Page 1

BA01149C/07/EN/07.19

71454911

2019-10-31

Products Solutions Services

Operating Instructions

Smartec CLD18

Conductivity measuring system

Page 2

Page 3

Smartec CLD18 Table of contents

Table of contents

1 About this document ........... 4

1.1 Warnings ........................... 4

1.2 Symbols used ........................ 4

1.3 Symbols on device .................... 5

2 Basic safety instructions ....... 5

2.1 Requirements for personnel ........... 5

2.2 Designated use ...................... 5

2.3 Workplace safety .................... 5

2.4 Operational safety ................... 7

2.5 Product safety ....................... 7

2.6 IT security .......................... 7

3 Product description ............. 8

3.1 Product design ....................... 8

4 Incoming acceptance and

product identification .......... 9

4.1 Incoming acceptance ................. 9

4.2 Product identification ................. 9

4.3 Scope of delivery .................... 10

4.4 Certificates and approvals ............ 11

5 Installation .................... 11

5.1 Installation conditions ............... 11

5.2 Mounting the compact device ......... 17

5.3 Post-installation check ............... 17

9 Diagnostics and

troubleshooting ............... 34

9.1 General troubleshooting ............. 34

9.2 Troubleshooting instructions ......... 34

9.3 Queued diagnostic messages .......... 35

10 Maintenance .................. 38

10.1 Maintenance tasks .................. 38

11 Repair .......................... 39

11.1 General notes ...................... 39

11.2 Return ............................ 39

11.3 Disposal ........................... 39

12 Accessories .................... 40

12.1 Calibration solutions ................ 40

13 Technical data ................. 40

13.1 Input .............................. 40

13.2 Output ............................ 41

13.3 Power supply ....................... 41

13.4 Performance characteristics .......... 42

13.5 Environment ....................... 42

13.6 Process ............................ 43

13.7 Mechanical construction ............. 44

Index ................................. 48

6 Electrical connection .......... 17

6.1 Connecting the transmitter ........... 17

6.2 Ensuring the degree of protection ..... 21

6.3 Post-connection check ............... 21

7 Operation options ............. 22

7.1 Overview of operating options ........ 23

7.2 Structure and function of the operating

menu ............................. 24

8 Commissioning ................ 25

8.1 Switching on the measuring device .... 25

8.2 Display settings (Display menu) ....... 25

8.3 Configuring the measuring device ..... 26

8.4 Advanced settings .................. 26

8.5 Calibration (Calibration menu) ........ 31

Endress+Hauser 3

Page 4

About this document Smartec CLD18

1 About this document

1.1 Warnings

Structure of information Meaning

DANGER

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

Corrective action

‣

NOTICE

Cause/situation

If necessary, Consequences of noncompliance (if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to property.

1.2 Symbols used

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

4 Endress+Hauser

Page 5

Smartec CLD18 Basic safety instructions

1.3 Symbols on device

Symbol Meaning

Reference to device documentation

2 Basic safety instructions

2.1 Requirements for personnel

• Installation, commissioning, operation and maintenance of the measuring system may be

carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the specified

activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions and

must follow the instructions contained therein.

• Faults at the measuring point may only be rectified by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

The compact measuring system is used for inductive conductivity measurement in liquids with

medium to high conductivity.

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

NOTICE

Applications outside specifications!

Incorrect measurements, malfunctions and even measuring point failure could result

Use the product only in accordance with the specifications.

‣

Pay attention to the technical data on the nameplate.

‣

2.3 Workplace safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

Endress+Hauser 5

Page 6

Basic safety instructions Smartec CLD18

Electromagnetic compatibility

• The product has been tested for electromagnetic compatibility in accordance with the

applicable international standards for industrial applications.

• The electromagnetic compatibility indicated applies only to a product that has been

connected in accordance with these Operating Instructions.

6 Endress+Hauser

Page 7

Smartec CLD18 Basic safety instructions

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

During operation:

If faults cannot be rectified:

‣

products must be taken out of service and protected against unintentional operation.

2.5 Product safety

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

international standards have been observed.

2.6 IT security

We only provide a warranty if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any

inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

Endress+Hauser 7

Page 8

Product description Smartec CLD18

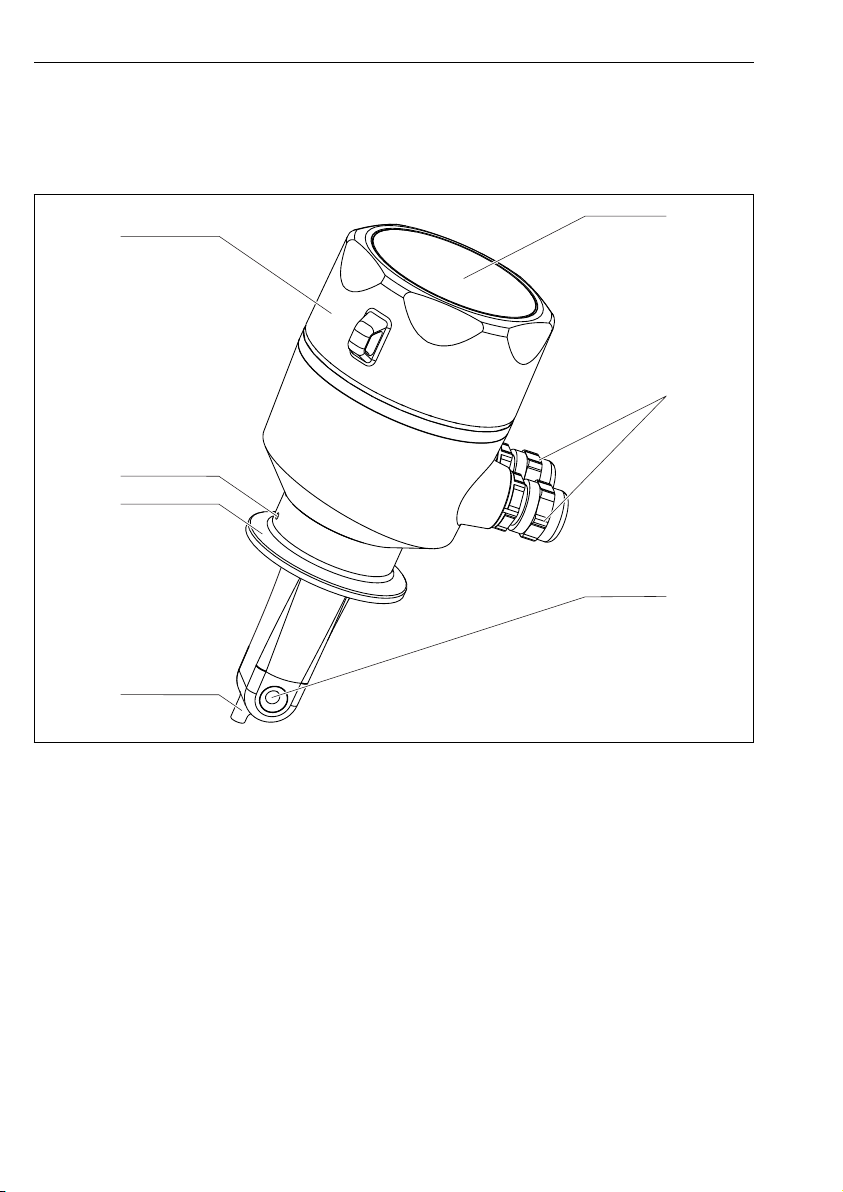

1

2

3

4

5

6

7

3 Product description

3.1 Product design

1 Elements

1 Temperature sensor

2 Process connection

3 Leakage bore (offset by 90° in relation to the flow direction)

4 Removable housing cover

5 Window for display

6 Cable glands (M12)

7 Flow opening of sensor

8 Endress+Hauser

A0019184

Page 9

Smartec CLD18 Incoming acceptance and product identification

4 Incoming acceptance and product identification

4.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify the supplier of any damage to the packaging.

Keep the damaged packaging until the issue has been resolved.

2. Verify that the contents are undamaged.

Notify the supplier of any damage to the delivery contents.

Keep the damaged goods until the issue has been resolved.

3. Check that the delivery is complete and nothing is missing.

Compare the shipping documents with your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

Make sure to comply with the permitted ambient conditions.

If you have any questions, please contact your supplier or your local Sales Center.

Technical data→ 40

4.2 Product identification

4.2.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Order code

• Extended order code

• Serial number

• Firmware version

• Ambient and process conditions

• Input and output values

• Measuring range

• Safety information and warnings

• Protection class

Compare the information on the nameplate with the order.

‣

Endress+Hauser 9

Page 10

Incoming acceptance and product identification Smartec CLD18

4.2.2 Product identification

Product page

www.endress.com/CLD18

Interpreting the order code

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Go to www.endress.com.

2. Call up the site search (magnifying glass).

3. Enter a valid serial number.

4. Search.

The product structure is displayed in a popup window.

5. Click on the product image in the popup window.

A new window (Device Viewer) opens. All of the information relating to your

device is displayed in this window as well as the product documentation.

Manufacturer's address

Endress+Hauser Conducta GmbH+Co. KG

Dieselstraße 24

D-70839 Gerlingen

4.3 Scope of delivery

The delivery comprises:

• A Smartec CLD18 measuring system in the version ordered

• Operating Instructions BA01149C/07/EN

10 Endress+Hauser

Page 11

Smartec CLD18 Installation

4.4 Certificates and approvals

4.4.1 Declaration of Conformity

The product meets the requirements of the harmonized European standards. As such, it

complies with the legal specifications of the EU directives. The manufacturer confirms

successful testing of the product by affixing to it the mark.

4.4.2 Hygiene FDA

All materials in contact with the product are FDA-listed materials (apart from the PVC process

connections).

EHEDG

Certified cleanability according to EHEDG Type EL Class I.

When using the sensor in hygienic applications, please note that the cleanability of the

sensor also depends on the way the sensor is installed. To install the sensor in a pipe, use

the appropriate and EHEDG-certified flow vessels for the particular process connection.

3-A

Certified according to 3-A Standard 74- ("3-A Sanitary Standards for Sensor and Sensor

Fittings and Connections Used on Milk and Milk Products Equipment").

EC Regulation No. 1935/2004

The sensor meets the requirements of EC Regulation No. 1935/2004 on materials and articles

intended to come into contact with food.

4.4.3 Pressure approval

Canadian pressure approval for pipes according to ASME B31.3

5 Installation

5.1 Installation conditions

5.1.1 Installation instructions

For a 3-A compliant installation, the following must be noted:

After the instrument is installed its hygienic integrity shall be maintained. The

instrument shall be installed with the leakage detection at the lowest point of the

assembly. Furthermore all process connections must be 3-A compliant.

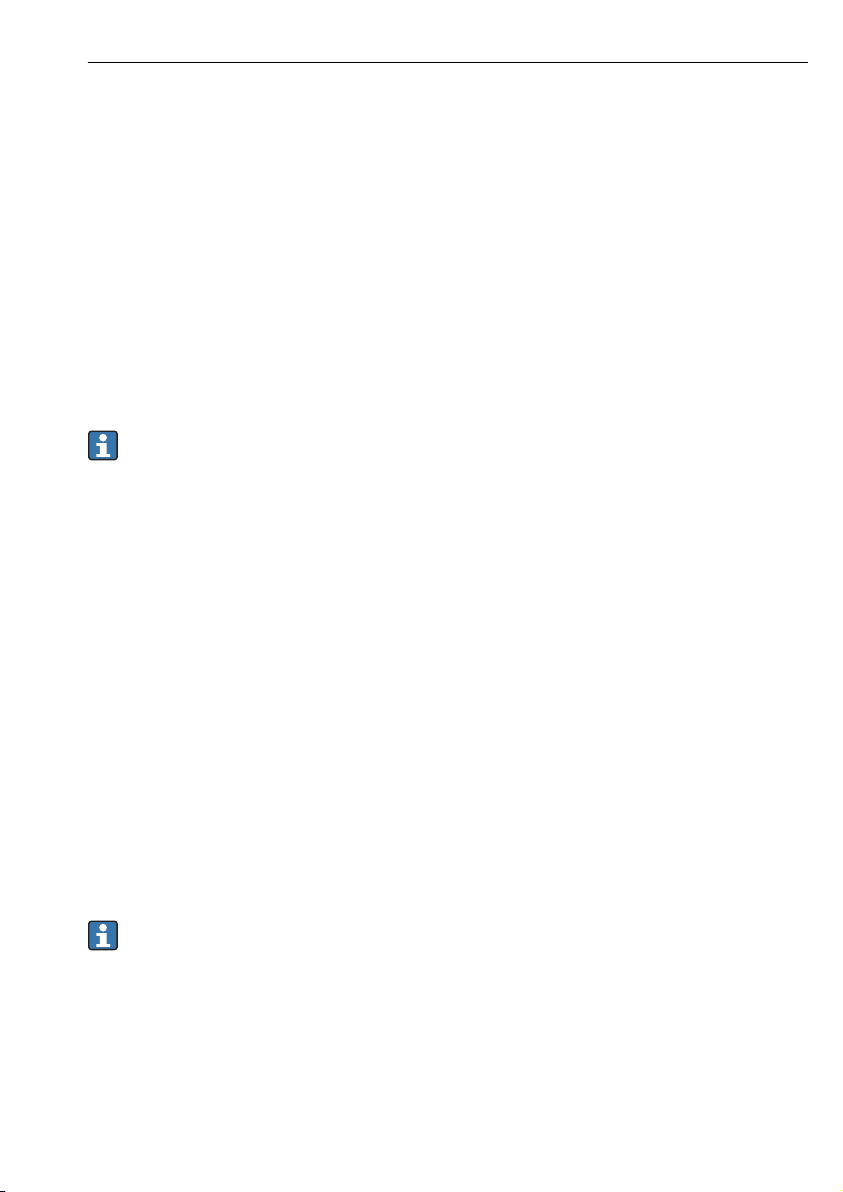

Orientations

The sensor must be completely immersed in the medium. Avoid air bubbles in the area of the

sensor.

Endress+Hauser 11

Page 12

Installation Smartec CLD18

> 1 (3.3)

a

A0037970

2 Orientation of conductivity sensors. Engineering unit: m (ft)

If the flow direction changes (after pipe bends), turbulence in the medium can result.

Install the sensor at a distance of at least 1 m (3.3 ft) downstream from a pipe bend.

‣

The product should flow along the hole of the sensor (see the arrows on the housing). The

symmetrical measuring channel allows flow in both directions.

In confined installation conditions, the walls affect the ionic

current in the liquid. This effect is offset by what is referred to

as the installation factor. The installation factor can be entered

in the transmitter for the measurement or the cell constant is

corrected by multiplying by the installation factor.

The value of the installation factor depends on the diameter

and the conductivity of the pipe nozzle as well as the distance a

between the sensor and the wall.

The installation factor can be disregarded (f = 1.00) if the

distance to the wall is sufficient (a > 20 mm, from DN 60).

If the distance to the wall is smaller, the installation factor

increases for electrically insulating pipes (f > 1) and decreases

for electrically conductive pipes (f < 1).

It can be measured using calibration solutions, or a close

approximation can be determined from the following diagram.

12 Endress+Hauser

A0037972

3 Installation of CLD18

a Wall distance

Page 13

Smartec CLD18 Installation

1

2

a [inch]

0

10

20 30

40

a [mm]

0.95

1 00.

1.05

f

0.39

0.79

1.18

1.57

A0020517

4 Relationship between installation factor f and wall distance a

1 Electrically conductive pipe wall

2 Electrically insulating pipe wall

Install the measuring system in such a way that the housing is not exposed to direct

sunlight.

Endress+Hauser 13

Page 14

Installation Smartec CLD18

28 (1.10)

73.5

(0.91)

86 (3.39)

136.5 (5.37)

101.7 (4.00)

28 (1.10)

78 (3.07)

85 (3.35)

6

53.3

(2.10)

127 (5.00)

69 (2.72)

112 (4.41)

85 (3.35)

114.5 (4.51)

53.3

(2.10)

69

(2.72)

5.2

20.5

(0.81)

123 (4.84)

12.3 (0.49)

17.1 (0.67)

32.8 (1.29)

123 (4.84)

A A

B B

C

D

(0.24)

(2.89)

(0.20)

23

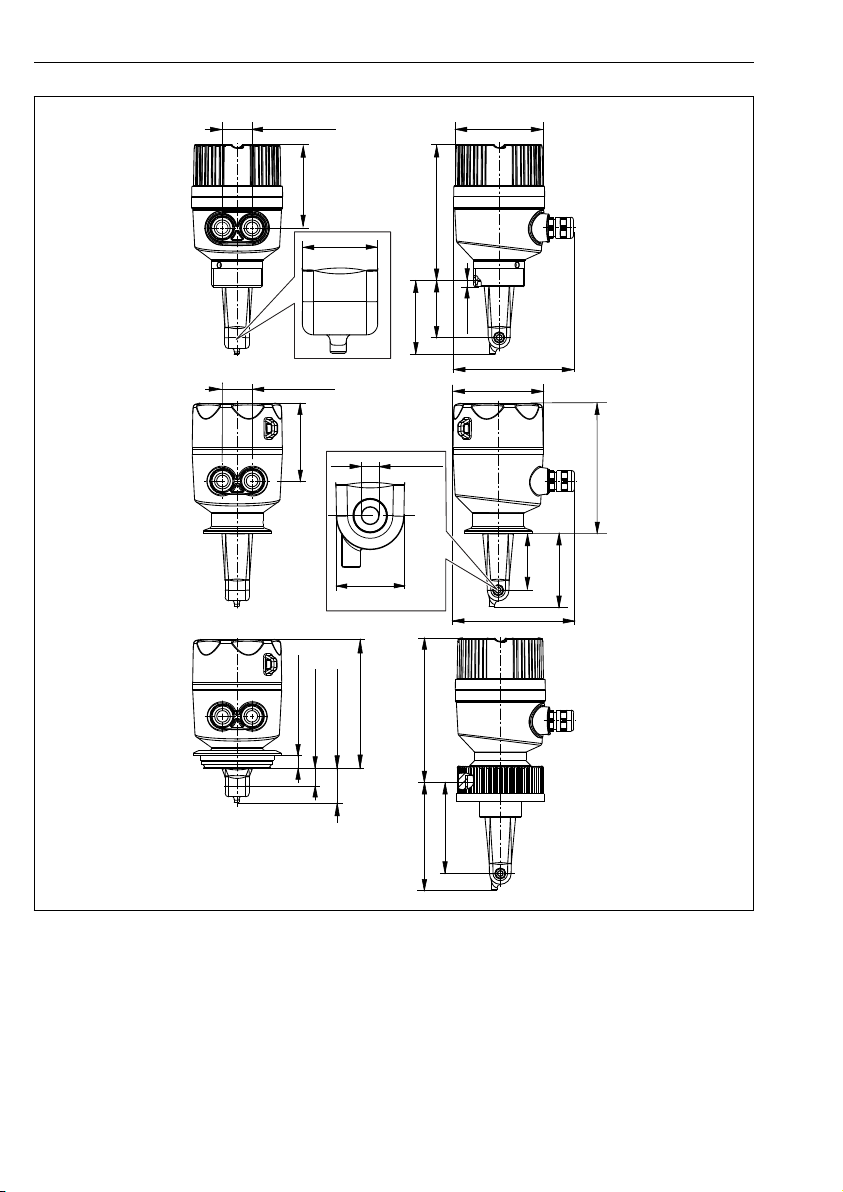

5 Dimensions and versions (examples). Dimensions: mm (in)

A Plastic housing with thread G 1½

B Stainless steel housing with ISO 2852 clamp 2"

C Stainless steel housing with Varivent DN 40 to 125

D Plastic housing with coupling nut 2¼" PVC

A0018942

14 Endress+Hauser

Page 15

Smartec CLD18 Installation

51 (2.01)

Ø 44.3

(1.74)

Ø 48.3

(1.90)

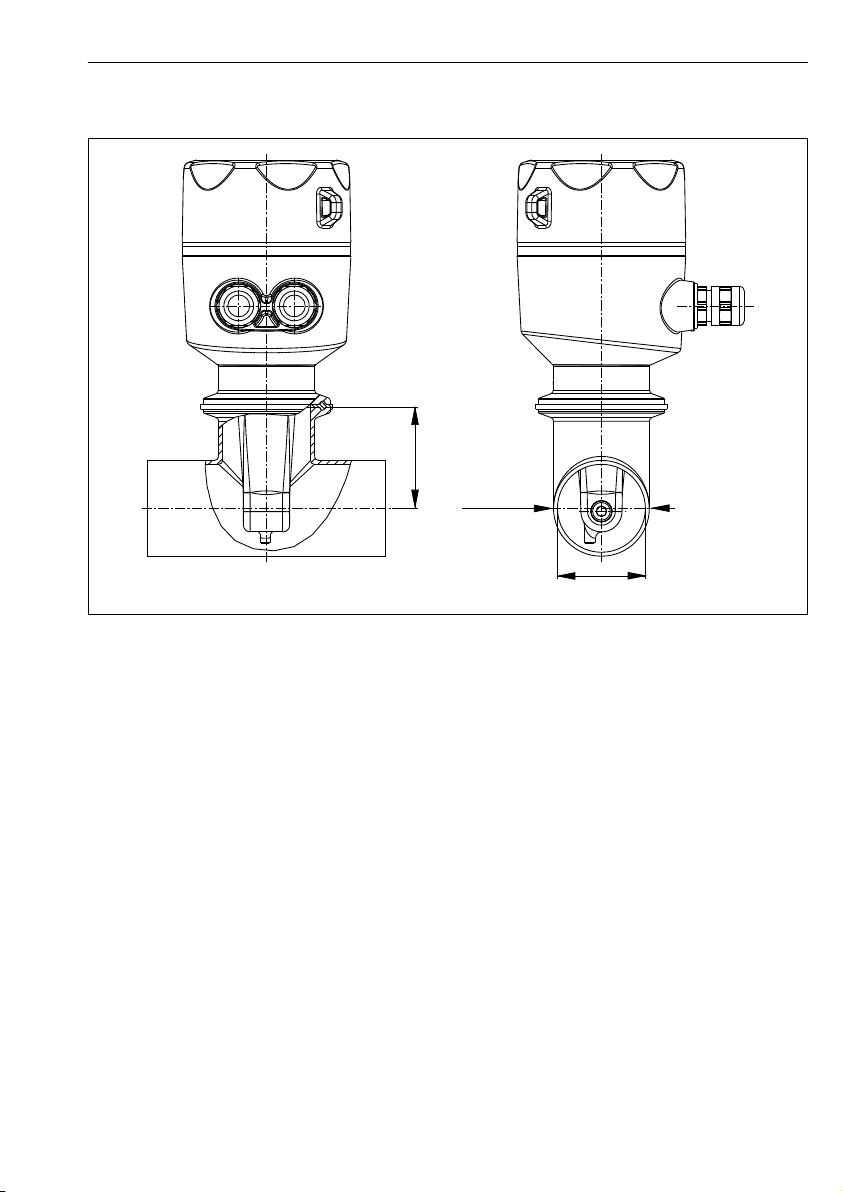

5.1.2 Installation examples

A0019302

6 Installation in DN 40 pipe with Tri-Clamp 2" process connection. Dimensions: mm (in)

Endress+Hauser 15

Page 16

Installation Smartec CLD18

31

(1.22)

Ø 38

(1.50)

Ø 41

(1.61)

57.5

(2.26)

Ø 40 (1.58)

Ø 50 (1.97)

A0022166

7 Installation in DN 40 pipe with Varivent process connection. Dimensions: mm (in)

8 Installation in DN 40 pipe with 2¼" PVC coupling nut process connection. Dimensions: mm (in)

16 Endress+Hauser

A0024073

Page 17

Smartec CLD18 Electrical connection

5.2 Mounting the compact device

Choose the installation depth of the sensor in the medium such that the coil body is

‣

completely immersed in the medium.

Pay attention to the information on wall clearance → 11

1. Mount the compact device directly on a pipe nozzle or tank nozzle via the process

connection.

2. For the 1½" threaded connection, use a Teflon tape to seal the connection and an

adjustable pin wrench (DIN 1810, flat face, size 45 to 50 mm (1.77 to 1.97 in)) to

tighten it.

3. When installing, align the compact device in such a way that the medium flows through

the flow opening of the sensor in the direction of medium flow. Use the arrow on the

nameplate to help you align the device.

4. Tighten the flange.

5.3 Post-installation check

1. Following installation, check the compact device for damage.

2. Ensure that the compact device is protected against direct sunlight.

6 Electrical connection

WARNING

L

Device is live!

Incorrect connection may result in injury or death!

The electrical connection may be performed only by an electrical technician.

‣

The electrical technician must have read and understood these Operating Instructions and

‣

must follow the instructions contained therein.

Prior to commencing connection work, ensure that no voltage is present on any cable.

‣

6.1 Connecting the transmitter

WARNING

L

Risk of electric shock!

At the supply point, the power supply must be isolated from dangerous live cables by

‣

double or reinforced insulation in the case of devices with a 24 V power supply.

Endress+Hauser 17

Page 18

Electrical connection Smartec CLD18

Lf

mA

mA

X

I ut1O

I ut2O

L

MRS

Alarm Out

6.1.1 Direct connection of the cables

A0033106

9 Electrical connection

18 Endress+Hauser

Page 19

Smartec CLD18 Electrical connection

-

+

L

L

L+

L-

Out+

Out-

MRS+

MRS-

I ut1-O

I ut2+O

I ut1+O

I ut2-O

X

1

2

A0029684

10 Terminal assignment

IOut1

Current output conductivity (active)

IOut2 Current output temperature (active)

Out Alarm output (open-collector)

MRS Binary input (measuring range switch)

L+/L- Power supply

X Grounding pin (flat male tab 4.8 mm)

1 Cover on electronics box

2 Electronics box

NOTICE

Removing the electronics box will destroy the sensor connection!

The electronics box must not be removed under any circumstances.

‣

Do not open the cover on the electronics box.

‣

The recommended cable cross-section for the connecting cables is 0.5 mm2. The

maximum cable cross-section is 1.0 mm2.

Connect the transmitter of the compact device as follows:

1. Unscrew the housing cover.

Endress+Hauser 19

Page 20

Electrical connection Smartec CLD18

3

2

1

4

4

3

2

1

7

6

5

8

2. Guide the connecting cables through the cable glands.

3. Connect the cables as per the terminal assignment diagram.

4. Connect the protective ground to the terminal pin for the housing ground.

6.1.2 Connection via M12 connector

A0033108

11 View of connector, 4-pin, data cable (at device)

1 IOUT1+ Conductivity 3 IOUT2- Temperature

2 IOUT2+ Temperature 4 IOUT1- Conductivity

12 View of connector, 8-pin, power supply/controller (at device)

1 L+ Power supply 5 Out+ Alarm output+

2 L- Power supply 6 Out- Alarm output3 MRS+ Binary input 7 GND Functional ground

4 MRS- Binary input 8 GND Functional ground

20 Endress+Hauser

A0033109

Page 21

Smartec CLD18 Electrical connection

6.2 Ensuring the degree of protection

Guarantee the degree of protection as follows:

1. Verify that the O-ring is seated correctly in the housing cover.

2. Screw the housing cover tight until the stop.

3. Screw the cable glands tight.

6.3 Post-connection check

Once you have performed the electrical connections, carry out the following checks :

Instrument status and specifications Notes

Are the transmitter and cables free from damage on the outside? Visual inspection

Electrical connection Notes

Are the installed cables strain-relieved and not twisted?

Is the cable run correct, without loops and cross-overs?

Are the signal cables correctly connected as per the wiring diagram?

Are all the cable entries fitted, tightened and leak-proof?

Are the PE distributor blocks grounded (if present)? Grounding is carried out at the point

of installation.

Endress+Hauser 21

Page 22

Operation options Smartec CLD18

E

+

_

ESC

- -

Main µS/cm

1

2

3

4

7 Operation options

13 Display and keys of the CLD18

1 Parameters

2 Measured value

3 Unit

4 Operating keys

The ASTN display (Advanced Super Twisted Nematic) is split into two sections. The segment

section displays the measured value. The dot-matrix section displays the parameter and unit.

The operating texts are displayed in English.

In the event of an error the device automatically alternates between displaying the error and

the measured value.

A0018963

22 Endress+Hauser

Page 23

Smartec CLD18 Operation options

E

7.1 Overview of operating options

• Open the Configuration menu

• Confirm the entry

• Select a parameter or submenu

A0029236

Within the Configuration menu:

• Gradually select the specified menu items / characters for the

parameter

• Change the selected parameter

A0029235

Outside the Configuration menu:

Display enabled and calculated channels, as well as minimum and

maximum values, for all the active channels.

Press both keys simultaneously (< 3 s) to quit the setup without

saving any changes.

Always quit menu items / submenus at the end of the menu via "x Back".

Symbols in the editing mode:

Accept entry.

A0020597

If this symbol is selected, the entry is applied at the position specified by the user, and you quit editing mode.

Reject entry.

If this symbol is selected, the entry is rejected and you quit editing mode. The previously set text remains.

A0020598

Jump one position to the left.

A0020599

If this symbol is selected, the cursor jumps one position to the left.

Delete backwards.

If this symbol is selected, the character to the left of the cursor position is deleted.

A0020600

Delete all.

if this symbol is selected, the entire entry is deleted.

A0020601

Endress+Hauser 23

Page 24

Operation options Smartec CLD18

7.2 Structure and function of the operating menu

The operating functions of the compact measuring device are divided into the following

menus:

Display Settings for the device display: contrast, brightness, time for alternating measured values on the display

Setup Device settings

Calibration Perform sensor calibration*

Diagnostics Device information, diagnostics logbook, sensor information, simulation

* The air set and the correct cell constant have already been configured at the factory for the

Smartec CLD18. A sensor calibration is not necessary during commissioning.

24 Endress+Hauser

Page 25

Smartec CLD18 Commissioning

8 Commissioning

8.1 Switching on the measuring device

1. Familiarize yourself with the operation of the transmitter before it is first switched on.

After power-up, the device performs a self-test and then goes to the measuring

mode.

2. If you are commissioning the device for the first time, Setup program the as described in

the following sections of the Operating Instructions.

8.2 Display settings (Display menu)

1. Use the 'E' key to call up the main menu.

The menu appears on the display Display.

2. Press the 'E' key again to open the menu.

3. Use the option, Back which can be found at the bottom of each menu, to move up a

level in the menu structure.

Parameter Possible settings Description

Contrast 1 to 7

Default: 5

Brightness 1 to 7

Default: 5

Alternating time 0, 3, 5, 10 s

Default: 5

Setting for the contrast

Setting for the brightness of the display

Alternating time between the two measured values

0 means that the values do not alternate on the display

Endress+Hauser 25

Page 26

Commissioning Smartec CLD18

8.3 Configuring the measuring device

1. Use the 'E' key to call up the main menu.

2. Navigate through the available menus with the '+' and '–' keys.

3. Press the 'E' key to open the desired menu.

4. Use the option, Back which can be found at the bottom of each menu, to move up a

level in the menu structure.

Default settings are in bold.

Parameter Possible settings Description

Current range 4-20 mA

0-20 mA

Out1 0/4 mA 0 to 2000000 μS/cm

0 μS/cm

Out1 20 mA 0 to 2000000 μS/cm

0 μS/cm

Select the current range.

‣

Enter the measured value at which the min. current value (0/4 mA) is

‣

present at the transmitter output.

Enter the measured value at which the max. current value (20 mA) is

‣

present at the transmitter output.

Out2 0/4 mA -50 to 250 °C

0.0 °C

Out2 20 mA -50 to 250 °C

100.0 °C

Damping main 0 ... 60 s

0 s

Extended setup

Manual hold Off, On Function for freezing the current and alarm outputs

Enter the measured value at which the min. current value (0/4 mA) is

‣

present at the transmitter output.

Enter the measured value at which the max. current value (20 mA) is

‣

present at the transmitter output.

Damping value for the conductivity measured value

Advanced settings→ 26

8.4 Advanced settings

1. Use the 'E' key to call up the main menu.

2. Navigate through the available menus with the '+' and '–' keys.

3. Press the 'E' key to open the desired menu.

4. Use the option, Back which can be found at the bottom of each menu, to move up a

level in the menu structure.

Default settings are in bold.

Parameter Possible settings Description

System General settings

Device tag Customized text

Max. 16 characters

Enter the device designation

26 Endress+Hauser

Page 27

Smartec CLD18 Commissioning

Parameter Possible settings Description

Temp. unit °C

°F

Hold release 0 to 600 s

0 s

Alarm delay 0 to 600 s

0 s

Input Setting for the inputs

Cell const. Read only Displays the cell constant

Inst. factor 0.1 to 5.0

1.0

Unit Auto, μS/cm, mS/cm Unit of conductivity

Damping main 0 ... 60 s

0 s

Temp. comp. Off, Linear Setting for temperature compensation

Alpha coeff. 1.0 to 20.0 %/K

2.1 %/K

Ref. temp. +10 to +50 °C

25 °C

Process check The process check checks the measuring signal for stagnation. An

Function On, Off

Duration 1 to 240 min

60 min

Observation width 1 to 20 %

0.0 %

Analog output Setting for analog outputs

Current range 4-20 mA

0-20 mA

Out1 0/4 mA 0 to 2000000 μS/cm

0 μS/cm

Out1 20 mA 0 to 2000000 μS/cm

0 μS/cm

Out2 0/4 mA -50 to 250 °C

0.0 °C

Out2 20 mA -50 to 250 °C

100.0 °C

Setting for the temperature unit

Prolongs the device hold when the hold condition no longer

applies

Time delay after which an alarm is output

This suppresses alarm conditions that are present for a period

that is shorter than the alarm delay time.

The effects of the distance from the wall can be corrected

with the installation factor → 29

"auto" automatically switches between μS/cm and mS/cm.

Setting for the damping

Coefficient for linear temperature compensation

Enter the reference temperature

alarm is triggered if the measuring signal does not change over a

specific period (several measured values).

Switch the process check on or off.

‣

The measured value must change within this time as otherwise

an error message is triggered.

Bandwidth for the process check

Current range for analog output

Enter the measured value at which the min. current value

‣

(0/4 mA) is present at the transmitter output.

Enter the measured value at which the max. current value

‣

(20 mA) is present at the transmitter output.

Enter the measured value at which the min. current value

‣

(0/4 mA) is present at the transmitter output.

Enter the measured value at which the max. current value

‣

(20 mA) is present at the transmitter output.

Endress+Hauser 27

Page 28

Commissioning Smartec CLD18

Parameter Possible settings Description

MRS

Setting for measuring range switching → 31

Out1 0/4 mA 0 to 2000000 μS/cm

0 μS/cm

Out1 20 mA 0 to 2000000 μS/cm

0 μS/cm

Out2 0/4 mA -50 to 250 °C

0.0 °C

Out2 20 mA -50 to 250 °C

100.0 °C

Damping main 0 ... 60 s

0 s

Alpha coeff. 1.0 to 20 %/K

2.1 %/K

Factory default Factory settings

Please confirm No

No, Yes

Enter the measured value at which the min. current value

‣

(0/4 mA) is present at the transmitter output.

Enter the measured value at which the max. current value

‣

(20 mA) is present at the transmitter output.

Enter the measured value at which the min. current value

‣

(0/4 mA) is present at the transmitter output.

Enter the measured value at which the max. current value

‣

(20 mA) is present at the transmitter output.

Setting for the damping

Coefficient for linear temperature compensation

28 Endress+Hauser

Page 29

Smartec CLD18 Commissioning

1

2

a [inch]

0

10

20 30

40

a [mm]

0.95

1 00.

1.05

f

0.39

0.79

1.18

1.57

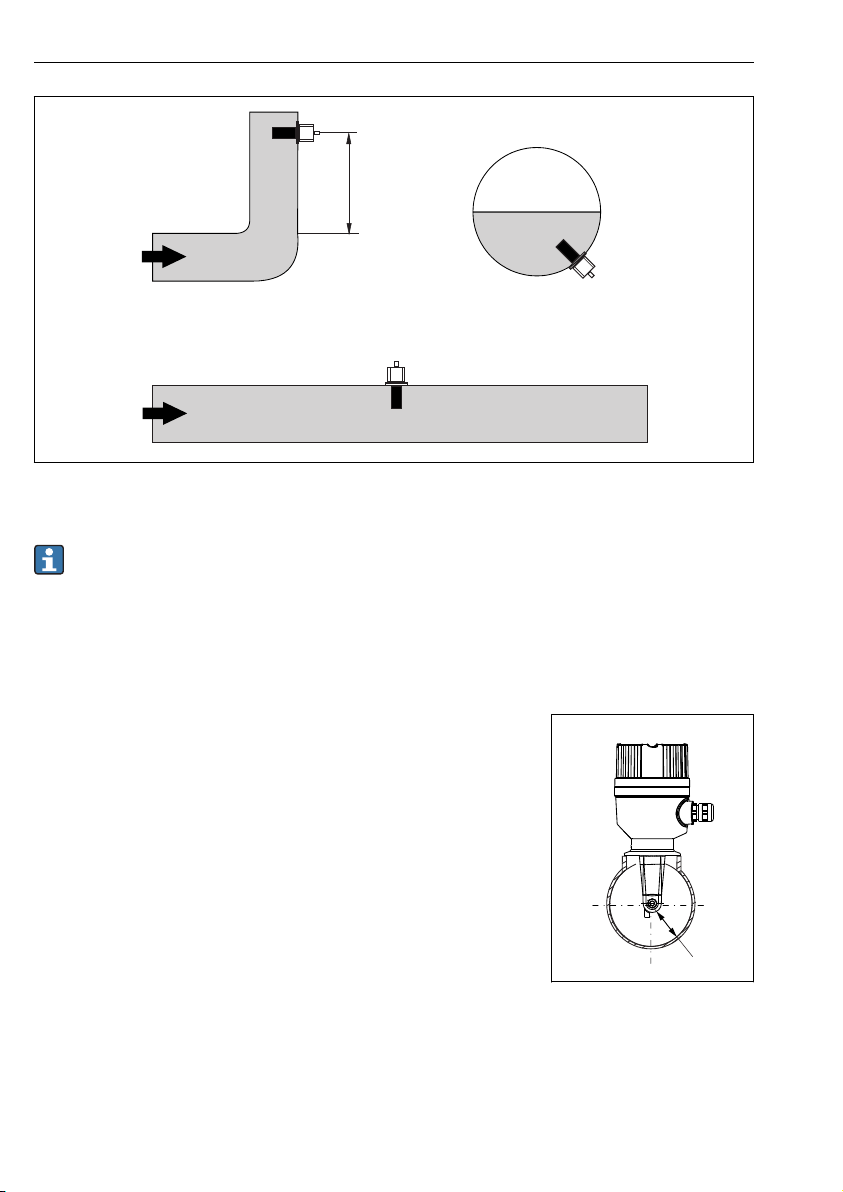

8.4.1 Installation factor

In confined installation conditions, the conductivity measurement in the liquid is affected by

the pipe walls. This effect is offset by the installation factor. The cell constant is corrected by

multiplying by the installation factor.

The value of the installation factor depends on the diameter and the conductivity of the pipe

nozzle as well as the sensor's distance to the wall.

The installation factor f (f = 1.00) can be disregarded if the distance to the wall is sufficient

(a>20 mm (0.79 in), from DN60).

If the distance to the wall is small, the installation factor increases for electrically insulating

pipes (f > 1), and decreases for electrically conductive pipes (f < 1).

It can be measured using calibration solutions, or a close approximation determined from the

following diagram.

14 Relationship between the installation factor (f) and the distance from wall (a)

1 Electrically conductive pipe wall

2 Electrically insulating pipe wall

Endress+Hauser 29

A0020517

Page 30

Commissioning Smartec CLD18

k(T) k(T )

0

(1+

=

(T - T ))

0

a

.

.

8.4.2 Temperature compensation

The conductivity of a liquid depends heavily on the temperature, as the mobility of the ions

and the number of dissociated molecules are temperature-dependent. In order to compare

measured values, they must be referenced to a defined temperature. The reference

temperature is 25 °C (77 °F).

The temperature is always specified when the conductivity is specified. k(T0) represents the

conductivity measured at 25 °C (77 °F) or referenced back to 25 °C (77 °F).

The temperature coefficient α represents the percentage change in the conductivity per degree

of temperature change. The conductivity k at the process temperature is calculated as follows:

A0009163

Where

k(T) = conductivity at process temperature T

k(T0) = conductivity at process temperature T

0

The temperature coefficient depends on both the chemical composition of the solution and on

the temperature, and is between 1 and 5 % per °C. The electrical conductivity of the majority

of diluted saline solutions and natural waters changes in a close-to-linear fashion.

Typical values for the temperature coefficient α:

Natural waters

Approx. 2 %/K

Salts (e.g. NaCl) Approx. 2.1 %/K

Alkali (e.g. NaOH) Approx. 1.9 %/K

Acids (e.g. HNO3) Approx. 1.3 %/K

30 Endress+Hauser

Page 31

Smartec CLD18 Commissioning

8.4.3 Measuring range switch (MRS)

Measuring range switching involves a parameter set changeover for two substances:

• in order to cover a large measuring range

• in order to adjust temperature compensation in the event of a product change

The two analog outputs can each be configured with two parameter sets.

• Parameter set 1:

• The parameters for the current outputs and the damping can be set Setup in the menu.

• The alpha coefficient for temperature compensation can be set Setup/Extended setup/

Input in the menu.

• Parameter set 1 is active if the "MRS" binary input is Low .

• Parameter set 2:

• The parameters for the current outputs, the damping and the alpha coefficient for

temperature compensation can be configured Setup/Extended setup/Remote switch in

the menu.

• Parameter set 2 is active if the "MRS" binary input High is .

The settings for parameter set 1 are also listed in Extended setup/Analog output the

menu.

Technical data→ 41

8.5 Calibration (Calibration menu)

In the case of the Smartec CLD 18, the air set and the correct cell constant have already been

configured at the factory. A sensor calibration is not necessary during commissioning.

8.5.1 Types of calibration

The following types of calibration are possible:

• Cell constant with calibration solution

• Air set (residual coupling)

8.5.2 Cell constant

General

The calibration of a conductivity measuring system is always performed in such a way that the

suitable calibration solutions determine or verify the exact cell constant. This process is

described in the standards EN 7888 and ASTM D 1125, for example, and the method for

producing a number of calibration solutions is explained.

Endress+Hauser 31

Page 32

Commissioning Smartec CLD18

Calibrating the cell constant

With this type of calibration, enter a reference value for the conductivity.

‣

In the result, the device calculates a new cell constant for the sensor.

First switch off the temperature compensation:

1. Select the menu Setup/Extended setup/Input/Temp. comp. .

2. Off Select .

3. Return to the menu Setup .

Perform the calculation of the cell constant as follows:

1. Select the menu Calibration/Cell const. .

2. Cond. ref. Select and enter the value of the standard solution.

3. Place the sensor in the medium.

4. Start the calibration.

"Wait calib." - wait for calibration to end. The new value is displayed after the

calibration.

5. Press the Plus key.

"Save calib data?"

6. Yes Select .

"Calib successful"

7. Switch the temperature compensation back on.

32 Endress+Hauser

Page 33

Smartec CLD18 Commissioning

8.5.3 Air set (residual coupling)

For physical reasons, the calibration line goes through zero in the case of conductive sensors

(a current flow of 0 corresponds to a conductivity of 0). When working with inductive sensors,

the residual coupling between the primary coil (transmitter coil) and secondary coil (receiver

coil) must be taken into account or compensated for. The residual coupling is not only caused

by the direct magnetic coupling of the coils but also by crosstalk in the supply cables.

As is the case with the sensors, the cell constant is then determined using a precise calibration

solution.

To perform an airset, the sensor must be dry.

Perform an airset as follows:

1. Calibration/Airset Select .

The current value is displayed.

2. Press the Plus key.

"Keep sensor in air"

3. Keep the dried sensor in air and press the Plus key.

"Wait calib." - wait for calibration to end. The new value is displayed after the

calibration.

4. Press the Plus key.

"Save calib data?"

5. Yes Select .

"Calib successful"

6. Press the Plus key.

The device switches back to the measuring mode.

Endress+Hauser 33

Page 34

Diagnostics and troubleshooting Smartec CLD18

9 Diagnostics and troubleshooting

9.1 General troubleshooting

User interface Cause Solution

No measured value displayed No power supply connected Check the device's power supply.

Power is supplied, device is defective The device must be replaced.

Diagnostic message is displayed

9.2 Troubleshooting instructions

1. Use the 'E' key to call up the main menu.

2. Navigate through the available menus with the '+' and '–' keys.

3. Press the 'E' key to open the desired menu.

4. Use the option, Back which can be found at the bottom of each menu, to move up a

level in the menu structure.

Parameter Possible settings Description

Current diag. Read only Displays the current diagnostic message

Last diag. Read only Displays the last diagnostic message

Diag. logbook Read only Displays the last diagnostic messages

Device info Read only Displays device information

Sensor info Read only Displays sensor information

Simulation

Analog out 1 Off

0 mA, 3.6 mA, 4 mA, 10 mA, 12 mA,

20 mA, 21 mA

Analog out 2 Off

0 mA, 3.6 mA, 4 mA, 10 mA, 12 mA,

20 mA, 21 mA

Alarm out Off

Active

Inactive

Reset device

Diagnostic messages → 35

Outputs a corresponding value at the "Analog out 1"

output.

Outputs a corresponding value at the "Analog out 2"

output.

34 Endress+Hauser

Page 35

Smartec CLD18 Diagnostics and troubleshooting

9.3 Queued diagnostic messages

The diagnostic message consists of a diagnostic code and a message text. The diagnostic code

consists of the error category as per Namur NE 107 and the message number.

Error category (letter in front of the message number):

• F = Failure, a malfunction has been detected

The measured value of the affected channel is no longer reliable. Look for the cause in the

measuring point. If a control system is connected, it must be switched to manual mode.

• M = Maintenance required, action should be taken as soon as possible

The device still measures correctly. Immediate measures are not necessary. Proper

maintenance efforts may prevent a possible malfunction in the future.

• C = Function check, waiting (no error)

Maintenance work is being performed on the device. Wait until the work has been

completed.

• S = Out of specification, the measuring point is being operated outside your specification

Operation is still possible. However, you run the risk of increased wear, shorter operating

life or reduced measurement accuracy. Look for the cause in the measuring point.

Diagnostic code Message text Description

F61 Sensor elec. Sensor electronics defective

Remedy:

Contact the Service Department

F62 Sens. Connect Sensor connection

Remedy:

Contact the Service Department

F100 Sensor comm. Sensor not communicating

Possible reasons:

No sensor connection

Remedy:

Contact the Service Department

F130 Sensor supply Sensor check

F143 Selftest Sensor self-test error

F152 No airset Sensor data

No conductivity displayed

Possible reasons:

• Sensor in air

• Sensor defective

Remedy:

• Check sensor installation

• Contact the Service Department

Remedy:

Contact the Service Department

No calibration data available

Remedy:

Perform an air set

Endress+Hauser 35

Page 36

Diagnostics and troubleshooting Smartec CLD18

Diagnostic code Message text Description

F523 Cell constant Sensor calibration warning

F524 Cell constant Sensor calibration warning

F845 Device id Incorrect hardware configuration

F847 Couldn’t save param Incorrect parameters

F848 Calib AO1 Incorrect calibration values for analog output 1

F849 Calib AO2 Incorrect calibration values for analog output 2

F904 Process check Process check system alarm

Invalid cell constant, max. range reached

Remedy:

• Enter cell constant as per factory specifications

• Contact the Service Department

Min. possible cell constant is undershot

Remedy:

• Enter cell constant as per factory specifications

• Contact the Service Department

Measuring signal has not changed for a long time

Possible reasons:

• Contaminated sensor, or sensor in air

• No flow to sensor

• Sensor defective

• Software error

Remedy:

• Check electrode system

• Check sensor

• Restart device

Diagnostic code Message text Description

C107 Calib. active Sensor calibration is active

Remedy:

Wait for calibration to be finished

C154 No calib. data Sensor data

C850 Simu AO1 Simulation of analog output 1 is active

C851 Simu AO2 Simulation of analog output 2 is active

36 Endress+Hauser

No calibration data available, factory settings are used

Remedy:

• Check the calibration information of the sensor

• Contact the Service Department

Page 37

Smartec CLD18 Diagnostics and troubleshooting

Diagnostic code Message text Description

S844 Process value Measured value outside the specified range

Possible reasons:

• Sensor in air

• Incorrect flow to sensor

• Sensor defective

Remedy:

• Increase process value

• Check electrode system

Diagnostic code Message text Description

M500 Not stable Sensor calibration aborted

M526 Cell constant Sensor calibration warning

M528 Cell constant Sensor calibration warning

Main measured value fluctuating

Possible reasons:

• Sensor in air

• Sensor fouled

• Incorrect flow to sensor

• Sensor defective

Remedy:

• Check sensor

• Check installation

Invalid cell constant, max. range reached

Remedy:

• Repeat the calibration

• Enter cell constant as per factory specifications

• Contact the Service Department

Min. possible cell constant is undershot

Remedy:

• Repeat the calibration

• Enter cell constant as per factory specifications

• Contact the Service Department

Endress+Hauser 37

Page 38

Maintenance Smartec CLD18

10 Maintenance

WARNING

L

Risk of injury if medium escapes!

Before each maintenance task, ensure that the process pipe is unpressurized, empty and

‣

rinsed.

The electronics box does not contain any parts that the user must maintain.

• The cover on the electronics box may be opened only by Endress+Hauser Service staff.

• The electronics box may be removed only by Endress+Hauser Service staff.

10.1 Maintenance tasks

10.1.1 Cleaning the housing

Clean the front of the housing using commercially available cleaning agents only.

‣

The front of the housing is resistant to the following in accordance with DIN 42 115:

• Ethanol (for a short time)

• Diluted acids (max. 2% HCl)

• Diluted bases (max. 3% NaOH)

• Soap-based household cleaning agents

When performing any work on the device, bear in mind any potential impact this may have

‣

on the process control system or on the process itself.

NOTICE

Prohibited cleaning agents!

Damage to the housing surface or housing seal

Never use concentrated mineral acids or alkaline solutions for cleaning.

‣

Never use organic cleaners such as benzyl alcohol, methanol, methylene chloride, xylene or

‣

concentrated glycerol cleaner.

Never use high-pressure steam for cleaning.

‣

38 Endress+Hauser

Page 39

Smartec CLD18 Repair

11 Repair

The O-ring is defective if medium escapes from the leakage hole.

Contact the E+H Service department to replace the O-ring.

‣

11.1 General notes

Only use spare parts from Endress + Hauser to guarantee the safe and stable functioning of

‣

the device.

Detailed information on the spare parts is available at:

www.endress.com/device-viewer

11.2 Return

The product must be returned if repairs or a factory calibration are required, or if the wrong

product was ordered or delivered. As an ISO-certified company and also due to legal

regulations, Endress+Hauser is obliged to follow certain procedures when handling any

returned products that have been in contact with medium.

To ensure the swift, safe and professional return of the device:

Refer to the website www.endress.com/support/return-material for information on the

‣

procedure and conditions for returning devices.

11.3 Disposal

The device contains electronic components. The product must be disposed of as electronic

waste.

Observe the local regulations.

‣

Endress+Hauser 39

Page 40

Accessories Smartec CLD18

12 Accessories

The following are the most important accessories available at the time this documentation

was issued.

For accessories not listed here, please contact your Service or Sales Center.

‣

12.1 Calibration solutions

Conductivity calibration solutions CLY11

Precision solutions referenced to SRM (Standard Reference Material) by NIST for qualified

calibration of conductivity measuring systems in accordance with ISO 9000:

• CLY11-C, 1.406 mS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081904

• CLY11-D, 12.64 mS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081905

• CLY11-E, 107.00 mS/cm (reference temperature 25 °C (77 °F)), 500 ml (16.9 fl.oz)

Order No. 50081906

For further information on "Calibration solutions", see the Technical Information

13 Technical data

13.1 Input

13.1.1 Measured variable

Conductivity

Temperature

13.1.2 Measuring range

Conductivity:

Temperature: –10 to 130 °C (14 to 266 °F)

40 Endress+Hauser

Recommended range: 200 μS/cm to 1000 mS/cm

(uncompensated)

Page 41

Smartec CLD18 Technical data

13.1.3 Binary input

The binary input is used for measuring range switching.

Voltage range 0 V to 30 V

Voltage High Min. 12 V

Voltage Low max. 9.0 V

Current consumption at 24 V 30 mA

Undefined voltage range 9.0 to 12 V

13.2 Output

13.2.1 Output signal

Conductivity:

Temperature: 0 / 4 to 20 mA, galvanically isolated

13.2.2 Load

Max. 500 Ω

13.2.3 Characteristic

Linear

13.2.4 Signal resolution

Resolution:

Accuracy: ± 20 μA

13.2.5 Alarm output

The alarm output is implemented as an "open collector".

Max. current

Max. voltage 30 V DC

Error or device without supply voltage Alarm output blocked (0 mA)

No error Alarm output open (up to 200 mA)

0 / 4 to 20 mA, galvanically isolated

> 13 bit

200 mA

13.3 Power supply

13.3.1 Supply voltage

24 V DC ± 20 %, protected against reverse polarity

13.3.2 Power consumption

3 W

Endress+Hauser 41

Page 42

Technical data Smartec CLD18

13.3.3 Cable specification

Recommendation 0.5 mm

max. 1.0 mm

2

2

13.3.4 Overvoltage protection

Overvoltage category I

13.4 Performance characteristics

13.4.1 Response time

Conductivity: t95 < 1.5 s

Temperature: t90 < 20 s

13.4.2 Maximum measured error

Conductivity:

Temperature: ± 1.5 K

Signal outputs ± 50 μA

13.4.3 Repeatability

Conductivity:

13.4.4 Cell constant

11.0 cm

-1

± (2.0 % of measured value + 20 µS/cm)

max. 0.5 % of measured value ± 5 µS/cm ± 2 digits

13.4.5 Temperature compensation

Range

–10 to 130 °C (14 to 266 °F)

Types of compensation • None

• Linear with user-configurable temperature

coefficient

13.4.6 Reference temperature

25 °C (77 °F)

13.5 Environment

13.5.1 Ambient temperature range

Stainless steel process connection:

PVC process connection: –10 to 60 °C (14 to 60 °F)

42 Endress+Hauser

–20 to 60 °C (–4 to 140 °F)

Page 43

Smartec CLD18 Technical data

13.5.2 Storage temperature

Stainless steel process connection: –25 to 80 °C (–13 to 176 °F)

PVC process connection: –10 to 60 °C (14 to 140 °F)

13.5.3 Humidity

≤ 100 %, condensating

13.5.4 Climate class

Climate class 4K4H as per EN 60721-3-4

13.5.5 Degree of protection

IP 69k as per EN 40050:1993

Degree of protection NEMA TYPE 6P as per NEMA 250-2008

13.5.6 Shock resistance

Complies with IEC 61298-3, certified up to 5 g

13.5.7 Vibration resistance

Complies with IEC 61298-3, certified up to 5 g

13.5.8 Electromagnetic compatibility

Interference emission as per EN 61000-6-3:2007 + A1:2011 and EN 55011:2009 + A1:2010

Interference immunity as per EN 61326-1:2013

13.5.9 Degree of contamination

Pollution level 2

13.5.10 Altitude

<2000 m (6500 ft)

13.6 Process

13.6.1 Process temperature

Stainless steel process connection:

–10 to 110 °C (14 to 230 °F)

Max.130 °C (266 °F) up to 60 minutes

PVC process connection:

–10 to 60 °C (14 to 140 °F)

13.6.2 Absolute process pressure

Stainless steel process connection:

13 bar (188.5 psi), abs to up to 50 °C (122 °F)

Endress+Hauser 43

Page 44

Technical data Smartec CLD18

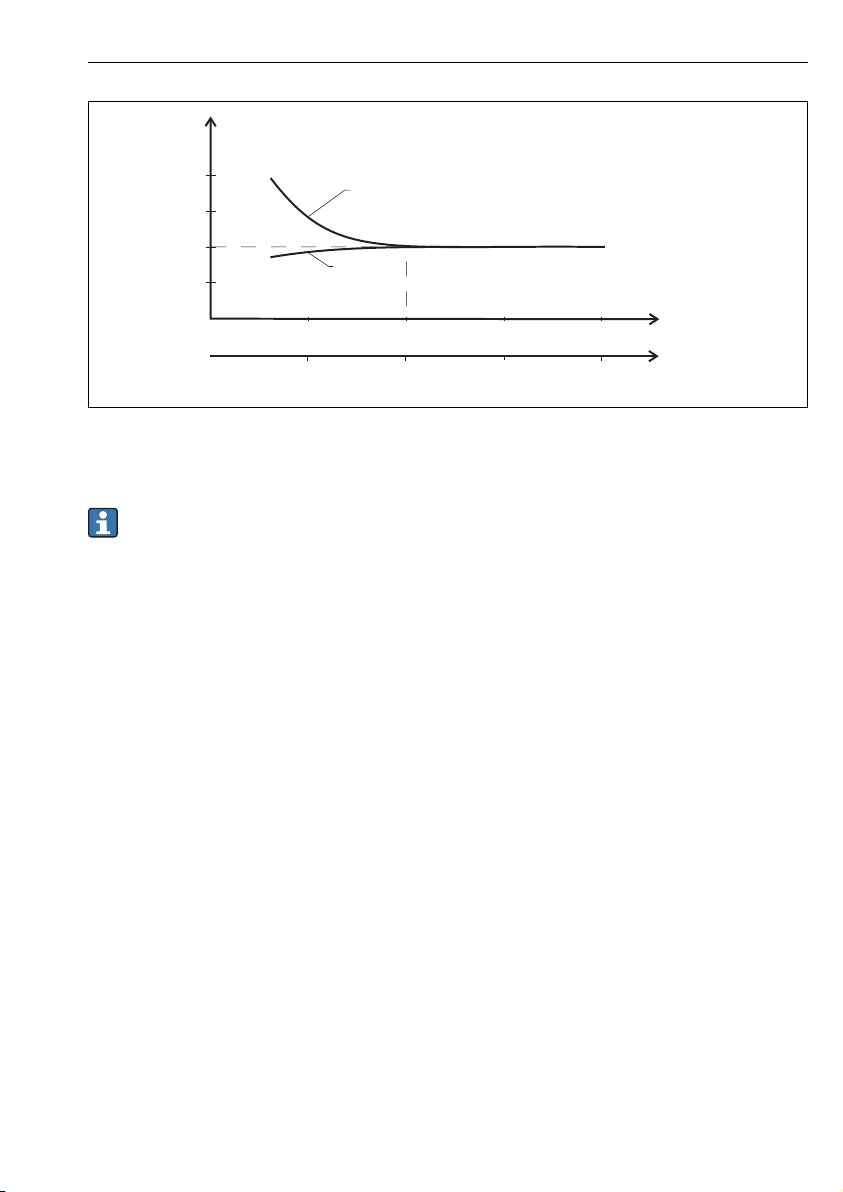

p (abs.)

T

[bar]

[°C]

6

13

130

110

[psi]

188.5

87

T

[°F]

230

266

50

122

A

60

140

9

130.5

1

2

1

14.5

7.75 bar (112 psi), abs at 110 °C (230 °F)

6.0 bar (87 psi), abs at 130 °C (266 °F) max. 60 minutes

1 to 6 bar (14.5 to 87 psi), abs in CRN environment tested with 50 bar (725 psi)

PVC process connection:

9 bar (130.5 psi), abs to up to 50 °C (122 °F)

6.0 bar (87 psi), abs at 60 °C (140 °F)

1 to 6 bar (14.5 to 87 psi), abs in CRN environment tested with 50 bar (725 psi)

13.6.3 Pressure-temperature ratings

15 Pressure-temperature ratings

1 Stainless steel process connection

2 PVC process connection

A Process temperature increased briefly (max. 60 minutes)

13.6.4 Flow velocity

max. 10 m/s (32.8 ft/s) for low-viscosity media in pipe DN 50

13.7 Mechanical construction

13.7.1 Dimensions

→ 11

44 Endress+Hauser

A0030822-EN

Page 45

Smartec CLD18 Technical data

13.7.2 Weight

Stainless steel housing: up to 1.870 kg (4.12 lbs)

Plastic housing: up to 1.070 kg (2.36 lbs)

13.7.3 Materials

In contact with medium

Sensor: PEEK (polyetheretherketone)

Process connection: Stainless steel 1.4435 (AISI 316 L), PVC-U

Seal: EPDM

Not in contact with medium

Stainless steel housing: Stainless steel 1.4308 (ASTM CF-8, AISI 304)

Plastic housing: PBT GF20, PBT GF10

Seals: EPDM

Window: PC

Cable glands: PA, TPE

Endress+Hauser 45

Page 46

Technical data Smartec CLD18

53.3

(2.10)

(2.72)

69

53.3

(2.10)

(2.72)

69

53.3

(2.10)

(2.72)

69

GGE / GCP

MDK

MEK

MOK

MQK MXK

MYK

TXJ TDK

17.1

(0.67)

(1.29)

32.8

TSK

LQP

Ø 39.7

(1.56)

7 (0.28)

32.7

(1.29)

86 (3.39)

101.7 (4.00)

Ø 48.5

(1.90)

Ø 92 (3.62) Ø 78 (3.07)

Ø 92 (3.62) Ø 78 (3.07) Ø 82 (3.23)

Ø 94 (3.70)

Ø 84 (3.31)

Ø 64 (2.52)

Ø 84 (3.31)

Ø 83 (3.27)

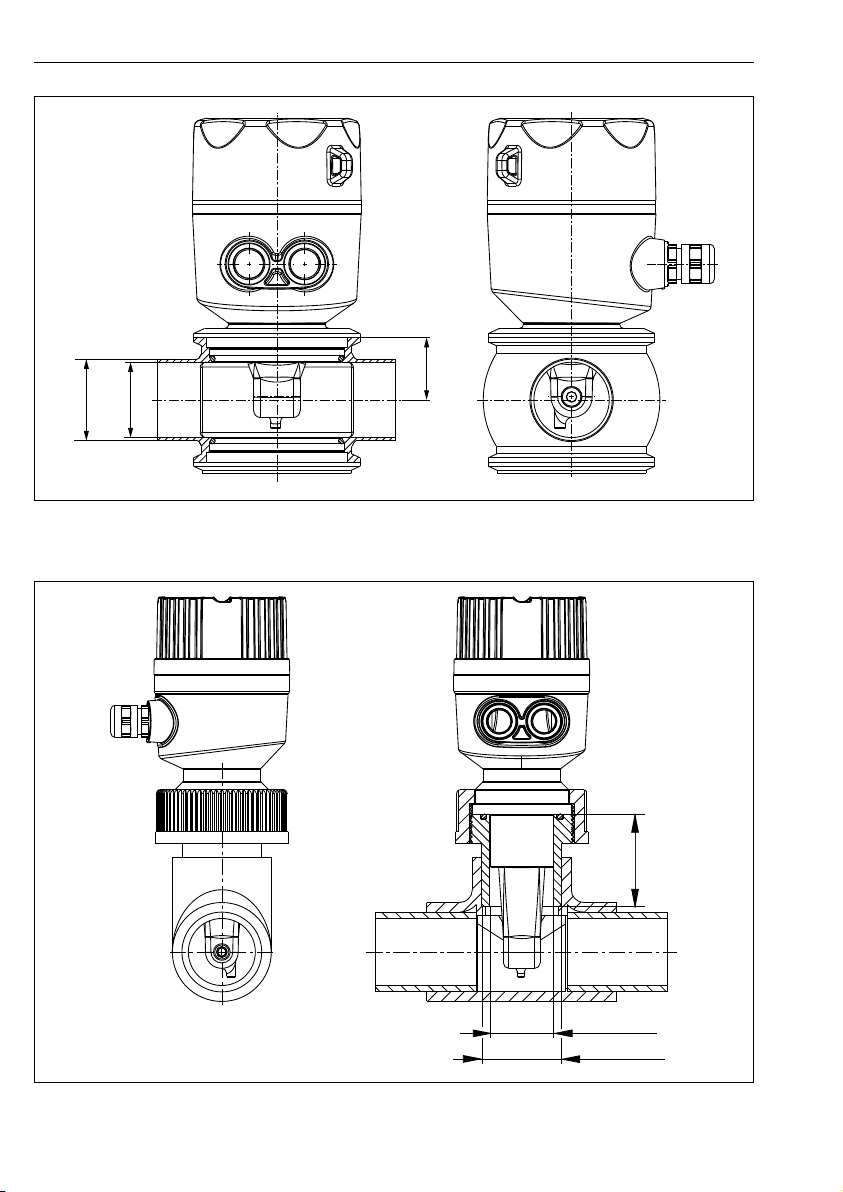

13.7.4 Process connections

16 Process connections, dimensions in mm (inch)

46 Endress+Hauser

A0018955

Page 47

Smartec CLD18 Technical data

GGE

GCP

MDK

MEK

MOK

MQK

MXK

MYK

TXJ

TDK

TSK

LQP

Thread G1½

Thread G1½ PVC

Aseptic DIN 11864-1-A DN 50

Aseptic DIN 11864-1-A DN 40

Dairy fitting DIN 11851 DN 50

Dairy fitting DIN 11851 DN 40

Dairy fitting DIN 11853 -2 DN 40

Dairy fitting DIN 11853 -2 DN 50

SMS 2"

Tri-Clamp ISO 2852 2"

Varivent N DN 40 to 125

Coupling nut 2¼" PVC

13.7.5 Temperature sensor

Pt1000

Endress+Hauser 47

Page 48

Index Smartec CLD18

Index

A

Accessories ..................... 40

Advanced Setup .................. 26

Air set ........................ 33

Application examples ............... 15

C

Calibration ..................... 31

Cell constant .................... 31

Certificates and approvals .............11

Cleaning the housing ............... 38

Commissioning ...................25

D

Declaration of Conformity .............11

Designated use ....................5

Device configuration ................26

Device diagnostics ................. 34

Diagnostic messages ................35

Diagnostics ..................... 34

Display settings ...................25

Disposal ....................... 39

E

Electrical connection ................17

Ensuring the degree of protection ........ 21

I

Incoming acceptance ................ 9

Installation ................... 11, 17

Installation conditions ...............11

Installation examples ............... 15

Installation factor ................. 29

Interpreting the order code ............ 10

IT security measures .................7

M

Maintenance .................... 38

Manufacturer's address .............. 10

Measuring range switch ..............31

Menu .........................26

Calibration .................. 31

Diagnostics .................. 34

Display .....................25

Setup ......................26

Menus ........................ 24

MRS ......................... 31

N

Nameplate ...................... 9

O

Operating keys ................... 23

Operation ...................... 22

Operational safety ..................7

Orientations .....................11

P

Post-connection check ...............21

Post-installation check .............. 17

Power up ...................... 25

Product description ................. 8

Product identification ................ 9

Product page .................... 10

Product safety .................... 7

R

Repair ........................ 39

Residual coupling ..................33

Return ........................ 39

S

Safety instructions ..................5

Scope of delivery .................. 10

Symbols ........................ 4

T

Technical data ................... 40

Temperature compensation ............30

Troubleshooting .................. 34

Troubleshooting instructions ...........34

W

Warnings ....................... 4

Wiring ........................17

Workplace safety .................. 5

48 Endress+Hauser

Page 49

Page 50

Page 51

Page 52

*71454911*

71454911

www.addresses.endress.com

Loading...

Loading...