Page 1

TI00374C/07/EN/13.13

71212355

Products Solutions Services

Technical Information

Ceragel CPS72 and CPS72D

ORP electrodes, analog and digital with Memosens

technology

For process technology, hygienic and sterile applications

with poison-resistant reference with ion trap

Application

• Hygienic and sterile applications (sterilizable, autoclavable)

–Fermenters

– Biotechnology

– Pharmaceutical industry

– Food industry

• Process technology and monitoring of processes with:

– Rapidly changing ORP measured values

– High proportion of electrode poisons such as H

With ATEX, FM and CSA approval for use in hazardous areas

Your benefits

• Certified biocompatibility, no cytotoxicity

• Acrylamide-free bridging electrolyte

• Integrated temperature sensor in the case of Memosens

• Poison-resistant reference with ion trap, resulting in a very long service life

• Bridging electrolyte free of silver ions

• Suitable for CIP/SIP cleaning and autoclavable, depending on version up to 140 ˚C

(284 °F)

S

2

Page 2

Function and system design

Measuring principle ORP measurement

The oxidation-reduction potential is an indicator of the equilibrium between oxidizing and reducing

substances in the medium. The oxidation-reduction potential is measured with a gold or platinum

electrode instead of the pH-sensitive glass membrane. As in the case of pH measurement, an

integrated Ag/AgCl reference system is used as the reference electrode.

General characteristics • Short response times

The ceramic junction allows sufficiently fast diffusion of the medium, thereby enabling short

response times.

• Long service life

Use of an ion trap as standard ensures that the reference is protected against poisoning, results in a

significantly longer service life and guarantees immunity to temperature and pressure fluctuations.

The ion trap also effectively prevents the diffusion of silver ions into the bridging electrolyte.

CPS72/CPS72D

Communication and data processing CPS72D

CPS72D dependability Maximum process safety

Measuring system data which digital sensors can save in the sensor include:

• Manufacturer data

– Serial number

–Order code

–Date of manufacture

• Calibration data

– Date of calibration

– Calibrated offset ("mV" measuring mode)

– % slope ("%" measuring mode)

– Number of calibrations

– Serial number of the transmitter used to perform the last calibration

• Operating data

– Temperature application range

– ORP area of application

– Date of initial commissioning

–Operating hours

You can display the data listed above using the Liquiline CM44x or Liquiline M CM42 transmitter.

With its inductive transmission of the measured value via a non-contact plug-in connection,

Memosens guarantees maximum process safety and offers the following advantages:

• All problems caused by moisture are eliminated:

– The plug-in connection is free from corrosion

– Moisture cannot corrupt the measured value

– Plug-in system can even be connected under water

• The transmitter is galvanically decoupled from the medium.

This means there is no need to choose between "symmetrical high-impedance" or "unsymmetrical"

solutions and impedance converters when it comes to pH/ORP measurement.

• EMC safety is guaranteed by screening measures in the digital measured value transmission.

• Can easily be used in hazardous areas thanks to intrinsically safe electronics.

Memosens technology digitizes the measured values in the sensor and transmits them to the

transmitter via a non-contact connection in a way that is free from any potential interference. The

result:

• Automatic error message generation if the sensor fails or the connection between sensor and

transmitter is interrupted

• Immediate error detection increases measuring point availability

2

Page 3

CPS72/CPS72D

Ease of use

Sensors with Memosens technology have integrated electronics that save calibration data and other

information, such as total hours of operation and operating hours at very high temperatures etc. When

the sensor is mounted, the sensor data are automatically sent to the transmitter and used to calculate

the current ORP potential.

Saving the calibration data makes it possible to calibrate and adjust the sensor irrespective of the

measuring point. The result:

• Convenient calibration in the measuring lab under optimum external conditions improves the

quality of the calibration.

• Measuring point availability is dramatically increased by the quick and easy replacement of

precalibrated sensors.

• Installing the transmitter in the measuring container with integrated measuring devices reduces the

amount of fastening material and cabling work required.

• The availability of the sensor data makes it possible to accurately determine the maintenance

intervals of the measuring point and enables predictive maintenance.

• The sensor history can be documented with external storage media and evaluation programs. The

sensor's field of application can be determined based on its previous history.

Communication with the transmitter

Always connect digital sensors with Memosens technology to a transmitter with Memosens

technology. It is not possible to transfer data to a transmitter for analog sensors.

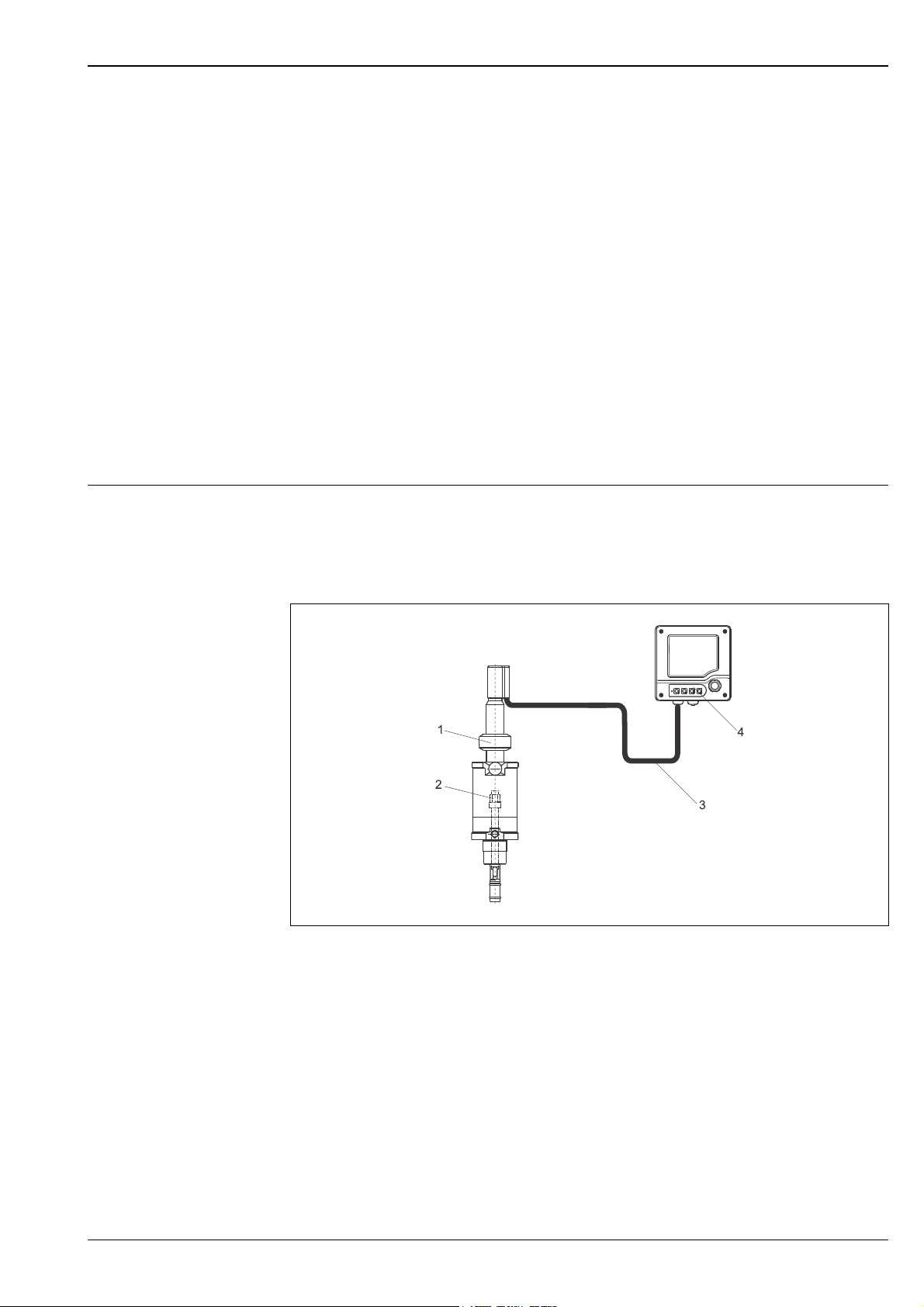

Measuring system A complete measuring system comprises:

• ORP electrode CPS72 or CPS72D

• Transmitter, e.g. Liquiline CM42 or Liquiline CM44x (for CPS72D with Memosens technology)

• Special measuring cable. e.g. CPK9 or Memosens data cable CYK10 for CPS72D

• Immersion, flow or retractable assembly, e.g. Cleanfit H CPA475

Fig. 1: Measuring system for ORP measurement

1 Process assembly Cleanfit H CPA475

2 ORP electrode CPS72 / CPS72D

3 Special measuring cable CPK9 (for electrodes with TOP68 plug-in head) / CYK10 for digital sensors

4 Liquiline CM42 transmitter

a0003706

3

Page 4

Input

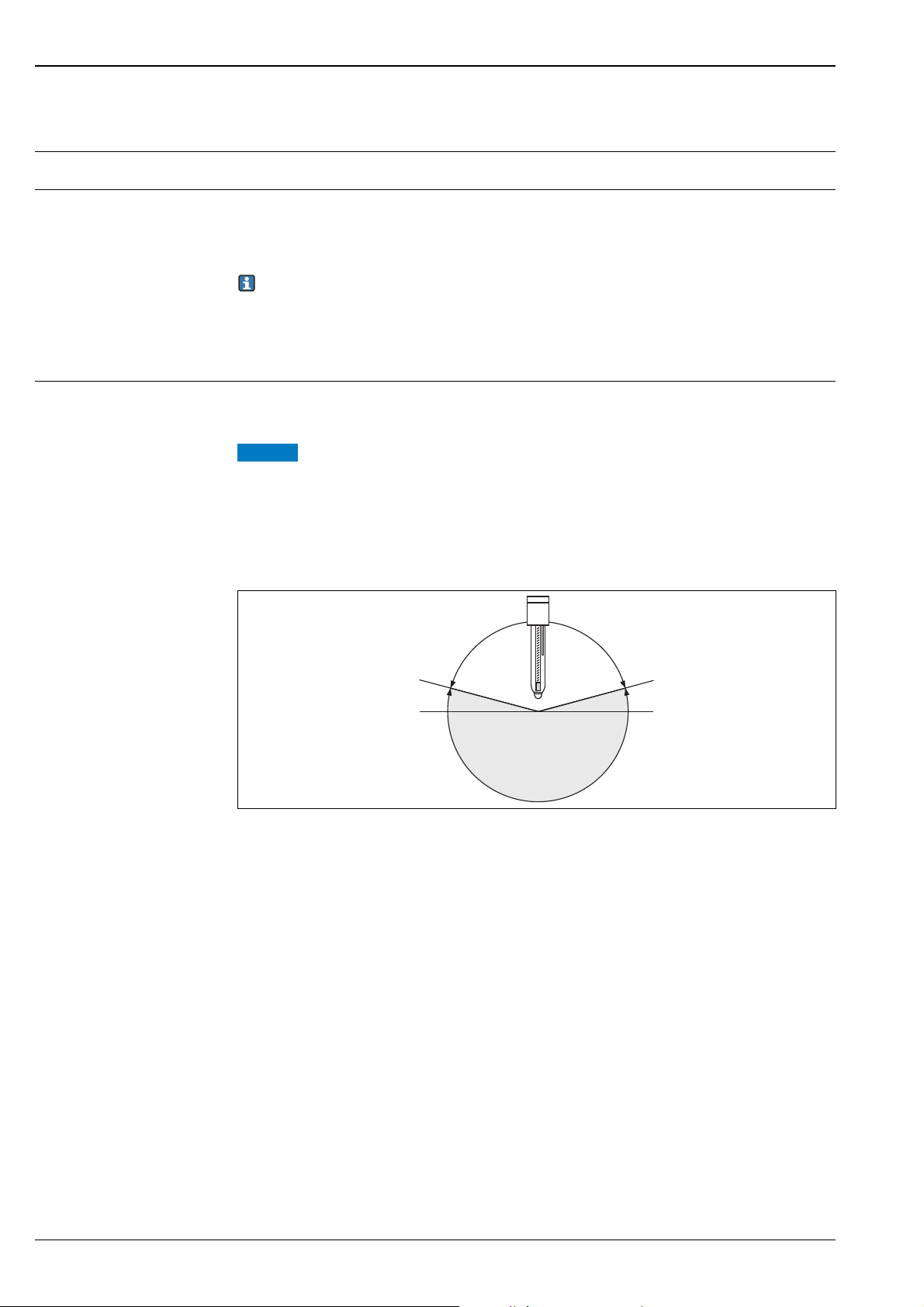

NOTICE

15°

15°

A

B

Measured variables ORP

CPS72/CPS72D

Measuring range

ORP -1500 to 1500 mV

Temperature: -15 to 140 ˚C (5 to 284 ˚F)

0 to 135 ˚C (32 to 275 ˚F) for sensors with Ex approval and analog sensors

Pay attention to the application conditions in the process.

Installation

Installation instructions Do not install the electrodes upside down. The inclination angle must be at least 15° from the

horizontal. A smaller installation angle is not permitted as it could cause an air bubble to form,

preventing contact between the reference and the reference lead.

Before screwing in, make sure the threaded connection of the assembly is clean and runs

smoothly.

‣ Screw in the electrode finger-tight (3 Nm)! (Information valid only when installing in

Endress+Hauser assemblies.)

‣ Also pay attention to the installation instructions provided in the Operating Instructions of the

assembly used.

a0003686

Electrode installation; installation angle at least 15˚ from the horizontal

A Permitted orientation

B Forbidden orientation

4

Page 5

CPS72/CPS72D

NOTICE

CAUTION

!

NOTICE

Environment

Ambient temperature range

Risk of damage due to frost

‣ The sensor must not be used at temperatures below –15 ˚C (5 ˚F).

Storage temperature 0 to 50 ˚C (32 to 120 ˚F)

Degree of protection

Process temperature range

Process pressure (absolute)

Pressure-temperature ratings

IP 67: GSA plug-in head (with closed connector system)

IP 68: ESA plug-in head (1 m (3.3 ft) water column, 50 ˚C (120 ˚F), 168 h)

IP 68: Memosens plug-in head (10 m (33 ft) water column, 25 ˚C (77 ˚F), 45 days, 1 M KCl)

Process

-15 to 140 ˚C (5 to 284 ˚F)

-15 to 135 ˚C (5 to 275 ˚F) for sensors with Ex approval and analog sensors

0.8 to 11 bar (12 to 160 psi)

Sensor is exposed to pressure when used for longer periods under increased process pressure

Risk of injury due to glass breakage

‣ Do not apply too much heat to sensors of this type if they are being used under reduced process

pressure or under atmospheric pressure.

‣ Wear protective goggles and suitable gloves when handling this type of sensor.

a0020349

Pressure-temperature ratings

Application Hygienic and sterile applications, but also applications such as chromate reduction and chlorine

metering in swimming pools

Risk of damage to electrode

‣ Never use the electrode outside of the listed specifications!

5

Page 6

Design, dimensions CPS72

CPS72/CPS72D

Mechanical construction

Design, dimensions CPS72D

CPS72 with GSA plug-in head, dimensions in mm (inch)

1 GSA electrode plug-in head, Pg 13.5

2 Viton O-ring with thrust collar

3 External reference lead with ion trap

4Diaphragm

5Ag wire

6 Platinum element

a0020432

CPS72 with ESA plug-in head, dimensions in mm (inch)

1 ESA electrode plug-in head, Pg 13.5

2 Viton O-ring with thrust collar

3 External reference lead with ion trap

4Diaphragm

5Ag wire

6 Platinum element

a0020433

a0020434

CPS72D with Memosens plug-in head, dimensions in mm (inch)

1 Memosens plug-in head

2 Viton O-ring with thrust collar

3 External reference lead with ion trap

4 Temperature sensor

5Diaphragm

6Ag wire

7 Platinum element

6

Page 7

CPS72/CPS72D

Weight 0.1 kg (0.22 lbs)

Materials

Process connection Pg 13.5

Temperature sensor

Plug-in heads

Reference system Ag/AgCl reference lead with gel, acrylamide-free bridging electrolyte, non-cytotoxic, AgCl-free, ion

Electrode shaft Glass to suit process

Metal lead Ag/AgCl

Junction Ceramic, sterilizable and autoclavable

ORP-sensitive element Platinum

Gel Bridging electrolyte acrylamide-free, no cytotoxicity

In contact with medium polyacrylamide-free

CPS72D: NTC 30K

CPS72:

ESA: Threaded plug-in head Pg 13.5, TOP68, 16 bar (232 psi), Ex

GSA: Threaded plug-in head Pg 13.5, non-Ex

CPS72D: Memosens plug-in head for digital, non-contact data transmission, 16 bar (232 psi),

Ex or non-Ex

trap

Certificates and approvals

Ex approval CPS72 (ESA) and CPS72D

Biocompatibility Biocompatibility certified in accordance with:

TÜV certificate ESA and Memosens plug-in head

Electromagnetic compatibility CPS72D

ATEX/NEPSI

• II 1G Ex ia IIC T3/T4/T6 Ga

FM/CSA

• IS/NI CL. I. Div 1, Group A-D

IECEx

• Ex ia IIC T3/T4/T6 Ga

• ISO 10993?5:1993

• USP <87>, agar diffusion test and decoloration test

Pressure resistance 16 bar (232 psi), process overpressure minimum three times the safety pressure

Interference emission and interference immunity as per EN 61326: 2006

7

Page 8

CPS72/CPS72D

Ordering information

Product page You can create a valid and complete order code on the Internet with the Configurator tool.

Enter the following addresses in the browser to access the relevant product page:

www.endress.com/cps72

www.endress.com/cps72d

Product structure

The navigation area is located on the right of the product page.

1. Under "Device support" click "Configure your selected product".

The Configurator opens in a separate window.

2. Configure the device as per your requirements by selecting all the options.

This results in a valid and complete order code.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button at the top of the

screen.

8

Page 9

CPS72/CPS72D

Accessories

The most important accessories available at the time this document went to print are listed below.

Contact your service department or sales center for accessories that are not listed here.

Assemblies Cleanfit W CPA450

• Manual retractable assembly for pH/ORP electrodes for installation of 120 mm electrodes in tanks

and pipes

• Order according to product structure (-> online Configurator, www.endress.com/cpa450)

• Technical Information TI183C/07/EN

Cleanfit P CPA471

• Compact stainless steel retractable assembly for installation in tanks and pipes, for manual or

pneumatically remote -controlled operation

• Order according to product structure (-> online Configurator, www.endress.com/cpa471)

• Technical Information TI217C/07/EN

Cleanfit P CPA472

• Compact plastic retractable assembly for installation in tanks and pipes, for manual or pneumatically

remote-controlled operation

• Order according to product structure (-> online Configurator, www.endress.com/cpa472)

• Technical Information TI223C/07/EN

Cleanfit P CPA472D

• Robust retractable assembly for pH, ORP and other industrial sensors, for manual or pneumatically

remote-controlled operation, heavy?duty version made from very durable materials

• Order according to product structure (-> online Configurator, www.endress.com/cpa472d)

• Technical Information TI403C/07/EN

Cleanfit P CPA473

• Stainless steel process retractable assembly with ball valve shutoff for particularly reliable separation

of the medium from the environment

• Order according to product structure (-> online Configurator, www.endress.com/cpa473)

• Technical Information TI344C/07/EN

Cleanfit P CPA474

• Plastic process retractable assembly with ball valve shutoff for particularly reliable separation of the

medium from the environment

• Order according to product structure (-> online Configurator, www.endress.com/cpa474)

• Technical Information TI345C/07/EN

Cleanfit H CPA475

• Retractable assembly for pH/ORP measurement in tanks and pipes under sterile measuring

conditions

• Order according to product structure (-> online Configurator, www.endress.com/cpa475)

• Technical Information TI240C/07/EN

Unifit H CPA442

• Process assembly for food, biotechnology and chemicals; for 120 mm electrodes

• Order according to product structure (-> online Configurator, www.endress.com/cpa442)

• Technical Information TI306C/07/EN

Dipfit W CPA111

• Immersion and installation assembly made of plastic for open and closed containers

• Order according to product structure (-> online Configurator, www.endress.com/cpa111)

• Technical Information TI112C/07/EN

Dipfit P CPA140

• pH/ORP immersion assembly with flange connection for very demanding processes

• Order according to product structure (-> online Configurator, www.endress.com/cpa140)

• Technical Information TI178C/07/EN

Flowfit P CPA240

• pH/ORP flow assembly for very demanding processes

• Order according to product structure (-> online Configurator, www.endress.com/cpa240)

• Technical Information TI179C/07/EN

9

Page 10

Flowfit W CPA250

• Flow assembly for pH/ORP measurement

• Order according to product structure (-> online Configurator, www.endress.com/cpa250)

• Technical Information TI041C/07/EN

Ecofit CPA640

• Set comprising adapter for 120 mm pH sensors and sensor cable with TOP68 coupling

• Order according to product structure (-> online Configurator, www.endress.com/cpa640)

• Technical Information TI264C/07/EN

Buffer solutions Technical ORP buffer solutions

• +220 mV, pH 7, 100 ml (3.4 fl.oz.); Order No. CPY3-0

• +468 mV, pH 0.1, 100 ml (3.4 fl.oz.); Order No. CPY3-1

Measuring cable Measuring cable

• For sensors with ESA plug-in head, for high-temperature and high-pressure applications, IP 68

• Order according to product structure

• Technical Information TI00501C/07/EN

Special measuring cable CPK1

• For pH/ORP electrodes with GSA plug-in head

• Order according to product structure

• Technical Information TI00501C/07/EN

Memosens data cable CYK10

• For digital sensors with Memosens technology

• Order according to product structure (-> online Configurator, www.endress.com/cyk10)

• Technical Information TI00118C/07/EN

Versions of the CYK10 that are suitable for use in hazardous areas are marked by an orange/red

coupling end element.

CPS72/CPS72D

10

Page 11

CPS72/CPS72D

11

Page 12

www.addresses.endress.com

Loading...

Loading...