Endress+Hauser CM42 Specifications

TI00381C/07/EN/15.14

71254164

Products Solutions Services

Technical Information

Liquiline M CM42

Memosens: pH/ORP, oxygen, conductivity

Analog sensors: pH/ORP, conductivity, concentration,

resistivity

Two-wire transmitter for Ex and non-Ex areas

Application

Liquiline M CM42 is a modular two-wire transmitter for all

areas of process engineering.

Depending on the version ordered, Liquiline has one or two

analog current outputs. In addition, it can be connected to

fieldbuses in accordance with the FOUNDATION Fieldbus,

PROFIBUS PA and HART protocol.

The transmitter is suitable for pollution degree 3.

The highly robust plastic version and the hygienic stainless steel

version are tailored to the following applications:

• Chemical processes

• Pharmaceuticals industry

• Foodstuff technology

• Applications in hazardous areas

Your benefits

• Cost-saving:

– Simple commissioning with Quick Setup and Navigator

– Memosens: Plug & play laboratory-calibrated sensors

– Predictive maintenance system detects when a sensor

needs to be cleaned, calibrated or replaced.

– Less storage thanks to modular design

– Effective asset management using FieldCare and W@M

•Safe:

– Memosens: Active display of cable interruption

– User-guided commissioning, graphic display and plain text

guidance for maximum operating safety

– Approvals: ATEX, FM, CSA, NEPSI, TIIS

– User administration: Code-protected commissioning

– pH glass with Memosens: SIL2 measuring point with TÜV

approval

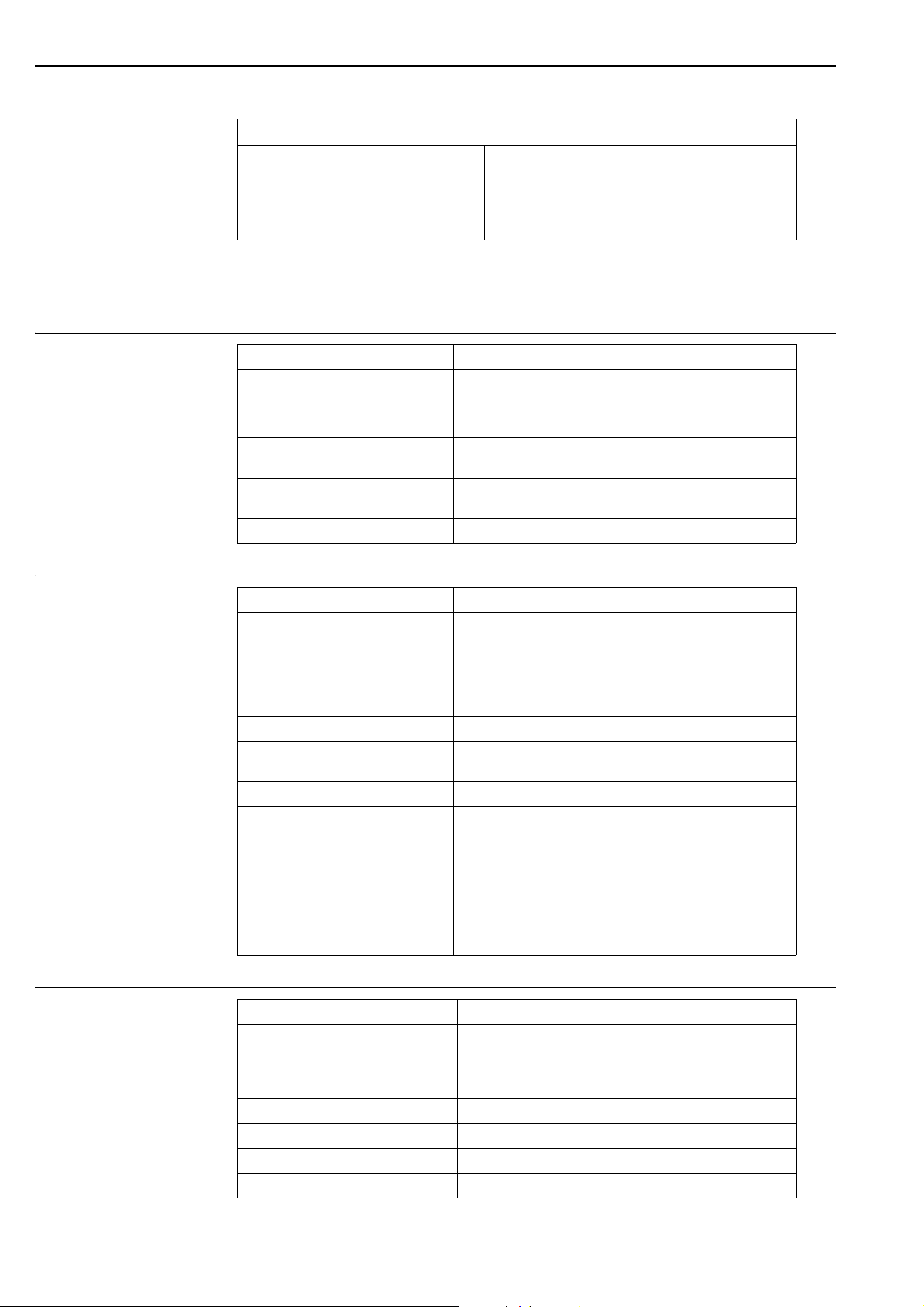

Table of contents

Liquiline M CM42

Function and system design . . . . . . . . . . . . . . . . . . . . . .3

Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment architecture . . . . . . . . . . . . . . . . . . . . . . . . . .4

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DAT memory modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Suitable sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dependability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Maintainability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Measured variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Measuring ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Binary input (Memosens): pH/ORP, oxygen, conductivity . . . . 8

Analog input: pH / ORP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Analog input: Conductivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Output signal range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ex specification current output . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ex specification PROFIBUS and FOUNDATION Fieldbus . . . . 12

Protocol-specific data . . . . . . . . . . . . . . . . . . . . . . . . . . 12

HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PROFIBUS PA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

FOUNDATION Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Wall securing plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Weather protection cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installation options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installation in Ex area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Relative humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Pollution degree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Mechanical construction . . . . . . . . . . . . . . . . . . . . . . . 29

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Operability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Operation concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Display characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Product page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Product configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Certificates and approvals . . . . . . . . . . . . . . . . . . . . . . 32

CE mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Ex approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Current output, passive . . . . . . . . . . . . . . . . . . . . . . . . 13

Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Signal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cable specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cable specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Grounding the housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Supply and signal voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sensor connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Sensor connection: Memosens sensors . . . . . . . . . . . . . . . . . . 18

Sensor connection: analog pH/ORP sensors . . . . . . . . . . . . . . 19

Sensor connection: analog conductivity sensors . . . . . . . . . . . 23

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Mounting kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Weather protection cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Active barrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Fieldbus accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Measuring cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Software update and upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Performance characteristics . . . . . . . . . . . . . . . . . . . . 24

Reference temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Current output response time . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Memosens measured error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Tolerance, current outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Repeatability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Temperature compensation conductivity . . . . . . . . . . . . . . . . . 24

Temperature adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2 Endress+Hauser

Liquiline M CM42

NOTICE

Function and system design

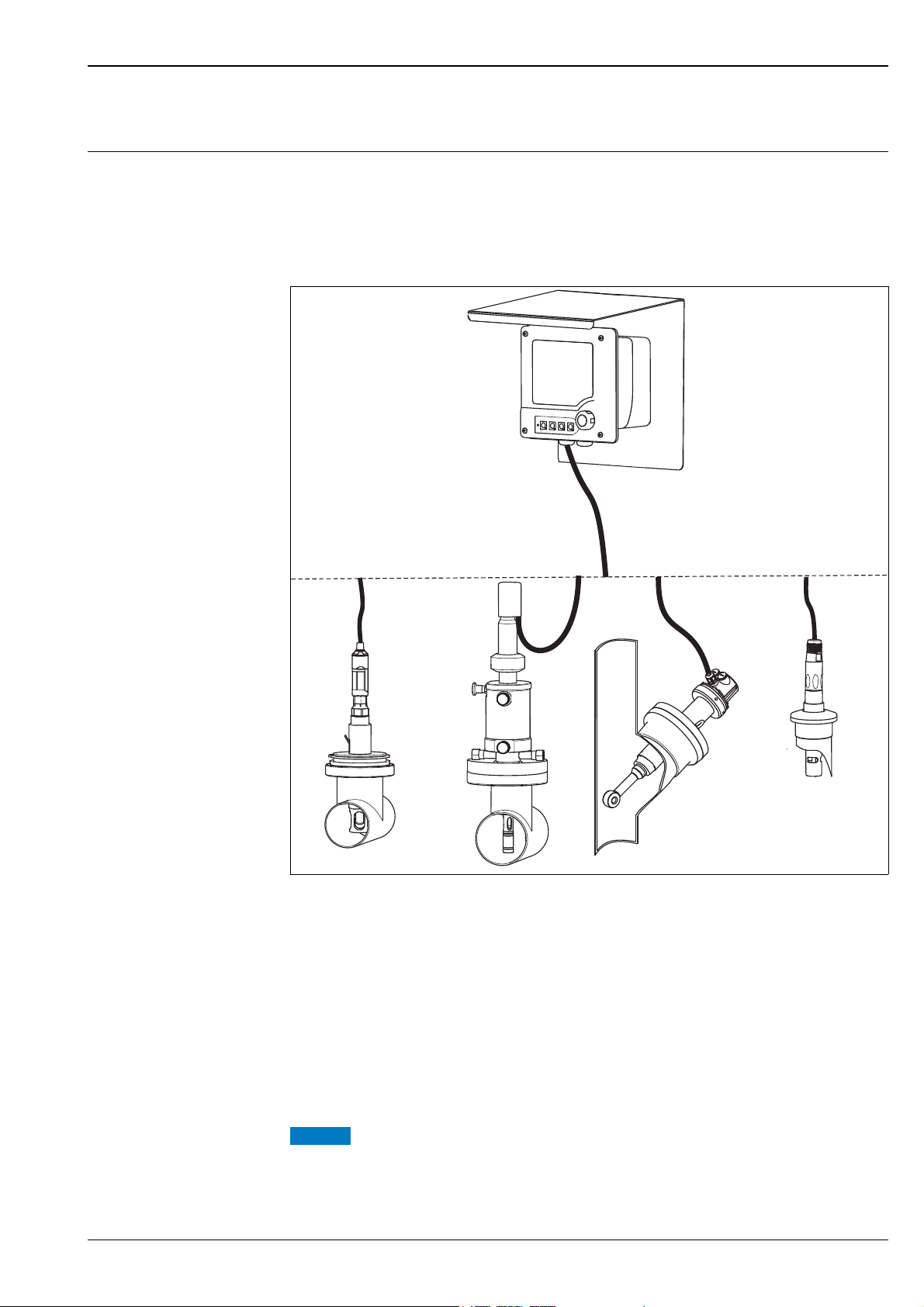

Measuring system A complete measuring system consists of:

• Liquiline M CM42 transmitter with mounting plate (e.g. for wall mounting)

• sensor and suitable sensor cable

• assembly suitable for the sensor (optional)

• post retainer (optional)

• weather protection cover (optional)

a0002012

Examples of a measuring system

pH / ORP (analog)

• CM42-P...

• Measuring cable CPK9

•Cleanfit CPA471

assembly

• Orbisint CPS11 sensor

1)

CPS11D (pH glass), CPS471D (pH ISFET), CPS16D (pH/ORP combined), CPS341D (enamel pH), COS22D/

COS51D (DO), CLS15D/CLS16D/CLS21D (LFc), CLS50D (LFi)

Conductivity, inductive

measurement (analog)

• CM42-I...

• Dipfit CLA111 assembly

• Indumax CLS50 sensor

Conductivity, conductive

measurement (analog)

• CM42-C...

• Measuring cable CPK9

• Condumax CLS16 sensor

Memosens (digital)

• CM42-K/L/M/N/O...

• Measuring cable CYK10

• (Unifit CPA442

assembly)

• Sensor

1)

You can combine your measuring point with a range of assemblies and sensors. Details can be found

in the "Accessories" section and in the documentation listed there. For additional information, see

www.endress.com/cm42

Effect of climatic conditions: rain, snow, direct sun

Impaired operation to complete transmitter failure

‣ When installing outside, always use the weather protection cover (see accessories).

Endress+Hauser 3

Equipment architecture

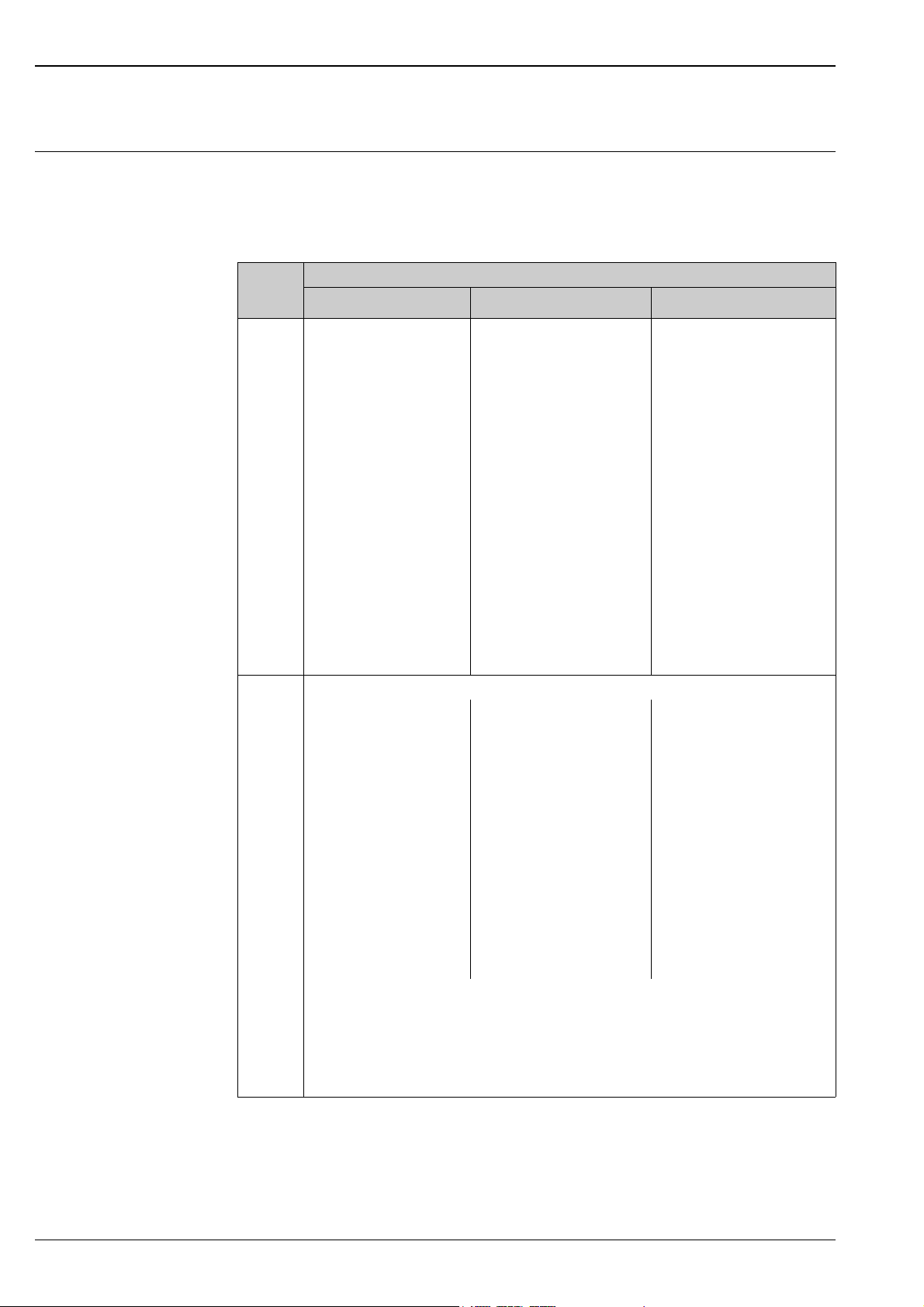

Software You can choose from the following software packages:

•Standard:

Standard application for the most common measuring points

• Advanced:

Many additional functions that increase safety and quality

Package Features

pH /ORP (glass/ISFET) Conductivity Oxygen

Liquiline M CM42

Standard Analog sensors

– Offset and two-point

calibration

–Sample calibration

– Calibration with standard

buffers

– Manual buffer specification

–Temperature

compensation

–Temperature adjustment

– Isotherm intersection

– Simulation of current

output

– Self-diagnosis

– Calibration stability

settings

–Clock

Memosens sensors

as for analog with the

addition of:

– Sensor information

– Sensor check

Advanced "Standard" software package with the addition of:

Analog sensors

– Medium compensation

–Calibration timer

– Sensor Condition Check

(SCC)

– Process Check System

(PCS)

Memosens sensors

as for analog with the

addition of:

– Operated hours counter

– Sterilization cnt.

All devices, regardless of measurement parameter

– Logbooks

– Data logbook

– Free assignment of measured values to current outputs (optional)

– Switching on and off of diagnostic function

– Extended user administration

– Current output tables

Analog sensors

– Sample calibration

– Temperature calibration: one-

point

– Temperature compensation:

linear, NaCl, ultrapure water

(NaCl, HCl)

– Simulation of current output

– Self-diagnosis

– Concentration measurement

–Clock

Memosens sensors

as for analog with the addition

of:

– Sensor information

– Sensor check

Analog sensors

– Calibration with separate

installation factor (inductive

measurement only)

– Polarization detection

(conductive measurement

only)

– Temperature compensation

via user table

– Two-point temperature

adjustment: offset and slope

– USP alarm and prealarm

Memosens sensors

as for analog with the addition

of:

– Operated hours counter

– Sterilization cnt.

Memosens sensors

– Slope calibration

– in air (100% rF)

– in water (100% air-

saturated)

– in air (with input of current

absolute air pressure and

relative humidity)

– Zero point calibration

– Sample calibration

–Temperature adjustment

– Medium compensation

– Calibration stability settings

– Simulation of current output

–Self-diagnosis

–Clock

– Sensor information

– Sensor check

Memosens sensors

– Polarization voltage setting

– Calibration timer

– Sensor statistics

– Operated hours counter

– Sterilization cnt.

4 Endress+Hauser

Liquiline M CM42

MEMO SENS

DAT memory modules There are 3 different types of DAT module, which can be ordered as an optional accessory or are

already included in the scope of delivery:

• SystemDAT

Firmware updates (newer firmware version) or change of language pack

• FunctionDAT

Extended functional range ("Advanced" firmware or second current output)

• CopyDAT

Memory for own configuration settings

Test the extensibility of your device

‣ Before ordering a FunctionDAT, check if it is possible to extend the functional range of your device.

Suitable sensors pH/ORP

• Analog and Memosens glass electrodes

• Analog and Memosens ISFET sensors

• Analog and Memosens ORP sensors

• Memosens pH/ORP combined sensors

• Analog and Memosens enamel pH electrodes

• Analog single electrodes (glass or antimony)

Conductivity

• Analog and Memosens, conductive sensors

– Two-electrode sensors

– Four-electrode sensors

• Analog and Memosens, inductive sensors

Oxygen

Amperometric sensors:

• with Memosens technology

• 12 and 40 mm design

Dependability

Reliability Memosens

Memosens makes your measuring point safer:

• No-contact, digital signal transmission allows optimum galvanic isolation

• No contact corrosion

• Completely watertight

• Sensors can be calibrated in a lab, which increases the availability of measured values

• Predictive maintenance thanks to recording of sensor data, e.g.:

– Total hours of operation

– Hours of operation with very high or very low measured values

– Operating hours at high temperatures

– Number of steam sterilizations

– Sensor status

Quick Setup

To the first measured value within 1 minute

Once you have set up the few parameters in the Quick Setup menu, the measuring point is ready to

measure. The first measured value is reliably displayed.

Endress+Hauser 5

Liquiline M CM42

t

y

y

T

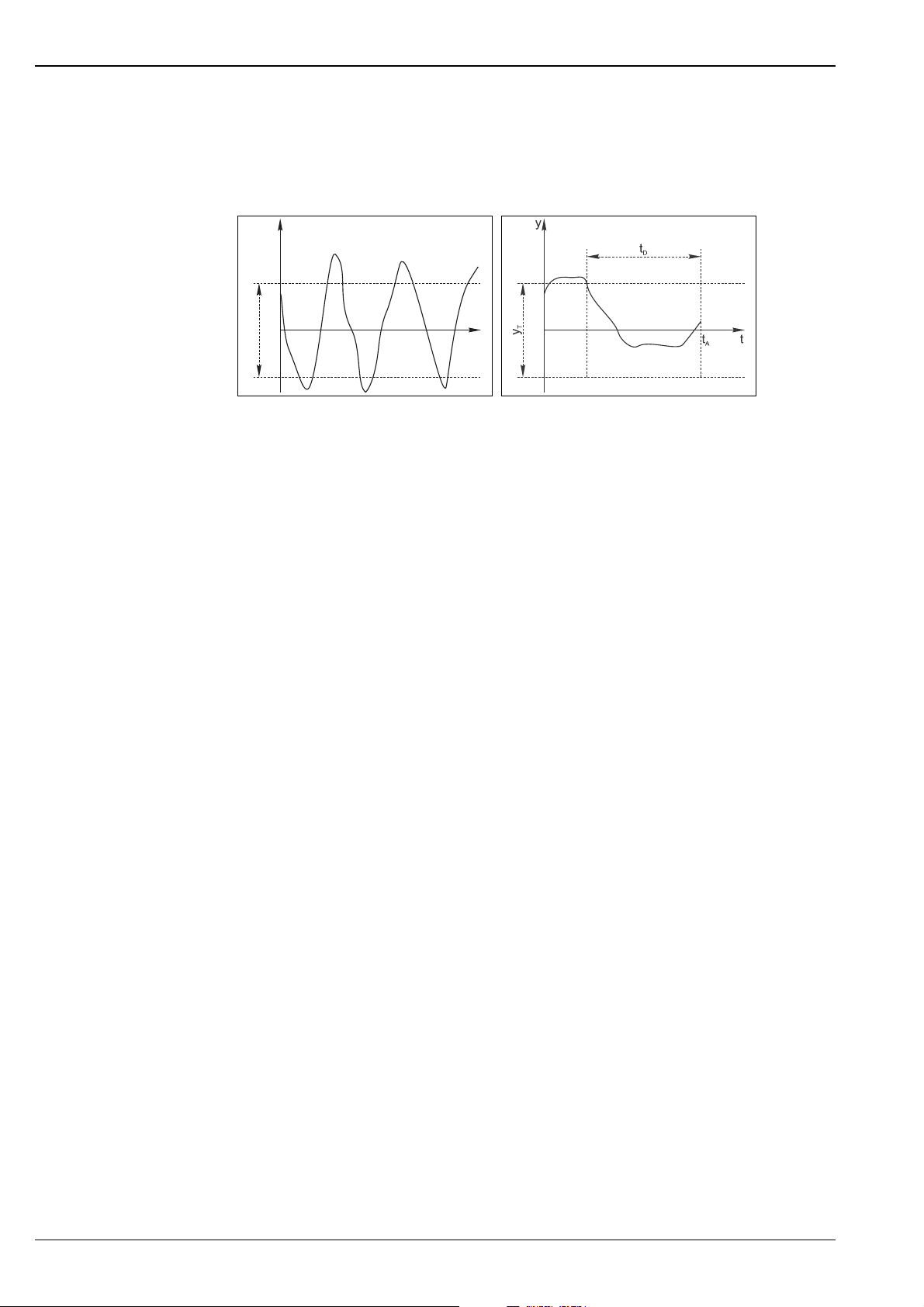

Process Check System (PCS): Life check

This function is used to check the measuring signal for stagnation. An alarm is triggered if the

measuring signal does not change over a certain period (several measured values). The reason for such

behavior can be contamination, clogging or similar.

Normal measuring signal, no alarm

y Measuring signal

Minimum signal fluctuation

y

T

a0013107

Stagnating signal, alarm is triggered

Specified time interval

t

D

Time at which the alarm is triggered

t

A

a0013106

Sensor Condition Check (SCC, pH only)

This function monitors the electrode status and the degree of electrode aging. The status is displayed

with the messages "SCC electrode condition bad" or "SCC electrode condition sufficient". The status of

the electrode is updated after every calibration.

Sensor Check System (SCS, pH only)

The Sensor Check System monitors the pH glass resistance or reference resistance (for analog and

combined sensors only), thus indicating possible incorrect measurements that may occur as a result of

damage to or clogging of the pH electrode.

In addition, the SCS detects glass breakage in the case of classic glass electrodes as well as leaks in the

case of ISFET sensors.

Polarization monitoring (conductivity only, conductively measured)

Polarization effects in the boundary layer between the sensor and the measuring solution limit the

measuring range of conductive conductivity sensors.

The transmitter can detect and report polarization effects using an intelligent signal evaluation

process.

United States Pharmacopeia, USP and European Pharmacopeia, EP (conductivity only)

The requirements for ultrapure water in the pharmaceutical industry are determined primarily by the

American USP and European EP.

The transmitter complies with USP/EP requirements for conductivity measuring systems:

• Exact temperature measurement at the place of conductivity measurement

• Simultaneous display of uncompensated conductivity values and temperature is possible

• Display resolution 0.01 μS/cm

• Exact factory calibration of the transmitter with traceable precision resistance (optional)

• Exact adjustment of sensors in the factory as per ASTM D 1125–91 or ASTM D 5391–99 (optional)

• Temperature-dependent measured value monitoring as per USP and EP.

The limit functions for pharmaceutical water are implemented in the "Advanced" software package in

accordance with USP and EP: For conductivity measurements, the limit functions for pharmaceutical

water are implemented in the software in accordance with USP and EP:

• Water for Injection (WFI) as per USP <645> and EP

• Highly purified water (HPW) as per EP

• Purified water (PW) as per EP

The uncompensated conductivity value and the temperature are measured for the USP/EP limit

functions. The measured values are compared with the tables set down in the standards. An alarm is

triggered if the limit value is exceeded. In addition, a prealarm can be set that flags undesirable

operating statuses before they occur.

6 Endress+Hauser

Liquiline M CM42

Application-optimized calibration models (oxygen)

In separate functions, the transmitter allows process-adjusted zero point sensor calibration or sensor

calibration via the slope.

There are different calibration models for this, ranging from simple slope calibration in air that is

saturated with water vapor to slope calibration with input of the absolute air pressure and relative

humidity at the measuring location.

The latter model allows in-process calibration during operation as well as during sterilization and

cleaning.

The number of calibrations and sterilizations are tracked separately for the sensor and membrane cap.

The relevant counter can be reset if the membrane cap is replaced.

Maintainability Modular design

Interior of Liquiline (version with sensor module)

Sensor monitor ("Advanced" only)

You will find the sensor monitor in the DIAG menu. Important sensor data incl. warning and alarm

limits are displayed either graphically or numerically.

a0010474

Sensor monitor, graphical display (example)

Safety User administration ("Advanced" only)

To avoid unscheduled changes to the measuring point, the device features a user administration

function.

You need to log on as an Expert to switch on the user administration function. The first time you log

onto the device, you will therefore be asked to enter a password (the "Admin" user name is already

entered).

The user administration function makes two different modes available in the Advanced version:

Roles

• There are 3 fixed user roles (Expert, Maintenance, Operator).

• "Experts" always have all the rights. "Operator" is the role with the least amount of rights.

• Each role has its own individual password. This password can be changed.

• No other user roles can be created.

a0010477

Plug-in modules

Sensor monitor, numerical display (example)

a0010476

a0014566

Endress+Hauser 7

Liquiline M CM42

MEMO SENS

User accounts

• You can create and manage a maximum of 15 user accounts.

• You need to be logged on as an "Expert" to be able to manage accounts.

• In each user account you specify the user name and the password and assign the new user one of 3

user roles (Operator, Maintenance and Expert).

• Multiple user accounts with the "Expert" role are possible.

SIL

A TÜV-approved SIL2 version of the Liquiline M CM42 is also available (CM42-M* only, without

HART).

Safety functions

• Safe output of the digitized value at the current output

• Monitoring of the measured value for leaving a defined interval

• Safe calibration and adjustment

Additional information and Safety Manuals can be found at:

www.endress.com/SIL

Input

Measured variables --> Documentation of the connected sensor

Measuring ranges --> Documentation of the connected sensor

Binary input (Memosens): pH/ORP, oxygen, conductivity

Cable specification

CYK10, CYK20 with Memosens

Fixed cable with Memosens (CLS50D, CLS54D)

Ex specification

Intrinsically safe sensor circuit with protection type: Ex ia IIC

Max. output voltage U

Max. output current I

Max. output P

o

Max. external inductance L

Max. external capacitance C

1) CM42-*G*********, CM42-*E*********, CM42-*I*********, CM42-*J*********,

CM42-*X*********, CM42-*Z*********

2) CM42-*V*********, CM42-*F*********

3) CM42-*T*********

o

o

o

o

5.04 V

80 mA

112 mW

2 μH

55 μF

Max. cable length 100 m (330 ft)

Max. cable length 100 m (330 ft)

1)

or Ex ic IIC2) or Ex ib IIC

3)

8 Endress+Hauser

Liquiline M CM42

Analog input: pH / ORP Cable specification

Without SCS Max. cable length 50 m (160 ft)

With SCS Max. cable length 20 m (65 ft)

Applicable temperature sensors

• Pt100

• Pt1000

• NTC 30K

Ex specification

Intrinsically safe sensor circuit with protection type: Ex ia IIC

Max. output voltage U

Max. output current I

Max. output P

o

Max. external inductance L

Max. external capacitance C

Connection class as per NE116

1)

or Ex ic IIC

Glass

o

o

10.08 V

4.1 mA

10.2 mW

o

o

3)

1 mH

250 nF

SensISCO1X -

2)

ISFET

10.08 V

50.7 mA

128 mW

1 mH

250 nF

1) CM42-*G*********, CM42-*E*********, CM42-*I*********, CM42-*X*********,

CM42-*Z*********

2) CM42-*V*********, CM42-*F*********

3) CM42-*G*********, CM42-*E*********, CM42-*F*********

When pH/ORP glass electrodes are connected to terminals 317, 318, 320, 111, 112 and 113, the

device corresponds to connection class 1 as per NAMUR Recommendation NE116 (SensISCO).

Terminals 315 and 316 may not be connected for this categorization.

The device is labeled SensISCO1X.

Input impedance

12

> 1*10

(under nominal operating conditions)

Input leakage current

-13

< 1*10

A (under nominal operating conditions)

Endress+Hauser 9

Analog input: Conductivity Cable specification

Liquiline M CM42

Conductivity/specific resistivity, conductively

measured

Two-electrode sensor

10 μS

5 μS.k to 20 mS.k / 0.2 M/k to 50 /k

1)

.

k to 20 mS.k / 0.1 M/k to 50 /k

Max. cable length 100 m (330 ft)

Max. cable length 50 m (160 ft)

Max. cable length 15 m (50 ft)

0.1 μS.k to 20 mS.k / 20 M/k to 50 /k

Conductivity, measured conductively

Four-electrode sensor

.

k to 1.5 S.k

10 μS

0.1 μS.k to 20 mS.k

Conductivity, measured inductively

2)

Max. cable length 100 m (330 ft)

Max. cable length 15 m (50 ft)

max. cable length 55 m (180 ft)

(CLS50)

max. cable length 50 m (160 ft)

(CLS54)

1) with cable CYK71, CPK9 or fixed cable

2) with cable CLK5, CLK6 or fixed cable

Applicable temperature sensors

• Pt100

• Pt1000

Ex specification, conductive sensors

Intrinsically safe sensor circuit with protection type: Ex ia IIC

Max. output voltage U

Max. output current I

Max. output P

o

o

o

Max. external inductance L

Max. external capacitance C

o

o

10.08 V

23 mA

57 mW

300 μH

50 nF

1)

or Ex ic IIC

2)

1) CM42-*G*********, CM42-*E*********, CM42-*I*********, CM42-*X*********,

CM42-*Z*********

2) CM42-*V*********, CM42-*F*********

Ex specification, inductive sensors

1)

Intrinsically safe sensor circuit with protection type: Ex ia IIC

Max. output voltage U

Max. output current I

Max. output P

o

Max. external inductance L

Max. external conductivity C

1) CM42-*G*********, CM42-*E*********, CM42-*I*********, , CM42-*J*********,

CM42-*X*********, CM42-*Z*********

2) CM42-*V*********, CM42-*F*********

3) CM42-*T*********

o

o

o

o

10.08 V

64 mA

128 mW

0.1 mH

1.8 μF

or Ex ic IIC2) or Ex ib IIC

3)

10 Endress+Hauser

Liquiline M CM42

Output

Output signal Current output

1x 4 to 20 mA, passive, potentially isolated against sensor circuit (Memosens only)

2x 4 to 20 mA, passive, potentially isolated against sensor circuit (Memosens only) and against each

1)2)3)

other

HART

Signal coding FSK ± 0.5 mA via current signal

Data transmission rate 1200 Baud

Load (communication resistor) 250

PROFIBUS PA

Signal coding Manchester Coding Bus Powered (MBP), compliant with IEC

Data transmission rate 31.25 kBit/s

Bus termination external

Connection to PROFIBUS-DP network via segment coupler (in non-Ex mode)

1)2)

61158-2

FOUNDATION Fieldbus

Signal coding Manchester Coding Bus Powered (MBP), compliant with IEC

61158-2

Data transmission rate 31.25 kBit/s

Bus termination external

Signal on alarm 3.6 to 21.5 mA (4.0 mA fixed value in HART multidrop mode)

digitally via fieldbus

4)

Load Max. load with supply voltage of 24 V: 500

Max. load with supply voltage of 30 V: 750

Output signal range 3.6 to 21.5 mA

Ex specification current output

Intrinsically safe supply and signal circuits, passive

Max. input voltage U

Max. input current I

Max. input P

i

i

i

Max. internal inductance L

i

30 V

100 mA

800 mW (all except TIIS) or 750 mW (TIIS)

29 μH (output 1)

24 μH (output 2)

Max. internal capacitance C

i

1.2 nF (output 1)

0.2 nF (output 2)

1) Potential isolation for Memosens in sensor plug

2) For inductive sensors with Memosens protocol CLS50D and CLS54D not potentially isolated against sensor circuit!

3) Current output 1 and current output 2 (optional)

4) For version with PROFIBUS PA or FOUNDATION Fieldbus

Endress+Hauser 11

Liquiline M CM42

Ex specification PROFIBUS and FOUNDATION Fieldbus

HART

Suitable for use as a field device in a FISCO system as per EN/IEC 60079-27

Max. input voltage U

Max. input current I

Max. input P

i

i

i

Max. internal inductance L

Max. internal capacitance C

i

i

17.5 V

380 mA

5.32 W

<10 μH

< 5 nF

Protocol-specific data

Manufacturer ID 11

Device type

Device revision 001

Device description files (DD/DTM) www.endress.com

Device variables 7 (CM42-M/N/O/P), 3 (CM42-C/I/K/L), pre-defined device

Supported features PDM DD, AMS DD, DTM, handheld DDs

h

11A0

(CM42-M/N/P), 11A1h (CM42-C/I/K/L), 11A1h

h

(CM42-O)

h

Device Integration Manager (DIM)

variables, dynamic variables PV, SV, TV, QV

PROFIBUS PA

FOUNDATION Fieldbus

Manufacturer ID 11

Device type

h

1565

(CM42-M/N/P), 1566h (CM42-C/I/K/L),

h

1567

(CM42-O)

h

in compatibility mode

1543

(CM42-M/N/P), 1544h (CM42-C/I/K/L),

h

1545

(CM42-O), 9750h (profile identifier, analyzer PA

h

devices)

Profile version PA Profile 3.02

GSD files www.endress.com/profibus

Device Integration Manager DIM

Output variables 6 AI blocks

Supported features • 1 MSCY0 connection (cyclical communication, master class 1

to slave)

• 1 MSAC1 connection (acyclical communication, master

class 1 to slave)

• 2 MSAC2 connections (acyclical communication, master

class 2 to slave)

• Addressing with DIL switches or via software

• GSD, PDM DD, DTM

• Status output: condensed or classic

Manufacturer name: Endress+Hauser

Model name: Liquiline_Cond

Manufacturer ID (hex): 452B48

Device type (hex): 10A1

Device revision (hex): 2

Device class: Link master

ITK version: 6.1.1

Function and other blocks: 1xRB, 6xAI, 2xDI, 1xPID, 2xAALM, 1xISEL, 1xSC, 7xTB

12 Endress+Hauser

Loading...

Loading...