Page 1

BA00135C/07/EN/13.15

71293522

Products Solutions Services

Operating Instructions

Dipfit CLA111

Immersion and installation assembly for conductivity

measurement

Page 2

Table of contents Dipfit CLA111

Table of contents

1 Document information .............. 3

1.1 Safety information ...................... 3

1.2 Symbols .............................. 3

2 Basic safety instructions ............ 4

2.1 Requirements for personnel ............... 4

2.2 Designated use ........................ 4

2.3 Occupational safety ..................... 4

2.4 Operational safety ...................... 5

2.5 Product safety ......................... 5

3 Incoming acceptance and product

identification ....................... 6

3.1 Incoming acceptance .................... 6

3.2 Product identification .................... 6

3.3 Scope of delivery ....................... 7

4 Installation ........................ 8

4.1 Installation conditions ................... 8

4.2 Installing the assembly ................. 11

4.3 Installing the sensor ................... 14

4.4 Post-installation check .................. 14

5 Electrical connection .............. 14

5.1 Connecting the sensor .................. 15

5.2 Post-connection check .................. 16

6 Maintenance ...................... 17

6.1 Servicing the assembly .................. 17

6.2 Cleaning the sensor .................... 17

7 Repairs ........................... 18

7.1 Spare parts .......................... 18

7.2 Return .............................. 18

7.3 Disposal ............................ 18

8 Accessories ....................... 19

8.1 Installation accessories ................. 19

8.2 Sensors ............................. 19

8.3 Extension cable ....................... 20

8.4 Chemoclean .......................... 20

9 Technical data .................... 21

Index .................................. 22

2 Endress+Hauser

Page 3

Dipfit CLA111 Document information

1 Document information

1.1 Safety information

Structure of information Meaning

DANGER

L

Causes (/consequences)

Consequences of non-compliance

(if applicable)

Corrective action

‣

WARNING

L

Causes (/consequences)

Consequences of non-compliance

(if applicable)

Corrective action

‣

CAUTION

L

Causes (/consequences)

Consequences of non-compliance

(if applicable)

Corrective action

‣

NOTICE

Cause/situation

Consequences of non-compliance

(if applicable)

Action/note

‣

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious

injury.

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

This symbol alerts you to situations which may result in damage to

property.

1.2 Symbols

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

Endress+Hauser 3

Page 4

Basic safety instructions Dipfit CLA111

2 Basic safety instructions

2.1 Requirements for personnel

• Installation, commissioning, operation and maintenance of the measuring system may

be carried out only by specially trained technical personnel.

• The technical personnel must be authorized by the plant operator to carry out the

specified activities.

• The electrical connection may be performed only by an electrical technician.

• The technical personnel must have read and understood these Operating Instructions

and must follow the instructions contained therein.

• Measuring point faults may be repaired only by authorized and specially trained

personnel.

Repairs not described in the Operating Instructions provided may only be carried out

directly by the manufacturer or by the service organization.

2.2 Designated use

The assembly is suitable for universal use in water and wastewater applications. Thanks to

its design, it can be used in pressurized systems (→ 21).

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Occupational safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

4 Endress+Hauser

Page 5

Dipfit CLA111 Basic safety instructions

2.4 Operational safety

1. Before commissioning the entire measuring point, verify that all connections are

correct. Ensure that electrical cables and hose connections are undamaged.

2. Do not operate damaged products, and safeguard them to ensure that they are not

operated inadvertently. Label the damaged product as defective.

3. If faults cannot be rectified:

Take the products out of operation and safeguard them to ensure that they are not

operated inadvertently.

2.5 Product safety

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

European standards have been observed.

Endress+Hauser 5

Page 6

Incoming acceptance and product identification Dipfit CLA111

3 Incoming acceptance and product

identification

3.1 Incoming acceptance

1. Verify that the packaging is undamaged.

Notify your supplier of any damage to the packaging.

Keep the damaged packaging until the matter has been settled.

2. Verify that the contents are undamaged.

Notify your supplier of any damage to the delivery contents.

Keep the damaged products until the matter has been settled.

3. Check the delivery for completeness.

Check it against the delivery papers and your order.

4. Pack the product for storage and transportation in such a way that it is protected

against impact and moisture.

The original packaging offers the best protection.

The permitted ambient conditions must be observed (see "Technical data").

If you have any questions, please contact your supplier or your local sales center.

3.2 Product identification

3.2.1 Nameplate

The nameplate provides you with the following information on your device:

• Manufacturer identification

• Extended order code

• Serial number

• Ambient and process conditions

• Safety information and warnings

Compare the data on the nameplate with your order.

3.2.2 Product identification

Product page

www.endress.com/cla111

Interpreting the order code

The order code and serial number of your product can be found in the following locations:

• On the nameplate

• In the delivery papers

Obtaining information on the product

1. Go to the product page for your product on the Internet.

2. In the navigation area on the right-hand side, select "Check your device features"

under "Device support".

An additional window opens.

3. Enter the order code from the nameplate into the search field.

You will receive information on each feature (selected option) of the order code.

6 Endress+Hauser

Page 7

Dipfit CLA111 Incoming acceptance and product identification

3.3 Scope of delivery

The delivery comprises:

• Assembly in the version ordered

• Measuring cable with connector for two-electrode sensor CLS21

• O-ring for sensors CLS21 and CLS21D

• Operating Instructions

If you have any questions, please contact your supplier or your local sales center.

Endress+Hauser 7

Page 8

Installation Dipfit CLA111

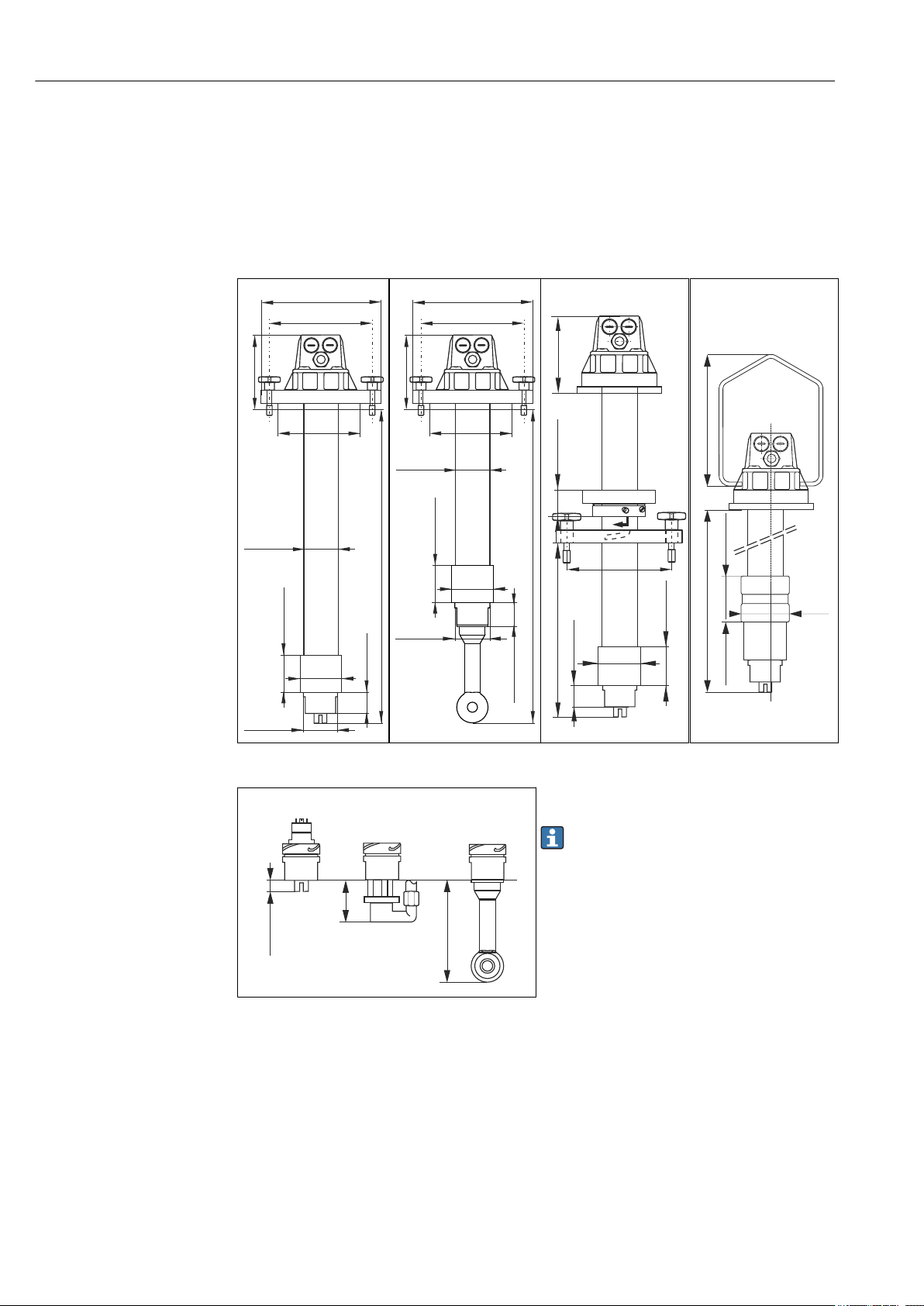

1000, 2000, 500 ... 3000 (39.4, 78.7, 19.7 to 118)

140 (5.51)

Ø 220 (8.66)

194 (7.64)

Ø 63 (2.48)

Ø 76

(2.99)

Ø 60 (2.36)

Ø 151 (5.94)

68 (2.68)

28 (1.1)

1000, 2000, 500 ... 3000 (39.4, 78.7, 19.7 to 118)

140 (5.51)

Ø 220 (8.66)

194 (7.64)

Ø 63 (2.48)

Ø 60 (2.36)

Ø 151 (5.94)

68 (2.68)

28 (1.1)

Ø 76

(2.99)

36 (1.42)

140 (5.51)

194 (7.64)

68

(2.68)

Ø 76

(2.99)

28

(1.1)

250 ... 2950

(9.84 ... 116)

205 (8.07)

85

(3.35)

Ø90

(3.54)

????? ()

24 (0.94)

67

(2.64)

148/153*

(5.83/6.02*)

CLS21

CLR30 CLS50

4 Installation

4.1 Installation conditions

4.1.1 Dimensions

1 CLA111-A/C with

CLS21D/21

8 Endress+Hauser

5 Length below the sensor holder

* PEEK version

2 CLA111-A/C with

CLS50D/50

A0007462

3

CLA111-B

All dimensions in mm (inch)

* Illustrations with CLS21D/21

Immersion length is the same when CLS50D/50 is

installed. The length of the assembly pipe changes

accordingly → 2.

*

4

CLA111-D

*

Page 9

Dipfit CLA111 Installation

Ø18(0.71)

24(0.94)

133(5.24)

180(7.09)

220(8.66)

a

a

194(7.64)

133(5.24)

180(7.09)

220(8.66)

Ø18(0.71)

24(0.94)

A0007041

6 Pressurized flange DN 100

for CLA111-C

7 Flange DN 100 for

CLA111-A/B

A0007046

All dimensions in mm (inch) a = bore holes for cross formed screws

Endress+Hauser 9

Page 10

Installation Dipfit CLA111

5

4.1.2 Measuring system

8 Example of a measuring system

1 Assembly holder CYH112 (with chain) 4 Sensor CLS50D

2 Sensorkabel CYK10 (CLS21D) bzw. Festkabel

(CLS50D)

3 Transmitter CM442 with weather protection

cover

5 Sensor CLS21D

6 Assembly CLA111-D (with suspension bracket)

A0026966

10 Endress+Hauser

Page 11

Dipfit CLA111 Installation

1 2

3

4

5

6

7

8

9

10

11

12

1 2

3

6

4

5

6

4.2 Installing the assembly

4.2.1 Versions with a flange

A0007455

9 Version A and C with flange DN 100

1 Phillips screw (x 4)

2 Assembly head

3 Dummy plug

4 Quick connect coupling for Chemoclean cleaning

5 Connection pipe with pipe unions for Chemoclean

cleaning

6 Sensor holder

7 Spray head for Chemoclean cleaning

8 Sensor holder with fixing bolts for Chemoclean

spray head CLR30

9 Assembly pipe

10 Flange DN 100 , A: standard , C: pressurized flange

11 Cross formed screws (not for pressurized version)

12 Gland Pg 13.5

10 Version B with adjustable flange DN 100

1 Adjustable flange adapter (2 half-shells)

2 O-ring for tolerance compensation

3 Tensioning screws (x 2)

4 Flange DN 100

5 Sensor holder

6 Bayonet lock

Installing the assembly with flange DN 100 (version A and C)

Use the drawing as a guide (→ 9).

‣

A0007459

Endress+Hauser 11

Page 12

Installation Dipfit CLA111

1 2

3

4

Installing the assembly with adjustable flange DN 100 (version B)

1

Phillips screws

2

Half-shells

3

Assembly pipe

4

"Final position" marker

A0007049

11 Adjustable flange adapter

1. Mount the flange DN 100 on the frame.

2. Fit the half-shells (→ 11, item 2) of the adapter in the desired position on the

pipe.

3. Tighten the half-shells with the two Phillips screws (item 1).

4. Insert the O-ring into the O-ring groove (adjustable flange adapter on outside).

5. Insert the assembly into the ready-mounted flange DN 100.

6. Holding the assembly by the assembly head, screw the assembly clockwise into the

bayonet lock as far as the "final position" marker (item 4).

Removing the assembly

1. Leave the mounted flange DN 100 on the frame.

2. Holding the assembly by the assembly head, screw the assembly counter-clockwise

out of the bayonet lock and remove the assembly from the medium.

12 Endress+Hauser

Page 13

Dipfit CLA111 Installation

1 2

3

4

5

6

7

8

9

4.2.2 Version with suspension bracket

1

Suspension bracket

2

Dummy plug Pg 16

3

Assembly head

4

Weight (half-shells)

5

Sleeve

6

Sensor CLS50

7

Sensor holder

8

Cable clamp for fixing the half-shells

9

Gland Pg 13.5

A0007460

12 Version with suspension bracket

Installing the assembly in the measuring point

1. You can install the assembly on the basin.

To do so, suspend the assembly from the chain retainer CYH112.

The mounting chain enables a flexible immersion depth.

2. The weight (item 4) is required to stabilize the assembly.

Push the weight down as far as the sleeve (item 5).

3. Then fix the cable clamp (item 8).

Endress+Hauser 13

Page 14

Electrical connection Dipfit CLA111

4.3 Installing the sensor

4.3.1 CLS21D and CLS21

1. Unscrew the sensor holder from the bayonet lock.

2. Push the O-ring over the threaded shaft of the sensor.

3. Screw the sensor into the sensor holder from above.

Connect the sensor cable (→ 15).

4. Screw the sensor holder into the bayonet lock.

4.3.2 CLS50D and CLS50

1. Unscrew the sensor holder from the bayonet lock.

2. Push the O-ring over the threaded shaft of the sensor.

3. Guide the sensor cable through the sensor holder and the assembly pipe and screw

the sensor into the sensor holder from below.

4. Screw the sensor holder into the bayonet lock.

4.4 Post-installation check

1. After mounting, check all the connections to ensure they are secure and leak-tight.

2. Check the hoses for damage.

5 Electrical connection

WARNING

L

Device is live

Incorrect connection may result in injury or death.

The electrical connection may be performed only by an electrical technician.

‣

The electrical technician must have read and understood these Operating Instructions

‣

and must follow the instructions contained therein.

Prior to commencing connection work, ensure that no voltage is present on any cable.

‣

14 Endress+Hauser

Page 15

Dipfit CLA111 Electrical connection

1

2

3

4

5

6

1

2

3 4

5

6

7

BK

BU

YE

BN

GN

WH

YE

1

2

3

5.1 Connecting the sensor

Connecting the CLS21D, CLS50D or CLS50

The sensor can be connected to a variety of transmitters.

Pay attention to the connection instructions, e.g. for the terminal assignment, in the

Operating Instructions of the transmitter used.

1. Guide the sensor cable from the sensor through the sensor holder and assembly pipe

to the assembly head and through the Pg 13.5 cable gland to the outside.

2. Connect the sensor cable directly to the transmitter.

Connecting the CLS21

A special measuring cable is included with the assembly delivery to connect the CLS21

sensor. Connect this cable to the terminals in the assembly head.

A0007457

14 Terminals

1 Measuring cable CYK71 (to transmitter)

2 Terminals

3 Measuring cable (to sensor)

A0007456

13 Measuring cable connection for CLS21

1 Assembly head cover

2 Terminals

3 Assembly head

4 Measuring cable connector

5 Sensor CLS21

6 Sensor holder

1. Unscrew the cover (→ 13, item 1) of the assembly head (item 3).

2. Push the measuring cable supplied through the assembly pipe from below.

3. Connect the cable to the terminals in the assembly head (→ 14, item 2 and 3).

4. Attach the connector (→ 13, item 4) of the cable to the sensor plug-in head (item

5).

5. Screw the sensor holder (item 6) into the bayonet lock of the assembly pipe.

Endress+Hauser 15

Page 16

Electrical connection Dipfit CLA111

6. Mount a Pg 13.5 cable gland in the assembly head cover.

7. Guide the measuring cable CYK71 (not included in the delivery for the assembly)

through the Pg gland.

8. Connect the cable to the terminals (→ 14, item 1 and 2).

9. Screw the assembly head cover onto the assembly head.

5.2 Post-connection check

Device condition and specifications Notes

Are the outside of the sensor, assembly, cable undamaged? Visual inspection

Electrical connection Notes

Are the installed cables strain-relieved and not twisted?

Is a sufficient length of the cable cores stripped, and is it

positioned in the terminal correctly?

Are all the screws terminals properly tightened? Tighten

Are all cable entries mounted, tightened and leak-tight? For lateral cable entries, make sure the

Are all cable entries installed downwards or mounted laterally?

Check the fit (by pulling gently)

cables loop downwards to allow water to

drip off

16 Endress+Hauser

Page 17

Dipfit CLA111 Maintenance

6 Maintenance

WARNING

L

Risk of injury if medium escapes

Before every maintenance task make sure that the process pipe or container is empty

‣

and rinsed.

Take all the necessary precautions in time to ensure the operational safety and reliability

of the entire measuring system.

NOTICE

Effects on process and process control

When carrying out any work on the system, take into account possible repercussions

‣

for process control or the process itself.

For your own safety, only use genuine accessories. With genuine parts, the function,

‣

accuracy and reliability are also ensured after maintenance work.

6.1 Servicing the assembly

The assembly must be serviced at regular intervals. The frequency and type of servicing

depend on the medium.

1. Remove buildup on the assembly from time to time.

2. Keep O-rings and sealing surfaces clean.

3. Replace damaged O-rings.

Versehen Sie trockene O-Ringe mit einem dünnen Fettfilm (z.B. Syntheso Glep).

4. Replace damaged parts of the assembly.

Most common types of fouling and suitable cleaning agents

Fouling Suitable cleaning agent

Greases and oils Agents containing surfactants (alkaline agents) or water-soluble

organic solvents (halogen-free, e.g. ethanol)

Limescale deposits, metal hydroxide

buildup, lyophobic biological buildup

Sulfide deposits Mixture of 3% hydrochloric acid and thiocarbamide (commercially

Protein buildup Mixture of 3% hydrochloric acid and pepsin (commercially available)

Fibers, suspended substances Pressurized water, possibly surface-active agents

Light biological buildup Pressurized water

WARNING

L

Solvents containing halogens and acetone

Gesundheitsgefährdung durch Einatmen, können Krebs verursachen (z.B. Chloroform) und

Kunststoffteile der Armatur oder Sensors zerstören (Aceton).

Never use acetone or any solvents containing halogens.

‣

Approx. 3% hydrochloric acid

available)

6.2 Cleaning the sensor

You must clean the sensor:

• Before every calibration

• Regularly during operation

• Before returning it for repairs

Endress+Hauser 17

Page 18

Repairs Dipfit CLA111

1 2

3

4

You can remove the sensor and clean it manually. Alternatively you can use the

Chemoclean automatic spray cleaning system for cyclic sensor cleaning. The complete

cleaning system includes:

• Spray head CLR30

• Cleaning injector CYR10

• Cleaning control, e.g. internally via transmitter Liquisys CLM223/253 with a Plus

Package.

7 Repairs

7.1 Spare parts

A0007491

15 Spare parts

7.2 Return

Item

No.

1 Conductivity sensor cable; 3 m with straight connector for

2 O-ring; ID = 28.17; W = 3.53; OD = 35.23; EPDM 50051753

3 PP sensor holder G¾ (without accessories) for CLS50D/

3 Kit for PP sensor holder G1

4 O-ring; ID = 53.57; W = 3.53; OD = 60.63; VITON 50009289

Description and contents Order No.

50015632

CLS21

51500640

CLS50 installation

50074080

• O-ring; ID = 53.57; W = 3.53; OD = 60.63; VITON

• O-ring; ID = 28.17; W = 3.53; OD = 35.23; EPDM

• Cable; 3 m with straight connector for CLS21

The product must be returned if repairs or a factory calibration are required, or if the

wrong product was ordered or delivered. As an ISO-certified company and also due to legal

regulations, Endress+Hauser is obliged to follow certain procedures when handling any

returned products that have been in contact with medium.

To ensure swift, safe and professional device returns, please read the return procedures

and conditions at www.endress.com/support/return-material.

7.3 Disposal

The device contains electronic components and must therefore be disposed of in

accordance with regulations on the disposal of electronic waste.

18 Endress+Hauser

Observe the local regulations.

Page 19

Dipfit CLA111 Accessories

300 (11.8)

300 (11.8)

165 (6.50)

52.5 (2.07)

30 (1.18)

40 (1.57)

10 (0.39) 10 (0.39)

10 (0.39)

30 (1.18)

2 x M10

144 (5.67)

4 x Ø9 (0.35)

150 (5.91)

35 (1.38)

150 (5.91)

10 (0.39)

10 (0.39)

7.5 (0.30)

15 (0.59)

8 Accessories

The following are the most important accessories available at the time this

documentation was issued. For accessories not listed here, please contact your service

or sales office.

8.1 Installation accessories

Flexdip CYH112

• Modular holder system for sensors and assemblies in open basins, channels and tanks

• For Flexdip CYA112 water and wastewater assemblies

• Can be affixed anywhere: on the ground, on the capstone, on the wall or directly onto

railings.

• Stainless steel version

• Product Configurator on the product page: www.endress.com/cyh112

Technical Information TI00430C

Mounting frame

For CPA111, CPA510, CPA530 and CLA111

• Material: stainless steel 1.4301 (AISI 304)

• Order number: 50066561

A0007060

16 Mounting frame in mm (inch)

Adjustable flange adapter DN 100

• For CPA111 and CLA111 for variable immersion depths

• Order number: 50070514

Flange DN 100, unpressurized

• For CPA111 and CLA111 suitable for adjustable flange adapter

• Order number: 50066632

8.2 Sensors

Condumax CLS21D/ CLS21

• Two-electrode sensor in plug-in head version and fixed cable version

Endress+Hauser 19

• Product Configurator on the product page: www.endress.com/CLS21d or

www.endress.com/CLS21

Technical Information TI00085C

Page 20

Accessories Dipfit CLA111

48(1.89)

Ø10(0.39)

Indumax CLS50D/ CLS50

• High-durability inductive conductivity sensor

• For standard and hazardous area applications

• With Memosens technology (CLS50D)

• Product Configurator on the product page: www.endress.com/cls50d or

www.endress.com/cls50

Technical Information TI00182C

8.3 Extension cable

Memosens data cable CYK11

• Extension cable for digital sensors with Memosens protocol

• Product Configurator on the product page: www.endress.com/cyk11

Technical Information TI00118C

Measuring cable CYK71

• Unterminated cable for connecting analog sensors and for extending sensor cables

• Sold by the meter, order numbers:

– Non-Ex version, black: 50085333

– Ex-version, blue: 50085673

8.4 Chemoclean

Chemoclean CLR30

Automatic spray cleaning system for cleaning the sensors CLS21/CLS21D

Order according to product structure

Materials in contact with the medium

Spray head PP-GF20

O-rings EPDM / VITON

Operating data

Process pressure Max. 4 bar (58 psi) absolute, at 20 °C

Process temperature Max. 80 °C (176 °F) at ambient

Cleaner pressure 4 to 6 bar (58 to 87 psi) absolute, at

(68 °F)

pressure

20 °C (68 °F)

20 Endress+Hauser

Page 21

Dipfit CLA111 Technical data

9 Technical data

9.1 Environment

Ambient temperature range

-10 to +80 °C (+10 to +180 °F)

9.2 Process

Process temperature -10 to +80 °C (+10 to +180 °F)

Process pressure

CLA111-A/B/D Unpressurized

CLA111-C Max. 5 bar (72 psi) abs. at 20 °C (68 °F),

9.3 Mechanical construction

Dimensions → 8

Weight Approx. 4.0 kg (8.8 lbs)

Materials

Sensor holder PP-GF 20

Immersion tube PP

O-ring VITON

Only version CLA111-D:

Half-shells Cast iron, PVC-coated

Cable clamp Stainless steel 1.4401 (AISI 316)

unpressurized up to 80 °C (176 °F)

Cable entries 1 x Pg 13.5 and 2 x Pg 16

Sensors suitable for use CLS21D, CLS21, CLS50D, CLS50

Immersion depth Standard 1000 mm (39.4 inch), 2000 mm (78.8 inch)

Other length 500 to 3000 mm (19.7 to 118 inch)

Process connections CLA111-A Flange DN 100, additionally with captive cross

formed screws

CLA111-B Adjustable flange DN 100

CLA111-C Pressurized flange DN 100

CLA111-D Stainless steel suspension bracket (1.4571 (AISI 316

Ti))

Endress+Hauser 21

Page 22

Index Dipfit CLA111

Index

A

Ambient temperature range ................... 21

Assembly

Installation ............................. 11

Servicing ............................... 17

C

Check

Connection ..............................16

Installation ............................. 14

Chemoclean ............................... 20

D

Designated use .............................. 4

Disposal .................................. 18

E

Electrical connection ......................... 14

I

Incoming acceptance ......................... 6

Installation

Check ..................................14

Installation conditions ...................... 8

Installing the assembly ..................... 11

Sensor ................................. 14

Installation conditions

Dimensions .............................. 8

Measuring system ........................ 10

T

Technical data

Environment ............................ 21

Mechanical construction ....................21

Process ................................ 21

U

Use .......................................4

M

Maintenance ...............................17

N

Nameplate ................................. 6

P

Process pressure ............................ 21

Process temperature ......................... 21

Product identification ......................... 6

R

Repairs ................................... 18

Return ................................... 18

S

Safety information ........................... 3

Safety instructions ............................4

Scope of delivery ............................. 7

Sensor

Accessories ............................. 19

Cleaning ............................... 17

Connecting ..............................15

Installing ............................... 14

Spare parts ................................ 18

Suspension bracket .......................... 13

Symbols ................................... 3

22 Endress+Hauser

Page 23

Page 24

*71293522*

71293522

www.addresses.endress.com

Loading...

Loading...