Page 1

BA01845C/07/EN/01.18

71406304

2018-04-30

Products Solutions Services

Operating Instructions

Liquiline Compact CM82

Compact transmitter configurable for Memosens sensors

from the Liquiline series

Page 2

Page 3

Liquiline Compact CM82 Table of contents

Table of contents

1 Document information .............. 4

1.1 Warnings ............................ 4

1.2 Symbols .............................. 4

1.3 Symbols at the device .................... 4

1.4 Documentation ........................ 5

2 Basic safety instructions ............ 6

2.1 Requirements for personnel ............... 6

2.2 Designated use ........................ 6

2.3 Occupational safety ..................... 6

2.4 Operational safety ...................... 6

3 Product description ................. 8

3.1 Product design ......................... 8

4 Incoming acceptance and product

identification ....................... 9

4.1 Incoming acceptance .................... 9

4.2 Product identification .................... 9

4.3 Scope of delivery ...................... 10

4.4 Certificates and approvals ............... 10

5 Installation ....................... 12

5.1 Dimensions .......................... 12

6 Electrical connection .............. 13

6.1 Connection .......................... 13

6.2 Post-connection check .................. 14

7 Operation options ................. 15

7.1 Overview of operating options ............ 15

7.2 Access to operating menu via SmartBlue

(app) ............................... 15

7.3 Access to operating menu via RIA15 ........ 17

10 Operation ......................... 35

10.1 Reading measured values ................ 35

10.2 Adapting the measuring device to the process

conditions ........................... 36

11 Diagnostics and troubleshooting ... 38

11.1 Diagnostic information via LED ........... 38

11.2 Adapting the diagnostic information ....... 38

11.3 Adapting sensor diagnostic information ..... 39

11.4 Simulation ........................... 47

11.5 Diagnostic list ........................ 48

11.6 Event logbook ........................ 62

11.7 Resetting the measuring device ........... 62

11.8 Device information .................... 63

11.9 Firmware history ..................... 63

12 Maintenance ...................... 64

12.1 Maintenance tasks ..................... 64

13 Repair ............................ 65

13.1 General notes ........................ 65

13.2 Return .............................. 65

13.3 Disposal ............................ 65

14 Accessories ....................... 66

14.1 Sensors ............................. 66

14.2 Software ............................ 69

14.3 Other accessories ...................... 69

15 Technical data .................... 71

15.1 Input ............................... 71

15.2 Output ............................. 71

15.3 Power supply ......................... 71

15.4 Performance characteristics .............. 72

15.5 Environment ......................... 72

15.6 Mechanical construction ................ 73

8 System integration ................ 18

8.1 Integrating the measuring device into the

system ............................. 18

Index .................................. 75

9 Commissioning .................... 19

9.1 Preparatory steps ...................... 19

9.2 Function check ....................... 19

9.3 Establishing connection via SmartBlue (app) .. 20

9.4 Establishing a connection via RIA15 ........ 21

9.5 Setting the operating language ............ 27

9.6 Date and time ........................ 27

9.7 Configuring the measuring device .......... 27

9.8 Configuration management .............. 34

9.9 Unauthorized access ................... 34

Endress+Hauser 3

Page 4

Document information Liquiline Compact CM82

1 Document information

1.1 Warnings

Structure of information Meaning

DANGER

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

NOTICE

Cause/situation

If necessary, Consequences of

non-compliance (if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to

property.

1.2 Symbols

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

1.3 Symbols at the device

Symbol Meaning

Reference to device documentation

4 Endress+Hauser

Page 5

Liquiline Compact CM82 Document information

1.4 Documentation

The following instructions complement these Operating Instructions and are available on

the product pages on the Internet:

Operating Instructions Memosens, BA01245C

– Software description for Memosens inputs

– Calibration of Memosens sensors

– Sensor-specific diagnostics and troubleshooting

Endress+Hauser 5

Page 6

Basic safety instructions Liquiline Compact CM82

2 Basic safety instructions

2.1 Requirements for personnel

• Installation, commissioning, operation and maintenance of the measuring system may

be carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the

specified activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions

and must follow the instructions contained therein.

• Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

The Liquiline CM72 Liquiline CM82 is a transmitter for connecting digital sensors with

Memosens technology, configurable, with 4..20 mA/HART communication and optional

operation via smartphone or other mobile devices via Bluetooth.

The device is designed for use in the following industries:

• Life science

• Chemical industry

• Water and wastewater

• Food and beverages

• Power stations

• Other industrial applications

2.3 Occupational safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

• Regulations for explosion protection

Electromagnetic compatibility

• The product has been tested for electromagnetic compatibility in accordance with the

applicable European standards for industrial applications.

• The electromagnetic compatibility indicated applies only to a product that has been

connected in accordance with these Operating Instructions.

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

6 Endress+Hauser

Page 7

Liquiline Compact CM82 Basic safety instructions

During operation:

If faults cannot be rectified:

‣

products must be taken out of service and protected against unintentional operation.

CAUTION

L

Cleaning not switched off during calibration or maintenance activities

Risk of injury due to medium or cleaning agent!

If a cleaning system is connected, switch it off before removing a sensor from the

‣

medium.

If you wish to check the cleaning function and have therefore not switched off the

‣

cleaning system, wear protective clothing, goggles and gloves or take other appropriate

measures.

Endress+Hauser 7

Page 8

Product description Liquiline Compact CM82

1

2

3

4

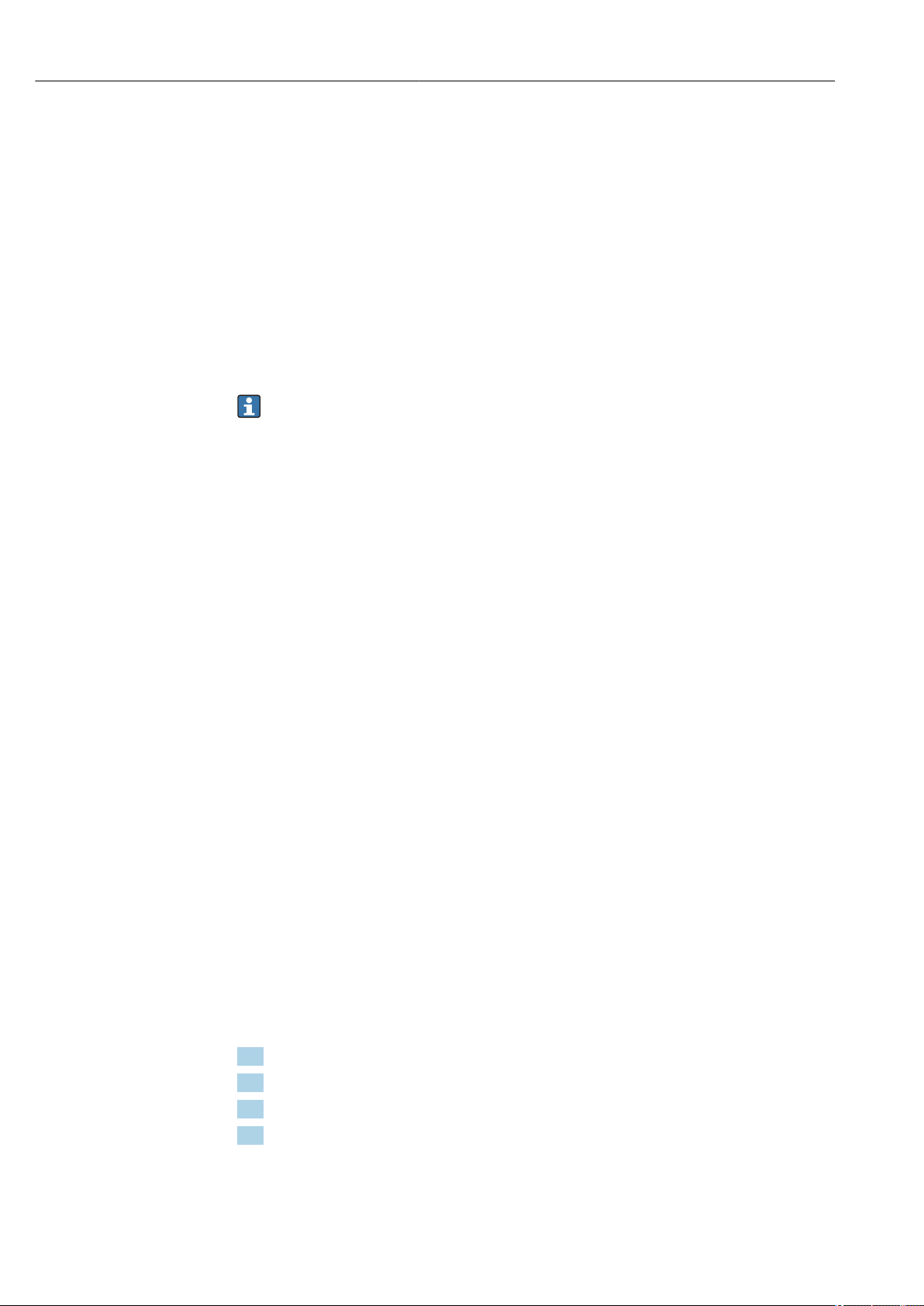

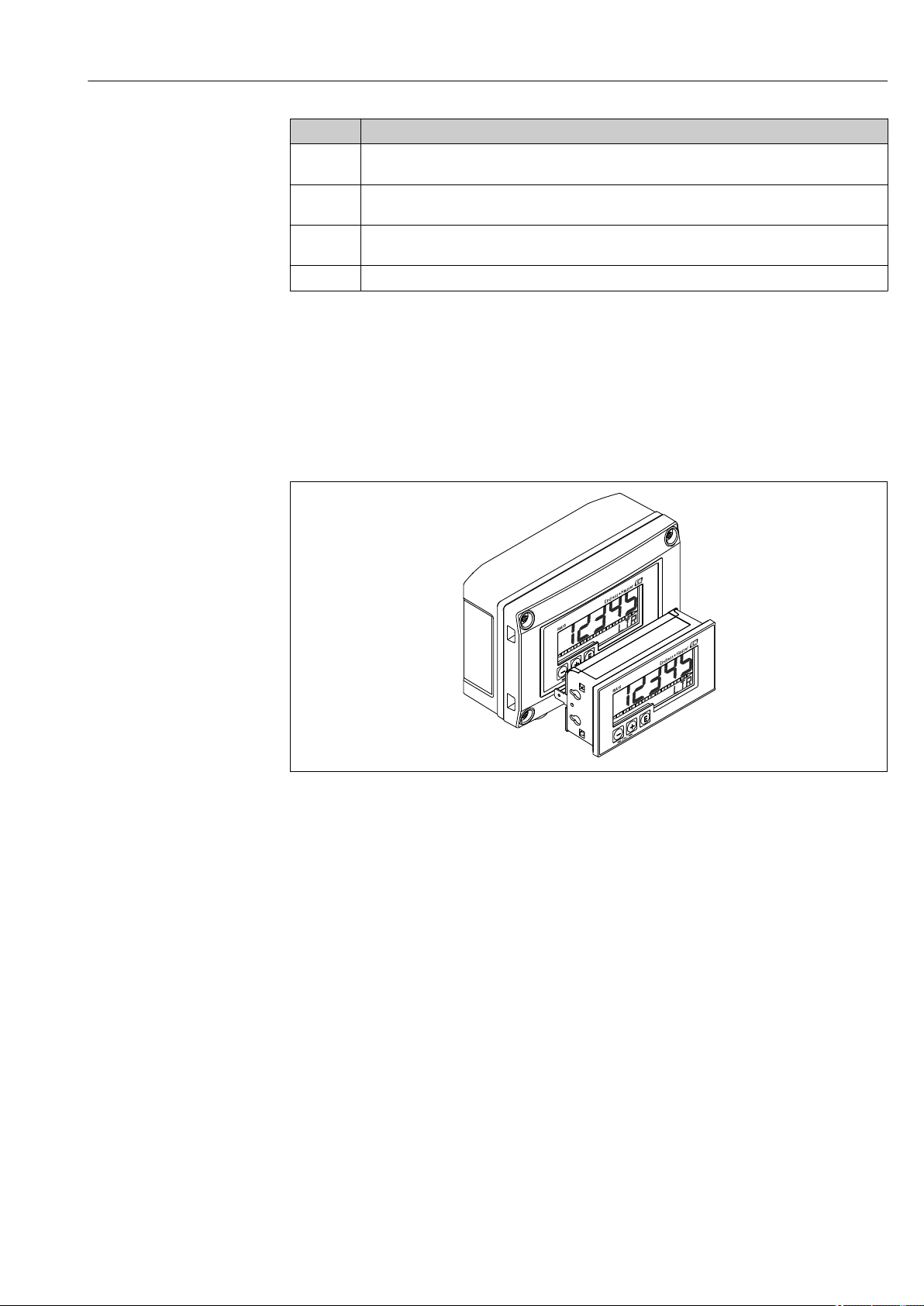

3 Product description

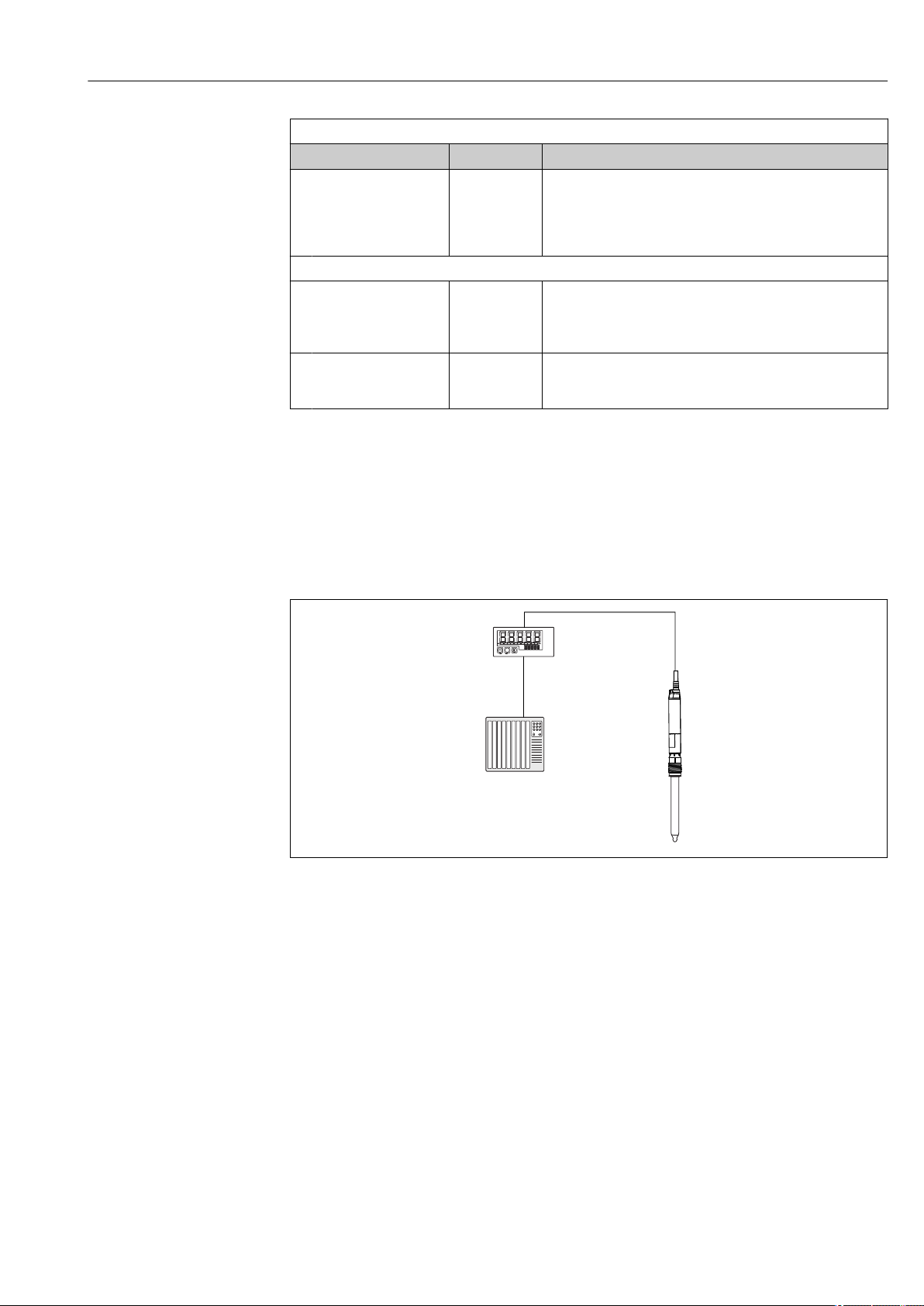

3.1 Product design

A0036216

1 Transmitter design

1 Cable

2 Housing

3 Memosens connection

4 LED, for optical signaling of operating statuses of measuring point

3.1.1 Measuring parameters

The transmitter is designed for digital Memosens sensors with inductive plug-in head:

• pH, ORP. pH/ORP combined sensors

• Conductive Conductivity

• Dissolved oxygen

8 Endress+Hauser

Page 9

Liquiline Compact CM82 Incoming acceptance and product identification

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify the supplier of any damage to the packaging.

Keep the damaged packaging until the issue has been resolved.

2. Verify that the contents are undamaged.

Notify the supplier of any damage to the delivery contents.

Keep the damaged goods until the issue has been resolved.

3. Check that the delivery is complete and nothing is missing.

Compare the shipping documents with your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

Make sure to comply with the permitted ambient conditions.

If you have any questions, please contact your supplier or your local Sales Center.

4.2 Product identification

4.2.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Order code

• Extended order code

• Serial number

• Firmware version

• Ambient and process conditions

• Input and output values

• Safety information and warnings

• Approvals as per version ordered

Compare the data on the nameplate with your order.

‣

4.2.2 Product identification

Product page

www.endress.com/CM82

Interpreting the order code

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Open the product website.

2. In the page header, select: Product tools.

Online Tools: An additional area opens up.

Endress+Hauser 9

Page 10

Incoming acceptance and product identification Liquiline Compact CM82

3. Select: Access device specific information.

An additional window opens.

4. Enter the order code from the nameplate into the search field. Then select: Show

details.

Details of each feature (selected option) of the order code are displayed.

4.3 Scope of delivery

The scope of delivery includes:

• CM82

• Brief Operating Instructions

If you have any queries:

‣

Please contact your supplier or local sales center.

4.4 Certificates and approvals

4.4.1

Endress+Hauser Conducta GmbH+CO. KG hereby declares that the radio system type

CM82 complies with directives 2014/53/EU and 2011/65/EU.

The complete text of the EU declaration of conformity can be found at the following web

address: "http://www.endress.com/CM82"

Frequency band: 2400-2483.5 MHz, power output: < 10dBm EIRP

mark

4.4.2 FCC/IC

Radio approval for USA/Canada

This device complies with Part 15 of the FCC Rules [and with Industry Canada licenseexempt RSS standard(s)]. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Any changes or modifications made to this equipment not expressly approved by Endress

+Hauser may void the FCC authorization to operate this equipment. This device complies

with Part 15 of the FCC Rules and with Industry Canada license- exempt RSS standard(s).

Operation is subject to the following two conditions:

• this device may not cause harmful interference, and

• this device must accept any interference received, including interference that may cause

undesired operation.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils

radio exempts de licence. L'exploitation est autorisée aux deux conditions suivantes:

• l'appareil ne doit pas produire de brouillage, et

• l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement.

Note: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

10 Endress+Hauser

Page 11

Liquiline Compact CM82 Incoming acceptance and product identification

202-LSF040

R

R-CRM-E1H-CM82A

user is encouraged to try to correct the interference by one or more of the following

measures:

• Increase the separation between the equipment and receiver.

• Consult the dealer or an experienced radio technician for help.

Radio approval for Japan

A0036603

Japanese Radio Law and Japanese Telecommunications Business Law Compliance. This

device is granted pursuant to the Japanese Radio Law (電波法). This device should not be

modified (otherwise the granted designation number will become invalid).

Radio approval for China

Certification number: CMIIT ID: 2017DJ6495

Radio approval for South Korea

A0036602

Endress+Hauser 11

Page 12

Installation Liquiline Compact CM82

110.8 (4.33)

99.8 (3.92)

32.75 (1.29)

114.7 (4.52)

124.6 (4.90)

Ø

18.95 (0.75)

Ø

5.5 (0.22)

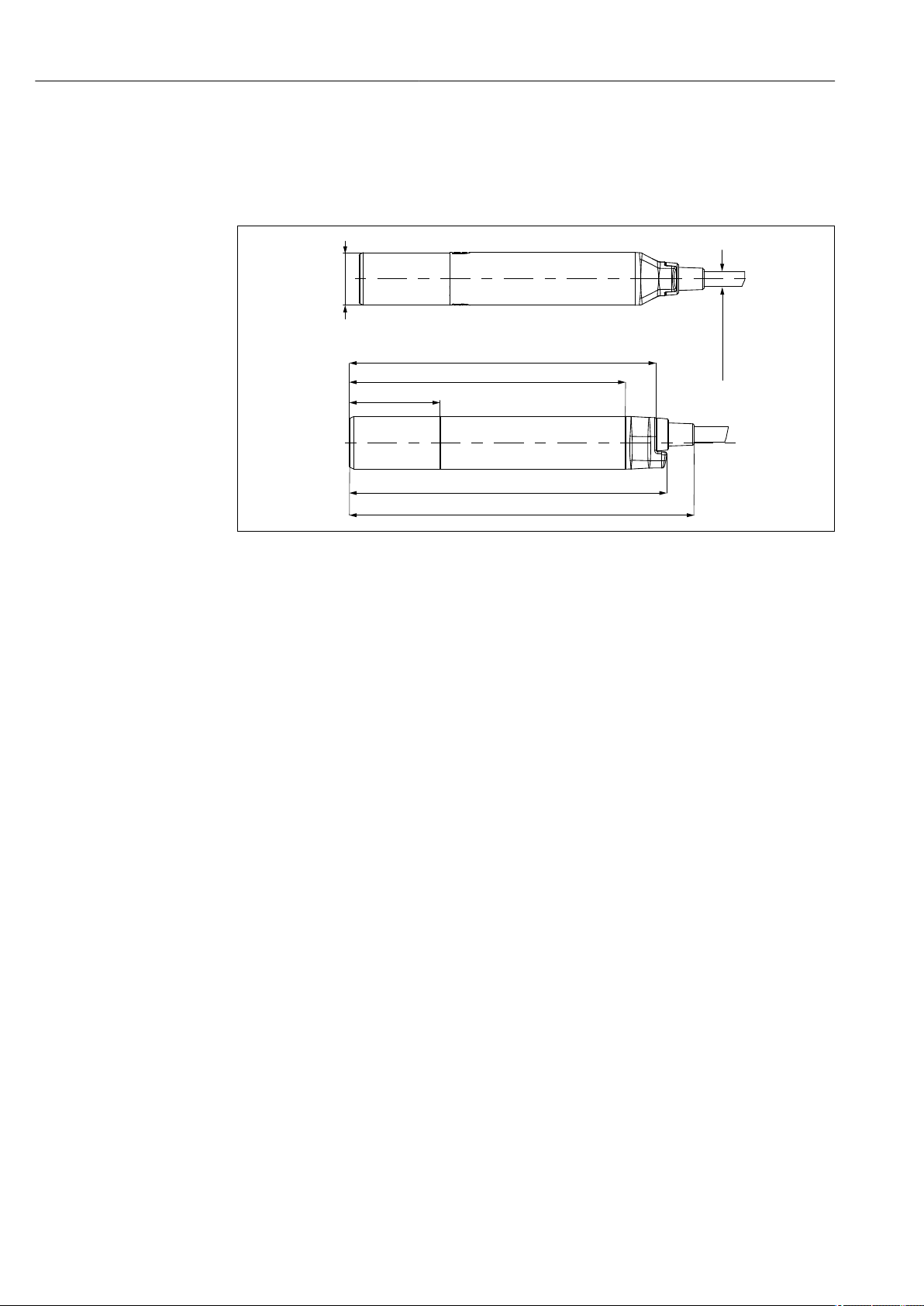

5 Installation

5.1 Dimensions

2 Dimensions in mm (inch)

A0033272

12 Endress+Hauser

Page 13

Liquiline Compact CM82 Electrical connection

GN/YE

BU

WH

+

–

GN/YE

GND

GY

6 Electrical connection

WARNING

L

Device is live!

Incorrect connection may result in injury or death!

The electrical connection may be performed only by an electrical technician.

‣

The electrical technician must have read and understood these Operating Instructions

‣

and must follow the instructions contained therein.

Prior to commencing connection work, ensure that no voltage is present on any cable.

‣

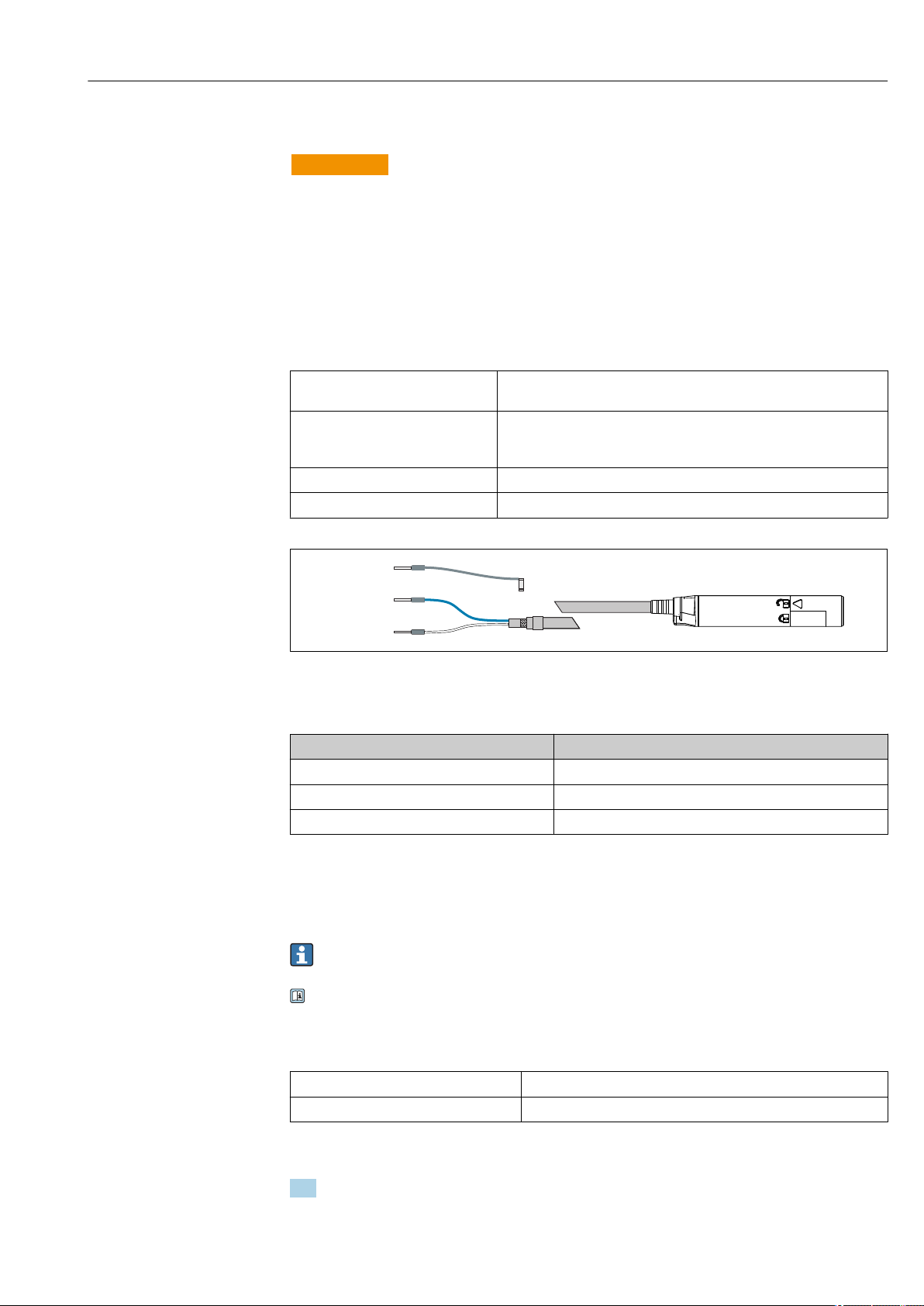

6.1 Connection

Supply voltage: 12,6 to 30 VDC (In the case of a residual current > 20 mA)

14 to 30 VDC (When the failure current is set to 3.6 mA.)

Cable length: 3 m (10 ft)

7 m (23 ft)

15 m (46 ft)

Signal output: 4 to 20 mA

Signal on alarm: 3.6 to 23 mA

3 Electrical connection

Connect ferrules as specified in the table:

‣

Cable Function

Gray (GY) Grounding, GND

BU (blue) 4 to 20 mA +

White (WH) 4 to 20 mA -

The grounding cable must be provided by the customer.

6.1.1 With RIA15

The RIA15 process display unit is loop-powered and does not require any external

power supply.

Further information is available in the RIA15 Operating Instructions BA01170K.

6.1.2 With junction box

Max. operating voltage: 30 V

Max. operating current 30 mA

A0033282

Wiring

1. Unscrew cover and remove.

The terminal assignment is indicated in the box.

Endress+Hauser 13

Page 14

Electrical connection Liquiline Compact CM82

1

2

3

4

5

6

7

8

9

10

11

12

0/4...20 mA Source+

0/4...20 mA Source+

0/4...20 mA Source-

Display+

Display (Bridge)

Display- or LED

Sensor+ (w/Display)

Sensor+ (w/o Display)

Sensor-

Shield

HART-

HART+

2. Guide the cable cores through the M16 cable gland.

3. Connect cores in accordance with the assignment provided.

A0034718

4 Terminal diagram

Further information is available in the Operating Instructions BA01802C.

6.2 Post-connection check

WARNING

L

Connection errors

The safety of people and of the measuring point is under threat. The manufacturer does

not accept any responsibility for errors that result from failure to comply with the

instructions in this manual.

Put the device into operation only if you can answer yes to all the following questions.

‣

Electrical connection

Is the device or cable undamaged (visual inspection)?

‣

Do the mounted cables have adequate strain relief?

‣

Are the cables routed without loops and cross-overs?

‣

Does the supply voltage match the specifications on the nameplate?

‣

No reverse polarity, is terminal assignment correct?

‣

14 Endress+Hauser

Page 15

Liquiline Compact CM82 Operation options

EH_FMRx0_0123456

CM82_M50053105G11

7 Operation options

7.1 Overview of operating options

Operation and settings via:

• SmartBlue (app)

• RIA15 (with reduced operating function compared to app and HART)

• PLC control station (via HART)

7.2 Access to operating menu via SmartBlue (app)

SmartBlue is available as a download for Android terminals from the Google Playstore and

for iOS devices from the Apple iTunes Store.

If you scan the QR code, you will be brought directly to the app:

5 Download links

6 SmartBlue App

A0031189-EN

A0029747

7 Livelist

The Livelist displays all of the devices that are within range.

Endress+Hauser 15

A0035117

Page 16

Operation options Liquiline Compact CM82

System requirements

• iOS devices: iPhone 4S or higher from iOS9.0; iPad2 or higher from iOS9.0; iPod Touch

5. Generation or higher from iOS9.0

• Devices with Android: from Android 4.4 KitKat and Bluetooth® 4.0

7.2.1 Structure and function of the operating menu

In the Home view, the current measured values are displayed along with the device

information (tag, serial number, firmware version, order code).

8 Overview of current measured values

1 System and device information CM82

2 Shortcut to diagnostic list

3 Overview of measured values of connected sensor

The device is operated via four main menus:

• Guidance

• Diagnostics

• Application

• System

9 Main menu

16 Endress+Hauser

Page 17

Liquiline Compact CM82 Operation options

Menu Function

Guidance Contains functions involving a self-contained sequence of activities, e.g. for calibration (="Wizard",

guided operation).

Diagnostics Contains information regarding operation, diagnostics and troubleshooting, as well as

configuration of the diagnostic behavior.

Application Sensor data for specific optimization and for detailed process adjustment. Adjustment of

measuring point to the application.

System These menus contain parameters for configuring the overall system.

7.3 Access to operating menu via RIA15

The RIA15 process indicator is incorporated into the 4 to 20 mA/HART® loop and displays

the measuring signal in digital form. The process indicator does not require an external

power supply. It is powered directly from the current loop.

By means of HART® communication, the RIA15 enables configuration and commissioning

of selected field devices and readouts of device/sensor status messages.

10 Process display unit RIA15

A0017816

Endress+Hauser 17

Page 18

System integration Liquiline Compact CM82

1

2

8 System integration

8.1 Integrating the measuring device into the system

Interfaces for measured value transmission:

• 4 to 20 mA

• Bluetooth® LE wireless technology

• HART

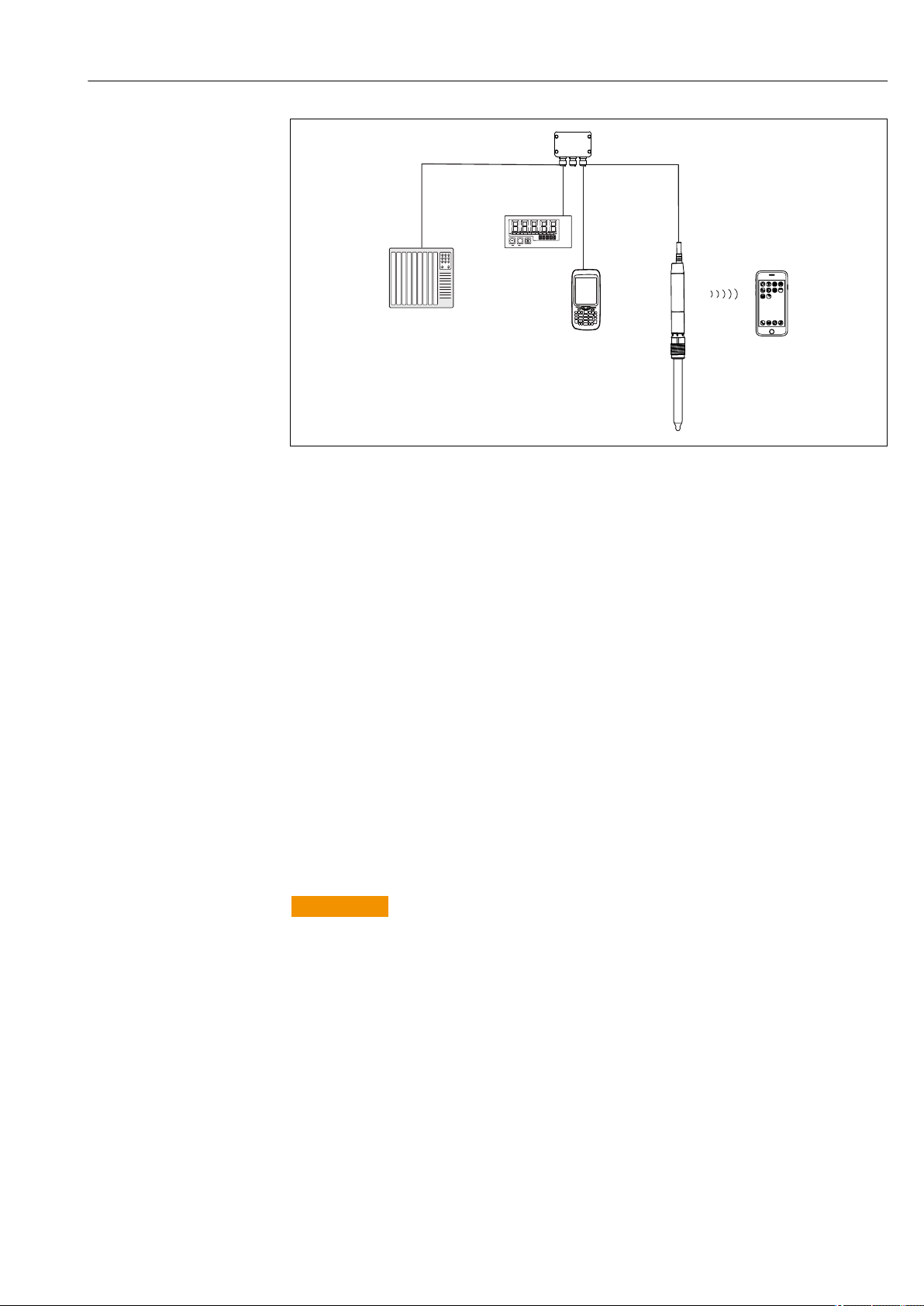

8.1.1 Bluetooth® wireless technology

11 Options for remote operation via Bluetooth® LE wireless technology

1 Smartphone / tablet with SmartBlue (app)

3 Transmitter with Bluetooth® wireless technology

8.1.2 HART

In addition to the analog 4 ... 20 mA signal, as well as the status of the device can be

transmitted digitally.

Parameterisation is also possible using an additional control unit and a suitable driver.

HART operation is possible via the following hosts (at least):

• Fieldcare und kompatible DTM-Hosts

• SFX350 Handheld

• Emerson 475 Handheld

• Emerson AMS

• Siemens PDM

A0036075

18 Endress+Hauser

Page 19

Liquiline Compact CM82 Commissioning

ESC

E

+

1

3

4

2

5

6

A0036740

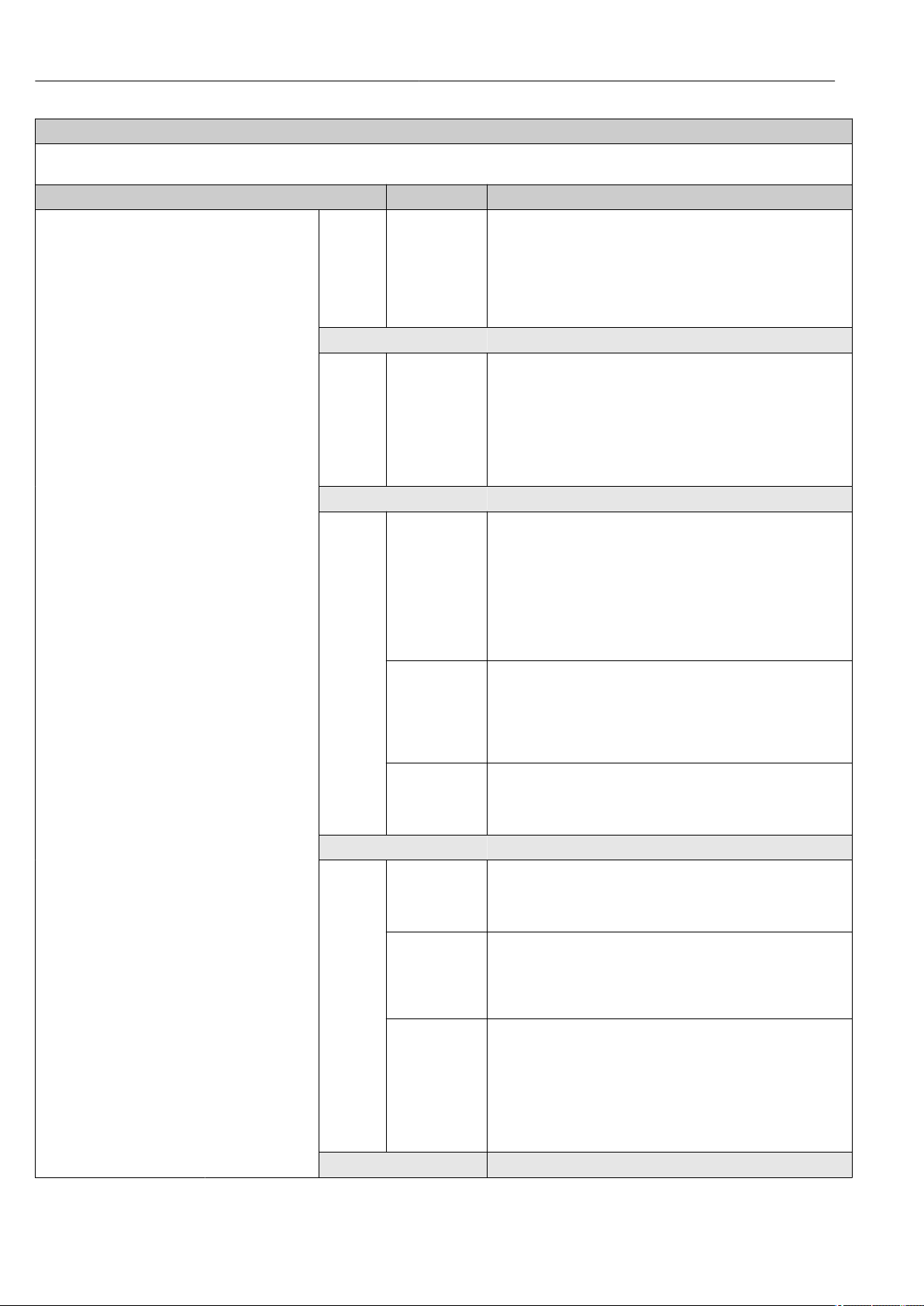

12 Wiring options for remote operation via HART protocol

1 PLC (programmable logic controller)

2 Loop-powered process display unit RIA15, optional

3 HART control unit (e.g. SFX350)

4 Junction box

5 Transmitter with Bluetooth® LE wireless technology

6 Optional: Smartphone / tablet with SmartBlue (app)

9 Commissioning

9.1 Preparatory steps

Connect the device.

‣

The device starts up and transmits the measured value as a current value.

To operate via the SmartBlue, the Bluetooth® LE signal on the smartphone or tablet must

be switched on.

9.2 Function check

WARNING

L

Incorrect connection, incorrect supply voltage

Safety risks for staff and device malfunctions!

Check that all connections have been established correctly in accordance with the

‣

wiring diagram.

Ensure that the supply voltage matches the voltage indicated on the nameplate.

‣

Familiarize yourself with the operation of the device before it is first switched on. In

particular please read the "Basic safety instructions" sections. After power-up, the device

performs a self-test and then goes to the measuring mode.

Endress+Hauser 19

Page 20

Commissioning Liquiline Compact CM82

9.2.1 LED display

LED messages signal the status of the device and sensor.

LED behavior Status

Green

Flashes quickly

Green

Flashes twice

Green

Flashes slowly

Green

Flashes quickly three times

Red

Flashes quickly

Red, green

Three red flashes

alternating with three

green flashes

Everything OK

Device starting up

Everything OK

Read out Memosens sensor information from sensor to transmitter (sensor type,

calibration data, etc.)

Everything OK

Sensor and device OK and functioning correctly.

Everything OK

Measured value at PLC in automatic HOLD.

If the "Sensor replacement alarm delay" is exceeded, the device transmits a signal

on alarm.

The automatic hold is set to 30 seconds but can be configured to suit the

customer's needs.

Failure of device or sensor

Fault state as per NAMUR NE107

Squawk

Squawk is signaled briefly while the connection is established. Squawk can also be

activated via the app. This makes it possible to locate the device more quickly, e. g.

when several devices are installed, you can see which one the connection is

established with.

9.3 Establishing connection via SmartBlue (app)

1. Download and install the SmartBlue.

2. Start the SmartBlue.

3. Select device from livelist displayed. All available devices are displayed.

4. Perform login

5. Enter user name -> admin

6. Enter initial password -> device serial number

7. It is advisable to change the user name and password after logging in for the first

time.

You can drag additional information (e.g. main menu) onto the screen by swiping

across the screen

9.3.1 System settings

Path: Settings

Function Options Info

Information

Version Displays the app version

About Endress+Hauser Manufacturer's information

User interface

Language Picklist of

different

languages

Change language

20 Endress+Hauser

Page 21

Liquiline Compact CM82 Commissioning

ESC

E

+

1

4

2

3

A

B

Path: Settings

Function Options Info

Save device login

passwords

Device List

Sorting Selection

Show demo devices Selection

Selection

• Off

• 5 minutes

• 15 minutes

• 60 minutes

• Signal

strength

• Name

•

•

Options for saving password

The password is stored temporarily for the selected time period.

It does not need to be entered when re-establishing a

connection, e.g. to replace a sensor.

Sorting options

Which devices are displayed in the list

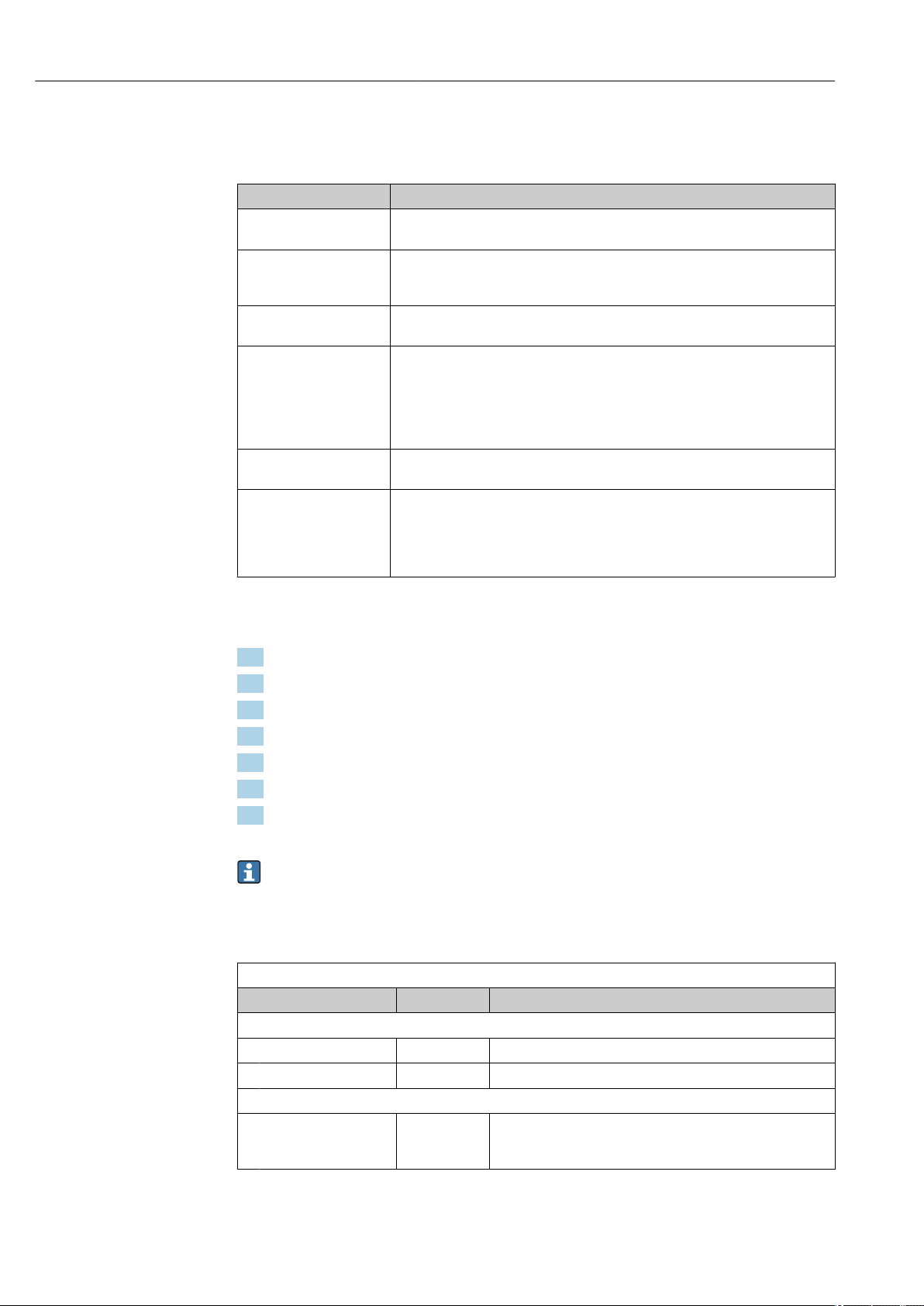

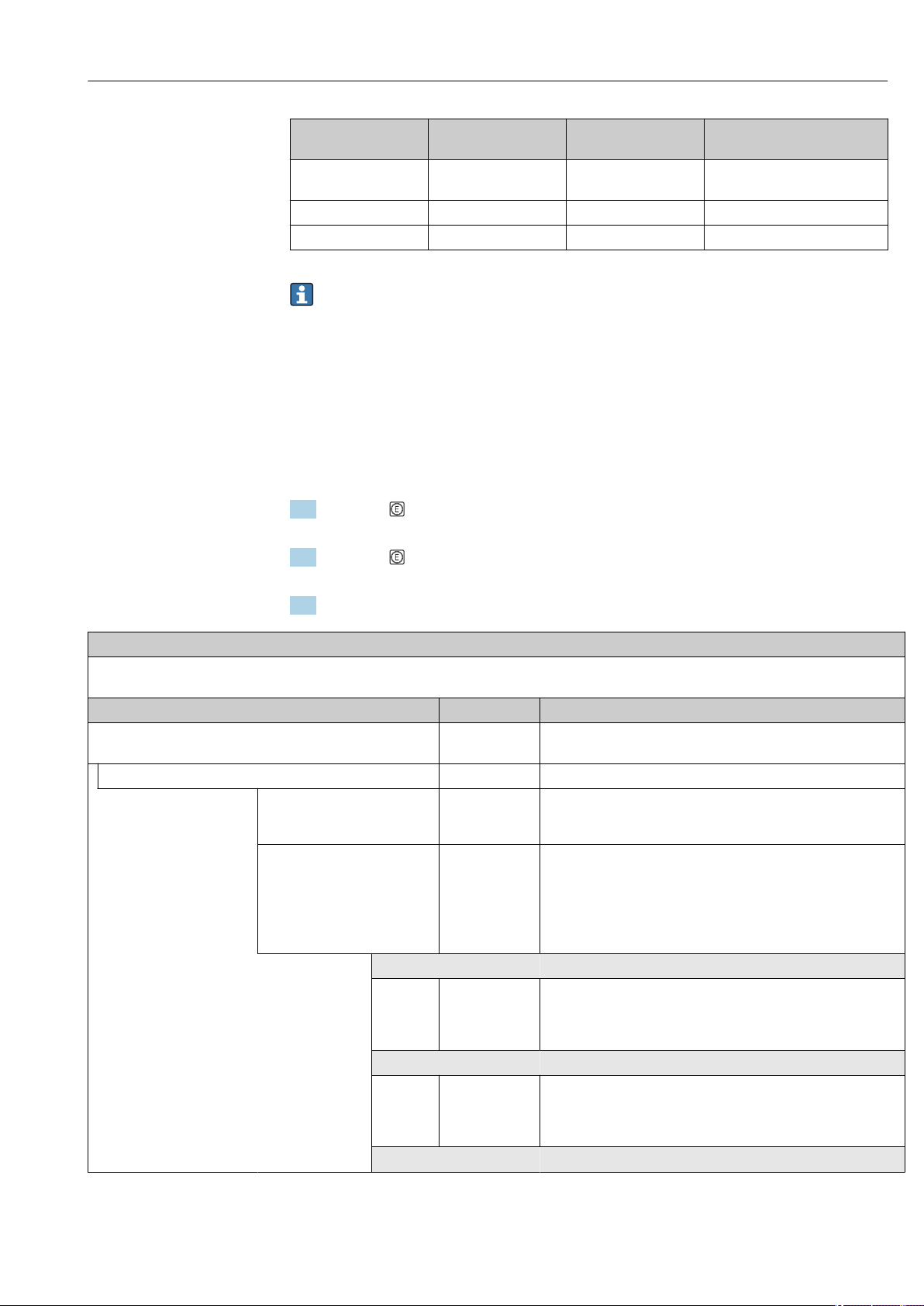

9.4 Establishing a connection via RIA15

The RIA15 can be used as a local indicator of the measured values as well as for basic

configuration of the Liquiline CM82 via HART®.

Here, the RIA15 communicates with the CM82 via HART as a secondary master in

addition to the PLC or process control system. The RIA15 is not invisible to the PLC in this

case. The RIA15 does not alter the current value of the current output of the CM82.

A0036208

13 Remote operation of CM82 via RIA15

1 PLC

2 RIA15 loop-powered process display unit

3 CM82 transmitter

4 Memosens sensor (e.g. pH sensor)

A 4 to 20mA (HART optional)

B 4 to 20mA with HART

Endress+Hauser 21

Page 22

Commissioning Liquiline Compact CM82

1

2

3

4

5

6

7

8

A0017719

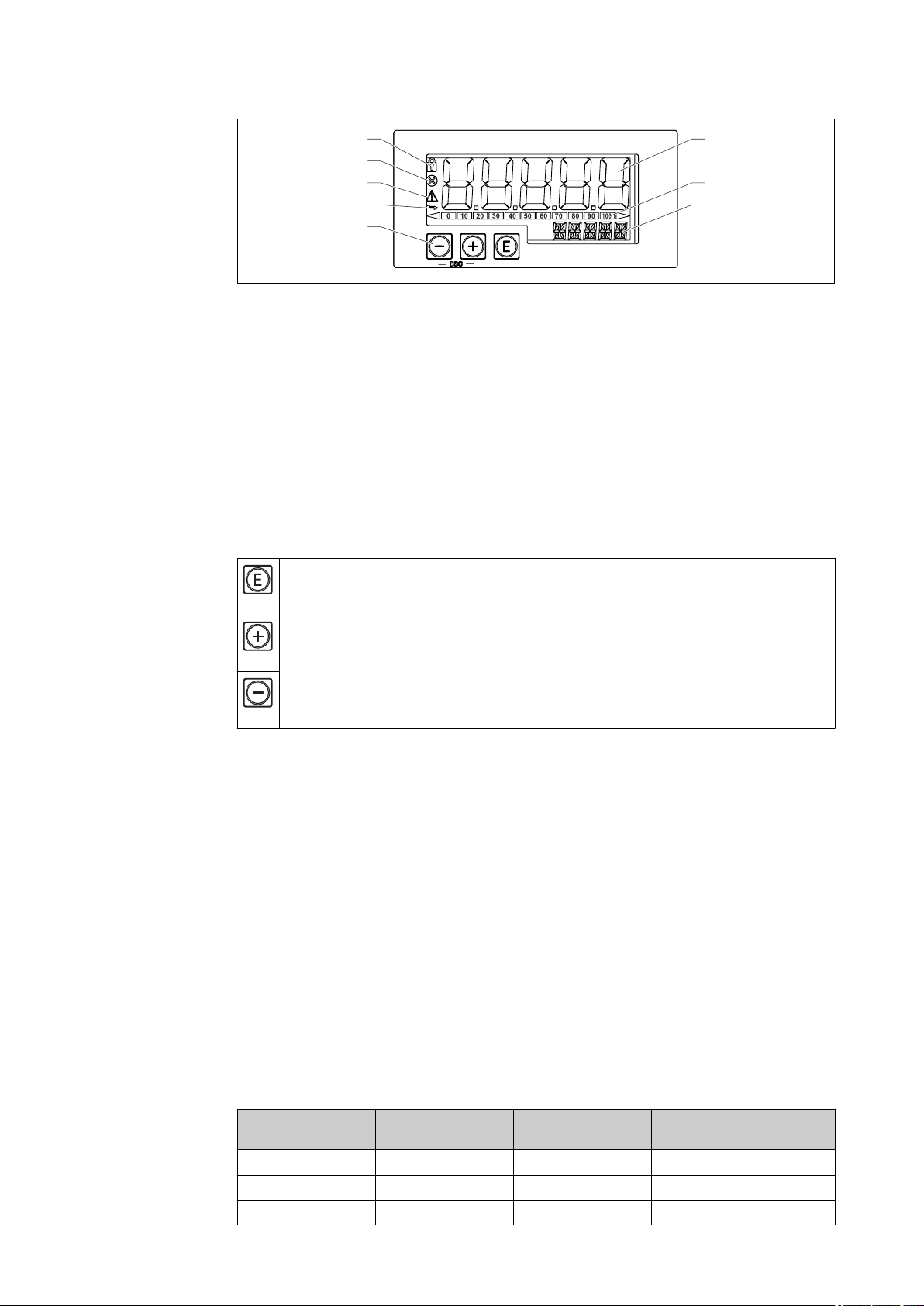

14 Display and operating elements of the process display unit

1 Operating menu locked

2 Error

3 Warning

4 HART communication enabled

5 Operating keys "-", "+", "E"

6 14-segment display for unit/TAG

7 Bar graph with indicators for under range and over range

8 5-digit 7-segment display for measured value, digit height 17 mm (0.67 in)

The device is operated using three operating keys on the front of the housing.

The device setup can be disabled with a 4-digit user code. If the setup is disabled, a padlock

symbol appears on the display when an operating parameter is selected.

Enter key; calling up the operating menu, confirming the option/setting parameters in the operating

menu

A0017716

Selecting and setting/changing values in the operating menu; pressing the '-' and '+' keys simultaneously

takes the user back up a menu level. The configured value is not saved.

A0017715

A0017714

9.4.1 RIA15 operating matrix

In HART mode, the RIA15 with "Analysis" option can be used for basic configuration of the

Liquiline CM82.

The measuring ranges are dependent on the connected sensor and can be found in the

relevant sensor documentation.

Local measured value display and basic configuration of the CM82

The RIA15 can be used as a local indicator of the measured values as well as for basic

configuration of the Liquiline CM82 via HART®.

The following values are output here: Digital output (HART®): Measured value and unit

depending on the connected sensor

PV: Configured primary value (CMAIN operating parameter)

SV: Temperature (sensor)

TV: Dependent on the connected transmitter parameter + sensor type

QV: Dependent on the connected transmitter parameter + sensor type

Transmitter

parameter

pH Glass Raw value in mV Glass impedance in MOhm

pH ISFET Raw value in mV Leak current in nA

pH ORP Relative ORP value as % Raw value in mV

22 Endress+Hauser

Sensor type "TV" value "QV" value

Page 23

Liquiline Compact CM82 Commissioning

Transmitter

parameter

pH pH/ORP combined

Conductivity Resistance Conductivity, raw value

Dissolved oxygen Liquid concentration Saturation as %

Sensor type "TV" value "QV" value

pH ORP in mV

sensor

If "UC170" is displayed instead of the unit, see footnote in table.

The following settings for the CM82 can be made using the three operating keys on the

front of the RIA15:

• Units of connected sensor

• Current output range

• Retrieval of diagnostic information

Basic configuration of the CM82

The RIA15 must be in the HART mode (MODE = HART) to make the basic settings. The

ANALYSIS menu is not visible in analog mode (MODE = 4-20).

1. Press the key.

The Setup menu opens.

2. Press the key.

The CT submenu opens.

3. Set the desired parameters. For parameter descriptions, see the following table.

Setup -> ANALYSIS menu

The CT menu and all of the associated submenus are visible only if the RIA15 was ordered with the "Analysis" option, the HART option has been

configured and a CM82 has been detected by the RIA15. Using this menu, the basic settings for the CM82 can be made via the RIA15.

Parameter Values Description

CT This menu contains the parameters for configuring the CM82

compact transmitter.

CSET Access the "CM82 setup" submenu

TUNIT °C

°F

°K

OUTS Access the "CM82 - Output Setting" submenu to change the setting

pH glass sensors

CMAIN pH

mV_PH

IMPGL

TEMP

pH/ISFET sensors

CMAIN pH

mV_PH

LEAKC

TEMP

pH/ORP sensors

Select the unit for temperature on the CM82.

on the CM82.

The primary value (CMAIN) of the CM82 is assigned here and the

measuring range (4-20mA) configured.

Depending on the sensor type connected, only certain

measured values can be configured/displayed.

PH: pH measured value in pH

mV_PH: pH raw value in mV

IMPGL: Glass impedance in MOhm

TEMP: Temperature in °C/°F/K (unit as per setting in TUNIT)

PH: pH measured value in pH

mV_PH: pH raw value in mV

LEAKC: ISFET leak current in "nA"

TEMP: Temperature in °C/°F/K (unit as per setting in TUNIT)

1)

1)

Endress+Hauser 23

Page 24

Commissioning Liquiline Compact CM82

Setup -> ANALYSIS menu

The CT menu and all of the associated submenus are visible only if the RIA15 was ordered with the "Analysis" option, the HART option has been

configured and a CM82 has been detected by the RIA15. Using this menu, the basic settings for the CM82 can be made via the RIA15.

Parameter Values Description

CMAIN mVORP

%_ORP

TEMP

pH/ORP combined sensors

CMAIN pH

mV_PH

IMPGL

IMPRE

mVORP

%_ORP

RH

TEMP

Oxygen sensors

CMAIN PAR_P

%SAT

C_LIQ

C_GAS

CURR

RTIME

TEMP

UCLIQ

mG_L

uG_L

PPM

PPB

UCGAS

%_VOL

PPM_V

Conductivity sensors

CMAIN COND

RESIS

RAWC

TEMP

URES

KO*CM

MO*CM

KO*M

UCOND

uS/cm

mS/cm

S/cm

uS/m

mS/m

S/m

for all sensors

mVORP: ORP measured value in mV

%_ORP: Percentage ORP value as %

TEMP: Temperature in °C/°F/K (unit as per setting in TUNIT)

PH: pH measured value in pH

mV_PH: pH raw value in mV

IMPGL: Glass impedance in MOhm

1)

IMPRE: Reference impedance in Ohm

mVORP: ORP measured value in mV

%_ORP: Percentage ORP value as %

RH: rH value in rH

TEMP: Temperature in °C/°F/K (unit as per setting in TUNIT)

PAR_P: Partial pressure of oxygen in hPa

%SAT: Percentage saturation as %

C_LIQ: Liquid concentration (unit as per setting in UCLIQ)

C_GAS: Gas concentration (unit as per setting in UCGAS)

CURR: Raw value, measuring current of sensor in nA

1)

(visible only

in the case of amperometric oxygen sensors)

RTIME: Decay time, raw value in μs (visible only in the case of

optical oxygen sensors)

TEMP: Temperature in °C/°F/K (unit as per setting in TUNIT)

Unit of upper and lower turndown setting if the primary value

(CMAIN) is set to C_LIQ

mG_L: milligram/liter

1)

uG_L: microgram/liter

PPM: parts per million

PPB: parts per billion

Unit of upper and lower turndown setting if the primary value

(CMAIN) is set to C_GAS

%_VOL: percent by volume

PPM_V: parts per million

COND: specific conductivity (unit as per setting in UCOND)

RESIS: specific resistance (unit as per setting in URES)

RAWC: uncompensated conductivity (unit as per setting in UCOND)

TEMP: temperature (unit as per setting in TUNIT)

Unit of upper and lower turndown setting if the primary value

(CMAIN) is set to RESIS

KO*CM: kOhm*cm

MO*CM: MOhm*cm

KO*M: kOhm*m

Unit of upper and lower turndown setting if the primary value

(CMAIN) is set to COND or RESIS

uS/cm: microsiemens/cm

mS/cm: millisiemens/cm

S/cm: siemens/cm

uS/m: microsiemens/m

mS/m: millisiemens/m

S/m: siemens/m

24 Endress+Hauser

Page 25

Liquiline Compact CM82 Commissioning

Setup -> ANALYSIS menu

The CT menu and all of the associated submenus are visible only if the RIA15 was ordered with the "Analysis" option, the HART option has been

configured and a CM82 has been detected by the RIA15. Using this menu, the basic settings for the CM82 can be made via the RIA15.

Parameter Values Description

LOW -19,999 to

99,999

Configure turndown of current output. The measured value that

corresponds to 4 mA is set here. The limits of adjustment vary

depending on the sensor type and measured value. The position of

the decimal point is permanently preset depending on the primary

value (CMAIN) configured.

Valid ranges of adjustment:

pH sensor:

PH: -2.00 to 16.00 pH

mV_PH: -2000 to 2000 mV

LEAKC: -4000.0 to 4000.0 nA

IMPGL: 0 to 99999 MOhm

IMPRE: 0 to 99999 Ohm

mVORP: -2000 to 2000 mV

%_ORP: -3000.0 to 3000.0 %

RH: 0.0 to 70.0 rH

TEMP: -50.0 to 150.0 °C (depending on the unit configured under

TEMP)

-58.0 to 302.0°F

223.1 to 423.1 K

dissolved oxygen sensor:

PAR_P: 0.0 to 2500.0 hPa

%SAT: 0.02 to 200.00 % saturation

C_LIQ:

-0.02 to 120.00 mg/l

-20.00 to 999.99 ug/l

-0.02 to 120.00 ppm

-20.00 to 999.99 ppb

(depending on the unit configured in UCLIQ)

C_GAS:

-0.02 to 200 .00 % Vol

-0.02 to 200 .00 % Vol

-200.00 to 999.99 ppm Vol

(depending on the unit configured under UCGAS)

CURR: 0.0 to 9999.9 nA

RTIME: 0.0 to 100.0 µs

TEMP:

-10.0 to 140.0 °C

14.0 to 284 °F

263.1 to 413.1 K

(depending on the unit configured under TEMP)

Conductivity sensor:

COND:

0.000 to 99.999 uS/cm

0.000 to 99.999 mS/cm

0.000 to 2.000 S/cm

0.000 to 99.999 uS/m

0.000 to 99.999 mS/m

0.000 to 99.999 S/m

(depending on the unit configured in UCOND)

RESIS:

0.00 to 999.99 kOhm*cm

0.00 to 200.00 MOhm*cm

0.00 to 999.99 kOhm*m

(depending on the unit configured in URES)

RAWC:

0.000 to 99.999 uS/cm

0.000 to 99.999 mS/cm

0.000 to 2.000 S/cm

0.000 to 99.999 uS/m

0.000 to 99.999 mS/m

0.000 to 99.999 S/m

(depending on the unit configured in UCOND)

Endress+Hauser 25

Page 26

Commissioning Liquiline Compact CM82

Setup -> ANALYSIS menu

The CT menu and all of the associated submenus are visible only if the RIA15 was ordered with the "Analysis" option, the HART option has been

configured and a CM82 has been detected by the RIA15. Using this menu, the basic settings for the CM82 can be made via the RIA15.

Parameter Values Description

TEMP:

-50.0 to 250.0 °C

-58.0 to 482.0 °F

223.1 to 523.1 K

(depending on the unit configured under TEMP)

HIGH -19,999 to

99,999

ERRC 3.6 to 23.0 Configure the error current on the CM82 in mA

CDIAC Access the "CM82 - Device diagnostics" submenu

FCSM Error category as

per NAMUR and

error number

DTAG Device tag Display the device tag of the CM82 (use +/- keys to scroll through

DSER Device serial

number

SENOC Sensor order

code

SENSN Sensor serial

number

CTRES Access the "CM82 -Reset" submenu

RBOOT No

YES

FDEF No

YES

CTSIM Access the "CM82 -Simulation" submenu

SIMUL OFF

ON

VALUE 3.6 to 23.0 Configure current output value on CM82 for simulation in mA

Configure turndown of current output. The measured value that

corresponds to 20 mA is set here. The limits of adjustment vary

depending on the sensor type and measured value. The position of

the decimal point is permanently preset depending on the primary

value (CMAIN) and units (UCLIQ, UCGAS, URES, UCOND)

configured.

For valid ranges of adjustment, see LOW (setting for 4 mA)

Display the error message with the highest priority on the CM82

text)

Display the serial number of the CM82 (use +/- keys to scroll

through text)

Display the oder code of the sensor (use +/- keys to scroll through

text)

Display the serial number of the sensor (use +/- keys to scroll

through text)

Trigger a restart of the CM82

Reset the CM82 to factory settings

Switch on simulation for current output value on CM82

1) If "UC170" is displayed instead of unit. To remedy this, the unit must be set individually and manually in the "TEXT1" menu item. (SETUP => HART

=> HART1-4 => UNIT1-4 => TEXT1-4) → 26

Further information is available in the RIA15 Operating Instructions BA01170K.

"UC170" displayed instead of HART® unit

By default, the unit of the transmitted measured value is automatically read out and

displayed using a HART® command. If the transmitted "unit code" cannot be uniquely

assigned by the RIA15, the unit code (UC170) is displayed instead of the unit. To remedy

this, the unit must be set manually. (SETUP => HART => HART1-4 => UNIT1-4 =>

TEXT1-4).

26 Endress+Hauser

Page 27

Liquiline Compact CM82 Commissioning

The unit codes 170 to 219 are assigned multiple times as per the HART® specification. As

the UC170 is also used with the CM82, the unit must be assigned manually. This applies to

the following measured values/units:

PV (TEXT1):

Transmitter parameter Primary value (CMAIN) Unit

pH Leak current (LEAKC) nA

pH Glass impedance (IMPGL) MOhm

Dissolved oxygen Liquid concentration (C_LIQ) mg/l

Dissolved oxygen Raw value of sensor (CURR) nA

QV (TEXT4):

Transmitter parameter Sensor type Unit

pH Glass MOhm

pH ISFET nA

9.5 Setting the operating language

You can change the operating language in the app settings:

Settings/User interface/Language

9.6 Date and time

Configure the date and time under System/Date/Time .

The date and time function runs only while the device is supplied with power. They

must be reset if the power supply is interrupted.

(Start time: 01.01.1970 0:00 hours...)

9.7 Configuring the measuring device

Path: Application

Function Options Info

Units

Temperature unit Selection

• °C

• °F

• K

Factory setting

°C

Cond. unit Selection

• Automatic

• µS/cm

• mS/cm

• S/cm

• µS/m

• mS/m

• S/m

Factory setting

mS/cm

To be selected for conductivity

Endress+Hauser 27

Page 28

Commissioning Liquiline Compact CM82

Path: Application

Function Options Info

Conc. (liquid) unit Selection

• mg/l

• µg/l

• ppm

• ppb

Conc. (gaseous)

unit

Selection

• %vol

• ppm

To be selected for oxygen.

9.7.1 Changing the device tag

You can change the device tag here:

System/Device management/TAG

9.7.2 Configuring the sensor

Path: Application

Function Options Info

Sensor Sensor-dependent settings

Sensor type Display the sensor type

Order code Order code of sensor

Damping The damping causes a floating average curve of

the measured values over the time specified.

Damping ORP,

Damping pH,

Damping DO,

Damping conductivity

Damping temperature 0 to 60 s

Tag control

Sensor check Selection

Group Range: 0 to 65535

Extended setup

Conductivity:

Current cell constant Read only Value currently saved in the sensor

Compensation Selection

0 ... 60 s

Factory setting

0 s

Factory setting

0 s

• Off

• Tag

• Group

Factory setting

Off

• None

• Linear

• NaCl (IEC 746-3)

• Water ISO7888

(20 °C)

• Water ISO7888

(25°C)

Factory setting

Linear

These functions determine the damping of the

primary value of the connected sensor.

These functions determine the damping of the

integrated temperature sensor.

Various methods are available to compensate for

the temperature dependency. Depending on your

process, decide which type of compensation you

want to use.

Alternatively, you can also select None and thus

measure uncompensated conductivity.

28 Endress+Hauser

Page 29

Liquiline Compact CM82 Commissioning

Path: Application

Function Options Info

Meas. ref. temp. -5.0 to 100.0 °C

(23.0 to 212.0 °F)

Factory setting

25.0 °C (77.0 °F)

Factor alpha 0.000 to 20.000 %/K

Factory setting

2.100 %/K

pH:

Temp. compensation Selection

• Off

• Automatic

• Manual

Factory setting

Automatic

Medium comp. Selection

• Off

• 2-point calibration

• Table

Factory setting

Off

Offset -18.00 to 18.00 pH

-100 to 100 mg/l

Factory setting

0.00 pH

0.00 mg/l

Internal buffer pH 0 to 14

Factory setting

pH 7.00

Oxygen:

Medium pressure Selection

• Process pressure

• Air pressure

• Altitude

• Measured value

Factory setting

Air pressure

Air pressure Choose from

Medium pressure

Salinity Selection

• Fixed value

• Measured value

Factory setting

Fixed value

Reference temperature for calculating the

temperature-compensated conductivity

Enter the conductivity coefficient of your process

medium

Decide how you want to compensate the medium

temperature:

• Automatically using the temperature sensor of

your sensor (ATC)

• Manually by entering the medium temperature

• Not at all

Take a sample from the medium and determine

its pH value at different temperatures in the lab.

Decide whether you want to compensate using

two points or several points in a table.

The offset compensates for a difference between

a laboratory measurement and an online

measurement which is caused by interference

ions. Enter this value manually. If you are using a

compensation electrode, keep the offset at zero.

Only change the value if you are using a sensor

with an internal buffer other than pH 7.

Press Measured value you can connect a

pressure measured value via a fieldbus input or a

current input. This measured value is then used

for medium pressure compensation.

For the other types of compensation, specify a

compensation value for the measurement in each

case.

1. Specify either the altitude (-300 to

4000 m), the process pressure (500 to

9999 hPa) or the air pressure (500 to

1200 hPa) of the measuring point.

The pressure used during the

calibration is also displayed for

information purposes. You can change

this pressure in: Calib. settings/

Medium pressure.

2. Confirm.

Specify air pressure (500 to 9999 hPa) of

measuring point

Endress+Hauser 29

Page 30

Commissioning Liquiline Compact CM82

Path: Application

Function Options Info

Diagnostic settings For diagnostic settings of sensor, see

section→ 39

Format settings Number of decimal places

Calibration settings

Path: Application/Sensor/Extended setup/Calibration settings

Function Options Info

pH:

Stability criteria Once the stability criterion is met, the measured

value is displayed in mV.

Delta mV 0.20 to 2.00 %

Factory setting

0 %

Duration 0 ... 60 s

Factory setting

0 s

Temp. compensation Selection

• Off

• Automatic

• Manual

Factory setting

Automatic

Buffer recognition Selection

• Fixed

• Automatic

• Manual

Factory setting

Fixed

Buffer manufacturer Selection

• Endress+Hauser

• Ingold/Mettler

• DIN 19266

• DIN 19267

• Merck/Riedel

• Hamilton

• Special buffer

Factory setting

Endress+Hauser

Calibration buffer 1 ... 2 The possible options and the factory setting

Oxygen:

1)

Measured value depending on connected sensor

Decide how you want to compensate the buffer

temperature:

• Automatically using the temperature sensor of

your sensor (ATC)

• Manually by entering the medium temperature

• Not at all

Fixed

You choose values from a list. This list depends on

the setting for Buffer manufacturer.

Automatic

The device recognizes the buffer automatically.

The recognition depends on the setting for Buffer

manufacturer.

As their zero point is offset, enamel pH

sensors cannot be calibrated and adjusted

with automatic buffer recognition.

Manual

You enter any two buffer values. These must

differ in terms of their pH value.

Temperature tables are stored internally in the

unit for the following pH values:

• Endress+Hauser

2.00 / 4.00 / 7.00 / (9.00) / 9.22 / 10.00 /

12.00

• Ingold/Mettler

2.00 / 4.01 / 7.00 / 9.21

• DIN 19266

1.68 / 4.01 / 6.86 / 9.18

• DIN 19267

1.09 / 4.65 / 6.79 / 9.23 / 12.75

• Merck/Riedel

2.00 / 4.01 / 6.98 / 8.95 / 12.00

• Hamilton

1.09 / 1.68 / 2.00 / 3.06 / 4.01 / 5.00 / 6.00

7.00 / 8.00 / 9.21 / 10.01 / 11.00 / 12.00

depend on the Buffer manufacturer

30 Endress+Hauser

Page 31

Liquiline Compact CM82 Commissioning

Path: Application/Sensor/Extended setup/Calibration settings

Function Options Info

Stability criteria

Delta signal 0.1 to 2.0 %

Factory setting

0.2 %

Delta temperature 0.10 to 2.00 K

Factory setting

0.50 K

Duration 5 to 60 s

Factory setting

20 s

Ambient conditions

Medium pressure Selection

• Process pressure

• Air pressure

• Altitude

Factory setting

Air pressure

Process pressure

Medium pressure = Process

pressure

Air pressure

Medium pressure = Air

pressure

Altitude

Medium pressure = Altitude

Rel. hum. (air variable) 0 to 100 %

Calibration timer

Function Selection

Calibration check The function checks whether the calibration of a

Function Selection

500 to 9999 hPa

Factory setting

1013 hPa

500 to 1200 hPa

Factory setting

1013 hPa

-300 to 4000 m

Factory setting

0 m

Factory setting

100 %

• Off

• On

Factory setting

Off

• Off

• On

Factory setting

Off

Permitted measured value fluctuation during

calibration.

Referenced to the raw value in nA in the case of

amperometric sensors, and referenced to the raw

value in µS in the case of optical sensors.

Permitted temperature fluctuation during

calibration

Timeframe within which the permitted measured

value variation may not be exceeded

Enter the altitude or the average air pressure of

the place of calibration (mutually dependent

values).

If you specify the altitude, the average air

pressure is calculated from the barometric

altitude formula and vice versa.

If you are compensating using the process

pressure, enter the pressure in your calibration

medium here. The pressure is then independent

of the altitude.

sensor is still valid. Example: you install a precalibrated sensor. The function checks how long

ago the sensor was last calibrated. A diagnostics

message is displayed if the time since the last

calibration is longer than specified by the

predefined warning and alarm limit.

Endress+Hauser 31

Page 32

Commissioning Liquiline Compact CM82

Path: Application/Sensor/Extended setup/Calibration settings

Function Options Info

Warning limit 1 to 50 w

Factory setting

0 w

Alarm limit 1 to 50 w

Factory setting

0 w

1) Only pH sensor or pH/ORP combined sensor

Warning and alarm limits mutually influence

each other's possible adjustment range.

Warning and alarm limits mutually influence

each other's possible adjustment range.

9.7.3 Current output

Path: Application

Function Options Info

Current output

Output value pH, ISFET, ORP and

combined options

• pH

• Raw value pH

• Impedance glass

• Impedance reference

• rH

• ISFET Leakage current

• ORP mV

• ORP %

• Temperature

Oxygen options

• Partial pressure

• % saturation

• Conc. (liquid) unit

• Conc. (gaseous) unit

• Raw value µs

• Raw value nA

• Temperature

Conductivity options

• Conductivity

• Resistivity

• Raw value (cond.

uncomp.)

• Temperature

Range lower value (4mA) The unit depends on the

Range upper value (20mA)

sensor configured.

Depends on connected sensor

Enter the measuring range. The lower and

upper range values are assigned to the 3.6

mA value and the 20 mA value respectively.

The system uses the engineering unit which

you entered beforehand.

9.7.4 HART

Path Application/HART

Function Options Info

Bus address 0 to 63

Factory setting

0

PV value Choose from Current

output/Output value

Partial pressure Partial pressure dependence for oxygen

32 Endress+Hauser

Enter the bus address

Address 1 to 63 Multidrop - mode

Primary process value

Page 33

Liquiline Compact CM82 Commissioning

Path Application/HART

Function Options Info

SV value pH, ISFET, ORP and

TV value

QV value

combined units

• pH

• Raw value pH

• Impedance glass

• Impedance reference

• rH

• ISFET Leakage current

• ORP mV

• ORP %

• Temperature

Oxygen units

• Partial pressure

• % saturation

• Conc. (liquid) unit

• Conc. (gaseous) unit

• Raw value µs

• Raw value nA

• Temperature

Conductivity units

• Conductivity

• Resistivity

• Raw value (cond.

uncomp.)

• Temperature

Protocol-specific data, dynamic variables of

HART communication.

SV = Secondary

TV = Tertiary

QV = Quaternary

9.7.5 Hold

The hold state is a safe condition during configuration and calibration.

Path:System/Hold

Function Options Info

Hold release time 0 to 600 s

Factory setting

0 s

Hold behavior Selection

• None

• Freeze

• Fixed value

Factory setting

Freeze

Hold current 3.6 to 23 mA

Factory setting

0 mA

Manual hold Selection

• Off

• On

Factory setting

Off

Calibration hold Selection

• Off

• On

Factory setting

Off

The hold status is maintained for the

duration of the delay time when you

switch to the measuring mode.

On

You can use this function to set the

channel manually to "Hold".

Off

No channel-specific hold

During calibration, the output signal is set

to "HOLD"

Endress+Hauser 33

Page 34

Commissioning Liquiline Compact CM82

9.8 Configuration management

Display the following configurations:

System/System information

• General information

• HART

System/Sensor information

• General information

• Extreme values

• Sensor operation

• Sensor specifications

• Calibration information

– Temperature adjustment

– Primary value

9.9 Unauthorized access

The compact transmitter is password-protected against unauthorized access.

You can change this password immediately after the password has been entered or under:

System/Bluetooth password

9.9.1 Resetting the password

The recovery password is used to resolve password problems during commissioning of the

device. Data security is achieved only if the default setting for the recovery password is

changed by the user.

If the user-defined password is lost, access can be restored via a recovery password.

The recovery password is the serial number of the device in reverse.

NOTICE

Forgotten recovery password.

If lost, passwords can be reset via Bluetooth only if HART is used. The device cannot be

used if it does not have HART communication.

Ensure that the login and recovery password are stored in a safe place.

‣

9.9.2 Safe signal transmission via Bluetooth® LE

Signal transmission via Bluetooth® wireless technology uses a cryptographic

technique tested by the Fraunhofer Institute.

• Without the SmartBlue app, the device is not visible via Bluetooth® wireless technology.

• Only one point-to-point connection is established between a sensor and a smartphone or

tablet.

• The Bluetooth® wireless technology interface can be disabled via the SmartBlue.

• Bluetooth® is optional. It can be ordered with this functionality enabled.

If ordered with Bluetooth® disabled, Bluetooth® can be enabled at a later stage by means

of an activation code (accessory kit) linked to the serial number.

• If the Bluetooth® interface has been disabled, it can be reactivated only via HART.

9.9.3 RIA15 locking

The device setup can be disabled with a 4-digit user code.

Further information is available in the RIA15 Operating Instructions BA01170K.

34 Endress+Hauser

Page 35

Liquiline Compact CM82 Operation

10 Operation

10.1 Reading measured values

The display of the primary values in the app is dependent on the connected sensor.

HOME view

Function

Measurement values

For pH glass, ISFET, ORP or combined sensors:

pH

Raw value pH

Impedance glass

Impedance reference

ORP mV

ORP %

rH

Temperature

For oxygen sensors:

Partial pressure

% saturation

Conc. (liquid) unit

Conc. (gaseous)

Raw value nA

Raw value µs

Temperature

For conductivity sensors:

Conductivity

Resistivity

Raw value (cond. uncomp.)

Temperature

Current output

Data relating to the transmitter:

TAG

Device type

Serial number

Firmware version

Order code

10.1.1 Changing the parameters

The device functions according to the plug & play principle of Memosens technology.

Endress+Hauser 35

Page 36

Operation Liquiline Compact CM82

However, to ensure that the settings of the previous sensor type do not get lost, the new

sensor type must be selected in the software.

Path: Guidance/Measurement parameter

Function Options Info

Measurement parameter Selection

• pH

• Dissolved oxygen

• Conductivity

With "Finish" the device will be restarted and the measurement parameter change will be executed.

This may take a few minutes.

Select the parameters supported by the

device.

10.2 Adapting the measuring device to the process

conditions

10.2.1 Medium compensation (in the process) for oxygen

Path: Application/Sensor/Extended setup

Function Options Info

Medium pressure Selection

• Process pressure

• Air pressure

• Altitude

Salinity 0 to 40 g/kg

Factory setting

0 g/kg

Specify altitude (-300 to 4000 m),

process pressure (500 to 9999 hPa)

or air pressure (500 to 1200 hPa) of measuring

point

The influence of salt content on oxygen

measurement is compensated with this function.

Example: sea water measurement as per

Copenhagen Standard (30 g/kg).

36 Endress+Hauser

Page 37

Liquiline Compact CM82 Operation

10.2.2 LED settings (optical oxygen sensors only)

Path: Application/Sensor/Extended setup

Function Options Info

LED temp. mode Selection

• Off

• On

Factory setting

Off

LED temp. threshold 30 to 130 °C (86 to 266 °F)

Factory setting

80 °C (176 °F)

LED measuring interval Selection

• 1 second

• 3 seconds

• 10 seconds

• 30 seconds

Factory setting

1 second

Measurement filter Selection

• Off

• Weak

• Normal

• Strong

• Very strong

Switches off the LED when the set temperature

threshold is exceeded.

This prevents the premature aging of the sensor

cap, e.g. during a CIP or SIP cycle.

The LED measuring interval influences the

response time on the one hand and the

operating life of the sensor cap on the other.

Shorter intervals improve the response time but

reduce the operating life of the sensor cap.

Make your setting depending on the

requirements of your process.

Use this function to select how strong or weak

the signal filtering in sensor COS81D should be.

Off

No signal filtering takes place the recorded

signals are passed through virtually unfiltered.

Weak

Signal filtering is weak.

Normal

Signal filtering is normal.

Strong

Signal filtering is strong.

Very strong

Signal filtering is very strong. Widely fluctuating

raw signals are greatly attenuated by the sensor.

Endress+Hauser 37

Page 38

Diagnostics and troubleshooting Liquiline Compact CM82

11 Diagnostics and troubleshooting

11.1 Diagnostic information via LED

See LED display in Commissioning section. (→ 20)

11.2 Adapting the diagnostic information

Path: Diagnostics/Diagnostic settings

Function Options Info

Sensor change alarm delay 0 ... 180 s

Factory setting

30 s

Error current 3.6 to 23.0 mA

Factory setting

22.5 s

LED shows NAMUR status signal Selection

• Off

• On

Factory setting

Off

Diagnostics behavior The list of diagnostic messages

Status signal The messages are divided into

Diagnostics behavior Selection

• Warning

• Alarm

Sensor HOLD

Possible range of error current.

* Additional LED signals for

diagnostic messages as per

NAMUR NE107 categories.

displayed. There are devicespecific messages, and

messages that depend on what

sensor is connected.

Select the message to be

adapted. Only then can you

make the settings for this

message.

different error categories in

accordance with NAMUR NE

107.

* LED as per NAMUR NE107 categories:

Three rapid green flashes at the start of the message means: Everything OK - but pay

attention!

The more red flashes there are at the end of a message, the more critical the diagnosis as

per NE107. Continuous red only flashing means: Error in device or sensor, take action

immediately.

LED behavior Status

Three rapid green flashes and a single rapid red

flash

Three rapid green flashes and two rapid red flashes Device and sensor are being operated out of specification.

Three rapid green flashes and three rapid red

flashes

Red

Flashes quickly

Device or sensor requires maintenance.

M status signal as per NAMUR NE107

S status as per NAMUR NE107

Device or sensor undergoing function check.

C status signal as per NAMUR NE107

Failure of device or sensor

F status signal as per NAMUR NE107

38 Endress+Hauser

Page 39

Liquiline Compact CM82 Diagnostics and troubleshooting

11.3 Adapting sensor diagnostic information

This menu branch is used for specifying warning limits, and for defining whether and how

diagnostics tools should be used.

11.3.1 Impedance monitoring

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info

Glass impedance

Upper limit Selection

• Off

• On

Factory setting

Off

Upper limit Selection

• Off

• On

Factory setting

On

Upper alarm limit 0 to 10000 MΩ

Factory setting

3000 MΩ

Upper warning limit 0 to 10000 MΩ

Factory setting

2500 MΩ

Lower limit Selection

• Off

• On

Factory setting

Off

Lower limit Selection

• Off

• On

Factory setting

On

Lower warning limit 0 to 10000 MΩ

Factory setting

0.1 MΩ

Lower alarm limit 0 to 10000 MΩ

Factory setting

0 MΩ

On

The Sensor Check System (SCS)

operates with the following

settings for the upper warning

and alarm limits.

Off

Monitoring of the upper

warning and alarm limits is

switched off.

On

The Sensor Check System (SCS)

operates with the following

settings for the upper warning

and alarm limits.

Off

Monitoring of the upper

warning and alarm limits is

switched off.

Diagnostics code and associated

message text: 124 Sensor glass

Diagnostics code and associated

message text: 125 Sensor glass

On

The Sensor Check System (SCS)

operates with the following

settings for the lower warning

and alarm limits.

Off

Monitoring of the lower

warning and alarm limits is

switched off.

On

The Sensor Check System (SCS)

operates with the following

settings for the lower warning

and alarm limits.

Off

Monitoring of the lower

warning and alarm limits is

switched off.

Diagnostics code and associated

message text: 123 Sensor glass

Diagnostics code and associated

message text: 122 Sensor glass

Endress+Hauser 39

Page 40

Diagnostics and troubleshooting Liquiline Compact CM82

11.3.2 Slope

pH, oxygen

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info

pH

Slope The slope characterizes the

sensor condition. The greater

the deviation from the ideal

value (pH), the worse the

condition of the sensor.

Warning limit 5.00 to 99.00 mV/pH

Factory setting

55.00 mV/pH

Oxygen

Upper warning limit 0.0 to 200.0 %

Factory setting

140.0 %

Lower warning limit 0.0 to 200.0 %

Factory setting

60.0 %

Specify your limit values for

slope monitoring. Associated

diagnostic code and message

text: 509 sensor calibration

Associated diagnostics code and

message text: 511 Sensor

calibration

Associated diagnostics code and

message text: 509 Sensor

calibration

11.3.3 Delta slope

pH, pH/ORP combined sensor, oxygen

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info

pH and pH/ORP combined sensors

Delta slope The device determines the

difference in slope between the

last calibration and the

penultimate calibration, and

issues a warning or an alarm

depending on the setting

configured. The difference is an

indicator for the condition of

the sensor. The greater the

change, the greater the wear

experienced by the pH-sensitive

glass membrane as a result of

chemical corrosion or abrasion.

Function Selection

• Off

• On

Warning limit 0.10 to 10.00 mV/pH

Factory setting

5.00 mV/pH

Oxygen

Switches the function on or off

Specify your limit values for

monitoring the slope

differential.

Associated diagnostics code and

message text: 518 Sensor

calibration

40 Endress+Hauser

Page 41

Liquiline Compact CM82 Diagnostics and troubleshooting

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info

Delta slope The device determines the

difference in slope between the

last calibration and the

penultimate calibration, and

issues a warning or an alarm

depending on the setting

configured. The difference is an

indicator for the condition of

the sensor.

An increasing change indicates

the formation of buildup on the

sensor diaphragm or electrolyte

contamination. Replace the

diaphragm and electrolyte as

specified in the instructions in

the sensor operating manual.

Function Selection

• Off

• On

Factory setting

Off

Warning limit 0.0 to 50.0 %

Factory setting

5.0 %

Switches the function on or off

Specify your limit values for

monitoring the slope

differential.

Associated diagnostics code and

message text: 518 Sensor

calibration

11.3.4 Zero point and operating point

pH, ISFET, oxygen

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info

pH, ISFET

Zero point

(pH glass)

Operating point

(ISFET)

Upper warning limit Lower warning limit ...

pH 12.00

Lower warning limit ...

950 mV

1)

2)

Factory setting

pH 8.00 / 300 mV

Lower warning limit pH 2.00 to Upper warning

limit

-950 mV to Upper

warning limit

2)

Factory setting

pH 6.00 / ‐300 mV

Oxygen

The zero point or operating

point characterizes the

condition of the sensor

reference. The bigger the

deviation from the ideal value

(pH 7.00) the poorer the

condition. This can be caused by

KCl dissolving away or reference

contamination, for example.

Associated diagnostics code and

message text:

505 Sensor calibration

515 Sensor calibration

Associated diagnostics code and

message text:

507 Sensor calibration

517 Sensor calibration

2)

2)

Endress+Hauser 41

Page 42

Diagnostics and troubleshooting Liquiline Compact CM82

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info

Zero point The zero point corresponds to

the sensor signal that is

measured in a medium in the

absence of oxygen. You can

calibrate the zero point in water

that is free from oxygen or in

high-purity nitrogen. This

improves accuracy in the trace

range.

Warning limit 0.0 to 10.0 nA

Factory setting

3.0 nA

1) pH Glass

2) pH ISFET

Specify the limit values for zero

point monitoring in your sensor.

Associated diagnostics code and

message text: 513 Zero

Warning

11.3.5 Delta zero point/operating point

pH, ISFET, oxygen

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info

pH, ISFET

Delta zero point The device determines the

difference between the last

calibration and the penultimate

calibration, and issues a

warning or an alarm depending

on the setting configured. The

difference is an indicator for the

condition of the sensor.

Function Selection

• Off

• On

Warning limit pH 0.00 to 2.00 (pH glass)

Factory setting

pH 0.50 / 25 mV

Oxygen

Function Selection

• Off

• On

Factory setting

Off

Warning limit 0.0 to 10 nA

Factory setting

1.0 nA

Switches the function on or off

Specify your limit values for

monitoring the slope

differential.

Associated diagnostics code and

message text:

• 520 Sensor calibration (pH

glass)

• 522 Sensor calibration

(ISFET)

Switches the function on or off

Specify your limit values for

monitoring the slope

differential.

Associated diagnostics code and

message text: 520 Sensor

calibration

42 Endress+Hauser

Page 43

Liquiline Compact CM82 Diagnostics and troubleshooting

11.3.6 Operating hours limits

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info

Limits operating hours The total operating time of the

sensor and its use under

extreme conditions is

monitored. If the operating time

exceeds the defined threshold

values, the device issues a

corresponding diagnostics

message.

Function Selection

• Off

• On

Operating time Factory setting

60000 h

Operating time > 80 °C Factory setting

50000 h

Operating time > 80 °C < 100 nS/cm Factory setting

30000 h

Operating time > 100 °C Factory setting

50000 h

Operating time > 120 °C Factory setting

10000 h

Operating time > 150 °C Factory setting

10000 h

Operating time < -300 mV Factory setting

60000 h

Operating time > 300 mV Factory setting

60000 h

On

The operation of the sensor

under extreme conditions is

monitored, recorded in the

sensor and diagnostics

messages are displayed on the

controller.

Off

No diagnostics messages.

However, the time the sensor

operates under extreme

conditions is recorded in the

sensor and can be read in the

sensor information in the

diagnostics menu.

Diagnostics code and associated

message text: 193 Operating

time

Only conductive sensors

Diagnostics code and associated

message text: 194 Operating

time

Diagnostics code and associated

message text: 195 Operating

time

Diagnostics code and associated

message text: 198 Operating

time

Only pH sensor or pH/ORP

combined sensor

Only pH sensor or pH/ORP

combined sensor

Endress+Hauser 43

Page 44

Diagnostics and troubleshooting Liquiline Compact CM82

11.3.7 Sterilizations

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info

Sterilizations The system counts the number

of operating hours in which the

sensor is exposed to a

temperature that is typical for a

sterilization. This temperature

depends on the sensor.

Function Selection

• Off

• On

Warning limit 0 to 1000

Factory setting

800

Cap sterilizations (only sterilizable sensors)

Switches the function on or off

Specify the limit value for the

number of sensor sterilizations.

Diagnostics code and associated

message text: 108 SIP, CIP,

autoclaving

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info

No. sterilizations cap Not displayed for optical oxygen

sensors.

The sterilization counters in the

sensor make a distinction

between the sensor and the

membrane/fluorescence cap

currently used. If this cap is

replaced, only the (cap) counter

is reset.

Function Selection

• Off

• On

Factory setting

Off

Warning limit 0 to 100

Factory setting

25

Specify how many sterilizations

may be performed with a

membrane cap before the cap

has to be replaced. The number

depends heavily on the process

and must be determined

individually.

Associated diagnostics code and

message text: 109 Sterilization

cap

44 Endress+Hauser

Page 45

Liquiline Compact CM82 Diagnostics and troubleshooting

11.3.8 Sensor Condition Check (SCC)

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info

Sensor condition check Sensor condition check (SCC)

monitors the electrode status

and the degree of electrode

aging. The condition of the

electrode is updated after every

calibration.

The main reasons for a

deteriorating electrode status

are:

• Glass membrane blocked or

dry

• Diaphragm (reference)

blocked

Function Selection

• Off

• On

Switches the function on or off

Diagnostics code and associated

message text:

127 SCC adequate

126 SCC poor

11.3.9 Process monitoring

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info

Process check system The process check system (PCS)

checks the measuring signal for

stagnation. An alarm is

triggered if the measuring

signal does not change over a

specific period (several

measured values).

Function Selection

Duration 0 to 240 min Once this time has elapsed, the

Tolerance width

Not for pH/ORP sensors

• Off

• On

The range depends on the

sensor

Factory setting

Depends on the sensor

Switches the function on or off

calibration timer diagnostic

message, along with the code

102, appears on the display.

Interval around the measuring

signal (raw value) for detecting

stagnation.

Measured values within the set

interval are regarded as

stagnating.

11.3.10 Measured value

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info

ORP-Meas value

Function Selection

• Off

• On

Upper alarm value 0 to 10000 mV Diagnostics code and associated

Endress+Hauser 45

Switches the function on or off

message text: 124 Sensor glass

Page 46

Diagnostics and troubleshooting Liquiline Compact CM82

Path: Application/Sensor/Extended setup/Diagnostic settings

Function Options Info