Page 1

E

BA01270P/00/EN/04.16

71344744

Products Solutions Services

Operating Instructions

Ceraphant PTP31B, PTP33B

Process pressure measurement

Pressure switch for safe measurement and monitoring of

absolute and gauge pressure

Page 2

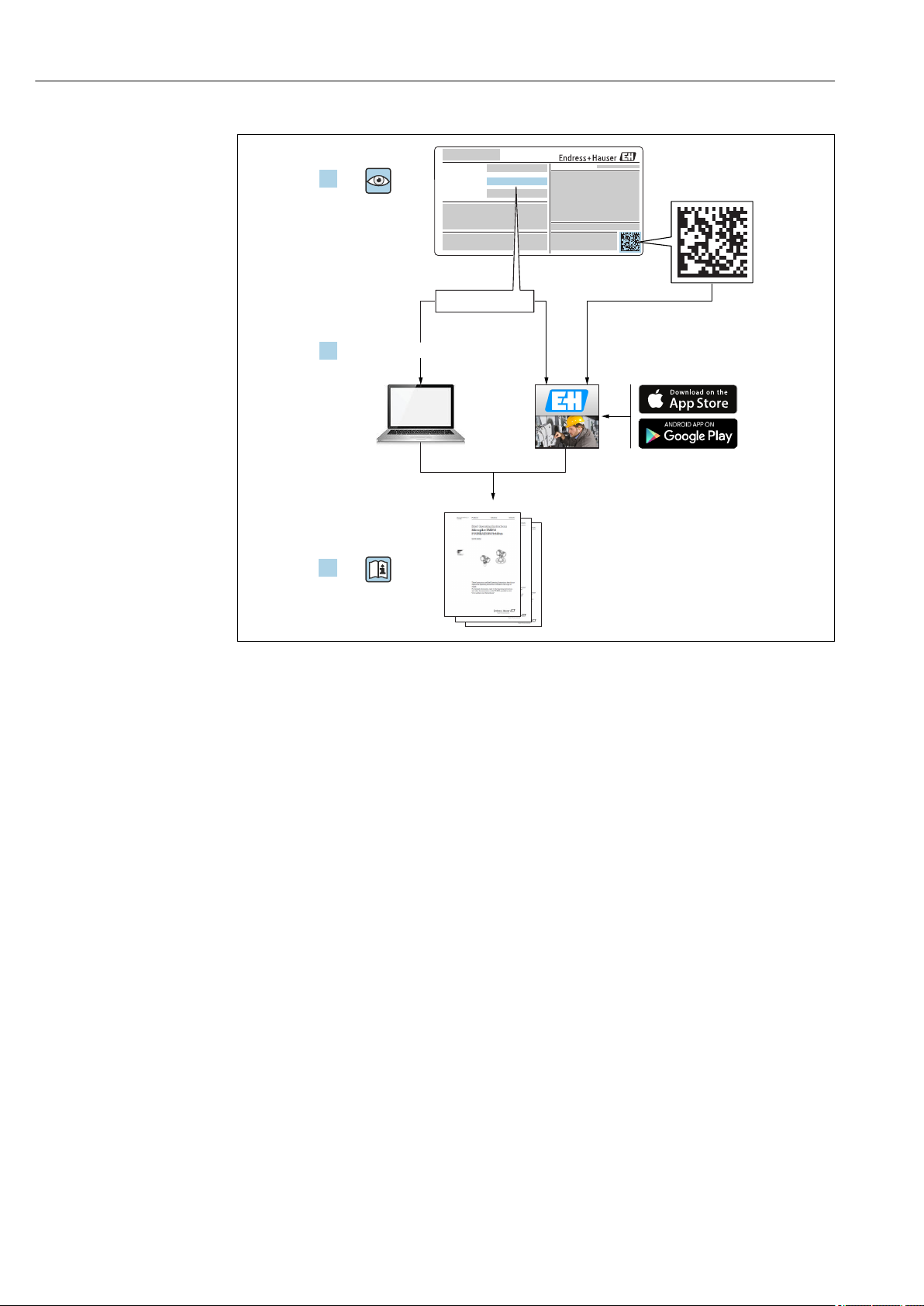

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

1.

3.

2.

A0023555

• Make sure the document is stored in a safe place such that it is always available when

working on or with the device.

• To avoid danger to individuals or the facility, read the "Basic safety instructions" section

carefully, as well as all other safety instructions in the document that are specific to

working procedures.

• The manufacturer reserves the right to modify technical data without prior notice. Your

Endress+Hauser distributor will supply you with current information and updates to

these Instructions.

2 Endress+Hauser

Page 3

Table of contents

Table of contents

1 Document information .............. 5

1.1 Document function ..................... 5

1.2 Symbols used .......................... 5

1.3 Documentation ........................ 6

1.4 Terms and abbreviations ................. 7

1.5 Turn down calculation ................... 8

2 Basic safety instructions ............ 9

2.1 Requirements concerning the staff .......... 9

2.2 Designated use ........................ 9

2.3 Workplace safety ...................... 10

2.4 Operational safety ..................... 10

2.5 Product safety ........................ 10

3 Product description ................ 11

3.1 Product design ........................ 11

3.2 Function ............................ 11

4 Incoming acceptance and product

identification ..................... 12

4.1 Incoming acceptance ................... 12

4.2 Product identification ................... 13

4.3 Storage and transport .................. 13

5 Installation ....................... 15

5.1 Mounting dimensions .................. 15

5.2 Installation conditions .................. 15

5.3 Influence of the installation position ........ 15

5.4 Mounting location ..................... 16

5.5 Post-installation check .................. 18

6 Electrical connection .............. 19

6.1 Connecting the measuring unit ............ 19

6.2 Relay switching capacity ................. 20

6.3 Connection conditions .................. 21

6.4 Connection data ....................... 21

6.5 Post-connection check .................. 21

7 Operation options ................. 22

7.1 Operation with an operating menu ......... 22

7.2 Structure of the operating menu ........... 22

7.3 Operation with local display .............. 22

7.4 General value adjustment and rejection of

illegal entries ......................... 23

7.5 Navigation and selection from list ......... 23

7.6 Locking and unlocking operation .......... 24

7.7 Navigation examples ................... 26

7.8 Status LEDs .......................... 26

7.9 Resetting to factory settings (reset) ........ 26

8 Commissioning .................... 27

8.1 Function check ....................... 27

8.2 Enabling configuration/operation .......... 27

8.3 Commissioning with an operating menu ..... 27

8.4 Configuring pressure measurement (only for

devices with a current output) ............ 27

8.5 Performing position adjustment ........... 29

8.6 Configuring process monitoring ........... 32

8.7 Functions of switch output ............... 32

8.8 Current output ........................ 35

8.9 Application examples ................... 37

8.10 Configuring the local display ............. 37

8.11 Protecting settings from unauthorized

access .............................. 38

9 Diagnostics and troubleshooting ... 39

9.1 Troubleshooting ...................... 39

9.2 Diagnostic events ...................... 40

9.3 Behavior of the device in the event of a

fault ............................... 42

9.4 Response of output to errors .............. 42

9.5 Behavior of the device in the event of a

voltage drop ......................... 43

9.6 Behavior of the device in the event of an

incorrect entry ....................... 43

9.7 Disposal ............................ 43

10 Maintenance ...................... 44

10.1 Exterior cleaning ...................... 44

11 Repair ............................ 45

11.1 General notes ........................ 45

11.2 Return .............................. 45

12 Overview of the operating menu .... 46

13 Description of device parameters ... 49

13.1 Switch output 1 and switch output 2 ........ 49

13.2 Current output ........................ 53

13.3 EF menu (extended functions) ............ 54

13.4 DIAG menu (diagnosis) ................. 64

14 Accessories ....................... 66

14.1 Weld-in adapter ...................... 66

14.2 Process adapter M24 ................... 66

14.3 M12 plug connectors ................... 67

15 Technical data .................... 68

15.1 Input ............................... 68

15.2 Output ............................. 70

Endress+Hauser 3

Page 4

Table of contents

15.3 Performance characteristics of metallic

process isolating diaphragm .............. 73

15.4 Environment ......................... 75

15.5 Process ............................. 76

Index .................................. 77

4 Endress+Hauser

Page 5

Ceraphant PTP31B, PTP33B Document information

DANGER

WARNING

CAUTION

NOTICE

1 Document information

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

1.2 Symbols used

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning Symbol Meaning

Protective ground connection

A terminal which must be connected

to ground prior to establishing any

other connections.

Ground connection

A grounded terminal which, as far as

the operator is concerned, is

grounded via a grounding system.

1.2.3 Tool symbols

Symbol Meaning

Open-ended wrench

A0011222

1.2.4 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Endress+Hauser 5

Page 6

Document information Ceraphant PTP31B, PTP33B

A

,…,

1.

2.

3.

,…,

1.

2.

3.

Symbol Meaning

Reference to documentation

Reference to page

Reference to graphic

Series of steps

Result of a step

Visual inspection

1.2.5 Symbols in graphics

Symbol Meaning

1, 2, 3 ... Item numbers

Series of steps

A, B, C, ... Views

1.3 Documentation

The document types listed are available:

In the Download Area of the Endress+Hauser Internet site: www.endress.com →

Download

1.3.1 Technical Information (TI): planning aid for your device

PTP31B: TI01130P

PTP33B: TI01246P

The document contains all the technical data on the device and provides an overview of

the accessories and other products that can be ordered for the device.

1.3.2 Brief Operating Instructions (KA): getting the 1st measured value quickly

KA01163P:

The Brief Operating Instructions contain all the essential information from incoming

acceptance to initial commissioning.

6 Endress+Hauser

Page 7

Ceraphant PTP31B, PTP33B Document information

URL OPLMWP

LRL

0

p

LRV

URV

1

2

3

4

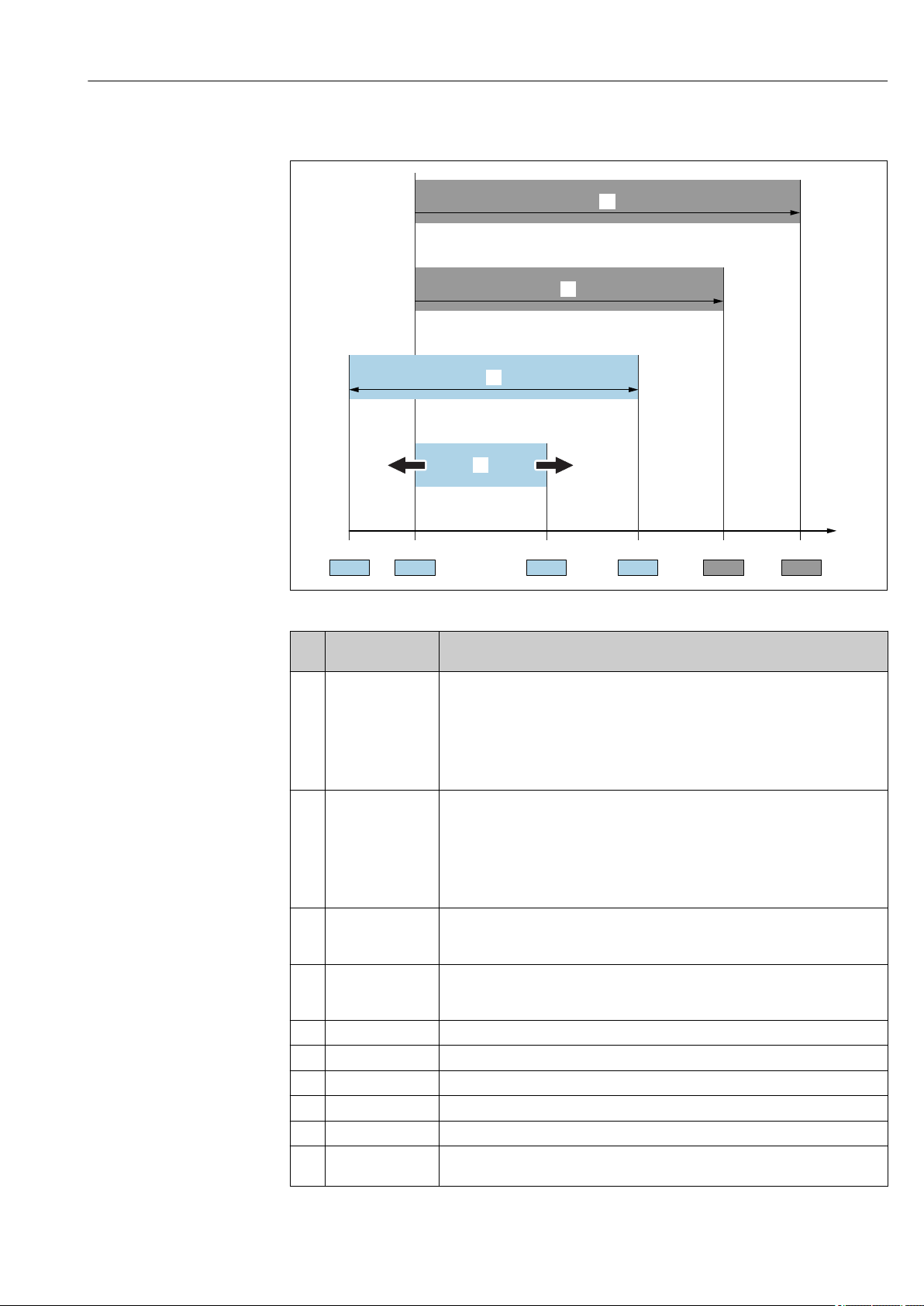

1.4 Terms and abbreviations

A0029505

Item Term/

abbreviation

1 OPL The OPL (over pressure limit = sensor overload limit) for the measuring device

2 MWP The MWP (maximum working pressure) for the sensors depends on the lowest-

3 Maximum sensor

measuring range

4 Calibrated/adjusted

span

p - Pressure

- LRL Lower range limit

- URL Upper range limit

- LRV Lower range value

- URV Upper range value

- TD (turn down) Turn down

Explanation

depends on the lowest-rated element, with regard to pressure, of the selected

components, i.e. the process connection has to be taken into consideration in

addition to the measuring cell. Also observe pressure-temperature dependency. For

the relevant standards and additional notes, see the "Pressure specifications" section

→ 76 .

The OPL may only be applied for a limited period of time.

rated element, with regard to pressure, of the selected components, i.e. the process

connection has to be taken into consideration in addition to the measuring cell.

Also observe pressure-temperature dependency. For the relevant standards and

additional notes, see the "Pressure specifications" section → 76 .

The MWP may be applied at the device for an unlimited period.

The MWP can also be found on the nameplate.

Span between LRL and URL

This sensor measuring range is equivalent to the maximum calibratable/adjustable

span.

Span between LRV and URV

Factory setting: 0 to URL

Other calibrated spans can be ordered as customized spans.

Example - see the following section.

Endress+Hauser 7

Page 8

Document information Ceraphant PTP31B, PTP33B

LRV

URLURV

LRL

1 = 2

3

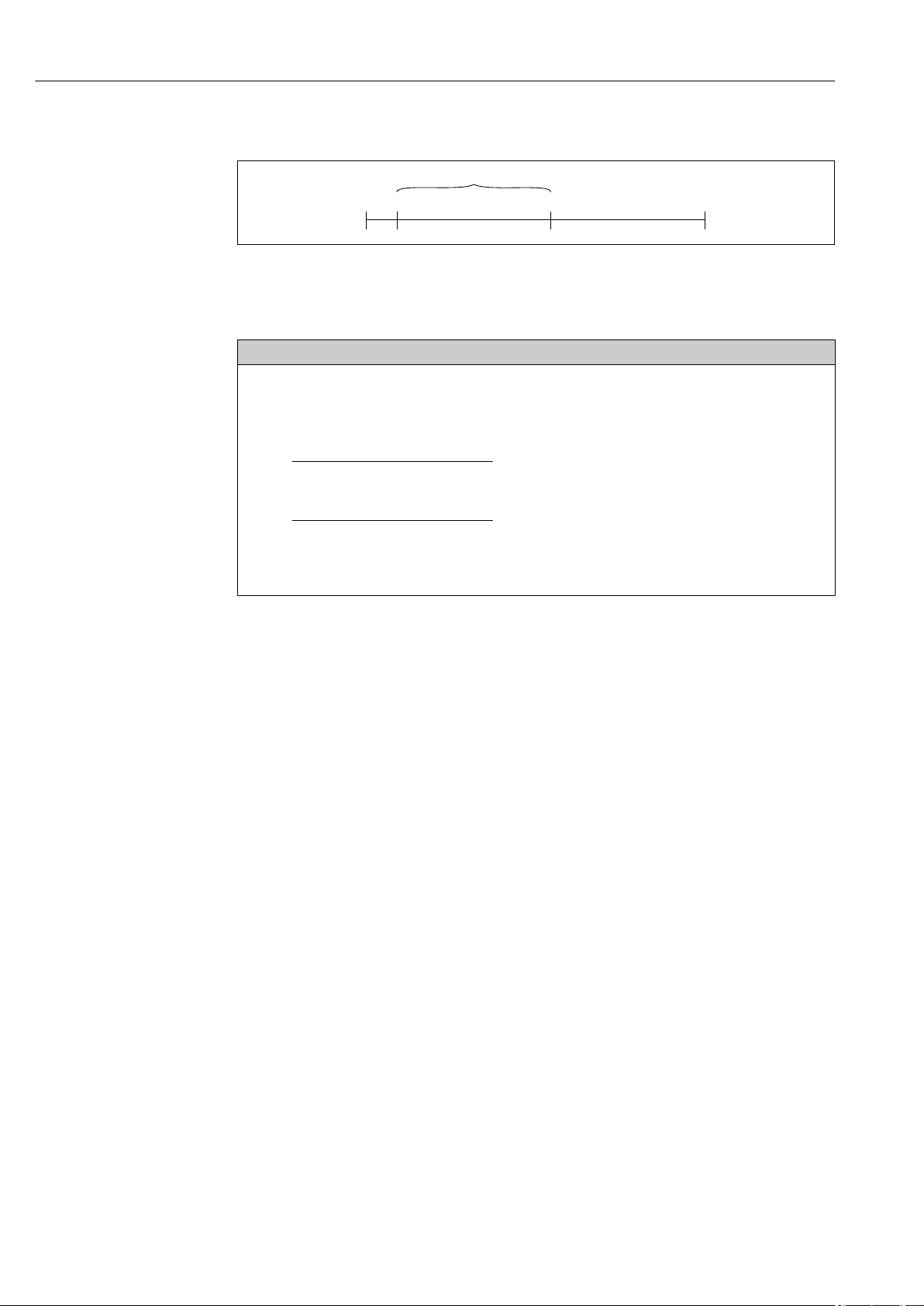

1.5 Turn down calculation

A0029545

1 Calibrated/adjusted span

2 Zero point-based span

3 URL sensor

Example

• Sensor:10 bar (150 psi)

• Upper range value (URL) = 10 bar (150 psi)

Turn down (TD):

• Calibrated/adjusted span: 0 to 5 bar (0 to 75 psi)

• Lower range value (LRV) = 0 bar (0 psi)

• Upper range value (URV) = 5 bar (75 psi)

TD =

URL

|URV - LRV|

10 bar (150 psi)

TD =

|5 bar (75 psi) - 0 bar (0 psi)|

In this example, the TD is 2:1.

This span is based on the zero point.

= 2

8 Endress+Hauser

Page 9

Ceraphant PTP31B, PTP33B Basic safety instructions

2 Basic safety instructions

2.1 Requirements concerning the staff

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

Trained, qualified specialists: must have a relevant qualification for this specific

‣

function and task

Are authorized by the plant owner/operator

‣

Are familiar with federal/national regulations

‣

Before beginning work, the specialist staff must have read and understood the

‣

instructions in the Operating Instructions and supplementary documentation as well as

in the certificates (depending on the application)

Following instructions and basic conditions

‣

The operating personnel must fulfill the following requirements:

Being instructed and authorized according to the requirements of the task by the

‣

facility's owner-operator

Following the instructions in these Operating Instructions

‣

2.2 Designated use

2.2.1 Application and media

The Ceraphant is a pressure switch for measuring and monitoring absolute and gauge

pressure in industrial systems. The process-wetted materials of the measuring device must

have an adequate level of resistance to the media.

The measuring device may be used for the following measurements (process variables)

• in compliance with the limit values specified under "Technical data"

• in compliance with the conditions that are listed in this manual.

Measured process variable

Gauge pressure or absolute pressure

Calculated process variable

Pressure

2.2.2 Incorrect use

The manufacturer is not liable for damage caused by improper or non-designated use.

Verification for borderline cases:

For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance

‣

in verifying the corrosion resistance of process-wetted materials, but does not accept

any warranty or liability.

2.2.3 Residual risks

When in operation, the housing may reach a temperature close to the process

temperature.

Danger of burns from contact with surfaces!

For elevated process temperatures, ensure protection against contact to prevent burns.

‣

Endress+Hauser 9

Page 10

Basic safety instructions Ceraphant PTP31B, PTP33B

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

Switch off the supply voltage before connecting the device.

‣

2.4 Operational safety

Risk of injury!

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with Endress+Hauser.

‣

Hazardous area

To eliminate the risk of danger to persons or the facility when the device is used in the

approval-related area (e.g. pressure equipment safety):

Check the nameplate to verify if the device ordered can be put to its intended use in the

‣

approval-related area.

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EU

directives listed in the device-specific EU Declaration of Conformity. Endress+Hauser

confirms this by affixing the CE mark to the device.

10 Endress+Hauser

Page 11

Ceraphant PTP31B, PTP33B Product description

A B C

D

E

D

E

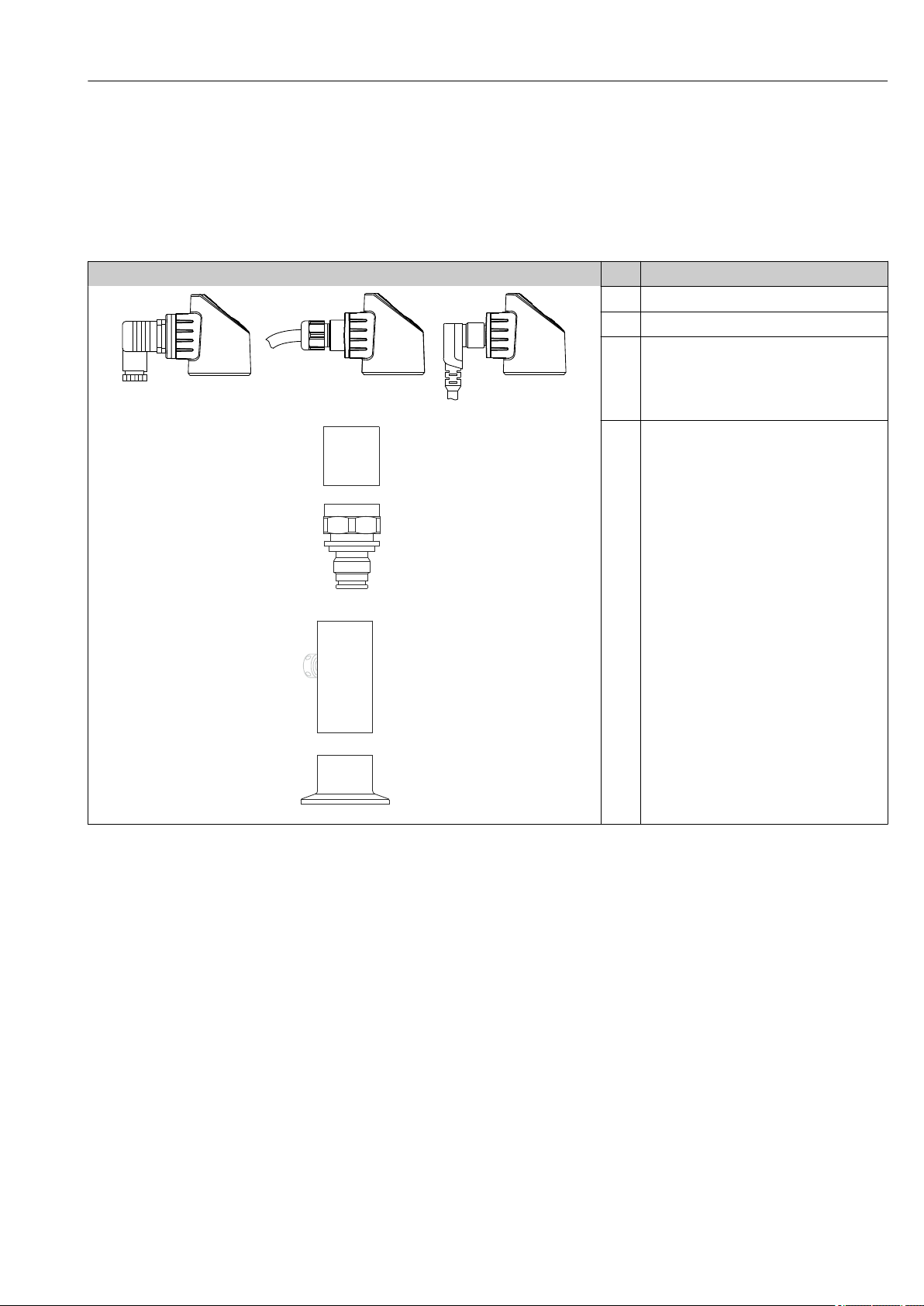

3 Product description

3.1 Product design

Overview Item Description

A Valve plug

B Cable

C M12 plug

Housing cap made of plastic

A0022015

D

Housing

E

Process connection (sample illustration)

A0027215

A0027227

3.2 Function

3.2.1 Calculating the pressure

Devices with metallic process isolating diaphragm

The process pressure deflects the metal process isolating diaphragm of the sensor and a fill

fluid transfers the pressure to a Wheatstone bridge (semiconductor technology). The

pressure-dependent change in the bridge output voltage is measured and evaluated.

Endress+Hauser 11

Page 12

Incoming acceptance and product identification Ceraphant PTP31B, PTP33B

DELIVERY NOTE

1 = 2

E

E

DELIVERYNOTE

E

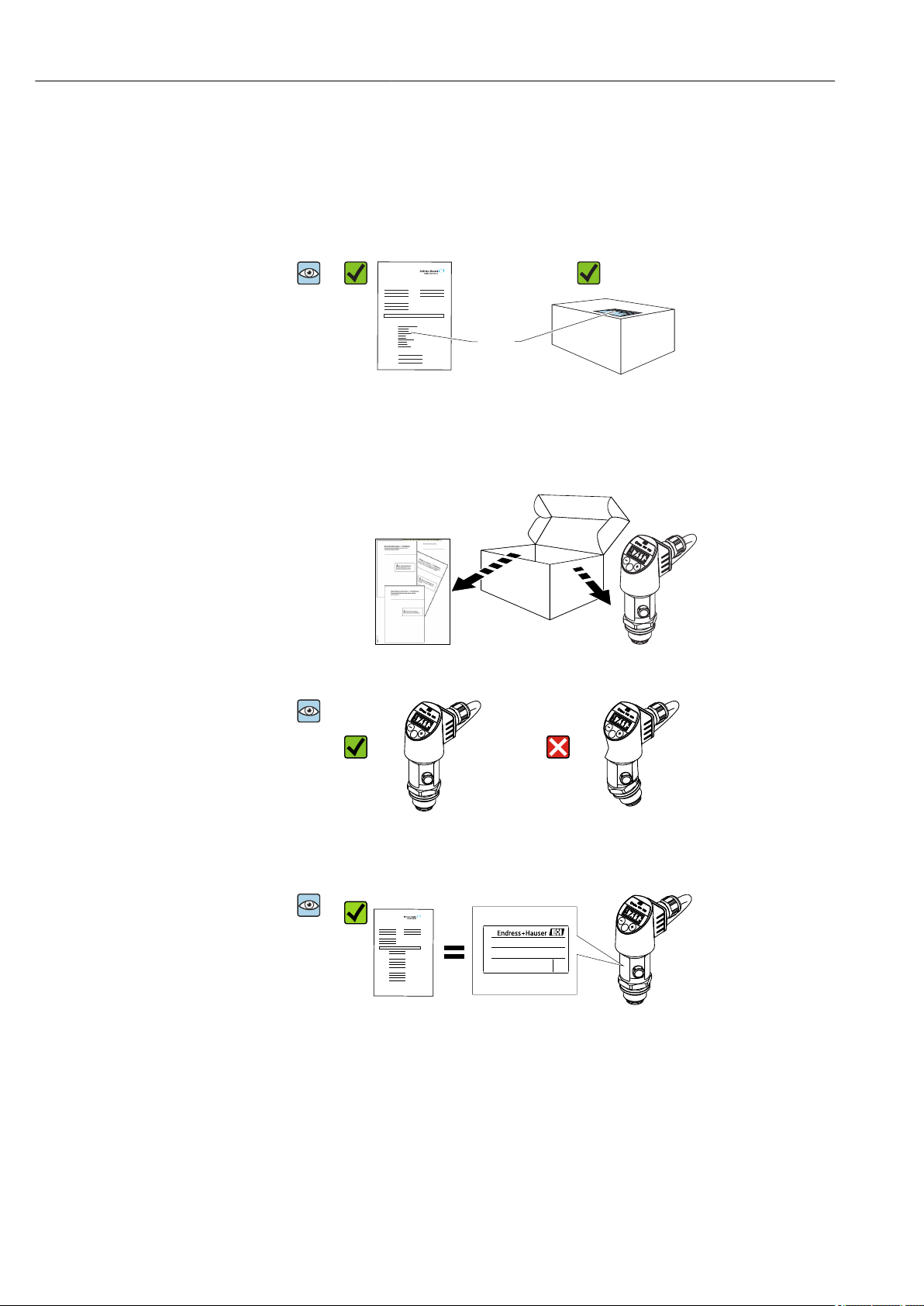

4 Incoming acceptance and product

identification

4.1 Incoming acceptance

A0028673

A0016870

Is the order code on the delivery note (1) identical to the order code on

the product sticker (2)?

A0028673

A0028673

A0022099

A0022101

Are the goods undamaged?

A0022104

Do the data on the nameplate correspond to the order specifications and

the delivery note?

12 Endress+Hauser

Page 13

Ceraphant PTP31B, PTP33B Incoming acceptance and product identification

Ser. no.:

Ord. cd.:

Ext. ord. cd.:

D-79689 Maulburg

Made in Germany,

Ceraphant

5

1

2

3

4

Date:

TAG:

A0028673

A0022106

Is the documentation available?

If required (see nameplate): Are the safety instructions (XA) present?

If one of these conditions does not apply, please contact your

Endress+Hauser sales office.

4.2 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

(www.endress.com/deviceviewer): All information about the measuring device is

displayed.

For an overview of the technical documentation provided, enter the serial number from

the nameplates in the W@M Device Viewer (www.endress.com/deviceviewer)

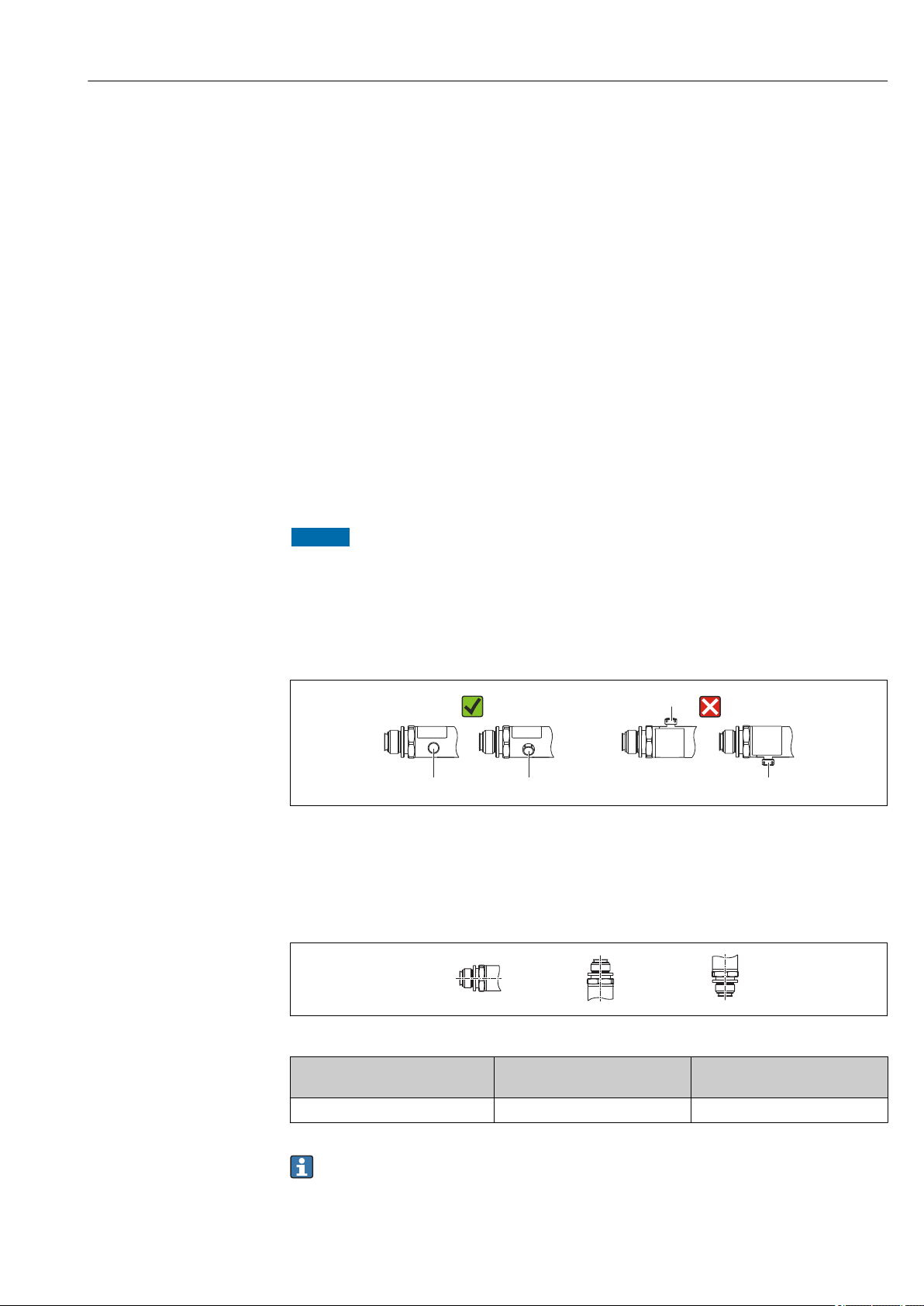

4.2.1 Nameplate

1 Manufacturer's address

2 Device name

3 Order number

4 Serial number

5 Extended order number

4.3 Storage and transport

4.3.1 Storage conditions

A0030101

Use original packaging.

Store the measuring device in clean and dry conditions and protect from damage caused by

shocks (EN 837-2).

Storage temperature range

–40 to +85 °C (–40 to +185 °F)

Endress+Hauser 13

Page 14

Incoming acceptance and product identification Ceraphant PTP31B, PTP33B

4.3.2 Transporting the product to the measuring point

WARNING

L

Incorrect transport!

Housing and diaphragm may become damaged, and there is a risk of injury!

Transport the measuring device to the measuring point in its original packaging or by

‣

the process connection.

14 Endress+Hauser

Page 15

Ceraphant PTP31B, PTP33B Installation

1

1

1

1

C

A

B

5 Installation

5.1 Mounting dimensions

For dimensions, see the "Mechanical construction" section in the Technical Information.

5.2 Installation conditions

• No moisture may enter the housing when installing or operating the device, or when

establishing the electrical connection.

• Do not clean or touch process isolating diaphragms with hard and/or pointed objects.

• Do not remove the protector on the process isolating diaphragm until just before

installation.

• Always firmly tighten the cable entry.

• Point the cable and connector downwards where possible to prevent moisture from

entering (e.g. rain or condensation water).

• Protect the housing from impact

• The following instruction applies for devices with a gauge pressure sensor and M12 plug

or valve plug:

NOTICE

If a heated device is cooled during the cleaning process (e.g. by cold water), a vacuum

develops for a short time, whereby moisture can penetrate the sensor through the

pressure compensation element (1).

Device could be destroyed!

In this case, mount the device with the pressure compensation element (1) pointing

‣

diagonally downwards where possible or to the side.

A0022252

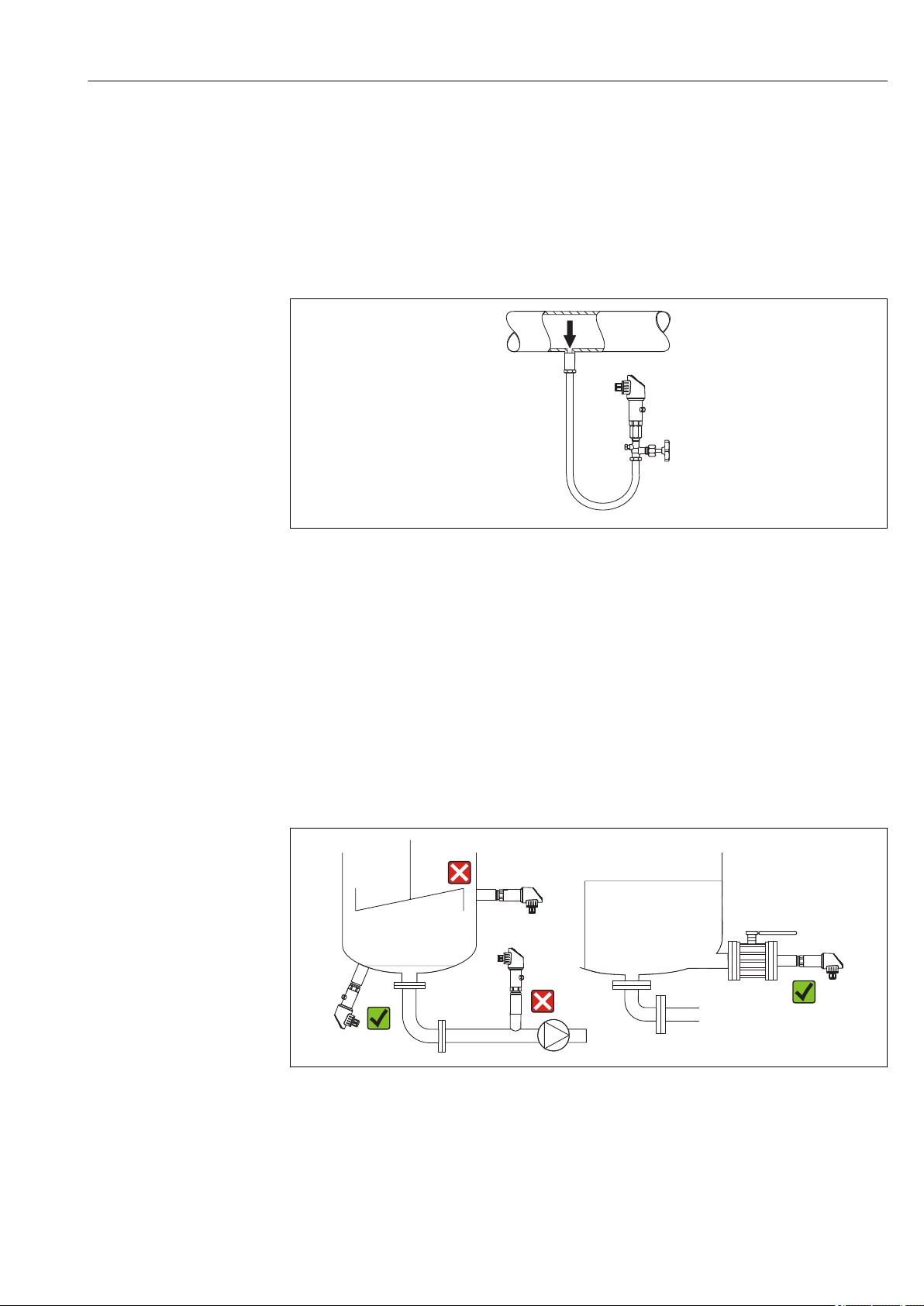

5.3 Influence of the installation position

Any orientation is possible. However, the orientation may cause a zero point shift i.e. the

measured value does not show zero when the vessel is empty or partially full.

A0024708

Process isolating diaphragm axis

is horizontal (A)

Calibration position, no effect Up to +4 mbar (+0.058 psi) Up to –4 mbar (–0.058 psi)

Process isolating diaphragm

pointing upwards (B)

Process isolating diaphragm

pointing downwards (C)

A position-dependent zero shift can be corrected on the device .

Endress+Hauser 15

Page 16

Installation Ceraphant PTP31B, PTP33B

1

2

1

1

2

2

3

4

5.4 Mounting location

5.4.1 Pressure measurement

Functional testing can be carried out more easily if you mount the device downstream

from a shutoff device.

Pressure measurement in gases

Mount the device with shutoff device above the tapping point so that any condensate can

flow into the process.

A0025920

1 Device

2 Shutoff device

Pressure measurement in vapors

For pressure measurement in vapors, use a siphon. The siphon reduces the temperature to

almost ambient temperature. Preferably mount the device with the shutoff device and

siphon below the tapping point.

Advantage:

• defined water column causes only minor/negligible measuring errors and

• only minor/negligible heat effects on the device.

Mounting above the tapping point is also permitted.

Note the max. permitted ambient temperature of the transmitter!

Take the influence of the hydrostatic water column into consideration.

A0025921

1 Device

16 Endress+Hauser

2 Shutoff device

3 Siphon

4 Siphon

Page 17

Ceraphant PTP31B, PTP33B Installation

1

2

3

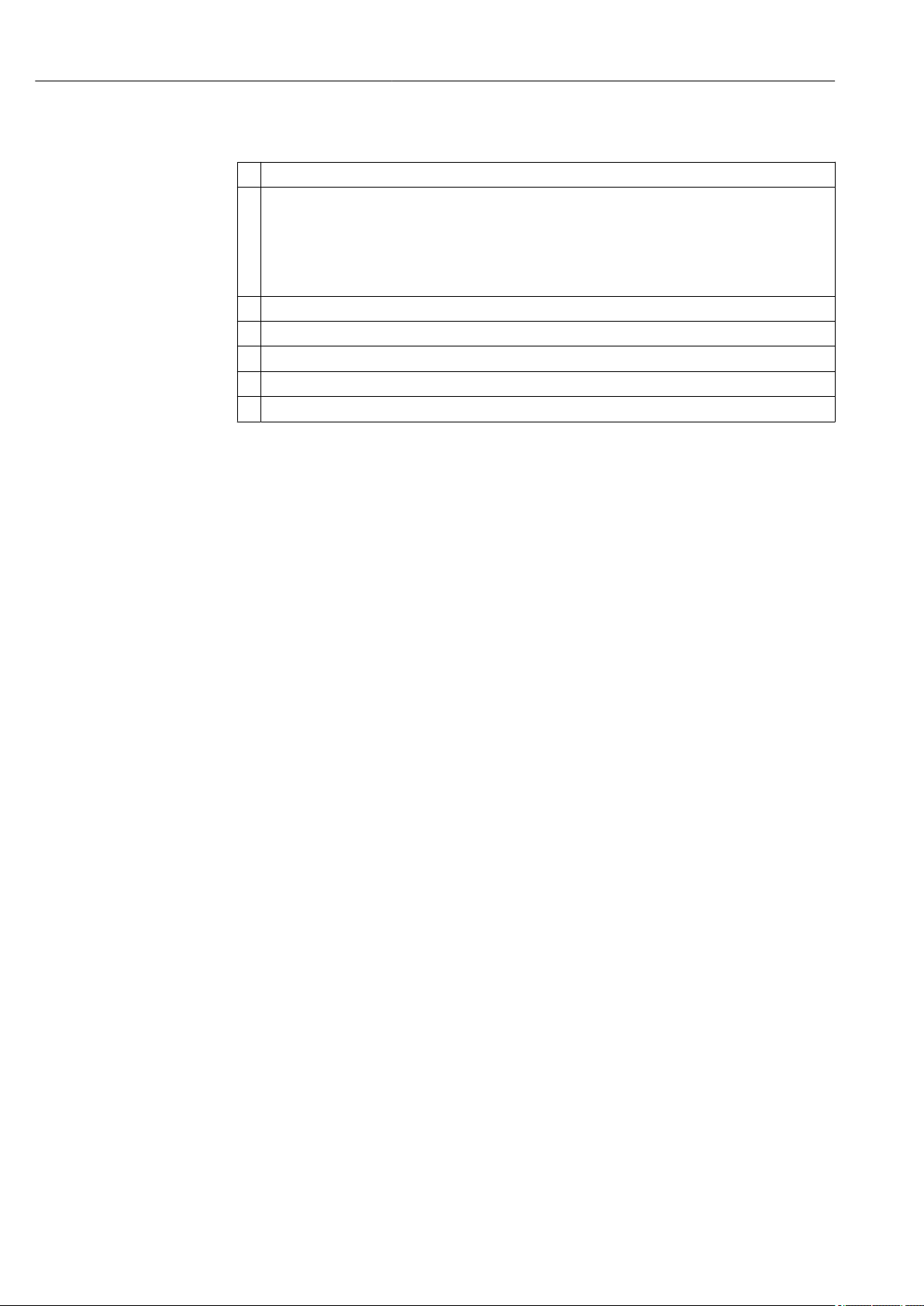

Pressure measurement in liquids

Mount the device with a shutoff device and siphon below or at the same height as the

tapping point.

Advantage:

• defined water column causes only minor/negligible measuring errors and

• air bubbles can be released to the process.

Take the influence of the hydrostatic water column into consideration.

1 Device

2 Shutoff device

3 Siphon

5.4.2 Level measurement

• Always install the device below the lowest measuring point.

• Do not install the device at the following positions:

– In the filling curtain

– In the tank outlet

– In the suction area of a pump

– Or at a point in the tank which could be affected by pressure pulses from the agitator.

• Functional testing can be carried out more easily if you mount the device downstream

from a shutoff device.

A0025922

Endress+Hauser 17

A0025923

Page 18

Installation Ceraphant PTP31B, PTP33B

5.5 Post-installation check

Is the device undamaged (visual inspection)?

Does the device conform to the measuring point specifications?

For example:

• Process temperature

• Process pressure

• Ambient temperature range

• Measuring range

Are the measuring point identification and labeling correct (visual inspection)?

Is the device adequately protected from precipitation and direct sunlight?

Are the securing screws tightened securely?

Does the pressure compensation element point downwards at an angle or to the side?

To prevent the penetration of moisture: are the connecting cables/plugs pointing downwards?

18 Endress+Hauser

Page 19

Ceraphant PTP31B, PTP33B Electrical connection

L–

L+

0.63A

2

1

3

4

R1

R1

"

L–

L+

1

2

3

4

0.63A

L–

L+

1

2a

3

4

2b

R1

"

(a)

0.63A

6 Electrical connection

6.1 Connecting the measuring unit

6.1.1 Terminal assignment

WARNING

L

Risk of injury from the uncontrolled activation of processes!

Switch off the supply voltage before connecting the device.

‣

Make sure that downstream processes are not started unintentionally.

‣

WARNING

L

Limitation of electrical safety due to incorrect connection!

In accordance with IEC/EN61010 a separate circuit breaker must be provided for the

‣

device .

The device must be operated with a 630 mA fine-wire fuse (slow-blow).

‣

Protective circuits against reverse polarity are integrated.

‣

NOTICE

Damage to analog input of PLC resulting from incorrect connection

Do not connect the active PNP switch output of the device to the 4 to 20 mA input of a

‣

PLC.

Connect the device in the following order:

1. Check whether the supply voltage matches the supply voltage indicated on the

nameplate.

2. Connect device in accordance with the following diagram.

Switch on supply voltage.

For devices with a cable connection: do not close reference air hose (see (a) in the

following drawings)! Protect reference air hose against penetration by water/condensate.

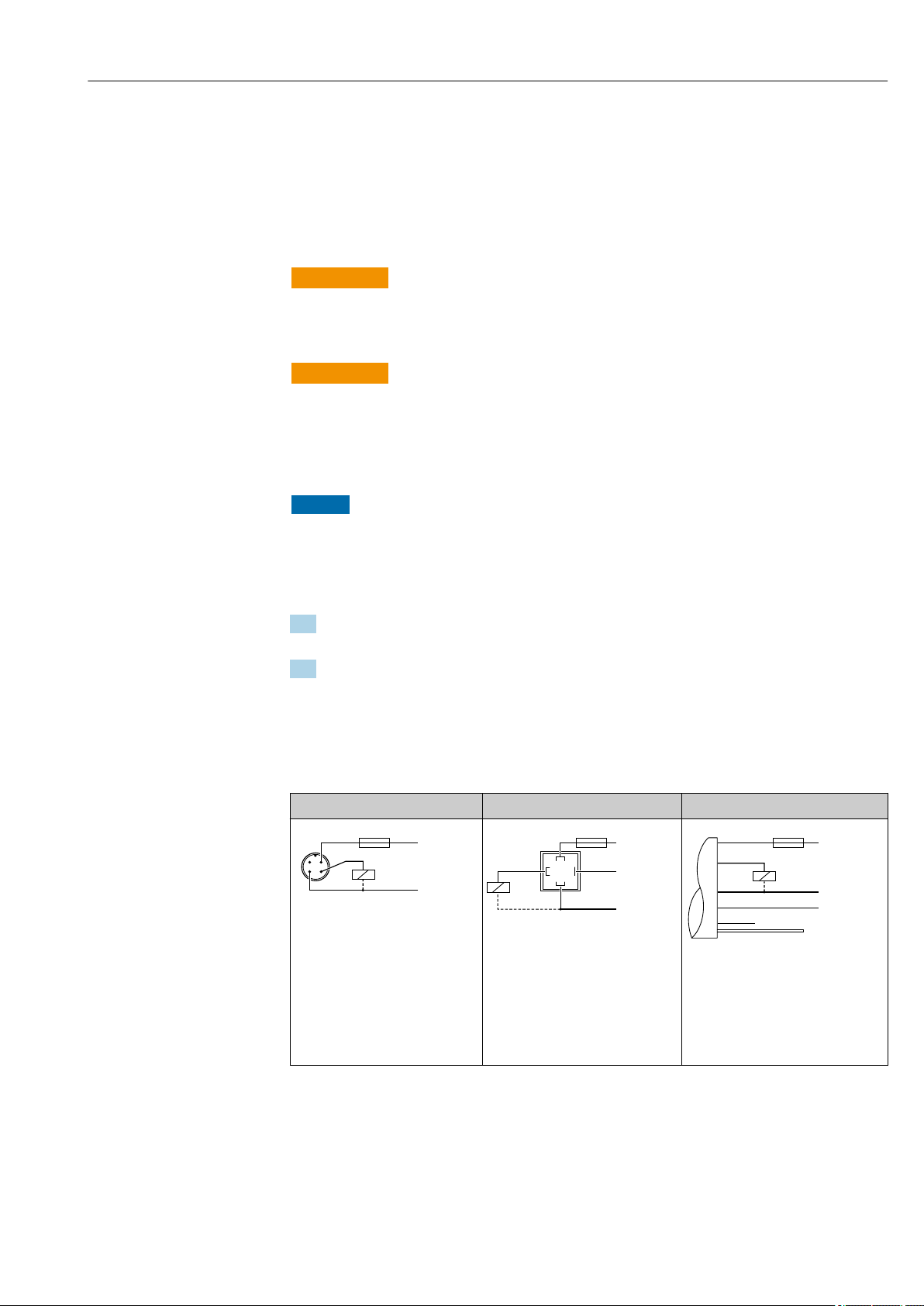

1 x PNP switch output R1

M12 plug Valve plug Cable

A0029268

A0023271

A0022801

1 brown = L+

2a black = switch output 1

2b white = not assigned

3 blue = L4 green/yellow = ground

(a) reference air hose

Endress+Hauser 19

Page 20

Electrical connection Ceraphant PTP31B, PTP33B

L–

L+

2

1

3

4

R1

R2

0.63A

L–

L+

1

2b

2a

3

4

R2

(a)

0.63A

R1

"

L–

L+

2

1

3

4

R1

0.63A

L–

L+

1

2b

2a

3

4

(a)

0.63A

R1

"

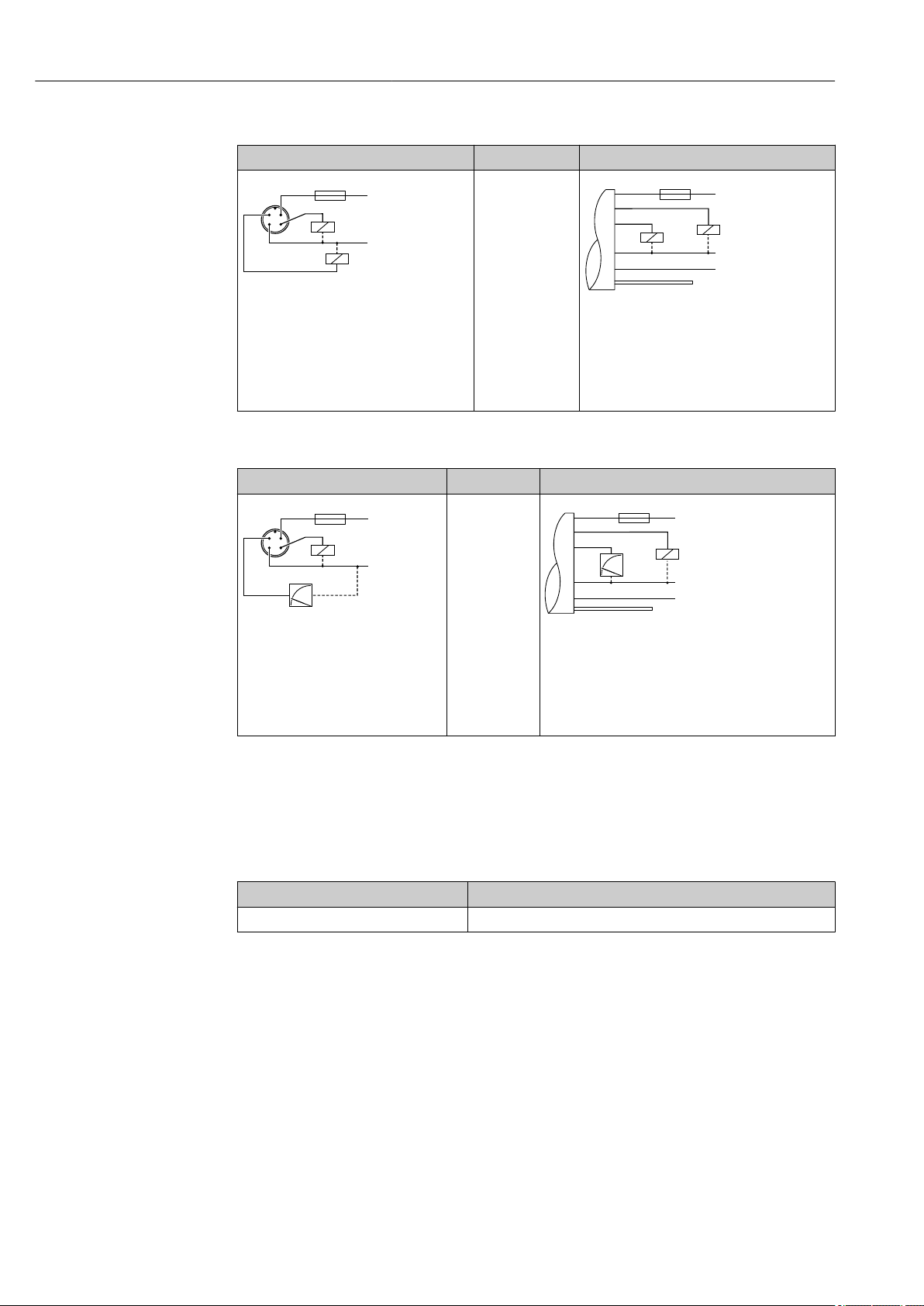

2 x PNP switch outputs R1 and R2

M12 plug Valve plug Cable

-

A0023248

A0023282

1 brown = L+

2a black = switch output 1

2b white = switch output 2

3 blue = L4 green/yellow = ground

(a) reference air hose

1 x PNP switch output R1 with additional analog output 4 to 20 mA (active)

M12 plug Valve plug Cable

-

A0023249

1 brown = L+

2a black = switch output 1

2b white = analog output 4 to 20 mA

3 blue = L4 green/yellow = ground

(a) reference air hose

6.1.2 Supply voltage

Supply voltage: 10 to 30 V DC

6.1.3 Current consumption and alarm signal

Intrinsic power consumption Alarm current (for devices with analog output)

≤ 60 mA ≥21 mA (factory setting)

6.2 Relay switching capacity

• Switch state ON: Ia ≤ 250 mA; switch state OFF: Ia ≤1 mA

• Switch cycles: >10,000,000

• Voltage drop PNP: ≤2 V

• Overload protection: Automatic load testing of switching current;

– Max. capacitance load: 14 μF at max. supply voltage (without resistive load)

– Max. cycle duration: 0.5 s; min. ton: 4 ms

– Periodic disconnection from protective circuit in the event of overcurrent (f = 2 Hz) and

"F804" display

A0030519

20 Endress+Hauser

Page 21

Ceraphant PTP31B, PTP33B Electrical connection

[ ]W

20 30

10

0

1022

587

152

U

[V]

1

2

R

R

L

L

max

max

£

-U 6.5V

23mA

B

B

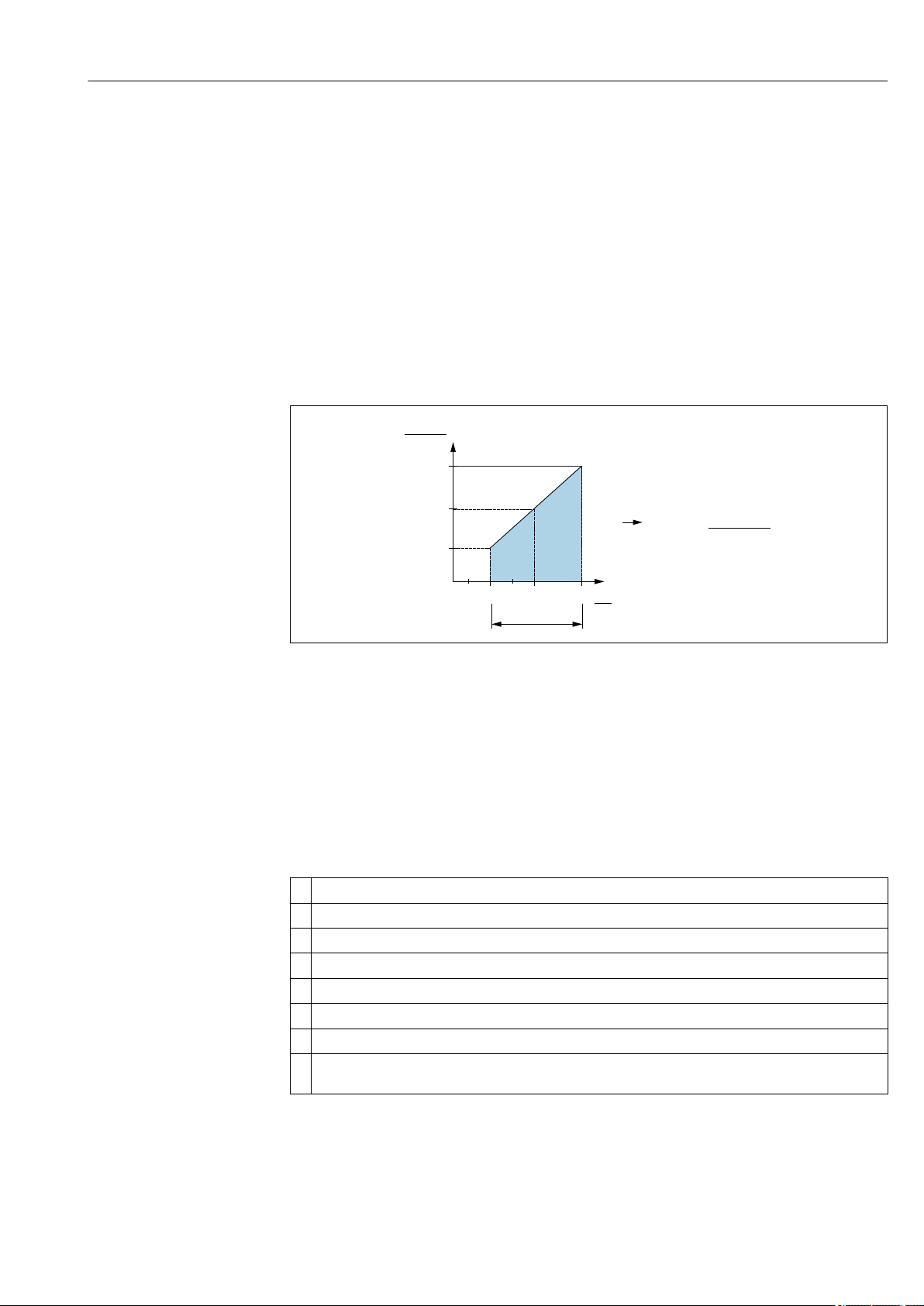

6.3 Connection conditions

6.3.1 Cable specification

For valve plug: < 1.5 mm2 (16 AWG) and Ø3.5 to 6.5 mm (0.14 to 0.26 in)

6.4 Connection data

6.4.1 Load (for devices with analog output)

The maximum load resistance depends on the terminal voltage and is calculated according

to the following formula:

1 Power supply 10 to 30 V DC

2 R

UBSupply voltage

maximum load resistance

Lmax

When excessively high load:

• Output of the fault current and display of " S803 "

• Periodic review whether error condition may be left

6.5 Post-connection check

Is the device or cable undamaged (visual check)?

Do the cables comply with the requirements ?

Do the cables have adequate strain relief?

Are all the cable glands installed, firmly tightened and leak-tight?

Does the supply voltage match the specifications on the nameplate?

Is the terminal assignment correct ?

If required: Has protective ground connection been established ?

If supply voltage is present, is the device ready for operation and do values appear on the display module or

is the green LED lit on the electronic insert?

A0031107

Endress+Hauser 21

Page 22

Operation options Ceraphant PTP31B, PTP33B

7 Operation options

7.1 Operation with an operating menu

7.1.1 Operating concept

Operation with an operating menu is based on an operation concept with "user roles" .

User role Meaning

Operator

(display level)

Maintenance

(user level)

Operators are responsible for the devices during normal "operation". This is usually limited to

reading process values either directly at the device or in a control room. Should an error occur,

these users simple forward the information on the errors but do not intervene themselves.

Service engineers usually work with the devices in the phases following device commissioning.

They are primarily involved in maintenance and troubleshooting activities for which simple

settings have to be made at the device. Technicians work with the devices over the entire life

cycle of the product. Thus, commissioning and advanced settings and configurations are some

of the tasks they have to carry out.

7.2 Structure of the operating menu

The menu structure has been implemented according to VDMA 24574-1 and

complemented by Endress+Hauser-specific menu items.

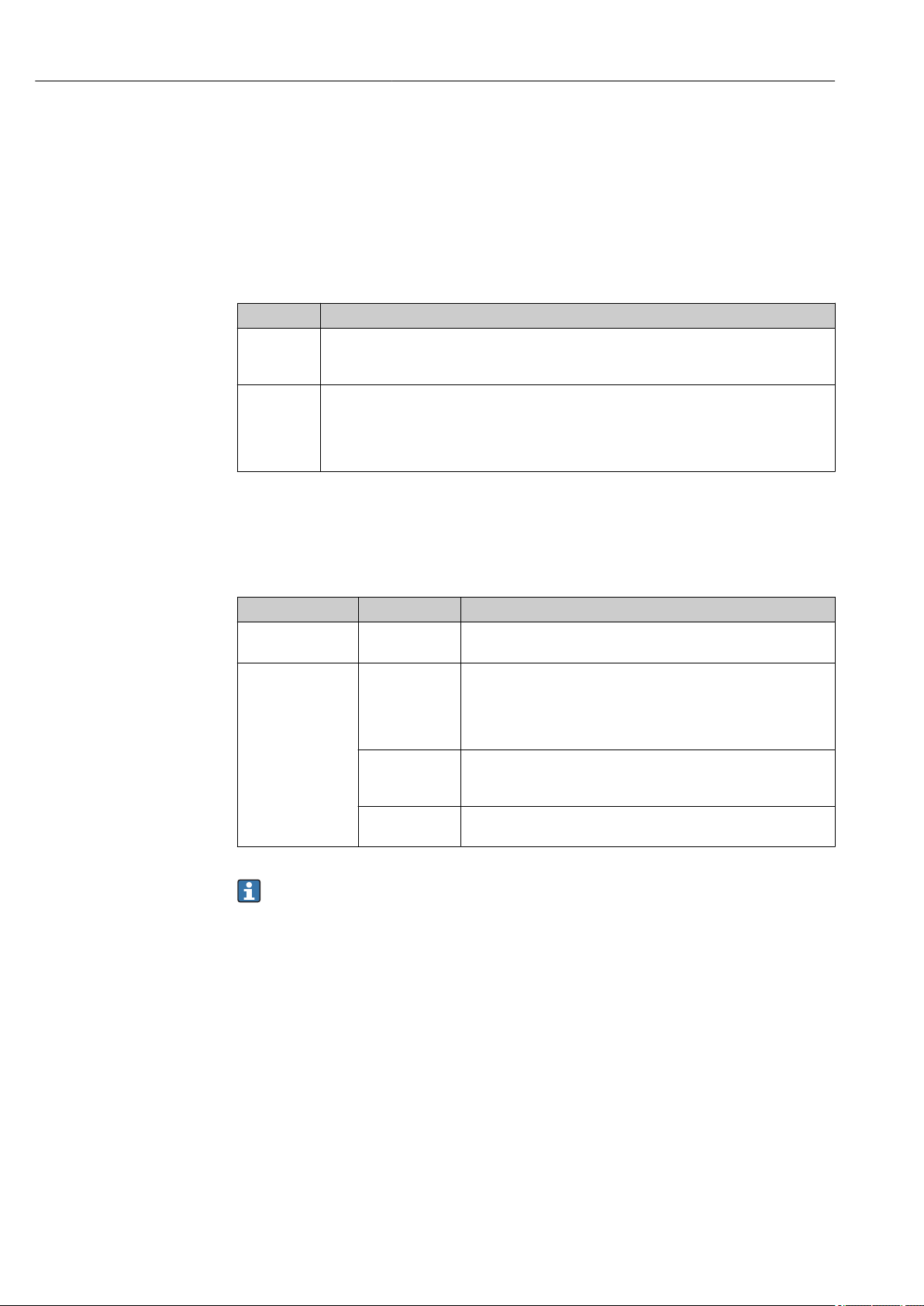

User role Submenu Meaning/use

Operator (display

level)

Maintenance (user

level)

Display/operat. Display of measured values, fault and information messages

Parameters on

the topmost

menu level.

EF The submenu "EF" contains additional parameters which allow more

DIAG Contains all the parameters that are needed to detect and analyze

Contains all the parameters that are needed to commission

measuring operations. A wide range of parameters, which can be

used to configure a typical application, is available at the start. After

making settings for all these parameters, the measuring operation

should be completely configured in the majority of cases.

accurate configuration of the measurement, conversion of the

measured value and scaling of the output signal.

operating errors.

For an overview of the entire operating menu, see the → 46

7.3 Operation with local display

7.3.1 Overview

A 1-line liquid crystal display (LCD) is used for display and operation. The local display

shows measured values, fault messages and information messages and therefore supports

the user through each operating step.

The display is fixed to the housing and the values can be rotated electronically by 180° (see

parameter description for "DRO" → 62). This ensures optimum readability of the local

display and allows the device to be mounted upside down also.

During measuring operation, the display shows measured values, fault messages and

notice messages. In addition, it is possible to switch to menu mode via the operating keys.

22 Endress+Hauser

Page 23

Ceraphant PTP31B, PTP33B Operation options

2

E

54

3

1

A0022121

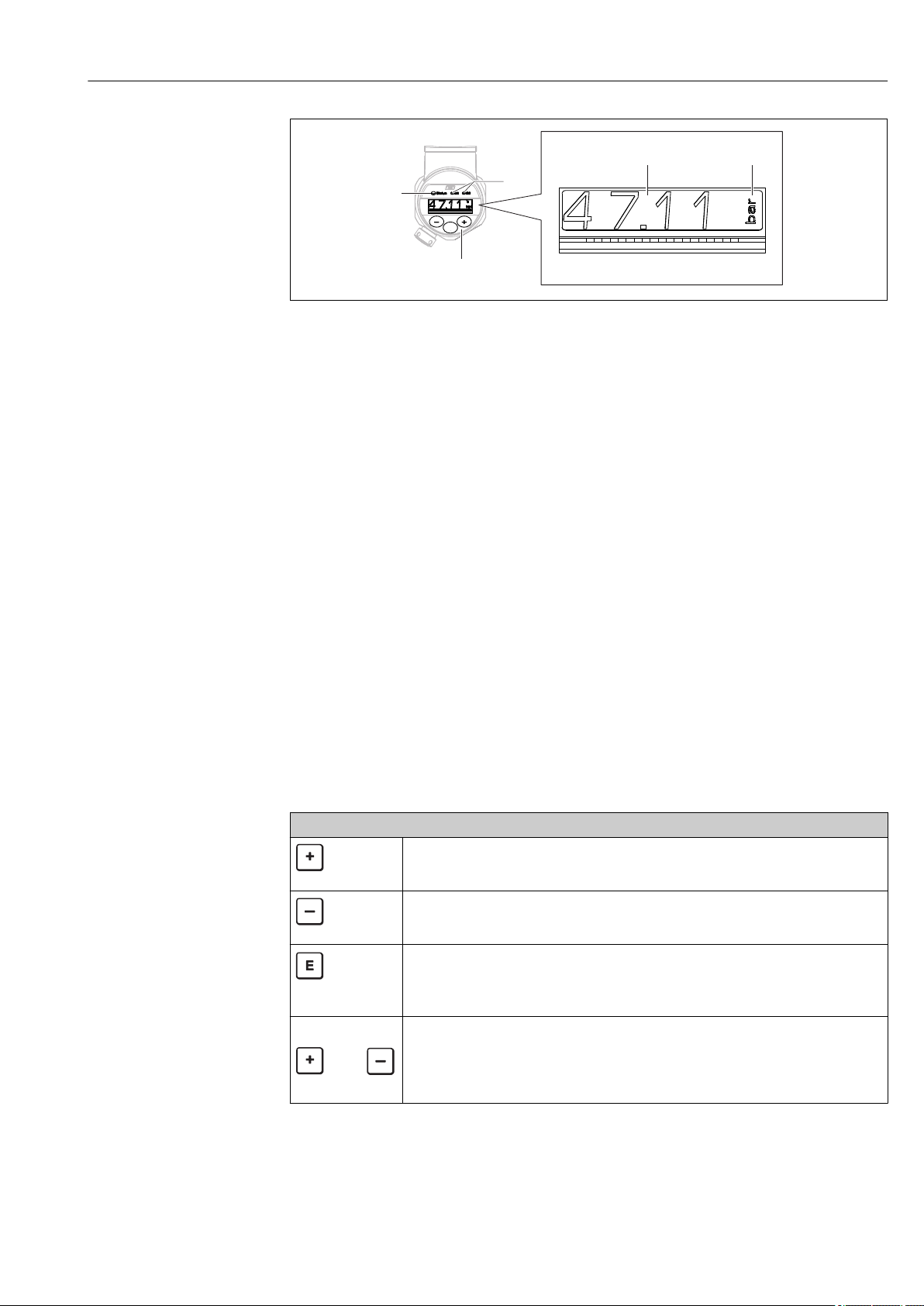

1 Operating keys

2 Status LED

3 Switch output LEDs

4 Measured value

5 Unit

7.4 General value adjustment and rejection of illegal entries

Parameter (not numerical value) is flashing: parameter can be adjusted or selected.

When adjusting a numerical value: the numerical value does not flash. The first digit of the

numerical value starts to flash only when the key is pressed by way of confirmation.

Enter the desired value with the or key and press the key to confirm. Following

confirmation, the data are recorded directly and are active.

– Entry is OK: value is accepted and shown for one second on the display against a white

background.

– Entry is not OK: the message "FAIL" appears for one second on the display against a red

background. The value entered is rejected. In the event of an incorrect setting which

effects the TD, an diagnostic message is issued.

7.5 Navigation and selection from list

The capacitive operating keys are used for navigation in the operating menu and to select

an option from a picklist.

Operating key(s) Meaning

• Navigate downwards in the picklist

A0017879

A0017880

A0017881

Simultaneously ESC functions:

and

A0017879

• Edit the numerical values and characters within a function

• Navigate upwards in the picklist

• Edit the numerical values and characters within a function

• Confirm entry

• Jump to the next item

• Selection of a menu item and activation of edit mode

• The key lock function (KYL) is accessed by pressing the key for longer than 2 seconds

• Exit edit mode for a parameter without saving the changed value.

• You are in a menu at a selection level. Each time you press the keys simultaneously, you

A0017880

go up a level in the menu.

• Long ESC: press the keys for longer than 2 seconds

Endress+Hauser 23

Page 24

Operation options Ceraphant PTP31B, PTP33B

7.6 Locking and unlocking operation

The device features

• Automatic key locking

• Parameter settings lock.

Key locking is indicated on the local display by "E > 2".

Locking of the parameter settings is indicated as soon as an attempt is made to change a

parameter.

7.6.1 Disabling the key lock

The keys are locked automatically if the device remains at the topmost menu level (display

of pressure measurement value) for 60 seconds.

Call up the key lock function (KYL)

1. Press the key for at least 2 seconds and then release it

2. By confirming with "ON" is displayed

3. Use and to toggle between "ON" and "OFF"

4. Key locking is disabled as soon as is pressed to confirm "OFF"

The display changes to the main value level (topmost menu level) if the key is pressed

briefly. The display changes to the key locking if the key is pressed for at least 2

seconds.

If in the case of "KYL", "ON" or "OFF", more than 10 seconds elapse without a key being

pressed, you return to the topmost menu level with active key locking.

The function can be accessed anytime outside the main measured value display and within

the operating menu, i.e. if the key is pressed for at least 2 seconds key locking can be

performed anytime at any menu item. Locking is effective immediately. If you quit the

context menu, you will return to the same point from which key locking was selected.

7.6.2 Locking parameter settings

COD locking code

Navigation EF → ADM → COD

Description A code can be entered to protect parameter settings against unauthorized and unwanted

access.

Selection

Factory setting 0000

To lock: Enter a number ¹ the LCK release code (value range: 1 to 9999).

7.6.3 Unlocking parameter settings

If parameters are locked, the word "LCK" appears on the local display as soon as an attempt

is made to change a parameter.

LCK unlocking code

24 Endress+Hauser

Page 25

Ceraphant PTP31B, PTP33B Operation options

Navigation EF → ADM → LCK

Description Use this function to enter the code (which was defined in the COD parameter) to enable

configuration.

Keys are evaluated but parameters are read only. The parameters can only be changed

after unlocking.

If an attempt is made to write to a parameter, a prompt for the device access code appears.

To unlock, enter the user-defined device access code (which was specified in the COD

parameter).

User entry To unlock: Enter the access code.

Factory setting 0000

Note The access code is "0000" in the order configuration. Another access code can be defined in

the parameter "COD".

Endress+Hauser 25

Page 26

Operation options Ceraphant PTP31B, PTP33B

1

E

2

7.7 Navigation examples

7.7.1 Parameters with a picklist

Example: Display measured value rotated by 180°

Menu path: EF → DIS → DRO

Press or key until "DRO" is displayed.

Initial setting is "NO" (display not rotated).

Press or until "YES" appears (display is rotated by 180 °).

Press to confirm the setting.

7.7.2 User-definable parameters

Example: setting the "TAU" damping parameter.

Menu path: EF → TAU

Press or key until "TAU" is displayed.

Press to set the damping (min. = 0.0 s; max.= 999.9 s).

Press or to go up or down.

Press to confirm the entry and to go to the next position.

Press to quit the setting function and to go to the "TAU" menu item.

D R O

N O

Y E S

D R O

T A U

0. 3 0

1. 5

T A U

7.8 Status LEDs

The Ceraphant also uses LEDs to signal the status:

• Two LEDs indicate the status of the switch outputs

• One LED indicates if the device is switched on or if an error or fault has occurred

1 Status LED

2 Switch output LEDs

7.9 Resetting to factory settings (reset)

See parameter description for RES → 54

26 Endress+Hauser

A0032027

Page 27

Ceraphant PTP31B, PTP33B Commissioning

8 Commissioning

If an existing configuration is changed, measuring operation continues! The new or

modified entries are only accepted once the setting has been made.

WARNING

L

Risk of injury from the uncontrolled activation of processes!

Make sure that downstream processes are not started unintentionally.

‣

WARNING

L

If a pressure smaller than the minimum permitted pressure or greater than the

maximum permitted pressure is present at the device, the following messages are

output in succession:

S971

‣

S140

‣

F270

‣

8.1 Function check

Before commissioning your measuring point, ensure that the post-installation and postconnection check have been performed:

• "Post-installation check" checklist → 18

• "Post-connection check" checklist → 21

8.2 Enabling configuration/operation

The device features

• Automatic key locking → 24

• Parameter locking → 24.

8.3 Commissioning with an operating menu

Commissioning comprises the following steps:

• Configuration of pressure measurement → 27

• If necessary, perform position adjustment → 29

• If necessary, Configuration of process monitoring if necessary → 32

• If necessary, Configuration of the local display if necessary → 37

• If necessary, Protection of settings from unauthorized access if necessary → 38

8.4 Configuring pressure measurement (only for devices with a current output)

8.4.1 Calibration without reference pressure (dry calibration = calibration without medium)

Example:

In this example, a device with a 400 mbar (6 psi) sensor is configured for the measuring

range 0 to 300 mbar (0 to 4.4 psi).

The following values should be assigned:

• 0 mbar = 4 mA value

• 300 mbar (4.4 psi) = 20 mA value

Endress+Hauser 27

Page 28

Commissioning Ceraphant PTP31B, PTP33B

Prerequisite:

This is a theoretical calibration, i.e. the pressure values for the lower and upper range are

known. It is not necessary to apply pressure.

Due to the orientation of the device, there may be pressure shifts in the measured

value, i.e. the measured value is not zero in a pressureless condition. For information

on how to perform position adjustment, see the "Position adjustment"→ 29

section.

For a description of the parameters mentioned and possible error messages, see the

"Description of device parameters" section → 49 and .

Performing the calibration

1. Select a pressure engineering unit via the "UNI" parameter, here "BAR" for example.

Menu path: EF → UNI

2. Select the "STL" parameter. Menu path: STL. Enter the value (0 bar (0 psi)) and

confirm.

This pressure value is assigned to the lower current value (4 mA).

3. Select the "STU" parameter. Menu path: STL. Enter the value (300 mbar (4.4 psi)) and

confirm.

This pressure value is assigned to the upper current value (20 mA).

The measuring range is configured for 0 to 300 mbar (0 to 4.4 psi).

28 Endress+Hauser

Page 29

Ceraphant PTP31B, PTP33B Commissioning

8.4.2 Calibration with reference pressure (wet calibration = calibration with medium)

Example:

In this example, a device with a 400 mbar (6 psi) sensor is configured for the measuring

range 0 to 300 mbar (0 to 4.4 psi).

The following values should be assigned:

• 0 mbar = 4 mA value

• 300 mbar (4.4 psi) = 20 mA value

Prerequisite:

The pressure values 0 mbar and 300 mbar (4.4 psi) can be specified. For example, the

device is already installed.

Due to the orientation of the device, there may be pressure shifts in the measured

value, i.e. the measured value is not zero in a pressureless condition. For information

on how to perform position adjustment, see the "Position adjustment" → 29

section.

For a description of the parameters mentioned and possible error messages, see the

"Description of device parameters" section → 49 and .

Performing the calibration

1. Select a pressure engineering unit via the "UNI" parameter, here "BAR" for example.

Menu path: EF → UNI

2. The pressure for the LRV (4 mA value) is present at the device, here 0 bar (0 psi) for

example. Select the "GTL" parameter. Menu path: EF → I → GTL. Confirm the present

value by selecting "YES".

The present pressure value is assigned to the lower current value (4 mA).

3. The pressure for the URV (20 mA value) is present at the device, here

300 mbar (4.4 psi) for example. Select the "GTU" parameter. Menu path: EF → I →

GTU. Confirm the present value by selecting "YES".

The present pressure value is assigned to the upper current value (20 mA).

The measuring range is configured for 0 to 300 mbar (0 to 4.4 psi).

8.5 Performing position adjustment

ZRO manual position adjustment (typically for absolute pressure sensor)

Navigation EF → ZRO

Description The pressure resulting from the orientation of the device can be corrected here.

The pressure difference between zero (set point) and the measured pressure must be

known.

Endress+Hauser 29

Page 30

Commissioning Ceraphant PTP31B, PTP33B

Prerequisite An offset is possible (parallel shifting of the sensor characteristic) to correct the

orientation and any zero point drift. The set value of the parameter is subtracted from the

"raw measured value". The requirement to be able to perform a zero point shift without

changing the span is met with the offset function.

Maximum offset value = ± 20 % of the sensor nominal range.

If an offset value is entered that shifts the span beyond the physical limits of the sensor,

the value is admitted but a warning message is generated and shown on the display. The

warning message only disappears when the span is within the sensor limits, taking the

offset value currently configured into consideration.

The sensor can

• be operated in a physically unfavorable range, i.e. outside its specifications, or

• be operated by making appropriate corrections to the offset or span.

Raw measured value – (manual offset) = display value (measured value)

Example • Measured value = 2.2 mbar (0.033 psi)

• Set the measured value in the parameter to 2.2.

• Measured value (after position adjustment) = 0.0 mbar

• The current value is also corrected.

Note Setting in increments of 0.1. As the value is entered numerically, the increment depends

on the measuring range

Options No selection. The user is free to edit the values.

Factory setting 0

GTZ automatic position adjustment (typically for gauge pressure sensor)

Navigation EF → GTZ

Description The pressure resulting from the orientation of the device can be corrected here.

The pressure difference between zero (set point) and the measured pressure need not be

known.

Prerequisite An offset is possible (parallel shifting of the sensor characteristic) to correct the

orientation and any zero point drift. The set value of the parameter is subtracted from the

"raw measured value". The requirement to be able to perform a zero point shift without

changing the span is met with the offset function.

Maximum offset value = ± 20 % of the sensor nominal range.

If an offset value is entered that shifts the span beyond the physical limits of the sensor,

the value is admitted but a warning message is generated and shown on the display. The

warning message only disappears when the span is within the sensor limits, taking the

offset value currently configured into consideration.

The sensor can

• be operated in a physically unfavorable range, i.e. outside its specifications, or

• be operated by making appropriate corrections to the offset or span.

Raw measured value – (manual offset) = display value (measured value)

30 Endress+Hauser

Page 31

Ceraphant PTP31B, PTP33B Commissioning

Example 1 • Measured value = 2.2 mbar (0.033 psi)

• You use the "GTZ" parameter to correct the measured value with the value, e.g.

2.2 mbar (0.033 psi). This means that you are assigning the value 0 mbar (0 psi) to the

pressure present.

• Measured value (after pos. zero adjust) = 0 mbar (0 psi)

• The current value is also corrected.

• If necessary, check and correct switch points and span settings.

Example 2 Sensor measuring range: –0.4 to +0.4 bar (–6 to +6 psi) (SP1 = 0.4 bar (6 psi); STU =

0.4 bar (6 psi))

• Measured value = 0.08 bar (1.2 psi)

• You use the "GTZ" parameter to correct the measured value with the value, e.g.

0.08 bar (1.2 psi). This means that you are assigning the value 0 mbar (0 psi) to the

pressure present.

• Measured value (after pos. zero adjust) = 0 mbar (0 psi)

• The current value is also corrected.

• Warnings C431 or C432 appear because the value 0 bar (0 psi) was assigned to the real

value of 0.08 bar (1.2 psi) present and the sensor measuring range was thus exceeded

by ± 20%.

SP1 and STU values must be readjusted downwards by 0.08 bar (1.2 psi).

Factory setting 0.0

Endress+Hauser 31

Page 32

Commissioning Ceraphant PTP31B, PTP33B

8.6 Configuring process monitoring

To monitor the process, it is possible to specify a pressure range which is monitored by the

limit switch. Depending on the device version, the process can be monitored using one PNP

switch output, or optionally using a second PNP switch output or an analog 4 to 20 mA

output. Both monitoring versions are described below. The monitoring function allows the

user to define optimum ranges for the process (with high yields etc.) and deploy limit

switches to monitor the ranges.

8.6.1 Digital process monitoring (switch output)

It is possible to select defined switch points and switchback points which act as NO or NC

contacts depending on whether a window function or hysteresis function is configured

→ 32.

Function Output Abbreviation for operation

Hysteresis Closing HNO

Hysteresis NC contact HNC

Window Closing FNO

Window NC contact FNC

If the device is restarted within the specified hysteresis, both switch outputs are open (0 V

present at the output).

8.6.2 Analog process monitoring (4 to 20 mA output)

• The 3.8 to 20.5 mA signal range is controlled according to NAMUR NE 43.

• The alarm current and current simulation are exceptions:

– If the defined limit is exceeded, the device continues measuring in a linear fashion.

The output current increases linearly up to 20.5 mA and holds the value until the

measured value drops below 20.5 mA again or the device detects an error .

– If the defined limit is undershot, the device continues measuring in a linear fashion.

The output current decreases linearly to 3.8 mA and holds the value until the

measured value rises above 3.8 mA again or the device detects an error .

8.7 Functions of switch output

The switch output can be used for two-point control (hysteresis) or for monitoring a

process pressure range (window function).

8.7.1 Hysteresis

SP1/SP2 switch point value, output 1/2

RP1/RP2 switchback point value, output 1/2

Navigation SP1/SP2

RP1/RP2

32 Endress+Hauser

Page 33

Ceraphant PTP31B, PTP33B Commissioning

1

2

0

SP1/SP2

RP1/RP2

0

HNO

p

t

1

HNC

Note The hysteresis is implemented using the "SP1/SP2" and "RP1/RP2" parameters. Since the

parameter settings depend on one another, the parameters are described all together.

• SP1 = switch output 1

• SP2 = switch output 2 (optional)

• RP1 = switchback point 1

• RP2 = switchback point 2 (optional)

A0022943

1 SP1/SP2: switch point 1/2; RP1/RP2: switch-back point 1/2

0 0-signal. Output open in quiescent state.

1 1-signal. Output closed in quiescent state.

2 Hysteresis

HNO Closing

HNC NC contact

Description The switch point "SP1/SP2" and the switchback point "RP1/RP2" can be defined with these

functions (e.g. for pump control).

When the set switch point "SP1/SP2" is reached (with increasing pressure), an electrical

signal change takes place at the switch output.

When the set switchback point "RP1/RP2" is reached (with decreasing pressure), an

electrical signal change takes place at the switch output.

The difference between the value of the switch point "SP1/SP2" and the switchback point

"RP1/RP2" is known as the hysteresis.

Prerequisite • These functions are only available if the hysteresis function has been defined for the

switch output.

• The configured value for the switch point "SP1/SP2" must be greater than the switchback

point "RP1/RP2"!

A diagnostic message is displayed if a switch point "SP1/SP2" is entered that is ≤ the

switchback point "RP1/RP2". While it is possible to make this entry, it does not take

effect in the device. The entry must be corrected!

Note To prevent constant switch-on and switch-off if values are around the switch point "SP1/

SP2" and switchback point "RP1/RP2", a delay can be set for the relevant points. See the

parameter description for "dS1/dS2" and "dR1/dR2" for this purpose.

Selection No selection. The user is free to edit the values.

Factory setting Factory setting (if no customer-specific setting is ordered):

Switch point SP1: 45 %; switchback point RP1: 44.5 %

Endress+Hauser 33

Switch point SP2: 55 %; switchback point RP2: 54.5 %

Page 34

Commissioning Ceraphant PTP31B, PTP33B

1

2

0

FH1/FH2

FL1/FL2

0

FNO

p

t

1

FNC

8.7.2 Window function

• SP1 = switch output 1

• SP2 = switch output 2 (optional)

FH1/FH2 Upper value for pressure window, output 1/2

FL1/FL2 Lower value for pressure window, output 1/2

Navigation FH1/FH2

FL1/FL2

Note The window function is implemented using the "FH1/FH2" and "FL1/FL2" parameters. Since

the parameter settings depend on one another, the parameters are described all together.

• FH1 = Upper value of pressure window 1

• FH2 = Upper value of pressure window 2 (optional)

• FL1 = Lower value of pressure window 1

• FL2 = Lower value of pressure window 2 (optional)

2 FH1/FH2: upper value of pressure window; FL1/FL2: lower value of pressure window

0 0-signal. Output open in quiescent state.

1 1-signal. Output closed in quiescent state.

2 Pressure window (difference between the value of the high window "FH1/FH2" and the low window "FL1/

FL2")

FNO Closing

FNC NC contact

Description The upper value of the pressure window "FH1/FH2" and the lower value of the pressure

window "FL1/FL2" can be defined with these functions (e.g. for monitoring a certain

pressure range).

When the lower value of the pressure window "FL1/FL2" is reached (with increasing or

decreasing pressure), an electrical signal change takes place at the switch output.

When the upper value of the pressure window "FH1/FH2" is reached (with increasing or

decreasing pressure), an electrical signal change takes place at the switch output.

The difference between the upper value of the pressure window "FH1/FH2" and the lower

value of the pressure window "FL1/FL2" is known as the pressure window.

34 Endress+Hauser

A0027370

Page 35

Ceraphant PTP31B, PTP33B Commissioning

Prerequisite • This function is only available if the window function has been defined for the switch

output.

• The upper value of the pressure window "FH1/FH2" must be greater than the lower value

of the pressure window "FL1/FL2"!

A diagnostic message is displayed if the upper value entered for the pressure window

"FH1/FH2" is smaller than the lower value of the pressure window "FL1/FL2". While it is

possible to make this entry, it does not take effect in the device. The entry must be

corrected!

Selection No selection. The user is free to edit the values.

Factory setting Factory setting if no customer-specific setting is ordered:

Switch point FH1: 45 %; switchback point FL1: 44.5 %

Switch point FH2: 55 %; switchback point FH2: 54.5 %

8.8 Current output

STL value for 4 mA (LRV)

Navigation STL

Description Assignment of the pressure value which should correspond to the 4 mA value.

It is possible to invert the current output. To do so, assign the pressure upper range value

to the lower measuring current.

Prerequisite Electronic version with current output

Note Enter the value for 4 mA in the selected pressure unit anywhere within the measuring

range. The value can be entered in increments of 0.1 (increment depends on the

measuring range).

Selection No selection. The user is free to edit the values.

Factory setting 0.0 or as per order specifications

STU value for 20 mA (URV)

Navigation STU

Description Assignment of the pressure value which should correspond to the 20 mA value.

It is possible to invert the current output. To do so, assign the pressure lower range value

to the upper measuring current.

Prerequisite Electronic version with current output

Note Enter the value for 20 mA in the selected pressure unit anywhere within the measuring

range. The value can be entered in increments of 0.1 (increment depends on the

measuring range).

Endress+Hauser 35

Page 36

Commissioning Ceraphant PTP31B, PTP33B

Selection No selection. The user is free to edit the values.

Factory setting Upper measuring limit or as per order specifications.

GTL Pressure applied for 4mA (LRV)

Navigation EF → I → GTL

Description The pressure value present is automatically adopted for the 4 mA current signal.

Parameter for which the current range can be assigned to any section of the nominal

range. This occurs by assigning the pressure lower range value to the lower measuring

current and the pressure upper range value to the upper measuring current.

The pressure lower range value and upper range value can be configured independently of

one another so the pressure measuring span does not remain constant.

The LRV and URV pressure measuring span can be edited over the entire sensor range.

An invalid TD value is indicated by diagnostic message S510. An invalid position offset is

indicated by diagnostic message C431.

The editing operation cannot result in the device being operated outside the minimum and

maximum sensor limits.

If the entry is not OK, it is rejected, the message "FAIL" appears on the local display and the

last valid value before the change is used again.

The measured value currently present is accepted as the value for 4mA anywhere within

the measuring range.

There is a parallel shift of the sensor characteristic so that the pressure present becomes

the zero value.

Selection • NO

• YES

Factory setting NO

GTU Pressure applied for 20 mA (URV)

Navigation EF → I → GTU

36 Endress+Hauser

Page 37

Ceraphant PTP31B, PTP33B Commissioning

Description The pressure value present is automatically adopted for the 20 mA current signal.

Parameter for which the current range can be assigned to any section of the nominal

range. This occurs by assigning the pressure lower range value to the lower measuring

current and the pressure upper range value to the upper measuring current.

The pressure lower range value and upper range value can be configured independently of

one another so the pressure measuring span does not remain constant.

The LRV and URV pressure measuring span can be edited over the entire sensor range.

An invalid TD value is indicated by diagnostic message S510. An invalid position offset is

indicated by diagnostic message C431.

The editing operation cannot result in the device being operated outside the minimum and

maximum sensor limits.

If the entry is not OK, it is rejected, the message "FAIL" appears on the local display and the

last valid value before the change is used again.

The measured value currently present is accepted as the value for 20 mA anywhere within

the measuring range.

There is a parallel shift of the sensor characteristic so that the pressure present becomes

the max value.

Selection • NO

• YES

Factory setting NO

8.9 Application examples

8.9.1 Compressor control with hysteresis function

Example: The compressor is started when the pressure drops below a certain value. The

compressor is switched off when a certain value is exceeded.

1. Set the switch point to 2 bar (29 psi)

2. Set the switchback point to 1 bar (14.5 psi)

3. Configure the switch output as an "NC contact" (HNC function)

The compressor is controlled by the defined settings.

8.9.2 Pump control with hysteresis function

Example: The pump should switch on when 2 bar (29 psi) is reached (increasing pressure)

and switch off when 1 bar (14.5 psi) is reached (decreasing pressure).

1. Set the switch point to 2 bar (29 psi)

2. Set the switchback point to 1 bar (14.5 psi)

3. Configure the switch output as an "NC contact"

The pump is controlled by the defined settings.

8.10 Configuring the local display

8.10.1 Adjusting the local display

The local display can be adjusted in the following menu:

EF → DIS

Endress+Hauser 37

Page 38

Commissioning Ceraphant PTP31B, PTP33B

8.11 Protecting settings from unauthorized access

→ 24

38 Endress+Hauser

Page 39

Ceraphant PTP31B, PTP33B Diagnostics and troubleshooting

9 Diagnostics and troubleshooting

9.1 Troubleshooting

If an illegal configuration exists in the device, the device switches to error mode.

Example:

• Diagnostic message "C469", for example, appears on the local display, the status LED is lit

red and the background of the local display changes from white to red.

• The switch outputs are opened. The current output adopt the alarm current that has

been set.

• If the device configuration is corrected, e.g. by resetting the device, the device quits the

fault state and switches to the measuring mode.

• Errors and warning messages relating to several channels appear on the display with the

same error number and associated output.

General errors

Error Possible cause Solution

Device is not responding. Supply voltage does not match that

specified on the nameplate.

Supply voltage has incorrect polarity. Reverse polarity of supply voltage.

Connecting cables are not in contact with

the terminals.

No display The local display might be switched off. Switch on the local display (see the

Output current

≤ 3.6 mA

Device measures

incorrectly.

Signal line is not wired correctly. Check wiring.

Configuration error. Check and correct the parameter

Apply correct voltage.

Check the contacting of the cables and

correct if necessary.

"DOF" parameter description).

configuration.

Endress+Hauser 39

Page 40

Diagnostics and troubleshooting Ceraphant PTP31B, PTP33B

9.2 Diagnostic events

9.2.1 Diagnostic message

Faults detected by the self-monitoring system of the measuring device are displayed as a

diagnostic message in alternation with the measured value display.

Status signals

The table lists the messages that may occur. The ALARM STATUS parameter shows the

message with the highest priority. The device has four different status information codes

according to NE107:

"Failure"

A device error has occurred. The measured value is no longer valid.

A0013956

"Maintenance required"

Maintenance is required. The measured value remains valid.

A0013957

"Function check"

The device is in service mode (e.g. during a simulation).

A0013959

"Out of specification"

The device is being operated:

• Outside its technical specifications (e.g. during warmup or cleaning processes)

A0013958

• Outside the parameter configuration undertaken by the user (e.g. level outside of configured range)

Diagnostics event and event text

The fault can be identified by means of the diagnostic event.

Diagnostic event

Status signal Event number

↓ ↓

Example

A0013959

469

If two or more diagnostic events are pending simultaneously, only the message with the

highest priority is shown.

The last diagnostic message is displayed - see the LST parameter in the DIAG

submenu → 64.

40 Endress+Hauser

Page 41

Ceraphant PTP31B, PTP33B Diagnostics and troubleshooting

9.2.2 List of diagnostic events

Diagnostic event Cause Corrective measure

Code Description

0 No error - -

1)

C431

C432

alternating with

1)

Ou1

C432

alternating with

1)

Ou2

C469

alternating with

OU1 or OU2

C485 Simulation active During simulation of the switch output or

2) 3)

F270

F437 Incompatible configuration Invalid device configuration • Restart the device

F804 Overload at switch output 1

S140 Sensor signal outside of

S510 Turn down violated A change in the span results in a violation

S803 Current loop 2 Impedance of load resistance at analog

Invalid position adjustment The calibration performed would cause the

sensor nominal range to be exceeded or

undershot.

Position adjustment + parameter of the current output

must be within the sensor nominal range

• Check the position adjustment (see the ZRO

parameter)

• Check the measuring range (see the STU and STL

parameters)

Invalid position adjustment,

output 1

The calibration performed causes the

switch points to be outside the sensor

nominal range.

Position adjustment + parameter of the hysteresis and

window function must be within the sensor nominal

range

• Check the position adjustment (see the ZRO

parameter)

• Check the switch point, switchback point for

hysteresis and window function

Invalid position adjustment,

output 2

The calibration performed causes the

switch points to be outside the sensor

nominal range.

Position adjustment + parameter of the hysteresis and

window function must be within the sensor nominal

range

• Check the position adjustment (see the ZRO

parameter)

• Check the switch point, switchback point for

hysteresis and window function

Switch points output 1 or 2

Switch point ≤ switchback point Check switch points at output

violated

Switch off simulation

current output, the device issues a warning

message for the duration of the simulation.

Overpressure/low pressure Overpressure or low pressure present • Check the process pressure

• Check sensor range

• Restart the device

Defect in electronics/sensor Defect in electronics/sensor Replace device

• Reset device

• Replace device

4)

Increase load resistance at switch output

or 2 or both switch outputs

Load current > 250 mA per per output

Switch output defective • Check output circuit

• Replace device

Overpressure or low pressure present Operate device in the specified measuring range

permitted ranges

Sensor defective Replace device

• Operate device in the specified measuring range

of the turn down (max. TD 5:1)

• Check the measuring range

Values for calibration (lower range value

and upper range value) are too close

together

• Check the cabling and load at the current output.

output is too high

• If the current output is not required, switch the

current output off via the configuration.

Endress+Hauser 41

Page 42

Diagnostics and troubleshooting Ceraphant PTP31B, PTP33B

Diagnostic event Cause Corrective measure

Code Description

Current output not

connected

S971 Measured value is outside

sensor range

1) Without a corrective measure, the warning messages are available after device restart with a relative pressure device >URL + 10% or < LRL + 5%

and with an absolute pressure device> URL + 10% or < LRL.

2) The switch outputs are opened and the current output adopts the configured alarm current. Errors concerning the switch output are not displayed

because the switch output is in a safe state.

3) The device outputs an error current of 0 mA in the event of an internal communication error. In all other cases, the device returns the configured

error current.

4) The device can be subjected to a total maximum load current of 500 mA at the switch outputs. This load can be distributed asymmetrically

between the two outputs.

Current output not connected • Connect current output with load.

• If the current output is not required, switch the

current output off via the configuration.

The current is outside the permitted range

from 3.8 to 20.5 mA.

The present pressure value is outside the

configured measuring range (but within the

sensor range, if applicable).

Operate the device within the set span

9.3 Behavior of the device in the event of a fault

The device displays warnings and faults on the local display and indicates them via the

status LEDs. All the device warnings and faults are for information purposes only and do

not have a safety function. The errors diagnosed by the device are shown on the local

display in accordance with NE107. In accordance with the diagnostic message, the device

behaves as per a warning or fault condition. It is necessary to distinguish between the

following types of errors here:

• Warning:

– The device continues measuring if this type of error occurs. The output signal is not

affected (exception: simulation is active).

– The local display alternates between the warning and the main measured value.

– The switch outputs remain in the state defined by the switch points.

– Status LED flashes red.

– The background remains white in the event of a warning

• Fault:

– The device does not continue measuring if this type of error occurs. The output signal

adopts its fault state (value in the event of an error - see the following section).

– The fault state is indicated on the local display.

– The switch outputs assume the "opened" state.

– For the analog output option, an error is signaled with the configured alarm current

behavior.

9.4 Response of output to errors

The response of the output to error is regulated in accordance with NAMUR NE43.

42 Endress+Hauser

Page 43

Ceraphant PTP31B, PTP33B Diagnostics and troubleshooting

The behavior of the current output in case of fault is defined by the following parameters:

• FCU "MIN": Lower alarm current (≤3.6 mA) (optional, see the following table)→ 58

• FCU "MAX" (factory setting): Upper alarm current (≥21 mA) → 58

• FCU "HLD" (HOLD): Last measured current value is held. When the device starts, the

current output is set to "Lower alarm current" (≤3.6 mA). → 58

• The selected alarm current is used for all errors.

• Errors and warning messages are displayed only on the primary value page

(topmost display level) and are not displayed in the operating menu.

• In the operating menu the error is only indicated by the color of the display

background.

• The status LED always indicates an error.

• It is not possible to acknowledge errors and warnings. The relevant message

disappears if the event is no longer pending.

• The failsafe mode can be changed directly when a device is running (see the

following table).

Changing the failsafe mode After confirming with

from MAX to MIN active immediately

from MIN to MAX active immediately

from HLD (HOLD) to MAX active immediately

from HLD (HOLD) to MIN active immediately

from MIN to HLD (HOLD) outside the error condition active

from MAX to HLD (HOLD) outside the error condition active

9.4.1 alarm current

Device Description Option

PTP31B

PTP33B

PTP31B

PTP33B

1) Product Configurator order code for "Service"

2) Product Configurator order code for "Calibration/unit"

Adjusted min. alarm current IA

1 low ≤3.6 mA

2 high ≥21 mA

3 last current value

1)

2)

U

9.5 Behavior of the device in the event of a voltage drop

A diagnostic message is not output. The configuration and the settings made are retained.

9.6 Behavior of the device in the event of an incorrect entry

In the case of incorrect entries, the value entered is not accepted. No fault or warning is

issued in this case. The value to be adjusted cannot be changed to a value outside the

specified limit. This makes it impossible to configure the device using incorrect values. An

exception to this is the configuration of the span, which results in a violation of the turn

down, which in turn gives rise to a fault state.

9.7 Disposal

When disposing, separate and recycle the device components based on the materials.

Endress+Hauser 43

Page 44

Maintenance Ceraphant PTP31B, PTP33B

1

10 Maintenance

No special maintenance work is required.

Keep the pressure compensation element (1) free from contamination.

A0022140

10.1 Exterior cleaning

Please note the following points when cleaning the device:

• The cleaning agents used should not corrode the surface and the seals.

• Mechanical damage to the process isolating diaphragm, e.g. due to sharp objects, must

be avoided.

• Observe the degree of protection of the device. See the nameplate if necessary → 13.

44 Endress+Hauser

Page 45

Ceraphant PTP31B, PTP33B Repair

11 Repair

11.1 General notes

11.1.1 Repair concept

Repairs are not possible.

11.2 Return

The measuring device must be returned if the wrong device has been ordered or delivered.

As an ISO-certified company and also due to legal regulations, Endress+Hauser is obliged

to follow certain procedures when handling any returned products that have been in

contact with medium. To ensure swift, safe and professional device returns, please read

the return procedures and conditions on the Endress+Hauser website at

www.services.endress.com/return-material

Endress+Hauser 45

Page 46

Overview of the operating menu Ceraphant PTP31B, PTP33B

12 Overview of the operating menu

Depending on the parameter configuration, not all submenus and parameters are

available. Information on this can be found in the parameter description under

"Prerequisite".

Switch output

1 x PNP 2 x PNP 1 x PNP +

KYL If "KYL" is shown on the display, this means that the keys of the device are locked.

SP1 Switch point value, output 1 → 32

RP1 Switchback point value, output 1 → 32

FH1 Upper value for pressure window, output 1 → 34

FL1 Lower value for pressure window, output 1 → 34

SP2 Switch point, output 2 → 32

RP2 Switchback point, output 2 → 32

FH2 Upper value for pressure window, output 2 → 34

FL2 Lower value for pressure window, output 2 → 34

EF Extended functions

RES Enter reset code → 54

dS1 Switching delay time, output 1 → 54

dR1 Switchback delay time, output 1 → 54

dS2 Switching delay time, output 2 → 54

dR2 Switchback delay time, output 2 → 54

Ou1 Output 1

Ou2 Output 2

1)

4 to 20 mA

STL Value for 4 mA (LRV) → 35

STU Value for 20 mA (URV) → 35

I Current output

GTL Pressure applied for 4mA (LRV) → 36

GTU Pressure applied for 20mA (URV) → 36

Level 1 Level 2 Level 3 Description Details

To unlock the keys, see → 24

NO No

YES Yes

HNO NO contact for hysteresis function → 55

HNC NC contact for hysteresis function → 56

FNO NO contact for window function → 56

FNC NC contact for window function → 56

HNO NO contact for hysteresis function → 55

HNC NC contact for hysteresis function → 56

FNO NO contact for window function → 56

FNC NC contact for window function → 56

NO

YES

NO

YES

46 Endress+Hauser

Page 47

Ceraphant PTP31B, PTP33B Overview of the operating menu

Switch output

1 x PNP 2 x PNP 1 x PNP +

UNI Unit changeover → 59

HI Max value (maximum indicator) → 59

LO Min value (minimum indicator) → 60

ZRO Zero point configuration → 29

GTZ Zero point adoption → 30

TAU Damping → 61

DIS Display → 62

DVA PV Display measured value → 62

DRO Display measured value rotated by 180° → 62

DOF Display off → 62

ADM Administration

DIAG Diagnostics

SM1 Simulation output 1 → 64

1)

4 to 20 mA

FCU alarm current → 58

OFF Switch off the current output (only visible if switch output is "ON") → 58

ON Switch on the current output (only visible if switch output is "OFF") → 59

Level 1 Level 2 Level 3 Description Details

MIN In the event of an error: MIN (≤3.6 mA)

MAX In the event of an error: MAX (≥21 mA)

HLD Last current value (HOLD)

NO

YES

NO

YES

BAR Unit bar

KPA Unit kPa (depends on the sensor measuring range))

MPA Unit MPa (depends on the sensor measuring range)

PSI Unit psi

PV'/, Display the measured value as a percentage of the set span

SP Display set switch point

NO

YES

NO

YES

LCK Unlocking code → 24

COD Locking code → 24

STA Current device status → 64

LST Last device status → 64

RVC Change counter → 64

OFF

OPN Switch output opened

CLS Switch output closed

Endress+Hauser 47

Page 48

Overview of the operating menu Ceraphant PTP31B, PTP33B

Switch output

1)

Level 1 Level 2 Level 3 Description Details

1 x PNP 2 x PNP 1 x PNP +

4 to 20 mA

SM2

2)

Simulation output 2 → 65

OFF

OPN Switch output opened

CLS Switch output closed

3.5 Simulation value for analog output in mA

4.0 Simulation value for analog output in mA

8.0 Simulation value for analog output in mA

12.0 Simulation value for analog output in mA

16.0 Simulation value for analog output in mA

20.0 Simulation value for analog output in mA