Page 1

BA01030C/09/EN/02.19

71471370

2019-11-05

Valid as of version

2.01 (device version)

Products Solutions Services

Operating Instructions

CM14

Transmitter, conductivity

Page 2

Page 3

CM14 Table of contents

Table of contents

1 Safety instructions .............. 4

1.1 Workplace safety .................... 4

1.2 Requirements concerning the staff ...... 4

1.3 Operational safety ................... 4

1.4 Designated use ...................... 5

1.5 Technical improvement ............... 5

1.6 Return ............................. 5

1.7 Notes on safety conventions and

icons ............................... 5

2 Identification .................... 7

2.1 Device name ........................ 7

2.2 Scope of delivery ..................... 7

2.3 Certificates and approvals ............. 8

3 Installation ...................... 9

3.1 Incoming acceptance, transport,

storage ............................. 9

3.2 Installation ......................... 9

3.3 Dimensions ......................... 9

3.4 Installation procedure ............... 10

3.5 Post-installation check ............... 10

4 Wiring .......................... 11

4.1 Connecting the transmitter ........... 12

4.2 Post-connection check ............... 13

5 Operation ...................... 14

5.1 Display and device status indicator /

LED ............................... 14

5.2 Local operation at the device .......... 14

5.3 Icons .............................. 15

5.4 Operating functions ................. 16

5.5 Hold function ...................... 16

7 Calibration (Calibration

menu) .......................... 28

7.1 General ........................... 28

7.2 Device functions for calibration ....... 28

8 Maintenance .................. 29

9 Accessories .................... 30

9.1 Sensors ........................... 30

10 Troubleshooting ............... 31

10.1 Troubleshooting instructions ......... 31

10.2 Diagnostic messages ................ 31

10.3 Firmware history ................... 36

10.4 Spare parts ........................ 36

10.5 Return ............................ 37

10.6 Disposal ........................... 37

11 Technical data ................. 37

11.1 Input .............................. 37

11.2 Output ............................ 38

11.3 Current outputs, active ............... 38

11.4 Relay outputs ...................... 39

11.5 Wiring ............................ 39

11.6 Performance characteristics .......... 40

11.7 Mounting conditions ................ 41

11.8 Environment ....................... 41

11.9 Mechanical construction ............. 42

11.10 Display and operating elements ....... 43

11.11 Certificates and approvals ............ 44

Index ................................. 45

6 Commissioning ................ 17

6.1 Post-installation check and switching

on the device ....................... 17

6.2 Display settings (Display menu) ....... 17

6.3 Notes on setup access protection ...... 17

6.4 Configuration of the device (Setup

menu) ............................ 18

6.5 Extended configuration (Extended

setup menu) ....................... 19

6.6 Device diagnostics (Diagnostics

menu) ............................ 26

Endress+Hauser 3

Page 4

Safety instructions CM14

1 Safety instructions

Safe operation of the transmitter is only guaranteed if these Operating Instructions have been

read and the safety instructions have been observed.

1.1 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

If working on and with the device with wet hands:

Due to the increased risk of electric shock, gloves must be worn.

‣

1.2 Requirements concerning the staff

The personnel for installation, commissioning, diagnostics and maintenance must fulfill the

following requirements:

Trained, qualified specialists: must have a relevant qualification for this specific function

‣

and task

Are authorized by the plant owner/operator

‣

Are familiar with federal/national regulations

‣

Before beginning work, the specialist staff must have read and understood the instructions

‣

in the Operating Instructions and supplementary documentation as well as in the

certificates (depending on the application)

Following instructions and basic conditions

‣

The operating personnel must fulfill the following requirements:

Being instructed and authorized according to the requirements of the task by the facility's

‣

owner-operator

Following the instructions in these Operating Instructions

‣

1.3 Operational safety

Risk of injury.

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with Endress+Hauser.

‣

Repair

To ensure continued operational safety and reliability,

Carry out repairs on the device only if they are expressly permitted.

‣

Observe federal/national regulations pertaining to repair of an electrical device.

‣

Use original spare parts and accessories from Endress+Hauser only.

‣

4 Endress+Hauser

Page 5

CM14 Safety instructions

1.4 Designated use

The transmitter evaluates measured values of an analytical sensor and visualizes them on its

multicolored display. Processes can be monitored and controlled with the unit's outputs and

limit relays. The device is equipped with a wide array of software functions for this purpose.

• The manufacturer does not accept liability for damage caused by improper or non-

designated use. The device may not be converted or modified in any way.

• The device is designed for installation in a panel and must only be operated in an installed

state.

1.5 Technical improvement

The manufacturer reserves the right to adapt technical details to the most up-to-date

technical developments without any special announcement. Please contact your sales center

for information on modifications or updates to the Operating Instructions.

1.6 Return

For a return, e.g. in case of repair, the device must be sent in protective packaging. The

original packaging offers the best protection. Repairs must only be carried out by your

supplier's service organization.

When returning the device for repair, enclose a note with a description of the problem

and the application.

1.7 Notes on safety conventions and icons

1.7.1 Warnings

DANGER

L

Causes (/consequences)

Consequences of non-compliance (if applicable)

Corrective action

‣

This symbol alerts you to a dangerous situation. Failure to avoid the situation will result in

‣

a fatal or serious injury.

WARNING

L

Causes (/consequences)

Consequences of non-compliance (if applicable)

Corrective action

‣

This symbol alerts you to a dangerous situation. Failure to avoid the situation can result in

‣

a fatal or serious injury.

CAUTION

L

Causes (/consequences)

Consequences of non-compliance (if applicable)

Corrective action

‣

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

‣

minor or more serious injuries.

Endress+Hauser 5

Page 6

Safety instructions CM14

NOTICE

Causes (/consequences)

Consequences of non-compliance (if applicable)

Corrective action

‣

This symbol alerts you to situations which may result in damage to property.

‣

1.7.2 Document symbols

Allowed

Indicates procedures, processes or actions that are allowed.

Preferred

Indicates procedures, processes or actions that are preferred.

Forbidden

Indicates procedures, processes or actions that are forbidden.

Additional information, tips

Reference to documentation

Reference to a page in this manual

Reference to a graphic

6 Endress+Hauser

Page 7

CM14 Identification

-10°C (14°F) < Ta < 60°C (140°F)

4

5

1

3

2

6

â 1

Liquiline

2 Identification

2.1 Device name

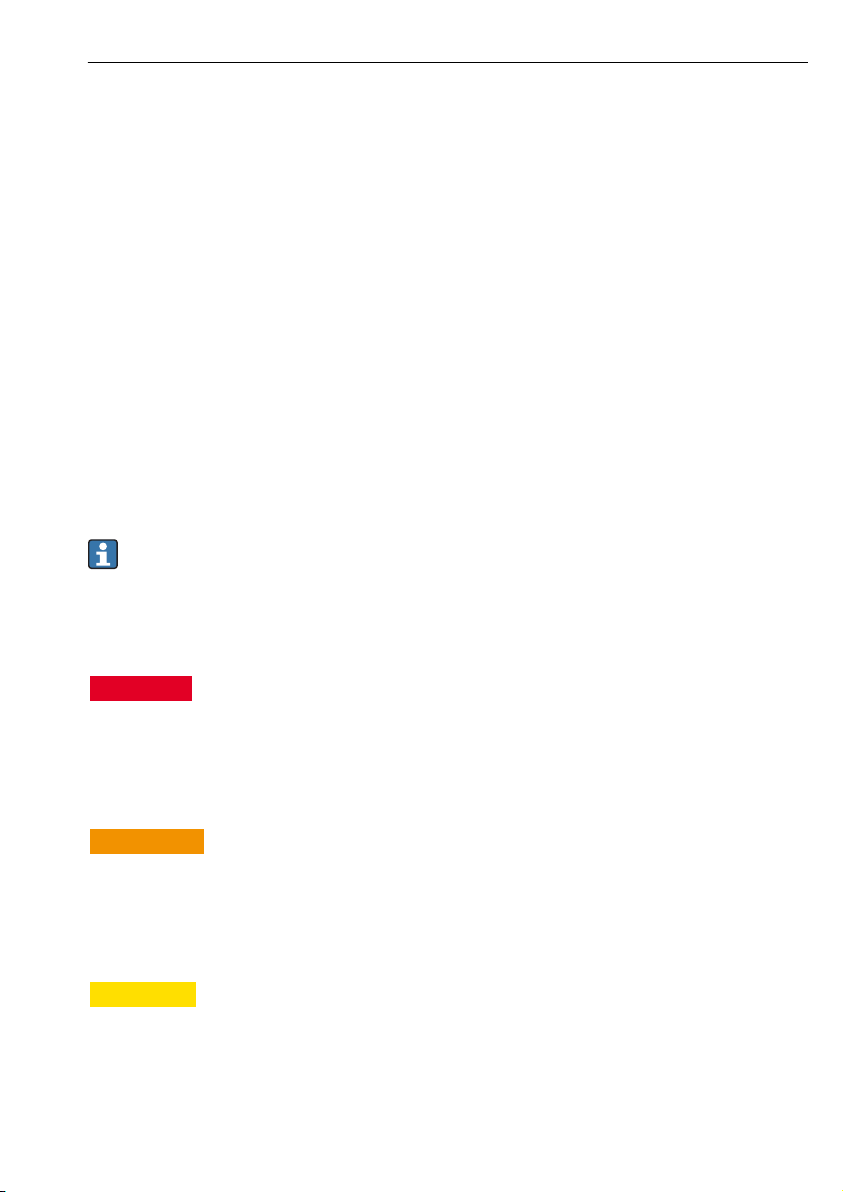

2.1.1 Nameplate

Compare the nameplate with the following diagram:

A0015221

1 Nameplate of the transmitter (example)

1 Device name

2 Device order code, serial number and ID number

3 Power supply

4 Power consumption

5 Output values

6 Temperature range

2.2 Scope of delivery

The scope of delivery of the transmitter comprises:

• Transmitter for panel mounting

• Operating Instructions

• Fastening fixtures

Endress+Hauser 7

Page 8

Identification CM14

2.3 Certificates and approvals

2.3.1 CE mark

The product meets the requirements of the harmonized European standards. As such, it

complies with the legal specifications of the EC directives. The manufacturer confirms

successful testing of the product by affixing to it the CE-mark.

2.3.2 EAC mark

The product meets the legal requirements of the EEU guidelines. The manufacturer confirms

the successful testing of the product by affixing the EAC mark.

8 Endress+Hauser

Page 9

CM14 Installation

3 Installation

3.1 Incoming acceptance, transport, storage

The permitted ambient and storage conditions must be observed. The precise specifications

can be found in Section "Technical data" → 37.

3.1.1 Incoming acceptance

On receipt of the goods, check the following points:

• Are the packaging or contents damaged?

• Is anything missing from the delivery? Compare the scope of delivery with the information

you specified in the order.

3.1.2 Transportation and storage

Note the following points:

• Pack the device so that is protected against impact for storage and transportation. The

original packaging provides optimum protection.

• The permitted storage temperature range is –40 to +85 °C (–40 to +185 °F); it is possible to

store the device in the borderline temperature ranges for a limited period (maximum 48

hours).

3.2 Installation

NOTICE

Overheating due to heat accumulation in the device

To avoid heat accumulation, please always make sure the device is sufficiently cooled.

‣

If the device is operated in the upper temperature limit range, this reduces the operating

life of the display.

The transmitter is designed to be used in a panel.

The orientation is determined by the readability of the display. Connections and outputs are

fitted on the rear of the device. The wires are connected by means of number-coded terminals.

Ambient temperature range:–10 to +60 °C (14 to 140 °F)

3.3 Dimensions

Observe the installation depth of 150 mm (5.91 ") for the device incl. terminals and fastening

clips.

More dimensions can be found in Section "Technical data" → 37.

• Panel cutout: 92 mm x 45 mm (3.62 in x 1.77 in).

• Panel thickness: max. 26 mm (1 in).

• Max. viewing angle range: 45° to the left and right from the central display axis.

• If the devices are arranged horizontally beside one another in the X-direction, or arranged

vertically on top of one another in the Y-direction, the mechanical distance (specified by the

housing and front section) must be observed.

Endress+Hauser 9

Page 10

Installation CM14

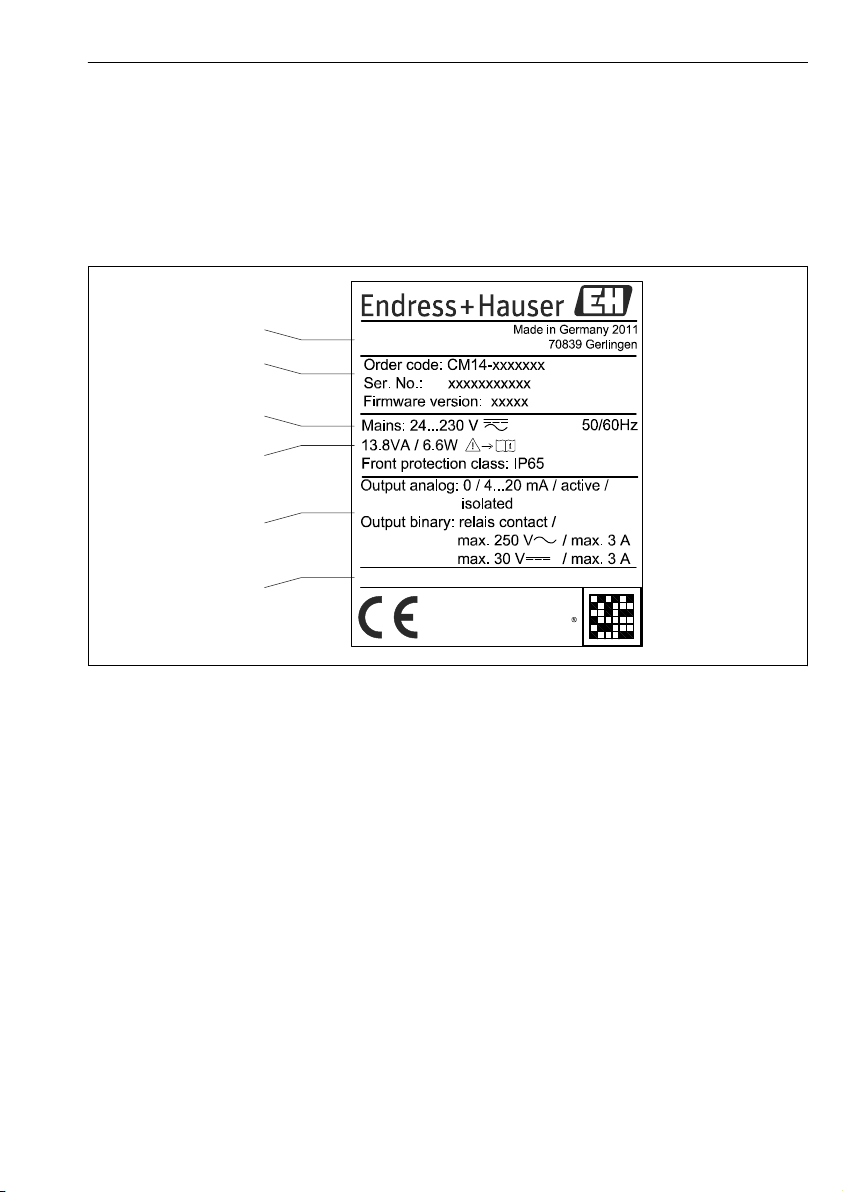

3.4 Installation procedure

The required panel cutout is 92 mm x 45 mm (3.62 in x 1.77 in).

A0015216

2 Installation in the panel

1. Screw the threaded rods (item 2) into the positions provided on the mounting frame

(item 1). Four opposing screw positions (item 3/4) are available for this purpose.

2. Push the device with the sealing ring through the panel cutout from the front.

3. To secure the tube in the panel, hold the device in a horizontal position and push the

installation frame (item 1), with the threaded rods screwed in, over the tube until the

frame locks into position.

4. Tighten the threaded rods to fasten the device in place.

To disassemble the device, the mounting frame can be unlocked at the locking elements (item

5) and then removed.

3.5 Post-installation check

• Is the sealing ring undamaged?

• Is the mounting frame securely engaged on the housing of the device?

• Are the threaded rods tightened?

• Is the device positioned in the center of the panel cutout?

10 Endress+Hauser

Page 11

CM14 Wiring

4 Wiring

WARNING

L

Danger from electrical voltage

The entire connection of the electrical system must take place while the device is de-

‣

energized.

Danger if protective ground is interrupted

The protective ground connection must be established before any other connection is

‣

made.

NOTICE

Thermal load of the lines

Use suitable lines for temperatures of 5 °C (9 °F) above ambient temperature.

‣

Malfunction or destruction of the device due to incorrect supply voltage

Prior to commissioning, make sure the supply voltage matches the specifications on the

‣

nameplate (bottom side of the housing).

Ensure the emergency shutoff of the device

Provide a suitable switch or power-circuit breaker in the building installation. This switch

‣

must be provided within easy reach of the device and be labeled as a disconnector.

Protect device from overload

Provide a overload protection unit (rated current = 10 A) for the power supply line.

‣

Incorrect wiring can cause destruction of the device

Observe the terminal designation on the rear of the device.

‣

Energy-rich transients in long signal lines

Connect suitable upstream overvoltage protection in series.

‣

It is permitted to connect a mixture of safety extra low voltage and voltage which poses a

shock hazard to the relays.

Endress+Hauser 11

Page 12

Wiring CM14

4.1 Connecting the transmitter

A0015215

3 Connection diagram of the transmitter

Terminal Description

87 Terminal for Memosens cable, brown, sensor power supply U+

88 Terminal for Memosens cable, white, sensor power supply U-

97 Terminal for Memosens cable, green, Com A

98 Terminal for Memosens cable, yellow, Com B

SHD Terminal for Memosens cable, shield

D11 Terminal for alarm output, +

D12 Terminal for alarm output, -

L/+

N/-

PE

133 Terminal for analog output 1, +

134 Terminal for analog output 1, -

233 Terminal for analog output 2, +

234 Terminal for analog output 2, -

R11, R12, R13 Terminal for relay 1

R21, R22, R23 Terminal for relay 2

Terminal for transmitter supply voltage

12 Endress+Hauser

Page 13

CM14 Wiring

4.2 Post-connection check

Device condition and specifications Notes

Are the device or cables damaged? Visual inspection

Electrical connection Notes

Does the supply voltage match the specifications on the nameplate? 24 to 230 V AC/DC

Are all of the terminals firmly engaged in their correct slots? Is the coding on the

individual terminals correct?

Are the mounted cables strain-relieved? -

Are the supply voltage and signal cables connected correctly? See connection diagram,

(–20 % / +10 %) 50/60 Hz

-

→ 3, 12 and on the

housing.

Endress+Hauser 13

Page 14

Operation CM14

5 Operation

The device's simple operating concept enables you to perform commissioning for many

applications without the need for hardcopy operating instructions.

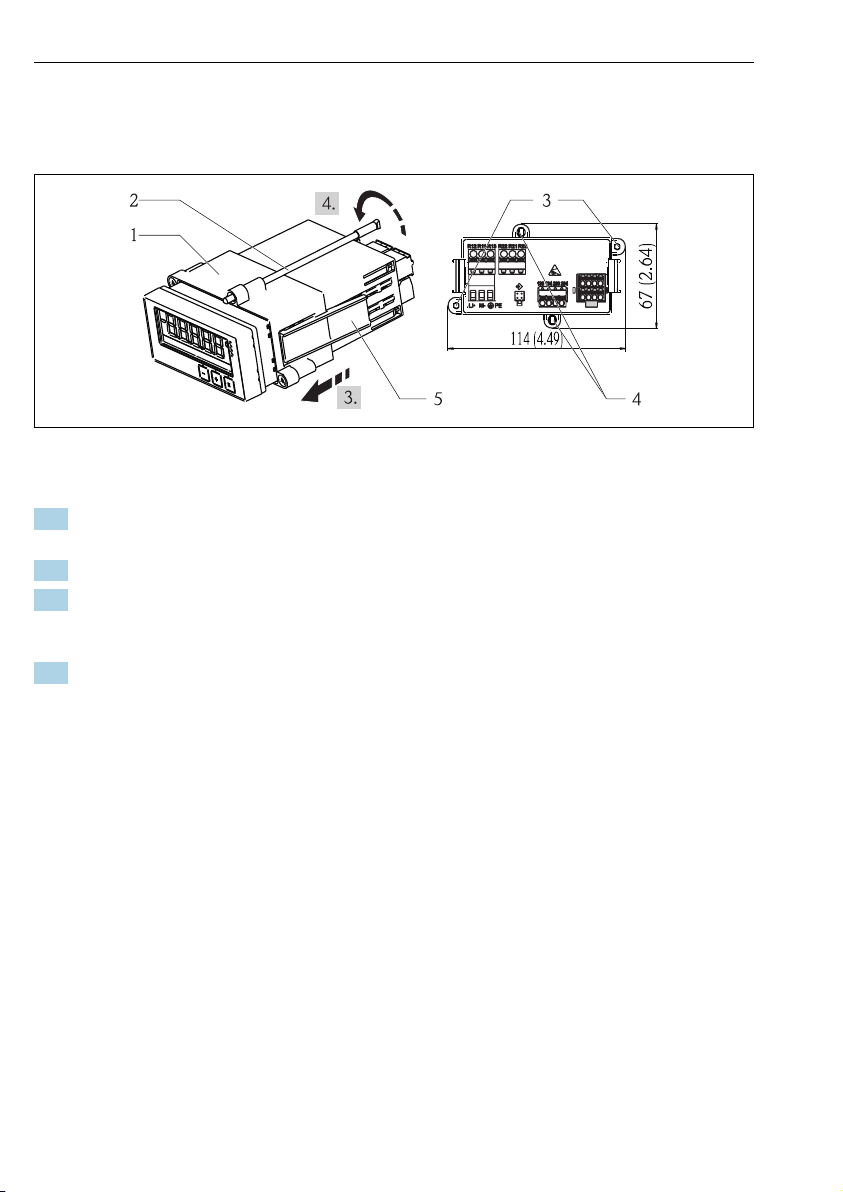

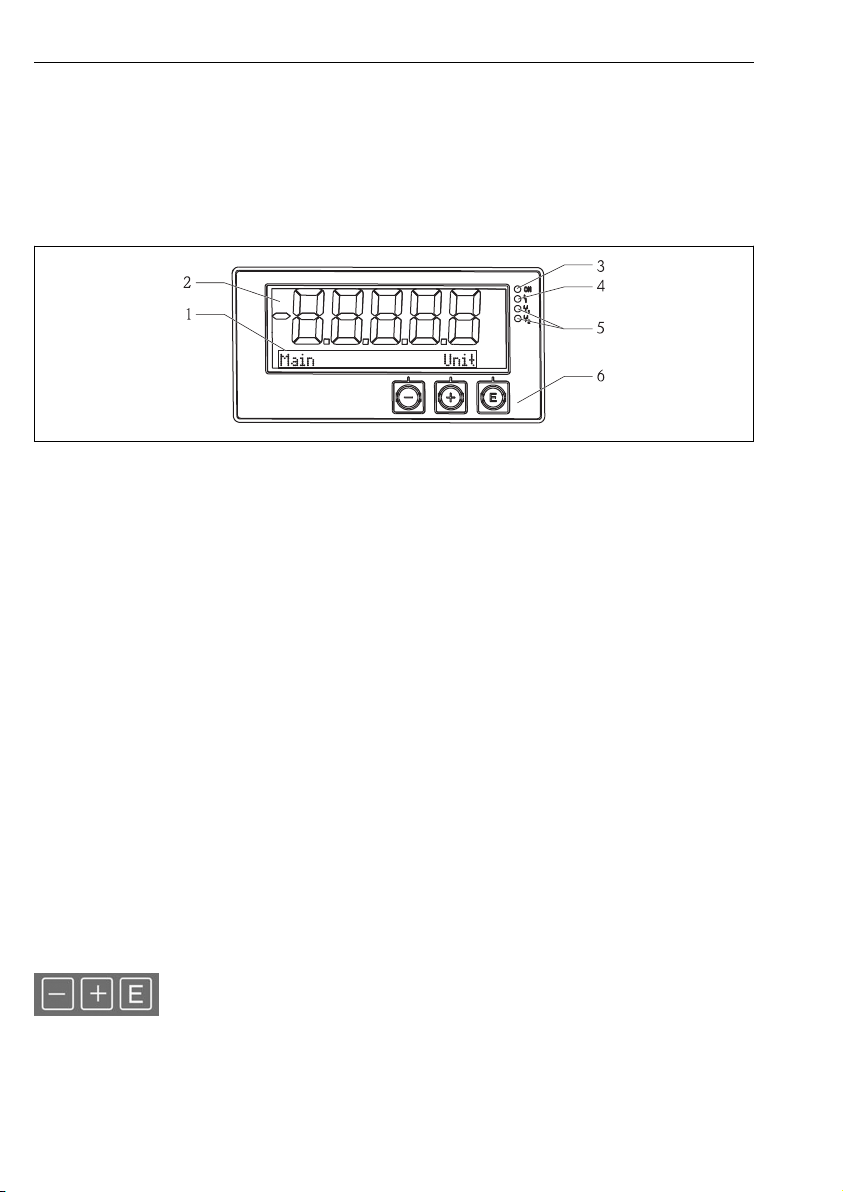

5.1 Display and device status indicator / LED

A0015891

4 Device display

1 Dot matrix section

2 7-segment display

3 LED status indicator, power supply connected

4 LED status indicator, alarm function

5 LED status indicator, limit switch relay 1/2

6 Operating keys

The device offers users a backlit LC display which is divided into two sections. The segment

section displays the measured value.

In the dot matrix section, additional channel information, such as the TAG, unit or bar graph,

is shown in the display mode. Operating text in English is displayed here during operation.

The parameters for configuring the display are explained in detail in the "Commissioning"

section.

In the event of an error, the device automatically switches between displaying the error and

displaying the channel, see the "Device diagnostics" → 26 and "Troubleshooting"

→ 31 sections.

5.2 Local operation at the device

The device is operated using the three keys integrated in the front of the device

14 Endress+Hauser

Page 15

CM14 Operation

• Open the Configuration menu

• Confirm an entry

• Select a parameter or submenu offered in the menu

Within the Configuration menu:

• Gradually scroll through the parameters / menu items / characters offered

• Change the value of the selected parameter (increase or decrease)

Outside the Configuration menu:

Display enabled and calculated channels, as well as minimum and maximum values, for all the active

channels.

You can always exit menu items / submenus by selecting "x Back" at the end of the menu.

Leave the setup directly without saving the changes by pressing the ‘-’ and ‘+’ keys

simultaneously for longer (> 3 s).

5.3 Icons

5.3.1 Display symbols

Hold function → 16 active.

Max Maximum value/value of the maximum indicator of the channel displayed

Min Minimum value/value of the minimum indicator of the channel displayed

Error, under/over range.

No measured value is displayed.

The device is locked / operator lock; the device setup is locked for changes to parameters; the

display can be changed.

The error and the channel identifier (TAG) are specified in the dot matrix section.

5.3.2 Icons in the editing mode

The following characters can be used to enter user-defined text:

‘0-9’, ‘a-z’, ‘A-Z’, ‘+’, ‘-’, ‘*’, ‘/’, ‘\’, ‘%’, ‘°’, ‘2’, ‘3’, ‘m’, ‘.’, ‘,’, ‘;’, ‘:’, ‘!’, ‘?’, ‘_’, ‘#’, ‘$’, ‘"’, ‘´’, ‘(’, ‘)’,

‘~’

For numerical entries, the numbers ‘0-9’ and the decimal point are available.

Furthermore, the following icons are used in the editing mode:

Symbol for setup

Symbol for expert setup

Symbol for diagnostics

Accept entry.

If this symbol is selected, the entry is applied at the position specified by the user, and you quit editing

mode.

Endress+Hauser 15

Page 16

Operation CM14

Reject entry.

If this symbol is selected, the entry is rejected and you quit editing mode. The previously set text

remains.

Jump one position to the left.

If this symbol is selected, the cursor jumps one position to the left.

Delete backwards.

If this symbol is selected, the character to the left of the cursor position is deleted.

Delete all.

if this symbol is selected, the entire entry is deleted.

5.4 Operating functions

The operating functions of the transmitter are organized into the following menus:

Display Settings for the device display: contrast, brightness, time for alternating measured values on the

Setup Device settings

Calibration Execution of the sensor calibration

Diagnostics Device information, diagnostics logbook, sensor information, simulation

display

A description of the individual settings is provided in the "Commissioning" section → 17.

A description of the functions for calibration is provided in the "Calibration" section.

5.5 Hold function

The hold function causes the current outputs and relay states to "freeze". This function can be

switched on and off manually (menu Setup → Manual hold). In addition, the hold function is

automatically activated during sensor calibration.

When the hold condition no longer applies, the hold function continues to be active for the

configurable hold release time. The hold release time is configured in the menu Setup →

Extended setup → System → Hold release.

The hold function does not affect the display of the measured value. The hold symbol is also

displayed after the measured value.

16 Endress+Hauser

Page 17

CM14 Commissioning

6 Commissioning

6.1 Post-installation check and switching on the device

Make sure that all post-connection checks have been carried out before you commission your

device:

• Checklist for "post-installation check", → 10.

• Checklist for "post-connection check" → 13.

After the operating voltage is applied, the green LED lights up and the display indicates the

device is ready for operation.

If you are commissioning the device for the first time, program the setup as described in the

following sections of the Operating Instructions.

When commissioning a device already configured or preset, measuring is immediately started

as per the settings. The values of the channels currently activated are shown on the display.

Remove the protective film from the display as this would otherwise affect the

readability of the display.

6.2 Display settings (Display menu)

You can access the main menu by pressing the 'E' key during operation. The Display menu

appears on the display. Press the 'E' key again to open this menu. Use the "x Back" option,

which can be found at the bottom of each menu/submenu, to move up one level in the menu

structure.

Parameters Possible settings Description

Contrast 1-7

Default: 5

Brightness 1-7

Default: 5

Alternating time 0, 3, 5, 10 sec Switching time between the two measured

Setting for the display contrast.

Setting for the brightness of the display.

values.

0 means that the values do not alternate on

the display.

6.3 Notes on setup access protection

Access to the setup is enabled by default (factory setting) and can be locked via the setup

settings.

Proceed as follows to lock the device:

1. Press E to enter the configuration menu.

2. Press + repeatedly until Setup is displayed.

3. Press E to open the Setup menu.

4. Press + repeatedly until Extended Setup is displayed.

Endress+Hauser 17

Page 18

Commissioning CM14

5. Press E to open the Extended Setup menu; System is displayed.

6. Press E to open the System menu.

7. Press + repeatedly until Access code is displayed.

8. Press E to open the setting for access protection.

9. Set the code: press the + and - buttons to set the desired code. The access code is a fourdigit number. The corresponding position of the number is displayed in plain text. Press

E to confirm the value entered and go to the next position.

10. Confirm the last position of the code to exit the menu. The full code is displayed. Press +

to scroll back to the last item of the x Back submenu and confirm this item. By

confirming the point, the value is adopted and the display returns to the Setup level.

Again select the last parameter x Back to also exit this submenu and return to the

measured value/channel display level.

Once access protection has been successfully activated, the lock symbol appears on the

display.

Access to the calibration function can also be blocked by a code. The same procedure is

required here as for locking the setup. To activate it, however, press + repeatedly in step

7 until Calib Code is displayed.

The x Back item at the end of every picklist/menu item takes the user from the submenu

to the next menu level up.

If access protection is enabled, the device locks automatically after 600 seconds without

operation. The display switches back to the operating display.

To enable the setup, set the setup access code in the System Setup to 0000 or delete the

code by pressing C.

If you lose/misplace the code, a reset can only be performed by the Service Department.

6.4 Configuration of the device (Setup menu)

You can access the main menu by pressing the 'E' key during operation. Navigate through the

available menus with the '+' and '–' keys. When the desired menu is displayed, press the 'E' key

to open the menu. Use the "x Back" option, which can be found at the bottom of each menu/

submenu, to move up one level in the menu structure.

The Setup menu contains the most important settings for the operation of the device.

Parameters Possible settings Description

Tag Customized text

Max. 16 characters

Current range 4-20 mA

0-20 mA

18 Endress+Hauser

Use this function to enter the device tag.

Configuration of the measuring range for the

current output.

Page 19

CM14 Commissioning

Parameters Possible settings Description

Out 1

0/4 mA

Out 1

20 mA

Out 2

0/4 mA

Out 2

20 mA

Damping main value 0 to 60 s

Extended setup Advanced settings for the device, such as the

Manual hold Off, On Function for freezing the current and relay

Numerical value

0.000 to 99 999

0.0 mS/cm

Numerical value

0.000 to 99 999

0.2 mS/cm(conductive)

200 mS/cm(inductive)

Numerical value –50 to 250 °C

0.0 °C

Numerical value –50 to 250 °C

100 °C

0 s

Physical value which corresponds to the lower

range limit of the analog output.

When the configured value is undershot, the

current output is set to the saturation current

of 0/3.8 mA.

Physical value which corresponds to the upper

range limit of the analog output.

When the configured value is exceeded, the

current output is set to the saturation current

of /20.5 mA.

Temperature which corresponds to the

measuring range lower limit of the

temperature input.

When the configured value is undershot, the

current output is set to the saturation current

of 0/3.8 mA.

Temperature which corresponds to the

measuring range upper limit of the

temperature input.

When the configured value is exceeded, the

current output is set to the saturation current

of /20.5 mA.

Configuration of the damping for low-pass

filtering of the input signals.

relay, limit values etc.

The functions are described in the following

section, → 19.

outputs

6.5 Extended configuration (Extended setup menu)

You can access the main menu by pressing the 'E' key during operation. Navigate through the

available menus with the '+' and '–' keys. When the desired menu is displayed, press the 'E' key

to open the menu. Use the "x Back" option, which can be found at the bottom of each menu/

submenu, to move up one level in the menu structure.

Parameters Possible settings Description

System General settings

Tag Customized text, max. 16

characters

Default: Aa

Temp. unit °C

°F

Endress+Hauser 19

Use this function to enter the device tag.

Setting for the temperature unit

Page 20

Commissioning CM14

Parameters Possible settings Description

Hold release 0 to 600 s

0 s

Alarm delay 0 to 600 s

0 s

Access code 0000 to 9999

Default: 0000

Calib Code 0000 to 9999

Default: 0000

Input Input settings

Operating mode conductivity

resistivity

TDS

Cell constant Read only

(Only available if a sensor is

connected)

Install factor 0.1 to 5.0

1.0

Unit auto, µS/cm, mS/cm Unit of the physical value.

Format None, one, two Number of places after decimal point for the

Damping main value 0 to 60 s

0 s

Temp. comp. off,

Linear,

UPW HCl,

UPW NaCl,

NaCl (IEC 746-3),

Water ISO 7888

T. comp. cal. off, Linar Configuration of the temperature

Alpha coeff. 1.0 to 20.0 %/K

2.1 %/K

Sets the time by which a device hold is

extended after the hold condition is

discontinued.

Delay time for outputting an alarm. This

suppresses alarm conditions that are present

for a period that is shorter than the alarm

delay time.

User code to protect the device configuration.

Additional information: 0000 = user code

protection is disabled

User code to protect the calibration function.

Additional information: 0000 = user code

protection is disabled

Configuration of the operating mode

Displays the cell constant of the connected

sensor (see sensor certificate).

Installation factor for inductive sensors to

correct the conductivity measurement.

Configuration by entering the factor. For

additional information on the installation

factor, → 22.

"auto" toggles automatically between µS/cm

and mS/cm.

display.

Configuration of the damping for low-pass

filtering of the input signals.

Configuration of the temperature

compensation.

Various methods are available to compensate

for the temperature dependency. This depends

on the processes in which the measurement is

used. For additional information on

temperature compensation, → 23.

compensation for cell constant calibration.

Coefficient for linear temperature

compensation.

20 Endress+Hauser

Page 21

CM14 Commissioning

Parameters Possible settings Description

Ref. temp. 25 °C Reference temperature for calculating the

Process check Checks the process settings

Function On, Off Switch on the process check.

Inactive time 1 to 240 min

Band width 1 to 20 %

Analog outputs Settings for analog outputs

Current range 4-20 mA

Out 1

0/4 mA

Out 1

20 mA

Out 2

0/4 mA

Out 2

20 mA

Damping main value 0 to 60 s

Relay 1/2 Settings for the relay outputs. For additional

Function Off, USP alarm, EP alarm, USP

Assignment Main, Temp Assignment of the relay to the main input or

Set point Numerical value

Set point 2 Numerical value

60 min

1 %

0-20 mA

Numerical value 0.000 99999

0.1 mS/cm

Numerical value 0.000 99999

200 mS/cm

Numerical value –50 to 250 °C

0 °C

Numerical value –50 to 250 °C

100 °C

0 s

pre-alarm, EP pre-alarm, Min

limit, Max limit, In band, Out

band, Error

0.0

0.0

linear temperature-compensated conductivity.

For more information on alpha coefficients and

the alpha reference temperature, refer to the

"Temperature compensation" section,

→ 23.

Duration of the process check

Bandwidth for the process check

Current range for analog output

Physical value which corresponds to the lower

range limit of the analog output.

Physical value which corresponds to the upper

range limit of the analog output.

Temperature which corresponds to the

measuring range lower limit of the

temperature input.

Temperature which corresponds to the

measuring range upper limit of the

temperature input.

Configuration of the damping for low-pass

filtering of the input signals.

information on the configuration of the relays,

→ 25.

Configuration of the relay function.

temperature input

Cannot be configured for the Error function

(error signaling relay).

Only for the In band or Out band function

Endress+Hauser 21

Page 22

Commissioning CM14

Parameters Possible settings Description

Hyst. Numerical value

0.0

Delay time 0 to 60 s

0 s

Factory default Resets the device settings to the factory default

Please confirm no, yes Confirm the reset.

Configuration of the hysteresis. Not for the

Error function.

Configuration of the delay time until the relay

switches. Not for the Error function.

settings.

6.5.1 Configuration of the relays

The device has two relays with limit values that are either switched off or can be allocated to

the input signal. The limit value is entered as a numerical value including the decimal

position. The operating mode of the relays as normally open or normally closed is determined

by the wiring of the changeover contact (→ 39). Limit values are always assigned to a

relay. Each relay can be assigned to a channel or a calculated value. In the "Error" mode, the

relay functions as an alarm relay and switches each time a fault or alarm occurs.

The following settings can be made for each of the 2 limit values: assignment, limit,

hysteresis, switching behavior, delay and failure mode.

6.5.2 Installation factor (inductive sensors only)

In confined installation conditions, the conductivity measurement is affected by the pipe walls.

The installation factor compensates for this effect. The transmitter corrects the cell constant

by multiplying by the installation factor.

The value of the installation factor depends on the diameter and the conductivity of the pipe

nozzle as well as the sensor's distance to the wall.

If the wall distance is sufficient (a > 15 mm (0.59 in), DN 80 or higher), the installation factor

f does not have to be taken into account (f = 1.00).

For small distances to the wall, the installation factor increases for electrically insulating pipes

(f > 1) and decreases for electrically conductive pipes (f < 1).

It can be measured using calibration solutions, or determined by approximation from the

following diagram.

22 Endress+Hauser

Page 23

CM14 Commissioning

1

2

a[inch]

0

5

10 15

20

2525

a[mm]

0.80

1.00

1.20

1.40

f

0.20

0.39

0.59

0.79

0.98

A0005441

5 Relationship between the installation factor (f) and the distance from wall (a)

1 Electrically conductive pipe wall

2 Electrically insulating pipe wall

6.5.3 Temperature compensation

The conductivity of a liquid depends heavily on the temperature, as the mobility of the ions

and the number of dissociated molecules are temperature-dependent. In order to compare

measured values, they must be referenced to a defined temperature. The reference

temperature is 25 °C (77 °F).

When specifying the conductivity, it is always necessary to specify the temperature. К(T0) is

the conductivity measured at 25 °C (77 °F) or recalculated to 25 °C (77 °F).

The temperature coefficient α represents the percentage change in the conductivity per degree

of temperature change. The conductivity К at the process temperature is calculated as follows:

К(T) = К(T0) (1 + α(T - T0))

К(T) conductivity at process temperature T

К(T0) conductivity at reference temperature T

The temperature coefficient depends on both the chemical composition of the solution and on

0

the temperature, and is between 1 % and 5 % per °C. The electrical conductivity of the majority

of diluted saline solutions and natural waters changes in a close-to-linear fashion.

Typical values for the temperature coefficient Alpha:

Natural water Approx. 2 %/K

Salts (e.g. NaCl) Approx. 2.1 %/K

Endress+Hauser 23

Page 24

Commissioning CM14

0

48

96

144

2.1

2.3

2.5

2.7

T [°C]

a [%/K]

Alkali (e.g. NaOH) Approx. 1.9 %/K

Acids (e.g. HNO3) Approx. 1.3 %/K

NaCl compensation

NaCl compensation is activated using the setting Extended setup → Input → Temp. comp. =

NaCl (IEC 746-3).

In the case of NaCl compensation (as per IEC 60746), a fixed non-linear curve specifying the

relationship between the temperature coefficient and temperature is saved in the device. This

curve applies to low concentrations of up to approx. 5 % NaCl.

Compensation for natural water

Compensation for natural water is activated using the setting Extended setup → Input →

Temp. comp. = Water ISO 7888.

A non-linear function in accordance with ISO 7888 is saved in the device for temperature

compensation in natural water.

Ultrapure water compensation (for conductive sensors)

Compensation for ultrapure water is activated using the setting Extended setup → Input →

Temp. comp. = UPW HCl or UPW NaCl.

Algorithms for pure and ultrapure water are stored in the device. These algorithms take the

dissociation of the water and its temperature dependency into account. They are used up to

conductivity levels of approx. 100 µS/cm.

24 Endress+Hauser

A0008939

Page 25

CM14 Commissioning

• UPW NaCl: optimized for pH-neutral impurities

• UPW HCl: optimized for measuring the acid conductivity downstream of a cation exchanger.

Also suitable for ammonia (NH3) and caustic soda (NaOH).

6.5.4 Configuration of the relays

The device has two relays with limit values that are either switched off or can be allocated to

the input signal. The limit value is entered as a numerical value including the decimal

position. Limit values are always assigned to a relay. Each relay can be assigned to a channel

or a calculated value. In the "Error" mode, the relay functions as an alarm relay and switches

each time a fault or alarm occurs.

The following settings can be made for each of the 2 limit values: assignment, operating

mode, limit, hysteresis, switching behavior, delay and failure mode.

Limit values for pharmaceutical water according to United States Pharmacopoeia (USP)

and European Pharmacopoeia (EP) (only for conductive sensors)

For conductive sensors, the transmitter has functions for monitoring "Water for Injection"

(WFI), "Highly Purified Water" (HPW) and "Purified Water" (PW) according to the United

States Pharmacopoeia (USP) Part 645 and European Pharmacopoeia (EP) standards.

USP function: The temperature-dependent limit values in the following table apply for "Water

for Injection" (WFI) according to USP and EP and for "Highly Purified Water" (HPW) according

to EP. The table is programmed into the transmitter.

Temperature [°C] Conductivity [µS/cm] Temperature [°C] Conductivity [µS/cm]

0 0.6 55 2.1

5 0.8 60 2.2

10 0.9 65 2.4

15 1.0 70 2.7

20 1.1 75 2.7

25 1.3 80 2.7

30 1.4 85 2.7

35 1.5 90 2.7

40 1.7 95 2.9

45 1.8 100 3.1

50 1.9

The measurement is performed in the following steps:

• The transmitter determines the uncompensated conductivity and the water temperature.

• The transmitter rounds the temperature down to the nearest 5 °C and compares the

measured conductivity with the associated value in the table.

• If the measured value is greater than the value in the table, an alarm is triggered (E151).

Endress+Hauser 25

Page 26

Commissioning CM14

EP-PW function: The following table lists the temperature-dependent limit values for

"Purified Water" (PW) in accordance with EP; this table is also programmed into the

transmitter.

Temperature [°C] Conductivity [µS/cm] Temperature [°C] Conductivity [µS/cm]

0 2.4 60 8.1

10 3.6 70 9.1

20 4.3 75 9.7

25 5.1 80 9.7

30 5.4 90 9.7

40 6.5 100 10.2

50 7.1

The measurement is performed in the following steps:

• The transmitter determines the uncompensated conductivity and the water temperature.

• If the temperature is between two table entries, the limit value for the conductivity is

determined by interpolation of the two neighboring points.

• An alarm is triggered if the measured value is greater than the limit value.

Pre-alarm

In addition, a USP pre-alarm is available that is activated at an adjustable switch-on point of

80 % of the USP/EP limit value. This means that users are alerted in time to the need to

regenerate their system.

6.6 Device diagnostics (Diagnostics menu)

You can access the main menu by pressing the 'E' key during operation. Navigate through the

available menus with the '+' and '–' keys. When the desired menu is displayed, press the 'E' key

to open the menu. Use the "x Back" option, which can be found at the bottom of each menu/

submenu, to move up one level in the menu structure.

Parameters Possible settings Description

Current diag. Read only. Displays the current diagnostic message

Last diag. Read only. Displays the last diagnostic message

Diagnost logbook Read only Displays the last diagnostic messages

Device info Read only. Displays the device information

Device tag Read only. Displays the device tag

Device name Read only. Displays the device name

Serial number Read only. Displays the serial number of the device

Order ident Read only. Displays the order code of the device

FW revision Read only. Displays the firmware version

26 Endress+Hauser

Page 27

CM14 Commissioning

Parameters Possible settings Description

ENP version Read only. Displays the version of the electronic

Module ID Read only. Displays the module ID

Manufact. ID Read only. Displays the manufacturer ID

Manufact. name Read only. Displays the manufacturer name

nameplate

Endress+Hauser 27

Page 28

Calibration (Calibration menu) CM14

7 Calibration (Calibration menu)

7.1 General

Determining the relationship between the measured or expected value of the output variable

and the corresponding true or correct value of the measured variable (input variable) for a

measuring device under specified conditions.

During calibration, there is no intervention that changes the measuring instrument.

7.2 Device functions for calibration

Press the 'E' button during operation to call up the main menu. Use the '+'- and '-' buttons to

navigate through the available menus. When the desired menu is displayed, press the 'E' key

to open the menu. Select the "x Back" option at the end of each menu/submenu to navigate

one level higher in the menu structure.

Parameter Configuration options Description

Conductivity Calibrate the conductivity measurement.

C calib. start Read only

k Read only Current cell constant

C cal. Numerical value

k Read only Newly calculated cell constant

Save calib data? Yes, No Save or discard calibration data?

Temperature Calibrate the temperature measurement.

T cal. start Read only

T cal. Numerical value

Save calib data? Yes, No Save or discard calibration data?

0 mS/cm

7.2.1 Calibrate cell constant

A conductivity measurement system is always calibrated such that the exact cell constant is

determined/verified using suitable calibration solutions. This method is described, for

example, in the EN 7888 and ASTM D 1125 standards, each of which details the manufacture

of a few calibration solutions. Another option is to obtain international calibration standards

from government metrology authorities. This is particularly important in the pharmaceutical

industry, where traceability of the calibration to internationally recognized standards is

mandatory. To calibrate its test equipment, Endress+Hauser uses the SRM (Special Reference

Material) of the US government agency NIST (National Institute of Standards and

Technology).

28 Endress+Hauser

Page 29

CM14 Maintenance

Calibrating the cell constant

In the cell constant calibration, always use a defined conductivity reference solution with raw

conductance values that are specified at the various temperatures. The correct calibration

always takes place without temperature compensation.

Setting: In the menus, navigate to Extended Setup → Input → T.comp.cal: Select "off".

This switches off the temperature compensation for the calibration.

The new cell constant is calculated from the new conductivity reference solution.

The method for cell constant calibration is the same for conductive and inductive conductivity.

Only the conductivity reference or standard solutions that are adapted to the measuring

ranges may be used.

For the conductive sensors (CLS15D,CLS16D and CLS21D), standard solution CLY11-A

74.02 µS/cm, CLY11-B 149.75 µS/cm.

For the inductive sensor (CLS50D), standard solution CLY11-C 1.40 mS/cm, CLY11-D

12.65 mS/cm.

1. Press "E" to call up the main menu.

2. Press the "+" button to navigate to the "Calibration" menu.

3. Press "E" to open the menu.

4. Press "E" to open the "Cell const." submenu.

The current cell constant is displayed.

5. Remove the sensor from the measurement medium, flush with distilled water and dry.

6. Press "+" to enter the conductivity reference solution "cond. Ref."

Entering the value of the conductivity reference solution at the current temperature

7. Press "+".

"Insert sensor in med." is displayed.

8. Insert the sensor into the conductivity reference solution.

9. Press "+".

"wait for stable value" is displayed.

Display reads "wait for stable value", when the value is stable, the display switches to

"New cell constant".

10. Press "+".

"Save Calib. Data" is displayed.

Press E and apply calibration data using "Yes".

8 Maintenance

No special maintenance work is required on the device.

Endress+Hauser 29

Page 30

Accessories CM14

9 Accessories

9.1 Sensors

Conductive conductivity sensors

Condumax W CLS15D

• Conductive conductivity sensor for pure water, ultrapure water and Ex applications

• Order as per product structure, see Technical Information TI00109C/07/en

Condumax H CLS16D

• Hygienic, conductive conductivity sensor for pure water, ultrapure water and Ex applications

• With EHEDG and 3A approval

• Order depending on version, see Technical Information TI00227C/07/en

Condumax W CLS21D

• Two-electrode sensor in plug-in head and fixed cable version

• Order as per product structure, see Technical Information TI00085C/07/en

Inductive conductivity sensors

Indumax CLS50D

• Highly resistant inductive conductivity sensor for standard, Ex and high-temperature

applications

• Memosens protocol

• Order as per product structure, see Technical Information TI00182C/07/en

30 Endress+Hauser

Page 31

CM14 Troubleshooting

10 Troubleshooting

To help you troubleshoot, the following section is designed to provide an overview of possible

causes of errors and initial remedial measures.

10.1 Troubleshooting instructions

WARNING

L

Danger! Electric voltage!

Do not operate the device in an open condition for error diagnosis!

‣

User interface Reason Solution

No measured value displayed No power supply connected Check the power supply to the device.

Power is supplied, device is defective The device must be replaced.

Diagnostic message is displayed The list of diagnostic messages is provided in the following section.

10.2 Diagnostic messages

The diagnostic message consists of a diagnstic code and a message text.

The diagnostic code consists of an error category according to Namur NE 107 and a message

number.

Error category (character front of message number)

• F = Failure, a malfunction has been detected.

The measured value of the respective channel is no longer reliable. The cause can be found

at the measuring point. If a control system is connected, you should switch to manual

operation.

• M = Maintenance required, action has to be taken as soon as possible.

Functionality of the measurement is fulfilled. No immediate measure needs to be taken.

However, maintenance prevents possible future malfunction.

• C = Function check, wait loop (no error).

Maintenance is performed on the device. Wait for completion of the process.

• S = Out of specification, the measurement point is operated out of specification.

Measurement is still possible. However, operation takes place with risk of higher wear,

shortened lifespan or lower measurement accuracy. The cause can be found at the

measurement point.

Endress+Hauser 31

Page 32

Troubleshooting CM14

Examples:

F 61

sensor elec.

A0015896

M 915

USP warning

A0015897

S 844

Process value

A0015898

C 107

Calib. active

A0015899

Diagnostic

Message text Description

code

Sensor data invalid.

F5 Sensor data

Remedy:

• Update date of the transmitter

• Replace sensor

The sensor data could not be written.

F12 Writing data

Remedy:

• Repeat writing of the sensor data

• Replace sensor

Incorrect sensor type.

F13 Sensor type

Remedy:

Switch to a sensor of the configured type.

Sensor electronics defective.

F61 Sensor elec.

Remedy:

• Replace sensor

• Contact service

Sensor connection.

F62 Sens. Connect

Remedy:

• Replace sensor

• Contact service

32 Endress+Hauser

Page 33

CM14 Troubleshooting

Diagnostic

code

F100 Sensor comm.

F130 Sensor supply

F142 Sensor signal

F143 Self test

F152 No airset

F523 Cell const.

F524 Cell const.

Message text Description

No sensor communication.

Possible reasons:

• No sensor connection

• Faulty sensor connection

• Short-circuit in the sensor cable

• Short-circuit in the neighboring channel

• Sensor firmware update canceled with an error

Remedy:

• Check sensor cable connection

• Check sensor cable for short-circuit

• Replace sensor

• Restart firmware update

• Contact service

Sensor check.

Poor energy supply to sensor.

Remedy:

• Check cable connections

• Replace sensor

Sensor check.

No conductivity display.

Possible reasons:

• Sensor in air

• Sensor defective

Remedy:

• Check sensor installation

• Replace sensor

Sensor self-test error.

Remedy:

• Replace sensor

• Contact service

Sensor data.

No calibration data present

Remedy:

Carry out airset calibration

Sensor calibration warning.

Invalid cell constant, max. range reached.

Remedy:

• Recalibrate

• Enter cell constant according to factory specifications

• Replace sensor

Sensor calibration alarm.

Min. possible cell constant undershot.

Remedy:

• Recalibrate

• Enter cell constant according to factory specifications

Endress+Hauser 33

Page 34

Troubleshooting CM14

Diagnostic

code

F845 Device id Faulty hardware configuration

F846 Param error

F847 Couldn't save param Parameters could not be saved

F848 Calib AO1 Faulty calibration values for analog output 1

F849 Calib AO2 Faulty calibration values for analog output 2

F904 Process check

Diagnostic

code

C107 Calib. active

C154 No calib. data

C850 Simu AO1 Simulation of analog output 1 is active

C851 Simu AO2 Simulation of analog output 2 is active

C852 Simu DO Simulation of status output is active

C853 Download act. Parameter transmission is active

Message text Description

Faulty parameter checksum

Possible cause:

Firmware update

Remedy:

Reset parameters to factory defaults

Process check system alarm.

No change in measurement signal for a long time.

Possible reasons

• Sensor dirty or in air

• No sensor inflow

• Sensor defective

• Software error

Remedy:

• Check measuring chain

• Inspect sensor

• Carry out software restart

Message text Description

Sensor calibration is active.

Remedy:

Wait for calibration

Sensor data.

No calibration data present, factory settings will be used.

Remedy:

• Check calibration information of the sensor

• Calibrate cell constant

34 Endress+Hauser

Page 35

CM14 Troubleshooting

Diagnostic

code

S844 Process value

S910 Limit switch Limit switch energized

Diagnostic

code

M500 Not stable

M526

M528 Cell const.

M914 USP alarm

M915 USP warning

Message text Description

Measured value outside the specified range.

Possible reasons:

• Sensor in air

• Air cushion in the assembly

• Incorrect sensor inflow

• Sensor defective

Remedy:

• Increase process value

• Check measuring chain

• Change sensor type

Message text Description

Sensor calibration canceled.

Main measured value unsteady.

Possible reasons:

• Sensor overaged

• Sensor temporarily dry

• Buffer value not constant

Remedy:

• Check sensor, replace if required

• Check buffer

Sensor calibration warning.

Invalid cell constant, max. range reached.

Cell const.

Remedy:

• Recalibrate

• Enter cell constant according to factory specifications

• Replace sensor

Sensor calibration warning.

Min. possible cell constant undershot.

Remedy:

• Recalibrate

• Enter cell constant according to factory specifications

USP alarm.

Conductivity limit value for USP exceeded.

Remedy:

Check process

USP warning.

Conductivity limit value for USP undershot.

Remedy:

Check process

Endress+Hauser 35

Page 36

Troubleshooting CM14

10.3 Firmware history

Revision history

The firmware version (FW) on the nameplate and in the Operating Instructions indicates the

device release: XX.YY.ZZ (example 01.02.01).

XX Change to main version. No longer compatible. The device and Operating

Instructions change.

YY Change to functions and operation. Compatible. The Operating Instructions

change.

ZZ Fixes and internal changes. No changes to the Operating Instructions.

Date Firmware Version Changes Documentation

09/2011 01.01.00 Original firmware BA01030C/09/en/01.11

11/2019 02.01.00 Password protection for users amended BA01030C/09/en/02.19

10.4 Spare parts

A0015745

6 Spare parts of the device

36 Endress+Hauser

Page 37

CM14 Technical data

Item no. Description Order no.

1 Housing front + foil, incl. keyboard CM14, without display XPM0004-DA

2 CPU/Display board CM14 conductivity conductive

CPU/Display board CM14 conductivity inductive

3 Mainboard 24-230VDC/AC, CM14 XPM0004-NA

4 Relay board + 2 limit relays RIA45X-RA

5 Fixing frame for housing W07 71069917

6 Terminal, 3-pole (power supply) 50078843

7 Pluggable terminal, 4-pole (Memosens input) 71037350

8 Pluggable terminal, 4-pole (current output) 71075062

9 Pluggable terminal, 3-pole (relay terminal) 71037408

10 Threaded bar for tube fixing clip 105mm 71081257

XPM0004-CK

XPM0004-CL

10.5 Return

For a return, e.g. in case of repair, the device must be sent in protective packaging. The

original packaging offers the best protection. Repairs must only be carried out by your

supplier's service organization.

When sending for repair, please enclose a note with a description of the error and the

application.

10.6 Disposal

The device contains electronic components and must, therefore, be disposed of as electronic

waste in the event of disposal. Please pay particular attention to the local regulations

governing waste disposal in your country.

11 Technical data

11.1 Input

11.1.1 Measured variables

--> Documentation of the connected sensor

11.1.2 Measuring ranges

--> Documentation of the connected sensor

11.1.3 Input types

Digital sensor inputs, Memosens and Memosens protocol

Endress+Hauser 37

Page 38

Technical data CM14

11.1.4 Cable specification Cable type

Memosens data cable or fixed sensor cable, each with cable end sleeves

Cable length

Max. 100 m (330 ft)

11.2 Output

11.2.1 Output signal

2 x 0/4 to 20 mA active, potentially isolated from the sensor circuits and from each other

11.2.2 Load

Max. 500 Ω

11.2.3 Linearization/transmission behavior

Linear

11.2.4 Alarm output

The alarm output is designed as an "open collector." In normal operation the alarm output is

closed. In the event of a fault (F-fault, device without current) the "open collector" opens.

Current max. 200 mA

Voltage max. 30 V DC

11.3 Current outputs, active

11.3.1 Span

0 to 23 mA

11.3.2 Signal characterization

Linear

11.3.3 Electrical specification Output voltage

Max. 24 V

11.3.4 Cable specification Cable type

Recommendation: shielded line

Cross-section

Max. 1.5 mm² (16 AWG)

38 Endress+Hauser

Page 39

CM14 Technical data

133

0/4...20 mA

0/4...20 mA

134

233

234

+

-

+

-

R12

R11

R13

R22

R21

R23

YE

GN

WH

BN

+

-

98

97

88

87

SHD

SHD

D11

D12

Sensor

Com B

Com A

U-

U+

max 30 V

200 mA

11.4 Relay outputs

11.4.1 Relay types

2 changeover contacts

11.4.2 Relay switching capacity

Max. 3 A24 V DC

Max. 3 A253 V AC

Min. 100 mW (5 V / 10 mA)

11.4.3 Cable specification

Cross-section

Max. 2.5 mm² (14 AWG)

11.5 Wiring

11.5.1 Electrical connection

A0015303

Endress+Hauser 39

Page 40

Technical data CM14

Connection Description

87 Terminal for Memosens cable, brown, sensor power supply U+

88 Terminal for Memosens cable, white, sensor power supply U-

97 Terminal for Memosens cable, green, Com A

98 Terminal for Memosens cable, yellow, Com B

SHD Terminal for Memosens cable, shield

D11 Terminal for alarm output, +

D12 Terminal for alarm output, -

L/+

N/-

PE

133 Terminal for analog output 1, +

134 Terminal for analog output 1, -

233 Terminal for analog output 2, +

234 Terminal for analog output 2, -

R11, R12, R13 Terminal for relay 1

R21, R22, R23 Terminal for relay 2

Terminal for transmitter supply voltage

11.5.2 Supply voltage

Wide range power unit 24 to 230 V AC/DC (-20 % / +10 %) 50/60Hz

The device does not have a power switch

• The customer must provide a protected circuit breaker in the vicinity of the device.

• The circuit breaker must be a switch or power switch, and must be labeled as the

circuit breaker for the device.

11.5.3 Power consumption

Max. 13.8 VA / 6.6 W

11.6 Performance characteristics

11.6.1 Response time

Current outputs

t90 = max. 500 ms for a jump from 0 to 20 mA

11.6.2 Reference temperature

25 °C (77 °F)

40 Endress+Hauser

Page 41

CM14 Technical data

92 (3.62)

45 (1.77)

11.6.3 Maximum measured error of inputs

--> Documentation of the connected sensor

11.6.4 Resolution of current output

> 13 bit

11.6.5 Repeatability

--> Documentation of the connected sensor

11.7 Mounting conditions

11.7.1 Installation instructions Mounting location

Panel, cutout 92 x 45 mm (3.62 x 1.77 in)

Max. panel thickness 26 mm (1 in)

Installation position

The orientation is determined by the legibility of the display.

Max. viewing angle range of +/- 45° from the central display axis in every direction.

7 Panel cutout, dimensions in mm (in)

11.8 Environment

11.8.1 Ambient temperature range

–10 to +60 °C (14 to 140 °F)

11.8.2 Storage temperature

–40 to +85 °C (–40 to +185 °F)

Endress+Hauser 41

A0010351

Page 42

Technical data CM14

96 (3.78)

48 (1.89)

16.7

(0.66)

151.8 (5.98)

118.6 (4.67)

41.9 (1.65)

43.9 (1.73)

90.9 (3.56)

88.9 (3.50)

11.8.3 Operating height

< 2 000 m (6 561 ft) above MSL

11.8.4 Electromagnetic compatibility

Emitted interference and interference immunity to EN 61326-1:2006, Class A for industrial

areas

11.8.5 Degree of protection Front

Front IP65 / NEMA 4X

Tube

Shock protection IP20

11.8.6 Relative humidity

5 to 85 %, non-condensing

11.9 Mechanical construction

11.9.1 Dimensions

8 Dimensions of the transmitter in mm (in)

42 Endress+Hauser

A0015925

Page 43

CM14 Technical data

Y

1

Y

2

1

2

3

4

5

6

77 7

11.9.2 Weight

0.3 kg (0.66 lbs)

11.9.3 Materials

Housing, casing: Polycarbonate

Front foil: Polyester, UV-resistant

11.9.4 Terminals

Max. 2.5 mm² (22-14 AWG; tightening torque 0.4 Nm (3.5 lb in)) line, relay

11.10 Display and operating elements

11.10.1 Operating elements

9 Display and operating elements

A0018699

1 LC display for displaying the measured values and configuration data

2 Status LED, power supply connected

3 Status LED, alarm function

4 Status LED for limit switch relay 1

5 Status LED for limit switch relay 2

6 Dot matrix display for displaying the dimensions and menu items

7 Operating keys

Endress+Hauser 43

Page 44

Technical data CM14

11.11 Certificates and approvals

11.11.1 mark

Declaration of Conformity

The product fulfills the requirements of harmonized European standards.

Thus it fulfills the legal requirements of the EC Directives.

The manufacturer confirms successful testing of the device by affixing to it the mark.

Other standards and guidelines

• IEC 60529:

Degree of protection by housing (IP code)

• IEC 61010-1: 2001 Cor 2003

Safety requirements for electrical equipment for measurement, control and laboratory use

44 Endress+Hauser

Page 45

CM14 Index

Index

C

Calibration

Cell constant ................. 28

CE mark ........................8

D

Device configuration

Setup access protection ........... 17

Diagnostic messages ................31

Display symbols .................. 15

E

Error messages ................... 31

European Pharmacopoeia (EP) ..........25

I

Icons

Display .....................15

Editing mode ................. 15

Installation factor ................. 22

O

Operational safety .................. 4

R

Relay ...................... 22, 25

S

Staff

Requirements ..................4

T

Temperature compensation ............23

U

United States Pharmacopoeia (USP) .......25

W

Workplace safety .................. 4

Endress+Hauser 45

Page 46

Page 47

Page 48

www.addresses.endress.com

Loading...

Loading...