Page 1

Product Data Document

420DS-2b

July 16, 2007 - Page 1

Bristol® ControlWave® Remote Ethernet I/O

With the ever-increasing demand for distributed

I/O architectures Bristol® ControlWave® Remote

I/O modules, from Emerson Process Management,

are the ideal solution to minimize installation cost.

The compact DIN-rail mount modules provide an

open connectivity through 10 Mbps Ethernet and

38.4 KB serial RS 485. The wide range of module

I/O congurations brings exceptional exibility to

network diversity. Each module is designed and

rated for harsh industrial environments, a perfect

compliment to the ControlWave Process Automation

Management Solution as well as our Network 3000

measurement and control system.

Humidity: 5 – 95% non-condensing

Features

Open Modbus (Modbus TCP) Ethernet

•

connectivity

RS 485 Modbus RTU or Modbus ASCII

•

Easy-to-use CongTools software conguration

•

Internal 24 V dc loop power minimizes wiring

•

cost

‘Hot Swap’ I/O module replacement

•

10 – 30 V dc power input

•

-30 to +70°C operating temperature range

•

CSA, UL Class I, Div. 2 Groups A-D, and CE

•

approved

Specications

All I/O

Compact 4 ¾” W x 3 ¼” H x 4 1/8” D

•

10 – 30 V dc power input

•

1.2 Watt typical per module (48 mA @ 24 Vdc)

•

– varies by module and load

Temperature: -30 to +70°C operating

•

temperature range

•

RS 485 port Master or Slave up to 38400 baud

•

– up to 32 nodes per line

Up to 16,000 nodes per network

•

10Base T at 10 Mbps Ethernet port

•

1200 V RMS 1 minute isolation on Ethernet

•

port

ESD (Electro Static Discharge) withstand: 8KV

•

Vibration meets IEC 68-2-6

•

1g for 10 Hz to 150 Hz

.5g for 150 Hz to 2000 Hz

The ControlWave Remote Ethernet I/O series consists of seven modules

ControlWave Discrete Input Module

Number of inputs: 16

•

Input source or sink: Congurable

•

Input voltage: 12/24 V AC/DC

•

Input resistance: 3.6 KΩ

•

One High Speed Counter channel up to 2 KHz

•

Scan rate: 2 mS

•

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Power: .75 watt

•

Page 2

Product Data Document

420DS-2b

July 16, 2007 - Page 2

Bristol® Remote Ethernet I/O

ControlWave Discrete Output Module

Number of outputs: 16

•

Output voltage: 10 to 30 Vdc

•

Maximum output current per channel: 1 Amp

•

Maximum output current (all 8 channels): 8 Amp

•

Maximum off state leakage current: 0.05 mA

•

Pulse duration output: Congurable

•

Scan rate: 2 mS

•

ControlWave Analog Input Module

Number of inputs: 16

•

Input range: 4-20 mA - internal or external loop

•

powered

A/D resolution: 14 bit (0.01%)

•

Full scale accuracy @ 20°C: +/-0.05%

•

Span and offset temp. coefcient: +/- 50 ppm

•

per°C

Input impedance: 100 Ohms

•

Between inputs and ground: 1200 Volts

•

Input impedance: Voltage 200 KΩ Current 100

•

Ohms

Input current protection: eld replaceable

•

fusible shunts

Scan rate: 100 mS

•

ControlWave RTD/DI Input Module

Number of inputs: 4 RTD inputs and 4 DI

•

RTD inputs: 100 ohm platinum, -200 to +850°C

•

A/D resolution: 16 bit (0.0031%)

•

Scan rate: 700 ms (4 RTD)

•

DI specications same as for 16 DI module

•

Scan rate: 20 ms (4 DI)

•

ControlWave Mixed 8DI/8AI Input Module

Number of inputs: 8 AI and 8 DI

•

Specication same as 16 AI module and 16 DI

•

module

Input current protection: eld replaceable

•

fusible shunts

Scan rate: 5 mS

•

ControlWave Analog Instrumentation Input Module

Number of inputs: 8

•

Input range: Isolated Current or Thermocouple

•

4-20 mA - internal or external loop powered

•

J, K, E, R, T, B, C, N, S thermocouple Cold-

•

junction compensated and reported as °F, °C,

or 0.1°C

A/D resolution: 16 bit (0.0031%)

•

Full scale accuracy @ 20°C: +/-0.02%

•

Span and offset temp. coefcient: +/- 30 ppm

•

per°C

Common mode isolation:

•

Between two input terminals: +/-25 V dc

•

ControlWave Mixed 8DI/8DO Input Module

Number of inputs: 8 DI and 8 DO

•

Specication same as 16 DI module and 16 DO

•

modules

ControlWave Mixed 8AI/4AO Module

Number of inputs: 8 AI and 4 AO

•

Specication for AI’s same as 16 AI module

•

Output range: 4 – 20 mA

•

D/A resolution: 16 bit

•

Full scale accuracy @ 20°C: +/-0.02%

•

Maximum output settling time: 5 mS

•

External loop supply: 10 – 30 V dc

•

Load resistance: 0 – 750 Ω

•

Short circuit protection: Current limiting

•

Scan rate: 5 mS

•

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote

Page 3

Product Data Document

420DS-2b

July 16, 2007 - Page 3

Bristol® Remote Ethernet I/O

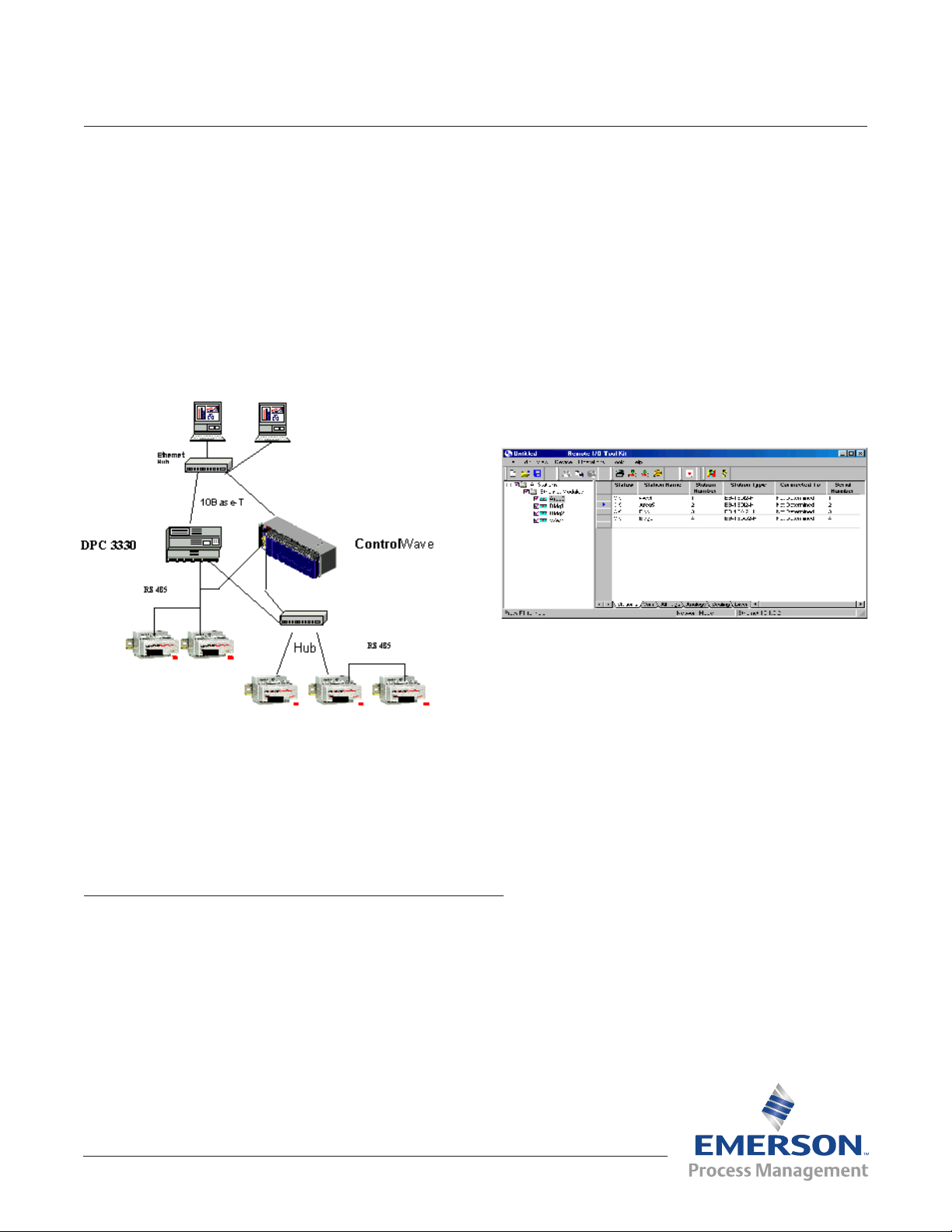

ControlWave Ethernet I/O Conguration Tools

The ControlWave Ethernet I/O Tool Kit is a Windows

conguration utility for initial setup and testing of all

Ethernet I/O modules. This easy to use utility allows

assignment of communication paramenters

including I/P address, comm port baud rate and

module address. It also provides I/O setup, tag

name assignment, scaling factors, etc.

Once the module is congured it can be tested for

proper operation before being put into operation.

Remote Setup Module

In conjunction with the conguration software, the

Remote Setup Module provides a RS 232 interface

to the PC allowing the Ethernet module base to be

initially congured with a I/P, module address RS

485 port baud rate, etc. The Setup module plugs

into any Ethernet I/O base so one Setup module

can be used for the entire system. All Ethernet I/O

modules can be congured through a local Ethernet

connection with the conguration software only or

through a Ethernet network using the Setup module.

The Setup module is most useful when conguring a RS 485 network since it allows conguration

through a RS 232 PC port rather than requiring the

RS 485 in the PC.

© 2007 Remote Automation Solutions, division of Emerson Process Management. All rights reserved.

Bristol, Inc., Bristol Babcock Ltd, Bristol Canada, BBI SA de CV and the Flow Computer Division , are wholly owned subsidiaries of Emerson Electric Co. doing business as Remote Automation Solutions (“RAS”), a division of Emerson Process Management. FloBoss, ROCLINK, Bristol, Bristol Babcock, ControlWave, TeleFlow and Helicoid are trademarks of RAS. AMS,

PlantWeb and the PlantWeb logo are marks of Emerson Electric Co. The Emerson logo is a trademark and service mark of the Emerson Electric Co. All other marks are property of their

respective owners.

The contents of this publication are presented for informational purposes only. While every effort has been made to ensure informational accuracy, they are not to be construed as war-

ranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. RAS reserves the right to modify or improve the designs or

specications of such products at any time without notice. All sales are governed by RAS’ terms and conditions which are available upon request. RAS does not assume responsibility for

the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any RAS product remains solely with the purchaser and end-user.

Emerson Process Management

Remote Automation Solutions

Watertown, CT 06795 USA T 1 (860) 945-2200

Mississauga, ON 06795 Canada T 1 (905) 362-0880

Worcester WR3 8YB UK T 44 (1) 905-856950

Website: www.EmersonProcess.com/Remote

Loading...

Loading...