Page 1

BA00465C/07/EN/24.20

71473511

2020-03-19

Valid as of version

01.07.00

Products Solutions Services

Operating Instructions

Liquiport CSP44

Portable sampler for liquid media

Page 2

Page 3

Liquiport CSP44 Table of contents

Table of contents

1 About this document ................ 5

1.1 Warnings ............................ 5

1.2 Symbols .............................. 5

1.3 Symbols on the device ................... 5

1.4 Documentation ........................ 6

2 Basic safety instructions ............ 7

2.1 Requirements for personnel ............... 7

2.2 Designated use ........................ 7

2.3 Workplace safety ....................... 7

2.4 Operational safety ...................... 8

2.5 Product safety ......................... 9

3 Product description ................ 10

3.1 Device design ......................... 10

3.2 Terminal diagram ..................... 11

4 Incoming acceptance and product

identification ..................... 12

4.1 Incoming acceptance ................... 12

4.2 Product identification ................... 12

4.3 Scope of delivery ...................... 12

4.4 Certificates and approvals ............... 13

5 Installation ....................... 14

5.1 Installation conditions .................. 14

5.2 Installation .......................... 16

5.3 Connecting the suction line .............. 16

5.4 Post-installation check .................. 16

6 Electrical connection .............. 17

6.1 Connecting the sampler ................. 17

6.2 Connecting modules and sensors .......... 19

6.3 Terminal assignment for input/output

signals .............................. 19

6.4 Signal cable connection (optional) ......... 20

6.5 Ensuring the degree of protection .......... 21

6.6 Post-connection check .................. 22

7 System integration ................ 23

7.1 Service interface ...................... 23

8 Operation options ................. 24

8.1 Overview ............................ 24

8.2 Access to the operating menu via the local

display ............................. 25

8.3 Configuration options .................. 26

9 Commissioning .................... 29

9.1 Function check ....................... 29

9.2 Switching on the measuring device ......... 29

9.3 Setting the operating language ............ 30

9.4 Configuring the measuring device .......... 30

10 Operation ......................... 35

10.1 Display ............................. 35

10.2 General settings ....................... 36

10.3 Programming ........................ 47

10.4 Inputs .............................. 81

10.5 Outputs ............................. 86

11 Diagnostics and troubleshooting ... 94

11.1 General troubleshooting ................. 94

11.2 Diagnostic information on local display ...... 95

11.3 Adapting the diagnostic information ....... 95

11.4 Overview of diagnostic information ........ 97

11.5 Pending diagnostic messages ............ 104

11.6 Diagnosis list ........................ 104

11.7 Logbooks ........................... 104

11.8 Device information ................... 110

11.9 Simulation .......................... 111

11.10 Device test .......................... 113

11.11 Resetting the measuring device .......... 115

11.12 Information on operating times .......... 115

11.13 Status of inputs/outputs ................ 115

11.14 Firmware history ..................... 116

12 Maintenance .................... 120

12.1 Recommended maintenance ............ 120

12.2 Calibration ......................... 121

12.3 Replacing the pump tube ............... 122

12.4 Cleaning ........................... 124

12.5 Replacing the rechargeable batteries ...... 126

12.6 Technical support .................... 127

13 Repair ........................... 128

13.1 Spare parts ......................... 128

13.2 Return ............................. 129

13.3 Disposal ........................... 129

14 Accessories ...................... 130

14.1 Measuring cable ..................... 131

14.2 Sensors ............................ 131

15 Technical data ................... 136

15.1 Input .............................. 136

15.2 Binary input, passive (optional) .......... 136

15.3 Temperature inputs (optional) ........... 136

15.4 Analog input, passive/active (optional) ..... 136

Endress+Hauser 3

Page 4

Table of contents Liquiport CSP44

15.5 Output optional ...................... 136

15.6 Power supply ........................ 137

15.7 Performance characteristics ............. 137

15.8 Environment ........................ 138

15.9 Process ............................ 138

15.10 Mechanical construction ............... 139

Index ................................. 141

4 Endress+Hauser

Page 5

Liquiport CSP44 About this document

1 About this document

1.1 Warnings

Structure of information Meaning

DANGER

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

NOTICE

Cause/situation

If necessary, Consequences of

non-compliance (if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to

property.

1.2 Symbols

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

1.3 Symbols on the device

Symbol Meaning

Reference to device documentation

Endress+Hauser 5

Page 6

About this document Liquiport CSP44

1.4 Documentation

The following manuals which are available on the complement these Brief Operating

Instructions Operating Instructions:

• Brief Operating Instructions for Liquiport CSP44, BA00465C

• Operating Instructions for Memosens, BA01245C

• Software description for Memosens inputs

• Calibration of Memosens sensors

• Sensor-specific diagnostics and troubleshooting

• Guidelines for communication via fieldbus and web server

• Special Documentation: Sampler application manual SD01068C

• Documentation on other devices in the Liquiline platform:

• Liquiline CM44xR (DIN rail device)

• Liquiline System CA80 (analyzer)

• Liquiline System CAT8x0 (sample preparation)

• Liquistation CSFxx (sampler)

• Liquiport CSP44 (sampler)

6 Endress+Hauser

Page 7

Liquiport CSP44 Basic safety instructions

2 Basic safety instructions

2.1 Requirements for personnel

• Installation, commissioning, operation and maintenance of the measuring system may

be carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the

specified activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions

and must follow the instructions contained therein.

• Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

Liquiport 2010 CSP44 is a portable sampler for liquid media in non-hazardous areas. The

samples are taken discontinuously using a peristaltic pump and are then distributed into

sampling containers.

The sampler is designed for use in the following applications:

• Communal and industrial wastewater treatment plants

• Laboratories and water management offices

• Monitoring of liquid media in industrial processes

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted. The

manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Workplace safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

• Regulations for explosion protection

Electromagnetic compatibility

• The product has been tested for electromagnetic compatibility in accordance with the

applicable international standards for industrial applications.

• The electromagnetic compatibility indicated applies only to a product that has been

connected in accordance with these Operating Instructions.

Endress+Hauser 7

Page 8

Basic safety instructions Liquiport CSP44

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

During operation:

If faults cannot be rectified:

‣

products must be taken out of service and protected against unintentional operation.

8 Endress+Hauser

Page 9

Liquiport CSP44 Basic safety instructions

2.5 Product safety

2.5.1 State of the art

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

international standards have been observed.

Devices connected to the sampler must comply with the applicable safety standards.

2.5.2 IT security

We only provide a warranty if the device is installed and used as described in the

Operating Instructions. The device is equipped with security mechanisms to protect it

against any inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

Endress+Hauser 9

Page 10

Product description Liquiport CSP44

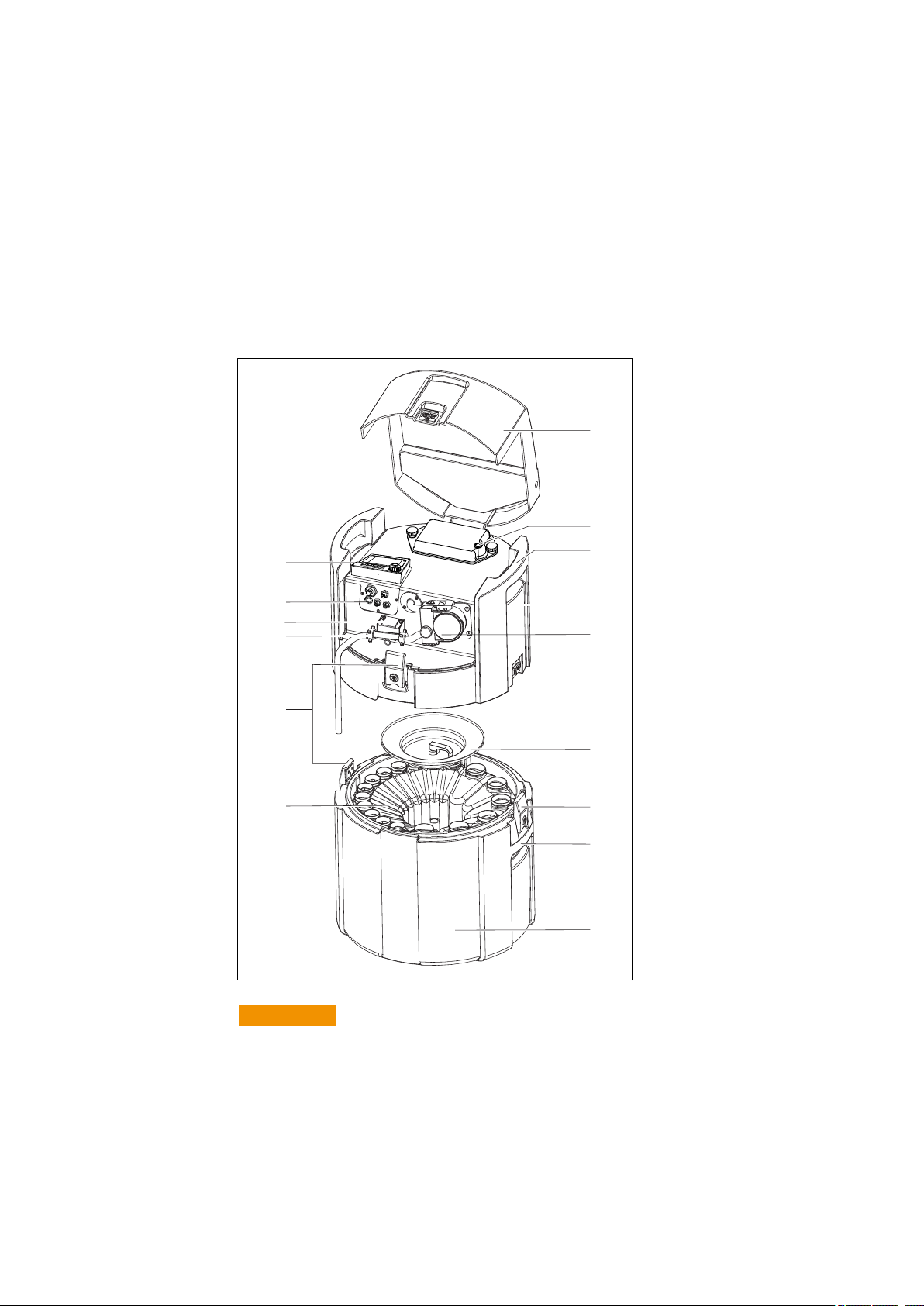

1

2

3

4

5

6

7

8

9

10

11

12

13

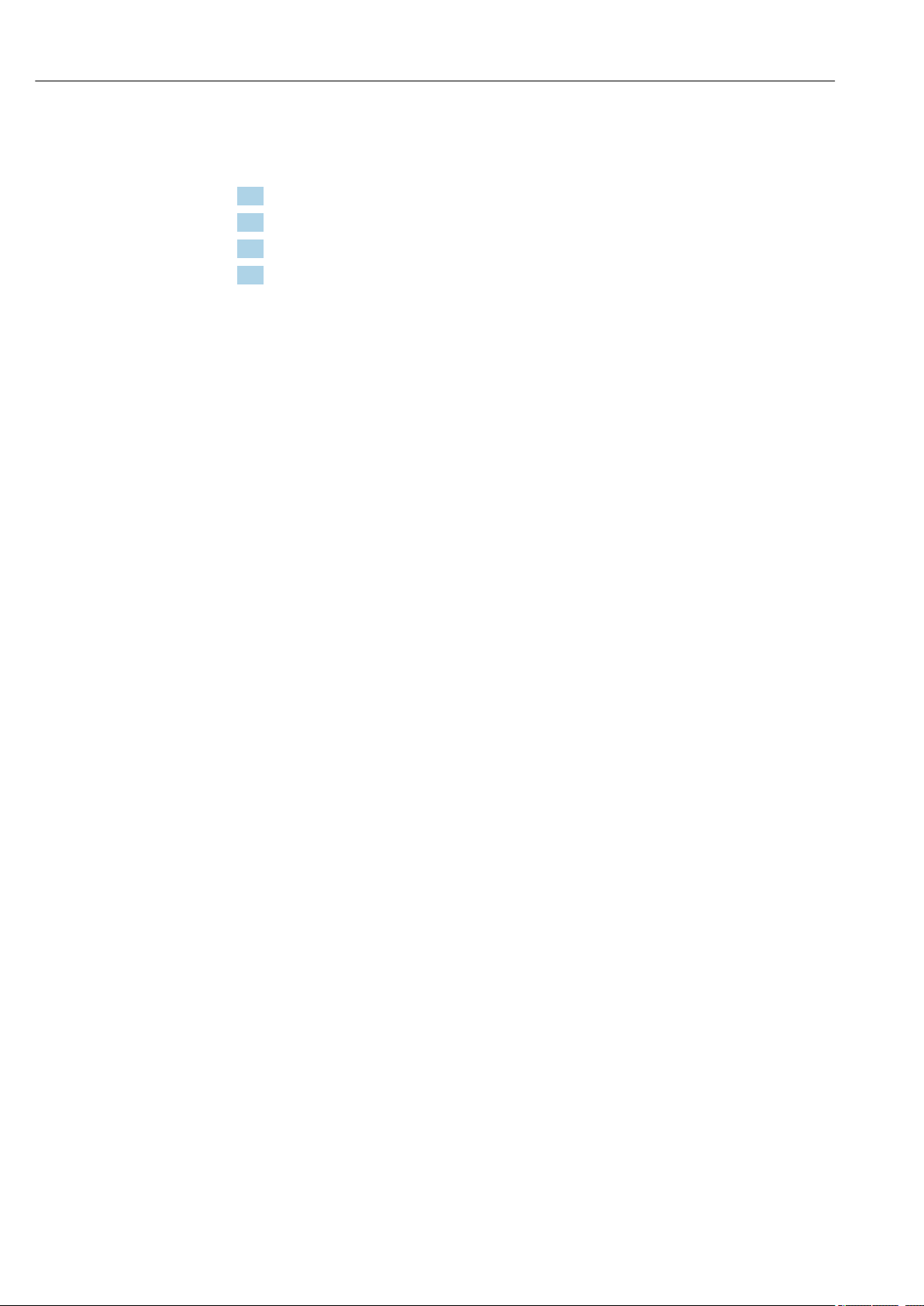

3 Product description

3.1 Device design

A complete sampling unit comprises:

• Controller with display, soft keys and navigator

• Vacuum or peristaltic pump for sampling

• PE or glass sample bottles for sample preservation

• Sampling chamber temperature regulator (optional) for safe sample storage

• Suction line with suction head

1 Device cover

2 Battery compartment cover

with switch

3 Upper carrying handles

4 Unit upper compartment

5 Peristaltic pump with pump

tubing

6 Bottle retaining cover

7 Lockable latches

8 Lower carrying handles

9 Unit lower compartment

10 Bottle distribution

11 Lockable latches

12 Hose connection

13 Medium detection

14 Electrical connections

15 Controller

WARNING

L

A0013533

Risk of injury

Danger of injury due to rotating parts

Secure the sampler against unintentional start-up whilst you work on the opened hose

‣

pump.

10 Endress+Hauser

Page 11

Liquiport CSP44 Product description

3.2 Terminal diagram

The unique terminal name is derived from:

Slot no. : Port no. : Terminal

Example, NO contact of a relay

Device with inputs for digital sensors, 4 current outputs and 4 relays

• Base module BASE2-E (contains 2 sensor inputs, 2 current outputs)

• 2AO module (2 current outputs)

• 4R module (4 relays)

Endress+Hauser 11

Page 12

Incoming acceptance and product identification Liquiport CSP44

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify the supplier of any damage to the packaging.

Keep the damaged packaging until the issue has been resolved.

2. Verify that the contents are undamaged.

Notify the supplier of any damage to the delivery contents.

Keep the damaged goods until the issue has been resolved.

3. Check that the delivery is complete and nothing is missing.

Compare the shipping documents with your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

Make sure to comply with the permitted ambient conditions.

If you have any questions, please contact your supplier or your local Sales Center.

4.2 Product identification

Nameplates can be found:

• On the inside of the door

• On the packaging (adhesive label, portrait format)

• On the inside of the device cover

4.2.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Order code

• Extended order code

• Serial number

• Firmware version

• Ambient and process conditions

• Input and output values

• Activation codes

• Safety information and warnings

• Certificate information

Compare the information on the nameplate with the order.

‣

4.3 Scope of delivery

The scope of delivery comprises:

• 1 Liquiport 2010 CSP44 with:

• The ordered bottle configuration

• Optional hardware

• 1 print version of Brief Operating Instructions in the language ordered

• Optional accessories

If you have any queries:

‣

Please contact your supplier or local sales center.

12 Endress+Hauser

Page 13

Liquiport CSP44 Incoming acceptance and product identification

4.4 Certificates and approvals

4.4.1

Declaration of Conformity

The product meets the requirements of the harmonized European standards. As such, it

complies with the legal specifications of the EU directives. The manufacturer confirms

successful testing of the product by affixing to it the mark.

MCERTS

The device has been assessed by Sira Certification Service and complies with "MCERTS

Performance Standards for Water Monitoring Equipment Part 1, Version 2.1 dated

November 2009"; certificate no.: Sira MC100176/02.

EAC

The product has been certified according to guidelines TP TC 004/2011 and TP TC

020/2011 which apply in the European Economic Area (EEA). The EAC conformity mark

is affixed to the product.

mark

Endress+Hauser 13

Page 14

Installation Liquiport CSP44

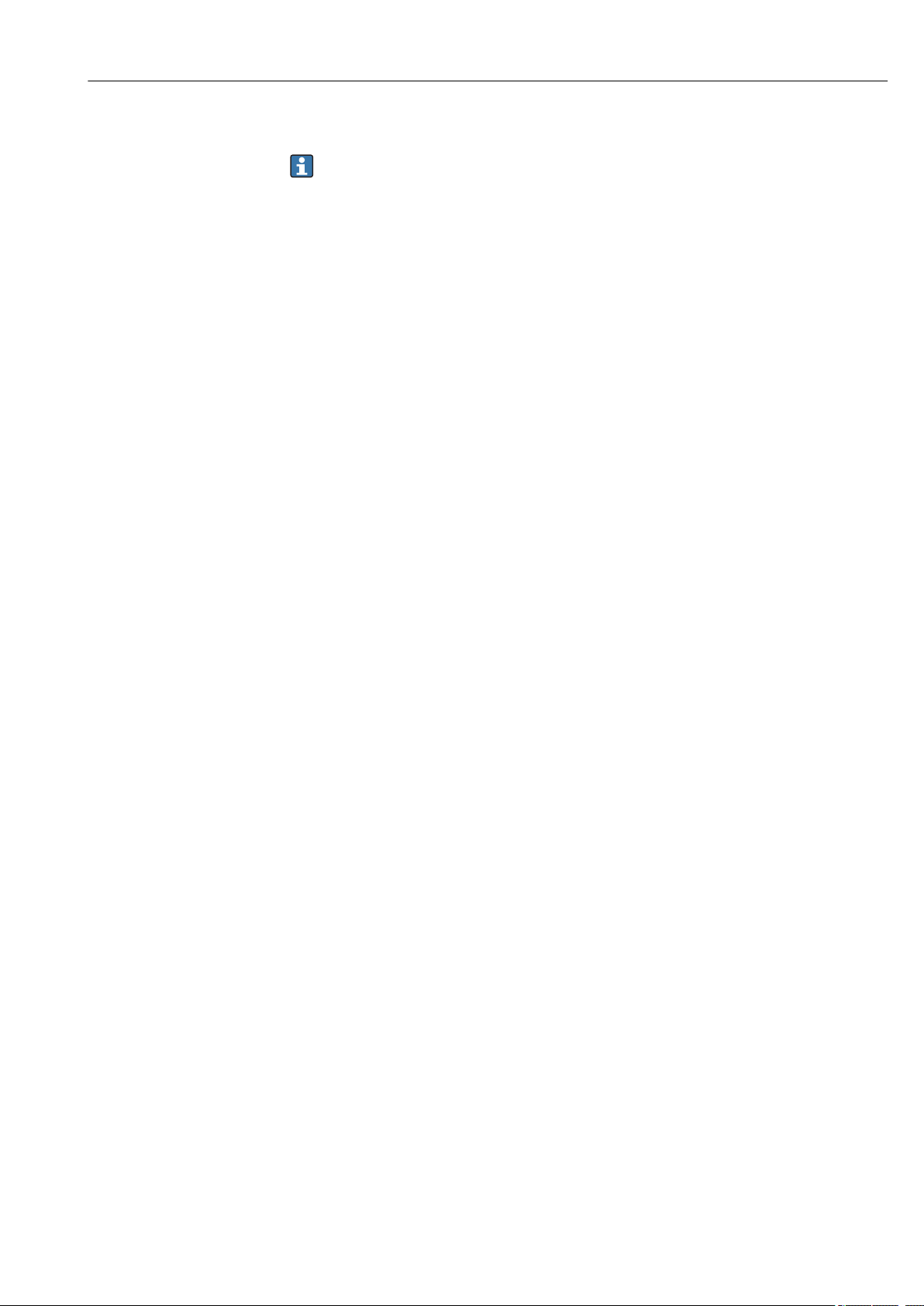

480 (18.9)

675 (26.6)

320 (12.6)

355 (14.0)

5 Installation

5.1 Installation conditions

5.1.1 Dimensions

A0013473

1 CSP44 standard version, dimensions in mm (in)

14 Endress+Hauser

Page 15

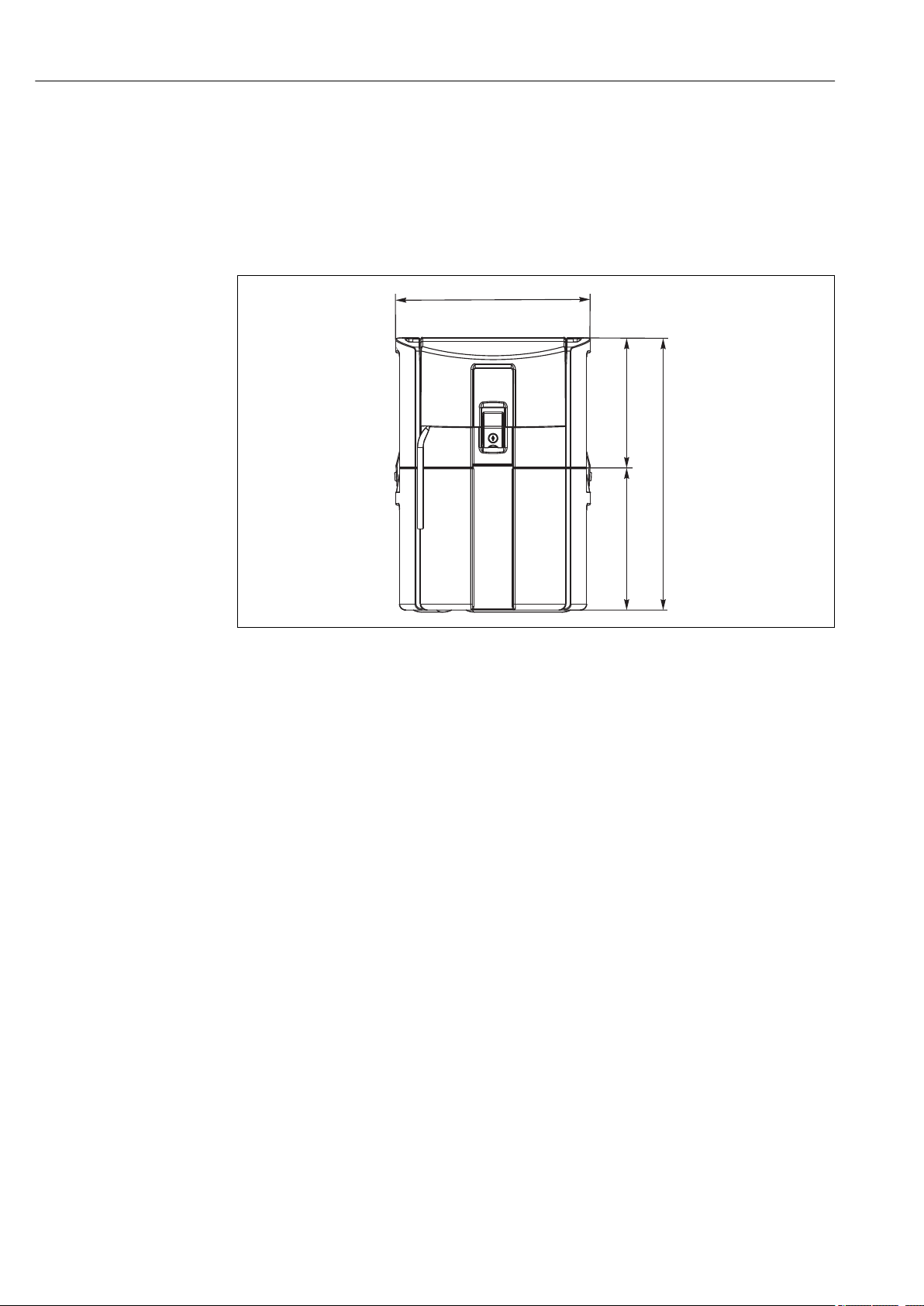

Liquiport CSP44 Installation

5.1.2 Installation site

A0013474

2 Installation site, example

The suction line must be routed with a downward slope to the sampling point. Avoid

siphon formation!

Note the following when erecting the device:

• Erect the device on a level surface.

• Securely connect the device at the fastening points to the surface underneath.

• Protect the device against additional heating (e.g. heater or direct sunlight in the case of

PS housing).

• Protect the device against mechanical vibrations.

• Protect the device against strong magnetic fields.

5.1.3 Connection for suctioning samples

• Maximum suction height: 8 m (26 ft)

• Maximum hose length: 30 m (98 ft)

• Diameter of hose connection: 10 mm (3/8")) internal diameter

• Intake speed:

> 0.5 m/s (> 1.6 ft/s) as per EN 25667, ISO 5667

> 0.6 m/s (> 1.9 ft/s) as per Ö 5893, US EPA

Note the following when erecting the device:

• Always route the suction line so that it slopes upwards from the sampling point to the

sampler.

• The sampler must be located above the sampling point.

• Avoid siphoning effects in the suction line.

Endress+Hauser 15

Page 16

Installation Liquiport CSP44

Requirements for the sampling point:

• Do not connect the suction line to pressurized systems.

• Use the suction filter to impede coarse and abrasive solids and solids which can cause

clogging.

• Immerse the suction line in the direction of flow.

• Take the sample at a representative point (turbulent flow, not directly at the bottom of

the channel).

Useful sampling accessories

Suction filter:

Impedes coarser solids and solids which can cause clogging.

5.1.4 Connection for sample intake on version with sample pump

• Maximum suction height: 8 m (26 ft)

• Maximum hose length: 30 m (98 ft)

• Diameter of hose connection: 10 mm (3/8")) internal diameter

• Intake speed:

> 0.5 m/s (> 1.6 ft/s) as per EN 25667, ISO 5667

> 0.6 m/s (> 1.9 ft/s) as per Ö 5893, US EPA

Note the following when erecting the device:

• Always route the suction line so that it slopes upwards from the sampling point to the

sampler.

• The sampler must be located above the sampling point.

• Avoid siphoning effects in the suction line.

Requirements for the sampling point:

• Do not connect the suction line to pressurized systems.

• Use the suction filter to impede coarse and abrasive solids and solids which can cause

clogging.

• Immerse the suction line in the direction of flow.

• Take the sample at a representative point (turbulent flow, not directly at the bottom of

the channel).

Useful sampling accessories

Suction filter:

Impedes coarser solids and solids which can cause clogging.

5.2 Installation

5.3 Connecting the suction line

1. When installing the device, take the installation conditions into account.

2. Open the device cover at the front fastening clasp.

3. Route the suction line from the sampling point to the device.

4. Screw the suction line onto the device's hose connection.

5.4 Post-installation check

1. Verify that the suction line is securely connected to the device.

2. Visually check that the suction line is installed correctly from the sampling point to

the device.

3. Verify that the rotating arm is correctly engaged.

16 Endress+Hauser

Page 17

Liquiport CSP44 Electrical connection

1

2

3

4

5

OFFON

6 Electrical connection

6.1 Connecting the sampler

WARNING

L

Device is live!

Incorrect connection may result in injury or death!

The electrical connection may be performed only by an electrical technician.

‣

The electrical technician must have read and understood these Operating Instructions

‣

and must follow the instructions contained therein.

Prior to commencing connection work, ensure that no voltage is present on any cable.

‣

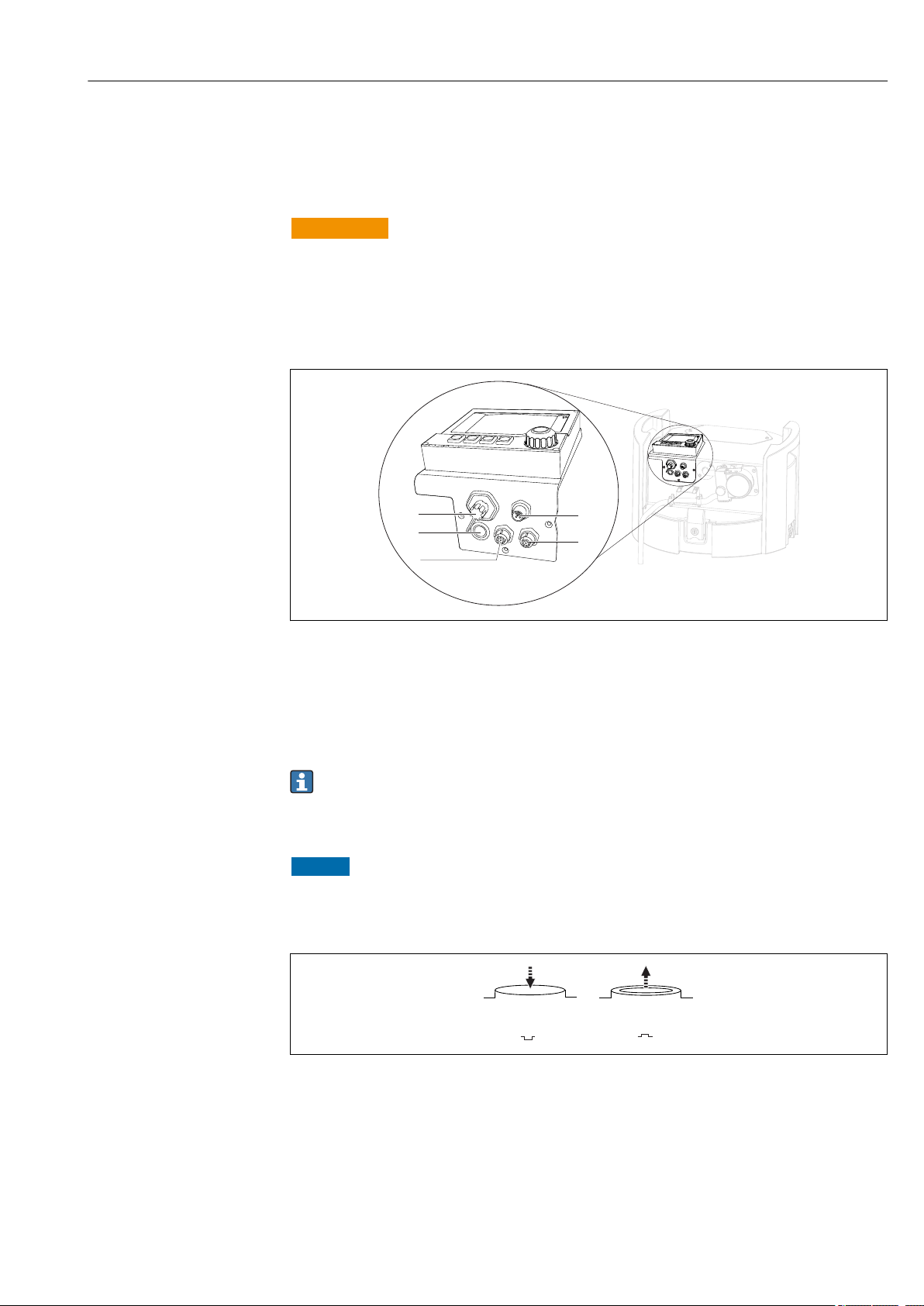

3 Electrical connections of the controller

1 Connection socket for charger

2 Socket for M12 sensor connector (optional)

3 Socket for M12 sensor connector (optional)

4 Connection socket for signal cable (optional)

5 Service interface

The polarity of the switch connections does not have to be taken into account.

6.1.1 Charging the battery

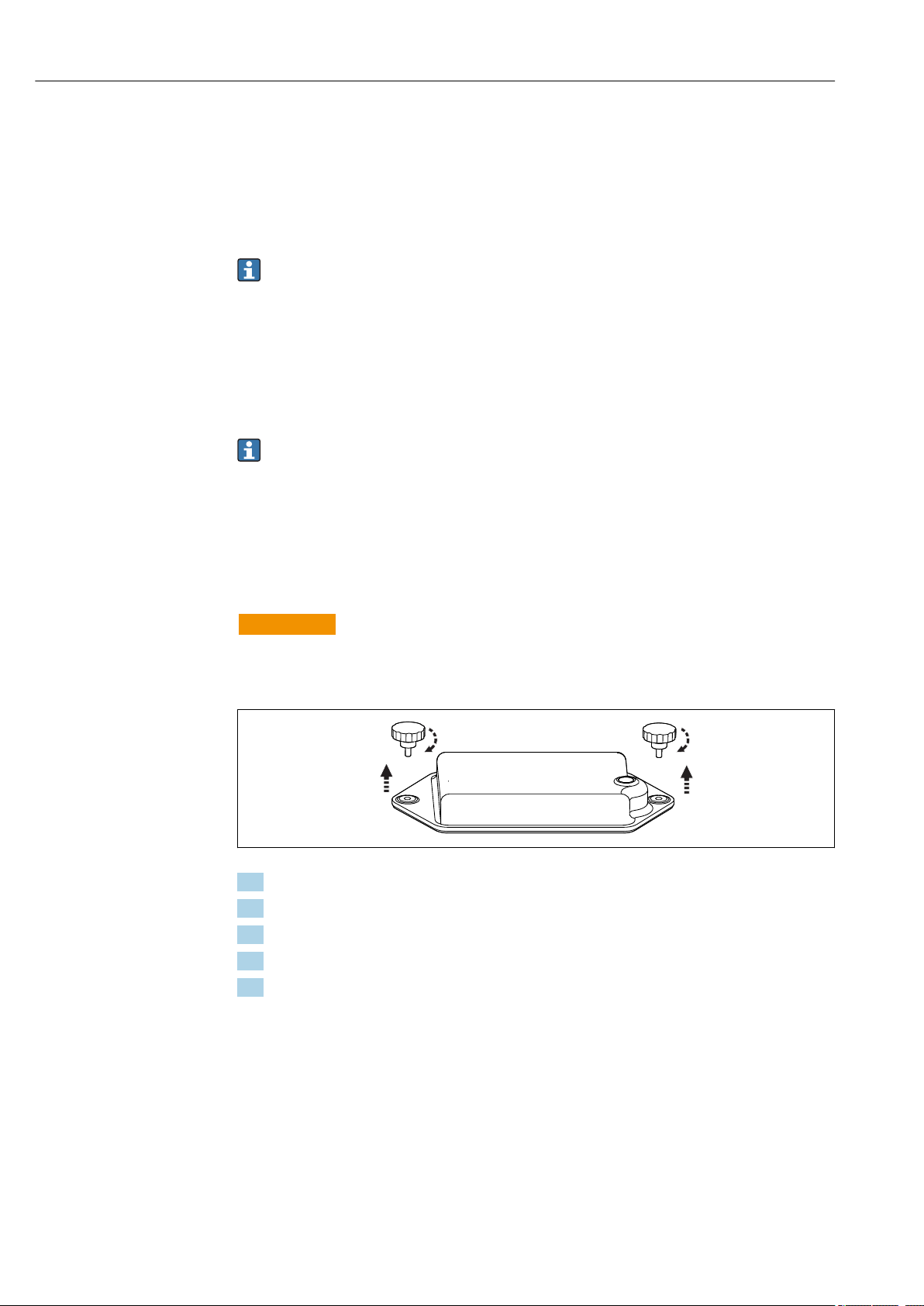

NOTICE

Defective batteries

The batteries can be destroyed if they are discharged completely.

To prevent complete discharge, move the switch to the "OFF" position.

‣

4 Switch position

A0029150

A0035816

Endress+Hauser 17

Page 18

Electrical connection Liquiport CSP44

Charge the battery before initial commissioning. It takes approx. 5 hours to fully charge

the battery. Please refer to the charger's operating manual for detailed information on the

charger.

Connect the device with the mains plug to the supply voltage.

‣

The battery starts charging as soon as the power unit is connected, regardless of

the switch position.

Only replace batteries with the following battery type: Panasonic LC-R127R2PG1.

Connecting the charger when the batteries are installed

The mains plug of the charger must be easily accessible so that the charger can be easily

disconnected from the power supply.

Connect the battery charger to the connection socket (item 1). If the battery is not fully

‣

charged, it is recharged by the charger.

Only use the chargers specified by the manufacturer. → 136

Connecting the charger when the batteries are removed

If you are charging batteries that have been removed, you require the adapter cable

(accessory no.: 71111882) to connect to the charger.

6.1.2 Removing the cover

WARNING

L

Device is live

Incorrect connection may result in injury or death

If a power unit or charger is connected, disconnect it from the power supply.

‣

1. Release both securing screws.

2. Remove the cover of the battery compartment.

3. Remove the old batteries and release the plug-in connections.

4. Connect the new batteries (pay attention to the battery polarity).

5. Insert the new batteries and secure the battery compartment cover.

A0035817

18 Endress+Hauser

Page 19

Liquiport CSP44 Electrical connection

1

2

6.2 Connecting modules and sensors

6.2.1 Connecting the sensors

Sensor connection

A0028664

5 Connection sockets for sensors

1 Socket for M12 sensor connector (= channel 1 for version with one sensor)

2 Socket for M12 sensor connector (= channel 2 for version with two sensors)

6.3 Terminal assignment for input/output signals

Input signals

• 2 analog signals 0/4 to 20 mA (optional)

• 2 binary signals > 100 ms pulse width or edge (optional)

Signals of digital sensors with Memosens protocol (optional)

Output signals

2 binary signals > 1 s pulse width or edge (optional)

2 current outputs 0/4 to 20 mA (optional)

Endress+Hauser 19

Page 20

Electrical connection Liquiport CSP44

+

-

+

-

-

-

+

+

R R

l l

Ui

Ui

1

(A)

(K)

(J)

(H)

(M)

(G)

(F)

(E)

(D)

(C)

(L)

(B)

(A)

(B)

(C)

(D)

(E)

(F)

(G)

(H)

(J)

(K)

(L)

(M)

1

2

3

4

U1-

U1+

B 1+I

B 1-I

B 2+I

B 2-I

B 1+O

B 1-O

B 2+O

B 2-O

AI1

In

AI1

GND

WH

BN

BU

RD

GN

YE

GY

PK

BK

VT

GY/PK

RD/BU

+

-

Ui

-

+

Ui

1

(A)

(K)

(J)

(H)

(M)

(G)

(F)

(E)

(D)

(C)

(L)

(B)

(A)

(B)

(C)

(D)

(E)

(F)

(G)

(H)

(J)

(K)

(L)

(M)

1

2

3

4

-

+

-

+

U1-

U1+

B 1+I

B 1-I

B 1+O

B 1-O

AI1

OUT

AI1

IN

AI1

GND

AI2

OUT

AI2

IN

AI2

GND

WH

BN

BU

RD

GN

YE

GY

PK

BK

VT

GY/PK

RD/BU

6.4 Signal cable connection (optional)

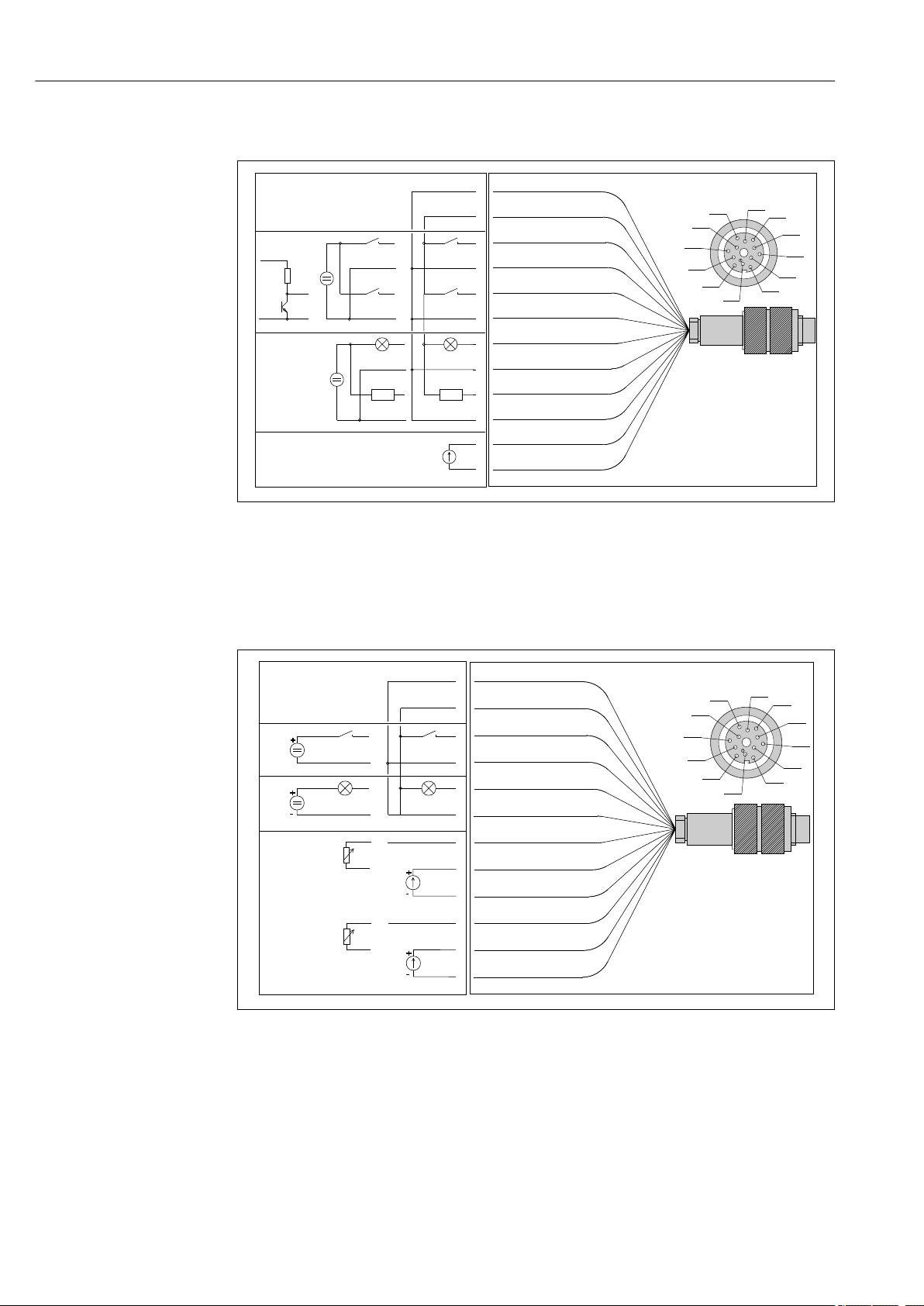

A0014162

6 Pin assignment and wiring diagram of signal cable (version K3)

1 Auxiliary voltage U: 24 V max. 30 mA load capacity

2 Binary inputs BI: > 20 ms, only extra-low voltage Ui £ 30 V DC

3 Binary outputs BO: only extra-low voltage Ui £ 30 V DC, max. current when using ext. auxiliary voltage (max.

200 mA)

4 Analog input AI: 0 to 20 mA, 4 to 20 mA

20 Endress+Hauser

7 Pin assignment and wiring diagram of signal cable (version K4)

1 Auxiliary voltage U: 24 V max. 30 mA load capacity

2 Binary input BI: > 20 ms, only extra-low voltage Ui £ 30 V DC

3 Binary output BO: only extra-low voltage Ui £ 30 V DC, max. current when using ext. auxiliary voltage (max.

200 mA)

4 Analog inputs AI: 0 to 20 mA, 4 to 20 mA

A0014197

Page 21

Liquiport CSP44 Electrical connection

+

-

Ui

-

+

Ui

-

+

Ui

1

(A)

(K)

(J)

(H)

(M)

(G)

(F)

(E)

(D)

(C)

(L)

(B)

(A)

(B)

(C)

(D)

(E)

(F)

(G)

(H)

(J)

(K)

(L)

(M)

1

2

3

4

-

+

A

-

+

A

U1-

U1+

B 1+I

B 1-I

B 1+O

B 1-O

B 2+O

B 2-O

I 1+O

I 1-O

I 2+O

I 2-O

WH

BN

BU

RD

GN

YE

GY

PK

BK

VT

GY/PK

RD/BU

A0014198

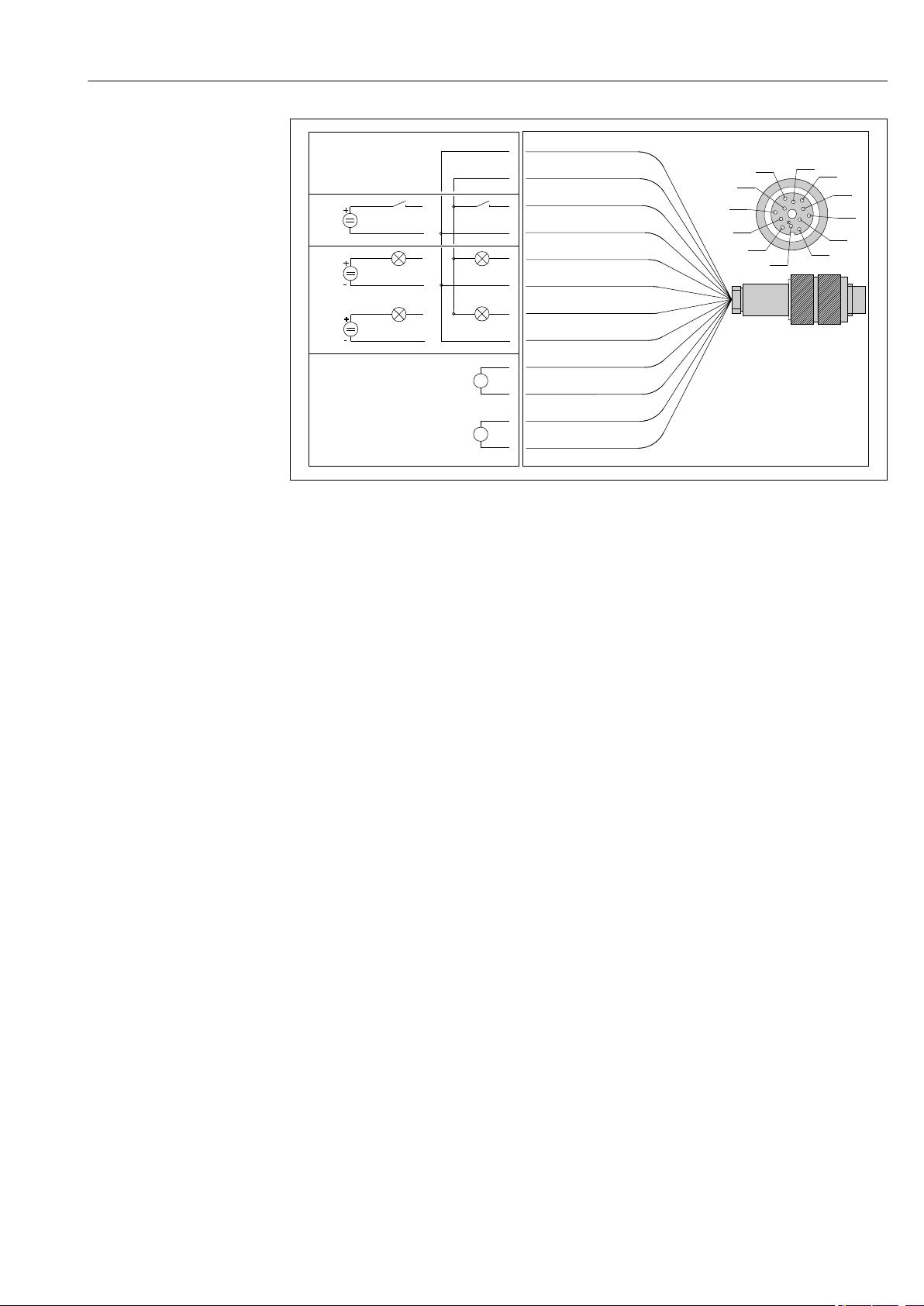

8 Pin assignment and wiring diagram of signal cable (version K5)

1 Auxiliary voltage U: 24 V max. 30 mA load capacity

2 Binary input BI: > 20 ms, only extra-low voltage Ui £ 30 V DC

3 Binary output BO: only extra-low voltage Ui £ 30 V DC, max. current when using ext. auxiliary voltage (max.

200 mA)

4 Analog inputs AI: 0 to 20 mA, 4 to 20 mA

6.5 Ensuring the degree of protection

Only the mechanical and electrical connections which are described in these instructions

and which are necessary for the required, designated use, may be carried out on the device

delivered.

Exercise care when carrying out the work.

‣

Individual types of protection permitted for this product (impermeability (IP), electrical

safety, EMC interference immunity, Ex protection) can no longer be guaranteed if, for

example :

• Covers are left off

• Different power units to the ones supplied are used

• Cable glands are not sufficiently tightened (must be tightened with 2 Nm (1.5 lbf ft) for

the permitted level of IP protection)

• Unsuitable cable diameters are used for the cable glands

• Modules are not fully secured

• The display is not fully secured (risk of moisture entering due to inadequate sealing)

• Loose or insufficiently tightened cables/cable ends

• Conductive cable strands are left in the device

Endress+Hauser 21

Page 22

Electrical connection Liquiport CSP44

6.6 Post-connection check

WARNING

L

Connection errors

The safety of people and of the measuring point is at risk! The manufacturer does not

accept any responsibility for errors that result from failure to comply with the instructions

in this manual.

Put the device into operation only if you can answer yes to all the following questions.

‣

Instrument status and specifications

Are the device and all the cables free from damage on the outside?

‣

Electrical connection

Are the mounted cables strain relieved?

‣

Are the cables routed without loops and cross-overs?

‣

Are the signal cables correctly connected as per the wiring diagram?

‣

Are all plug-in terminals securely engaged?

‣

Are all the connection wires securely positioned in the cable terminals?

‣

22 Endress+Hauser

Page 23

Liquiport CSP44 System integration

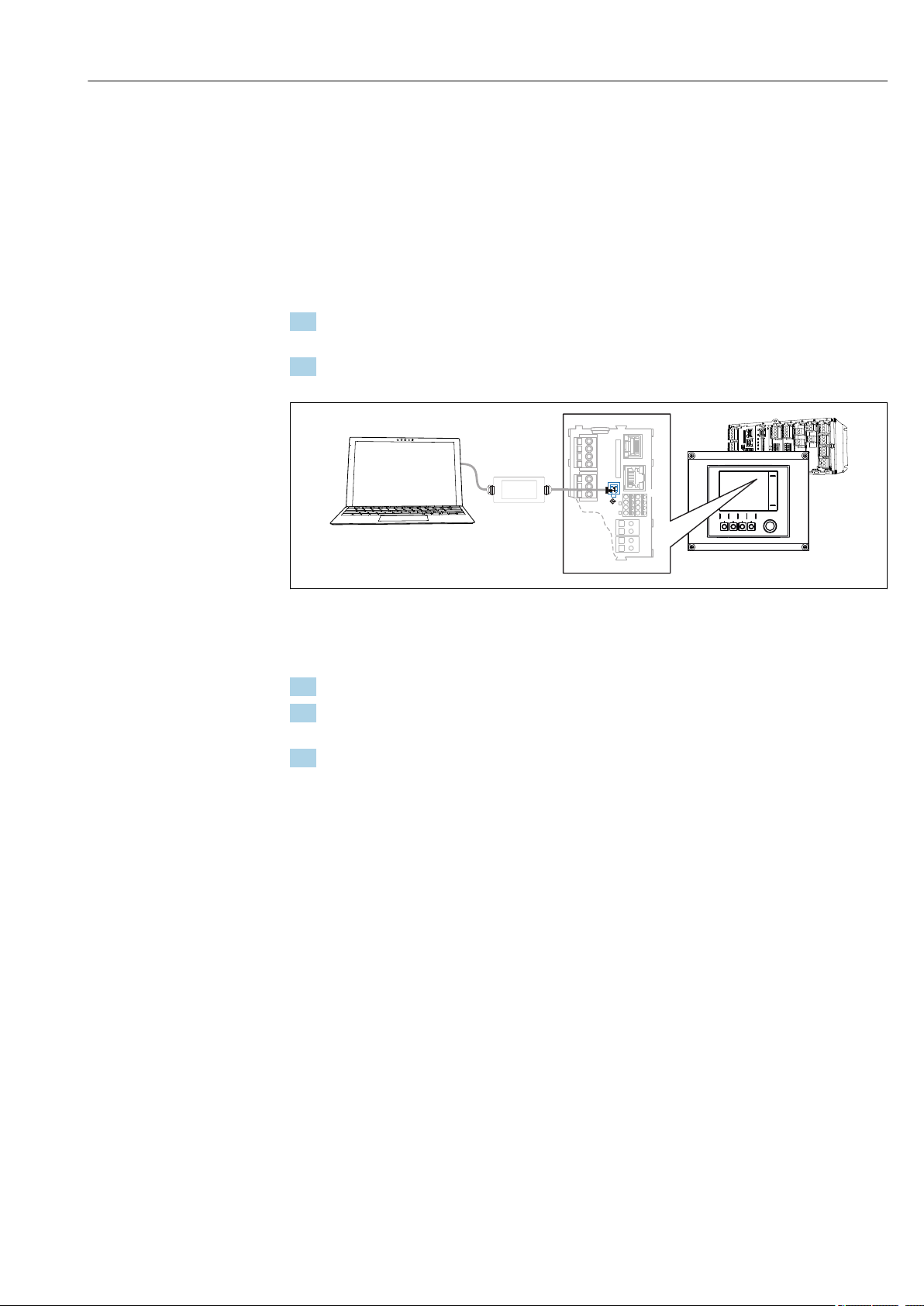

FieldCare

Service

FXA291

7 System integration

7.1 Service interface

You can connect the device to a computer via the service interface and configure it using

"FieldCare" . Furthermore, configurations can also be saved, transferred and documented.

7.1.1 Connection

1. Connect the service connector to the interface on the Liquiline base module and

connect it to the Commubox.

2. Connect the Commubox via the USB connection to the computer on which FieldCare

is installed.

A0039618

9 Connection overview

7.1.2 Establishing the data connection

1. Start FieldCare.

2. Establish a connection to the Commubox. To do so, select the "CDI Communication

FXA291" ComDTM.

3. Then select the "Liquiline CM44x" DTM and start configuration.

You can now start online configuration via the DTM.

Online configuration competes with onsite operation, i. e. each of the two options blocks

the other one. On both sides it is possible to take away access from the other side.

7.1.3 Operation

• In the DTM the menu structure corresponds to the onsite operation. The functions of the

Liquiline soft keys are found in the main window on the left.

• Clicking a menu name or a function corresponds to pressing the navigator.

• You can make your settings conveniently via the computer keyboard.

• You can use FieldCare to save logbooks, make backups of configurations and transfer

configurations to other devices.

• You can also print out configurations or save them as PDFs.

Endress+Hauser 23

Page 24

Operation options Liquiport CSP44

EH_CSF

09:11:05 31.03.2015

MODE

4

3

2

1

1

2

3

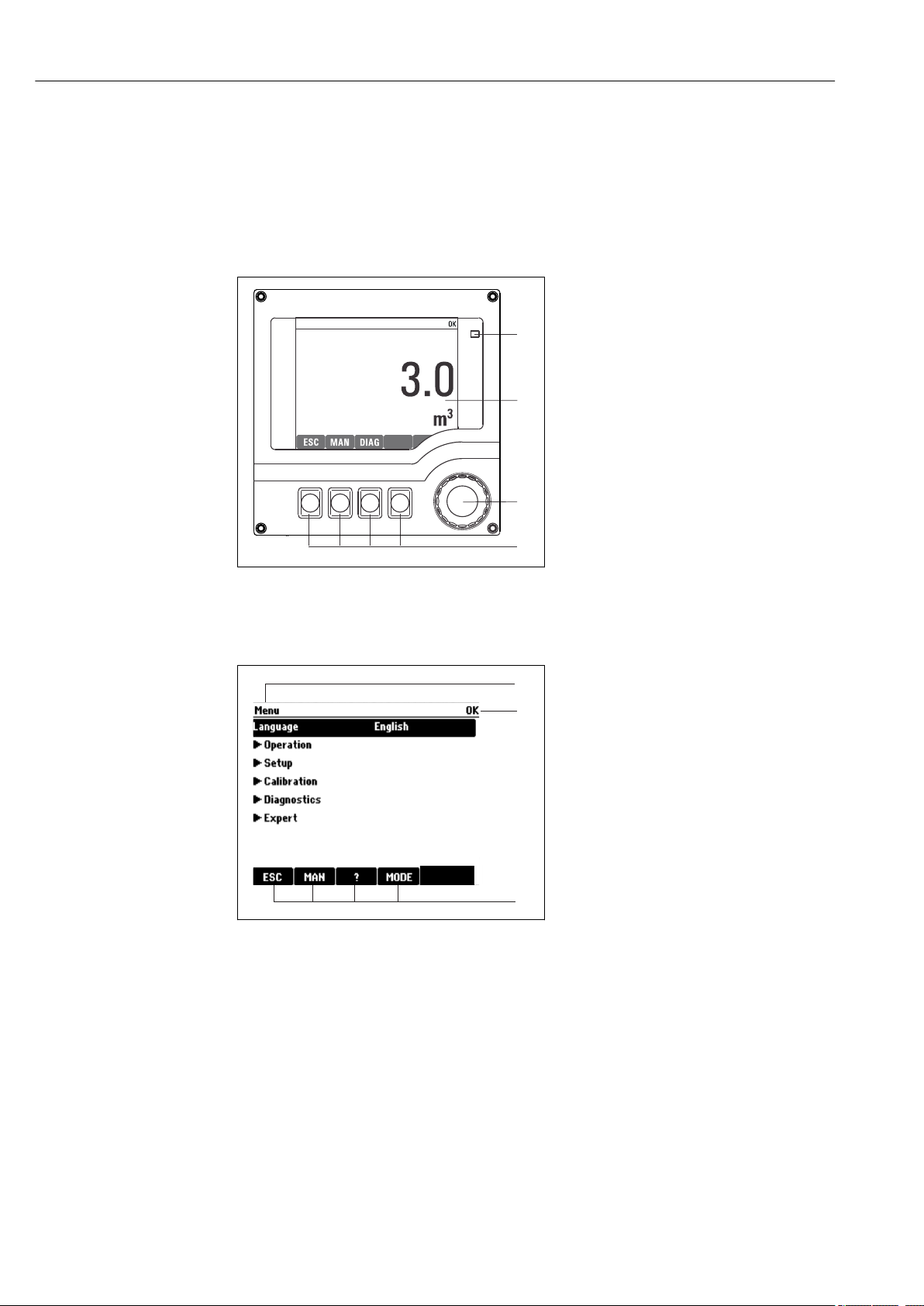

8 Operation options

8.1 Overview

8.1.1 Display and operating elements

1

LED

2

Display (with red display background in alarm

3

condition)

4

Navigator (jog/shuttle and press/hold function)

Soft keys (function depends on menu)

10 Overview of operation

8.1.2 Display

11 Display (example)

A0025501

A0029090-EN

1

Menu path and/or device designation

2

Status display

3

Assignment of soft keys, e. g.:

ESC: escape or abortion of a sampling process

MAN: manual sample

?: Help, if available

MODE: switch the device to standby or cancel the

program

24 Endress+Hauser

Page 25

Liquiport CSP44 Operation options

MODE

MODE

MODE

Menu/Language

Menu/LanguageMenu/Language

MODE

8.2 Access to the operating menu via the local display

8.2.1 Operating concept

Pressingthe soft key: selecting the menu directly

Pressingthe navigator: launching a function

Turningthe navigator: moving the cursor in the menu

Turningthe navigator: selecting a value (e.g. from a list)

Pressingthe navigator: accepting the new value

New setting is accepted

8.2.2 Locking or unlocking operating keys

Locking operating keys

Press the navigator for longer than 2 s.

‣

A context menu for locking the operating keys is displayed.

You have the choice of locking the keys with or without password protection. "With

Endress+Hauser 25

password" means that you can only unlock the keys again by entering the correct

Page 26

Operation options Liquiport CSP44

password. This password is set here: MenuSetupGeneral settingsExtended setupData

managementChange lock password

Choose whether you want to lock without or without a password.

‣

The keys are locked. No more entries can be made. In the soft key bar, you will see

the symbol.

The password is 0000 when the device is delivered from the factory. Make sure to

note down any changes to the password, as otherwise you will not be able to unlock

the keypad yourself.

Unlocking operating keys

1. Press the navigator for longer than 2 s.

A context menu for unlocking the operating keys is displayed.

2. Select Key unlock

The keys are unlocked immediately if you did not choose to lock with a password.

Otherwise you are asked to enter your password.

3. Only if keypad is password-protected: enter the right password.

The keys are unlocked. It is possible to access the entire onsite operation again.

The symbol is no longer visible on the display.

The password is 0000 when the device is delivered from the factory. Make sure to

note down any changes to the password, as otherwise you will not be able to unlock

the keypad yourself.

8.3 Configuration options

8.3.1 Display only

• You can only read the values but cannot change them.

• Typical read-only values are: sensor data and system information

• Example: Menu/Setup/Inputs/../Sensor type

8.3.2 Picklists

• You receive a list of options. In a few cases, these also appear in the form of multiple

choice boxes.

• Usually you just select one option; in rare instances you select one or more options.

• Example: Menu/Setup/General settings/Temperature unit

26 Endress+Hauser

Page 27

Liquiport CSP44 Operation options

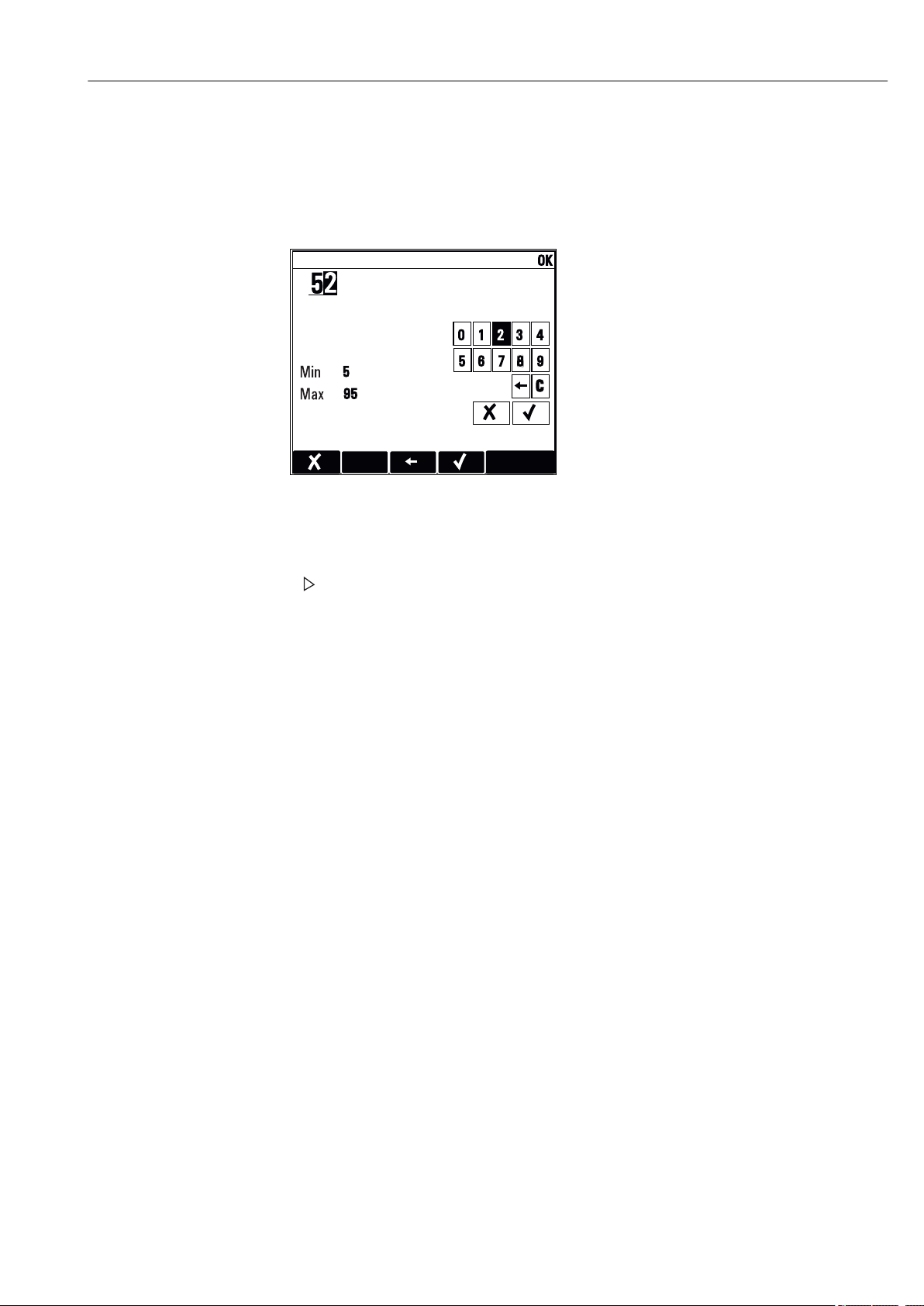

8.3.3 Numerical values

• You are changing a variable.

• The maximum and minimum values for this variable are shown on the display.

• Configure a value within these limits.

• Example: Menu/Operation/Display/Contrast

8.3.4 Actions

• You trigger an action with the appropriate function.

• You know that the item in question is an action if it is preceded by the following symbol:

• Examples of typical actions include:

• Deleting log entries

• Saving or loading configurations

• Triggering cleaning programs

• Examples of typical actions include:

• Start a sampling program

• Start manual sampling

• Saving or loading configurations

• Example: Menu/Manual sampling/Start sampling

Endress+Hauser 27

Page 28

Operation options Liquiport CSP44

E+H CSP4

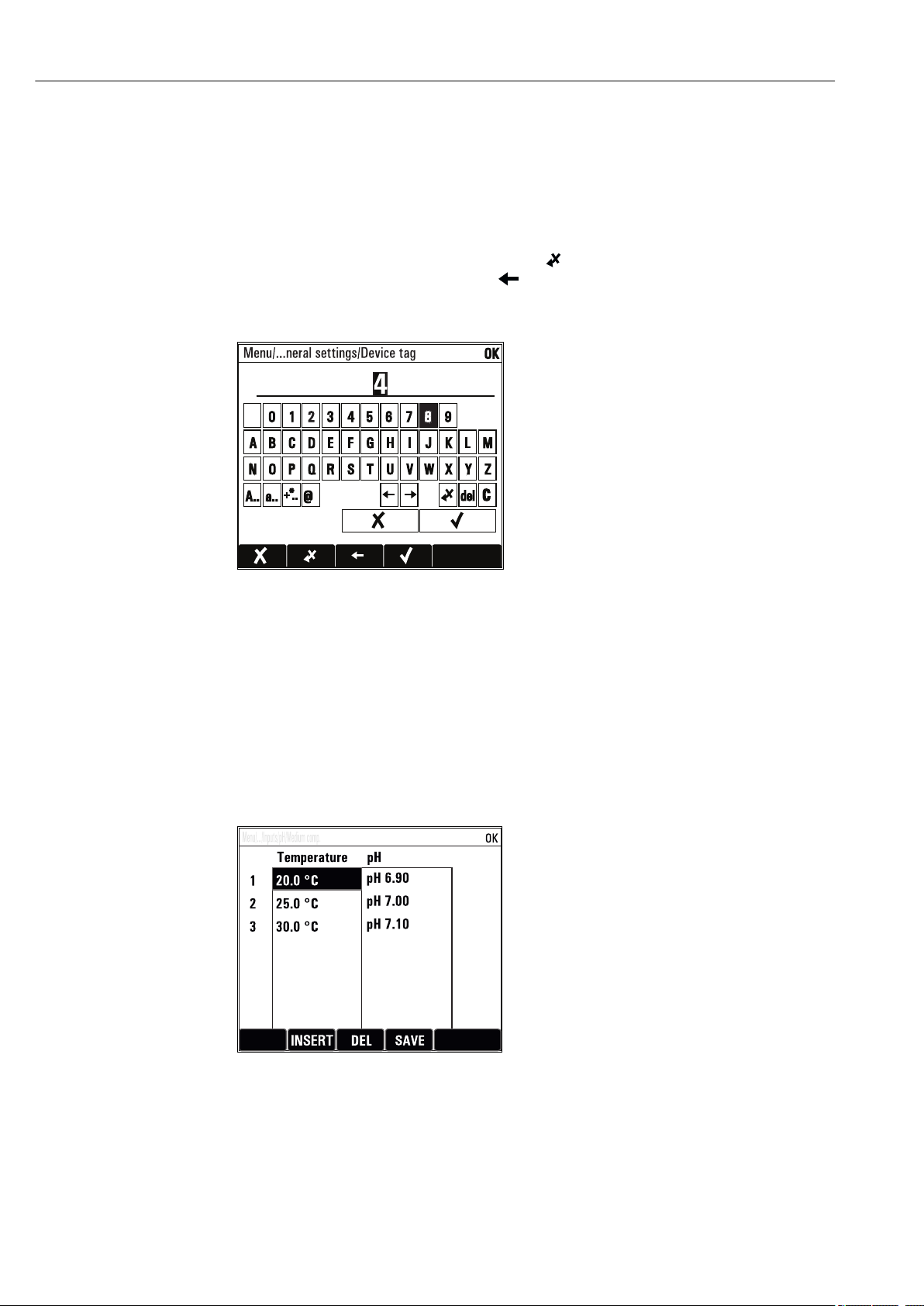

8.3.5 Free text

• You are assigning an individual designation.

• Enter a text. You can use the characters in the editor for this purpose (upper-case and

lower-case letters, numbers and special characters).

• Using the soft keys, you can:

• Cancel your entries without saving the data ()

• Delete the character in front of the cursor ( )

• Move the cursor back one position ( )

• Finish your entries and save ()

• Example: Menu/Setup/General settings/Device tag

8.3.6 Tables

• Tables are needed to map mathematical functions or to enter irregular interval samples.

• You edit a table by navigating through rows and columns with the navigator and

changing the values of the cells.

• You only edit the numerical values. The controller automatically takes care of the

engineering units.

• You can add lines to the table ( INSERT) or delete lines from the table ( DEL).

• Afterwards, you save the table ( SAVE).

• You can also cancel your entries any time using the soft key.

• Example: Menu/Setup/Inputs/pH/Medium comp.

28 Endress+Hauser

Page 29

Liquiport CSP44 Commissioning

OFFON

9 Commissioning

9.1 Function check

WARNING

L

Incorrect connection, incorrect supply voltage

Safety risks for staff and device malfunctions!

Check that all connections have been established correctly in accordance with the

‣

wiring diagram.

Ensure that the supply voltage matches the voltage indicated on the nameplate.

‣

Saving displays as a screenshot

Via the local display, you can take screenshots at any time and save them to an SD

card.

1. Insert an SD card into the SD card slot in the basic module.

2. Press the navigator button for at least 3 seconds.

3. In the context menu select the "Screenshot" item.

The current screen is saved as a bitmap file to the SD card in the "Screenshots"

folder.

9.2 Switching on the measuring device

The device is delivered with a built-in rechargeable battery. The switch in the battery cover

is set to "OFF".

A0035816

12 Switch position

1. Prior to initial commissioning, charge the batteries by connecting the power unit.

The battery starts charging as soon as the power unit is connected, regardless of

the switch position. It takes approx. 5 hours to fully charge the battery. Please

refer to the charger's operating manual for detailed information on the charger.

2. Once the charging process is complete, press the switch on the battery cover to the

"ON" position.

The transmitter starts up.

3. Wait for the boot process to complete.

Disconnecting the batteries when the sampler is not in use:

Press the switch on the battery cover to the "OFF" position.

‣

When the switch is in the "OFF" position, it provides reliable and effective

protection against the battery discharging completely and thus becoming

irreparably damaged.

Endress+Hauser 29

Page 30

Commissioning Liquiport CSP44

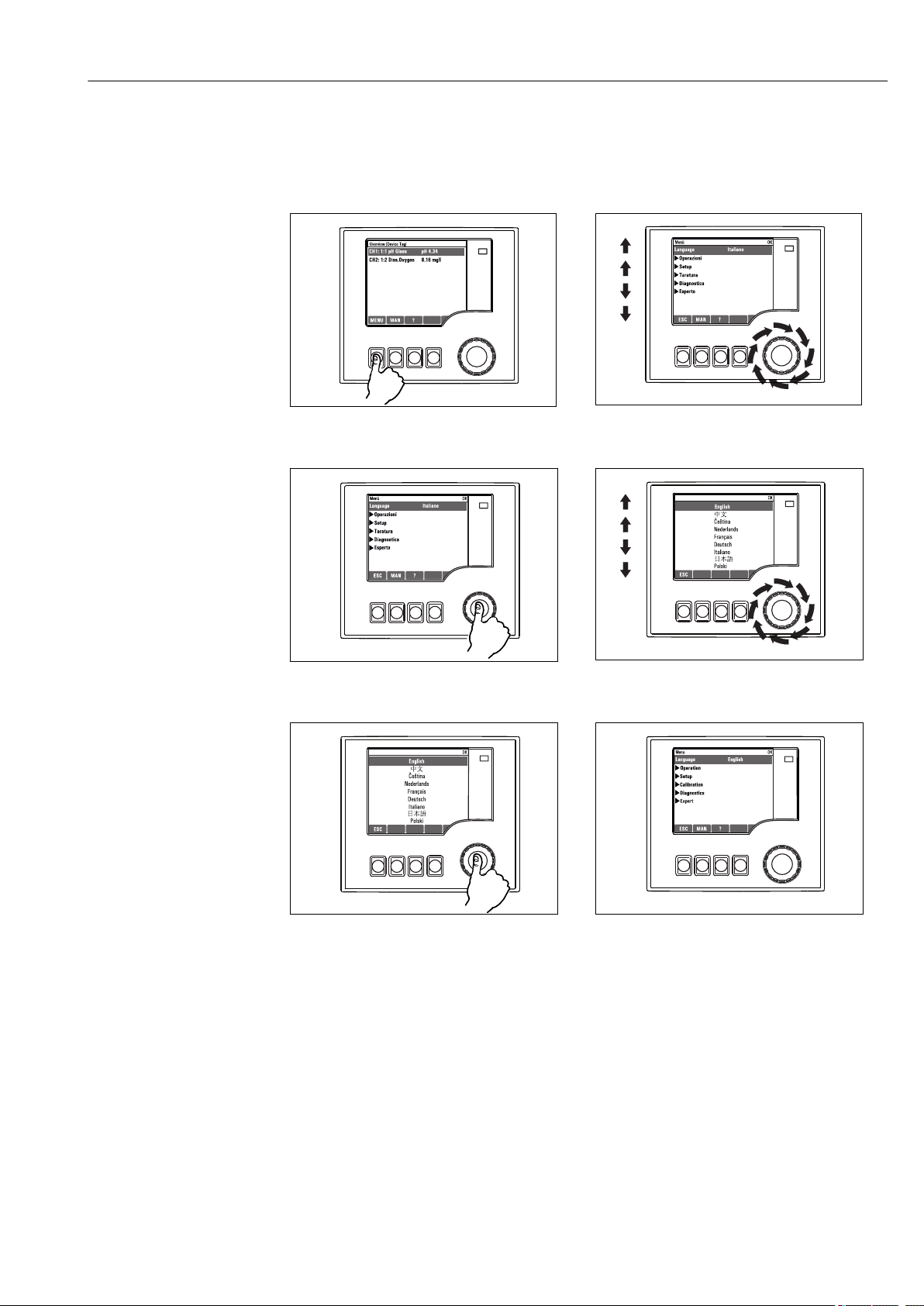

9.3 Setting the operating language

Configuring the language

If you have not already done so, close the housing cover and screw the device closed.

1. Connect the rechargeable battery (see "Electrical connection" section).

Wait for the initialization to finish.

2. Press the soft key MENU . Set your language in the top menu item.

The device can now be operated in your chosen language.

9.4 Configuring the measuring device

9.4.1 Start screen

You can find the following menu items and soft keys on the initial screen:

• Select sampling program

• Edit program %0V

• Start program %0V

• MENU

• MAN

• MEAS

• MODE

1)

1)

9.4.2 Display behavior

Menu/Operation/Display

Function Options Info

Contrast 5 to 95 %

Factory setting

50 %

Backlight Selection

• On

• Off

• Automatic

Factory setting

Automatic

Screen rotation Selection

• Manual

• Automatic

Factory setting

Manual

Current program: Read only The name of the sampling program currently

Status Read only Active

Start Action The selected sampling program is started.

Adjust the screen settings to suit your working

environment.

Backlight = Automatic

The backlighting is switched off automatically

after a short time if a button is not pressed. It

switches back on again as soon as you press the

navigator button.

Backlight = On

The backlighting does not switch off

automatically.

If Automatic is selected, the single‐channel

measured value display switches from one

channel to the next every second.

selected is displayed.

The sampling program has been started and the

device takes a sample as per the set parameters.

Inactive

No sampling program has been started, or a

program that was running has been stopped.

1) "%0V" here stands for text that depends on the context. This text is generated automatically by the software and inserted in place of %0V.

30 Endress+Hauser

Page 31

Liquiport CSP44 Commissioning

Menu/Operation/Display

Function Options Info

Measurement Current measured values at the inputs are

displayed. Analog and binary inputs cannot be

modified here.

Show summary of current

program

Show summary of inputs The configured counters of the analog and

The bottle statistics for the sampler are

displayed. The statistics appear for each

individual bottle after the start of the program.

You can find more information in the Chap.

"Bottle statistics".

binary input are displayed.

Max. 8 lines

9.4.3 User definable screens

Menu/Operation/User definable screens

Function Options Info

Meas. screen 1 ... 6 You can create 6 measuring screens of your own

and give them a name. The functions are

identical for all 6 measuring screens.

Meas. screen Selection

• On

• Off

Factory setting

Off

Label Customized text, 20

characters

Number of lines 1 to 8

Factory setting

8

Line 1 ... 8 User interface

Label

Source of data Selection

• None

• See list in "Info" column

Factory setting

None

Measured value

Source of data is an

input

Selection

Depends on the input

Factory setting

None

Once you have defined your own measuring

screen, you can switch it on here. You can find

the new screen under User definable screens.

Name of the measuring screen

Appears in the status bar of the display.

Specify the number of measured values

displayed.

Specify the content of Label in the submenu of

each line.

Select a source of data.

‣

You can choose from the following:

• Sensor inputs

• Binary inputs

• Current inputs

• Temperature

• Memosens sensor input (optional)

• Fieldbus signals

• Mathematical functions

• Binary inputs and outputs

• Current outputs

• Relay

• Measuring range switching

You can display different main, secondary and

raw measured values depending on the type of

input.

No options can be selected for outputs here.

Endress+Hauser 31

Page 32

Commissioning Liquiport CSP44

Menu/Operation/User definable screens

Function Options Info

Label Customized text, 20

characters

Set label to "%0V"

1) "%0V" here stands for text that depends on the context. This text is generated automatically by the

software and inserted in place of %0V. In the simplest situations, the generated text could be the name of

the measuring channel, for example.

1)

Action If you perform this action you accept the

User-defined name for the parameter to be

displayed

parameter name that is automatically suggested.

Your own parameter name (Label) is lost!

9.4.4 Basic setup

Making basic settings

1. Switch to the Setup/Basic setup menu.

Make the following settings.

2. Device tag: Give your device any name of your choice (max. 32 characters).

3. Set date: Correct the set date if necessary.

4. Set time: Correct the set time if necessary.

5. Number of bottles: Correct the set number of bottles if necessary.

6. Bottle volume: Correct the set bottle volume if necessary.

For quick commissioning, you can ignore the additional settings for outputs etc.

You can make these settings later in the specific menus.

7. To return to the display overview: press the soft key for ESC for at least one second.

Your sampler now works with your basic settings.

If you wish to configure your most important input and output parameters in the Basic

setup :

Configure the current inputs, limit switches, cleaning cycles and device diagnostics with

‣

the following submenus.

9.4.5 Sampling programs

Difference between program types

The following box provides an overview of the differences between the Basic, Standard and

Advanced program types.

Basic (1 sampling program)

Start condition:

• Immediate

• Date/time

• Immediate activation

• Time-paced, volume-paced or

flow-paced (CTCV, VTCV, CTVV),

external signal,

• Bottle change after time or

number of samples, external

signal

• Bottle synchronization

• Multiple bottles

Stop condition:

• Program end

• Continuous operation

32 Endress+Hauser

Page 33

Liquiport CSP44 Commissioning

15000 ml

MODE

1

Menu/Manual sampling

Distribution position

Bottle 1

Multiplier

Standard (1 sampling program with 1-5 sub-programs)

Start condition:

• Immediate

• Date/time

• Volume

Advanced (1 sampling program with 1-24 sub-programs)

Start condition:

• Immediate

• Date/time

• Volume

• External signal

• Immediate activation, individual

times, multiple times, interval,

deactivation of sub-program 1

• Time-paced, volume-paced or

flow-paced (CTCV, VTCV, CTVV),

external signal

• Bottle change after time or

number of samples, external

signal

• Bottle synchronization

• Multiple bottles

• Immediate activation, individual

times, multiple times, interval,

event, external start,

deactivation of sub-program 1

• Time-paced, volume-paced or

flow-paced (CTCV, VTCV, CTVV),

single sample, sample table,

external signal

• Bottle change after time or

number of samples, external

signal, fieldbus

• Sample synchronization

• Bottle synchronization

• Multiple bottles

Stop condition:

• Program end

• Continuous operation

• Date/time

Stop condition:

• Program end

• Continuous operation

• Date/time

Manual sampling

A0036865-EN

1. Manual sampling is triggered by the MAN soft key. This pauses any program

currently running.

The current bottle configuration and the current sample volume are displayed.

You can select the distributor position. In peristaltic systems, you can also change

the sample volume.

In vacuum systems, Multiplier a multiple of a single manual sample can be taken

under . Specification of Multiplierrange of adjustment 1 to 50.

2. Select Start sampling

A new screen is displayed indicating the progress of the sampling process.

Endress+Hauser 33

Page 34

Commissioning Liquiport CSP44

15000 ml

100 ml

144

MODE

144

2

3. After manual sampling, a running program can be displayed and continued with the

ESC ESC button.

The sample volume for "Manual sampling" is not taken into account in the

calculated bottle volumes.

Programming for automatic sampling

Create a simple sampling program in the general overview under Select sampling

program/New/Basic or in the menu Menu/Setup/Sampling programs/Setup

program/New/Basic :

1. Enter the "Program name".

2. The settings from the Basic setup for bottle configuration and bottle volume are

displayed.

3. Sampling mode=Time paced CTCV is preset.

4. Enter the Sampling interval .

5. Enter the Sampling volume per sample. (For version with vacuum pump, configure

under Menu/Setup/General settings/Sampling .)

6. Select the Bottle change mode after number of samples or time for average samples.

With the option "Bottle change after a time", you can enter the change time and bottle

synchronization (None, 1st bottle change time, 1st time of change + bottle number).

The description for this can be found in the "Bottle synchronization" section.

With the option "Bottle change after a time", you can choose the bottle

synchronization before the start condition (None, 1st bottle change time, 1st time of

change + bottle number). The description for this can be found in the "Bottle

synchronization" section.

1. For Multiple bottles enter the number of bottles the sample should be distributed

over.

2. Start condition: immediately or after date/time

3. Stop condition: after program end or continuous operation.

4. Pressing the SAVE saves the program and ends data entry.

Example:

A0029242-EN

The program can be started.

34 Endress+Hauser

Page 35

Liquiport CSP44 Operation

10 Operation

10.1 Display

10.1.1 Measuring mode

To display the measured values, press the soft key MEAS in the start screen, or during

‣

operation press STAT under Measurement.

Press the navigator button to change the mode

There are various display modes:

• Channel overview

The names of all the channels, the sensor type connected and the current main value are

displayed.

• Main value of the selected channel

The name of the channel, the sensor type connected and the current main value are

displayed.

• Main value and secondary value of the selected channel

The name of the channel, the connected sensor type and the current main value and

secondary value are displayed.

Temperature sensor 1 has a special function. The states of the compressor, ventilator

and heater are displayed (on/off).

• All the measured values of all the inputs and outputs

The current main value and secondary value as well as all the raw values are displayed.

• User-defined measuring screens

You configure what values you want to display. You can choose from all the measured

values of physical and "virtual" sensors (calculated using mathematical functions) and

output parameters.

In the first 3 modes, you can switch between channels by turning the navigator. In

addition to having an overview of all the channels, in the 4th mode you can also select

a value and press the navigator to see more details for the value. You can also find

your user-defined screens in this mode.

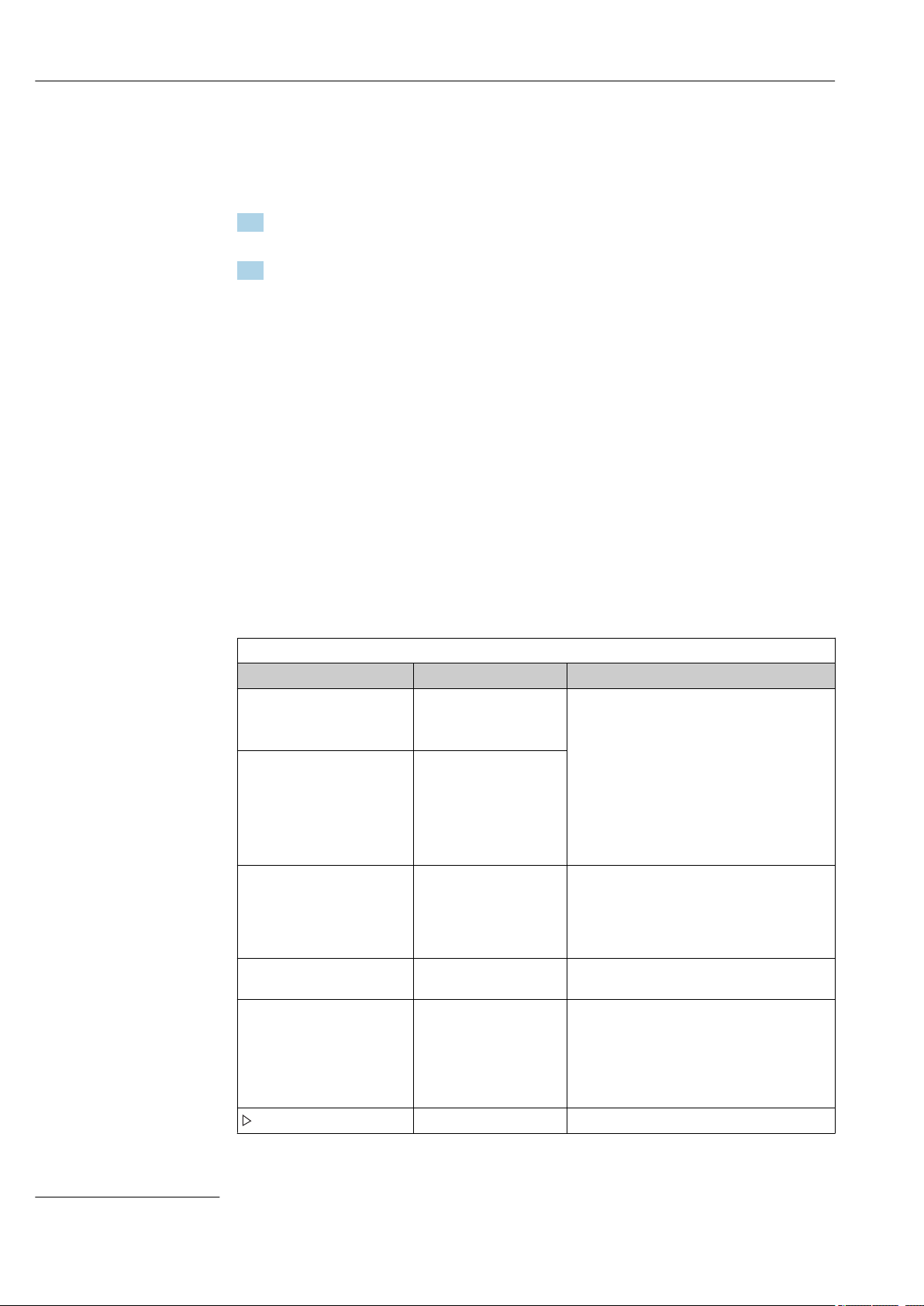

10.1.2 Device status

Icons on the display alert you to special device states.

Icon Location Description

Header bar Diagnostic message "Failure"

Header bar Diagnostic message "Maintenance request"

Header bar Diagnostic message "Check"

Header bar Diagnostic message "Out of specification"

Header bar Fieldbus or TCP/IP communication active

Header bar Hold active (for sensors)

At measured value Hold for the actuator (current output, limit switch etc.) is active

At measured value

At measured value Measured value in "Bad" or "Alarm" state

At measured value Automatic temperature compensation active (for sensors)

At measured value Manual temperature compensation active (for sensors)

Header bar Simulation mode active or Memocheck SIM connected

At measured value The measured value is influenced by a simulated value

Endress+Hauser 35

1)

An offset has been added to the measured value

Page 36

Operation Liquiport CSP44

Icon Location Description

At measured value The displayed measured value is simulated (for sensors)

Header bar Controller is active

1) Only pH or ORP measurement

If two or more diagnostic messages occur simultaneously, only the icon for the

message with the highest priority is shown on the display (for the order of priority

according to NAMUR, → 95).

10.1.3 Assignment views

Assignment views, e.g. Channel assignment view, appear as the last function in many

sections of the menu. You can use this function to see which actuators or functions are

connected to an input or output. The assignments appear in hierarchical order.

10.2 General settings

10.2.1 Basic settings

Some settings are visible with optional hardware only.

Menu/Setup/General settings

Function Options Info

Device tag Customized text, 32

characters

Temperature unit Selection

• °C

• °F

• K

Factory setting

°C

Current output range Selection

• 0..20 mA

• 4..20 mA

Factory setting

4..20 mA

Failure current 0.0 to 23.0 mA

Factory setting

22.5 mA

The value for Failure current should be outside the measuring range. If you decided that your Current

output range = 0..20 mA you should set an error current between 20.1 and 23 mA. If the Current

output range = 4..20 mA you could also define a value < 4 mA as the error current.

The device allows an error current within the measuring range. In such instances pay attention to any

effects this may have on your process.

Select any name for your controller, e.g. use

‣

the TAG name.

In accordance with Namur NE43, the linear

range is from 3.8 to 20.5 mA (4..20 mA) or

from 0 to 20.5 mA (0..20 mA). If the range is

exceeded or undershot, the current value stops

at the range limit and a diagnostic message (460

or 461) is output.

The function meets NAMUR NE43.

Set the current value that should be output

‣

at the current outputs in the event of an

error.

36 Endress+Hauser

Page 37

Liquiport CSP44 Operation

Menu/Setup/General settings

Function Options Info

Alarm delay 0 to 9999 s

Factory setting

0 s

Device hold Selection

• Disabled

• Enabled

Factory setting

Disabled

The software displays only the errors that are

present longer than the set delay time. This

makes it possible to suppress messages that only

occur briefly and are caused by normal processspecific fluctuations.

You can enable an immediate, general hold (for

sensors) here. The function acts in the same way

as the HOLD soft key in the screens.

10.2.2 Date and time

Menu/Setup/General settings/Date/Time

Function Options Info

Set date Depends on the format Editing mode:

Day (two-digit): 01 to 31

Month (two-digit): 01 to 12

Year (four-digit): 1970 to 2106

Set time Depends on the format Editing mode:

hh (hour): 00 to 23 / 0 am to 12 pm

mm (minutes): 00 to 59

ss (seconds): 00 to 59

Extended setup

Date format Selection

• DD.MM.YYYY

• YYYY-MM-DD

• MM-DD-YYYY

Factory setting

DD.MM.YYYY

Time format Selection

• hh:mm am (12h)

• hh:mm (24h)

• hh:mm:ss (24h)

Factory setting

hh:mm:ss (24h)

Time zone Selection

• None

• Choice of 35 time zones

Factory setting

None

DST Selection

• Off

• Europe

• USA

• Manual

Factory setting

Off

Select a date format.

‣

Choose between 12-hour display or 24-hour

‣

display. Seconds can also be displayed with

the latter version.

None = Greenwich Mean Time (London).

The controller adapts the summertime/normal

time changeover automatically if you choose

European or American daylight saving time.

Manual means that you can specify the start and

end of daylight saving time yourself. Here, two

additional submenus are displayed in which you

specify the changeover date and time.

Endress+Hauser 37

Page 38

Operation Liquiport CSP44

10.2.3 Hold settings

Menu/Setup/General settings/Hold settings

Function Options Info

Settings automatic Hold

Hold release time 0...600 s

Factory setting

0 s

Setup menu Selection

Diagnostics menu Decide whether a hold should be output at the

Calibration active Factory setting

• Disabled

• Enabled

Factory setting

Disabled

Enabled

If a device-specific hold is enabled, any cleaning that was previously started is

stopped. You can only start a manual cleaning if a hold is active. The hold has no

influence on the sampling.

The hold is maintained for the duration of the

delay time when you switch to the measuring

mode.

current output when the particular menu is

opened.

10.2.4 Logbooks

Logbooks record the following events:

• Calibration/adjustment events

• Operator events

• Diagnostic events

• Programming events

You define how the logbooks should store the data.

In addition, you can also define individual data logbooks .

1. Assign the logbook name.

2. Select the measured value to be recorded.

3. Set the scan time (Scan time).

You can set the scan time individually for every data logbook.

Further information on the logbooks: .

Menu/Setup/General settings/Logbooks

Function Options Info

Logbook ident Customized text, 16

characters

Event logbook Selection

• Off

• Ring buffer

• Fill up buffer

Factory setting

Ring buffer

Part of the file name when exporting a logbook

All diagnostic messages are recorded

Ring buffer

If the memory is full, the most recent entry

automatically overwrites the oldest entry.

Fill up buffer

If the memory is full, there is an overflow,i. e.

you cannot store any new values. The controller

displays a corresponding diagnostic message.

The memory then has to be cleared manually.

38 Endress+Hauser

Page 39

Liquiport CSP44 Operation

Menu/Setup/General settings/Logbooks

Function Options Info

Logbook program Selection

• Off

• Ring buffer

• Fill up buffer

Factory setting

Ring buffer

Overflow warnings

Event logbook = Fill up buffer

Calibration logbook Selection

Diagnostic logbook

Configuration logbook

Data logbooks

New You can create a maximum of 8 data logbooks.

Logbook name Customized text, 20

Source of data Selection

Measured value Selection

Scan time 0:00:01 to 1:00:00

Data logbook Selection

Overflow warnings

Event logbook =

Fill up buffer

Add another

logbook

Finished Action This allows you to exit the New menu.

• Off

• On

Factory setting

Off

characters

• Sensor inputs

• Controller

• Current inputs

• Temperature

• Fieldbus signals

• Binary inputs

• Mathematical functions

Factory setting

None

Depends on Source of data

Factory setting

None

Factory setting

0:01:00

• Ring buffer

• Fill up buffer

Factory setting

Ring buffer

Selection

• Off

• On

Factory setting

Off

Action Only if you want to create another data logbook

All program cycles are recorded

Ring buffer

If the memory is full, the most recent entry

automatically overwrites the oldest entry.

Fill up buffer

If the memory is 80 % full, the device displays a

diagnostic message.

If the memory is full, there is an overflow, i. e. no

new values can be saved. The controller displays

a corresponding diagnostic message. The

memory then has to be cleared manually.

Decide whether you want to receive a

‣

diagnostic message if the fill buffer of the

relevant logbook overflows.

Select a data source for the logbook entries.

‣

You can choose from the following:

• Connected sensors

• Available controllers

• Current inputs

• Fieldbus signals

• Binary input signals

• Mathematical functions

You can record different measured values

depending on the data source.

Minimum time interval between two entries

Format: H:MM:SS

Ring buffer

If the memory is full, the most recent entry

automatically overwrites the oldest entry.

Fill up buffer

If the memory is full, there is an overflow,i. e. no

new values can be saved. The controller displays

a corresponding diagnostic message. The

memory then has to be cleared manually.

Decide whether you want to receive a

‣

diagnostic message if the fill buffer of the

relevant logbook overflows.

immediately. You add a new data logbook at a

later date using New.

Endress+Hauser 39

Page 40

Operation Liquiport CSP44

Menu/Setup/General settings/Logbooks

Function Options Info

Start/stop

simultaneously

Logbook name The name of this submenu is based on the name

This menu appears several times if you have several data logbooks.

Source of data Read only This is for information purposes only. If you

Measured value

Log time left

Event logbook =

Fill up buffer

Log size

Event logbook =

Fill up buffer

Logbook name Customized text, 20

Scan time 0:00:01 to 1:00:00

Data logbook Selection

Overflow warnings

Event logbook =

Fill up buffer

Action Appears if you have created more than one data

logbook. With one mouse click, you can start or

stop recording all the data logbooks.

of the logbook and only appears once you have

created a logbook.

want to record another value, delete this logbook

and create a new data logbook.

Read only Displays the days, hours and minutes remaining

until the logbook is full.

Read only Displays the number of entries remaining until

the logbook is full.

You can change the name here again.

characters

As above

Factory setting

0:01:00

• Ring buffer

• Fill up buffer

Factory setting

Ring buffer

Selection

• Off

• On

Factory setting

Off

Minimum time interval between two entries

Format: H:MM:SS

Ring buffer

If the memory is full, the most recent entry

automatically overwrites the oldest entry.

Fill up buffer

If the memory is full, there is an overflow, i. e. no

new values can be saved. The controller displays

a corresponding diagnostic message. The

memory then has to be cleared manually.

Decide whether you want to receive a

‣

diagnostic message if the fill buffer of the

relevant logbook overflows.

40 Endress+Hauser

Page 41

Liquiport CSP44 Operation

Menu/Setup/General settings/Logbooks

Function Options Info

Line plotter Menu to define the graphic display

Axes Selection

• Off

• On

Factory setting

On

Orientation Selection

• Horizontal

• Vertical

Factory setting

Horizontal

X-Description Selection

Y-Description

Grids

Pitches

X Pitch/Grid distance 10 to 50%

Y Pitch/Grid distance

Remove Action This action removes the data logbook. Any data

• Off

• On

Factory setting

On

Factory setting

10 %

Should the axes (x, y) be displayed (On) or not

(Off)?

You can choose whether the value curves should

be displayed from left to right (Horizontal) or

from top to bottom (Vertical). If you want to

display two data logbooks simultaneously, make

sure that both logbooks have the same settings

here.

Decide whether a description should be

‣

displayed for the axes and whether gridlines

should be shown. In addition, you can also

decide whether pitches should be displayed.

Determine the pitch.

‣

that have not been saved are lost.

Example: New data logbook (Setup/General settings/Logbooks/Data logbooks/New)

1. Make the settings:

• Logbook name

Assign a name. Example: "01".

• Source of data

Select a data source. Example: Sensor connected to channel 1 (CH1).

• Measured value

Select the measured value to be recorded. Example: pH value.

• Scan time

Specify the time interval between two logbook entries.

• Data logbook

Activate the logbook: specify the data storage method.

2. ../Finished: Perform the action.

The device shows the new logbook in the list of data logbooks.

3. Select data logbook "01".

Additional display: Log time left.

4. Only in the case of Fill up buffer:

Decide to set Overflow warning: On or Off.

On: The device displays a diagnostic message in the event of memory overflow.

5. Line plotter submenu: Specify the type of graphic representation.

10.2.5 Configuring the sampling depending on the device version

The list of functions displayed depends on the device version selected with:

• Vacuum pump

• Peristaltic pump

• Distribution drive

• Sampling assembly:

Endress+Hauser 41

1)

2)

3)

4)

Page 42

Operation Liquiport CSP44

Menu/Setup/General settings/

Function Options Info

Sampling

Number of bottles Choice of all possible bottle

combinations

Bottle volume 0 to 100000 ml

Factory setting

Depends on the bottle

configuration

Distribution parking

(only for version with

distributor drive)

3)

Selection

• Back

• None

Factory setting

Back

Distribution reference

(only for version with

distributor drive)

Selection

• Pre sampling

• Pre bottle change

• Pre program start

Factory setting

Pre sampling

Power failure Selection

• Resume program

• Stop program

Factory setting

Resume program

Sample retries

1), 2), 3)

0 to 3

Factory setting

0

Sampling delay 0 to 99 s

Factory setting

0 s

Liquid detection Selection

• Automatic

• Semi automatic

• Off

Factory setting

Automatic

Rinse cycles 0 to 3

Factory setting

0

The bottle configuration you ordered

is preset in the device.

If continuous operation is selected for

a sampling program, there is the

danger of overfilling the bottles. Do

not forget to empty the bottles!

Causes the distribution arm to go to

the center at the back or remain

parked in the current position when

the device is started or the program is

ended.

The distributor arm goes through a

reference point depending on the

option selected.

Decide how the sampler should react

when it is energized after a power

failure.

Resume program:

• Time and flow-paced

The program calculates the omitted

samples and enters them in the

logbook as failed. When the

program is restarted, it continues

where it was interrupted.

• Flow-paced

No samples are entered in the

logbook during the power failure.

When the program is restarted, it

continues where it was interrupted.

If sampling is started and no sample is

drawn in, sampling can be repeated

up to 3 times.

The start of the sampling cycle can be

delayed by up to 99 s. The binary

output is switched without any delay.

If "Semiautomatic" is selected, the

purge times and intake times can be

defined separately.

Off:

The definition of the purge times and

intake times is completely timecontrolled.

Automatic:

The last intake time determined is the

new purge time.

Semi automatic:

If the suction heights tend to vary

greatly.

The suction line is rinsed with the

sample up to 3 times.

42 Endress+Hauser

Page 43

Liquiport CSP44 Operation

Menu/Setup/General settings/

Function Options Info

Safety interlock(optional) Selection

Off

Factory setting

Off

Diagnostics settings

Pump tube life

Control Selection

Warning 10 to 50 h

Alarm 10 to 50 h

Totalizer 00-00:00 to 49710-06:28

Reset Action The tube life counter is reset to 0:00

2)

• Off

• On

Factory setting

On

Factory setting

30 h

Factory setting

30 h

Factory setting

00-00:00

If the peristaltic pump is opened, the

safety interlock stops all the

functions.

Indicates the pump hose has to be

exchanged.

When the tube has been in operation

for this length of time, a diagnostic

message is displayed to indicate that

the tube should be replaced in time.

Operating time of the current pump

hose in days, hours and minutes

h.

10.2.6 Advanced setup

Diagnostics settings

The list of diagnostic messages displayed depends on the path selected. There are devicespecific messages, and messages that depend on what sensor is connected.

Menu/Setup/(General settings or Inputs<Sensor channel>)/Extended setup/Diagnostics settings/Diag.

behavior

Function Options Info

List of diagnostic messages

Diag. code Read only

Diagnostic message Selection

• On

• Off

Factory setting

Depends on the message

Failure current Selection

• On

• Off

Factory setting

Depends on the message

Select the message to be changed. Only then

‣

can you make the settings for this message.

You can deactivate or reactivate a diagnostic

message here.

Deactivating means:

• No error message in the measuring mode

• No error current at the current output

Decide whether an error current should be

‣

output at the current output if the diagnostic

message display is activated.

In the event of general device errors, the

error current is output at all the current

outputs. In the event of channel-specific

errors, the error current is only output at

the assigned current output.

Endress+Hauser 43

Page 44

Operation Liquiport CSP44

Menu/Setup/(General settings or Inputs<Sensor channel>)/Extended setup/Diagnostics settings/Diag.

behavior

Function Options Info

Status signal Selection

• Maintenance (M)

• Out of specification (S)

• Function check (C)

• Failure (F)

Factory setting

Depends on the message

Diag. output Selection

• None

• Alarm relay

• Binary output

• Relay 1 to n (depends on

the device version)

Factory setting

None

An alarm relay is always available, regardless of the device version. Other relays are optional.

The messages are divided into different error

categories in accordance with NAMUR NE 107.

Decide whether you want to change a status

‣

signal assignment for your application.

You can use this function to select a binary

output to which the diagnostic message should

be assigned.

For sensors with the Memosens protocol: Before

being able to assign the message to an output

you must first configure a relay output to

Diagnostics .

(Menu/Setup/Outputs: Assign the Diagnostics

function and set the Operating mode to as

assigned .)

Cleaning program Selection

• None

• Cleaning 1

• Cleaning 2

• Cleaning 3

• Cleaning 4

Factory setting

None

Detail information Read only Here you can find more information on the

Decide whether the diagnostic message

‣

should trigger a cleaning program.

You can define the cleaning programs under:

Menu/Setup/Additional functions/Cleaning.

diagnostic message and instructions on how to

resolve the problem.

Modbus

Menu/Setup/General settings/Extended setup/Modbus

Function Options Info

Enable Selection

• Off

• On

Factory setting

On

Termination Read only If the device is the last in the bus, you can

You can switch off communication at this point.

The software can then only be accessed via local

operation.

terminate via the hardware.

44 Endress+Hauser

Page 45

Liquiport CSP44 Operation

Menu/Setup/General settings/Extended setup/Modbus

Function Options Info

Settings

Transmission Mode Selection

• TCP

• RTU

• ASCII

Factory setting

(Modbus-RS485 only)

RTU

Parity

Modbus-RS485 only

Byte order Selection

Watchdog 0 to 999 s

Selection

• Even (1 Stopbit)

• Odd (1 Stopbit)

• None (2 Stopbit)

Factory setting

Even (1 Stopbit)

• 1-0-3-2

• 0-1-2-3

• 2-3-0-1

• 3-2-1-0

Factory setting

1-0-3-2

Factory setting

5 s

The transmission mode is displayed depending

on the version ordered.

In the case of RS485 transmission, you can

choose between RTU and ASCII . There are no

choices for Modbus-TCP.

If no data transmission takes place for longer

than the time set, this is an indicator that

communication has been interrupted. After this

time, input values received via the Modbus are

considered to be invalid.

Data management

Firmware update

Please contact your local sales office for information on firmware updates available

for your controller and its compatibility with earlier versions.

Current firmware version : Menu/Diagnostics/System information/.

Back up your current setup and your logbooks to an SD card.

‣

To install a firmware update, you must have the update available on an SD card.

1. Insert the SD card into the controller card reader.

2. Go to Menu/Setup/General settings/Extended setup/Data management/

Firmware update .

The update files on the SD card are displayed.

3. Select the desired update and select yes when asked the following:

The current firmware will be overwritten.

After this the device will reboot.

Do you want to proceed?

The firmware is loaded and the device is then started with the new firmware.

Saving the setup

Saving a setup offers the following advantages, among others :

• Copying settings for other devices

• Quick and easy switching between various setups, e. g. for different user groups or for

recurring sensor type changes

• Restoring a tried-and-tested setup, e. g. if you have changed a lot of settings and no

longer know what the original settings were

Endress+Hauser 45

Page 46

Operation Liquiport CSP44

1. Insert the SD card into the controller card reader.

2. Go to Menu/Setup/General settings/Extended setup/Data management/Save

setup .

3. Name: Assign a file name.

4. Then select Save .

If you have already assigned the file name, you will be asked whether you want to

overwrite the existing setup.

5. Use OK to confirm or cancel and assign a new file name.

Your setup is stored on the SD card and you can upload it quickly to the device at

a later date.

Loading the setup

When you load a setup, the current configuration is overwritten.

1. Insert the SD card into the controller card reader. A setup must have been saved to

the SD card.

2. Go to Menu/Setup/General settings/Extended setup/Data management/Load

setup .

A list of all the setups on the SD card is displayed.

An error message is displayed if there is no valid setup on the card.

3. Select the desired setup.

A warning is displayed:

The current parameters will be overwritten and the device will reboot.

Warning: Please note that cleaning and controller programs can be active.

Do you want to proceed?

4. Use OK to confirm or cancel.

If you select OK to confirm, the device restarts with the desired setup.

Exporting the setup

Exporting a setup offers the following advantages, among others:

• Export in XML format with a stylesheet for formatted display in an XML-compatible

application, such as . Microsoft Internet Explorer

• Importing the data (drag and drop the XML file into a browser window)

1. Insert the SD card into the controller card reader.

2. Go to Menu/Setup/General settings/Extended setup/Data management/Export

setup .

3. Name: Assign a file name.

4. Then select Export .

If you have already assigned the file name, you will be asked whether you want to

overwrite the existing setup.

5. Use OK to confirm or cancel and assign a new file name.

Your setup is saved on the SD card in the "Device" folder.

You cannot upload the exported setup to the device again. You must use the Save

setup . This is the only way you can save a setup to an SD card and reload it later on or

upload it to other devices.

46 Endress+Hauser

Page 47