Products Solutions Services

Operating Instructions

Chloromax CCS142D

Digital sensor with Memosens technology for

determining free chlorine

BA00419C/07/EN/15.17

71378188

AUTHORIZED DISTRIBUTOR:

InstrumentsAndControl.com

Houston, Texas USA

sales@InstrumentsAndControl.com

281-609-7170

Chloromax CCS142D Table of contents

Endress+Hauser 3

Table of contents

1 Document information ......... 4

1.1 Warnings ........................... 4

1.2 Symbols used ........................ 4

2 Basic safety instructions ....... 6

2.1 Requirements for the personnel ........ 6

2.2 Designated use ...................... 6

2.3 Occupational safety .................. 6

2.4 Operational safety ................... 7

2.5 Product safety ....................... 7

3 Product description ............. 8

3.1 Product design ....................... 8

4 Incoming acceptance and

product identification ......... 13

4.1 Incoming acceptance ................ 13

4.2 Product identification ................ 13

5 Installation .................... 16

5.1 Installation conditions ............... 16

5.2 Mounting the sensor ................ 18

5.3 Post-installation check ............... 19

6 Electrical connection .......... 20

6.1 Connecting the sensor ............... 20

6.2 Ensuring the degree of protection ..... 20

6.3 Post-connection check ............... 20

7 Commissioning ................ 22

7.1 Function check ..................... 22

7.2 Sensor polarization .................. 22

7.3 Calibrating the sensor ............... 22

8 Diagnostics and

troubleshooting ............... 24

9 Maintenance .................. 26

9.1 Maintenance schedule ............... 26

9.2 Maintenance tasks .................. 26

10 Repair .......................... 31

10.1 Spare parts ........................ 31

10.2 Return ............................ 31

10.3 Disposal ........................... 31

11 Accessories .................... 32

11.1 Device-specific accessories ............ 32

12 Technical data ................. 33

13 Installation and operation in

hazardous environment Class

I Div. 2 .......................... 36

Index ................................. 38

Document information Chloromax CCS142D

4 Endress+Hauser

1 Document information

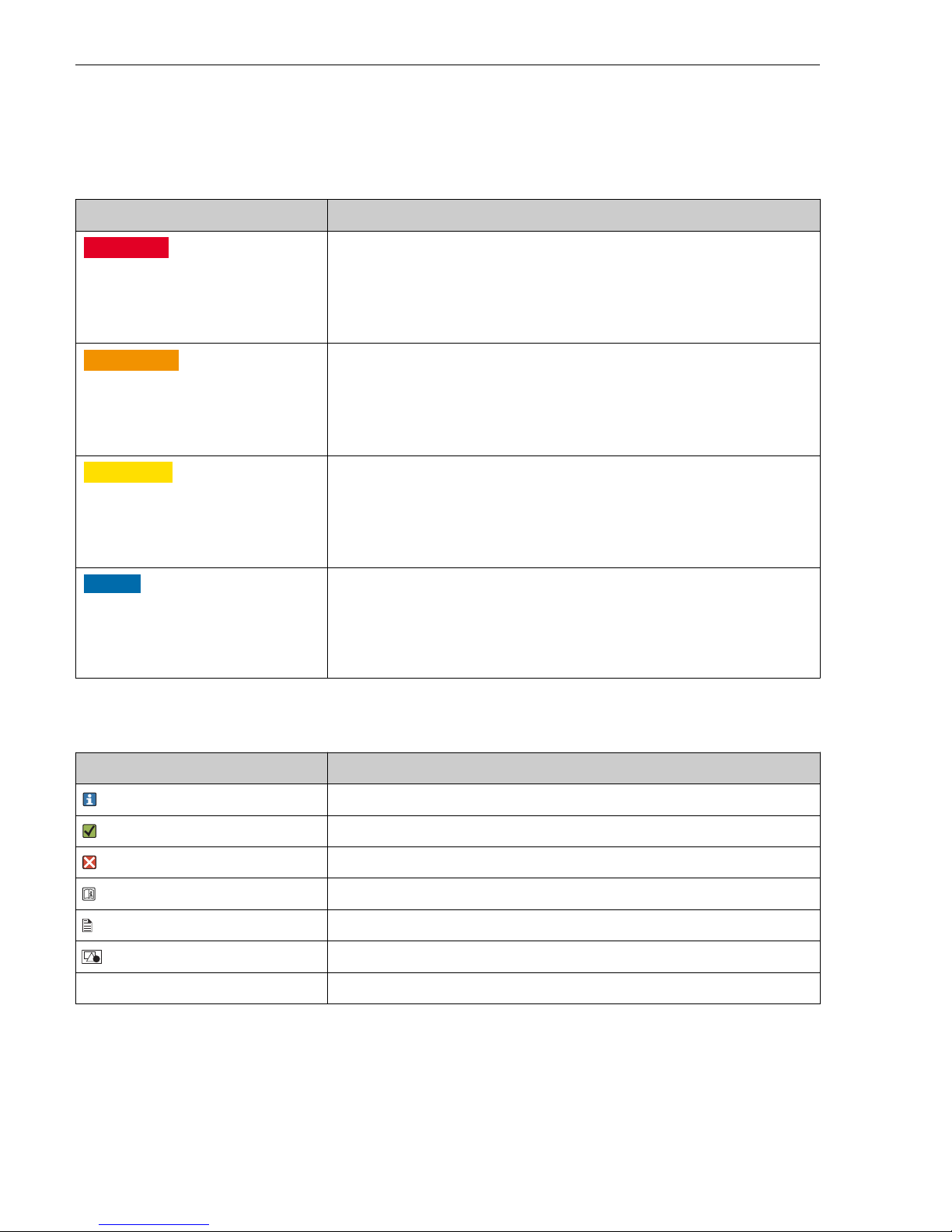

1.1 Warnings

Structure of information Meaning

L

DANGER

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

‣

Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation will result in a fatal or serious injury.

L

WARNING

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

‣

Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid the dangerous situation can result in a fatal or serious injury.

L

CAUTION

Causes (/consequences)

If necessary, Consequences of noncompliance (if applicable)

‣

Corrective action

This symbol alerts you to a dangerous situation.

Failure to avoid this situation can result in minor or more serious injuries.

NOTICE

Cause/situation

If necessary, Consequences of noncompliance (if applicable)

‣

Action/note

This symbol alerts you to situations which may result in damage to property.

1.2 Symbols used

Symbol Meaning

Additional information, tips

Permitted or recommended

Not permitted or not recommended

Reference to device documentation

Reference to page

Reference to graphic

Result of a step

Chloromax CCS142D Document information

Endress+Hauser 5

1.2.1 Symbols on the device

Symbol Meaning

Reference to device documentation

Basic safety instructions Chloromax CCS142D

6 Endress+Hauser

2 Basic safety instructions

2.1 Requirements for the personnel

Installation, commissioning, operation and maintenance of the measuring system may be

carried out only by specially trained technical personnel.

‣

The technical personnel must be authorized by the plant operator to carry out the specified

activities.

‣

The electrical connection may be performed only by an electrical technician.

‣

The technical personnel must have read and understood these Operating Instructions and

must follow the instructions contained therein.

‣

Measuring point faults may be repaired only by authorized and specially trained personnel.

Repairs not described in the Operating Instructions provided must be carried out only

directly at the manufacturer's site or by the service organization.

2.2 Designated use

Drinking water, process water and bathing water must be disinfected through the addition of

appropriate disinfectants such as chlorine gas or inorganic chlorine compounds. The dosing

quantity involved must be adapted to continuously fluctuating operating conditions. Too low

concentrations in the water could jeopardize the effectiveness of the disinfection process. Too

high concentrations can lead to signs of corrosion and have an adverse effect on taste, while

also generating unnecessary costs.

The sensor was specifically developed for this application and is designed for continuous

measurement of free chlorine in water. In conjunction with measuring and control equipment,

it allows optimum control of the disinfection process.

Use of the device for any purpose other than that described, poses a threat to the safety of

people and of the entire measuring system and is therefore not permitted.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.2.1

Hazardous environment in accordance with cETLus NI Cl. I, Div. 2

1)

‣

Please note the control drawing and the specified application conditions in the appendix of

these Operating Instructions and follow the instructions.

2.3 Occupational safety

As the user, you are responsible for complying with the following safety conditions:

• Installation guidelines

• Local standards and regulations

1) Only if connected to CM444R-EA* or CM448R-EA*

Chloromax CCS142D Basic safety instructions

Endress+Hauser 7

Electromagnetic compatibility

• The product has been tested for electromagnetic compatibility in accordance with the

applicable European standards for industrial applications.

• The electromagnetic compatibility indicated applies only to a product that has been

connected in accordance with these Operating Instructions.

2.4 Operational safety

Before commissioning the entire measuring point:

1. Verify that all connections are correct.

2. Ensure that electrical cables and hose connections are undamaged.

3. Do not operate damaged products, and protect them against unintentional operation.

4. Label damaged products as defective.

During operation:

‣

If faults cannot be rectified:

products must be taken out of service and protected against unintentional operation.

2.4.1 Special instructions

‣

Do not operate the sensors under process conditions where it is expected that osmotic

conditions will cause electrolyte components to pass through the membrane and into the

process.

Use of the sensor for its intended purpose in liquids with a conductivity of at least 10 nS/cm

can be classified as electrostatically safe.

2.5 Product safety

The product is designed to meet state-of-the-art safety requirements, has been tested, and

left the factory in a condition in which it is safe to operate. The relevant regulations and

European standards have been observed.

Product description Chloromax CCS142D

8 Endress+Hauser

3 Product description

3.1 Product design

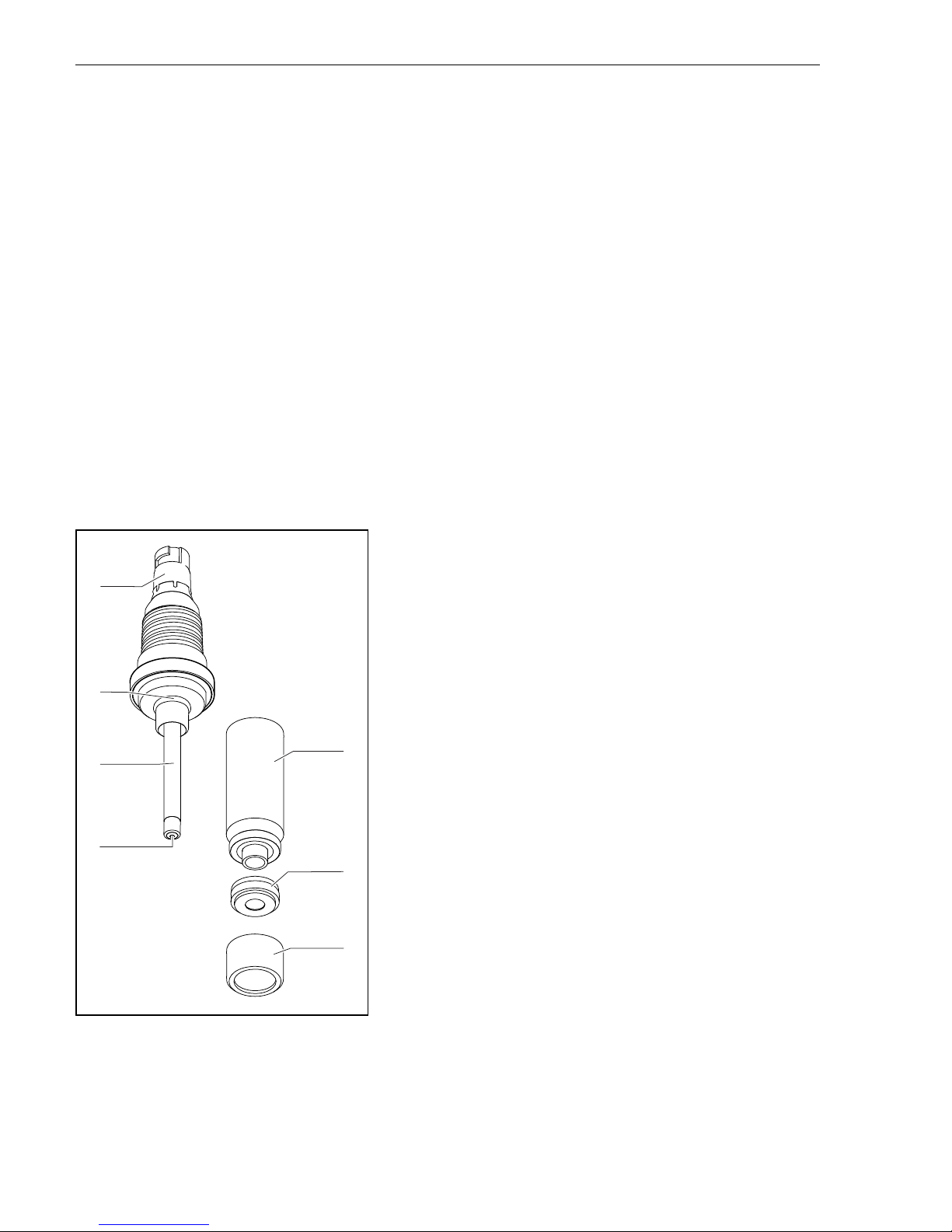

The sensor consists of the following function units:

• Measuring chamber

– To protect the anode or cathode from the medium

– With a large volume of electrolyte for a long service life in combination with the large

anode and the small cathode

• Sensor shaft with

– Large anode

– Cathode embedded in plastic

– Temperature sensor

• Membrane cap with

– Robust PTFE membrane

– Special support grid between cathode and membrane for a specified and constant

electrolyte film and thus a relatively constant indication even at varying pressures and

flows

3

4

5

6

7

1

2

A0026479

1 Sensor structure

1 Memosens plug-in head

2 O-ring

3 Large anode, silver/silver chloride

4 Gold cathode

5 Measuring chamber

6 Membrane cap with dirt-repellent membrane

7 Screw cap for securing the membrane cap

3.1.1 Measuring principle

Free chlorine is determined as hypochlorous acid according to the amperometric measuring

principle.

Chloromax CCS142D Product description

Endress+Hauser 9

The hypochlorous acid (HOCl) contained in the medium diffuses through the sensor

membrane and is reduced to chloride ions (Cl-) at the gold cathode. At the silver anode, silver

is oxidized to silver chloride. Electron donation at the gold cathode and electron acceptance at

the silver anode causes a current to flow which is in proportion to the concentration of free

chlorine in the medium at constant conditions.

The concentration of hypochlorous acid depends on the pH value. This dependency can be

compensated for by measuring the pH value in the flow assembly.

The transmitter uses the current signal to calculate the measured variable for concentration in

mg/l.

3.1.2 Effects on the measuring signal

pH value

pH-dependency

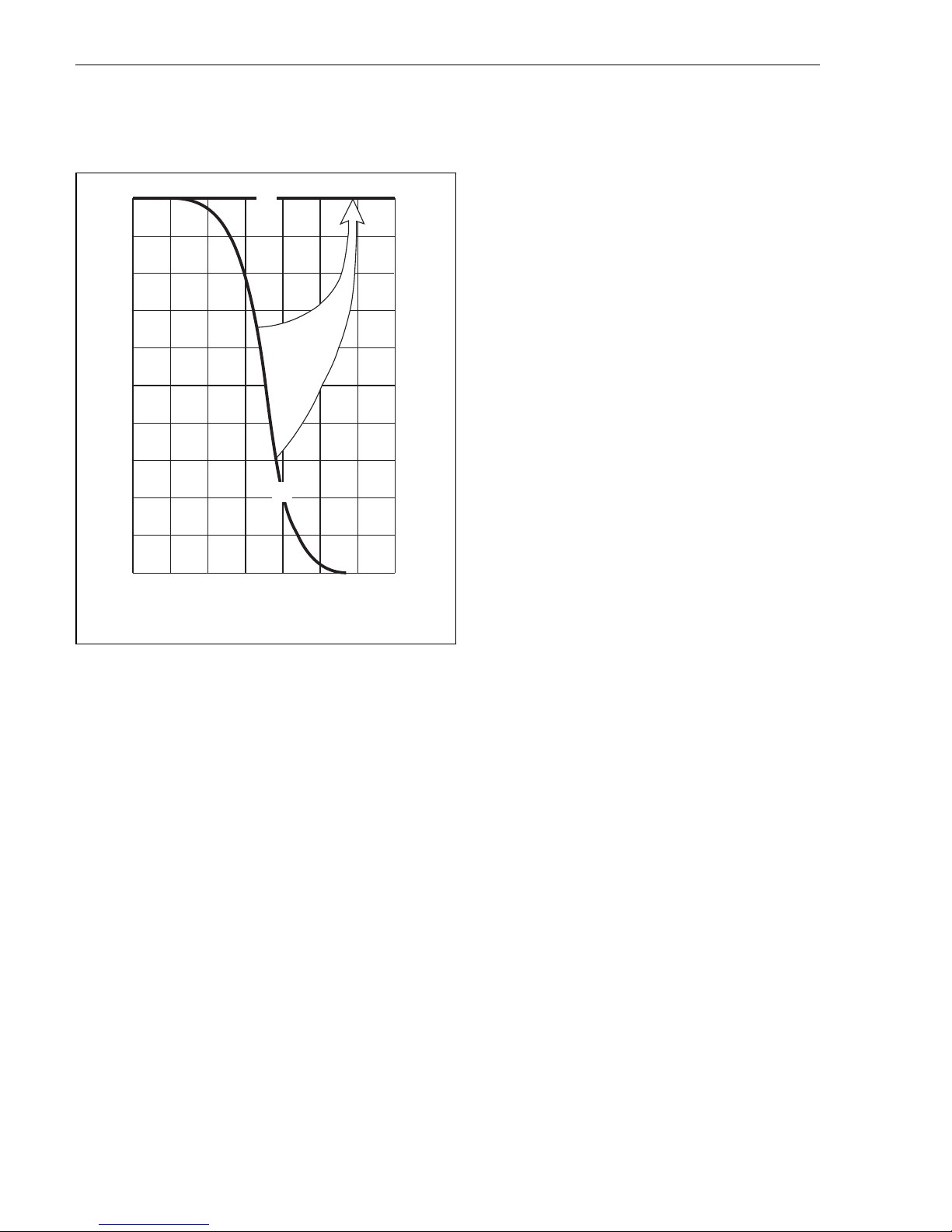

Molecular chlorine (Cl2) is present at pH values < 4. Consequently, hypochlorous acid (HOCl)

and hypochlorite (OCl– remain within the range of pH 4 to 11 as components of free chlorine.

As hypochlorous acid splits up (dissociates) with an increasing pH value to form hypochlorite

ions (OCl–) and hydrogen ions (H+), the amounts of the individual components of free

Product description Chloromax CCS142D

10 Endress+Hauser

effective chlorine change with the pH value. For example, if the proportion of hypochlorous

acid is 97 % at pH 6, it drops to approx. 3 % at pH 9.

%

100

80

60

40

20

0

4

5 6 7 8 9 10 11

100

%

80

60

40

20

0

A

pH

OCl

-

HOCl

C

B

A0002017

2 Principle of pH compensation

A Measured value with pH compensation

B Measured value without pH compensation

C pH compensation

For amperometric measurement using the CCS142D chlorine sensor, only the amount of

hypochlorous acid is selectively measured. This works as a powerful disinfectant in a watery

solution. In contrast to this, hypochlorite is an extremely weak disinfectant. Therefore, when

used as a disinfectant at higher pH values, the effectiveness of chlorine is limited. As

hypochlorite ions cannot permeate the sensor membrane, the sensors do not record this

value.

pH compensation of chlorine sensor signal

To calibrate and verify the chlorine measuring system, a colorimetric reference measurement

must be carried out using the DPD method. Free chlorine reacts with diethyl-pphenylendiamine to form a red dye. The intensity of the red color increases proportionally to

the chlorine content. With the DPD method, the sample is buffered to a pH value of approx.

6.3. Therefore, the pH value of the sample is not included in the DPD measurement. Due to

the buffer function in the DPD method, all components of free effective chlorine are recorded

and thus the total free chlorine is measured.

If pH compensation is switched on in the transmitter, the sum of hypochlorous acid (HOCl)

and hypochlorite corresponding to the DPD measurement is calculated from the chlorine

Chloromax CCS142D Product description

Endress+Hauser 11

sensor's measuring signal that corresponds to hypochlorous acid (HOCl) and by taking into

account the pH value in the range of pH 4 to 9. For this calculation, the curve is stored in the

transmitter.

When free chlorine is measured with pH compensation switched on, always perform

calibration in pH-compensated mode.

When you use pH compensation, the measured chlorine value that is displayed and applied to

the device output corresponds to the DPD measured value even if the pH values fluctuate. If

you do not use pH compensation, the measured chlorine value corresponds to the DPD

measurement only if the pH value remains unchanged compared with the calibration.

Without pH compensation, the chlorine measuring system must be recalibrated when the pH

value changes.

Accuracy of pH compensation

The accuracy of the pH-compensated measured chlorine value is derived from the sum of

several individual deviations (chlorine, pH, temperature, DPD measurement etc.).

High levels of hypochlorous acid (HOCl) during chlorine calibration have a positive effect on

accuracy, whereas low levels of hypochlorous acid have a negative effect. The inaccuracy of

the pH-compensated measured chlorine value increases the greater the pH difference

between measuring mode and chlorine calibration or the more inaccurate the underlying

individual measured values are.

Calibration taking into account the pH value

The reference measurement (DPD method, photometer) determines the total free chlorine by

buffering to pH 6.3. In contrast to this, amperometric measurement determines only the HOCl

component.

During operation, pH compensation is effective up to a pH value of 9. However, there is hardly

any HOCl left at this pH value, and the measured current is very low. At this point, pH

compensation has the effect of increasing the measured HOCl value to the actual value of the

free chlorine. Calibration of the complete measuring system makes sense only if the medium

has a pH value up to 8 or 8.2.

Sensor pH value HOCl content Uncompensated value Compensated value

CCS142D-G 8.2 15 % 12 nA 80 nA

CCS142D-A 8.0 20 % 4 nA 20 nA

Above these pH values, the total error of the measuring system is unacceptably high.

Flow

The minimum flow velocity of the membrane-covered sensor is 15 cm/s (0.5 ft/s).

When using the CCA250 flow assembly, this corresponds to a flow rate of 30 l/h (8 gal/h)

(upper edge of float at level of red bar mark).

At higher flow rates, the measuring signal is virtually flow-independent. However, if the flow

rate falls below the specified value, the measuring signal depends on the flow.

Product description Chloromax CCS142D

12 Endress+Hauser

The installation of an INS proximity switch in the assembly enables reliable detection of this

prohibited operating status, thus triggering an alarm or causing the dosing process to be

switched off if necessary.

Temperature

Changes in the temperature of the medium affect the measured value:

• Increases in temperature result in a higher measured value (approx. 4 % per K)

• Decreases in temperature result in a lower measured value

Use of the sensor in conjunction with the Liquiline enables automatic temperature

compensation (ATC). In this case, the temperature does not need to remain constant, and a

recalibration in the event of temperature changes is not required.

1. If automatic temperature compensation is disabled at the transmitter, maintain the

temperature following calibration at a constant level.

2. Otherwise, recalibrate the sensor.

Loading...

Loading...