Page 1

Operating Instructions – Description of Device Functions

Cerabar S PMP71 with MID Part Certificate

Process pressure measurement

BA00413P/00/EN/03.14

71270370

Valid for software version:

02.10.54

Page 2

Cerabar S 4 to 20mA HART

TAG No.: XXX000

Ser. No.: X000X000000

Order code 00X00-XXXX0XX0XXX

www.endress.com/deviceviewer Endress+Hauser Operations App

Serial number

A0023555

2 Endress+Hauser

Page 3

Cerabar S 4 to 20mA HART Table of contents

Table of contents

1 Notes on use . . . . . . . . . . . . . . . . . . . . 4

1.1 Finding parameter description using ID numbers . . . 4

1.2 Finding function group using graphic representation . 4

1.3 Finding parameter description using parameter names

(index) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Finding parameter description using ID

numbers . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Graphic representation of function groups

7

4 Pressure measurement. . . . . . . . . . . . . 8

4.1 Calibration with reference pressure . . . . . . . . . . . . . 8

4.2 Calibration without reference pressure . . . . . . . . . . . 9

5 Description of parameters . . . . . . . . . 10

6 Troubleshooting . . . . . . . . . . . . . . . . . 38

6.1 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.2 Response of outputs to errors . . . . . . . . . . . . . . . . . 45

6.3 Confirming messages . . . . . . . . . . . . . . . . . . . . . . . 46

7 Appendix . . . . . . . . . . . . . . . . . . . . . . 47

7.1 Operating menu for onsite display and digital

communication . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Endress+Hauser 3

Page 4

Notes on use Cerabar S 4 to 20mA HART

1 Notes on use

Section 5 describes all the parameters in the order of how they appear in the menu. Section 4

describe typical configuration examples.

Section 1.1 to Section 1.3 describe ways of finding a certain parameter description more easily.

1.1 Finding parameter description using ID numbers

Each parameter is shown on the onsite display with a unique identification number (ID). All the

parameters are listed in numerical order in Section 2. The page reference/link takes you to the

parameter in question.

In the operating program, additional parameters and, to an extent, other parameters are displayed.

These parameters are not shown in Section 2. You can find these parameters by means of the index.

See also Section 1.3.

1.2 Finding function group using graphic representation

Section 3 provides an outline of all of the function groups in tables. The page reference/link takes

you to the function group in question. In Section 5, all of the parameters in a function group are

summarized in a table.

1.3 Finding parameter description using parameter names (index)

The index lists all the parameters in alphabetical order. The page reference/link takes you to the parameter in question.

4 Endress+Hauser

Page 5

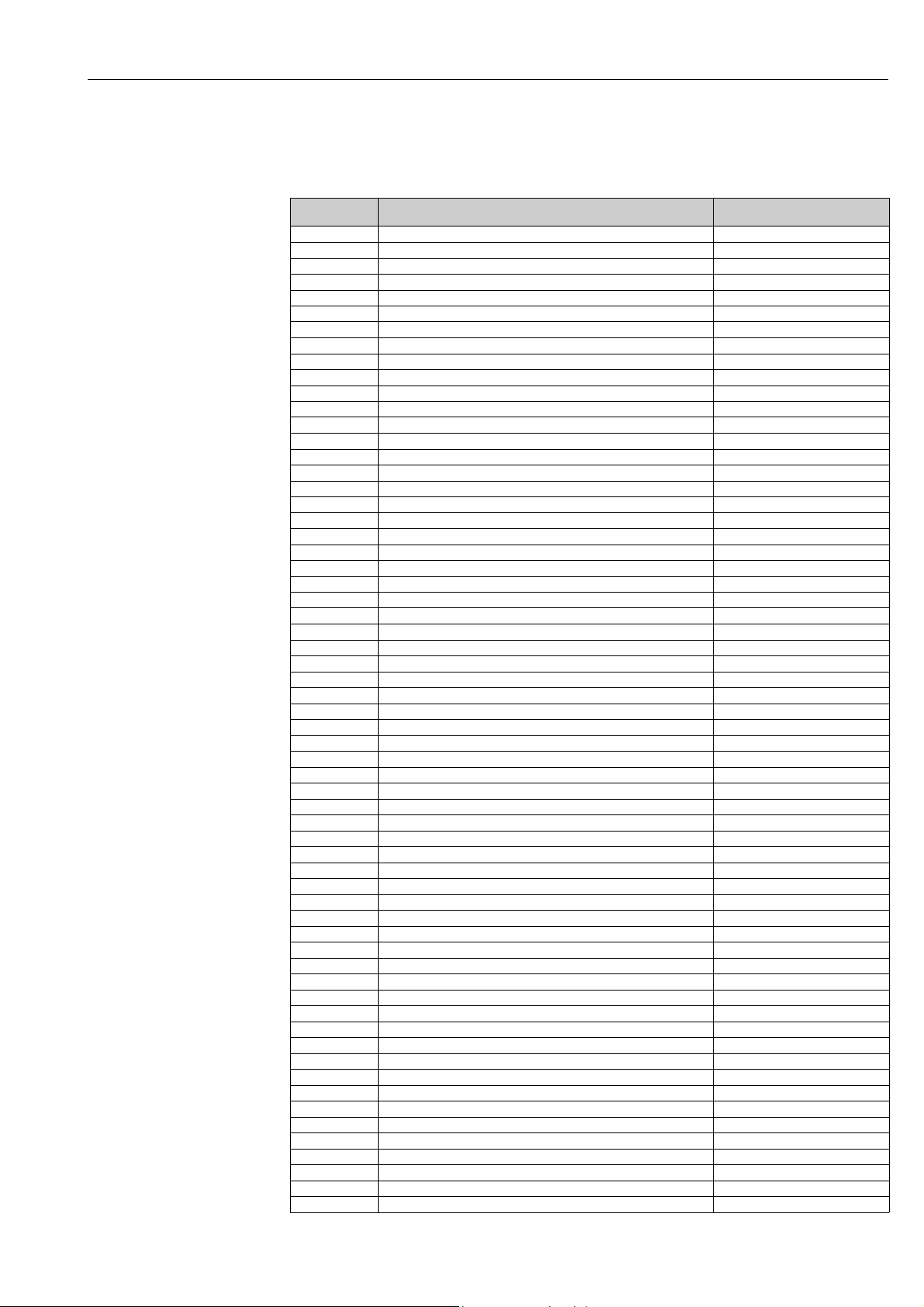

Cerabar S 4 to 20mA HART Finding parameter description using ID numbers

2 Finding parameter description using ID

numbers

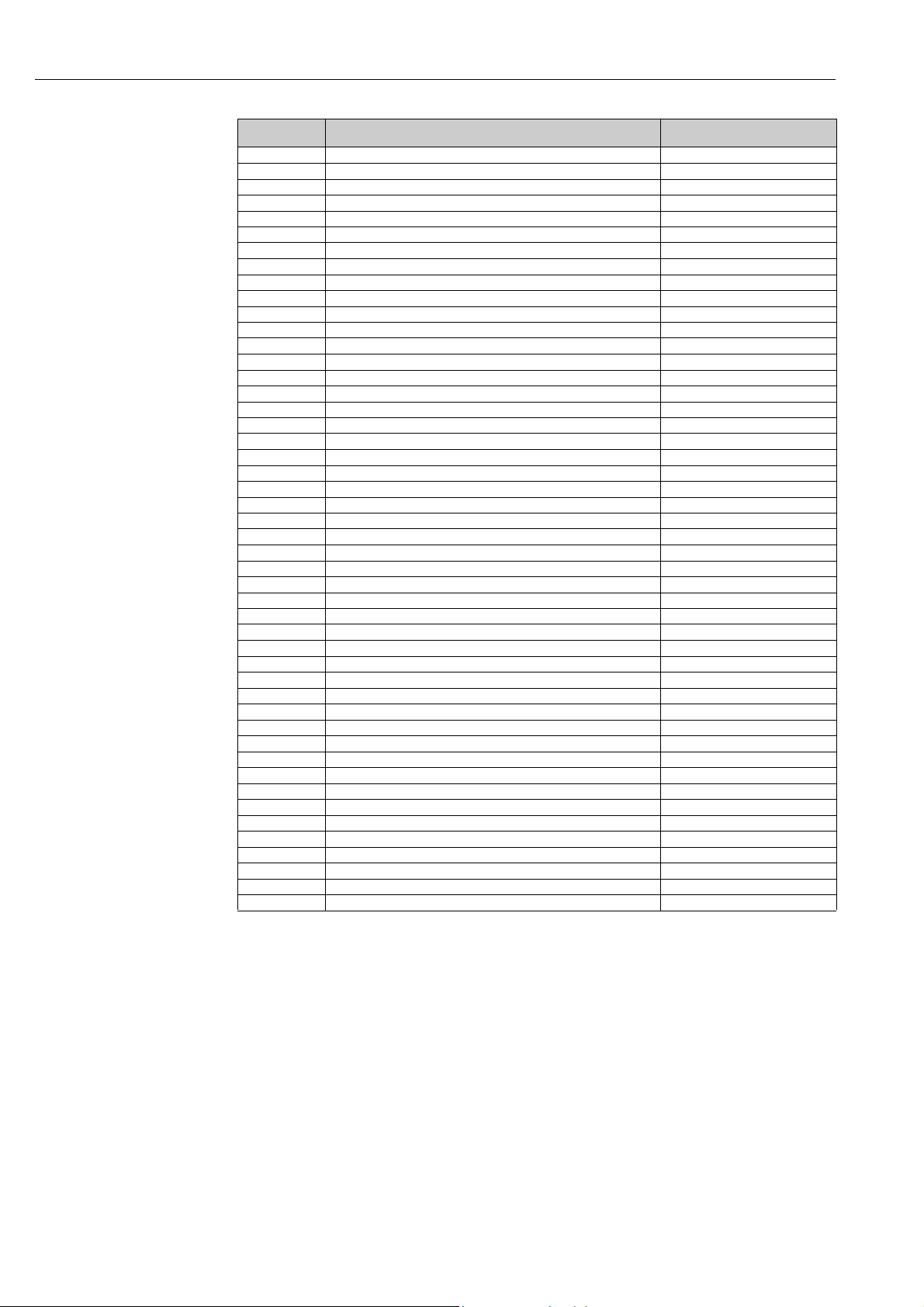

ID number Parameter name Description, see Page

014 DOWNLOAD SELECT 32

015 FULL PRESSURE See

016 EMPTY PRESSURE See

017 FULL CALIB. See

018 EMPTY CALIB. See

021 SET LRV See

022 SET URV See

036 PREAMBLE NUMBER 24

042 CURR. TRIM 20mA 36

043 OFFSET 4mA TRIM 37

044 OFFSET 20mA TRIM 37

045 CURR. TRIM 4mA 36

046 ALARM STATUS 33

047 ENTER RESET CODE 31

048 INSERT PIN No 32

055 CUST. TAG NUMBER 25

060 PRESS. ENG. UNIT 15

075 CUSTOMER UNIT P 15

079 LANGUAGE 10

245 SET LRV – "Pressure" measuring mode 12 or 15

246 SET URV – "Pressure" measuring mode 12 or 15

247 DAMPING TIME 12, 16

250 SENSOR SER. No. 28

254 OUTPUT CURRENT 20

264 SOFTWARE VERSION 25

266 HARDWARE REV. 25

270 SIM. CURRENT 33

271 HART MESSAGE 24

272 ADDITIONAL INFO. 25

301 PRESSURE – "Pressure" measuring mode 30

305 LONG TAG NUMBER 25

309 GET LRV 16

310 GET URV 16

317 CUST.UNIT FACT.P 15

318 TEMP. ENG. UNIT – "Pressure" measuring mode 17

319 CALIB. OFFSET 13

332 Pmin ALARM WINDOW 35

333 Pmax ALARM WINDOW 35

334 Tmin ALARM WINDOW 35

335 Tmax ALARM WINDOW 35

336 ALARM DELAY 35

339 DISPLAY CONTRAST 19

342 SET MAX. ALARM 22

343 SET MIN. CURRENT 22

345 BUS ADDRESS 23

350 DEVICE DESIGN. 25

352 CONFIG RECORDER 25

354 DEVICE SERIAL No 25

357 PCB TEMPERATURE 25

358 ALLOWED MIN. TEMP 25

359 ALLOWED MAX. TEMP 25

360 MAT. PROC. CONN. + 26

362 SEAL TYPE 27

363 DIP STATUS 26

365 MAT. 28

366 FILLING FLUID 28

367 SENSOR TEMP. 30

368 Tmin SENSOR 28

369 Tmax SENSOR 28

378 MEAS. VAL. TREND 30

386 ELECTR. SERIAL NO. 25

388 OUTPUT FAIL MODE 21

1)

1)

1)

1)

1)

1)

Endress+Hauser 5

Page 6

Finding parameter description using ID numbers Cerabar S 4 to 20mA HART

ID number Parameter name Description, see Page

389 MEASURING MODE 11, 14

401 ACK. ALARM MODE 34

409 OPERATING HOURS 31

413 SIMULATION MODE 33

414 SIM. PRESSURE 33

419 MENU DESCRIPTOR 18

423 ALTERNATE DATA 19

432 MANUFACTOR ID 24

434 CORRECTED PRESS. – "Pressure" measuring mode 30

476 SIM. ERROR NO. 33

480 ALARM DISPL. TIME 35

481 HART DATE 24

482 PROC. CONN. TYPE 26

484 PRESS. SENS LOLIM 28

485 PRESS. SENS HILIM 28

487 SENS H/WARE REV 28

500 ACK. ALARM 34

563 POS. INPUT VALUE 11 or 13

564 LAST DIAG. CODE 34

570 Pmax PROC. CONN. 26

581 SENSOR MEAS.TYPE 28

584 SENSOR PRESSURE – "Pressure" measuring mode 30

591 MINIMUM SPAN 28

595 SELECT ALARMTYPE 34

597 ALT.CURR.OUTPUT 21

600 SELECT ALARMTYPE 34

603 RESET ALL ALARMS 34

679 MEASURED VALUE – "Pressure" 29

688 MAIN DATA FORMAT 18

694 CURR. CHARACT. – "Pressure" 21

696 CURR. CHARACT. – "Height" 21

699 DEVICE REVISION 23

764 CURR. CHARACT. – "Tank content" 21

802 DEVICE TYPE, Cerabar S 23

831 HistoROM AVAIL. 32

832 HistoROM CONTROL 32

836 SAFETY LOCKSTATE See

838 SAFETY PASSWORD See

840 DIGITS SET 19

841 DIGITS SET See

844 ACK. ALARM MODE See

845 MEASURING MODE See

847 CALIB. OFFSET See

852 SET LRV See

853 SET URV See

855 DAMPING TIME See

856 CONF. PASSWORD See

875 CURRENT OUTPUT See

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1)

1) For further information, see the Cerabar S Functional Safety Manual (SD00190P).

6 Endress+Hauser

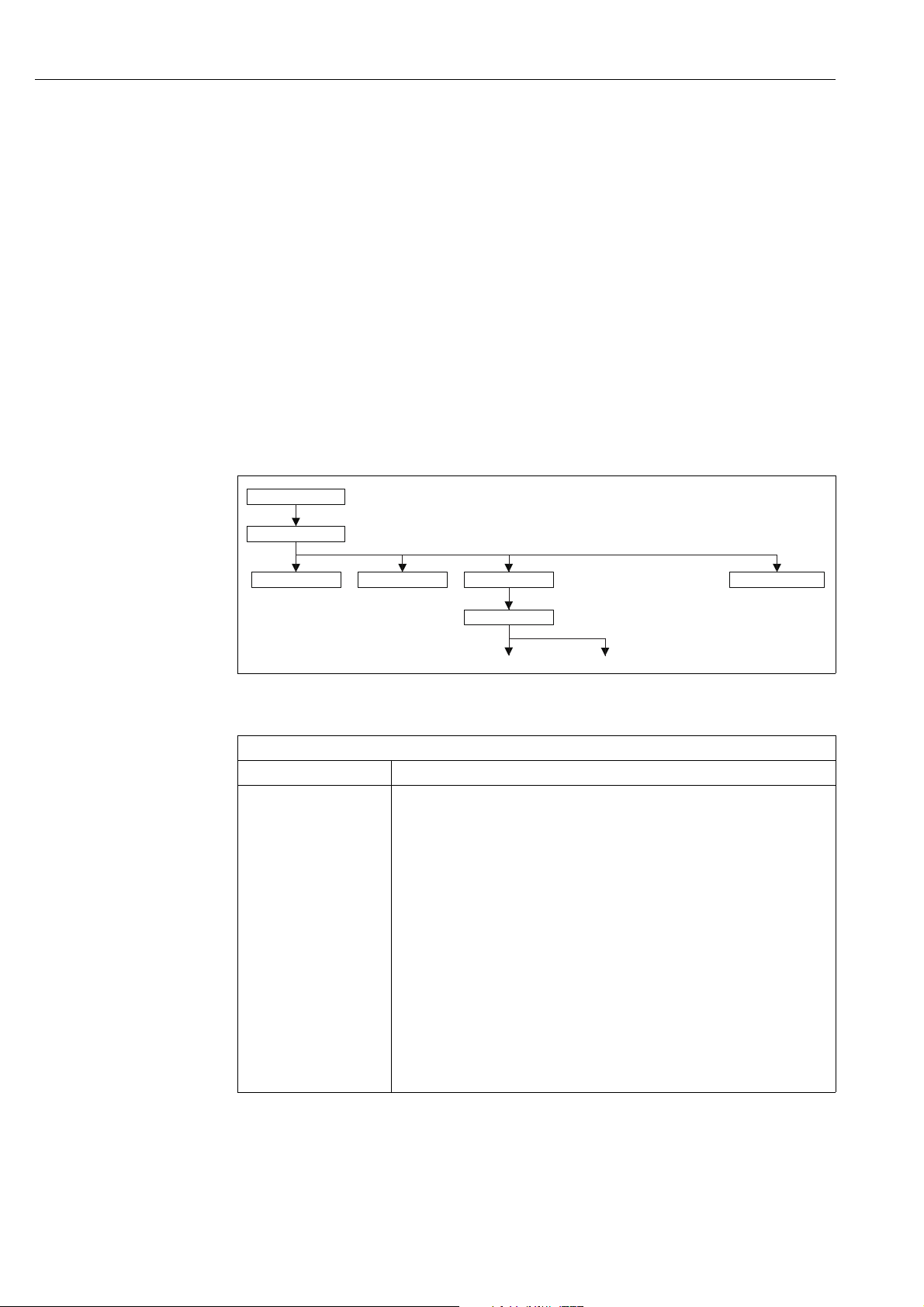

Page 7

Cerabar S 4 to 20mA HART Graphic representation of function groups

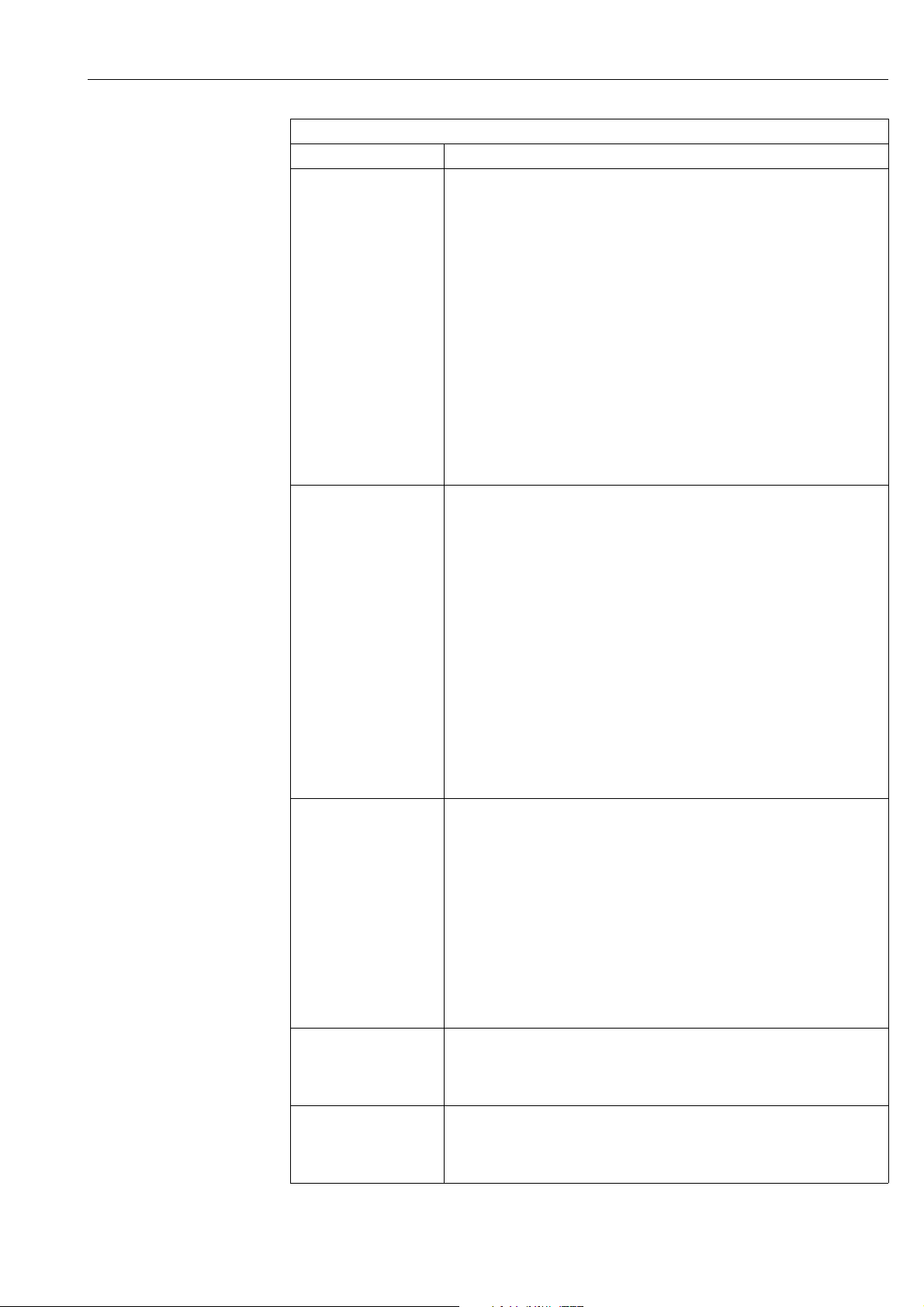

3 Graphic representation of function groups

1st Selection level 2nd Selection level (groups) Function groups Description,

see Page

LANGUAGE LANGUAGE (079) 10

OPERATING MODE OPERATING MODE (389) 10

QUICK SETUP pressure 11

OPERATING MENU (555) SETTINGS (557) POSITION ADJUSTMENT 12

BASIC SETUP pressure 14

EXTENDED SETUP pressure 17

SAFETY CONFIRM. See

DISPLAY (558) 18

OUTPUT (559) 20

TRANSMITTER INFO (560) HART DATA 23

TRANSMITTER DATA 25

PROCESS CONNECTION 26

SENSOR DATA 28

PROCESSINFO (561) PROCESS VALUES pressure 29

OPERATING 31

DIAGNOSTICS (562) SIMULATION MODE 33

MESSAGES 33

USER LIMITS 35

SERVICE (561) SYSTEM 2 36

1)

1) For further information, see the Cerabar S Functional Safety Manual (SD00190P).

Endress+Hauser 7

Page 8

Pressure measurement Cerabar S 4 to 20mA HART

20

4

I

[mA]

04

p

[bar]

➀

➁

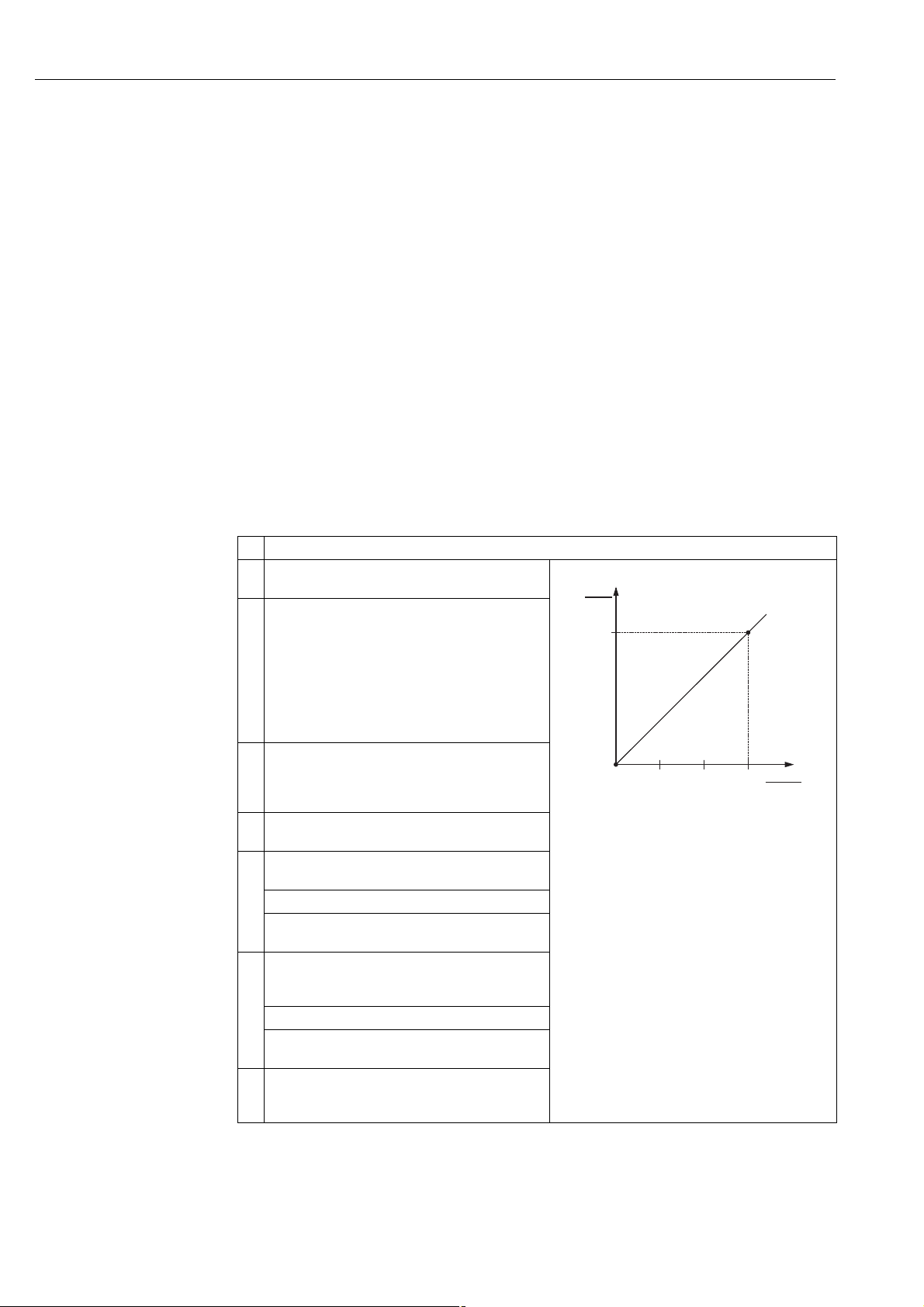

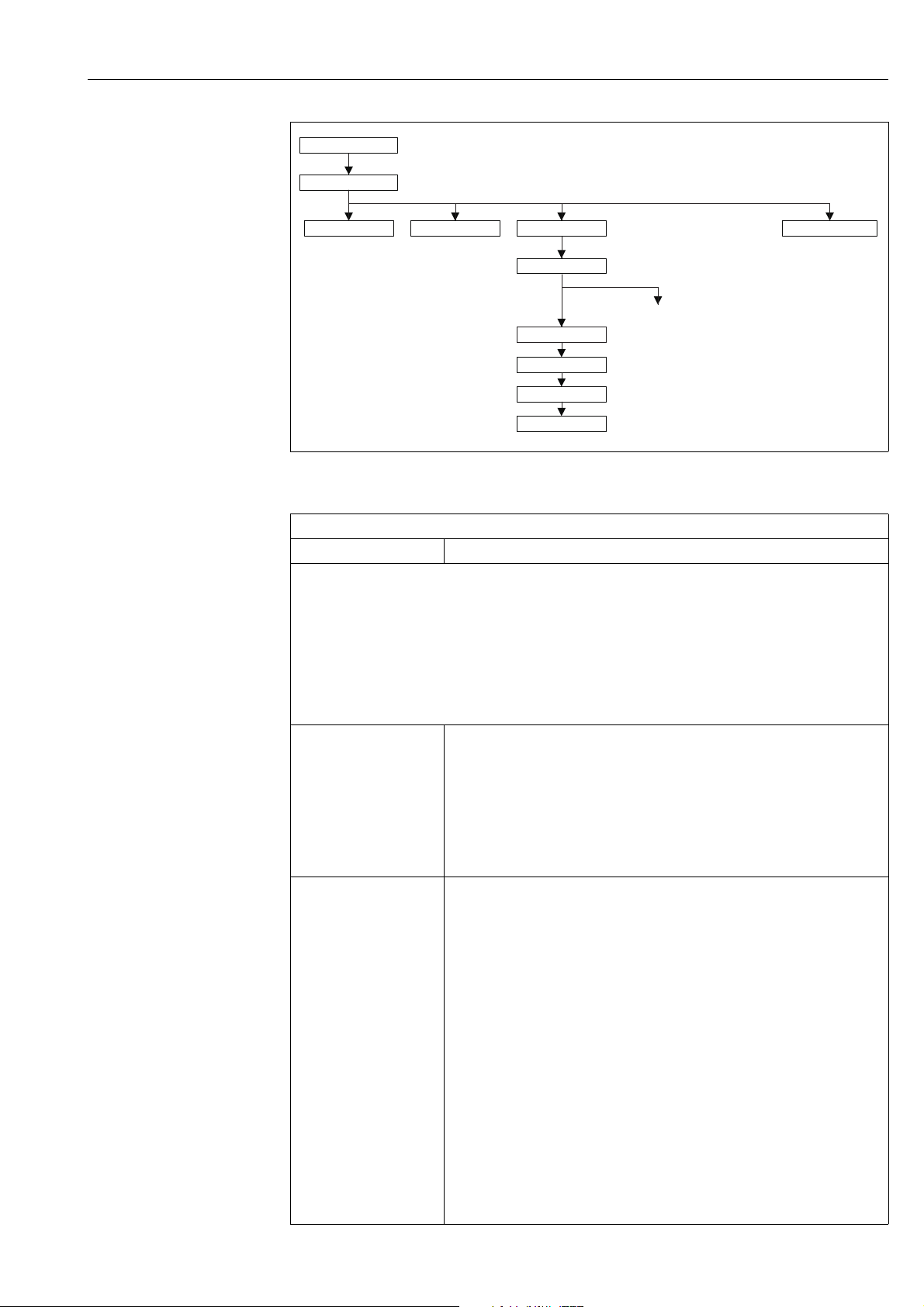

4 Pressure measurement

4.1 Calibration with reference pressure

Example:

In this example, a device with a 10 bar (150 psi) sensor is configured for the 0 to +4 bar (60 psi) measuring range, i.e. 0 bar is assigned to the 4 mA value and 4 bar (60 psi) to the 20 mA value.

Prerequisite:

• The pressure values 0 bar and 4 bar (60 psi) can be specified. The device is already installed, for

example.

!

Note!

• See also Operating Instructions for Cerabar S (BA00412P), "Pressure measurement" section.

• For a description of the parameters mentioned, see

– Page 10, Table 1: MEASURING MODE

– Page 12, Table 3: POSITION ADJUSTMENT

– Page 14, Table 4: BASIC SETUP.

• For a description of further relevant parameters, see

– Page 17, Table 5: EXTENDED SETUP

– Page 29, Table 12: PROCESS VALUES.

Description

1 Carry out position adjustment if necessary. See Page 12,

Table 5: POSITION ADJUSTMENT.

2 If necessary, select the "Pressure" measuring mode via

the MEASURING MODE parameter.

Onsite display:

Menu path: GROUP SELECTION MEASURING

MODE

Digital communication

Menu path: OPERATING MENU SETTINGS

BASIC SETUP MEASURING MODE

3 Onsite display:

Select BASIC SETUP function group. Menu path:

GROUP SELECTION OPERATING MENU

SETTINGS BASIC SETUP

4 Select a pressure unit via the PRESS. ENG. UNIT

parameter, here mbar for example.

5 The pressure for the lower range value (4 mA value) is

present at the device, here 0 mbar for example.

Select GET LRV parameter.

Confirm value present. The pressure value present is assigned to the lower current value (4 mA).

6 The pressure for the upper range value (20 mA value) is

present at the device, here 300 mbar (4.5 psi) for

example.

Select GET URV parameter.

Confirm value present. The pressure value present is assigned to the upper current value (20 mA).

7Result:

The measuring range is configured for 0 to +300 mbar

(4.5 psi).

Fig. 1: Calibration with reference pressure

1 See Table, Step 5.

2 See Table, Step 6.

P01-MIDxxxxx-05-xx-xx-xx-004

!

Note!

• You can also specify a customer-specific unit. See parameter description for PRESS. ENG. UNIT

(Page 15).

8 Endress+Hauser

Page 9

Cerabar S 4 to 20mA HART Pressure measurement

20

4

I

[mA]

04

p

[bar]

➀

➁

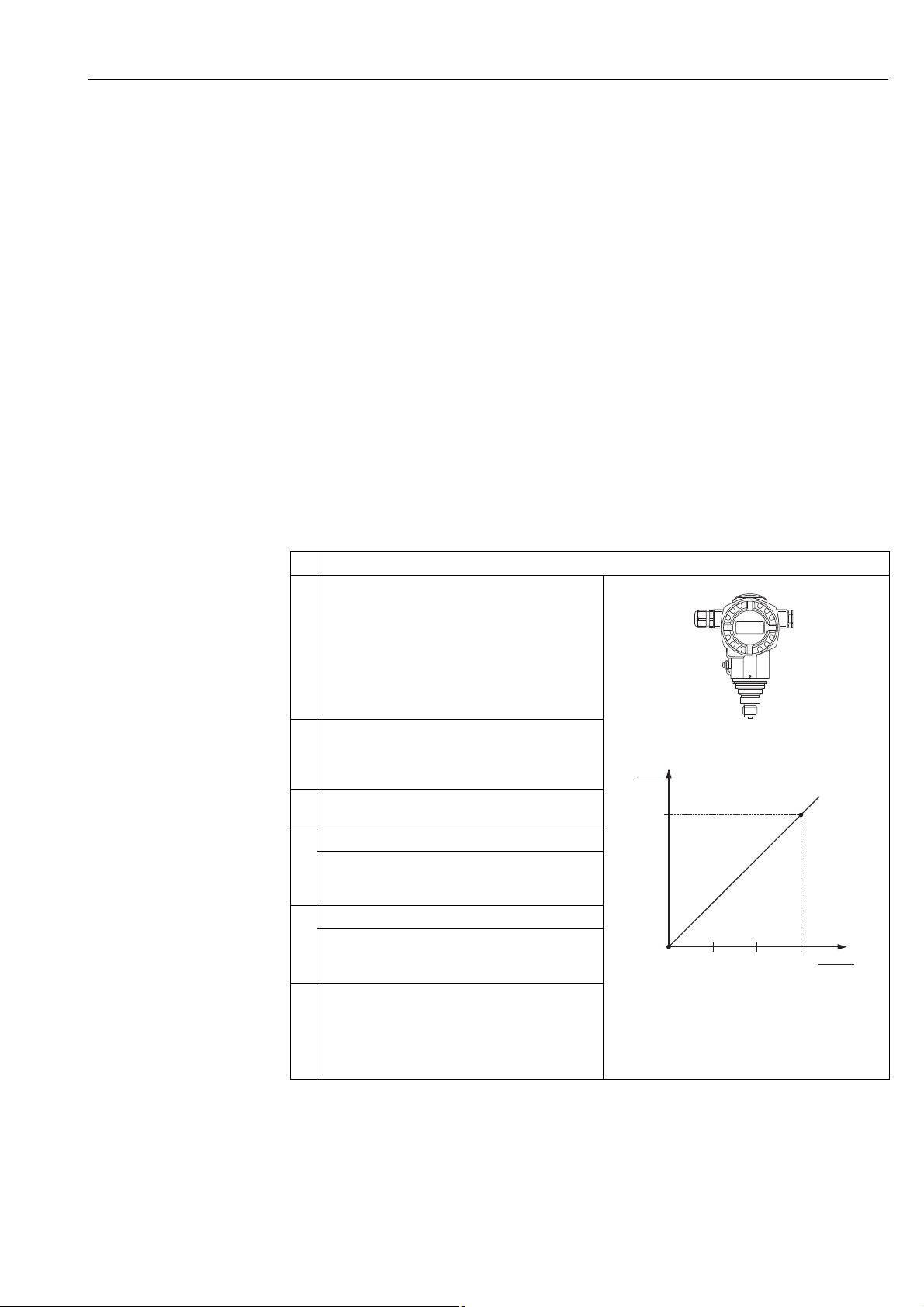

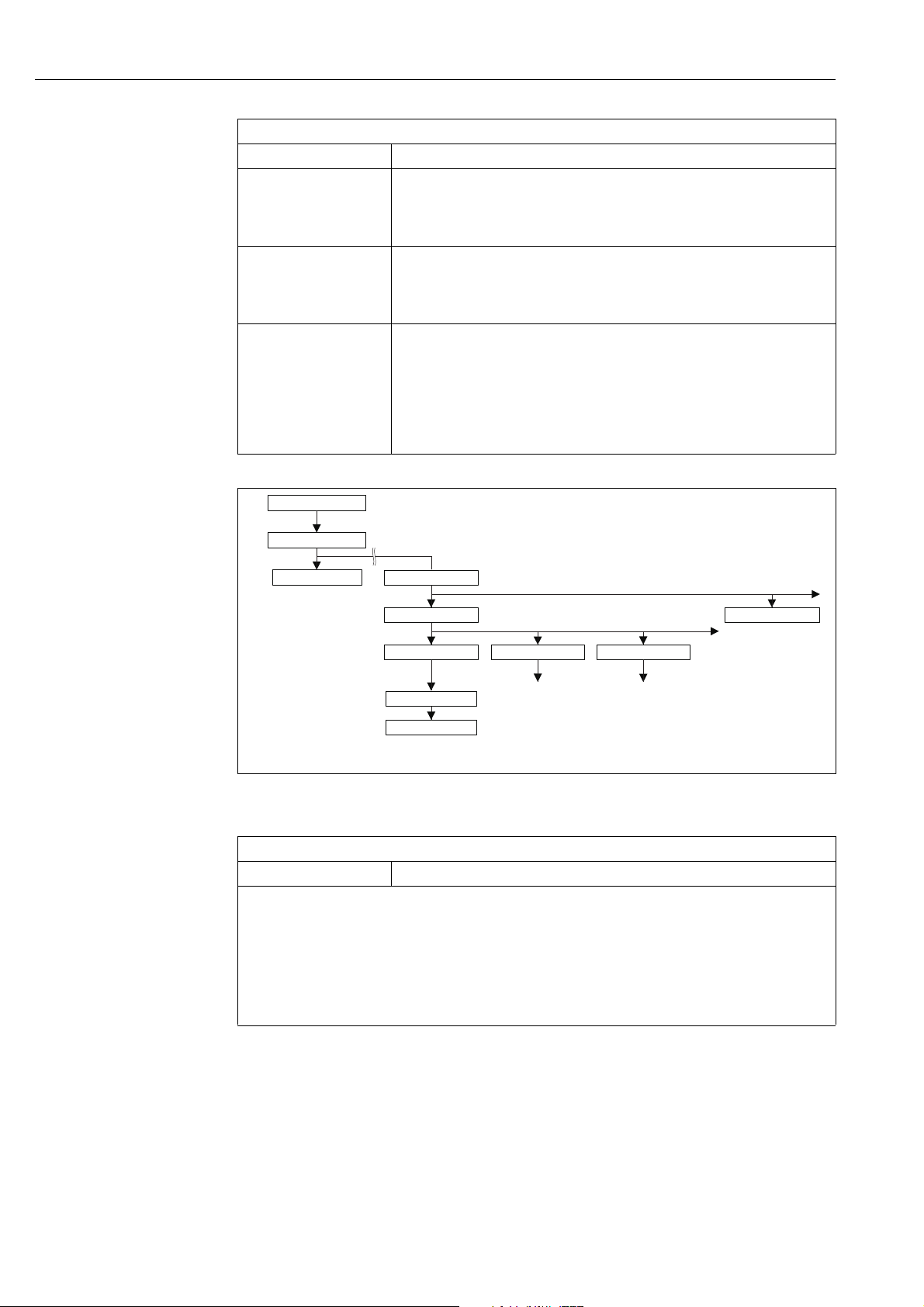

4.2 Calibration without reference pressure

Example:

In this example, a device with a 400 mbar (6 psi) sensor is configured for the 0 to +300 mbar (4.5 psi) measuring range, i.e. 0 mbar is assigned to the 4 mA value and 300 mbar (4.5 psi) to the 20 mA value.

Prerequisite:

• This is a theoretical calibration, i.e. the pressure values for the lower range and upper range value are known.

!

Note!

• See also Operating Instructions for Cerabar S (BA00412P), "Pressure measurement" section.

• Due to the orientation of the device, there may be a shift in the measured value, i.e. when the

container is empty or partially filled, the MEASURED VALUE parameter does not display zero.

For information on how to perform position adjustment, see also Page 12, Table 3: Position

adjustment.

• For a description of the parameters mentioned, see

– Page 10, Table 1: MEASURING MODE

– Page 12, Table 3: POSITION ADJUSTMENT

– Page 14, Table 4: BASIC SETUP.

• For a description of further relevant parameters, see

– Page 17, Table 5: EXTENDED SETUP

– Page 29, Table 12: PROCESS VALUES.

Description

1 If necessary, select the "Pressure" measuring mode via

the MEASURING MODE parameter.

Onsite display:

Menu path: GROUP SELECTION MEASURING

MODE

Digital communication

Menu path: OPERATING MENU SETTINGS

BASIC SETUP MEASURING MODE

2 Onsite display:

Select BASIC SETUP function group. Menu path:

GROUP SELECTION OPERATING MENU

SETTINGS BASIC SETUP

3 Select a pressure unit via the PRESS. ENG. UNIT

parameter, here mbar for example.

4 Select SET LRV parameter.

Enter value, here 0 mbar, for the SET LRV

and confirm. This pressure value is assigned to the lower

current value (4 mA).

5 Select SET URV parameter.

Enter the value for the "SET URV" parameter (here 300 mbar (4.5 psi)) and confirm. This pressure value is assigned to the upper current value (20 mA).

6Result:

The measuring range is configured for 0 to +300 mbar

(4.5 psi).

parameter

Fig. 2: Calibration without reference pressure

1 See Table, Step 4.

2 See Table, Step 5.

P01-PMP71xxx-19-xx-xx-xx-000

P01-MIDxxxxx-05-xx-xx-xx-004

Endress+Hauser 9

!

Note!

• You can also perform calibration without reference pressure by means of the QUICK SETUP

menu. See Page 11 ff, Table 2: QUICK SETUP menu.

• You can also specify a customer-specific unit. See parameter description for PRESS. ENG. UNIT

(Page 15).

Page 10

Description of parameters Cerabar S 4 to 20mA HART

1)

1)

1)

2)

1) Display via on-site display only

2) Display via digital communication

Pressure

OPERATING MENU

Measured value

GROUP SELECTION

LANGUAGEMEASURING MODE

QUICK SETUP

MEASURING MODE

Level (not

for PMP71 with MID)

provided

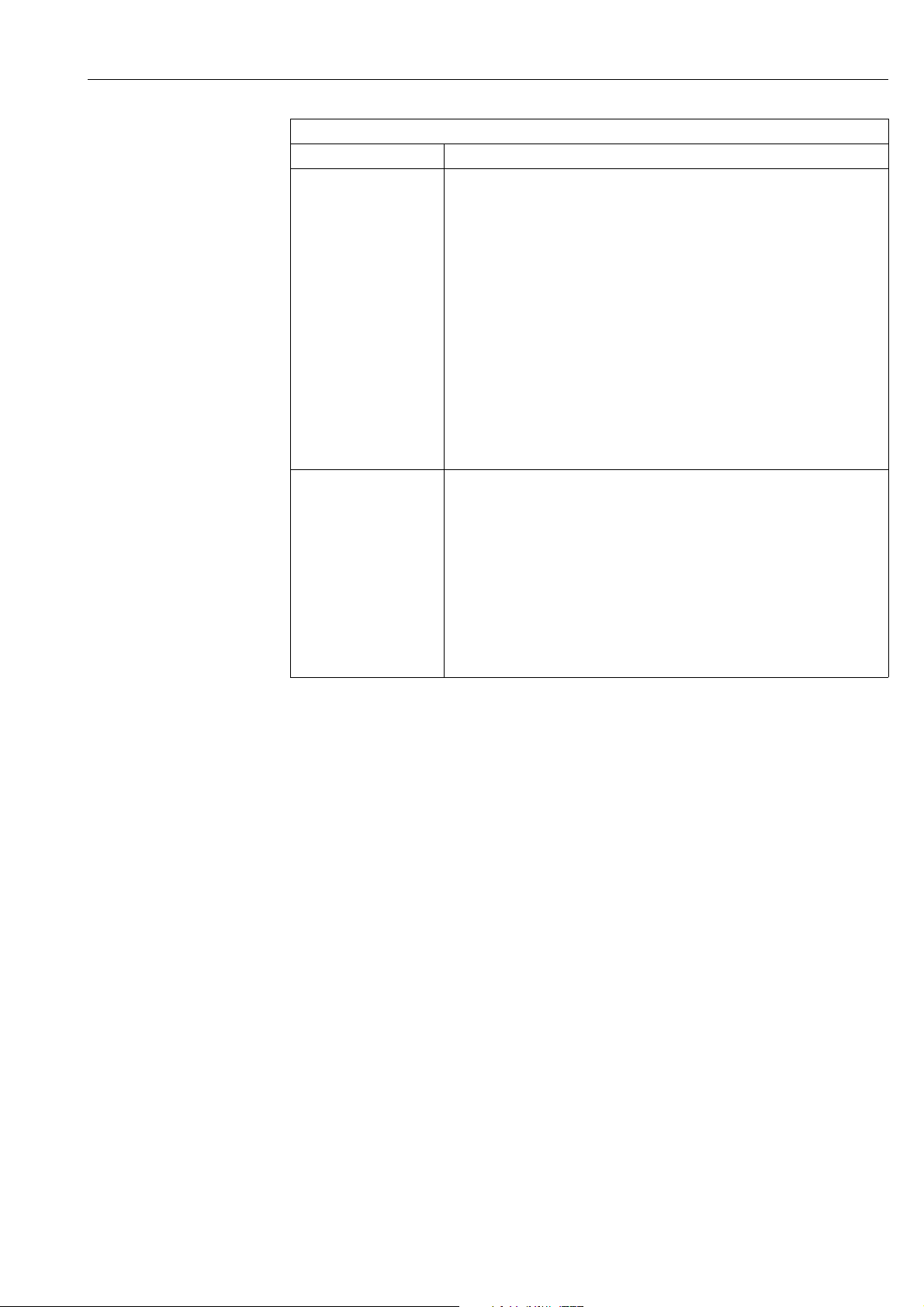

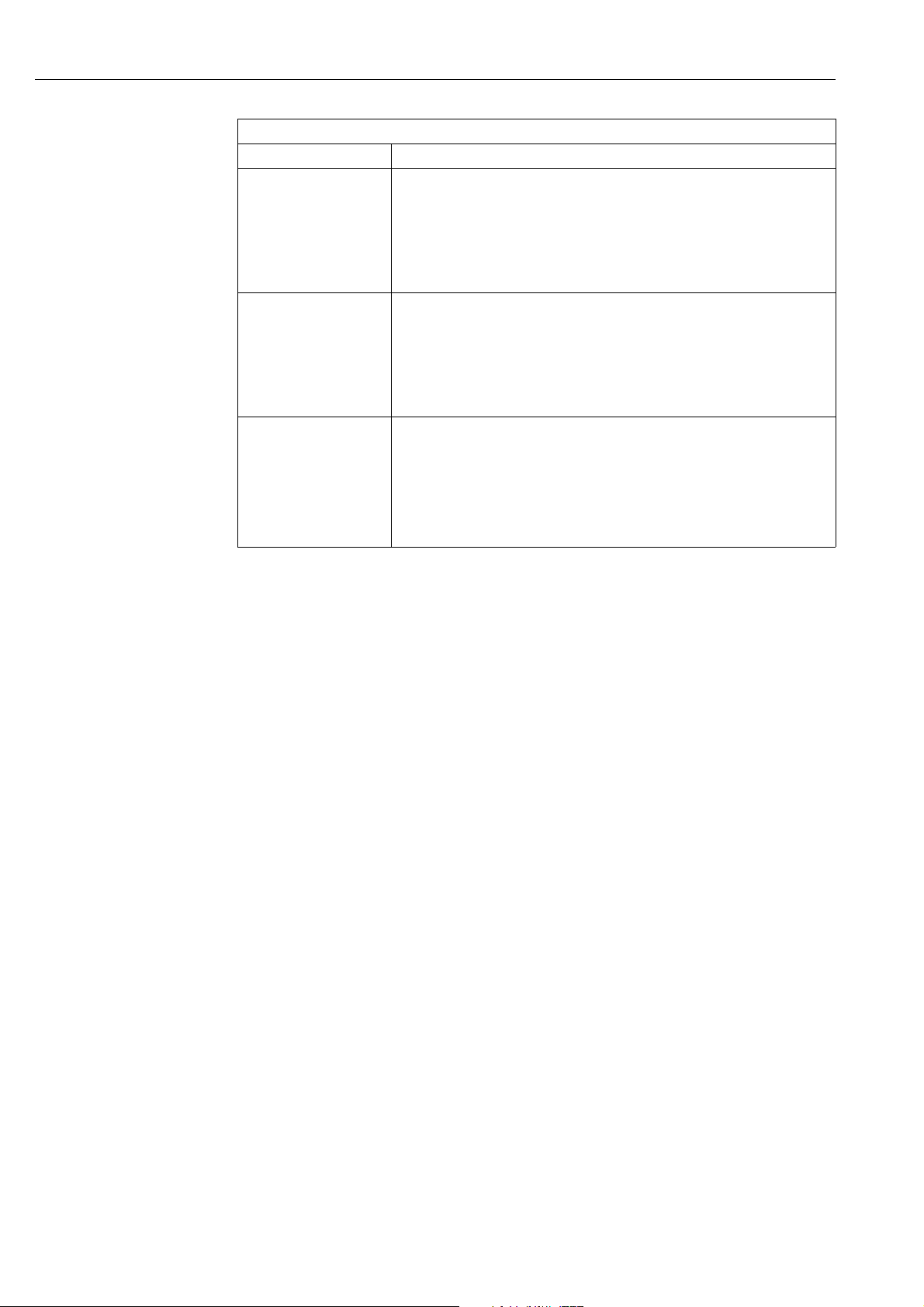

5 Description of parameters

!

Note!

• The following tables list all the parameters as per the menu structure. Each table corresponds to

a function group in the menu tree. The overall menu structure is illustrated in Section 7.1.

• The menu structure for local operation and digital communication are slightly different. The differences mainly affect the MEASURING MODE and LANGUAGE parameters.

• In the operating program or HART handheld terminal, additional parameters are displayed. These parameters are marked accordingly .

• The menu path is indicated in the header of each table. You can use this path to get to the parameters in question.

• The menu has a different structure depending on the measuring mode selected. This means that

some function groups are only displayed for one measuring mode. If certain requirements have to

be met for a function group, these are listed in the first row of the table.

• Some parameters are only displayed if other parameters are appropriately configured.

• Parameter names are written in upper case in the text.

• In the "Parameter name" column, the unique identification number (ID) of the parameter is indicated in brackets. This ID only appears on the onsite display.

Fig. 3: 1st selection level in menu, LANGUAGE ( see Page 10, Table 1)

Table 1: GROUP SELECTION LANGUAGE – Onsite display

Parameter name Description

LANGUAGE (079)

Options

Select the menu language for the onsite display.

Note!

!

• In the operating program and in the HART handheld terminal, the LANGUAGE parameter is arranged in the DISPLAY function group.

• Select the menu language for the operating program via the "Options" menu

"Settings" "Language" tab "Tool Language" field.

Options:

•Deutsch

• English

• Français

• Italiano

•Español

• Nederlands

• Chinese (CHS)

• Japanese (JPN)

Factory setting: English

P01-MIDxxxxx-19-xx-xx-EN-001

10 Endress+Hauser

Page 11

Cerabar S 4 to 20mA HART Description of parameters

1)

1)

2)

1)

1) Display via on-site display only

2) Display via

digital communication

SET LRV

SET URV

DAMPING VALUE

POS. INPUT VALUE

Pressure

OPERATING MENU

Measured value

GROUP SELECTION

LANGUAGEMEASURING MODE

QUICK SETUP

MEASURING MODE

Level (not

for PMP71 with MID)

provided

P01-MIDxxxxx-19-xx-xx-EN-003

Fig. 4: Quick Setup menu for the "Pressure" measuring mode

Table 2: (GROUP SELECTION ) QUICK SETUP "Pressure"

Parameter name Description

This menu displays the most important parameters for the "Pressure" measuring mode.

Prerequisite:

•MEASURING MODE = Pressure

Note:

See also

– Page 14 ff, Table 6: BASIC SETUP

– Page 17, Table 13: EXTENDED SETUP

– Page 29 ff, Table 23: PROCESS VALUES

– Page 8 ff, Section 4 "Pressure measurement".

MEASURING MODE Options

POS. INPUT VALUE (563)

Entry

Select the measuring mode.

The operating menu is structured according to the selected measuring mode.

Prerequisite:

• Digital communication

Options:

• Pressure

Factory setting:

• Pressure

Position adjustment – the pressure difference between zero (set point) and the measured

pressure need not be known. To correct the pressure difference, you need a reference

measured value (e. g. from a reference device).

Due to the orientation of the device, there may be a shift in the measured value, i.e. for

example, when the container is empty or partially filled, the MEASURED VALUE

parameter does not display zero or the desired value.

Example:

– MEASURED VALUE = 0.5 mbar (0.0075 psi)

– For the POS. INPUT VALUE parameter, specify the desired set point for the

MEASURED VALUE, e.g. 2 mbar (0.03 psi).

(MEASURED VALUE

– MEASURED VALUE (after entry for POS. INPUT VALUE) = 2.0 mbar ( 0.03 psi)

– The CALIB. OFFSET parameter displays the resulting pressure difference (offset) by

which the MEASURED VALUE was corrected.

The following applies: CALIB. OFFSET = MEASURED VALUE

= POS. INPUT VALUE)

new

– POS. INPUT

old

VALUE,

here: CALIB. OFFSET = 0.5 mbar (0.0075 psi) – 2.0 mbar (0.03 psi) = – 1.5 mbar

(-0.0225 psi)

– The current value is also corrected.

Factory setting:

0.0

Endress+Hauser 11

Page 12

Description of parameters Cerabar S 4 to 20mA HART

1)

1)

LANGUAGE

BASIC SETUP

DISPLAYSETTINGS

POSITION ADJUSTMENT

OPERATING MENU

GROUP SELECTION

Measured value

EXTENDED SETUP

CALIB. OFFSET

POS. INPUT VALUE

1) Display via

on-site display only

Table 2: (GROUP SELECTION ) QUICK SETUP "Pressure"

Parameter name Description

SET LRV (245)

Entry

SET URV (246)

Entry

DAMPING VALUE (247)

Entry

Set lower range value – without reference pressure.

Enter pressure value for the lower current value (4 mA).

Factory setting:

0.0 or as per order specifications

Set upper range value – without reference pressure.

Enter pressure value for the upper current value (20 mA).

Factory setting:

High sensor limit (see PRESS. SENS HILIM, Page 28) or as per order specifications

Enter damping time (time constant ). The damping affects the speed at which all subsequent elements, such as the onsite display, measured value and current output react to a change in the pressure.

Input range:

0.0 to 999.0 s

Factory setting:

2.0 s or as per order specifications

P01-MIDxxxxx-19-xx-xx-EN-026

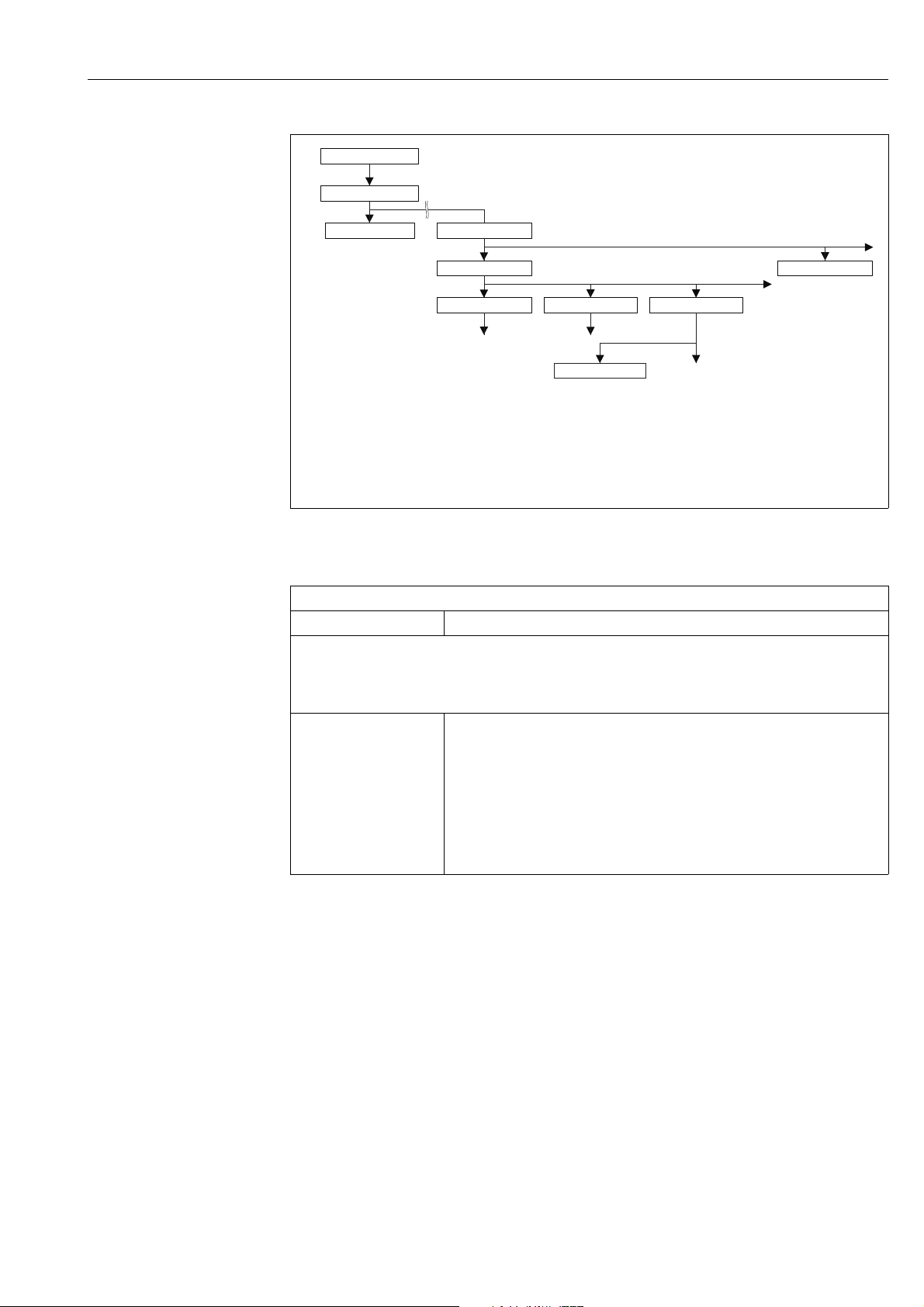

Fig. 5: Function group POSITION ADJUSTMENT

Table 3: (GROUP SELECTION ) OPERATING MENU SETTINGS POSITION ADJUSTMENT

Parameter name Description

Due to the orientation of the device, there may be a shift in the measured value, i.e. when the container is empty or

partially filled, the measured value does not display zero. Cerabar S provides two different options for carrying out

position adjustment.

Recommendation:

• The pressure difference between zero (set point) and the measured pressure need not be known.

–POS. INPUT VALUE

• The pressure difference between zero (set point) and the measured pressure is known.

– CALIB. OFFSET

12 Endress+Hauser

Page 13

Cerabar S 4 to 20mA HART Description of parameters

Table 3: (GROUP SELECTION ) OPERATING MENU SETTINGS POSITION ADJUSTMENT

Parameter name Description

POS. INPUT VALUE (563)

Entry

CALIB. OFFSET (319)

Entry

Position adjustment – the pressure difference between zero (set point) and the measured pressure need not be known. To correct the pressure difference, you need a reference measured value (e. g. from a reference device).

Example:

– MEASURED VALUE = 0.5 mbar (0.0075 psi)

– For the POS. INPUT VALUE parameter, specify the desired set point for the

MEASURED VALUE, e.g. 2.0 mbar (0.03 psi).

(MEASURED VALUE

= POS. INPUT VALUE)

new

– MEASURED VALUE (after entry for POS. INPUT VALUE) = 2.0 mbar ( 0.03 psi)

– The CALIB. OFFSET parameter displays the resulting pressure difference (offset) by

which the MEASURED VALUE was corrected.

The following applies: CALIB. OFFSET = MEASURED VALUE

VALUE,

– POS. INPUT

old

here: CALIB. OFFSET = 0.5 mbar (0.0075 psi) – 2.0 mbar (0.03 psi) = – 1.5 mbar

(-0.0225 psi)

– The current value is also corrected.

Factory setting:

0.0

Position adjustment – the pressure difference between zero (set point) and the measured pressure is known.

Example:

– MEASURED VALUE = 2.2 mbar (0.033 psi)

– Via the CALIB. OFFSET parameter, enter the value by which the MEASURED VALUE

should be corrected. To correct the MEASURED VALUE to 0.0 mbar, you must enter

the value 2.2 here.

(MEASURED VALUE

– MEASURED VALUE (after entry for calib. offset) = 0.0 mbar

= MEASURED VALUE

new

– CALIB. OFFSET)

old

– The current value is also corrected.

Factory setting:

0.0

Endress+Hauser 13

Page 14

Description of parameters Cerabar S 4 to 20mA HART

*

*

1)

2)

1)

*

Parameters marked with an asterisk "*"

are not always displayed.The display

depends on the settings of other parameters,

see the following Table.

LANGUAGE

Pressure

BASIC SETUP

DISPLAYSETTINGS

POSITION ADJUSTMENT

OPERATING MENU

GROUP SELECTION

Measured value

MEASURING MODE

EXTENDED SETUP

PRESS. ENG. UNIT

CUSTOMER UNIT P

CUST. U NIT FACT. P

SET LRV

DAMPING VALUE

GET LRV

GET URV

SET URV

1) Display via on-site display only

2) Display via digital communication

Level (not

for PMP71 with MID)

provided

P01-MIDxxxxx-19-xx-xx-EN-005

Fig. 6: BASIC SETUP function group for the "Pressure" measuring mode

Table 4: (GROUP SELECTION ) OPERATING MENU SETTINGS BASIC SETUP "Pressure"

Parameter name Description

Prerequisite:

• MEASURING MODE = Pressure

Note:

See also

– Page 11, Table 3: QUICK SETUP

– Page 17, Table 13: EXTENDED SETUP

– Page 29 ff, Table 23: PROCESS VALUES

– Page 8 ff, Section 4 "Pressure measurement".

MEASURING MODE Options

Select the measuring mode.

The operating menu is structured according to the selected measuring mode.

Note!

!

When the measuring mode is changed, no conversion takes place. The device has to be recalibrated if the measuring mode is changed.

Prerequisite:

• Digital communication

Options:

• Pressure

Factory setting

• Pressure

14 Endress+Hauser

Page 15

Cerabar S 4 to 20mA HART Description of parameters

Table 4: (GROUP SELECTION ) OPERATING MENU SETTINGS BASIC SETUP "Pressure"

Parameter name Description

PRESS. ENG. UNIT (060)

Options

CUSTOMER UNIT P (075)

Entry

Select pressure unit.

If a new pressure unit is selected, all pressure-specific parameters are converted and

displayed with the new unit.

Options:

• mbar, bar

• mmH2O, mH2O, inH2O, ftH2O

• Pa, hPa, kPa, MPa

•psi

• mmHg, inHg

•Torr

2

2

, kg/cm

•g/cm

2

•lb/ft

•atm

•gf/cm

2

, kgf/cm

2

• User unit See also the following parameter description for CUSTOMER UNIT P and

CUST.UNIT FACT.P.

Factory setting:

Depends on the sensor nominal measuring range mbar or bar or as per order specifications

Enter text (unit) for customer-specific pressure unit.

You can enter a maximum of eight alphanumeric characters here. See also

CUST.UNIT FACT.P.

Prerequisite:

• PRESS. ENG. UNIT = User unit

CUST.UNIT FACT.P (317)

Entry

SET LRV (245)

Entry

SET URV (246)

Entry

Note!

!

Only the first five characters are shown on the onsite display. For example, if "crates" is

specified as the customer-specific unit, "crate" is displayed.

If the unit contains a slash, up to eight characters can be shown on the onsite display. The

maximum number of characters in the counter is again limited to five. For example, if

"crates/m2" is specified as the customer-specific unit, "crate/m2" is displayed. In

FieldCare, all eight characters are displayed.

In the HART handheld terminal, the customer-specific unit is only displayed in the

CUSTOMER UNIT P parameter. The measured value is displayed with the additional text

"User Unit".

Factory setting:

_ _ _ _ _ _ _ _

Enter conversion factor for a customer-specific pressure unit.

The conversion factor must be entered in relation to the SI unit "Pa". See also

CUSTOMER UNIT P.

Prerequisite:

• PRESS. ENG. UNIT = User unit

Example:

– You want the measured value to be displayed in "PU" (PU: packing unit).

– MEASURED VALUE =10,000 Pa i 1 PU

– Entry CUSTOMER UNIT P: PU

– Entry CUST.UNIT FACT.P: 0.0001

– Result: MEASURED VALUE = 1 PU

Factory setting:

1.0

Set lower range value – without reference pressure.

Enter pressure value for the lower current value (4 mA).

Factory setting:

0.0 or as per order specifications

Set upper range value – without reference pressure.

Enter pressure value for the upper current value (20 mA).

Factory setting:

High sensor limit ( see PRESS. SENS HILIM, Page 28)

Endress+Hauser 15

Page 16

Description of parameters Cerabar S 4 to 20mA HART

Table 4: (GROUP SELECTION ) OPERATING MENU SETTINGS BASIC SETUP "Pressure"

Parameter name Description

GET LRV (309)

Entry

GET URV (310)

Entry

DAMPING VALUE (247)

Entry

Set lower range value – reference pressure is present at device.

The pressure for the lower current value (4 mA) is present at device. With the "Confirm"

option, you assign the lower current value to the pressure value present.

Onsite display: the pressure value present is displayed in the bottom line.

Options:

• Abort

•Confirm

Set upper range value – reference pressure is present at device.

The pressure for the upper current value (20 mA) is present at device. With the "Confirm"

option, you assign the upper current value to the pressure value present.

Onsite display: the pressure value present is displayed in the bottom line.

Options:

• Abort

•Confirm

Enter damping time (time constant ). The damping affects the speed at which all subsequent elements, such as the onsite display, measured value and current output react to a change in the pressure.

Input range:

0.0 to 999.0 s

Factory setting:

2.0 s or as per order specifications

16 Endress+Hauser

Page 17

Cerabar S 4 to 20mA HART Description of parameters

1)

1)

*

LANGUAGE

Pressure

BASIC SETUP

DISPLAYSETTINGS

POSITION ADJUSTMENT

OPERATING MENU

GROUP SELECTION

Measured value

EXTENDED SETUP

TEMP. ENG. UNIT

1) Display via on-site display only

Parameters marked with an asterisk "*"

are not always displayed.The display

depends on the settings of other parameters,

see the following Table.

Level (not

for PMP71 with MID)

provided

P01-MIDxxxxx-19-xx-xx-EN-012

Fig. 7: EXTENDED SETUP function group

for measuring mode "Pressure", see Page 17, Table 5

Table 5: (GROUP SELECTION ) OPERATING MENU SETTINGS EXTENDED SETUP "Pressure"

Parameter name Description

Prerequisite:

•MEASURING MODE = Pressure

Note:

• See also Page 8 ff, Section 4 "Pressure measurement".

TEMP. ENG. UNIT (318)

Options

Select the unit for the temperature measured values.

See also PCB TEMPERATURE (Page 25) and SENSOR TEMP. (Page 30).

Options:

•°C

•°F

•K

•R

Factory setting:

°C

Endress+Hauser 17

Page 18

Description of parameters Cerabar S 4 to 20mA HART

1)

1)

2)

DIGITS SETS

LANGUAGE

TOTALIZER SETUP

MENU DESCRIPTION

MAIN DATA FORMAT

ALTERNATE DATA

DISPLAYCONTRAST

LANGUAGE

DISPLAYSETTINGS

POSITION ADJUSTMENT

OPERATINGMENU

GROUP SELECTION

Measured value

1) Display via on-site display only

2) Display via digital communication

P01-xxxxxxxx-19-xx-xx-xx-093

Fig. 8: DISPLAY group

Table 6: (GROUP SELECTION ) OPERATING MENU DISPLAY

Parameter name Description

MENU DESCRIPTOR (419)

Options

Specify contents for the main line of the onsite display in the measuring mode. See also Operating Instructions BA00412P, Section "Onsite display".

Options:

• Main measured value (PV)

• Main measured value (%)

• Pressure

• Level

• Tank content

• Current

•Temperature

• Error number

The selection depends on the measuring mode chosen.

Factory setting:

Main measured value (PV)

MAIN DATA FORMAT (688)

Options

Specifies the number of places after the decimal point for the value displayed in the main line. See also Operating Instructions BA00412P, Section "Onsite display".

Options:

•Auto

•x.x

•x.xx

•x.xxx

• x.xxxx

• x.xxxxx

Factory setting:

Auto

18 Endress+Hauser

Page 19

Cerabar S 4 to 20mA HART Description of parameters

Table 6: (GROUP SELECTION ) OPERATING MENU DISPLAY

Parameter name Description

ALTERNATE DATA (423)

Options

LANGUAGE Selection

DISPLAY CONTRAST (339)

Entry

DIGITS SET (840)

Display

Switch on "Alternating display" mode.

In this display mode, the onsite display alternates between the following measured values

depending on the measuring mode selected.

– Pressure: primary value (PV), pressure, temperature and current

Options:

•Off

•On

Factory setting:

Off

Select the menu language for the onsite display.

Note!

!

• In the case of local operation, the LANGUAGE parameter is arranged directly under

the GROUP SELECTION (menu path: GROUP SELECTION LANGUAGE, see also

Page 10).

• Select the menu language for the operating program via the "Options" menu

"Settings" "Language" tab "Tool Language" field.

Options:

•Deutsch

• English

• Français

• Italiano

•Español

• Nederlands

• Chinese (CHS)

• Japanese (JPN)

Factory setting: English

Adjust contrast of onsite display.

You specify the contrast of the display with a number. Changes are only accepted as single

steps, i.e. to change the value from "8" to "4", you need to save four times. You can also

adjust the contrast of the display by means of the keys on the electronic insert or at the

device.

See also Operating Instructions BA00412P, the section on operating keys function.

Input range:

4...13, 4: contrast weaker (brighter), 13: contrast stronger (darker).

Factory setting:

8

This parameter is used to verify correct display of characters and digits on the user interface. If the characters and digits are correctly displayed, this parameter shows the string "0123456789.-".

Endress+Hauser 19

Page 20

Description of parameters Cerabar S 4 to 20mA HART

1)

1)

SET MIN. CURRENT

ASSIGN CURRENT

Level measuring

mode only

ALT. CURR. OUTPUT

TOTALIZER SETUP

OUTPUT CURRENT

CURR. CHARACT.

OUTPUT FAIL MODE

SET MAX. ALARM

LANGUAGE

OUTPUTSETTINGS

POSITION ADJUSTMENT

OPERATING MENU

GROUP SELECTION

Measured value

1) Display via on-site display only

Fig. 9: Group OUTPUT

Table 7: (GROUP SELECTION ) OPERATING MENU OUTPUT

Parameter name Description

OUTPUT CURRENT (254)

Displays the current current value.

Display

P01-MIDxxxxx-19-xx-xx-EN-013

20 Endress+Hauser

Page 21

Cerabar S 4 to 20mA HART Description of parameters

LRV

➂

➁

➀

4mA

0

20 mA

➁

➃➃

URVURV

I

p

Table 7: (GROUP SELECTION ) OPERATING MENU OUTPUT

Parameter name Description

CURR. CHARACT.

(694), (695), (696), (764)

Options

Select curve of current output.

Options:

P01-xxxxxxxx-05-xx-xx-xx-009

Fig. 10: Illustration of current output curves

1 Linear: lower range value = 4 mA, upper range value = 20 mA

2 Bi-linear: lower range value = 4 mA, center or zero = 20 mA,

upper range value = 4 mA

3 Linear inverse: lower range value = 20 mA, upper range value = 4 mA

4 Bi-linear inverse: lower range value = 20 mA, center or zero = 4 mA,

upper range value = 20 mA

LRV Lower Range Value

URV Upper Range Value

I Current

p Measured value (pressure)

The 3-digit ID number on the onsite display depends on the MEASURING MODE

selected:

– (694): MEASURING MODE "Pressure"

Factory setting:

Linear

OUTPUT FAIL MODE (388)

Entry

ALT.CURR.OUTPUT (597)

Options

Select the current value in the event of an alarm.

In the event of an alarm, the current assumes the current value specified with this

parameter.

Options:

• Max. alarm (110%): can be set between 21...23 mA

• Hold meas. value: last measured value is kept.

• Min. alarm (–10%): 3.6 mA

See also this table SET MAX. ALARM and Operating Instructions BA00412P,

Section "Configuring current output for an alarm".

Factory setting:

Max. alarm 110% (22 mA)

Set current output if sensor limits undershot or overshot.

Options:

• Normal: the current output assumes the value set via the OUTPUT FAIL MODE and

SET MAX. ALARM parameters.

•NAMUR:

– Lower sensor limit undershot (E120):

Current output = 3.6 mA

– Upper sensor limit overshot (E115): current output assumes the value set via the

SET MAX. ALARM parameter

Factory setting:

Normal

Endress+Hauser 21

Page 22

Description of parameters Cerabar S 4 to 20mA HART

Table 7: (GROUP SELECTION ) OPERATING MENU OUTPUT

Parameter name Description

SET MAX. ALARM (342)

Entry

SET MIN. CURRENT (343)

Entry

Enter current value for maximum alarm current. See also OUTPUT FAIL MODE.

Input range:

21...23 mA

Factory setting:

22 mA

Enter lower current limit.

Some switching units do not accept current values lower than 4.0 mA.

Options:

• 3.8 mA

• 4.0 mA

Factory setting:

3.8 mA

22 Endress+Hauser

Page 23

Cerabar S 4 to 20mA HART Description of parameters

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

2)

1)

1)

2)

2)

DIP STATUS

DIAPHRAGM SEAL +

DIAPHRAGM SEAL –

NROF REMOTE SEAL

FILL FLUID

PCB TEMPERATURE

ALLOWED MIN. TEMP

ALLOWED MAX. TEMP

Tmax SENSOR

SENS H/WARE REV.

MOUNTINGTHREAD

REMOTE SEAL +

REMOTE SEAL –

DEVICE DESIGN.

HARDWARE REV.

SOFTWARE VERSION

CONFIG RECORDER

MAT. MEMBRANE

FILLING FLUID

Tmin SENSOR

NUTS MATERIAL

DRAIN

VE

NTMAT.

DRAIN VENT POS.

THREAD

ADDITIONAL INFO. SEAL TYPE SENSOR MEAS. TYPE

BOLTSMATERIAL

DEVICE REVISION

ELECTR. SERIAL No

CUST.TAG NUMBER

LONGTAGNUMBER

PROC. CONN TYPE

MAT. PROC. CONN. +

MAT. PROC. CONN. –

PRESS. SENS LOLIM

PRESS: SENS HILIM

MINIMUM SPAN

HART DATA

BUS ADRESS

TRANSMITTER INFO

TRANSMITTER DAT

A

DEVICE SERIAL No

PROCESS CONNECTION

Pmax PROC. CONN.

SENSOR DATEN

SENSOR SER.No.

TOTALIZER SETUP

4THVALUE IS

4 THVALUE

SECONDARY VALUE

THIRD VALUE IS

THIRD VALUE

HART DATE

PRIMARY VALUE IS

PRIMARY VALUE

SECONDARY VAL.IS

HART MESSAGE

MANUFACTORID

PREAMBLE NUMBER

LANGUAGE

SETTINGS

POSITION ADJUSTMENT

OPERA

TIN

GMENU

GROUP SELECTION

Measured value

DEVICE TYPE

1) Display via on-site display only

2) Display via digital communication

BURST MODE

BURST OPTION

Endress+Hauser 23

Fig. 11: TRANSMITTER INFO group

For the HART DATA function group, see Page 23, Table 8

For the TRANSMITTER DATA function group, see Page 25, Table 9

For the PROCESS CONNECTION function group, see Page 26, Table 10

For the SENSOR DATA function group, see Page 28, Table 11

Table 8: (GROUP SELECTION ) OPERATING MENU TRANSMITTER INFO HART DATA

Parameter name Description

BUS ADDRESS (345)

Entry

DEVICE TYPE (802)

Display

DEVICE REVISION (699)

Display

Enter the address for the exchange of data with the HART protocol.

(HART 5.0: range 0...15, HART 6.0: range 0...63)

Factory setting:

0

Displays the device identification number in decimal numerical format, here Cerabar S: 24

Prerequisite:

• Cerabar S pressure transmitter

Displays the device revision

P01-xxxxxxxx-19-xx-xx-xx-095

Page 24

Description of parameters Cerabar S 4 to 20mA HART

Table 8: (GROUP SELECTION ) OPERATING MENU TRANSMITTER INFO HART DATA

Parameter name Description

BURST MODE

Options

BURST OPTION

Entry

PREAMBLE NUMBER (036)

Entry

MANUFACTOR ID (432)

Display

HART MESSAGE (271)

Entry

HART DATE (481)

Entry

PRIMARY VALUE IS

Display

PRIMARY VALUE

Display

SECONDARY VAL. IS Select second process value.

SECONDARY VALUE Display second process value. See also SECONDARY VAL. IS.

THIRD VALUE IS Select third process value. See also . SECONDARY VAL. IS.

Switch the burst mode on and off.

Options:

•On

•Off

Prerequisite:

• Digital communication

Use this parameter to specify what command is sent to the master.

Prerequisite:

• Digital communication

Factory setting:

3 (HART command 3)

Enter the number of preambles in the HART protocol. (Synchronization of the modem modules along a transmission path, each modem module could "swallow" a byte - at least 2 bytes must arrive.)

Input range:

2...20

Factory setting:

5

Displays the manufacturer number in a decimal numerical format.

Here: 17 Endress+Hauser

Enter a message (max. 32 alphanumeric characters). On command from the master, this message is sent via the HART protocol.

Factory setting:

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ or as per order specifications

Enter the date of the last configuration change.

Factory setting:

DD.MM.YY (date of final test)

This parameter displays the following measured value depending on the measuring mode

selected:

– Measuring mode "Pressure": PRESSURE

See also PRIMARY VALUE.

Prerequisite:

• Digital communication

Display of primary value. See also PRIMARY VALUE IS.

Prerequisite:

• Digital communication

You can choose between the following process values depending on the measuring mode

selected:

– PRESSURE

– CORRECTED PRESS.

– SENSOR PRESSURE

– SENSOR TEMP.

– PCB TEMPERATURE

–LEVEL BEFORE LIN

–TANK CONTENT

Prerequisite:

• Digital communication

Prerequisite:

• Digital communication

Prerequisite:

• Digital communication

24 Endress+Hauser

Page 25

Cerabar S 4 to 20mA HART Description of parameters

Table 8: (GROUP SELECTION ) OPERATING MENU TRANSMITTER INFO HART DATA

Parameter name Description

THIRD VALUE Display third process value. See also SECONDARY VAL. IS.

Prerequisite:

• Digital communication

4TH VALUE IS Select fourth process value. See also . SECONDARY VAL. IS.

Prerequisite:

• Digital communication

4TH VALUE Display fourth process value. See also SECONDARY VAL. IS.

Prerequisite:

• Digital communication

Table 9: (GROUP SELECTION ) OPERATING MENU TRANSMITTER INFO TRANSMITTER DATA

Parameter name Description

DEVICE SERIAL No (354)

Display

ELECTR. SERIAL No (386)

Display

CUST. TAG NUMBER (055)

Entry

LONG TAG NUMBER (305)

Entry

ADDITIONAL INFO. (272)

Entry

DEVICE DESIGN. (350)

Display

HARDWARE REV. (266)

Display

SOFTWARE VERSION (264)

Display

CONFIG RECORDER (352)

Display

PCB TEMPERATURE (357)

Display

ALLOWED MIN. TEMP

(358)

Display

ALLOWED MAX. TEMP

(359)

Display

Displays the serial number of the device (11 alphanumeric characters).

Displays the serial number of the main electronics (11 alphanumeric characters).

Enter device tag e.g. TAG number (max. 8 alphanumeric characters).

Factory setting:

_ _ _ _ _ _ _ _ or as per order specifications

Enter device tag e.g. TAG number (max. 32 alphanumeric characters).

Factory setting:

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ or as per order specifications

Enter the tag description (max. 16 alphanumeric characters).

Factory setting:

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ or as per order specifications

Displays the device designation and order code.

Displays the revision number of the main electronics e.g.: V02.00

Displays the software version V02.10.54

Displays the configuration counter.

This counter is increased by one with each change to a parameter or group. The counter

counts to 65535 and then starts again at zero. Changes in the parameters of the DISPLAY

function group do not increase the counter.

Displays the measured temperature of the main electronics.

Displays the lower temperature limit of the main electronics.

Displays the upper temperature limit of the main electronics.

Endress+Hauser 25

Page 26

Description of parameters Cerabar S 4 to 20mA HART

Table 9: (GROUP SELECTION ) OPERATING MENU TRANSMITTER INFO TRANSMITTER DATA

Parameter name Description

DIP STATUS (363)

Display

Table 10: (GROUP SELECTION ) OPERATING MENU TRANSMITTER INFO

PROCESS CONNECTION

Parameter name Description

Pmax PROC. CONN. (570)

Entry

PROC. CONN. TYPE (482)

Options

MAT. PROC. CONN. +

(360)

Options

Displays the status of DIP switch 1 on the electronic insert.

You can lock or unlock parameters relevant to the measured value with DIP switch 1.

If operation is locked by means of the INSERT PIN No. parameter, you can only unlock

operation again by means of this parameter. (INSERT PIN NO, see Page 32.)

See also Operating Instructions BA00412P, "Locking/unlocking operation".

Display:

• On (locking switched on)

• Off (locking switched off)

Factory setting:

Off (locking switched off)

For entering and displaying the maximum permitted pressure of the process connection.

Factory setting:

as per nameplate data (see also Operating Instructions BA00412P,

Section "Nameplate")

For selecting and displaying the process connection type.

Options:

•Not used

•Unknown

• Special

•Oval flange

•Thread female

•Thread male

•Flange

•Remote seal

For selecting and displaying the material of the process connection (P+). See also parameter description for MAT. PROC. CONN. -

Options:

•Not used

•Unknown

• Special

• Steel

• 304 st. steel

• 316 st. steel

• Alloy C

•Monel

•Tantalum

• Titanium

•PTFE (Teflon)

• 316L st. steel

•PVC

•Inconel

•PVDF

•ECTFE

Factory setting:

As per order specifications

26 Endress+Hauser

Page 27

Cerabar S 4 to 20mA HART Description of parameters

Table 10: (GROUP SELECTION ) OPERATING MENU TRANSMITTER INFO

PROCESS CONNECTION

Parameter name Description

SEAL TYPE (362)

Options

BOLTS MATERIAL For selecting and displaying the material of the bolts.

NUTS MATERIAL For selecting and displaying the material of the nuts.

DRAIN VENT MAT. For selecting and displaying the material of the vent valves.

DRAIN VENT POS. For selecting and displaying the position of the vent valves.

THREAD PROCESS For selecting and displaying the process connection thread.

MOUNTING THREAD For selecting and displaying the ways of securing the device.

REMOTE SEAL + For selecting and displaying the diaphragm seal type on the positive side.

REMOTE SEAL - For selecting and displaying the diaphragm seal type on the negative side.

DIAPHRAG. MAT. + For selecting and displaying the diaphragm material on the positive side

DIAPHRAG. MAT. - For selecting and displaying the diaphragm material on the negative side.

NR OF REMOTE SE For selecting and displaying the number of diaphragm seals.

For selecting and displaying the material of the process seal.

Options:

•Not used

•Unknown

• Special

• FKM Viton

•NBR

•EPDM

•Urethane

•IIR

•Kalrez

• FKM Viton oxyg

•CR

•MVQ

•PTFE glass

•PTFE graphite

• PTFE oxygen

• Copper

• Copper f. oxygen

Factory setting:

As per order specifications

Prerequisite:

• Digital communication

Prerequisite:

• Digital communication

Prerequisite:

• Digital communication

Prerequisite:

• Digital communication

Prerequisite:

• Digital communication

Prerequisite:

• Digital communication

Prerequisite:

• Digital communication

Prerequisite:

• Digital communication

Prerequisite:

• Digital communication

Prerequisite:

• Digital communication

Prerequisite:

• Digital communication

Endress+Hauser 27

Page 28

Description of parameters Cerabar S 4 to 20mA HART

Table 10: (GROUP SELECTION ) OPERATING MENU TRANSMITTER INFO

PROCESS CONNECTION

Parameter name Description

FILL FLUID For selecting and displaying the diaphragm seal fill fluid.

Prerequisite:

• Digital communication

Table 11: (GROUP SELECTION ) OPERATING MENU TRANSMITTER INFO SENSOR DATA

(all measuring modes)

Parameter name Description

SENSOR SER. No. (250)

Display

PRESS. SENS LOLIM (484)

Display

PRESS. SENS HILIM (485)

Display

MINIMUM SPAN (591)

Display

SENSOR MEAS.TYPE (581)

Display

MAT. MEMBRANE (365)

Display

FILLING FLUID (366)

Display

Tmin SENSOR (368)

Display

Tmax SENSOR (369)

Display

SENS H/WARE REV (487)

Display

Displays the serial number of the sensor (11 alphanumeric characters).

Displays the lower measuring limit of the sensor.

Displays the upper measuring limit of the sensor.

Displays the smallest possible span.

Displays the sensor type.

• Cerabar S with absolute pressure sensor = Absolute

Displays the material of the process isolating diaphragm.

Factory setting:

as per version in order code

See Technical Information for Cerabar S TI00383P, Section "Ordering information".

Displays the filling fluid.

Displays the lower nominal temperature limit of the sensor.

Displays the upper nominal temperature limit of the sensor.

Displays the revision number of the sensor hardware. e.g.: 1

28 Endress+Hauser

Page 29

Cerabar S 4 to 20mA HART Description of parameters

2)

1)

1)

PRESSURE

CORRECTED PRESS.

SENSOR PRESSURE

SENSOR TEMP.

MEAS. VAL.TREND

MEASURED VALUE

Pressure

PROCESS VALUE

PROCESS INFO

TOTALIZER SETUP

LANGUAGE

SETTINGS

POSITION ADJUSTMENT

OPERATING MENU

GROUP SELECTION

Measured value

1) Display via on-site display only

2) Display via digital communication

Level (not

for PMP71 with MID)

provided

P01-MIDxxxxx-19-xx-xx-EN-014

Fig. 12: PROCESSINFO group

For function group PROCESS VALUES, measuring mode "Pressure", see Page 29, Table 12

Table 12: (GROUP SELECTION ) OPERATING MENU PROCESSINFO PROCESS VALUES "Pressure"

Parameter name Description

Prerequisite:

•MEASURING MODE = Pressure

MEASURED VALUE (679) Displays the measured value

In the "Pressure" measuring mode, this value corresponds to the PRESSURE parameter.

Prerequisite:

• Digital communication

Onsite operation:

• In the case of local operation, the MEASURED VALUE parameter is displayed on the

top level.

Endress+Hauser 29

Page 30

Description of parameters Cerabar S 4 to 20mA HART

P

I

Sensor

Current

output

Pressure

PRESSURE

Damping

CORRECTED PRESS.

Position

adjustment

Sensor

trim

SENSOR

PRESSURE

Table 12: (GROUP SELECTION ) OPERATING MENU PROCESSINFO PROCESS VALUES "Pressure"

Parameter name Description

PRESSURE (301)

Display

CORRECTED PRESS. (434)

Display

SENSOR PRESSURE (584)

Display

SENSOR TEMP. (367)

Display

MEAS. VAL. TREND (378)

Display

Displays the measured pressure after sensor recalibration, position adjustment and damping. This value corresponds to the MEASURED VALUE parameter in the "Pressure" measuring mode.

P01-MIDxxxxx-05-xx-xx-EN-001

Displays the measured pressure after sensor trim and position adjustment and before

damping. See also PRESSURE diagram.

Displays the measured pressure before sensor trim, position adjustment and damping.

See also PRESSURE diagram.

Displays the temperature currently measured in the sensor. This can deviate from the process temperature.

Displays the trend of the pressure measured value.

Possibilities: increasing, decreasing, constant

30 Endress+Hauser

Page 31

Cerabar S 4 to 20mA HART Description of parameters

*

I

J

*

I

J J J J J

1)

1)

2)

*

*

none Pressure Tank content

Current

Alarm Warning

LANGUAGE

SETTINGS

POSITION ADJUSTMENT

OPERATING MENU

GROUP SELECTION

Measured value

SIM. PRESSURE SIM. TANK CONT. SIM. CURRENT SIM. ERROR NO.

OPERATION

ENTER RESET CODE

OPERATING HOURS

INSERT PIN NO

DIAGNOSTICS

SIMULATION

SIMULATION MODE

MESSAGES

RESETALL ALARMS

SELECTALARMTYPE

ALARM DELAY

ALARM DISPL. TIME

ALARM STATUS

LASTDIAG. CODE

ACK. ALARM MODE

ACK. ALARM

Pmin ALARM WINDOW

Pmax ALARM WINDOW

Tmin ALARM WINDOW

Tmax ALARM WINDOW

USER LIMITS

HistoROM AVAIL.

HistoROM CONTROL

ERROR No.

Parameters marked with an asterisk "*"

are not always displayed.The display

depends on the settings of other parameters,

see the following Table.

1) Display via on-site display only

2) Display via digital communication

DOWNLOAD SELECT.

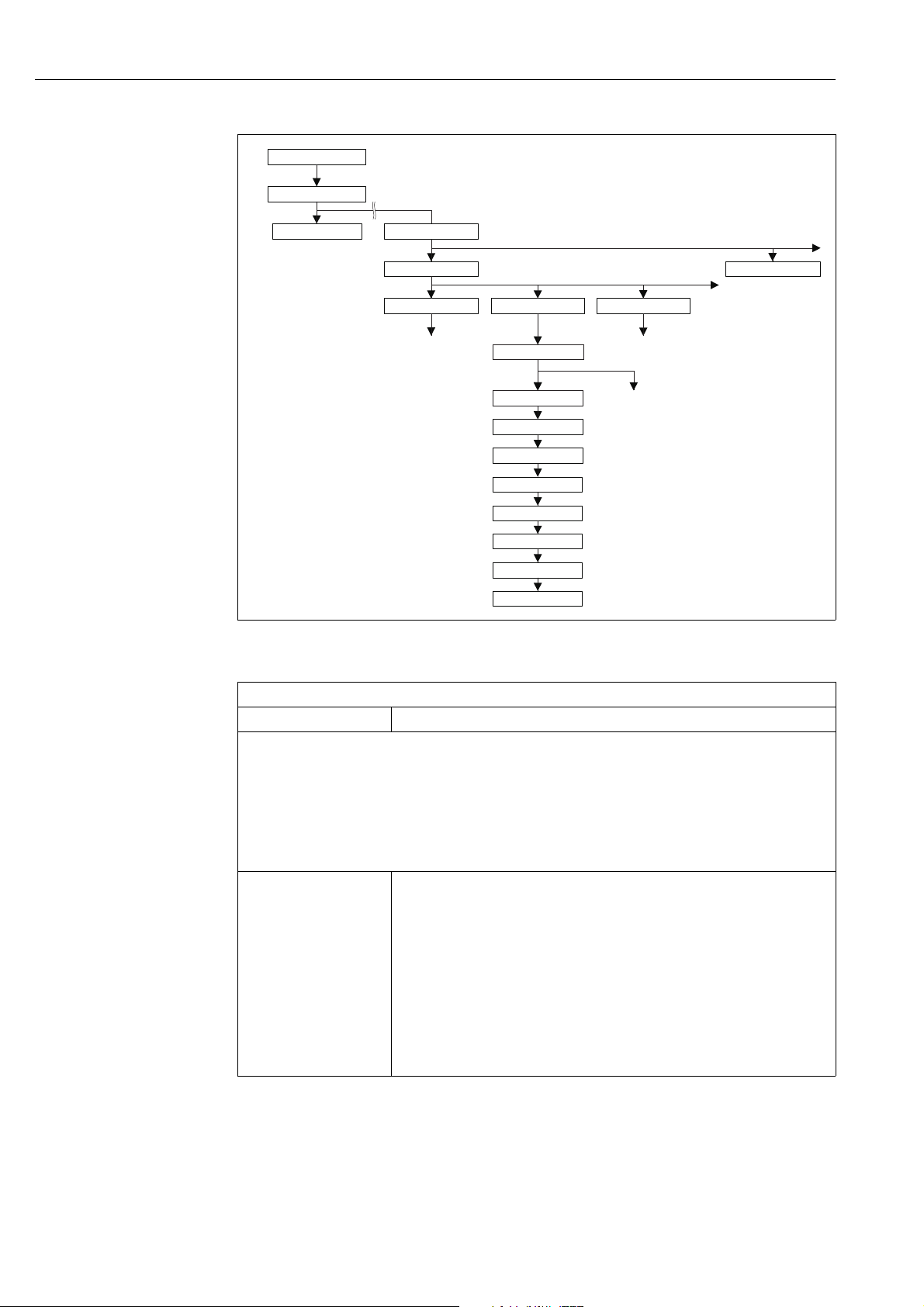

Fig. 13: OPERATING and DIAGNOSTICS group

For the OPERATING group, see Page 31, Table 13

For the SIMULATION MODE function group, see Page 33, Table 14

For the MESSAGES function group, see Page 33, Table 15

For the USER LIMITS function group, see Page 35, Table 16

Table 13: (GROUP SELECTION ) OPERATING MENU OPERATING

Parameter name Description

ENTER RESET CODE (047)

Entry

OPERATING HOURS (409)

Display

Reset parameters completely or partially to factory values or delivery status. See also Operating Instructions BA00412P, Section "Factory setting (reset)".

Factory setting:

0

Displays the hours of operation. This parameter cannot be reset.

P01-MIDxxxxx-19-xx-xx-EN-015

Endress+Hauser 31

Page 32

Description of parameters Cerabar S 4 to 20mA HART

Table 13: (GROUP SELECTION ) OPERATING MENU OPERATING

Parameter name Description

INSERT PIN NO (048)

Entry

HistoROM AVAIL. (831)

Display

DOWNLOAD SELECT (014)

Options

HistoROM CONTROL (832)

Options

For entering a code to lock or unlock operation.

Note!

!

• The symbol on the onsite display indicates that operation is locked. Parameters which refer to how the display appears, e.g. LANGUAGE and DISPLAY CONTRAST can still be altered.

• If operation is locked by means of the DIP switch, you can only unlock operation again

by means of the DIP switch. If operation is locked by means of the onsite display or

remote operation e.g. FieldCare, you can unlock operation again either by means of the

onsite display or remote operation.

See also Operating Instructions BA00412P, "Locking/unlocking operation".

Options:

• Lock: enter a number between 0 and 9999 that is 100.

• Unlock: enter the number 100.

Factory setting:

100

Indicates whether the optional HistoROM®/M-DAT memory module is connected to the electronic insert. See also Operating Instructions BA00412P, Section "HistoROM

Options:

•Yes (HistoROM

• No (HistoROM

®

/M-DAT is attached to the electronic insert)

®

/M-DAT is not attached to the electronic insert)

®

/M-DAT (optional)".

Select download function from HistoROM to device. The option selected has no effect on an upload from the device to the HistoROM.

Prerequisite:

•A HistoROM

®

/M-DAT is attached to the electronic insert

(HistoROM AVAIL. = Yes)

Options:

• Configuration copy: With this option, all parameters apart from the TRANSMITTER

SERIAL No, DEVICE DESIGN., CUST. TAG NUMBER, LONG TAG NUMBER,

ADDITIONAL INFO., BUS ADDRESS and the parameters of the POSITION

ADJUSTMENT and PROCESS CONNECTION group are overwritten.

• Device replacement: With this option, all parameters except for TRANSMITTER SERIAL No, DEVICE DESIGNATION and the parameters of the POSITION ADJUSTMENT and PROCESS CONNECTION group are overwritten.

• Electronics replace: With this option, all parameters except for the parameters of the POSITION ADJUSTMENT group are overwritten.

Factory setting:

Configuration copy (if HistoROM

For selecting the direction for copying the data. See also Operating Instructions BA00412P, Section "HistoROM

Prerequisite:

•A HistoROM

®

/M-DAT is attached to the electronic insert

®

/M-DAT is attached to the electronic insert)

®

/M-DAT (optional)".

(HistoROM AVAIL. = Yes)

Options:

• Abort

•HistoROM Device

• Device HistoROM

Factory setting:

Abort (if HistoROM

®

/M-DAT is attached to the electronic insert)

32 Endress+Hauser

Page 33

Cerabar S 4 to 20mA HART Description of parameters

P

I

Simulation value pressure

Simulation value

current

Sensor

Current

output

Pressure

Damping

Position

adjustment

Sensor

trim

Table 14: (GROUP SELECTION ) OPERATING MENU DIAGNOSTICS SIMULATION MODE

Parameter name Description

SIMULATION MODE (413)

Options

Switch on simulation and select simulation type.

Any simulation running is switched off if the measuring mode or level type is changed.

Options:

•None

• Pressure, see also this table, parameter description for SIM. PRESSURE.

• Tank content, see also this table, parameter description for SIM. TANK CONT.

• Current, see also this table, parameter description for SIM. CURRENT

• Alarm/warning, , see also this table, parameter description for SIM. ERROR NO.

SIM. PRESSURE (414)

Entry

SIM. CURRENT (270)

Entry

SIM. ERROR NO. (476)

Entry

P01-MIDxxxxx-05-xx-xx-EN-003

Factory setting:

None

Enter simulation value. See also SIMULATION MODE.

Prerequisite:

• SIMULATION MODE = Pressure

Factory setting:

Current pressure measured value

Enter simulation value. See also SIMULATION MODE.

Prerequisite:

• SIMULATION MODE = Current value

Factory setting:

Current current value

Enter message number.

See also SIMULATION MODE.

See also these Operating Instructions, Section 6.1 "Messages", "Code" table column.

Prerequisite:

• SIMULATION MODE = Alarm/warning

Factory setting:

613 (simulation active)

Table 15: (GROUP SELECTION ) OPERATING MENU DIAGNOSTICS MESSAGES

Parameter name Description

ALARM STATUS (046)

Display

Displays the current messages present. See also these Operating Instructions,

Section 6.1 "Messages" and Section "Confirming messages".

Onsite display

• The measured value display shows the message with the highest priority.

• The ALARM STATUS parameter shows all the messages in descending order of

priority. You can scroll through all the messages present with the O or S key.

Operating program

• The "Status" field and the ALARM STATUS parameter show the message with the highest priority.

Endress+Hauser 33

Page 34

Description of parameters Cerabar S 4 to 20mA HART

Table 15: (GROUP SELECTION ) OPERATING MENU DIAGNOSTICS MESSAGES

Parameter name Description

LAST DIAG. CODE (564)

Display

ACK. ALARM MODE (401)

Options

ACK. ALARM (500)

Options

RESET ALL ALARMS (603)

Options

ERROR No.

Entry

SELECT ALARMTYPE

(595) – Entry

(600) – Selection

Displays the last messages that occurred and were eliminated.

Note!

!

• Onsite display: you can scroll through the last 15 messages with the O or S key.

• Digital communication: the last message is displayed.

• Use the RESET ALL ALARMS parameter to delete the messages listed in the LAST DIAG. CODE parameter.

Switch on acknowledge alarm mode. See also ACK. ALARM.

Options:

•On

•Off

Factory setting:

Off

Acknowledge alarm.

Prerequisite:

• ACK. ALARM MODE = On

Options:

• Abort

•Confirm

The cause of the alarm must be eliminated, the message must be acknowledged via the

ACK. ALARM parameter and, where applicable, the ALARM DISPL. TIME (Page 35)

has to have elapsed before the device starts measuring again following an alarm.

See also these Operating Instructions, Section 6.3 "Confirming messages".

Factory setting:

Abort

Use this parameter to reset all the messages of the LAST DIAG. CODE parameter.

Options:

• Abort

•Confirm

Factory setting:

Abort

For "Error"-type messages, you can decide whether the device should behave as in the

event of an alarm (A) or as in the event of a warning (W). Enter the corresponding

message number for this parameter. See also SELECT ALARMTYPE.

See also these Operating Instructions, Section 6.1 "Messages" and Section 6.2

"Response of outputs to errors".

Prerequisite:

• Digital communication

For "Error"-type messages, you can decide whether the device should behave as in the

event of an alarm (A) or as in the event of a warning (W). See also ERROR No.

See also these Operating Instructions, Section 6.2 "Response of outputs to errors".

Options:

• Alarm (A): output current assumes a defined value.

• Warning (W): device continues measuring

Onsite operation:

1. Enter the corresponding message number for ERROR No. field.

2. Select "Alarm" or "Warning" option.

Digital communication

1. Enter the corresponding message number via the ERROR No. parameter.

2. Use the SELECT ALARMTYPE parameter to select the "Alarm" or "Warning" option.

34 Endress+Hauser

Page 35

Cerabar S 4 to 20mA HART Description of parameters

Table 15: (GROUP SELECTION ) OPERATING MENU DIAGNOSTICS MESSAGES

Parameter name Description

ALARM DELAY (336)

Entry

ALARM DISPL. TIME (480)

Entry

Enter the alarm response time for all "Error"-type messages.

Note!

!

There is no alarm if the cause of the error is eliminated within the alarm delay time.

Input range:

0...100 s

Factory setting:

0.0 s

Enter the alarm delay time for all "Error"-type messages. Once the cause of the error is rectified, the alarm display time starts running.

Note!

!

The following applies if the setting for ACK. ALARM MODE = On

If an alarm appears and the alarm display time elapses before the alarm has been

acknowledged, the message will be cleared once it has been acknowledged.

See also these Operating Instructions, Section 6.3 "Confirming messages".

Input range:

0 to 999.9 s

Factory setting:

0.0 s

Table 16: (GROUP SELECTION ) OPERATING MODE DIAGNOSTICS USER LIMITS

Parameter name Description

Pmin ALARM WINDOW

(332)

Entry

Pmax ALARM WINDOW

(333)

Entry

Tmin ALARM WINDOW

(334)

Entry

Tmax ALARM WINDOW

(335)

Entry

Customer-specific process monitoring – enter lower pressure limit.

You can use the SELECT ALARMTYPE parameter to enter how the device responds if the

operating pressure undershoots the specified value.

See also these Operating Instructions, Section 6.1 "Messages", Table, code E730 and

Section 6.2 "Response of outputs to errors".

Factory setting:

Low sensor limit •1.1

(For the low sensor limit, see PRESS. SENS LOLIM.)

Customer-specific process monitoring – enter upper pressure limit.

You can use the SELECT ALARMTYPE parameter to enter how the device responds if the

operating pressure undershoots the specified value.

See also these Operating Instructions, Section 6.1 "Messages", Table, code E731 and

Section 6.2 "Response of outputs to errors".

Factory setting:

High sensor limit • 1.1

(For the high sensor limit, see PRESS. SENS HILIM.)

Customer-specific process monitoring – enter lower temperature limit.

You can use the SELECT ALARMTYPE parameter to enter how the device responds if the

operating pressure undershoots the specified value.

See also these Operating Instructions, Section 6.1 "Messages" Table, code E732 and

Section 6.2 "Response of outputs to errors".

Factory setting:

Lower sensor temperature application limit – 10 K

(For the lower temperature application limit, see Tmin SENSOR)

Customer-specific process monitoring – enter upper temperature limit.

You can use the SELECT ALARMTYPE parameter to enter how the device responds if the

operating pressure undershoots the specified value.

See also these Operating Instructions, Section 6.1 "Messages" Table, code E733 and

Section 6.2 "Response of outputs to errors".

Factory setting:

Upper sensor temperature application limit +10 K

(For the upper temperature application limit, see Tmax SENSOR)

Endress+Hauser 35

Page 36

Description of parameters Cerabar S 4 to 20mA HART

1)

1)

SERVICE

CURR. TRIM 4mA

CURR. TRIM 20mA

OFFSET 4mA TRIM

OFFSET 20mA TRIM

SYSTEM 2

LANGUAGE

SETTINGS

POSITION ADJUSTMENT

OPERATING MENU

GROUP SELECTION

Measured value

1) Display via on-site display only

P01-MIDxxxxx-19-xx-xx-EN-016

Fig. 14: SYSTEM 2 group

Table 17: (GROUP SELECTION ) OPERATING MENU SERVICE SYSTEM 2

Parameter name Description

CURR. TRIM 4mA (045)

Entry

Enter the current value for the lower point (4 mA) of the current linear regression line.

You can adapt the current output to the transmission conditions with this parameter and

"CURR. TRIM 20mA".

Perform the current trim for the lower point as follows:

1. Select the SIMULATION MODE group.

(Menu path: (GROUP SELECTION) OPERATING MENU DIAGNOSTICS

SIMULATION MODE)

2. Select the "Current" option via the SIMULATION MODE parameter.

3. Enter "4 mA" for the SIM. CURRENT parameter.

4. Select the SYSTEM 2 group.

(Menu path: (GROUP SELECTION) OPERATING MENU SERVICE)

5. Enter the current value measured with the switching unit in the "CURR. TRIM 4mA"

parameter.

Input range:

Measured current ±0.2 mA

Factory setting:

4 mA

CURR. TRIM 20mA (042)

Entry

Enter the current value for the upper point (20 mA) of the current linear regression line.

You can adapt the current output to the transmission conditions with this parameter and

"CURR. TRIM 4mA".

Perform the current trim for the upper point as follows:

1. Select the SIMULATION MODE group.

(Menu path: (GROUP SELECTION) OPERATING MENU DIAGNOSTICS

SIMULATION MODE)

2. Select the "Current" option via the SIMULATION MODE parameter.

3. Enter "20 mA" for the SIM. CURRENT parameter.

4. Select the SYSTEM 2 group.

(Menu path: (GROUP SELECTION) OPERATING MENU SERVICE)

5. Enter the current value measured with the switching unit in the "CURR. TRIM

20mA" parameter.

Input range:

Measured current ±0.2 mA

Factory setting:

20 mA

36 Endress+Hauser

Page 37

Cerabar S 4 to 20mA HART Description of parameters

Table 17: (GROUP SELECTION ) OPERATING MENU SERVICE SYSTEM 2

Parameter name Description

OFFSET 4mA TRIM (043)

Display

OFFSET 20mA TRIM (044)

Display

Displays the difference between 4 mA and the value entered for the "CURR. TRIM 4mA" parameter.

Factory setting:

0

Displays the difference between 20 mA and the value entered for the "CURR TRIM 20mA" parameter.

Factory setting:

0

Endress+Hauser 37

Page 38

Troubleshooting Cerabar S 4 to 20mA HART

6Troubleshooting

6.1 Messages

The following table lists all the possible messages that can occur.

The device makes a distinction between the error types "Alarm", "Warning" and "Error". You may

specify whether the device should react as if for an "Alarm" or "Warning" for "Error" messages.

See "Error type/NA 64" column and parameter description for ERROR No. and SELECT

ALARMTYPE (Page 34).

In addition, the "Error type/NA 64" column classifies the messages in accordance with NAMUR Recommendation NA 64:

• Break down: indicated with "B"

• Maintenance need: indicated with "C" (check request)

• Function check: indicated with "I" (in service)

Error message display on the onsite display:

• The measured value display shows the message with the highest priority. See the "Priority"

column.

• The ALARM STATUS parameter (Page 33) shows all the messages in descending order of

priority. You can scroll through all the messages present with the S key or O key.

Message display via digital communication:

• The ALARM STATUS parameter (Page 33) shows the message with the highest priority.

See the "Priority" column.

!

Note!

• If the device detects a defect in the onsite display during initialization, special error messages are

generated. For the error messages, see Page 45, Section 6.1.1 "Onsite display error messages".

• For support and further information, please contact Endress+Hauser Service.

Code Error type/

NA 64

101 (A101) Alarm

B

106 (W106) Warning

C

110 (A110) Alarm

B

113 (A113) Alarm

B

115 (E115) Error

B

Factory

setting:

Warning

Message/description Cause Measure Priority

B>Sensor electronic EEPROM error

C>Downloading - please wait – Downloading. – Wait for download to complete. 52

B>Checksum error in EEPROM: configuration segment

B>ROM failure in transmitter electronic

B>Sensor overpressure – Overpressure present. – Reduce pressure until message

– Electromagnetic effects are greater

than specifications in the technical

data.

See Technical Information

TI00383P. This message normally

only appears briefly.

–Sensor defective. –Replace sensor.

– The supply voltage is disconnected

when writing.

– Electromagnetic effects are greater

than specifications in the technical

data.

See Technical Information

TI00383P.

– Main electronics defective. – Replace main electronics.

– Main electronics defective. – Replace main electronics. 1

–Sensor defective. –Replace sensor.

– Wait a few minutes.

– Restart the device. Perform reset

(Code 62).

– Block off electromagnetic effects or

eliminate source of disturbance.

– Reestablish supply voltage. Perform

reset (Code 7864) if necessary.

Carry out calibration again.

– Block off electromagnetic effects or

eliminate sources of disturbance.

disappears.

17

6

29

38 Endress+Hauser

Page 39

Cerabar S 4 to 20mA HART Troubleshooting

Code Error type/

NA 64

116 (W116) Warning

C

120 (E120) Error

B

Factory

setting:

Warning

121 (A121) Alarm

B

122 (A122) Alarm

B

130 (A130) Alarm

B

131 (A131) Alarm

B

132 (A132) Alarm

B

133 (A133) Alarm

B

602 (W602) Warning

C

604 (W604) Warning

C

613 (W613) Warning

I

Message/description Cause Measure Priority

C>Download error, repeat download

B>Sensor low pressure – Pressure too low. – Increase pressure until message

B>Checksum error in factory segment of EEPROM

B>Sensor not connected – Cable connection sensor –main

B>EEPROM is defective. – Main electronics defective. – Replace main electronics. 10

B>Checksum error in EEPROM: min/max segment

B>Checksum error in totalizer EEPROM

B>Checksum error in History EEPROM

C>Linearization curve not monotone

C>Linearization table not valid. Less than 2 points or points too close

is active – Simulation is switched on, i.e. the

I>Simulatio

n

– The file is defective. – Use another file. 36

– During the download, the data are

not correctly transmitted to the

processor, e.g. because of open cable

connections, spikes (ripple) on the

supply voltage or electromagnetic

effects.

– Sensor defective. – Replace sensor.

– Main electronics defective. – Replace main electronics. 5

electronics disconnected.

– Electromagnetic effects are greater

than specifications in the technical

data.

See Technical Information

TI00383P.

– Main electronics defective. – Replace main electronics.

– Sensor defective. – Replace sensor.

– Main electronics defective. – Replace main electronics. 9

– Main electronics defective. – Replace main electronics. 7

– An error occurred when writing. – Perform reset (Code 7864) and carry

– Main electronics defective. – Replace main electronics.

– The linearization table is not

monotonic increasing or decreasing.

– The linearization table consists of

less than 2 points.

– At least 2 points in the linearization

table are too close together. A

minimum gap of 0.5 % of the span

must be maintained between two

points.

Spans for the "Pressure linearized"

option: HYDR. PRESS MAX. –

HYDR. PRESS MIN.; TANK

CONTENT MAX. – TANK

CONTENT MIN.

Spans for the "Height linearized"

option: LEVEL MAX – LEVEL MIN;

TANK CONTENT MAX. – TANK

CONTENT MIN.

device is not measuring at present.

– Check cable connection PC –

transmitter.

– Block off electromagnetic effects or

eliminate sources of disturbance.

– Perform reset (Code 7864) and carry

out calibration again.

– Repeat download.

30

disappears.

– Check cable connection and repair if

necessary.

– Block off electromagnetic effects or

eliminate source of disturbance.

out calibration again.

– Add to or correct linearization table.

Then accept linearization table

again.

– Add to linearization table. If

necessary, confirm linearization

table again.

– Correct linearization table and

accept again.

– Switch off simulation. 60

13

8

57

58

Endress+Hauser 39

Page 40

Troubleshooting Cerabar S 4 to 20mA HART

Code Error type/

NA 64

620 (E620) Error

C

Factory

setting:

Warning

700 (W700) Warning

C

701 (W701) Warning

C

702 (W702) Warning

C

703 (A703) Alarm

B

704 (A704) Alarm

B

705 (A705) Alarm

B

706 (W706) Warning

C

707 (A707) Alarm

B

Message/description Cause Measure Priority

C>Current output out of range The current is outside the permitted

C>Last configuration not stored – An error occurred when writing or

C>Measuring chain config. exceeds sensor range

C>HistoROM data not consistent. – Data were not written correctly to

B>Measurement error – Fault in the main electronics. – Briefly disconnect device from the

B>Measurement error – Fault in the main electronics. – Briefly disconnect device from the

B>Measurement error – Fault in the main electronics. – Briefly disconnect device from the

C>Configuration in HistoROM and device not identical

B>X-VAL. of lin. table out of edit limits.

range 3.8 to 20.5 mA.

– The pressure applied is outside the

set measuring range (but within the

sensor range).

– Loose connection at sensor cable – Wait a short period of time and

reading configuration data or the

power supply was disconnected.

– Main electronics defective. – Replace main electronics.

– The calibration carried out would

result in the sensor nominal

operating range being undershot or

overshot.

the HistoROM, e.g. if the HistoROM

was detached during the writing

process.

– HistoROM does not have any data. – Copy suitable data to the HistoROM.

– Main electronics defective. – Replace main electronics.

– Main electronics defective. – Replace main electronics.

– Main electronics defective. – Replace main electronics.

– Configuration (parameters) in the

HistoROM and in the device is not

identical.

least one X-VALUE in the

At

–

linearization table is either below

the value for HYDR. PRESS MIN. or

MIN. LEVEL or above the value for

HYDR. PRESS. MAX. or LEVEL

MAX

– Check pressure applied, reconfigure

measuring range if necessary.

See also these Operating

Instructions Section 4.

– Perform reset (Code 7864) and carry

out calibration again.

tighten the connection, or avoid

loose connection.

– Perform reset (Code 7864) and carry

out calibration again.

– Carry out calibration again. 51

– Repeat upload.

– Perform reset (Code 7864) and carry

out calibration again.