Page 1

BA01570C/07/EN/07.19

71463751

2019-11-30

Valid as of version

01.07.00

Products Solutions Services

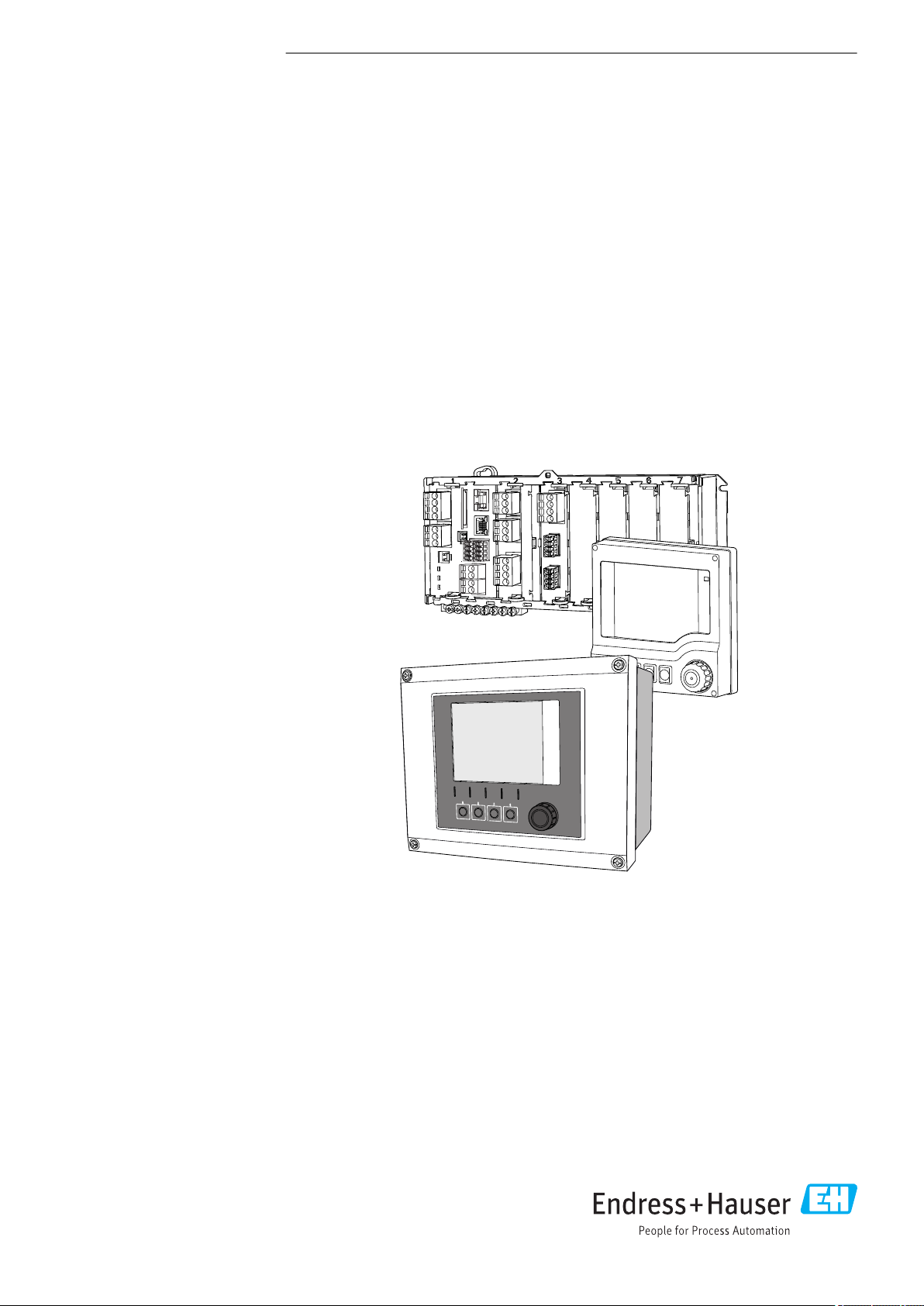

Operating Instructions

Liquiline CM44P

Universal four-wire multichannel controller for process

photometers and Memosens sensors

Page 2

Page 3

Liquiline CM44P Table of contents

Table of contents

1 About this document ................ 5

1.1 Warnings ............................ 5

1.2 Symbols .............................. 5

1.3 Symbols on the device ................... 5

1.4 Documentation ........................ 6

2 Basic safety instructions ............ 7

2.1 Requirements for personnel ............... 7

2.2 Designated use ........................ 7

2.3 Workplace safety ....................... 8

2.4 Operational safety ...................... 8

2.5 Product safety ......................... 9

3 Device description ................. 10

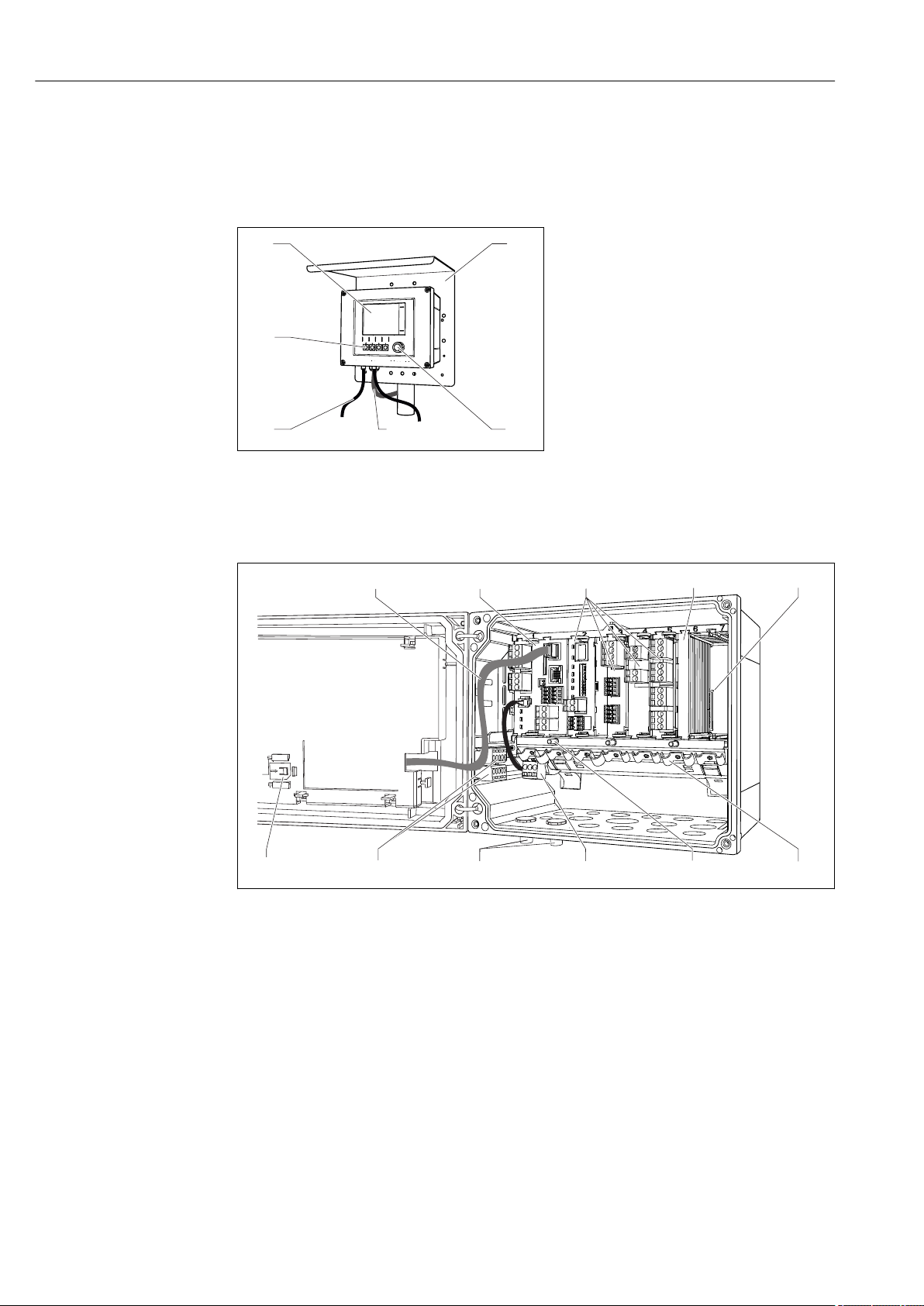

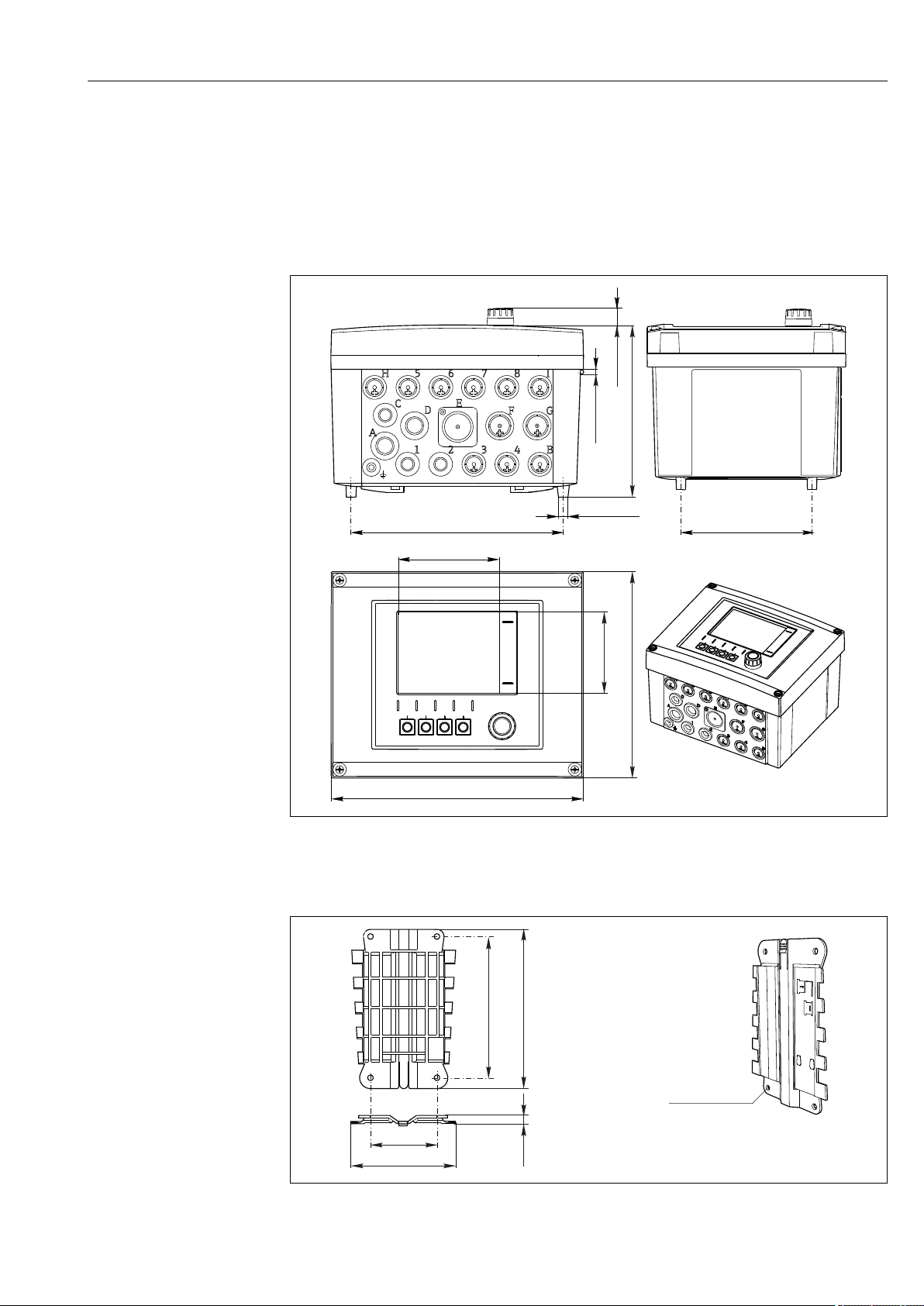

3.1 Housing closed (field device) ............. 10

3.2 Housing open (field device) .............. 10

3.3 Overview (cabinet device) ................ 11

3.4 Slot and port assignment ................ 12

3.5 Terminal diagram ..................... 13

4 Incoming acceptance and product

identification ..................... 14

4.1 Incoming acceptance ................... 14

4.2 Product identification ................... 14

4.3 Scope of delivery ...................... 15

4.4 Certificates and approvals ............... 15

5 Installation ....................... 17

5.1 Installation conditions .................. 17

5.2 Mounting the measuring device (field

device) ............................. 21

5.3 Mounting the measuring device (cabinet

device) ............................. 26

5.4 Post-installation check .................. 29

6 Electrical connection .............. 30

6.1 Connection conditions .................. 30

6.2 Connecting the measuring device .......... 31

6.3 Connecting the sensors ................. 36

6.4 Connecting additional inputs, outputs or

relays .............................. 40

6.5 Connecting PROFIBUS DP or Modbus RS

485 ................................ 44

6.6 Hardware settings ..................... 47

6.7 Ensuring the degree of protection .......... 48

6.8 Post-connection check .................. 49

7 System integration ................ 50

7.1 Web server .......................... 50

7.2 Service interface ...................... 51

7.3 Fieldbuses ........................... 52

8 Operation options ................. 54

8.1 Overview ............................ 54

8.2 Access to the operating menu via the local

display ............................. 55

8.3 Configuration options .................. 56

9 Commissioning .................... 59

9.1 Function check ....................... 59

9.2 Power up ............................ 59

9.3 User definable screens ................. 60

9.4 Basic setup .......................... 61

10 Operation ......................... 62

10.1 Display ............................. 62

10.2 General settings ....................... 64

10.3 Inputs .............................. 78

10.4 Outputs ............................. 86

10.5 Binary inputs and outputs ............... 95

10.6 Additional functions .................. 100

11 Calibration ...................... 130

11.1 Calibration instructions ................ 130

11.2 Menu CAL .......................... 132

12 Diagnostics and troubleshooting .. 136

12.1 General troubleshooting ................ 136

12.2 Diagnostic information on the local display .. 137

12.3 Diagnostic information via web browser .... 137

12.4 Diagnostic information via fieldbus ........ 137

12.5 Adapting the diagnostic information ...... 137

12.6 Overview of diagnostic information ....... 139

12.7 Pending diagnostic messages ............ 158

12.8 Diagnostics list ...................... 159

12.9 Event logbook ....................... 159

12.10 Simulation ......................... 162

12.11 Device test .......................... 164

12.12 Resetting the measuring device .......... 164

12.13 Device information ................... 165

12.14 Firmware history ..................... 168

13 Maintenance .................... 170

13.1 Cleaning ........................... 170

14 Repair ........................... 172

14.1 Spare parts ......................... 172

14.2 Return ............................. 175

14.3 Disposal ........................... 175

15 Accessories ...................... 176

15.1 Measuring cable ..................... 176

15.2 Sensors ............................ 176

Endress+Hauser 3

Page 4

Table of contents Liquiline CM44P

15.3 Additional functionality ................ 182

15.4 Software ........................... 183

15.5 Other accessories ..................... 184

16 Technical data ................... 186

16.1 Input .............................. 186

16.2 Digital inputs, passive ................. 187

16.3 Current input, passive ................. 187

16.4 Output ............................ 187

16.5 Digital outputs, passive ................ 189

16.6 Current outputs, active ................. 189

16.7 Relay outputs ........................ 190

16.8 Protocol-specific data .................. 191

16.9 Power supply ........................ 194

16.10 Performance characteristics ............. 195

16.11 Environment ........................ 196

16.12 Mechanical construction ............... 198

17 Installation and operation in

hazardous environment Class I Div.

2 ................................ 199

Index ................................. 200

4 Endress+Hauser

Page 5

Liquiline CM44P About this document

1 About this document

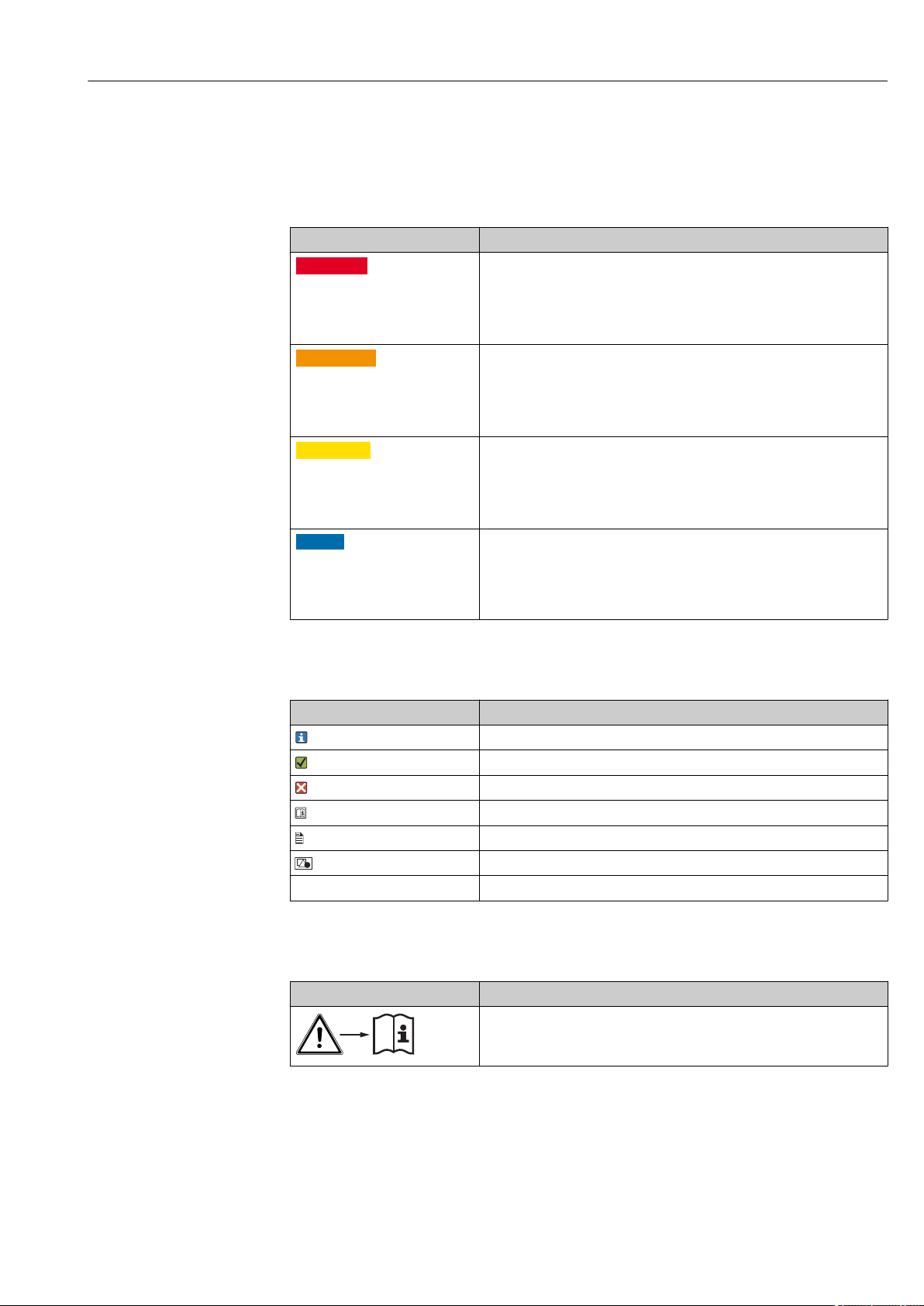

1.1 Warnings

Structure of information Meaning

DANGER

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

If necessary, Consequences of

non-compliance (if applicable)

Corrective action

‣

NOTICE

Cause/situation

If necessary, Consequences of

non-compliance (if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to

property.

1.2 Symbols

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

1.3 Symbols on the device

Symbol Meaning

Reference to device documentation

Endress+Hauser 5

Page 6

About this document Liquiline CM44P

1.4 Documentation

The following instructions complement these Operating Instructions and are available on

the product pages on the Internet:

• Brief Operating Instructions Liquiline CM44P, KA01213C

• Operating Instructions Memosens, BA01245C

• Software description for Memosens inputs

• Calibration of Memosens sensors

• Sensor-specific diagnostics and troubleshooting

• Operating Instructions for HART communication, BA00486C

• Onsite settings and installation instructions for HART

• Description of HART driver

• Guidelines for communication via fieldbus and web server

• HART, SD01187C

• PROFIBUS, SD01188C

• Modbus, SD01189C

• Web server, SD01190C

• Ethernet/IP, SD01293C

• PROFINET, SD02490C

6 Endress+Hauser

Page 7

Liquiline CM44P Basic safety instructions

2 Basic safety instructions

2.1 Requirements for personnel

• Installation, commissioning, operation and maintenance of the measuring system may

be carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the

specified activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions

and must follow the instructions contained therein.

• Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

2.2.1 Non-hazardous atmosphere

Liquiline CM44P is a multichannel controller for connecting analog photometers and

digital sensors with Memosens technology in non-hazardous environments.

The device is designed for use in the following applications:

• Food and beverages

• Life science

• Power stations

• Chemical industry

• Other industrial applications

2.2.2 Hazardous environment in accordance with cCSAus Class I Div.

2

Please pay attention to the control drawing and specified operating conditions in the

‣

appendix of this manual and follow the instructions.

2.2.3 Non-designated use and improper use

NOTICE

Objects stored on top of the housing

May cause short-circuits or fire or result in the failure of individual cabinet components or

complete failure of the measuring point!

Never place any objects, such as tools, cables, paper, food, liquid containers or similar,

‣

on top of the housing.

Always observe the operator's regulations, in particular with regard to fire safety

‣

(smoking) and foodstuffs (beverages).

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

Endress+Hauser 7

Page 8

Basic safety instructions Liquiline CM44P

2.2.4 Installation environment (cabinet device only)

The device and the associated power units can be operated with 24 V AC, 24 V DC or 100

to 230 V AC and provide shock protection in accordance with IP20.

The components have been designed for pollution degree 2, and moisture must not be

allowed to collect in them. The components must therefore be installed in an appropriate

enclosure for protection. The ambient conditions specified in the instructions must be

observed here.

2.3 Workplace safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

• Regulations for explosion protection

Electromagnetic compatibility

• The product has been tested for electromagnetic compatibility in accordance with the

applicable international standards for industrial applications.

• The electromagnetic compatibility indicated applies only to a product that has been

connected in accordance with these Operating Instructions.

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

During operation:

If faults cannot be rectified:

‣

products must be taken out of service and protected against unintentional operation.

CAUTION

L

Cleaning not switched off during calibration or maintenance activities

Risk of injury due to medium or cleaning agent!

If a cleaning system is connected, switch it off before removing a sensor from the

‣

medium.

If you wish to check the cleaning function and have therefore not switched off the

‣

cleaning system, wear protective clothing, goggles and gloves or take other appropriate

measures.

8 Endress+Hauser

Page 9

Liquiline CM44P Basic safety instructions

2.5 Product safety

2.5.1 State of the art

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

international standards have been observed.

2.5.2 IT security

We only provide a warranty if the device is installed and used as described in the

Operating Instructions. The device is equipped with security mechanisms to protect it

against any inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

Endress+Hauser 9

Page 10

Device description Liquiline CM44P

1 2

3

4

5

6

2

3

4 5

6

789

10

11

1

3 Device description

3.1 Housing closed (field device)

1 Display

2 Weather protection cover (optional)

3 Navigator

4 Sensor cable or current output cable

5 Power supply cable

6 Soft keys, assignment depends on menu

A0025813

1 Mounted on a post

3.2 Housing open (field device)

A0039719

2 Example of a four-channel device with an open display cover (without wiring)

1 Display cable 7 Threaded bolt for protective ground connection

2 Basic module 8 Extension power unit with internal cable

3 Extension modules (optional) 9 M12 connectors for sensor connection

(optional)

4 Shock protection, dummy cover and end cover 10 Distributor terminals for user-defined use

5 Extension backplane 11 Storage slot for SD card

6 Cable mounting rail

1)

1) Example: you want to loop the signal from the alarm relay to a siren and a lamp. The terminals on the

alarm relay only accommodate one cable. Route the signal from the alarm relay to a terminal on the

distributor block. The block's terminals are all interconnected. You therefore have 3 additional terminals on

this block from where you can carry the signal forward to the consumer (siren, lamp etc.). The signal can

be multiplied in this way.

10 Endress+Hauser

Page 11

Liquiline CM44P Device description

1 2

3

4

5

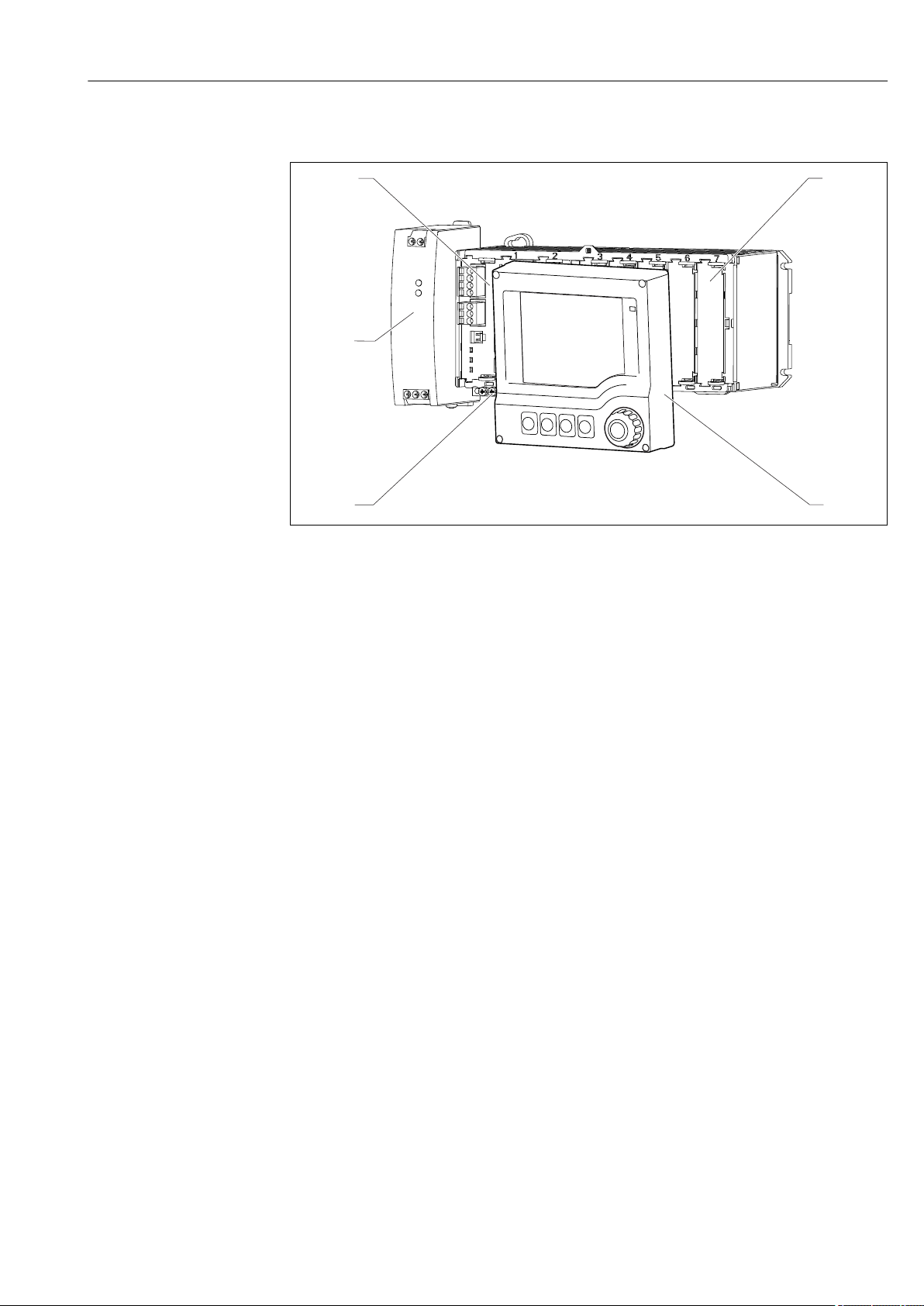

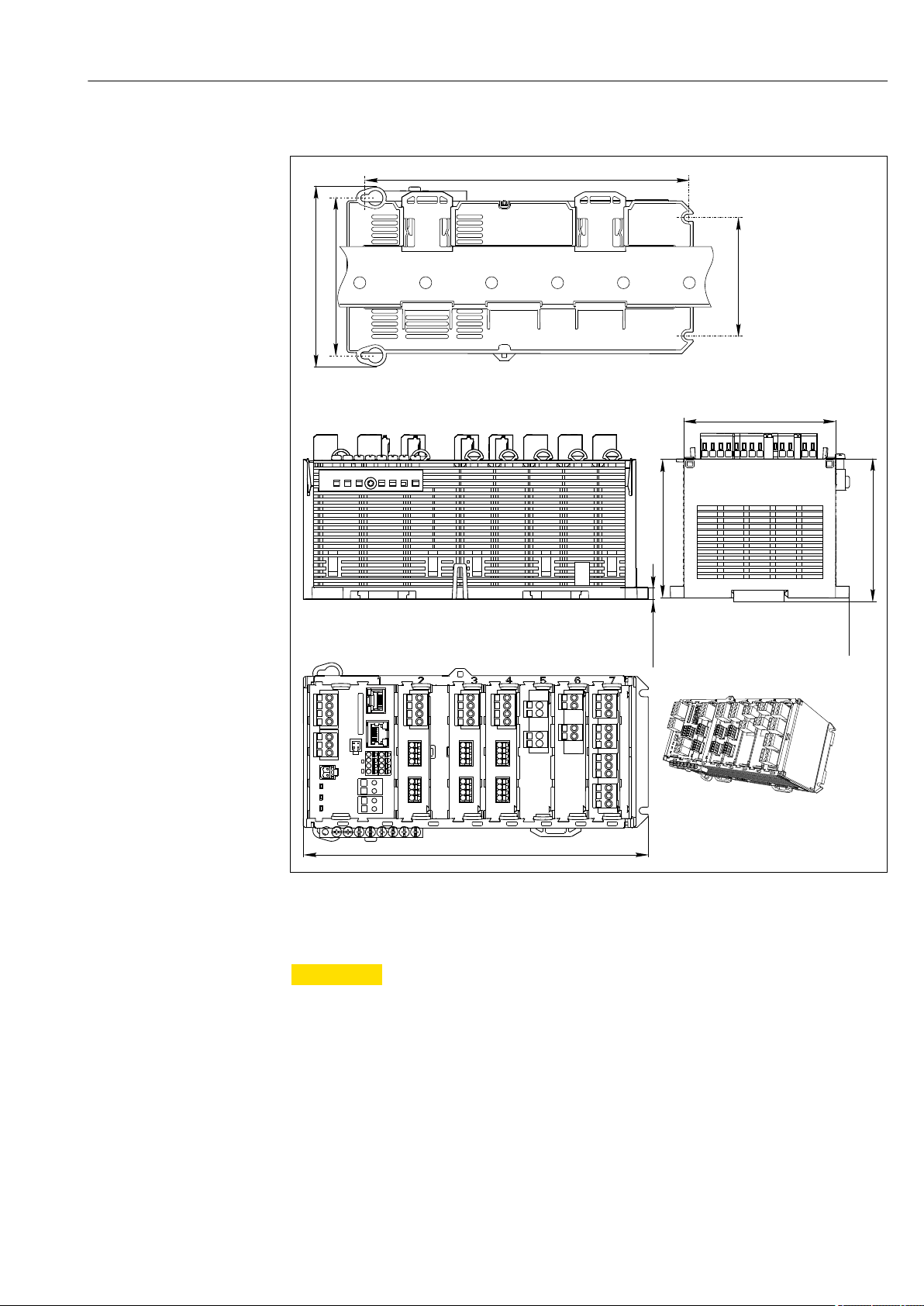

3.3 Overview (cabinet device)

3 Device with optional, external display (excluding cables)

1 Basic module 5 Terminal strip

2 Shock protection, dummy module 6 External power unit

3 External display (optional)

A0039727

Endress+Hauser 11

Page 12

Device description Liquiline CM44P

BASE2-E

Slots

1

2

1

2

1

2

1

2

Ports

2DS 2DS 2DS 2AI 2AO 4R

1

2

Sensor 1

Sensor 1

Sensor 1

Sensor 2

Sensor 2

Sensor 2

1

2

1

2

1

2

1

2

3

4

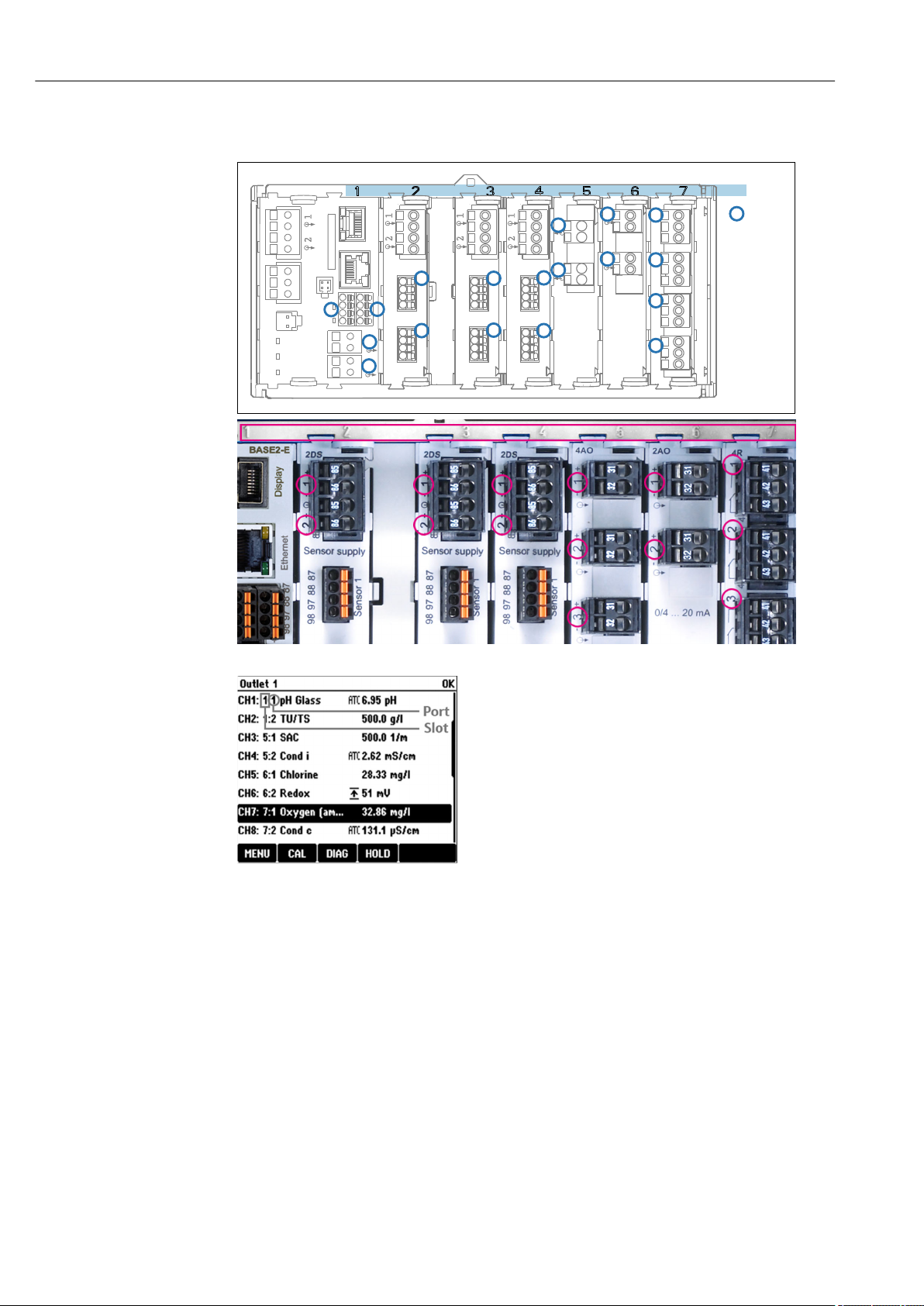

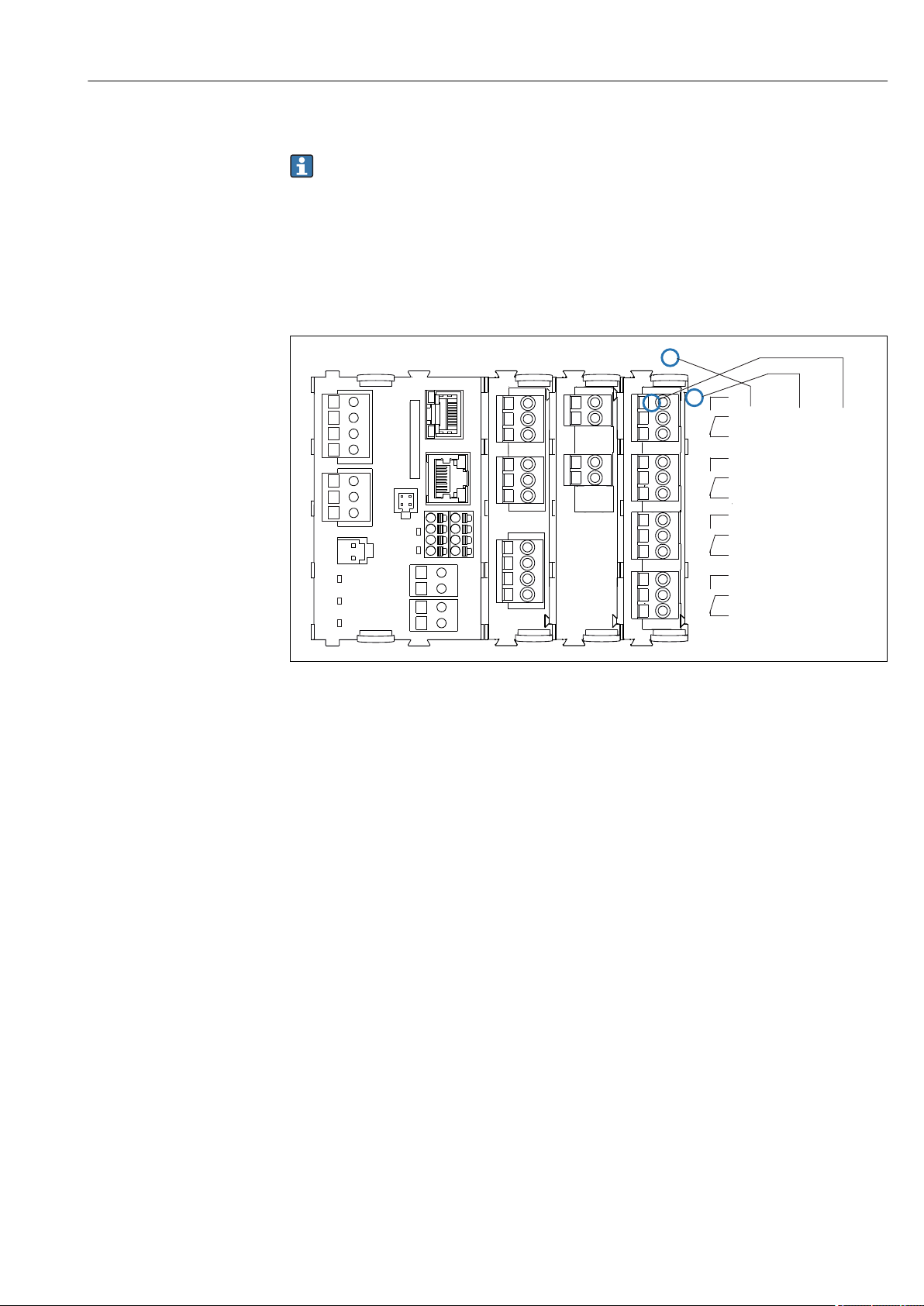

3.4 Slot and port assignment

4 Slot and port assignment of the hardware modules

• Inputs are assigned to measuring channels in the

ascending order of the slots and ports.

Adjacent example:

"CH1: 1:1 pH glass" means:

Channel 1 (CH1) is slot 1 (basic module) : Port 1 (input

1), pH glass sensor

• Outputs and relays are named according to their

function, e.g. "current output", and are displayed in

ascending order with the slot and port numbers

5 Slot and port assignment on the

display

12 Endress+Hauser

Page 13

Liquiline CM44P Device description

1 2

3

4

43

42 41

43

42 41

43

42 41

43

42 41

Relay 1

Relay 2

Relay 3

Relay 4

Slot

Slot 4

Port 1

Pin 41

BASE2-E

3.5 Terminal diagram

The unique terminal name is derived from:

Slot no. : Port no. : Terminal

Example, NO contact of a relay

Device with 2 inputs for digital sensors, 4 current outputs and 4 relays

• Base module BASE2-E (contains 2 sensor inputs, 2 current outputs)

• PEM module (1 photometer sensor)

• 2AO module (2 current outputs)

• 4R module (4 relays)

6 Creating a terminal diagram using the example of the NO contact (terminal 41) of a relay

A0039659

Endress+Hauser 13

Page 14

Incoming acceptance and product identification Liquiline CM44P

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify the supplier of any damage to the packaging.

Keep the damaged packaging until the issue has been resolved.

2. Verify that the contents are undamaged.

Notify the supplier of any damage to the delivery contents.

Keep the damaged goods until the issue has been resolved.

3. Check that the delivery is complete and nothing is missing.

Compare the shipping documents with your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

Make sure to comply with the permitted ambient conditions.

If you have any questions, please contact your supplier or your local Sales Center.

4.2 Product identification

4.2.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Order code

• Extended order code

• Serial number

• Ambient and process conditions

• Input and output values

• Activation codes

• Safety information and warnings

Compare the information on the nameplate with the order.

‣

4.2.2 Product identification

Product page

www.endress.com/cm44p

Interpreting the order code

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Go to www.endress.com.

2. Call up the site search (magnifying glass).

3. Enter a valid serial number.

14 Endress+Hauser

Page 15

Liquiline CM44P Incoming acceptance and product identification

4. Search.

The product structure is displayed in a popup window.

5. Click on the product image in the popup window.

A new window (Device Viewer) opens. All of the information relating to your

device is displayed in this window as well as the product documentation.

Manufacturer's address

Endress+Hauser Conducta GmbH+Co. KG

Dieselstraße 24

D-70839 Gerlingen

4.3 Scope of delivery

The scope of delivery comprises:

• 1 multichannel controller in the version ordered

• 1 mounting plate

• 1 wiring label (attached at the factory to the inside of the display cover)

• 1 external display (if selected as an option)

• 1 DIN rail power unit incl. Cable (cabinet device only)

• 1 printed copy of the Operating Instructions for DIN rail power unit (cabinet device only)

• 1 printed copy of the Brief Operating Instructions in the language ordered

If you have any queries:

‣

Please contact your supplier or local sales center.

1)

4.4 Certificates and approvals

4.4.1

The product meets the requirements of the harmonized European standards. As such, it

complies with the legal specifications of the EU directives. The manufacturer confirms

successful testing of the product by affixing to it the mark.

4.4.2 cCSAus

The device has been certified with regard to its electrical safety and for NI Class I Div. 2

cCSAus explosion-proof environments. It meets the requirements in accordance with:

• CLASS 2252 06 - Process Control Equipment

• CLASS 2252 86 - Process Control Equipment - Certified to US Standards

• CLASS 2258 03 - Process Control Equipment - Intrinsically Safe and Non-incendive

Systems - For Hazardous Locations

• CLASS 2258 83 - Process Control Equipment - Intrinsically Safe and Non-incendive

Systems - For Hazardous Locations - Certified to US Standards

• FM3600

• FM3611

• FM3810

• UL50E

• IEC 60529

• CAN/CSA-C22.2 No. 0

• CAN/CSA C22.2 No. 94

• CSA Std. C22.2 No. 213

• CAN/CSA-C22.2 No. 61010-1

mark

1) The external display can be selected as an option in the order structure or ordered as an accessory at a later stage.

Endress+Hauser 15

Page 16

Incoming acceptance and product identification Liquiline CM44P

• CAN/CSA-C22.2 No. 60529

• UL/ANSI/ISA 61010-1

• ANSI - ISA 12 12 01

16 Endress+Hauser

Page 17

Liquiline CM44P Installation

H 5 6 7 8 I

GF

E

D

C

A

1 2 3 4 B

162 (6.38)

14 (0.55)

Ø4 (0.16)

Ø9 (0.35)

199 (7.38) 128 (5.04)

237 (9.33)

194 (7.64)

76 (2.99)

95 (3.74)

80 (3.15)

190 (7.48)

3 (0.12)

4 x 6.5 (0.26)

170 (6.69)

125 (4.92)

5 Installation

5.1 Installation conditions

5.1.1 Dimensions

Endress+Hauser 17

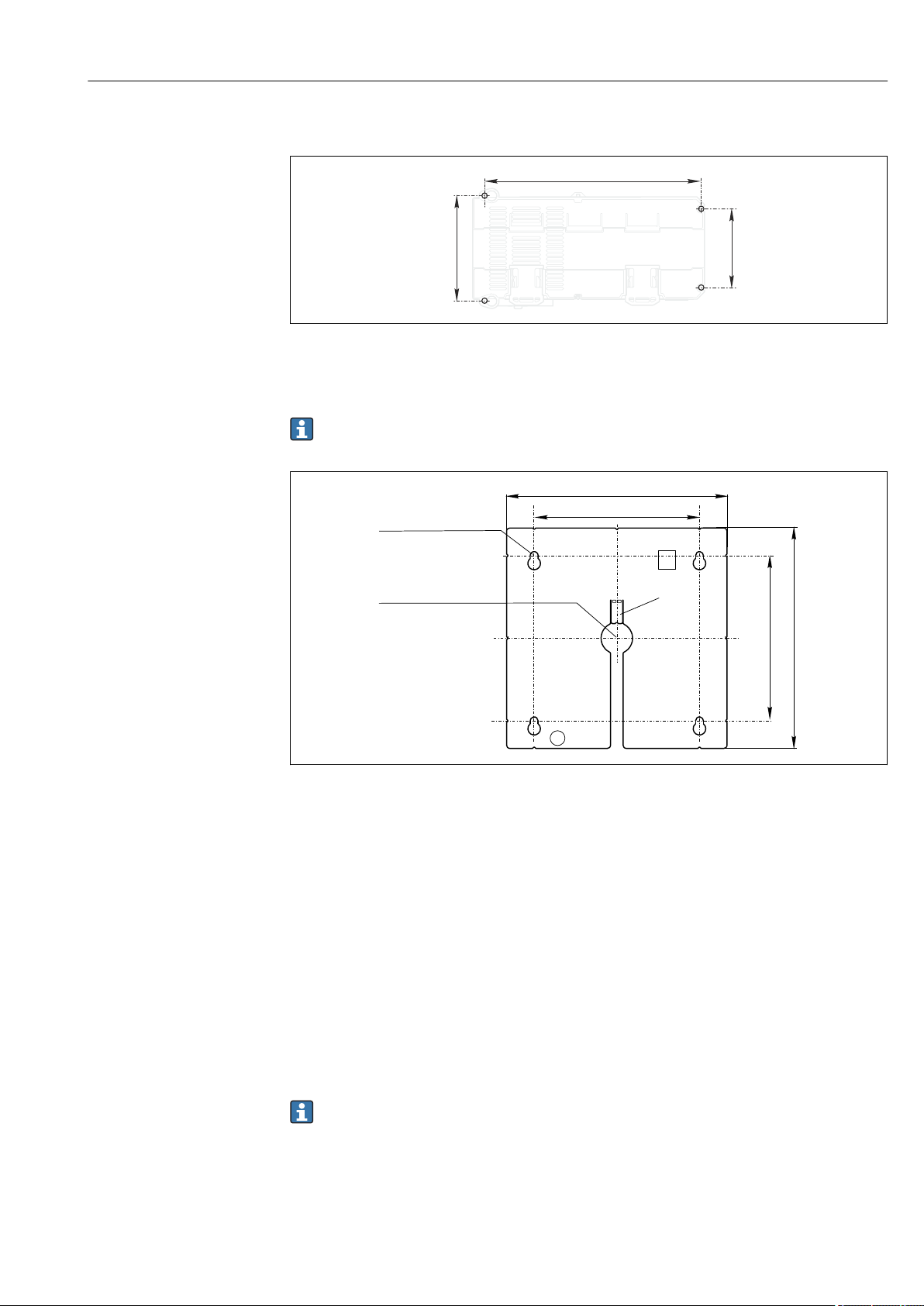

7 Dimensions of field housing in mm (inch)

5.1.2 Mounting plate

8 Mounting plate, dimensions in mm (in)

A0012396

A0012426

Page 18

Installation Liquiline CM44P

320 (12.6)

270 (10.6)

300 (11.8)

80 (3.15)

170 (6.69)

170 (6.69)

80 (3.15)

8 x Ø 7 (0.28)

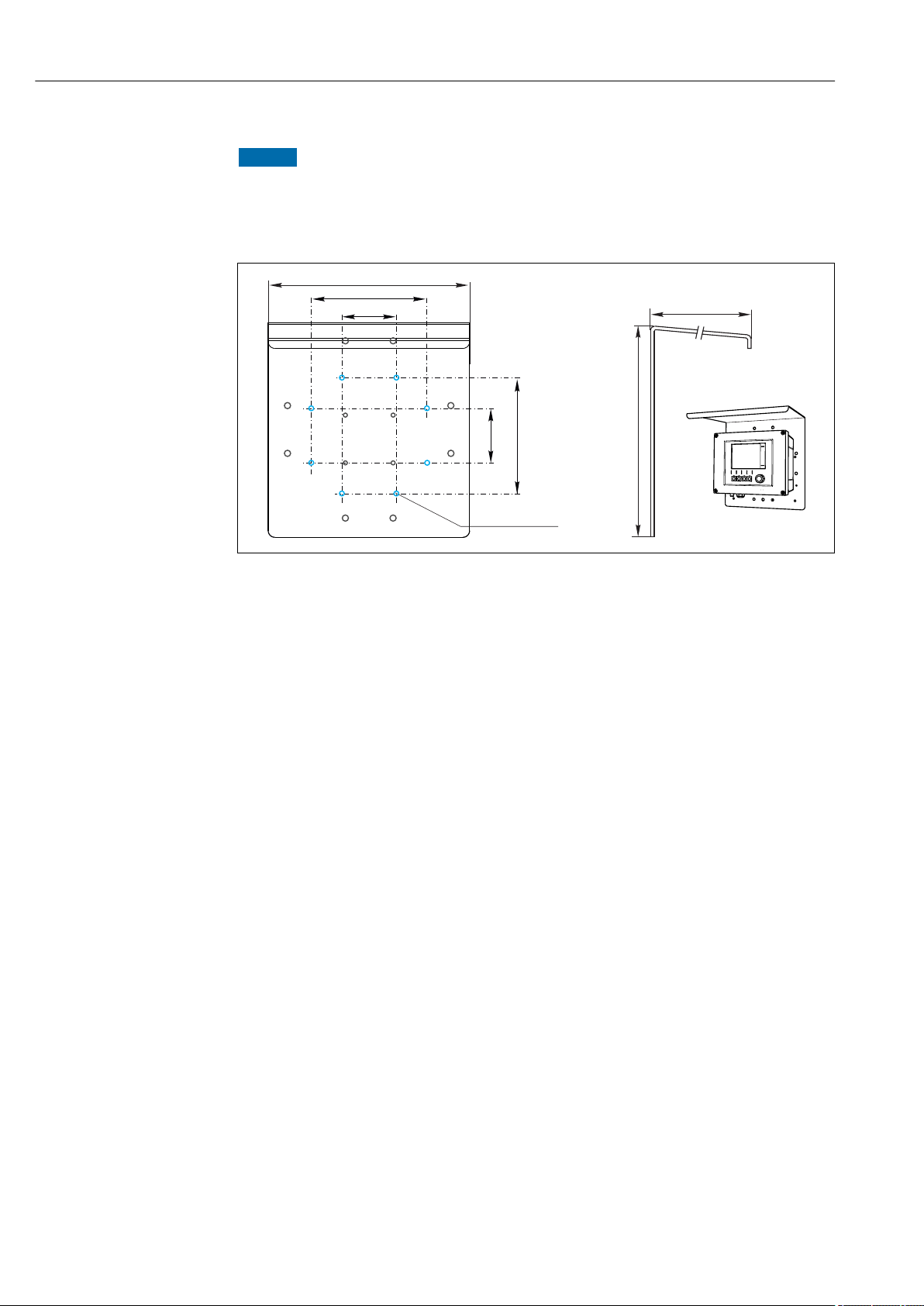

5.1.3 Protective cover

NOTICE

Effect of climatic conditions (rain, snow, direct sunlight etc.)

Impaired operation to complete transmitter failure are possible!

Always use the weather protection cover (accessory) when installing the device

‣

outdoors.

9 Dimensions in mm (in)

A0012428

18 Endress+Hauser

Page 19

Liquiline CM44P Installation

220 (8.66)

97 (3.82)

7.5 (0.30)

100 (3.94)

75 (2.95)

205.5 (8.09)

114 (4.49)

TS 35

TS 35

89 (3.50)

91 (3.58)

5.1.4 Dimensions (cabinet device)

10 Dimensions in mm (inch)

5.1.5 Mounting on DIN rail as per IEC 60715

CAUTION

L

The power unit can get very hot under full load

Burn hazard!

Avoid touching the power unit during operation.

‣

The minimum distances to other devices must be observed.

‣

After switching off the power unit, allow it to cool down before carrying out any work

‣

on it.

A0039730

Endress+Hauser 19

Page 20

Installation Liquiline CM44P

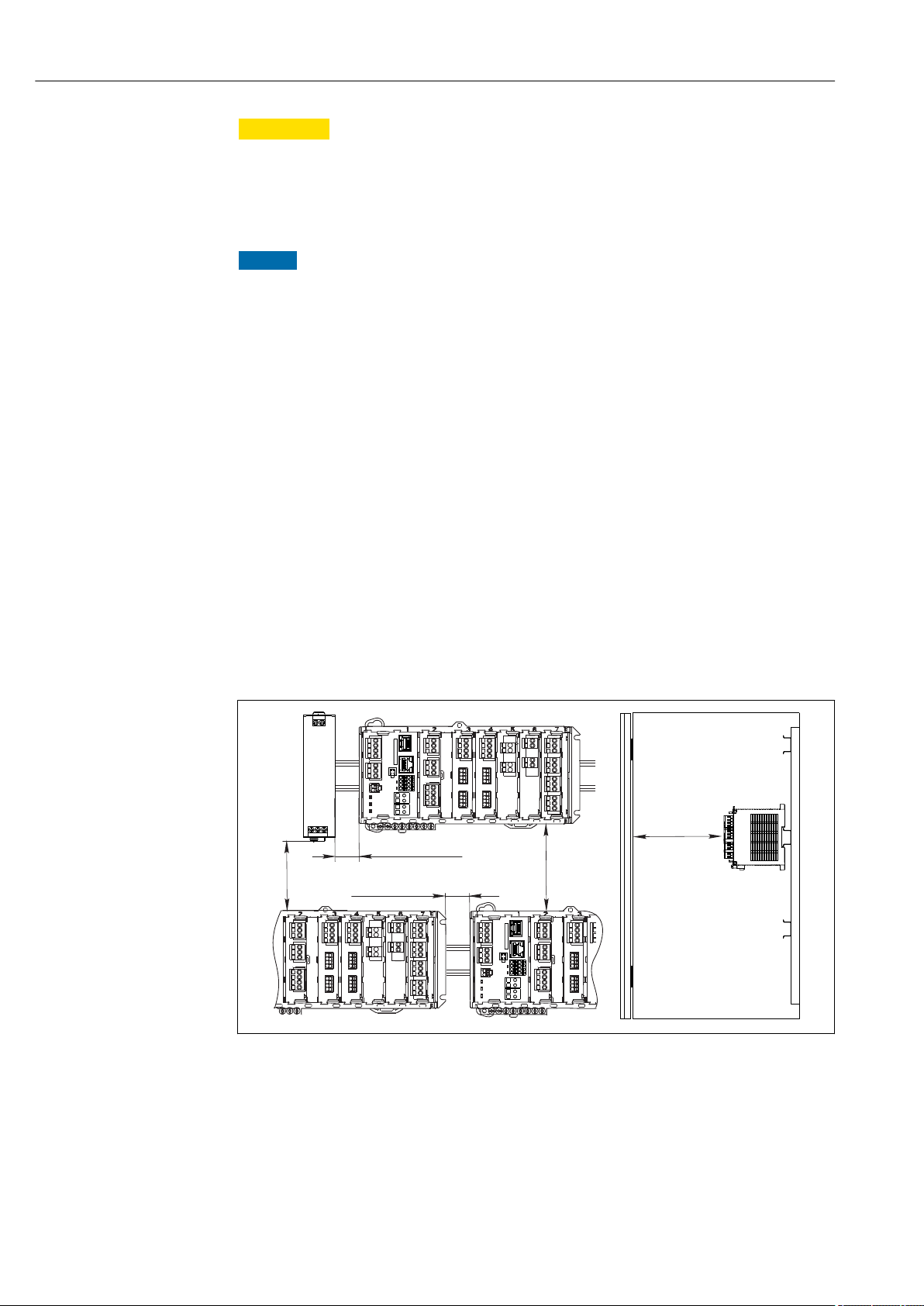

min. 50 (1.97)

min. 20 (0.79)

min. 50 (1.97)

min. 20 (0.79)

min. 50 (1.97)

CAUTION

L

Impermissible collection of moisture in the device

Puts the safety of the user at risk!

The device has IP20 shock protection. Never allow moisture to collect in the device.

‣

Comply with the specified ambient conditions,e.g. by installing the device in an

‣

appropriate protective enclosure.

NOTICE

Incorrect mounting location in the cabinet, spacing regulations not observed

Possible malfunctions as a result of heat buildup and interference from neighboring

devices!

Do not position the device directly above sources of heat. The temperature specification

‣

must be observed.

The components are designed for convection-based cooling. Avoid heat buildup. Ensure

‣

openings are not covered, e.g. by cables.

Observe the specified distances to other devices.

‣

Physically separate the device from frequency converters and high-voltage devices.

‣

Recommended installation direction: horizontal. The specified ambient conditions, and

‣

particularly the ambient temperatures, only apply for horizontal installation.

Vertical orientation is also possible. However, this requires additional fixing clips at the

‣

place of installation to hold the device in position on the DIN rail.

Recommended installation of power unit: to the left of the device.

‣

The following minimum clearance specifications must be observed:

• Distances at the side in relation to other devices incl. power units and to the wall of the

cabinet:

at least 20 mm (0.79 inch)

• Distance above and below the device and depth distance (to control cabinet door or other

devices installed there):

at least 50 mm (1.97 inch)

11 Minimum clearance in mm (in)

20 Endress+Hauser

A0039736

Page 21

Liquiline CM44P Installation

205.5 (8.09)

100 (3.94)

75 (2.95)

4 x Ø 4.5 (0.18)

4 x min. Ø 8 (0.31)

min. Ø 15 (0.59)

140 (5.51)

105 (4.13)

105 (4.13)

140 (5.51)

a

b

b

5.1.6 Wall mounting

A0027859

12 Drilling pattern for wall mounting in mm (in)

5.1.7 Mounting the external display

The mounting plate also serves as the drilling template. The marks on the side help

you mark the position of the drill holes.

13 Mounting plate of external display, dimensions in mm (in)

a Retaining tab

b Production-related recesses, no function for the user

5.1.8 Cable length for optional display

Length of display cable provided (cabinet device only):

3 m (10 ft)

Maximum permitted length of a display cable (cabinet device only):

5 m (16.5 ft)

5.2 Mounting the measuring device (field device)

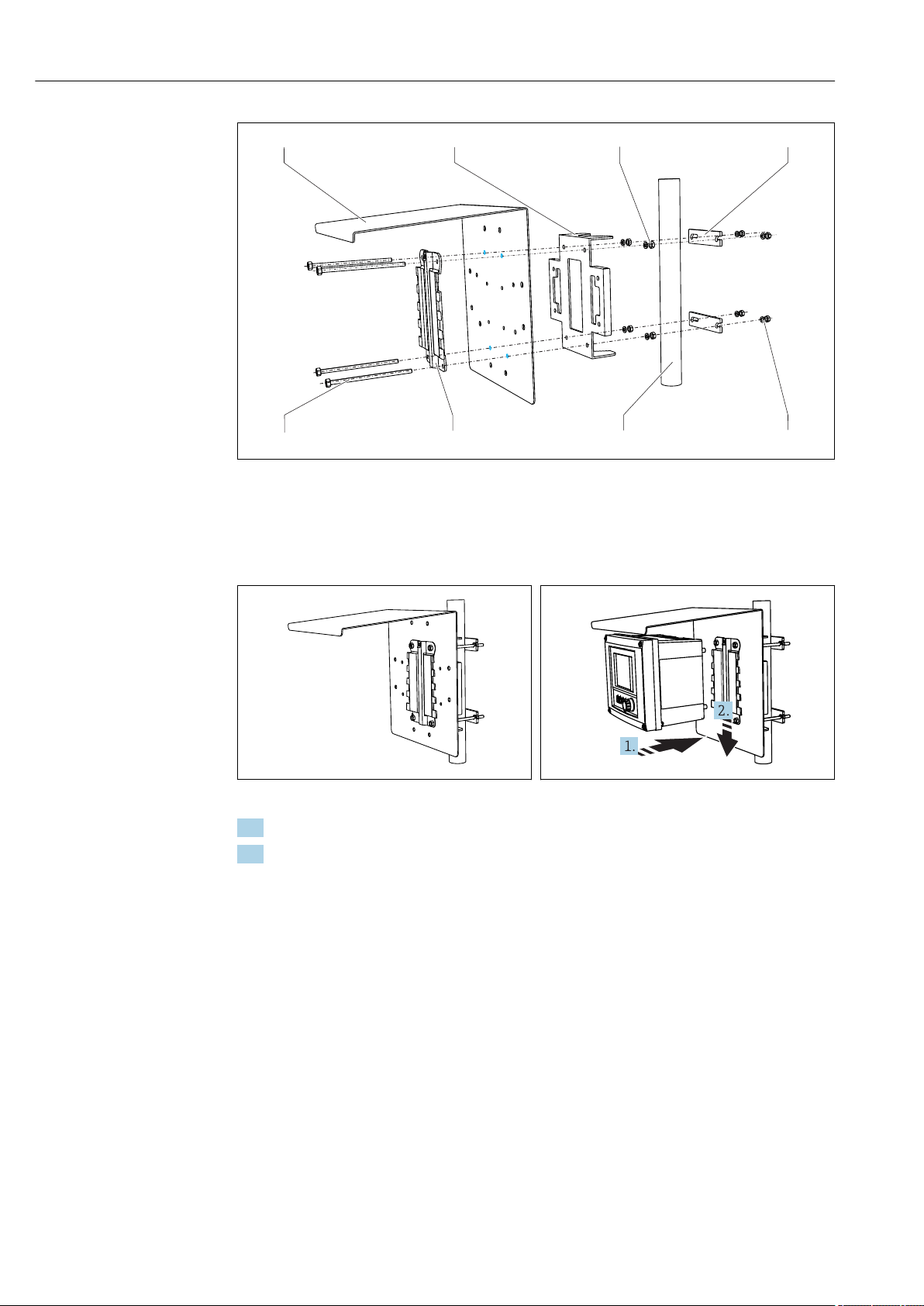

5.2.1 Post mounting

You require the post mounting kit (optional) to mount the unit on a pipe, post or

railing (square or circular, clamping range 20 to 61 mm (0.79 to 2.40")).

A0025371

Endress+Hauser 21

Page 22

Installation Liquiline CM44P

1

2

3

4

56

7

8

A0033044

14 Post mounting

1 Weather protection cover (optional) 5 Spring washers and nuts (post mounting kit)

2 Post mounting plate (post mounting kit) 6 Pipe or railing (circular/square)

3 Spring washers and nuts (post mounting kit) 7 Mounting plate

4 Pipe clamps (post mounting kit) 8 Threaded rods (post mounting kit)

15 Post mounting

A0033045

16 Attach the device and click it into place

A0025885

1. Place the device on the mounting plate.

2. Slide the device downwards in the guide on the mounting rail until it clicks into place.

22 Endress+Hauser

Page 23

Liquiline CM44P Installation

1 2

3

4

56

7

8

9

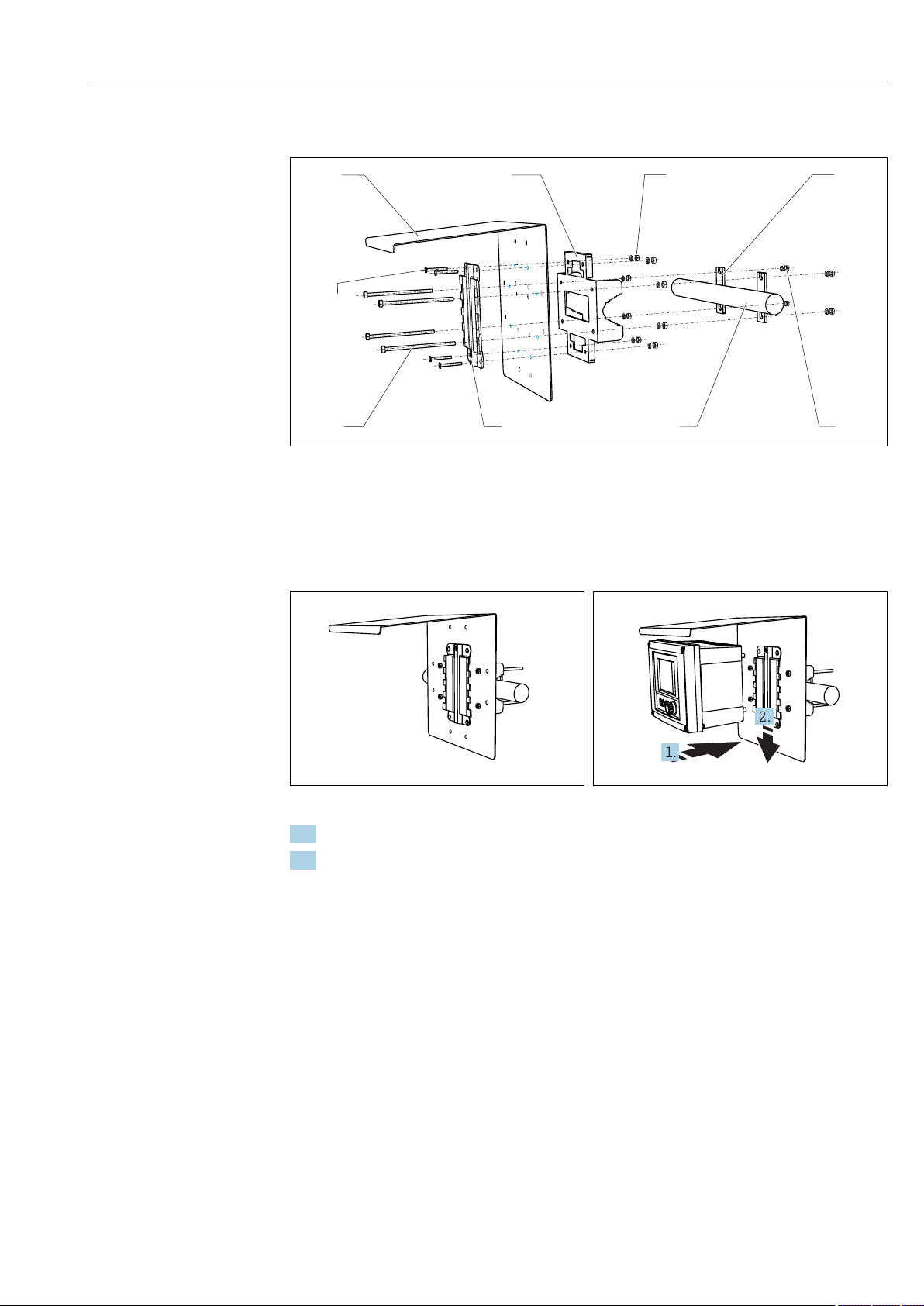

5.2.2 Rail mounting

A0012668

17 Rail mounting

1 Weather protection cover (optional) 6 Pipe or railing (circular/square)

2 Post mounting plate (post mounting kit) 7 Mounting plate

3 Spring washers and nuts (post mounting kit) 8 Threaded rods (post mounting kit)

4 Pipe clamps (post mounting kit) 9 Screws (post mounting kit)

5 Spring washers and nuts (post mounting kit)

18 Rail mounting

A0025886

19 Attach the device and click it into place

A0027803

1. Place the device on the mounting plate.

2. Slide the device downwards in the guide on the mounting rail until it clicks into place.

Endress+Hauser 23

Page 24

Installation Liquiline CM44P

≥ 340 (13.4)

≥

150 (5.91)

1

3

4

2

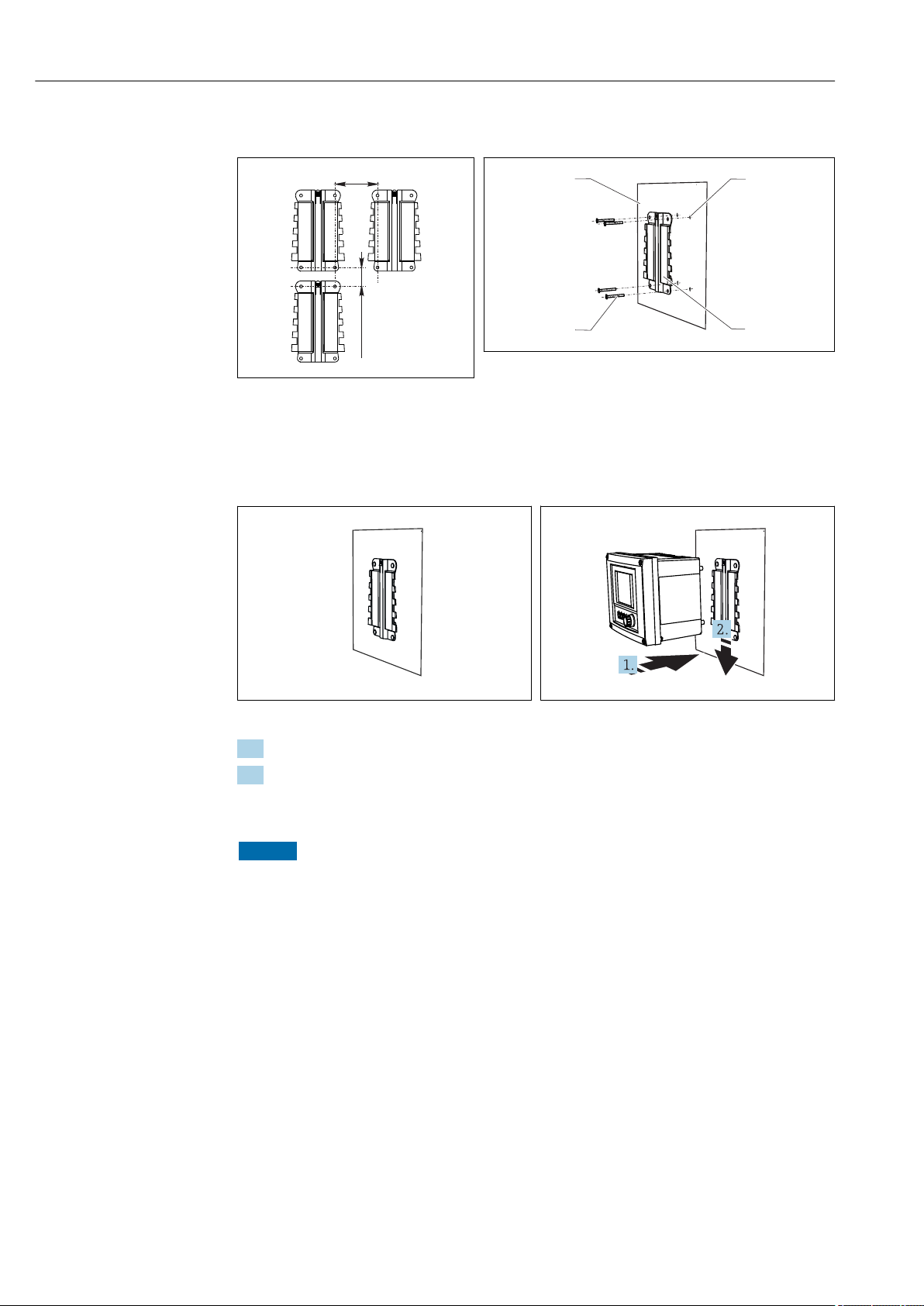

5.2.3 Wall mounting

A0027798

21 Wall mounting

A0012686

20 Installation clearance in mm (in)

1)

The size of the drill holes depends on the wall plugs used. The wall plugs and screws must be provided by the

customer.

1 Wall

2

4 drill holes

3 Mounting plate

4 Screws Ø 6 mm (not part of scope of supply)

1)

22 Wall mounting

A0027799

23 Attach the device and click it into place

A0027797

1. Place the device on the mounting plate.

2. Slide the device downwards in the guide on the mounting rail until it clicks into place.

5.2.4 Disassembly (for conversion, cleaning etc.)

NOTICE

The device can be damaged if dropped

When pushing the housing out of the holder, secure the housing to prevent it from

‣

falling. If possible, ask a second person to help you.

24 Endress+Hauser

Page 25

Liquiline CM44P Installation

A0025890

24 Disassembling

25 Disassembling

1. Hold down the latch.

2. Push up the device to remove it from the holder.

3. Remove the device towards the front.

A0025891

Endress+Hauser 25

Page 26

Installation Liquiline CM44P

a

b

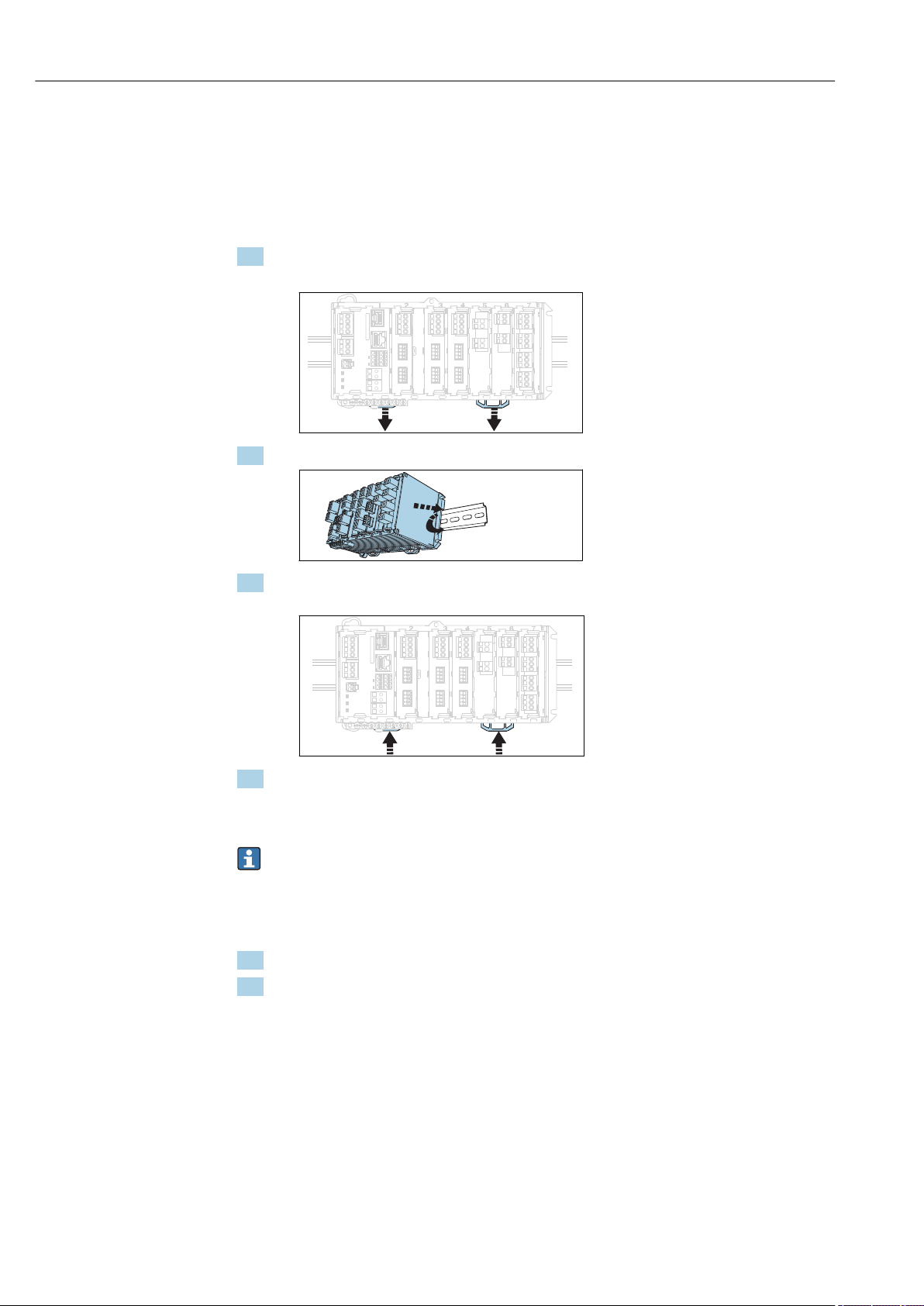

5.3 Mounting the measuring device (cabinet device)

5.3.1 DIN rail mounting

The mounting procedure is the same for all Liquiline devices. The example shows a

CM448R.

1. In the order configuration, the securing clips are "tightened" to secure the DIN rail.

Release the securing clips by pulling them downwards.

2. Attach the device from the top to the DIN rail (a) and secure it by pressing down (b).

3. Slide the securing clips upwards until they click, thereby securing the device to the

DIN rail.

4. Mount the external power unit in the same way.

5.3.2 Wall mounting

Mounting material (screws, dowels) are not included in the scope of delivery and must

be provided by the customer.

The external power unit can be mounted on a DIN rail only.

Use the back of the housing to mark the mounting holes.

1. Drill the corresponding holes and insert wall plugs if necessary.

2. Screw the housing onto the wall.

26 Endress+Hauser

Page 27

Liquiline CM44P Installation

.

.

.

. .

.

.

.

..

.

.

.

.

.

. .

.

.

.

..

.

.

4 x Ø 8 (0.31)

Ø 20 (0.79)

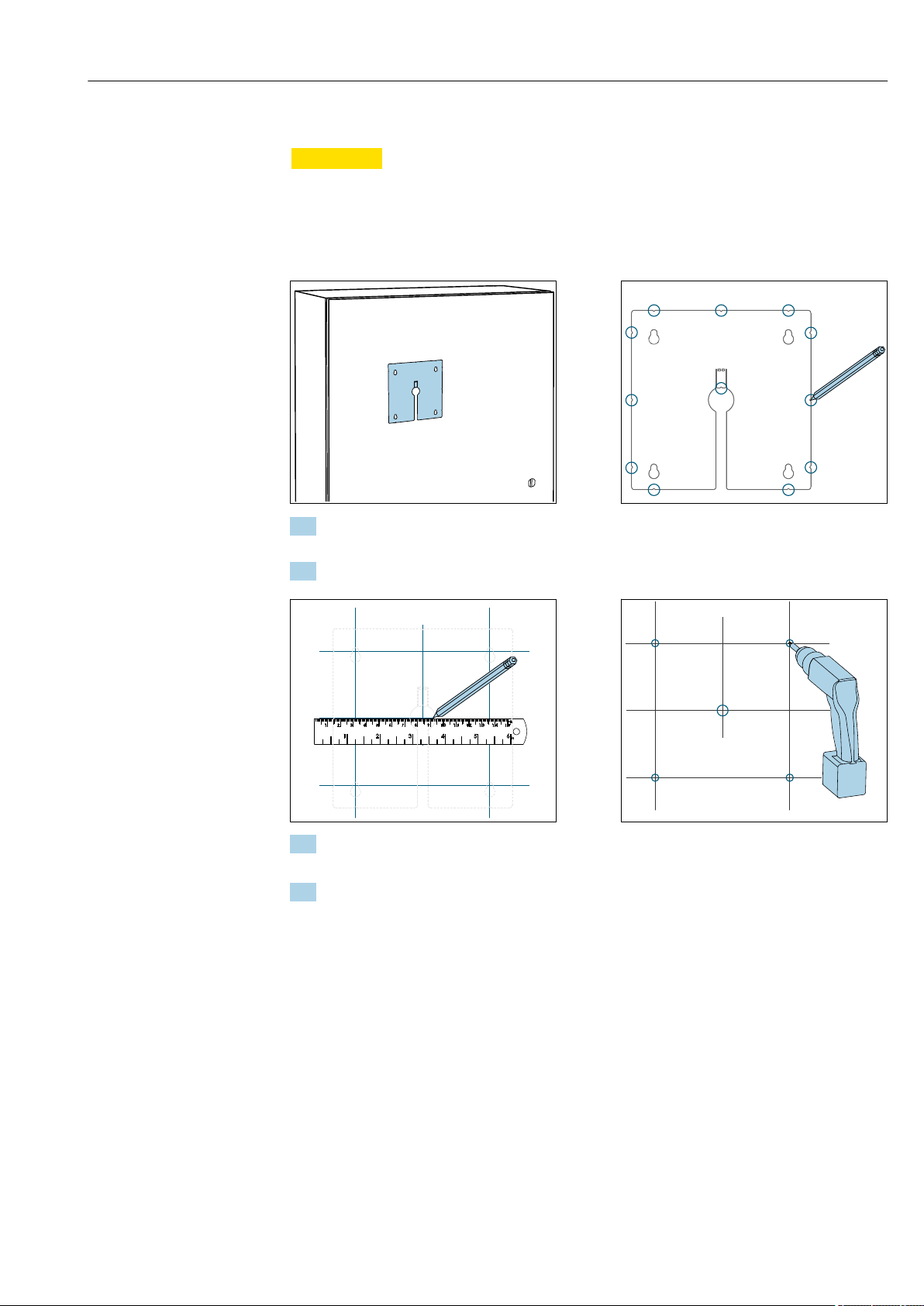

5.3.3 Mounting the optional external display

CAUTION

L

Sharp-edged, non-deburred drill holes

Risk of injury, display cable may get damaged!

In particular, deburr the central drill hole for the display cable.

‣

Mounting the display on the door of the cabinet

1. Hold the mounting plate from the outside against the door of the control cabinet.

Choose the point at which you wish to install the display.

2. Make all the markings.

3. Draw lines to interconnect all the marks.

This will indicate the position of the five drill holes needed.

4. Drill the holes (→ 13, 21).

Endress+Hauser 27

Page 28

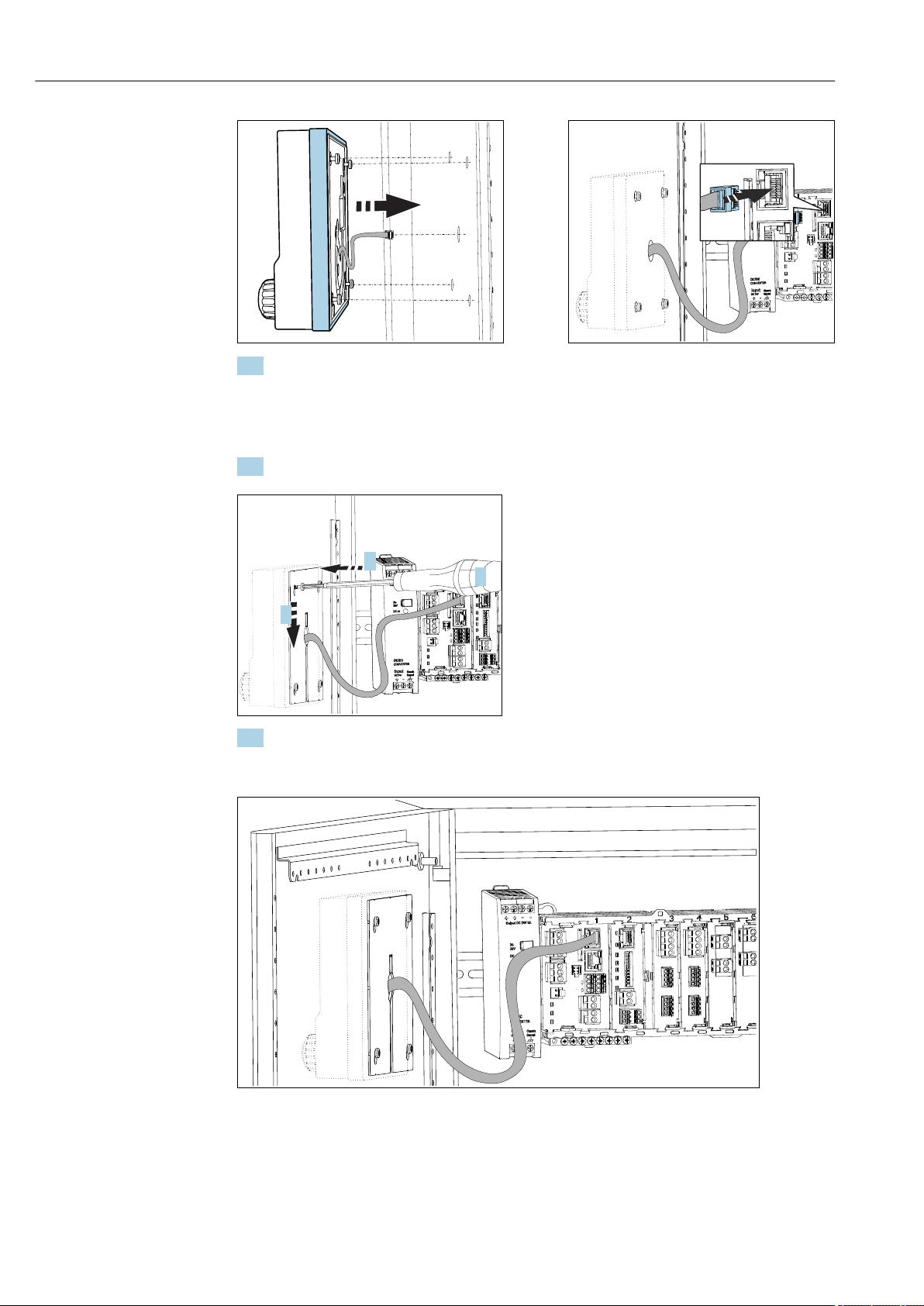

Installation Liquiline CM44P

a

b

c

5. Pull the display cable through the hole in the middle, and place the display from the

outside through the four holes drilled for this purpose, ensuring that the torx screws

have been unscrewed to the last half turn but are still in place. Ensure that the rubber

frame (seal, highlighted blue) does not become damaged and is properly positioned

on the surface of the door.

6. Connect the display cable to the RJ-45 socket in the base module.

7. Place the mounting plate on the inside over the screws (a), slide it down (b) and

tighten the screws (c).

The display is now mounted and ready to use.

26 Mounted display

28 Endress+Hauser

Page 29

Liquiline CM44P Installation

NOTICE

Incorrect installation

Damage, e.g. to the cable, or malfunctions are possible!

Lay cables in such a way that they do not get squashed e.g. when closing the cabinet

‣

door.

Plug the display cable only into the RJ45 socket in the base module. Otherwise, the

‣

display will not function.

5.4 Post-installation check

1. After installation, check the transmitter for damage.

2. Check whether the transmitter is protected against precipitation and direct sunlight

(e.g. by the weather protection cover).

3. After mounting, check all devices (controller, power unit, display) for damage.

4. Verify that the specified installation clearances have been observed.

5. Verify that all securing clips have been snapped into place and that the components

are securely positioned on the DIN rail.

6. Ensure that the temperature limits are observed at the mounting location.

Endress+Hauser 29

Page 30

Electrical connection Liquiline CM44P

1

3

2

USB

31

32

250 ... 500 Ω

FXA291

Master class 1

(PLC, DCS)

T T

Ethernet

PROFIBUS DP

(RS485)

Master class 2 (FieldCare, PDM)

6 Electrical connection

6.1 Connection conditions

6.1.1 Via HART (e.g. via HART modem and FieldCare)

27 HART using modem

1 Device module Base2-L, -H or -E: current output 1 with HART

2

HART modem for connection to PC, e.g. Commubox FXA191 (RS232) or FXA195 1) (USB)

3 HART handheld terminal

1)

Switch position "on" (substitutes the resistor)

6.1.2 Via PROFIBUS DP

A0039620

28 PROFIBUS DP

T Terminating resistor

30 Endress+Hauser

A0039617

Page 31

Liquiline CM44P Electrical connection

FXA291

Ethernet

Modbus Master / Gateway

T T

Modbus RS485

(RTU, ASCII)

FieldCare/

Webbrowser

FXA291

Ethernet

Ethernet client

6.1.3 Via Modbus RS485

A0039615

29 Modbus RS485

T Terminating resistor

6.1.4 Via Ethernet: web server/Modbus TCP/PROFINET/ EtherNet/IP

A0039616

30 Modbus TCP or EtherNet/IP or PROFINET

6.2 Connecting the measuring device

WARNING

L

Device is live!

Incorrect connection may result in injury or death!

The electrical connection may be performed only by an electrical technician.

‣

The electrical technician must have read and understood these Operating Instructions

‣

and must follow the instructions contained therein.

Prior to commencing connection work, ensure that no voltage is present on any cable.

‣

Endress+Hauser 31

Page 32

Electrical connection Liquiline CM44P

1.

2.

3.

4.

≤180°

NOTICE

The device does not have a power switch!

Provide a protected circuit breaker in the vicinity of the device at the place of

‣

installation.

The circuit breaker must be a switch or power switch, and must be labeled as the circuit

‣

breaker for the device.

At the supply point, the power supply must be isolated from dangerous live cables by

‣

double or reinforced insulation in the case of devices with a 24 V supply voltage.

6.2.1 Opening the housing

NOTICE

Pointed or sharp tools

If unsuitable tools are used, they can scratch the housing or damage the seal, and thus

have a negative impact on the leak-tightness of the housing!

Do not use pointed or sharp objects,e.g. knives, to open the housing.

‣

Only use a suitable Phillips screwdriver.

‣

31 Releasing housing screws in a diagonally

opposite sequence with Phillips screwdriver

32 Opening display cover, max. opening angle

180˚ (depends on installation position)

1. Release the housing screws on a step-by-step basis. Start with any screw of your

choice. Then release the screw diagonally opposite this screw etc.

2. To close the housing: tighten the screws in a similar step-by-step, diagonally opposite

sequence.

32 Endress+Hauser

Page 33

Liquiline CM44P Electrical connection

1 32 4

1

2

3

4

6.2.2 Cable mounting rail

A0025171

33 Cable mounting rail and associated function (field device)

A0025366

34 Mounting rail for functional ground connections (cabinet device)

1 Cable mounting rail 3 Additional threaded bolts for ground connections

2 Threaded bolt (protective ground connection,

central grounding point)

4 Cable clamps (fixing and grounding the sensor

cables)

6.2.3 Connecting the cable shield

If possible, only use terminated original cables. The sensor, fieldbus and Ethernet

cables must be shielded cables.

Cable sample (does not necessarily correspond to the original cable supplied)

35 Terminated cable

1 Outer shield (exposed)

2 Cable cores with ferrules

3 Cable sheath (insulation)

1) Please note the instructions in the "Ensuring the degree of protection" section (→ 48)

1. Release a suitable cable gland on the bottom of the housing and remove the dummy

plug.

2. Making sure the gland is facing the right direction, thread the gland onto the cable

end and pull the cable through the entry and into the housing.

3. Route the cable in the housing in such a way that the exposed cable shield fits into

one of the cable clamps and the cable cores can be easily routed as far as the

connection plug on the electronics module.

4. Screw the cable clamp on.

5. Clamp the cable into place.

6. Then tighten the screw of the cable clamp again.

7. Connect cable cores as per the wiring diagram.

Endress+Hauser 33

36 Insert the cable

4 Grounding clip

37 Tighten screw (2 Nm)

The cable shield is grounded using

the grounding clamp.

1)

Page 34

Electrical connection Liquiline CM44P

8. Tighten the cable gland from outside.

6.2.4 Cable terminals

Plug-in terminals for Memosens and PROFIBUS/RS485 connections

Insert the cable until the limit

Press the screwdriver against

‣

the clip (opens the terminal).

After connection, make sure that every cable end is securely in place. Terminated

cable ends, in particular, tend to come loose easily if they have not been correctly

inserted as far as the limit stop.

‣

stop.

Remove the screwdriver (closes

‣

the terminal).

All other plug-in terminals

Press the screwdriver against

‣

the clip (opens the terminal).

Insert the cable until the limit

‣

stop.

Remove the screwdriver (closes

‣

the terminal).

34 Endress+Hauser

Page 35

Liquiline CM44P Electrical connection

L+ N- PE

A

B

85

85

86

86

SD

Display

Sensor supply

+

+

–

Service

PK

GY

PK

GY

1

2

–

+

–

A

B

41

43

42

Alarm

31

31

32

32

0/4 ... 20 mA

+

+

–

–

HART

+

–

A

B

Sensor 2

Ethernet

87

88

97

98

87

88

97

98

BN

WH

GN

YE

BN

WH

GN

YE

Sensor 1

1

2

L/+

N/–

*

Power

L/+

N/–

PE

Power

(internal)

B

L N

+ RD

- BK

*

85

85

86

86

SD

Display

Sensor supply

+

+

–

Service

PK

GY

PK

GY

1

2

–

+

–

A

B

41

43

42

Alarm

31

31

32

32

0/4 ... 20 mA

+

+

–

–

HART

+

–

A

B

Sensor 2

Ethernet

87

88

97

98

87

88

97

98

BN

WH

GN

YE

BN

WH

GN

YE

Sensor 1

1

2

L/+

N/–

*

Power

L/+

N/–

PE

Power

(internal)

B

6.2.5 Connecting the supply voltage

A0039626

38 Power supply connection on the BASE2-E

(field device)

A Internal power supply cable

B Extension power unit

40 Connecting power supply with BASE2-E

(cabinet device)

* Assignment depending on power unit, make sure

to connect correctly

The two device versions may only be operated with the power unit supplied and the

power unit cable. Also pay attention to the information in the operating manual

supplied for the power unit.

39 Overall wiring diagram for BASE2-E and

extension power unit (B)

A0039668

41 Overall wiring diagram for BASE2-E and

external power unit (B)

Endress+Hauser 35

A0039624

A0039624

Page 36

Electrical connection Liquiline CM44P

Connecting the supply voltage

1. Route the power supply cable into the housing through the suitable cable entry.

2. Step 2 applies only to the 100 to 230 V AC power unit.

Connect the protective ground of the power unit to the threaded bolt specially

provided on the cable mounting rail.

3. Protective ground or grounding provided by customer (absolutely essential for 24 V

power unit, additionally recommended for 100 to 230 V AC power unit): Provide

a ground cable (min. 0.75 mm2 (corresponding to 18 AWG))1! Guide the ground

cable also through the cable entry and connect it to the threaded bolt on the cable

mounting rail.

4. Connect the cable cores L and N (100 to 230 V AC) or + and ‐ (24 V DC) to the plugin terminals on the power unit in accordance with the wiring diagram.

NOTICE

Protective ground/ground cable with end sleeve or open cable lug

The cable can become loose. Loss of the protective function!

To connect the protective ground or ground cable to the threaded bolt, only use a cable

‣

with a closed cable lug as per DIN 46211, 46225, form A.

Never connect the protective ground or ground cable to the threaded bolt with an end

‣

sleeve or an open cable lug!

NOTICE

Incorrect connection and cable run not separate

Interference on signal or display cable, incorrect measured values or failure of display may

occur!

Do not connect the cable shield of the display cable to PE (terminal strip of device)!

‣

Run the signal/display cable in the control cabinet separately from live (current-

‣

carrying) cables.

6.3 Connecting the sensors

6.3.1 Sensor types

Photometer sensors

Sensor types Sensor cable Sensors

Analog photometer sensors without additional internal

power supply

CUK80 • OUSAF12

• OUSAF21

• OUSAF22

• OUSAF44

• OUSAF46

• OUSTF10

• OUSBT66

Fixed cable OUSAF11

36 Endress+Hauser

Page 37

Liquiline CM44P Electrical connection

GN/YE

Sensors with Memosens protocol

Sensor types Sensor cable Sensors

Digital sensors without

additional internal power

supply

Digital sensors with

additional internal power

supply

With plug-in

connection and

inductive signal

transmission

Fixed cable Conductivity sensors with inductive measurement of

Fixed cable • Turbidity sensors

• pH sensors

• ORP sensors

• Combined sensors

• Oxygen sensors (amperometric and optical)

• Conductivity sensors with conductive measurement

of conductivity

• Chlorine sensors (disinfection)

conductivity

• Sensors for interface measurement

• Sensors for measuring the spectral absorption

coefficient (SAC)

• Nitrate sensors

• Optical oxygen sensors

• Ion-sensitive sensors

The following rule applies if connecting CUS71D sensors:

• The maximum number of Memosens inputs is limited to two.

• Any combination of CUS71D or other sensors is possible.

6.3.2 Connecting the functional ground (cabinet device)

You must always connect the terminal strip with PE from the central node in the cabinet.

Use the conductor with cable clamp that is included with the Memosens cable to connect

the functional earth to the terminal strip of the device.

42 Functional earth connection

You must only ever connect one functional earth to each screw in the terminal strip.

Otherwise, shielding is not guaranteed.

6.3.3 Connecting the sensors

Types of connection

• Direct connection of the sensor cable to the terminal connector of the sensor module

PEM and the Memosens module 2DS or of the base module-E (→ 43 ff.)(Memosens

sensors only)

• Optional for Memosens sensors: Sensor cable plug connected to the M12 sensor socket

on the underside of the device (field device)

With this type of connection, the device is already wired at the factory (→ 47).

Endress+Hauser 37

Page 38

Electrical connection Liquiline CM44P

98 97 88 87

86 85 86 85

BN

WH

GN

YE

Sensor

98 97 88 87

86 85 86 85

GN

YE

Sensor

PK

GY

85 86

85

2DS

1

2

86

97 88 8798

97 88 8798

Sensor 1

Sensor 2

PK

GY

GN

YE

BN

WH

GN

YE

Sensor

Sensor

1. Sensor cable connected directly

Connect the sensor cable to the terminal connector of the sensor module PEM 2DS or

of the module Base2-E.

2. When connecting via M12 connector (Memosens sensors only)

Connect the sensor connector to an M12 sensor socket which has been previously

installed or is supplied on delivery.

Sensor cable connected directly

A0039629

43 Memosens sensors without additional supply

voltage

A0033206

45 Memosens sensors with and without

44 Memosens sensors with additional supply

voltage

46 PEM module

A0039622

A0028599

additional supply voltage at sensor module 2DS

38 Endress+Hauser

Page 39

Liquiline CM44P Electrical connection

Connecting photometer sensors to PEM module

Sensor Cable color PEM terminal Assignment

OUSAF11

OUSAF12

OUSAF21

OUSAF22

OUSTF10

OUSAF44

OUSAF46

2 PEM modules

necessary

YE (thick) P+ Lamp voltage +

YE (thin) S+ Recording lamp voltage +

BK (thin) S- Recording lamp voltage -

BK (thick) P- Lamp voltage -

RD A (1) Sensor +

1)

/ WH

2)

C(1) Sensor -

BK

GY SH (1) Shield

YE (thick) P+ Lamp voltage +

YE (thin) S+ Recording lamp voltage +

BK (thin) S- Recording lamp voltage -

BK (thick) P- Lamp voltage -

RD A (1) Measuring detector sensor +

BK C(1) Measuring detector sensor -

GY SH (1) Measuring detector screening

WH A (2) Sensor reference +

GN C(2) Sensor reference -

GY SH (2) Reference screening

PEM module 1

YE (thick) P+ Lamp voltage +

YE (thin) S+ Recording lamp voltage +

BK (thin) S- Recording lamp voltage -

BK (thick) P- Lamp voltage -

RD A (1) Measuring detector sensor +

BK C(1) Measuring detector sensor -

GY SH (1) Measuring detector screening

WH (lamp) A (2) Sensor reference +

GN (lamp) C(2) Sensor reference -

GY (lamp) SH (2) Reference screening

PEM module 2

WH A (1) Measuring detector sensor +

GN C(1) Measuring detector sensor -

GY SH (1) Measuring detector screening

RD (lamp) A (2) Sensor reference +

BK (lamp) C(2) Sensor reference -

GY (lamp) SH (2) Reference screening

Endress+Hauser 39

Page 40

Electrical connection Liquiline CM44P

85 86

85

1

2

86

97 88 8798

Sensor 1

PK

GY

GN

YE

BN

WH

1

6

4

1

NC

2

3

5

7

4

6

2

NC

1

7

5

3

Sensor Cable color PEM terminal Assignment

OUSBT66 BN P+ Lamp voltage +

BN S+ Recording lamp voltage +

BK P- Lamp voltage -

BK S- Recording lamp voltage -

RD A (1) Sensor +

OG C(1) Sensor -

TP SH (1) Shield

1) OUSAF12

2) OUSAF11

Memosens connection via M12 plug-in connection (field device only)

Device versions with a pre-installed

M12 socket are ready-wired upon

delivery.

Version without a pre-installed M12

socket

1. Insert an M12 socket

(accessory) into a suitable

opening in the base of the

housing.

2. Connect the cable to a

Memosens terminal as per the

wiring diagram.

Connecting the sensor

Plug the connector of the sensor

‣

A0018019

47 M12 plug-in connection (e.g.

at sensor module)

1 Sensor cable with M12

connector

A0018021

48 M12 assignment Top:

socket Bottom: connector

(top view in each case)

1 PK (24 V)

2 GY (Ground 24 V)

3 BN (3 V)

4 WH (Ground 3 V)

5 GN (Memosens)

6 YE (Memosens)

7,NCNot connected

cable (→ 47item 1) directly into

the M12 socket.

Please note the following:

• The internal device wiring is always

the same regardless of what kind of

sensor you connect to the M12

socket (plug&play).

• The signal or power supply cables

are assigned in the sensor head in

such a way that the PK and GY

power supply cables are either used

(e.g. optical sensors) or not (e.g. pH

or ORP sensors).

6.4 Connecting additional inputs, outputs or relays

WARNING

L

40 Endress+Hauser

Module not covered

No shock protection. Danger of electric shock!

Change or extend the hardware: always fill the slots from left to right. Do not leave any

‣

gaps.

If all of the slots are not occupied: always insert a dummy cover or end cover in the slot

‣

to the right of the last module(→ 2, 10). This ensures that the unit is shockprotected.

Always ensure shock protection is guaranteed particularly in the case of relay modules

‣

(2R, 4R, AOR).

The terminal strip (cabinet unit) is used to connect the cable shields.

Page 41

Liquiline CM44P Electrical connection

47

47

48

48

+

+

–

1

2

–

1

2

1

2

+

–

–

+

+

–

+

–

45

46

45

46

91

92

91

92

2324

2324

23

23

24

24

0/4 ... 20 mA

+

+

–

1

2

–

If additional shields are required, connect them with PE centrally in the control cabinet

‣

via terminal blocks supplied by the customer.

6.4.1 Digital inputs and outputs

DIO module

49 Module

50 Wiring

diagram

6.4.2 Current inputs

Module 2AI

Endress+Hauser 41

51 Module

52 Wiring

diagram

Page 42

Electrical connection Liquiline CM44P

31

31

32

32

0/4 ... 20 mA

+

+

–

1

2

–

31

31

32

32

0/4 ... 20 mA

+

+

–

1

2

–

31

31

32

32

0/4 ... 20 mA

+

+

–

3

4

–

41

43

42

Relay 1

41

43

42

Relay 2

41

43

42

Relay 3

41

43

42

Relay 4

41

43

42

Relay 1

41

43

42

Relay 2

6.4.3 Current outputs

2AO 4AO

53 Module

54 Wiring

diagram

55 Module

6.4.4 Relay

Module 2R Module 4R

56 Wiring

diagram

57 Module

42 Endress+Hauser

58 Wiring

diagram

59 Module

60 Wiring

diagram

Page 43

Liquiline CM44P Electrical connection

PE L1 N PE

T2.0A

230 V AC / 50 Hz

1

41

43

42

Liquiline/Sampler/

Analyzer:

AOR/2R/4R

41

43

42

Relay 1

41

43

42

Relay 2

1

2

1

2

NL PE

CM44x/CM44xR/

CM44P

CYR10

1

2

3

4

5

Example: Connecting the cleaning unit 71072583 for CAS40D

NOTICE

Power consumption too high for the Liquiline alarm relay!

Can cause irreparable damage to the base module

Connect the cleaning unit only to terminals of an additional module (AOR, 2R or 4R),

‣

not to the alarm relay of the base module.

Endress+Hauser 43

61 Connecting the cleaning unit for CAS40D

Example: Connecting the Chemoclean CYR10 injector cleaning unit

62 Connecting the CYR10 injector cleaning unit

1 External power supply

2 Cleaner to spray head

3 Container with cleaner

4 Motive water 2 to 12 bar (30 to 180 psi)

5 Backflow valve (to be provided by the customer)

A0028597

A0028598

Page 44

Electrical connection Liquiline CM44P

Ethernet

81

82

DIP switch

on

1

2

4

8

16

32

64

128/SW

Service

T

COM

SF

BF

PWR

DGND

VP

96'

95'

99'

Termination

DP/

RS485

96

95

99

6.5 Connecting PROFIBUS DP or Modbus RS 485

6.5.1 Module 485

63 Module

64 Wiring

diagram

Terminal PROFIBUS DP Modbus RS485

95 A B

96 B A

99 Not connected C

82 DGND DGND

81 VP VP

LEDs on front of module

LED Identifier Color Description

RJ45 LNK/ACT GN RJ45 is disabled. Ethernet communication is via the BASE2 module

RJ45 10/100 YE

PWR Power GN Supply voltage is applied and module is initialized

BF Bus failure RD Bus failure

SF System failure RD Device error

COM Communication YE Modbus message sent or received

T Bus termination YE • Off = No termination

• On = Termination is used

DIP switches on front of module

44 Endress+Hauser

DIP Factory setting Assignment

1-128 ON Bus address (→ "Commissioning/communication")

OFF Write protection: "ON" = configuration not possible via the bus, only via local

operation

Service OFF The switch has no function

Page 45

Liquiline CM44P Electrical connection

RD

GN

P0V

P5V

82

81

J1

P2

P1

96

95

99

P2

J1

1

2

3

4

5

1

2

3

4

5

P1

1

2

3

4

5

1 2

34

5

2 1

43

5

RD

GN

P0V

P5V

82

81

J1

P2

P1

96

95

99

P2

J1

1

2

3

4

5

1

2

3

4

5

P1

1

2

3

4

5

1 2

34

5

2 1

43

5

6.5.2 Connection via M12 connector (field device only)

PROFIBUS DP

M12 Y-section Wiring in M12 Y section Pin assignment in connector and

socket

67 Connector (left) and socket

(right)

1 P5V, 5 V power supply for

external terminating resistor

2 A

3 P0V, reference potential for

P5V

4 B

5 n.c., not connected

* Shielding

65 M12 connection

66 Wiring

When using the M12 Y-section, the maximum data transfer rate is limited to

1.5 MBit/s. For direct wiring, the maximum data transfer rate is 12 MBit/s.

Modbus RS485

M12 Y-section Wiring in M12 Y section Pin assignment in connector and

socket

70 Connector (left) and socket

(right)

1 P5V, 5 V power supply for

external terminating resistor

2 A

3 P0V, reference potential for

P5V

4 B

5 n.c., not connected

* Shielding

68 M12 connection

Endress+Hauser 45

69 Wiring

Page 46

Electrical connection Liquiline CM44P

3

4

1

2

4

3

2

1

Ethernet, web server, PROFINET

Internal connection Pin assignment in connector and socket

72 Connector (left) and socket (right)

1 Tx+

2 Rx+

3 Tx4 Rx-

Shielding (thread)

71 Ethernet socket

46 Endress+Hauser

Page 47

Liquiline CM44P Electrical connection

"ON"

"OFF"

390 W

220 W

390 W

VP

DGND

B/B' A/A'

6.5.3 Bus termination

There are 2 ways to terminate the bus:

1. Internal termination (via DIP switch on module board)

73 DIP switch for internal termination

Using a suitable tool such as a tweezer, move all four DIP switches to the "ON" position.

‣

The internal termination is used.

74 Structure of internal termination

2. External termination

Leave the DIP switches on the module board in the "OFF" position (factory setting).

Connect the external termination to terminals 81 and 82 on the front of module 485

‣

for 5‐V power supply.

The external termination is used.

6.6 Hardware settings

Setting the bus address

1. Open the housing.

2. Set the desired bus address via the DIP switches of module 485.

For PROFIBUS DP, valid bus addresses are anything between 1 and 126, and anything

between 1 and 247 for Modbus. If you configure an invalid address, software

addressing is automatically enabled via the local configuration or via the fieldbus.

Endress+Hauser 47

Page 48

Electrical connection Liquiline CM44P

1

2

4

8

16

32

64

128

on off

1

2

4

8

16

32

64

128

on off

1

2

4

8

16

32

64

128

on off

A0026776

75 Valid PROFIBUS address 67

1)

Order configuration, software addressing is active, software address configured at the factory: PROFIBUS 126,

Modbus 247

76 Valid Modbus address 195

A0026777

77

Invalid address 255

A0026778

1)

6.7 Ensuring the degree of protection

Only the mechanical and electrical connections which are described in these instructions

and which are necessary for the required, designated use, may be carried out on the device

delivered.

Exercise care when carrying out the work.

‣

Individual types of protection permitted for this product (impermeability (IP), electrical

safety, EMC interference immunity, Ex protection) can no longer be guaranteed if, for

example :

• Covers are left off

• Different power units to the ones supplied are used

• Cable glands are not sufficiently tightened (must be tightened with 2 Nm (1.5 lbf ft) for

the permitted level of IP protection)

• Unsuitable cable diameters are used for the cable glands

• Modules are not fully secured

• The display is not fully secured (risk of moisture entering due to inadequate sealing)

• Loose or insufficiently tightened cables/cable ends

• Conductive cable strands are left in the device

48 Endress+Hauser

Page 49

Liquiline CM44P Electrical connection

6.8 Post-connection check

WARNING

L

Connection errors

The safety of people and of the measuring point is at risk! The manufacturer does not

accept any responsibility for errors that result from failure to comply with the instructions

in this manual.

Put the device into operation only if you can answer yes to all the following questions.

‣

Instrument status and specifications

Are the device and all the cables free from damage on the outside?

‣

Electrical connection

Are the mounted cables strain relieved?

‣

Are the cables routed without loops and cross-overs?

‣

Are the signal cables correctly connected as per the wiring diagram?

‣

Have all the other connections been established correctly?

‣

Are unused connection wires connected to the protective ground connection?

‣

Are all plug-in terminals securely engaged?

‣

Are all the connection wires securely positioned in the cable terminals?

‣

Are all cable entries mounted, tightened and leak-tight?

‣

Does the supply voltage match the voltage indicated on the nameplate?

‣

Endress+Hauser 49

Page 50

System integration Liquiline CM44P

Base2

Web Browser

7 System integration

7.1 Web server

Versions without a fieldbus: you require an activation code for the web server.

7.1.1 Connection

Connect the communication cable of the computer to the Ethernet port of the Base2

‣

module.

A0039619

78 Web server/Ethernet connection

7.1.2 Establishing the data connection

All versions with the exception of PROFINET:

To ensure that your device has a valid IP address, you must disable the DHCP parameter in

the Ethernet settings. (Menu/Setup/General settings/Extended setup/Ethernet/

Settings)

You can assign the IP address manually in the same menu (for point-to-point

connections).

All versions including PROFINET:

The device's IP address and subnet mask can be found at: DIAG/System information/

Ethernet.

1. Start your PC.

2. First, configure a manual IP address in the network connection settings of the

operating system.

Example: Microsoft Windows 10

3. Open Network and Sharing Center.

Apart from your standard network, you should see an additional Ethernet

connection (e.g. as "Unidentified network" ).

4. Select the link to this Ethernet connection.

5. In the pop-up window select the "Properties" button.

6. Double-click "Internet Protocol Version 4 (TCP/IPv4)".

7. Select "Use the following IP Address".

8. Enter the desired IP address. This address must be in the same subnet as the IP

address of the device, e.g.:

IP address for Liquiline: 192.168.1.212 (as configured previously)

IP address for PC: 192.168.1.213.

50 Endress+Hauser

9. Start the internet browser.

Page 51

Liquiline CM44P System integration

10. If you use a proxy server to connect to the internet:

Disable the proxy (browser settings under "Connections/LAN settings").

11. Enter the IP address of your device in the address bar (192.168.1.212 in the

example).

The system takes a few moments to establish the connection and then the CM44

web server starts. You might be asked for a password. The factory setting is

"admin" for the user name and "admin" for the password.

12. Enter the following address(es) to download logbooks:

192.168.1.212/logbooks_csv.fhtml (for logbooks in CSV format)

192.168.1.212/logbooks_fdm.fhtml (for logbooks in FDM format)

Downloads in FDM format can be securely transmitted, saved and visualized with

Endress+Hauser's "Field Data Manager Software".

(→ www.endress.com/ms20)

7.1.3 Operation

The menu structure of the web server corresponds to the onsite operation.

A0026780

79 Example of web server (menu/language=English)

• Clicking a menu name or a function corresponds to pressing the navigator.

• You can make your settings conveniently via the computer keyboard.

Instead of using an internet browser, you can also use FieldCare for configuration via

Ethernet. The Ethernet DTM required for this is an integral part of the "Endress

+Hauser Interface Device DTM Library".

Download: https://portal.endress.com/webdownload/FieldCareDownloadGUI/

7.2 Service interface

You can connect the device to a computer via the service interface and configure it using

"FieldCare" . Furthermore, configurations can also be saved, transferred and documented.

7.2.1 Connection

1. Connect the service connector to the interface on the Liquiline base module and

connect it to the Commubox.

2. Connect the Commubox via the USB connection to the computer on which FieldCare

is installed.

Endress+Hauser 51

Page 52

System integration Liquiline CM44P

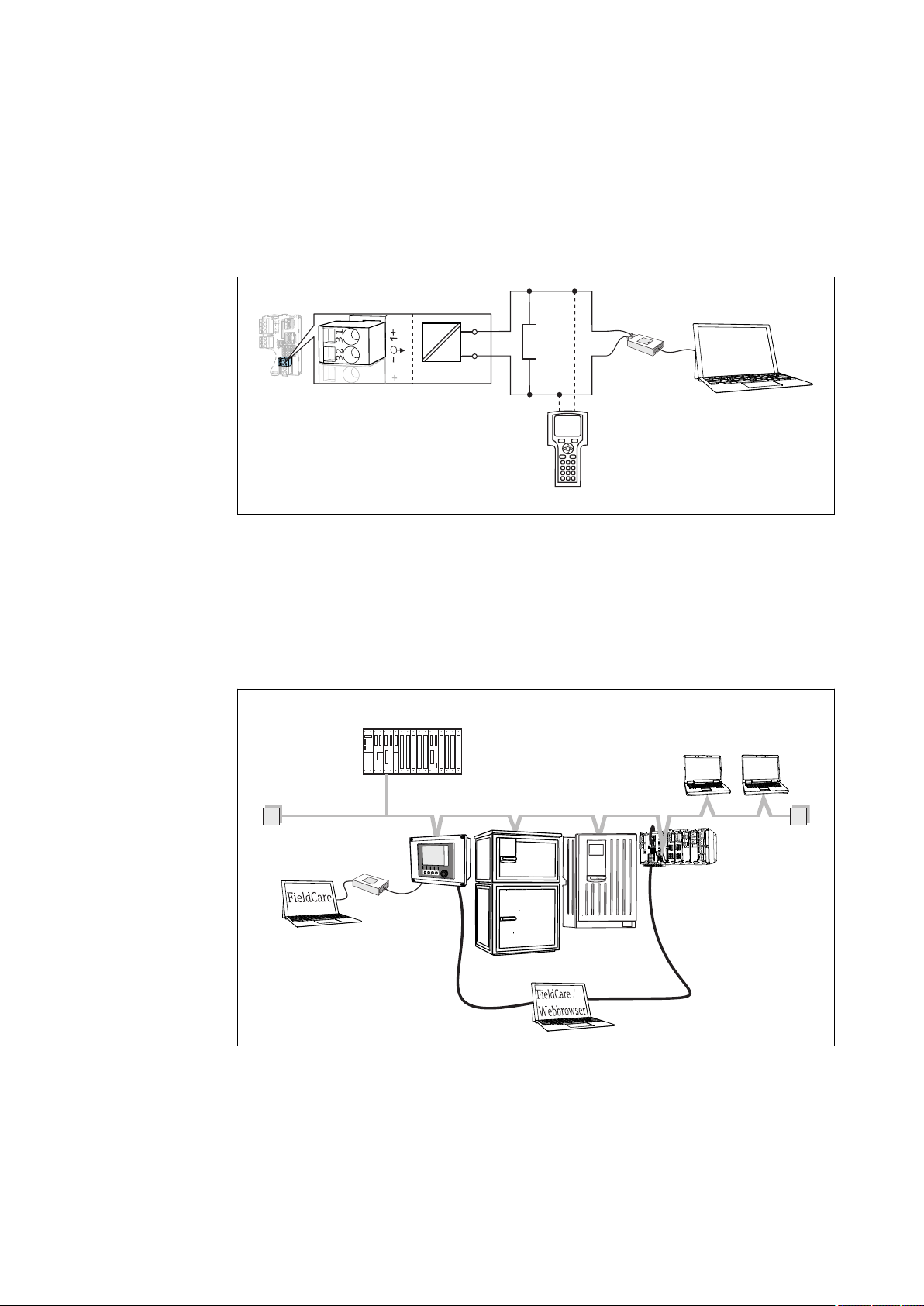

FieldCare

Service

FXA291

A0039618

80 Connection overview

7.2.2 Establishing the data connection

1. Start FieldCare.

2. Establish a connection to the Commubox. To do so, select the "CDI Communication

FXA291" ComDTM.

3. Then select the "Liquiline CM44x" DTM and start configuration.

You can now start online configuration via the DTM.

Online configuration competes with onsite operation, i. e. each of the two options blocks

the other one. On both sides it is possible to take away access from the other side.

7.2.3 Operation

• In the DTM the menu structure corresponds to the onsite operation. The functions of the

Liquiline soft keys are found in the main window on the left.

• Clicking a menu name or a function corresponds to pressing the navigator.

• You can make your settings conveniently via the computer keyboard.

• You can use FieldCare to save logbooks, make backups of configurations and transfer

configurations to other devices.

• You can also print out configurations or save them as PDFs.

7.3 Fieldbuses

7.3.1 HART

You can communicate using the HART protocol via current output 1.

1. Connect the HART modem or HART handheld terminal to current output 1

(communication load 250 ‐ 500 Ohm).

2. Establish a connection via your HART device.

3. Operate the Liquiline via the HART device. To do so, follow the instructions in the

manual.

More detailed information on HART communication is provided on the product pages

on the Internet (→ BA00486C).

52 Endress+Hauser

Page 53

Liquiline CM44P System integration

7.3.2 PROFIBUS DP

With the fieldbus module 485 and the appropriate device version, you can communicate

via PROFIBUS DP.

Connect the PROFIBUS data cable to the terminals of the fieldbus module as described

‣

(→ 44).

For detailed information on "PROFIBUS communication", see the product pages on the

Internet (→ SD01188C).

7.3.3 Modbus

With the fieldbus module 485 and the appropriate device version, you can communicate

via Modbus RS485.

You use the BASE2 module for Modbus TCP.

The RTU and ASCII protocols are available when connecting via Modbus RS485. You can

switch to ASCII on the device.

Connect the Modbus data cable to the terminals of the fieldbus module (RS 485) or to

‣

the RJ45 socket of the BASE2 module as described.

For detailed information on "Modbus communication", see the product pages on the

Internet (→ SD01189C).

7.3.4 Ethernet/IP

With the BASE2 module and the appropriate device version, you can communicate via

Ethernet/IP.

Connect the Ethernet/IP data cable to the RJ45 socket of the BASE2 module.

‣

For detailed information on "Ethernet/IP communication", see the product pages on

the Internet (→ SD01293C).

7.3.5 PROFINET

With the BASE2 module and the appropriate device version, you can communicate via

PROFINET.

Connect the PROFINET data cable to the RJ45 socket of the BASE2 module.

‣

For detailed information on "PROFINET communication", see the product pages on the

internet (→ SD02490C).

Endress+Hauser 53

Page 54

Operation options Liquiline CM44P

1

2

3

1 2

3

4

8 Operation options

8.1 Overview

8.1.1 Display and operating elements

81 Overview of operation (using the example of the field device)

1 Display (with red display background in alarm condition)

2 Navigator (jog/shuttle and press/hold function)

3 Soft keys (function depends on menu)

8.1.2 Display

1 Menu path and/or device designation

2 Status display

3 Help if available

4 Assignment of the soft keys

A0037692

A0011764

54 Endress+Hauser

Page 55

Liquiline CM44P Operation options

Menu/Language

English

!"

Čeština

Nederlands

Français

Deutsch

Italiano

#$%

Polski

Menu/Language

English

!"

Čeština

Nederlands

Français

Deutsch

Italiano

#$%

Polski

8.2 Access to the operating menu via the local display

8.2.1 Operating concept

Pressing the soft key: selecting the menu directly

‣

Pressing the navigator: launching a function

‣

Turning the navigator: moving the cursor in the

‣

menu

Turning the navigator: selecting a value (e.g. from

‣

a list)

Pressing the navigator: accepting the new value New setting is accepted

‣

8.2.2 Locking or unlocking operating keys

Locking operating keys

1. Press the navigator for longer than 2 s.

A context menu for locking the operating keys is displayed.

You have the choice of locking the keys with or without password protection.

"With password" means that you can only unlock the keys again by entering the

correct password. Set this password here: Menu/Setup/General settings/

Extended setup/Data management/Change lock password.

Endress+Hauser 55

Page 56

Operation options Liquiline CM44P

2. Select whether to lock keys with or without a password.

The keys are locked. No more entries can be made. In the soft key bar, you will

see the symbol.

The password is 0000 when the device is delivered from the factory. Make sure to

note down any changes to the password, as otherwise you will not be able to unlock

the keypad yourself.

Unlocking operating keys

1. Press the navigator for longer than 2 s.

A context menu for unlocking the operating keys is displayed.

2. Key unlock .

The keys are unlocked immediately if you did not choose to lock with a password.

Otherwise you are asked to enter your password.

3. Only if keypad is password-protected: enter the right password.

The keys are unlocked. It is possible to access the entire onsite operation again.

The symbol is no longer visible on the display.

8.3 Configuration options

8.3.1 Display only

• You can only read the values but cannot change them.

• Typical read-only values are: sensor data and system information

• Example: Menu/Setup/Inputs/../Sensor type

8.3.2 Picklists

• You receive a list of options. In a few cases, these also appear in the form of multiple

choice boxes.

• Usually you just select one option; in rare instances you select one or more options.

• Example: Menu/Setup/General settings/Temperature unit

8.3.3 Numerical values

• You are changing a variable.

• The maximum and minimum values for this variable are shown on the display.

• Configure a value within these limits.

• Example: Menu/Operation/Display/Contrast

56 Endress+Hauser

Page 57

Liquiline CM44P Operation options

8.3.4 Actions

• You trigger an action with the appropriate function.

• You know that the item in question is an action if it is preceded by the following symbol:

• Examples of typical actions include:

• Deleting log entries

• Saving or loading configurations

• Triggering cleaning programs

• Example: Diagnostics/Logbooks/Configuration logbook/Delete all entries

8.3.5 Free text

• You are assigning an individual designation.

• Enter a text. You can use the characters in the editor for this purpose (upper-case and

lower-case letters, numbers and special characters).

• Using the soft keys, you can:

• Cancel your entries without saving the data ()

• Delete the character in front of the cursor ( )

• Move the cursor back one position ( )

• Finish your entries and save ()

• Example: Menu/Setup/General settings/Device tag

Endress+Hauser 57

Page 58

Operation options Liquiline CM44P

8.3.6 Tables

• Tables are needed to map mathematical functions .

• You edit a table by navigating through rows and columns with the navigator and

changing the values of the cells.

• You only edit the numerical values. The controller automatically takes care of the

engineering units.

• You can add lines to the table ( INSERT) or delete lines from the table ( DEL).

• Afterwards, you save the table ( SAVE).

• You can also cancel your entries any time using the soft key.

• Example: Menu/Setup/Inputs/pH/Medium comp.

58 Endress+Hauser

Page 59

Liquiline CM44P Commissioning

9 Commissioning

9.1 Function check

WARNING

L

Incorrect connection, incorrect supply voltage

Safety risks for staff and device malfunctions!

Check that all connections have been established correctly in accordance with the

‣

wiring diagram.

Ensure that the supply voltage matches the voltage indicated on the nameplate.

‣

Saving the configuration settings as a screenshot

Via the local display , you can take screenshots at any time and save them to an SD card.

1. Insert an SD card into the SD card slot in the base module.

2. Press the navigator button for at least 3 seconds.

3. In the context menu, select the Screenshot item.

The current screen is saved as a bitmap file to the SD card in the "Screenshots"

folder.

9.2 Power up

During the device startup phase, the relays and current outputs have an undefined

status for a few seconds prior to initialization. Watch out for possible effects on any

actuators which may be connected.

9.2.1 Setting the operating language

Configuring the language

If you have not already done so, close the housing cover and screw the device closed.

1. Switch on the supply voltage.

Wait for the initialization to finish.

2. Press the soft key MENU . Set your language in the top menu item.

The device can now be operated in your chosen language.

Endress+Hauser 59

Page 60

Commissioning Liquiline CM44P

9.2.2 Display behavior

Menu/Operation/Display

Function Options Info

Contrast 5 to 95 %

Factory setting

50 %

Backlight Selection

• On

• Off

• Automatic

Factory setting

Automatic

Screen rotation Selection

• Manual

• Automatic

Factory setting

Manual

Adjust the screen settings to suit your working

environment.

Backlight = Automatic

The backlighting is switched off automatically

after a short time if a button is not pressed. It

switches back on again as soon as you press the

navigator button.

Backlight = On

The backlighting does not switch off

automatically.

If Automatic is selected, the single‐channel

measured value display switches from one

channel to the next every second.

9.3 User definable screens

Menu/Operation/User definable screens

Function Options Info

Meas. screen 1 ... 6 You can create 6 measuring screens of your own

and give them a name. The functions are

identical for all 6 measuring screens.

Meas. screen Selection

• On

• Off

Factory setting

Off

Label Customized text, 20

characters

Number of lines 1 to 8

Factory setting

8

Line 1 ... 8 User interface

Label

Source of data Selection

• None

• See list in "Info" column

Factory setting

None

Measured value

Source of data is an

input

Selection