Endress+Hauser CPA250 Specifications

Technical Information

Flowfit CPA250

Flow assembly for pH and ORP sensors

Application

The CPA250 assembly is totally made of corrosion resistant

plastic. It is designed for pipeline installation of Pg 13.5 pH or

ORP sensors with installation length 120 mm (4.72 inch).

Inlet and outlet of the fluid lie on one axis. Due to especially

designed internal fluid deviation and siphon, the sensors are

kept wet even when the flow is interrupted.

Main areas of application are:

• Water treatment

• Drinking water

• Process applications

• Cooling water cycle

Your benefits

• Mounting places for max. three analog or digital sensors with

Pg 13.5 thread (pH, ORP, temperature)

• Threaded cap:

– easy installation and removal of the sensors

– protection of the sensor connection compartment

• Potential matching pin selectable:

– stainless steel 1.4571 (AISI 316Ti) or titane

– no potential matching pin for Memosens sensors

• Extension options:

– Connection to the electrolyte vessel CPY7

– Adaption of the Chemoclean system

• Economic flow assembly concept for in-line installation

• Easy calibration by removable calibration vessel

TI041C/07/en/04.09

71093745

Function and system design

12

3

4

5

6

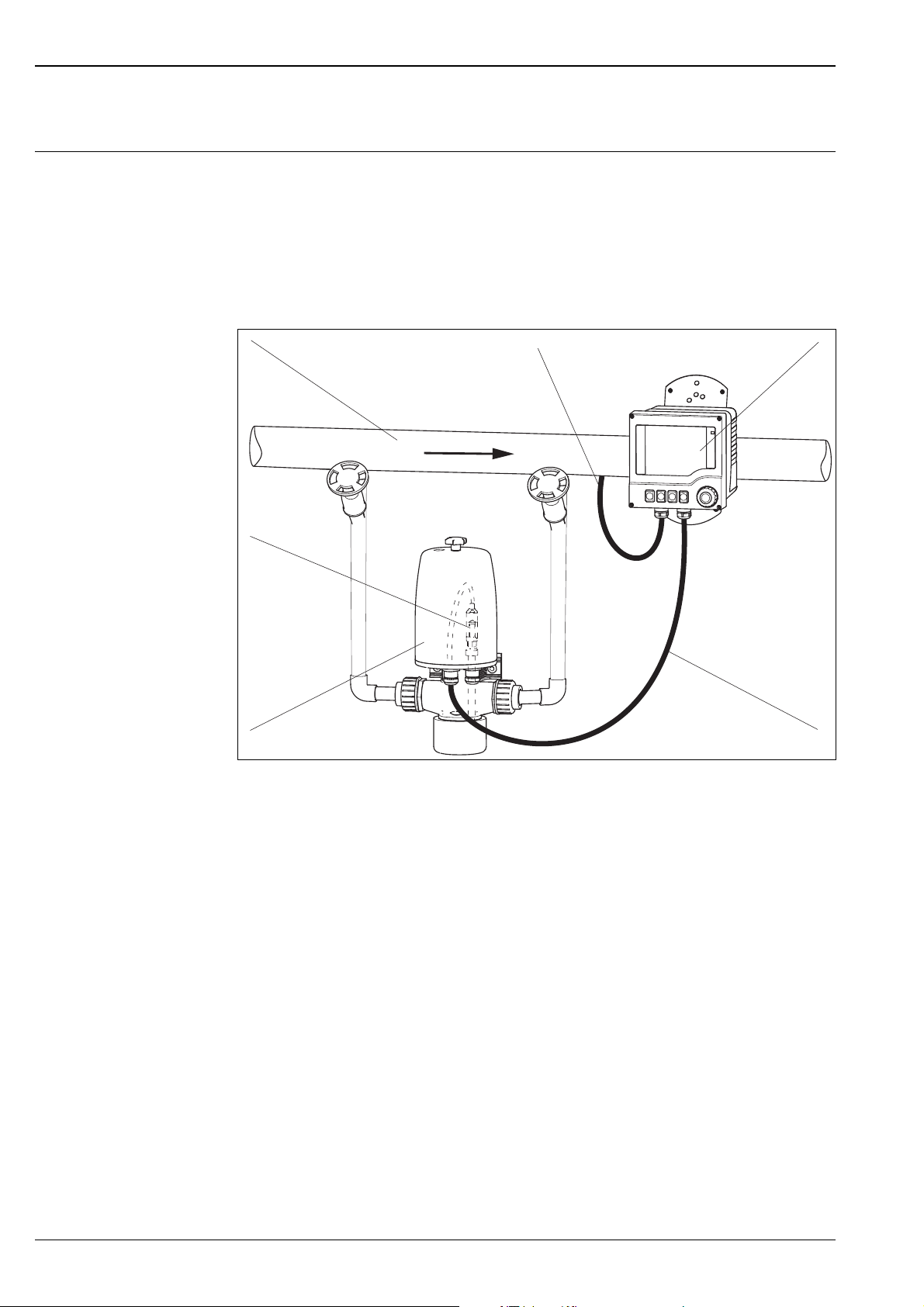

Measuring system A complete measuring system comprises:

• Flowfit CPA250

• pH or ORP sensor, e.g. CPS71D

• Measuring cable, e.g. CYK10

• Transmitter, e.g. Liquiline M CM42

Optional:

• up to two more pH/ORP sensors or single electrodes or temperature sensors

• Junction box for cable extension, e.g. RM junction box

Flowfit CPA250

Fig. 1: Measuring system (bypass installation)

1 Process line with bypass and valves

2 Supply line of the transmitter

3 Transmitter Liquiline M CM42

4 Measuring cable CYK10

5 Flowfit CPA250

6 pH sensor CPS71D

a0007329

2 Endress+Hauser

Flowfit CPA250

p

1

p>p

12

p

2

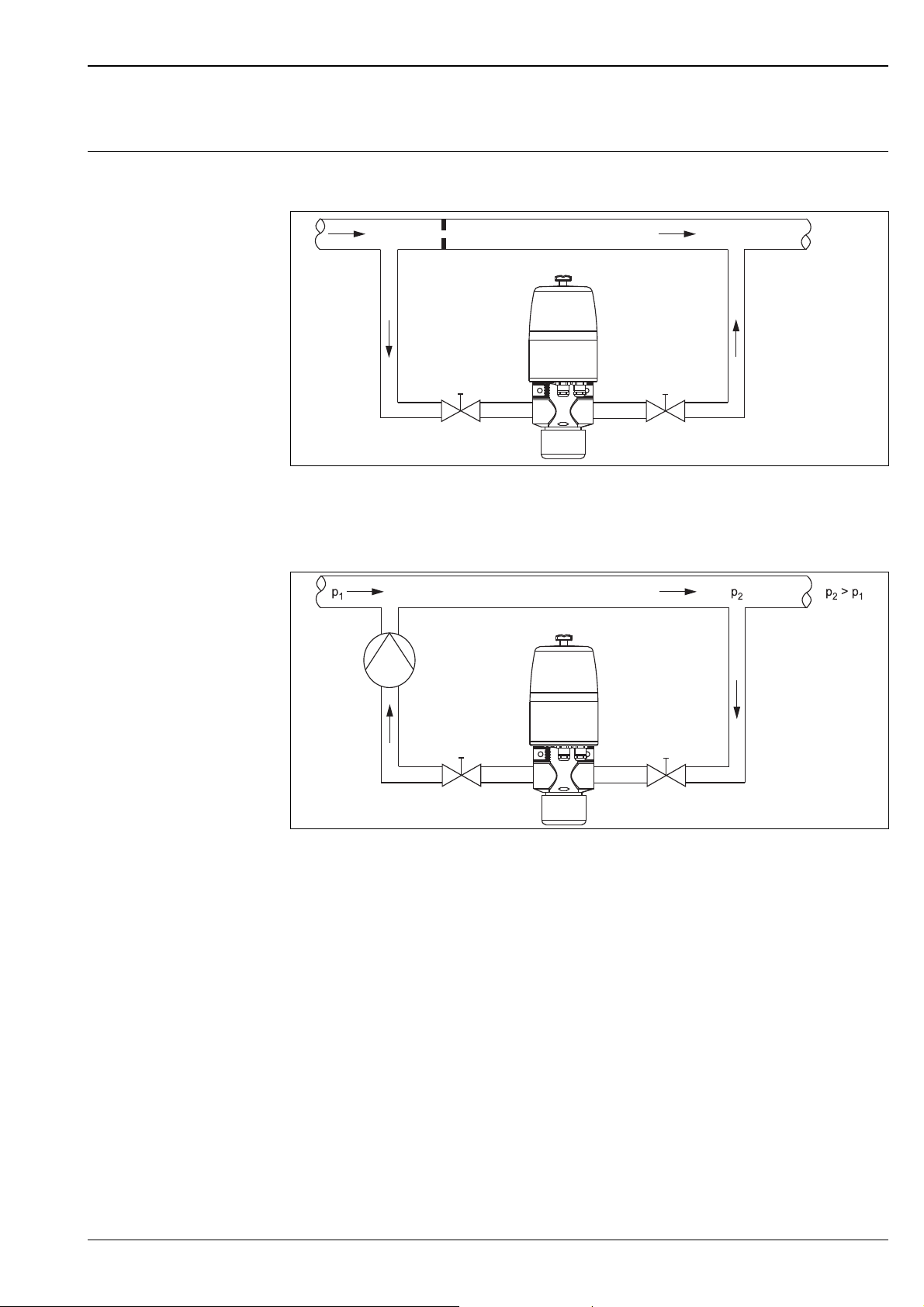

Installation

Installation instructions To get a flow through the by-pass, pressure p1 has to be higher than pressure p2. Therefore, you have to install

an aperture or a throttle in the main conduit (→ å 2).

Fig. 2: Installation example with by-pass and aperture in the main conduit

a0007334

Alternatively, you can install a booster pump in the bypass conduit to produce the required pressure (→ å 3).

Fig. 3: Installation example with open outlet

a0007335

Endress+Hauser 3

Loading...

Loading...