Endress+Hauser CPA450 Specifications

TI00183C/07/EN/14.18

71446840

2018-12-31

Products Solutions Services

Technical Information

Cleanfit CPA450

Retractable assembly for fitting and removing

12 mm sensors for pH, redox and oxygen

measurement under process conditions

Application

• Universal flow assembly for pH/ORP, oxygen and conductivity sensors

• Power stations

• Chemical industry

• Industrial water treatment

• Supply technology

Your benefits

• Simple fitting and removal of the pH/redox or oxygen sensor for easy maintenance

• Sensor cleaned and calibrated without interrupting the process

• Process is reliably screened off by stainless steel ball valve, ensuring safety during

maintenance work

• Use of ISFET sensors and standard gel electrodes 120 mm long

• Three immersion depths up to 700 mm (27.5")

• Safety equipment can be used up to 12 bar (175 psi)

• Integrated rinse connections

• Assembly available in stainless steel, ultra corrosion-resistant C22 nickel alloy and

titanium

Function and system design

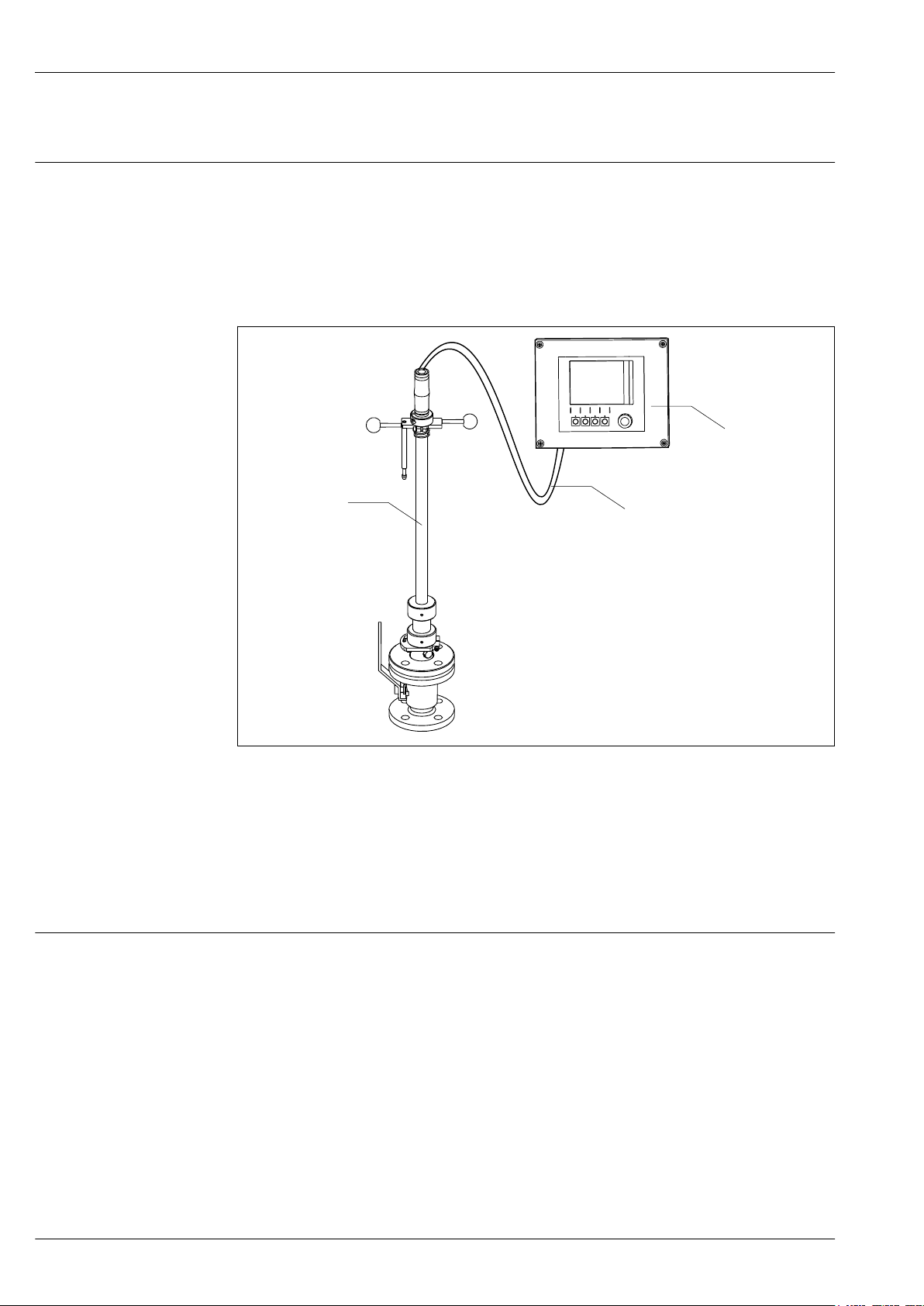

1

2

3

Cleanfit CPA450

Measuring system

A complete measuring system comprises:

• Assembly Cleanfit CPA450

• Oxygen/pH/ORP electrode, length 120 mm (4.72"), e.g. Orbisint CPS11D

• Transmitter, e.g. Liquiline CM44x or Liquiline CM42

• measuring cable, e.g. CYK10

Optional:

• Junction box M12 socket/cable or cable/cable

• Extension cable CYK11

Installation instructions

1 Measuring system with CPA450

1 Transmitter Liquiline CM44x

2 Measuring cable CYK10

3 Assembly Cleanfit CPA450

Mounting

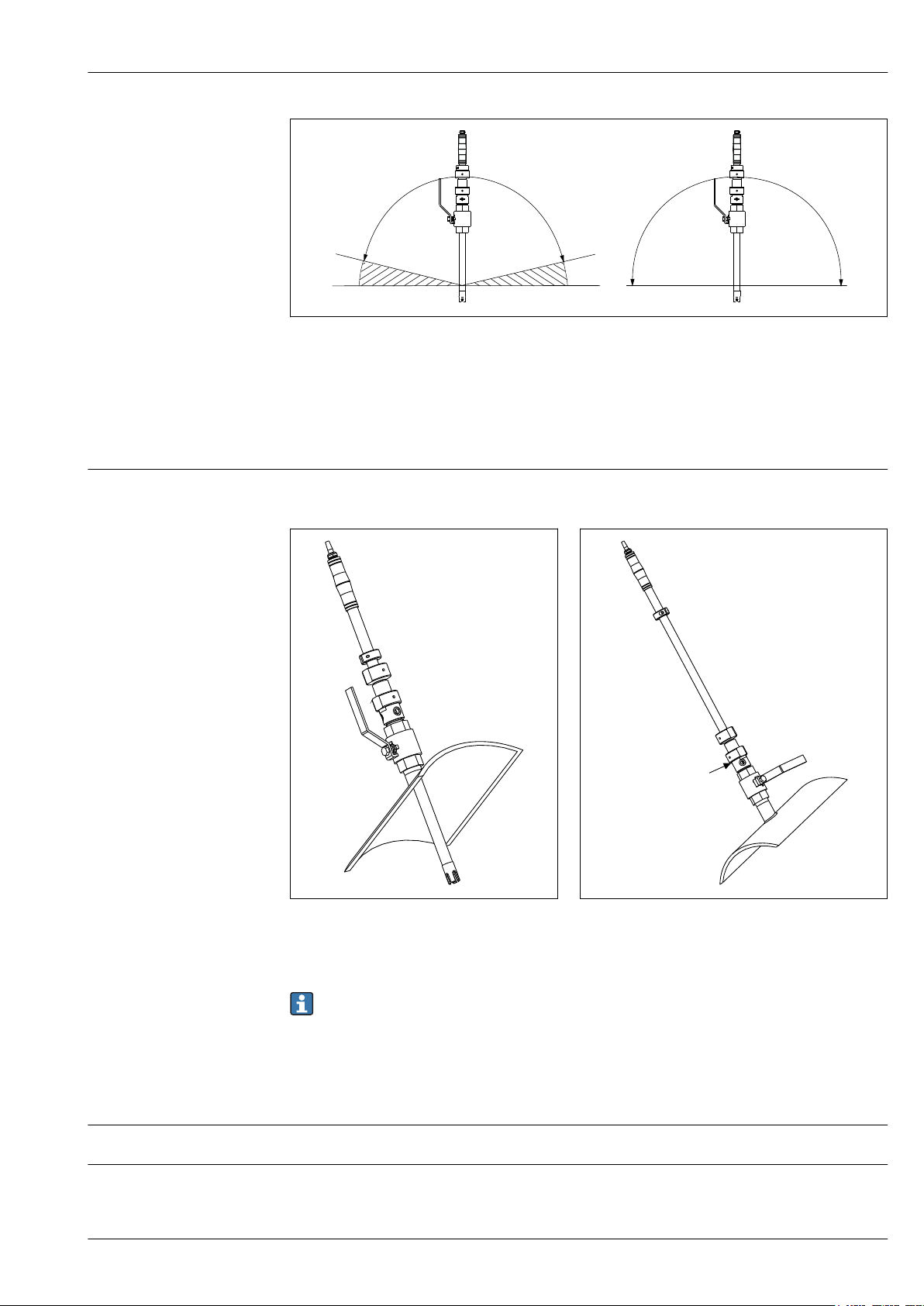

The permitted orientation of the assembly depends on the sensor used:

• Digital sensors with Memosens technology, pH/ORP glass electrodes:

Install the assembly at an angle of at least 15° to the horizontal → 2, 3.

• ISFET sensors:

For ISFET sensors, there are basically no restrictions regarding orientation. The installation angle

should be from 0 to 180°.

• All other sensors:

Pay attention to the information in the relevant TI.

A0038005

2 Endress+Hauser

Cleanfit CPA450

15°

15°

A B

A

A0011679

2 Orientations

A Glass sensors: 15 ° to the horizontal

B ISFET sensors: 0 to 180° recommended

Insert the immersion assembly into the vessel or pipe to a depth that will ensure that medium

continuously washes around the electrode, even at the minimum level.

Installation with ball valve

To replace the sensor without interrupting the process, a ball valve is required. Depending on the

version, the ball valve forms part of the assembly or must be installed by the customer.

A0010209

3 Measuring mode (ball valve is open):

assembly is retracted

4 Service position (ball valve is closed): assembly is

extended for electrode replacement, calibration,

rinsing

A Top edge of adapter

Depending on the assembly version, a mounting clearance of at least 700 or 1150 mm (27.6" or

45.3") is required from the top edge of the adapter.

A0010210

Environment

Ambient temperature range

Storage temperature

Endress+Hauser 3

0 to 80 °C (32 to 176 °F)

0 to 80 °C (32 to 176 °F)

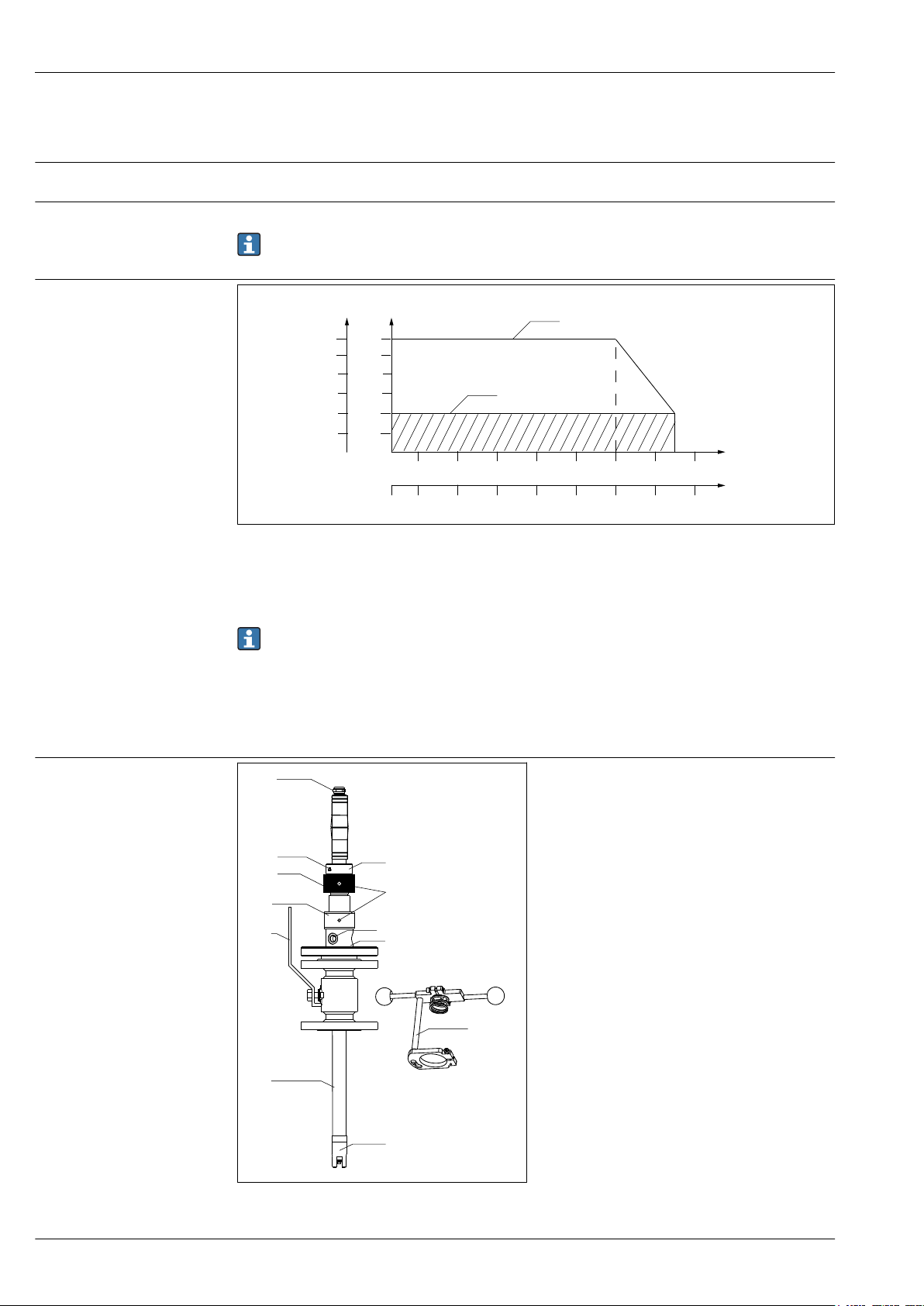

Process

200

4

8

-15

40 60 80 100 120 140

130

A

10

p [bar]

T [°C]

B

58

116

145

p [psi]

2

29

68

32

5

104

140

176 212 248

284

266

T [°F]

6

87

12

174

12

11

10

9

8

7

1

2

3

6

5

4

Cleanfit CPA450

Process temperature

Process pressure

Pressure-temperature chart

-15 to 130 °C (5 to 266 °F)

max. 12 bar at 100 °C (175 psi at 212 °F)

At pressures above 4 bar (58 psi) the use of a safety kit is strongly recommended.

A0038118-EN

5 Pressure/temperature ratings

A Maximum process pressure (static), only for fully installed assembly

B Maximum pressure for moving the assembly (functional)

Observe the maximum permitted process temperature and process pressure of the sensor.

Mechanical construction

Design

4 Endress+Hauser

6 Assembly in operational state (ball valve open)

A0010207

1 Setting collar for fixing the immersion depth

2 Bore for hook wrench

3 Rinse connection thread ¼ (316L) NPT ¼" (alloy

C22 or titanium)

4 Service chamber

5 Safety kit

6 Sensor holder with basket protector

7 Immersion tube

8 Lever for opening/closing the ball valve

9 Lock ring (metal)

10 Thread adapter nut (black)

11 M5/SW4 hexagon socket

12 Cable protector/cable gland

Loading...

Loading...