Endress+Hauser CPA875 Specifications

TI01168C/07/EN/03.16

71323650

Products Solutions Services

Technical Information

Cleanfit CPA875

Retractable process assembly for sterile and hygienic

applications for in-line measurement with standard 12

mm sensors for parameters such as pH, ORP, oxygen and

NIR

Application

The modular retractable assembly has been consistently

developed with safety in mind:

• Safety in operation

• Safety during cleaning for hygienic processes

• Protection against contamination in sterile processes

The assembly is therefore perfectly suitable for use in the

following industries:

• Food and beverages

• Biotechnology

• Life sciences

• Special chemicals

Your benefits

• Maximum availability with minimum maintenance

• Safe measurement and accurate measured values

• Higher product quality thanks to reliable measurement

results

• Modular design ensures investment is secure

• EHEDG-certified assembly: process connection and service

chamber

• Features certified to FDA and USP Class VI

Function and system design

Cleanfit CPA875

Mode of operation

Design

Safety function

With the Cleanfit CPA875 retractable assembly, you can carry out pH, ORP, oxygen and other

measurements reliably using suitable sensors. You can remove, clean, sterilize or calibrate/adjust the

sensors without interrupting the process.

The assembly can be installed in both vessels and pipes.

The retractable assembly has a modular design and can therefore be flexibly adapted to a wide array

of applications. It is available with both a manual and a pneumatic drive.

A choice of two chamber systems is available for the assembly:

• Single-chamber system with a service chamber or

• double-chamber system with an "inner" service chamber and a "front" service chamber

It is possible to choose between the following strokes for the electrode guide:

• 36 mm for flow housing, for example, and

• 78 mm for installation in vessels, for example

This minimizes boundary effects both in the event of flow and in the event of measured values in

cooled or heated vessels.

All common process connections are available:

Clamp / Aseptic DIN 11864 / BioControl / BioConnect / Dairy fitting / ISO228 Thread / Varivent

Locking mechanism without sensor

If the sensor is not installed, it is not possible to pneumatically or manually move the assembly from

the service position to the measuring position.

Manual or pneumatic drive

The sensor can be driven both manually and pneumatically. The manual drive has a self-retaining

thread to hold the sensor in any intermediate position. The manual drive can be used for process

pressures up to 8 bar (116 psi). The pneumatic drive can be used for process pressures up to

16 bar (232 psi).

Limit position locking if compressed air fails

If the compressed air fails in pneumatic assemblies, the assembly remains in the position previously

selected. The process pressure cannot force it out of the measuring position and into an intermediate

position.

Limit position locking with manual drive

For position locking, the manual version has an unlocking button in both the measuring position and

the service position.

Impossible to remove sensor in the measuring position

The protection cap for covering the sensor has the following functions:

– Mechanical sensor safety

– Prevents sensor removal in the assembly measuring position

The bottom part of the protection cap is partly inserted into the drive and cannot be opened as a

result.

Non-rotating sensor guide

During insertion/retraction, the position of the ridges of the immersion tube in the area of the

sensor head retains the pre-setting once selected. This guarantees optimum and clear positioning of

the sensor in the process and during cleaning.

Limit position detection (can be retrofitted)

In the case of assemblies with a pneumatic drive, the service and measuring position of the sensor

are detected inductively and reported to connected systems (only for the measuring position in the

case of the manual drive assembly).

Cleaning

Medium drains completely out of "inner" service chamber and the "front" service chamber"

If the assembly is mounted in an angle of up to 15° to the horizontal, the cleaning medium can drain

off completely, without leaving any residue.

Special process seal without openings

Special, patented aseptic seals are used to avoid any openings that cannot be cleaned. These meet

the same hygienic requirements as pipe connections used in corresponding applications (not for NA

process connection).

2 Endress+Hauser

Cleanfit CPA875

Certified materials

All sealing materials that are in contact with the medium are FDA-certified and meet USP Class VI

specifications.

Electropolished materials 1.4435 (AISI 316 L)

All metal parts that are in contact with the medium have a surface roughness of Ra <0.76 µm or

optionally Ra <0.38 µm.

The Cleanfit CPA875 assembly has been developed to meet cleanability and sterility demands.

Both versions feature different sealing principles to meet these requirements.

• Double-chamber system with sensor cleaning in the "front" service chamber and single-chamber

system for certified cleanability

• Double-chamber system with sensor cleaning in the "inner" service chamber for certified

cleanability and sterility

Certified cleanability

Certified sterility

EHEDG-certified sterilisability

The assembly, including the service chamber and process connection, can be sterilized according to

EHEDG specifications.

EHEDG-certified cleanability of service chamber and process seal

In connection with process seal cleaning in a defined third rest position, the assembly, along with the

service chamber and process adapter, have been designed according to the EHEDG guidelines for

cleanability and sterilizability and certified by the EHEDG. This certifies that residual medium is not

only destroyed but is also removed completely from the service chamber and the sealing surface

without leaving any residue. Therefore the service chamber and sealing surface are free from product

residue and microorganisms.

Safety in sterile processes with the CPA875 double-chamber system

Contamination-free assembly insertion/retraction thanks to dynamic sealing based on the

"syringe principle"

The moving seals in the "inner" service chamber of the double-chamber assembly prevent already

sterilized parts from being contaminated by still non-sterilized parts of the sensor guide. This rules

out the possibility of contamination of the service chamber, and ultimately the process, even with

strict sterility requirements.

Double-chamber system for safe separation between the process and service chamber

On-the-fly cleaning, recalibration and testing of the sensor in a process with sensitive medium

requires the reliable and safe separation of the service chamber from the process. For this purpose

the "front" chamber of the double chamber assembly can be exposed to sealing medium, for instance.

At the same time, this chamber isolates the temperature from the process. The sensor can therefore

be removed, calibrated/adjusted or simply cleaned and tested without affecting the process.

Endress+Hauser 3

Cleanfit CPA875

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

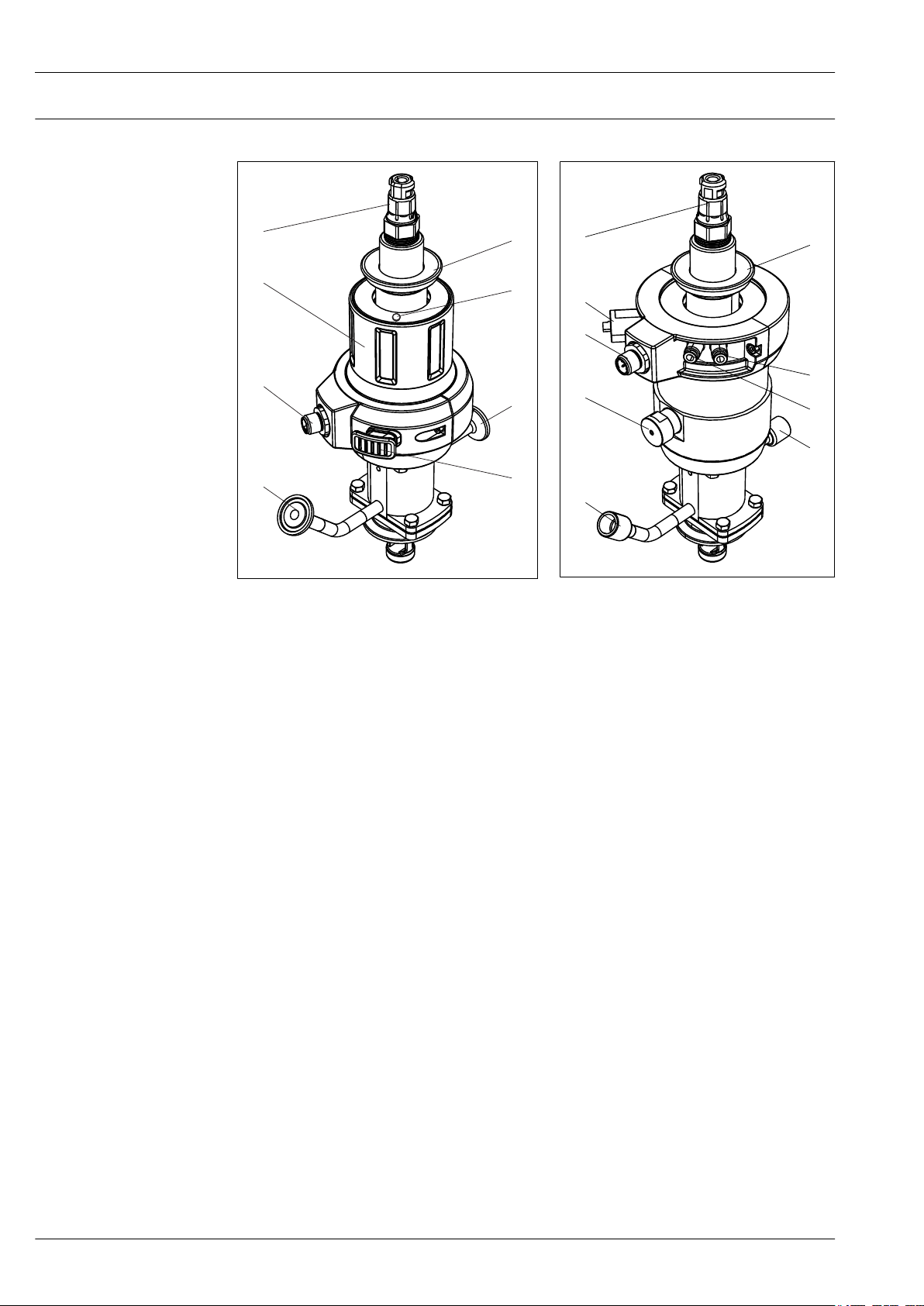

Elements

The assembly is available with a manual or pneumatic drive.

A0020086

1 Assembly with manual drive (without protection

cap)

1 Rinse connection

2 Connection for limit position switch

3 Manual drive

4 Sensor head

5 Fastening ring for protective cap

6 Unlocking button (service position)

7 Rinse connection

8 Unlocking button (measuring position)

2 Assembly with pneumatic drive (without

1 Rinse connection

2 Automatic limit position lock, process

3 Connection for limit position switch

4 Automatic limit position lock, service

5 Sensor head

6 Fastening ring for protective cap

7 Pneumatic connection (move to measuring

8 Pneumatic connection (move to service

9 Rinse connection

A0029435

protective cap)

position)

position)

4 Endress+Hauser

Cleanfit CPA875

2

2

A B

C

D

1

1

2

3

4

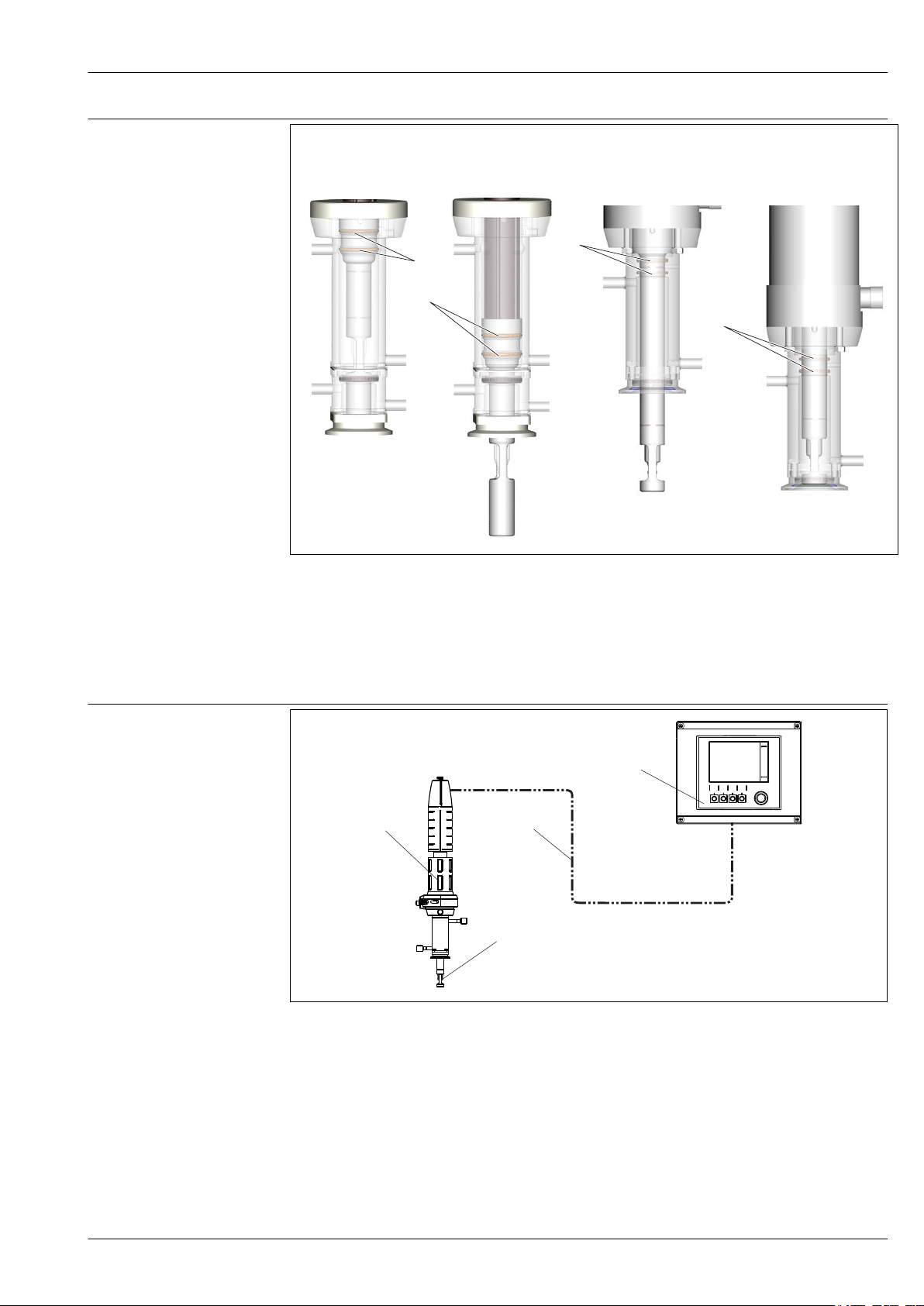

Sealing principle

Measuring system with single chamber

3 Sealing principle

A Double chamber in service position

B Double chamber in measuring position

C Single chamber in measuring position

D Single chamber in service position

1 "Moving" seals in the double chamber

2 "Fixed" seals in the single chamber

4 Measuring system (example)

1 Cleanfit assembly CPA875

2 Measuring cable

3 Liquiline CM44x transmitter

4 Sensor

A0021906

A0017811

Endress+Hauser 5

Measuring system with

3

4

1 2

3

5

6

6

7

8

11

12

21

22

31 32

double chamber

Cleanfit CPA875

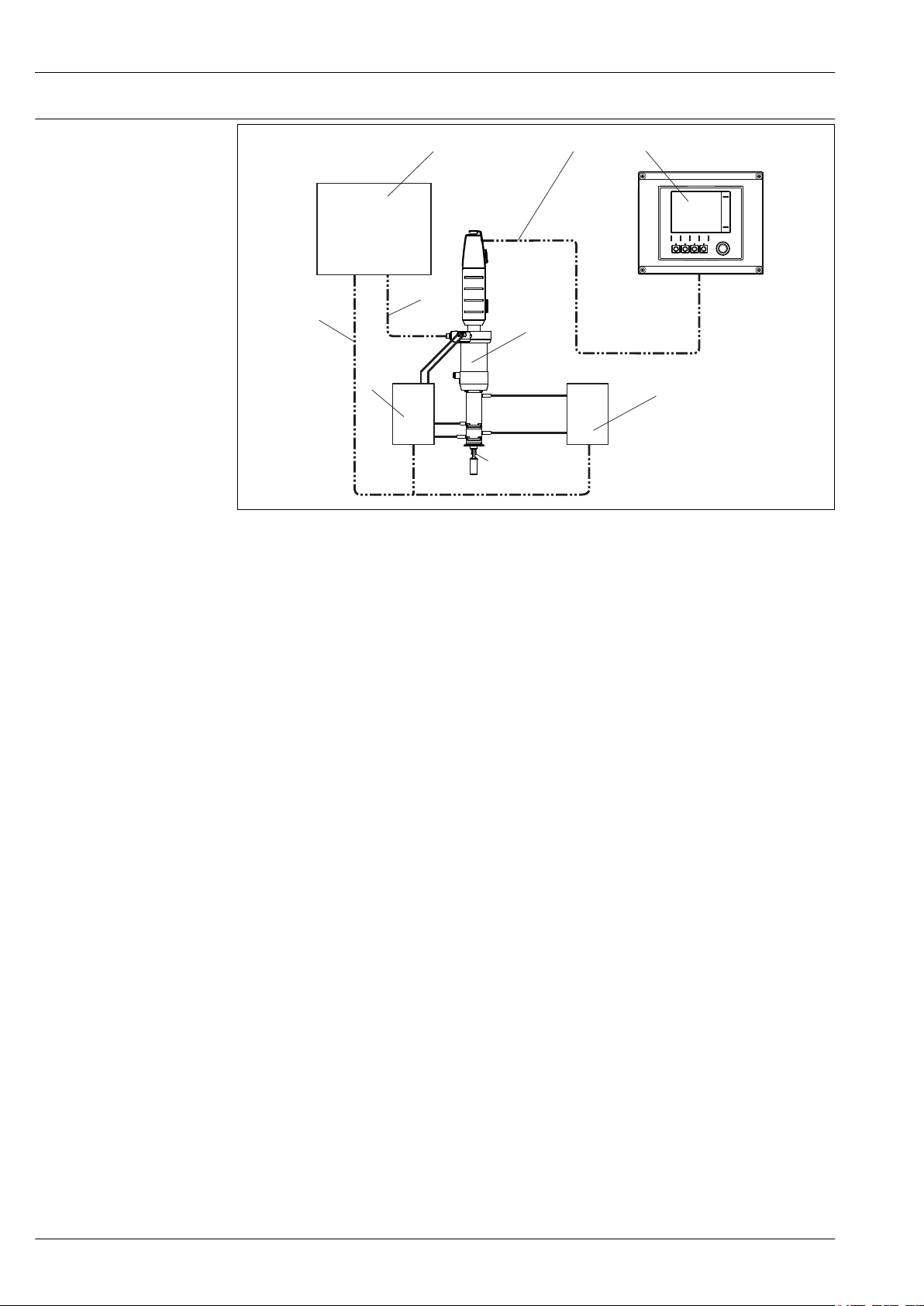

5 Measuring system with pneumatic drive and double chamber (example)

1

2 Measuring cable 8 Control signals (electric/pneumatic)

3 Liquiline CM44x transmitter 11/12 Inlet/outlet of "inner" service chamber

4 Cleanfit assembly CPA875 21/22 Inlet/outlet of "front" service chamber

5 Sensor 31/32 Drive control

6 Valve block

A0022821

Control unit 7 Limit position switch relay signal

6 Endress+Hauser

Cleanfit CPA875

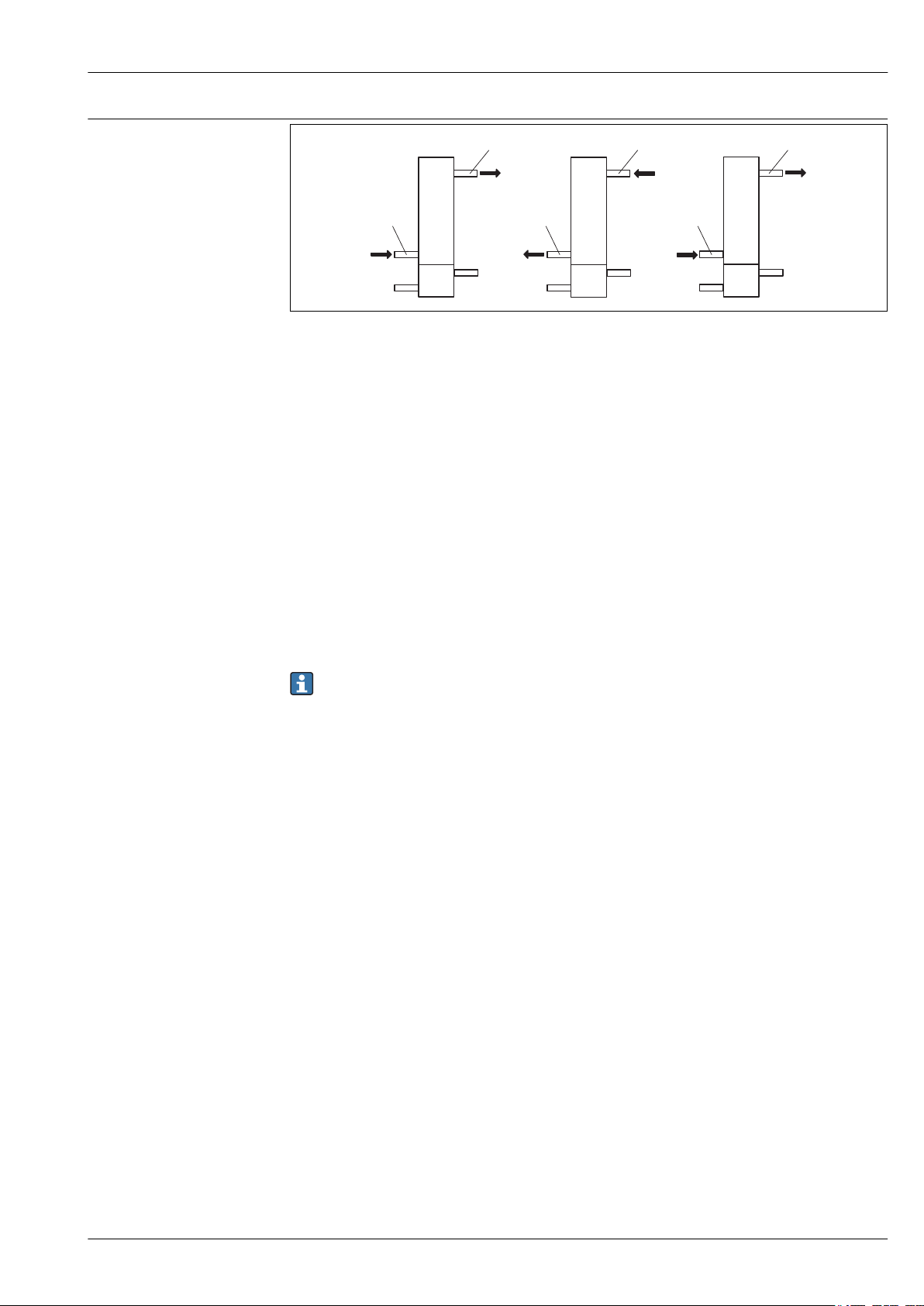

A B

C

1

2

1

2

1

2

Assignment of rinse connections for pressure compensation

A0022805

6 Assignment of rinse inlet and outlet

A "Cleaning" state

B "Move from service position to measuring position" state

C "Move from measuring position to service position" state

1 Inlet of "inner" service chamber

2 Outlet of "inner" service chamber

In the "Cleaning" state (A), the inlet and outlet of the "inner" service chamber are assigned as follows:

• Depending on the cleaning method, cleaning agent and purge gas are supplied via the inlet (1).

• These media are removed via the outlet (2).

In the "Move from service position to measuring position" state (B), the pressure conditions in the

"inner" service chamber must be balanced when moving. The inlet and outlet of the "inner" service

chamber are assigned as follows:

• The air is removed via the inlet (1) (inlet is open).

• The air is supplied via the outlet (2).

In the "Move from measuring position to service position" state (C), the pressure conditions in the

"inner" service chamber must be balanced when moving. The inlet and outlet of the "inner" service

chamber are assigned as follows:

• The air is supplied via the inlet (1).

• The air is removed via the outlet (2) (outlet is open).

The drive must be controlled simultaneously with the control of the inlets and outlets of the

"inner" service chamber.

The controller for the inlets, outlets and the drive is installed at the place of installation. It is

not included in the scope of delivery of the assembly.

The "front" service chamber can be cleaned as standard. Pressure compensation is not necessary here.

Endress+Hauser 7

Installation

Cleanfit CPA875

Orientation

Pneumatic connections for automatic operation

The assembly is designed for installation on tanks and pipes. Suitable process connections must be

available for this.

NOTICE

Frost damage to the assembly

If used outdoors, ensure that water cannot penetrate the drive.

‣

For 3-A-compliant installation, please observe the following:

After the device has been mounted, hygienic integrity must be guaranteed. To do so, the

leakage hole must be located at the lowest point on the device. In addition, 3-A-compliant

process connections must be used.

The assembly is designed in such a way that there are no restrictions with regard to the orientation.

The sensor that is used can restrict the orientation.

The "inner" service chamber and "front" service chamber can drain on their own with an

installation position of between 0° and 15° to the horizontal.

Prerequisites:

• Air pressure 4 to 7 bar (58 to 102 psi)

• Compressed air quality in accordance with ISO 8573-1:2001

Quality class 3.3.3 or 3.4.3

• Solids class 3 (max. 5 μm, max. 5 mg/m3, contamination with particles)

• Water content for temperatures ≥ 15 °C: class 4 pressure condensation point 3 °C or lower

• Water content for temperatures of 5 to 15 °C: class 3 pressure condensation point -20 °C or lower

• Oil content class 3 (max. 1 mg/m3)

• Air temperature: 5 °C or higher

• No continuous air consumption

• Minimum nominal diameter of air pipes: 2 mm (0.08 ")

Connection: Push-in fitting M5, hose 4/2 mm OD/ID (adapter for 6/4 mm OD/ID enclosed)

Damage to seals due to excessive air pressure!

If the air pressure can increase to more than 7 bar (102 psi) (even short pressure surges), a pressurereducing valve must be installed upstream.

Rinse connection

Ambient temperature range

Storage temperature

The service chamber connections of the sterile CPA875 retractable assembly make it possible to

clean the chamber and the sensor with water or a cleaning solution at a pressure of

6 bar (87 psi) max. or to sterilize it with steam (SIP).

The retractable assembly can be selected with a single- or double-chamber system. If the doublechamber system is used, all four connections must be connected to inlet and outlet pipes.

Seals can be damaged if the water pressure is too high.

Install an pressure-reducing valve upstream if there is a possibility that the water pressure will

increase to more than 6 bar (87 psi) (including any short pressure surges).

Environment

-10 to +70 °C (+10 to +160 °F)

-10 to +70 °C (+10 to +160 °F)

8 Endress+Hauser

Loading...

Loading...