Page 1

TI00109C/07/EN/14.14

71268306

Products Solutions Services

Technical Information

Condumax CLS15D/CLS15

Conductivity sensors, analog or digital with

Memosens technology

Cell constant k = 0.01 cm–1 or k = 0.1 cm

Application

Measurement in pure and ultrapure water range:

• Monitoring of ion exchangers

• Reverse osmosis

• Distillation

• Chip cleaning

Sensors with temperature probes are used in conjunction with conductivity

measuring devices that support automatic temperature compensation:

• Liquiline CM442/CM444/CM448 (only CLS15D)

• Liquiline CM42

• Liquiline CM14 (only CLS15D)

• Liquisys CLM223/253 (only CLS15)

• Mycom CLM153 (only CLS15)

The resistivity in MΩ · cm can also be measured using these transmitters.

Your benefits

• High measuring accuracy as cell constant is individually measured

• Installation in pipe or flow assembly

• Compact design

• With plug-in head (IP68 (CLS15D), IP67 (CLS21)) or fixed cable (IP67)

• Easy to clean thanks to electropolished surfaces

• Sterilizable up to 140 °C (284 °F)

• Stainless steel 1.4435 (AISI 316L)

• Quality certificate stating the individual cell constant

• Inspection certificate EN 10204 3.1 (optional)

Other advantages of Memosens technology

• Maximum process safety owing to non-contact, inductive signal transmission

• Data security thanks to digital data transmission

• Very easy to use as sensor data saved in the sensor

• Predictive maintenance possible as sensor load data logged in the sensor

–1

Page 2

Function and system design

AC

I

U

1

2

3

Condumax CLS15D/CLS15

Measuring principle

Measuring system

Conductivity of liquids is determined with a measuring

arrangement where two electrodes are located in the

medium. An alternating voltage that causes a current

to flow through the medium is applied at these

electrodes. The electrical resistance, or its reciprocal

value - conductance G - is calculated based on Ohm's

law. The specific conductance κ is determined from the

conductance value using the cell constant k, which

depends on the sensor geometry.

A0024260

1 Conductive measurement of conductivity

AC Alternating voltage source

I Current intensity measurement

U Voltage measurement

A complete measuring system comprises the following components at least:

• The conductively measuring conductivity sensor CLS15D or CLS15

• A transmitter, e.g. Liquiline M CM42

• A measuring cable, e.g. Memosens data cable CYK10 or CYK71 for analog sensors

2 Example of a measuring system (with Memosens sensor)

1 Liquiline M CM42 transmitter

2 Memosens data cable

3 Condumax CLS15D

2 Endress+Hauser

A0022850

Page 3

Condumax CLS15D/CLS15

Communication and data processing (only CLS15D)

Communication with the transmitter

Always connect digital sensors with Memosens technology to a transmitter with Memosens

technology. Data transmission to a transmitter for analog sensors is not possible.

Digital sensors are able to store the following system data in the sensor

• Manufacturing data

– Serial number

– Order code

– Date of manufacture

• Calibration data

– Calibration date

– Cell constant

– Delta cell constant

– Number of calibrations

– Serial number of the transmitter used for the last calibration

• Application data

– Temperature application range

– Conductivity application range

– Date of first commissioning

– Maximum temperature value

– Hours of operation at high temperatures

Reliability

Maintainability

Integrity

Dependability (only CLS15D)

Memosens technology digitizes the measured values in the sensor and transmits the data to the

transmitter using a non-contact connection that is free from potential interference. The result:

• Automatic error message if sensor fails or connection between sensor and transmitter is

interrupted

• Immediate error detection increases measuring point availability

Easy handling

Sensors with Memosens technology have integrated electronics that allow for saving calibration data

and further information such as total hours of operation and operating hours under extreme

measuring conditions. Once the sensor has been connected, the sensor data are transferred

automatically to the transmitter and used to calculate the current measured value. As the calibration

data are stored in the sensor, the sensor can be calibrated and adjusted independently of the

measuring point. The result:

• Easy calibration in the measuring lab under optimum external conditions increases the quality of

the calibration.

• Pre-calibrated sensors can be replaced quickly and easily, resulting in a dramatic increase in the

availability of the measuring point .

• Maintenance intervals can be defined based on all stored sensor load and calibration data and

predictive maintenance is possible.

• The sensor history can be documented on external data carriers and evaluation programs at any

time. Thus, the current application of the sensors can be made to depend on their previous history.

With inductive transmission of the measured value using a non-contact connection, Memosens

guarantees maximum process safety and offers the following benefits:

• All problems caused by moisture are eliminated.

– Plug-in connection free from corrosion

– Measured value distortion from moisture is not possible.

– The plug-in system can even be connected under water.

• The transmitter is galvanically decoupled from the medium.

• EMC safety is guaranteed by screening measures for the digital transmission of measured values.

Endress+Hauser 3

Page 4

Input

GN/YE

YE

GN

BN

WH

GND

+

–

Com A

Com B

GY

GN/YE

Outer shield

(see wiring diagram

of transmitter)

YE

GN

WH

Pt 100

Coax BK

Coax inner

shield (outer electrode)

BN n.c.

conductivity (inner electrode)

}

Cable

}

GY

Sensor

Plug

2

3

1

)

Condumax CLS15D/CLS15

Measured variables

• Conductivity

• Temperature

Measuring ranges

Conductivity (in relation to water at 25 °C (77 °F))

CLS15D/CLS15-A 0.04 to 20 μS/cm

CLS15D/CLS15-B 0.10 to 200 μS/cm

Temperature

CLS15D

CLS15

Cell constant

CLS15D/CLS15-A

CLS15D/CLS15-B k = 0.1 cm

Temperature compensation

NTC 30K (CLS15D)

Pt 100 (class A as per IEC 60751) (CLS15)

Power supply

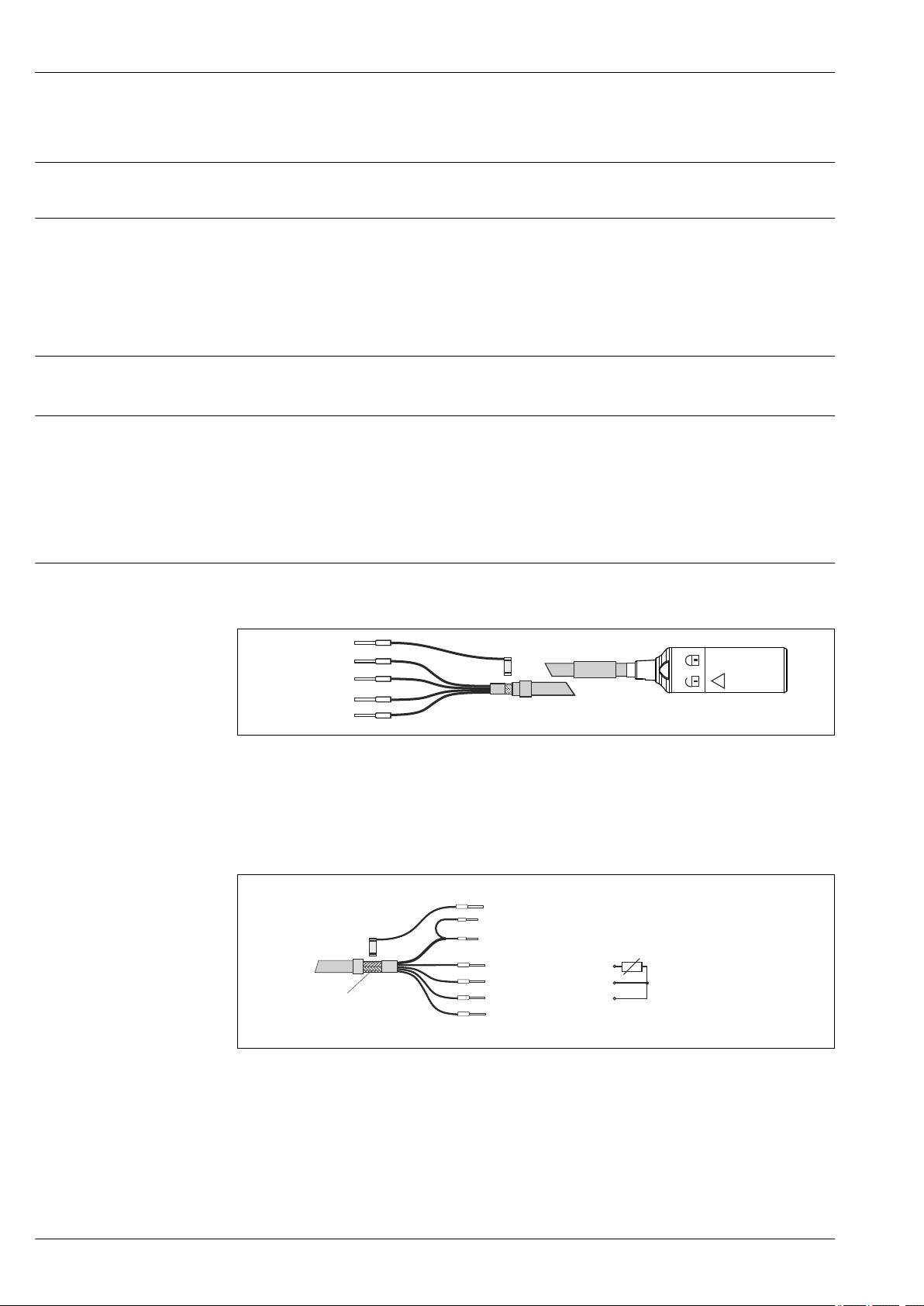

Electrical connection CLS15D

The sensor is electrically connected to the transmitter via the CYK10 measuring cable.

-20 to 100 °C (-4 to 212 °F)

-20 to 140 °C (-4 to 280 °F)

k = 0.01 cm

–1

–1

3 Measuring cable CYK10

CLS15

The sensor is connected via the fixed cable or via the CYK71 measuring cable with a shield. The

wiring diagram is provided in the Operating Instructions of the transmitter used.

4 Measuring cable CYK71

A compatible cable connector is included in the delivery for the plug-in head versions. You must

terminate the CYK71 cable (not included in the delivery) with the cable connector at the sensor end

according to the connection diagram above.

4 Endress+Hauser

A VMB junction box and another CYK71 cable are required for the cable extension.

A0024019

A0024205-EN

Page 5

Condumax CLS15D/CLS15

Performance characteristics, general

Uncertainty of measurement

Response time

Maximum measured error

Repeatability

Each individual sensor is factory-measured in a solution of approx. 5 μS/cm for cell constant

0.01 cm-1 or approx. 50 μS/cm for cell constant 0.1 cm-1 using a reference measuring system

traceable to NIST or PTB. The exact cell constant is entered into the quality certificate supplied. The

uncertainty of measurement in determining the cell constant is 1.0 %.

Performance characteristics (only CLS15D)

Conductivity

Temperature

CLS15D-A t90 ≤ 39 s

CLS15D-B t90 ≤ 17 s

2% of reading

0.2% of reading

t95 ≤ 3 s

Endress+Hauser 5

Page 6

Installation

2

1

3

35 (1.38)

½”NPT

160 (6.30)

Ø 29 (1.14)

Ø 6 (0.24)

30 (1.18)

25 (0.98)

Ø 6 (0.24)

38.5

(1.52)

1

2

3

Condumax CLS15D/CLS15

Installation instructions

The sensors are installed directly via the process connection thread NPT ½" or ¾" or Clamp 1 ½". As

an option, the sensor can also be installed using a commercially available T-piece or cross fitting or

using a flow assembly.

CLS15D is depicted in the graphics. The analog sensor is only different in terms of its terminal head.

Ambient temperature range

Storage temperature

Humidity

Degree of protection

A0019015

5 With NPT ½" thread in T-piece or cross

fitting

1 T-piece or cross fitting (DN 32, 40 or 50)

2 Glue-in VC threaded coupling (NPT ½" for DN

20, see "Accessories")

3 Glue-in adapter coupling (for DN 32, 40, 50, see

"Accessories")

Environment

-20 to +60 °C (0 to 140 °F)

-25 to +80 °C (-10 to +180 °F)

5 to 95 %

CLS15D

CLS15 IP 67 / NEMA 6

IP 68 / NEMA type 6P (1 m water column, 25 °C, 24 h)

A0019014

6 With NPT ½" thread in flow assembly

71042405, dimensions in mm (inch)

1 Sensor holder NPT ½"

2 Inlet

3 Outlet

6 Endress+Hauser

Page 7

Condumax CLS15D/CLS15

A

14010060

68

20

-4

180 220 260

248

284

14

43

72

101

130

159

188

[psi]

[°F]

–20

1

[bar]

3

5

7

9

11

13

0 20 40 60 80 100 120 140

[°C]

212

p (abs.)

T

A

14010060

68

20

-4

180 220 260

248

284

–20

0 20 40 60 80 100 120 140

B

212

[psi]

[°F]

[bar]

[°C]

p (abs.)

T

14

43

72

101

130

159

188

1

3

5

7

9

11

13

Process

Process temperature

Process pressure (absolute)

Temperature-pressure ratings

Threaded version with fixed cable -20 to 100 °C (-4 to 212 °F)

Threaded version with plug-in head, Clamp version

Normal operation -20 to 120 °C (-4 to 248 °F)

Sterilization (max. 1 h)

1) Threaded versions: max. 30 minutes

1)

max. 140 °C (284 °F)

The maximum temperature for communication with the transmitter is 130 °C (266°F) for the

Memosens versions.

CLS15D/CLS15

13 bar (188 psi) at 20 °C (68 °F)

1 bar (14 psi) at 120 °C (248 °F)

CLS15D

Endress+Hauser 7

7 Mechanical pressure-temperature resistance

A Can be sterilized for a short time (1 hour)

CLS15

8 Mechanical pressure-temperature resistance

A Can be sterilized for a short time (1 hour)

B Threaded version with fixed cable

A0024165

A0024885

Page 8

Design CLS15D

}

1

4

2

3

5

}

1

2

3

4

5

1

2

3

4

}

Condumax CLS15D/CLS15

Mechanical construction

A0024268

9 CLS15D

1 Memosens plug-in head

2 Wrench flats for mounting

3 Minimum immersion depth

4 Coaxial measuring electrodes

5 Process connection (thread, clamp)

Design CLS15

10 Design with plug-in head

1 Cable connector

2 Plug-in head

3 Coaxial measuring electrode

4 Thread NPT ½"

5 Minimum immersion depth

A0024270

11 Design with fixed cable

1 fixed cable

2 Clamp 1½"

3 Coaxial measuring electrode

4 Minimum immersion depth

A0024269

8 Endress+Hauser

Page 9

Condumax CLS15D/CLS15

161 (6.34)

39 (1.54)

73 (2.87)

62.5 (2.46)

25.5

(1.00)

17 (0.67)

Ø 16 (0.63)

½” NPT

161 (6.34)

39 (1.54)

73 (2.87)

62.5 (2.46)

25.5

(1.00)

Ø 50.5 (1.99)

Ø 16 (0.63)

14 (0.55)

NPT ¾"

NPT ¾"

AF 27

56 (2.20)

112 (4.41)

152 (5.98)

Ø 16 (0.63)

Ø 16 (0.63)

Ø 50.5 (1.99)

AF 32

54 (2.13)

73 (2.87)

104 (4.09)

144 (5.67)

Dimensions CLS15D

Dimensions CLS15

12 Version with thread

Measurements in mm (inch)

A0024275

13 Version with Clamp

A0024276

14 Fixed cable version with NPT ¾"

A0024271

15 Fixed cable version with Clamp 1½"

Endress+Hauser 9

A0024272

Page 10

Condumax CLS15D/CLS15

167 (6.57)

73 (2.87)

31 (1.22)

17 (0.67)

Ø 39 (1.54)

AF 32

½" NPT

Ø 16 (0.63)

167 (6.57)

31 (1.22)

73 (2.87)

54 (2.13)

Ø 16 (0.63)

50.5 (2.00)

Weight

Materials (in contact with medium)

Process connections

Surface roughness

A0024273

16 Plug-in head version with NPT ½"

Measurements in mm (inch)

17 Plug-in head version with Clamp 1½"

Approx. 0.3 kg (0.66 lbs) depending on version

Electrodes

Polished, stainless steel 1.4435 (AISI 316L)

Sensor shaft Polyethersulfone (PES-GF20)

O-ring, in contact with medium

EPDM

(only Clamp version)

Thread NPT ½" and ¾"

Clamp 1½" as per ISO 2852

R

≤ 0.8 μm

a

A0024274

10 Endress+Hauser

Page 11

Condumax CLS15D/CLS15

Certificates and approvals

mark

Ex approvals

Quality certificate

Inspection certificate in

accordance with EN 10204

3.1

Declaration of Conformity

The product meets the requirements of the harmonized European standards. As such, it complies

with the legal specifications of the EC directives. The manufacturer confirms successful testing of the

product by affixing to it the mark.

CLS15D-**G

ATEX / NEPSI II 1G Ex ia IIC T3/T4/T6 Ga, IECEx Ex ia IIC T3/T4/T6 Ga

CLS15D-**O

FM/CSA IS/NI Cl. I Div.1&2 Gr. A-D in conjunction with Liquiline M CM42 transmitter

CLS15D-**V

ATEX/NEPSI II 3G Ex ic IIC T3/T4/T6 Gc for use in Zone 2 with Liquiline M CM42-KV*** transmitter

CLS15

ATEX II 1G EEx ia IIC T3/T4/T6

FM/CSA IS/NI Cl. I Div.1&2 Gr. A-D in conjunction with Liquiline M CM42 transmitter

ATEX and FM/CSA versions of digital sensors with Memosens technology are indicated by a

red-orange ring in the plug-in head.

Stating the individual cell constant

A test certificate 3.1 in accordance with EN10204 is supplied depending on the version (→ Product

Configurator on the product page).

Product page

Product Configurator

Scope of delivery

Ordering information

www.endress.com/cls15d

www.endress.com/cls15

The navigation area is located on the right of the product page.

1. Under "Device support" click "Configure your selected product".

The Configurator opens in a separate window.

2. Select all the options to configure the device in line with your requirements.

In this way, you receive a valid and complete order code for the device.

3. Export the order code as a PDF or Excel file. To do so, click the appropriate button at the top of

the screen.

The scope of delivery includes:

• Sensor in the version ordered

• Cable connector, for connecting to CYK71 measuring cable (only for plug-in head versions CLS15)

• Operating Instructions

Endress+Hauser 11

Page 12

Condumax CLS15D/CLS15

Accessories

The following are the most important accessories available at the time this documentation was

issued. For accessories not listed here, please contact your service or sales office.

Threaded and adapter couplings

Flow assembly

For sensors with NPT ½" process connection (CLS15-/CLS15D-x1Axx)

PVC threaded coupling

• For gluing into commercially available PVC cross fittings or T-pieces with DN 20

• With G½ internal thread, self-sealing with NPT ½" sensor thread

• Order No. 50066536

PVDF threaded coupling

• With G½ internal thread and G1 external thread

• Explosion-proof up to 12 bar at 20 °C (174 psi at 68 °F), max. 120 °C at 1 bar (248 °F at 14.5 psi),

including O-ring

• Self-sealing internal thread with NPT ½" sensor thread

• Order No. 50004381

PVC adapter couplings AM

• For adapting the PVC threaded coupling to larger nominal diameters

• Diameter, order numbers:

– AM 32: for cross-fittings or T-pieces DN 32, Order No. 50004738

– AM 40: for cross-fittings or T-pieces DN 40, Order No. 50004739

– AM 50: for cross-fittings or T-pieces DN 50, Order No. 50004740

For installing conductivity sensors with NPT ½" thread

• Material: Stainless steel 1.4404 (AISI 316 L)

• Connections: 90°, Ø 6 mm (0.24")

• Volume: 0.69 l (0.18 US gal)

• Max. temperature: 100 °C (212 °F)

• Max. pressure: 16 bar (232 psi)

• Order No.: 71042405

Measuring cable

Junction boxes (only CLS15)

CYK10 Memosens data cable

• For digital sensors with Memosens technology

• Product Configurator on the product page: www.endress.com/cyk10

Technical Information TI00118C

Memosens data cable CYK11

• Extension cable for digital sensors with Memosens protocol

• Product Configurator on the product page: www.endress.com/cyk11

Technical Information TI00118C

Measuring cable CYK71

• Unterminated cable for connecting analog sensors and for extending sensor cables

• Sold by the meter, order numbers:

– Non-Ex version, black: 50085333

– Ex-version, blue: 50085673

VBM

• Junction box for cable extension

• 10 terminal strips

• Cable entries: 2 x Pg 13.5 or 2 x NPT ½"

• Material: aluminum

• Degree of protection: IP 65

• Order numbers

– Cable entries Pg 13.5 : 50003987

– Cable entries NPT ½": 51500177

VBM-Ex

• Junction box for cable extension in hazardous area

• 10 terminal strips (blue)

• Cable entries: 2 x Pg 13.5

12 Endress+Hauser

Page 13

Condumax CLS15D/CLS15

• Material: aluminum

•

Degree of protection: IP 65 ( NEMA 4X)

• Order number: 50003991

Calibration solutions

Calibration set

Conductivity calibration solutions CLY11

Precision solutions referenced to SRM (Standard Reference Material) by NIST for qualified

calibration of conductivity measuring systems in accordance with ISO 9000

• CLY11-A, 74 μS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081902

• CLY11-B, 149.6 μS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081903

Technical Information TI00162C

Conducal CLY421

• Conductivity calibration set (case) for ultrapure water applications

• Complete, factory-calibrated measuring system with certificate, traceable to SRM by NIST and PTB,

for comparison measurement in ultrapure water up to max. 20 μS/cm

• Product Configurator on the product page: www.endress.com/cly421

Technical Information TI00496C/07/EN

Endress+Hauser 13

Page 14

Page 15

Page 16

www.addresses.endress.com

Loading...

Loading...