Page 1

CFA-3000

Ion Selective Electrode (ISE) Analyzer

Instruction Manual

PN 51CFA3000ISE/rev.F

December 2013

Page 2

ESSENTIAL INSTRUCTIONS

READ THIS PAGE BEFORE PROCEEDING!

Your purchase from Rosemount Analytical, Inc. has

resulted in one of the finest instruments available for

your particular application. These instruments have

been designed, and tested to meet many national

and international standards. Experience indicates

that its performance is directly related to the quality

of the installation and knowledge of the user in oper

ating and maintaining the instrument. To ensure their

continued operation to the design specifications, per

sonnel should read this manual thoroughly before

proceeding with installation, commissioning, opera

tion, and maintenance of this instrument. If this

equipment is used in a manner not specified by the

manufacturer, the protection provided by it against

hazards may be impaired.

• Failure to follow the proper instructions may cause

any one of the following situations to occur: Loss

of life; personal injury; property damage; damage

to this instrument; and warranty invalidation.

• Ensure that you have received the correct model

and options from your purchase order. Verify that

this manual covers your model and options. If not,

call 18008548257 or 9497578500 to request

correct manual.

• For clarification of instructions, contact your

Rosemount representative.

• Follow all warnings, cautions, and instructions

marked on and supplied with the product.

• Use only qualified personnel to install, operate,

update, program and maintain the product.

• Educate your personnel in the proper installation,

operation, and maintenance of the product.

• Install equipment as specified in the Installation

section of this manual. Follow appropriate local

and national codes. Only connect the product to

electrical and pressure sources specified in this

manual.

• Use only factory documented components for

repair. Tampering or unauthorized substitution of

parts and procedures can affect the performance

and cause unsafe operation of your process.

• All equipment doors must be closed and protective

covers must be in place unless qualified personnel

are performing maintenance.

• If this equipment is used in a manner not specified

by the manufacturer, the protection provided by it

against hazards may be impaired.

WARNINGS

RISK OF ELECTRICAL SHOCK

Equipment protected throughout by double insulation.

• Installation of cable connections and servicing of this

product require access to shock hazard voltage levels.

• Main power and relay contacts wired to separate power

source must be disconnected before servicing.

• Do not operate or energize instrument with case open!

• Signal wiring connected in this box must be rated at least

240 V.

• Nonmetallic cable strain reliefs do not provide grounding

between conduit connections! Use grounding type bush

ings and jumper wires.

• Unused cable conduit entries must be securely sealed by

nonflammable closures to provide enclosure integrity in

compliance with personal safety and environmental protec

tion requirements. Unused conduit openings must be

sealed with NEMA 4X or IP65 conduit plugs to maintain

the ingress protection rating (NEMA 4X).

• Electrical installation must be in accordance with the

National Electrical Code (ANSI/NFPA70) and/or any

other applicable national or local codes.

• Operate only with front and rear panels fastened and in

place over terminal area.

• Safety and performance require that this instrument be

connected and properly grounded through a threewire

power source.

• Proper relay use and configuration is the responsibility of

the user.

CAUTION

This product generates, uses, and can radiate radio frequency

energy and thus can cause radio communication interference.

Improper installation, or operation, may increase such interfer

ence. As temporarily permitted by regulation, this unit has not

been tested for compliance within the limits of Class A comput

ing devices, pursuant to Subpart J of Part 15, of FCC Rules,

which are designed to provide reasonable protection against

such interference. Operation of this equipment in a residential

area may cause interference, in which case the user at his

own expense, will be required to take whatever measures may

be required to correct the interference.

WARNING

This product is not intended for use in the light

industrial, residential or commercial environments

per the instrument’s certification to EN500812.

Emerson Process Management

2400 Barranca Parkway

Irvine, CA 92606 USA

Tel: (949) 7578500

Fax: (949) 4747250

http://www.rosemountanalytical.com

© Rosemount Analytical Inc. 2012

Page 3

CFA3000 ISE Analyzer TABLE OF CONTENTS

Instruction Manual

1.0 INTRODUCTION...........................................................................................................................1

1.1 Thoroughly Read This Manual......................................................................................................2

1.2 Analyzer Benefits...........................................................................................................................2

1.3 WARNING Electrical Shock Hazard..........................................................................................3

2.0 INSTALLING THE ANALYZER....................................................................................................4

2.1 Unpack Parts .................................................................................................................................4

2.2 Mount Main Cabinet ......................................................................................................................6

2.3 Mount Reagent Cabinet ................................................................................................................6

2.4 Install Waste Tube .........................................................................................................................8

2.5 Mount Overflow Sampling Assembly............................................................................................8

2.6 Prepare Electrical Connections...................................................................................................10

2.7 Install Valve Pump Assembly ......................................................................................................11

2.8 Prepare Reagent Containers ......................................................................................................13

3.0 OPERATING THE ANALYZER ..................................................................................................14

3.1 Operational Overview..................................................................................................................14

3.2 Check Sample Stream ................................................................................................................15

3.2.1 Check Fluidics .............................................................................................................................15

3.2.2 Check Reagents..........................................................................................................................15

3.2.3 Turn On Power ............................................................................................................................15

3.2.4 Test Valve Pump Operation ........................................................................................................16

3.2.5 Set Up Stream Parameters ........................................................................................................20

3.3 Set Reagent Supply Time ..........................................................................................................22

3.4 Set Scaling Outputs.....................................................................................................................22

3.4.1 Record mV ................................................................................................................................23

3.4.2 Initiate Auto Calibration ..............................................................................................................23

3.5 Process a Grab Sample .............................................................................................................24

3.6 Manually Sample a Particular Stream .......................................................................................25

3.7 Shutdown ................................................................................................................................25

3.8 Quick Start ................................................................................................................................26

4.0 MAINTAINING THE ANALYZER ...............................................................................................27

4.1 Analyzer Equipment ....................................................................................................................27

5.0 TROUBLESHOOTING PROCEDURES....................................................................................28

5.1 Troubleshooting Chart.................................................................................................................28

5.2 Test Functions .............................................................................................................................29

6.0 REPAIR PROCEDURES ............................................................................................................31

6.1 Replace Valve Pump Assembly..................................................................................................31

6.2 Replace Circuit Boards ...............................................................................................................32

6.3 Replace Fuses.............................................................................................................................33

6.4 Replace ISE Components...........................................................................................................33

7.0 INSTRUMENT DESCRIPTION ..................................................................................................34

7.1 Analyzer Front View ....................................................................................................................34

7.1.1 Main Cabinet ...............................................................................................................................34

7.1.2 Reagent Cabinet .........................................................................................................................34

7.2 Keypad Panel ..............................................................................................................................36

7.3 Card Cage 41 ............................................................................................................................37

7.3.1 Card Cage and Door ...................................................................................................................37

7.3.2 CPU Board 41 ............................................................................................................................37

7.3.3 Analog Board...............................................................................................................................37

7.3.4 Valve Board 41 ............................................................................................................................37

7.3.5 Power Supply Board ...................................................................................................................37

i

CFA3000 ISE Analyzer

TABLE OF CONTENTS

Page 4

ii

CFA3000 ISE Analyzer TABLE OF CONTENTS

Instruction Manual

7.3.6 Analog Board DIP Switches........................................................................................................39

7.4 Rear of Main Cabinet ..................................................................................................................40

7.5 Valve Pump Assembly.................................................................................................................41

7.6 Interface Ports .............................................................................................................................42

7.7 Relay Output Option....................................................................................................................42

7.8 MultiOutput Board ......................................................................................................................42

7.9 Overflow Sampling Assemblies ..................................................................................................43

8.0 ADDITIONAL FEATURES .........................................................................................................45

8.1 Chart Recorders and Data Loggers............................................................................................45

8.2 Computer Interface......................................................................................................................48

8.2.1 Data Output Format.....................................................................................................................48

8.2.2 Data Configuration.......................................................................................................................48

8.2.3 RS232C Function Commands...................................................................................................48

8.2.4 Initiating RS232C Communications to Computer .....................................................................49

8.2.5 Printer Interface ...........................................................................................................................51

8.2.6 Set Printer Internal Clock ............................................................................................................51

Appendix A. CHEMISTRIES..................................................................................................................52

Appendix B. SPECIFICATIONS ........................................................................................................5354

Appendix C. POWER INTERCONNECT DESCRIPTION .....................................................................55

Appendix D. BYPASS FOR CALIBRATION..........................................................................................56

Appendix E. KEYPAD HELP SHEETS .................................................................................................57

ORDERING INFORMATION ....................................................................................................................63

WARRANTY ................................................................................................................................64

9.0 RETURN OF MATERIAL............................................................................................................65

TABLE OF CONTENTS (CON’T)

Page 5

iii

TABLE OF CONTENTS (CON’T)

CFA3000 ISE Analyzer TABLE OF CONTENTS

Instruction Manual

LIST OF FIGURES

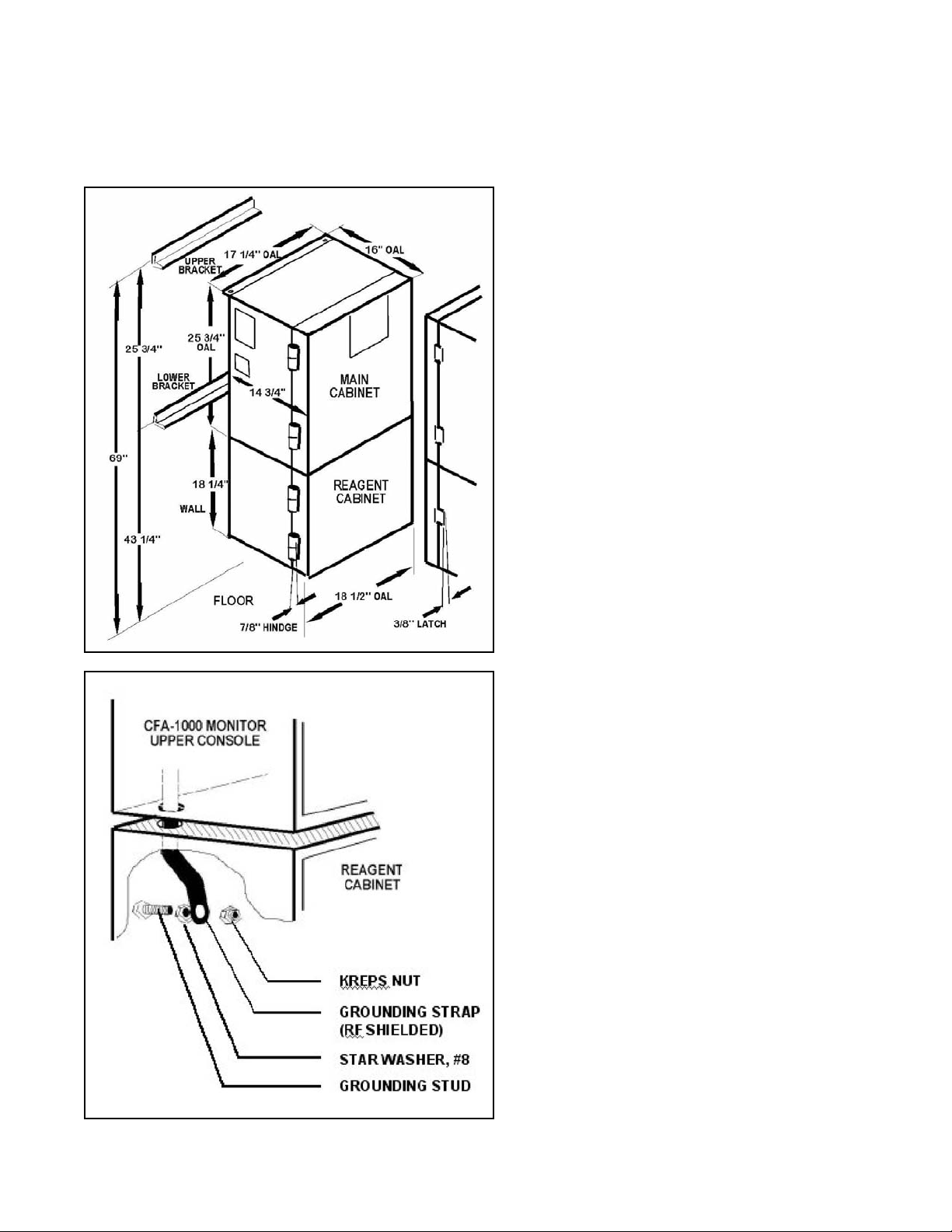

Figure 21 Opened Assembled Cabinet....................................................................................5

Figure 22 Mounting Main and Reagent Cabinets ....................................................................7

Figure 23 Attaching Grounding Strap.......................................................................................7

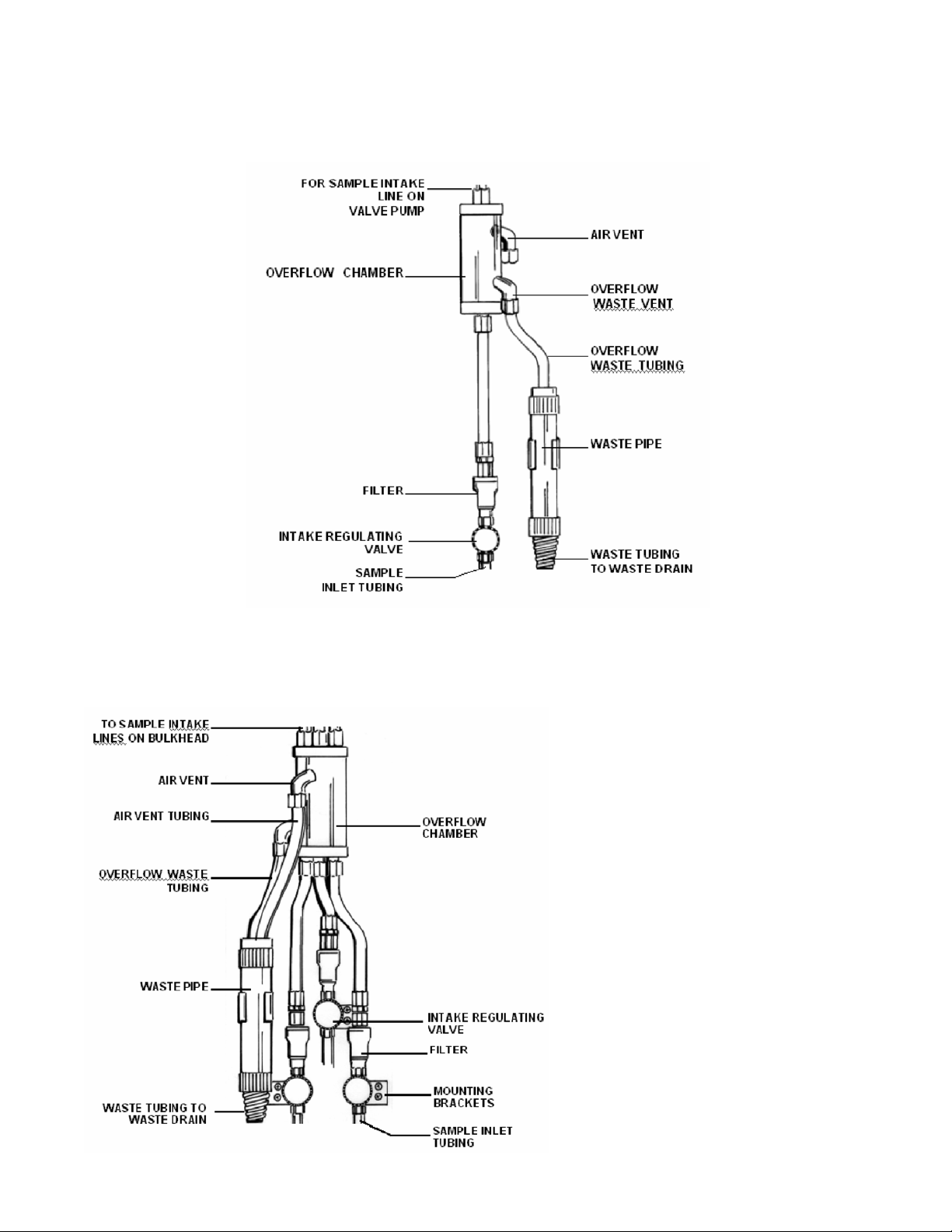

Figure 24a Singlestream Overflow Sampling Assembly...........................................................9

Figure 24b Multistream Overflow Sampling Assembly.............................................................9

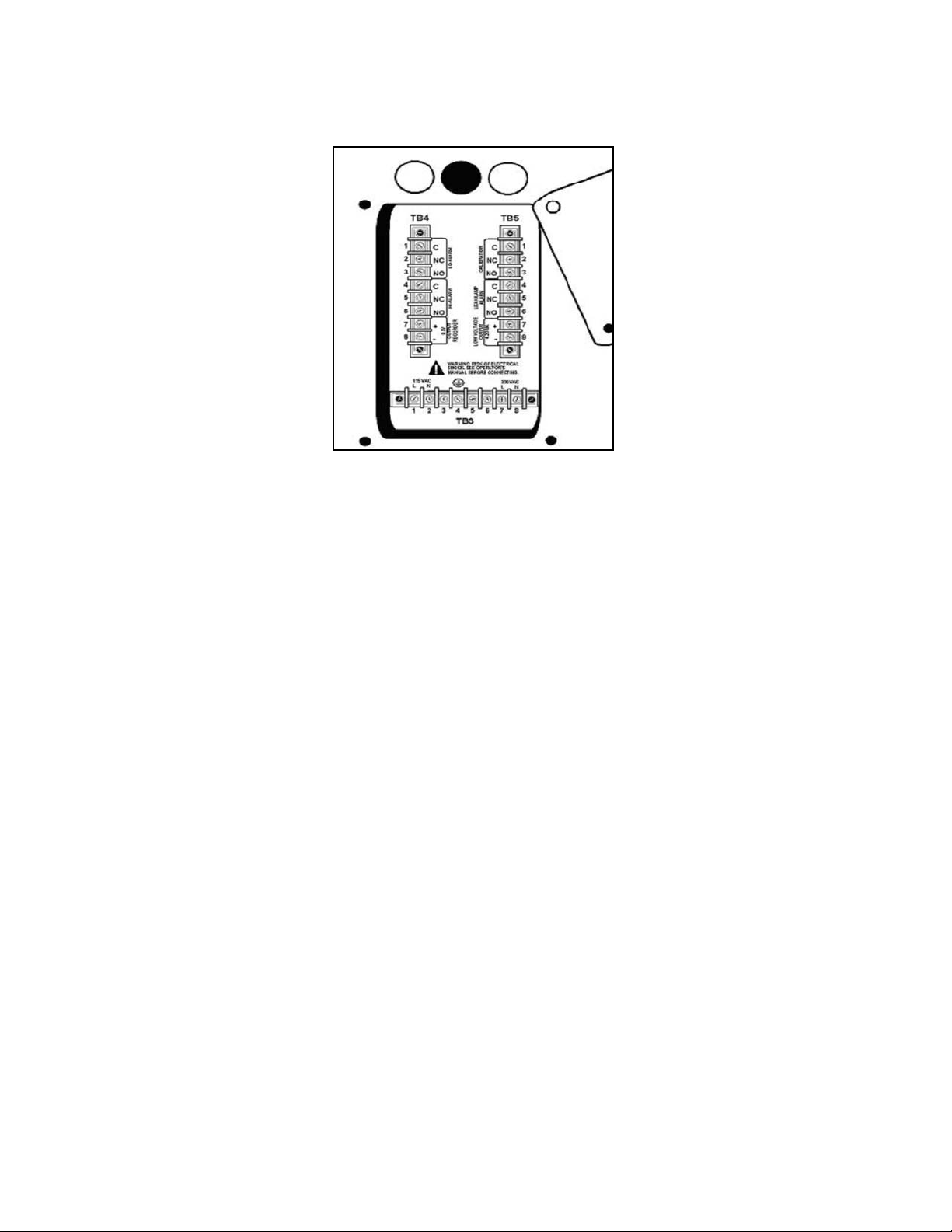

Figure 25 Input/Output Panel..................................................................................................11

Figure 26 Valve Pump Assembly............................................................................................12

Figure 27 Pump Connectors ..................................................................................................12

Figure 28 Sample Bottle Placement in Cabinet (for all methods; colors refer to

reagent straw colors)..............................................................................................13

Figure 31 Simple Block Diagram............................................................................................14

Figure 32 Numbered Positions on a SingleStream Keypad.................................................17

Figure 33 Valve Pump LED Designations..............................................................................19

Figure 34 Logic Flow for Singlestream Parameter Definition...............................................20

Figure 35 Logic Flow for Multistream Parameter Definition .................................................21

Figure 61 Remove Valve Pump Assembly.............................................................................31

Figure 62 Card Cage ..............................................................................................................32

Figure 63 ISE Reaction Cell Assembly, Electrodes ...............................................................33

Figure 71 Analyzer Front View ...............................................................................................35

Figure 72 Card Cage and Boards ..........................................................................................38

Figure 73 Analog Board DIP Switches (with #3 set in OFF position for multi..........................

stream analyzer)....................................................................................................39

Figure 74 Electrical Wiring and Components in Rear Cabinet..............................................40

Figure 75 Valve Pump Assembly............................................................................................41

Figure 76 Interface Ports ........................................................................................................42

Figure 77 "D" Connector for Relay Output.............................................................................42

Figure 78 SingleStream Overflow Sampling Assembly ........................................................43

Figure 79 Multistream Overflow Sampling Assembly (threestream option)........................44

Figure 81 Input/Output Panel .................................................................................................45

Figure 82 Typical Trace Recording with Calibration of Single Stream System.....................46

Figure 83 Typical Stream Trace Recording with Calibration of Multistream

System....................................................................................................................47

Figure 84 Numbered Positions on a SingleStream Keypad................................................49

Figure D1 Calibration Bypass Wiring......................................................................................56

Figure E1 Keypad Panel for Single Stream Option................................................................57

Figure E2 Number Positions on a SingleStream Keypad....................................................57

Figure E3 Keypad Panel for Multistream Option...................................................................60

Page 6

iv

CFA3000 ISE Analyzer TABLE OF CONTENTS

Instruction Manual

TABLE OF CONTENTS (CON’T)

LIST OF TABLES

Table 51 Troubleshooting Chart.....................................................................................28

Table 52 Test Functions .................................................................................................29

Table 71 Main Cabinet Parts..........................................................................................34

Table 72 Reagent Cabinet Parts ....................................................................................34

Table 73 Buttons/LED Functions ...................................................................................36

Table 74 Card Cage Parts .............................................................................................37

Table 75 CPU Board Components.................................................................................37

Table 76 Analog Board Components .............................................................................37

Table 77 Valve Board Components ...............................................................................37

Table 78 Power Supply Board Components ..................................................................37

Table 79 Analog Board DIP Switch Positions ................................................................39

Table 710 Back Cabinet Parts .........................................................................................40

Table 711 Valve Pump Parts............................................................................................41

Table 712 Interface Ports.................................................................................................42

Table 713 Relay Output Option Pin Assignments ............................................................42

Table 714 Multioutput Pin Assignments on “D” Connector .............................................42

Table 715 Overflow Sampling Assembly Parts ................................................................43

Table 81 Stream Identification Blips (SIBs)....................................................................45

Table 82 Normal Data Output Format............................................................................48

Table 83 Data Configuration ..........................................................................................48

Table 84 RS232C Pin Configuration .............................................................................48

Table 85 RS232C Commands ......................................................................................50

Table 86 Printer Port Pin Configuration .........................................................................51

Table E1 Singlestream Keypad Help Sheet.............................................................5859

Table E2 Multistream Keypad Help Sheet ...............................................................6062

Table E3 Replacement Parts .........………..……………………………………….…….63

Page 7

1

CFA3000 MANUAL SECTION 1

INTRODUCTION

SECTION 1

INTRODUCTION

The Rosemount Analytical CFA3000 Series analyzers are designed for minimum maintenance and maximum

reliability. The touch of a button starts the microprocessorcontrolled program, calibrates the analyzer, keeps it

calibrated, and reports results directly unattended for months at a time. Maintenance is simplified by a modular

design with special fittings, labeled tubing, and colorcoded components.

The CFA3000 Series includes analyzers for parameters commonly measured using Ion Selective Electrode (ISE)

technology including sodium, fluoride and chloride. Sample concentration is clearly indicated on the digital display

panel, and output signals are provided to drive recorders, alarms, or other external devices such as printers or

computers. The specific chemistry of your individual analyzer is discussed in Appendix A, Chemistries, or in an

accompanying method sheet..

Your purchase from Rosemount Analytical provides you with one of the finest instruments available for your

particular application. These instruments have been designed and tested to meet many national and international

standards. Experience indicates that its performance is directly related to the quality of the installation and knowl

edge of the user in operating and maintaining the instrument.

Page 8

2

CFA3000 ISE Analyzer

Instruction Manual

1.1 Thoroughly Read This Manual

This instruction manual describes installation, operation, and maintenance of the CFA3000 ISE Analyzer. To

ensure continued operation to the design specifications, personnel should read this manual thoroughly before

proceeding with installation, operation, or maintenance of the analyzer.

• Ensure that you have received the correct model and options from your purchase order. Verify that this

manual covers your model and options. If not, call: 18008548257 or 9497578500 to request the correct

manual.

• For any inquiries about your analyzer, contact your Rosemount Analytical representative.

• Failure to follow the documented instructions may cause any one of the following situations to occur: damage

to this instrument and warranty invalidation.

• Follow all warnings, cautions, and instructions supplied with the product.

• Only qualified personnel should install, operate, update, program, and maintain the product.

• All personnel must learn proper installation, operation, and maintenance of the product.

• Install, operate, and maintain equipment exactly as specified in this manual.

• Follow appropriate local and national codes.

• Only connect the analyzer to electrical sources specified in this manual.

• Use only components supplied by Rosemount Analytical or recommended by them for replacement.

Tampering or unauthorized substitution of parts and procedures may affect the performance of the analyzer

as well as void the warranty.

• All protective covers must be in place and cabinet panels must be closed at all times after installation or

maintenance.

1.2 Analyzer Benefits

Rosemount Analytical listened to you and decided to move away from a peristaltic pump assembly requiring

monthly replacement of the pump tubing. The new pump assembly has a vacuum/pressure valve system which

eliminates pump tubing and used significantly less reagent. Since the new valve pump swiftly moves fluids through

the analyzer, the potential for clogging within any internal component is reduced. Significantly. As a result, mainte

nance is required less frequently and procedures such as cleaning flow cells and the mixing system are no longer

required.

The upgraded software now identifies a fixed standard that allows one to change the range of the 05 V and the

420 mA output signals to your requirements.

Page 9

3

CFA3000 ISE Analyzer

Instruction Manual

1.3 WARNING – Electrical Shock Hazard

Installation of cable connections and servicing of this product require access to shock hazard voltage levels.

Main power and relay contacts wired to separate power sources must be disconnected before servicing.

Nonmetallic cable strain relief does not provide grounding between conduit connections! Use grounding

type bushings and jumper wires.

Electrical installation must be in accordance with the National Electrical Code (ANSI/NFPA 70) and/or any

other applicable national or local codes.

Operate only with:

1. Main console rear cover fastened.

2. Left side power terminal cover closed.

3. Keypad assembly latched closed.

Safety and performance require that this instrument be connected and properly grounded through a three

wire power source.

Proper configuration and use is the responsibility of the user.

Mark

ID Description

EN 610101 Safety of electrical equipment

EN 55011 Limits of RF equipment

EN 500821:92

Generic immunity from electrostatic

discharge, RF & Fast

Transient/Burst Immunity

EtL

9700516

ETL LISTED CONFORMS TO UL

STD. 31011

EtL

ETL LISTED CERTIFIED

TOCAN/CSA C22.2 No. 1010.192

Page 10

4

CFA3000 ISE Analyzer

Instruction Manual

2.0 INSTALLING THE ANALYZER

2.1 UNPACK PARTS

When you receive your new CFA3000 analyzer, carefully unpack the items in the following list.

√ Main cabinet

√ Reagent cabinet

√ Mounting brackets

√ Overflow sampler assembly

√ Waste tube assembly

√ Accessories pack

√ Startup reagents

√ Valve pump assembly (integrated housing includes pump, labeled tubes with straws)

If any of the items are missing or damaged, contact Rosemount Analytical at: our:

Tollfree number: (800) 8548257

Direct number: (949) 7578500

Fax: (949) 8639159

Inspect each piece to confirm that there is no damage or loose parts. If anything is missing or appears broken or

damaged, contact Rosemount Analytical at the tollfree phone number above.

SECTION 2

INSTALLING THE ANALYZER

Page 11

5

CFA3000 ISE Analyzer

Instruction Manual

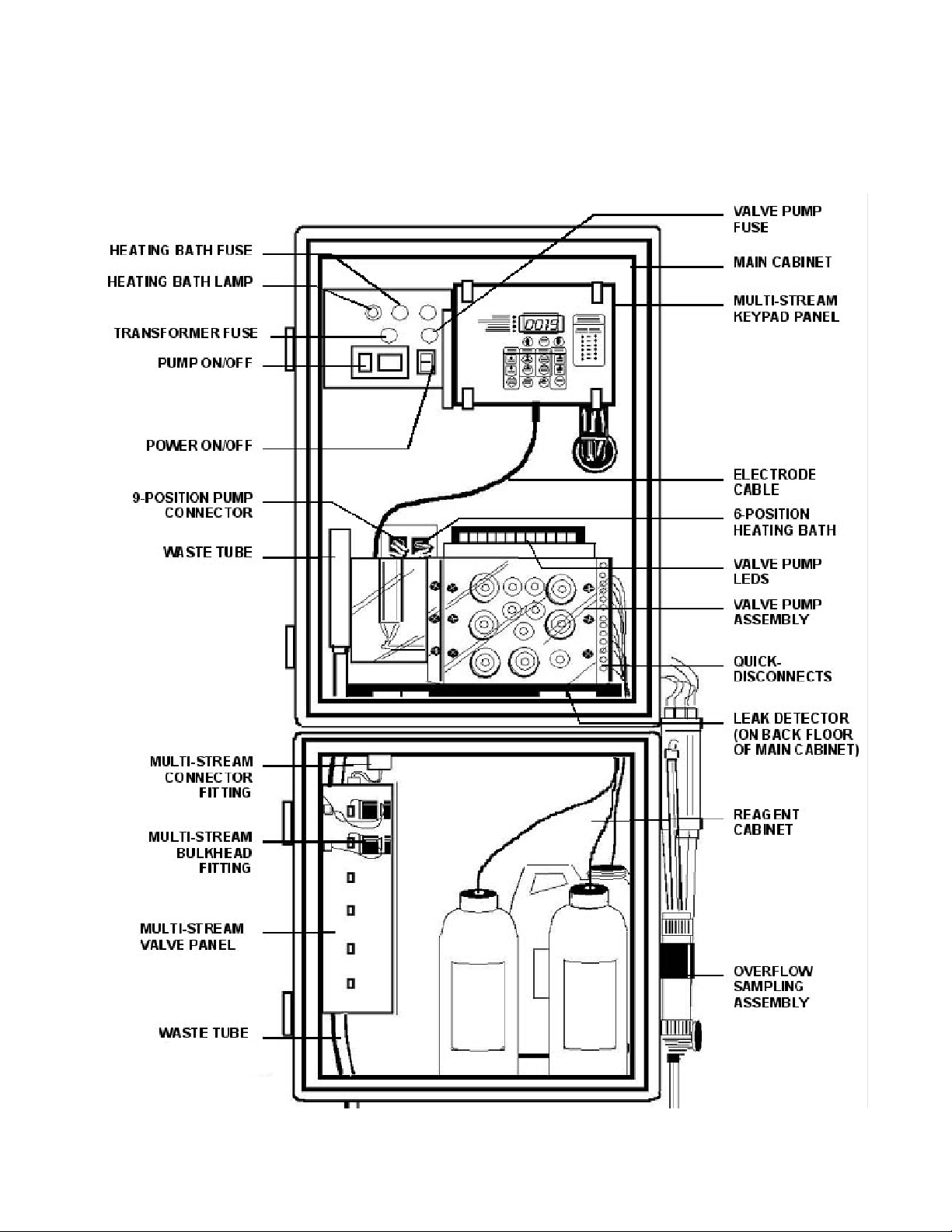

After analyzer has been unpacked and all parts accounted for, install as described in following sections. Refer to

Figure 21 to view a completely installed analyzer.

Figure 21. Opened Assembled Cabinet

Page 12

To mount main cabinet, proceed as follows (see Figure 22):

1. Securely attach supplied "L" brackets to wall using suitable hardware. Brackets must be anchored properly

to support 250 pounds (113.6 kg).

2. Attach main cabinet to "L" brackets using supplied four bolts, split ring washers, and hex nuts.

2.3 Mount Reagent Cabinet

To mount reagent cabinet, proceed as follows:

1. Loosen the four bolts in bottom of main cabinet.

2. Lift reagent cabinet and attach to main cabinet by placing heads of bolts into keyhole slots in top of

reagent cabinet.

3. Slide reagent cabinet back.

4. Feed grounding strap on bottom of main cabinet through notched hole in left rear corner and attach it to

stud on back of reagent cabinet (see Figure 23).

5. Tighten screws to attach reagent cabinet to main cabinet.

6. For multistream units, plug valve bank cable into positive fit receptacle at left side of cabinet (refer to

Figure 71, “Multistream Valve Panel Connector”).

6

CFA3000 ISE Analyzer

Instruction Manual

2.2 Mount Main Cabinet

General Recommendations

This cabinet is not for outdoor installation.

Environmental conditions of enclosed facility:

• Temperature:

min. 50°F to max. 113°F

(min 10°C – max. 45°C)

±10° within regulated range.

• Humidity: noncondensing

Mount cabinet on a wall or other suitable vertical surface, at least 42” (107 cm) wide and

431/2” (111 cm) off the floor.

Mounting surface must be able to support 250 pounds (113.6 kg).

Allow 11/2 feet (.5 m) of clearance at left side of analyzer for access to input/output panel,

and allow for swing out for rear access.

Allow 12” (.3 m) at right side for access to overflow tube assembly (if single stream).

Mount cabinet level, or with a slight backward tilt for proper leak detector operation.

Page 13

7

CFA3000 ISE Analyzer

Instruction Manual

Figure 22. Mounting Main and

Reagent Cabinets

Figure 23. Attaching

Grounding Strap

Page 14

8

CFA3000 ISE Analyzer

Instruction Manual

2.4 Install Waste Tube

To install waste tube, proceed as follows (refer to Figure 21):

1. Guide waste tube through main cabinet into reagent cabinet and out through bottom of reagent cabinet.

2. Secure plastic waste tube in clamp in lower right side of main cabinet.

3. Insert Colorimeter drain tube into waste tube.

2.5 Mount Overflow Sampling Assembly

To mount overflow sampling assembly proceed as follows (for sample configurations, see Figures 24a and 24b):

1. Mount overflow sampler assembly on outer, right side of reagent cabinet using the provided four machine

screws. For multistream units, mount overflow assembly on left side of cabinet. (If using IF100 InLine

Filter, refer to instruction sheet accompanying filter for complete installation instructions.)

2. Place ends of air vent tubing and overflow waste tubing into waste pipe.

3. Connect waste pipe to drain.

4. Supply sample stream to regulating or intake valve with 1/4” tubing (plastic or steel) as follows: Insert

tubing into tube fitting. Make sure tubing rests firmly on shoulder of fitting and nut is fingertight. Mark

nut at 6 o’clock position. While holding fitting body steady with a wrench, tighten nut 11/4 turns (go to 9

o’clock position).

5. For multistream assembly, connect sample intake line to bulkhead fitting.

6. For singlestream assembly, attach sample intake line to valve pump.

7. Make sure that sample liquid overflows into overflow chamber.

The Sample intake tube should extend into

The overflow tube approximately 1½” – 2”

3.81 –5.08 cm).

Page 15

9

CFA3000 ISE Analyzer

Instruction Manual

Figure 24b. Multi

stream Overflow

Sampling Assembly,

threestream option)

Figure 24a. Singlestream Overflow Sampling Assembly

Page 16

10

CFA3000 ISE Analyzer

Instruction Manual

Electrical connections are made to and from the cabinet at the input/output panel, located on the left side of the

analyzer. See Figure 25.

• Terminals are provided for ground, power supply, high/low alarms, output signals, calibration and status

relays

• Output signals a voltage output of 05 Vdc and a floating, ungrounded current output of 420 mA are

available for remote readout or control of a process.

• Also available are contact closures for the following:

High alarm Calibration

Low Alarm Leak Alarm

To make electrical connections, proceed as follows:

1. Remove solid caps from the holes above the input/output panel by puncturing with an awl and prying

them out. (Note: remove caps only from those holes that will be used.)

2. Replace with permanent connectors.

3. Connect alarms and external computer interfaces (if any).

4. Feed 3wire power cable into analyzer through hole above the input/output panel.

5. Connect wires to appropriate contacts on Terminal Strip TB3.(See next page)

2.6 Prepare Electrical Connections

Use cable glands to hold cables securely in holes above input/output panel.

WARNING:

Connect output signals, if any before connecting the power supply.

CAUTION:

For proper operation and for safety, electrical connections to this equipment must be

made in accordance with local or national electrical code as applicable.

This equipment must be grounded. A qualified electrician should wire this equipment to an

electrical circuit.

Page 17

11

CFA3000 ISE Analyzer

Instruction Manual

Figure 25.

Input/Output Panel

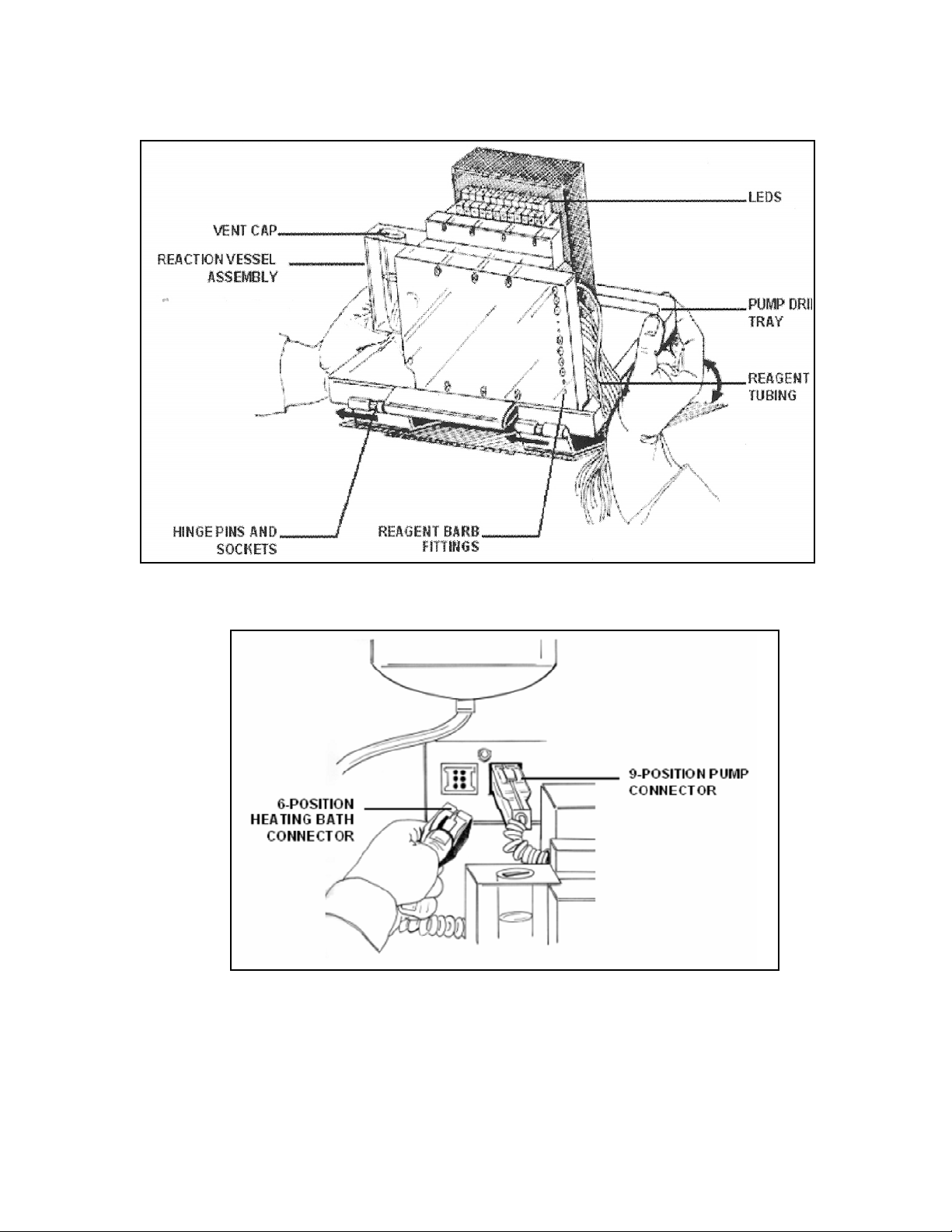

2.7 Install Valve Pump Assembly

The pump assembly has a vacuum pressure system that:

l Eliminates internal pump tubing

l Uses significantly less reagent

l Accurately moves fluids through the analyzer.

Perform the following procedure to install valve pump assembly:

1. Tilt pump assembly towards you.

2. Align the hinge pins and sockets, and slide assembly tray as far as possible to right (see Figure 27).

Carefully lay tray down into cabinet

3. Plug in the two connectors to the back of the cabinet (6position connector for heating bath; 9position

connector for pump) (see Figure 28).

4. Connect 16pin connector from pump assembly to small connector on CPU board (yellow ejector) above

connector for keypad panel.

5. Attach colorimeter inlet tubing on left side of pump to flowcell inlet (see Figure 21).

6. Continue with procedure depending on whether system is singlestream or multistream.

For singlestream, continue:

6. Thread tube labeled Sample" through hole 0n bottom of shelf to the right of pump assembly, and out

through hole on left side of cabinet.

7. Connect Sample tube to top of overflow sample on left side of cabinet.

8. Guide all other tubes that are attached to valve pump assembly through reagent cabinet access hole.

For multistream, continue:

6. Thread Sample tube from pump assembly through reagent access hole on the right side of the valve

pump assembly, and connect to Common (C) on #1 multistream solenoid valve on left side of reagent

cabinet.

Guide all other tubes that are attached to valve pump assembly through reagent cabinet access hole.

Page 18

12

CFA3000 ISE Analyzer

Instruction Manual

Figure 26. Valve Pump Assembly

Figure 27. Pump Connector

Page 19

13

CFA3000 ISE Analyzer

Instruction Manual

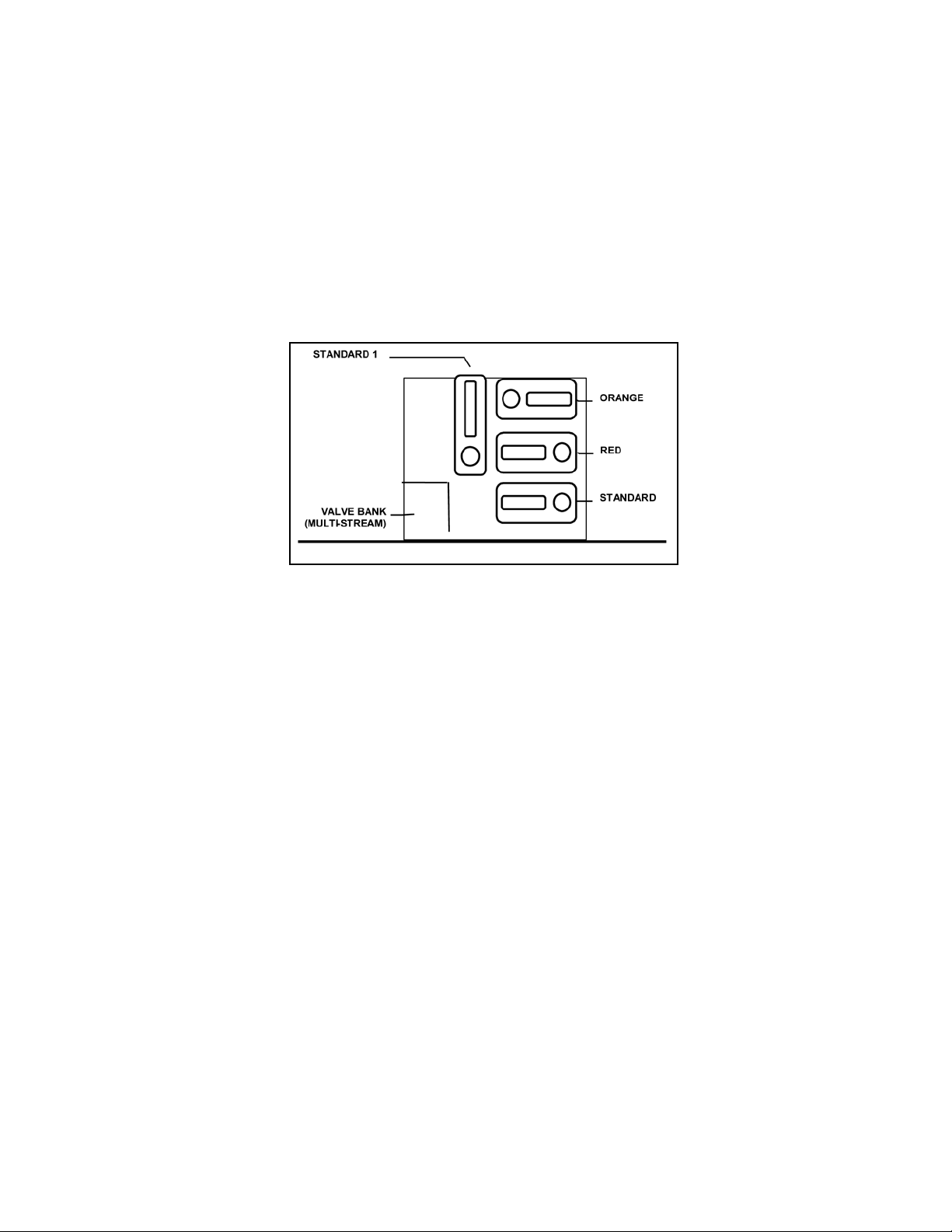

2.8 Prepare Reagent Containers

Prepare reagent containers as follows:

1. Remove screw caps from reagent bottles.

2. Using an awl, make one hole in foil for the reagent straw. Do not allow awl to touch reagent or standards.

3. Place Standard and Reagent bottles into reagent cabinet, as shown in Figure 28.

4. Insert colorcoded reagent straws and labeled Standard straw leading from valve pump assembly into holes

punched in corresponding bottles.

Figure 28. Sample Bottle Placement in Cabinet (for all methods; colors refer to reagent straw colors)

Page 20

14

CFA3000 ISE Analyzer

Instruction Manual

3.0 Operating the Analyzer

3.1 Operational Overview

The analyzer uses a batch flow method for automatically analyzing a sample against a fixed standard (refer to block

diagram in Figure 31). That is, the touch of a button starts the microprocessorcontrolled program, calibrates the

analyzer, takes measurements of samples, and reports results directly unattendedfor months at a time.

The automated monitoring program determines the sequence for activating each of the valve pumps in the valve

pump assembly to inject air and fluids into the reaction chamber. Each valve pump is associated with a specific

input via the quick disconnect connector on the side of the assembly (the number of reagents is determined by

your particular chemistry and procedure).For example, the inputs for sodium chemistry would be:

• Buffer or Ionic Strength Adjustor, reagent #1

• Sample

• Grab sample

• Baseline

• Standard

• Air

• Evacuation of chamber

• Recirculate

For a multistream system, solenoid valves in the analyzer reagent cabinet open and close streams for sampling.

When sampling, the keypad panel LEDs identify which sample stream (valve number) is associated with the dis

played value, and which valve is now open for sampling. Although the system runs samples on its own, you may

also perform a manual grab sampling or a manual calibration at any time.

Figure 31. Simple Block Diagram

Valve

Pump

Electronics

Data output

ISE

(ion selective

electrode)

Reaction

Cell

SECTION 3

OPERATING THE ANALYZER

Page 21

15

CFA3000 ISE Analyzer

Instruction Manual

3.2 Check Sample Stream

• Check that the sample intake tube is 1½ to 2 inch (3.81 to 5.08 cm) into the liquid.

• Sample should just overflow the overflow tube. There should be no particulate or bubbles in the tube.

Using a MultiStream Overflow Sampler

Multistream analysis requires an overflow sampler assembly that will accommodate the extra sample streams.

One multistream chamber allows for up to three sample streams; for 4 6 streams, use two chambers.

The sample tubes connect to solenoid valves in the reagent cabinet. The analyzer uses the valves to cycle

through all sample lines, in sequence. First, stream 1 valve is opened, and Valve 1 LED on the keypad panel is

lit. When the measurement is complete, Valve 1 will be closed, and Valve 2 is opened to begin sampling stream

2. The keypad panel will show Valve 1 LED lit as the Displayed Stream, and Valve 2 LED is lit for the Selected

Stream.

LED's on the valve pump assembly light up when a particular fluid is taken up by the valve pump assembly.

Figure 32 identifies the valve pump LED designations.

3.2.1 Check Fluidics

Check the following:

• Liquid should overflow in overflow chamber.

• Waste tubing is in waste pipe.

• Sample tube is connected to Overflow Sampler Assembly for single stream; and, for multistream, it is

connected to Common (C) port of sample solenoid valve #1, on left side of reagent cabinet.

• System has no leaks.

3.2.2 Check Reagents

Check the following:

• One hole has been punched in all reagent cap liners.

• Reagent straws are placed in appropriate reagent containers.

• High and low standard tubing are in appropriate containers.

3.2.3 Turn On Power

1. Open the keypad panel door to expose the circuit boards.

2. Press each board in to ensure proper seating.

3. Simultaneously press Power button on the back wall of upper cabinet and Reset button on the CPU board

(yellow ejector), then release.

4. First release the Power button, then the Reset button. The Keypad should display ”H E L O", then four

dashes " ".

5. Pull pump forward and check leak detector by dipping finger in tap water and touching detector behind

pump. Leak detector LED on keypad panel will light up.

6. Turn main power switch to OFF.

7. Dry leak detector

8. Wait 20 seconds, then switch main power switch back to ON. Leak detector LED should be off.

Page 22

16

CFA3000 ISE Analyzer

Instruction Manual

3.2.4 Test Valve Pump Operation

Reaction cell takes approx. 30 minutes to heat up.

If leak detector LED does not light up:

Adjust potentiometer on analog board counterclockwise for more sensitivity.

Turn off power to reset system.

Wait 20 seconds, and simultaneously press Power and Reset buttons.

Dip finger in tap water and touch leak detector contacts on bottom of cabinet behind the valve

pump. LED should light up.

If problem persists, contact Rosemount Analytical.

The test procedure allows you to confirm that all physical connections are installed properly,

and to ensure that the pump is taking up the proper fluids at the correct time.

Enter Test Mode:

1. Put all straws and Sampling tube into a beaker of DI water.

2. Turn power on by simultaneously pressing Power button on the back of

upper cabinet and Reset button on CPUboard (yellow ejector).

3. First release Power button, then Reset button. Keypad should display "H E L O",

then four dashes " ".

To enter test mode, continue with the step appropriate for your analyzer setup:

For singlestream,

continue:

For multistream,

continue:

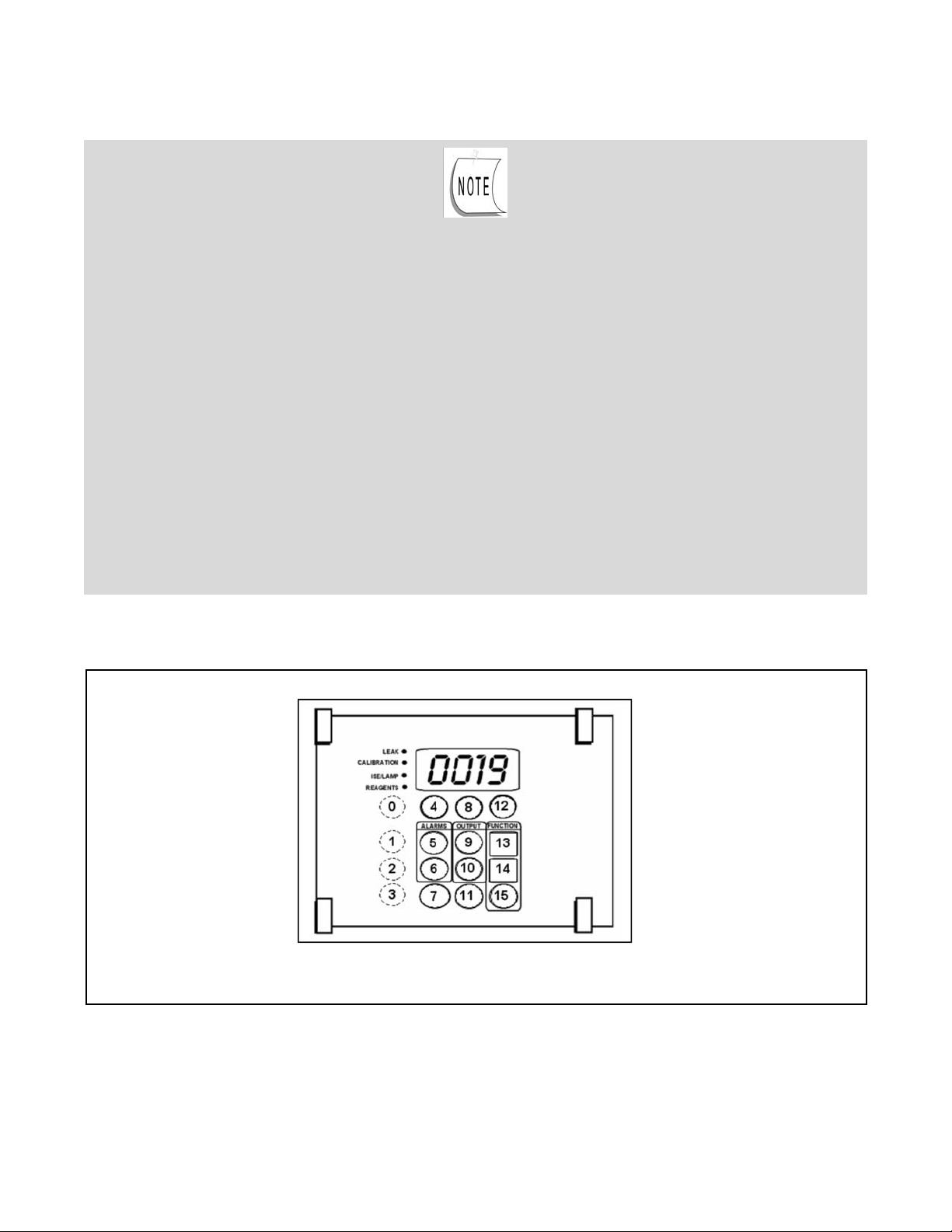

Referring to Figure

32, on keypad

panel, press posi

tion 15 and then 2

On keypad panel,

press: then

.

DECIMAL

MANUAL

Page 23

17

CFA3000 MANUAL SECTION 3

INSTRUMENT DESCRIPTION

FIGURE 32. KEYPAD PANEL

The keypad buttons may now be used to test pump operation. Do not rush through

the test steps – when a specific step is initiated, it takes approx. 2 seconds to pump air

through the system. Actual pumping of a liquid takes approximately 4 seconds. After this operation

is finished, another 4 seconds elapses before the pump is primed for the next test step.

To exit the test at any time, press the ENTER button on the keypad panel.

If a test step does not work properly, try the following:

√ Take a syringe and shoot air through straw to make sure it is not clogged.

√ Check that corresponding LED on valve pumps lights up (refer to Figure 41).

√ Check that fluid is picked up in correct tube.

If the problem still persists, contact Rosemount Analytical.

Begin Test:

Confirm that the corresponding Pump LED lights up for each step (refer to Figure 33 for LED designations during

test):

Page 24

18

CFA3000 MANUAL SECTION 3

INSTRUMENT DESCRIPTION

2. Press to simulate one shot of Reagent #4. Look at blue straw to confirm that water is pumped up

through tube. Repeat a few times until you see water is in clear section of tube

3. Press to simulate one shot of Reagent #3. Check green straw and its clear tube

4. Press to simulate one shot of Reagent #2. Check orange straw and its clear tube.

5. Press to simulate one shot of Reagent #1. Check red straw and its clear tube

6. Press to simulate one shot of Sample coming from overflow sampler. Check tube labeled "Sample."

7. Confirm that fluid is going to flowcell.

8. Press to simulate one shot of Standard. Check corresponding clear straw and its clear tube.

9. Press to pump one shot of air into analyzer.

10. Press to simulate one shot of Baseline solution. Check clear straw labeled, BASELINE, and tube.

11. Repeat Step 9 until you see fluid shoot into reaction chamber.

12. Press to simulate evacuation from the reaction chamber to the flowcell. Check the tube going up to

flowcell.

13. Press to simulate one shot of Grab solution. Check clear straw and tube.

14. Press to wash flowcell.

1. Press ZERO to test air. Press ZERO to turn off.

Page 25

19

CFA3000 MANUAL SECTION 3

INSTRUMENT DESCRIPTION

15. Press to empty reaction chamber. If there is any fluid left, it will be shot through to Waste.

16. Press once to exit test.

NOTE: The LCD on the display board will display the keypad position which is assigned to a specific

valvepump. When the LCD number disappears, the next position may be pressed. The sequence is

given on page 24.

Figure 33. Valve Pump LED Designations

Page 26

20

CFA3000 MANUAL SECTION 3

INSTRUMENT DESCRIPTION

3.2.5 Set Up Stream Parameters

The analyzer is programmed to measure a singlestream system at 4 sample cycles per hour. The multistream

default is 1 cycle per stream, but you may define parameters for individual streams, such as modifying the num

ber of cycles or the alarm threshold values.

The alarm values are used to activate alarms or controllers when the sample is outside of the specified concen

tration range. A high alarm will activate when the sample concentration exceeds a preset limit. A low alarm will

activate when the sample concentration is below the preset limit.

The contacts for the alarm outputs are located at the input/output panel on the cabinet side. The system must be

in an alarm condition for at least one minute to activate the alarm contact.

Use the logical flows below to define desired stream parameters.

Figure 34. Logic Flow for Singlestream Parameter Definition

Page 27

21

CFA3000 MANUAL SECTION 3

INSTRUMENT DESCRIPTION

Figure 35. Logic Flow for Multistream Parameter Definition

(Note: Use decimal on the keypad using arrows to place decimal in the correct position)

Page 28

22

CFA3000 MANUAL SECTION 3

INSTRUMENT DESCRIPTION

3.3 Set Reagent Supply Time

Use the keypad panel to remind you when you need to replace the reagent. The analyzer will count pump cycles

and count down the number of days left. To specify the duration, proceed as follows:

1. Press once to set counter for 90 days (3 months).

Sample Display: 0 0 9 0

2. Press to exit and clear display.

To determine how many days are left until you have to replace reagent,

Press: once.

Look at the LCD and record the number of days;

then press: again to get out of mode.

3.4 Set Scaling Outputs

Set output 420 mA 05 Vdc from the keypad panel, (refer to Figures 72 and 73), then adjust 420 mA and 05

Vdc at your external device.

Set output scale to: 4 mA/0 V

1. Press: .once then .to display 4 mA and for 0 Vdc.

The sample Display for 4 mA and for 0 Vdc: 0 0 0 4

2. To exit, press

Set output scale to: 20 mA/5 V

1. Press once then to display 20 mA and 5 Vdc.

Page 29

23

CFA3000 MANUAL SECTION 3

INSTRUMENT DESCRIPTION

2. The sample display for 20 mA and for 5 Vdc: 0020

2. To exit, press .

To display the fullscale concentration embedded in the EProm:

Press two times. To exit, press .

3.4.1 Record

mV

Use the mV value to determine that the method’s span and slope are correct. The change in millivolts (mV)

is the spread between a baseline and a fullscale standard at the time of calibration. The values are relative to

the chemical parameter being measured

Record the millivolt values for both baseline and fullscale standard.

1. Press

The sample Display for value of 150 mV is: 0 1 5 0

2. To exit function, press once.

3.4.2 Initiate Auto Calibration

The analyzer is calibrated automatically usually every two days, depending on the chemistry. Auto calibration

performs both baseline and fullscale calibration. Baseline calibration measures a solution with 10% concentra

tion of the species of interest. Fullscale calibration measures a standard solution in the upper range of the

parameter of interest.

Before starting calibration, make sure that the analyzer is running reaqgents and baseline

solution for at least 20 minutes.

Page 30

24

CFA3000 MANUAL SECTION 3

INSTRUMENT DESCRIPTION

To initiate auto calibration, press on the keypad panel – the CALIBRATION LED will light. When multi

stream systems are being calibrated, only Stream 1 LED is lit.

Baseline calibration will run first for approximately 15 minutes. Fullscale calibration follows, lasting approximately

15 minutes (the actual time for calibration depends on the chemistry). When fullscale calibration is finished,

CALIBRATION LED goes out and the value is displayed on the LCD. The “ ” display signifies that a delay

is required before the next sample is displayed.

Sample analysis automatically begins after calibration. The time delay from the start of sample analysis to dis

play of results is approximately 15 minutes. This allows sufficient time for the previous solution to wash through

system, for sample and reagents to react, for analyzer to measure sample and display concentration value.

When the CALIBRATION LED and the ”000” display in a singlestream system go out, the displayed value on

the keypad panel is the actual stream value.

For a multistream system, after auto calibration, Sample Stream status LED’s will light to show sample stream

valve currently selected and sample stream concentration currently displayed. For example, for the first stream

sample, VALVE SELECTED LED is lit for that stream; dashes display on the keypad panel. When analyzer finish

es sampling one stream and moves on to the next, the display shows the previous sample stream concentration

value, and its VALVE DISPLAYED LED lights up. VALVE SELECTED LED will be lit for next valve in sequence.

Note: If for any reason a calibration is not wanted and needs to be aborted, press:

then, , then to abort the calibration. Press twice in rapid succession on initial

startup for priming of sample & reagents

3.5 Process a Grab Sample

The analyzer allows you to rapidly analyze a grab sample.

Press on the keypad panel, to introduce a grab sample into the analyzer from the holder on the overflow

sample panel.

If visible, suspended solids are present in the sample, filter it to 8 microns or less.

Page 31

25

CFA3000 MANUAL SECTION 3

INSTRUMENT DESCRIPTION

Place the clear grab sample inlet tube into a beaker containing the grab sample.

2. Press one time. The display shows flashing dashes, “ “ .

The system analyzes the grab sample and after 15 minutes, displays the results when complete (The results

are “flashed” on the display).

Grab Sample Display: 10.0 (flashing for three minutes)

After the display of the grab sample’s value, a multistream analyzer begins processing the next stream in sequence.

3. To display measurement for previous grab sample, press twice.

4. Press button to return to normal operation.

3.6 Manually Sample a Particular Stream.

Use this procedure to manually switch between sample streams in a multistream system. This operation can be

performed at any time, except during calibration.

Press one time. Sample Display: 0 0 0 1 .

Press and to change stream number. Sample Display: 0 0 0 3

Press to start sampling desired stream.

Press to return to multistream automatic analysis.

3.7 Shutdown

To shut down the CFA3000 for only a few days, press main Power button in back of upper cabinet to OFF

position. Leave reagent straws in reagent containers.

Page 32

26

CFA3000 MANUAL SECTION 3

INSTRUMENT DESCRIPTION

To shut down the analyzer for more than a day, perform the following procedure

1. Remove straws from reagent containers and place them into a beaker of DI water.

2. Press twice within a twosecond interval to activate priming. This allows wash solution or DI

water to be injected rapidly through system.

3. After priming finishes (after 15 minutes or when “auto cal” starts), press the main Power button in back of

upper cabinet to OFF position.

3.8 Quick Start

If the analyzer has been shut down during normal operations, turn power on and

press once.

If the CFA3000 has been turned off for an extended shutdown:

Press twice to prime; the system will automatically go into :”Auto Cal” after priming

Some chemistries may require specific wash solutions. Check Appendix A,

"Chemistries," for details.

Page 33

27

CFA3000 MANUAL SECTION 4

MAINTAINING THE ANALYZER

Your CFA3000 Series analyzer is a precision instrument which, if maintained properly, should provide years of

accurate and reliable service.

4.1 Analyzer Equipment.

Even though the analyzer normally runs automatically, perform the following activities, quarterly:

1. Start Auto Calibration after reagent replenishment (see Section, "Perform Auto Calibration").

2. Check mV value

SECTION 4

MAINTAINING THE ANALYZER

Page 34

28

CFA3000 MANUAL SECTION 5

TROUBLESHOOTING PROCEDURES

This chapter is divided into two sections:

• Troubleshooting Chart: a list of symptoms, probable causes, and remedies.

• Test Functions:– test functions for diagnostic information.

5.1 Troubleshooting Chart

Symptoms observed during operation are generally enough to identify a faulty component.Such symptoms,

together with probable causesand remedies are listed in the following troubleshooting chart.

Problem Probable Cause Remedy

No power

Power switch

OFF

Press power

switch ON

Power switch

failed

Call Rosemount

Analytical

Pump is

inoperative

Valve pump

switch OFF

Press switch ON

Blown fuse Replace fuse

Leak detector

activated

Find and fix

leaking; check

pump’s electrical

connection

Bad electrical

connection

Check pump’s

plugs to CPU &

connector

Still inoperative

Call Rosemount

Analytical

Keypad lights or

display fails to

light up

or buttons fail to

operate

Circuit boards

are not seated

properly

Remove and

reinstall circuit

boards

Display or

associated

power circuit

faulty

Call Rosemount

Analytical

Problem Probable Cause Remedy

Keypad lights or

display fails to

light up

or buttons fail to

operate

Display or

associated

power circuit

faulty

Call Rosemount

Analytical

Connector faulty

or not properly

inserted

Check

connection

SECTION 5

TROUBLESHOOTING PROCEDURES

Table 51: Troubleshooting Chart

Page 35

29

CFA3000 MANUAL SECTION 5

TROUBLESHOOTING PROCEDURES

Problem Probable Cause Remedy

Alarms not

activated

Incorrect

settings

Readjust

settings, making

sure that low

alarm is set

lower than

high alarm

Insufficient time

for alarm to

respond

Alarm condition

must exist for

minimum of 60

seconds before

alarm activates

Signal not

repetitive

(same sample

not repetitive)

Small leak or

clogging in

fluidics

Check all tubing

lines and

connections

Clogged tubing Replace tubing

No signal, or

signal “offscale”

high

Connector or

wires loose

Faulty circuit

board

Incorrect mV

value

Check circuit

boards for

proper seating

Replace power

supply circuit

board

Loss of mV

Sensitivity

LED ISE on

Reagents,

standards old,

contaminated or

improperly

prepared

Change

reagents

Reagent straws

in wrong

reagent or

standard

Check

placement of

straws

Problem Probable Cause Remedy

Loss of sample

flow

Replace sample

filter on overflow

panel

Decreased

pumping volume

Tubes pinched

shut or clogged

from deposits

Remove

condition

causing

“pinched” lines;

replace sample

filter at overflow

panel

Leak detector

LED lights up

Leak in fluidics Repair leak and

dry leak detector

contacts; turn

main power

OFF for

20 seconds

High humidity Adjust screw on

leak detector

potentiometer

on analog

board; turn

clockwise to

decrease

sensitivity

Connector faulty

or not properly

insertede

Check

connection to

analog board;

replace analog

board.

5.2 Test Functions

Table 52: Test Functions

Problem Probable Cause Remedy

Front panel

display

Test LED’s and

LCD on keypad:

a. Press Power

button and reset

button on the

CPU board (yel

low ejector)

b. Release

power, then

Reset button.

Press power

Press:

Page 36

30

CFA3000 MANUAL SECTION 5

TROUBLESHOOTING PROCEDURES

Check

button.

Test Procedure

Exit

Front panel

display

c. Press the

following keys in

sequence: (key

#’s 15, 5, 6)

Press:

Sensitivity

(mV)

Press:

then

Press:

then

Page 37

31

SECTION 6

REPAIR PROCEDURES

CFA3000 MANUAL SECTION 6

REPAIR PROCEDURES

The Ionselective electrode analyzers are designed with modular components for quick and easy replacement.

The following sections contain instructions to remove parts and replace them. For more complex repairs, or diag

nostic assistance, contact Rosemount Analytical at:

• Telephone: (800) 8548257, (949) 7578500

• Fax: (949) 4747250

• Email: www.raihome.com

6.1 Replace Valve Pump Assembly

Use the following procedure to replace pump assembly:

1. Turn off power to analyzer.

2. Pull back of pump assembly towards you to a 45degree angle (see Figure 61).

3. Unplug the two connectors from the back of the cabinet. (9position connector for pump).

4. Disconnect pump assembly’s “D” connector from right side of pump.

5. Remove all liquid tubes from pump.

6. Disconnect waste tube from bottom of reaction cell (right side of valve pump).

7. Slide assembly to the left to disengage from pins, and remove pump assembly.

8. To install a new pump assembly, refer to Section, " Install Valve Pump Assembly".

Figure 61. Remove Valve Pump Assembly

Page 38

32

6.2 Replace Circuit Boards

Use the following procedure to replace circuit boards:

1. Turn off power.

2. Open latch from right side of keypad panel; and open door.

3. Disconnect all cables and plugs from board to be replaced.

4. Unlatch colored clip from board to be replaced (refer to Figure 62).

5. Pull circuit board straight out.

6. Reverse steps to replace board and reconnect cables. Press firmly to ensure that boards are

properly seated.

7. Turn power on.

8. Perform Automatic Calibration (refer to Section, “Initiate Auto Calibration”).

Please NOTE: Valvepump connector is on CPU board

Figure 62. Card Cage

CFA3000 MANUAL SECTION 6

REPAIR PROCEDURES

IMPORTANT: Do Not remove any PC board or component without first shutting off Power to the analyzer.

Page 39

33

6.3 Replace Fuses

Use the following procedure to replace fuses (all fuses are 1A):

1. Turn off power.

2. From inside upper left corner near pump switch, press down on fuse cap and turn counterclock

wise to remove.

3. Pull fuse and cap straight out.

4. Replace fuse in cap (make sure the new fuse is the same type and rating as the one you are

replacing).

5. Press fuse cap in place and turn clockwise.

6. Turn power on.

6.4 ISE Reaction Cell Assembly, Electrodes

Figure 63. ISE Reaction Cell Assembly, Electrodes

CFA3000 MANUAL SECTION 6

REPAIR PROCEDURES

6.4.1 The sodium electrode used in the CFA3011 sodium analyzer is a proprietary “solid state” electrode

which is joined with a reference electrode in a sealed cartridge. The buffered sample stream flows into the

reaction cell—through the ground stud to the sodium electrode, then into the reference electrode, out through

the ground stud and then to waste. The sample concentration is measured in the sodium electrode, compared to

the reference value and the sodium concentration is determined.

Page 40

34

CFA3000 MANUAL SECTION 7

INSTRUMENT DESCRIPTION

SECTION 7

INSTRUMENT DESCRIPTION

Part Function

Main Cabinet Splashproof enclosure

protects analyzer

Reagent Cabinet Splashproof enclosure

protects reagents and

solenoid valves

Door Hinges Pin hinges mount doors

on main and reagent

cabinets

Door Latch Secures cabinet door

Keypad Panel and Driver

Board

External side contains

touch buttons for

controlling analyzer,

digital display, and status

panels. Internal side

contains driver board

HB Lamp Indicates when propor

tional controller is heating

the heat bath

HB T 1 A 1 A fuse for heating bath

LAMP PS T 1.0 A 1 A fuse for power supply

to ise lamp

PUMP T 1.0 A 1 A fuse for pump

XFMR T 1.0 A 1 A fuse for transformer

Pump On/Off Lighted switch controls

power to pump

On/Off Main power switch

Colorimeter Detector

Waste Drain Pan Drain pan directs waste

solutions to waste tube

Pump Connector 9position connector

connects pump to main

cabinet electronics

Heating Bath Connector 6position connector

connects to heating bath

assembly

Valve Pump Assembly Includes pump, PC

board, labeled tubes, and

reaction vessel assembly

(chemistry module with

integrated

Part Function

Chemistry Module Tubing Carries sample and

reagent to valve pump

assembly

Quickdisconnects Connects reagents,

samples, and standards

to valve pump assembly

Waste Tube Carries waste solutions

to drain

Leak Detector Senses leakage of

solutions in main cabinet,

shuts pump off, and

activates leak LED

Part Function

MultiStream Valve Panel

(MultiStream option

only)

Allows sequential

analysis of up to six

sample streams

MultiStream Connector

(MultiStream option

only)

Positive fit connector

connects Multistream

valve panel to main cabi

net electronics

Bulkhead Fitting Fitting that directs

individual sample stream

to sample valve

Overflow Sample

Assembly

Supplies continuous

sample streams for

analyzer

7.1 Analyzer Front View (Refer to Fig. 71).

Table 71.1: Main Cabinet Parts

7.1.1 Main Cabinet

7.1.2 Reagent Cabinet

Table 72. Reagent Cabinet Parts

(heating bath)

Page 41

35

Note: For multistream monitor, Overflow Sampling assembly mounts on left side, facing the analyzer

Figure 71. Analyzer Front View

CFA3000 MANUAL SECTION 7

INSTRUMENT DESCRIPTION

Page 42

36

CFA3000 MANUAL SECTION 7

INSTRUMENT DESCRIPTION

Button/LED Function

For Both Single and Multistream Options

LEAK LED When lit, indicates leak in

main cabinet

CALIBRATION LED When lit, indicates

calibration in progress

ISE/LAMP LED Will light when millivolt

level is below default

levels.e

REAGENTS LED When lit, indicates

reagents need to be

replaced

UP or DOWN

Arrow

Increases or decreases

displayed value

Sets value or exits

function

Sets high alarm limit

Sets low alarm limit

Two functions:

Sets 90 day clock for

reagent usage

Displays number of

days remaining until next

replacement of reagents

Sets scale to adjust out

put to 4 mA and 0 Vdc

on recording device

Sets scale to adjust out

put to 20 mA and 5 Vdc

on recording device

Button/LED Function

Function:

Displays Systems mV

Initiates processing from

grab sample

Initiates automatic

calibration of analyzer

Used for setting alarm

values.

For Multistream option only

Sample Streams

LED’s

VALVE SELECTED

shows which valve

(stream) is being

analyzed, and VALVE

DISPLAYED shows

which valve is associated

with completed and

displayed value

Initiates automatic

multistream analysis

Initiates single stream

analysis

Enters function to identify

parameters for each

stream (such as number

of cycles and high and

low alarms)

(Not used)

7.2 Keypad Panel

The keypad panel has a fourdigit liquid crystal display with an adjustable decimal point. The panel also has indi

cator LED’s and pressuresensitive buttons.

Table 73 Buttons/LED Functions

Page 43

37

CFA3000 MANUAL SECTION 7

INSTRUMENT DESCRIPTION

Part Function

Keypad Panel Door Opens to access card

cage

Display Board Circuit board contains

electronics for keypad

and LCD display

CPU Board

180B02801

Central processing circuit

board processes the

signal fed to the digital

display and any external

devices. (Yellow ejector)

Valve Board

180B01601

(only supplied for

multistream option or for

RS232 output on single

stream)

Circuit board controls

multistream accessory.

Jumper should be

installed on back of valve

board. (Purple ejector)

Analog Board

180B02502

For multistream

configurations:

180B02501*

Circuit board converts

signals from analog to

digital and processes

signals from "fault" detec

tors (Orange ejector)

Power Supply Board

180B01203

Supplies voltage to

electrical circuitry

(Blue ejector)

7.3 Card Cage

The card cage is located directly behind the keypad

panel. To access the card cage, lift latches from right

side of keypad panel and open hinged door. (Refer to

Figure 72.)

7.3.1 Card Cage and Door

Table 74: Card Cage Parts

Component Function

0Vdc 5Vdc Connector To recording device.

4mA –20mA Connector To recording device.

Computer Memory Reset Clears microprocessor

memory

Computer Memory Reset Clears microprocessor

memory

Valve Pump Connector Connector for cable from

valve pump

Display Board Cable

Connector

Connector for display

board cable

Component Function

Potentiometer Adjusts sensitivity of leak

detector – clockwise for

less sensitivity;

counterclockwise for

greater sensitivity

Analog Board DIP Switch Contains 8 rocker switches

for setting various

functional processes

(see Figure 73)

Signal Input Connector For process signals

On 180B02501: 20

multistream output

potentiometers

For each stream 2 – 6,

potentiometers for 4 mA,

20 mA, 0 V, 5 V

(multistream only)

Component Function

Multistream Panel

Connector

Connector for cable

connector from display

board

7.3.2 CPU Board

Table 75: CPU Board Components

7.3.3 Analog Board

Table 76: Analog Board Components

7.3.4 Valve Board

Table 77: Valve Board Components

Part Function

18pin Female Connector For relays

6pin Male Connector Operating power

6pin Female Connector Valve Pump Power

7.3.5 Power Supply Board

Table 78 Power Supply Board

Page 44

38

CFA3000 MANUAL SECTION 7

INSTRUMENT DESCRIPTION

PLEASE NOTE: VALVEPUMP CONNECTOR IS ON CPU BOARD

FIGURE 72. CARD CAGE AND BOARDS

IMPORTANT: DO NOT remove any PC board or component without first shutting off Power to the analyzer.

Page 45

39

Figure 73. Analog Board DIP Switches

(with #3 set in OFF position for multistream analyzer) Colorimeter Assembly

CFA3000 MANUAL SECTION 7

INSTRUMENT DESCRIPTION

7.3.6. Analog Board DIP Switches

The following list describes the conditions for each switch to be in the ON or OFF position:

Table 79. Analog Board DIP Switch Positions

Switch No. Position Condition Remarks

1 ON

When using Analog Board, Part

# 180B02602

Analog Board has no adjustment

ports for individual output device

and/or 05 Vdc, 420 mA outputs.

1 OFF

When using Analog Board, Part

# 180B02601

Analog Board has individual ports

for adjusting each output device

(up to 6) and/or 05 Vdc,

420 mA outputs.

2 ON Quick calibration on

2 OFF Quick calibration off

3 ON

4 ON Nonfunctioning switch

5 ON Nonfunctioning switch

6 ON Nonfunctioning switch

7 ON

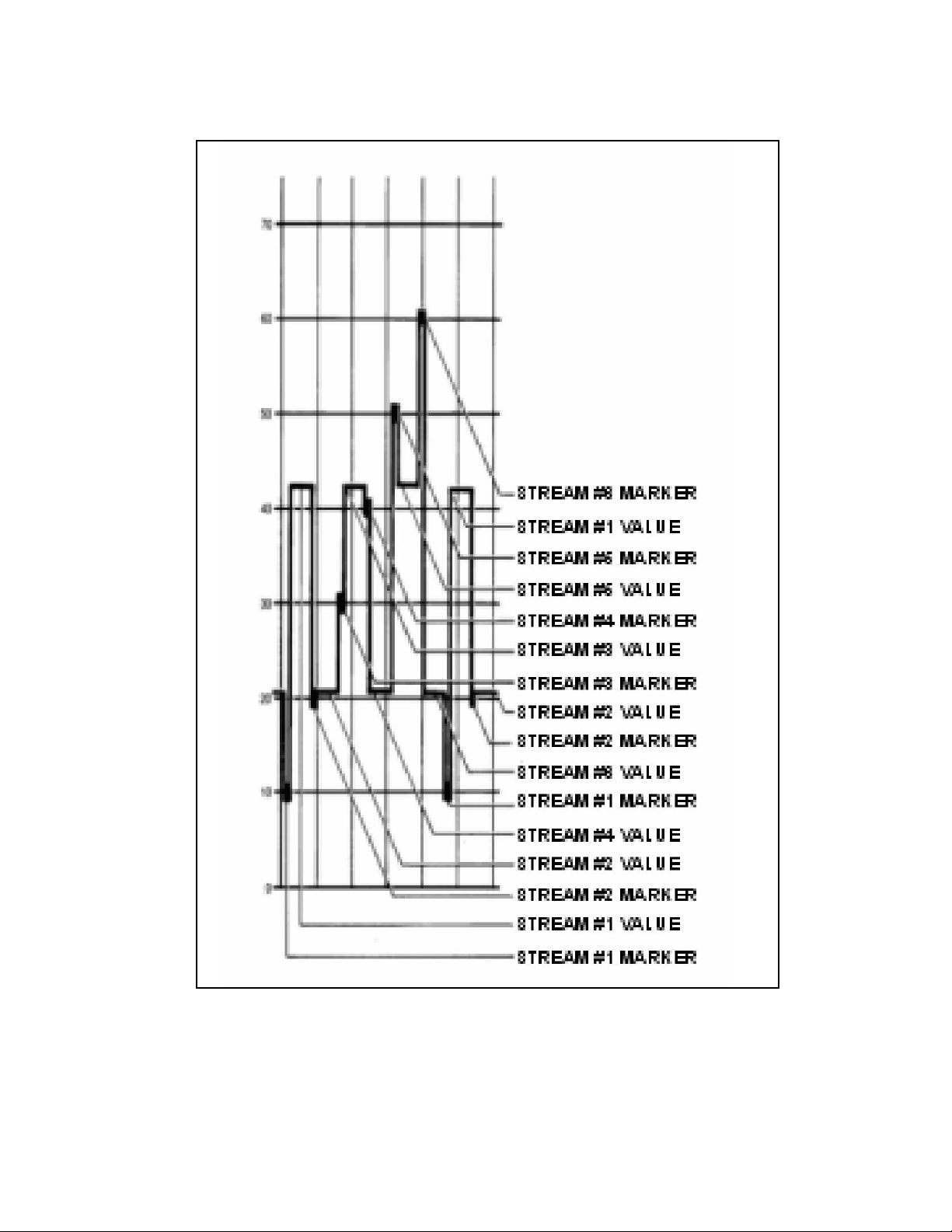

For stream ID and “brackets” before

and after calibration

Allows markers to be recorded on

strip charts and other recording

devices.

7 OFF

No markers will be recorded on

strip charts and other recording

devices.

8 ON For 80 column printers Formats printer output

8 OFF For 40 column printers Formats printer output

Page 46

40

CFA3000 MANUAL SECTION 7

INSTRUMENT DESCRIPTION

Component Function

Backplane Board Circuit boards plug into

front side

Power Transformer Supplies ac voltage to

electronics

Heating Bath Connector Interconnect to heating

bath

Pump Connector Interconnect to valve

pump

220Vdc Transformer Optional part for specific

electrical requirements

(208 V – 240 V)

Table 710: Back Cabinet Parts

FIGURE 74. REAR OF MAIN CABINET

7.4 Rear of Main Cabinet

In the rear of the main cabinet are a number of

electrical components and connectors. The following

diagram is for reference, only.

Page 47

41

CFA3000 MANUAL SECTION 7

INSTRUMENT DESCRIPTION

Part Function

Pump Housing Contains and protects

valve pump electronics

Pump Valve pump routes

sample and reagents

through the analyzer

Reagent Barb Fittings Male half of tubing

connector. Tubes are

connected to reagents

and sample

Reaction Vessel

Assembly

Contains reaction cell,

heating block

6position Connector Electrical power to

heating bath

9position Connector Electrical power to pump

LED Green is OK; RED is

Low pressure

Part Function

Sample and Reagent

Tubing

Colorcoded straws and

labeled tubes for

transport of solutions

“D” Connector Connects to small, 16pin

connector on CPU boards

Vent Line Vents reaction cell to

waste

Pump Drip Tray Catches leaks and

directs them to the leak

detector

LEDS Identify which injector is

active.

7.5 Valve Pump Assembly

The vacuum pump assembly includes the pump, PC

board, and reaction cell.

Table 7 11: Valve Pump Parts

* Vacuum/Pressure LED is located on the upper right

corner of the ValvePump as it is installed

Figure 75. Valve Pump Assembly

Page 48

42

CFA3000 MANUAL SECTION 7

INSTRUMENT DESCRIPTION

Port Function

RS232C For connection of

computer interface or

other accessories

Relay Output Optional relay contact

(multistream analyzer

only)

Printer For connection of printer

cable

Recorder For connection of

external recorder; for

multioutput, 420 mA

and 05 Vdc outputs for

streams 2 through 6.

Pin No. Description

1 NO 9 C Stream #1 Alarm or ID

2 NO 10 C Stream #2 Alarm or ID

3 NO 11 C Stream #3 Alarm or ID

4 NO 12 C Stream #4 Alarm or (#1*) ID

5 NO 13 C Stream #5 Alarm or (#2*) ID

6 NO 14 C Stream #6 Alarm or (#3*) ID

7.6 Interface Ports

The interface ports (labeled for recorder, printer,

relay output, and RS232) are located on the lower,

left outside wall.

Table 712: Interface Ports

If there are 3 streams or less, both stream ID and

alarms may be optionally configured.

7.8 MultiOutput Board

The output for Stream #1 is obtained from the

Input/Output Panel (see Figure 25). The additional

five outputs are obtained from the lower lefthand side

of the analyzer. Table 714 gives the pin assignments

on the “D” connector for a multistream system:

Figure 76. Interface Ports

7.7 Relay Output Option

This port (see Figure 77) is a collection of contact

closures that can be used to identify either the

stream being displayed or the alarm that is activated

(multistream systems only). these are not “powered”

contacts.

Relay Contact Ratings:

100 Vdc max voltage

10 Vdc max DC current

1.0 A max carry current

0.5 A max switched current

Table 713: Relay Output Option

Pin Assignments

\ 1 2 3 4 5 6 7 8 9 10 11 12 13 14 /

\

15 16 17 18 19 20 21 22 23 24 25 /

Figure 77. "D" Connector for Relay Output

Table 714: Multioutput Pin Assignments on

“D” Connector

2 15 2 14 1

3 17 4 16 3

4 19 6 18 5

5 21 8 20 7

6 23 10 22 9

Page 49

43

CFA3000 MANUAL SECTION 7

INSTRUMENT DESCRIPTION

Part Function

Intake/Regulating Valve Regulates flow of

sample into overflow

sampler assembly

Overflow Tube Assures adequate supply

of sample and

reproducible results by

eliminating positive

pressure from sample

stream.

Sample Intake Tubing Tubing which carries

sample from overflow

tube to analyzer (one to

six stream configurations)

NOTE: Sample intake

tube should be no more

than 1 to 11/2" into the

sample.

Air Vent Allows air to escape

overflow tube as it fills

with sample.

Part Function

Overflow Waste Vent Allows excess sample

to escape.

Waste Pipe Carries waste to drain.

Overflow Tubing All overflow tubes feed

into common waste pipe.

Filters

(180134108)

Replaceable filters are

mounted down stream

from each intake

regulating valve.

Sample Inlet Tubing 1/8" x 1/4" tubing

(provided by customer).

Common Panel Mounts multistream

Overflow Sampler

Assembly to left side of

analyzer (facing front

panel).

Panel with dimensions

221/4” x 9" will support