Page 1

TI01396C/07/EN/01.18

71413693

2018-02-15

Products

Solutions Services

Technical Information

Memosens CPS77D

Sterilizable and autoclavable ISFET sensor for pH

measurement

Digital with Memosens technology

Application

• Hygienic and sterile applications

• Food and pharmaceutical industry

• Biotechnology

Your benefits

• Break-resistant

– Sensor body made entirely of PEEK (FDA compliant)

– Can be installed directly in the process, saving time and cost for sampling and

laboratory analysis

• Biocompatibility successfully tested with regard to biological reactivity in vitro

(cytotoxicity) and in vivo in accordance with USP <87> and USP <88> Cl. VI

(121 °C)

• Operation at low temperatures

– Short response time

– Consistently high accuracy

• Sterilizable and autoclavable

• Longer calibration intervals than with glass electrodes

– Shorter hysteresis in event of temperature change

– Smaller measuring error following exposure to high temperatures

– Virtually no acid and alkaline errors

• Integrated temperature sensor for effective temperature compensation

• Improved alkaline stability

• Ideally suited for CIP processes when combined with an automatic retractable

assembly

• Documentation to certify compliance with requirements of pharmaceutical

industry with serial number of sensor (optional)

Advantages offered by Memosens technology

• Maximum process safety thanks to non-contact, inductive signal transmission

• Data security thanks to digital data transmission

• Very easy to use as sensor data saved in the sensor

• Predictive maintenance possible as sensor load data are recorded in the sensor

• Heartbeat

Page 2

Function and system design

U

D

U

GS

1

2

S

D

Si (n)

Si (p)

Si (p)

I

D

U

D

U

GS

1

3

4

5

6

2

D

Si (n)

Si (p)

Si (p)

I

D

S

Memosens CPS77D

Measuring principle

Ion-selective, or more generally, ion-sensitive field effect transistors (ISFET) were developed in the

1970s as an alternative to glass electrodes for pH measurement.

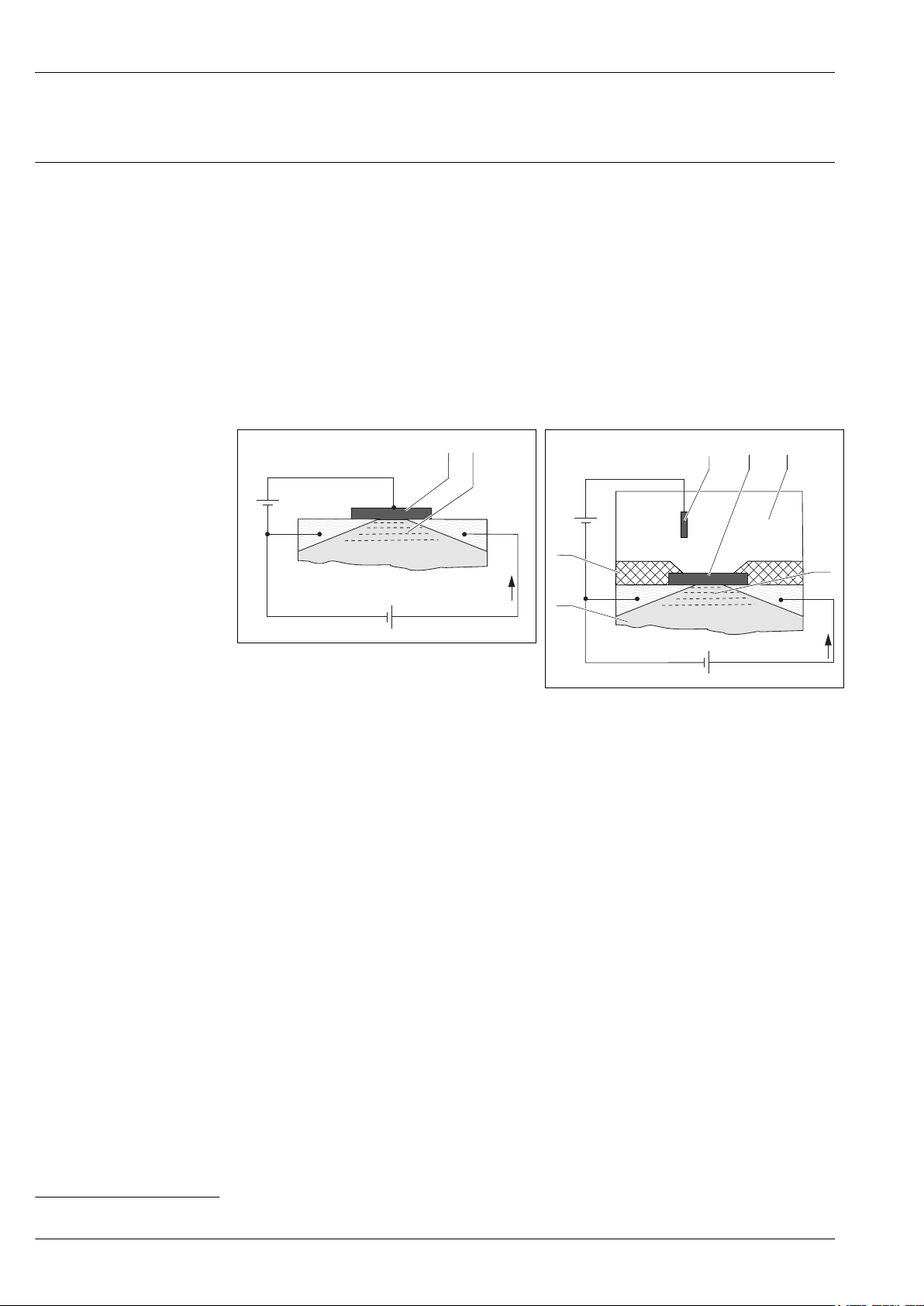

General principles

Ion-selective field effect transistors are based on an MOS

1)

transistor arrangement → 1, 2.

Unlike the MOS, however, the ISFET sensor does not have a metal gate (item 1) as the control

electrode. Instead, in the ISFET sensor → 2, 2 the medium (item 3) is in direct contact with

the gate insulator layer (item 2). Two highly p-conducting regions are diffused into the n-conducting

substrate material (item 5) of the semi-conductor (Si). They act as the charge-supplying electrode

("Source", S) and the charge-accepting electrode ("Drain", D). The metal gate electrode (in the case of

the MOSFET) and the medium (in the case of the ISFET) forms a capacitor with the underlying

substrate. A difference in potential (voltage) between the gate and substrate (UGS) increases the

electron density in the area between the "Source" and "Drain". A conductive channel forms

→ 2, 2(item 4), such that a current ID flows when a voltage UD is applied.

A0036074

1 MOSFET principle

1 Metal gate

2 Conductive channel (N-conducting)

2 ISFET principle

1 Reference electrode

2 Gate insulator layer

3 Medium

4 Conductive channel (N-conducting)

5 N-doped silicon substrate

6 Sensor shaft

A0003856

With the ISFET, ions that are in the medium and located in the boundary layer between the

medium/gate insulator generate the electric field (gate potential). The effect described above causes

a conductive channel to form in the silicon semi-conductor substrate between the "Source" and

"Drain", and causes current to flow between the "Source" and "Drain".

Suitable sensor circuits use the dependence of the ion-selective gate potential to generate an output

signal that is proportional to the concentration of the ion type.

pH-selective ISFET

The gate insulator acts as an ion-selective layer for H+ ions. While the gate insulator is also

impermeable to these ions (insulator effect), it allows reversible surface reactions with H+ ions.

Depending on the acidic or alkaline character of the medium, functional groups in the insulator

surface either accept or donate H+ ions (amphoteric character of the functional groups). This results

in positive charging at the insulator surface (H+ ions accepted in the acidic medium) or negative

charging at the insulator surface (H+ ions donated in the alkaline medium). Depending on the pH

value, a defined surface charge can be used to control the field effect in the channel between the

1) Metal Oxide Semiconductor

2 Endress+Hauser

Page 3

Memosens CPS77D

"Source" and "Drain". The processes which lead to the creation of a charge potential and therefore to a

control voltage UGS between the "Gate" and "Source" are described by the Nernst equation:

Measuring system

UGS = U0 +

U

GS

U

0

R Gas constant (8.3143 J/molK) 2.3 . RT

T Temperature [K]

n Valency (1/mol)

2.3 . RT

Potential between gate and source F Faraday constant (26.803 Ah)

Offset voltage a

nF

.

lg a

ion

ion

Activity of ion type (H+)

Nernst factor

nF

At 25 °C (77 °F) the Nerst factor of the pH measurement has the value -59.16 mV/pH.

The complete measuring system comprises at least:

• ISFET sensor

• Memosens data cable: CYK10 (Memosens, digital sensor)

• Transmitter, e.g. Liquiline CM44, Liquiline CM42

• Assembly

– Immersion assembly, e.g. Dipfit CPA111

– Flow assembly, e.g. Flowfit CPA250

– Retractable assembly, e.g. Cleanfit CPA875

– Permanent installation assembly, e.g. Unifit CPA842

Additional options are available depending on the application:

Automatic cleaning and calibration system, e.g. Liquiline Control CDC90

Endress+Hauser 3

Page 4

Food industry

1

2

3

4

5

6

7

9

10

11

8

Memosens CPS77D

A0035661

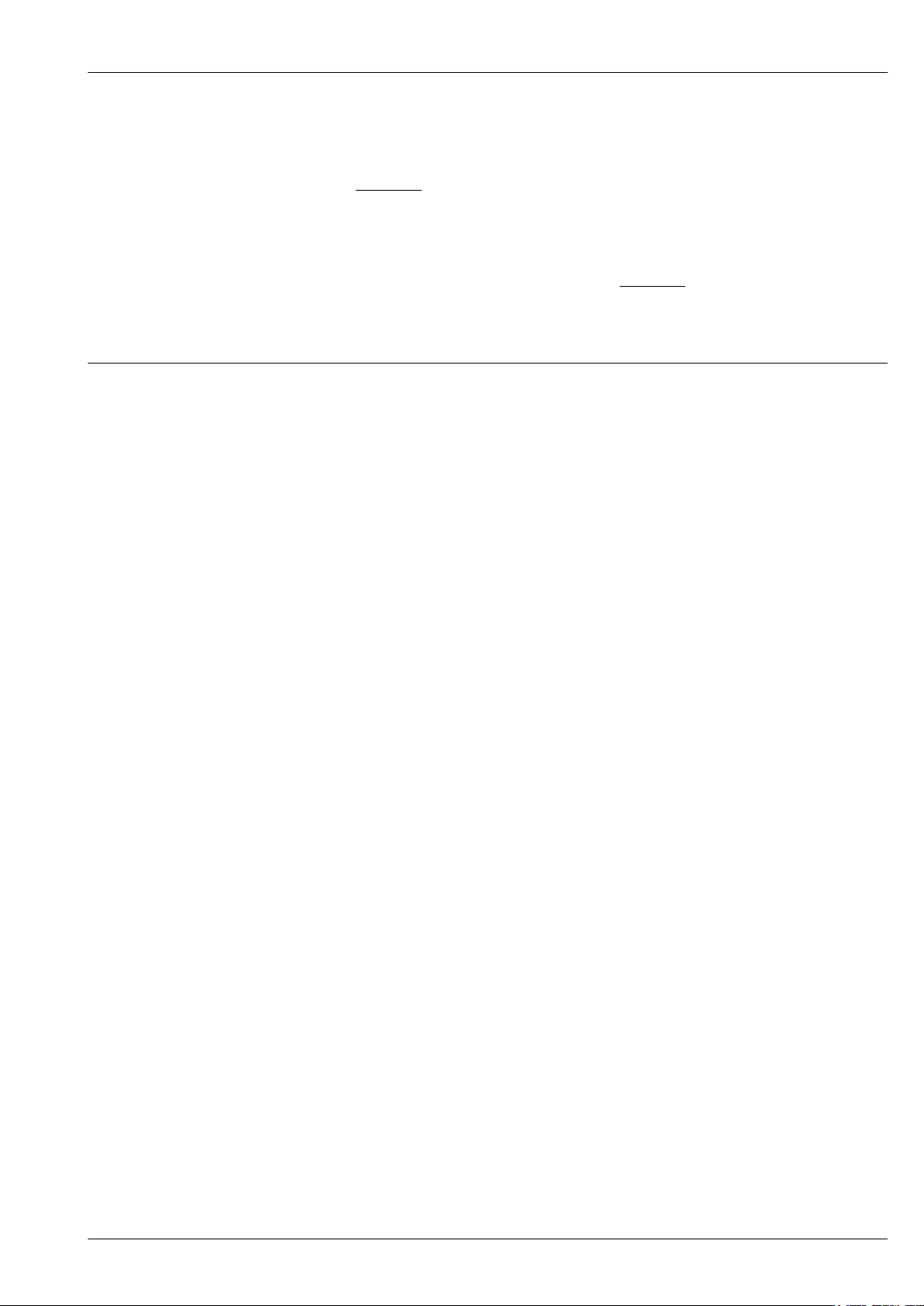

3 Complete measuring system

1 Water connection, at installation location

2 Assembly

3 Process/medium

4 Rinsing block

5 Pump canister unit

6 Pneumatic control unit

7 CDC90 control unit

8 Ethernet switch

9 Media (cleaners, buffers)

10 Compressed air line

11 Electric cable, signal cable

For detailed information on Liquiline Control CDC90: Operating Instructions BA01707C,

Technical Information TI01340C

As the ISFET sensor can be used in a broad range of applications - both with regard to temperature

and the pH value - sterilization in place (SIP) is not a problem. There is only a small range involving

high pH values in combination with high temperatures where the sensor's long-term stability is

somewhat compromised. Media with such properties reduce the insulator oxide of the ISFET chip. As

this is the pH and temperature range of CIP cleaning media, the ISFET sensor is only used here in

combination with an automatic retractable assembly.

Advantages of the CDC90 fully automated cleaning and calibration system:

• Cleaning in place (CIP):

The sensor in the retractable assembly is automatically retracted from the medium for the

duration of the alkaline phase or for the entire CIP process. The sensor is then rinsed with a

suitable cleaning agent in the rinse chamber.

• Calibration cycles can be set individually

• Reduced maintenance thanks to fully automated cleaning and calibration

• Optimum reproducibility of the measurement results

• Very low individual value tolerances thanks to automatic calibration

4 Endress+Hauser

Page 5

Memosens CPS77D

1

2

3

4

Δ

pH

0

-0,05

-0,1

-0,15

0,05

0,1

0,15

0,2

0,25

0,3

0,35

1 M HCI

pH 1...3

1 M NaOH

ISFET CPSx7D

glass 1

glass 2

Pharmaceutical industry and biotechnology

A0036026

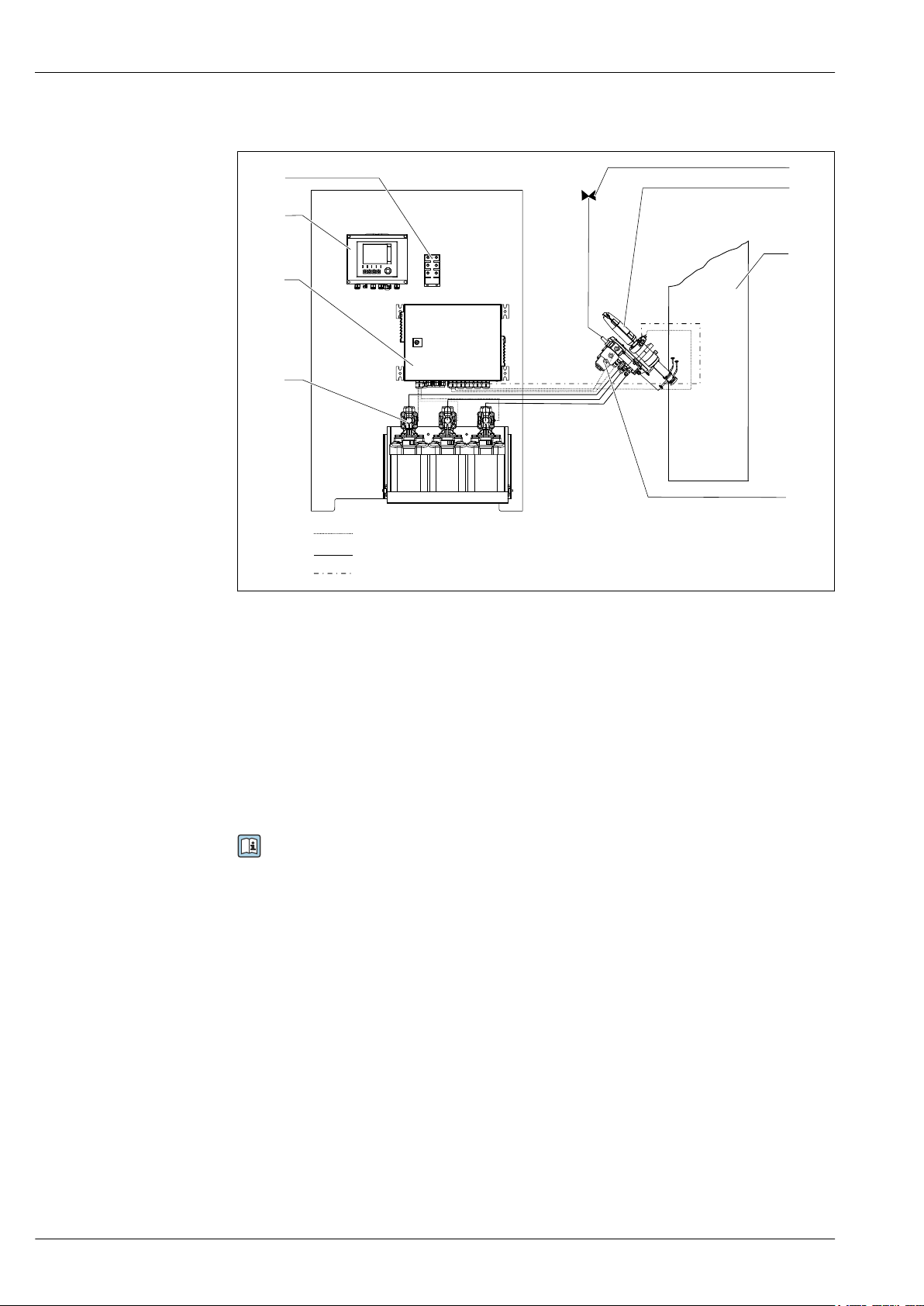

4 Measuring system for pharmaceutics and biotechnology

1 ISFET sensor

2 Installation assembly Unifit CPA842

3 Memosens data cable CYK10

4 Liquiline CM42 transmitter

Properties

Acid or alkaline errors

Another important advantage over the glass electrode is the lower acid or alkaline errors in extreme

pH ranges. In contrast to the glass electrode, almost no foreign ions can build up at the ISFET gate.

Between pH 1 and pH 13, the measured error averages Δ pH 0.02 (at 25 °C (77 °F)) and is therefore

at the detection limit. The following graphic shows the average measured error of the ISFET sensor

in the pH 1 to 13 range compared with two glass electrodes (2 different pH glasses) at the extreme

values of pH 0.09 (1 M HCl) and 13.86 (1 M NaOH).

5 Measured errors of the ISFET sensor compared to two different pH glass electrodes

Endress+Hauser 5

A0038183-EN

Page 6

Memosens CPS77D

• Resistance to breaking

The sensor's resistance to breaking is its most distinctive external feature. The entire sensor

technology is embedded in a PEEK shaft. Only the highly durable ISFET chip and the reference are

in direct contact with the medium.

• Measurement stability and sensor response time

The ISFET response times are extremely short over the entire temperature range. With the ISFET

sensor, there is no (temperature-dependent) equilibrium setting as in the gel layer of the pH glass

in a glass electrode. This means it can also be used at low temperatures without a deceleration in

the response time. The effect of large and fast temperature and pH value fluctuations on the

measured error (hysteresis) is smaller than with a glass electrode, as the stress on the pH glass

does not apply here.

Communication and data processing

Dependability Maintainability

Communication with the transmitter

Always connect digital sensors with Memosens technology to a transmitter with Memosens

technology. Data transmission to a transmitter for analog sensors is not possible.

Digital sensors can store measuring system data in the sensor. These include the following:

• Manufacturer data

– Serial number

– Order code

– Date of manufacture

• Calibration data

– Calibration date

– Calibration values

– Number of calibrations

– Serial number of the transmitter used to perform the last calibration

• Operating data

– Temperature application range

– Date of initial commissioning

– Hours of operation under extreme conditions

– Number of sterilizations

– Sensor monitoring data

Easy handling

Sensors with Memosens technology have integrated electronics that store calibration data and other

information (e. g. total hours of operation or operating hours under extreme measuring conditions).

Once the sensor has been connected, the sensor data are transferred automatically to the transmitter

and used to calculate the current measured value. As the calibration data are stored in the sensor,

the sensor can be calibrated and adjusted independently of the measuring point. The result:

• Easy calibration in the measuring lab under optimum external conditions increases the quality of

the calibration.

• Pre-calibrated sensors can be replaced quickly and easily, resulting in a dramatic increase in the

availability of the measuring point.

• Thanks to the availability of the sensor data, maintenance intervals can be accurately defined and

predictive maintenance is possible.

• The sensor history can be documented on external data carriers and in evaluation programs,.

• Thus, the current application of the sensors can be made to depend on their previous history.

Integrity

Data security thanks to digital data transmission

Memosens technology digitizes the measured values in the sensor and transmits the data to the

transmitter via a non-contact connection that is free from potential interference. The result:

• Automatic error message if sensor fails or connection between sensor and transmitter is

interrupted

• Immediate error detection increases measuring point availability

6 Endress+Hauser

Page 7

Memosens CPS77D

GN/YE

YE

GN

BN

WH

GND

+

–

Com A

Com B

GY

Safety

Maximum process safety

With inductive transmission of the measured value using a non-contact connection, Memosens

guarantees maximum process safety and offers the following benefits:

• All problems caused by moisture are eliminated:

– Plug-in connection free from corrosion

– Measured values cannot be distorted by moisture

– Can even be connected under water

• The transmitter is galvanically decoupled from the medium. Issues concerning "symmetrical highimpedance" or "asymmetry" or an impedance converter are a thing of the past.

• EMC safety is guaranteed by screening measures for the digital transmission of measured values.

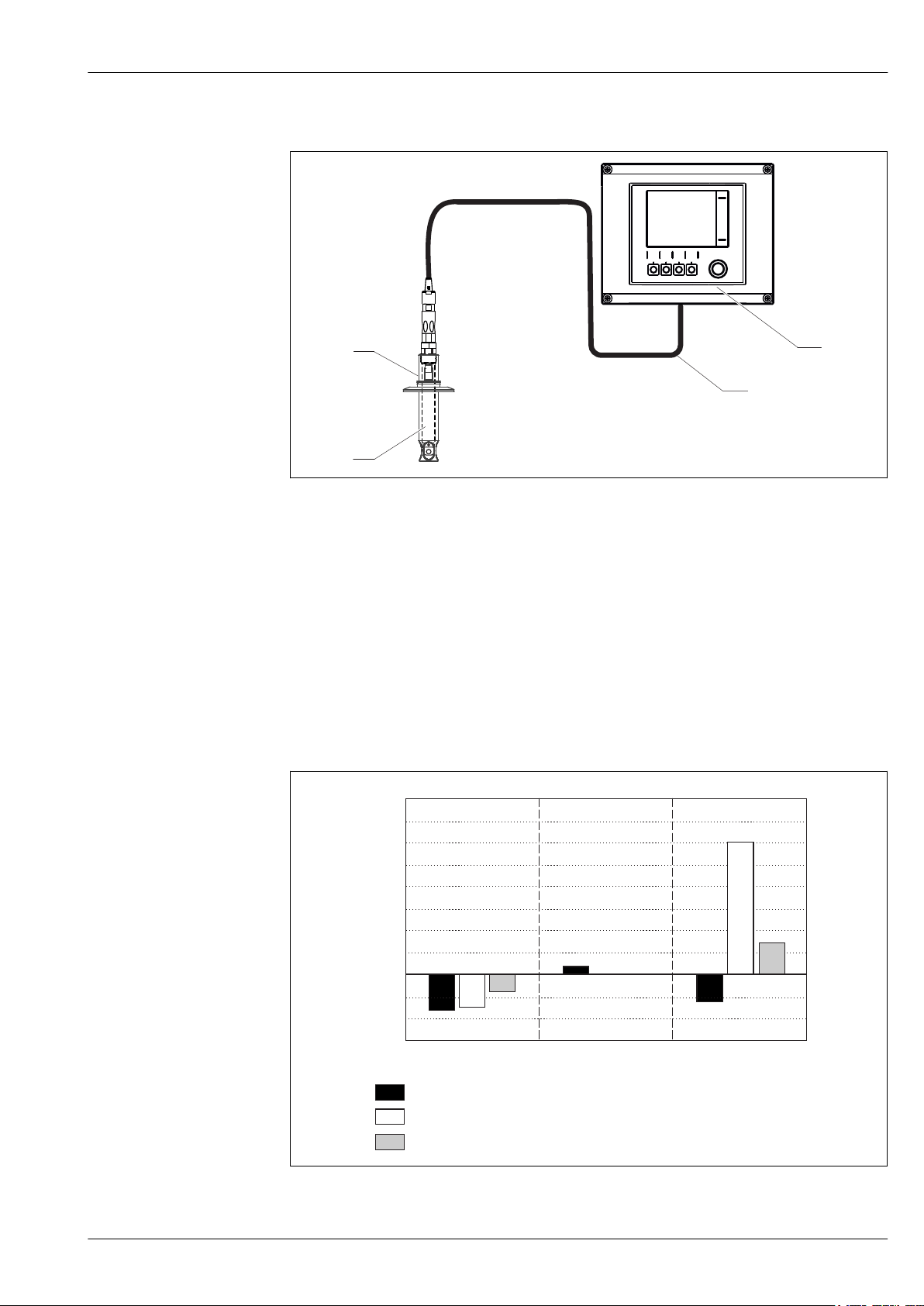

Input

Measured variable

Measuring range

Electrical connection

pH value

Temperature

0 to 14pH

–15 to 135 °C (5 to 275 °F)

Pay attention to the operating conditions in the process.

Power supply

The sensor is connected to the transmitter via the Memosens data cable CYK10.

A0024019

6 Memosens data cable CYK10

Performance characteristics

Reference operating conditions

Reference system

Reference temperature:

Reference pressure: 1013 hPa (15 psi)

The integrated reference electrode is a double-chamber reference system with a bridging electrolyte.

This has the advantage of an effective and stable contact between the junction and reference lead

and an extremely long poison diffusion path. The bridging electrolyte is highly resistant to

temperature and pressure changes.

Ag/AgCl reference lead (bridging electrolyte) with Advanced Gel 3M KCl, non-cytotoxic

Repeatability

Response time

± 0.01 pH

A closed-control loop is created each time the measuring system is switched on. The measured value

adjusts to the real value during this time.

Endress+Hauser 7

25 °C (77 °F)

Page 8

Memosens CPS77D

z

y

1

2

N10019

05E03

y

x

z

1

2

30 ... 45°

The settling time depends on the type and duration of the interruption:

• Supply voltage interruption, sensor remains in the medium: approx. 3-5 minutes

• Interruption of the film of liquid between the ISFET and reference: approx. 5-8 minutes

• Dry storage of the sensor for an extended period: up to 30 minutes

Response time t

Orientation

90

t < 5 s

for a buffer change from pH 4 to pH 7 and under reference operating conditions

The response of the integrated temperature sensor can be slower in the event of extreme

temperature changes. In this case, regulate the temperature of the sensor before a calibration

or measurement.

Installation

Note the direction of medium flow when installing the sensor.

Position the ISFET chip so that it is at an angle of approx. 30 to 45 ° to the flow direction (item

‣

2).

Use the rotatable terminal head for this purpose.

A0037400

7 Sensor orientation, front view

1 Serial number

2 Nameplate

8 Sensor orientation, 3D view

1 ISFET chip

2 Direction of medium flow

A0036028

When installing the sensor in an assembly, use the serial number engraved on the terminal head to

ensure correct sensor orientation. The engraving is always on the same plane as the ISFET chip and

the nameplate (z-y direction).

ISFET sensors are not designed for use in abrasive media. If these sensors are nevertheless used

in such applications, avoid direct flow to the chip. This increases the sensor operating life and

improves the sensor drift behavior. The disadvantage is that the pH value displayed is not

stable.

8 Endress+Hauser

Page 9

Memosens CPS77D

A

B

Installation instructions

ISFET sensors can be installed in any position because there is no liquid inner lead. However, in the

event of upside-down installation an air bubble

1)

may form in the reference system and interrupt

the electrical contact between the medium and the junction.

The installed sensor should remain in dry

conditions for a maximum of 6 hours (also

applies to upside-down installation).

Make sure to follow the installation

instructions in the Operating Instructions of the

assembly used.

A0030407

9 Angle of installation

A Recommended

B Permitted, please pay careful attention to basic

conditions!

1) The sensor is free of air bubbles when delivered from the factory. Air bubbles occur, however, when

working with negative pressure, e.g. when emptying a tank.

Environment

Ambient temperature range NOTICE

Risk of damage from frost!

Do not use the sensor at temperatures below –15 °C (5 °F) .

‣

Storage temperature

Degree of protection

0 to 50 °C (32 to 122 °F)

Memosens

IP 68 (10 m (33 ft) water column, 25 °C (77 °F), 45 days, up to 135 °C (275 °F)) autoclavable

Electromagnetic compatibility (EMC)

Interference emission and interference immunity as per

• EN 61326-1:2013

• EN 61326-2-3:2013

• NAMUR NE21: 2012

Sensitivity to light

Like all semiconductor components, the ISFET chip is sensitive to light. The measured value may

fluctuate. For this reason, avoid direct sunlight during calibration and operation. Normal ambient

light does not have any significant effect on the measurement.

Process

Process temperature range t

a

–15 to 70 °C (5 to 158 °F)

t

p

–15 to 135 °C (5 to 275 °F)

Endress+Hauser 9

Page 10

Memosens CPS77D

0

0 2 4 6 8

° C

pH

° F

80

60

40

20

100

120

32

68

104

140

176

212

248

12

14

10

A

B

C

Medium temperature depending on the pH value

At high temperatures, alkalis can irreversibly damage the gate insulator oxide over the longer term.

The sensor can only be used in the marked range (→ 10, 10) to the detriment of the sensor

operating life. If permanently exposed to 1 molar NaOH at temperatures over 65 °C (149 °F), the

sensor operating life is reduced to such an extent that permanent operation in this range is not

recommended.

Process pressure range

Conductivity

Pressure-temperature ratings

10 Area of application depending on the temperature and pH value

A Can be used without any problems

B Limited operating life

C Use not recommended

Operation at low temperatures

Sensor range of application according to the order code. Ordering information → 12

Max. 11 bar (abs.)/100 °C (160 psi (abs.)/212 °F)

0.8 bar (12 psi)(abs.) is possible as minimum.

Minimum conductivity

2)

: 50 μS/cm

Max. 11 bar (abs.)/100 °C (160 psi (abs.)/212 °F)

Sterilizable: 4 bar (abs.)/135 °C (58 psi (abs.)/275 °F), 1 h

A0037987

2) Reference conditions: Demineralized water as the measuring medium whose conductivity has been adjusted with NaOH, KCI or HCI; room

temperature; unpressurized sensor operation; change between stationary medium and flow to the sensor with 2 m/s (6.6 ft/s) fluid velocity with

lateral medium flow in the direction of the ISFET chip; the conductivity value indicated is the value determined when the measured value changes

by less than 0.2 pH in all media between stationary media and flowing media.

10 Endress+Hauser

Page 11

Memosens CPS77D

4

100

11

° F

psi

160

212

275

135

58

1

15

° C

bar (abs.)

ISFET application range

12

(0.47)

120

(4.7)

5.7

(0.22)

50

(2)

A0036111-EN

11 Pressure-temperature rating

Design, dimensions

NOTICE

Risk of damage to electrode!

Never use the electrode outside of the listed specifications!

‣

Mechanical construction

12 Dimensions. Dimensions: mm (in)

Weight

CPS77D length 2 (120 mm (4.7 in)):

35.4 g (1.25 oz)

CPS77D length 4 (225 mm (8.7 in)): 50.3 g (1.77 oz)

CPS77D length 5 (360 mm (14.2 in)): 66 g (2.3 oz)

Endress+Hauser 11

A0036053

Page 12

Materials Materials in contact with the medium

Sensor shaft PEEK (FDA, 3-A)

Seals FFKM (FDA, 3-A)

Junction Ceramic, suitable for sterilization

Materials not in contact with the medium

Temperature sensor

Pt1000 (Class A according to DIN IEC 60751)

Plug-in head

CPS77D:

Memosens, rotatable

Process connections

Pg 13.5

Memosens CPS77D

Surface roughness

Ra < 0.76 µm (30 µin)

Certificates and approvals

mark

Sanitary compatibility 3-A

The product meets the requirements of the harmonized European standards. As such, it complies

with the legal specifications of the EU directives. The manufacturer confirms successful testing of the

product by affixing to it the mark.

Certified according to 3-A Standard No. 74-06

FDA compatibility

The manufacturer declares the use of FDA-listed materials.

EHEDG

Compliance with EHEDG's criteria for hygienic design

• Technical University of Munich, Research Center for Brewing and Food Quality, Freising-

• Certificate type: Type EL Class I aseptic

ASME BPE-2018

Designed in accordance with ASME criteria (American Society of Mechanical Engineers)

Weihenstephan

Regulation (EC) No. 1935/2004

Meets the requirements of Regulation (EC) No. 1935/2004

Biocompatibility

Biocompatibility successfully tested with regard to

• Biological reactivity, in vitro (cytotoxicity) according to USP <87>

• Biological reactivity, in vivo according to USP <88> Class VI, 121 °C (250 °F)

Ordering information

www.endress.com/CPS77D

12 Endress+Hauser

Page 13

Memosens CPS77D

Accessories

Device-specific accessories Transmitter

Liquiline CM42

• Modular two-wire transmitter for hazardous and non-hazardous areas

• Hart®, PROFIBUS or FOUNDATION Fieldbus possible

• Order according to product structure

Technical Information TI00381C

Liquiline CM44

• Modular multi-channel transmitter for hazardous and non-hazardous areas

• Hart®, PROFIBUS, Modbus or EtherNet/IP possible

• Order according to product structure

Technical Information TI00444C

Cleaning and calibration system

Liquiline Control CDC90

• Fully automatic cleaning and calibration system for pH and ORP measuring points in all industries

• Cleaned, validated, calibrated and adjusted

• Product Configurator on the product page: www.endress.com/cdc90

Technical Information TI01340C

Assemblies (selection)

Dipfit CPA111

• Immersion and installation assembly made of plastic for open and closed vessels

• Product Configurator on the product page: www.endress.com/cpa111

Technical Information TI00112C

Cleanfit CPA871

• Flexible process retractable assembly for water, wastewater and the chemical industry

• For applications with standard sensors with 12 mm diameter

• Product Configurator on the product page: www.endress.com/cpa871

Technical Information TI01191C

Cleanfit CPA875

• Retractable process assembly for sterile and hygienic applications

• For in-line measurement with standard sensors with 12 mm diameter, e.g. for pH, ORP, oxygen

• Product Configurator on the product page: www.endress.com/cpa875

Technical Information TI01168C

Cleanfit CPA450

• Manual retractable assembly for installing sensors with a diameter of 120 mm in tanks and pipes

• Product Configurator on the product page: www.endress.com/cpa450

Technical Information TI00183C

Flowfit CPA250

• Flow assembly for pH/ORP measurement

• Product Configurator on the product page: www.endress.com/cpa250

Technical Information TI00041C

Unifit CPA842

• Installation assembly for food, biotechnology and pharmaceutics

• With EHEDG and 3A certificate

• Product Configurator on the product page: www.endress.com/cpa442

Technical Information TI00306C

Endress+Hauser 13

Page 14

Memosens CPS77D

Buffer solutions

High-quality buffer solutions from Endress+Hauser - CPY20

The secondary buffer solutions have been referenced to primary reference material of the PTB

(German Federal Physico-technical Institute) or to standard reference material of NIST (National

Institute of Standards and Technology) according to DIN 19266 by a laboratory accredited by the

DAkkS (German accreditation body) according to DIN 17025.

Product Configurator on the product page: www.endress.com/cpy20

Measuring cable

Memosens data cable CYK10

• For digital sensors with Memosens technology

• Product Configurator on the product page: www.endress.com/cyk10

Technical Information TI00118C

Memosens laboratory cable CYK20

• For digital sensors with Memosens technology

• Product Configurator on the product page: www.endress.com/cyk20

Software

Memobase Plus CYZ71D

• PC software to support laboratory calibration

• Visualization and documentation of sensor management

• Sensor calibrations stored in database

• Product Configurator on the product page: www.endress.com/cyz71d

Technical Information TI00502C

Handheld instrument

Liquiline To Go CYM290, CYM291

• Portable multiparameter device for Memosens pH, conductivity and oxygen sensors

• Product Configurator on the product page: www.endress.com/cym290, www.endress.com/cym291

Technical Information TI01198C

Refer to the Operating Instructions for CYM290 or CYM291 for information on the sensors that

can be connected.

14 Endress+Hauser

Page 15

Page 16

www.addresses.endress.com

Loading...

Loading...