Page 1

Instruction Manual

CI-ControlWave EFM

Oct., 2006

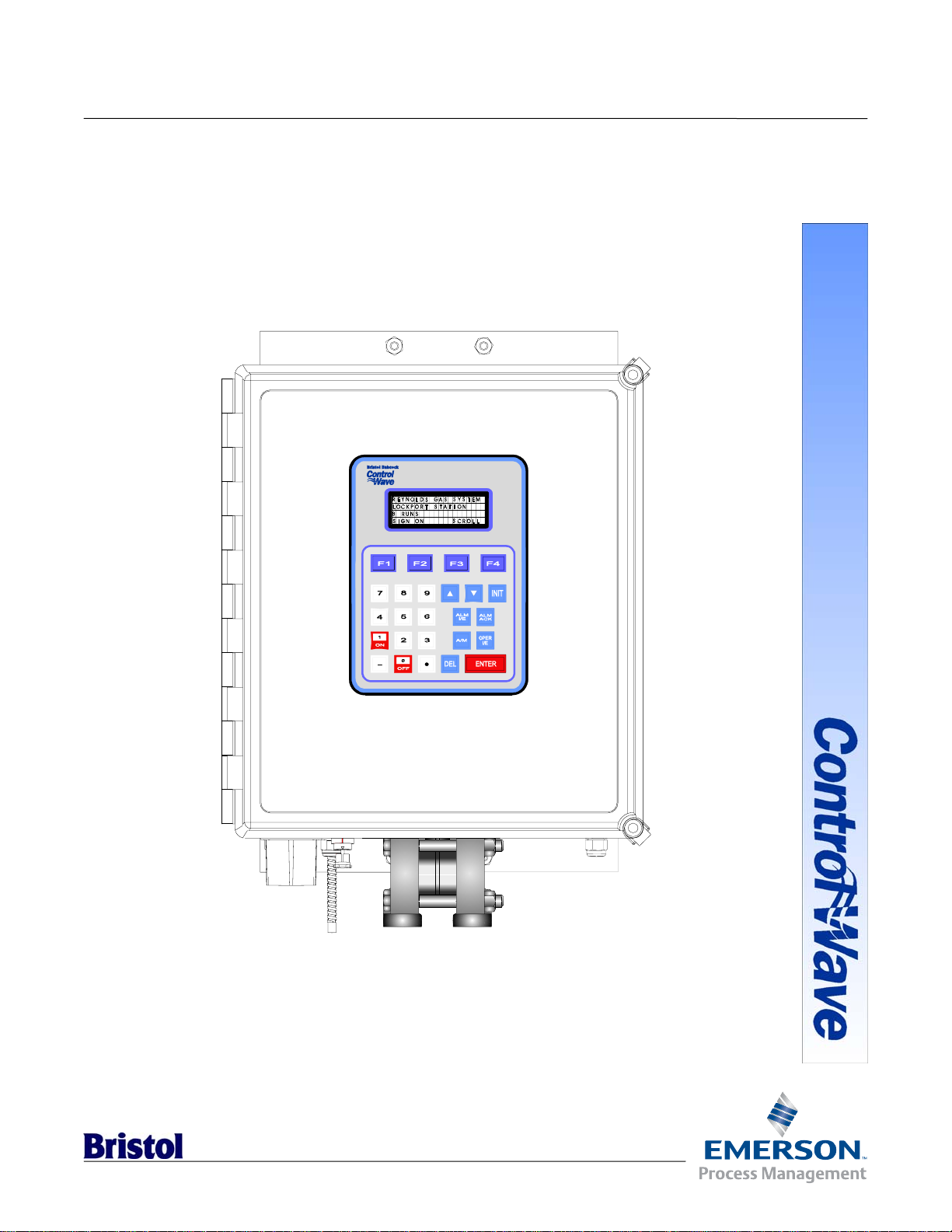

ControlWave EFM

(Electronic Flow Meter)

ontrolWave EFM

www.EmersonProcess.com/Bristol

Page 2

IMPORTANT! READ INSTRUCTIONS BEFORE STARTING!

Be sure that these instructions are carefully read and understood before any

operation is attempted. Improper use of this device in some applications may result in

damage or injury. The user is urged to keep this book filed in a convenient location for

future reference.

These instructions may not cover all details or variations in equipment or cover

every possible situation to be met in connection with installation, operation or maintenance. Should problems arise that are not covered sufficiently in the text, the purchaser is advised to contact Bristol for further information.

EQUIPMENT APPLICATION WARNING

The customer should note that a failure of this instrument or system, for

whatever reason, may leave an operating process without protection. Depending upon

the application, this could result in possible damage to property or injury to persons.

It is suggested that the purchaser review the need for additional backup equipment

or provide alternate means of protection such as alarm devices, output limiting, failsafe valves, relief valves, emergency shutoffs, emergency switches, etc. If additional

in-formation is required, the purchaser is advised to contact Bristol .

RETURNED EQUIPMENT WARNING

When returning any equipment to Bristol for repairs or evaluation, please note

the following: The party sending such materials is responsible to ensure that the

materials returned to Bristol are clean to safe levels, as such levels are defined and/or

determined by applicable federal, state and/or local law regulations or codes. Such

party agrees to indemnify Bristol and save Bristol harmless from any liability or

damage which Bristol may incur or suffer due to such party's failure to so act.

ELECTRICAL GROUNDING

Metal enclosures and exposed metal parts of electrical instruments must be

grounded in accordance with OSHA rules and regulations pertaining to "Design

Safety Standards for Electrical Systems," 29 CFR, Part 1910, Subpart S, dated: April

16, 1981 (OSHA rulings are in agreement with the National Electrical Code).

The grounding requirement is also applicable to mechanical or pneumatic instruments that include electrically-operated devices such as lights, switches, relays,

alarms, or chart drives.

EQUIPMENT DAMAGE FROM ELECTROSTATIC DISCHARGE VOLTAGE

This product contains sensitive electronic components that can be damaged by

exposure to an electrostatic discharge (ESD) voltage. Depending on the magnitude

and duration of the ESD, this can result in erratic operation or complete failure of the

equipment. Read supplemental document S14006 at the back of this manual for

proper care and handling of ESD-sensitive components.

Bristol 1100 Buckingham Street, Watertown, CT 06795

Telephone (860) 945-2200

Page 3

WARRANTY

A. Bristol warrants that goods described herein and manufactured by Bristol are free

from defects in material and workmanship for one year from the date of shipment

unless otherwise agreed to by Bristol in writing.

B. Bristol warrants that goods repaired by it pursuant to the warranty are free from

defects in material and workmanship for a period to the end of the original warranty

or ninety (90) days from the date of delivery of repaired goods, whichever is longer.

C. Warranties on goods sold by, but not manufactured by Bristol, are expressly limited

to the terms of the warranties given by the manufacturer of such goods.

D. All warranties are terminated in the event that the goods or systems or any part

thereof are (i) misused, abused or otherwise damaged, (ii) repaired, altered or

modified without Bristol's consent, (iii) not installed, maintained and operated in

strict compliance with instructions furnished by Bristol, or (iv) worn, injured or

damaged from abnormal or abusive use in service time.

E. THESE WARRANTIES ARE EXPRESSLY IN LIEU OF ALL OTHER

WARRANTIES EXPRESS OR IMPLIED (INCLUDING WITHOUT LIMITATION

WARRANTIES AS TO MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE), AND NO WARRANTIES, EXPRESS OR IMPLIED, NOR ANY

REPRESENTATIONS, PROMISES, OR STATEMENTS HAVE BEEN MADE BY

BRISTOL UNLESS ENDORSED HEREIN IN WRITING. FURTHER, THERE ARE

NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION OF THE

FACE HEREOF.

F. No agent of Bristol is authorized to assume any liability for it or to make any written

or oral warranties beyond those set forth herein.

A. Buyer's sole remedy for breach of any warranty is limited exclusively to repair or

replacement without cost to Buyer of any goods or parts found by Seller to be

defective if Buyer notifies Bristol in writing of the alleged defect within ten (10) days

of discovery of the alleged defect and within the warranty period stated above, and if

the Buyer returns such goods to Bristol's Watertown office, unless Bristol's Watertown office designates a different location, transportation prepaid, within thirty (30)

days of the sending of such notification and which upon examination by Bristol

proves to be defective in material and workmanship. Bristol is not responsible for

any costs of removal, dismantling or reinstallation of allegedly defective or defective

goods. If a Buyer does not wish to ship the product back to Bristol, the Buyer can

arrange to have a Bristol service person come to the site. The Service person's

transportation time and expenses will be for the account of the Buyer. However,

labor for warranty work during normal working hours is not chargeable.

B. Under no circumstances will Bristol be liable for incidental or consequential

damages resulting from breach of any agreement relating to items included in this

quotation, from use of the information herein or from the purchase or use by Buyer,

its em-ployees or other parties of goods sold under said agreement.

REMEDIES

Page 4

How to return material for Repair or Exchange

Before a product can be returned to Bristol for repair, upgrade, exchange, or to verify

proper operation, form (GBU 13.01) must be completed in order to obtain a RA (Return

Authorization) number and thus ensure an optimal lead time. Completing the form is very

important since the information permits the Bristol Repair Dept. to effectively and

efficiently process the repair order.

You can easily obtain a RA number by:

A. FAX

Completing the form (GBU 13.01) and faxing it to (860) 945-3875. A Bristol Repair

Dept. representative will return call (or other requested method) with a RA number.

B. E-MAIL

Accessing the form (GBU 13.01) via the Bristol Web site (www.bristolbabcock.com)

and sending it via E-Mail to brepair@bristolbabcock.com

representative will return E-Mail (or other requested method) with a RA number.

C. Mail

Mail the form (GBU 13.01) to

Bristol Inc.

Repair Dept.

1100 Buckingham Street

Watertown, CT 06795

A Bristol Repair Dept. representative will return call (or other requested method)

with a RA number.

D. Phone

Calling the Bristol Repair Department at (860) 945-2442. A Bristol Repair Depart-

ment representative will record a RA number on the form and complete Part I, then

send the form to the Customer via fax (or other requested method) for Customer

completion of Parts II & III.

A copy of the completed Repair Authorization Form with issued RA number should be included with the product being returned. This will allow us to quickly track, repair, and

return your product to you.

. A Bristol Repair Dept.

Page 5

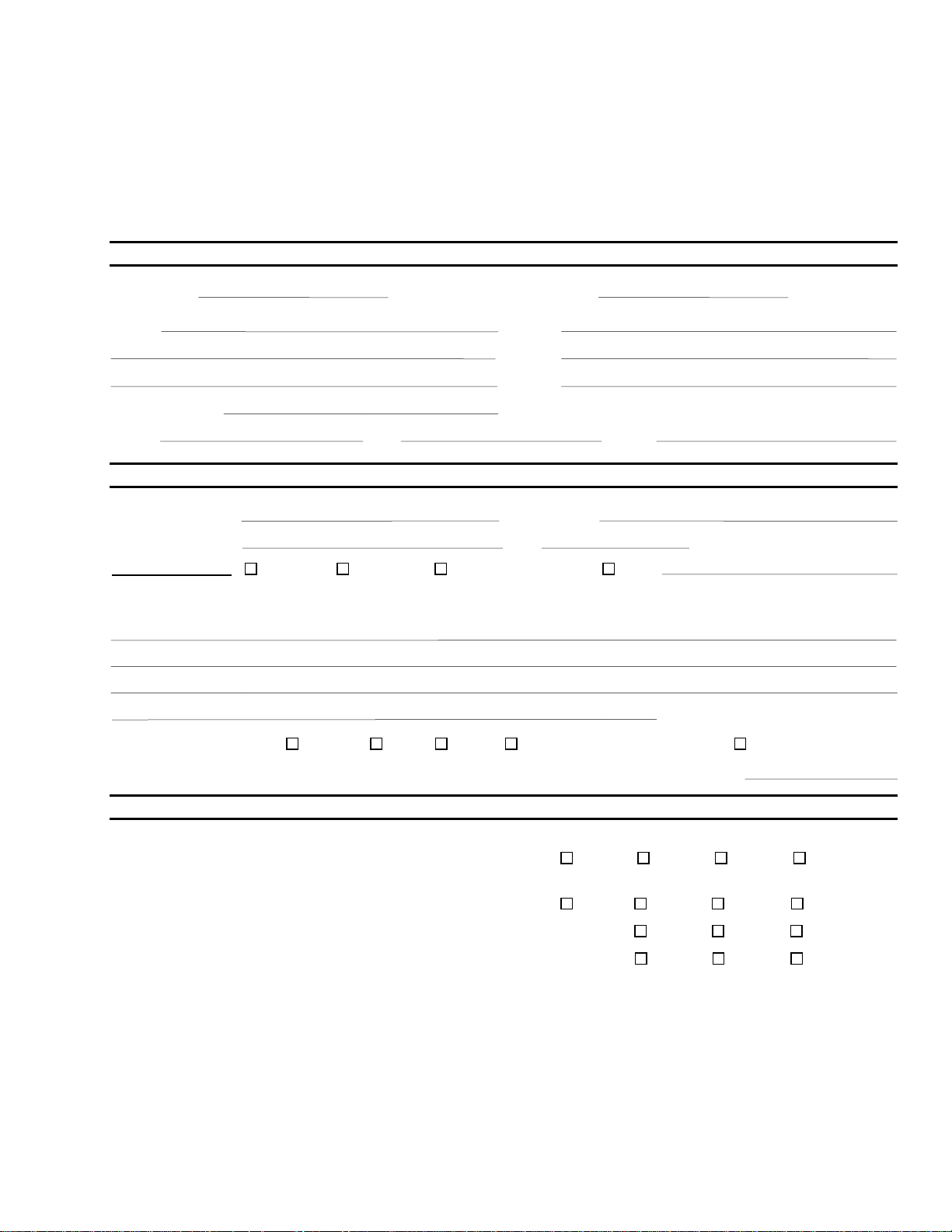

Bristol Inc. Repair Authorization Form (off-line completion)

(Providing this information will permit Bristol Inc. to effectively and efficiently process your return. Completion is required

to receive optimal lead time. Lack of information may result in increased lead times.)

Date___________________ RA #___________________SH_ Line No.____________

Standard Repair Practice is as follows: Variations to this is

practice may be requested in the “Special Requests” section.

• Evaluate / Test / Verify Discrepancy

• Repair / Replace / etc. in accordance with this form

• Return to Customer

Part I Please complete the following information for single unit or multiple unit returns

Address No. (office use only) Address No. (office use only)

Bill to : Ship to:

Purchase Order: Contact Name:____________________________________

Phone: Fax: E-Mail:

Part II Please complete Parts II & III for each unit returned

Model No./Part No. Description

Please be aware of the Non warranty standard charge:

• There is a $100 minimum evaluation charge, which is

applied to the repair if applicable (√ in “returned”

B,C, or D of part III below)

Range/Calibration S/N

Reason for return

: Failure Upgrade Verify Operation Other

1. Describe the conditions of the failure (Frequency/Intermittent, Physical Damage, Environmental Conditions,

Communication, CPU watchdog, etc.)

(Attach a separate sheet if necessary)

2. Comm. interface used: Standalone RS-485 Ethernet Modem (PLM (2W or 4W) or SNW) Other:______________

3. What is the Firmware revision? _____________________ What is the Software &version?

Part III If checking “replaced” for any question below, check an alternate option if replacement is not available

A. If product is within the warranty time period but is excluded due

to Bristol’s warranty clause, would you like the product:

repaired returned replaced scrapped?

B. If product were found to exceed the warranty period,

would you like the product:

C. If product is deemed not repairable would you like your product:

D. If Bristol is unable to verify the discrepancy, would you like the product:

repaired returned replaced scrapped?

returned replaced scrapped?

returned replaced *see below?

* Continue investigating by contacting the customer to learn more about the problem experienced? The person to contact

that has the most knowledge of the problem is: ______________________________ phone_____________________

If we are unable to contact this person the backup person is: _________________________

Special Requests: ____________________________________________________________________________________

phone_____________________

____________________________________________________________________________________________________

Ship prepaid to: Bristol Inc., Repair Dept., 1100 Buckingham Street, Watertown, CT 06795

Phone: 860-945-2442 Fax: 860-945-3875 Form GBU 13.01 Rev. B 04/11/06

Page 6

Bristol

Training

GET THE MOST FROM YOUR BRISTOL

BABCOCK INSTRUMENT OR SYSTEM

• Avoid Delays and problems in getting your system on-line

• Minimize installation, start-up and maintenance costs.

• Make the most effective use of our hardware and software.

• Know your system.

As you know, a well-trained staff is essential to your operation. Bristol Inc. offers a full

schedule of classes conducted by full-time, professional instructors. Classes are offered

throughout the year at three locations: Houston, Orlando and our Watertown, CT

headquarters. By participating in our training, your personnel can learn how to install,

calibrate, configure, program and maintain any and all Bristol products and realize the full

potential of your system.

For information or to enroll in any class, contact our training department in Watertown at

(860) 945-2343. For Houston classes, you can also contact our Houston office, at (713) 685-

6200.

Page 7

A Few Words About Bristol Inc.

For over 100 years, Bristol® has been providing innovative solutions for the measurement

and control industry. Our product lines range from simple analog chart recorders, to

sophisticated digital remote process controllers and flow computers, all the way to turnkey

SCADA systems. Over the years, we have become a leading supplier to the electronic gas

measurement, water purification, and wastewater treatment industries.

On off-shore oil platforms, on natural gas pipelines, and maybe even at your local water

company, there are Bristol Inc. instruments, controllers, and systems running year-in and

year-out to provide accurate and timely data to our customers.

Getting Additional Information

In addition to the information contained in this manual, you may receive additional assistance in using this product from the following sources:

Help Files / Release Notes

Many Bristol software products incorporate help screens. In addition, the software typically

includes a ‘read me’ release notes file detailing new features in the product, as well as other

information which was available too late for inclusion in the manual.

Contacting Bristol Inc. Directly

Bristol's world headquarters is located at 1100 Buckingham Street, Watertown,

Connecticut 06795, U.S.A.

Our main phone numbers are:

(860) 945-2200

(860) 945-2213 (FAX)

Regular office hours are Monday through Friday, 8:00AM to 4:30PM Eastern Time,

excluding holidays and scheduled factory shutdowns. During other hours, callers may leave

messages using Bristol's voice mail system.

Telephone Support - Technical Questions

During regular business hours, Bristol's Application Support Group can provide telephone

support for your technical questions.

For technical questions about TeleFlow products call (860) 945-8604.

For technical questions about ControlWave call (860) 945-2394 or (860) 945-2286.

For technical questions regarding Bristol’s OpenEnterprise product, call (860) 945-3865

or e-mail: scada@bristolbabcock.com

Page 8

For technical questions regarding ACCOL products, OpenBSI Utilities, UOI and all other

software except for ControlWave and OpenEnterprise products, call (860) 945-2286.

For technical questions about Network 3000 hardware, call (860) 945-2502.

You can e-mail the Application Support Group at: bsupport@bristolbabcock.com

The Application Support Group maintains an area on our web site for software updates and

technical information. Go to: www.bristolbabcock.com/services/techsupport/

For assistance in interfacing Bristol hardware to radios, contact Bristol’s Communication

Technology Group in Orlando, FL at (407) 629-9463 or (407) 629-9464.

You can e-mail the Communication Technology Group at:

orlandoRFgroup@bristolbabcock.com

Telephone Support - Non-Technical Questions, Product Orders, etc.

Questions of a non-technical nature (product orders, literature requests, price and delivery

information, etc.) should be directed to the nearest sales office (listed on the rear cover of

this manual) or to your Bristol-authorized sales representative.

Please call the main Bristol Inc. number (860-945-2200) if you are unsure which office

covers your particular area.

Visit our Site on the World Wide Web

For general information about Bristol Inc. and its products, please visit our site on the

World Wide Web at: www.bristolbabcock.com

Training Courses

Bristol’s Training Department offers a wide variety of courses in Bristol hardware and

software at our Watertown, Connecticut headquarters, and at selected Bristol regional

offices, throughout the year. Contact our Training Department at (860) 945-2343 for course

information, enrollment, pricing, and scheduling.

Page 9

CI-ControlWave EFM

ControlWave EFM

Electronic Flow Meter

INSTALLATION FORWARD

NOTE for all ControlWave EFM Installers:

READ THIS SECTION FIRST!

This manual has been designed for the following audience:

• Customer Site Engineers, who must plan for the installation and implementation of the

ControlWave EFM.

• Instructors who must become familiar with and teach Field Engineers/Technicians on

the installation, operation and repair of ControlWave EFM.

• Field Engineers/Technicians who must install and service the ControlWave EFM.

Installation of the ControlWave EFM electronic flow meter is provided in two formats as

follows:

Section 2 - Installation & Operation

operation of the ControlWave EFM. Section 2 provides all the information required for

instructors who are training individuals unfamiliar with the ControlWave EFM. It is also

intended to support anyone who needs to learn how to install and operate the

ControlWave EFM for the first time.

Appendix C - Hardware Installation Guide

familiar with the ControlWave EFM but need the configuration information in a concise

format. Field Engineers/Technicians who have previously installed one or more

ControlWave EFM electronic flow meters will find the necessary installation information

logically sequenced for their convenience.

A Windows driven diagnostic tool referred to as WINDIAG is provided on the

OpenBSI Software CDROM. WINDIAG is documented in instruction manual

D4041A – Window Diagnostics for Bristol Controllers

provides menu driven diagnostics that have been designed to assist a technician

or Process Engineer in troubleshooting the various ControlWave EFM circuits. A

brief overview is provided in Section 3.5 of this manual. For more detailed

descriptions of ControlWave EFM Windows Diagnostics than those provided

herein, see Document D4041A – Chapters 1 and 7B.

provides a detailed overview of the installation and

is intended for individuals who are already

NOTE:

. Bristol’s WINDIAG program

CI-ControlWave EFM - Installation Forward

Page 10

CI-ControlWave EFM

ControlWave EFM

Electronic Flow Meter

TABLE OF CONTENTS

SECTION TITLE PAGE #

Section 1 - ControlWave EFM INTRODUCTION

1.1 GENERAL DESCRIPTION ........................................................................................... 1-1

1.2 ControlWave PROGRAMMING ENVIRONMENT ....................................................1-5

1.3 PHYSICAL DESCRIPTION........................................................................................... 1-7

1.3.1 Enclosure......................................................................................................................... 1-8

1.3.2 CPU Module .................................................................................................................... 1-8

1.3.2.1 CPU Module Connectors .............................................................................................. 1-10

1.3.2.2 CPU Memory................................................................................................................. 1-10

1.3.2.3 CPU Module Configuration Jumpers .......................................................................... 1-11

1.3.2.4 CPU Module Configuration Switches.......................................................................... 1-11

1.3.2.5 CPU Module LEDs ....................................................................................................... 1-12

1.3.3 System Controller Module (SCM) ................................................................................ 1-12

1.3.3.1 SCM Mode Switch.........................................................................................................1-13

1.3.3.2 SCM Board Fuse........................................................................................................... 1-13

1.3.3.3 SCM Board Connectors ................................................................................................ 1-14

1.3.3.4 SCM Jumpers ............................................................................................................... 1-14

1.3.3.5 SCM LEDs.....................................................................................................................1-14

1.3.4 ControlWave EFM Backplanes.................................................................................. 1-14

1.3.5 ControlWave EFM Base Assembly Chassis.............................................................. 1-15

1.3.6 ControlWave EFM I/O Modules ................................................................................ 1-16

1.3.6.1 Non-isolated Analog I/O & Analog Input Modules ..................................................... 1-17

1.3.6.2 Non-isolated Digital Input/Output Module................................................................. 1-17

1.3.6.3 Non-isolated High Speed Counter Input Module........................................................ 1-17

1.3.6.4 Non-isolated Mixed Input/Output Module .................................................................. 1-17

1.3.7 ControlWave EFM Expansion Communications Modules ....................................... 1-17

1.3.8 Internal Mounting Brackets ........................................................................................ 1-18

1.3.9 Multivariable Transducer ............................................................................................1-19

1.3.10 Power Distribution Board ............................................................................................ 1-19

1.3.11 Digital to Relay I/O Option .......................................................................................... 1-19

1.3.12 21V Power Supply Option ............................................................................................1-20

1.3.13 Power System................................................................................................................ 1-20

1.3.14 RTD Probe..................................................................................................................... 1-21

1.3.15 External Radio/Modem................................................................................................. 1-21

1.4 FIELD WIRING............................................................................................................1-21

1.5 FUNCTIONS................................................................................................................. 1-21

1.5.1 Data Acquisition ........................................................................................................... 1-22

1.5.2 Flow and Volume Calculations ....................................................................................1-22

1.5.2.1 Flow Rate and Flow Time Calculations (AGA3) ......................................................... 1-23

1.5.2.2 Flow Rate Calculations and Flow Time Accumulations (AGA7) ...............................1-23

1.5.2.3 Extension Calculation and Analog Averaging ............................................................1-23

1.5.2.3.1 Energy Calculation ....................................................................................................... 1-23

1.5.2.3.2 Volume and Energy Integration ..................................................................................1-23

1.5.2.4 Downstream Pressure Tap........................................................................................... 1-23

1.5.3 Archives.........................................................................................................................1-24

1.5.3.1 Hourly Historical Data Log.......................................................................................... 1-24

CI-ControlWave EFM Contents / 0 - 1

Page 11

CI-ControlWave EFM

ControlWave EFM

Electronic Flow Meter

TABLE OF CONTENTS

SECTION TITLE PAGE #

Section 1 - ControlWave EFM INTRODUCTION (Continued)

1.5.3.2 Daily Historical Data Log ............................................................................................1-24

1.5.3.3 Periodic Historical Data Log........................................................................................ 1-25

1.5.3.4 Alarm and Event Storage............................................................................................. 1-25

1.5.4 LCD Display..................................................................................................................1-25

1.5.5 Communications ........................................................................................................... 1-26

1.5.5.1 BSAP Message Support................................................................................................ 1-27

1.5.6 Discrete and Analog I/O EFM Functionality .............................................................. 1-27

1.5.6.1 Flow Rate Control - DDC (jog control) using PID....................................................... 1-27

1.5.6.2 Pulse Output for External Totalizer or Sampler ........................................................ 1-28

1.5.6.3 Nominations..................................................................................................................1-28

1.5.7 Self Test & Diagnostics ................................................................................................1-28

Section 1A - PRODUCT FEATURES & OVERVIEW

1A.1 PRODUCT OVERVIEW.............................................................................................. 1A-1

1A.1.1 Hardware Features......................................................................................................1A-1

1A.1.2 Firmware and Software Features............................................................................... 1A-1

1A.2 PRODUCT FAMILY COMPATIBILITY .................................................................... 1A-2

1A.2.1 Open Standards for Programming, Network Config. and Communication ............. 1A-2

1A.2.2 ControlWave Designer with ACCOL III................................................................... 1A-2

1A.2.3 ACCOL III.................................................................................................................... 1A-2

1A.3 STANDARD APPLICATION PROGRAM.................................................................. 1A-3

1A.3.1 OpenBSI - Simply Creative......................................................................................... 1A-3

1A.3.2 OpenBSI Utilities ........................................................................................................ 1A-4

1A.3.3 Real-time ActiveX Controls......................................................................................... 1A-4

1A.3.3.1 ActiveX Controls .......................................................................................................... 1A-5

1A.3.3.2 Required Software ....................................................................................................... 1A-5

1A.3.4 Historical Data Collection ........................................................................................... 1A-5

1A.3.5 OPC Server .................................................................................................................. 1A-5

1A.4 ControlWave OPEN NETWORK CONNECTIVITY................................................ 1A-6

1A.4.1 Communication Protocols............................................................................................ 1A-6

1A.4.1.1 BSAP Protocol .............................................................................................................. 1A-6

1A.4.1.2 Modbus Protocol........................................................................................................... 1A-7

1A.4.1.3 Generic Serial Interface ..............................................................................................1A-7

Section 2 - INSTALLATION & OPERATION

2.1 INSTALLATION IN HAZARDOUS AREAS................................................................. 2-1

2.2 SITE LOCATION CONSIDERATIONS........................................................................ 2-4

2.2.1 Temperature & Humidity Limits .................................................................................. 2-4

2.2.2 Vibration Limits ............................................................................................................. 2-4

2.3 ControlWave EFM INSTALLATION/CONFIGURATION ........................................ 2-4

2.3.1 Mounting the ControlWave EFM Enclosure ..............................................................2-8

0 - 2 / Contents CI-ControlWave EFM

Page 12

CI-ControlWave EFM

ControlWave EFM

Electronic Flow Meter

TABLE OF CONTENTS

SECTION TITLE PAGE #

Section 2 - INSTALLATION & OPERATION (Continued)

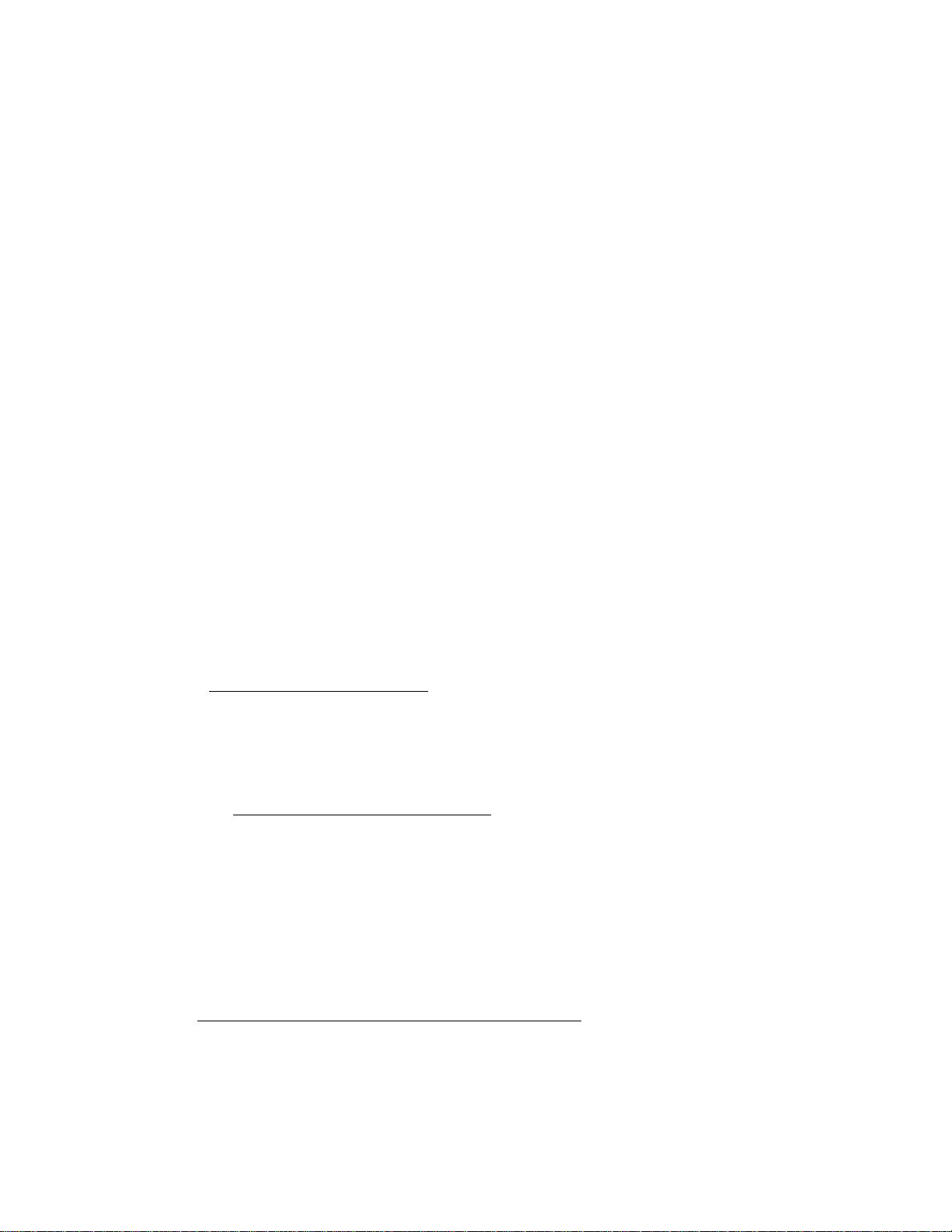

2.3.1.1 Connection to the Multivariable Transducer (MVT) .................................................. 2-10

2.3.1.2 Process Pipeline Connection (Meter Runs without Cathodic Protection) ................. 2-11

2.3.1.3 Process Pipeline Connection (Meter Runs with Cathodic Protection)....................... 2-11

2.3.2 System Controller Module (SCM) Configuration........................................................ 2-13

2.3.3 CPU Module & ECOM Module Configuration ............................................................ 2-14

2.3.3.1 CPU Module Switch Configuration .............................................................................2-14

2.3.3.2 Communication Ports................................................................................................... 2-16

2.3.3.3 RS-232 & RS-485 Interfaces ........................................................................................2-17

2.3.3.4 Piggy-back Spread Spectrum Modem (Radio) Port .................................................... 2-22

2.3.3.5 Piggy-back 56K PSTN Modem Port............................................................................. 2-23

2.3.3.6 Radio Ready and External (Case Mounted) Modem or Radio.................................... 2-27

2.3.4 I/O Module Installation & Wiring................................................................................ 2-27

2.3.4.1 Installation of I/O Modules ..........................................................................................2-27

2.3.4.2 I/O Wire Connections....................................................................................................2-30

2.3.4.3 Shielding and Grounding ............................................................................................. 2-30

2.3.4.4 Non-isolated Digital Input/Output Module................................................................. 2-30

2.3.4.4.1 Digital Input/Output Configurations .......................................................................... 2-30

2.3.4.5 Non-isolated Analog Input/Output & Analog Input Modules .................................... 2-31

2.3.4.5.1 Analog Input/Output Configurations ..........................................................................2-33

2.3.4.6 Non-isolated High Speed Counter Input Module........................................................ 2-33

2.3.4.6.1 High Speed Counter Configurations............................................................................ 2-35

2.3.4.7 Non-isolated Mixed I/O Module ................................................................................... 2-35

2.3.4.7.1 Mixed I/O Module Configuration ................................................................................. 2-37

2.3.5 RTD Wiring ................................................................................................................... 2-38

2.3.6 21V Power Supply Option ............................................................................................2-39

2.3.7 Digital to Relay I/O Board Option ...............................................................................2-40

2.3.7.1 Digital to Relay I/O Board Jumper Settings ............................................................... 2-40

2.3.8 Connection to a Model 3808 Transmitter.................................................................... 2-42

2.3.9 Power Wiring & Distribution ....................................................................................... 2-44

2.3.9.1 Bulk Power Supply Current Requirements ................................................................2-45

2.3.9.2 Power Wiring ................................................................................................................ 2-46

2.3.9.3 Mounting an Optional Solar Panel .............................................................................. 2-47

2.3.9.3.1 Swivel (Directional Facing) ..........................................................................................2-47

2.3.9.3.2 Tilt Angle....................................................................................................................... 2-48

2.3.9.4 Installing the Rechargeable Battery and Solar Panel Harness................................. 2-48

2.3.9.5 ControlWave EFM System Grounding...................................................................... 2-49

2.3.10 Operation of the Lithium Backup Coin-cell Battery .................................................. 2-49

2.3.11 Installation of a Bezel Assembly.................................................................................. 2-50

2.4 OPERATIONAL DETAILS .......................................................................................... 2-51

2.4.1 Downloading the Application Load.............................................................................. 2-51

2.4.2 Upgrading ControlWave EFM Firmware .................................................................2-51

2.4.2.1 Using LocalView to Upgrade ControlWave EFM Firmware ...................................2-52

2.4.2.2 Using Hyperterminal to Upgrade ControlWave EFM Firmware............................ 2-55

CI-ControlWave EFM Contents / 0 - 3

Page 13

CI-ControlWave EFM

ControlWave EFM

Electronic Flow Meter

TABLE OF CONTENTS

SECTION TITLE PAGE #

Section 2 - INSTALLATION & OPERATION (Continued)

2.4.2.3 Remote Upgrade of ControlWave EFM Firmware ................................................... 2-58

2.4.3 Operation of the Mode Switch...................................................................................... 2-59

2.4.4 Soft Switch Configuration and Communication Ports ...............................................2-59

2.4.5 Optional Display/Keypad Assemblies.......................................................................... 2-60

2.4.5.1 Operation of the Dual-button Display/Keypad Assembly ..........................................2-62

Section 3 - SERVICE

3.1 SERVICE INTRODUCTION ........................................................................................3-1

3.2 COMPONENT REMOVAL/REPLACEMENT PROCEDURES................................... 3-1

3.2.1 Accessing Modules For Testing...................................................................................... 3-1

3.2.2 Removal/Replacement of the Bezel Assembly............................................................... 3-2

3.2.3 Removal/Replacement of the CPU Module ................................................................... 3-2

3.2.4 Removal/Replacement of the System Controller Module ............................................. 3-2

3.2.5 Removal/Replacement of an I/O Module .......................................................................3-2

3.2.6 Removal/Replacement of an Expansion Comm. Module ..............................................3-3

3.2.7 Removal/Replacement of a Rechargeable Lead-acid Battery....................................... 3-3

3.2.8 Removal/Replacement of a Power Distribution Board .................................................3-4

3.2.9 Removal/Replacement of a 21V Power Supply Board .................................................. 3-5

3.2.10 Removal/Replacement of a Digital to Relay I/O Board................................................. 3-5

3.2.11 Removal/Replacement of an External Radio/Modem ................................................... 3-5

3.3 TROUBLESHOOTING TIPS......................................................................................... 3-5

3.3.1 System Controller Module (SCM) Voltage Checks ....................................................... 3-5

3.3.2 LED Checks .................................................................................................................... 3-6

3.3.3 Wiring/Signal Checks ................................................................................................... 3-10

3.4 GENERAL SERVICE NOTES..................................................................................... 3-10

3.4.1 Extent of Field Repairs................................................................................................. 3-11

3.4.2 Disconnecting RAM Battery ........................................................................................ 3-11

3.4.3 Maintaining Backup Files............................................................................................ 3-11

3.5 WINDIAG DIAGNOSTICS .......................................................................................... 3-11

3.5.1 Diagnostics Using WINDIAG ...................................................................................... 3-14

3.5.1.1 Communications Diagnostic Port Loop-back Test...................................................... 3-14

3.5.1.2 Serial Comm. Port Eternal Loop-back Test Procedure ..............................................3-14

3.6 CORE UPDUMP........................................................................................................... 3-16

3.7 CALIBRATION CHECKS............................................................................................ 3-16

Section 4 - SPECIFICATIONS

4.1 CPU, MEMORY & PROGRAM INTERFACE .............................................................. 4-1

4.2 COMMUNICATION PORTS ......................................................................................... 4-1

4.3 SYSTEM CONTROLLER MODULE ............................................................................ 4-2

4.3.1 Input Power Specs. ......................................................................................................... 4-2

4.3.2 Power Supply Sequencer Specs. .................................................................................... 4-3

0 - 4 / Contents CI-ControlWave EFM

Page 14

CI-ControlWave EFM

ControlWave EFM

Electronic Flow Meter

TABLE OF CONTENTS

SECTION TITLE PAGE #

Section 4 - SPECIFICATIONS (Continued)

4.3.3 Power Supply External Power Monitor Specs. ............................................................4-3

4.3.4 System Controller Module Connectors.......................................................................... 4-3

4.4 INPUT/OUTPUT MODULE SPECIFICATIONS......................................................... 4-4

4.4.1 Non-isolated Analog Input/Output Module................................................................... 4-4

4.4.2 Non-isolated Digital Input/Output Module ................................................................... 4-5

4.4.3 Non-isolated High Speed Counter Input Module.......................................................... 4-6

4.4.4 Non-isolated Mixed Input/Output Module .................................................................... 4-6

4.5 DIGITAL TO RELAY I/O BOARD SPECIFICATION ................................................. 4-9

4.6 21V POWER SUPPLY BOARD SPECIFICATIONS.................................................... 4-9

4.7 ENVIRONMENTAL SPECIFICATIONS.................................................................... 4-10

4.8 DIMENSIONS ..............................................................................................................4-10

APPENDICES/SUPPLEMENTAL INSTRUCTION

Special Instructions for Class I, Division 2 Hazardous Locations .................Appendix A

Reserved ............................................................................................................Appendix B

HARDWARE INSTALLATION GUIDE..........................................................Appendix C

ECOM MODULE RADIO/MODEM INSTALLATION GUIDE .................... Appendix D

DISPLAY/KEYPAD ASSEMBLY GUIDE.......................................................Appendix E

Using ControlWave EFM WebBSI Web Pages .............................................Appendix F

RADIO READY INSTALLATION GUIDE .................................................... Appendix G

MATERIAL SAFETY DATA SHEETS ........................................................... Appendix Z

Site Considerations for Equipment Installation, Grounding & Wiring ...........S1400CW

Care and Handling of PC Boards and ESD-Sensitive Components .....................S14006

REFERENCED Bristol CUSTOMER INSTRUCTION MANUALS

WINDIAG - Windows Diagnostics for BBI Controllers ........................................ D4041A

ControlWaveMICRO Quick Setup Guide ............................................................. D5124

Open BSI Utilities Manual ...................................................................................... D5081

Getting Started with ControlWave Designer.......................................................... D5085

Web_BSI Manual...................................................................................................... D5087

ControlWave Designer Reference Manual .............................................................. D5088

ControlWave Designer Programmer’s Handbook................................................... D5125

TechView User’s Guide............................................................................................. D5131

ControlWave Loop Power Supply Product Installation Guide........ PIP-ControlWaveLS

REFERENCED OEM MANUALS

Expansion Comm. Module Piggy-back Modem/Radio OEM Manuals

MDS Transnet Radio wired to Polyphaser - Spread Spectrum Data Transceiver

MDS document MDS 05-3946A01, Rev. A April, 2003 (PDF = 3946A-TNET_OEM-web.pdf)

CI-ControlWave EFM Contents / 0 - 5

Page 15

CI-ControlWave EFM

ControlWave EFM

Electronic Flow Meter

TABLE OF CONTENTS

SECTION TITLE PAGE #

REFERENCED OEM MANUALS (Continued)

Expansion Comm. Module Piggy-back Modem/Radio OEM Manuals (Continued)

Internal FreeWave Radio (wired to Polyphaser) - Spread Spectrum Data Transceiver

FreeWave Spread Spectrum Wireless Data Transceiver User Manual - V5.0R (model FGR09CSU)

Contact the FreeWave Tech Support group @ 303-444-3862 or at www.freewave.com to request the

latest copy of the user manual.

MultiTech Systems wired to Surge Suppressor - Modem Module MT3334SMI & MT5634SMI

MultiTech Systems Developer Guide PN S000181C, version C 6/24/02 (PDF = S000181C.pdf)

MDS Transnet 900 - Spread Spectrum Data Transceiver

MDS TransNET 900 Spread Spectrum Data Transceiver Installation & Operation Guide – MDS Doc.

MDS 05-2708A01, Rev. C, Feb., 2004 (PDF = 2708C-TransNET-web.pdf) for MDS TransNet 900

MDS 4710A – Remote Data Transceiver (Radio)

MDS 4710/9710 Series 400MHz/900 MHz Remote Data Transceiver Installation and Operation Guide

– MDS Doc. 05-3305A01, Rev. B, Sept. 2000

(PDF = 3305B-710AC.pdf) for model MDS 4710A

MDS 4710B – Data Transceiver (Radio)

MDS 4710B/9710B Data Transceiver Installation and Operation Guide – MDS Doc. 05-3316A01, Rev.

E, Sept. 2000

(PDF = 3316E-x710B.pdf) for model MDS 4710B

MDS 9810 – Spread Spectrum Data Transceiver (Radio)

MDS 9810/24810 900 MHz/2.4GHz Spread Spectrum Transceivers Installation and Operation Guide

– MDS Doc. 05-3301A01, Rev. B, April 2000

(PDF = 3301B-x810.pdf) for model MDS 9810

MDS 9710A Remote Data Transceiver (Radio)

MDS 4710/9710 Series 400MHz/900 MHz Remote Data Transceiver – MDS Doc. 05-3305A01, Rev. B,

Sept. 2000

(Installation & Operation) (PDF = 3305B-710AC.pdf) for model MDS 9710A

MDS 9710B Data Transceiver (Radio)

MDS 4710B/9710B Data Transceiver Installation and Operation Guide – MDS Doc. 05-3316A01, Rev.

E, Sept. 2000

(PDF = 3316E-x710B.pdf) for model MDS 9710B

External Modem/Radio OEM Manuals

0 - 6 / Contents CI-ControlWave EFM

Page 16

CI-ControlWave EFM

ControlWave EFM

Electronic Flow Meter

TABLE OF CONTENTS

SECTION TITLE PAGE #

REFERENCED OEM MANUALS (Continued)

External Modem/Radio OEM Manuals (Continued)

MDS iNET 900 Ethernet Radio

MDS iNET 900 Wireless IP/Ethernet Transceiver – User Guide = MDS 05-2806A01, Rev. D, Aug.

2003

(PDF = 2806D-iNET_User-web.pdf) for iNET 900 Ethernet Radio

Center Insert (Installation Reference Chart) = (PDF = 2873D-iNET_Center_Sheet.pdf)

MDS iNET 900 Wireless IP/Ethernet Transceiver – Installation Guide = MDS 05-2873A01, Rev. D,

Aug. 2003

(PDF = 2873D-iNET-Install_web.pdf) for iNET 900 Ethernet Radio

MDS entraNET Extended Range IP Networking Transceivers

MDS entraNET Extended Range IP Networking Transceivers – System Guide = MDS 05-4055A01,

Rev. A, Oct. 2003

(Installation & Operation) (PDF = 4055A-entraNET-web.pdf) for MDS entraNET 900 System

FreeWave Radio - Spread Spectrum Data Transceiver Model FGRM-501X005

Contact the FreeWave Tech Support group @ 303-444-3862 or at www.freewave.com to request the

latest copy of the user manual.

CI-ControlWave EFM Contents / 0 - 7

Page 17

Section 1

ControlWave EFM INTRODUCTION

1.1 GENERAL DESCRIPTION

ControlWave EFM electronic flow meters measure differential pressure, static pressure

and temperature for a single run and compute flow for both volume and energy. In addition

to operation in an unprotected outdoor environment, the ControlWave EFC electronic flow

meter provides the following key features.

• ARM processor provides exceptional performance and low power consumption

• Wide operating temperature range: (-40 to +70°C) (-40 to 158°F)

• CPU, SCM & I/O Modules provide LED status Indicators

• Battery backup for the real-time clock and the system’s SRAM is provided by a 3.0V,

300mA-hr lithium coin cell battery located on the CPU Module.

• Very low power consumption

• Integral Multivariable Transducer (MVT) with “smart” performance

• Standard Application Program supports the following Flow calculations:

• Calculates AGA3-1995/NX-19

• AGA3-1992 with selectable AGA8 Gross or AGA8 Detail

• AGA7/NX-19

• AGA7 with selectable AGA8 Gross or AGA8 Detail

• Auto Adjust AGA7/NX-19

• Auto Adjust AGA7 with selectable AGA8 Gross or AGA8 Detail

• Instromet Modbus AGA7 with selectable AGA8 Gross or AGA8 Detail

• Daniel Modbus AGA7 with selectable AGA8 Gross or AGA8 Detail

• Three serial communications ports (Two RS-232 & One RS-485)

• Four line alphanumeric display (with dual-button Keypad or 25-button Keypad)

• User choice of I/O Modules (AI/AO, AI, DI/DO, HSC and Mixed I/O)

• RTD input

• Nonincendive Class I, Div. 2, Groups C & D Hazardous Locations (see Appendix A)

• RTD input

• Optional Expansion Comm. Modules with/without built-in modem and/or radio

• Chassis Slots 3 and 4 support Expansion Comm. Modules or I/O Modules or one of each

• Optional Display/Keypad System

• Mixed I/O Modules provide cost effective I/O for small RTU applications

ControlWave EFC electronic flow meters are furnished in a NEMA 3X rated Hoffman®

Enclosure. The flow computer hardware is comprised of a Backplane Board (mounted in a

Housing), a System Controller Module and a CPU Module. Optional Expansion

Communication Modules may reside in Slots 3 and 4 of the Housing in lieu of I/O Modules.

The CPU Module utilizes Sharp’s LH7A400 System-on-Chip Advanced RISC Machine

(ARM) microprocessor with 32-bit ARM9TDMI Reduced Instruction Set Computer (RISC)

Core. In addition to the microprocessor and control logic, the CPU Board includes two RS232 communication ports, one RS-485 Communication port, 2MB of battery backed Static

RAM (SRAM), 512kB Boot/Downloader FLASH, 8MB simultaneous read/write FLASH, and

an I/O Bus Connector.

All system modules plug into the Backplane Board (4-Slot or 8-Slot). Each I/O Module

provides the circuitry and field interface hardware necessary to interconnect the assigned

field I/O circuits. Non-isolated power is generated and regulated by the System Controller

Module (SCM) that provides +3.3Vdc for all logic and bulk power for I/O field circuits from

either a bulk 6Vdc or bulk 12Vdc source. +1.8Vdc, used by the ARM microprocessor, is

CI-ControlWave EFM Introduction / 1-1

Page 18

generated on the CPU Module (derived from the regulated 3.3Vdc logic power). In addition

to Idle and Watchdog LEDs, there are six status LEDs located on the SCM that will display

run time status information.

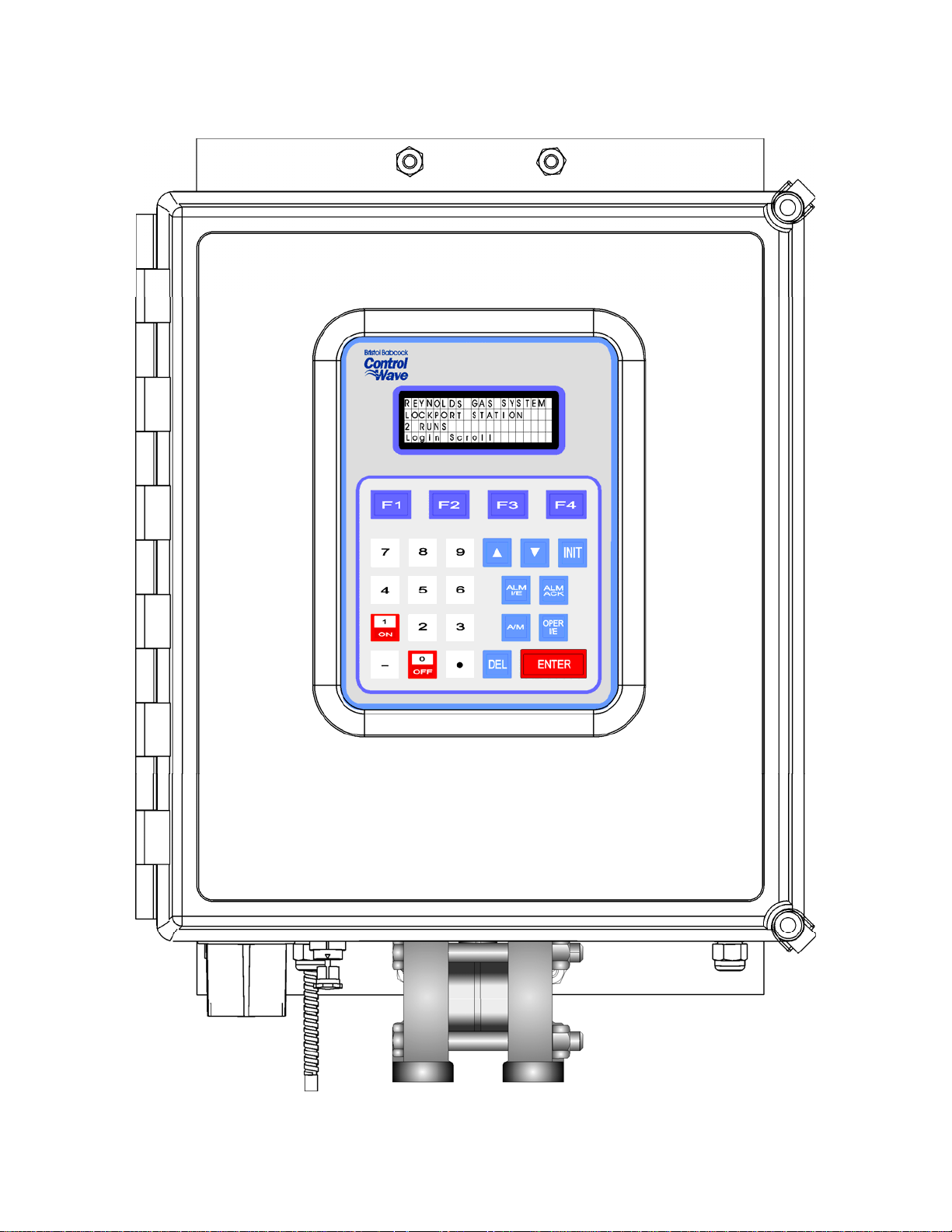

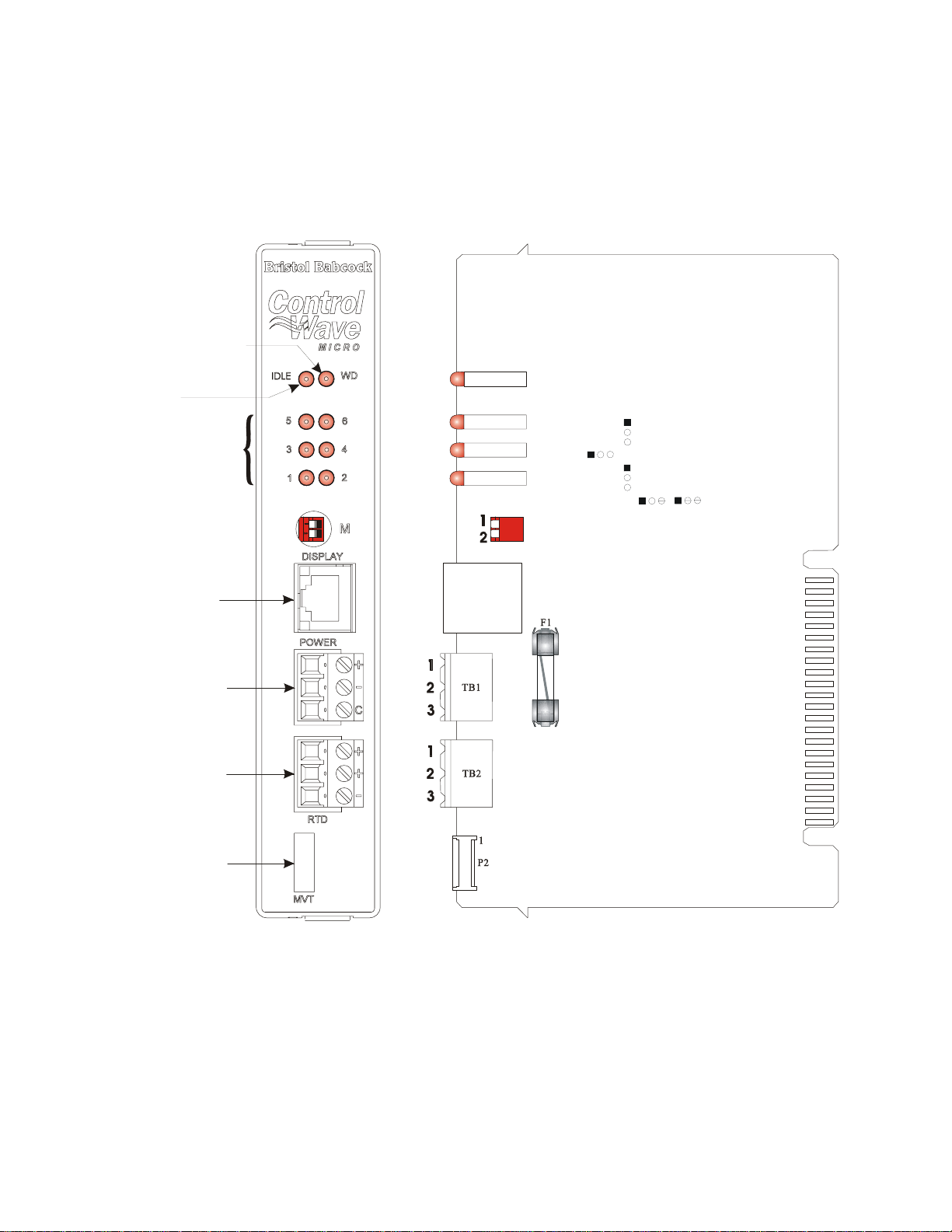

Figure 1-1 - ControlWave EFM Enclosure

(with 25-Button Display/Keypad Assembly)(Shown with Circular Local Port)

1-2 / Introduction CI-ControlWave EFM

Page 19

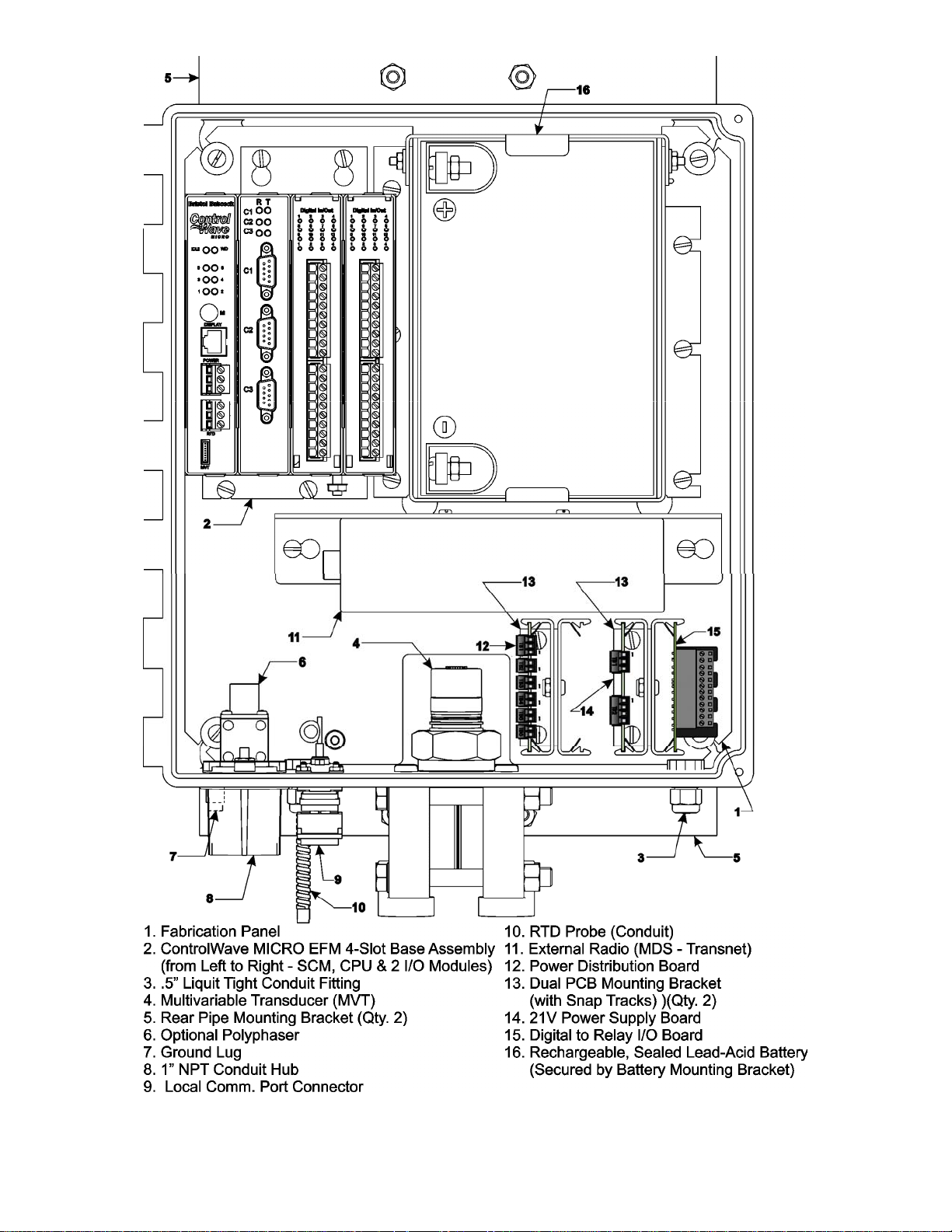

Figure 1-2A - 4-Slot ControlWave EFM (Internal View)

Component Identification Diagram (Shown with D-Type Local Port)

CI-ControlWave EFM Introduction / 1-3

Page 20

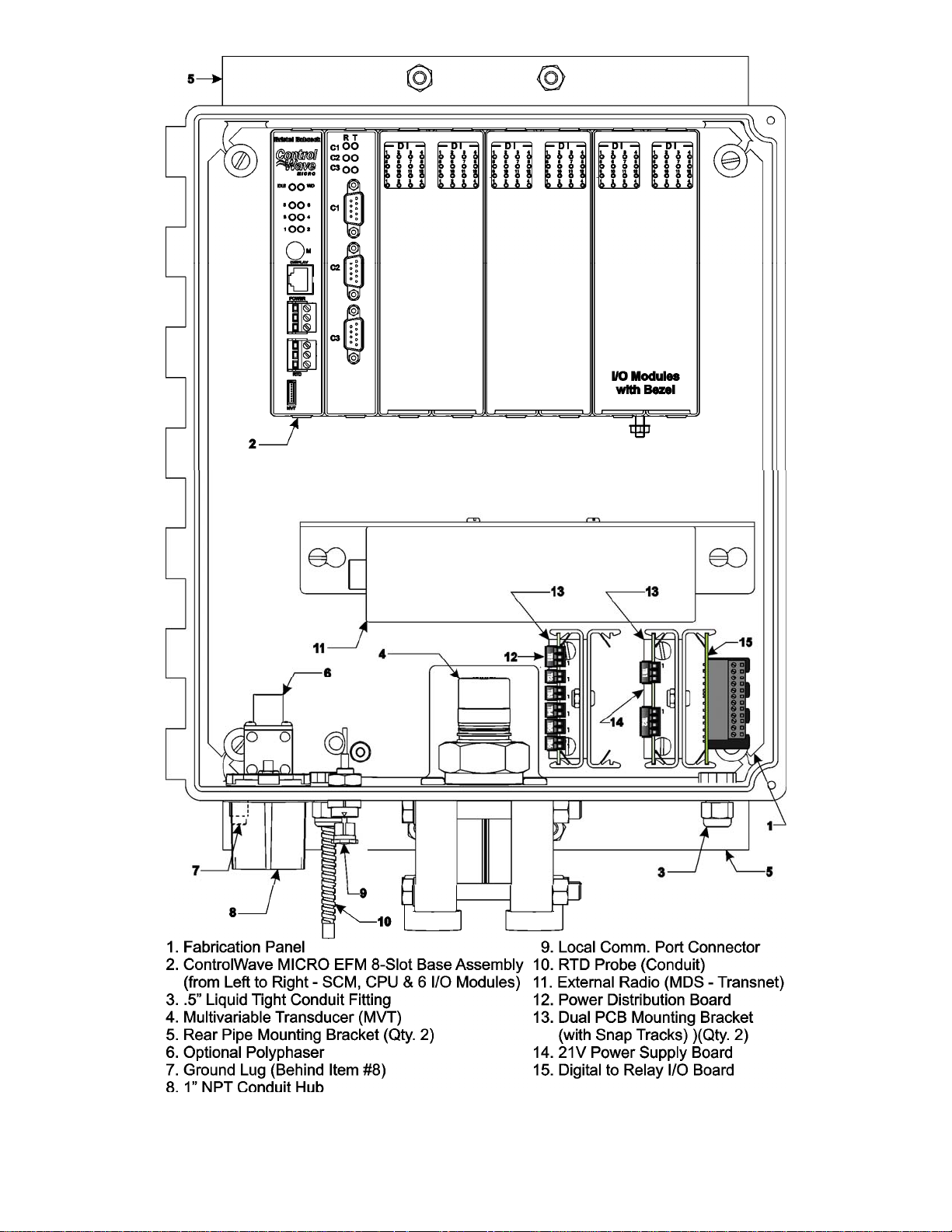

Figure 1-2B - 8-Slot ControlWave EFM (Internal View)

Component Identification Diagram (Shown with Circular Local Port)

1-4 / Introduction CI-ControlWave EFM

Page 21

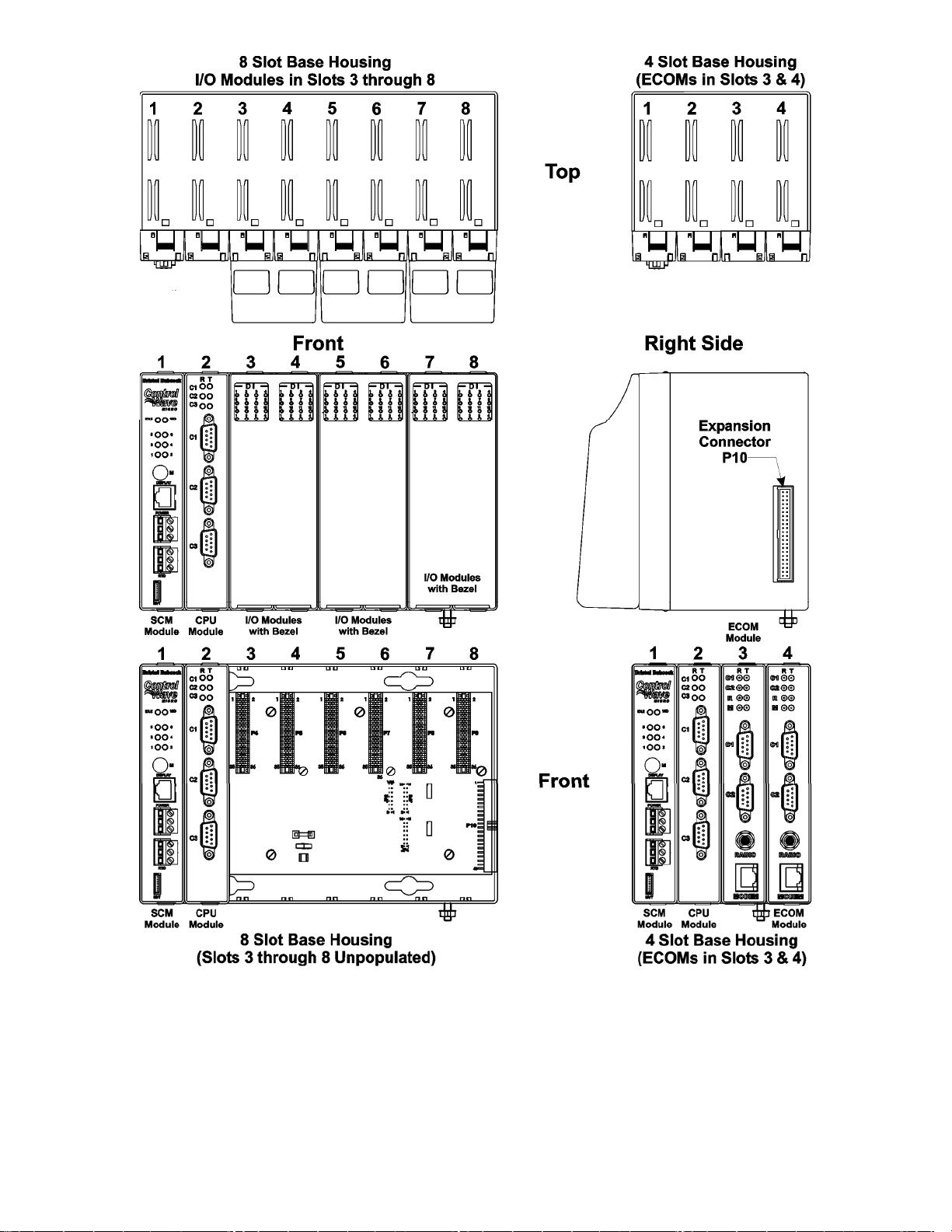

Figure 1-3 - 8/4-Slot ControlWave EFM (Electronic Flow Meter) Base Assemblies

(The 4-Slot Chassis is shown with ECM Modules in Slots 3 & 4)

1.2 ControlWave PROGRAMMING ENVIRONMENT

The ControlWave programming environment uses industry-standard tools and protocols to

provide a flexible, adaptable approach for various process control applications in the water

treatment, wastewater treatment, and industrial automation business.

CI-ControlWave EFM Introduction / 1-5

Page 22

ControlWave EFM units provide an ideal platform for remote site automation,

measurement, and data management in the oil and gas industry.

The control strategy file created and downloaded into the controller is referred to as a

ControlWave project. The ControlWave EFM ships from Bristol Babcock with a

standard ControlWave project, pre-configured for gas flow measurement, already loaded

and ready to run.

The ControlWave programming environment consists of a set of integrated software tools

which allow a user to modify the standard gas flow measurement project to fit the needs of

their own particular application, as well as to create, test, implement, and download a

different ControlWave project, if desired.

The tools that make up the programming environment are:

• ControlWave Designer load building package offers several different methods for

generating and debugging control strategy programs including function blocks, ladder

logic, structured languages, etc. The resulting process control load programs are fully

compatible with IEC 61131-3 standards. Various communication methods as offered,

including TCP/IP, serial links, as well as communication to Bristol Babcock’s Open BSI

software and networks

.

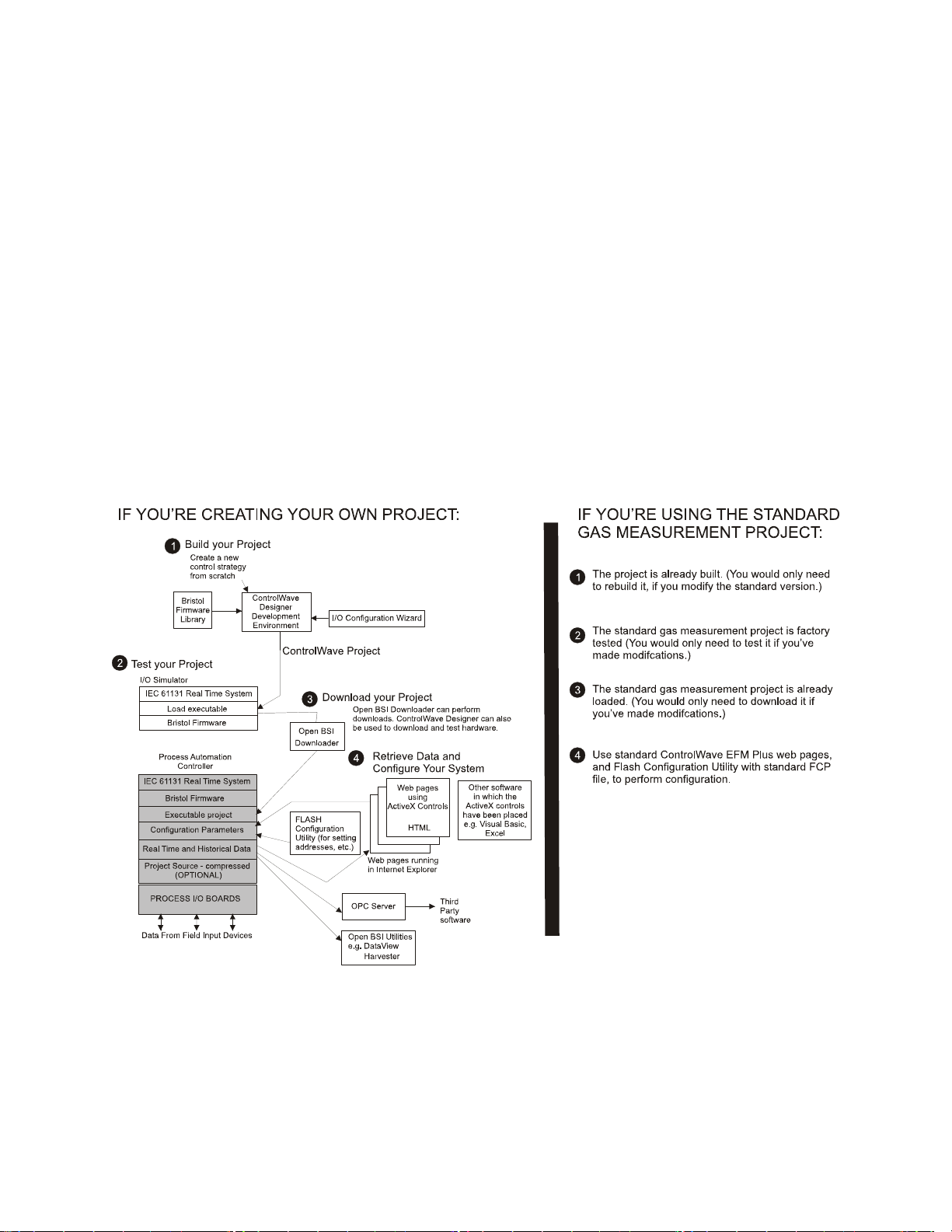

Figure 1-4 - ControlWave - Control Strategy Software Diagram

• The I/O Configuration Wizard, accessible via a menu item in ControlWave Designer,

allows you to define process I/O modules in the ControlWave and con-figure the

individual mapping of I/O points for digital and analog inputs and outputs.

• The ACCOL3 Firmware Library which is imported into ControlWave Designer,

includes a series of Bristol Babcock specific function blocks. These pre-programmed

1-6 / Introduction CI-ControlWave EFM

Page 23

function blocks accomplish various tasks common to most user applications including

alarming, historical data storage, as well as process control algorithms such as PID

control.

• The OPC Server (Object Linking and Embedding (OLE) for Process Control) allows

real-time data access to any OPC [Object Linking and Embedding (OLE) for Process

Control] compliant third-party software packages.

• A set of ControlWave EFM web pages is provided to set configuration parameters for

the standard gas flow measurement project, running in the unit. These web pages use

Bristol Babcock-specific ActiveX controls for retrieval of real-time data values and

communication statistics from the unit. The ActiveX controls are compatible with

Microsoft® Internet Explorer. Alternatively, developers can place the ActiveX controls

in third-party ActiveX compatible containers such as Visual BASIC or Microsoft® Excel.

• User-defined Web Pages – Users can place the same ActiveX controls into their own

web pages to provide a customized human-machine interface (HMI) to the Control-

Wave EFM.

• Flash Configuration Utility – Parameters such as the BSAP local address, IP ad-

dress, etc. are set using the Flash Configuration Utility, accessible via Open BSI

LocalView or NetView. The ControlWave EFM ships with a standard Flash Configuration Profile (FCP) file, with default configuration parameters already set.

1.3 PHYSICAL DESCRIPTION

ControlWave EFM electronic flow meters are comprised of the following major com-

ponents:

• Enclosure with Local Communications Port (RS-232) and LCD Display (Section 1.3.1)

• CPU Module (Section 1.3.2)

• System Controller Module (Section 1.3.3)

• Backplane (Section 1.3.4)

• Base Assembly (Chassis) (Section 1.3.5)

• Up to two I/O Modules (Section 1.3.6) or two Expansion Communication Modules (see

Section 1.3.7) - (or one of either, one of each, or none)

• Internal Mounting Brackets (Section 1.3.8)

ControlWave EFMs can be factory configured with the following options:

• Multivariable Transducer (Section 1.3.9)

• Power Distribution Board (Section 1.3.10)

• Digital to Relay I/O Board (Section 1.3.11)

• 21V Power Supply Board (Section 1.3.12)

• Power System - Solar Panel (30W) & 33AH Lead-acid Battery (with Battery Charger/-

Power Manager Board (Section 1.3.13)

• RTD Probe (Section 1.3.14)

• External Radio/Modem (Section 1.3.15)

CI-ControlWave EFM Introduction / 1-7

Page 24

1.3.1 Enclosure

ControlWave EFMs are housed in a standard Hoffman® Enclosure. External dimensions

(excluding added hardware and Cover Latches) are approximately 14.56” high, by 12.97”

wide, by 8.31” deep. When present, the Multivariable Transducer adds 2.89” to the height of

the unit. The enclosure consists of two pieces, the body and the Instrument Front Cover. A

continuous gasket seals the unit when the Instrument Front Cover is closed. A hinge on the

left side (facing the front of the unit) is formed by molded channels on the Instrument Front

Cover and the body that capture a stainless steel pin. Two latches on the enclosure’s right

side secure the Instrument Front Cover when it is closed.

A weatherproof communication connector, either a 9-Pin male D-Type connector or a a

circular 3-pin connector, (the Local Port) is mounted to the bottom of the enclosure and

connected internally to RS-232 Comm. Port 1 provides connection for a local

communications device, typically a PC. Communications rate is configurable 300 to 115.2

KB (115.2 KB - default).

Enclosures are provided with either a 2-button 4 X 20 LCD display or a 4 X 20 LCD display

supported by a 25-button keypad. In normal operation, the display stays off after the unit

has been configured and placed into service. The operator may activate the display at any

time by pressing the appropriate front panel button.

1.3.2 CPU Module

The CPU Module houses the CPU Board. This multilayer board provides ControlWave

MICRO EFM CPU, I/O monitor/control, memory and communication functions. Control-

Wave MICRO EFM CPU Modules operate over an extended temperature range with longterm product reliability.

ControlWave EFM CPU Boards are based on Sharp’s LH7A400 System-on-Chip ARM

microprocessor with 32-bit ARM9TDMI RISC Core. The CPU operates at 1.8V with a

system clock speed of 33 MHz. The Microcontroller is packaged in a 256-pin Plastic Ball

Grid Array. In addition to the microprocessor and control logic, the CPU Board includes two

RS-232 and one RS-485 communication ports, 2MB of battery backed Static RAM (SRAM),

512kB Boot/Downloader FLASH, 8MB simultaneous read/write FLASH and an I/O Bus

Connector.

CPU Modules are provided backup power via a piggyback mounted Battery Backup board

equipped with a coin cell socket that accepts a 3.0V, 300mA-hr lithium battery. This 3.0V

battery provides backup power for the real-time clock and the system’s Static RAM (SRAM).

Backup power is enabled when JP1 on the Battery Backup Bd. is installed.

If the 3.3Vdc that powers the unit goes out of specification, a supervisory circuit on the

Battery Backup Board switches the battery voltage to the VBAT3.3 hardware signal (used

by the CPU’s SRAM and RTC). This supervisory circuit also generates a BATTERYGOOD

signal when the battery voltage is above 2.2V.

The system SRAM is specified to have a standby current of 20:A maximum for each part

(plus 2uA for the RTC). For a system containing 2MB of System SRAM, a worst-case

current draw of 42:A allows a battery life of approximately 7142 hours.

A supervisory circuit is used to switch to battery power when VCC falls out of specification.

For maximum shelf life, the battery may be isolated from the circuit by removing the

1-8 / Introduction CI-ControlWave EFM

Page 25

Backup Battery Jumper JP1 (on the Battery Backup Board) from position 1 to 2 and then

storing it on either pin. If the Real-time clock looses its battery backup a ControlWave

Designer system variable bit (_QUEST_DATE) is set. This bit can be used to post a

message or alarm to the PC (see the ‘Systems Variables’ section of the ControlWave

Designer Programmer’s Handbook D5125).

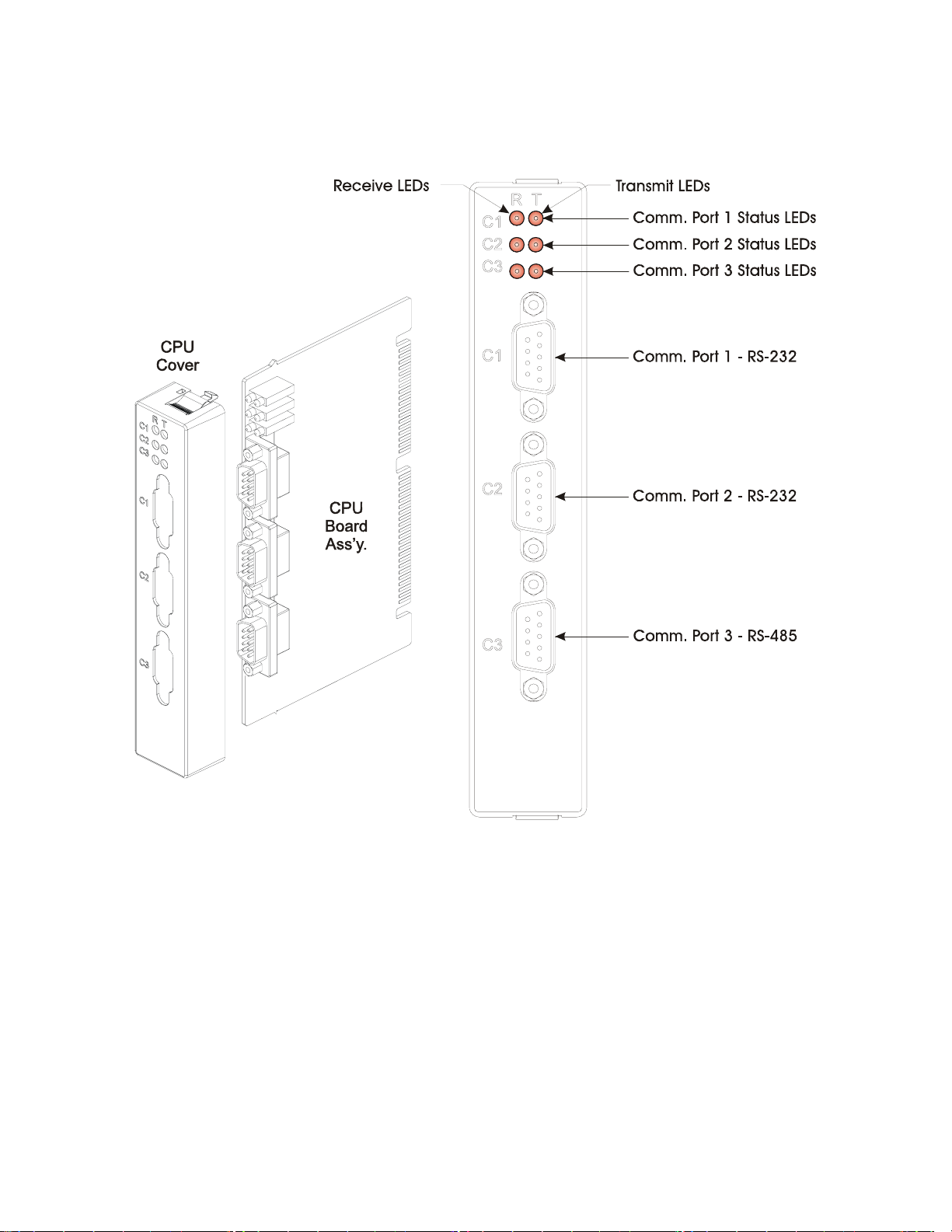

Figure 1-5 – ControlWave EFM CPU Module

Basic CPU components and features are summarized as follows:

• LH7A400 System-on-Chip 32-bit ARM9TDMI RISC Core microprocessor

• 512KB FLASH Boot/Downloader, 29LV040B, 90 nS, 8-bit access

• 2MB SRAM, 3.3V, 512K x 32, with Battery Back-up

• 8MB simultaneous read/write FLASH, TSOP sites

• Two 9 wire PC2 compatible (RS-232) serial communications ports with modem control

pins and one 5 wire RS-485 Comm. port

• I/O Bus Interface capable of driving up to 14 I/O Modules

• Spread Spectrum clock for lower EMI

• Two Status LEDs per Comm. Port

• 8-Position general-purpose switch bank plus a 4-Position recovery switch bank

• Coin cell socket accepts a 3.0V, 300mA-hr lithium battery

CI-ControlWave EFM Introduction / 1-9

Page 26

1.3.2.1 CPU Module Connectors

The CPU Modules contain up to seven connectors that function as follows (see Table 1-1):

Table 1-1 - CPU Board Connector Summary

Ref. # Pins Function Notes

P1 76-Pin Factory Debug Not user accessible

P2 36-pin Card Edge Backplane I/O Bus Intf. see Figure 2-9

P3 44-pin Card Edge Backplane SCM Intf. see Figure 2-8

J2 10-Pin PLD JTAG Header Not user accessible

J3 9-pin COM1 9-pin male D-sub (RS-232) see Figure 2-11 & Table 2-3 or 4-2

J4 9-pin COM2 9-pin male D-sub (RS-232) see Figure 2-11 & Table 2-3 or 4-2

J5 9-pin COM3 9-pin male D-sub (RS-485) see Figure 2-11 & Table 2-3 or 4-2

CPU Module Comm. Port Connectors J3, J4 and J5

The CPU Module supports up to two external 9-pin RS-232 serial communication ports

(COM1 and COM2) and an external 9-pin RS-485 serial communication port (COM3).

COM1 and COM2 and COM3 utilize standard 9-pin male D-sub connectors. RS-232 ports

are protected with LCDA12C devices to ±4KV ESD. RS-485 port COM3 is protected with

LCDA12C and LCDA05 devices to ±4KV ESD.

CPU Module I/OB Connector P2

CPU Module I/O Bus connector P2 provides a 36-pin interface between slot #2 (P3) of the

Backplane PCB and the CPU Module. Separate data, address and control buffers provide

access to the I/O bus which in turn provides up to 14 slots of memory mapped I/O Modules.

The CPU Module interface to the I/O Modules is through a set of buffers and transceivers

that are capable of driving up to fourteen I/O Modules.

CPU Module/System Controller Module Interface Connector (P3)

CPU Module/System Controller Module Interface connector (P3) provides a 44-pin interface

between slot #2 (P2) of the Backplane PCB and the CPU Module. The SCM provides:

- a wide input range Vin to 3.3V DC to DC Converter

- 1200 Millisecond good power detection

- Vin out of Spec. detection

- LED Status indication

1.3.2.2 CPU Memory

Boot/downloader FLASH

Boot/download code is contained in a single 512Kbytes uniform sector FLASH IC. This

device resides on the local bus, operates at 3.3V and is configured for 8-bit access. 4Position DIP-Switch SW1’s position 3 allows start-up menu options to be displayed or bootup from system FLASH. If SW1-3 is closed when a reset occurs, the boot-up code will cause

a recovery menu to be sent out the COM1 serial port to a terminal program running on an

external host computer. Note: Recovery Mode will also be initiated if SCM Switch SW1

positions 1 and 2 are both set OPEN (Right) or CLOSED (Left) when a reset occurs.

FLASH Memory

The base version of the CPU Module has 8Mbytes of 3.3V, simultaneous read/write (DL)

FLASH memory. Each CPU Board contains two 48-pin TSOP sites that will each accept 4

or 8 Mbytes of 3.3V, (DL) FLASH IC, for a total of 4 or 8 Mbytes of memory. FLASH

1-10 / Introduction CI-ControlWave EFM

Page 27

memory is 32-bits wide. System Firmware and the Boot Project are stored here. No

hardware write protection is provided for the FLASH array.

System Memory (SRAM)

The base version of the CPU Module has 2Mbytes of soldered-down static RAM, implemented with two 512K x 16 asynchronous SRAMs that are configured as a 512K x 32-bit

array. During power loss periods, SRAM is placed into data retention mode (powered by a

backup 3.0V lithium battery). SRAMs operate at 3.3V and are packaged in 44-pin TSOPs.

Critical system information that must be retained during power outages or when the

system has been disabled for maintenance is stored here. Data includes: Last states of all

I/O, historical data, retain variables and pending alarm messages not yet reported. The

SRAM supports 32-bit accesses and is connected to the GP bus.

1.3.2.3 CPU Module Configuration Jumpers

ControlWave EFM CPU Modules are provided with three User Configuration Jumpers

that function as follows:

• JP1 - Battery Backup Disable Jumper - On the Battery Backup Board - When JP1 is

removed, the CPU Module backup battery is disabled.

• JP4 - Status LEDs Disable Jumper - When JP4 is removed, the Status LEDs and the Idle

LED on the System Controller Module (SCM) are disabled.

• JP7 - Comm. port Status LEDs Disable Jumper - When JP7 is removed the CPU Comm.

Port Status LEDs are disabled.

1.3.2.4 CPU Module Configuration Switches

Three user configurable DIP-Switches are provided on the CPU Board; eight-bit DIP-

Switch SW2 is provided for user configuration settings while four-bit DIP-Switch SW1

provides forced recovery functions. Eight-bit DIP-Switch SW3 provides loopback,

termination control, and receiver bias settings for the RS-485 port (COM3).

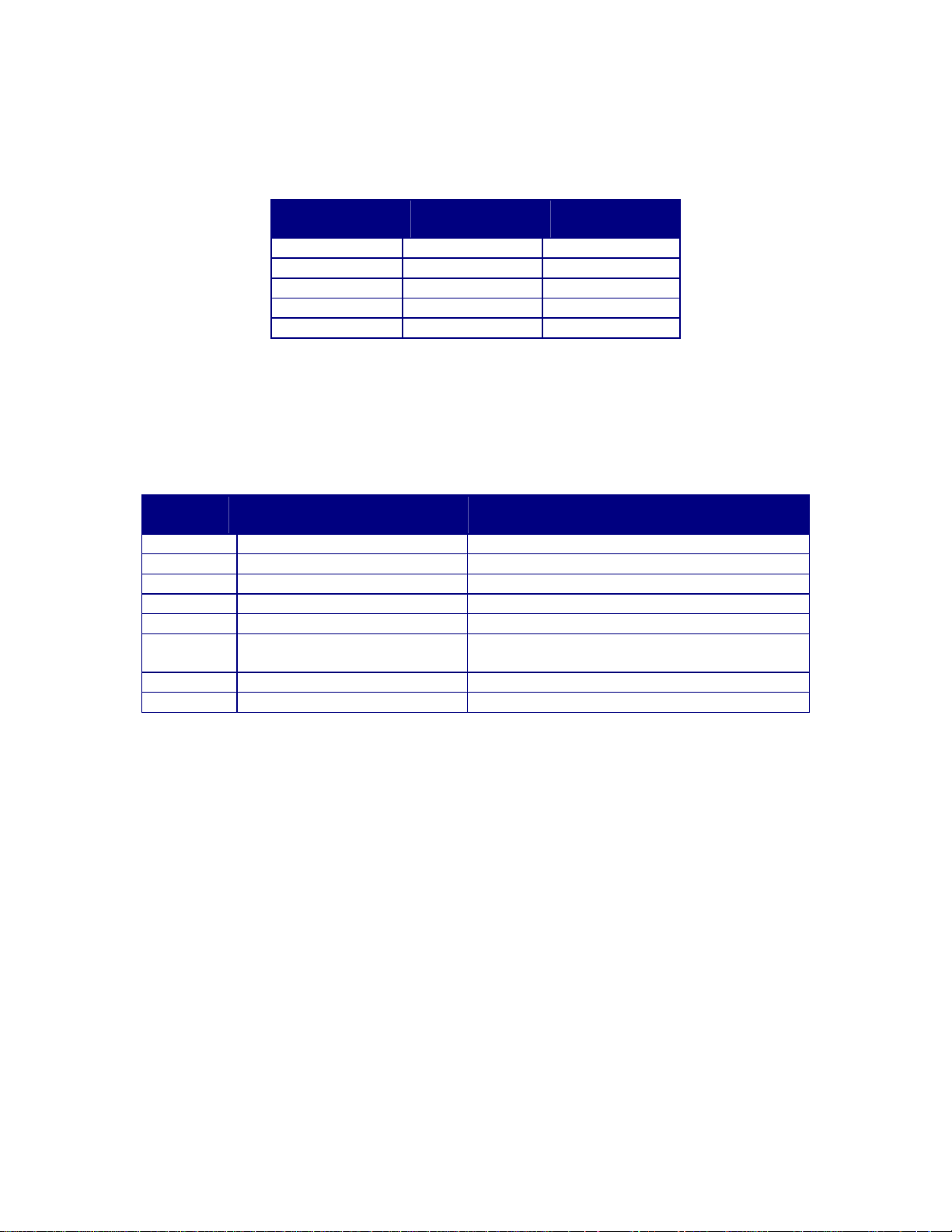

Table 1-2 - Assignment of CPU Bd. Switch SW2 - User Configurations

Switch Function Setting

SW2-1 Watchdog Enable

SW2-2

SW2-3

SW2-4

SW2-5 SRAM Control

SW2-6

SW2-8 Enable WINDIAG

Lock/Unlock

Soft Switches

Use/Ignore

Soft Switches

Core Updump

See Section 3.6

System Firmware

Load Control *

ON = Watchdog circuit is enabled

OFF = Watchdog circuit is disabled

ON = Write to Soft Switches or FLASH files

OFF = Soft Switches, configurations and FLASH files are locked

ON = Use Soft Switches (configured in FLASH)

OFF = Ignore Soft Switch Configuration and use factory defaults

ON = Core Updump Disabled

OFF = Core Updump via Mode Switch (SW1) on SCM

ON = Retain values in SRAM during restarts

OFF = Force system to reinitialize SRAM

ON = Enable remote download of System Firmware

OFF = Disable remote download of System Firmware

ON = Don’t allow WINDIAG to run test

OFF = Disable boot project and allow WINDIAG to run test

* = Boot PROM version 4.7 or higher and System PROM version 4.7 or higher

CI-ControlWave EFM Introduction / 1-11

Page 28

Table 1-3 - Assignment of CPU Bd. Switch SW1

Force Recovery Mode

Switch Function Setting

SW1-3 Force Recovery Mode

ON = Force recovery mode (via CW Console)

OFF = Recovery mode disabled

Table 1-4 - Assignment of CPU Module Switch SW3

COM3 -

Loopback & Termination Control

Switch RS-485 Function Setting

SW3-1 TX+ to RX+ Loopback ON - Only for Diagnostics

SW3-2 TX- to RX- Loopback ON - Only for Diagnostics

SW3-3 100 Ohm RX+ Termination ON - End Nodes Only

SW3-4 100 Ohm RX- Termination ON - End Nodes Only

SW3-7 RX+ Bias (End Node) ON - End Nodes Only

SW3-8 RX- Bias (End Node) ON - End Nodes Only

1.3.2.5 CPU Module LEDs

ControlWave EFM CPU Modules have six (6) LEDs on the CPU Board. Units equipped

with an optional Ethernet Port have two (2) additional LEDs (situated on the Ethernet RJ45 connector). Table 1-5 provides CPU Module LED assignments. An ON LED indicates an

associated transmit (TX) or receive (RX) activity.

Table 1-5 - Assignment of CPU Module LEDs

LED Ref. LED Function

C1 TX COM1

C1 RX COM1

C2 TX COM2

C2 RX COM2

C3 TX COM3

C3 RX COM3

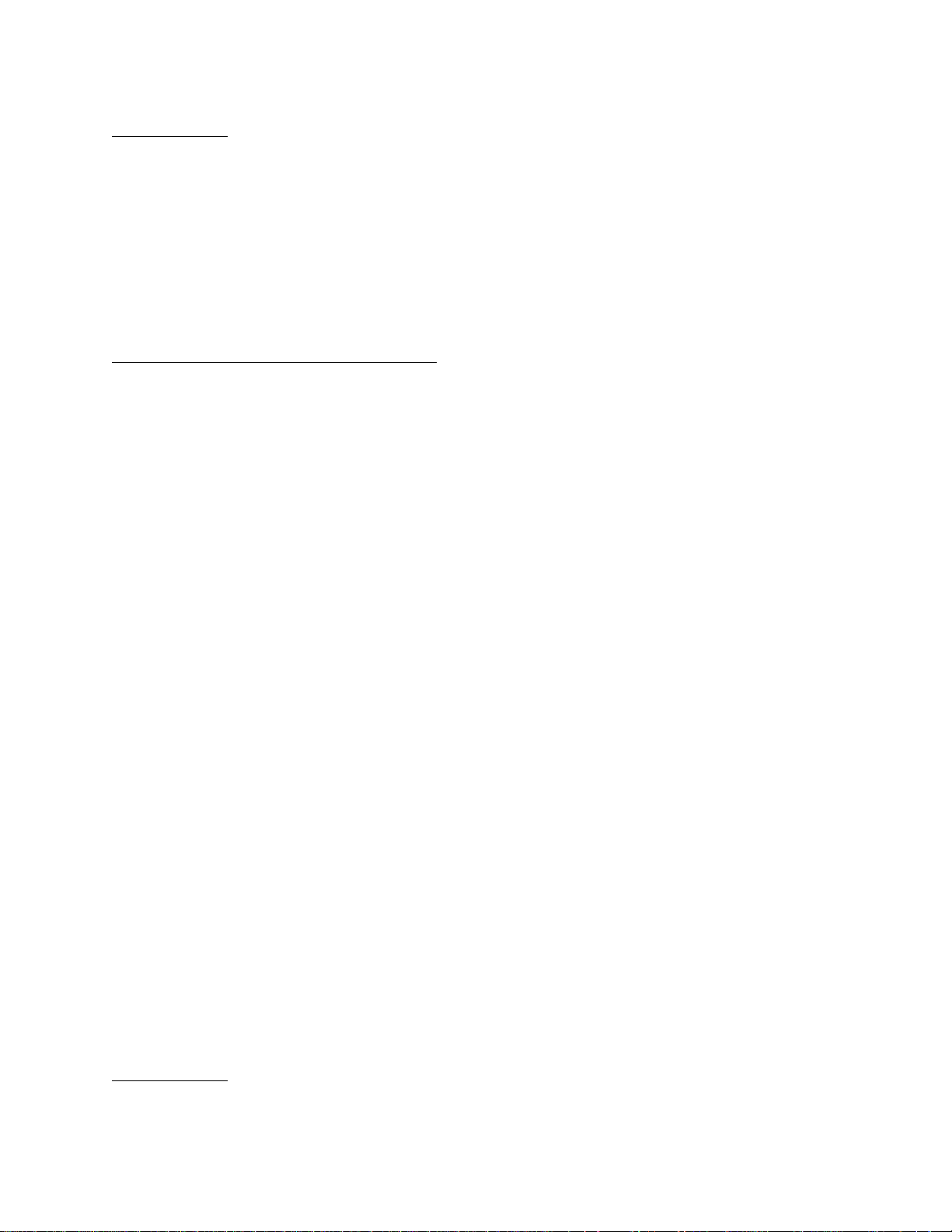

1.3.3 System Controller Module (SCM)

The System Controller Module (SCM) plugs into the system’s Backplane Board slot #1

(Connector P1 - a 44-pin female non-keyed header). The front of the SCM contains two

pluggable terminal blocks for external, input power (TB1) and RTD (TB2 - future) connections. An RJ-45 connector provides the interface to a remote Display/Keypad Assembly. Two

red LEDs, visible through the front panel, provide for the following status conditions when

lit: WD (Indicates a Watchdog condition has been detected) & IDLE (Indicates that the

CPU has free time at the end of its execution cycle. Normally, it should be ON most of the

time. When the Idle LED is OFF, it indicates that the CPU has no free time, and may be

overloaded). Six status LEDs provide run time status codes.

SCMs contain a DC to DC power supply that generates a +3.3Vdc supply for the entire unit,

i.e., the CPU and various I/O Modules that plug into the Backplane Board. Also contained

on the SCM is the sequencer circuit that monitors the external power supply as well as the

logic supplies (3.3Vdc and 1.8Vdc on the CPU Board). The sequencer circuit has a

reset/early power fail warning controller that is utilized by the CPU Board to generate a

master reset (MRESET) to the rest of the system and to generate a power fail interrupt to

the CPU.

1-12 / Introduction CI-ControlWave EFM

Page 29

The power supply operates from +4.5/+4.9 to +16Vdc or +9.6/10.3 to +16Vdc with the

y

m

nominal input supply configuration (+6V or +12V) user configured via on-board jumpers. A

supervisory circuit monitors the incoming power and the supply voltages. The isolated

supplies are shut down when the incoming voltage drops below +4.5V for a +6V system or

+9.6V, for a +12V system.

An external battery monitor is composed of an Analog to Digital Converter (ADC) and

interface circuitry.

WATCHDOG LED

(Red)

IDLE LED

(Red)

Sta us LEDs

(Red)

J2

Display Intf.

Connector

TB1

Input Power

Connector

TB2

RT D Inte rfa ce

Connector

CR27

CR26

CR25

CR24

J2

RJ- 45

JP5, JP6, JP7, JP8 & JP9

1-to-2 Installed = 12V Bulk System

2-to-3 Installed = 6V Bulk System

1

JP6

JP7

1

SW1 = Mode Switch

1A

1

JP5

JP8

1

JP9

1

2

P1

P2

MVT Interface

Connector

JP1 - Factory Configured

(Not Shown)

JP5 - Power Fail Trip Point Selection

1-to-2 Installed = 12V Bulk System

2-to-3 Installed = 6V Bulk System

JP6 - Supply Shutdown Trip Point Selection

1-to-2 Installed = 12V Bulk System

2-to-3 Installed = 6V Bulk System

(+4.5/4.9Vdc to +16.0Vdc for +6V supply)

+VIN (+9.6/10.3Vdc to +16.0Vdc for +12V supply)

TB1 - 1

-VIN (Supply Ground)

TB1 - 2

Chassis Ground (CHASSIS)

TB1 - 3

JP7 - 1.2V Reference Source Current Selection

1-to-2 Installed = 12V Bulk System

2-to-3 Installed = 6V Bulk System

JP8 - Supply Shutdown Trip Point Hysterisis

1-to-2 Installed = 12V Bulk System

2-to-3 Installed = 6V Bulk System

JP9- Power Fail Trip Point Hysterisis

1-to-2 Installed = 12V Bulk System

2-to-3 Installed = 6V Bulk S

ste

Figure 1-6 - ControlWave EFM System Controller Module

CI-ControlWave EFM Introduction / 1-13

Page 30

1.3.3.1 SCM Mode Switch

SCM Module’s Mode Switch (SW1), is a 2-position piano type DIP-Switch that is utilized for

recovery mode and core updump operations (see Sections 2.4.3 and 3.6)

1.3.3.2 SCM Board Fuse

The SCM is fused to protect the entire system. 5x20mm Slow Blow Fuse F1 is rated at 1A.

1.3.3.3 SCM Board Connectors

Connectors TB1, TB2, J1, J2 and P2 function as described below.

SCM Bd. Terminal Block Connector TB1

TB1 provides 3 input connections for bulk power:

TB1-1 = +VIN (+4.5/4.9 to +16.0V dc for +6Vdc supply)

(+9.6/10.3V to +16V dc for +12Vdc supply)

TB1-2 = -VIN (Supply Ground - PSGND)

TB1-3 = Chassis Ground - CHASSIS (

)

SCM Bd. Terminal Block Connector TB2

TB2 provides 3 connections for a 100-ohm platinum bulb (DIN 43760 curve) RTD:

TB2-1 = RTD + (Sense or Excitation)

TB2-2 = RTD + (Sense or Excitation)

TB2-3 = RTD – (Return)

SCM Bd. Connector P2

P2 is an 8-pin non-keyed male in-line connector that mates with the Multivariable

Transducers (MVT) Interface Cable’s female connector.

SCM Bd. Connector P1

P1 is a 44-pin non-keyed male card-edge connector that mates with Backplane connector P1

(slot #1) and interfaces Power, Ground, Status and Control signals to the system.

SCM Bd. Connector J2

RJ-45 Connector J2 provides an interface to a remote Display/Keypad Assembly.

1.3.3.4 SCM Jumpers

ControlWave EFM SCM Modules are provided with six User Configuration Jumpers (see

Figure 1-6 for jumper functionality).

1.3.3.5 SCM LEDs

In addition to WATCHDOG and IDLE LEDs, the SCM contains six status LEDs, which are

driven by a status register on the CPU Module. These LEDs are visible through the front

panel and provide run time status codes (see Section 2.4.2 or Section 3.3.2).

1-14 / Introduction CI-ControlWave EFM

Page 31

1.3.4 ControlWave EFM Backplanes

4-Slot or 8-Slot ControlWave EFM Backplanes provide for the electrical interconnection of

the System Controller Module (SCM), CPU Module, Expansion Communication Modules

(ECOMs) and/or I/O Modules. One or two Expansion Comm. Modules may be substituted

for I/O Modules in Backplane slots 3 & 4. Backplane module slot connections that support

Expansion Comm. Modules (slots 3 & 4) or I/O Modules (slots 3 through 8) are implemented

via 36-pin female Headers.

The main complement of signals on the Backplane, implement an I/O bus for data transfer

between the CPU and I/O Modules. Note: I/O Modules are Non Interrupt Capable.

+3.3Vdc and GND from the SCM are connected to the CPU. All I/O Module slot positions

receive +3.3Vdc and GND. Additionally, the SCM supplies switched field power

(FIELDVOUT) to all I/O Module slots. The power supply sequencer circuit (within the

SCM) provides POWERGOOD, POWERFAIL, VIN100M and PFDLYCLK signals to the

CPU thus providing properly timed early warning of low input or supply voltages followed

by a CPU reset to support the WARM START CPU function.

Figure 1-7 - Backplane Board Diagram

1.3.5 ControlWave EFM Base Assembly Chassis

A Gold Irridite Aluminum Chassis supports the ControlWave EFM Backplane PCBs and

the modules that comprise the system (see Figs. 1-3 & 4-3). Dimensions are provided in

Section 4 of this manual (see Figures 4-3 and 4-4 for 4-Slot and 8-Slot Chassis,

respectively).

CI-ControlWave EFM Introduction / 1-15

Page 32

The unit’s Base Assembly Chassis is mounted to the Fabrication Panel inside the Hoffman

Enclosure. ControlWave EFM Chassis’ contain a Ground Lug that accommodates up to a

#4 AWG Ground Wire. Grounding the unit is accomplished by connecting a ground wire

between the Ground Lug and a known good Earth Ground.

1.3.6 ControlWave EFM I/O Modules

Five unique I/O Modules are available factory configured for either local or remote field

device wiring termination. I/O Modules provide Configuration Jumpers that accommodate

individual field I/O user configuration. Terminations are pluggable and accept a maximum

wire size of 14 gauge. All I/O have surge protection that meets C37.90-1978 and IEC 801-5

specifications. Each I/O Module is connected to the ControlWave EFM Back-plane via a

36-pin male card-edge connector. With the exception of the Mixed Input/Output Module, all

I/O Modules are provided with two 10-point Terminal Block Assemblies (for local

termination) or two 14-pin Mass Termination Headers (for remote termination). Mixed I/O

Modules are provided with two 10-point Terminal Block Assemblies (for local termination).

A brief overview of each I/O Module type is provided below. Specifications are covered in

Section 4.4.

Figure 1-8 - Two ControlWave EFM I/O Modules (with Bezel)

1-16 / Introduction CI-ControlWave EFM

Page 33

1.3.6.1 Non-isolated Analog I/O & Analog Input Modules (also see Section 2.3.4.5)

ControlWave EFM AI/O Modules provide 6 Analog Inputs and optionally 2 Analog

Outputs. All Analog Inputs are externally sourced, single-ended and individually Jumper

configurable for either 4-20mA or 1-5Vdc. Analog Outputs are externally sourced and are

individually Jumper configurable for 4-20 mA or 1-5 Vdc. 30Vdc Transorbs provide surge

suppression between each signal and ground. Analog Input Modules are identical to AI/O

Modules but have a depopulated AO section.

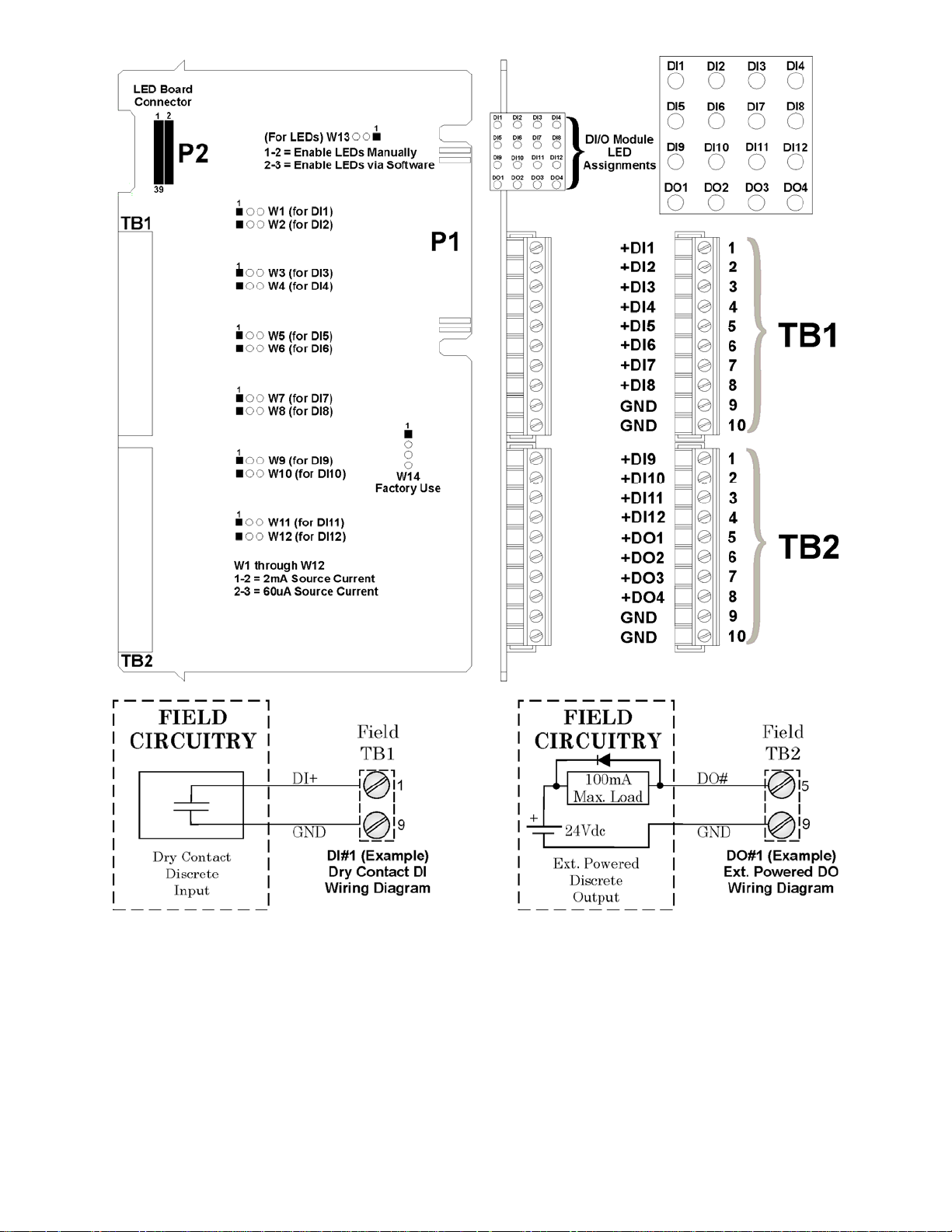

1.3.6.2 Non-isolated Digital Input/Output Module (also see Section 2.3.4.4)

ControlWave EFM DI/O Modules provide 12 Digital Inputs and 4 Digital Outputs. All

Digital Inputs support dry contact inputs internally sourced from the 3.3 Vdc supply and a

jumper selectable input current range of 60 uA (for low power applications) or 2 mA (for inplant noise immunity). 15 millisecond input filtering protects against contact bounce.

Digital Outputs have a 30 Vdc operating range and are driven by Open Drain FETs that

provide 100 mA (max) at 30Vdc. DI/O Modules support optional Status Indication with an

LED per I/O point. 31Vdc Transorbs provide surge suppression between each signal and

ground.

1.3.6.3 Non-isolated High Speed Counter Input Module (also see Section 2.3.4.6)

High Speed Counter Input (HSCI) Modules provide a total of 4 internally sourced inputs

that provide 2mA or 200uA (low power) input signals. Signal conditioning is provided by a

debounce circuit for a relay contact input source, followed by a one-shot pulse circuit that

generates a 65usec ±10% pulse. The signal conditioning circuitry also provides 20 microsecond filtering. All Input circuits have surge suppression. HSC inputs can be individually

configured for dry contact or externally generated signal inputs. HSCI Modules are

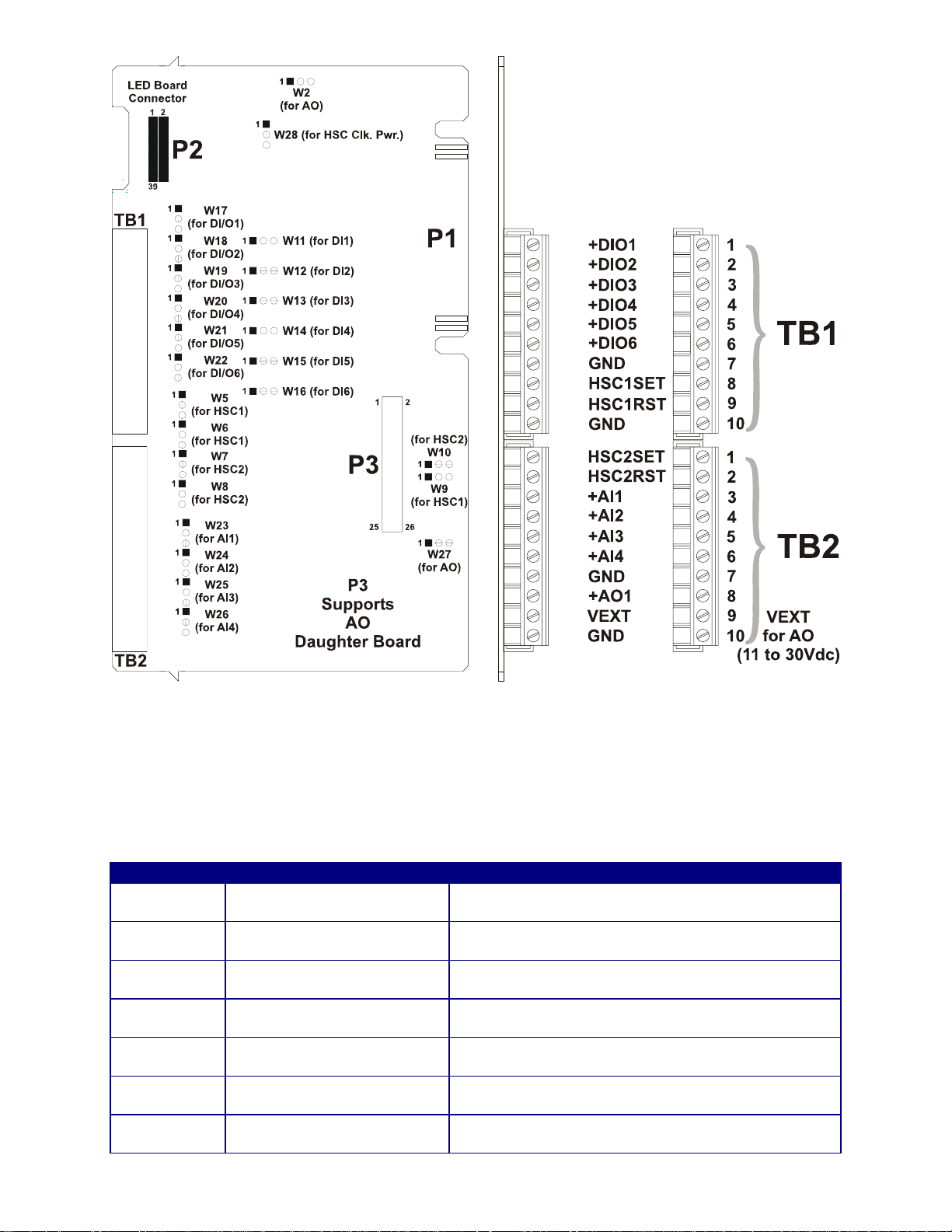

provided with thirteen (13) user Configuration Jumpers that accommodate LED