Page 1

TI00490C/07/EN/05.18

71413605

2018-05-01

Products Solutions Services

Technical Information

Turbimax CUS71D

Ultrasonic interface sensor

Application

CUS71D is a sensor designed for interface measurement in

water and wastewater.

The sensor is particularly suited for use in the following

applications:

• Wastewater treatment: primary clarifier, sludge thickener,

secondary clarifier

• Water treatment: sedimentation tank after flocculant

dosage, sludge height in contact sludge processes

• Static separation processes: with/without slow stirring and

without introduction of air

Your benefits

• Reliable: sensor guarantees accurate and continuous

measurement of interface level or range

• Safe: real-time interface information ensures quick control

of valves and actuators

• Easy: simple commissioning thanks to predefined calculation

models

• Cost-saving: automatic wiper cleaning function enables

long-term, maintenance-free operation

• Smart: all calibration- and sensor-related data saved in the

sensor

• Flexible: mounting hardware suits all clarifier designs,

ensuring optimum adaptation to the measurement task

Page 2

Function and system design

1

2

3

4

1

5

90°

6

7

Turbimax CUS71D

Measuring principle

Sensor monitoring

Measuring system

A piezoelectric crystal is enclosed in a flat cylindrical plastic housing. When the crystal is excited by

an electrical voltage, it generates a sonar signal. This causes ultrasonic waves to be transmitted at a

frequency of approx. 650 kHz and at an angle of 6° to scan the separation zones.

The measured variable is the time the transmitted ultrasonic signal needs to reach the solid particles

in the separation zone and return to the receiver. The separation zone is computed after the

maximum slope and the maximum signal amplitude.

A sensor version featuring a wiper is available to reliably avoid the buildup of deposit on the sensor

membrane.

The acoustic signals are continuously monitored and analyzed for plausibility. If inconsistencies

occur, an error message is output via the transmitter.

In addition, the following fault conditions are detected by the sensor diagnostics of Liquiline CM44x:

• Implausibly high or low measured values

• Disturbed regulation due to incorrect measured values

A complete measuring system comprises:

• Turbimax CUS71D ultrasonic sensor

• Liquiline CM44x multi-channel transmitter

and is optionally delivered with the following accessories:

• A weather protection cover CYY101

• A Flexdip CYH112 holder

• A fixed or rotatable Flexdip CYA112 dip pipe

2 Endress+Hauser

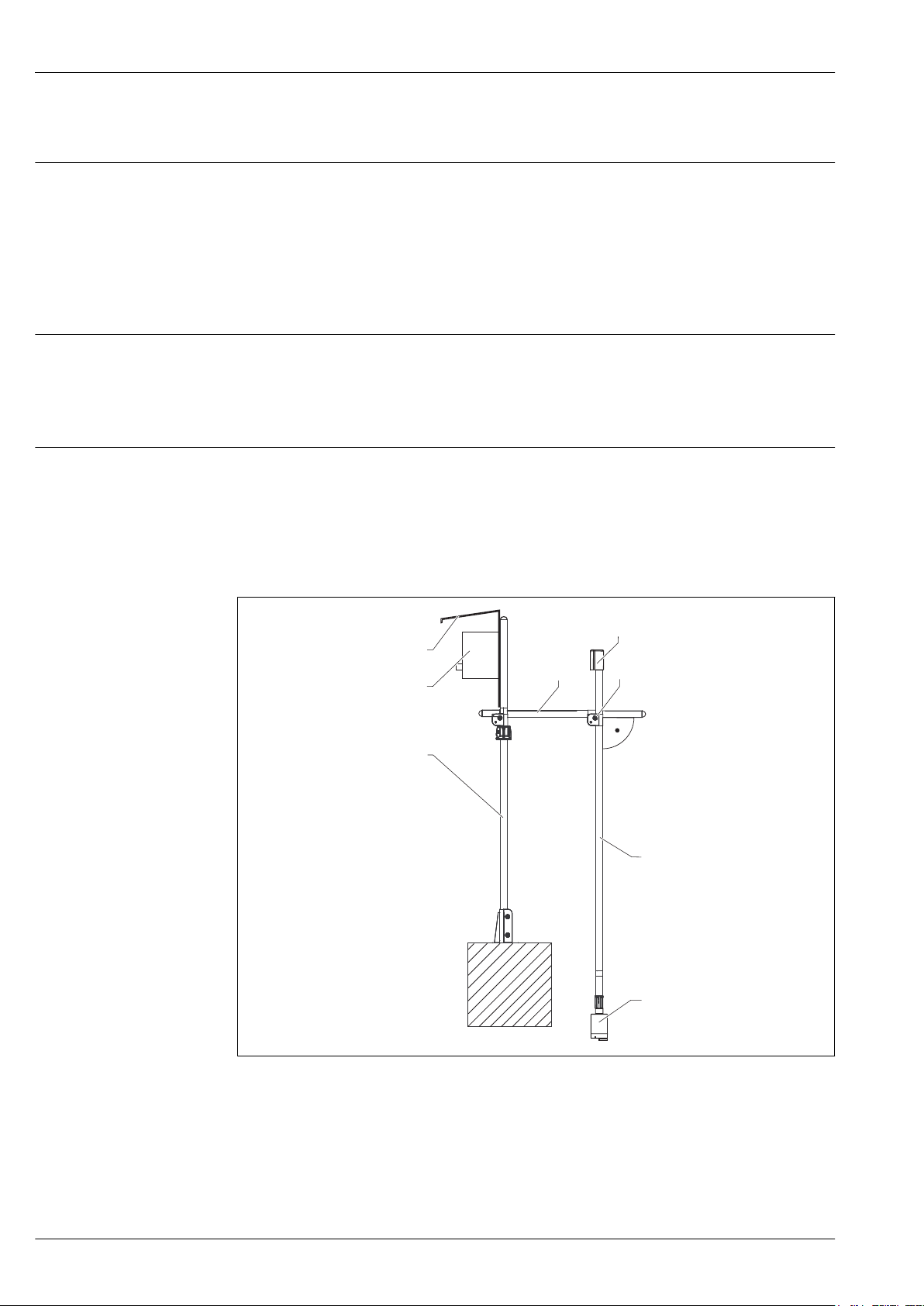

1 Ultrasonic sensor with basin holder system and multi-channel transmitter

1 Flexdip CYH112 holder

2 Liquiline CM44x multi-channel transmitter

3 Protective cover

4 Flexdip CYA112 assembly

5 Turbimax CUS71D ultrasonic sensor

6 Vertical from all sides

7 Splash protection cap

A0031577

Page 3

Turbimax CUS71D

1

2

3

4

5

MEMO SENS

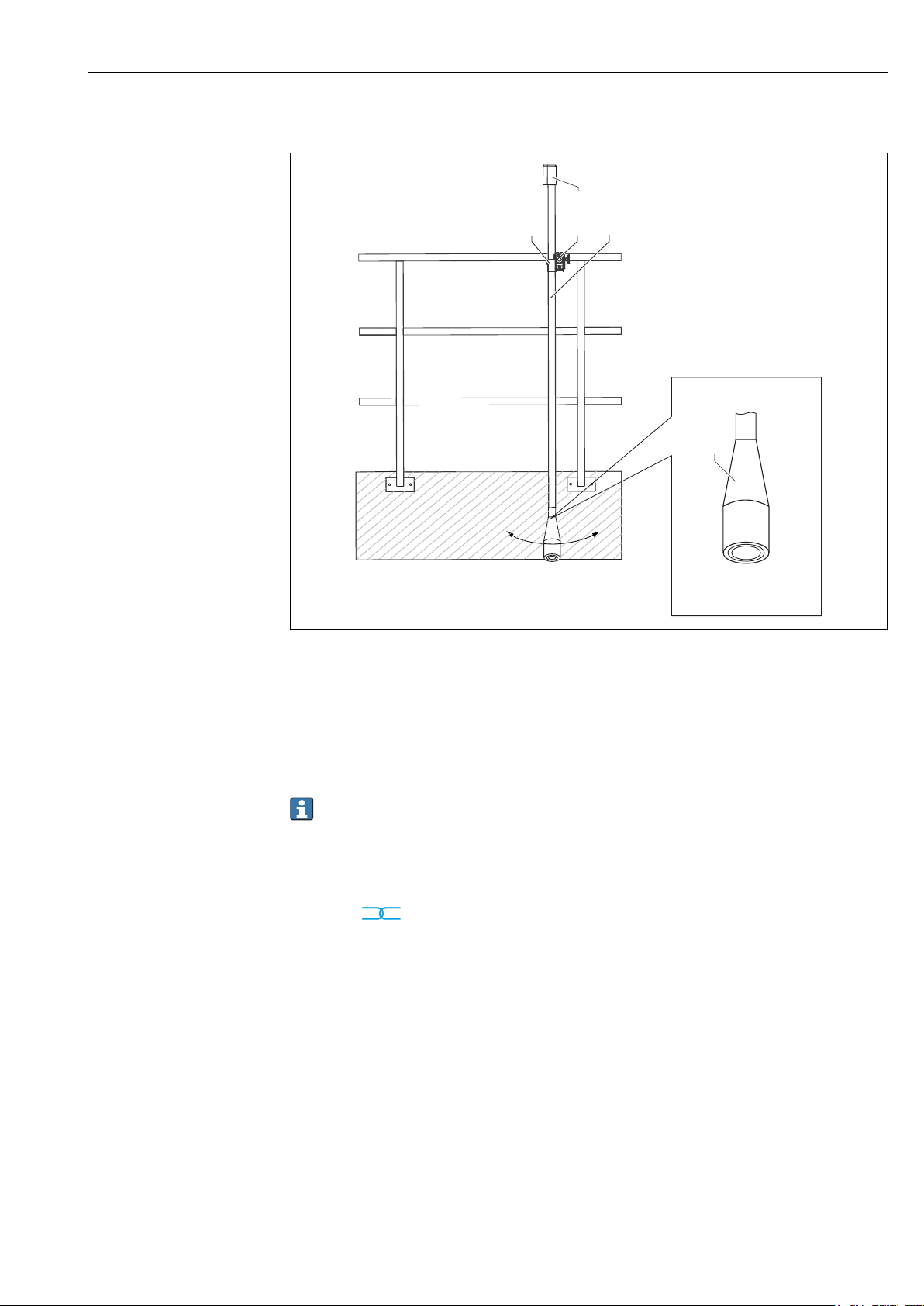

Measuring system with pendulum holder

A0031578

2 Measuring system with pendulum holder

1 Flexdip CYH112 holder (cross clamp)

2 Flexdip CYH112 holder (pendulum holder)

3 Flexdip CYA112 assembly with CUS71D

4 PVC sensor protector

5 Splash protection cap

The PVC sensor protector protects the ultrasonic sensor from being damaged by the surface

skimmer.

In the case of surface skimmers, only use the sensor without a wiper and with a PVC sensor

protector (→ 10).

Dependability

Reliability

Memosens

Memosens makes your measuring point safer and more reliable:

• Non-contact, digital signal transmission enables optimum galvanic isolation

• Completely watertight

• Sensor can be calibrated in a lab, thus increasing the availability of the measuring point in the

process

• Predictive maintenance thanks to recording of sensor data, e.g.:

– Total hours of operation

– Hours of operation with very high or very low measured values

– Hours of operation at high temperatures

– Number of steam sterilizations

– Sensor condition

Maintainability

Easy handling

Sensors with Memosens

technology have integrated electronics that store calibration data and other information (e.g. total hours of operation or operating hours under extreme measuring conditions).

Once the sensor has been connected, the sensor data are transferred automatically to the transmitter

Endress+Hauser 3

Page 4

Turbimax CUS71D

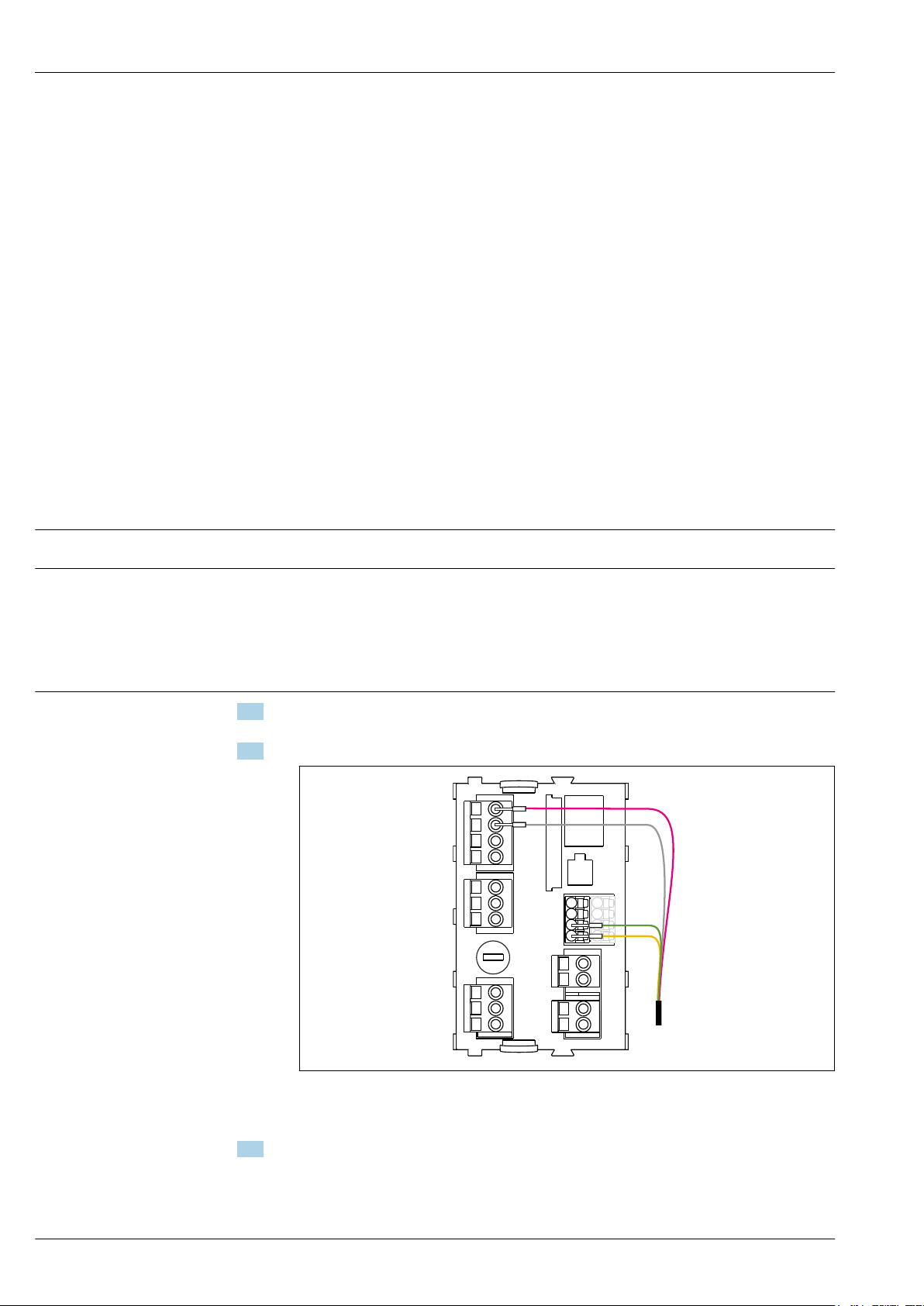

N L

43 42 41

86 85 86

85

98 97 88 87

32 31

32 31

PK

GY

GN

YE

Sensor

PE

and used to calculate the current measured value. As the calibration data are stored in the sensor,

the sensor can be calibrated and adjusted independently of the measuring point. The result:

• Easy calibration in the measuring lab under optimum external conditions increases the quality of

the calibration.

• Pre-calibrated sensors can be replaced quickly and easily, resulting in a dramatic increase in the

availability of the measuring point.

• Thanks to the availability of the sensor data, maintenance intervals can be accurately defined and

predictive maintenance is possible.

• The sensor history can be documented on external data carriers and in evaluation programs,.

• Thus, the current application of the sensors can be made to depend on their previous history.

Security

Data security thanks to digital data transmission

Memosens technology digitizes the measured values in the sensor and transmits the data to the

transmitter via a non-contact connection that is free from potential interference. The result:

• Automatic error message if sensor fails or connection between sensor and transmitter is

interrupted

• Immediate error detection increases measuring point availability

Input

Measured variable

Measuring range

Electrical connection

Interface

0.3 to 10 m (1 to 32 ft)

Power supply

1. Connect one sensor (maximum) to the Liquiline CM442. Connect up to 4 sensors to the

Liquiline CM444 and CM448 transmitters.

2. Connect the fixed cable of the sensor to the Liquiline CM44x transmitter as follows:

A0034802

3 Sensor connection

The maximum cable length is 100 m (328 ft).

3. Use the following accessories to extend the sensor cable if necessary:

• CYK11 measuring cable with ferrules → 11

• Cable/cable junction box → 11

4 Endress+Hauser

Page 5

Turbimax CUS71D

1

2

3

4

Connecting the cable shield

Only use terminated original cables where possible. The sensor cables must be shielded cables.

Cable sample (does not necessarily correspond to the original cable supplied)

Reference operating conditions

Measured value resolution

Maximum measured error

Measuring interval

Calibration

4 Terminated cable

1 Outer shield (exposed)

2 Cable cores with ferrules

3 Cable sheath (insulation)

5 Insert the cable

4 Grounding clip

6 Tighten screw (2 Nm)

The cable shield is grounded by the

grounding clip.

Performance characteristics

20 °C (68 °F), 1013 hPa

± 0.3 % with end of measuring range up to 3 m (9.8 ft)

± 0.15 % with end of measuring range from 3 m (9.8 ft)

± 2 % of end of measuring range

Sensor-internal

Sensor to transmitter 12 seconds

The sensor is factory-configured when delivered.

Configurable

Endress+Hauser 5

Page 6

Installation

A

B

C

D

E

6°

F

Turbimax CUS71D

Installation instructions

Basin configuration

A0031574

7 Basin configuration

A Sensor

B 50 cm (1.64 ft) Minimum distance between sensor and basin rim

C Fixed reference point, e.g. surface of water, basin rim, bridge/walkway etc.

D Sensor offset

E Basin depth

F Opening angle of ultrasonic cone 6°

Installation instructions

Find a suitable installation position for the sensor in the basin. Take the following points into

consideration when selecting the installation position:

1. Ensure the distance from the basin rim is at least 50 cm (1.64 ft) (the sensor emits ultrasonic

waves in a conical pattern).

There should not be any conduits or basin wall protrusions in the measuring range below

the sensor. Scraper units that are only temporarily in this area are permitted.

2. Mount the sensor so that it is straight and parallel to the basin wall (measured value offset).

Do not install the sensor in zones where air bubbles, turbulence, high concentrations of

turbid material and suspended matter, or foam formation occur (e.g. inlet).

3. Using a dip pipe, install the sensor at least 20 cm (0.66 ft) beneath the surface of the water.

6 Endress+Hauser

Page 7

Turbimax CUS71D

¹/₃

1

2

3

4

5

11

12

13

14

A

B

²/₃

¹/₃

²/₃

Circular clarifier

A0031579

8 Basin configuration in circular clarifiers

A View from above B Cross-section

1 Surface skimmer 11 Sensor

2 Bridge/walkway 12 Rail

Storage temperature

Degree of protection

3 Sensor position range 13 Surface skimmer

4 Floor rake 14 Floor rake

5 Direction of rake movement

Environment

–20 to 50 °C (–4 to 120 °F)

IP 68 (1 m (3.3 ft) water column over 60 days, 1 mol/l KCl)

Process

Process temperature range

Process pressure range

Endress+Hauser 7

1 to 50 °C (34 to 122 °F)

Standard version:

Version with wiper: 0 to 0.3 bar (0 to 4.4 psi)

0 to 6 bar (0 to 87 psi)

Page 8

Dimensions

Ø 74 (2.9)

Ø 75 (3.0)

Ø 33.7(1.3)

20.5

(0.8)

17

(0.7)

15

(0.6)

G1"

NPT 3/4"

43 (1.7)

68 (2.7)

60.5 (2.4)

AF 27

Ø 34.7(1.4)

Ø74(2.9)

110

(

4

.

3

)

8

135

(5.3)

6

0.5(2.4)

Ø75(3.0)

Ø34.7

(1.4)

17

(0.7)

20.5

(0.8)

1

5

(0.6)

Ø 33.7 (1.3)

G1"

NPT 3/4"

AF 27

Turbimax CUS71D

Mechanical construction

Weight

Materials

Process connections

mark

EAC

A0036897

9 Dimensions for standard sensor.

Dimensions: mm (in)

10 Dimensions for sensor with wiper. Dimensions:

mm (in)

Standard sensor:

1.02 kg (2.25 lb)

Sensor with wiper: 1.25 kg (2.75 lb)

Sensor:

ABS and epoxy resin

Wiper: EPDM

Housing: Polyamide

G1 and NPT ¾"

Certificates and approvals

The product meets the requirements of the harmonized European standards. As such, it complies

with the legal specifications of the EU directives. The manufacturer confirms successful testing of the

product by affixing to it the mark.

The product has been certified according to guidelines TP TC 004/2011 and TP TC 020/2011 which

apply in the European Economic Area (EEA). The EAC conformity mark is affixed to the product.

A0036898

8 Endress+Hauser

Page 9

Turbimax CUS71D

Electromagnetic compatibility

Product page

Product Configurator

Scope of delivery

Interference emission and interference immunity: Industrial environment as per

• EN 61326-1:2013

• EN 61326-2-3:2013

• NAMUR NE21: 2012

Ordering information

www.endress.com/cus71d

On the product page there is a Configure button to the right of the product image.

1. Click this button.

The Configurator opens in a separate window.

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button on the right

above the selection window.

For many products you also have the option of downloading CAD or 2D drawings of the

selected product version. Click the CAD tab for this and select the desired file type using

picklists.

The delivery comprises:

• 1 Turbimax CUS71D sensor, version as ordered

• 1 set of Operating Instructions BA00490C/07/EN

If you have any queries:

‣

Please contact your supplier or local sales center.

Endress+Hauser 9

Page 10

Accessories

Ø 50

(2.0)

Ø 76 (3)

Ø 99 (3.9)

44

(1.7)

144 (5.7)

Ø 41

(1.6)

1

2

3

The following are the most important accessories available at the time this documentation was

issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

Device-specific accessories Assemblies

FlexdipCYA112

• Immersion assembly for water and wastewater

• Modular assembly system for sensors in open basins, channels and tanks

• Material: PVC or stainless steel

• Product Configurator on the product page: www.endress.com/cya112

Technical Information TI00432C

PVC sensor protector for pendulum holder

• The PVC sensor protector protects the CUS71D ultrasonic sensor from being damaged by the

surface skimmer.

• Available for order via the product structure

• Can be ordered individually via order number: 71404869

Only use the PVC sensor protector for the sensor version without a wiper.

Turbimax CUS71D

11 PVC sensor protector for CUS71D. Dimensions: mm (in)

1 CYA112 assembly

2 PVC sensor protector

3 CUS71D ultrasonic sensor

Holder

Flexdip CYH112

• Modular holder system for sensors and assemblies in open basins, channels and tanks

• For Flexdip CYA112 water and wastewater assemblies

• Can be affixed anywhere: on the ground, on the capstone, on the wall or directly onto railings.

• Stainless steel version

10 Endress+Hauser

• Product Configurator on the product page: www.endress.com/cyh112

Technical Information TI00430C

A0037314

Page 11

Turbimax CUS71D

Cable extension

Memosens data cable CYK11

• Extension cable for digital sensors with Memosens protocol

• Product Configurator on the product page: www.endress.com/cyk11

Technical Information TI00118C

Junction box, cable/cable

• Material: aluminum, painted

• Cable extension: Memosens sensors, Liquiline

• Order number: 71145499

Endress+Hauser 11

Page 12

www.addresses.endress.com

Loading...

Loading...