Page 1

TI01136C/07/EN/05.20

71473307

2020-03-16

Products

Solutions Services

Technical Information

Turbimax CUS52D

Turbidity sensor

Application

Turbimax CUS52D is a sensor for measuring turbidity and low solids content in

drinking water and process water applications.

• Turbidity measurement at all stages of the water treatment process

• Final turbidity measurement in outlet of waterworks

• Turbidity measurement in inlet of waterworks

• Turbidity measurement for filter monitoring and filter backwashing

• Turbidity measurement in drinking water networks

• Turbidity measurement in saline media (plastic sensor only)

Your benefits

• Turbidity measurement in accordance with ISO 7027

• The hygienic design with the 2" clamp means it can be mounted directly in pipes

and fits into CUA252 (PE 100) and CUA262 (stainless steel) flow assemblies

• Immersion version can be installed in open channels and basins

• Can be used at high temperatures and high pressures

• Standardized communication (Memosens technology) enables "plug and play"

• Intelligent sensor - all characteristics and calibration values are stored in the

sensor

• Customer calibrations with 1 to 6 points can be performed in the lab or at place of

installation

• Completely safe, as the optical source requires little power to operate

Page 2

Table of contents

Turbimax CUS52D

Function and system design ................... 3

Measuring principle ............................ 3

Measuring system ............................. 4

Communication and data processing ................. 6

Dependability ................................ 7

Input ..................................... 7

Measured variable ............................. 7

Measuring range .............................. 7

Power supply .............................. 7

Electrical connection ........................... 7

Performance characteristics ................... 9

Reference operating conditions .................... 9

Maximum measured error ....................... 9

Repeatability ................................ 9

Long-term reliability ........................... 9

Response time ............................... 9

Detection limit ............................... 9

Installation ................................ 9

Orientation ................................. 9

Environment .............................. 13

Ambient temperature range ..................... 13

Storage temperature .......................... 13

Degree of protection .......................... 13

Electromagnetic compatibility (EMC) ............... 13

Mounting material ........................... 19

Compressed air cleaning ........................ 20

Ultrasonic cleaning ........................... 20

Bubble trap ................................ 21

Solid state reference .......................... 21

Calibration vessel ............................ 21

Process .................................. 13

Process temperature range ...................... 13

Process pressure range ......................... 13

Flow limit ................................. 13

Mechanical construction .................... 14

Dimensions ................................ 14

Weight ................................... 17

Materials .................................. 17

Process connections ........................... 17

Certificates and approvals ................... 18

mark ................................... 18

ISO 7027 .................................. 18

EAC ..................................... 18

Marine approvals ............................ 18

Ordering information ....................... 18

Scope of delivery ............................. 18

Product page ............................... 18

Product Configurator .......................... 18

Accessories ............................... 18

Assemblies ................................. 18

Holder .................................... 19

2 Endress+Hauser

Page 3

Turbimax CUS52D

90° ± 2.5°

20° - 30°

Function and system design

Measuring principle

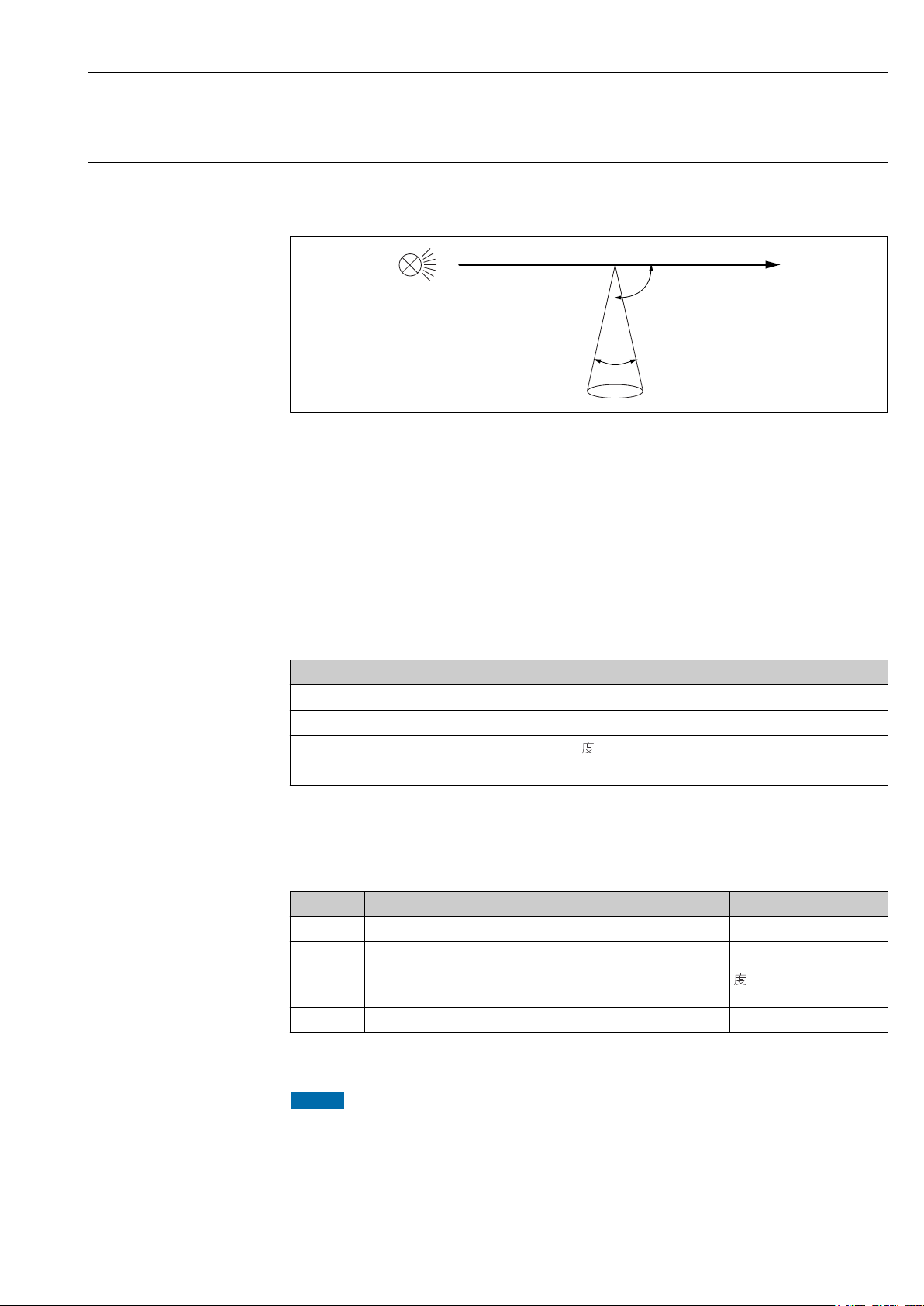

The sensor works using the 90° light scattering principle in accordance with ISO 7027 and meets all

the requirements of this standard (no divergence and a maximum convergence of 1.5°). The ISO

7027 standard is obligatory for turbidity measurements in the drinking water sector.

A0030701

1 Measurement in accordance with ISO 7027

Measurement is done using a wavelength of 860 nm.

Sensor monitoring

The optical signals are continuously monitored and analyzed for plausibility. If inconsistencies occur,

an error message is output via the transmitter. The function is disabled by default.

Applications

The formazine factory calibration is used as the basis for precalibrating additional applications and

optimizing them for the different media characteristics.

Application Specified operational range

Formazine 0.000 to 1000 FNU

Kaolin 0 to 150 mg/l

PSL 0 to 125

Diatomite 0 to 550 mg/l

To adapt to a specific application, customer calibrations can be carried out with up to 6 points.

During initial commissioning or calibration at the CM44x, select the appropriate application for

‣

your field of application.

Application Field of application Unit

Formazine Drinking water, process water FNU; NTU; TE/F; EBC; ASBC

Kaolin Drinking water, filterable matter, industrial water mg/l; g/l; ppm

PSL The calibration standard commonly used in Japan for drinking

water turbidity

Diatomite Mineral-based solids (sand) mg/l; g/l; ppm

(dough)

1 to 6 points can be calibrated for all applications.

NOTICE

Multiple scattering

If the specific operational range is exceeded, the measured value displayed by the sensor can

decrease despite increasing turbidity. The indicated operational range is reduced in the case of highly

absorbing (e.g. dark) media.

In the case of highly absorbing (e.g. dark) media, determine the operational range

‣

experimentally beforehand.

Endress+Hauser 3

Page 4

Turbimax CUS52D

1

2

3

4

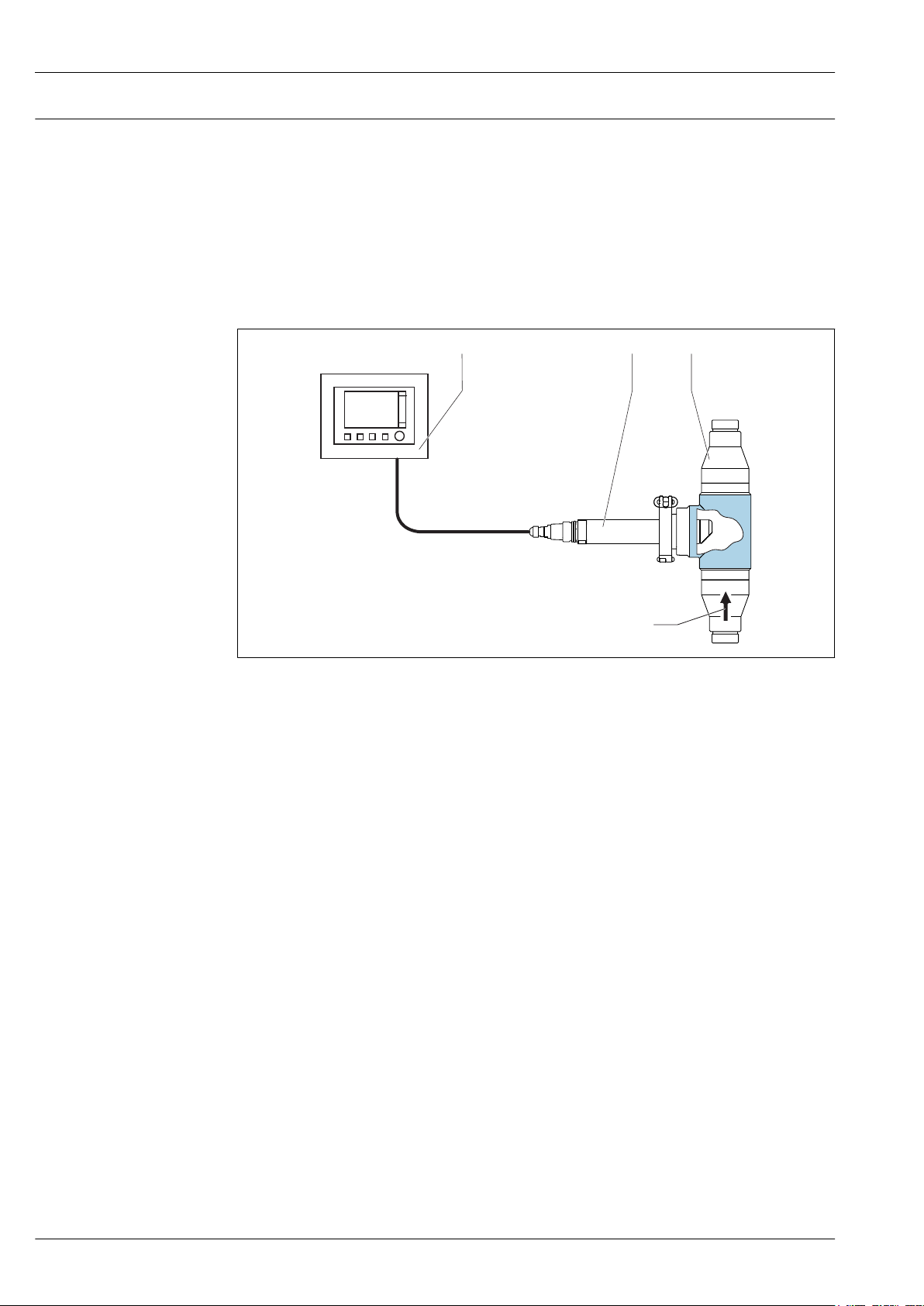

Measuring system

A complete measuring system comprises:

• Turbimax CUS52D turbidity sensor

• Liquiline CM44x multi-channel transmitter

• Assembly:

• CUA252 flow assembly (only possible for stainless steel sensor) or

• CUA262 flow assembly (only possible for stainless steel sensor) or

• Flexdip CYA112 assembly and Flexdip CYH112 holder or

• Retractable assembly, e.g. Cleanfit CUA451

• Or direct installation via pipe connection (only possible for stainless steel sensor)

• Clamp 2" or

• Varivent

A0030694

2 Example of measuring system with CUA252 flow assembly, for stainless steel sensor

1 Liquiline CM44x multi-channel transmitter

2 Turbimax CUS52D turbidity sensor

3 CUA252 flow assembly

4 Direction of flow

4 Endress+Hauser

Page 5

Turbimax CUS52D

1

2

3

1

4

5

1

2

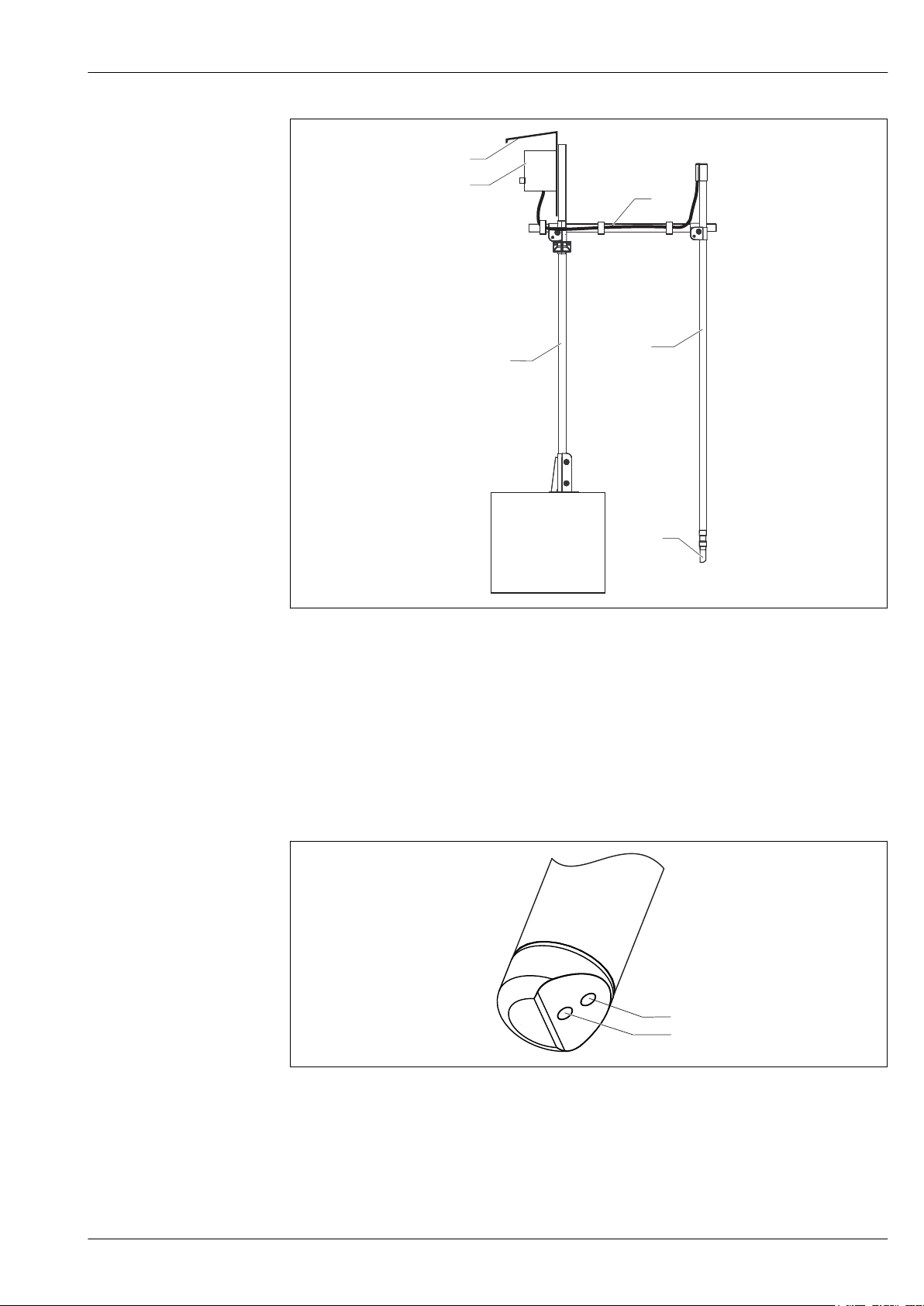

A0030696

3 Example of measuring system with immersion assembly

1 Flexdip CYH112 holder

2 Liquiline CM44x multi-channel transmitter

3 Protective cover

4 Flexdip CYA112 assembly

5 Turbimax CUS52D turbidity sensor

This type of installation is particularly suitable for strong or turbulent flow > 0.5 m/s (1.6 ft/s) in

basins or channels.

Sensor structure

4 Arrangement of light source and light receiver

1 Light receiver

2 Light source

A0030692

Solid state reference

The solid state reference can be used to check the functional integrity of the sensor.

Endress+Hauser 5

Page 6

Turbimax CUS52D

92

(3.62)

150 (5.91)

95°

293 (11.54)

42

80 (3.15)

95°

127 (5.00)

During factory calibration, each Calkit solid state reference is matched specifically to a special

CUS52D sensor and can be used only with this sensor. Therefore, the Calkit solid state reference and

the CUS52D sensor are permanently assigned (married) to one another.

The following Calkit solid state references are available:

• 5 FNU (NTU)

• 20 FNU (NTU)

• 50 FNU (NTU)

The reference value indicated on the Calkit solid state reference is reproduced with an accuracy of

± 10% when the sensor is operating correctly.

The CUY52 solid state reference with approx. 4.0 FNU/NTU is used to check the function of any

CUS52D sensors. The standard is not assigned to a specific sensor and delivers measured values in

the range of 4.0 FNU ± 1.5 FNU/NTU with all CUS52D sensors.

A0035755

5 Solid state reference

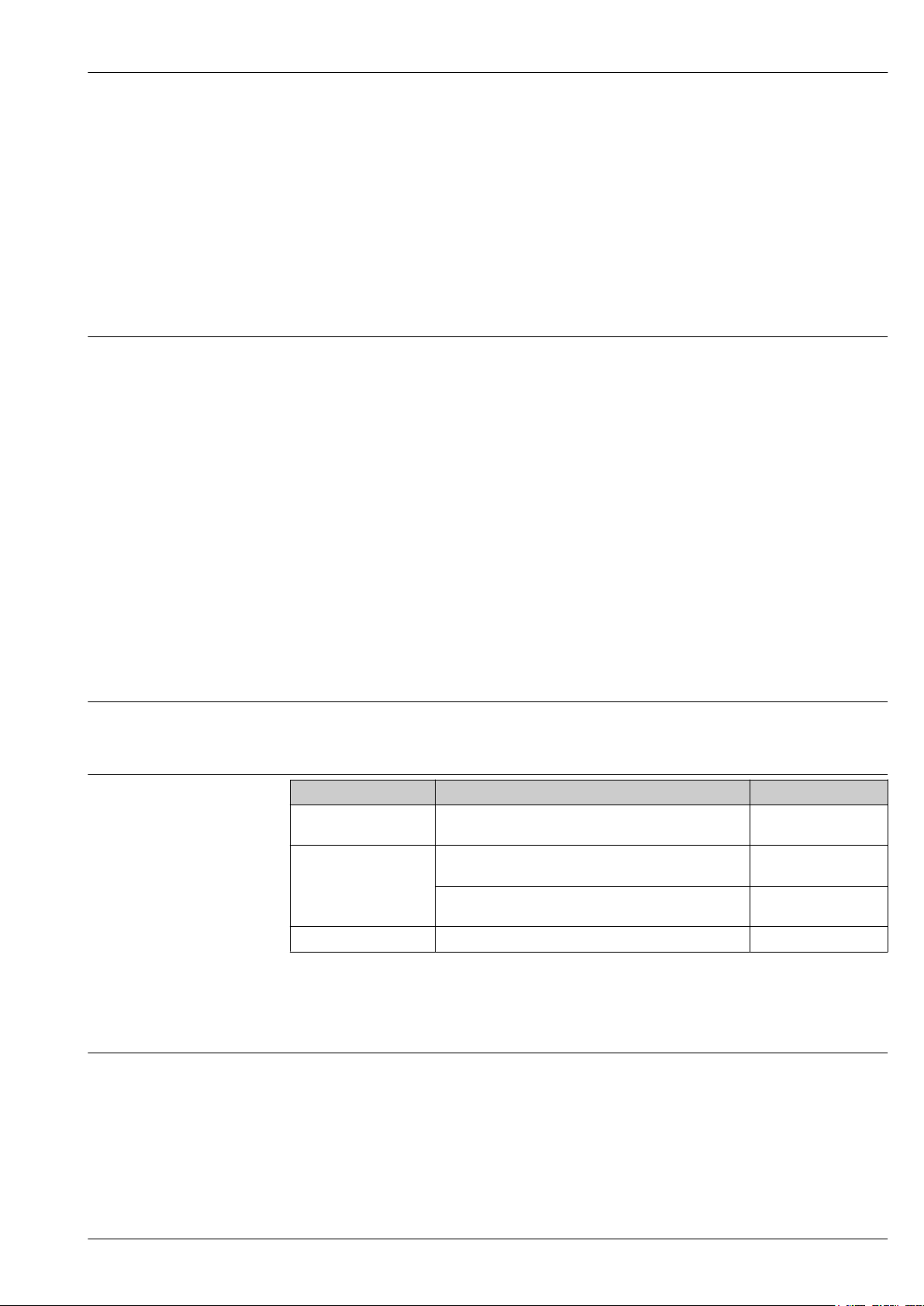

Calibration vessel

The CUY52 calibration vessel allows the sensors to be validated quickly and reliably. This makes it

easier to adapt to the actual measuring point by creating basic conditions that are reproducible (e.g.

vessels with minimal backscattering, shade from interfering light sources etc.). There are two

different types of calibration vessel into which the calibration solution (e.g. formazine) can be

transferred.

A0035756

6 Large calibration vessel (top) and small calibration vessel (bottom). Dimensions: mm (in)

Communication and data processing

For detailed information on calibration tools, see BA01309C

Communication with the transmitter

Always connect digital sensors with Memosens technology to a transmitter with Memosens

technology. Data transmission to a transmitter for analog sensors is not possible.

6 Endress+Hauser

Page 7

Turbimax CUS52D

Digital sensors can store measuring system data in the sensor. These include the following:

• Manufacturer data

• Serial number

• Order code

• Date of manufacture

• Calibration data

• Calibration date

• Number of calibrations

• Serial number of the transmitter used to perform the last calibration

• Operating data

• Temperature application range

• Date of initial commissioning

Dependability Maintainability

Easy handling

Sensors with Memosens technology have integrated electronics that store calibration data and other

information (e.g. total hours of operation or operating hours under extreme measuring conditions).

Once the sensor has been connected, the sensor data are transferred automatically to the transmitter

and used to calculate the current measured value. As the calibration data are stored in the sensor,

the sensor can be calibrated and adjusted independently of the measuring point. The result:

• Easy calibration in the measuring lab under optimum external conditions increases the quality of

the calibration.

• Pre-calibrated sensors can be replaced quickly and easily, resulting in a dramatic increase in the

availability of the measuring point.

• Thanks to the availability of the sensor data, maintenance intervals can be accurately defined and

predictive maintenance is possible.

• The sensor history can be documented on external data carriers and in evaluation programs.

• Thus, the current application of the sensors can be made to depend on their previous history.

Measured variable

Measuring range

Electrical connection

Input

• Turbidity

• Temperature

• Solids content

CUS52D Application

Turbidity 0.000 to 4000 FNU

Display range up to 9999 FNU

Solids 0 to 600 mg/l

Display range up to 3 g/l

0 to 2 200 mg/l

Display range up to 10 g/l

Temperature –20 to 85 °C (–4 to 185 °F)

Formazine

Kaolin

Diatomite

Power supply

The following connection options are available:

• via M12 connector (version: fixed cable, M12 connector)

• via sensor cable to the plug-in terminals of a sensor input on the transmitter (version: fixed cable,

end sleeves)

Endress+Hauser 7

Page 8

85 86

85

2DS

1

2

86

97 88 8798

97 88 8798

Sensor 1

Sensor 2

PK

GY

GN

YE

Sensor

85 86

85

1

2

86

97 88 8798

Sensor 1

PK

GY

GN

YE

BN

WH

Sensor

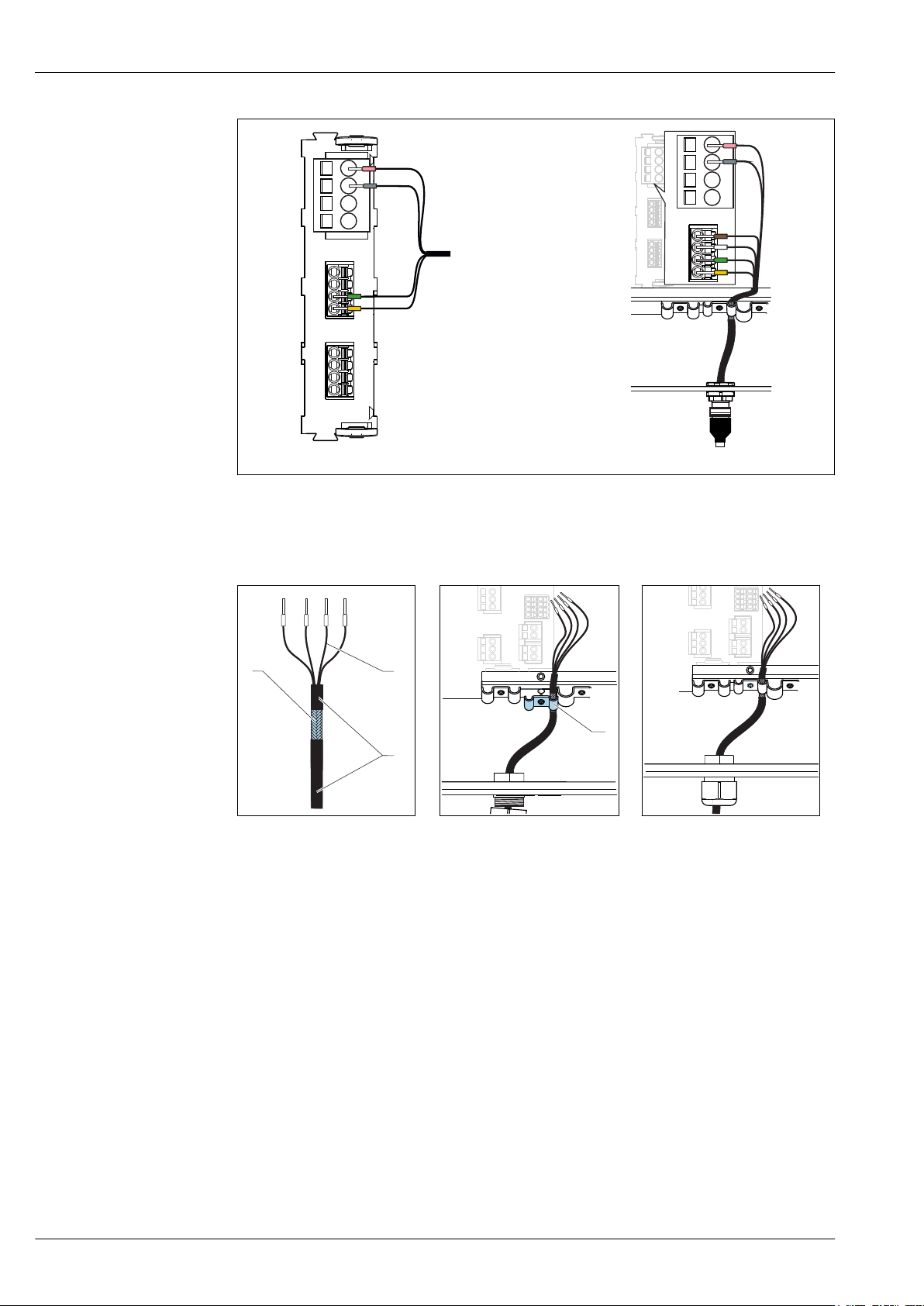

7 Sensor connection to sensor input (left) or via M12 connector (right)

1

2

3

4

Turbimax CUS52D

A0033092

Connecting the cable shield

Cable sample (does not necessarily correspond to the original cable supplied)

8 Terminated cable

1 Outer shield (exposed)

2 Cable cores with ferrules

3 Cable sheath (insulation)

9 Inserting the cable

4 Grounding clip

10 Tightening the screw

(2 Nm (1.5 lbf ft))

The cable shield is grounded by the

grounding clip

The maximum cable length is 100 m (328.1 ft).

8 Endress+Hauser

Page 9

Turbimax CUS52D

4

2

1

3

5

2

3

4

90°

Performance characteristics

Reference operating conditions

Maximum measured error

Repeatability

Long-term reliability Drift

Response time

20 °C (68 °F), 1013 hPa (15 psi)

Turbidity 2 % of the measured value or 0.1 FNU (the greater value applies in each case).

Solids < 5% of measured value or 1 % of the end of measuring range (the greater value applies

< 0.5 % of the measured value

Working on the basis of electronic controls, the sensor is largely free of drifts.

> 1 second, adjustable

Reference: measured value in recommended operational range, factory calibration

in each case). Applies for sensors that are calibrated to the particular measuring range

under analysis.

The measured error encompasses all inaccuracies of the measuring chain (sensor and

transmitter). However, it does not include the inaccuracy of the reference material used for

calibration.

For solids, the achievable measured errors depend very much on the media that are actually

present and may differ from the specified values. Extremely inhomogeneous media cause the

measured value to fluctuate and increase the measured error.

Detection limit

Detection limit in accordance with ISO 15839 in ultrapure water:

Application Measuring range Detection limit

Formazine 0 to 10 FNU (ISO 15839) 0.0015 FNU

Installation

Orientation Orientation in pipes

11 Permitted and unacceptable orientations in pipes

A0030698

Endress+Hauser 9

Page 10

Turbimax CUS52D

6

7

8

9

10

1

• Install the sensor in places with consistent flow conditions.

• The best installation location is in the ascending pipe (item 1). Installation in the horizontal pipe

(item 4) is also possible.

• Do not install the sensor in places where air spaces or bubbles occur (item 3) or where

sedimentation may occur (item 2).

• Avoid installation in the down pipe (item 5).

• Avoid fittings downstream from pressure reduction stages which can lead to outgassing.

Wall effects

Backscattering on the pipe wall may result in the distortion of measured values in the case of

turbidity values < 200 FNU. Therefore a pipeline diameter of at least 100 mm (3.9 in) is

recommended for reflecting materials (e.g. stainless steel). An assembly adjustment onsite is also

recommended.

Pipes made of stainless steel with diameter >DN 300 exhibit hardly any wall effects.

Black plastic pipes with diameter > DN 60 exhibit hardly any wall effects (<0.05 FNU). For this

reason, the use of black plastic pipes is recommended.

A0030704

12 Orientations for pipes and assemblies

• Install the sensor in such a way that the light beam is not reflected → 12, 10 (item 6).

• Avoid sudden changes in cross-section (item 9). Changes in cross-section should be gradual and

located as far away as possible from the sensor (item 10).

• Do not install the sensor directly downstream from a bend (item 7). Instead position it as far away

as possible from the bend (item 8).

Installation marking

A0030820

13 Installation marking for sensor alignment

1 Installation marking

10 Endress+Hauser

Page 11

Turbimax CUS52D

2

The installation marking on the sensor is aligned opposite the optical system.

Align the sensor against the flow direction.

‣

Mounting options

The installation angle is 90°.

The arrow points in the direction of

flow.

The optical windows in the sensor must

be aligned against the direction of flow.

The medium pressure may not exceed

2 bar (29 psi) for manual assembly

retraction.

A0022285

14 Installing with CUA451 retractable assembly

The installation angle is 0°.

The arrow points in the direction of

flow.

If the sensor is being used in open

‣

basins, install the sensor in such a

way that air bubbles cannot

accumulate on it.

15 Installing with immersion assembly

16 Installing with 2" clamp connection

A0022033

The installation angle is 90°.

The arrow points in the direction of

flow.

The optical windows in the sensor must

be aligned against the direction of flow.

A weld-in adapter is available as an

accessory for the installation → 11.

A0022032

The installation angle is 90°.

The arrow points in the direction of

flow.

The optical windows in the sensor must

be aligned against the direction of flow.

A0022034

17 Installing with CUA252 flow assembly

Endress+Hauser 11

Page 12

18 Installing with CUA262 flow assembly

60 ... 64

(2.36 ... 2.52)

> 100 (3.94)

36

(1.42)

19 Installing with standard Varivent connection

Turbimax CUS52D

The installation angle is 90°.

The arrow points in the direction of

flow.

The optical windows in the sensor must

be aligned against the direction of flow.

A0022281

The installation angle is 90°.

The arrow points in the direction of

flow.

The optical windows in the sensor must

be aligned against the direction of flow.

A0031130

A0031132

20 Installing with Varivent connection with extended

shaft

21 Pipe connection with weld-in adapter. Dimensions: mm (in)

For automatic sensor operation in pipe fittings or flow assemblies, there is the option of using the

ultrasonic cleaning system CYR52 (→ 20).

Bubbles result in errors in turbidity measurements. The effect of this interference can be minimized

by using a bubble trap (→ 21).

A0030819

12 Endress+Hauser

Page 13

Turbimax CUS52D

Environment

Ambient temperature range

Storage temperature

Degree of protection

Electromagnetic compatibility (EMC)

Process temperature range

–20 to 60 °C (–4 to 140 °F)

–20 to 70 °C (–4 to 158 °F)

IP 68 (1.8 m (5.91 ft) water column over 20 days, 1 mol/l KCl)

Interference emission and interference immunity as per

• EN 61326-1:2013

• EN 61326-2-3:2013

• NAMUR NE21: 2012

Process

Stainless steel sensor

–20 to 85 °C (–4 to 185 °F)

Plastic sensor

–20 to 60 °C (–4 to 140 °F)

Under high temperatures combined with extremely high or low pH values and chemical boundary

conditions, e.g. during CIP cleaning processes, the sensor has limited long-term stability.

To avoid damage to the sensor, only use the sensor in combination with a retractable assembly

in CIP cleaning processes. The retractable assembly allows the sensor to be removed from the

process during cleaning.

Process pressure range Stainless steel sensor

0.5 to 10 bar (7.3 to 145 psi) (abs.)

Plastic sensor

0.5 to 6 bar (7.3 to 87 psi)

Flow limit Minimum flow

No minimum flow required.

For solids which have a tendency to form deposits, ensure that sufficient mixing is performed.

Endress+Hauser 13

Page 14

Mechanical construction

Ø 40

(1.57)

NPT ¾“

G1

237.5 (9.35)

82.7 (3.26)

2 (0.08)

20.5 (0.81)

18.5 (0.73)

12.5

(0.49)

13.5

(0.53)

20.5

(0.81)

15

(0.59)

Dimensions Plastic version

Turbimax CUS52D

22 Dimensions of plastic sensor. Dimensions: mm (in)

A0042002

14 Endress+Hauser

Page 15

Turbimax CUS52D

Ø 40

(1.57)

NPT ¾“

G1

237.5 (9.35)

82.7 (3.26)

84.5 (3.33)

2 (0.08)

20.5 (0.81)

18.5 (0.73)

12.5

(0.49)

13.5

(0.53)

20.5

(0.81)

15

(0.59)

Stainless steel version

23 Dimensions of stainless steel sensor and stainless steel sensor with clamp connection (right). Dimensions:

mm (in)

A0030699

Endress+Hauser 15

Page 16

Turbimax CUS52D

18.5 (0.73)

82.7 (3.26)

237.5(9.35)

(1.57)

Ø 40

12.5

(0.49)

20.5

(0.81)

13.5

(0.53)

NPT ¾“

G1

15 (0.59)

2 (0.08)

20.5 (0.81)

42.5

(1.67)

22.5 (0.89)

35.5 (1.40)

13 (0.51)

A0035857

24 Dimensions of stainless steel sensor with standard Varivent connection (left) and extended shaft (right).

Dimensions: mm (in)

Compressed air cleaning

A0030691

25 Dimensions of sensor with compressed air cleaning. Dimensions: mm (in)

Compressed air cleaning accessory → 20

16 Endress+Hauser

Page 17

Turbimax CUS52D

45 (1.77)

58 (2.28)

60 (2.36)

43 (1.69)

86 (3.39)

30

(1.18)

Ø 40 (1.57)

9.5 (0.37)

Solid state reference

A0030821

26 Solid state reference Calkit CUS52D. Dimensions: mm (in)

Weight Plastic sensor

Plastic sensor: 0.72 kg (1.58 lb)

The specifications apply to the sensor with a 7 m (22.9 ft) cable.

Stainless steel sensor

With clamp 1.54 kg (3.39 lb)

Without clamp 1.48 kg (3.26 lb)

With Varivent connection, standard 1.84 kg (4.07 lb)

With Varivent connection, extended shaft 1.83 kg (4.04 lb)

The specifications apply to the sensor with a 7 m (22.9 ft) cable.

Materials

Sensor head: PEEK GF30 Stainless steel 1.4404 (AISI 316 L)

Sensor housing: PPS GF40 Stainless steel 1.4404 (AISI 316 L)

O-rings: EPDM EPDM

Optical windows Sapphire Sapphire

Process connections

Plastic and stainless steel sensor

G1 and NPT ¾'

Stainless steel sensor

• Clamp 2" (depending on sensor version)/DIN 32676

• Varivent N DN 65 - 125 standard immersion depth 22.5 mm

• Varivent N DN 65 - 125 immersion depth 42.5 mm

Plastic sensor Stainless steel sensor

Endress+Hauser 17

Page 18

Certificates and approvals

Turbimax CUS52D

mark

ISO 7027

EAC

Marine approvals

Scope of delivery

Product page

The product meets the requirements of the harmonized European standards. As such, it complies

with the legal specifications of the EU directives. The manufacturer confirms successful testing of the

product by affixing to it the mark.

The measurement method used in the sensor corresponds to the nephelometric turbidity method

according to ISO 7027-1:2016.

The product has been certified according to guidelines TP TC 004/2011 and TP TC 020/2011 which

apply in the European Economic Area (EEA). The EAC conformity mark is affixed to the product.

A selection of sensors have type approval for marine applications, issued by the following

classification societies: ABS (American Bureau of Shipping), BV (Bureau Veritas), DNV-GL (Det

Norske Veritas-Germanischer Lloyd) and LR (Lloyd’s Register). Details of the order codes of the

approved sensors, and the installation and ambient conditions, are provided in the relevant

certificates for marine applications on the product page on the Internet.

Ordering information

The delivery comprises:

• 1 sensor, version as ordered

• 1 Operating Instructions BA01275C

www.endress.com/cus52d

Product Configurator

Assemblies

On the product page there is a Configure button to the right of the product image.

1. Click this button.

The Configurator opens in a separate window.

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button on the right

above the selection window.

For many products you also have the option of downloading CAD or 2D drawings of the

selected product version. Click the CAD tab for this and select the desired file type using

picklists.

Accessories

The following are the most important accessories available at the time this documentation was

issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

FlowFit CUA120

• Flange adapter for mounting turbidity sensors

• Product Configurator on the product page: www.endress.com/cua120

Technical Information TI096C

Flowfit CUA252

• Flow assembly

• Product Configurator on the product page: www.endress.com/cua252

Technical Information TI01139C

18 Endress+Hauser

Page 19

Turbimax CUS52D

Ø 53 (2.09)

30 (1.18)

36 (1.42)

Ø 64 (2.52)

Flowfit CUA262

• Weld-in flow assembly

• Product Configurator on the product page: www.endress.com/cua262

Technical Information TI01152C

Flexdip CYA112

• Immersion assembly for water and wastewater

• Modular assembly system for sensors in open basins, channels and tanks

• Material: PVC or stainless steel

• Product Configurator on the product page: www.endress.com/cya112

Technical Information TI00432C

Cleanfit CUA451

• Manual retractable assembly made of stainless steel with ball valve shut-off for turbidity sensors

• Product Configurator on the product page: www.endress.com/cua451

Technical Information TI00369C

Flowfit CYA251

• Connection: See product structure

• Material: PVC-U

• Product Configurator on the product page: www.endress.com/cya251

Technical Information TI00495C

Holder

Mounting material

Flowfit CUA250

• Flow assembly for water and wastewater applications

• Product Configurator on the product page: www.endress.com/cua250

Technical Information TI00096C

Built-in adapter

• For installing CUS52D in CUA250 or CYA251 assembly

• Order number: 71248647

Flexdip CYH112

• Modular holder system for sensors and assemblies in open basins, channels and tanks

• For Flexdip CYA112 water and wastewater assemblies

• Can be affixed anywhere: on the ground, on the coping stone, on the wall or directly onto railings.

• Stainless steel version

• Product Configurator on the product page: www.endress.com/cyh112

Technical Information TI00430C

Weld-in adapter for clamp connection DN 50

• Material: 1.4404 (AISI 316 L)

• Wall thickness 1.5 mm (0.06 in)

• Order number: 71242201

A0030841

27 Weld-in adapter. Dimensions: mm (in)

Endress+Hauser 19

Page 20

60 ... 64

(2.36 ... 2.52)

> 100 (3.94)

36

(1.42)

28 Pipe connection with weld-in adapter. Dimensions: mm (in)

76.4 (3.01)

65.7 (2.59)

Ø 40 (1.57

)

60 (2.36)

8.75

(0.34)

25

(0.98)

18 (0.71)

21.7

(0.85)

x

Turbimax CUS52D

A0030819

Compressed air cleaning

Compressed air cleaning for stainless steel sensors

• Pressure 1.5 to 2 bar (21.8 to 29 psi)

• Connection: 6 mm (0.24 in) or 8 mm (0.31 in)

• Materials: POM black, stainless steel

• Order number: 71242026

29 Compressed air cleaning for stainless steel sensors. Dimensions: mm (in)

X 6 mm (0.2 in) hose barb

Compressor

• For compressed air cleaning

• 230 V AC, order number: 71072583

• 115 V AC, order number: 71194623

Ultrasonic cleaning

Ultrasonic cleaning system CYR52

• For attachment to assemblies and pipes

• Product Configurator on the product page: www.endress.com/cyr52

Technical Information TI01153C

20 Endress+Hauser

A0030837

Page 21

Turbimax CUS52D

254 (10.0)

12 (0.5)

12 (0.5)

1

2

3

Bubble trap

Bubble trap

• For sensor CUS52D

• Process pressure: up to 3 bar (43.5 psi)

• Process temperature: 0 to 50 °C (32 to 122 °F)

• D 12 adapter with connection for degassing line (upper connection on the CUA252) is included in

the scope of delivery.

• Orifice plates for the following volume flows:

• < 60 l/h (15.8 gal/h)

• 60 to 100 l/h (15.8 to 26.4 gal/h)

• 100 l/h (26.4 gal/h)

• The degassing line is fitted with a PVC hose, backpressure hose valve and luer lock adapter.

• Order number, suitable for CUA252 assembly: 71242170

• Order number, suitable for assembly S of CUS31: 71247364

A0035757

30 Bubble trap. Dimensions: mm (in)

1 Inlet for medium (without hose system)

2 Outlet for bubbles (hose system is included in scope of delivery)

3 Outlet for medium (without hose system)

Solid state reference

Calibration vessel

CUY52-AA+560

• Calibration tool for CUS52D turbidity sensor

• Easy and reliable validation and calibration of CUS52D turbidity sensors.

• Product Configurator on the product page: www.endress.com/cuy52

Technical Information TI01154C

CUY52-AA+640

• Calibration vessel for CUS52D turbidity sensor

• Easy and reliable validation and calibration of CUS52D turbidity sensors.

• Product Configurator on the product page: www.endress.com/cuy52

Technical Information TI01154C

Endress+Hauser 21

Page 22

Page 23

Page 24

www.addresses.endress.com

Loading...

Loading...