Page 1

Technical Information

Liquiline CM14

4-wire-controller based on digital Memosens technology for

pH/ORP, conductivity and oxygen

Application

Liquiline CM14 is a 4-wire-controller in compact design for

installation in panels or cabinets.

Application

• Wastewater treatment

• Water treatment and drinking water monitoring

• Ion exchanger

• Surface water monitoring

TI494C/07/EN/01.11

71132861

Your benefits

• Compact instrument in 48 x 96 mm panel mounted housing

• Easy to operate

• Memosens technology

– Use of precalibrated sensors

– Safety thanks to active detection of cable break

• Two contacts for limit contactor

• Second current output for temperature

Page 2

Function and system design

Memosens technology Memosens makes your measuring point safer and more reliable:

• Non-contact, digital signal transmission enables optimum galvanic isolation

• No galvanic corrosion

• Completely watertight

• Laboratory sensor calibration possible, thus increasing measured value availability

• Predictive maintenance thanks to recording of sensor data, e.g.:

– Total hours of operation

– Hours of operation with very high or very low measured values

– Hours of operation with high temperatures

– Number of steam sterilizations

– Sensor condition

pH/ORP measurement

Liquiline CM14

pH/ORP measurement with Liquiline CM14

Functions of the basic version

Mesaurement of pH and ORP value with glas elctrodes.

This is selected via the menu. The temperature is displayed alternatingly.

Process Check System (PCS)

The live check issues an alarm when the sensor signal does not change over a defined period of time. This may

be caused by blocking, passivation, separation from the process, etc.

a0015281

2 Endress+Hauser

Page 3

Liquiline CM14

Conductivity measurement Conductive or inductive

Two versions are available for the measurement with conductive (two electrode) sensors or inductive sensors.

An inductive sensor is recommended for the measurement of high conductivities, for concentration

measurement or adhering media.

a0015279

The measuring range of a measuring point is determined by the connected digital Memosens sensor.

Sensor Cell constant Measuring range

CLS15D-A1A1 k = 0.01 1/cm 0.05 μS/cm to 20 μS/cm

CLS15D-B1A1 k = 0.1 1/cm 0.1 μS/cm to 200 μS/cm

CLS16D-3C1P1 k = 0.1 1/cm 0.04 μS/cm to 500 μS/cm

CLS21D-C1E1 k = 1.0 1/cm 10 μS/cm to 20 mS/cm

CLS50D-AA1B11 k = 1.98 1/cm 0.1 mS/cm to 2000 mS/cm

Measurement of conductivity or resistivity (conductive)

This is selected via the menu.

Temperature compensation

The following temperature compensation selections are available:

• Linear

• NaCl curve according to IEC 746

• Ultrapure water NaCl (neutral compensation)

• Ultrapure water HCl (acid compensation, also ammonia)

Ultrapure water monitoring acc. to USP (United States Pharmacopeia) and EP (European

Pharmacopoeia)

Ultrapure water monitoring according to USP <645> and EP means that the uncompensated conductivity

value and the temperature are measured and the results are compared by a table.

The controller comes with the following functions:

• Monitoring of "Water for Injection" (WFI) according to USP and EP

• Monitoring of "Purified Water" (PW) according to EP

Endress+Hauser 3

Page 4

Oxygen measurement Measurement of the oxygen content und setting of the sea level

2

3

1

mS/cm

Y

1

Y

2

The oxygen content is displayed in mg/l. The setting of the sea level is performed in m or ft.

This is selected via the menu. The temperature is displayed alternatingly.

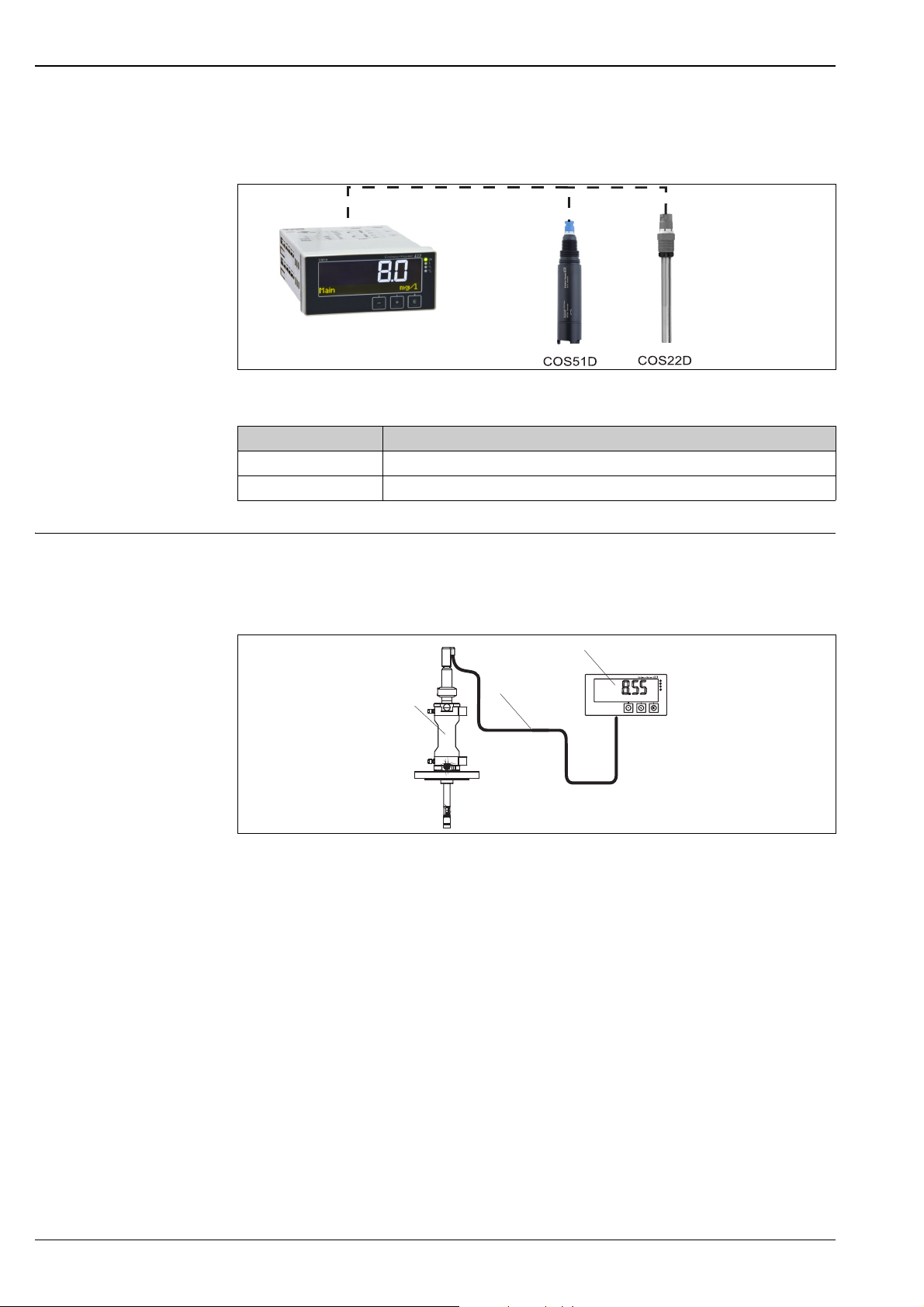

Liquiline CM14

Oxygen measurement with Liquiline CM14

Sensor Measuring range

COS51D 0.01 to 100 mg/l

COS22D-*1 0.01 to 60 mg/l

Measuring system A complete measuring system comprises:

• The controller Liquiline CM14

• An assembly with sensor

• A measuring cable

a0015280

Example of measuring system with Liquiline CM14

1 Assembly with sensor

2 Measuring cable

3 Controller Liquiline CM14

4 Endress+Hauser

a0015282

Page 5

Liquiline CM14

Input

Measuring variables --> Documentation of the connected sensor

Measuring range --> Documentation of the connected sensor

Input types Digital sensor inputs

Cable specification Cable type

Memosens data cable CYK10 or sensor fixed cable, each with cable end sleeves

Cable length

Max. 100 m (330 ft)

Output

Output signal 2 x 0/4 to 20 mA active, potentially isolated from one another and from the sensor circuit

Load Max. 500 Ω

Linearisation/transmission bevaviour

Alarm output The alarm output is designed as "open collector".

linear

Current max. 200 mA

Voltage max. 30 V DC

Current output, active

Span 0 to 23 mA

Signal characteriziation linear

Electrical specification Output voltage

Max. 24 V

Cable specification Cable type

Recommended: shielded cable

Cross section

2

max. 1.5 mm

(16 AWG)

Relay output

Relay type 2 changeover contacts

Switching current max. 3 A @ 24 V DC

max. 3 A @ 253 V AC

min. 100 mW (5 V / 10 mA)

Cable specification Cross section

2

Max. 2.5 mm

Endress+Hauser 5

(14 AWG)

Page 6

Electrical connection

133

0/4...20 mA

0/4...20 mA

134

233

234

+

-

+

-

R12

R11

R13

R22

R21

R23

YE

GN

WH

BN

+

-

98

97

88

87

SHD

SHD

D11

D12

Sensor

Com B

Com A

U-

U+

max 30 V

200 mA

Liquiline CM14

Power supply

Electrical connection of controller

Terminal Description

87 Connection Memosens cable, brown, sensor power U+

88 Connection Memosens cable, white, sensor power U-

97 Connection Memosens cable, green, Com A

98 Connection Memosens cable, yellow, Com B

SHD Connection Memosens cable, shield

D11 Connection alarm output, +

D12 Connection alarm output, -

L/+

Connection controller powerN/-

*PE

133 Connection analog output 1, +

134 Connection analog output 1, -

233 Connection analog output 2, +

234 Connection analog output 2, -

Power supply Wide range power supply 24 V to 230 V AC/DC (-20 % / +10 %) 50/60 Hz

R11, R12, R13 Connection relay 1

R21, R22, R23 Connection relay 2

Note!

The controller has no power switch

• A clearly marked mains disconnecting device must be installed in the vicinity of the instrument.

• Protect the controller by an appropriate fuse.

a0015303

Power consumption Max. 13.8 VA / 6.6 W

6 Endress+Hauser

Page 7

Liquiline CM14

92 (3.62)

45 (1.77)

mm (inch)

Performance characteristics

Response time Current output

t90 = max. 500 ms for an increase from 4 to 20 mA

Reference temperature 25 °C (77 °F)

Measuring error, input --> Documentation of the connected sensor

Resolution current output > 13 bit

Repeatability --> Documentation of the connected sensor

Installation conditions

Installation instructions Mounting location

Panel, cutout 92 x 45 mm (3.62 x 1.77 ")

Max. panel thickness 26 mm (1")

Mounting orientation

The mounting orientation is determined by the display readability

Max. angle of view +/- 45° of the display center axis in each direction.

Panel cutout

Environment

Ambient temperature range –10 to +60 °C (14 to 140 °F)

Storage temperature range –40 to +85 °C (-40 to 185 °F)

Altitude <2000 m (6561 ft) above sea level

Electromagnetic compatibility Interference emission and interference immunity as per EN 61326-1:2006, class A for industrial use

Ingress protection Front

IP65 / NEMA 4X

Body

Protection against contact IP20

Relative humidity 5 to 85 %, non-condensing

a0010351

Endress+Hauser 7

Page 8

Dimensions

96 (3.78)

48 (1.89)

16.7

(0.66)

151.8 (5.98)

118.6 (4.67)

41.9 (1.65)

43.9 (1.73)

90.9 (3.56)

88.9 (3.50)

mm (inch)

Liquiline CM14

Mechanical construction

Dimensions

Weight 0.3 kg (0.66 lbs)

Materials

Housing, body: Polycarbonate

Front membrane: Polyester, UV resistant

Terminals

max. 2.5 mm

2

(22-14 AWG; torque: 0.4 Nm (3.5 lb in)) Mains, relays

a0015302

8 Endress+Hauser

Page 9

Liquiline CM14

Operating elements

Operability

Display and operating elements

1 LC display for measuring values and configuration data

2 Status LED power connected

3 Status LED alarm function

4 Status LED limit contactor relay 1

5 Status LED limit contactor relay 2

6 Dot matrix display for measuring units and menu positions

7Operating keys

Certificates and approvals

4 mark Declaration of conformity

The product meets the requirements of the harmonized European standards. It thus complies with the legal

requirements of the EC directives.

The manufacturer confirms successful testing of the product by affixing the 4 symbol.

a0015311

Endress+Hauser 9

Page 10

Ordering information

Liquiline CM14

Product structure

CM14- order code

HC PWIS free, PWIS = paint- wetting impairment substances

LU UL listed

Z1 Tagging (TAG), see additional spec.

Approval

AA Non-hazardous area

CA CSA C/US general purpose

Sensor input

K Digital, Memosens conductivity conductive

L Digital, Memosens conductivity inductive

M Digital, Memosens pH, ORP (glass)

O Digital, Memosens oxygen amperom.

Service

Additional approval

Marking

Note!

To complete your order code, simply add the optional features to the end of order code. If you have any

questions, please contact your local sales office.

Scope of delivery The scope of delivery comprises:

• Controller CM14 in ordered version

• Installation kit

• Operating instructions

10 Endress+Hauser

Page 11

Liquiline CM14

Accessories

Measuring cable CYK10 Memosens data cable

• For digital sensors with Memosens technology

• Ordering according to product structure, see Technical Information (TI376C/07/en)

Sensors Glass electrodes pH measurement

Orbisint CPS11D

• pH electrode for process applications with Memosens technology

• Dirt-repellent PTFE diaphragm

• Ordering acc. to product structure, see Technical Information (TI028C/07/en)

Orbipore CPS91D

• pH sensor with Memosens technology

• With open aperture for media with high dirt load

• Ordering acc. to product structure, see Technical Information (TI375C/07/en)

Orbipac CPF81D

• Compact pH sensor for installation or immersion operation in process water and wastewater

• Ordering acc. to product structure, see Technical Information (TI191C/07/en)

ORP sensors

Orbisint CPS12D

• ORP sensor with Memosens technology

• Dirt-repellent PTFE diaphragm

• Ordering acc. to product structure, see Technical Information (TI367C/07/en)

Orbipore CPS92D

• ORP sensor with Memosens technology

• With open aperture for media with high dirt load

• Ordering acc. to product structure, see Technical Information (TI435C/07/en)

Orbipac CPF82D

• Compact ORP sensor for installation or immersion operation in process water and wastewater

• Ordering acc. to product structure, see Technical Information (TI191C/07/en)

Conductivity sensors, conductive

Condumax W CLS15D

• For measurement in pure and ultrapure water and in Ex applications

• Ordering according to product structure, see Technical Information TI109C/07/en

Condumax H CLS16D

• Hygienic sensor for measurement in pure and ultrapure water and in Ex applications

• With EHEDG and 3A certificates

• Ordering according to product structure, see Technical Information TI227C/07/en

Condumax W CLS21D

• Two-electrode sensor in fixed cable and plug-in head version

• Ordering according to product structure, see Technical Information TI085C/07/en

Conductivity sensors, inductive

Indumax CLS50D

• High-stability inductive conductivity sensor for standard, Ex and high-temperature applications

• Memosens technology

• Order as per product structure, see Technical Information TI182C/07/en

Oxygen sensors

Oxymax COS51D

• Amperometric sensor for dissolved oxygen, with Memosens technology

• Ordering acc. to product structure, see Technical Information (TI413C/07/en)

Oxymax H COS22D

• Sterilizable sensor for dissolved oxygen, with Memosens technology

• Ordering acc. to product structure, see Technical Information (TI446C/07/en)

Endress+Hauser 11

Page 12

TI494C/07/EN/01.11

71132861

Printed in Germany / FM+SGML 6.0 / DT

Loading...

Loading...