Endress+Hauser CPA871 Operating Manual

BA01323C/07/EN/05.19

71439183

2019-04-30

Products Solutions Services

Operating Instructions

Cleanfit CPA871

Flexible retractable process assembly for water,

wastewater, chemical industry and heavy industry

Cleanfit CPA871 Table of contents

Table of contents

1 About this document ................ 4

1.1 Warnings ............................ 4

1.2 Symbols used .......................... 4

1.3 Symbols on the device ................... 4

2 Basic safety instructions ............ 5

2.1 Requirements for the personnel ............ 5

2.2 Designated use ........................ 5

2.3 Occupational safety ..................... 5

2.4 Operational safety ...................... 6

2.5 Product safety ......................... 6

3 Product description ................. 7

3.1 Product design ......................... 7

4 Incoming acceptance and product

identification ....................... 9

4.1 Incoming acceptance .................... 9

4.2 Scope of delivery ....................... 9

4.3 Product identification ................... 10

4.4 Certificates and approvals ............... 11

10.3 Flow vessel .......................... 55

10.4 Sensors ............................. 56

10.5 Absorption sensor ..................... 58

11 Technical data .................... 59

11.1 Environment ......................... 59

11.2 Process ............................. 59

11.3 Mechanical construction ................ 63

Index .................................. 64

5 Installation ....................... 12

5.1 Installation conditions .................. 12

5.2 Mounting the assembly ................. 18

5.3 Installing the sensor ................... 26

5.4 Post-installation check .................. 31

6 Commissioning .................... 32

7 Operation ......................... 33

7.1 Adapting the assembly to the process

conditions ........................... 33

8 Maintenance ...................... 36

8.1 Maintenance intervals .................. 36

8.2 Cleaning the assembly .................. 38

8.3 Cleaning the sensor .................... 38

8.4 Cleaning agent ....................... 39

8.5 Replacing seals ....................... 40

9 Repair ............................ 52

9.1 Spare parts .......................... 52

9.2 Return .............................. 52

9.3 Disposal ............................ 52

10 Accessories ....................... 53

10.1 Installation material for rinse connections ... 54

10.2 Cleaning systems ...................... 54

Endress+Hauser 3

About this document Cleanfit CPA871

1 About this document

1.1 Warnings

Structure of information Meaning

DANGER

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

NOTICE

Cause/situation

If necessary, Consequences of

non-compliance (if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to

property.

1.2 Symbols used

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

1.3 Symbols on the device

Symbol Meaning

Reference to device documentation

4 Endress+Hauser

Cleanfit CPA871 Basic safety instructions

2 Basic safety instructions

2.1 Requirements for the personnel

• Installation, commissioning, operation and maintenance of the measuring system may

be carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the

specified activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions

and must follow the instructions contained therein.

• Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

The Cleanfit CPA871 retractable assembly, which can be manually or pneumatically

operated, is designed for the installation of sensors in vessels and pipes.

Thanks to its design, it can be operated in pressurized systems (→ 59).

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.2.1 Use in explosion-proof areas

As a manufacturer of products used for analysis, we declare that the product supplied has

undergone an ignition risk assessment and may be used in hazardous atmospheres once

the following conditions for safe usage have been met:

• The protective ring is labeled as follows: "CAUTION, DANGER DUE TO ELECTROSTATIC

CHARGES, CLEAN USING ONLY AN ANTISTATIC CLOTH". This instruction must be

observed.

• Assemblies comprising wetted parts made of non-conductive material, must not be used

in potentially explosive atmospheres.

• The compressed air supply, sensors and limit position switches must comply with the

applicable guidelines and standards for use in hazardous atmospheres, be labeled with

the degree of protection and meet the requirements of the relevant range of application.

The ambient temperatures must be observed. The limit position switch used in the

product complies with this requirement.

• Ensure that the compressed air does not contain a potentially explosive atmosphere.

• Care must be taken to ensure that movements during insertion and retraction of the

sensor do not damage the connection.

• The product must be incorporated into the local potential equalization system.

• The Operating Instructions for the product and in particular the conditions for safe usage

must be read, understood and implemented.

The product does not need to be labeled with the degree of protection.

2.3 Occupational safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

Endress+Hauser 5

Basic safety instructions Cleanfit CPA871

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

During operation:

If faults cannot be rectified:

‣

products must be taken out of service and protected against unintentional operation.

2.5 Product safety

2.5.1 State of the art

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

European standards have been observed.

6 Endress+Hauser

Cleanfit CPA871 Product description

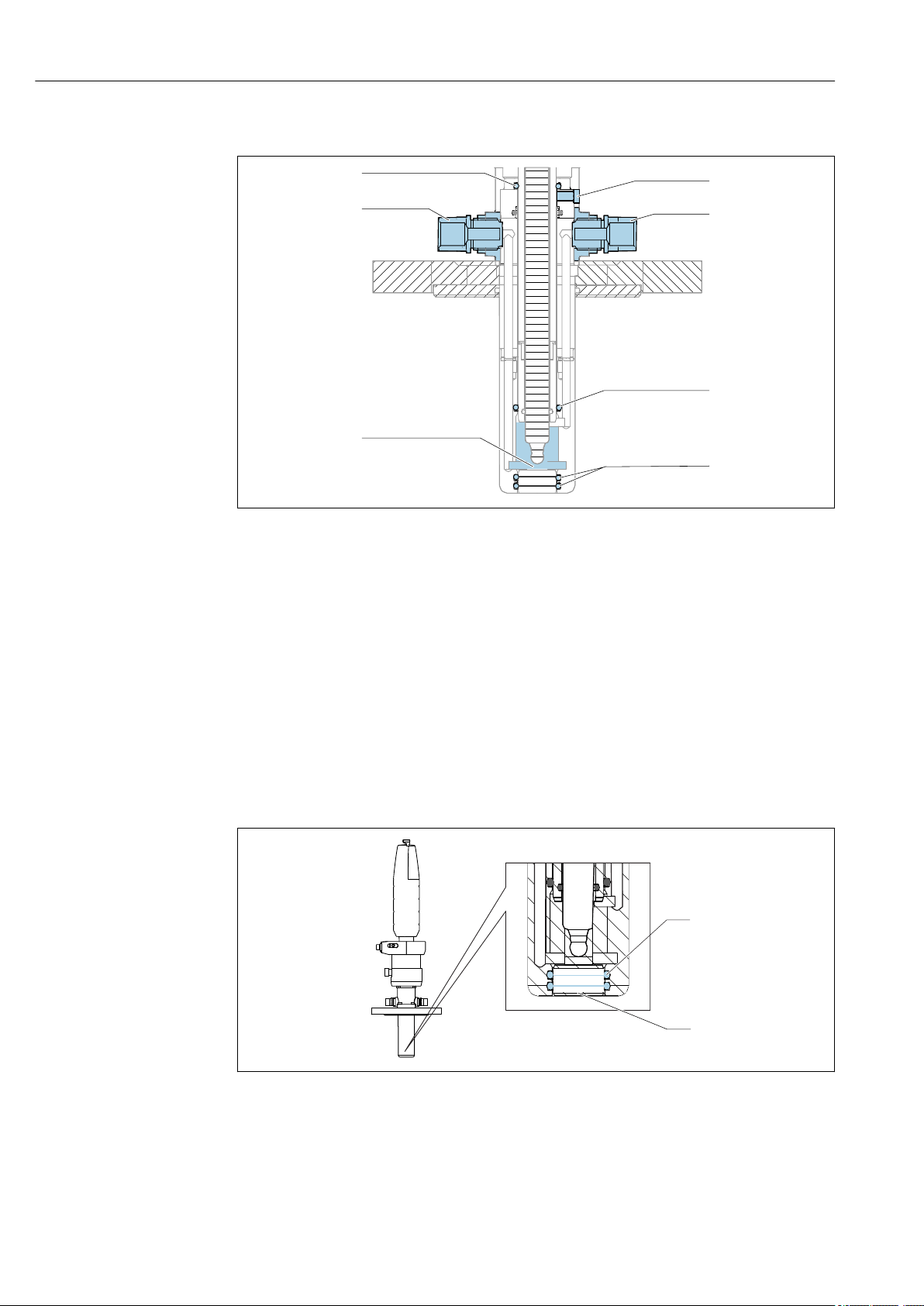

1

2

3

4

5

6

7

8

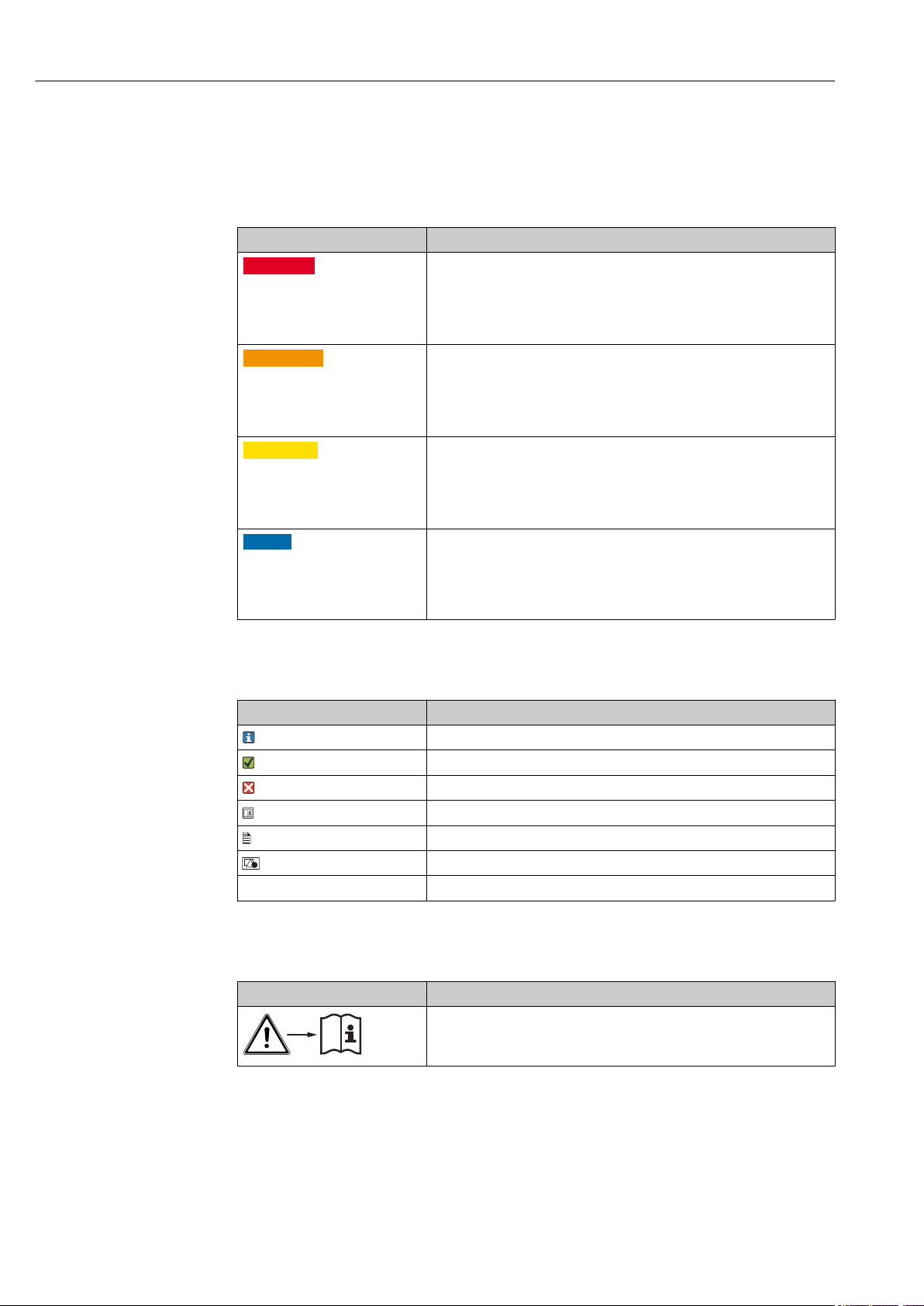

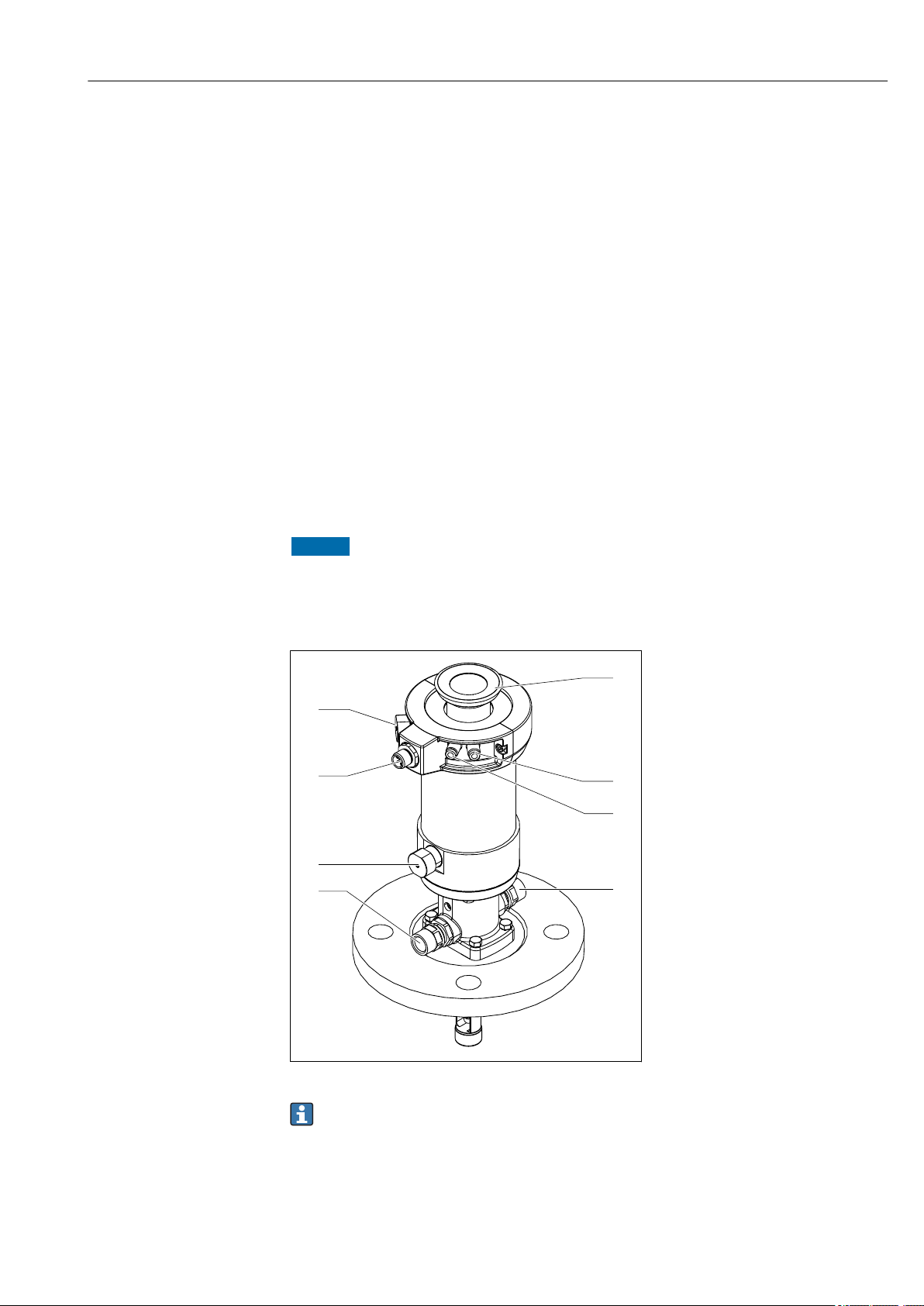

3 Product description

3.1 Product design

1 Rinse connection (outlet)

2 Automatic limit position lock,

process

3 Connection for limit position

switch

4 Automatic limit position lock,

service

5 Fastening ring for protective

cover

6 Pneumatic connection (move

to measuring position)

7 Pneumatic connection (move

to service position)

8 Rinse connection (inlet)

A0029614

1 Assembly with pneumatic drive (without protective cover)

Endress+Hauser 7

Product description Cleanfit CPA871

1

2

3

4

5

6

7

1

2

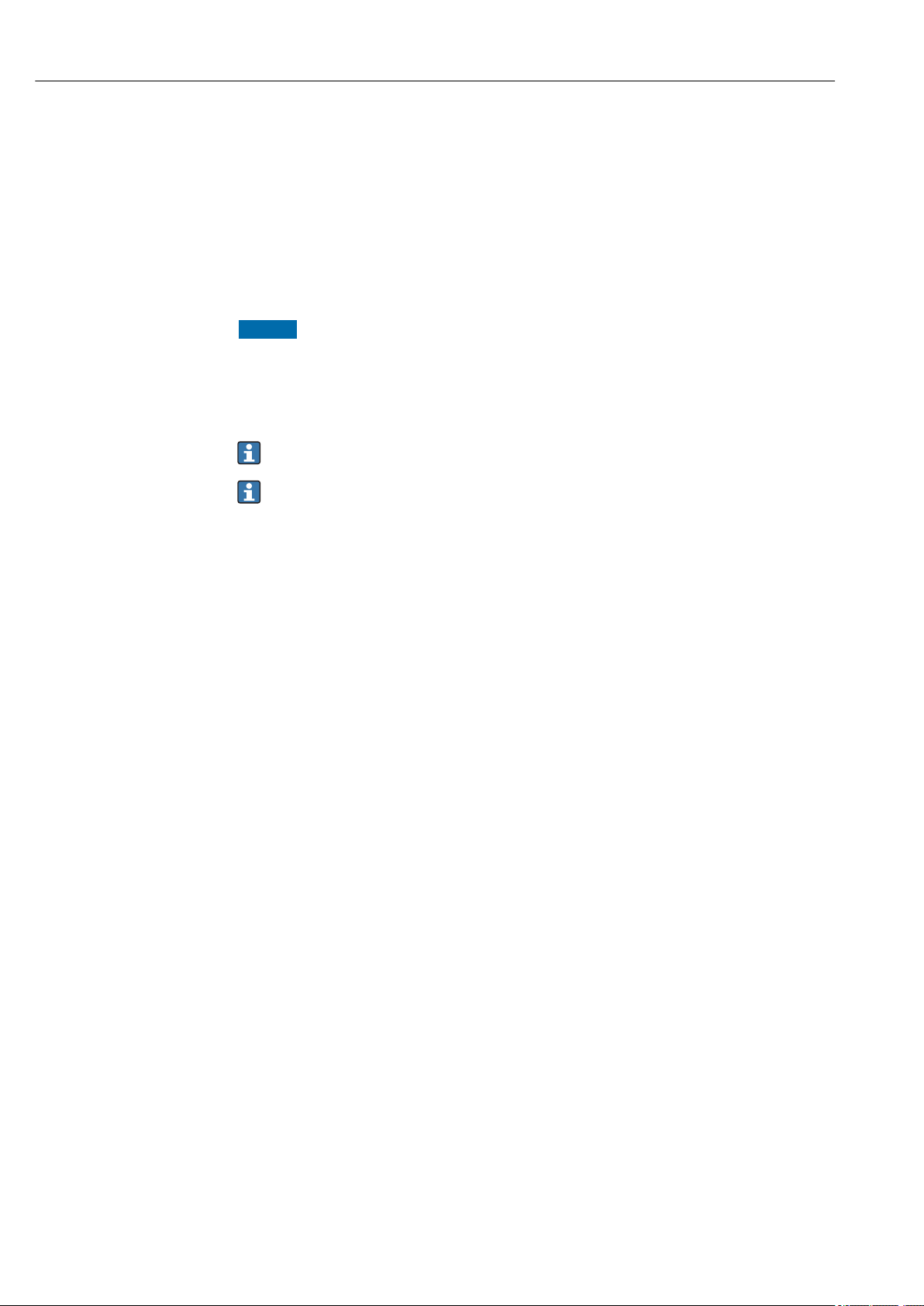

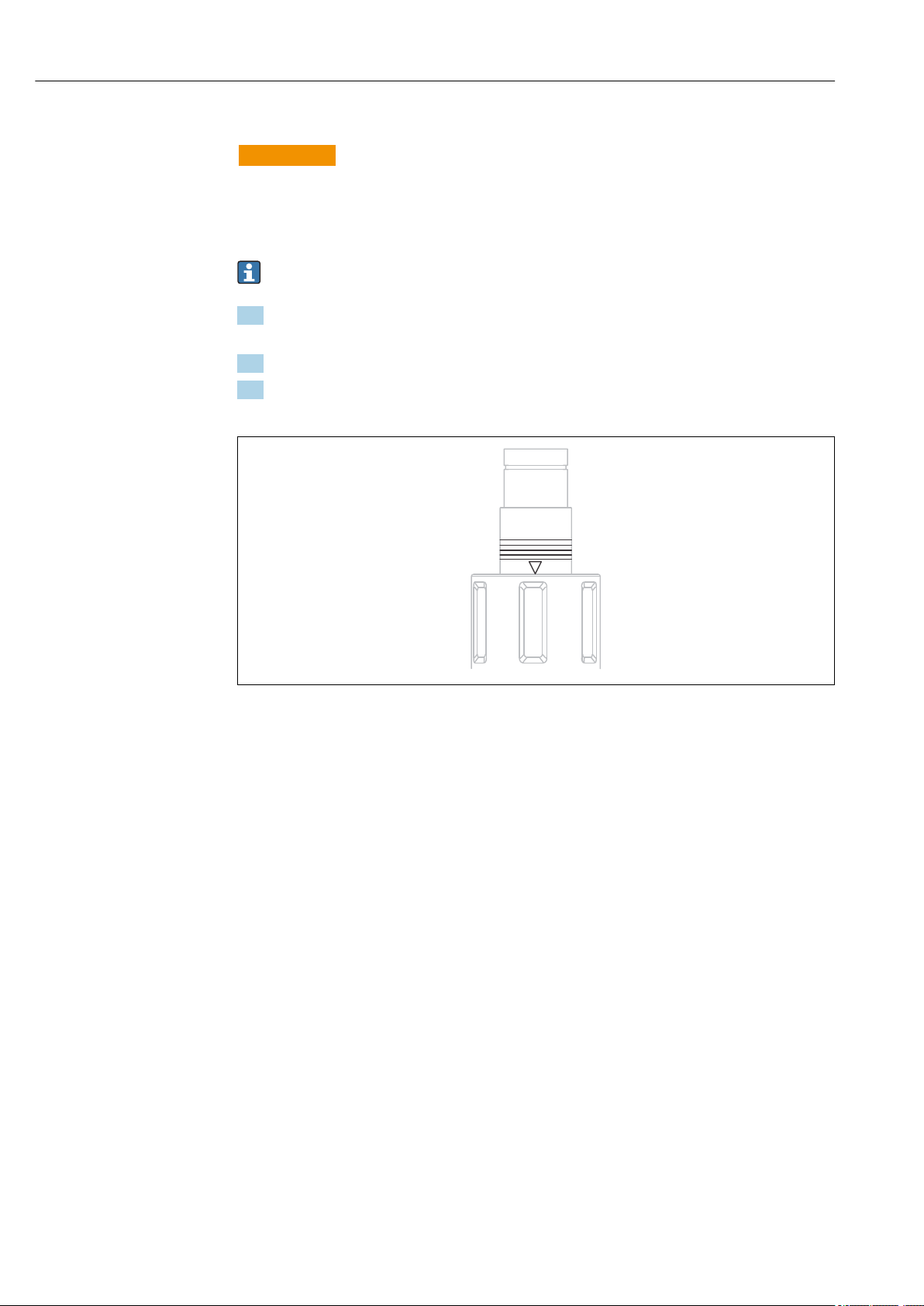

3.1.1 Operating principle

A0039361

2 Sealing system, assembly in service position

1 Rinse chamber, inlet

2 Seal, drive (1 x O-ring)

3 Leakage hole

4 Rinse chamber, outlet

5 Seal, rinse chamber (1 x O-ring)

6 Process seal (2 x O-ring)

7 Rinse chamber

The assembly is open to the process during insertion/retraction; the rinse connections

must either be pipe-fitted or sealed.

The assembly has a pin seal. This seals the assembly from the process in the relevant limit

position.

Process seal

3 Process seal, assembly in service position

1 Process seal (2 x O-ring)

2 Pin

A0039106

8 Endress+Hauser

Cleanfit CPA871 Incoming acceptance and product identification

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify the supplier of any damage to the packaging.

Keep the damaged packaging until the issue has been resolved.

2. Verify that the contents are undamaged.

Notify the supplier of any damage to the delivery contents.

Keep the damaged goods until the issue has been resolved.

3. Check that the delivery is complete and nothing is missing.

Compare the shipping documents with your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

Make sure to comply with the permitted ambient conditions.

If you have any questions, please contact your supplier or your local Sales Center.

4.2 Scope of delivery

The scope of delivery comprises:

• Ordered version of assembly

• Operating Instructions

• Adapter push connector 6 mm (0.24 in) of 4 mm (0.16 in) (outer diameter)

Endress+Hauser 9

Incoming acceptance and product identification Cleanfit CPA871

4.3 Product identification

4.3.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Order code

• Extended order code

• Serial number

• Ambient and process conditions

• Safety information and warnings

Compare the information on the nameplate with the order.

‣

4.3.2 Product identification

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Go to www.endress.com.

2. Call up the site search (magnifying glass).

3. Enter a valid serial number.

4. Search.

The product structure is displayed in a popup window.

5. Click on the product image in the popup window.

A new window (Device Viewer) opens. All of the information relating to your

device is displayed in this window as well as the product documentation.

Product page

www.endress.com/CPA871

10 Endress+Hauser

Cleanfit CPA871 Incoming acceptance and product identification

4.4 Certificates and approvals

CRN

The design of the assembly was reviewed and registered by the Canadian safety authorities

for all Canadian provinces in accordance with the requirements of the "Canadian

Registration Number (CRN)" system.

ATEX- 2014/34/EU

The assembly does not fall within the scope of the directive. However, if conditions for safe

use are adhered to, it may be deployed in the hazardous area.

DRGL- 2014/68/EU / PED- 2014/68/EU

The assembly has been manufactured according to good engineering practice as per Article

4, Paragraph 3 of the Pressure Equipment Directive 2014/68/EU and is therefore not

required to bear the CE label.

Endress+Hauser 11

Installation Cleanfit CPA871

5 Installation

5.1 Installation conditions

5.1.1 Orientation

The assembly is designed for installation on tanks and pipes. Suitable process connections

must be available for this.

NOTICE

Frost damage to the assembly

If used outdoors, ensure that water cannot penetrate the drive.

‣

The assembly is designed in such a way that there are no restrictions with regard to the

orientation.

The sensor that is used can restrict the orientation.

Ensure compliance with the Operating Instructions of the sensor installed.

12 Endress+Hauser

Cleanfit CPA871 Installation

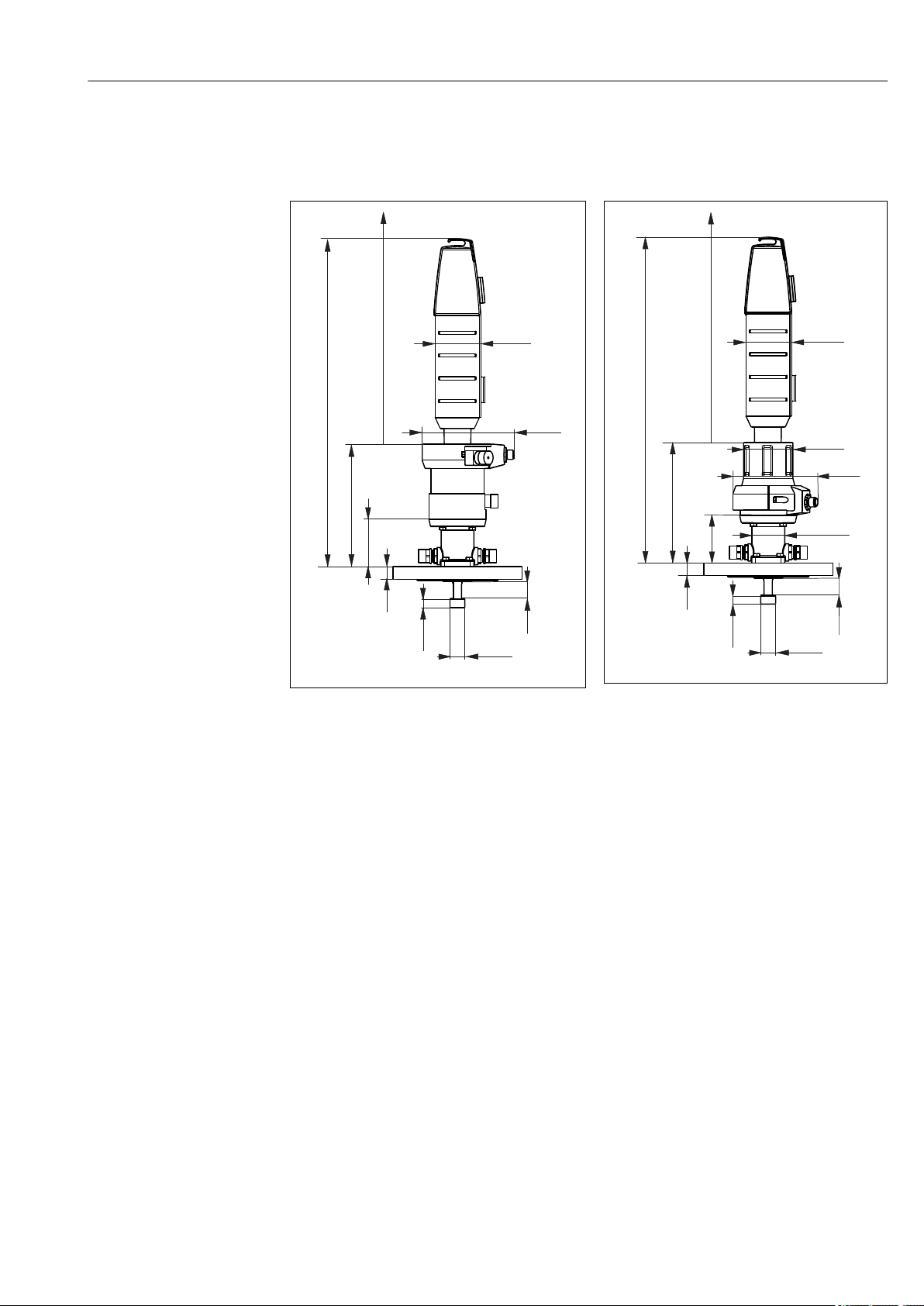

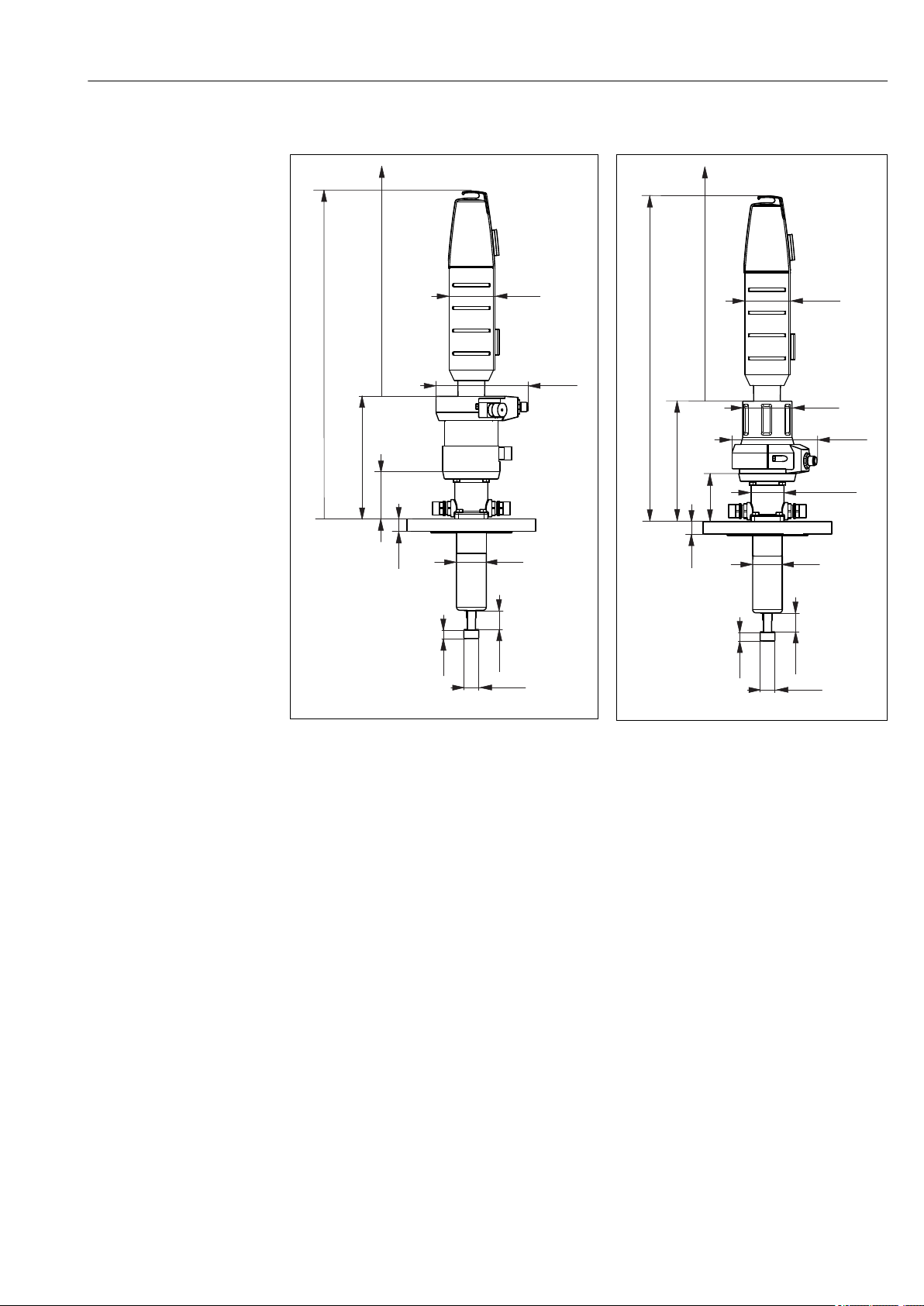

XP

XM/XS = 398/434 (15.67/17.09)

158 (6.22)

! 61

(2.40)

117

(4.61)

XA

63

(2.48)

19!

(0.47)

24

(0.9)

11,7

(4.6)

! 61

(2.40)

XA

! 61

(2.40)

107

(4.21)

42 (1.65)

63

(2.48)

XP

155 (6.10)

XM/XS = 398/434 (15.67/17.09)

19!

(0.47)

11,7

(4.6)

24

(0.9)

5.1.2 Dimensions

Short version

A0023894

4 Pneumatic drive, short version, dimensions in

mm (in)

XM

Assembly in measuring position

XS

Assembly in service position

XP

Height of particular process connection (see table below)

XA

Necessary mounting distance for sensor replacement

5 Manual drive, short version, dimensions in

mm (in)

The mounting distance XA is 280 mm (11.02") for 120 mm sensors

The mounting distance XA is 408 mm (15.94") for 225 mm sensors

A0023897

Endress+Hauser 13

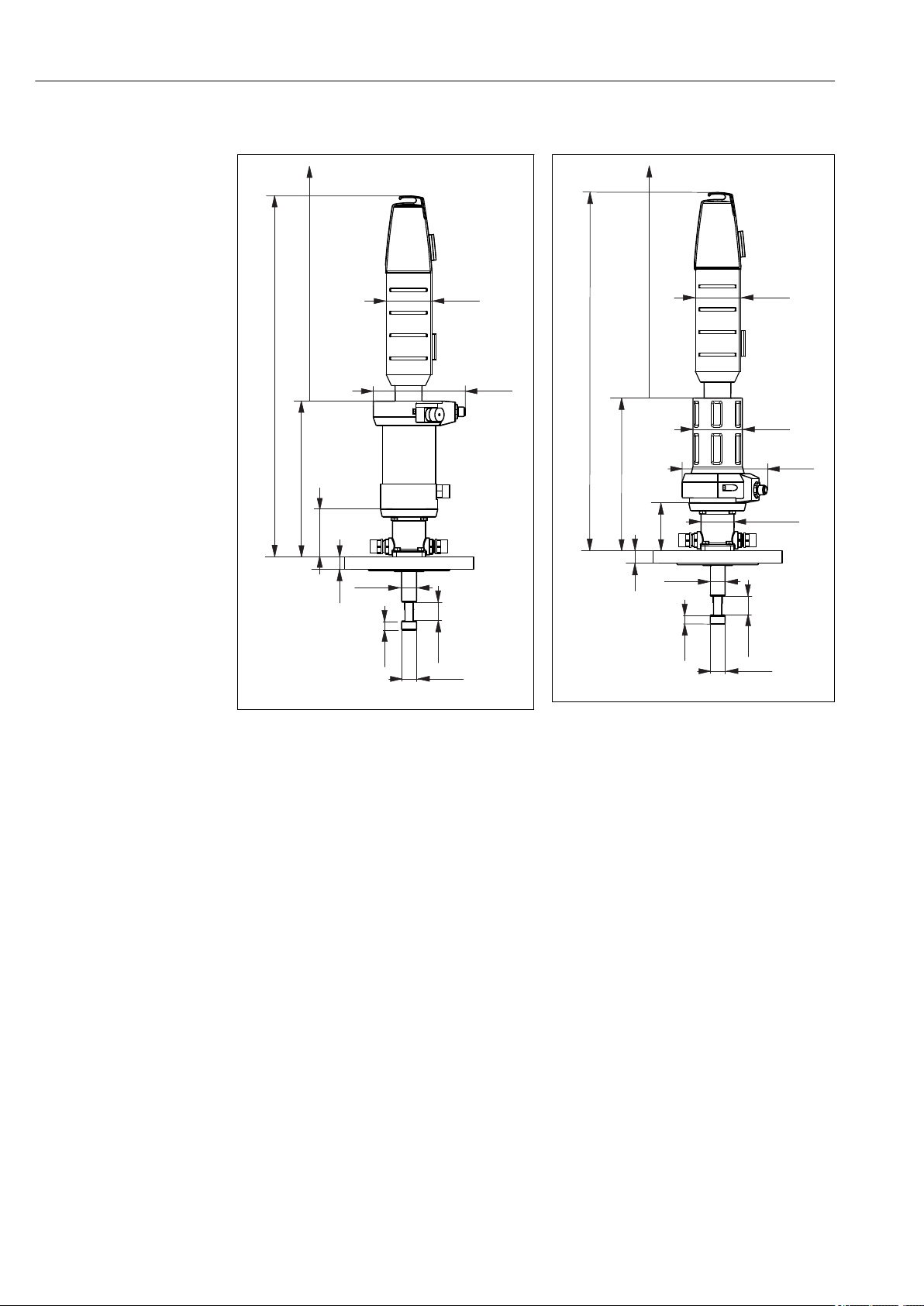

Installation Cleanfit CPA871

! 61

(2.40)

XP

200 (7.87)

107

(4.21)

63

XM/XS = 440/518 (17.32/20.39)

XA

(2.48)

24

(0.9)

11,7

(4.6)

! 19

(0.7)

19!

(0.47)

! 61

(2.40)

! 61

(2.40)

107

(4.21)

42 (1.65)

63

(2.48)

XP

197 (7.76)

XM/XS = 440/518 (17.32/20.39)

XA

24

(0.9)

11,7

(4.6)

! 19

(0.7)

19!

(0.47)

Long version

A0023895

6 Pneumatic drive, long version, dimensions in

mm (in)

XM

Assembly in measuring position

XS

Assembly in service position

XP

Height of particular process connection (see table below)

XA

Necessary mounting distance for sensor replacement

7 Manual drive, long version, dimensions in

mm (in)

The mounting distance XA is 360 mm (14.17") for 225 mm sensors

A0023898

14 Endress+Hauser

Cleanfit CPA871 Installation

! 61

(2.40)

117

(4.61)

158 (6.22)

63

XP

XM/XS = 398/434 (15.67/17.09)

XA

(2.48)

24

(0.9)

11,7

(4.6)

! 38

(1.5)

19!

(0.47)

XP

XM/XS = 398/434 (15.67/17.09)

155 (6.10)

! 61

(2.40)

107

(4.21)

42 (1.65)

63

(2.48)

! 61

(2.40)

XA

24

(0.9)

11,7

(4.6)

! 38

(1.5)

19!

(0.47)

Immersion chamber version

A0023896

8 Immersion chamber version with pneumatic drive,

dimensions in mm (in)

XM

Assembly in measuring position

XS

Assembly in service position

XP

Height of particular process connection (see table below)

XA

Necessary mounting distance for sensor replacement

9 Immersion chamber version with manual

drive, dimensions in mm (in)

The mounting distance XA is 280 mm (11.02") for 225 mm sensors

The mounting distance XA is 570 mm (22.44") for 360 mm sensors

A0023899

Endress+Hauser 15

Installation Cleanfit CPA871

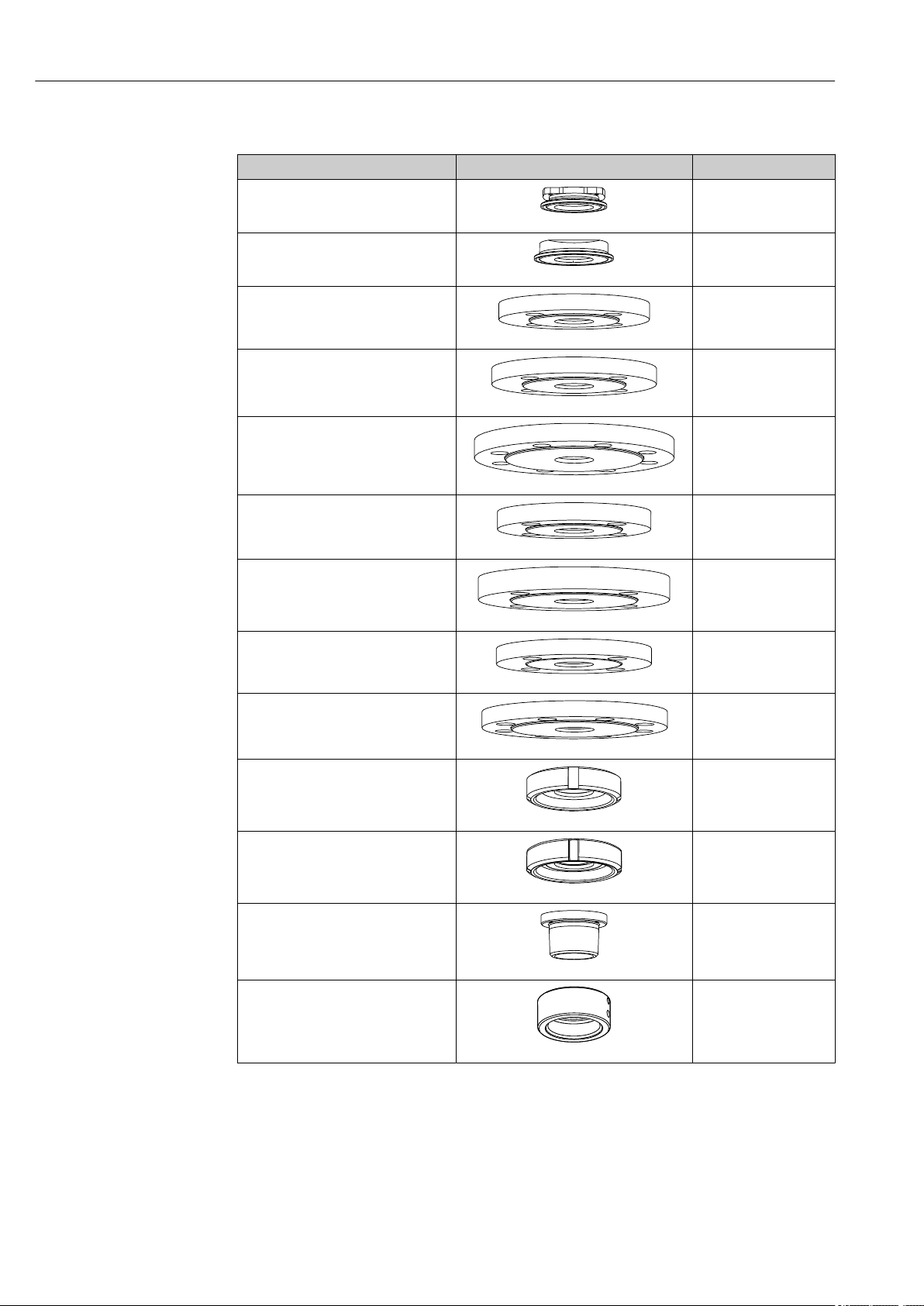

Process connection height

Process connection Height XP in mm (in)

CB Clamp 2"

ISO2852, ASME BPE-2012

CC Clamp 2½"

ISO2852, ASME BPE-2012

FA Flange DN 40 PN16, EN1092-1

FB Flange DN 50 PN16, EN1092-1

FC Flange DN 80 PN10, EN1092-1

FD Flange 2" 150 lbs, ASME B16.5

16 (0.63)

A0024100

16 (0.63)

A0024101

18 (0.71)

A0024102

18 (0.71)

A0024103

20 (0.79)

A0024104

19.1 (0.75)

FE Flange 3" 150 lbs, ASME B16.5

FF 10K50, JIS B2220

FG 10K80, JIS B2220

MA Dairy fitting DN 50 DIN 11851

MB Dairy fitting DN 65 DIN 11851

HB Thread NPT 1½"

NA

Thread ISO 228 G1¼

A0024105

23.8 (0.94)

A0024106

16 (0.63)

A0024107

18 (0.71)

A0024108

15.5 (0.61)

A0024109

15.5 (0.61)

A0024110

40.5 (1.57)

A0024111

31.1 (1.22)

A0039368

16 Endress+Hauser

Cleanfit CPA871 Installation

X1

X2

X1

X2

X1

X2

1 2

3/4

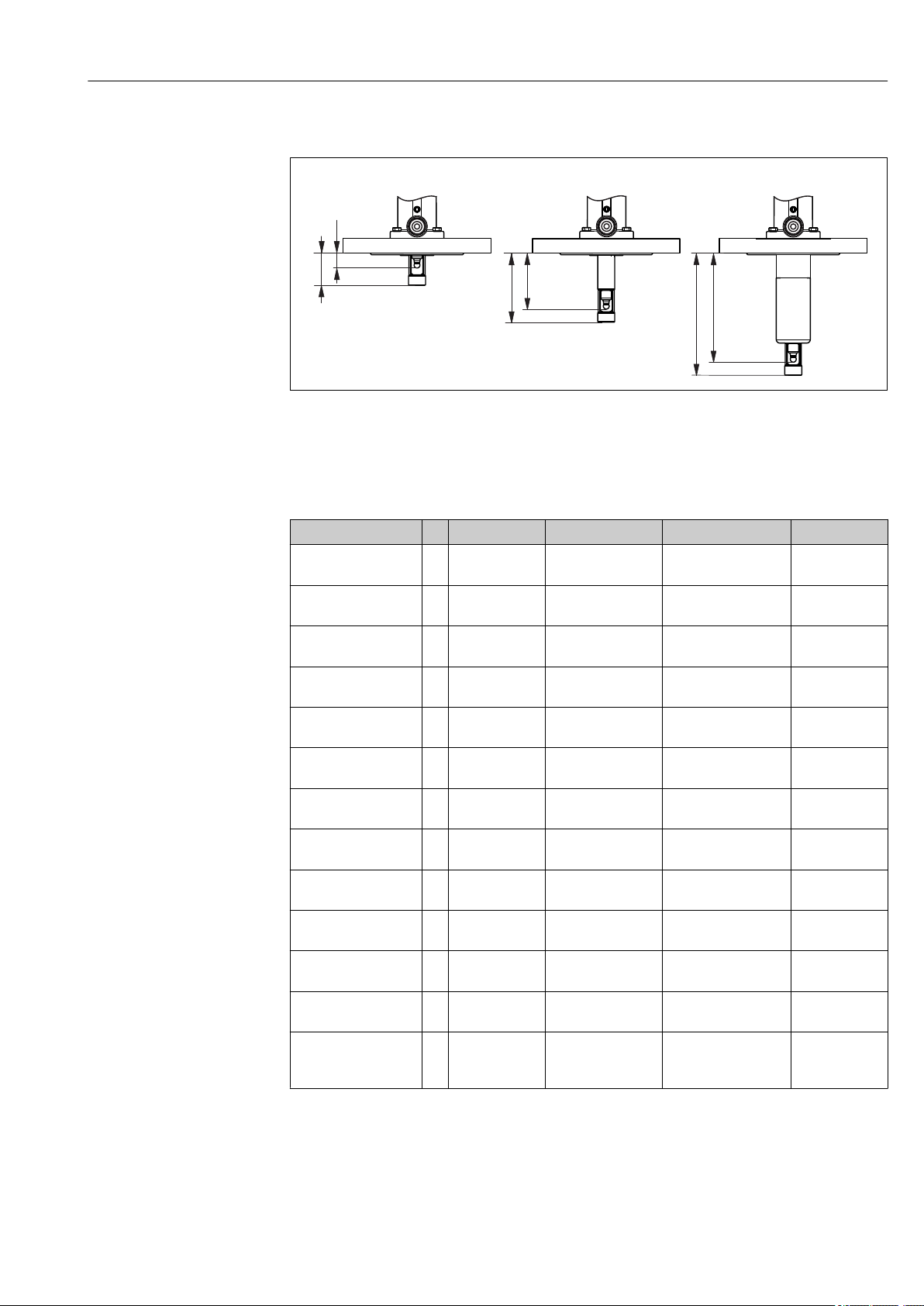

5.1.3 Immersion depths

A0023893

10 Immersion depths in mm (in)

1 Short stroke, 36 mm (1.42 in)

2 Long stroke, 78 mm (3.07 in)

3 Immersion version

Versions

Process connection 1 2 3 4

CB Clamp ISO2852

ASME BPE-2012 2"X1X2

CC Clamp ISO2852

ASME BPE-2012 2½"X1X2

FA Flange DN 40

EN1092-1

FB Flange DN 50

EN1092-1

FC Flange DN 80

EN1092-1

FD Flange 2" 150 lbs

ASME B16.5

FE Flange 3" 150 lbs

ASME B16.5

FF Flange 10K50

JIS B2220

FG Flange 10K80

JIS B2220

HB Thread NPT 1½" X1

MA Dairy fitting

DN 50 DIN 11851

MB Dairy fitting

DN 65 DIN 11851

NA Thread ISO 228

G 1¼

14.9 (0.59)

34.2 (1.35)

14.9 (0.59)

34.2 (1.35)

X1X214.9 (0.59)

34.2 (1.35)

X1X214.9 (0.59)

34.2 (1.35)

X1X212.9 (0.51)

32.2 (1.27)

X1X213.8 (0.54)

33.1 (1.30)

X1

X2

X1X214.4 (0.57)

X1X214.4 (0.57)

X2

X1X215.4 (0.61)

X1X215.4 (0.61)

X1

X2

X3

-

-

33.7 (1.33)

33.7 (1.33)

-

-

34.7 (1.37)

34.7 (1.37)

-

-

61.0 (2.40)

75.7 (2.98)

61.0 (2.40)

75.7 (2.98)

61.0 (2.40)

75.7 (2.98)

61.0 (2.40)

75.7 (2.98)

59.0 (2.32)

73.7 (2.90)

59.9 (2.36)

74.6 (2.94)

-

-

61.3 (2.41)

76.0 (2.99)

60.5 (2.38)

75.2 (2.96)

63.0 (2.48)

77.7 (3.06)

61.5 (2.42)

76.2 (3.00)

61.5 (2.42)

76.2 (3.00)

61.5 (2.42)

76.2 (3.00)

20.6 (0.81)

119.9 (4.72)

134.6 (5.30)

119.9 (4.72)

134.6 (5.30)

119.9 (4.72)

134.6 (5.30)

119.9 (4.72)

134.6 (5.30)

117.9 (4.64)

132.6 (5.22)

118.8 (4.68)

133.5 (5.26)

114.1 (4.49)

128.8 (5.07)

120.2 (4.73)

134.9 (5.31)

119.4 (4.70)

134.1 (5.28)

121.9 (4.80)

136.6 (5.38)

120.4 (4.74)

135.1 (5.32)

120.4 (4.74)

135.1 (5.32)

-

-

171.9 (6,76)

186.6 (7.35)

171.9 (6,76)

186.6 (7.35)

171.9 (6,76)

186.6 (7.35)

171.9 (6,76)

186.6 (7.35)

169.9 (6.69)

184.6 (7.27)

170.9 (6.73)

185.6 (7.30)

166.1 (6.54)

180.8 (7.11)

172.2 (6.78)

186.9 (7.36)

171.4 (6.75)

186.1 (7.33)

173.9 (6.85)

188.6 (7.40)

172.4 (6.79)

187.1 (6.37)

172.4 (6.79)

187.1 (6.37)

-

-

Endress+Hauser 17

Installation Cleanfit CPA871

X2

X3

X1

2

3

4

A0039342

11 Immersion depth in mm (in) for process connection NA thread ISO 228 G1¼

5.2 Mounting the assembly

5.2.1 Installation

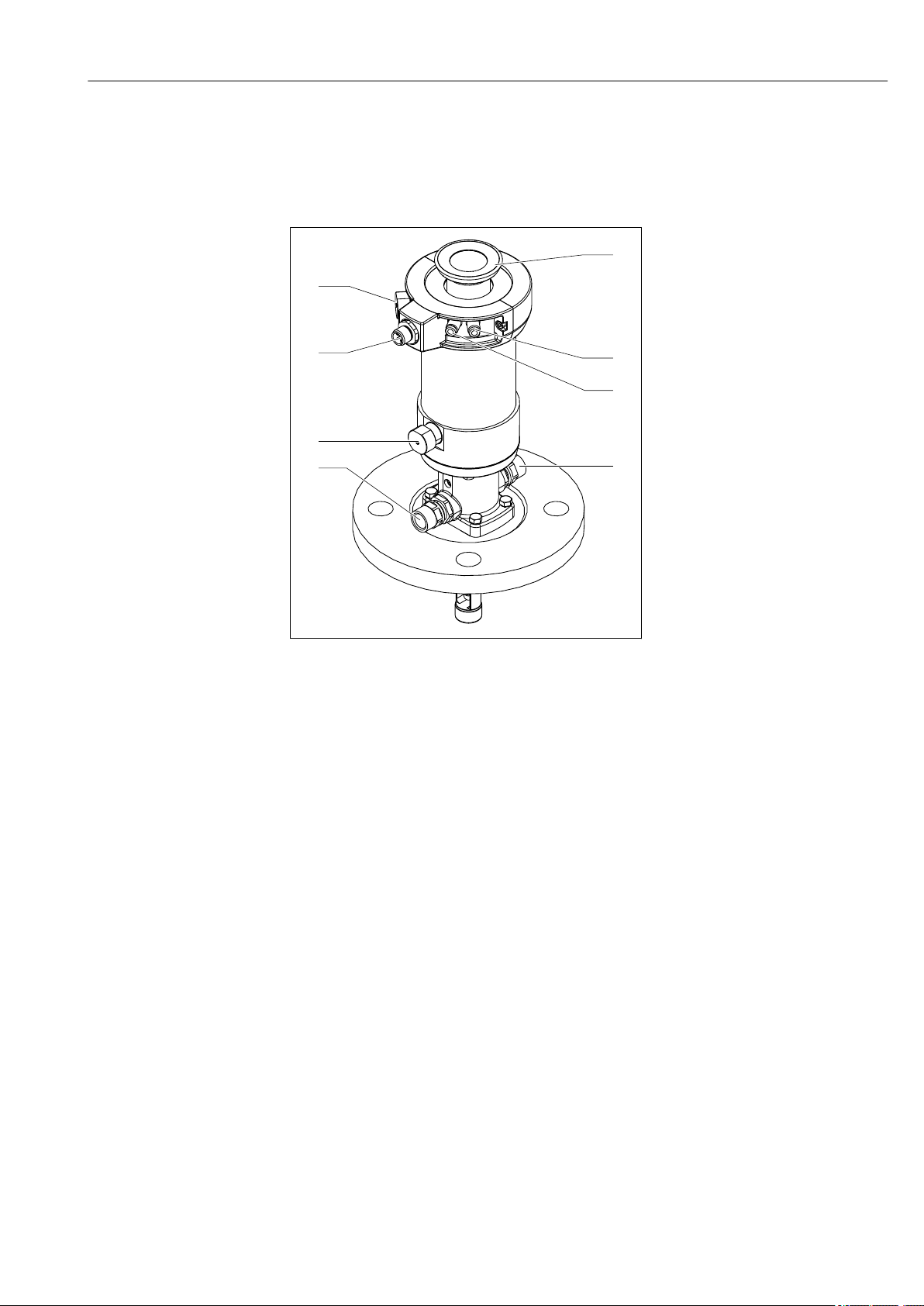

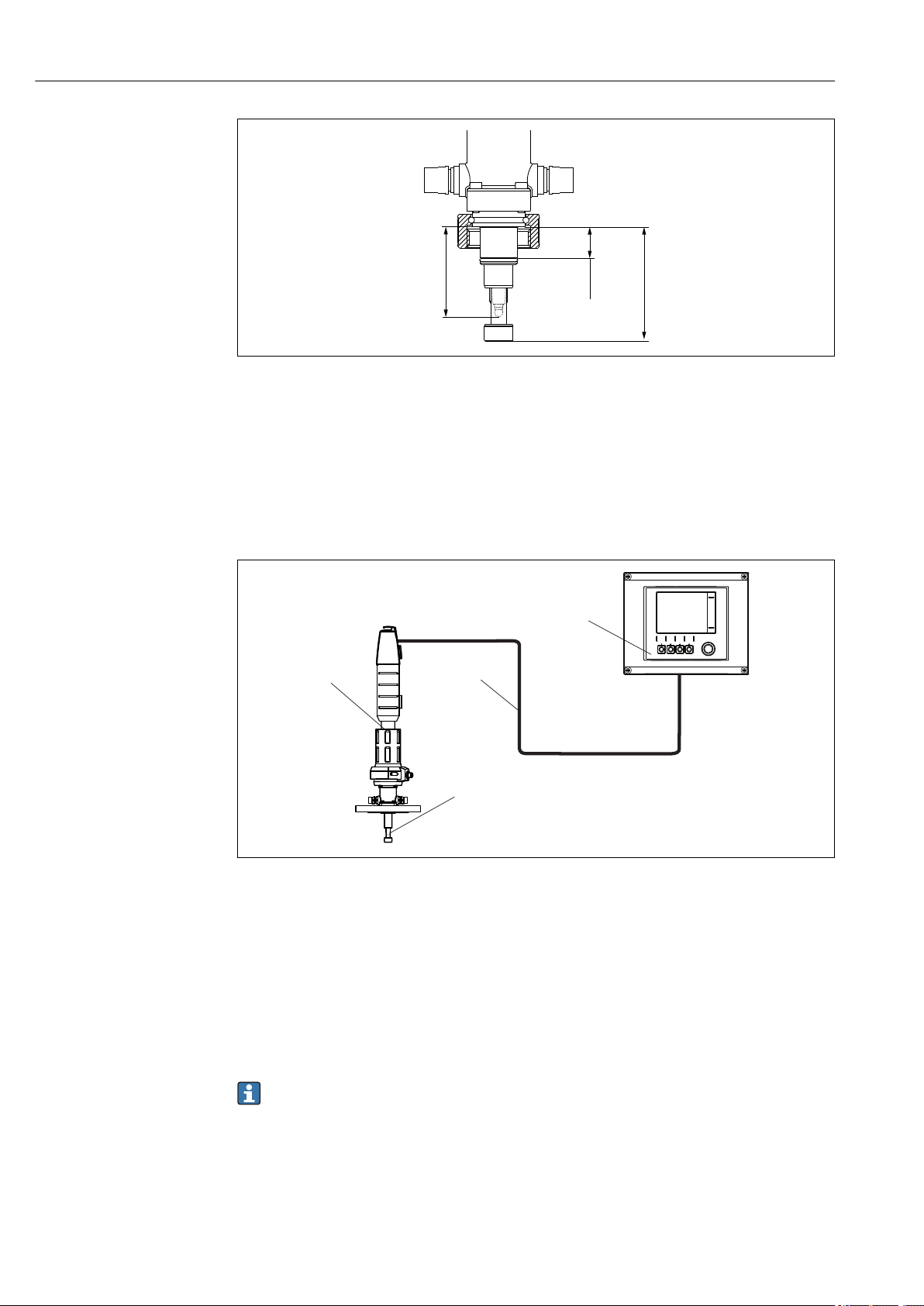

Measuring system

12 Measuring system (example)

1 Cleanfit assembly CPA871

2 Measuring cable

3 Liquiline CM44x transmitter

4 Sensor

A0029620

Installation recommendation

The two O-rings of the process seal close off the process in the relevant limit position. The

assembly is open to the process during insertion/retraction; the rinse connections must

either be pipe-fitted or sealed.

The connection between the service chamber and the process is open during

movement; the sealing water function can be used as a result. The rinse chamber

outlet must be blocked (e.g., with a shutoff valve) to implement the sealing water

18 Endress+Hauser

function.

Cleanfit CPA871 Installation

1

2

3

4

5

A0039105

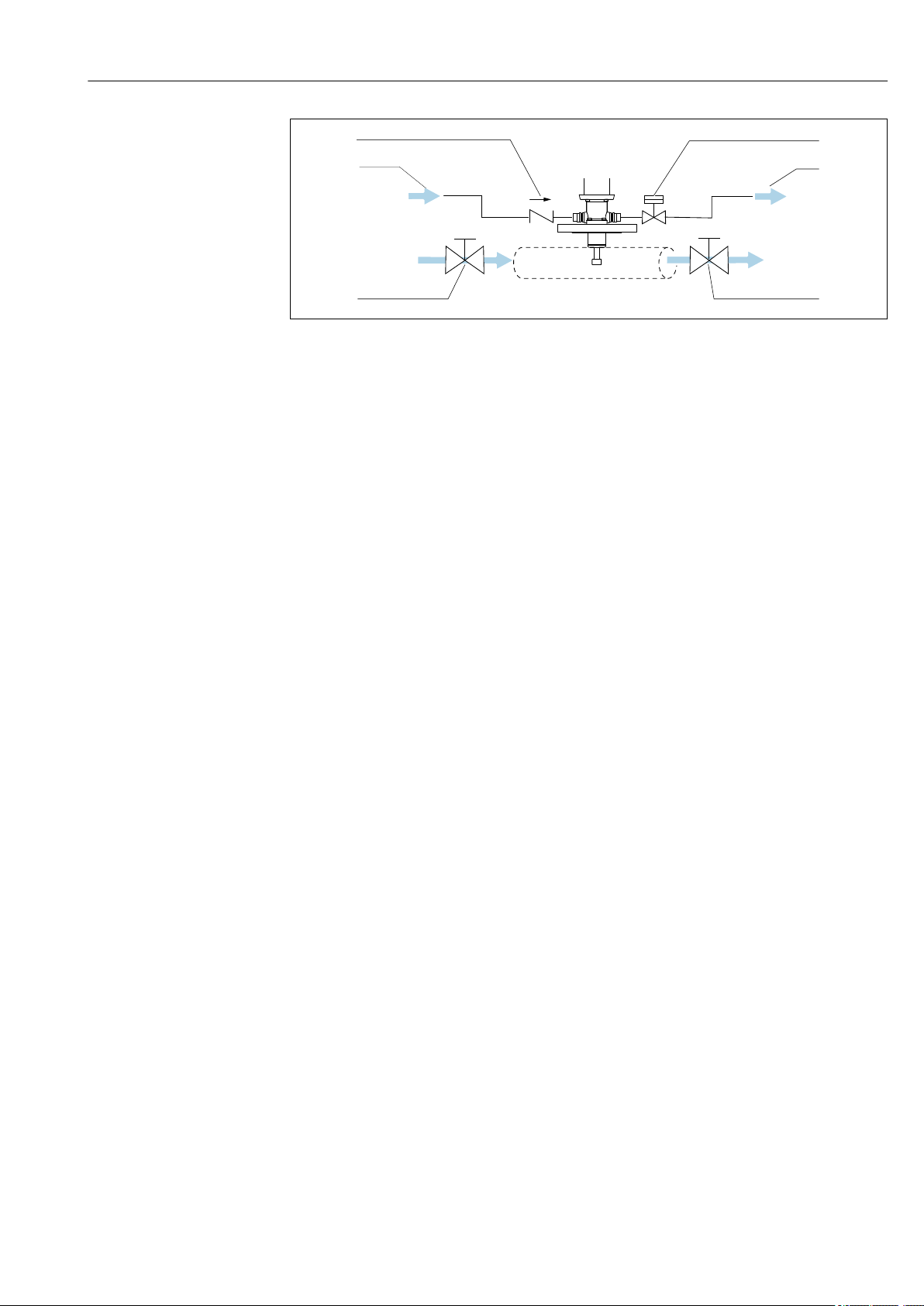

13 Sealing system using a bypass

1 Check valve

2 Valve open/closed, sealing water function

3 Wastewater

4 Shutoff valve open/closed

5 Water/cleaning agent

The seals must be checked and serviced regularly. Therefore measures must be taken to

separate the assembly from the process, e.g., by installing a bypass.

Endress+Hauser 19

Installation Cleanfit CPA871

Installing/removing the assembly from the process

WARNING

L

Risk of injury from high pressure, high temperature or chemical hazards if process

medium escapes.

Wear protective gloves, protective goggles and protective clothing.

‣

Mount the assembly only if vessels or pipes are empty and unpressurized.

‣

Prior to installation, check the flange seal between the flanges.

1. Move the assembly to the service position.

(The triangle position marking is visible (→ 14).

2. Secure the assembly on the tank or piping via the process connection.

3. Follow the instructions in the next section to connect pipes for compressed air and

rinse water (for the relevant assembly version).

14 Position markings (service position)

A0023307

20 Endress+Hauser

Cleanfit CPA871 Installation

1

2

3

4

5

6

7

8

Pneumatic connection for automatic operation

Prerequisites:

• Air pressure 4 to 7 bar (absolute pressure) (58 to 102 psi)

• Compressed air quality in accordance with ISO 8573-1:2001

Quality class 3.3.3 or 3.4.3

• Solids class 3 (max. 5 μm, max. 5 mg/m3, contamination with particles)

• Water content for temperatures ≥ 15 °C: Class 4 pressure condensation point 3 °C or

lower

• Water content for temperatures of 5 to 15 °C: Class 3 pressure condensation point -20 °C

or lower

• Oil content: Class 3 (max. 1 mg/m3)

• Air temperature: 5 °C or higher

• No continuous air consumption

• Minimum nominal diameter of air pipes: 2 mm (0.08 ")

A dual-operating cylinder is used to operate the pneumatic drive.

An automatic limit position lock both in service and measuring position secures the

assembly to prevent it from moving inadvertently in the event of a failure in the control

air. The assembly remains in the relevant position.

Connection: Push connector M5, hose 4/2 mm OD/ID (adapter for 6/4 mm OD/ID

enclosed)

NOTICE

Air pressure too high

Damage to seals.

Connect a pressure-reducing valve upstream if the air pressure is likely to rise to above

‣

7 bar (absolute pressure) (102 psi) (even short pressure surges).

1 Rinse connection

2 Automatic limit position lock,

process

3 Connection for limit position

switch, optional

4 Automatic limit position lock,

service

5 Fastening ring for protective

cover

6 Pneumatic connection (move

to measuring position)

7 Pneumatic connection (move

to service position)

8 Rinse connection

15 Assembly with pneumatic drive (without protective cover)

A0029614

Use a pneumatic pilot valve to insert/retract the assembly (4/2-way or 5/2-way

valve). Connect both inputs.

Endress+Hauser 21

Loading...

Loading...