Page 1

TI01395C/07/EN/04.20

71473152

2020-02-10

Products Solutions Services

Technical Information

Turbimax CUS50D

Absorption sensor for turbidity and solids measurements

Application

Turbimax CUS50D is an absorption sensor for measuring

turbidity or solids content. The sensor ensures reliable

measurements and efficient process monitoring, even in

aggressive media:

• Industrial wastewater and utilities:

• Measurement of solids content in process sludges and

wastewater sludges

• Flocculant dosing

• Measurement of concentration of dairy products in

wastewater

• Process media:

Concentration measurement in the product, e.g. in titanium

dioxide

• Highly absorptive media:

Concentration measurement in very dark media, e.g.

activated carbon concentration in the 4th treatment step of

wastewater treatment plants

Page 2

[Continued from front page]

Your benefits

• Turbidity measurement according to the principle of light

attenuation as per ISO7027

• Glass-free, non-adhesive sensor head with 2 path lengths (5

mm and 10 mm)

• Standardized communication (Memosens technology)

enables "plug and play"

• Sensor head made of a PTFE derivative is easy to keep clean

using the air cleaning unit

• Long service life of sensor thanks to resistant materials used

in sensor shaft and head

• Sensor is precalibrated ex works and includes different

application models

• Automatic sludge model independently selects the optimum

signal characteristics for each type of sludge

• 1-point calibration suffices in most applications

Page 3

Turbimax CUS50D

Table of contents

Function and system design ................... 4

Measuring principle ............................ 4

Measuring system ............................. 4

Sensor monitoring ............................. 5

Applications ................................. 5

Input ..................................... 6

Measured variable ............................. 6

Measuring range .............................. 6

Power supply .............................. 6

Electrical connection ........................... 6

Performance characteristics ................... 9

Reference operating conditions .................... 9

Maximum measured error ....................... 9

Repeatability ................................ 9

Drift ...................................... 9

Detection limits ............................... 9

Installation ............................... 10

Orientation ................................ 10

Environment .............................. 13

Ambient temperature range ..................... 13

Storage temperature .......................... 13

Degree of protection .......................... 13

Electromagnetic compatibility (EMC) ............... 13

Compressed air cleaning ........................ 18

Calibration kit ............................... 18

Process .................................. 13

Process temperature range ...................... 13

Process pressure range ......................... 13

Minimum flow .............................. 13

Mechanical construction .................... 14

Dimensions ................................ 14

Weight ................................... 15

Materials .................................. 15

Process connections ........................... 15

Certificates and approvals ................... 16

mark ................................... 16

Electromagnetic compatibility .................... 16

ISO 7027 .................................. 16

EAC ..................................... 16

Marine approvals ............................ 16

Ordering information ....................... 16

Product Configurator .......................... 16

Scope of delivery ............................. 16

Accessories ............................... 16

Assemblies ................................. 16

Holder .................................... 17

Mounting material ........................... 17

Endress+Hauser 3

Page 4

Function and system design

1

2

3

4

Turbimax CUS50D

Measuring principle

Measuring system

The sensor operates on the principle of light attenuation and meets the requirements of turbidity

measurement according to the principle of light attenuation as per ISO 7027. The measurement is

performed with a wavelength of 860 nm.

It is suitable for measurements in the average to high turbidity range and for the measurement of

solids content.

A complete measuring system comprises:

• Turbimax CUS50D turbidity sensor

• Liquiline CM44x multi-channel transmitter

• Direct installation in a pipe connection (Clamp 2" ) or

• Assembly:

• Flow assembly e.g. Flowfit CUA252 or CUA120 or

• Assembly e.g. Flexdip CYA112 and holder e.g. Flexdip CYH112 or

• Retractable assembly, e.g. Cleanfit CUA451

A0036713

1 Measuring system with CUA252 flow assembly

1 Liquiline CM44x multi-channel transmitter

2 Turbimax CUS50D turbidity sensor

3 CUA252 flow assembly

4 Direction of flow

Sensor structure

The sensor features a sensor head with 2 path lengths of 5 mm (0.2 in) and 10 mm (0.39 in).

4 Endress+Hauser

Page 5

Turbimax CUS50D

3

4

A

B

A0036825

2 CUS50D sensor head

1 Light sources 10 mm (0.39 in)

2 Light sources 5 mm (0.2 in)

3 Light receiver 5 mm (0.2 in)

4 Light receiver 10 mm (0.39 in)

A0036368

3 Versions

A With clamp

B With compressed air cleaning

Sensor monitoring

The optical signals are continuously monitored and analyzed for plausibility. If inconsistencies occur,

an error message is output via the transmitter. The function is disabled by default.

Applications

The "Absorption" and "Formazine" applications are calibrated at the factory. The absorption factory

calibration is used as the basis for precalibrating additional applications and optimizing them for the

different media characteristics.

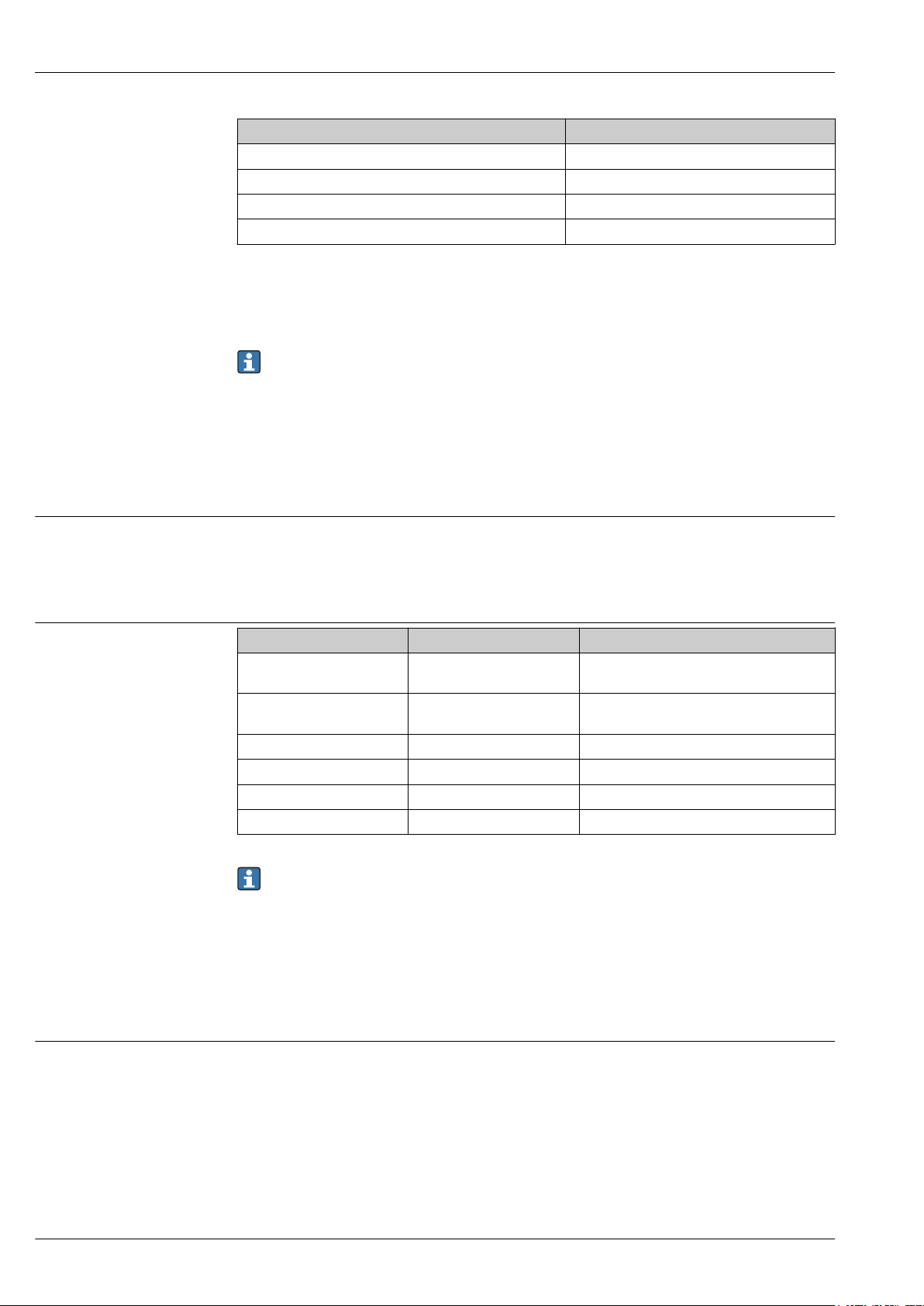

Application Specified operating range

Factory calibration for absorption 0.000 to 5.000 AU or

0.000 to 10.000 OD

Factory calibration for formazine 40 to 4,000 FAU

Endress+Hauser 5

Page 6

Turbimax CUS50D

Application Specified operating range

Application: Kaolin 0 to 60 g/l

Application: Sludge 0 to 25 g/l

Application: Auto sludge 0 to 25 g/l

Product loss 0 to 100 %

To adapt to a specific application, it is possible to perform customer calibrations with up to 10 points.

Application: Formazine

Factory calibration for the formazine application is carried out with the formazine turbidity standard.

Sensor measured values in the unit [FAU] are only comparable to the measured values of any

other sensor e.g. scattered light sensor with the unit [FNU] or [NTU] in this standard medium.

In any other medium, the measured values will be different to those obtained when measuring

with another scattered light sensor.

Input

Measured variable

Measuring range

• Turbidity

• Absorption

• Solids content

• Product loss

• Temperature

Application Specified operating range Maximum operating range

Absorption factory calibration 0.000 to 5.000 AU or

0.000 to 10.000 OD

Factory calibration for

formazine

Application: Kaolin 0 to 60 g/l 500 g/l

Application: Sludge 0 to 25 g/l 500 g/l

Application: Auto sludge 0 to 25 g/l 500 g/l

Product loss 0 to 100 % 1000%

Measuring range with solids content:

For solids, the achievable ranges depend very much on the media that are actually present and

may differ from the recommended operating ranges. Extremely inhomogeneous media may

cause fluctuations in measured values, thus narrowing the measuring range.

40 to 4,000 FAU 10000 FAU

Power supply

Electrical connection

6 Endress+Hauser

Connect the sensor to the CM44 transmitter for operation.

‣

Page 7

Turbimax CUS50D

GN

YE

GY

PK

M12

85 86

85

2DS

1

2

86

97 88 8798

97 88 8798

Sensor 1

Sensor 2

PK

GY

GN

YE

Sensor

85 86

85

1

2

86

97 88 8798

Sensor 1

PK

GY

GN

YE

BN

WH

Sensor

A0036365

4 Connection options

The following connection options are available:

• via M12 connector (version: fixed cable, M12 connector)

• via sensor cable to the plug-in terminals of a sensor input on the transmitter (version: fixed cable,

end sleeves)

A0033092

5 Sensor connection to sensor input (left) or via M12 connector (right)

Endress+Hauser 7

Page 8

Connecting the cable shield

1

2

3

4

Cable sample (does not necessarily correspond to the original cable supplied)

Turbimax CUS50D

6 Terminated cable

1 Outer shield (exposed)

2 Cable cores with ferrules

3 Cable sheath (insulation)

7 Inserting the cable

4 Grounding clip

The maximum cable length is 100 m (328.1 ft).

8 Tightening the screw

(2 Nm (1.5 lbf ft))

The cable shield is grounded by the

grounding clip

8 Endress+Hauser

Page 9

Turbimax CUS50D

Performance characteristics

Reference operating conditions

Maximum measured error

Repeatability

20 °C (68 °F), 1013 hPa (15 psi)

Absorption 0.5 % of the upper range value (corresponds to ± 50 mOD)

Formazine 10 % of the measured value or 10 FAU (the greater value applies in each case)

Kaolin 5 % of the upper range value; applies to sensors that are calibrated for the observed

measuring range

Sludge/auto

sludge

Product loss Not specified; very much depends on the condition of the measuring medium used

10 % of the measured value or 5 % of the upper range value (the greater value applies in

each case); applies to sensors that are calibrated for the observed measuring range

For solids, the achievable measured errors depend very much on the media that are actually

present and may differ from the specified values. Extremely inhomogeneous media cause the

measured value to fluctuate and increase the measured error.

The measured error encompasses all inaccuracies of the measuring chain (sensor and

transmitter). However, it does not include the inaccuracy of the reference material used for

calibration.

Application Repeatability

Absorption 0.001 OD or 0.2% of measured value (the greater value applies in each case)

Formazine 10 FAU for 800 FAU

Drift

Detection limits

For kaolin, sludge/autosludge and product loss, the repeatability depends very much on the

media that are actually present. It is therefore not possible to specify general values.

Working on the basis of electronic controls, the sensor is largely free of drifts.

• Formazine: drift 0.04% per day (for 2000 FAU)

• Absorption: drift 0.015% per day (for 5 OD)

Application Detection limit

Absorption 0.004 OD for 0.5 OD

Formazine 10 FAU

For kaolin, sludge/autosludge and product loss, the detection limit depends very much on the

media that are actually present. It is therefore not possible to specify general values.

Endress+Hauser 9

Page 10

Installation

41

5

2

3

Detail A

Detail A

90°

5

3

2

1

Orientation Orientation in pipes

9 Permitted and unacceptable orientations in pipes

Turbimax CUS50D

A0029259

• The pipeline diameter must be at least 50 mm (2 in).

• Install the sensor in places with consistent flow conditions.

• The best installation location is in the ascending pipe (item 1).

A0036370

10 Direction of flow

Align the sensor in such a way that the medium flows through the measuring gap (self-cleaning

‣

effect).

The arrow indicates the flow direction; it runs from the 10 mm (0.39 in) path to the 5 mm (0.2 in)

path.

Installation marking

11 Installation marking for sensor alignment

1 Installation marking

The installation marking on the sensor is opposite the optical system.

Using the installation marking, align the sensor against the flow direction.

‣

A0041341

10 Endress+Hauser

Page 11

Turbimax CUS50D

2

Installation options

Installation options:

• With flow assembly e.g. Flowfit CUA252 or CUA120

• with retractable assembly, e.g. Cleanfit CUA451

• with assembly e.g. Flexdip CYA112 and holder e.g. Flexdip CYH112

The installation angle is 90°.

The arrow indicates the flow direction; it runs from

the 10 mm (0.39 in) path to the 5 mm (0.2 in)

path.

A0036835

12 Installing with CUA120 flow assembly

Endress+Hauser 11

Page 12

A0036837

2

13 Installing with CUA252 flow assembly

Turbimax CUS50D

The installation angle is 90°.

The arrow indicates the flow direction; it runs from

the 10 mm (0.39 in) path to the 5 mm (0.2 in)

path.

The installation angle is 90°.

The arrow indicates the flow direction; it runs from

the 10 mm (0.39 in) path to the 5 mm (0.2 in)

path.

A0036836

14 Installing with CUA262 flow assembly

A0041336

15 Installing with CYA251 flow assembly

The installation angle is 90°.

The arrow indicates the flow direction; it runs from

the 10 mm (0.39 in) path to the 5 mm (0.2 in)

path.

The installation angle is 90°.

The arrow indicates the flow direction; it runs

from the 10 mm (0.39 in) path to the

5 mm (0.2 in) path.

The medium pressure may not exceed

2 bar (29 psi) for manual assembly retraction.

A0036838

16 Installing with CUA451 retractable assembly

12 Endress+Hauser

Page 13

Turbimax CUS50D

The installation angle is 0°.

The arrow indicates the flow direction; it runs from

the 10 mm (0.39 in) path to the 5 mm (0.2 in)

path.

If the sensor is used in open basins, install the

sensor in such a way that air bubbles cannot

accumulate on it.

A0036839

17 Installing with immersion assembly

Compressed air cleaning

Fit the compressed air cleaning unit onto the sensor head to the end stop. The nozzle of the

‣

compressed air cleaning unit must be located on the side of the wider 10 mm (0.4 in)

measurement gap.

Ambient temperature range

Storage temperature

Degree of protection

Electromagnetic compatibility (EMC)

Process temperature range

Process pressure range

Minimum flow

Environment

–20 to 60 °C (–4 to 140 °F)

–20 to 70 °C (–4 to 158 °F)

IP 68 (1.8 m (5.91 ft) water column over 20 days, 1 mol/l KCl)

Interference emission and interference immunity as per

• EN 61326-1:2013

• EN 61326-2-3:2013

• NAMUR NE21: 2012

Process

–20 to 85 °C (–4 to 185 °F)

0.5 to 4.5 bar (7.3 to 65.3 psi) absolute

No minimum flow required.

For solids which have a tendency to form deposits, ensure that sufficient mixing is performed.

Endress+Hauser 13

Page 14

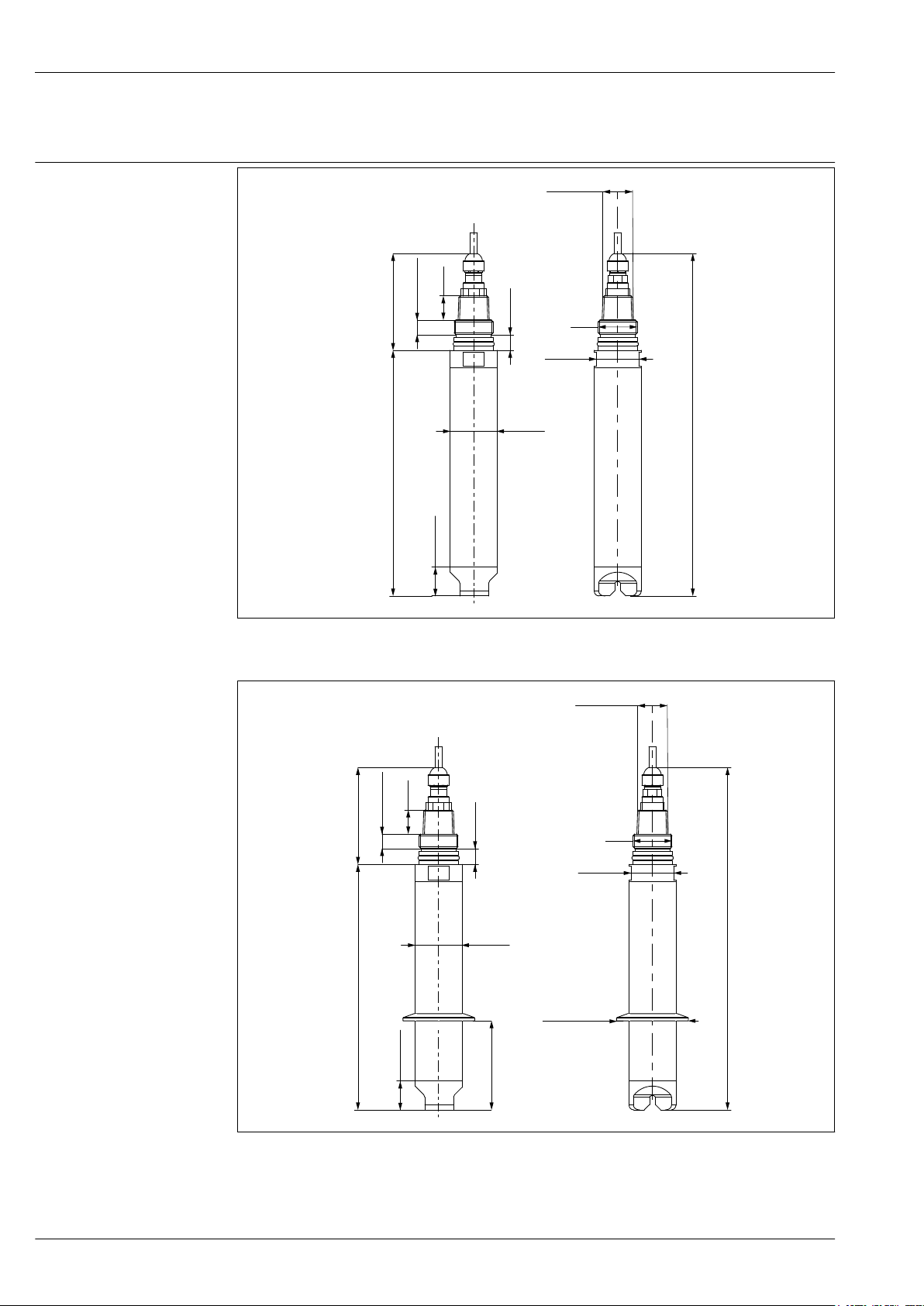

Dimensions

82.7 (3.26)

12.6

20.5

(0.8)

292.2 (11.5)

!40

(1.57)

209.5 (8.25)

24.5 (1)

NPT3/4"

GI“

36 (1.4)

(0.5)

13.4

(0.53)

82.7 (3.26)

12.6

20.5

(0.8)

292.2 (11.5)

!40

(1.57)

209.5 (8.25)

24.5 (1)

NPT3/4"

GI“

36 (1.4)

(0.5)

13.4

(0.53)

85.9 (3.38)

! 64

(2.52)

Turbimax CUS50D

Mechanical construction

A0036366

18 Dimensions. Dimensions: mm (in)

19 Dimensions with clamp. Dimensions: mm (in)

14 Endress+Hauser

A0036582

Page 15

Turbimax CUS50D

61 (2.4)

64.5 (2.5)

36.9 (1.5)

4.7 (0.19)

3.8 (1.5)

Ø 40 (1.6)

Weight

Materials

Process connections

20 Dimensions for compressed air cleaning. Dimensions: mm (in)

Compressed air cleaning: 2 bar (29 psi) maximum pressure

Cable length Plastic sensor Metal sensor Metal sensor with clamp

3 m (9.84 ft) 0.46 kg (1.5 lbs) 1.15 kg (2.54 lbs) 1.21 kg (2.67 lbs)

7 m (23 ft) 0.68 kg (1.5 lbs) 1.37 kg (3.81 lbs) 1.43 kg (3.15 lbs)

15 m (49.2 ft) 1.15 kg (2.54 lbs) 1.83 kg (4.03 lbs) 1.9 Kg (4.19 lbs)

Plastic sensor Metal sensor

Sensor head: PCTFE PCTFE

Sensor housing: PPS/GF40% 1.4571/AISI 316Ti

Sensor threaded connection: PPS/GF40% 1.4404/AISI316L

O-rings: EPDM EPDM

The data refer to the wetted materials when the sensor is installed correctly in Endress+Hauser

assemblies.

• G1 and NPT ¾'

• Clamp 2" (depending on sensor version)/DIN 32676

A0036826

Endress+Hauser 15

Page 16

Certificates and approvals

Turbimax CUS50D

mark

Electromagnetic compatibility

ISO 7027

EAC

Marine approvals

The product meets the requirements of the harmonized European standards. As such, it complies

with the legal specifications of the EU directives. The manufacturer confirms successful testing of the

product by affixing to it the mark.

Interference emission and interference immunity as per

• EN 61326-1:2013

• EN 61326-2-3:2013

• NAMUR NE21: 2012

The measuring method used in the sensor corresponds to the turbidimetric method (principle of

attenuation of light) according to ISO 7027-1:2016.

The product has been certified according to guidelines TP TC 004/2011 and TP TC 020/2011 which

apply in the European Economic Area (EEA). The EAC conformity mark is affixed to the product.

A selection of sensors have type approval for marine applications, issued by the following

classification societies: ABS (American Bureau of Shipping), BV (Bureau Veritas), DNV-GL (Det

Norske Veritas-Germanischer Lloyd) and LR (Lloyd’s Register). Details of the order codes of the

approved sensors, and the installation and ambient conditions, are provided in the relevant

certificates for marine applications on the product page on the Internet.

Ordering information

Product Configurator

Scope of delivery

On the product page there is a Configure button to the right of the product image.

1. Click this button.

The Configurator opens in a separate window.

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button on the right

above the selection window.

For many products you also have the option of downloading CAD or 2D drawings of the

selected product version. Click the CAD tab for this and select the desired file type using

picklists.

The delivery comprises:

• 1 Turbimax CUS50D sensor, version as ordered

• 1 Operating Instructions BA01846C

Accessories

The following are the most important accessories available at the time this documentation was

issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

Assemblies

FlowFit CUA120

• Flange adapter for mounting turbidity sensors

• Product Configurator on the product page: www.endress.com/cua120

Technical Information TI096C

16 Endress+Hauser

Page 17

Turbimax CUS50D

Ø 53 (2.09)

30 (1.18)

36 (1.42)

Ø 64 (2.52)

Flowfit CUA252

• Flow assembly

• Product Configurator on the product page: www.endress.com/cua252

Technical Information TI01139C

Flowfit CUA262

• Weld-in flow assembly

• Product Configurator on the product page: www.endress.com/cua262

Technical Information TI01152C

Flexdip CYA112

• Immersion assembly for water and wastewater

• Modular assembly system for sensors in open basins, channels and tanks

• Material: PVC or stainless steel

• Product Configurator on the product page: www.endress.com/cya112

Technical Information TI00432C

Cleanfit CUA451

• Manual retractable assembly made of stainless steel with ball valve shut-off for turbidity sensors

• Product Configurator on the product page: www.endress.com/cua451

Technical Information TI00369C

Holder

Mounting material

Flowfit CYA251

• Connection: See product structure

• Material: PVC-U

• Product Configurator on the product page: www.endress.com/cya251

Technical Information TI00495C

Flexdip CYH112

• Modular holder system for sensors and assemblies in open basins, channels and tanks

• For Flexdip CYA112 water and wastewater assemblies

• Can be affixed anywhere: on the ground, on the coping stone, on the wall or directly onto railings.

• Stainless steel version

• Product Configurator on the product page: www.endress.com/cyh112

Technical Information TI00430C

Weld-in adapter for clamp connection DN 50

• Material: 1.4404 (AISI 316 L)

• Wall thickness 1.5 mm (0.06 in)

• Order number: 71242201

21 Weld-in adapter. Dimensions: mm (in)

A0030841

Endress+Hauser 17

Page 18

60 ... 64

(2.36 ... 2.52)

> 100 (3.94)

36

(1.42)

22 Pipe connection with weld-in adapter. Dimensions: mm (in)

Turbimax CUS50D

A0030819

Compressed air cleaning

Calibration kit

Compressed air cleaning for CUS50D

• Connection: 6 mm (0.24 in)

• Pressure: 1.5 to 2 bar (21.8 to 29 psi)

• Materials: POM, PE, PA 6.6 30% glass fiber

• Order number: 71395617

Compressor

• For compressed air cleaning

• 230 V AC, order number: 71072583

• 115 V AC, order number: 71194623

CUS50D kit, solid state reference

• Calibration tool for CUS50D turbidity sensor

• Easy and reliable inspection of CUS50D turbidity sensors

• Order number: 71400898

18 Endress+Hauser

Page 19

Page 20

www.addresses.endress.com

Loading...

Loading...