Page 1

TI00465C/07/EN/20.19

71458788

2019-11-08

Products

Solutions Services

Technical Information

Liquiport CSP44

Automatic sampler for liquid media; integrated

multi-parameter controller with two measuring

channels and optional digital Memosens

technology

Applications

The Liquiport 2010 CSP44 is a portable sampler designed for the fully automated

sampling and defined distribution of liquid media.

• Communal and industrial wastewater treatment plants

• Self-monitoring

• Process monitoring

• Monitoring of indirect dischargers

• Monitoring of canal networks

• Authorities and water management offices:

• Water pollution control and water quality

• Monitoring of indirect/direct dischargers

• Laboratories and hydrological institutes

Depending on the version ordered, one or two digital sensors with Memosens

technology can be connected to the CSP44. In addition, two 0/4 to 20 mA analog

inputs/outputs, two binary inputs/outputs as well as a cleaning function are

optionally available.

Your benefits

• Easy and user-friendly:

• Swift menu guidance, navigator and large display

• Parts carrying medium are easy to disassemble, making cleaning and

maintenance tasks easier

• Sampler base can be locked and carried separately

• Flexible:

• Practice-oriented programs ranging from simple time programs to event

programs

• Functionality can be extended by installing modular electronic components

• Communicative:

• Integrated data logger for recording measured values

• Service interface for data transmission

• Safe:

Lockable sampler base for tamper-proof samples

Page 2

Table of contents

Liquiport CSP44

Function and system design ................... 3

Sampler Liquiport CSP44 ........................ 3

Mode of operation with a peristaltic pump ............. 4

Sample distribution ............................ 5

Sample preservation ........................... 5

Sampling control .............................. 6

Intake speed with different suction lines .............. 6

Sampler housing .............................. 7

Dependability .............................. 8

Reliability .................................. 8

Maintainability ............................... 8

Safety .................................... 10

Input .................................... 10

Types of input ............................... 10

Measured values ............................. 10

Temperature inputs ........................ 10

Measuring range ............................. 10

Type of input ............................... 10

Accuracy .................................. 10

Binary input, passive ....................... 11

Span ..................................... 11

Signal characteristics .......................... 11

Accuracy .................................. 11

Analog input, passive/active ................. 11

Span ..................................... 11

Accuracy .................................. 11

Output optional ........................... 11

Communication .............................. 11

Environment .............................. 15

Ambient temperature range ..................... 15

Storage temperature .......................... 15

Degree of protection .......................... 15

Electromagnetic compatibility .................... 15

Electrical safety .............................. 15

Relative humidity ............................ 15

Process .................................. 16

Process temperature .......................... 16

Process characteristics ......................... 16

Process pressure ............................. 16

Process connection ........................... 16

Mechanical construction .................... 17

Dimensions ................................ 17

Weight ................................... 17

Materials .................................. 18

Operability ............................... 19

Operating concept ............................ 19

Display ................................... 19

Local operation .............................. 19

Communication .............................. 20

Software .................................. 20

Certificates and approvals ................... 21

mark ................................... 21

MCERTS .................................. 21

cCSAus General purpose ........................ 21

Ordering information ....................... 22

Product page ............................... 22

Product Configurator .......................... 22

Scope of delivery ............................. 22

Power supply ............................. 12

Electrical connection .......................... 12

Supply voltage .............................. 12

Power consumption ........................... 12

Capacity of battery ............................ 12

Fuses .................................... 12

Accessories ............................... 23

Measuring cable ............................. 24

Sensors ................................... 24

Performance characteristics .................. 13

Sampling methods ............................ 13

Dosing volume .............................. 13

Dosing accuracy ............................. 13

Repeatability ............................... 13

Intake speed ................................ 13

Suction height .............................. 13

Hose length ................................ 13

Installation ............................... 14

Mounting conditions .......................... 14

2 Endress+Hauser

Page 3

Liquiport CSP44

1

2

3

4

5

6

7

8

9

10

11

12

13

Function and system design

Sampler Liquiport CSP44

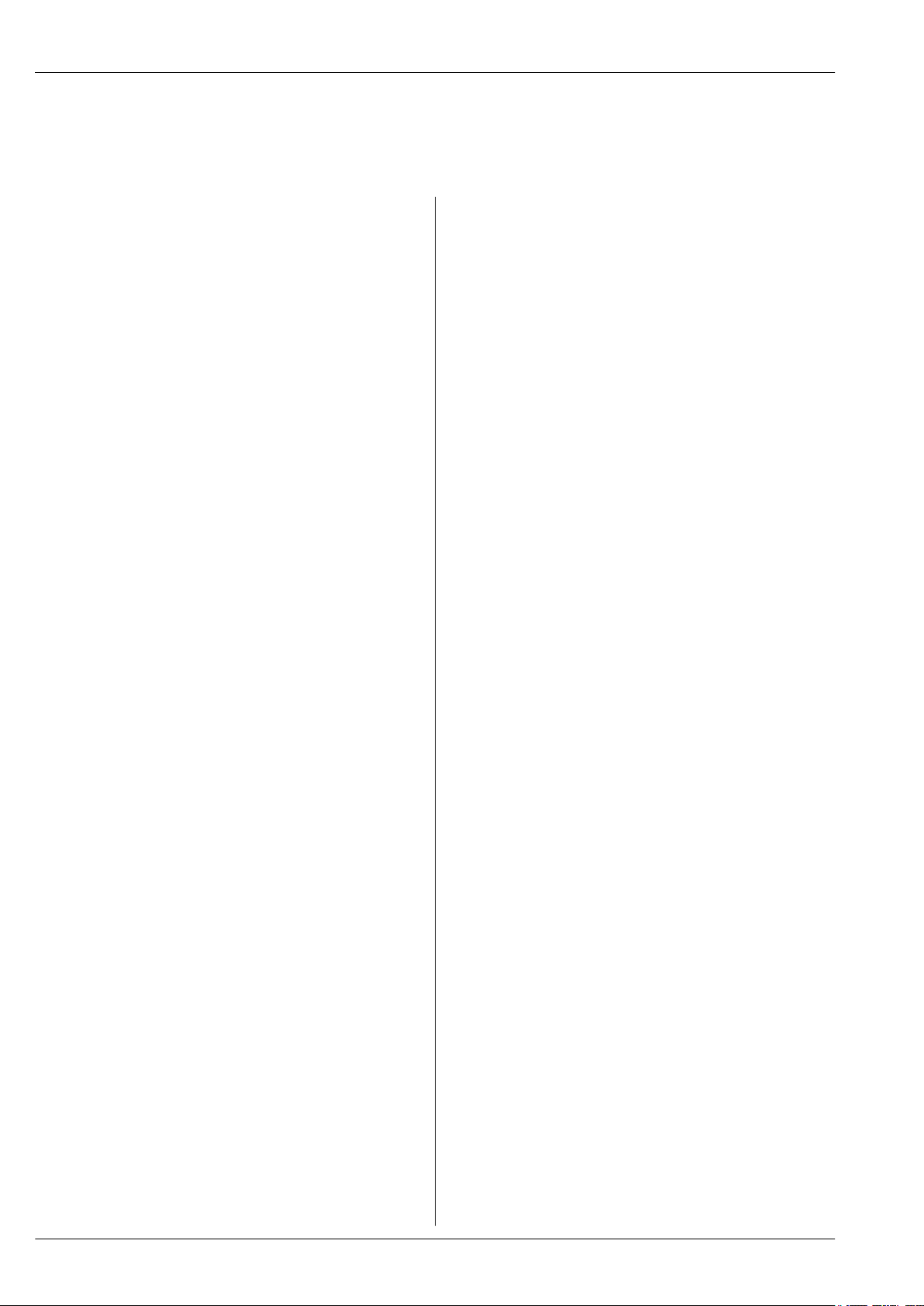

A complete sampling unit comprises:

• Controller with display, soft keys and navigator

• Vacuum or peristaltic pump for sampling

• PE or glass sample bottles for sample preservation

• Sampling chamber temperature regulator (optional) for safe sample storage

• Suction line with suction head

1 Device cover

2 Battery compartment cover

with switch

3 Upper carrying handles

4 Unit upper compartment

5 Peristaltic pump with pump

tubing

6 Bottle retaining cover

7 Lockable latches

8 Lower carrying handles

9 Unit lower compartment

10 Bottle distribution

11 Lockable latches

12 Hose connection

13 Medium detection

14 Electrical connections

15 Controller

A0013533

Endress+Hauser 3

Page 4

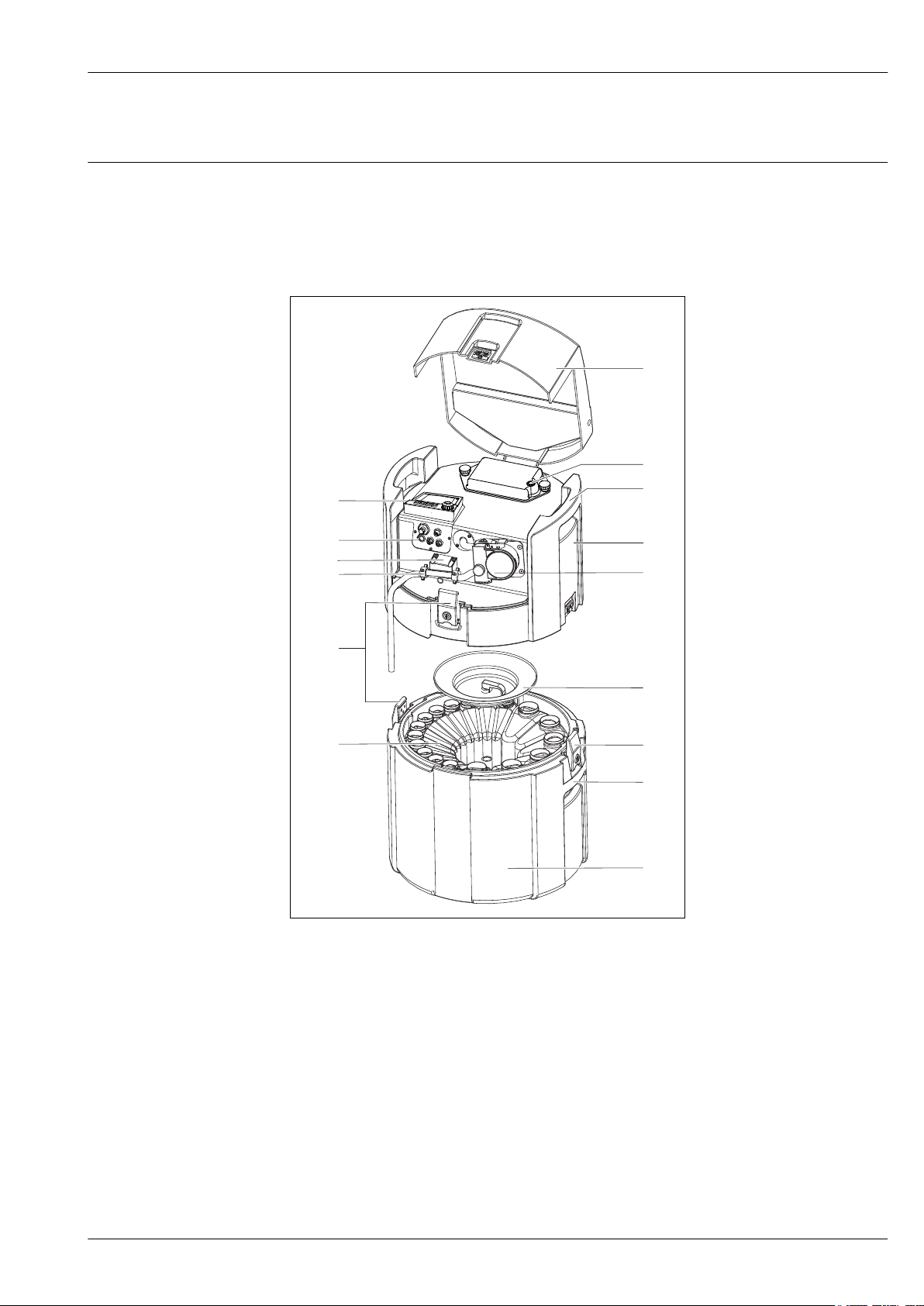

Mode of operation with a

1. 2.

3.

1

2

3

4

peristaltic pump

Liquiport CSP44

A0024341

1 Sampling steps with a peristaltic pump

Sampling takes place in three steps:

1. Rinse

The peristaltic pump runs in reverse and forces medium back to the sampling point.

2. Intake

The peristaltic pump runs forward and draws in medium. If the medium detection system

detects the sample, the pump is controlled by the flow and the specified sample volume is

calculated automatically.

3. Drain

The pump runs in reverse again and forces the medium back to the sampling point.

One advantage this system offers for obtaining a representative sample is the possibility of rinsing

the suction line several times: Medium is initially drawn in until the medium detection system reacts,

then the pump switches and forces the medium back to the sampling point. This process can be

repeated a maximum of three times. The sample is then taken as described.

A0024343

2 Peristaltic pump

1 Pump tube

2 Safety switch (optional)

3 Pump rollers

4 Medium detection system (patented)

The pump rollers deform the hose, thereby causing a negative pressure and the suction effect. The

medium detection system is based on a pressure sensor which detects the difference between a pipe

that is filled and not filled. Thanks to a patented process for automatically detecting the suction

height, the user does not have to enter the suction height or suction line length. The self-learning

software guarantees that the sample volume remains constant. An optional safety switch integrated

in the pump housing immediately switches off the pump when the pump is opened (recommended if

third-party staff are performing maintenance work).

4 Endress+Hauser

Page 5

Liquiport CSP44

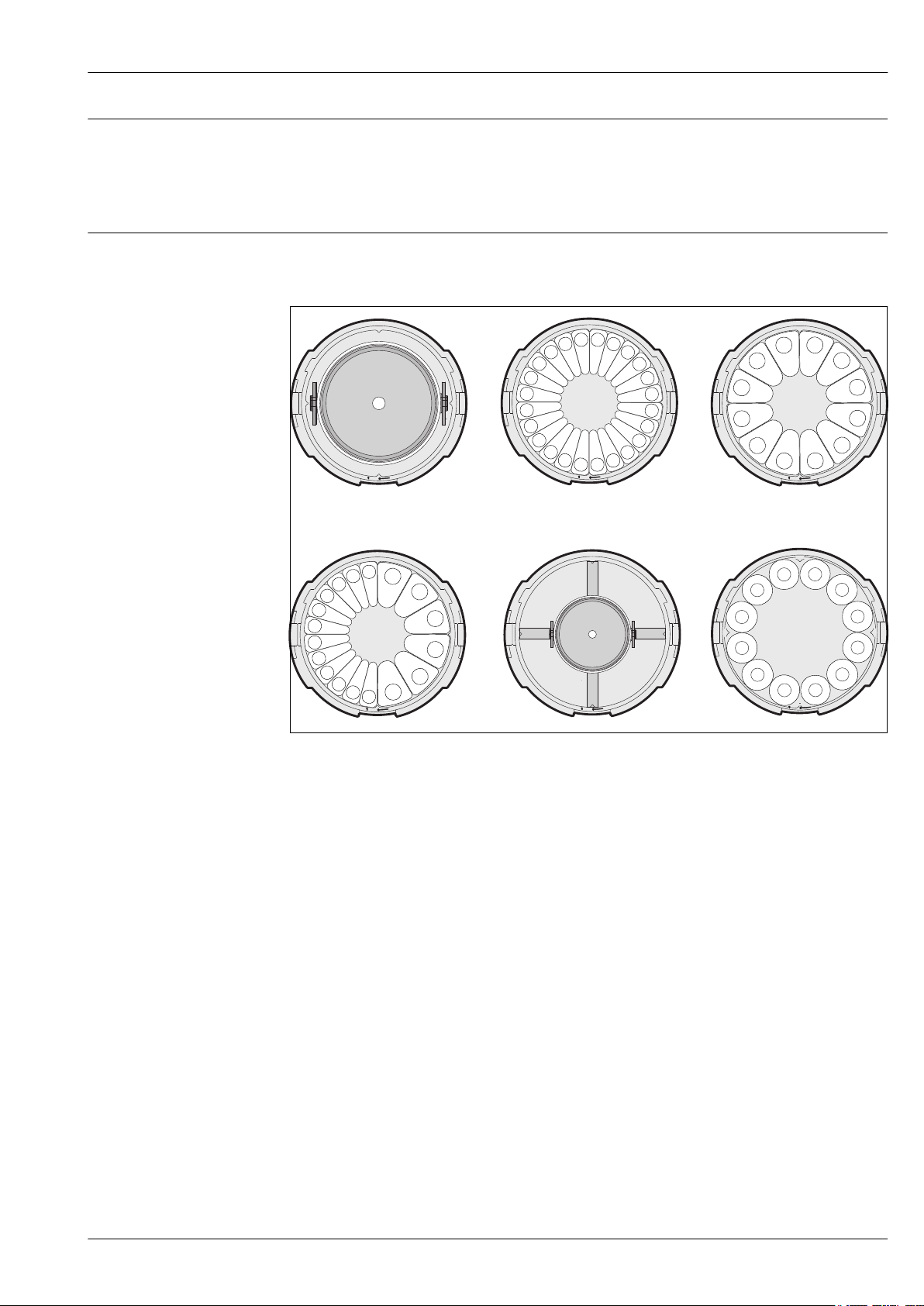

Sample distribution

Sample preservation

The Liquiport 2010 CSP44 allows flexible configuration of the sample distribution. Users can define

individual bottles and bottle groups as they wish for the main, switchover and event programs.

A distribution arm transfers the sample liquid into the individual bottles. in addition to a 20-liter

composite container made of PE, there are different bottle distributions available. The distribution

versions can be replaced easily and without the need for tools.

The sample bottles are located in the sample compartment. This is fitted with a seamless plastic dish

to ensure easy cleaning. All parts that transport medium (distribution arm, dosing system...) can be

removed and cleaned easily without the need for tools.

A0013470

Endress+Hauser 5

Page 6

Liquiport CSP44

a

b

c

d

e

1.2

1.0

0.8

0.6

0.4

0.2

2

3

4

5

6

7

8

m

6.6

9.9

13.1

16.4

19.7

23

26.3

ft

3.9

3.3

2.6

2.0

1.3

0.7

ft/s

m/s

1

a

b

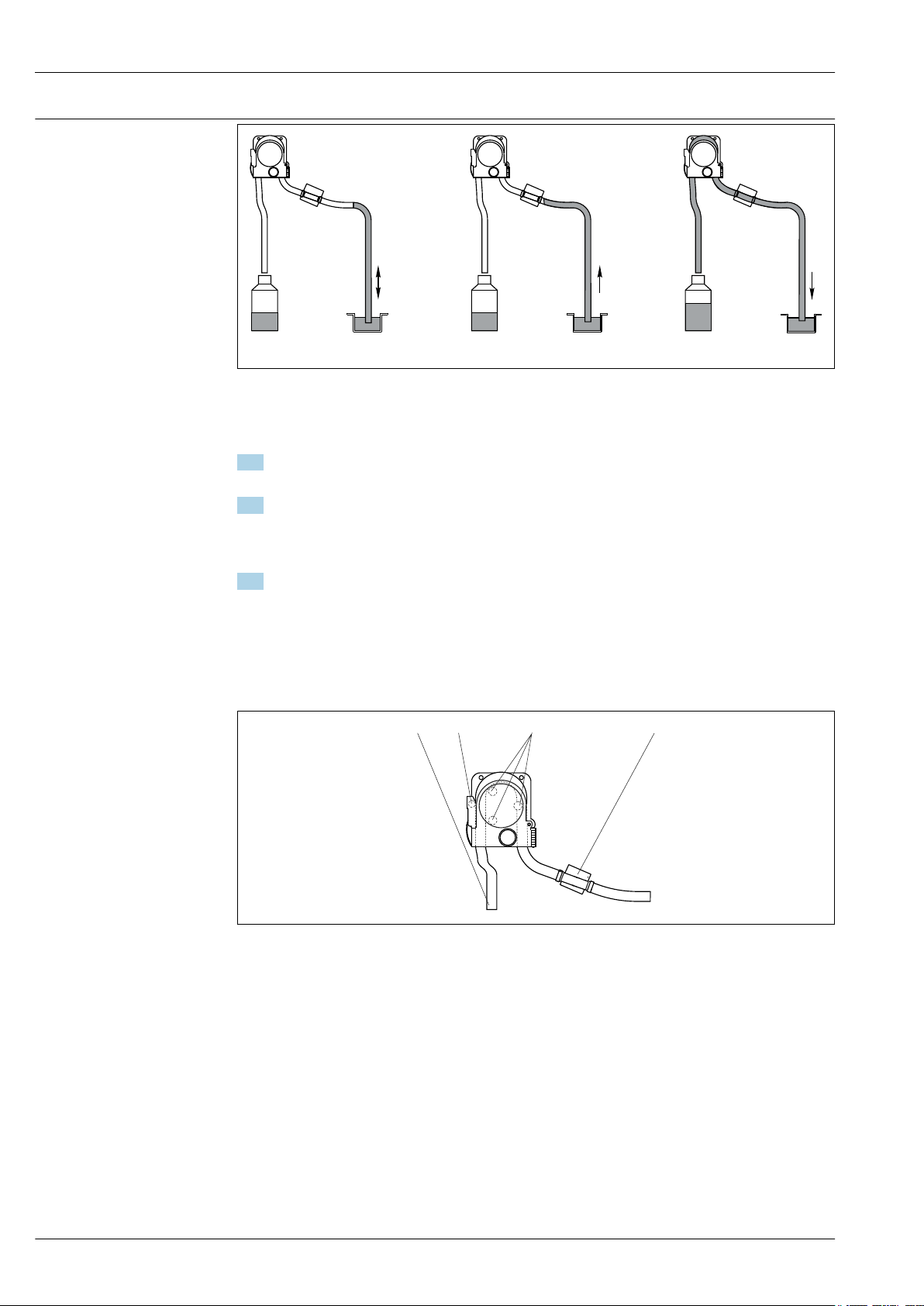

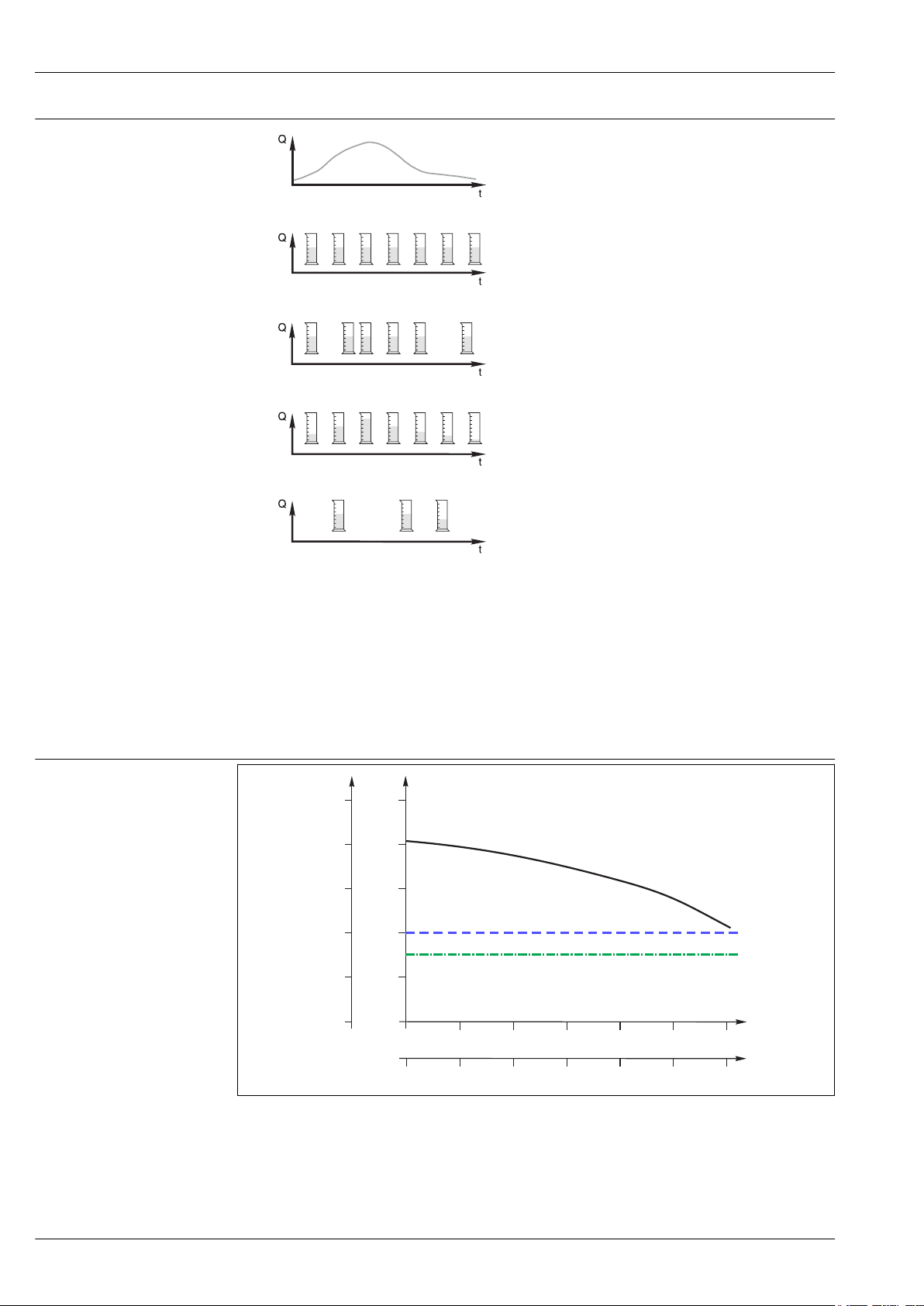

Sampling control

3 Sampling control

A0014045

a. Flow curve

b. Time-proportional sampling (CTCV)

A constant sample volume (e.g. 50 ml) is taken

at regular intervals (e.g. every 5 minutes).

c. Volume-proportional sampling (VTCV)

A constant sample volume is taken at variable

intervals (depending on the inflow volume).

Time override can be enabled in an

advanced program. This allows long,

flow-controlled sample intervals to be

interrupted if the flow rate is low. A

time-controlled sample is collected.

d. Flow-proportional sampling (CTVV)

A variable sample volume (the sample volume

depends on the flow rate) is taken at regular

intervals (e.g. every 10 min).

Only in version with peristaltic pump.

e. Event-controlled sampling

Sampling is triggered by an event (e.g. pH limit

value). Sampling can be time-paced, volumepaced or flow-paced, or single samples can be

taken.

Intake speed with different suction lines

Single and multiple samples can also be grouped in a program in addition to the sampling methods

listed. Furthermore, the software allows interval sampling, switchover and event functions. The

latter permit up to 24 subprograms to be active simultaneously for a variety of applications. A

sampling table makes it possible for users to program the bottle assignment, time interval and

sample volume. Signals for external control can be connected via 2 analog inputs and 2 binary inputs

in the standard version of the product. Customized text is entered to ensure the correct assignment

of the inputs in the memory.

6 Endress+Hauser

4 Intake speed in m/s with suction height in m

a Intake speed as per Ö 5893, US EPA

b Intake speed as per EN 25667, ISO 5667

1 ID 10 mm (3/8") peristaltic pump

A0013534

Page 7

Liquiport CSP44

Sampler housing

Pay attention to the installation conditions in the "Installation" section and the information on the

materials of the different housing types in the "Mechanical construction" section.

NOTICE

The plastic material polystyrene VO can discolor if exposed directly to sunlight.

In the case of stainless steel housings, the frame around the window can discolor if exposed directly

to sunlight.

The plastic material ASA+PC V0 is recommended for outdoor installations where a sun guard is

‣

not used. The discoloring does not affect the function and operation of the device.

Endress+Hauser 7

Page 8

Dependability

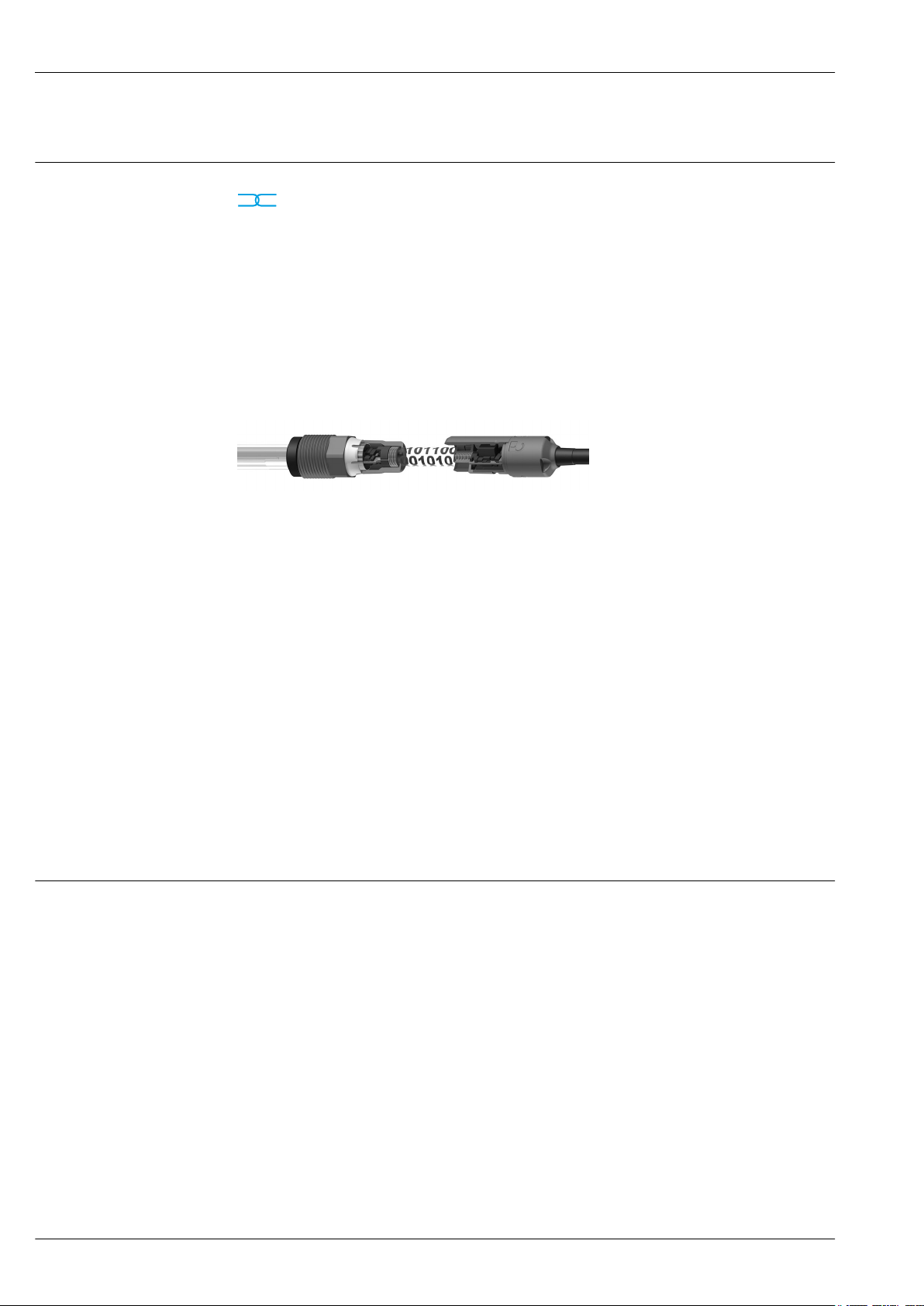

MEMO SENS

Liquiport CSP44

Reliability

Memosens technology

Memosens makes your measuring point safer and more reliable:

• Non-contact, digital signal transmission enables optimum galvanic isolation

• No contact corrosion

• Completely watertight

• Laboratory sensor calibration possible, thus increasing measured value availability

• Predictive maintenance thanks to recording of sensor data, e.g.:

• Total hours of operation

• Hours of operation with very high or very low measured values

• Hours of operation at high temperatures

• Number of steam sterilizations

• Sensor condition

A0024356

Sensor check system (SCS)

The sensor check system (SCS) monitors the high impedance of the pH glass. An alarm is triggered if

a minimum impedance value is undershot or a maximum impedance is exceeded.

• Glass breakage is the main reason for a drop in high impedance values.

• The causes of increasing impedance values are:

• Dry sensor

• Worn pH glass membrane

Process check system (PCS)

The process check system (PCS) checks the measuring signal for stagnation. An alarm is triggered if

the measuring signal does not change over a certain period (several measured values).

The main causes of stagnating measured values are:

• Sensor fouled or outside the medium

• Sensor defective

• Process error (e.g. through control system)

Sensor condition check (SCC)

This function monitors the electrode condition and the degree of electrode aging. The status is

indicated by the messages "SCC electrode condition bad" or "SCC electrode condition OK". The

electrode condition is updated after every calibration.

Maintainability

Modular design

The modular sampler can be easily adapted to suit your needs:

Retrofit extension modules for new or extended range of functions, e.g. current outputs and relays

Memory

• Independent, integrated ring memories (FIFO) or stack memories for recording:

• An analog value (e.g. flow, pH value, conductivity)

• Events (e.g. power failure)

• Sample statistics (e.g. sampling volume, filling times, bottle assignment)

• Program memory: max. 100 programs

• Data logbooks:

• Adjustable scan time: 1 to 3600 s (1 h)

• Max. 8 data logbooks

• 150,000 entries per logbook

• Graphic display (load curves) or numerical list

• Calibration logbook: max. 75 entries

• Hardware logbook:

• Hardware configuration and modifications

• Max. 125 entries

8 Endress+Hauser

Page 9

Liquiport CSP44

• Version logbook:

• Including software updates

• Max. 50 entries

• Operations logbook: max. 250 entries

• Diagnostic logbook: max. 250 entries

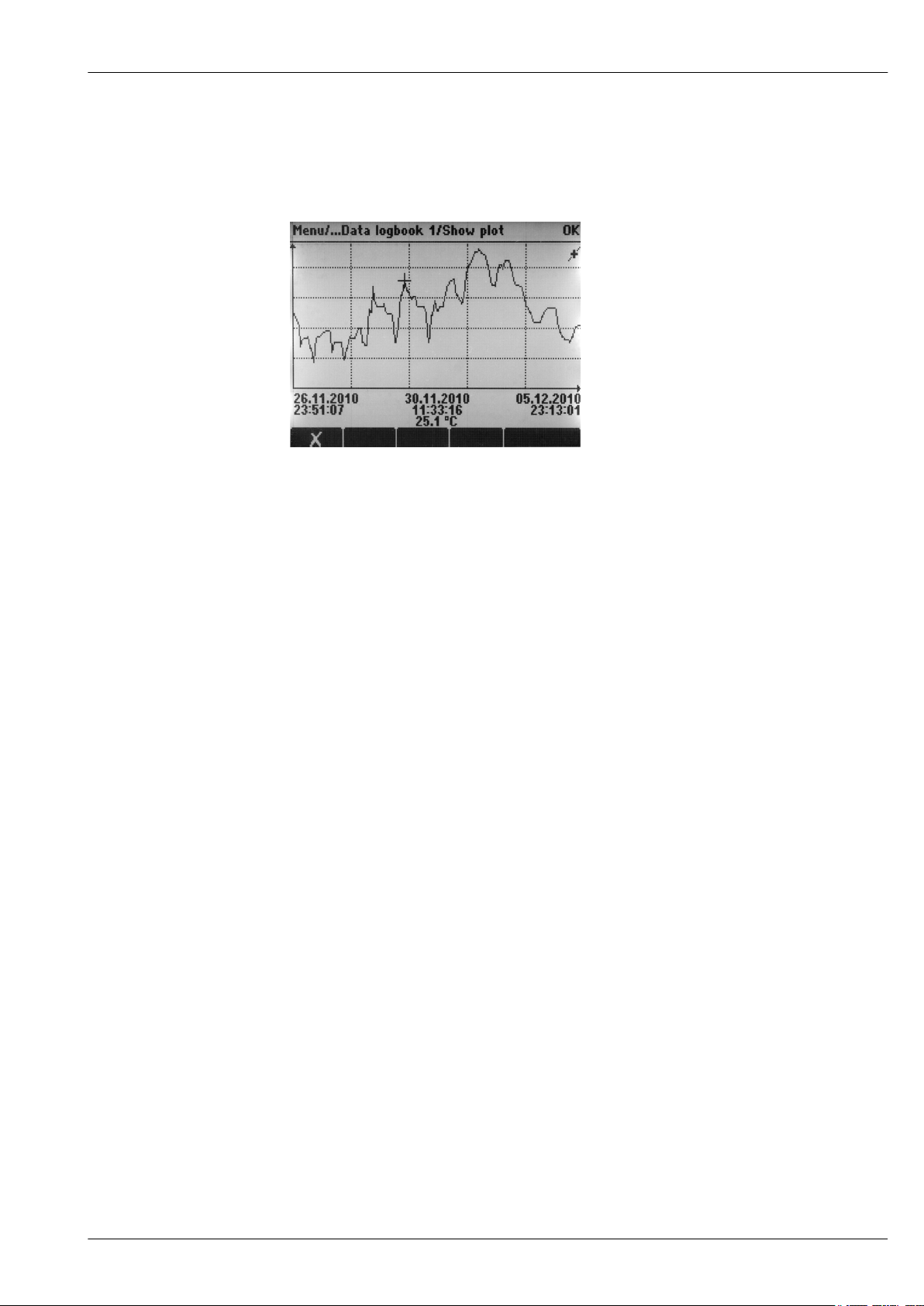

A0024359

5 Data logbook: Graphic display

Mathematical functions (virtual process values)

In addition to "real" process values, which are provided by connected physical sensors or analog

inputs, mathematical functions can be used to calculate a maximum of 6 "virtual" process values.

The "virtual" process values can be:

• Output via a current output or a fieldbus

• Used as a regulating control variable

• Assigned as a measured variable to a limit contactor

• Used as a measured variable to trigger cleaning

• Displayed in user-defined measuring menus

The following mathematical functions are possible:

• Calculation of pH from two conductivity values according to VGB Standard 405, e.g. in boiler

feedwater

• Difference between two measured values from different sources, e.g. to monitor membranes

• Differential conductivity, e.g. to monitor the efficiency of ion exchangers

• Degassed conductivity, e.g. for process controls in power plants

• Redundancy to monitor two or three redundant sensors

• rH calculation from the measured values of a pH and an ORP sensor

FieldCare and Field Data Manager

FieldCare

Configuration and asset management software based on FDT/DTM technology

• Complete device configuration when connected via FXA291 and service interface

• Access to a number of configuration parameters and identification, measuring and diagnostic data

when connected via HART modem

• Logbooks can be downloaded in CSV format or binary format for "Field Data Manager" software

Field Data Manager

Visualization software and database for measuring, calibration and configuration data

• SQL database which is protected against manipulation

• Functions to import, save and print out logbooks

• Load curves to display measured values

• All the logbooks can be read out and saved online

Endress+Hauser 9

Page 10

Liquiport CSP44

Safety

Types of input

Measured values

A0016009

6 Field Data Manager: Load curves

Real-time clock

The device has a real-time clock, which is backed up by a button cell in the event of a power failure.

This ensures that the device continues to keep the correct time and date if it is restarted and that the

time stamp for the logbooks is correct.

Data security

All settings, logbooks etc. are stored in a non-volatile memory to ensure that the data are retained

even in the event of a disruption to the power supply.

Input

Inputs and outputs must be selected in the structure if necessary. Installation at a later stage is

possible only at the place of manufacture.

• Up to two analog inputs

• Up to two binary inputs

• 1 to 2 digital inputs for sensors with Memosens protocol (optional)

→ Documentation of the connected sensor

Temperature inputs

Measuring range

Type of input

Accuracy

10 Endress+Hauser

Measuring range

-30 to 70 °C (-20 to 160 °F)

Pt1000

± 0.5 K

Page 11

Liquiport CSP44

Binary input, passive

Span

Signal characteristics

Accuracy

Span

Accuracy

Communication

12 to 30 V, galvanically isolated

Minimum pulse width: 100 ms

± 0.5 K

Analog input, passive/active

0/4 to 20 mA, galvanically isolated

±0.5 % of measuring range

Output optional

• 1 service interface

• Accessible via front panel connection (optional)

• Commubox FXA291 (accessory) required for communication with the PC

Endress+Hauser 11

Page 12

Power supply

1

2

3

4

5

Liquiport CSP44

Electrical connection

Supply voltage

--> For a detailed connection plan, see the Operating Instructions for Liquiport CSP44

A0013532

7 Electrical connections of the controller

1 Connection socket for charger

2 Socket for M12 sensor connector (optional)

3 Socket for M12 sensor connector (optional)

4 Connection socket for signal cable (optional)

5 Service interface

The sampler cannot be operated without the battery.

Power consumption

Capacity of battery

Internal 24 V DC, 7.2 Ah lead-acid battery

Field-suitable IP 67 100 to 240 V AC; charge current 2.0 A; also suitable for mains

operation

Indoor use 100 to 240 V AC; charge current 2.0 A; also suitable for mains

operation

Mains operation means that the sampler is in operation during the charging process.

Specification of charger for Liquiport 2010 CSP44:

• Max. output current = 2 A

• Max. output voltage = 29.5 V

• Double/reinforced insulation

• Constant current

• CSA or UL recognized according to UL 60950-1, UL 60601-1 or UL 61010-1 or the relevant CSA

standards

Max. 60 W (only when using the battery chargers indicated by the manufacturer)

42 hours for 168 samples (at a sampling interval of 15 minutes, a sampling volume of 100 ml and a

suction height of 4 meters)

Standby capacity: 144 hours

Data applicable if analog input is switched off and for devices without a Memosens input.

Fuses

Input fuse:

T3.15A (behind the plate of the distribution arm in the black box)

Electronics fuse:

T4.0A (in the controller)

12 Endress+Hauser

Page 13

Liquiport CSP44

Performance characteristics

Sampling methods

Dosing volume

Dosing accuracy

Repeatability

Intake speed

Suction height

Vacuum pump/peristaltic pump/sampling assembly:

• Event sampling

• Single and multiple samples

• Sampling table

Peristaltic pump:

• Time-paced

• In proportion to volume

• Flow proportional sampling/time override (CTVV)

Peristaltic pump:

10 to 10000 ml (0.3 to 340 fl.oz.)

The dosing accuracy and the repeatability of a sample volume < 20 ml can vary, depending on

the specific application.

Peristaltic pump:

± 5 ml (0.17 fl.oz.) or 5 % of the set volume

5 %

> 0.5 m/s (> 1.6 ft/s) for ≤ 13 mm (1/2") ID, as per EN 25667, ISO 5667, CEN 16479-1

> 0.6 m/s (> 1.9 ft/s) for 10 mm (3/8") ID, in accordance with Ö 5893; US EPA

Peristaltic pump:

Max. 8 m (26 ft)

Hose length

Max. 30 m (98 ft)

Endress+Hauser 13

Page 14

Mounting conditions

Liquiport CSP44

Installation

8 Installation site, example

The suction line must be routed with a downward slope to the sampling point. Avoid siphon

formation!

Note the following when erecting the device:

• Erect the device on a level surface.

• Securely connect the device at the fastening points to the surface underneath.

• Protect the device against additional heating (e.g. heater or direct sunlight in the case of PS

housing).

• Protect the device against mechanical vibrations.

• Protect the device against strong magnetic fields.

A0013474

14 Endress+Hauser

Page 15

Liquiport CSP44

Environment

Ambient temperature range

Storage temperature

Degree of protection

Electromagnetic compatibility

Electrical safety

Relative humidity

0 to 40 °C (32 to 104 °F)

Do not install the device in areas with high temperature and direct sunlight!

-20 to 60 °C (-4 to 140 °F)

• Sample compartment: IP 54

• Sampler with cover closed: IP 54

• Controller: IP 65

Interference emission and interference immunity as per EN 61326-1:2006, class A for industry

In accordance with EN 61010-1, protection class I, environment ≤ 2000 m (6500 ft) above MSL. The

device is designed for pollution degree 2.

10 to 95%, not condensing

Endress+Hauser 15

Page 16

Process

Liquiport CSP44

Process temperature

Process characteristics

Process pressure

Process connection

2 to 50 °C (36 to 122 °F)

Peristaltic pump

Sample media has to be free of abrasive substances.

Pay attention to the material compatibility of the wetted parts.

Unpressurized, open channel (unpressurized sampling)

• Vacuum pump:

Suction line ID 10 mm (3/8"), 13 mm (1/2"), 16 mm (5/8") or 19 mm (3/4")

• Peristaltic pump:

Intake hose ID 10 mm (3/8")

16 Endress+Hauser

Page 17

Liquiport CSP44

480 (18.9)

675 (26.6)

320 (12.6)

355 (14.0)

Dimensions

Mechanical construction

Weight

A0013473

9 CSP44 standard version, dimensions in mm (in)

Sampler version Weight

Empty weight 15 kg (33 lbs)

Overall weight with battery and 24 x 1 l bottles 19 kg (42 lbs)

Upper compartment with battery 10 kg (22 lbs)

Lower compartment with 24 x 1 l bottles 9 kg (20 lbs)

With full bottles the weight of the sampler is more than 25 kg (55 lbs). To comply with

ISO 11228-1 only transport the sampler together with a second person.

Endress+Hauser 17

Page 18

Liquiport CSP44

Materials

Plastic polystyrene VO can change color when exposed to direct sunlight. For outdoor use

without a weather protection cover, the use of Plastic ASA+PC V0 is recommended. The

functionality is not affected by the discoloration.

Wetted parts Peristaltic pump

Dosing tube -

Dosing chamber cover -

Conductivity sensors -

Conductivity sensors -

Dosing chamber -

Dosing system outflow hose -

Pump tubing Silicone

Process seal -

Distribution arm Plastic PP

Distribution arm cover Plastic PE

Distribution plate Plastic PS

Composite container/bottles Plastic PE, glass (depending on version)

Intake hose Plastic PVC, EPDM (depending on version)

Hose connection Plastic PP

Rinse connection -

Choose process seal depending on the application. Viton is recommended for standard

applications involving watery samples.

Liquiport 2010 CSP44

Housing Plastic PE

Housing parts Plastic PE

Bottles Plastic PE, glass (depending on version)

Distribution arm Plastic PE

Sensor housing Plastic PP

Pump tubing Silicone

Intake hose Plastic PVC reinforced braided, EPDM black

18 Endress+Hauser

Page 19

Liquiport CSP44

Operability

Operating concept

Display

The simple and structured operating concept sets new standards:

• Intuitive operation with the navigator and soft keys

• Fast configuration of application-specific measurement options

• Easy configuration and diagnosis thanks to plain-text display

• All languages that can be ordered are available in every device

10 Easy operation

A0013565

11 Plain-text menu

A0024443-EN

Graphic display:

• Resolution: 240 x 160 pixel

• Back light with switch-off function

• Red display background for alarms alerts users to errors

• Transflective display technology for maximum contrast even in bright environments

• User-definable measuring menus mean you can always keep track of the values that are important

for your application.

12 Example of program setup 13 Example of measuring menu

Local operation

A0024469

• LCD, illuminated (with red background in the event

of an error)

• 160 x 240 pixels

• 4 operating keys (soft key function) and navigator

(jog/shuttle and press/hold function)

• Menu-guided operation

Endress+Hauser 19

Page 20

Liquiport CSP44

Communication

Software

• 1 service interface

• Commubox FXA291 (accessory) required for communication with the PC

Field Data Manager

• Standardized user interface under Windows®

• Read-out of internal memory containing the measured flow rate, sample volume taken etc.

FieldCare

• Device settings saved in a database

• Configuration

20 Endress+Hauser

Page 21

Liquiport CSP44

Certificates and approvals

mark

MCERTS

cCSAus General purpose

Declaration of Conformity

The product meets the requirements of the harmonized European standards. As such, it complies

with the legal specifications of the EU directives. The manufacturer confirms successful testing of the

product by affixing to it the mark.

The device has been assessed by Sira Certification Service and complies with "MCERTS Performance

Standards for Water Monitoring Equipment Part 1, Version 2.1 dated November 2009"; certificate

no.: Sira MC100176/02.

The product meets the requirements in accordance with "Class 8721 05, laboratory equipment,

electrical; Class 8721 85, laboratory equipment, electrical, certified to US standards" for indoor use.

Certificate no.: 2318018

Endress+Hauser 21

Page 22

Ordering information

Liquiport CSP44

Product page

Product Configurator

Scope of delivery

www.endress.com/CSP44

On the product page there is a Configure button to the right of the product image.

1. Click this button.

The Configurator opens in a separate window.

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button on the right

above the selection window.

For many products you also have the option of downloading CAD or 2D drawings of the

selected product version. Click the CAD tab for this and select the desired file type using

picklists.

The scope of delivery comprises:

• 1 Liquiport 2010 CSP44 with:

• The ordered bottle configuration

• Optional hardware

• 1 print version of Brief Operating Instructions in the language ordered

• Optional accessories

22 Endress+Hauser

Page 23

Liquiport CSP44

Accessories

The following are the most important accessories available at the time this documentation was

issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

Order no. Complete suction line

71111233 Suction line ID 10 mm (3/8"), PVC clear, reinforced fabric, length 10 m (33 ft), suction

head V4A

71111234 Suction line ID 10 mm (3/8"), EPDM black, length 10 m (33 ft), suction head V4A

71111235 Suction line ID 13 mm (1/2"), PVC green, reinforced spiral wire, length 10 m (33 ft),

suction head V4A

71111236 Suction line ID 13 mm (1/2"), EPDM black, length 10 m (33 ft), suction head V4A

71111237 Suction line ID 16 mm (5/8"), PVC green, reinforced spiral wire, length 10 m (33 ft),

suction head V4A

71111238 Suction line ID 16 mm (5/8"), EPDM black, length 10 m (33 ft), suction head V4A

71111239 Suction line ID 19 mm (3/4"), PVC green, reinforced spiral wire, length 10 m (33 ft),

suction head V4A

71111240 Suction line ID 19 mm (3/4"), EPDM black, length 10 m (33 ft), suction head V4A

71111482 ... m; suction line coil ID 10 mm (3/8"), PVC

71111484 ... m; suction line coil ID 10 mm (3/8"), EPDM

Order no. Base, complemented

71111864 CSP44 base + 1 x 20 liter (5.28 US gal.), PE

71111866 CSP44 base + 12 x 2 liter (0.53 US gal.), PE

71111867 CSP44 base + 12 x 0.7 liter (0.18 US gal.), glass

71111868 CSP44 base + 24 x 1 liter (0.26 US gal.), PE

71111870 CSP44 base + 12 x 1 liter (0.26 US gal.) + 6 x 2 liter (0.53 US gal.), PE

Order no. Bottles + covers

71112221 20 liter (5.28 US gal.) PE + cover, 1 pc.

71111178 2 liter (0.53 US gal.) PE wedge-shaped bottle + cover, 12 pcs

71111176 1 liter (0.26 US gal.) PE wedge-shaped bottle + cover, 24 pcs.

71111874 0.7 liter (0.18 US gal.) glass + cover, 12 pcs.

Order no. Accessories base

71111878 Kit CSP44 base cover, transporting

71111880 Kit CSP44 freezer cartridge

Order no. Tubing customized

71114701 Pump tubing, 2 pcs.

71114702 Pump tubing, 25 pcs.

Order no. Installation

71111881 CSP44 suspension kit, for use in 500 to 600 mm diameter manhole

Endress+Hauser 23

Page 24

Liquiport CSP44

Order no. Power supply

71111872 Lead-acid battery 24 V DC

71111882 Kit CSP44 charger adapter cable, battery for power unit

71111883 Kit CSP44 power unit/charger for indoor use, 100 to 120/200 to 240 V AC ±10 %,

50/60 Hz

71111884 Kit CSP44 power unit/charger for outdoor use, IP 65, 100 to 120/200 to 240 V AC

±10 %, 50/60 Hz

Order no. Retrofit kits

71111879 Kit CSP44 retrofit distribution system (distribution arm, distribution drive)

71251042 Kit CSP44 power unit/charger for outdoors; UL, IP65, 115VAC, US connector

71389506 Kit CSP44 battery cover with switch

Order no. Suction head

71111184 Suction head V4A for ID 10 mm (3/8"), 1 pc.

Measuring cable

Sensors

Order no. Communication; software

51516983 Commubox FXA291 + FieldCare Device Setup

71129799 Field Data Manager software; 1 license, analysis report

Activation code for PROFIBUS DP

Memosens data cable CYK10

• For digital sensors with Memosens technology

• Product Configurator on the product page: www.endress.com/cyk10

Technical Information TI00118C

Measuring cable CYK81

• Unterminated cable for extending sensor cables (e.g. Memosens, CUS31/CUS41)

• 2 x 2 cores, twisted with shielding and PVC sheath (2 x 2 x 0.5 mm2 + shielding)

• Sold by meter, Order No.: 51502543

You can only connect sensors with M12 plug.

Glass electrodes

Orbisint CPS11D

• pH sensor for process technology

• Optional SIL version for connecting to SIL transmitter

• With dirt-repellent PTFE diaphragm

• Product Configurator on the product page: www.endress.com/cps11d

Technical Information TI00028C

Memosens CPS31D

• pH electrode with gel-filled reference system with ceramic diaphragm

• Product Configurator on the product page: www.endress.com/cps31d

Technical Information TI00030C

Ceraliquid CPS41D

• pH electrode with ceramic junction and KCl liquid electrolyte

• Product Configurator on the product page: www.endress.com/cps41d

Technical Information TI00079C

24 Endress+Hauser

Page 25

Liquiport CSP44

Ceragel CPS71D

• pH electrode with reference system including ion trap

• Product Configurator on the product page: www.endress.com/cps71d

Technical Information TI00245C

Orbipore CPS91D

• pH electrode with open aperture for media with high dirt load

• Product Configurator on the product page: www.endress.com/cps91d

Technical Information TI00375C

Orbipac CPF81D

• Compact pH sensor for installation or immersion operation

• In industrial water and wastewater

• Product Configurator on the product page: www.endress.com/cpf81d

Technical Information TI00191C

Pfaudler electrodes

Ceramax CPS341D

• pH electrode with pH-sensitive enamel

• Meets highest demands of measuring accuracy, pressure, temperature, sterility and durability

• Product Configurator on the product page: www.endress.com/cps341d

Technical Information TI00468C

ORP sensors

Orbisint CPS12D

• ORP sensor for process technology

• Product Configurator on the product page: www.endress.com/cps12d

Technical Information TI00367C

Ceraliquid CPS42D

• ORP electrode with ceramic junction and KCl liquid electrolyte

• Product Configurator on the product page: www.endress.com/cps42d

Technical Information TI00373C

Ceragel CPS72D

• ORP electrode with reference system including ion trap

• Product Configurator on the product page: www.endress.com/cps72d

Technical Information TI00374C

Orbipac CPF82D

• Compact ORP sensor for installation or immersion operation in process water and wastewater

• Product Configurator on the product page: www.endress.com/cpf82d

Technical Information TI00191C

Orbipore CPS92D

• ORP electrode with open aperture for media with high dirt load

• Product Configurator on the product page: www.endress.com/cps92d

Technical Information TI00435C

pH ISFET sensors

Tophit CPS441D

• Sterilizable ISFET sensor for low-conductivity media

• Liquid KCl electrolyte

• Product Configurator on the product page: www.endress.com/cps441d

Technical Information TI00352C

Endress+Hauser 25

Page 26

Liquiport CSP44

Tophit CPS471D

• Sterilizable and autoclavable ISFET sensor for food and pharmaceutics, process engineering

• Water treatment and biotechnology

• Product Configurator on the product page: www.endress.com/cps471d

Technical Information TI00283C

Tophit CPS491D

• ISFET sensor with open aperture for media with high dirt load

• Product Configurator on the product page: www.endress.com/cps491d

Technical Information TI00377C

Conductivity sensors with inductive measurement of conductivity

Indumax CLS50D

• High-durability inductive conductivity sensor

• For standard and hazardous area applications

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cls50d

Technical Information TI00182C

Conductivity sensors with conductive measurement of conductivity

Condumax CLS15D

• Conductive conductivity sensor

• For pure water, ultrapure water and hazardous area applications

• Product Configurator on the product page: www.endress.com/CLS15d

Technical Information TI00109C

Condumax CLS16D

• Hygienic, conductive conductivity sensor

• For pure water, ultrapure water and Ex applications

• With EHEDG and 3A approval

• Product Configurator on the product page: www.endress.com/CLS16d

Technical Information TI00227C

Condumax CLS21D

• Two-electrode sensor in plug-in head version version

• Product Configurator on the product page: www.endress.com/CLS21d

Technical Information TI00085C

Memosens CLS82D

• Four-electrode sensor

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cls82d

Technical Information TI01188C

Oxygen sensors

Oxymax COS22D

• Sterilizable sensor for dissolved oxygen

• With Memosens technology or as an analog sensor

• Product Configurator on the product page: www.endress.com/cos22d

Technical Information TI00446C

Oxymax COS51D

• Amperometric sensor for dissolved oxygen

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cos51d

Technical Information TI00413C

26 Endress+Hauser

Page 27

Liquiport CSP44

Oxymax COS61D

• Optical oxygen sensor for drinking water and industrial water measurement

• Measuring principle: quenching

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cos61d

Technical Information TI00387C

Memosens COS81D

• Sterilizable, optical sensor for dissolved oxygen

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cos81d

Technical Information TI01201C

Chlorine sensors

CCS142D

• Membrane-covered amperometric sensor for free chlorine

• Measuring range 0.01 to 20 mg/l

• With Memosens technology

• Product Configurator on the product page: www.endress.com/ccs142d

Technical Information TI00419C

Ion-selective sensors

ISEmax CAS40D

• Ion selective sensors

• Product Configurator on the product page: www.endress.com/cas40d

Technical Information TI00491C

Turbidity sensors

Turbimax CUS51D

• For nephelometric measurements of turbidity and solids in wastewater

• 4-beam scattered light method

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cus51d

Technical Information TI00461C

SAC and nitrate sensors

Viomax CAS51D

• SAC and nitrate measurement in drinking water and wastewater

• With Memosens technology

• Product Configurator on the product page: www.endress.com/cas51d

Technical Information TI00459C

Interface measurement

Turbimax CUS71D

• Immersion sensor for interface measurement

• Ultrasonic interface sensor

• Product Configurator on the product page: www.endress.com/cus71d

Technical Information TI00490C

Endress+Hauser 27

Page 28

www.addresses.endress.com

Loading...

Loading...