Page 1

TI01112C/07/EN/09.19

71478328

2019-11-30

Products Solutions Services

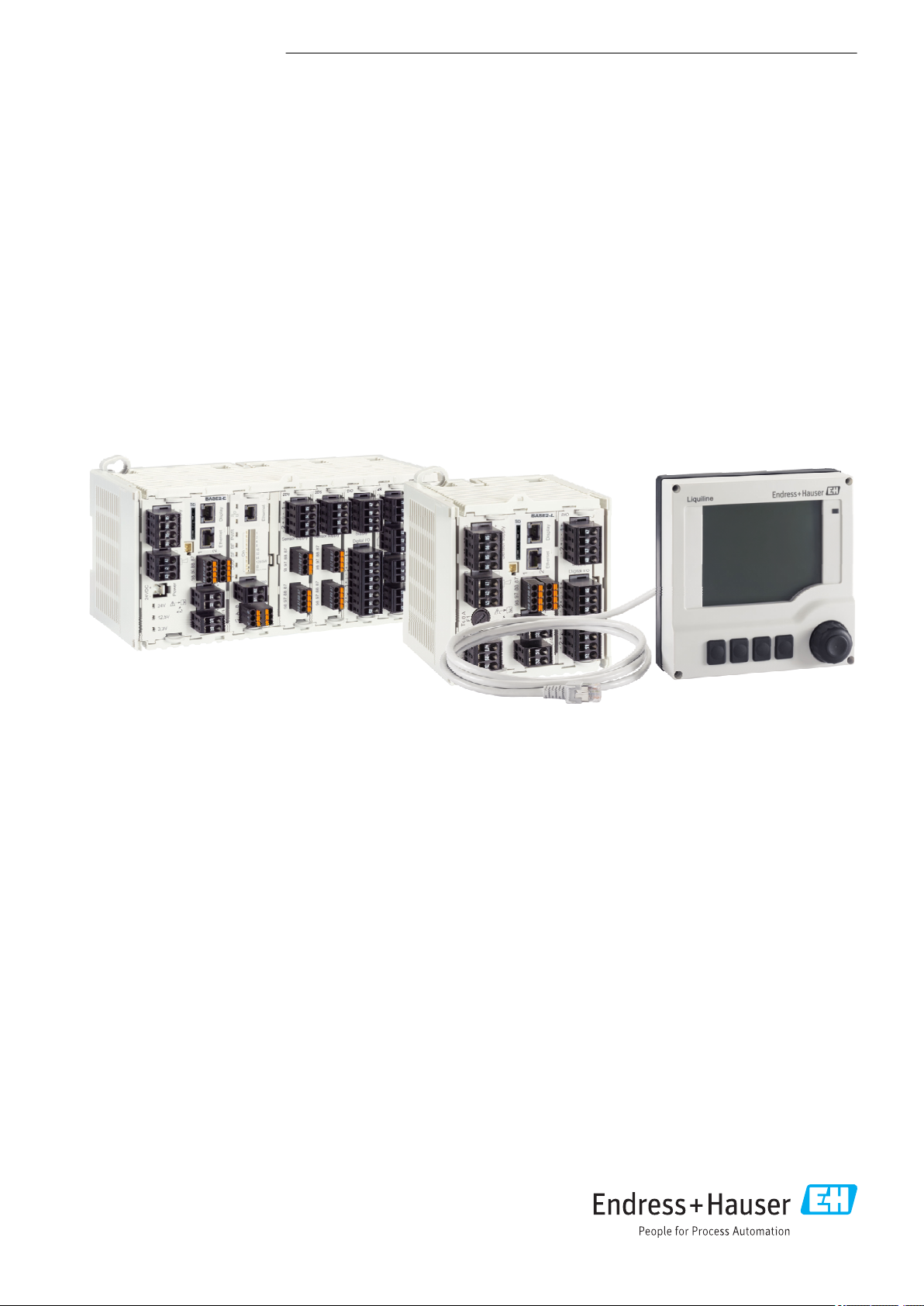

Technical Information

Liquiline CM442R/CM444R/

CM448R

Cabinet controller with a maximum of eight measuring

channels based on digital Memosens technology

For monitoring and controlling processes in industry and the environmental

sector

Application

• Food and beverages

• Life science

• Water and wastewater

• Chemical industry

Your benefits

• Highly flexible:

• Able to connect up to 8 Memosens sensors

• Mathematics functions calculate new measured values

• Digital fieldbuses (HART, PROFIBUS, Modbus,

Ethernet/IP, PROFINET) and integrated web server

• Choice of cleaning function, controller and alarm relay

• Optional digital or analog inputs/outputs

• Maximum process safety thanks to standardized operating

concept across all devices in the Liquiline, sampler and

analyzer platform

• Fast commissioning thanks to:

• Memosens: lab-calibrated sensors & hot plug-and-play

• Preconfigured Liquiline transmitters

• Easy extension and adaptation

• Minimum inventory:

• Cross-platform, modular concept (e.g. identical modules

irrespective of parameters)

• Integration into FieldCare and W@M facilitates effective

asset management

Page 2

Table of contents

Liquiline CM442R/CM444R/CM448R

Function and system design ................... 4

Measuring system ............................. 4

Application example ........................... 5

Device architecture .......................... 6

Slot and port assignment ........................ 6

Order of the modules ........................... 6

Basic rule for hardware upgrades ................... 6

Determining the hardware delivery status ............. 7

Terminal diagram ............................. 7

Device configuration using the example of a CM442R-

**M1A1F0* ................................ 8

Function diagram CM442R ....................... 9

Device configuration using the example of a CM444R-

**M42A1FA* .............................. 10

Function diagram CM444R ...................... 11

Device configuration using the example of a CM448R-

**26A1* .................................. 12

Function diagram CM448R ...................... 13

Communication and data processing ........... 14

Dependability ............................. 14

Reliability ................................. 14

Maintainability .............................. 16

Safety .................................... 19

Input .................................... 20

Measured variables ........................... 20

Measuring ranges ............................ 20

Types of input ............................... 20

Input signal ................................ 20

Cable specification ............................ 20

Digital inputs, passive ....................... 20

Electrical specification ......................... 20

Span ..................................... 20

Nominal input current ......................... 20

PFM function ............................... 20

Test voltage ................................ 20

Cable specification ............................ 20

Current input, passive ....................... 20

Span ..................................... 20

Signal characteristic ........................... 20

Internal resistance ............................ 20

Test voltage ................................ 20

Output .................................. 21

Output signal ............................... 21

Signal on alarm .............................. 22

Load ..................................... 22

Linearization/transmission behavior ................ 22

Digital outputs, passive ..................... 22

Electrical specification ......................... 22

External power supply ......................... 22

PFM function ............................... 22

Auxiliary voltage ............................. 22

Test voltage ................................ 22

Cable specification ............................ 22

Current outputs, active ...................... 22

Span ..................................... 22

Signal characteristic ........................... 22

Electrical specification ......................... 23

Cable specification ............................ 23

Relay outputs ............................. 24

Electrical specification ......................... 24

Cable specification ............................ 24

Protocol-specific data ....................... 24

HART .................................... 24

PROFIBUS DP ............................... 25

Modbus RS485 .............................. 25

Modbus TCP ................................ 25

Ethernet/IP ................................ 25

PROFINET ................................. 26

Web server ................................. 27

Power supply ............................. 27

Supply voltage .............................. 27

Power consumption ........................... 28

Fuse ..................................... 28

Overvoltage protection ......................... 28

Cable specification for optional display cable .......... 28

Electrical connection .......................... 29

Connecting optional modules ..................... 31

Protective ground connection .................... 33

Sensor connection ............................ 33

Performance characteristics .................. 35

Response time .............................. 35

Reference temperature ......................... 35

Measured error for sensor inputs .................. 35

Measured error for current inputs and outputs ......... 35

Frequency tolerance of digital inputs and outputs ....... 35

Resolution of current inputs and outputs ............. 35

Repeatability ............................... 35

Installation ............................... 35

Mounting on DIN rail as per IEC 60715 .............. 35

Wall mounting .............................. 36

Mounting the external display .................... 37

Environment .............................. 37

Ambient temperature range ..................... 37

Storage temperature .......................... 38

Humidity .................................. 38

Degree of protection .......................... 38

Climate class ............................... 38

Vibration resistance ........................... 38

2 Endress+Hauser

Page 3

Liquiline CM442R/CM444R/CM448R

Electromagnetic compatibility .................... 38

Electrical safety .............................. 39

Degree of contamination ....................... 39

Mechanical construction .................... 39

Dimensions ................................ 39

Weight ................................... 42

Materials .................................. 42

Operability ............................... 43

External display ............................. 43

Operating concept ............................ 43

Local operation via external, optional display .......... 43

Remote operation ............................ 44

Language packages ........................... 45

Certificates and approvals ................... 46

mark ................................... 46

EAC ..................................... 46

cCSAus ................................... 46

Marine approvals ............................ 46

Ordering information ....................... 46

Product page ............................... 46

Product Configurator .......................... 46

Scope of delivery ............................. 47

Accessories ............................... 47

Measuring cable ............................. 47

Sensors ................................... 47

Additional functionality ........................ 51

Software .................................. 53

Other accessories ............................. 53

Endress+Hauser 3

Page 4

Function and system design

1

5 4 3

2

Liquiline CM442R/CM444R/CM448R

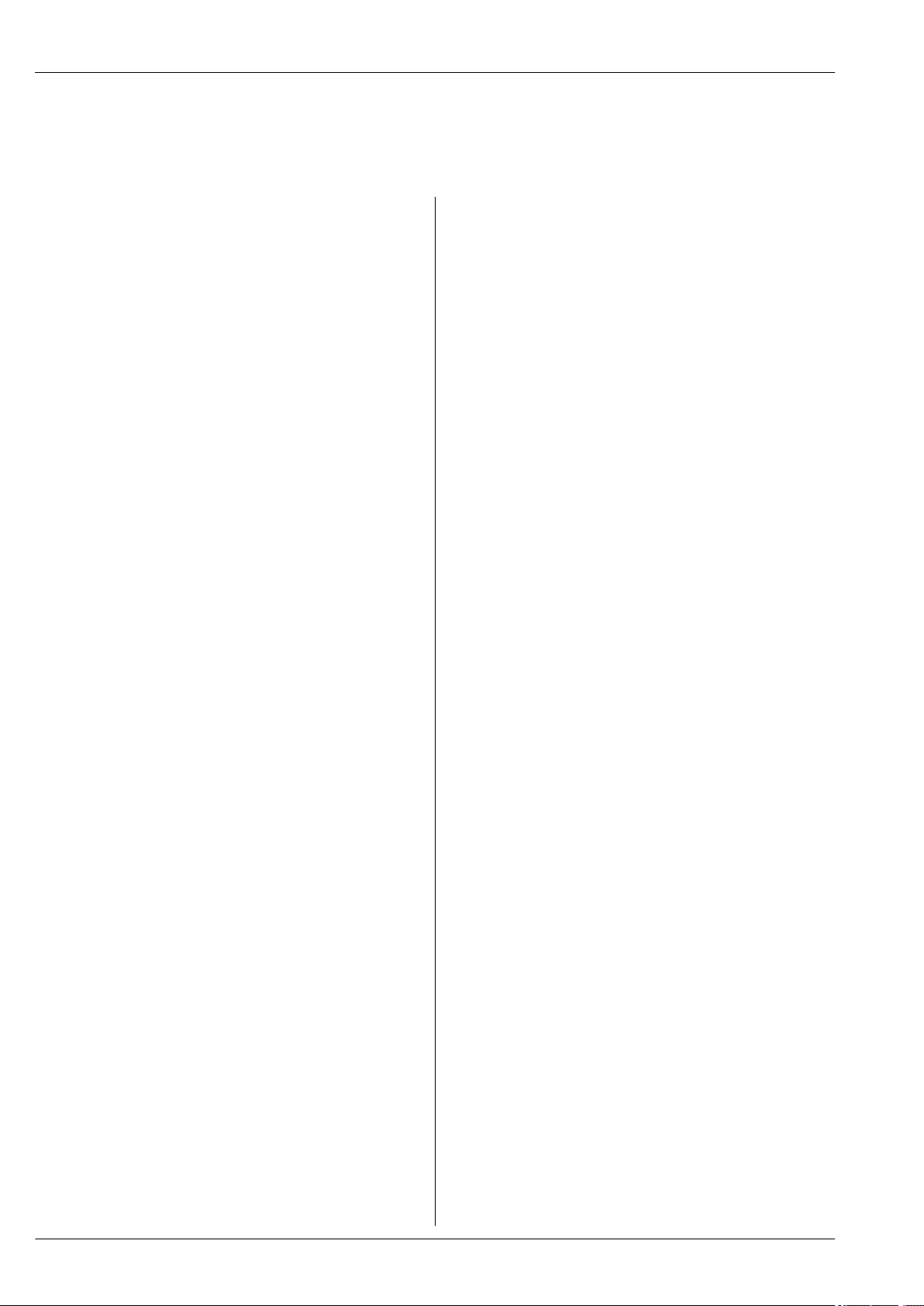

Measuring system

The overview shows examples of measuring systems. Other sensors and assemblies can be ordered

for conditions specific to your application (www.endress.com/products).

Measuring point pH value or ORP

A complete measuring system comprises:

• TransmitterLiquiline

• Optional display

• Sensors with Memosens technology

• Assemblies to suit the sensors used

1 Cabinet installation (without sensor and signal

cables)

1 Optional display (back)

2 Liquiline

3 External power unit (CM444R and CM448R only)

4 Power cable (to be provided by the customer)

5 Display cable

pH measurement in drinking

water (→ Fig.)

• Retractable assembly Cleanfit

CPA871

• Sensor Orbisint CPS11D

• Measuring cable CYK10

ORP in drinking water

• Dipfit CYA112 immersion

assembly

• Sensor Orbisint CPS12D

• Measuring cable CYK10

Conductivity

Inductive conductivity

measurement in wastewater

treatment

• Sensor Indumax CLS50D

• Sensor fixed cable

Conductive conductivity

measurement in power plant

cooling water

• Sensor Condumax CLS15D

• Measuring cable CYK10

Oxygen

Oxygen in aeration basins

A0042875

• Dipfit CYA112 immersion

assembly

• Holder CYH112

• Sensor

• COS61D (optical) with fixed

cable (→ Fig.)

• COS51D (amperometric),

cable CYK10

Nitrate and SAC Turbidity and interface

Nitrate in wastewater

• Sensor CAS51D-**A2 with fixed

cable

• Dipfit CYA112 immersion

assembly

• Holder CYH112

SAC in the wastewater treatment

outlet

• Sensor CAS51D-**2C2 with

fixed cable

• Dipfit CYA112 immersion

assembly

• Holder CYH112

Disinfection Ion-selective electrodes

Free available chlorine (and pH) in

drinking water

• Sensor CCS142D

• Sensor CPS11D

• Measuring cable CYK10

• Flow assembly CCA250

Turbidity in industrial water

• Sensor Turbimax CUS51D with

fixed cable (→ Fig.)

• Assembly Flowfit CUA250

• Spray head CUR3 (optional)

Interface in the primary clarifier

• Sensor Turbimax CUS71D

• Assembly CYA112

• Holder CYH112

Ammonium and nitrate

measurement in the aeration basin

• Sensor CAS40D with fixed cable

• Holder CYH112

4 Endress+Hauser

Page 5

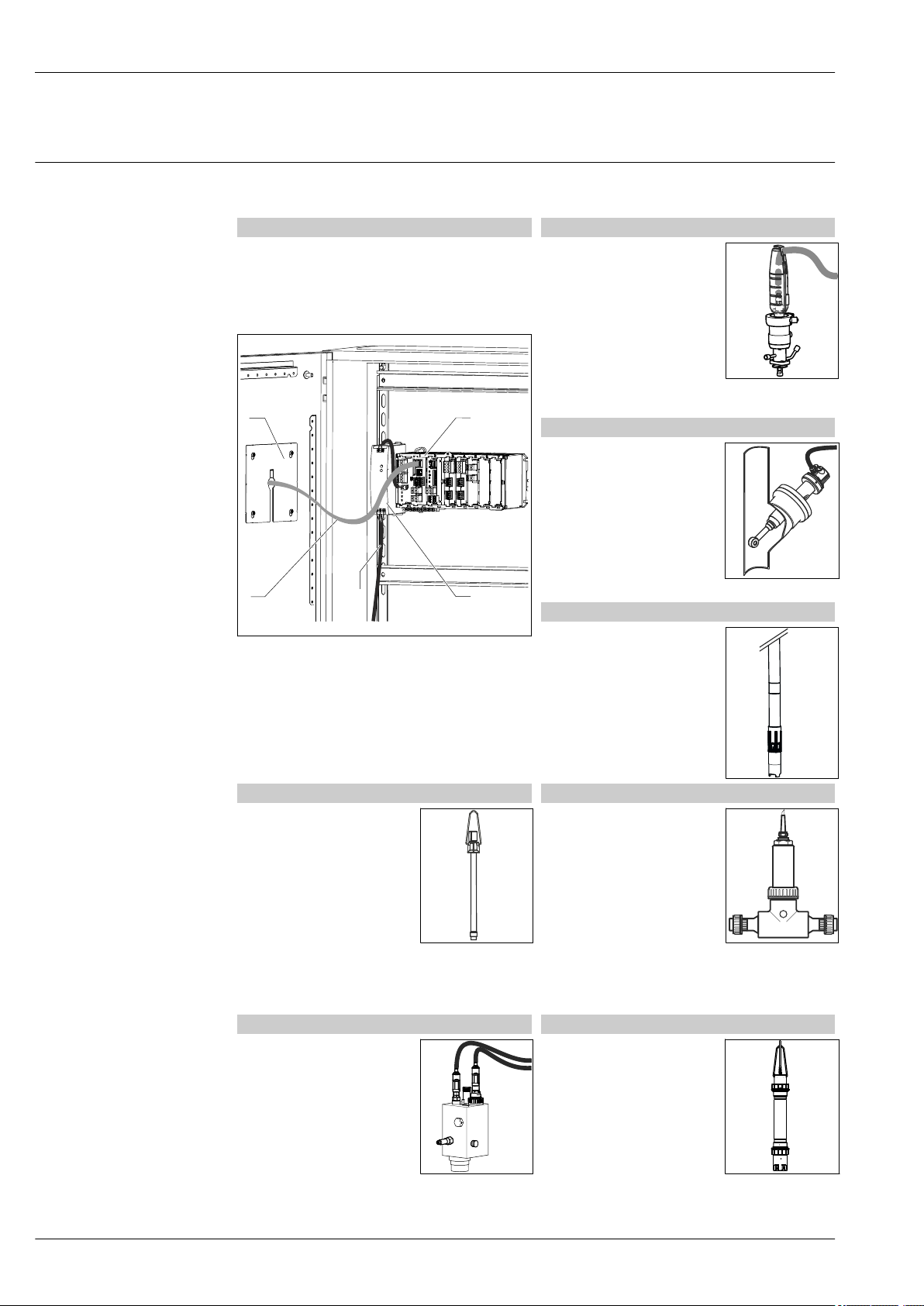

Liquiline CM442R/CM444R/CM448R

Outlet 1

MENU

CH 1:1 pH

CH 1:1 Temperature

CH 1:2 Cond I

CH 2:1 Cond I

CH 2:2 Chlorine

CH 3:1 Current Input [Flow]

6.99 pH

25.1 °C

9.02 mS/cm

13.41 mS/cm

9.03 mg/l

15.1 nA

11:12:13 29.06.2013

10.00

mS/cm

8.00

mS/cm

29.05.2013

10:02:20

29.06.2013

11:09:15

6.00

pH

29.05.2013

10:02:20

29.06.2013

11:09:15

12.00

pH

Field Data Manager

2

1

4

3

Application example

• Transmitter CM444R-AAM44A0FM6 with:

4 x Memosens, Modbus TCP, 2 digital inputs and 2 digital outputs, 2 x relays for cleaning/limit

value, 2 x analog current input

• pH and temperature with CPS11D, item 1 (www.endress.com/cps11d)

• Chlorine with CCS142D, item 4 (www.endress.com/ccs142d)

• 2 x conductivity, inductive measurement with CLS50D, item 2 and 3 (www.endress.com/cls50d)

• 1 x measuring range switching for conductivity via Modbus module

• Flow assembly CCA250 with optional proximity switch INS (www.endress.com/cca250)

• Chlorine regulation with dosing interrupted if no flow: proximity switch via digital input of DIO

module, flow feedforward control (via digital or analog input), PFM-controlled dosing pump via

digital output of DIO module

2 Measuring point in the CIP process

Data retention

• Storage of all measured values, incl. values of external sources, in the non-volatile memory

(data logbook)

• Data called up on site via user-defined measuring menu and load curve display of the data logbook

• Transmission of data by ethernet, CDI interface or SD card and storage in a tamper-proof database

(Field Data Manager)

• Data export to csv file (for Microsoft Excel)

Endress+Hauser 5

A0025347

Page 6

Slot and port assignment

BASE2-E

Slots

1

2

1

2

1

2

1

2

Ports

2DS 2DS 2DS 2AI 2AO 4R

1

2

Sensor 1

Sensor 1

Sensor 1

Sensor 2

Sensor 2

Sensor 2

1

2

1

2

1

2

1

2

3

4

Liquiline CM442R/CM444R/CM448R

Device architecture

Order of the modules

Basic rule for hardware upgrades

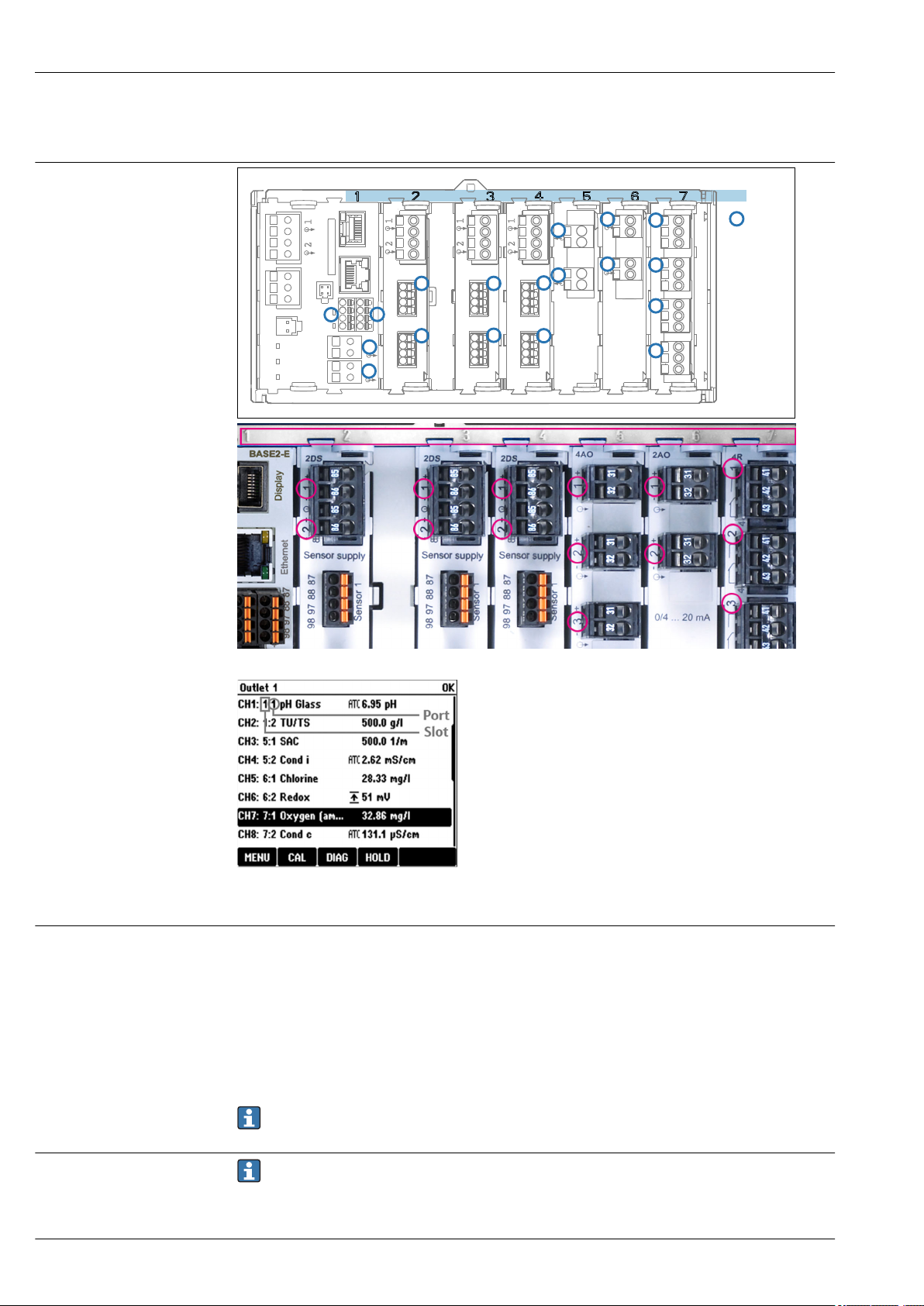

3 Slot and port assignment of the hardware modules

• Inputs are assigned to measuring channels in the

ascending order of the slots and ports.

Adjacent example:

"CH1: 1:1 pH glass" means:

Channel 1 (CH1) is slot 1 (basic module) : Port 1 (input

1), pH glass sensor

• Outputs and relays are named according to their

function, e.g. "current output", and are displayed in

ascending order with the slot and port numbers

4 Slot and port assignment on the

display

Depending on the version ordered, the device is supplied with a number of electronic modules, which

are assigned in a specific sequence in ascending order to slots 0 to 7. If you do not have a particular

module, the next moves up automatically:

• The basic module (which is always present) always occupies slots 0 and 1

• Fieldbus module 485

• Memosens input module 2DS (DS = digital sensor)

• Extension module for digital inputs and outputs DIO (DIO = digital input and output)

• Current input module 2AI (AI = analog input)

• Current output module 4AO or 2AO (AO = analog output)

• Relay modules AOR, 4R or 2R (AOR = analog output + relay, R = relay)

Modules with 4 ports are connected before modules of the same type with 2 ports.

Please note the following if upgrading the device:

• The sum of all current inputs and outputs may not exceed 8!

• A maximum of two "DIO" modules may be used.

6 Endress+Hauser

Page 7

Liquiline CM442R/CM444R/CM448R

1 2

3

4

43

42 41

Relay 1

Relay 2

Relay 3

Relay 4

Slot

Slot 4

Port 1

Pin 41

BASE2-E 2DS

4R

2AO

43

42 414342 41

43

42 41

43

42 41

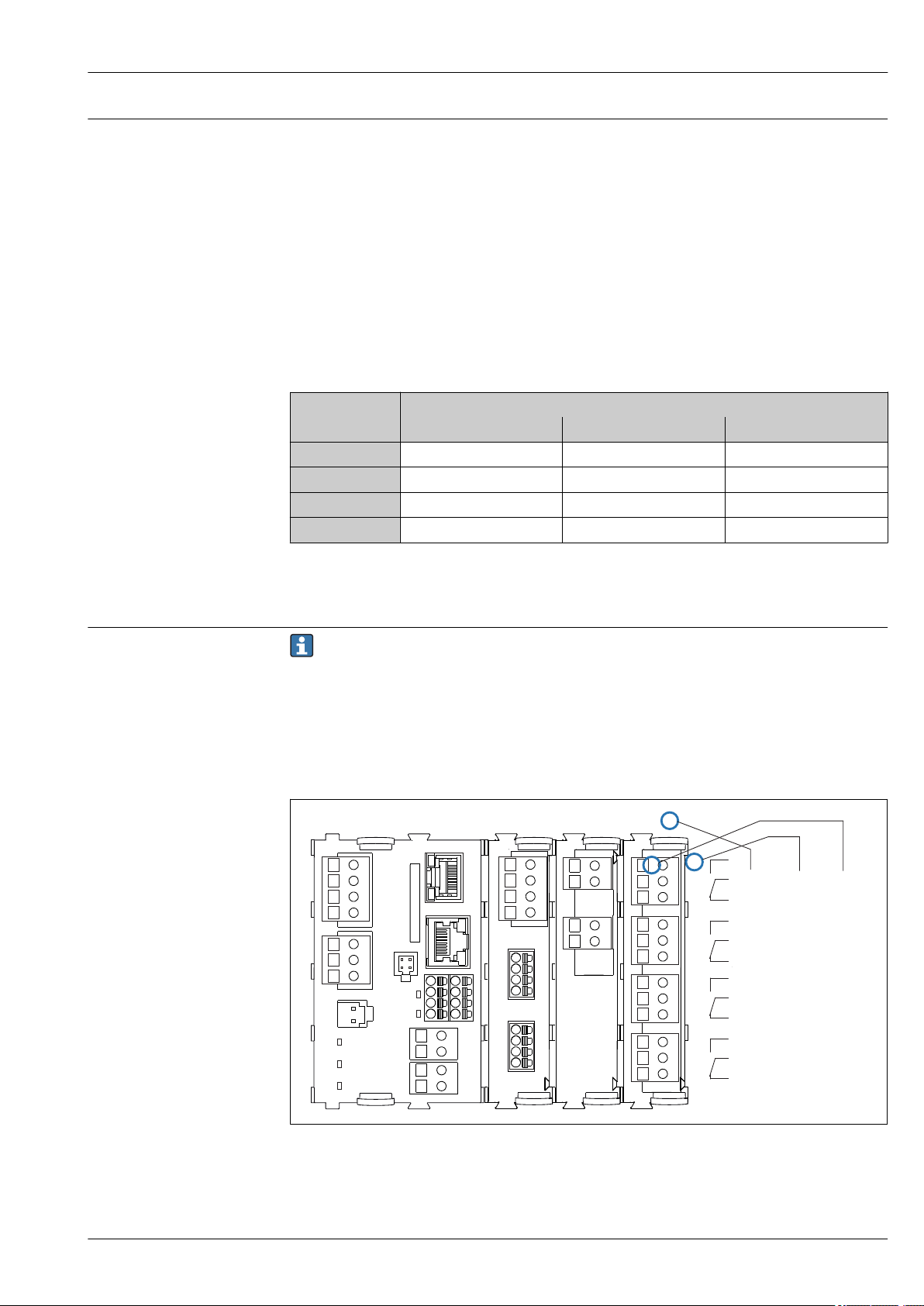

Determining the hardware delivery status

You must be aware of the type of modules and the number of them supplied with the device you

have ordered to determine the delivery status of your Liquiline.

• Basic module

One basic module in all versions. Always occupies slots 0 and 1.

• Fieldbus module

Optional, and only one fieldbus module is possible.

• Input modules

• Must be clearly assigned to the number of optional inputs ordered.

• Examples:

2 current inputs = module 2AI

4 Memosens inputs = 2 inputs with basic module + module 2DS with 2 further inputs

• Current outputs and relays

Various module combinations can exist.

The following table will help you determine which modules your device has, depending on the type

and number of outputs.

Relays

Current outputs

2 - 1 x 2R 1 x 4R

4 1 x 2AO 1 x AOR 1 x 2AO + 1 x 4R

6 1 x 4AO 1 x 4AO + 1 x 2R 1 x 4AO + 1 x 4R

8 1 x 4AO + 1 x 2AO 1 x 4AO + 1 x 2AO + 1 x 2R 1 x 4AO + 1x 2AO + 1 x 4R

Sum up the number of modules and sort them according to the specified sequence → 6.

‣

0 2 4

This will give you the slot assignment for your device.

Terminal diagram

The unique terminal name is derived from:

Slot no. : Port no. : Terminal

Example, NO contact of a relay

Device with 4 inputs for digital sensors, 4 current outputs and 4 relays

• Base module BASE2-E (contains 2 sensor inputs, 2 current outputs)

• 2DS module (2 sensor inputs)

• 2AO module (2 current outputs)

• 4R module (4 relays)

5 Creating a terminal diagram using the example of the NO contact (terminal 41) of a relay

Endress+Hauser 7

A0039621

Page 8

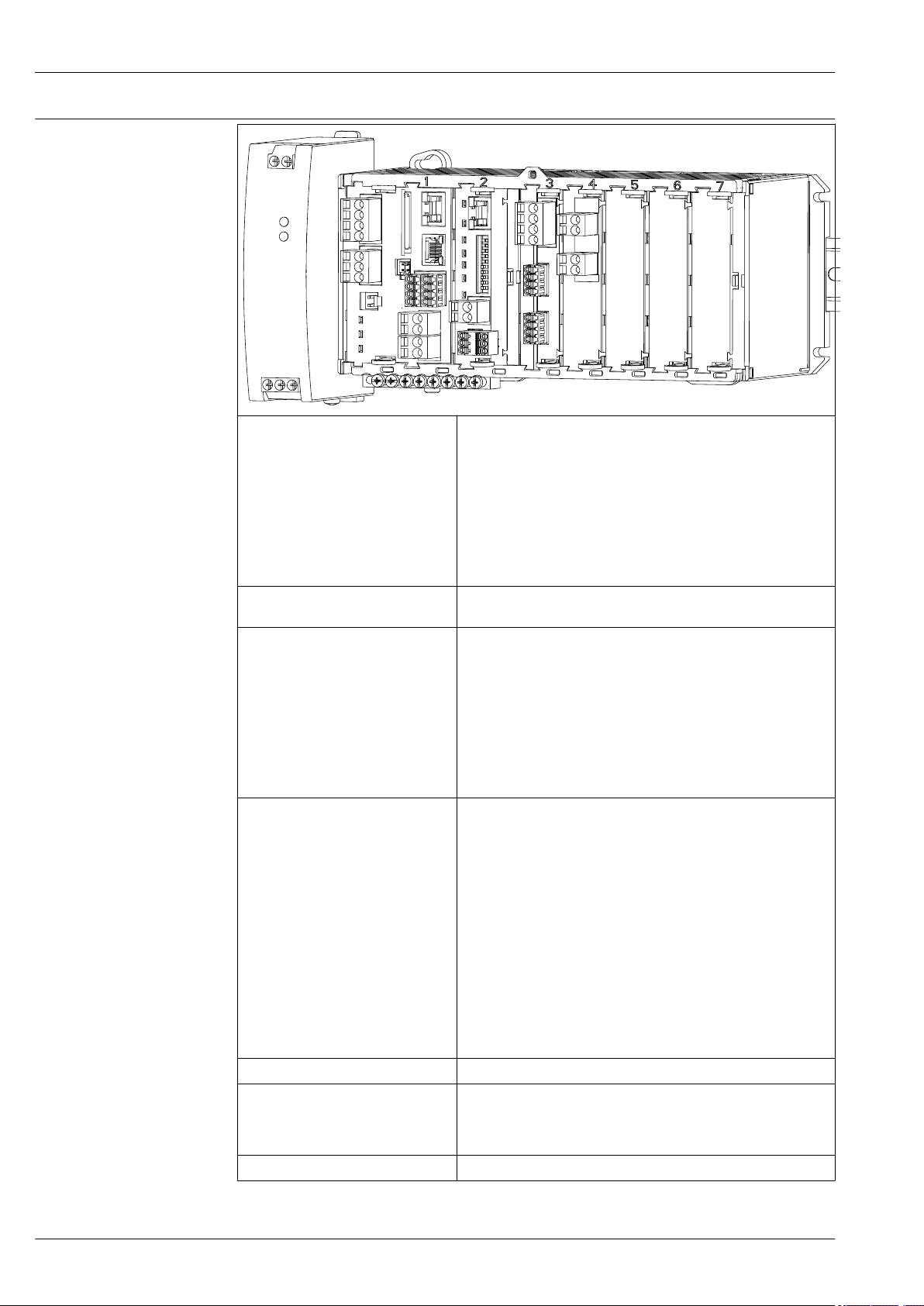

Device configuration using

the example of a CM442R**M1A1F0*

Liquiline CM442R/CM444R/CM448R

Ordered basic device (example) • Order code CM442R-**M1A1F0*

• Functionality: 1 x Memosens, 2 current outputs without HART

Extension options without additional

modules

Extension options by using an

extension module in free slot 2

Basic rule for extensions The sum of all current inputs and outputs may not exceed 8.

Restrictions if using CUS71D sensors

for interface measurement

Product Configurator www.endress.com/cm442r

Activation with activation code:

• Second Memosens input (71114663)

• HART (71128428)

• EtherNet/IP + web server (71449914)

• Modbus TCP + web server (71449915)

• PROFINET + web server (71449901)

• Web server (71449918)

PROFIBUS DP or Modbus RS485 with module 485 incl. activation

code:

• PROFIBUS DP (71140888)

• Modbus RS485 (71140889)

If module 485 is retrofitted, any existing current outputs are

disabled!

Additional inputs or outputs, relays:

• Module 2AI (71135639): 2 current inputs

• Module 2AO (71135632): 2 current outputs

• Module AOR (71111053): 2 current outputs, 2 relays

• Module 2R (71125375) or 4R (71125376): 2 or 4 relays

• Module DIO (71135638): 2 digital inputs and 2 digital outputs

Only one CUS71D can be connected. The second Memosens input

may not be used.

A0041706

8 Endress+Hauser

Page 9

Liquiline CM442R/CM444R/CM448R

mA

31

32

85

86

87

88

97

98

87

88

97

98

optional

L+L-L

N

~ =

HART

mA

31

32

optional

41

42

43

mA

31

32

mA

31

32

23

24

23

24

optional

optional

optional

optional

optional

1

2

3

3

4

2

2

5

5

6

8

8

9

10

10

10

10

7

41

42

43

41

42

43

41

42

43

41

42

43

PE

85

86

mA

mA

optional

47

48

+

–

+

–

47

48

45

46

+

–

11

45

46

+

–

91

92

91

92

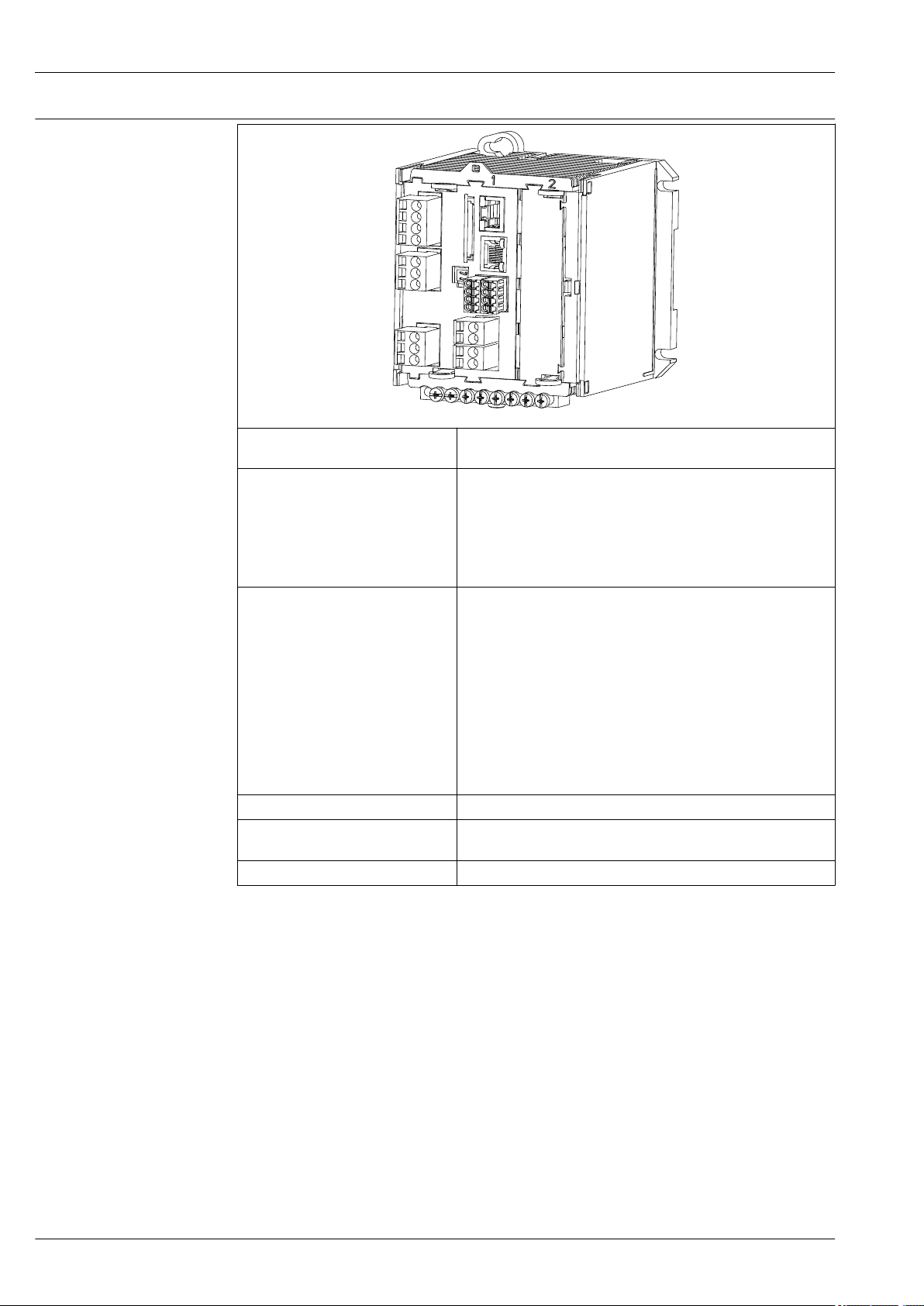

Function diagram CM442R

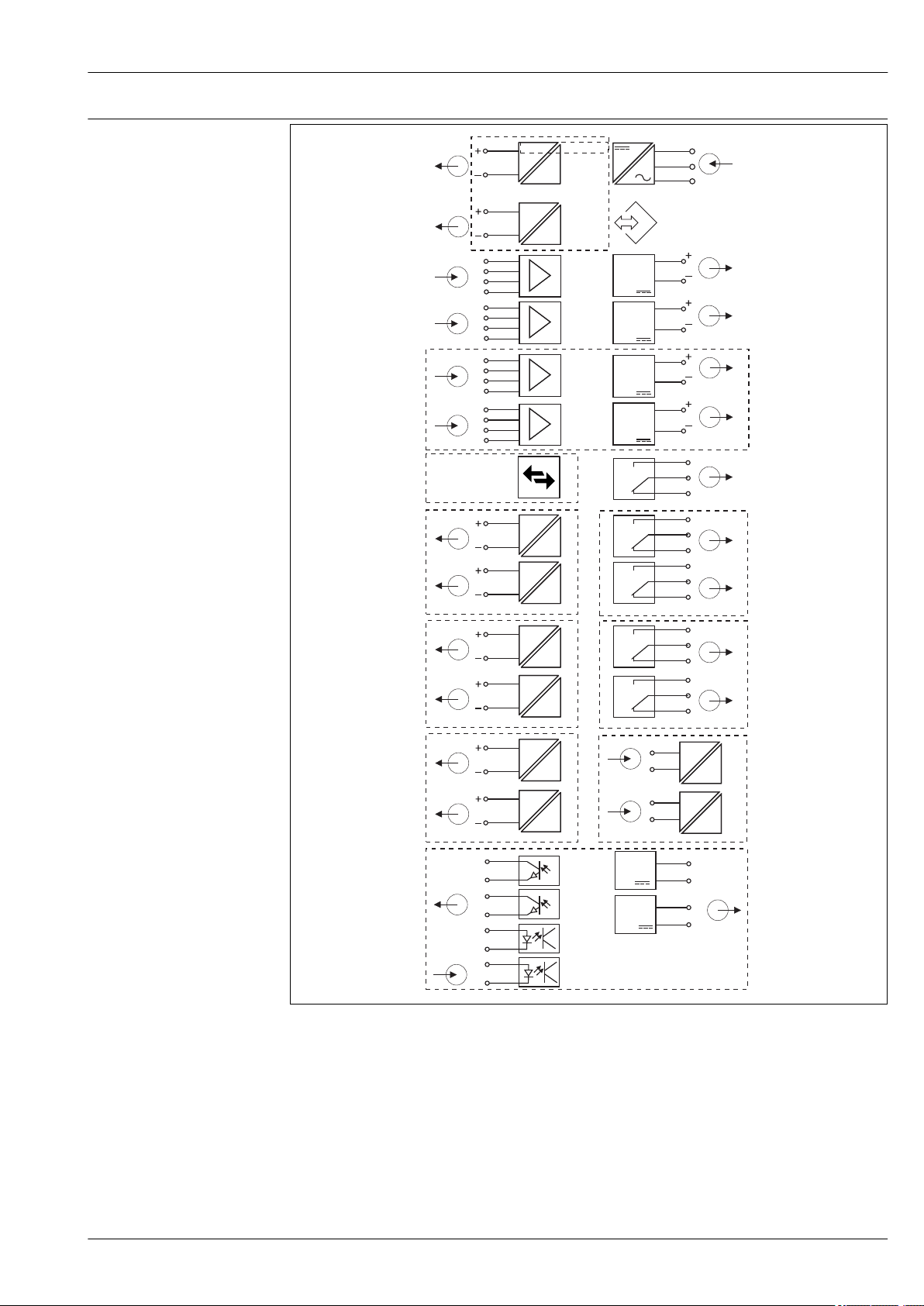

6 Function diagram CM442R

1 Current output 1:1, + HART (optional) 6 Power supply

Endress+Hauser 9

2 Current outputs (2 x optional) 7 Service interface

3 2 x Memosens input (1 x optional) 8 Power supply, fixed cable sensors

4 PROFIBUS DP/Modbus/Ethernet (optional) 9 Alarm relay

5 2 x current input (optional) 10 2 or 4 x relays (optional)

A0039427

11 2 digital inputs and outputs (optional)

Page 10

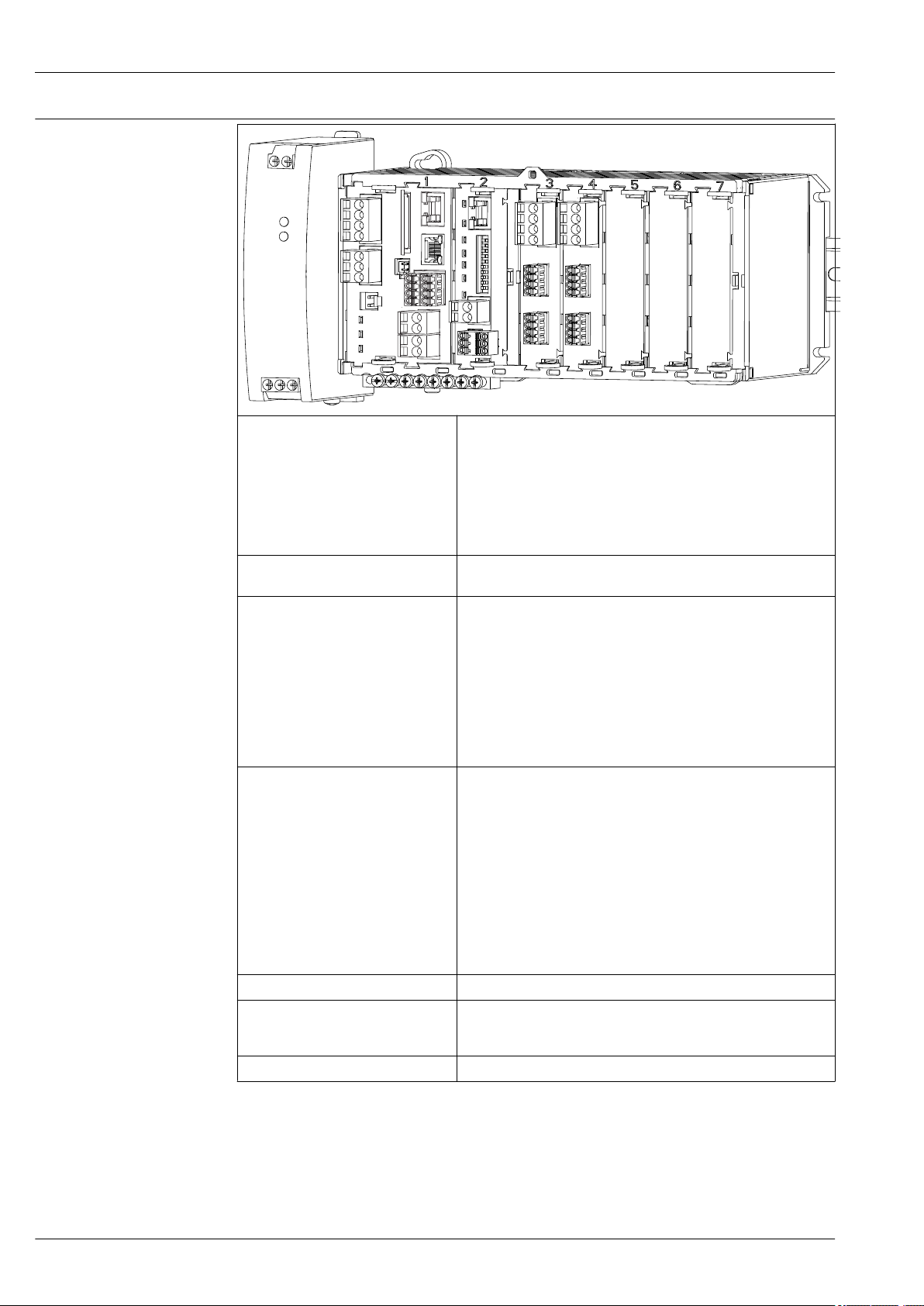

Device configuration using

the example of a CM444R**M42A1FA*

Liquiline CM442R/CM444R/CM448R

Ordered basic device (example) • Order code CM444R-**M42A1FA*

• Functionality:

• 4 x Memosens (2 on BASE2-E module + 2 on an extension

module 2DS)

• PROFIBUS communication (module 485)

• Web server (BASE2-E module)

• 2 current outputs without HART (on BASE2-E module)

• 2 current inputs (module 2AI)

3 slots are still free in this example. More or fewer slots can be free in

other versions.

Extension options without additional

modules

Modification options without

additional modules

Extension options by using extension

modules in free slots 5-7

Basic rule for extensions The sum of all current inputs and outputs may not exceed 8.

Restrictions if using CUS71D sensors

for interface measurement

Product Configurator www.endress.com/cm444r

None

Communication type changed by entering activation code. This

disables the communication type used previously!

Modbus RS485 + web server (71135636)

Retrofit by removing module 485 and entering the activation code

for:

• Modbus TCP + web server (71449915)

• EtherNet/IP + web server (71449914)

• PROFINET + web server (71449901)

• HART (71128428)

• Web server (71449918)

Only the following is possible for the example above:

• Module 2R (71125375) or 4R (71125376): 2 or 4 relays

• Module DIO (71135638): 2 digital inputs and 2 digital outputs

If extending to 8 measuring channels:

Module 2DS (71135631): 2 Memosens inputs

Additional inputs or outputs and relays if fieldbus module 485 is

removed:

• Module 2AO (71135632): 2 current outputs

• Module AOR (71111053): 2 current outputs, 2 relays

• Module 2R (71125375) or 4R (71125376): 2 or 4 relays

• Module DIO (71135638): 2 digital inputs and 2 digital outputs

If module 485 is removed and an Ethernet-based fieldbus is

used via BASE2-E module, a maximum of up to 6 current

outputs can be operated in addition. Only two current outputs

are possible with module 485.

• In the case of CM444R, every combination of Memosens sensors

(max. 4) is possible.

• An extension to CM448R is not advisable as the maximum number

of Memosens inputs when using CUS71D remains limited to 4.

10 Endress+Hauser

Page 11

Liquiline CM442R/CM444R/CM448R

mA

31

87

88

97

98

87

88

97

98

optional

optional

mA

mA

23

optional

optional

optional

optional

optional

1

2

3

3

4

2

2

5

5

6

8

8

9

10

10

10

10

7

32

31

32

31

32

24

23

24

87

88

97

98

3 8

87

88

97

98

3 8

mA

mA

optional

2

2

31

32

31

32

mA

mA

optional

2

2

31

32

31

32

HART

mA

31

32

optional

85

86

85

86

85

86

85

86

mA

mA

41

42

43

41

42

43

41

42

43

41

42

43

41

42

43

45

46

47

48

+

–

+

–

45

46

11

+

–

47

48

+

–

+

–

+

–

optional

L+L-L

N

~ =

PE

91

92

91

92

Function diagram CM444R

Endress+Hauser 11

7 Function diagram CM444R

1 Current output 1:1, + HART (both optional) 6 Power supply

2 Max. 7 x current output (optional) 7 Service interface

3 Memosens input (2 x standard + 2 x optional) 8 Power supply, fixed cable sensors

4 PROFIBUS DP/Modbus/Ethernet (optional) 9 Alarm relay

5 2 x current input (optional) 10 2 or 4 x relays (optional)

A0039431

11 2 digital inputs and outputs (optional)

Page 12

Device configuration using

the example of a CM448R**26A1*

Liquiline CM442R/CM444R/CM448R

Ordered basic device (example) • Order code CM448R-**26A1*

• Functionality:

• 6 x Memosens (2 on BASE2-E module + 2 on two 2DS extension

modules)

• PROFIBUS communication (module 485)

• Web server (BASE2-E module)

3 slots are still free in this example. More or fewer slots can be free in

other versions.

Extension options without additional

modules

Modification options without

additional modules

Extension options by using extension

modules in free slots 5-7

Basic rule for extensions The sum of all current inputs and outputs may not exceed 8.

Restrictions if using CUS71D sensors

for interface measurement

Product Configurator www.endress.com/cm448r

Activation code for the use of current outputs of the basic module:

2 current outputs (71140891)

Communication type changed by entering activation code. This

disables the communication type used previously!

Modbus RS485 + web server (71135636)

Retrofit by removing module 485 and entering the activation code for

communication via the BASE2 module:

• Modbus TCP + web server (71449915)

• EtherNet/IP + web server (71449914)

• PROFINET + web server (71449901)

• HART (71128428)

• Web server (71449918)

If extending to 8 measuring channels:

Module 2DS (71135631): 2 Memosens inputs

Additional inputs or outputs, relays:

• Module 2AO (71135632): 2 current outputs

• Module 2AI (71135639): 2 current inputs

• Module AOR (71111053): 2 current outputs, 2 relays

• Module 2R (71125375) or 4R (71125376): 2 or 4 relays

• Module DIO (71135638): 2 digital inputs and 2 digital outputs

If module 485 is removed and an Ethernet-based fieldbus is

used, a maximum of up to 6 current outputs can be operated in

addition. Only two current outputs are possible with module

485.

The maximum number of Memosens inputs that can be used is

limited to 4! Here, every combination of CUS71D and other

Memosens sensors is then possible.

12 Endress+Hauser

Page 13

Liquiline CM442R/CM444R/CM448R

87

88

97

98

87

88

97

98

optional

mA

mA

optional

optional

optional

optional

1

2

3

3

4

2

2

6

8

9

10

10

10

10

7

31

32

31

32

87

88

97

98

3

87

88

97

98

3 8

mA

mA

optional

2

2

31

32

31

32

mA

mA

optional

2

2

31

32

31

32

87

88

97

98

3

8

87

88

97

98

3

8

87

88

97

98

3

87

88

97

98

3

mA

31

optional

32

HART

mA

31

32

optional

85

86

85

86

85

86

85

86

8

8

8

8

85

86

85

86

85

86

85

86

41

42

43

41

42

43

41

42

43

41

42

43

41

42

43

47

48

+

–

47

48

+

–

optional

L+L-L

N

~ =

PE

45

46

+

–

+

–

45

46

+

–

+

–

91

92

91

92

23

optional

5

5

24

23

24

mA

mA

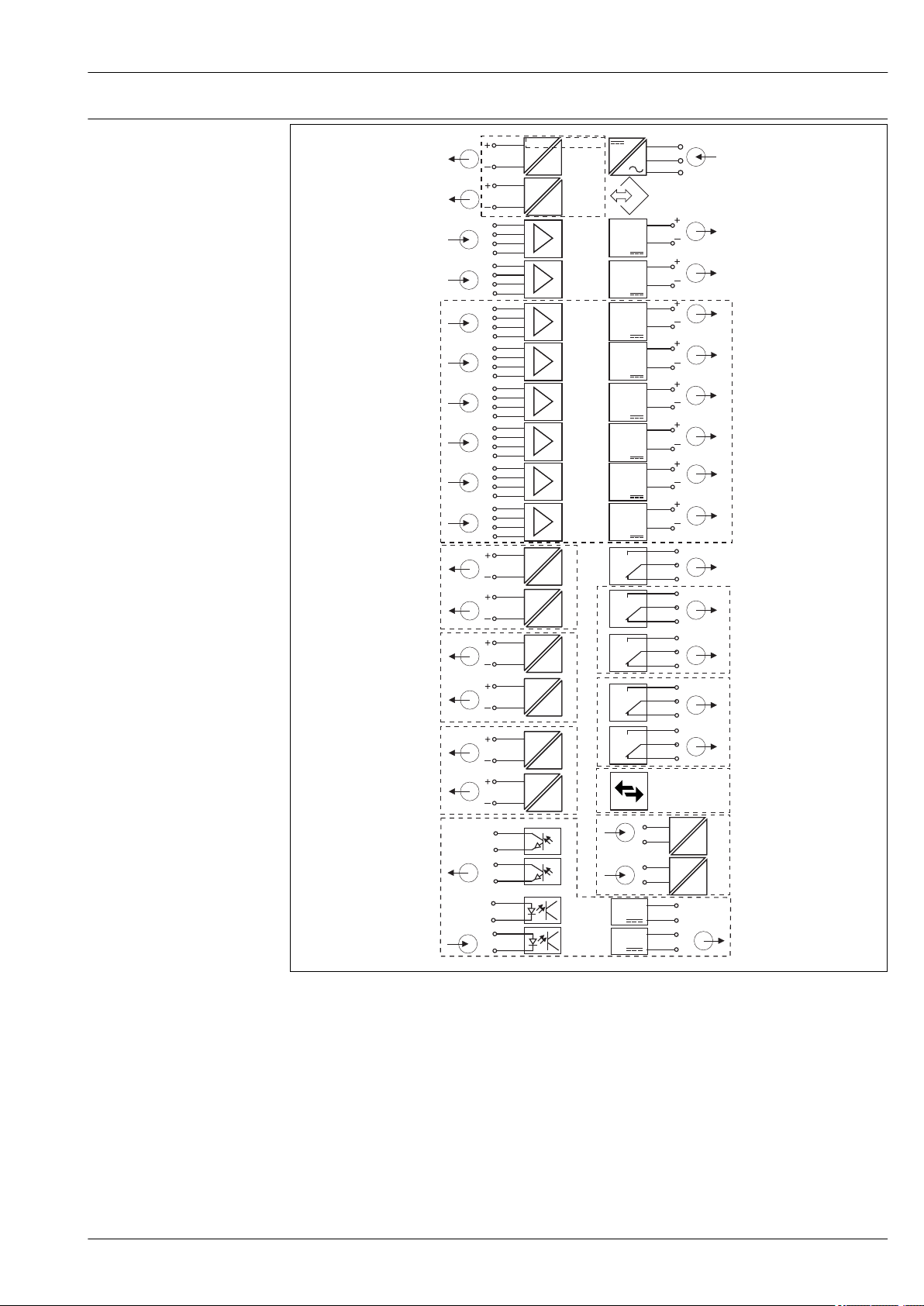

Function diagram CM448R

Endress+Hauser 13

8 Function diagram CM448R

1 Current output 1:1, + HART (both optional) 7 Service interface

2 Max. 7 x current output (optional) 8 Power supply, fixed cable sensors

3 Max 8 x Memosens input (2 x of which are

4 PROFIBUS DP/Modbus/Ethernet (optional) 10 2 or 4 x relays (optional)

5 2 x current input (optional) 11 2 digital inputs and outputs (optional)

6 Power supply

optional)

A0039429

9 Alarm relay

Page 14

Liquiline CM442R/CM444R/CM448R

MEMO SENS

Communication and data processing

Communication protocols:

Fieldbus systems

• HART

• PROFIBUS DP (Profile 3.02)

• Modbus TCP or RS485

• PROFINET

• Ethernet/IP

Only one type of Fieldbus communication can ever be active. The last activation code entered

decides which bus is used.

The device drivers available make it possible to perform a basic setup and display measured

values and diagnostics information via the fieldbus. A full device configuration via the fieldbus

is not possible.

Extension module 485 and current outputs

For PROFIBUS DP, and Modbus RS485 communication protocols:

• CM442R

Current outputs cannot be used in parallel. Any existing current outputs are deactivated with the

installation of 485.

• CM444R/CM448R

A maximum of 2 current outputs can be used in parallel.

Ethernet functionality via Base2 module and current outputs

• CM442R

A maximum of 2 current outputs can be used in parallel.

• CM444R and CM448R

A maximum of 6 current outputs can be used in parallel.

Bus termination on the device

• Via slide switch at bus module 485

• Displayed via LED "T" on bus module 485

Reliability

Dependability

Memosens

Memosens makes your measuring point safer and more reliable:

• Non-contact, digital signal transmission enables optimum galvanic isolation

• No contact corrosion

• Completely watertight

• Sensor can be calibrated in a lab, thus increasing the availability of the measuring point in the

process

• Intrinsically safe electronics mean operation in hazardous areas is not a problem.

• Predictive maintenance thanks to recording of sensor data, e.g.:

• Total hours of operation

• Hours of operation with very high or very low measured values

• Hours of operation at high temperatures

• Number of steam sterilizations

• Sensor condition

Heartbeat diagnostics

• Heartbeat diagnostics screen with graphic indicators for the health of the device and sensor and

with a maintenance or (sensor-dependent) calibration timer

• Heartbeat status information on the health of the device and the condition of the sensor

: Sensor/device condition or maintenance timer > 20 %; no action is required

•

• : Sensor/device condition or maintenance timer > 5 ≤ 20 %, maintenance not yet urgent but

should be scheduled

• : Sensor/device condition or maintenance timer < 5 %, maintenance is recommended

• The Heartbeat sensor condition is the assessment of the calibration results and the sensor

diagnostic functions.

14 Endress+Hauser

Page 15

Liquiline CM442R/CM444R/CM448R

An unhappy smiley can be due to the calibration result, the measured value status or to the

operating hours limit having been exceeded. These limits can be configured in the sensor setup in a

way that adapts the Heartbeat diagnostics to the application.

Heartbeat and NAMUR category

The Heartbeat status indicates the sensor or device condition while the NAMUR categories (F, C, M,

S) assess the reliability of the measured value. The two conditions can correlate but do not have to.

• Example 1

• The number of remaining cleaning cycles for the sensor reaches 20% of the defined maximum

number. The Heartbeat symbol changes from

NAMUR status signal does not change.

• If the maximum number of cleaning cycles is exceeded, the Heartbeat symbol changes from

to . While the measured value can still be reliable, the NAMUR status signal changes to M

(maintenance required).

• Example 2

The sensor breaks. The Heartbeat status changes immediately from

status signal also changes immediately to F (failure).

Heartbeat Monitoring

Sensor data from Memosens sensors are transmitted via the EtherNet/IP, PROFINET, PROFIBUS DP,

HART, Modbus RTU and Modbus TCP fieldbus protocols. These data can be used for predictive

maintenance, for instance.

Examples include:

• Total hours of operation

• Hours of operation with very high or very low measured values

• Hours of operation at high temperatures

• Number of steam sterilizations

• Sensor identification

• Calibration information

For detailed information on "Ethernet/IP communication", see the product pages on the Internet

(→ SD01293C).

For detailed information on "Modbus communication", see the product pages on the Internet (→

SD01189C).

For detailed information on "PROFINET communication", see the product pages on the internet

(→ SD02490C).

For detailed information on "PROFIBUS communication", see the product pages on the Internet

(→ SD01188C).

More detailed information on HART communication is provided on the product pages on the

Internet (→ SD01187C).

to . The measured value is still reliable so the

to and the NAMUR

Heartbeat Verification

Heartbeat Verification makes it possible to verify the correct operation of the measuring device

without interrupting the process. This verification can be documented anytime.

Sensor Check System (SCS)

The Sensor Check System (SCS) monitors the high impedance of the pH glass. An alarm is issued if a

minimum impedance value is undershot or a maximum impedance is exceeded.

• Glass breakage is the main reason for a drop in high impedance values

• The reasons for increasing impedance values include:

• Dry sensor

• Worn pH glass membrane

For the SCS, upper and lower limit values can be enabled or disabled independently of one

another.

Process Check System (PCS)

The process check system (PCS) checks the measuring signal for stagnation. An alarm is triggered if

the measuring signal does not change over a specific period (several measured values).

The main causes of stagnating measured values are:

• Contaminated sensor, or sensor outside of medium

• Sensor defective

• Process error (e.g. through control system)

Endress+Hauser 15

Page 16

Liquiline CM442R/CM444R/CM448R

Self-monitoring functions

Current inputs are deactivated in the event of overcurrent and reactivated once the overcurrent

stops. Board voltages are monitored and the board temperature is also measured.

USP and EP

The limit functions for pharmaceutical water in accordance with USP and EP specifications are

implemented in the software for conductivity measurements:

• "Water for Injection" (WFI) as per USP <645> and EP

• "Highly Purified Water" (HPW) as per EP

• "Purified Water" (PW) as per EP

The uncompensated conductivity value and the temperature are measured for the USP/EP limit

functions. The measured values are compared against the tables defined in the standards. An alarm

is triggered if the limit value is exceeded. Furthermore, it is also possible to configure an early

warning alarm that signals undesired operating states before they occur.

ChemocleanPlus

Freely programmable sequence control

• e.g. for automatic sensor cleaning in retractable assemblies for reliable measurement results in

processes with a high risk of contamination

• Individual, time-based activation of 4 outputs e.g. relays

• Starting, stopping or pausing of activities via digital input or fieldbus signals e.g. from limit

position switches

Maintainability Modular design

The modular transmitter design means it can be easily adapted to suit your needs:

• Retrofit extension modules for new or extended range of functions, e.g. current outputs, relays and

digital communication

• Upgrade to maximum eight-channel measurement

• Optional: M12 sensor connector for connecting any kind of Memosens sensor

• Optional: CDI connector for external access to the service interface (avoids having to unscrew the

housing cover)

9 CM444R: example

A0042325

A0042346

10 Extension module

16 Endress+Hauser

Page 17

Liquiline CM442R/CM444R/CM448R

Data logger function

• Adjustable scan time: 1 to 3600 s (1 h)

• Data logbooks:

• Max. 8 data logbooks

• 150,000 entries per logbook

• Graphic display (load curves) or numerical list

• Calibration logbook: max. 75 entries

• Hardware version logbook:

• Hardware configuration and modifications

• Max. 125 entries

• Version logbook:

• E.g. software updates

• Max. 50 entries

• Operation logbook: max. 250 entries

• Diagnostics logbook: max. 250 entries

A0015032

11 Data logbook: Graphic display

Logbooks remain unchanged even after a software update.

SD card

The exchangeable storage medium enables:

• Quick and easy software updates and upgrades

• Data storage of internal device memory (e.g. logbooks)

• Transfer of complete configurations to a device with an identical setup (backup function)

• Transfer of configurations without the TAG and bus address to devices with an identical setup

(copy function)

• Saving of screenshots for documentation purposes

Endress+Hauser offers industry-approved SD cards as accessories. These memory cards provide

maximum data security and integrity.

Other SD cards up to a maximum weight of 5 g can also be used. However, Endress+Hauser does not

accept any responsibility for the data security of such cards.

External signals for device control and for activating external devices

Hardware options, e.g. module "DIO" with 2 digital inputs and 2 digital outputs or fieldbus module

"485" enable the following:

• via a digital input signal

• measuring range switching for conductivity (upgrade code required, see accessories)

• switching between different calibration datasets in the case of optical sensors

• an external hold

• a cleaning interval to be triggered

• switching on and off a PID controller, e.g. via the proximity switch of the CCA250

• the use of the input as an "analog input" for pulse-frequency modulation (PFM)

• via a digital output signal

• the static transmission (similar to a relay) of diagnostic states, point level switch states etc.

• the dynamic transmission (comparable to a non-wearing "analog output") of PFM signals, e.g. to

control dosing pumps.

Endress+Hauser 17

Page 18

Liquiline CM442R/CM444R/CM448R

FieldCare and Field Data Manager

FieldCare

Configuration and asset management software based on FDT/DTM technology

• Complete device configuration when connected via FXA291 and service interface

• Access to a number of configuration parameters and identification, measuring and diagnostic data

when connected via HART modem

• Logbooks can be downloaded in CSV format or binary format for "Field Data Manager" software

Field Data Manager

Visualization software and database for measuring, calibration and configuration data

• SQL database which is protected against manipulation

• Functions to import, save and print out logbooks

• Load curves to display measured values

A0016009

12 Field Data Manager: Load curves

Virtual process values (mathematical functions)

In addition to "real" process values, which are provided by connected physical sensors or analog

inputs, mathematical functions can be used to calculate a maximum of 8 "virtual" process values.

The "virtual" process values can be:

• Output via a current output or a fieldbus

• Used as a controlled variable

• Assigned as a measured variable to a limit switch

• Used as a measured variable to trigger cleaning

• Displayed in user-defined measuring menus

The following mathematical functions are possible:

• Calculation of pH from two conductivity values according to VGB 405 RL, e. g. in boiler feedwater

• Difference between two measured values from different sources, e. g. for membrane monitoring

• Differential conductivity, e. g. for monitoring the efficiency of ion exchangers

• Degassed conductivity, e. g. for process controls in power plants

• Redundancy for monitoring two or three redundant sensors

• rH calculation based on the measured values of a pH and an ORP sensor

• Calculation of the remaining capacity of a cation exchanger

• Formula editor

18 Endress+Hauser

Page 19

Liquiline CM442R/CM444R/CM448R

Concentration tables

When the device is delivered from the factory, tables are saved in the device that allow inductive

conductivity measurements to be converted to concentrations of certain substances. 4 user-defined

tables are also possible.

The following factory concentration tables are available:

NaOH 0 to 15 % 0 to 100 ˚C (32 to 212 ˚F)

NaOH 25 to 50% 2 to 80 ˚C (36 to 176 ˚F)

HCl 0 to 20 % 0 to 65 ˚C (32 to 149 ˚F)

HNO

H2SO40.5 to 27 % and 35 to 85 % 0 to 100 ˚C (32 to 212 ˚F)

H2SO493 to 100 % 10 to 115 ˚C (50 to 239 ˚F)

H3PO40 to 40 % 2 to 80 ˚C (36 to 176 ˚F)

NaCl 0 to 26 % 2 to 80 ˚C (36 to 176 ˚F)

Safety Real-time clock

The device has a real-time clock, which is buffered by a button cell battery if the power supply fails.

This ensures that the device continues to keep the correct date and time when it is restarted and that

the time stamp for the logbooks is correct.

0 to 30 % 2 to 80 ˚C (36 to 176 ˚F)

3

Data security

All settings, logbooks etc. are stored in a non-volatile memory to ensure that the data are retained

even in the event of a disruption to the power supply.

Measuring range switching for conductivity

• Can be used in CIP processes e.g. for safe monitoring of phase separations

• Switching between 4 complete parameter sets:

• Conductivity operating mode

• Concentration tables

• Temperature compensation

• Output signal range

• Limit value switch

• Via digital inputs or fieldbus

Measured value compensation for oxygen and conductivity

• Pressure or temperature compensation

• Input signals from external sensors via current input or fieldbus

• Signals from connected temperature sensors

Password protection

Password-protected login

• For remote operation via web server

• For local operation

Process safety

Two independent PID controllers

• One- or two-sided control

• Limit switches

• 4 cleaning programs which can be programmed independently of each other

IT security

Our warranty is valid only if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any inadvertent

changes to the settings.

IT security measures, which provide additional protection for the device and associated data transfer,

must be implemented by the operators themselves in line with their security standards.

Endress+Hauser 19

Page 20

Input

Liquiline CM442R/CM444R/CM448R

Measured variables

Measuring ranges

Types of input

Input signal

Cable specification Cable type

→ Documentation of the connected sensor

→ Documentation of the connected sensor

• Digital sensor inputs for sensors with Memosens protocol

• Analog current inputs (optional)

• Digital inputs (optional)

Depending on version:

• Max. 8 x binary sensor signal

• 2 x 0/4 to 20 mA (optional), passive, potentially isolated from one another and from the sensor

inputs

• 0 to 30 V

Memosens data cable CYK10 or sensor fixed cable, each with cable end sleeves or M12 round-pin

connector (optional)

Cable length

Max. 100 m (330 ft)

Digital inputs, passive

Electrical specification

Span

Nominal input current

PFM function

Test voltage

Cable specification

Span

Signal characteristic

Internal resistance

• drawing power (passive)

• Galvanically isolated

• High: 11 to 30 V DC

• Low: 0 to 5 V DC

max. 8 mA

Minimum pulse width: 500 µs (1 kHz)

500 V

Max. 2.5 mm2 (14 AWG)

Current input, passive

> 0 to 20 mA

Linear

Non-linear

Test voltage

500 V

20 Endress+Hauser

Page 21

Liquiline CM442R/CM444R/CM448R

Output

Output signal

Depending on version:

• 2 x 0/4 to 20 mA, active, galvanically isolated from one another and from the sensor circuits

• 4 x 0/4 to 20 mA, active, galvanically isolated from one another and from the sensor circuits

• 6 x 0/4 to 20 mA, active, galvanically isolated from one another and from the sensor circuits

• 8 x 0/4 to 20 mA, active, galvanically isolated from one another and from the sensor circuits

• Optional HART communication (only via current output 1:1)

HART

Signal encoding FSK ± 0.5 mA via current signal

Data transmission rate 1200 baud

Galvanic isolation Yes

Load (communication resistor) 250 Ω

PROFIBUS DP/RS485

Signal encoding EIA/TIA-485, PROFIBUS DP-compliant acc. to IEC 61158

Data transmission rate 9.6 kBd, 19.2 kBd, 45.45kBd, 93.75 kBd, 187.5 kBd, 500 kBd,

1.5 MBd, 6 MBd, 12 MBd

Galvanic isolation Yes

Connectors Spring terminal (max. 1.5 mm), bridged internally (T‐function),

optional M12

Bus termination Internal slide switch with LED display

Modbus RS485

Signal encoding EIA/TIA-485

Data transmission rate 2,400, 4,800, 9,600, 19,200, 38,400, 57,600 and 115,200

baud

Galvanic isolation Yes

Connectors Spring terminal (max. 1.5 mm), bridged internally (T‐function),

optional M12

Bus termination Internal slide switch with LED display

Ethernet and Modbus TCP

Signal encoding IEEE 802.3 (Ethernet)

Data transmission rate 10/100 MBd

Galvanic isolation Yes

Connection RJ45

IP address DHCP (default) or configuration via menu

EtherNet/IP

Signal encoding IEEE 802.3 (Ethernet)

Data transmission rate 10/100 MBd

Galvanic isolation Yes

Connection RJ45

IP address DHCP (default) or configuration via menu

Endress+Hauser 21

Page 22

Liquiline CM442R/CM444R/CM448R

PROFINET

Signal encoding IEEE 802.3 (Ethernet)

Data transmission rate 100 MBd

Galvanic isolation Yes

Connection RJ45

Name of station Via DCP protocol using the configuration tool (e.g. Siemens

PRONETA)

IP address Via DCP protocol using the configuration tool (e.g. Siemens

PRONETA)

Signal on alarm

Load

Linearization/transmission behavior

Electrical specification

External power supply

Adjustable, as per NAMUR Recommendation NE 43

• In measuring range 0 to 20 mA (HART is not available with this measuring range):

Failure current from 0 to 23 mA

• In measuring range 4 to 20 mA:

Failure current from 2.4 to 23 mA

• Factory setting for failure current for both measuring ranges:

21.5 mA

Max. 500 Ω

Linear

Digital outputs, passive

• Passive

• Open collector, max. 30 V, 15 mA

• Maximum voltage drop 3 V

When using an onsite auxiliary voltage supply and an onsite digital input:

Recommended minimum auxiliary voltage = 3 V + V

(V

= minimum input voltage required (high-level input voltage)

IHmin

IHmin

PFM function

Auxiliary voltage

Minimum pulse width: 500 µs (1 kHz)

Electrical specification

• Galvanically isolated

• Unregulated, 24 V DC

• Max. 50 mA (per DIO module)

Test voltage

Cable specification

500 V

Max. 2.5 mm2 (14 AWG)

Current outputs, active

Span

Signal characteristic

22 Endress+Hauser

0 to 23 mA

2.4 to 23 mA for HART communication

Linear

Page 23

Liquiline CM442R/CM444R/CM448R

Electrical specification

Cable specification

Output voltage

Max. 24 V

Test voltage

500 V

Cable type

Recommended: shielded cable

Cable specification

Max. 2.5 mm2 (14 AWG)

Endress+Hauser 23

Page 24

Relay outputs

Liquiline CM442R/CM444R/CM448R

Electrical specification

Relay types

• 1 single-pin changeover contact (alarm relay)

• 2 or 4 single-pin changeover contacts (optional with extension modules)

Maximum load

• Alarm relay: 0.5 A

• All other relays: 2.0 A

Relay switching capacity

Base module (Alarm relay)

Switching voltage Load (max.) Switching cycles (min.)

230 V AC, cosΦ = 0.8 to 1 0.1 A 700,000

0.5 A 450,000

115 V AC, cosΦ = 0.8 to 1 0.1 A 1,000,000

0.5 A 650,000

24 V DC, L/R = 0 to 1 ms 0.1 A 500,000

0.5 A 350,000

Extension modules

Switching voltage Load (max.) Switching cycles (min.)

230 V AC, cosΦ = 0.8 to 1 0.1 A 700,000

0.5 A 450,000

2 A 120,000

115 V AC, cosΦ = 0.8 to 1 0.1 A 1,000,000

0.5 A 650,000

2 A 170,000

24 V DC, L/R = 0 to 1 ms 0.1 A 500,000

0.5 A 350,000

2 A 150,000

Cable specification

Max. 2.5 mm2 (14 AWG)

Protocol-specific data

HART

24 Endress+Hauser

Manufacturer ID 11

Device type 155D

Device revision 001

HART version 7.2

Device description files (DD/DTM) www.endress.com/hart

Device variables 16 user-definable and 16 predefined device variables, dynamic

Supported features PDM DD, AMS DD, DTM, Field Xpert DD

h

h

h

Device Integration Manager DIM

variables PV, SV, TV, QV

Page 25

Liquiline CM442R/CM444R/CM448R

PROFIBUS DP

Modbus RS485

Manufacturer ID 11

Device type 155D

h

h

Profile version 3.02

GSD files www.endress.com/profibus

Device Integration Manager DIM

Output values 16 AI blocks, 8 DI blocks

Input variables 4 AO blocks, 8 DO blocks

Supported features • 1 MSCY0 connection (cyclical communication, master class 1

to slave)

• 1 MSAC1 connection (acyclical communication, master class 1

to slave)

• 2 MSAC2 connections (acyclical communication, master class

2 to slave)

• Device lock: The device can be locked using the hardware or

software.

• Addressing using DIL switches or software

• GSD, PDM DD, DTM

Protocol RTU/ASCII

Function codes 03, 04, 06, 08, 16, 23

Broadcast support for function codes 06, 16, 23

Output data 16 measured values (value, unit, status), 8 digital values (value,

status)

Input data 4 setpoints (value, unit, status), 8 digital values (value, status),

diagnostic information

Supported features Address can be configured using switch or software

Modbus TCP

Ethernet/IP

TCP port 502

TCP connections 3

Protocol TCP

Function codes 03, 04, 06, 08, 16, 23

Broadcast support for function codes 06, 16, 23

Output data 16 measured values (value, unit, status), 8 digital values (value,

status)

Input data 4 setpoints (value, unit, status), 8 digital values (value, status),

diagnostic information

Supported features Address can be configured using DHCP or software

Log EtherNet/IP

ODVA certification Yes

Device profile Generic device (product type: 0x2B)

Manufacturer ID 0x049E

Device type ID 0x109C

h

h

Polarity Auto-MIDI-X

Connections CIP 12

I/O 6

Explicit message 6

Multicast 3 consumers

Minimum RPI 100 ms (default)

Endress+Hauser 25

Page 26

Liquiline CM442R/CM444R/CM448R

Maximum RPI 10000 ms

System integration EtherNet/IP EDS

Rockwell Add-on-Profile Level 3, Faceplate for Factory

Talk SE

IO data Input (T → O) Device status and diagnostic message with

highest priority

Measured values:

• 16 AI (analog input) + Status + Unit

• 8 DI (discrete input) + Status

Output (O → T) Actuating values:

• 4 A0 (analog output) + status + unit

• 8 DO (discrete output) + Status

PROFINET

Protocol "Application layer protocol for decentral device periphery and

distributed automation", PNIO Version 2.34

Communication type 100 MBit/s

Conformance Class Conformance Class B

Netload Class Netload Class II

Baud rate Automatic 100 Mbps with full-duplex detection

Cycle times From 32 ms

Device profile Application interface identifier 0xF600

Generic device

PROFINET interface 1 port, Realtime Class 1 (RT_CLASS_1)

Manufacturer ID 0x11

Device type ID 0x859C D

Device description files (GSD) Information and files under:

Polarity Auto-polarity for automatic correction of crossed TxD and RxD

Supported connections • 1 x AR (IO Controller AR)

Configuration options for measuring device • Web browser

Configuration of the device name DCP protocol

h

h

• www.endress.com

On the product page for the device: Documents/Software →

Device drivers

• www.profibus.com

On the website under Products/Product Finder

pairs

• 1 x AR (IO-Supervisor Device AR connection allowed)

• 1 x Input CR (Communication Relation)

• 1 x Output CR (Communication Relation)

• 1 x Alarm CR (Communication Relation)

• Manufacturer-specific software (FieldCare, DeviceCare)

• Device master file (GSD), can be read out via the integrated

web server of the measuring device

26 Endress+Hauser

Page 27

Liquiline CM442R/CM444R/CM448R

Supported functions • Identification & Maintenance

System integration For information on system integration, see the Operating

Simple device identification via:

• Process control system

• Nameplate

• Measured value status

The process variables are communicated with a measured

value status

• Blinking feature (FLASH_ONCE) via the local display for

simple device identification and assignment

• Device operation via operating tools (e.g. FieldCare,

DeviceCare)

Instructions

• Cyclic data transmission

• Overview and description of the modules

• Status coding

• Startup configuration

• Factory setting

Web server

Supply voltage

The Web server enables full access to the device configuration, measured values, diagnostic

messages, logbooks and service data via standard WiFi/WLAN/LAN/GSM or 3G routers with a userdefined IP address.

TCP port 80

Supported features • Remote-controlled device configuration(1 session)

• Save/restore device configuration (via SD card)

• Logbook export (file formats: CSV, FDM)

• Access to Web server via DTM or Internet Explorer

• Login

• Web server can be switched off

Power supply

CM442 R

Depending on version:

• 100 to 230 V AC, 50/60 Hz

Maximum permitted fluctuation of mains supply voltage: ± 15 % of nominal voltage

• 24 V AC/DC, 50/60 Hz

Maximum permitted fluctuation of mains supply voltage: + 20/- 15 % of nominal voltage

CM444 R and CM448 R

Depending on the version, via external DIN rail power unit:

• 100 to 230 V AC, 50/60 Hz

Maximum permitted fluctuation of mains supply voltage: ± 15 % of nominal voltage

• 24 V DC

Maximum permitted fluctuation of mains supply voltage: + 20/- 15 % of nominal voltage

1)

1)

NOTICE

The device does not have a power switch!

Provide a protected circuit breaker in the vicinity of the device at the place of installation.

‣

The circuit breaker must be a switch or power switch, and must be labeled as the circuit breaker

‣

for the device.

At the supply point, the power supply must be isolated from dangerous live cables by double or

‣

reinforced insulation in the case of devices with a 24 V supply voltage.

1) *Specifications only apply if used with power unit supplied by manufacturer.

Endress+Hauser 27

Page 28

Liquiline CM442R/CM444R/CM448R

Power consumption

Fuse

Overvoltage protection

Cable specification for optional display cable

CM442 R

Depending on supply voltage

• 100 to 230 V AC and 24 V AC:

Max. 55 VA

• 24 V DC:

Max. 22 W

CM444 R and CM448 R

Depending on supply voltage

• 100 to 230 V AC:

Max. 150 VA

• 24 V DC:

Max. 59 W

1)

1)

Fuse not exchangeable

Integrated overvoltage/lightning protection as per EN 61326

Protection category 1 and 3

Length of display cable provided:

3 m (10 ft)

Maximum permitted length of a display cable:

5 m (16.5 ft)

28 Endress+Hauser

Page 29

Liquiline CM442R/CM444R/CM448R

1 2

3

4

5

6

7

9

8

1 2

3

4

5

6

8

9

10

7

Electrical connection Basic module

13 Basic module BASE2-H or -L (two-channel

device)

1 Power supply for digital fixed cable sensors with

Memosens protocol

2 SD card slot

3

Slot for display cable

4 Ethernet interface

5 Connections for 2 Memosens sensors

6 Current outputs

7 Power connection

8 Service interface

9 Alarm relay connection

1)

For optional external display.

2)

Power supply to DIN rail power unit.

1)

A0040639

14 Basic module BASE2-E (four- and eight-

channel device)

1 Power supply for digital fixed cable sensors with

Memosens protocol

2 SD card slot

3

Slot for display cable

4 Ethernet interface

5 Connections for 2 Memosens sensors

6 Current outputs

7

Socket for internal supply cable

8 LEDs

9 Service interface

10 Alarm relay connection

1)

A0040640

2)

Endress+Hauser 29

Page 30

Connecting supply voltage for CM442R

N/- L/+PE

85

85

86

86

SD

Display

Sensor supply

+

+

–

Service

PK

GY

PK

GY

1

2

–

L

N

*

Power

L/+

N/–

PE

+

–

A

B

41

43

42

Alarm

31

31

32

32

0/4 ... 20 mA

+

+

–

–

HART

+

–

A

B

Sensor 2

Ethernet

87

88

97

98

87

88

97

98

BN

WH

GN

YE

BN

WH

GN

YE

Sensor 1

1

2

L N

+ RD

- BK

*

85

85

86

86

SD

Display

Sensor supply

+

+

–

Service

PK

GY

PK

GY

1

2

–

+

–

A

B

41

43

42

Alarm

31

31

32

32

0/4 ... 20 mA

+

+

–

–

HART

+

–

A

B

Sensor 2

Ethernet

87

88

97

98

87

88

97

98

BN

WH

GN

YE

BN

WH

GN

YE

Sensor 1

1

2

L/+

N/–

*

Power

L/+

N/–

PE

Power

(internal)

B

Liquiline CM442R/CM444R/CM448R

A0039665

15 Connecting power supply on the BASE2-H or -

L

H Power unit 100 to 230 VAC

L Power unit 24 VAC or 24 VDC

16 Overall wiring diagram for BASE2-H or -L

A0039625

Connecting supply voltage for CM444R and CM448R

30 Endress+Hauser

17 Connecting power supply with BASE2-E

* Assignment depending on power unit, make sure

to connect correctly

The two device versions may only be operated with the power unit supplied and the power unit

cable. Also pay attention to the information in the operating manual supplied for the power

unit.

A0039668

18 Overall wiring diagram for BASE2-E and

external power unit (B)

A0039624

Page 31

Liquiline CM442R/CM444R/CM448R

41

43

42

31

31

32

32

0/4 ... 20 mA

+

+

–

1

2

–

Relay

1

2

41

43

42

Relay

41

43

42

Relay 1

41

43

42

Relay 2

41

43

42

Relay 3

41

43

42

Relay 4

41

43

42

Relay 1

41

43

42

Relay 2

85

85

86

86

87

88

97

98

Sensor supply

+

+

–

PK

GY

PK

GYGY

1

2

–

BN

WH

GN

YE

+

–

A

B

87

88

97

98

BN

WH

GN

YE

+

–

A

B

Sensor 1

Sensor 2

47

47

48

48

+

+

–

1

2

–

1

2

1

2

+

–

–

+

+

–

+

–

45

46

45

46

91

92

91

92

Connecting optional modules

With extension modules you can purchase additional functions for your device.

NOTICE

Unacceptable hardware combinations (due to conflicts in power supply)

Incorrect measurements or total failure of the measuring point as a result of heat build-up or

overloading

If you are planning to extend your controller, make sure the resulting hardware combination is

‣

permitted (Configurator at www.endress.com/CM442R or .../CM444R or .../CM448R).

Remember that the sum of all current inputs and outputs may not exceed 8.

‣

Make sure not to use more than 2 "DIO" modules. More "DIO" modules are not permitted.

‣

Please contact your Endress+Hauser sales center should you have any questions.

‣

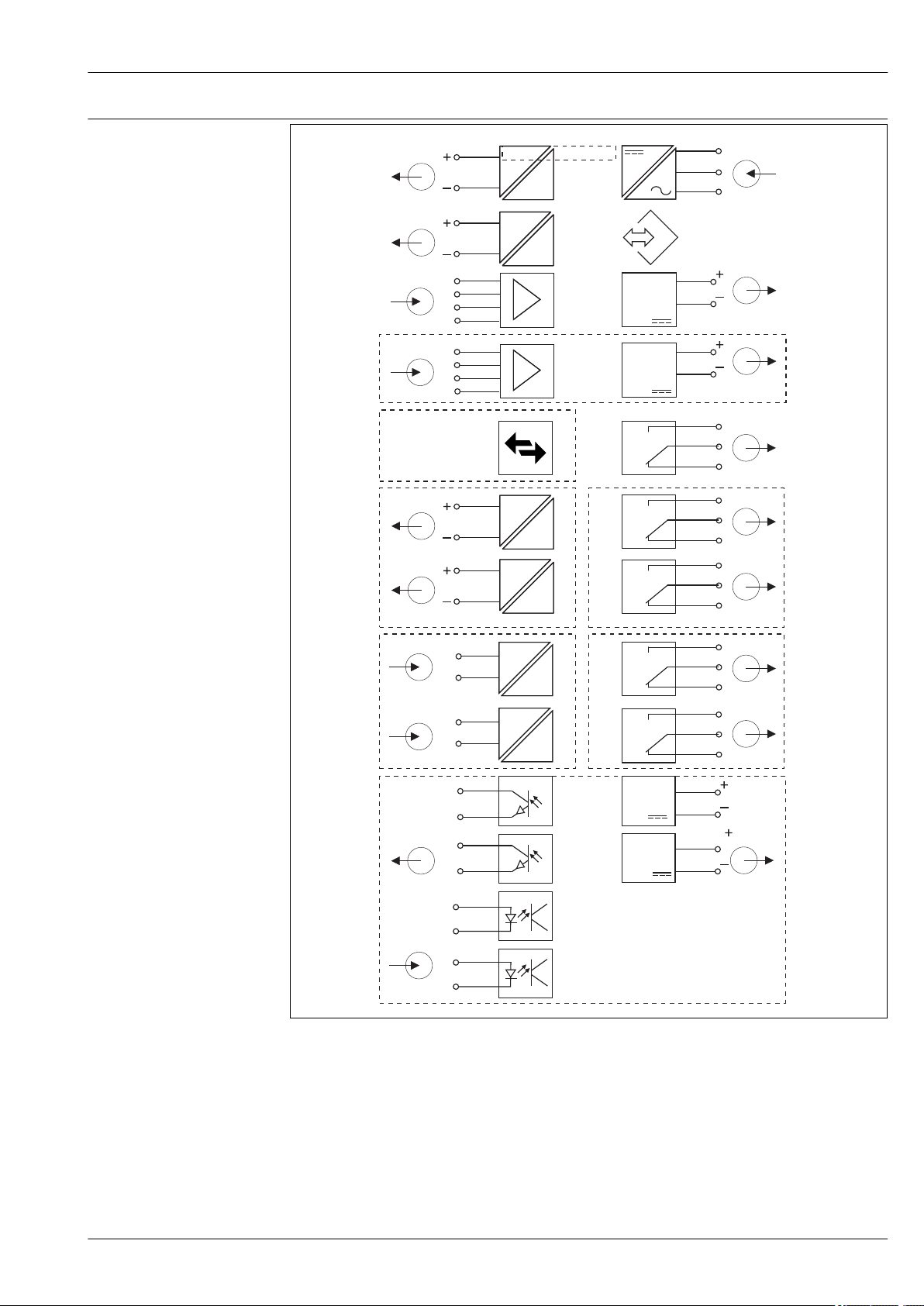

Overview of all the modules available

Module name

AOR 2R 4R 2DS DIO

• 2 x 0/4 to 20 mA

analog outputs

• 2 relays

• Order No.

71111053

Endress+Hauser 31

• 2 relays

• Order No.

71125375

• 4 relays

• Order No.

71125376

• 2 digital sensor

inputs

• 2 power supply

systems for digital

sensors

• Order No.

71135631

• 2 digital inputs

• 2 digital outputs

with auxiliary

voltage

• Order No.

71135638

Page 32

Liquiline CM442R/CM444R/CM448R

2324

2324

31

31

32

32

0/4 ... 20 mA

+

+

–

1

2

–

31

31

32

32

0/4 ... 20 mA

+

+

–

1

2

–

31

31

32

32

0/4 ... 20 mA

+

+

–

3

4

–

23

23

24

24

0/4 ... 20 mA

+

+

–

1

2

–

Ethernet

81

82

DIP switch

on

1

2

4

8

16

32

64

128/SW

Service

T

COM

SF

BF

PWR

DGND

VP

96'

95'

99'

Termination

DP/

RS485

96

95

99

Module name

2AO 4AO 2AI 485

• 2 x 0/4 to 20 mA

analog outputs

• Order No.

71135632

• 4 x 0/4 to 20 mA

analog outputs

• Order No.

71135633

• 2 x 0/4 to 20mA

analog inputs

• Order No.

71135639

• Ethernet (web

server or Modbus

TCP)

• 5V power supply

for PROFIBUS DP

termination

• RS485 (PROFIBUS

DP or Modbus

RS485)

• Use of BASE2

module disables

Ethernet port of

module 485

• Order No.

71135634

32 Endress+Hauser

PROFIBUS DP (module 485)

Contacts 95, 96 and 99 are bridged in the connector. This ensures that PROFIBUS

communication is not interrupted if the connector is disconnected.

Page 33

Liquiline CM442R/CM444R/CM448R

Protective ground connection

19 Mounting rail for functional ground connections

A0025366

Sensor connection

Sensors with Memosens protocol

Sensor types Sensor cable Sensors

Digital sensors without

additional internal power

supply

Digital sensors with

additional internal power

supply

With plug-in

connection and

inductive signal

transmission

Fixed cable Conductivity sensors with inductive measurement of

Fixed cable • Turbidity sensors

• pH sensors

• ORP sensors

• Combined sensors

• Oxygen sensors (amperometric and optical)

• Conductivity sensors with conductive measurement

of conductivity

• Chlorine sensors (disinfection)

conductivity

• Sensors for interface measurement

• Sensors for measuring the spectral absorption

coefficient (SAC)

• Nitrate sensors

• Optical oxygen sensors

• Ion-sensitive sensors

The following rule applies if connecting CUS71D sensors:

• CM442R

• Only one CUS71D is possible; an additional sensor is not permitted.

• The second sensor input may also not be used for another type of sensor.

• CM444R

No restrictions. All the sensor inputs can be used as required.

• CM448R

• If a CUS71D is connected, the number of sensor inputs that can be used is limited to a maximum

of 4.

• Of these, all 4 inputs can be used for CUS71D sensors.

• Every combination of CUS71D and other sensors is possible, provided that the total number of

connected sensors does not exceed 4.

Connection

Direct connection of the sensor cable to the terminal connector of the sensor module 2DS or of the

base module-L, -H or -E (→ 20 ff.)

Endress+Hauser 33

Page 34

Liquiline CM442R/CM444R/CM448R

98 97 88 87

86 85 86 85

BN

WH

GN

YE

Sensor

98 97 88 87

86 85 86 85

GN

YE

Sensor

PK

GY

85 86

85

2DS

1

2

86

97 88 8798

97 88 8798

Sensor 1

Sensor 2

PK

GY

GN

YE

BN

WH

GN

YE

Sensor

Sensor

20 sensors without additional supply voltage

22 sensors with and without additional supply

voltage at sensor module 2DS

A0039629

A0033206

A0039622

21 sensors with additional supply voltage

34 Endress+Hauser

Page 35

Liquiline CM442R/CM444R/CM448R

Performance characteristics

Response time

Reference temperature

Measured error for sensor inputs

Measured error for current inputs and outputs

Frequency tolerance of digital inputs and outputs

Resolution of current inputs and outputs

Current outputs

t90 = max. 500 ms for an increase from 0 to 20 mA

Current inputs

t90 = max. 330 ms for an increase from 0 to 20 mA

Digital inputs and outputs

t90 = max. 330 ms for an increase from low to high

25 °C (77 °F)

→ Documentation of the connected sensor

Typical measured errors:

< 20 µA (with current values < 4 mA)

< 50 µA (with current values 4 to 20 mA)

at 25 ˚C (77˚ F) each

Additional measured error depending on the temperature:

< 1.5 µA/K

≤ 1%

< 5 µA

Repeatability

Mounting on DIN rail as per IEC 60715

→ Documentation of the connected sensor

Installation

NOTICE

Incorrect mounting location in the cabinet, spacing regulations not observed

Possible malfunctions as a result of heat buildup and interference from neighboring devices!

Do not position the device directly above sources of heat. The temperature specification must be

‣

observed.

The components are designed for convection-based cooling. Avoid heat buildup. Ensure openings

‣

are not covered, e.g. by cables.

Observe the specified distances to other devices.

‣

Physically separate the device from frequency converters and high-voltage devices.

‣

Recommended installation direction: horizontal. The specified ambient conditions, and

‣

particularly the ambient temperatures, only apply for horizontal installation.

Vertical orientation is also possible. However, this requires additional fixing clips at the place of

‣

installation to hold the device in position on the DIN rail.

Recommended installation of power unit for CM444R and CM448R: to the left of the device.

‣

Endress+Hauser 35

Page 36

Liquiline CM442R/CM444R/CM448R

min. 50 (1.97)

min. 20 (0.79)

min. 50 (1.97)

min. 20 (0.79)

min. 50 (1.97)

83 (3.27) 205.5 (8.09)

75 (2.95)

75 (2.95)

100 (3.94)

100 (3.94)

4 x 4.5 (0.18)! 4 x 4.5 (0.18)!

The following minimum clearance specifications must be observed:

• Distances at the side in relation to other devices incl. power units and to the wall of the cabinet:

at least 20 mm (0.79 inch)

• Distance above and below the device and depth distance (to control cabinet door or other devices

installed there):

at least 50 mm (1.97 inch)

Wall mounting

A0039735

23 Minimum clearance in mm (in)

A0025370

24 Drilling pattern for wall mounting in mm (in)

36 Endress+Hauser

Page 37

Liquiline CM442R/CM444R/CM448R

4 x min. Ø 8 (0.31)

min. Ø 15 (0.59)

140 (5.51)

105 (4.13)

105 (4.13)

140 (5.51)

a

b

b

Mounting the external display

The mounting plate also serves as the drilling template. The marks on the side help you mark

the position of the drill holes.

A0025371

25 Mounting plate of external display, dimensions in mm (in)

a Retaining tab

b Production-related recesses, no function for the user

Ambient temperature range

Environment

CM442R

0 to 60 ˚C (32 to 140 ˚F)

CM444R

• Generally 0 to 55 ˚C (32 to 130 ˚F), with the exception of packages under the second list item

• 0 to 50 ˚C (32 to 120 ˚F) for the following packages:

• CM444R-**M40A7FI*+...

• CM444R-**M40A7FK*+...

• CM444R-**M4AA5F4*+...

• CM444R-**M4AA5FF*+...

• CM444R-**M4AA5FH*+...

• CM444R-**M4AA5FI*+...

• CM444R-**M4AA5FK*+...

• CM444R-**M4AA5FM*+...

• CM444R-**M4BA5F4*+...

• CM444R-**M4BA5FF*+...

• CM444R-**M4BA5FH*+...

• CM444R-**M4BA5FI*+...

• CM444R-**M4BA5FK*+...

• CM444R-**M4BA5FM*+...

• CM444R-**M4DA5F4*+...

• CM444R-**M4DA5FF*+...

• CM444R-**M4DA5FH*+...

• CM444R-**M4DA5FI*+...

• CM444R-**M4DA5FK*+...

• CM444R-**M4DA5FM*+...

Endress+Hauser 37

Page 38

Liquiline CM442R/CM444R/CM448R

CM448R

• Generally 0 to 55 ˚C (32 to 130 ˚F), with the exception of packages under the second list item

• 0 to 50 ˚C (32 to 120 ˚F) for the following packages:

• CM448R-***6AA*+...

• CM448R-***8A4*+...

• CM448R-***8A5*+...

• CM448R-**28A3*+...

• CM448R-**38A3*+...

• CM448R-**48A3*+...

• CM448R-**58A3*+...

• CM448R-**68A3*+...

• CM448R-**26A5*+...

• CM448R-**36A5*+...

• CM448R-**46A5*+...

• CM448R-**56A5*+...

• CM448R-**66A5*+...

• CM448R-**22A7*+...

• CM448R-**32A7*+...

• CM448R-**42A7*+...

• CM448R-**52A7*+...

• CM448R-**62A7*+...

• CM448R-**A6A5*+...

• CM448R-**A6A7*+...

• CM448R-**B6A5*+...

• CM448R-**B6A7*+...

• CM448R-**C6A5*+...

• CM448R-**C6A7*+...

• CM448R-**D6A5*+...

• CM448R-**D6A7*+...

External display (optional)

–20 to 60 ˚C (0 to 140 ˚F)

Storage temperature

Humidity

Degree of protection

Climate class

Vibration resistance

–25 to 85 °C (–13 to 185 °F)

DIN rail device

5 to 85%, not condensing

External display (in installed state)

5 to 95%, not condensing

DIN rail device

IP20 shock protection

External display

IP66 front-panel, when installed correctly including seal for housing door

As per IEC 60654-1: B2

Environmental tests

Vibration test based on DIN EN 60068-2, October 2008

Vibration test based on DIN EN 60654-3, August 1998

Wall mounting

Frequency range 10 to 150 Hz (sinusoidal)

Amplitude 10 to 12.9 Hz:

12.9 to 150 Hz:

0.75 mm

1)

0.5 g

Test duration 10 frequency cycles/ spatial axis, in 3 spatial axes (1 oct./min)

1)

g ... gravitational acceleration (1 g ≈ 9.81 m/s2)

Electromagnetic

Interference emission and interference immunity as per EN 61326-1:2013, Class A for Industry

compatibility

38 Endress+Hauser

Page 39

Liquiline CM442R/CM444R/CM448R

99 (3.90)

97 (3.82)

7.5 (0.30)

100 (3.94)

TS 35

114 (4.49)

89 (3.50)

91 (3.58)

TS 35

75 (2.95)

83 (3.27)

Electrical safety

Degree of contamination DIN rail device

IEC 61010-1, Class I equipment

Low voltage: overvoltage category II

Environment < 2000 m (< 6562 ft) above MSL

The product is suitable for pollution degree 2.

Optional display

The product is suitable for pollution degree 4.

Mechanical construction

Dimensions CM442R

26 Dimensions in mm (inch)

Endress+Hauser 39

A0039729

Page 40

CM444R and CM448R

220 (8.66)

97 (3.82)

7.5 (0.30)

100 (3.94)

75 (2.95)

205.5 (8.09)

114 (4.49)

TS 35

TS 35

89 (3.50)

91 (3.58)

Liquiline CM442R/CM444R/CM448R

27 Dimensions in mm (inch)

A0039730

40 Endress+Hauser

Page 41

Liquiline CM442R/CM444R/CM448R

144 (5.67)

144 (5.67)

39.5 (1.56)

54 (2.13)

125 (4.92)

121 (4.76)

32 (1.26)

40 (1.58) 99 (3.99)

90 (3.54)

out

in

75 (2.95)

45 (1.77) 100 (3.94)

32 (1.26)

102 (4.02)

124 (4.88)

Optional display

28 Dimensions in mm (inch)

External power units (CM444R and CM448R only)

Depending on the version ordered, a power unit for connection to 230 V or 24 V is supplied. There

are two delivery variants for each version (cannot be selected). The factory-preferred variant is

shown on the left in each case.

A0025738

29 Power unit 230 V

30 Power unit 230 V (optional)

A0025346

A0025739

Endress+Hauser 41

31 Power unit 24 V

A0025784

32 Power unit 24 V (optional)

A0025786

Page 42

Liquiline CM442R/CM444R/CM448R

A A

B

B

B-B

A-A

193 (7.60)

123 (4.84)

157 (6.18)

119 (4.69)

R16

13.5 (0.53)

36 (1.42)

143 (5.63)

40 (1.57)

47 (1.85)

144.5 (5.69)

Service display (accessories)

The service display comprises:

• Portable display (same dimensions as under "Optional display")

• Cover to protect the display and to hook it onto the (open) cabinet door

Weight

Materials

A0025343

33 Dimensions of the service display cover in mm (inch)

depending on the version:

CM442R (fully configured) Approx. 0.45 kg (1 lbs)

CM444R and CM448R (fully configured) Approx. 0.95 kg (2.1 lbs)

Individual module Approx. 0.06 kg (0.13 lbs)

External display (excluding cables) Approx. 0.56 kg (1.2 lbs)

Service display cover 0.46 kg (1 lbs)

External power unit (CM444R, CM448R) 0.27 to 0.42 kg (0.60 to 0.92 lbs), depending on the power

unit variant

DIN rail housing PC-FR

Display cover PC-FR

Display seal EPDM

Soft keys EPDM