Page 1

Quick Reference Guide

P/N 20001008, Rev. B

August 2005

Model 3700 Transmitter

(MVD) or

Model 3350 Peripheral

Installation Instructions for

Field-Mount

For technical support, phone the support center nearest you:

• In the U.S.A., phone 1-800-522-MASS

(1-800-522-6277)

• In Canada and Latin America, phone

(303) 527-5200

• In Asia, phone (65) 6770-8155

• In the U.K., phone 0800 - 966 180 (toll-free)

• Outside the U.K., phone +31 (0) 318 495 670

Page 2

BEFORE YOU BEGIN

This quick reference guide explains basic installation guidelines for

installing the Micro Motion

®

Model 3350/3700 MVD applications

platform.

For information on I.S. applications, refer to Micro Motion approval

documentation.

For complete instructions about configuration, maintenance, and service,

refer to the instruction manual shipped with the transmitter.

WARNING

Improper installation in a hazardous area can cause

an explosion.

For information about hazardous applications, refer to

Micro Motion approval documentation, shipped with the

transmitter or available from the Micro Motion web site.

WARNING

Hazardous voltage can cause severe injury or death.

Install transmitter and complete all wiring before

supplying power.

CAUTION

Improper installation could cause measurement error

or meter failure.

Follow all instructions to ensure transmitter will operate

correctly.

©2005, Micro Motion, Inc. All rights reserved. Micro Motion is a registered trademark of Micro Motion, Inc. The Micro

Motion and Emerson logos are trademarks of Emerson Electric Co. All other trademarks are property of their respective

owners.

1

Page 3

European installations

This Micro Motion product complies with all applicable European

directives when properly installed in accordance with the instructions in

this quick reference guide. Refer to the EC declaration of conformity for

directives that apply to this product.

The EC declaration of conformity, with all applicable European

directives, and the complete ATEX Installation Drawings and

Instructions are available on the web at www.micromotion.com/atex or

through your local Micro Motion support center.

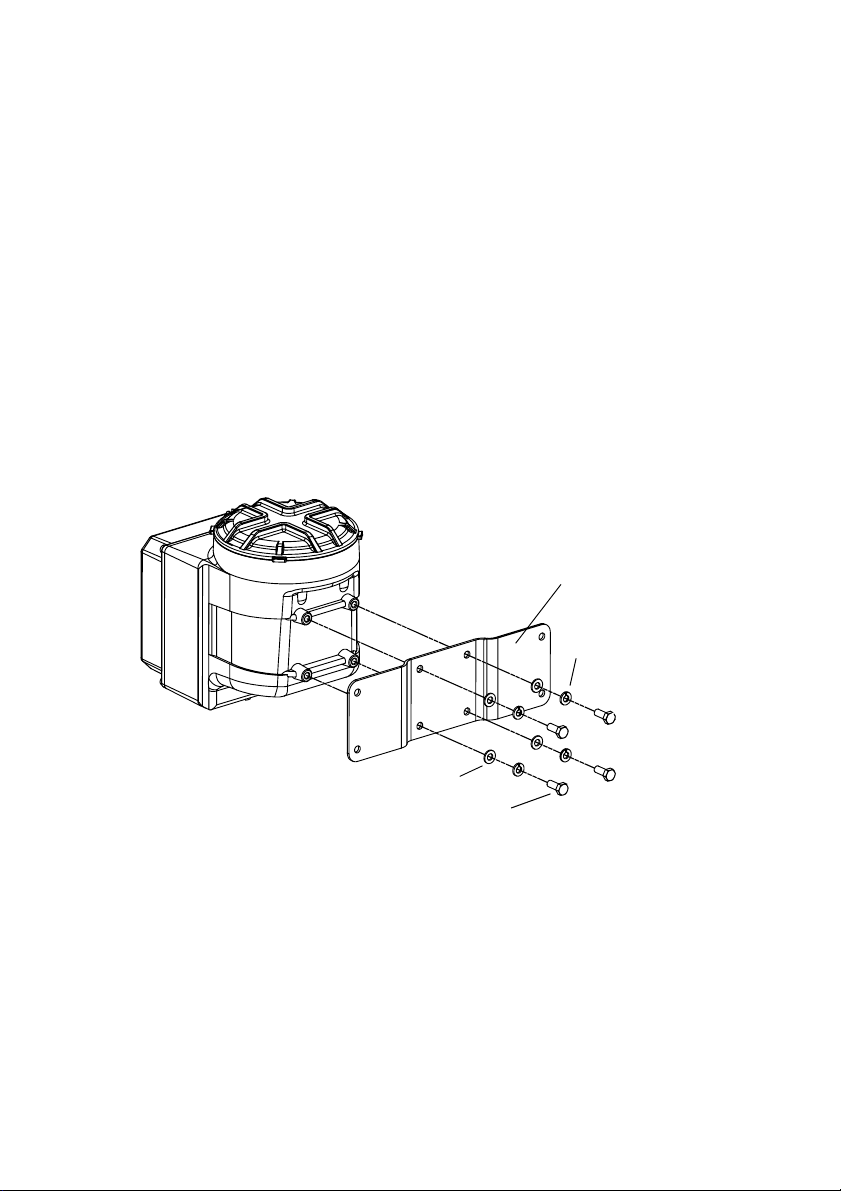

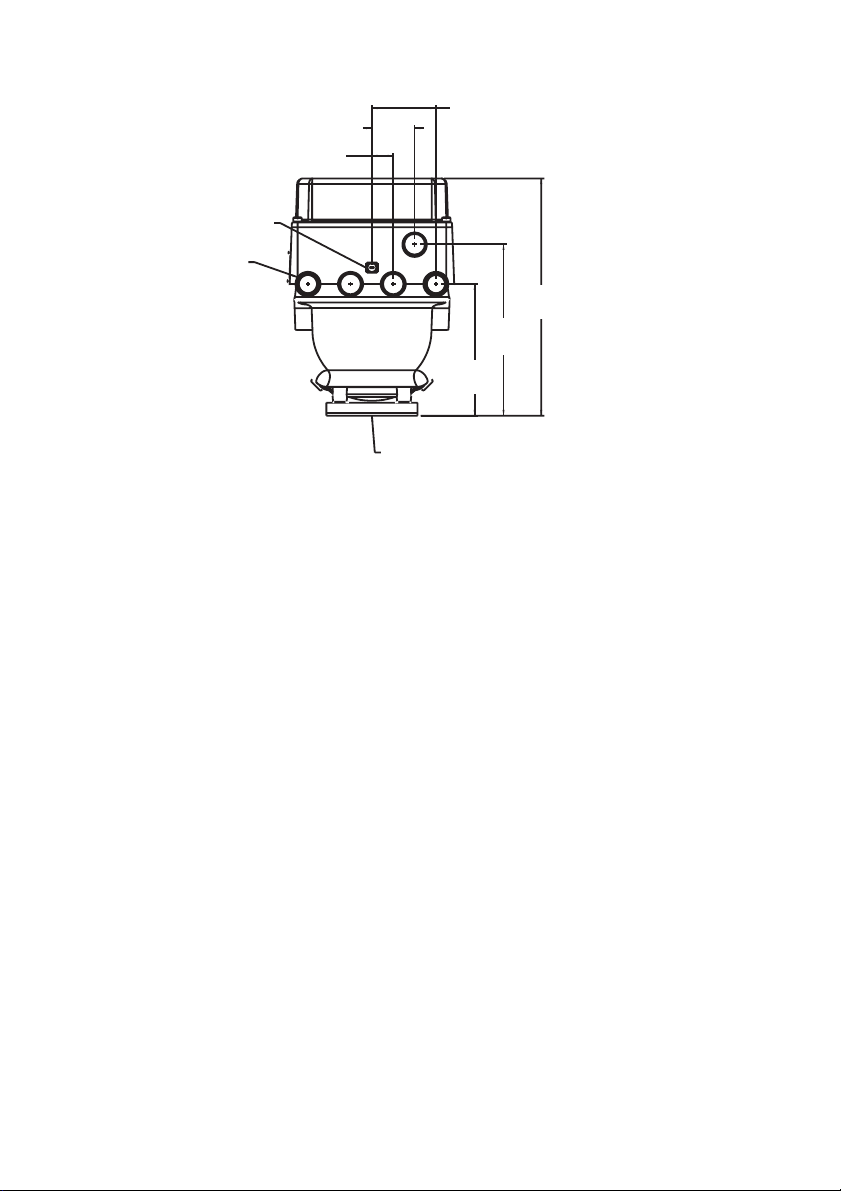

Installation kit

The Model 3350/3700 installation kit includes the parts shown in

Figure 1.

Figure 1. Field-mount installation kit

Mounting bracket

4 x Lock washer

Transmitter can be oriented

on bracket. See Step 3.

4 x Flat washer

4 x M8x16 Bolt assemblies

2

Page 4

STEP 1. Choosing a location

Choose a location for the transmitter based on the requirements described

below.

WARNING

Improper installation in a hazardous area could cause

an explosion.

Install the transmitter in an area that is compatible with

the rating on the approvals tag. See Figure 3.

Environmental requirements

Install the Model 3350/3700 according to specified limits:

• Ambient temperature: –4 to +140 °F (–20 to +60 °C)

Dimensions

See Figures 2, 3, and 4 for Model 3350/3700 dimensions.

Visibility of tags

To ensure personal and system safety, all tags attached to the housing

must remain visible. Clean them as often as necessary. Replace tags that

are damaged, missing, or worn. See Figure 3 for location of approvals tag.

3

Page 5

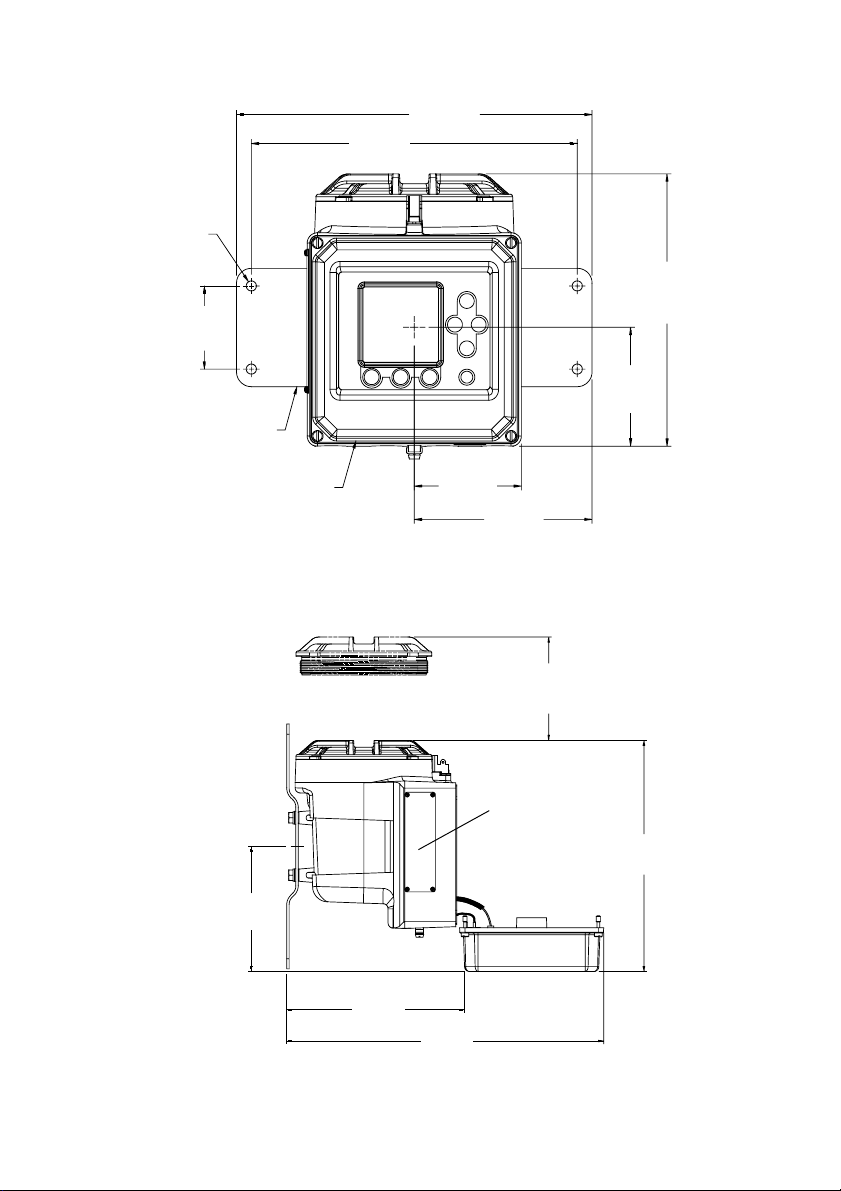

Figure 2. Dimensions – face view

inches

(mm)

4 x 5/16-inch

(9 mm)

diameter

2 13/16

(71)

Mounting bracket can

be rotated as needed

11

(279)

12

(305)

4

(102)

9 3/16

(234)

Display cover can be

rotated as needed

Figure 3. Dimensions – top view

inches

(mm)

6 1/8

(158)

8 11/16

(221)

3 5/8

(92)

6

(152)

5 1/16-inch (129 mm)

clearance for removal of

circuit boards

Approvals tag

15 1/2

(394)

11 5/16

(288)

4

Page 6

Figure 4. Dimensions – conduit openings view

inches

(mm)

Case ground

5 x 3/4–14 NPT

or

5 x M20 x 1.5 – 6H

2 x 15/16

(24)

1 7/8

(48)

Mounting surface

2 x 2 13/17

(71)

7 1/2

(191)

5 3/4

(147)

10 3/8

(265)

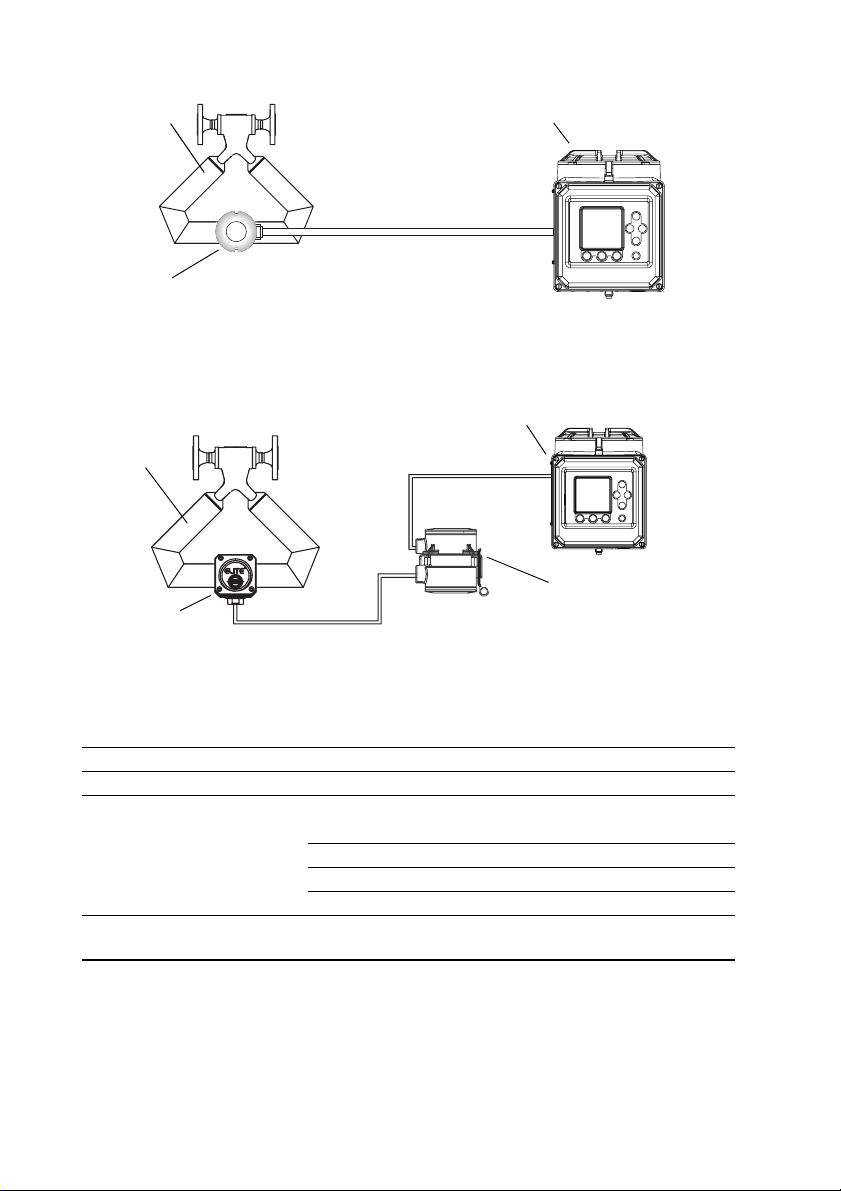

Cable lengths

Maximum cable length from the sensor to the Model 3700 transmitter

depends on the installation type and cable type:

• 4-wire remote transmitter: see Figure 5, then refer to Table 1 for

maximum length of the 4-wire cable.

• Remote core processor with remote transmitter: see Figure 6, then

refer to Table 1 for maximum length of the 4-wire cable and the

9-wire cable.

If you are installing the Model 3350 applications peripheral in

combination with a transmitter, the maximum cable length from the

transmitter’s frequency output to the Model 3350’s frequency input is

500 feet (150 meters).

5

Page 7

Figure 5. 4-wire remote transmitter

Sensor

Core processor

(standard or enhanced)

4-wire cable

Model 3700

Figure 6. Remote core processor with remote transmitter

Model 3700

Sensor

4-wire cable

Junction box

9-wire cable

Core processor

(standard only)

Table 1. Maximum cable lengths

Cable type Wire gauge Maximum length

Micro Motion 9-wire Not applicable 60 feet (20 meters)

Micro Motion 4-wire Not applicable 1000 feet (300 meters)

User-supplied 4-wire

• Power wires (VDC) 22 AWG

(0,35 mm

20 AWG (0,5 mm

18 AWG (0,8 mm

• Signal wires (RS-485) 22 AWG (0,35 mm

Cable from transmitter’s FO

to Model 3350’s FI

(1)

Not applicable 500 feet (150 meters)

(1) Applies only to the Model 3300 applications peripheral when receiving frequency input

from a remote Micro Motion transmitter such as an IFT9701 or RFT9739.

2

) 300 feet (90 meters)

2

) 500 feet (150 meters)

2

) 1000 feet (300 meters)

2

) or larger 1000 feet (300 meters)

6

Page 8

STEP 2. Preparing conduit openings for ATEX Zone 1

s

If the Model 3350/3700 carries an ATEX Zone 1 approval:

1. Remove thread protectors from conduit openings (see Figure 7).

2. Install factory-supplied cable glands or user-supplied EExe cable

entry devices in conduit openings that are in use.

3. Install EExe plugs in conduit openings that are not in use.

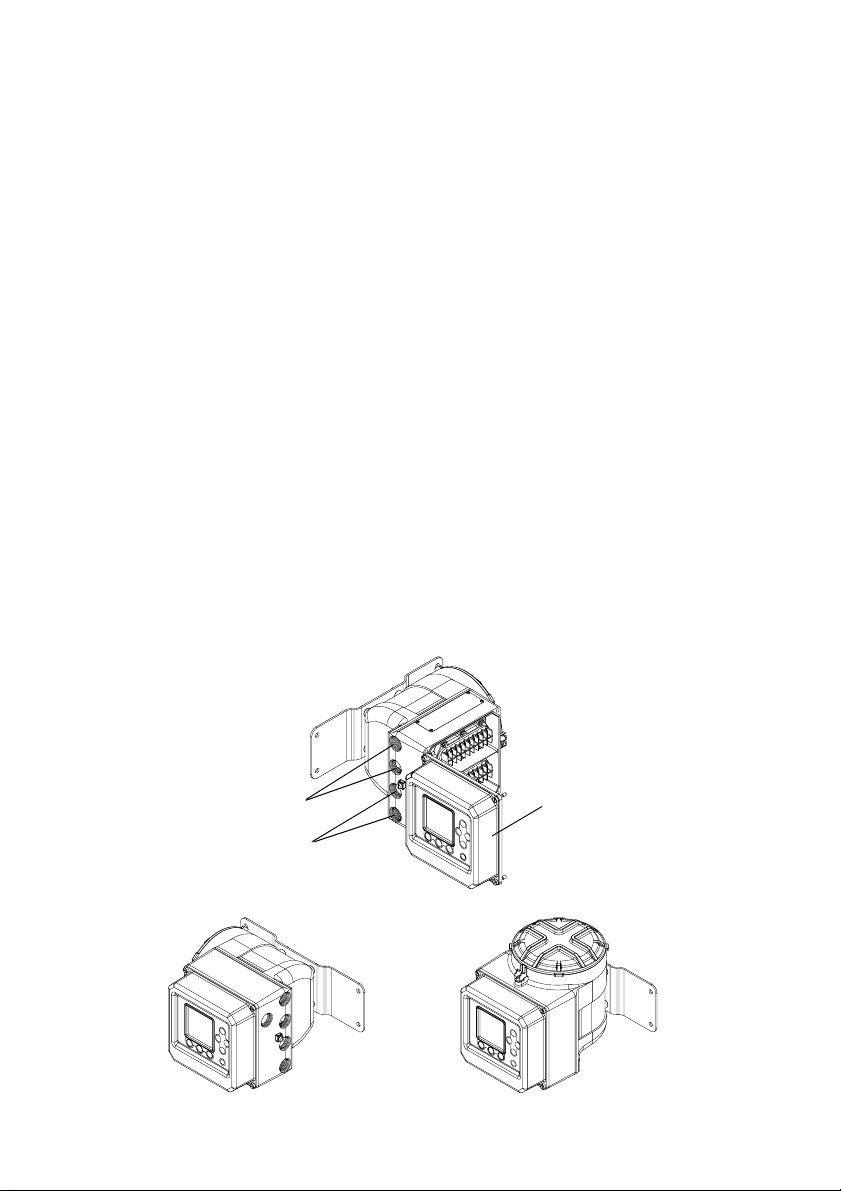

STEP 3. Orienting the Model 3350/3700 (optional)

The Model 3350/3700 can be oriented on the mounting bracket as

needed, and the display cover can be rotated on the applications platform.

Figure 7 provides orientation examples.

To orient the Model 3350/3700:

1. Use the four supplied mounting bolt assemblies.

2. Using a 13 mm hex wrench, install the bolt assemblies to 12 ft-lb

(16 Nm) of torque.

To rotate the display cover, if needed, see the transmitter installation

manual.

Figure 7. Orientation examples

Conduit openings

Conduit openings for

intrinsically safe

sensor wiring

Conduit openings for

non-intrinsically safe

input/output wiring

left

Conduit openings

right

Display cover

Conduit opening

down

7

Page 9

STEP 4. Mounting the applications platform

For flat-surface mounting, see Figure 8.

For pole mounting, see Figure 9.

Figure 8. Mounting to a flat surface

• Mount all four bolts to the same surface.

• If mounting surface is not flat, use

washers to shim the bracket.

• Do not secure bolts to separate beams,

girders, wall studs, etc., which can move

independently.

Figure 9. Mounting to a pole

4 x 5/16-inch or M8 bolt

(user-supplied)

4 x 5/16 inch nut

(user-supplied)

2 x 5/16-inch U bolt for

2-inch pipe (user-supplied)

8

Page 10

STEP 5. Mounting the core processor

This step is required only for remote core processor with remote

transmitter installations (see Figure 6). If you have a 4-wire remote

installation, go to Step 6.

Figure 10 shows the remote core processor and mounting bracket. Using

the mounting bracket, mount the core processor in a location compatible

with the cable length requirements discussed in Step 1.

Figure 10. Remote core processor components

Core processor lid

Upper conduit ring

Core processor

Mounting bracket

Lower conduit ring

End-cap

STEP 6. Connecting input and output wiring

Figure 11 shows the location of the wiring terminals on the Model

3350/3700.

1. Using a flat-head screwdriver, loosen the four captive screws that

secure the display cover to the housing.

2. Connect input/output wiring to the appropriate terminals on the gray

terminal block. Refer to Table 2 and to the label attached to the back

of the display cover (shown in Figure 12).

• Use 22 to 16 AWG (0,35 to 1,5 mm

2

) twisted-pair shielded wire.

• Ground the cable shields at a single point only.

• If more than two wires must be connected to a single terminal, use

a butt splice or spade lug to connect the wires.

9

Page 11

Figure 11. Wiring terminals

(not supplied with all units)

Lockout device

Intrinsically safe

sensor wiring terminals

(blue terminal block)

Wiring compartment

Should remain closed

while power is on

Label for sensor

wiring terminals

(see Figure 12)

Display cover

Table 2. Input/output wiring terminals

Terminal number Designation

1 – 2 + Primary 4–20 mA output / HART

3 – 4 + Secondary 4–20 mA output

5 – 6 + Frequency input

5 – 7 + Discrete input 1

5 – 8 + Discrete input 2

11 (B line) 12 (A line) RS-485 output

20 – 16 + Discrete output 3

20 – 17 + Discrete output 2

20 – 18 + Discrete output 1

20 – 19 + Frequency output

Circuit board

compartment

Non-intrinsically safe

input/output wiring

terminals

(gray terminal block)

Power supply

ground

Label for input/output

wiring terminals

10

Page 12

Figure 12. Wiring terminal labels

Model 3350/3700 with AC

power supply

Model 3350/3700 with DC

power supply

Terminal 9:

line

(L or L2)

Terminal 10:

neutral

(N or L1)

Terminal 9:

positive

Terminal 10:

negative

STEP 7. Connecting the Model 3700 to the sensor

If you are installing the Model 3350 applications peripheral, this step is

not required. Go to Step 8.

To connect the Model 3700 transmitter to a Micro Motion sensor, follow

the instructions in this section.

11

Page 13

Installation options

The Model 3700 can be wired to the sensor in either of the following

configurations:

• 4-wire remote transmitter (requires a 4-wire cable; see Figure 5 and

Wiring instructions for 4-wire remote installations)

• Remote core processor with remote transmitter (requires both a

4-wire and a 9-wire cable; see Figure 6 and Wiring instructions for

remote core processor with remote transmitter)

Wiring instructions for 4-wire remote installations

1. Prepare the cable as described in the sensor documentation.

2. Connect the cable to the core processor as described in the sensor

documentation.

3. To connect the cable to the transmitter:

a. Identify the wires in the 4-wire cable. The 4-wire cable supplied

by Micro Motion consists of one pair of 18 AWG (0,75 mm

wires (red and black), which should be used for the VDC

2

connection, and one pair of 22 AWG (0,35 mm

) wire (green and

white), which should be used for the RS-485 connection.

b. Connect the four wires from the core processor to the appropriate

terminals on the transmitter. See Table 3 and Figure 13 (standard

core processor) or Figure 14 (enhanced core processor). No bare

wires should remain exposed. Do not ground the shield or drain

wire(s) at the transmitter.

Table 3. Transmitter terminals for 4-wire cable

Terminal Wire color

13 Red VDC+

14 Black VDC–

15 White RS-485A

16 Green RS-485B

(1) Wire colors apply only to 4-wire cable supplied by Micro Motion.

(1)

Function

2

)

12

Page 14

Figure 13. 4-wire cable to Model 3700 – standard core processor

Core processor

VDC+

(Red)

VDC–

(Black)

terminals

RS-485B

(Green)

RS-485A

(White)

4-wire cable Model 3700 terminals

Maximum cable length:

see Table 1

User-supplied or

factory-supplied cable

blue terminal block

(see Figure 11)

16 RS-485B (Green)

15 RS-485A (White)

14 VDC– (Black)

13 VDC+ (Red)

Figure 14. 4-wire cable to Model 3700 – enhanced core processor

Core processor

terminals

RS-485A (White)

RS-485B (Green)

4-wire cable Model 3700 terminals

Maximum cable length:

see Table 1

User-supplied or

factory-supplied cable

blue terminal block

(see Figure 11)

VDC– (Black)

VDC+ (Red)

13

16 RS-485B (Green)

15 RS-485A (White)

14 VDC– (Black)

13 VDC+ (Red)

Page 15

Wiring instructions for remote core processor with remote transmitter

There are two phases to this procedure:

• Wiring the remote core processor to the transmitter

• Wiring the sensor to the remote core processor

To wire the remote core processor to the transmitter:

1. Use one of the following methods to shield the wiring:

• If you are installing unshielded wiring in continuous metallic

conduit that provides 360° termination shielding for the enclosed

wiring, go to Step 6.

• If you are installing a user-supplied cable gland with shielded

cable or armored cable, terminate the shields in the cable gland.

Terminate both the armored braid and the shield drain wires in the

cable gland. Go to Step 6.

• If you are installing a Micro Motion-supplied cable gland at the

core processor housing:

- If you are using shielded cable, prepare the cable and apply

shielded heat shrink as described in Step 4. The shielded heat

shrink provides a shield termination suitable for use in the

gland when using cable whose shield consists of foil and not

a braid. Go to Step 2.

- If you are using armored cable, prepare the cable as described

in Step 4, but do not apply heat shrink – omit Steps 4d, e, f,

and g. Go to Step 2.

2. Identify the components shown in Figure 10. Remove the core

processor lid.

3. Slide the gland nut and the clamping insert over the cable.

14

Page 16

3/4 in

(19 mm)

4 1/2 in

(114 mm)

Gland nut

Gland clamping

insert

7/8 in

(22 mm)

Shielded

heat shrink

7/8 in

(22 mm)

Gland body

4. For connection at the core processor housing, prepare shielded cable

as follows (for armored cable, omit steps d, e, f, g):

a. Strip 4 1/2 inches (114 mm) of cable jacket.

b. Remove the clear wrap that is inside the cable jacket, and remove

the filler material between the wires.

c. Remove the foil shield that is around the insulated wires, leaving

3/4 inch (19 mm) of foil or braid and drain wires exposed, and

separate the wires.

d. Wrap the shield drain wire(s) around the exposed foil twice. Cut

off the excess wire.

Shield drain wire(s) wrapped twice around exposed shield foil

e. Place the shielded heat shrink over the exposed shield drain

wire(s). The tubing should completely cover the drain wires.

f. Without burning the cable, apply heat (250 °F or 120 °C) to shrink

the tubing.

15

Page 17

Shielded heat shrink completely covers exposed drain wires

g. Position gland clamping insert so the interior end is flush with the

heat shrink.

h. Fold the cloth shield or braid and drain wires over the clamping

insert and approximately 1/8 inch (3 mm) past the O-ring.

i. Install the gland body into the core processor housing conduit

opening.

5. Insert the wires through the gland body and assemble the gland by

tightening the gland nut.

6. Identify the wires in the 4-wire cable. The 4-wire cable supplied by

Micro Motion consists of one pair of 18 AWG (0,75 mm

2

) wires (red

and black), which should be used for the VDC connection, and one

2

pair of 22 AWG (0,35 mm

) wire (green and white), which should be

used for the RS-485 connection. Connect the four wires to the

numbered slots on the core processor.

16

Page 18

Power supply +

(Red wire)

Power supply –

(Black wire)

Core processor housing internal ground screw

• For connections to earth ground (if core processor cannot be grounded via sensor piping and

local codes require ground connections to be made internally)

• Do not connect shield drain wires to this terminal

RS-485B

(Green wire)

RS-485A

(White wire)

7. Reinstall and tighten the core processor lid.

WARNING

Twisting the core processor will damage the sensor.

Do not twist the core processor.

8. To connect the cable to the transmitter, connect the four wires from the

core processor to the appropriate terminals on the transmitter. See

Table 3 and Figure 13. No bare wires should remain exposed. Do not

ground the shield or drain wire(s) at the transmitter.

To wire the sensor to the remote core processor:

CAUTION

Allowing the shield drain wires to contact the sensor

junction box can cause meter errors.

Do not allow the shield drain wires to contact the sensor

junction box.

17

Page 19

1. Refer to Micro Motion’s 9-Wire Flowmeter Cable Preparation and

Installation Guide for instructions on cable shielding and

preparation:

• At the sensor end, follow the instructions for your cable type.

• At the core processor end, follow the instructions for your cable

type with an MVD transmitter.

2. To connect the wires, refer to Micro Motion’s 9-Wire Flowmeter

Cable Preparation and Installation Guide and follow the instructions

for your sensor with an MVD transmitter. Additional information for

connecting the wires at the core processor is provided below:

a. Identify the components shown in Figure 10.

a. Remove the core processor’s end-cap.

b. Insert the 9-wire cable through the conduit opening.

c. Connect the wires to the plugs supplied with the core processor.

d. Insert the plugs into the sockets inside the lower conduit ring. See

Figure 15.

Figure 15. 9-wire cable to core processor

9-wire cable from

sensor

Black

(Drains from

all wire sets)

Brown

Red

Green

White

Blue

Gray

Orange

Violet

Yellow

Brown

Yellow

Plug and

socket

Core processor

Ground screw

Black

Violet

Mounting screw

Red

Green

White

Blue

Gray

Orange

3. Ground the cable. If using jacketed cable:

a. Ground the shield drain wires (the black wire) only on the core

processor end, by connecting it to the ground screw inside the

lower conduit ring. Do not ground to the core processor’s

mounting screw. Do not ground the cable at the sensor junction

box.

18

Page 20

If using shielded or armored cable:

a. Ground the shield drain wires (the black wire) only on the core

processor end, by connecting it to the ground screw inside the

lower conduit ring. Do not ground to the core processor’s

mounting screw. Do not ground the cable at the sensor junction

box.

b. Ground the cable braid on both ends, by terminating it inside the

cable glands.

4. Ensure integrity of gaskets, grease all O-rings, then close the junction

box housing and core processor end-cap, and tighten all screws.

CAUTION

Damaging the wires that connect the transmitter to

the sensor can cause measurement error or meter

failure.

To reduce the risk of measurement error or meter failure,

when closing the housings on the sensor and core

processor, make sure that the wires are not caught or

pinched.

STEP 8. Connecting power supply wiring

CAUTION

Improper wiring installation can cause device failure

or measurement error.

• To avoid device failure or measurement error, do not

install power supply wiring in the same cable tray or

conduit as input/output wiring.

• Shut off power supply before installing the applications

platform.

• Make sure power supply voltage matches voltage that

is indicated on power supply wiring terminals. See

Figure 12.

19

Page 21

Connect the Model 3350/3700 to a power supply as follows:

1. Use 18 to 12 AWG (0,75 to 4,0 mm

2

) wire.

2. Using a flat-head screwdriver, loosen the captive screws that secure

the display cover to the housing.

3. Ground the transmitter as follows:

• Connect the ground wire to the green screw (power supply

ground; see Figure 11).

• Connect the power supply ground wire directly to earth ground.

• Keep all ground leads as short as possible.

• Ground wiring must have less than 1 ohm impedance.

4. Connect wires to terminals 9 and 10 on the gray terminal block (see

Figures 11 and 12).

5. Close the display cover and tighten the screws.

6. A user-supplied switch may be installed in the power supply line. For

compliance with low-voltage directive 73/23/EEC (European

installations), a switch in close proximity to the Model 3350/3700 is

required.

20

Page 22

21

Page 23

22

Page 24

©2005, Micro Motion, Inc. All rights reserved. P/N 20001008, Rev. B

*20001008*

Visit us on the Internet at www.micromotion.com

Micro Motion Inc. USA

Worldwide Headquarters

7070 Winchester Circle

Boulder, Colorado 80301

T (303) 527-5200

(800) 522-6277

F (303) 530-8459

Micro Motion Europe

Emerson Process Management

Veenendaal

The Netherlands

T +31 (0) 318 495 670

F +31 (0) 318 495 689

Micro Motion United Kingdom

Emerson Process Management Limited

Horsfield Way

Bredbury Industrial Estate

Stockport SK6 2SU U.K.

T 0800 966 180

F 0800 966 181

Micro Motion Asia

Emerson Process Management

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T (65) 6777-8211

F (65) 6770-8003

Micro Motion Japan

Emerson Process Management

Shinagawa NF Bldg. 5F

1-2-5, Higashi Shinagawa

Shinagawa-ku

Tokyo 140-0002 Japan

T (81) 3 5769-6803

F (81) 3 5769-6843

Loading...

Loading...