main pipe

2 Cross clamp, closed side facing the basin

3 Cross clamp, closed side facing upwards

4 Holder transverse pipe

1. Adjust the clamps on the cross clamp → 7, 15.

2. Slide the cross clamp over the transverse pipe, making sure that the closed side of the

cross clamp is located at the top.

3. Attach the cross clamp, along with the transverse pipe, to the main pipe. Make sure

that the closed side of the cross clamp faces the basin.

4. Align the holder.

5. Tighten the clamping screws.

16 Endress+Hauser

Page 17

Flexdip CYH112 Installation

2

3

4

5

5.2.5 Mounting the flange clamp

A0038901

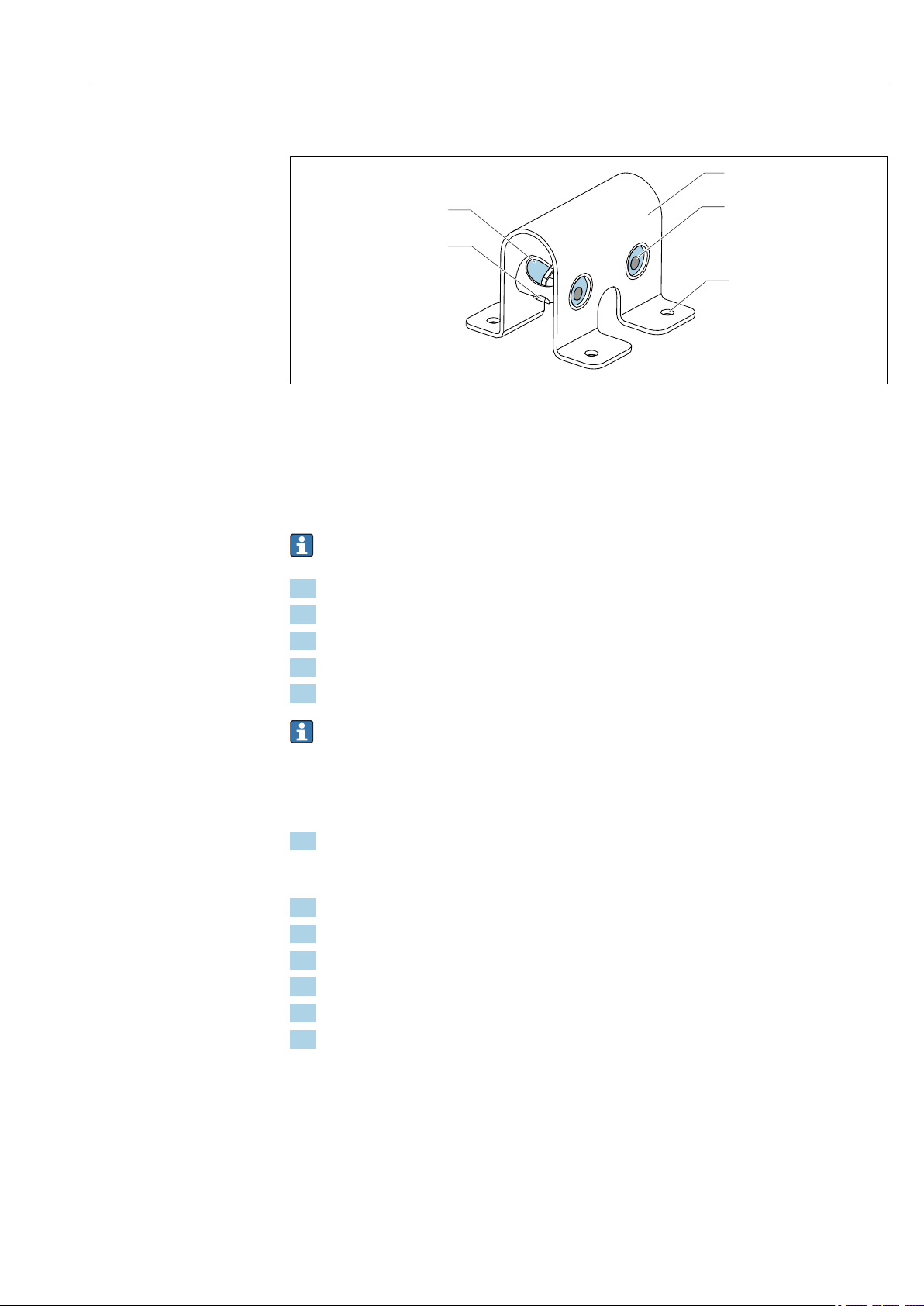

10 Flange clamp

1 Clamps

2 Hook-and-loop cable ties

3 Flange clamp

4 Clamp screw

5 Fastening holes on flange clamp

Use M8 chemical anchors to mount on a concrete floor or a concrete wall.

1. Mark the securing holes on the concrete.

2. Drill the securing holes with a 10 mm drill.

3. Install the chemical anchors.

4. Firmly tighten the flange clamp.

5. Ground the flange clamp with a ground cable (≥ 4 mm² (≥ 12 AWG)).

If mounting on a wall with two wall fasteners, initially only screw on the flange

clamps so that they sit loosely. This makes it easier to mount the main pipe on an

uneven wall.

5.2.6 Mounting the main pipe on the flange clamp

1. Attach the multifunctional clamp ring to the main pipe, with the funnel-shaped side

pointing downwards → 6, 15.

The multifunctional clamp ring acts as an anti-slip lock here.

2. Firmly tighten the multifunctional clamp ring.

3. Adjust the clamps on the flange clamp → 15.

4. Insert the main pipe through the flange clamp.

5. Align the main pipe.

6. Tighten the clamping screws.

7. Fit the protection cap on the top end of the main pipe.

Endress+Hauser 17

Page 18

Installation Flexdip CYH112

1

2

3

2

3

4

1

3

4

5

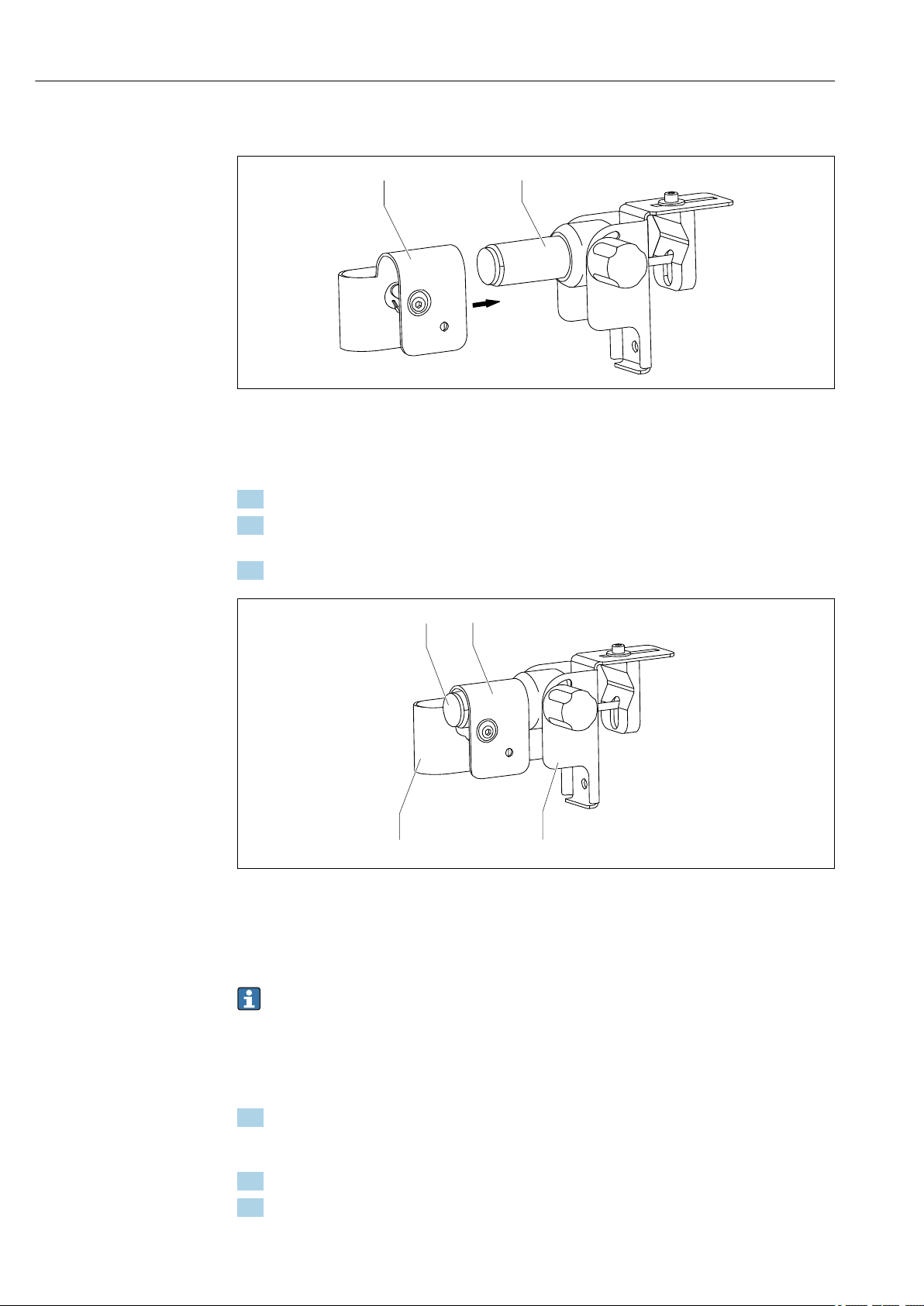

5.2.7 Installing the rail mounting, pendulum holder or immersion pipe tray

11 Rail mounting

1 Retaining screw in clamping jaw

2 Clamping jaw

3 Retaining screw

13 Pendulum holder with pendulum adapter

1 Clamping jaw

2 Retaining screw

3 Retaining screw in clamping jaw

4 Pendulum adapter

5 Pendulum holder

A0038906

A0038908

12 Immersion pipe tray

1 Clamping jaw

2 Retaining screw in clamping jaw

3 Retaining screw

4 Tray for the immersion pipe

A0038907

The rail mounting → 11, 18, the pendulum holder with pendulum adapter

→ 13, 18 or the immersion pipe tray → 12, 18 must each be fitted on a

support (square or circular).

Mount the holder in the desired position on the support using a clamping jaw and 2

‣

retaining screws.

18 Endress+Hauser

Page 19

Flexdip CYH112 Installation

1

2

3

4

3

4

A0011312

14 Fitting the holder on the support

1 Mounting on a square support

2 Mounting on a circular support

3 Retaining screw

4 Retaining screw in clamping jaw

In the case of square supports, mount the clamping jaw with the V-notch facing

outwards; in the case of circular supports, mount with the V-notch facing inwards.

Mounting the holder:

1. Screw in the retaining screws so that they sit loosely.

2. Press the clamping jaw against the support, ensuring that the clamping jaw is parallel

to the holder.

3. Tighten the retaining screw (item 4).

4. Position the retaining screw (item 3) close to the support.

5. Tighten the retaining screw (item 3).

5.2.8 Mounting the transverse pipe on rails or a coping stone for fixed-installation assemblies

1. Adjust the clamps on the cross clamp and the flange clamp → 15.

2. Mount the cross clamp for the assembly on the transverse pipe. Ensure that the

closed sides point upwards and towards the basin → 16.

3. Slide the transverse pipe through the flange clamp.

4. Align the holder.

5. Tighten the clamping screws.

Endress+Hauser 19

Page 20

Installation Flexdip CYH112

1

2

1

2

4

5.2.9 Mounting the cross clamp on the pendulum holder

A0038914

15 Mounting the cross clamp on the pendulum holder

1 Cross clamp

2 Pendulum holder with pendulum adapter

1. Adjust the clamps on the cross clamp → 15.

2. Slide the cross clamp onto the pendulum holder. Ensure that the closed sides point

upwards and to the basin.

3. Tighten the clamping screws.

A0035831

16 Cross clamp with pendulum holder

1 Pendulum holder

2 Cross clamp, closed side facing upwards

3 Cross clamp, closed side facing the basin

For information on the operation of the pendulum holder → 30

5.2.10 Mounting the transverse pipe for assembly chain retainer

Preparing the main pipe for mounting the transverse pipe:

1. Attach the multifunctional clamp ring to the main pipe, with the funnel-shaped side

pointing downwards. The distance between the upper edge of the multifunctional

clamp ring and the base plate may not exceed 1 100 mm (43.3 in).

2. Firmly tighten the multifunctional clamp ring.

3. Fit the protection cap on the top end of the main pipe.

20 Endress+Hauser

Page 21

Flexdip CYH112 Installation

1

3

2

4

A0035832

17 Mounting the multifunctional clamp rings on the transverse pipe

1 Triangular carabiner as anti-slip lock for the chain

2 Multifunctional clamp ring (stand side), slot facing downwards

3 Multifunctional clamp ring (basin side), slot facing upwards

4 Slot in the multifunctional clamp ring

Mounting the transverse pipe:

1. Adjust the clamps on the cross clamp → 15.

2. Slide the cross clamp over the transverse pipe. Ensure that the closed sides of the

cross clamp point upwards and towards the basin.

3. Mount a multifunctional clamp ring on each end of the transverse pipe (funnelshaped sides towards the outside → 6, 15).

4. Adjust the multifunctional clamp rings.

5. On the stand side, position the slot of the multifunctional clamp ring so that it is

pointing downwards, and on the basin side position the slot so that it is pointing

upwards.

6. Guide the chain through the transverse pipe.

7. Fit the chain into the slot of the multifunctional clamp ring (stand side).

8. Secure the chain with the triangular carabiner on both sides.

9. Attach the cross clamp, along with the transverse pipe, to the main pipe.

10. Align the holder.

11. Tighten the clamping screws.

Endress+Hauser 21

Page 22

Installation Flexdip CYH112

1

2

3

6

7

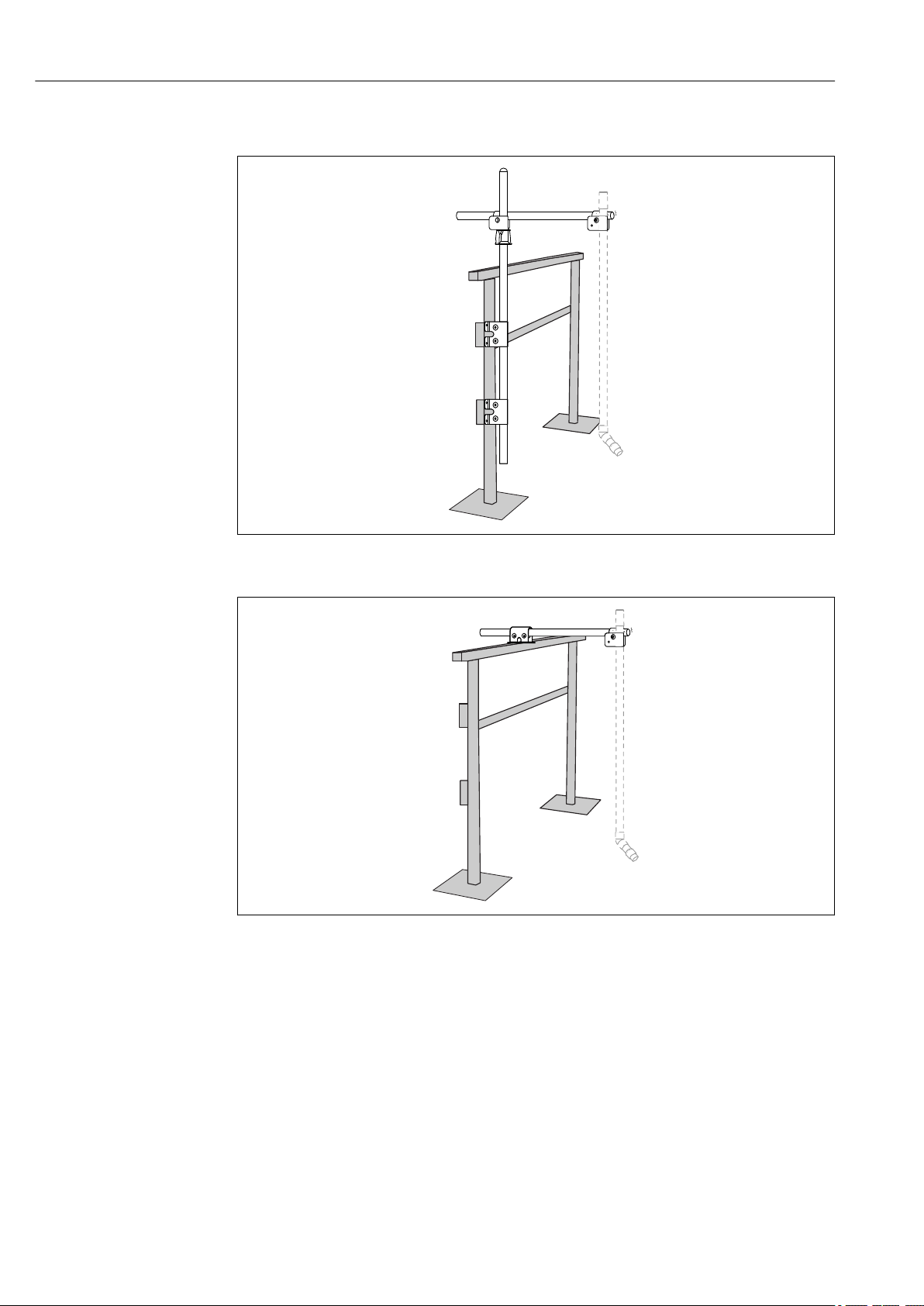

5.2.11 Mounting the transverse pipe for assembly chain retainer without a main pipe

A0035833

18 Installation on coping stone

1 Flange clamp

2 Transverse pipe

3 Multifunctional clamp ring (basin side), slot facing upwards

4 Multifunctional clamp ring (stand side), slot facing downwards

5 Chain

6 Triangular carabiner

7 Slot in the multifunctional clamp ring

1. Adjust the clamps on the flange clamp → 15.

2. Mount the multifunctional clamp ring on one end of the transverse pipe with the

funnel-shaped side facing towards the outside → 6, 15.

3. Slide the transverse pipe through the flange clamp.

4. Mount the second multifunctional clamp ring on the other end of the transverse pipe

with the funnel-shaped side facing towards the outside.

5. Guide the chain through the transverse pipe.

6. Secure the chain with the triangular carabiner.

7. Align the transverse pipe.

8. Ensure that the slot of the multifunctional clamp ring is pointing upwards on the

basin side, and is pointing downwards on the stand side.

9. Tighten the clamping screws.

22 Endress+Hauser

Page 23

Flexdip CYH112 Installation

1

2

3

4

4

5.2.12 Mounting the pendulum holder on the coping stone

A0038917

19 Mounting the pendulum adapter on a coping stone

Use M10 chemical anchors to mount the pendulum holder on a coping stone.

1. Mark the securing points for the pendulum holder on the floor.

2. Drill the securing holes with a 12 mm drill.

3. Install the 2 chemical anchors.

4. Firmly tighten the pendulum holder.

5. Ground the pendulum holder with a ground cable (≥ 4 mm² (≥12 AWG)).

5.2.13 Mounting the quick-action clamp

20 Cross clamp

1 Cross clamp

2 Clamps

3 Clamp screw

4 Hook-and-loop cable ties

A0038430

Endress+Hauser 23

Page 24

Installation Flexdip CYH112

1

2

3

A0011403

21 Mounting the quick-action clamp on the cross clamp

1 Quick-action clamp

2 Clamps

3 Clamp screw

1. Cut off the hook-and-loop cable ties used to secure the existing clamps.

2. Remove the clamping unit (clamps and clamping screw).

3. Insert the quick-action clamp.

4. Adjust the clamps.

5. Secure the quick-action clamp with a cable tie.

6. Mount the second quick-action clamp on the opposite side in the same way.

5.2.14 Mounting the anti-slip lock

A0011371

22 Anti-slip lock for rail mounting

1 Multifunctional clamp ring

24 Endress+Hauser

Page 25

Flexdip CYH112 Installation

In the case of rail mounting, the multifunctional clamp ring acts as an anti-slip lock.

Multifunctional clamp ring → 35

Mount the multifunctional clamp ring at the desired height.

‣

5.3 Mounting options

5.3.1 Floor mounting

23 Mounting on the floor with main pipe and transverse pipe

A0037664

A0037665

24 Mounting on the floor with main pipe, transverse pipe and chain

Endress+Hauser 25

Page 26

Installation Flexdip CYH112

5.3.2 Wall mounting

25 Mounting on a wall with main pipe and transverse pipe

26 Mounting on a wall with transverse pipe

A0037897

A0037899

26 Endress+Hauser

Page 27

Flexdip CYH112 Installation

27 Mounting on a wall with main pipe, transverse pipe and chain

28 Mounting on a wall with transverse pipe and chain

A0037901

A0037902

Endress+Hauser 27

Page 28

Installation Flexdip CYH112

5.3.3 Rail mounting

29 Mounting on a rail with main pipe and transverse pipe

30 Mounting on a rail with transverse pipe

A0037904

A0037906

28 Endress+Hauser

Page 29

Flexdip CYH112 Installation

31 Mounting on a rail with main pipe, transverse pipe and chain

32 Mounting on a rail with transverse pipe and chain

A0037907

A0037908

5.4 Post-installation check

• After mounting, check that all the screws are securely tightened.

• When fastening via the pendulum holder, check that the assembly can move freely.

Endress+Hauser 29

Page 30

Operation options Flexdip CYH112

1

2

3

4

6 Operation options

WARNING

L

Wastewater

There is a risk of infection when working with wastewater!

Wear protective gloves, protective goggles and protective clothing.

‣

6.1 Operating the pendulum holder

33 Specifying the swing axis

1 Swing axis with rotating sleeve blocked

2 Swing axis with rotating sleeve not blocked

3 Rotating sleeve

4 Blocking screw for rotating sleeve

At the pendulum holder, determine the swinging direction (swing axis):

Block the rotating sleeve (item 1) or do not block the rotating sleeve (item 2).

‣

Specifying swinging direction 1:

1. Unscrew the cross clamp from the pendulum holder.

2. Unscrew the blocking screw (item 4) slightly until the rotating sleeve can no longer

rotate.

3. Reattach the cross clamp to the pendulum holder and screw it tight.

4. Release the locking lever.

5. Press the locking button to release the square-headed bolt on the opposite side.

Specifying swinging direction 2:

1. Unscrew the cross clamp from the pendulum holder.

2. Screw the blocking screw into the plastic body until the rotating sleeve can rotate

slightly.

3. Reattach the cross clamp to the pendulum holder.

4. Firmly tighten the cross clamp.

5. Tighten the locking lever.

A0011366

30 Endress+Hauser

Page 31

Flexdip CYH112 Maintenance

1

7 Maintenance

WARNING

L

Wastewater

There is a risk of infection when working with wastewater!

Wear protective gloves, protective goggles and protective clothing.

‣

7.1 Maintenance tasks

A0011372

34 Immersion pipe tray for assembly maintenance position

1 Immersion pipe tray

The immersion pipe tray makes it easier to perform maintenance tasks with rail mounting

involving a pendulum holder and cross clamp.

Endress+Hauser 31

Page 32

Maintenance Flexdip CYH112

2

7.1.1 Setting the assembly to the service position (fixed installation)

A0037661

35 Setting the assembly to the service position

1 Rotational movement 1

2 Rotational movement 2

1. Release the clamp screws on the cross clamp.

2. Move the transverse pipe with the assembly to the stand side (rotational movement

2).

3. Turn the transverse pipe 90° (rotational movement 1).

The assembly tilts upwards.

4. Move the transverse pipe over the basin rim and the railing.

5. Move the transverse pipe back until the desired maintenance position is reached.

32 Endress+Hauser

Page 33

Flexdip CYH112 Maintenance

A

B

7.1.2 Setting the assembly to the service position (chain retainer)

A0037663

36 Setting the assembly to the service position

A Measuring position

B Service position

1. Pull up the assembly by the chain as far as possible.

2. Suspend the chain from the multifunctional clamp ring and secure the chain with the

triangular carabiner.

3. Release the clamp screws on the cross clamp.

4. Move the transverse pipe with the assembly towards the stand side to the desired

maintenance position. If necessary, lift the assembly over the railing.

7.1.3 Clamps and threads

Lubricate the clamps and threads at regular intervals.

1. Clean the clamps and threads with soapy water.

2. Dry the clamps and threads.

3. Apply a thin film of lubricant to the cleaned parts (e.g. Syntheso Glep1).

Endress+Hauser 33

Page 34

Repair Flexdip CYH112

8 Repair

8.1 Return

The product must be returned if repairs or a factory calibration are required, or if the

wrong product was ordered or delivered. As an ISO-certified company and also due to legal

regulations, Endress+Hauser is obliged to follow certain procedures when handling any

returned products that have been in contact with medium.

To ensure the swift, safe and professional return of the device:

Refer to the website www.endress.com/support/return-material for information on the

‣

procedure and conditions for returning devices.

8.2 Disposal

Please observe local regulations!

‣

34 Endress+Hauser

Page 35

Flexdip CYH112 Accessories

9 Accessories

The following are the most important accessories available at the time this documentation

was issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

Dipfit CLA111

• Immersion assembly for open and closed vessels with flange DN 100

• Product Configurator on the product page: www.products.endress.com/cla111

Technical Information TI00135C

Dipfit CPA111

• Immersion and installation assembly made of plastic for open and closed vessels

• Product Configurator on the product page: www.endress.com/cpa111

Technical Information TI00112C

Flexdip CYA112

• Immersion assembly for water and wastewater

• Modular assembly system for sensors in open basins, channels and tanks

• Material: PVC or stainless steel

• Product Configurator on the product page: www.endress.com/cya112

Technical Information TI00432C

Multifunctional clamp ring

• In the case of a chain retainer, the rear multifunctional clamp ring keeps the chain fixed

in place.

• In the case of the main pipe and transverse pipe, adjust the working height on the main

pipe with the multifunctional clamp ring.

• The multifunctional clamp ring acts as an anti-slip lock on transverse pipes, main pipes

and on assemblies.

• Material: POM - GF

• Order number: 71092049

Endress+Hauser 35

Page 36

Accessories Flexdip CYH112

B

B

B-B

Ø 86 (3.39)

Ø 80 (3.15)

100°

60 (2.36)

76.8

(3.02)

Ø 71.45

(2.81)

8 (0.31)

Ø 8 (031)

Ø 86 (3.39)

Ø 50 (1.97)

Ø 40 (1.57)

5 (0.2)

15 (0.59)

42

(1.65)

24.1

(0.95)

11.2 (0.44)

25

(0.98)

41.5

(1.63)

35

(1.83)

60 (2.36)

29.5

(1.16)

A0035699

37 Multifunctional clamp ring. Dimensions: mm (in)

Immersion pipe tray

• Is used to hold the immersion pipe during maintenance work

• Material: stainless steel 1.4404 (AISI 316L)

• Order number: 71092054

36 Endress+Hauser

Page 37

Flexdip CYH112 Accessories

47 (1.85)

73.5

(2.89)

10 (0.39)

31

(1.22

)

3

(0.12)

65 (2.56)

93.5 (3.68)

100

(3.94)

48 (1.89)

A A-A

A

89.5 (3.52)

23 (0.91)

9.1

(0.36)

B

B

B-B

9

(0.35)

55 (2.17)

79.9 (3.15)

9 (0.35)

M8

6 (0.24)

15

(0.59)

12

(0.47)

16 (0.63)

7

(0.28)

66.4 (2.61)

38 Immersion pipe tray. Dimensions: mm (in)

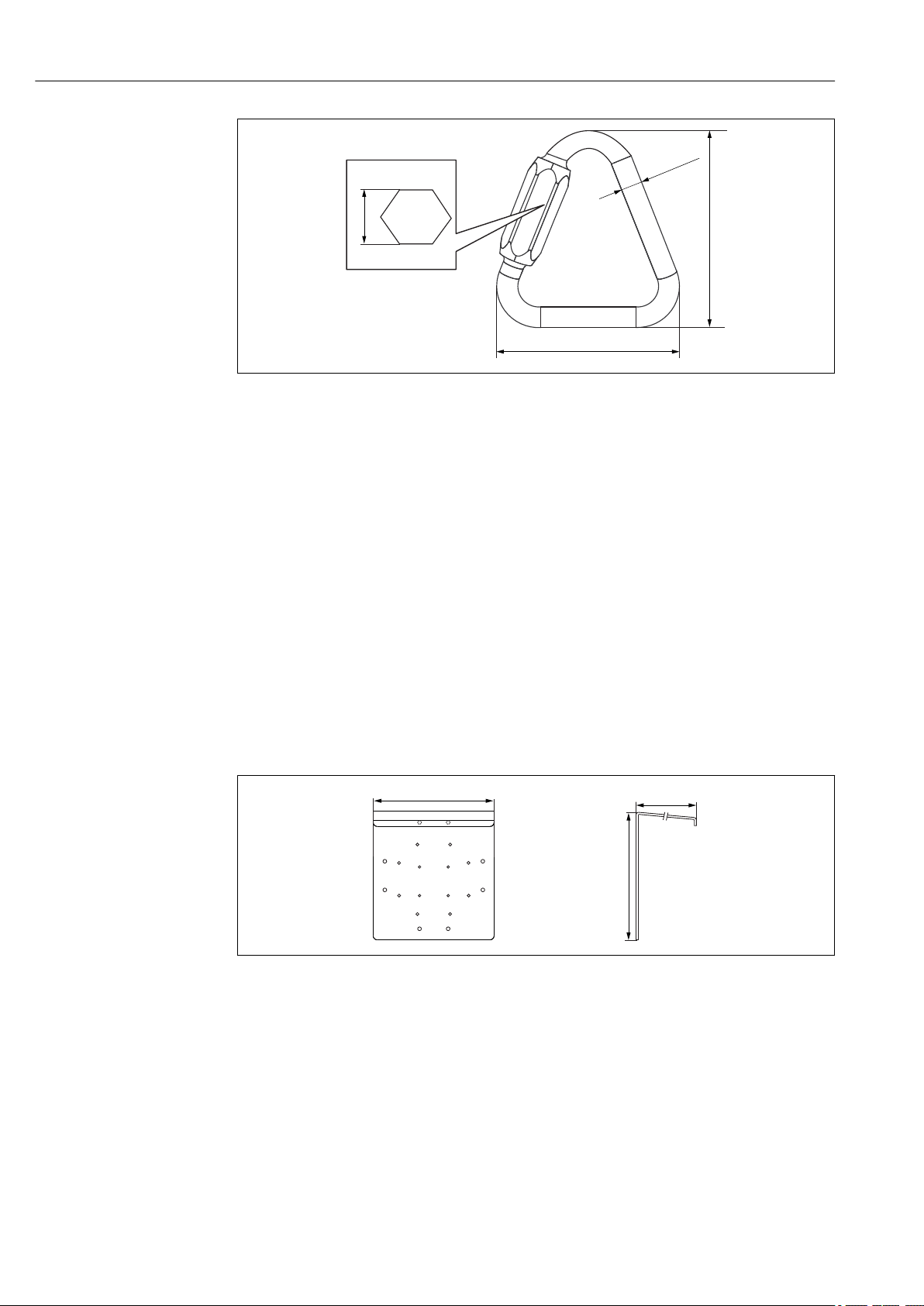

Triangular carabiner

• Is used to secure the chain

• Material: stainless steel, quality V4A

• Order number: 71092052

A0035703

Endress+Hauser 37

Page 38

Accessories Flexdip CYH112

58 (2.28)

46 (1.81)

Ø

6

(0.24)

10.9

(0.43)

320 (12.6)

270 (10.6)

300 (11.8)

A0035705

39 Triangular carabiner. Dimensions: mm (in)

Hook-and-loop cable ties (set of 4)

• Is used to secure the cables

• Material: PE/PA (polyethylene/polyamide)

• Order number: 71092051

Allen key

• Across flats: AF 6

• Order number: 71092057

Pipe protection cap

• Material: PE (polyethylene)

• Order number: 71092053

Weather protection cover CYY101 for field devices

• Absolutely essential for field installation

• Material: stainless steel 1.4301 (AISI 304)

• Order number CYY101-A

• Mounting kit to secure the CYY101 weather protection cover on vertical or horizontal

pipes with a diameter of up to 62 mm (2.44 in) Order No. 50062121

40 Weather protection cover for field devices. Dimensions: mm (in)

38 Endress+Hauser

A0035834

Page 39

Flexdip CYH112 Accessories

M6

55

(2.17)

66

(2.60)

70 (2.76)

(0.31)

30

(1.18)

90 (3.54)

A0005091

41 Circular post mounting for CYY101. Dimensions: mm (in)

Overvoltage protection

HAW56X surge arrester and associated installation material

Quick-action clamp

Order number: 71092050

Nylon chain

• Minimum length 5 m (16.4 ft)

• Order number: 71130145

Endress+Hauser 39

Page 40

Technical data Flexdip CYH112

150(5.91)

150

(5.91)

120

(4.72)

120(4.72)

12(0.47)

48.7

(1.92)

5 (0.2)

200

(7.87)

42.1(1.66)

41.5(1.63)

42(1.65)

50(1.97)

160

(6.30)

>

40

(1.57)

10 Technical data

10.1 Environment

Ambient temperature

-20 to 60 °C (-4 to 140 °F)

range

10.2 Mechanical construction

Design, dimensions Main pipe: Ø 40 mm (1.57 in), length: 500, 1000 and 1800 mm (19.7, 39.4 and

70.9 in)

Transverse pipe:Ø 40 mm (1.57 in), length: 500, 1000 and 1500 mm (19.7, 39.4 and 59

in)

Chain: 5 m (16.4 ft)

Dimensions Base

42 Dimensions of the base. Dimensions: mm (in)

A0035830

40 Endress+Hauser

Page 41

Flexdip CYH112 Technical data

111 (4.37)

47 (1.85)

110 (4.33)

3 (0.12)

85 (3.35)

Ø 40

(1.57)

25 (0.98)

43

(1.69)

60 (2.36)

37.5 (1.48)

80 (3.15)

80 (3.15)

Ø 9 (0.35)

Flange clamp

A0035771

43 Dimensions of the flange clamp. Dimensions: mm (in)

44 Dimensions of the boreholes of the flange clamp. Dimensions: mm (in)

A0010885

Endress+Hauser 41

Page 42

Technical data Flexdip CYH112

79 (3.11)

50 (1.97)

12 (0.47)

12 (0.47)

Pendulum adapter

45 Dimensions of the pendulum adapter. Dimensions: mm (in)

Weight • Main pipe

• Length 500 mm (19.7 in): 0.7 kg (1.5 lb)

• Length 1 000 mm (39.4 in): 1.5 kg (3.3 lb)

• Length 1 800 mm (70.9 in): 2.6 kg (5.7 lb)

• Transverse pipe

• Length 500 mm (19.7 in): 0.7 kg (1.5 lb)

• Length 1 000 mm (39.4 in): 1.5 kg (3.3 lb)

• Length 1 500 mm (59 in): 2.2 kg (4.9 lb)

• Flange clamp: 0.7 kg (1.5 lb)

• Cross clamp: 0.7 kg (1.5 lb)

• Base clamping element: 1.75 kg (3.86 lb)

• Pendulum holder: 1.1 kg (2.4 lb)

• Chain (synthetic): 0.7 kg (1.5 lb)

• Chain (stainless steel): 2.15 kg (4.7 lb)

• Multifunctional clamp ring: 0.15 kg (0.33 lb)

Materials

Main pipe: Stainless steel 1.4404 (AISI 316 L)

Transverse pipe: Stainless steel 1.4404 (AISI 316 L)

Flange clamp: Stainless steel 1.4404 (AISI 316 L) *

A0011252

Cross clamp: Stainless steel 1.4404 (AISI 316 L) *

Base clamping element: Stainless steel 1.4404 (AISI 316 L) *

Pendulum holder: Stainless steel 1.4404 (AISI 316 L) */POM/thermoplastic

Chain (synthetic): PA (polyamide) UV-resistant, tensile-tested

Chain (stainless steel): Stainless steel 1.4401 (AISI 316)

Multifunctional clamp ring: POM - GF

Cap for pipe end: PE

Quick-action clamp handle: PA

42 Endress+Hauser

Page 43

Flexdip CYH112 Technical data

* The flange clamp, cross clamp and base clamping element are made from the material

indicated with the exception of the clamps in the clamping device, which are made from

stainless steel 1.4301 or 1.4305 (AISI 304). The pendulum holder is made from the

material indicated with the exception of the shaft and the clamps in the clamping device,

which are made from stainless steel 1.4301 or 1.4305 (AISI 304).

Endress+Hauser 43

Page 44

Index Flexdip CYH112

Index

A

Accessories ................................ 35

Approvals ................................. 11

C

Certificates ................................ 11

D

Designated use .............................. 5

Disposal .................................. 34

I

Incoming acceptance .......................... 9

Installation ................................ 12

Installation conditions ........................ 12

M

Maintenance ...............................31

Mounting conditions ......................... 12

N

Nameplate ................................ 10

P

Post-installation check ....................... 29

Product identification ......................... 9

R

Repair ....................................34

S

Safety instructions ............................5

Scope of delivery ............................ 10

Symbols ................................... 4

U

Use .......................................5

W

Warnings .................................. 4

44 Endress+Hauser

Page 45

Page 46

Page 47

Page 48

*71453974*

71453974

www.addresses.endress.com

Loading...

Loading...