Page 1

TI01188C/07/EN/04.17

71358714

Products

Solutions Services

Technical Information

Memosens CLS82D

Hygienic conductivity sensors, digital with

Memosens technology, cell constant k = 0.57 cm

-1

Application

For measurements where very diverse conductivities must be measured by one

measuring system.

Typical applications include:

• Phase separations

• Chromatography

• Fermentations

• CIP monitoring in small pipes

• Ultrafiltration

Your benefits

• High measuring accuracy as cell constant is individually measured

• Quality certificate stating the individual cell constant

• Hygienic process connections for installation in pipes or flow vessel

• IP68 protection

• Easy to clean thanks to electropolished surfaces

• Can be sterilized up to 140 °C (284 °F)

• Stainless steel 1.4435 (AISI 316L) meets the highest demands of the

pharmaceutical industry

• The entire sensor is EHEDG- and 3A-certified

• FDA conformity

Other advantages of Memosens technology

• Maximum process safety thanks to non-contact, inductive signal transmission

• Data security thanks to digital data transmission

• Very easy to use as sensor data saved in the sensor

• Recording of sensor load data in the sensor enables predictive maintenance

Page 2

Function and system design

U

G

I

+

+

+

+

+

+

+

-

-

-

-

-

-

-

2

3

Memosens CLS82D

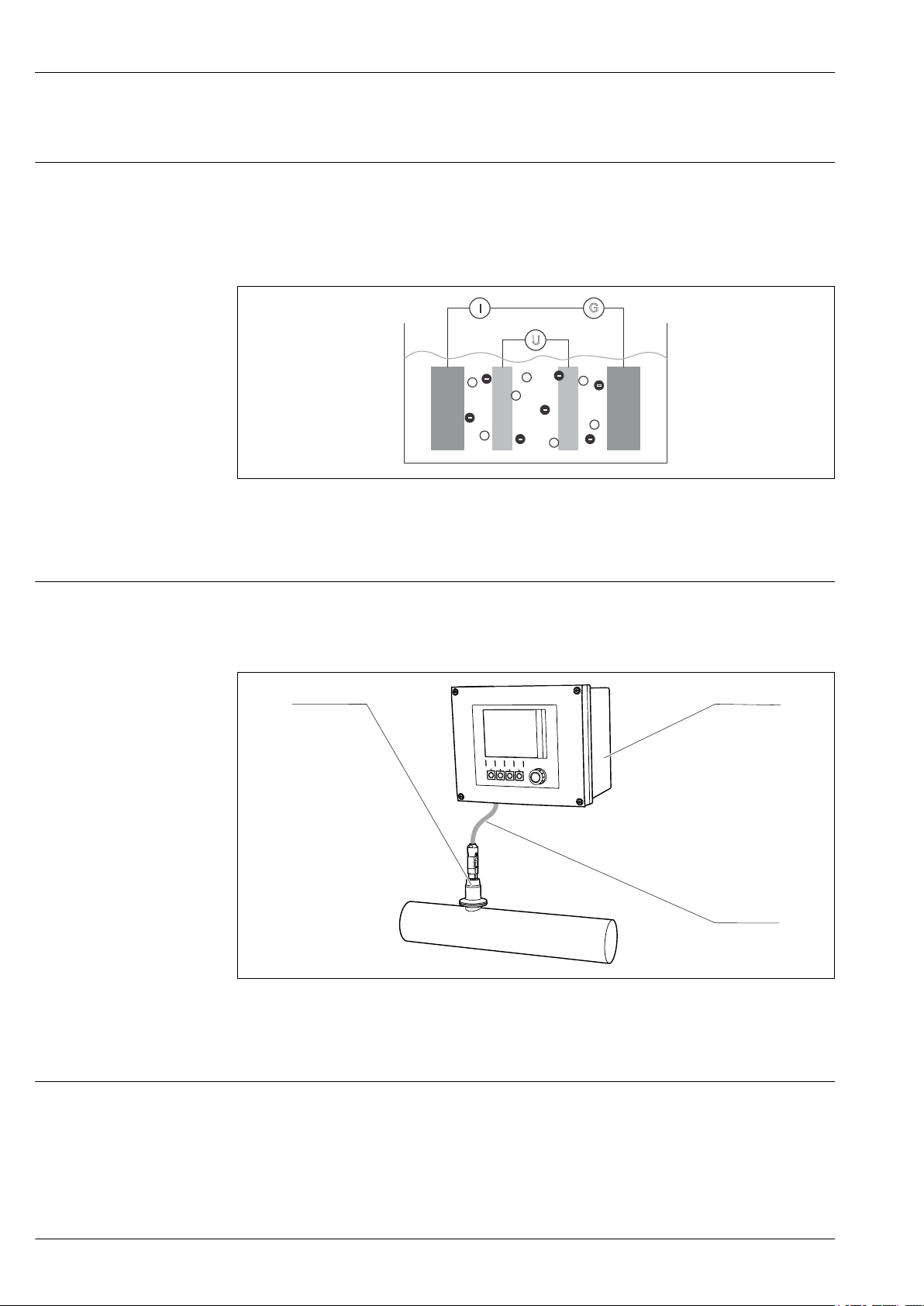

Measuring principle

Measuring system

The measuring cell has four electrodes. An alternating current is applied via the outer electrode pair.

At the same time, the voltage applied is measured at the two inner electrodes. The electrolytic

conductivity between the electrodes can be reliably established based on the measured voltage and

the current flow caused by the liquid's resistance. The advantage of this technology compared to

traditional two-electrode sensors is that electrochemical effects at the live electrodes are suppressed

by the two additional voltage measuring electrodes.

A0024312

1 Conductivity measurement

I Current intensity measurement

U Voltage measurement

G Generator

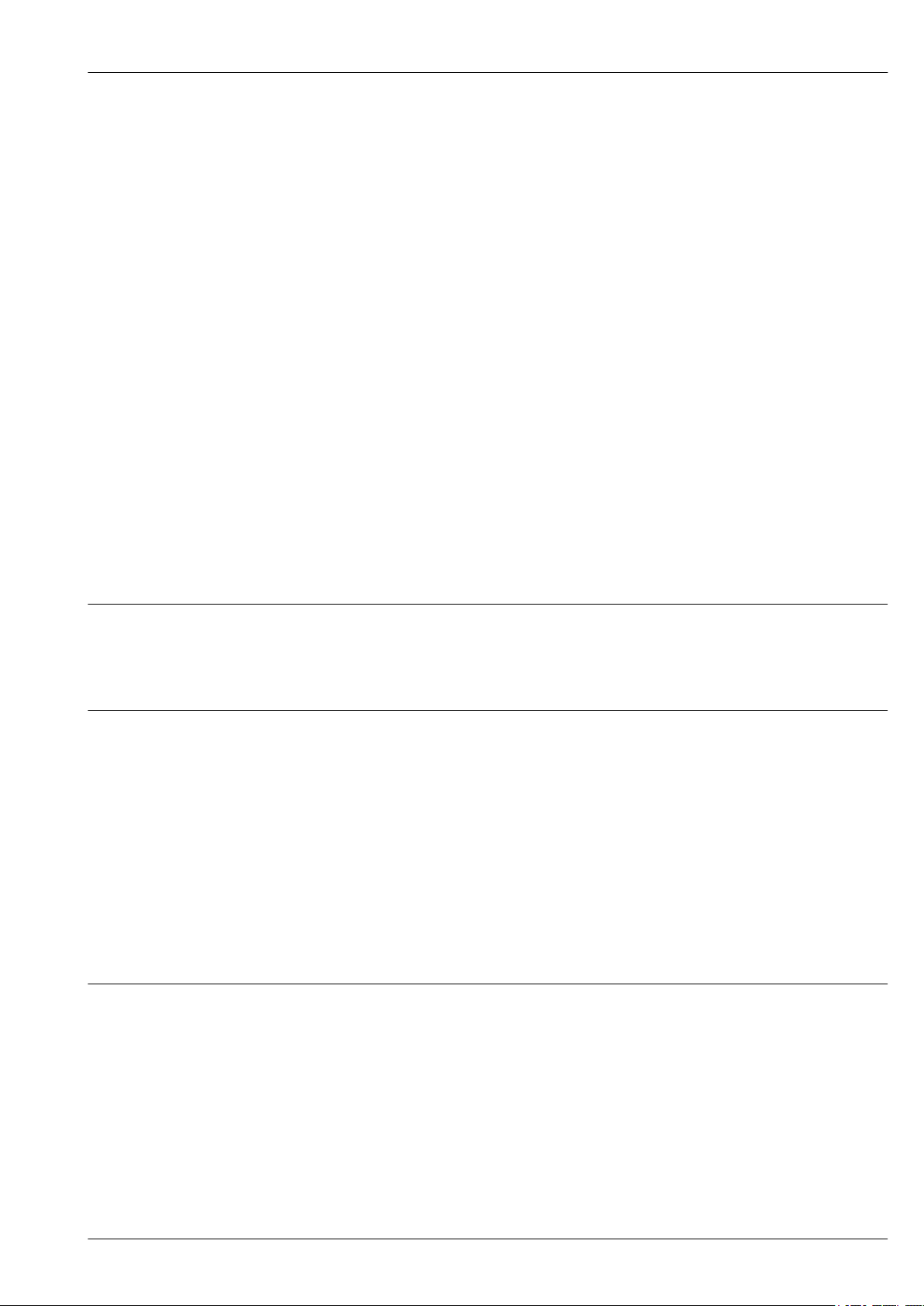

A complete measuring system consists of the following components at least:

• Conductive conductivity sensor CLS82D

• A transmitter, e.g. Liquiline CM44x

• A Memosens data cable CYK10

A0024179

2 Example of a measuring system

1 Memosens CLS82D

General properties

2 Liquiline CM44x transmitter

3 Measuring cable

Temperature measurement

In addition, a temperature probe is fitted in the sensor element to measure the temperature.

2 Endress+Hauser

Page 3

Memosens CLS82D

Communication and data processing

Communication with the transmitter

Always connect digital sensors with Memosens technology to a transmitter with Memosens

technology. Data transmission to a transmitter for analog sensors is not possible.

Digital sensors can store measuring system data in the sensor. These include the following:

• Manufacturer data

– Serial number

– Order code

– Date of manufacture

• Calibration data

– Calibration date

– Cell constant

– Delta cell constant

– Number of calibrations

– Serial number of the transmitter used to perform the last calibration

• Operating data

– Temperature application range

– Conductivity application range

– Date of initial commissioning

– Maximum temperature value

– Hours of operation at high temperatures

Dependability

Serviceability

Interference immunity

Reliability

Memosens technology digitizes the measured values in the sensor and transmits the data to the

transmitter using a non-contact connection that is free from potential interference. The result:

• Automatic error message if sensor fails or connection between sensor and transmitter is

interrupted

• Immediate error detection increases measuring point availability

Easy handling

Sensors with Memosens technology have integrated electronics that store calibration data and other

information (such as total hours of operation and operating hours under extreme measuring

conditions). Once the sensor has been connected, the sensor data are transferred automatically to

the transmitter and used to calculate the current measured value. As the calibration data are stored

in the sensor, the sensor can be calibrated and adjusted independently of the measuring point. The

result:

• Easy calibration in the measuring lab under optimum external conditions increases the quality of

the calibration.

• Pre-calibrated sensors can be replaced quickly and easily, resulting in a dramatic increase in the

availability of the measuring point .

• Maintenance intervals can be defined based on all stored sensor load and calibration data and

predictive maintenance is possible.

• The sensor history can be documented on external data carriers and in evaluation programs. Thus,

the current application of the sensors can be made to depend on their previous history.

With inductive transmission of the measured value using a non-contact connection, Memosens

guarantees maximum process safety and offers the following benefits:

• All problems caused by moisture are eliminated.

– Plug-in connection remains free from corrosion

– Measured value distortion from moisture is not possible.

– The plug-in system can even be connected under water.

• The transmitter is galvanically decoupled from the medium.

• EMC safety is guaranteed by screening measures for the digital transmission of measured values.

Endress+Hauser 3

Page 4

Input

GN/YE

YE

GN

BN

WH

GND

+

–

Com A

Com B

GY

Memosens CLS82D

Measured variable

Measuring range

Cell constant

Temperature compensation

Electrical connection

• Conductivity

• Temperature

Conductivity

1 µS/cm to 500 mS/cm

Temperature

-5 to 120 °C (23 to 248 °F)

CLS82D

k = 0.57 cm

-1

Pt1000 (Class A according to IEC 60751)

Power supply

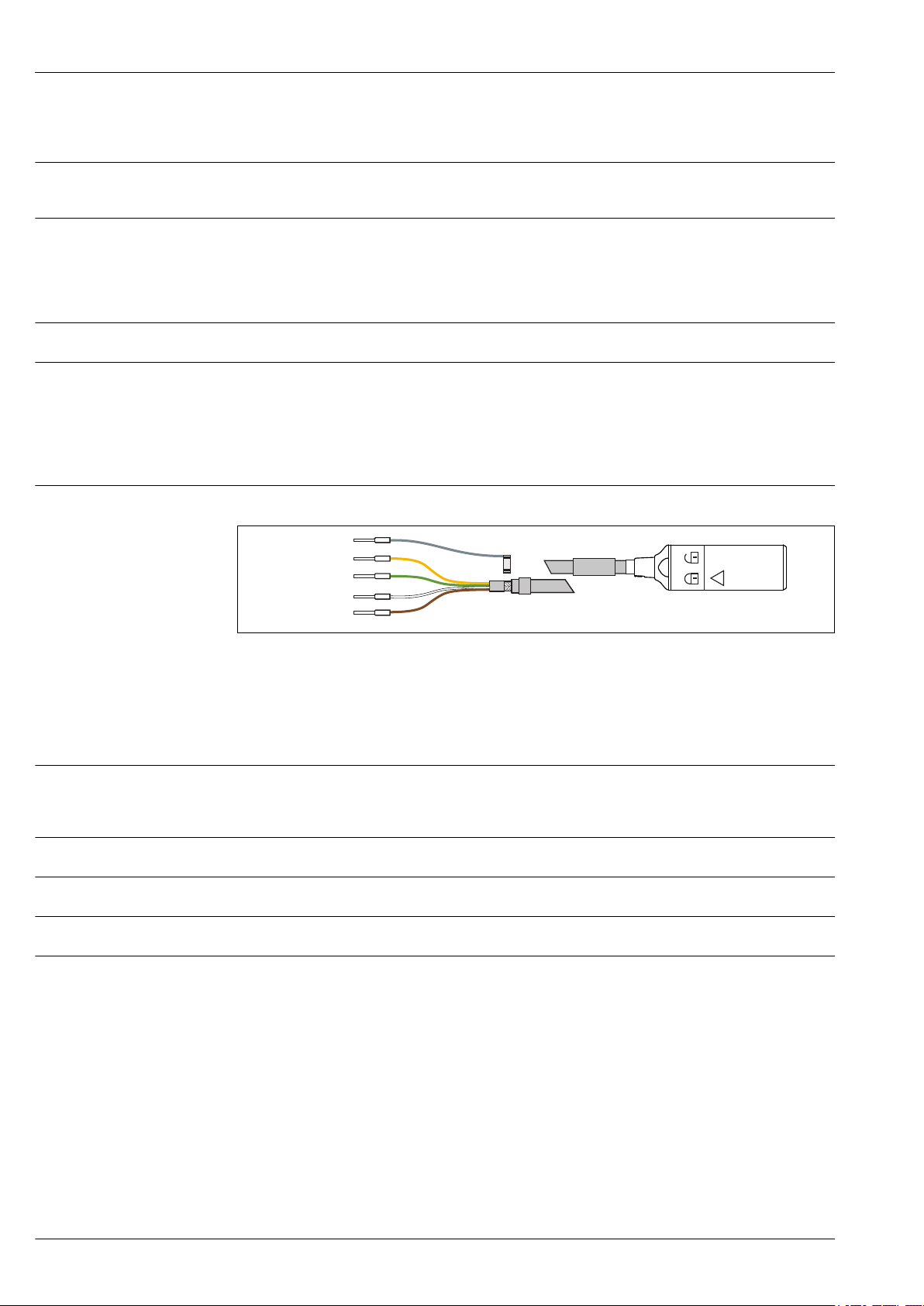

The sensor is connected to the transmitter via measuring cable CYK10.

Uncertainty of measurement

Conductivity response time

Temperature response time

Maximum measured error

Repeatability

A0024019

3 Measuring cable CYK10

Performance characteristics

Each individual sensor is factory-measured in a solution of approx. 50 μS/cm using a reference

measuring system traceable to NIST or PTB. The exact cell constant is entered into the quality

certificate supplied. The uncertainty of measurement in determining the cell constant is 1.0 %.

t90 ≤ 3 s

t90 ≤ 25 s

≤ 4 % of reading

0.2% of reading

4 Endress+Hauser

Page 5

Memosens CLS82D

a 15≥

1

2

3

b

a

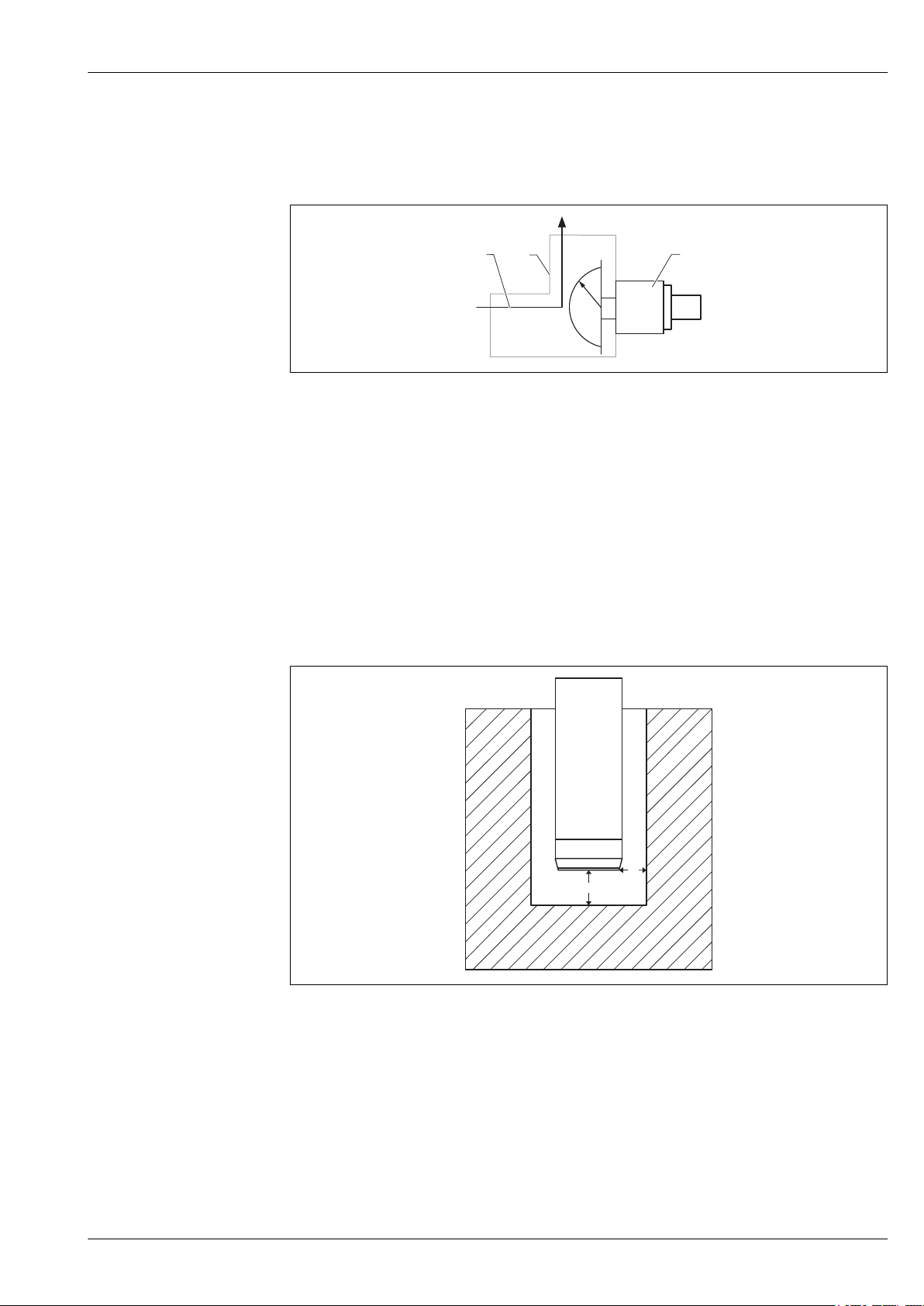

Installation

Symmetrical installation is recommended in order to guarantee linearity. The distance to the side

walls and opposite walls must be at least 15 mm.

A0024621

4 Minimum distance between pipe and end of the measuring cell

1 Sensor CLS82D

2 Pipe

3 Direction of flow

The ionic current in the liquid is affected by the walls in confined installation conditions. This effect

is compensated by what is referred to as the installation factor. The installation factor can be entered

in the transmitter for the measurement or the cell constant is corrected by multiplying by the

installation factor.

The value of the installation factor depends on the diameter and the conductivity of the pipe nozzle

as well as the sensor's distance to the wall. The installation factor can be disregarded (f = 1.00) if the

distance to the wall is sufficient (a > 15 mm). If the distance to the wall is smaller, the installation

factor increases for electrically insulating pipes (f > 1) and decreases for electrically conductive pipes

(f < 1). The installation factor can be determined using calibration solutions.

A0024626

5 Schematic drawing of the CLS82D in confined installation conditions

a Wall distance

b Gap width

Endress+Hauser 5

Page 6

5

10

15 20

3

f

1

2

0.12

a [inch]

0.20

0.39

0.59

0.79

a [ ]mm

6 Relationship between installation factor f and wall distance a

0.94

0.96

0.98

1.00

1.02

1.04

1.06

3

5

10 15 20

0.12

b [inch]

0.20

0.39

0.59

0.79

b [mm]

f

1

2

1 Electrically insulating pipe wall

2 Electrically conductive pipe wall

Memosens CLS82D

A0034378

7 Relationship between installation factor f and gap width b

1 Electrically insulating pipe wall

2 Electrically conductive pipe wall

Hygienic properties

For a 3-A compliant installation, the following must be noted:

After the instrument is installed its hygienic integrity shall be maintained. All process

connections must be 3-A compliant.

6 Endress+Hauser

A0024616

Page 7

Memosens CLS82D

6

87

–5

20 60 100 120

60

23

60

120

180

240

248

4

8

12

16

20 1 04

T [°C]

p [bar]

T [° ]F

p [ ]psi

A

284

17

247

9

131

1

15

absolute

Environment

Ambient temperature range

Storage temperature

Humidity

Degree of protection

Process temperature

Process pressure (absolute)

Pressure-temperature ratings

-20 to +60 °C (-4 to 140 °F)

-25 to +80 °C (-13 to +176 °F)

5 to 95 %

IP 68 / NEMA type 6P (1 m water column, 25 °C, 168 h)

Process

Normal operation:

Sterilization (max. 45 min.): Max. 140 °C (284 °F) at 6 bar (87 psi)

The maximum temperature for communication with the transmitter is 130 °C (266 °F).

17 bar (247 psi) at 20 °C (68 °F)

9 bar (131 psi) at 120 °C (248 °F)

-5 to 120 °C (23 to 248 °F)

8 Pressure-temperature ratings

A Can be sterilized for a short time (45 min.)

Endress+Hauser 7

A0034375-EN

Page 8

Design, dimensions

97 (3.82)

22 (0.87)

10 (0.39)

Ø 11.9 (0.47)

Ø 84 (3.31)

97 (3.82)

22 (0.87)

10 (0.39)

Ø 11.9 (0.47)

Ø 66 (2.60)

Ø 24.9

(0.98)

157.3 (6.19)

Ø 44.5

(1.75)

Ø 11.9 (0.47)

71 (2.80)

48.8 (1.92)

24.2

(1.0)

51.5 (2.02)

29.3

Ø 11.9

(0.47)

Ø 24.9

(0.98)

Ø 44.5

(1.75)

137.8 (5.43)

(1.15 )

24.2

(1.0)

Memosens CLS82D

Mechanical construction

9 Varivent N DN 40 - DN 125

11 DN 25 brown

A0034365

10 Varivent F DN 25

A0028461

12 DN 25 standard

A0024209

A0028462

8 Endress+Hauser

Page 9

Memosens CLS82D

155 (6.10)

Ø 11.9 (0.47)

G1

78 (3.07)

53 (2.09)

22 (0.87)

Ø 66 (2.60)

155 (6.10)

78 (3.07)

53 (2.09)

Ø 11.9 (0.47)

NPT1"

Ø 66 (2.60)

22 (0.87)

103 (4.06)

Ø 11.9 (0.47)

Ø 50.5 (1.99)

25 (0.98)

103 (4.06)

Ø 11.9 (0.47)

Ø 64 (2.52)

25 (0.98)

50 (1.97)

120 (4.72) / 215 (8.46)

Ø11.9 (0.47)

Ø 11.9

(0.47)

100.1 (3.94)

21 (0.83)

Ø 64 (2.52)

10 (0.39)

13 G1

15 Clamp 1.5"

A0034363

A0034361

A0034364

14 NPT1"

A0034362

16 Clamp 2"

17 Pg 13.5

All designs are supplied without a process seal.

A0034286

18 BioControl DN 25

A0028463

Endress+Hauser 9

Page 10

Memosens CLS82D

Weight

Materials in contact with the medium

Surface roughness

Ex approval

Approx. 0.06 to 0.950 kg (0.13 to 2.09 lbs) depending on the version

Sensor element: Platinum and ceramic (zirconium oxide)

Process connection: Stainless steel 1.4435 (AISI 316L)

Only for CLS82D-**NA*

Seal: EDPM

1) 1. Connection: DN25 standard

2) 2. Connection: DN25 brown

Ra < 0.38 µm

1)

and CLS82D-**NB*

2)

:

Certificates and approvals

Ex approvals in conjunction with the Liquiline CM42 transmitter

• ATEX II 1G Ex ia IIC T3/T4/T6 Ga

• CSA IS/NI Cl.1 Div.1&2 Grp.:A-D

• FM IS/NI Cl.1 Div.1&2 Grp.:A-D

• NEPSI Ex ia IIC T3/T4/T6 Ga

• TIIS Ex ib IIC T4

• EAC Ex, OEx ia IIC T6/T4/T3 GaX

All of the Ex versions listed here are identified by an orange-red ring on the plug-in head.

EHEDG

FDA

Quality certificate

Pharma CoC (optional)

Inspection certificate in acc. with EN10204-3.1 (optional)

ASME BPE-2002

Hygienic process connections Clamp 1.5'', Clamp 2'', Varivent F, Varivent N and BioControl DN

25 are certified in accordance with EHEDG, Document 8

Validated as follows:

• Cleanability in accordance with EHEDG, Document 2

• Sterilizability in accordance with EHEDG, Document 5

• Bacteria-tightness in accordance with EHEDG, Document 7

The CLS82D with process connection Pg 13.5 in conjunction with Unifit CPA442 is certified in

accordance with EHEDG, Document 8

Validated as follows:

Cleanability in accordance with EHEDG, Document 2

All materials in contact with the product are FDA-compliant.

Stating the individual cell constant

Certificate of conformity for pharmaceutical requirements, confirms conformity with biological

reactivity test USP Class VI, FDA material conformity, TSE-/BSE-free, surface roughness

• Concerning material traceability

Available for all process connections

• Concerning surface roughness

Available for all hygienic process connections

Manufactured in accordance with ASME criteria (American Society of Mechanical Engineers)

3-A

Regulation (EC) No. 1935/2004

Meets the requirements of 3-A Sanitary Standards.

Meets the requirements of Regulation (EC) No. 1935/2004

10 Endress+Hauser

Page 11

Memosens CLS82D

Ordering information

Product page

Product Configurator

www.endress.com/cls82d

On the product page there is a "Configure" button to the right of the product image Configure.

1. Click this button.

The Configurator opens in a separate window.

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button on the right

above the selection window.

For many products you also have the option of downloading CAD or 2D drawings of the

selected product version. Click the tab for this CAD and select the desired file type using

picklists.

Endress+Hauser 11

Page 12

Accessories

Ø25(0.98)

G1¼

Ø28 (1.1)

49(1.93) / 30(1.18)

44(1.73) /

24.5(0.96)

59 (1.97) / 39 (1.18)

15°

G1¼

Ø25(0.98)

44(1.73) /

24.5(0.96)

50(1.97) / 30(1.18)

Ø28(1.1)

Memosens CLS82D

Seals

Welding socket

Only for CLS82D-**NA*

1)

and CLS82D-**NB*

2)

:

• EPDM seals for CLS82D (x 2; FDA USP Class VI); Order No. 71307106

• FKM (Viton®) seals for CLS82D (x 2; FDA USP Class VI); Order No. 71307105

• Silicone seals for CLS82D (x 2, FDA USP Class VI); Order No. 71307107

A0034415

• Safety welding socket DN25, straight, stainless steel 1.4435, L=30; Order No. 51508051

Only for CLS82D-**NA*

• Safety welding socket DN25, angled, stainless steel 1.4435, L=30/40; Order No. 51508052

Only for CLS82D-**NA*

• Safety welding socket DN25, straight, stainless steel 1.4435, L=50; Order No. 51508049

Only for CLS82D-**NB*

• Safety welding socket DN25, angled, stainless steel 1.4435, L=50/60; Order No. 51508050

Only for CLS82D-**NB*

1)

1)

2)

2)

Existing standard welding sockets (for CPA440 / CPA441 / CPA460), Order Nos. 50005192

and 50028446, are also suitable for sensor CLS82D.

A0034416

Connection

CYK10 Memosens data cable

• For digital sensors with Memosens technology

• Product Configurator on the product page: www.endress.com/cyk10

Technical Information TI00118C

Memosens data cable CYK11

• Extension cable for digital sensors with Memosens protocol

• Product Configurator on the product page: www.endress.com/cyk11

Technical Information TI00118C

1) Process connection: DN25 standard

2) Process connection: DN25 brown

12 Endress+Hauser

Page 13

Memosens CLS82D

Calibration solutions

Calibration set

Conductivity calibration solutions CLY11

Precision solutions referenced to SRM (Standard Reference Material) by NIST for qualified

calibration of conductivity measuring systems in accordance with ISO 9000

• CLY11-A, 74 μS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081902

• CLY11-B, 149.6 μS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081903

• CLY11-C, 1.406 mS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081904

• CLY11-D, 12.64 mS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081905

• CLY11-E, 107.00 mS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081906

Technical Information TI00162C

Conducal CLY421

• Conductivity calibration set (case) for ultrapure water applications

• Complete, factory-calibrated measuring system with certificate, traceable to SRM by NIST and PTB,

for comparison measurement in ultrapure water up to max. 20 μS/cm

• Product Configurator on the product page: www.endress.com/cly421

Technical Information TI00496C/07/EN

Recalibration

• The conductivity calibration set must be calibrated regularly onsite at the manufacturer's

depending on the frequency of use and operating conditions.

• Recommended period: 1 year

Endress+Hauser 13

Page 14

Page 15

Page 16

www.addresses.endress.com

Loading...

Loading...