Endress+Hauser CLD18 Specifications

TI01080C/07/EN/05.19

71454912

2019-10-31

Products

Solutions Services

Technical Information

Smartec CLD18

Compact inductive conductivity measurement for the food

and beverage industry

Application

Compact measuring system for inductive conductivity

measurement in liquids with medium to high conductivity. The

structure is made from highly durable, food-safe

polyetheretherketone (PEEK). The excellent chemical

resistance properties of the sensor mean it can also be used in

applications outside the food industry. The measuring system

is perfectly suited for:

• Phase separation of product/water mixtures in the beverage

industry

• Control of cleaning-in-place facilities (CIP), concentration

control, separation in the cleaning return line

• Industrial water monitoring

• Rinsing processes in pickling plants

Your benefits

• Hygienic sensor design in accordance with EHEDG and 3-A

requirements, no risk of recontamination

• Stainless steel or plastic transmitter housing, IP 69K, can be

cleaned with high-pressure steam

• High level of repeatability, 0.5 % of reading, always

guarantees same separation or monitoring

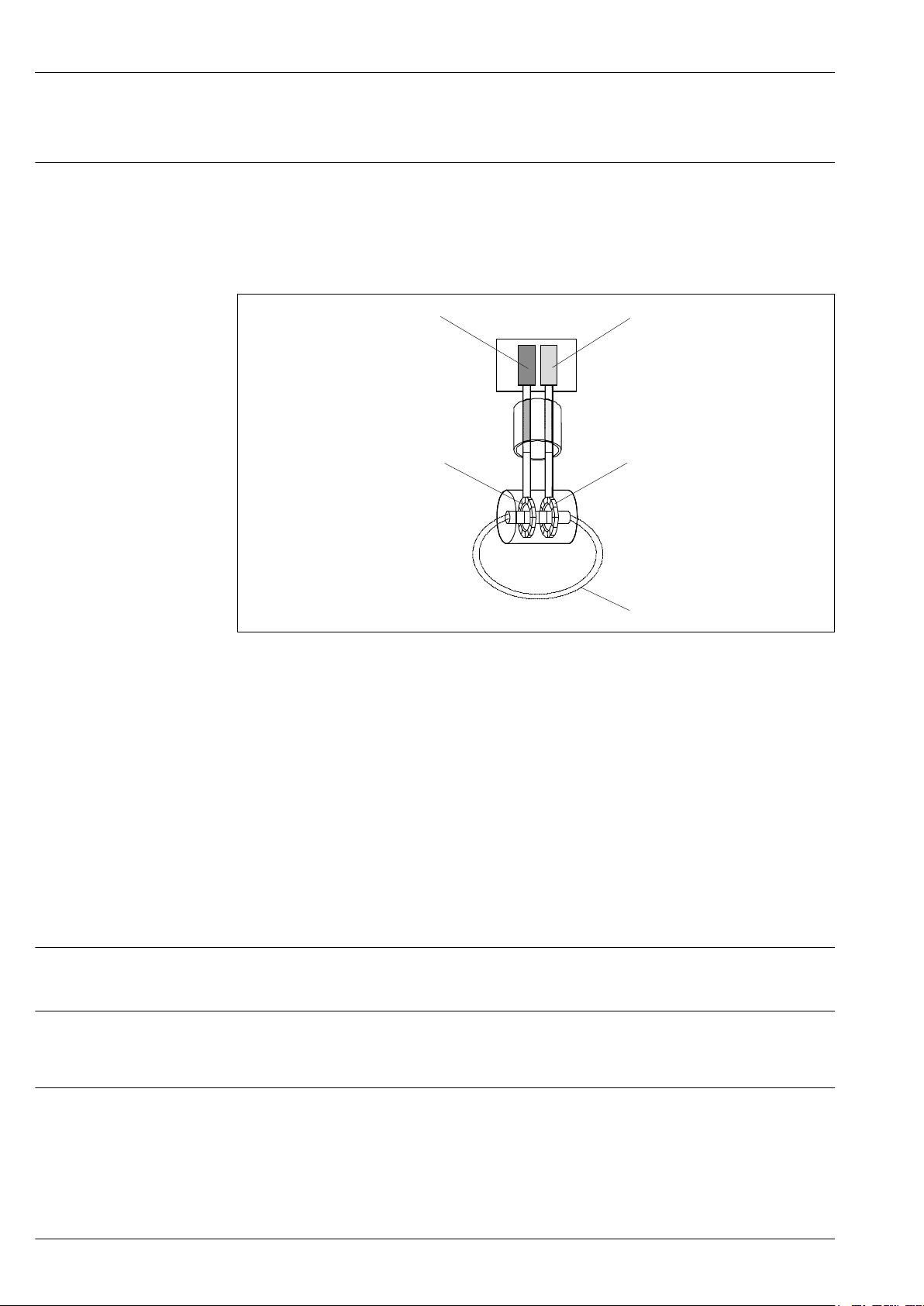

Function and system design

1

5

4

3

2

Smartec CLD18

Measuring principle

Inductive conductivity measurement

An oscillator (1) generates an alternating magnetic field in the primary coil (2), which induces a

current flow (3) in the medium. The strength of the current depends on the conductivity and thus on

the ion concentration in the medium. The current flow in the medium, in turn, generates a magnetic

field in the secondary coil (4). The resulting induced current is measured by the receiver (5) and used

to determine the conductivity.

Measured variables

Measuring range

1 Inductive conductivity measurement

1 Oscillator

2 Primary coil

3 Current flow in the medium

4 Secondary coil

5 Receiver

Advantages of inductive conductivity measurement:

• No electrodes and therefore no polarization effects

• Accurate measurement in media with a high degree of pollution and a tendency to form buildup

• Complete galvanic isolation of the measurement and the medium

Input

Conductivity

Temperature

Conductivity:

Temperature: –10 to 130 °C (14 to 266 °F)

Recommended range: 200 μS/cm to 1000 mS/cm

(uncompensated)

A0004894

Binary input

The binary input is used for measuring range switching.

Voltage range

Voltage High Min. 12 V

Voltage Low max. 9.0 V

0 V to 30 V

2 Endress+Hauser

Smartec CLD18

Lf

mA

mA

X

I ut1O

I ut2O

L

MRS

Alarm Out

Current consumption at 24 V 30 mA

Undefined voltage range 9.0 to 12 V

Output

Output signal

Load

Characteristic

Signal resolution

Alarm output

Electrical connection

Conductivity: 0 / 4 to 20 mA, galvanically isolated

Temperature: 0 / 4 to 20 mA, galvanically isolated

Max. 500 Ω

Linear

Resolution:

Accuracy: ± 20 μA

The alarm output is implemented as an "open collector".

Max. current

Max. voltage 30 V DC

Error or device without supply voltage Alarm output blocked (0 mA)

No error Alarm output open (up to 200 mA)

> 13 bit

200 mA

Power supply

2 Electrical connection

A0033106

Endress+Hauser 3

Terminal assignment

-

+

L

L

L+

L-

Out+

Out-

MRS+

MRS-

I ut1-O

I ut2+O

I ut1+O

I ut2-O

X

1

2

Smartec CLD18

Supply voltage

Power consumption

Cable specification

Overvoltage protection

3 Terminal assignment

IOut1

Current output conductivity (active)

IOut2 Current output temperature (active)

Out Alarm output (open-collector)

MRS Binary input (measuring range switch)

L+/L- Power supply

X Grounding pin (flat male tab 4.8 mm)

1 Cover on electronics box

2 Electronics box

24 V DC ± 20 %, protected against reverse polarity

3 W

Recommendation

max. 1.0 mm

0.5 mm

2

2

Overvoltage category I

A0029684

Performance characteristics

Response time

Maximum measured error

Conductivity:

Temperature: t90 < 20 s

Conductivity:

Temperature: ± 1.5 K

Signal outputs ± 50 μA

Repeatability

Cell constant

4 Endress+Hauser

Conductivity:

11.0 cm

-1

t95 < 1.5 s

± (2.0 % of measured value + 20 µS/cm)

max. 0.5 % of measured value ± 5 µS/cm ± 2 digits

Loading...

Loading...