Page 1

TopWorx™ D-ESD: Partial Stroke & Emergency Shutdown

Installation, Operation & Maintenance Manual

Page 2

Credible Solutions

Page 3

Table of Contents

Page 4 ESD Theory of Operation

Page 5 Installation on Actuator

Page 6 Pneumatic Hookup Procedures

Page 8 ESD Conventional Instruction & Operation-Fail Closed Valves Partial

Page 10 Stroke Tolerance Range Selection/Partial Stroke Test ESD

Page 11 Calibration-Fail Closed Valves

Page 12 ESD Conventional Instruction & Operation-Fail Open Valves Partial

Page 13 Stroke Tolerance Range Selection/Partial Stroke Test ESD

Page 15 Calibration/PST Flow Chart-Fail Open Close

Page 18 Dimensions and Materials: TopWorx™ DXP

Page 19 Dimensions and Materials: TopWorx™ DXP - Flameproof Ex d IIC

Page 20 Dimensions and Materials: TopWorx™ DXS

Page 21 Interior & Indicator Assembly

Page 22 Certications & Approvals

Page 25 Safe Use

Page 4

ESD Theory of Operation:

R

STROKE TEST

COM

INDI

The purpose of the TopWorx™ Emergency Shut-Down (ESD) model is to partially stroke a valve that maintains a full open or full closed

position for an extended period of time while offering an ESD function. A partial stroke test (PST) veries functionality of critical valves that

must be in their fail position during an emergency. Increasing the frequency of partial stroke testing (i.e. reducing the proof test interval)

improves the SIL (Safety Integrity Level) that the system can achieve through a reduction in the PFD avg (Average Probability of Failure On

Demand). These partial stroke tests can be performed without shutting down or disrupting the process. In an emergency, the ESD function

overrides partial stroke testing and the valve moves to its fail position.

This ESD unit incorporates a sensor communication module (SCM-ESD) to perform the partial stroke test, verify its status, and output

that status back to the user. In combination with the SCM, the ESD unit uses either the optional TopWorx™ pilot and spool valve or a

customersupplied solenoid valve to drive the actuator during both normal operation and partial stroke testing. A TopWorx™ GO™ Switch is

included for partial stroke conrmation and two (2) limit switches built into the SCM conrm open and close position.

Once the unit is installed, the SCM-ESD must be calibrated for that specic valve, actuator, and solenoid exhaust settings. During calibration,

the unit records the time to partially stroke the valve. All future PST times are compared to this original value for determining the test status.

To pass a PST, the time must be within +/-20%, 30%, or 40% of the stored calibration value. This PST time tolerance can be changed prior to

calibration.

The partial stroke test is initiated via an optional partial stroke test button with a lockable cover, the calibration button on the top of the SCM,

or a simulated closed dry contact from the PLC or DCS. Upon issuing a PST command, the SMC-ESD begins a timer while switching a relay to

de-energize the pilot/ solenoid. The valve moves from its normal position toward its fail position until the GO™ Switch is made. Once made,

the SCM energizes the pilot/solenoid and the valve moves to its normal position while outputting the PST status.

Option ES: SCM

PST

SWITCH

POSITION 1

INDICATION (OPEN)

POSITION 2

CATION (CLOSED)

CAL/ALARM

TopWorxTM ESD

POSITION 2

LED (RED)

CAL SW

ALARM

POSITION 1

LED (GREEN)

COMPSI

DIAGNOSTIC

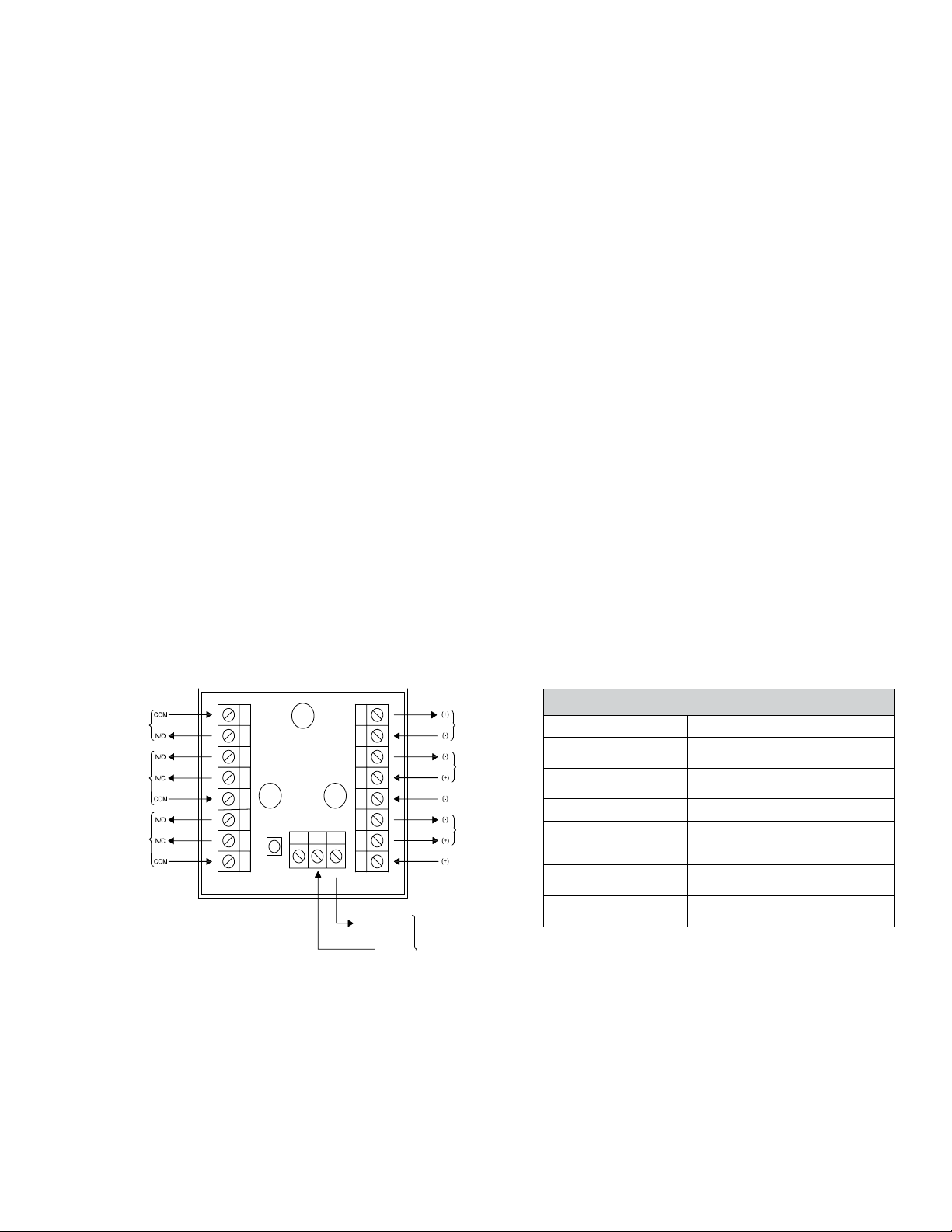

Figure 1: Input/Output Diagram

PARTIAL

PST / CAL

ACTIVATION

PARTIAL STROKE

MODULE POWE

PILOT VALV E

CONTROL

TO

PILOT VALV E

PILOT VALV E

CONTROL

Electrical Ratings

Current/Voltage

Open/Closed Indication 0.25A@24VDC w/5V drop

Dry Contact Rating Minimum Current Through Switch

Module Voltage 18-28VDC

Module Current 50mA (MAX)

Pilot Current (Standard) 20mA

PST Feedback Relays 800mA@24VDC MAX

Solenoid Pilot/SOV

Maximum PowerRating

0.25A@120VAC w/5V drop

Contacts: 5 mA

250mA@125VAC MAX

800mA@24VDC MAX

250mA@125VAC MAX

4

Page 5

Installation on Actuator

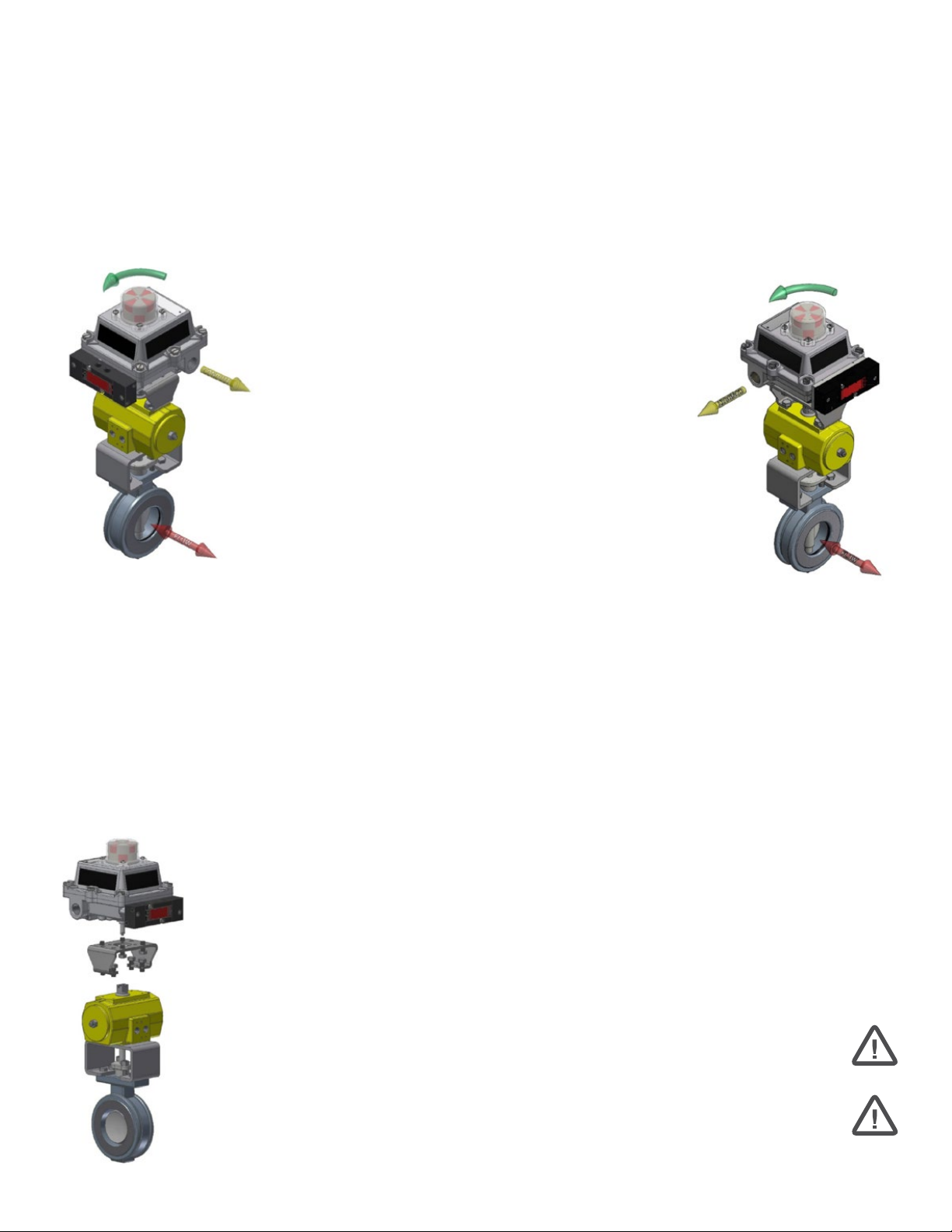

Orientations, Normal and Reverse Acting

Normal acting is full clockwise when the process valve is closed and counterclockwise when the process valve is open.

Reverse acting is full clockwise when the process valve is open and counterclockwise when the process valve is closed.

90° indicator dome assemblies are designed to accommodate any mounting arrangement and can be adjusted up to 9° off axis if needed.

45° indicator dome assemblies can only accommodate normal acting applications that are mounted parallel ±9°.

Consult your local distributor or factory representative for 45° reverse acting or mounted perpendicular applications.

The image to the left shows a TopWorx™ unit mounted parallel

to the process valve in the closed position. The green arrow at

the top shows the “normal acting” direction of travel to open

the valve. This is the standard orientation and unless otherwise

specied, your unit will be factory set to operate in this fashion.

The image to the right shows a TopWorx™ mounted

perpendicular to the process valve in the closed position. The

green arrow at the top shows the “normal acting” direction of

travel to open the valve.

Mounting

TopWorx™ has numerous mounting bracket kits, both rotary and linear, available to meet your specic application. Consult your local

distributor or factory representative for ordering information. The illustration below shows a direct NAMUR mount on a quarter turn valve.

Refer to your mounting kit documentation for specic mounting instructions.

Storage

Until conduit, conduit covers, and any applicable spool valve port connections are properly installed, the TopWorx™ unit will not support its

IP/NEMA rating as the unit ships with temporary covers. Ensure that it is stored in a dry environment with a relative humidity range between

10%-95% and a temperature ranging from -40°F (-40°C) to 160°F (71°C). Once properly installed, the temperature range listed on the

nameplate will supersede this storage temperature range.

Mounting Assembly

Installation Notes

Use caution not to allow undue axial (thrust) load on the shaft.

1. Cycle the valve a couple of times prior to nal tightening of the mounting kit hardware. This allows the shaft

to self-center in the pinion slot, or coupler. Refer to the dimensions and materials section of this document for

appropriate tightening torque. Please refer to the Proof Testing section for proper safety function setup.

2. Always use sound mechanical practices when applying torque to any hardware or making pneumatic

connections. Refer to the Integrated Pneumatic Control Valves section for detailed information.

3. This product comes shipped with conduit covers in an effort to protect the internal components

from debris during shipment and handling. It is the responsibility of the receiving and/or

installing personnel to provide appropriate permanent sealing devices to prevent the

intrusion of debris or moisture when stored or installed outdoors.

4. It is the responsibility of the installer, or end user, to install this product in accordance with

the National Electrical Code (NFPA 70) or any other national or regional code dening proper

practices.

Page 6

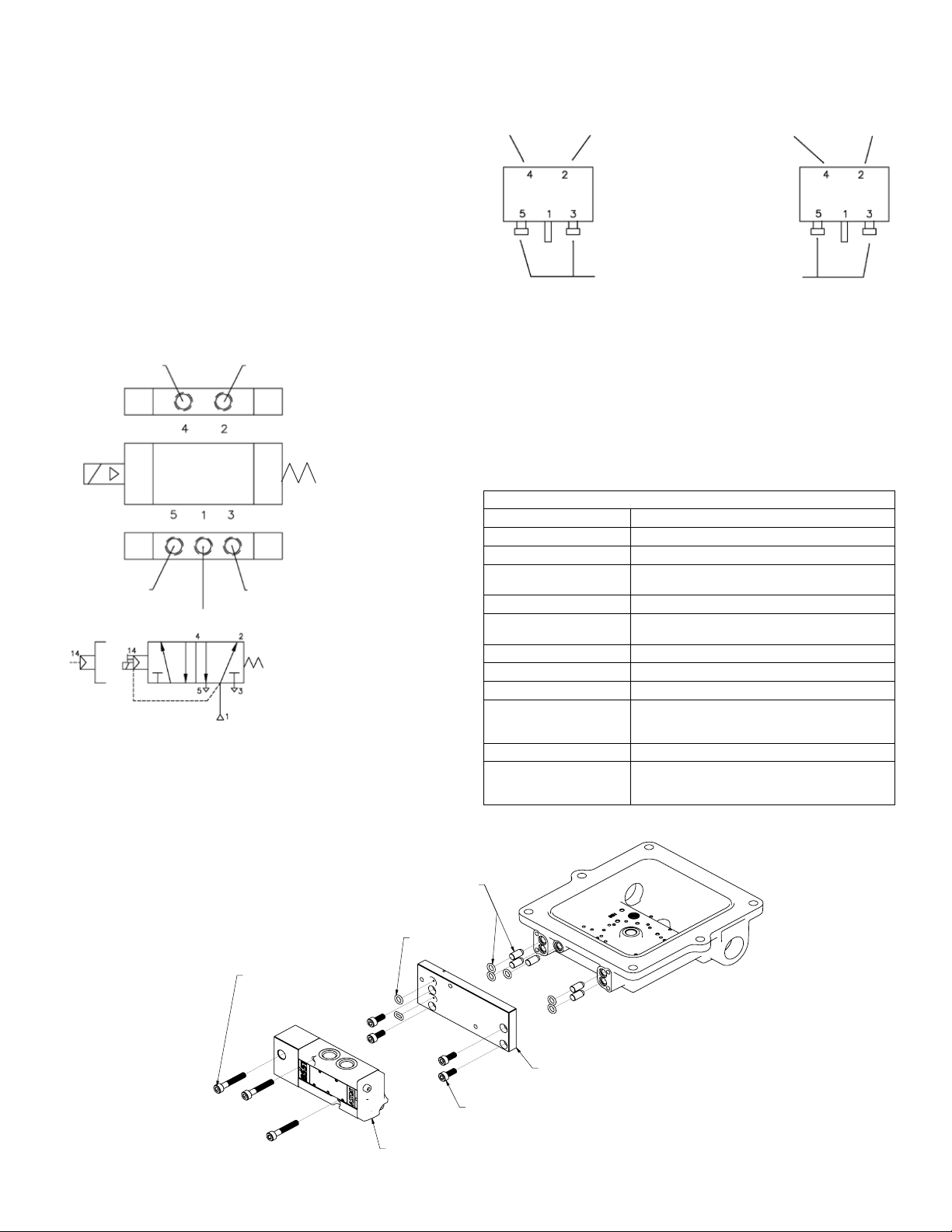

Pneumatic Hookup Procedures

Prior to connecting the supply air to the spool valve, ush the

system to remove any debris or contaminates. Galvanized pipe

can easily ake and contaminate the system and therefore is not

recommended. A 40 micron point of use lter at every device is

recommended.

PORT TO OPEN

PORT TO CLOSE

PORT TO OPEN/CLOSE

PLUG

4-Way Spool Valves

The TopWorx™ spool valve is a 5 port, 4-way valve driven by an

internally mounted pilot. The spool valve supply port and work ports

are marked as follows:

PORT TO

ACTUATOR OPEN

EXHAUST OF PORT 4

(WHEN ACTUATOR CLOSES)

(WHEN ACTUATOR OPENS)

SUPPLY

FAIL CLOSED

PORT TO

ACTUATOR CLOSE

EXHAUST OF PORT 2

Spool Valve Assembly

SUPPLY SUPPLY

DOUBLE ACTING ACTUATORS SPRING RETURN ACTUATORS

ALWAYS INSTALL VENTS ALWAYS INSTALL VENTS

Highly Recommended

TopWorx™ highly recommends Locktite 567 brand thread sealant.

Do not use a hard setting pipe compound. If Teon thread seal tape

is used, start the wrap on the second thread from the leading thread

of the tting. This will prevent tape shreds from contaminating the

spool valve seals.

Breathers (AL-M31) should be installed in the exhaust ports to keep

debris from falling into the spool valve and damaging the seals. This

must be addressed prior to installation, or storage.

VALVE SPECIFICATION

ITEM PERFORMANCE

Media Air

Media temperature Min: -40°C (-40°F); Max: 60°C (140°F)

Operational ambient

temperature

Inlet/system pressure Min: 45 PSI (3.1 bar); Max: 150 PSI (10.3 bar)

Operational pressure

differential

Safe working pressure 150 PSI (10.3 bar)

Flow / Cv (Kv) Cv = 0.86 (Kv = 0.74)

Body port connections 1/4” NPT

Allowable leakage External: 2 sccm

Optimal design life 500,000 cycles

Material in contact with

uid

* Refer to the wiring diagram on the inside lid of your product to determine actual

pin out location

Min: -40°C (-40°F); Max: 60°C (140°F)

Min: 45 PSI (3.1 bar); Max: 150 PSI (10.3 bar)

Internal: 10 cc/min max for -15°C to 60°C.

3300 cc/min max for -40°C to -15°C

Body: Aluminium (black anodized) and

Stainless Steel 316L

Internal: Stainless Steel, LT, nitrile, PTFE, Acetal

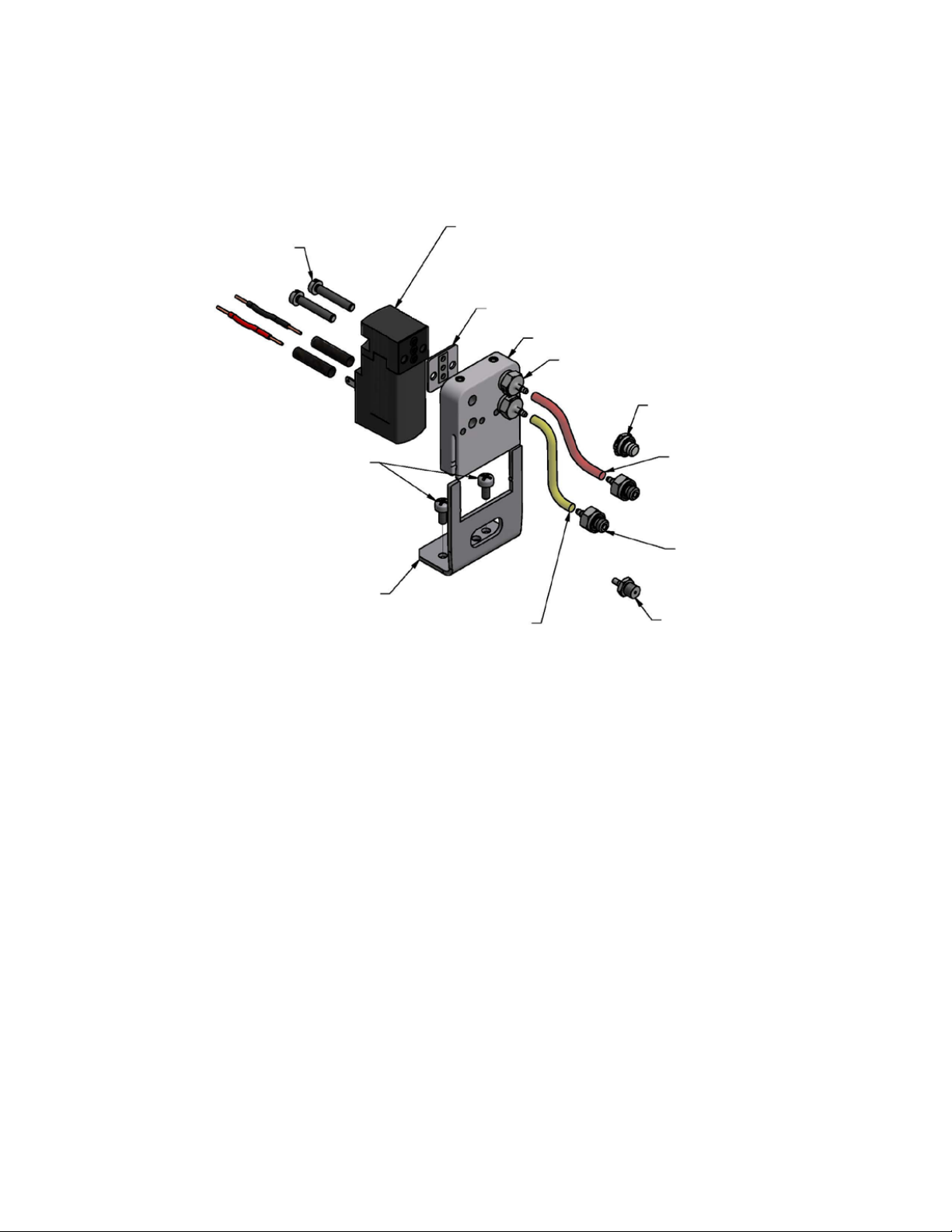

M5 X 30MM

SCHS (X3)(4MM

HEX WRENCH)

FLAME ARRESTORS & ORINGS (X5)

O-RINGS (X2)

ASCO™ VALVE WITHOUT

MANUAL OVERIDE

M5 X 12MM SCHS (X4)

(4MMHEX WRENCH)

6

ADAPTER PLATE

Page 7

Spool Valves and Pilots

M3 X 18 CHEESE HEAD SCREW

TORQUE TO 20 IN-OZ

SINGLE PILOT ASSEMBLY

PILOT

ASCO™ 302

MINI PIEZO

AMISCO 110 VAC

AMISCO 220 VAC

SEAL AND PLATE

(NOT USED WITH MINI PIEZO)

MANIFOLD

10-32 METAL BARB FITTING

TORQUE TO 60 IN-OZ

10-32 METAL PLUG

4-40 X .25” SEM SCREW

TORQUE TO 100 IN-OZ

BRACKET

YELLOW URETHANE

TUBING (WORK)

RED URRETHANE

TUBING (SUPPLY)

10-32 METAL BARB FITTING

TORQUE TO 60 IN-OZ

ORIFICE TO BE USED IN

EXPLOSION PROOF APPLICATIONS

Page 8

ESD CONVENTIONAL INSTRUCTION AND OPERATION—Fail Closed Valves

Operation: Before operation, the ESD must be calibrated (see Calibration below). After calibration, a Partial Stroke Test (PST) may be

performed (see Partial Stroke Test below). The partial stroke time tolerance range can be selected as 20%, 30% or 40% (see Partial Stroke Time

Tolerance Range Selection below). A single switch (on board and external) is used to perform the calibration, the partial stroke test and the

tolerance range selection. These operations can be initiated from the control room with no need to shut down the entire plant. Nonvolatile

memory stores the calibration value and the selected tolerance range value allowing for retention, even in the event of loss of power. The LED,

both onboard and in the control room, ashes unique visual indicators to signal pass/fail of tests and possible maintenance issues (please see

ESD Conventional Flow Chart and Message Table for ESD Conventional for more details).

*Note that the following instructions assume the valve is FAIL CLOSED and the direction of travel from CLOSED to OPEN is CCW.

Fail Closed

GO™ Switch connection (Prewired) Exte rnal PST but ton (Prew ired)

Valve Pos 1 (Op en) switch NO con tact. Du ring bench te sting only, ad d a

2500 Ohm, 1/2 W res istor for pat h back to DC supp ly via termin al 6.

Valve Pos 1 NC C ontact

Valve Posi tion 1 (Open). COM. T ie it to Valve Posi tion 1 COM 24VDC+

Valve Pos 2 (Clo sed) switc h NO contact . During ben ch testing o nly, add a

2500 Ohm, 1/2 W res istor for pat h back to DC supp ly via termin al 6.

Valve Pos 2 NC C ontact

Valve Posi tion 2(Closed) s witch COM con tact,

wire it ba ck to Terminal 5 24VD C+

Figure 2: Suggested Test Bench Setup for Fail Closed Applications

BLUE

Black

Calibration Switch

CALIBRATION

TopWorx™ ESD

POSITION 2

LED (RED)

CAL SW

LED (AMBER)

POSITION 1

LED (GREEN)

ALARM COM PSI

Power for electronics module 24VDC-

Power for electronics module 24VDC+

Soleno id Pilot or SOV O utput (-)

BL ACK (-)

To Solenoid P ilot or SOV

RE D (+)

Soleno id Pilot or SOV O utput (+)

800mA@24VDC MAX

250mA@125VAC MAX

Option al externa l diagnosti c signal. If wi red, will pas s pulses out

the same a s the LED ashe s for the calib ration diag nostic (pg. #16)

Option al externa l signal COMMO N.

Tie it to th e Valve Pos 1 and 2 COM

Optional external alarm signal.

If wired , will close i f PST calibr ation if pass es.

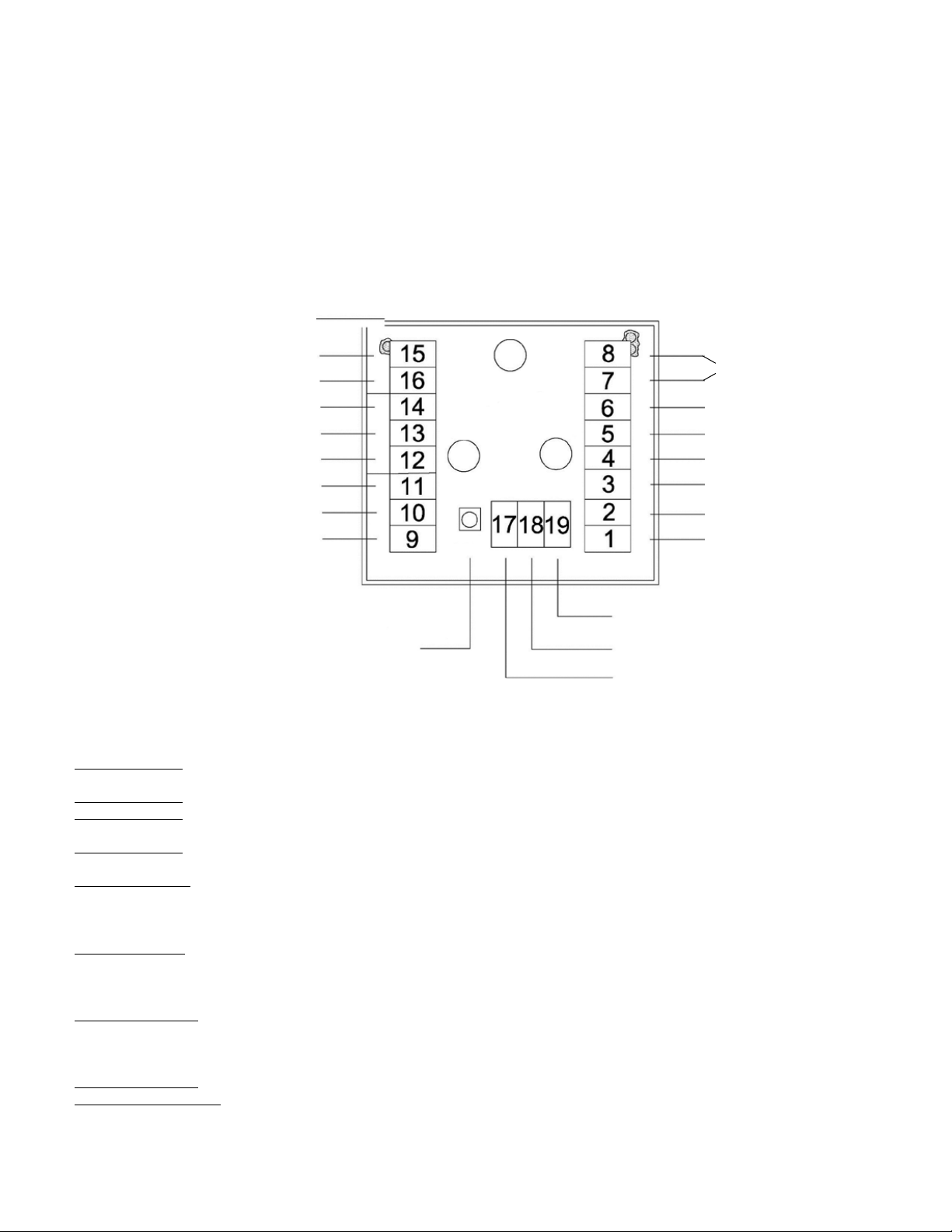

Wiring Connections:

1. Terminals 1 and 4: External power source for switching the solenoid valve. Type and voltage level must match type of solenoid selected.

Typical is 24VDC.

2. Terminals 2 and 3: Output to solenoid pilot or SOV.

3. Terminals 5 and 6: Power for electronics module. 5 MUST be +24VDC and 6 MUST be –24VDC.You can jumper the power from terminals 1

and 4 ifthe Solenoid is rated for 24VDC where a separate 24VDC supply is not available.

4. Terminals 7 and 8: Connection to external calibration and partial stroke test button (if installed). Can be used to remotely trigger PST and

Calibration from aDCS.

5. Terminals 9 and 11: Switch common and normally open connections for valve position 2 limit switch. Typically connected to DCS for limit

switch sensing. Forbench calibration or use in applications where alternate means of sensing valve position are used, these 2 terminals

must still be provided withsource and return. The source and return for the electronics module power can be used, but a 2500 Ohm, 1/2W

resistor MUST be installed betweenterminals 6 and 11 to prevent damage to the limit switch contacts from excess current.

6. Terminals 10 & 13: N/C side of Position 1 and 2 limit switch. Make sure current through switch is limited below maximum rating. If the

system this unit is implemented on is monitoring the N/C side of the switches, a 2500 ohm, 1/2W resistor will need to wired between

terminals 10 and 6, as well terminal 13 and 6 for visual indication. If the system is monitoring the N/O side, neither of these terminals are

used.

7. Terminals 12 and 14: Switch common and normally open connections 1 limit switch. Typically connected to DCS for limit switch sensing.

For benchcalibration or use in applications where alternate means of sensing valve position are used, these 2 terminals must still be

provided with source andreturn. The source and return for the electronics module power can be used, but a 2500 Ohm, 1/2W resistor

MUST be installed between terminals 6and 14 to prevent damage to the limit switch contacts from excess current.

8. Terminals 15 and 16: Prewired to the GO™ Switch. Do not change these connections.

9. Terminals 17, 18 and 19: External PST status signals:

A. Terminal 17: PST status signal. In combination with terminal 18, it forms a dry contact that closes if the PST passes.

B. Terminal 18: 24VDC source terminal for diagnostics and status output signal. Wire this to DCS 24VDC output.

C. Terminal 19: PST diagnostic signal. When wired to a DCS DC I/O input, will deliver a pulse train after PST completes to report any

diagnostic information.

8

Page 9

Partial Stroke Time Tolerance Range Selection:

1. The default partial stroke time tolerance range is set to 20%. This value can be selected as 20%, 30% or 40% anytime.The value will be

recorded in the EEPROM (memory) of the micro controller.

2. Press and hold the push button for ten to fteen seconds to set the partial stroke time tolerance range to 20%.If the value is saved to

memory successfully, the LED and diagnostic relay will ash message code 5-1.

3. Press and hold the push button for within fteen to twenty seconds to set the partial stroke time tolerance range to 30%.If the value is

saved to memory successfully, the LED and diagnostic relay will ash message code 5-2.

4. Press and hold the push button for more than twenty seconds to set the partial stroke time tolerance range to 40%.If the value is saved to

memory successfully, the LED and diagnostic relay will ash message code 5-3.

5. If there is a writing value to memory failure, the LED and diagnostic relay will ash message code 6-6. The Pass/Fail relay willbe turned OFF.

Figure 3

Hardware Conguration:

1. Ensure that the valve is in the OPEN position (the green position 1 LED should be

illuminated.)

2. Refer to Fig. 3 which shows the correct orientation of the GO™ Switch target and sensor

camsfor FAIL CLOSED valves.

3. If the unit conforms to this conguration, you may proceed to calibration. If not,

completeHardware Conguration steps 4-7.

4. Lift the target wheel and rotate it such that the magnet is counterclockwise from the

GO™ Switch.

5. Loosen and slide the magnet in the target wheel so as to position it approximately one

inch from theedge of the GO™ Switch. Tighten to 20 in-oz.

6. Lift up on the upper cam and rotate it such that it is squarely aligned to the front of the

electronicsmodule. The green light on the module should come on.

7. Press down on the lower cam and rotate it such that it is 90º counter clockwise from the

electronics module.

Calibration:

1. Before performing calibration, make certain the valve is fully open (the green position 1 LED should be illuminated,) and the target button

is set to the properpartial position.

*NOTE: If the valve is not fully open, the test will abort and the LED and diagnostic relay will ash message code 7- 7 indicating

thatthe valve is not fully open. The Pass/Fail relay will be turned OFF.

2. Press and hold the calibration button on board for ve to ten seconds.

3. The activation relay will be turned ON to initiate valve closing.

4. The valve will move until the GO™ Switch detects the partial stroke position.

5. The GO™ Switch will send feedback indicating that the predetermined position is reached.

6. The time required to move the valve from the “fully open position” to the “partially open position” is the partial stroke time of the valve.

The acceptable timeranges are from fty milliseconds to thirty seconds. This “partial stroke calibration time” will be recorded in the

EEPROM (memory) of the micro controller.EEPROM will retain the value until your next calibration.

7. If the calibration is successful, the Pass/Fail relay will be turned ON and both the LED and diagnostic relay will ash message code 3-3.

8. After the LED ashes code for three cycles, both the LED and diagnostic relay will be steady, signifying that the calibration is complete.

Reset of the ashingLED and the diagnostic relay may be performed at anytime while the LED is ashing by pressing the calibration button.

Page 10

Partial Stroke Test:

1. Before performing the Partial Stroke Test (PST), make certain the valve is fully open.

* NOTE: If the valve is not fully open, the test will abort and the LED and diagnostic relay will ash message code 7-7

indicating that the valve isnot fully open. The Pass/Fail relay will be turned OFF.

2. If using the onboard module calibration button, press the button and hold it for more than half a second and less than ve seconds.

If using the optional external PST button, push rmly once.

3. The activation relay will be turned ON to initiate valve closing.

4. The valve will move until the GO™ Switch detects the partial stroke position.

5. The time required to move the valve to the partial stroke position will be compared against the “partial stroke calibration time”

value stored in EEPROM (memory). The acceptable time ranges from “(1-tolerance range value) x partial stroke calibration time”

to”(1+tolerance range value) x partial stroke calibration time”. For example, if the partial stroke calibration time is 6 seconds and the

tolerance range value is 20%, the acceptable PST time ranges are from 4.8 to 7.2 seconds.

6. If the time required for moving the valve to the Partial Stroke position is outside the acceptable range of the “partial stroke

calibration time”, the test will beaborted, indicating valve failure. The Pass/Fail relay will remain OFF and both the LED and

diagnostic relay will ash message code 5-5 if the valve has moved. If the valve has not moved, the Pass/Fail relay will remain OFF

and both the LED and diagnostic relay will ash code 4-4.

CAUTION: Beforerecalibration, make sure any failure codes are addressed (see table pg.#16).

7. If the time required is within the acceptable range, the Pass/Fail relay will be turned ON and both the LED and Diagnostic Relay will

ash message code 2-2 .

8. After the LED ashes code for three times, both the LED and diagnostic relay will be steady, signifying that the Partial Stroke Test is

complete.

* Note: Partial Stroke Time Tolerance Range Selection, Calibration or Partial Stroke Test cannot be performed when the LED is

ashing. Before rerunning the test, please wait for the LED to become steady or clear it by pressing the button.

10

Page 11

ESD Calibration/PST Flow Chart—Fail Closed Valves

Apply power

NO

NO

Is partial stroke

position reached?

YES

Is minimum allewed

time (50ms) passed?

YES

Valve opens

LED displays

valve is not

calibrated code

1-1 pass/fail

relay state 0

Is memory ok?

NO

Is button

releasedbefore

5 seceonds?

YES

Begin partial stroke test

YES

Is valve fully open? Is valve fully open?

YES YES

Is device calibrated?

YES

Is stored calibrated value

for partial stroke time

within range?

YES

Valve closes

NO

NO

Has valve moved?

LED displays

valve closing

time failure code

5-5 pass/fail

relay state 0

NO

NO NO

Valve opens

NO

Is calibrartted

time passed?

Valve opens

NO

YES

LED displays

valve has not

moved code

4-4 pass/fail

relay state 0

Write uncalibrated status to momory

NO

Is maximum

allowed time

(30s) passed?

YES

Valve opens Valve opens

LED displays

valve is not

fully open code

7-7 pass/fail

relay state 0

Is device calibrated?

Is button pressed and held

for at least 0.5 seconds?

Is button

released before

10 seceonds?

Begin partial stroke calibration

Writing status value to

memory successful?

Valve closes

LED displays

valve closing

time failure code

5-5 pass/fail

relay state 0

YES

YES

YES

YES

YES

NO

stroke position

NO

allowed time (50ms)

calibrated value

NO

Is partial

reached?

YES

Is minimum

passed?

YES

Is writing

to memory

successful?

YES

NO

NO

Is button

released before

15 seceonds?

YES

Set partial stroke time

tolerance range to 20%

NO

NO

NO

LED displays

writing error code 6-6

pass/fail relay state 0

LED displays memory error

continuous fast ashing

Pass/fail relay state 0

NO

released before

tolerance range to 30%

Is writing

tolerance

range value to

memory

successful?

YES

Is writing

tolerance

range value to

memory

successful?

Is button

20 seceonds?

Set partial stroke time

YES YES

error code 6-6 pass/fail

NO

YES

Set partial stroke time

tolerance range to 40%

NO

LED displays writing

relay state 0

range value to

Is button

released?

YES

Is writing

tolerance

memory

successful?

NO

LED displays

partial stroke test

complete code 2-2

for all tolerance range

pass/fail relay state 1

LED displays

calibrarion

complete code

3-3 pass/fail

relay state 1

LED displays

range set to

20% complete

code 5-1

LED displays

range set to

30% complete

code 5-2

LED displays

range set to

40% complete

code 5-3

Page 12

ESD CONVENTIONAL INSTRUCTION AND OPERATION—Fail Open Valves

Operation:

For operation, the ESD must be calibrated (see Calibration below). After calibration, a partial stroke test may be performed (see Partial

Stroke Test below). The partial stroke time tolerance range can be selected as 20%, 30% or 40% (see Partial Stroke Time Tolerance Range

Selection below). A single switch (on board and external) is used to perform the calibration, the partial stroke test and the tolerance range

selection. These operations can be initiated from the control room with no need to shut down the entire plant. Nonvolatile memory stores the

calibration value and the selected tolerance range value allowing for retention, even in the event of loss of power. The LED, both onboard and

in the control room, ashes unique visual indicators to signal pass/fail of tests and possible maintenancei ssues (please see ESD Conventional

Flow Chart and Message Table for ESD Conventional on pg.#15 for more details).

*Note that the following instructions assume the valve is FAIL OPEN and the direction of travel from CLOSED to OPEN is CCW.

Fail Open

GO™ Switch connection (Prewired)

Valve Pos 1 (Clo sed) switc h NO contact , needs path

(Add a 2500 O hm 1/2W resistor to pa th)

Valve Posi tion 1(Closed) COM . Tie it to Valve P osition 1 COM

Valve Pos 2 (Op en) switch NO con tact, ne eds path back t o DC

Valve Posi tion 2(Open) swi tch COM contac t, wire it ba ck to

Figure 4:

Suggested Test Bench Setup for

Fail Open Applications

(Add a 2500 O hm 1/2W resistor to pa th)

BLUE

Black

back to DC

Valve Pos 1 NC C ontact

Valve Pos 2 NC C ontact

Terminal 5

CALIBRATION

LED (AMBER)

TopWorx™ ESD

POSITION 2

LED (RED)

CAL SW

Calibration

Switch

POSITION 1

LED (GREEN)

ALARM COM PSI

Exte rnal PST but ton (Prew ired)

Power for electronics module 24VDC-

Power for electronics module 24VDC+

Soleno id Pilot or SOV O utput (-)

BL ACK (-)

RE D (+)

Soleno id Pilot or SOV O utput (+)

800mA@24VDC MAx

250mA@125VAC Max

Option al externa l diagnosti c signal. If wi red, will pas s pulses out th e same as

the LED a shes for the ca libration d iagnostic ( pg.#16)

Option al externa l signal COMMO N.

Tie it to th e Valve Pos 1 and 2 COM

Optional external alarm signal. If wired, will close if PST calibration passes.

Wiring Connections:

1. Terminals 1 and 4: External power source for switching the solenoid valve. Type and voltage level must match type of solenoid selected.

Typical is 24VDC.

2. Terminals 2 and 3: Output to solenoid pilot or SOV.

3. Terminals 5 and 6: Power for electronics module. 5 MUST be +24VDC and 6 MUST be –24VDC.You can jumper the power from

terminals 1 and 4 if the Solenoid is rated for 24VDC where a separate 24VDC supply is not available.

4. Terminals 7 and 8: Connection to external calibration and partial stroke test button (if installed). Can be used to remotely trigger PST and

Calibration from a DCS.

5. Terminals 9 and 11: Switch common and normally open connections for valve position 2 limit switch. Typically connected to DCS for

limit switch sensing. For bench calibration or use in applications where alternate means of sensing valve position are used, these 2

terminals must still be provided with source and return. The source and return for the electronics module power can be used, but

a 2500 Ohm, 1/2W resistor MUST be installed between terminals 6 and 11 to prevent damage to the limit switch contacts from

excess current.

6. Terminals 10 & 13: N/C side of Position 1 and 2 limit switch. Make sure current through switch is limited below maximum rating. If

the system this unit is implemented on is monitoring the N/C side of the switches, a 2500 ohm, 1/2W resistor will need to wired

between terminals 10 and 6, as well terminal 13 and 6 for visual indication. If the system is monitoring the N/O side, neither of

these terminals are used.

7. Terminals 12 and 14: Switch common and normally open connections 1 limit switch. Typically connected to DCS for limit switch sensing.

For bench calibration or use in applications where alternate means of sensing valve position are used, these 2 terminals must still

be provided with source and return. The source and return for the electronics module power can be used, but a 2500 Ohm, 1/2W

resistor MUST be installed between terminals 6 and 14 to prevent damage to the limit switch contacts from excess current.

8. Terminals 15 and 16: Prewired to the GO™ Switch. Do not change these connections..

9. Terminals 17, 18 and 19: External PST status signals:

A. Terminal 17: PST status signal. In combination with terminal 18, it forms a dry contact that closes if the PST passes..

B. Terminal 18: 24VDC source terminal for diagnostics and status output signal. Wire this to DCS 24VDC output.

C. Terminal 19: PST diagnostic signal. When wired to a DCS DC I/O input, will deliver a pulse train after PST completes to report any

diagnostic information.

12

Page 13

Partial Stroke Time Tolerance Range Selection:

1. The default partial stroke time tolerance range is set to 20%. This value can be selected as 20%, 30% or 40% anytime.The value will be

recorded in the EEPROM (memory) of the micro controller.

2. Press and hold the push button for ten to fteen seconds to set the partial stroke time tolerance range to 20%.If the value is saved to

memory successfully, the LED and diagnostic relay will ash message code 5-1.

3. Press and hold the push button for within fteen to twenty seconds to set the partial stroke time tolerance range to 30%.If the value is

saved to memory successfully, the LED and diagnostic relay will ash message code 5-2.

4. Press and hold the push button for more than twenty seconds to set the partial stroke time tolerance range to 40%. If the value is saved

tomemory successfully, the LED and diagnostic relay will ash message code 5-3.

5. If there is a writing value to memory failure, the LED and diagnostic relay will ash message code 6-6. The Pass/Fail relay will be turned OFF.

Figure 5

Hardware Conguration:

1. Ensure that the valve is in the CLOSED position (the green position 1 LED should be

illuminated).

2. Refer to Fig. 5 which shows the correct orientation of the GO™ Switch target and sensor

cams for FAILOPEN valves.

3. If the unit conforms to this conguration, you may proceed to calibration. If not,

complete HardwareConguration steps 4-7.

4. Lift the target wheel and rotate it such that the magnet is counterclockwise from the

GO™ Switch.

5. Loosen and slide the magnet in the target wheel so as to position it approximately one

inch from the edgeof the GO™ Switch. Tighten to 20in-oz.

6. Lift up on the upper cam and rotate it such that it is squarely aligned to the front of the

electronicsmodule. The green light on the module should come on.

7. Press down on the lower cam and rotate it such that it is 90º counter clockwise from the

electronics module.

Calibration:

1. Before performing calibration, make certain the valve is fully closed (the green position 1 LED should be illuminated,) and the target

button is set to the properpartial position.

*NOTE: If the valve is not fully closed, the test will abort and the LED and diagnostic relay will ash message code 7-7 indicating

that the valve is not fully closed. The Pass/Fail relay will be turned OFF.

2. Press and hold the calibration button on board for ve to ten seconds.

3. The activation relay will be turned ON to initiate valve closing.

4. The valve will move until the GO™ Switch detects the partial stroke position.

5. The GO™ Switch will send feedback indicating that the predetermined position is reached.

6. The time required to move the valve from the “fully closed position” to the “partially closed position” is the partial stroke time of the

valve. The acceptable timeranges are from fty milliseconds to thirty seconds. This “partial stroke calibration time” will be recorded in the

EEPROM (memory) of the micro controller.EEPROM will retain the value until your next calibration.

7. If the calibration is successful, the Pass/Fail relay will be turned ON and both the LED and diagnostic relay will ash message code 3-3.

8. After the LED ashes code for three times, both the LED and diagnostic relay will be steady, signifying that the calibration is complete.

Reset of the ashingLED and the diagnostic relay may be performed at anytime while the LED is ashing by pressing the calibration button.

Page 14

Partial Stroke Test:

1. Before performing the Partial Stroke Test (PST), make certain the valve is fully open.

* NOTE: If the valve is not fully open, the test will abort and the LED and diagnostic relay will ash message code 7-7

indicating that the valve isnot fully open. The Pass/Fail relay will be turned OFF.

2. If using the onboard module calibration button, press the button and hold it for more than half a second and less than ve seconds.

If using the optional external PST button, push rmly once.

3. The activation relay will be turned ON to initiate valve closing.

4. The valve will move until the GO™ Switch detects the partial stroke position.

5. The time required to move the valve to the partial stroke position will be compared against the “partial stroke calibration time”

value stored in EEPROM (memory). The acceptable time ranges from “(1-tolerance range value) x partial stroke calibration time”

to”(1+tolerance range value) x partial stroke calibration time”. For example, if the partial stroke calibration time is 6 seconds and the

tolerance range value is 20%, the acceptable PST time ranges are from 4.8 to 7.2 seconds.

6. If the time required for moving the valve to the Partial Stroke position is outside the acceptable range of the “partial stroke

calibration time”, the test will beaborted, indicating valve failure. The Pass/Fail relay will remain OFF and both the LED and

diagnostic relay will ash message code 5-5 if the valve has moved. If the valve has not moved, the Pass/Fail relay will remain OFF

and both the LED and diagnostic relay will ash code 4-4.

CAUTION: Beforerecalibration, make sure any failure codes are addressed (see table pg.#16).

7. If the time required is within the acceptable range, the Pass/Fail relay will be turned ON and both the LED and Diagnostic Relay will

ash message code 2-2 .

8. After the LED ashes code for three times, both the LED and diagnostic relay will be steady, signifying that the Partial Stroke Test is

complete.

* Note: Partial Stroke Time Tolerance Range Selection, Calibration or Partial Stroke Test cannot be performed when the LED is

ashing. Before rerunning the test, please wait for the LED to become steady or clear it by pressing the button.

14

Page 15

ESD Calibration/PST Flow Chart—Fail Closed Valves

Apply power

NO

NO

Is partial stroke

position reached?

YES

Is minimum allewed

time (50ms) passed?

YES

Valve closes

LED displays

valve is not

calibrated code

1-1 pass/fail

relay state 0

Is memory ok?

YES

NO

Is button

releasedbefore

5 seceonds?

YES

Begin partial stroke test

YES

Is valve fully closed? Is valve fully closed?

YES YES

Is device calibrated?

YES

Is stored calibrated value

for partial stroke time

within range?

YES

Valve opens

NO

NO

Has valve moved?

LED displays

valve opening

time failure code

5-5 pass/fail

relay state 0

NO

NO NO

Valve closes

NO

Is calibrartted

time passed?

Valve closes

NO

YES

LED displays

valve has not

moved code

4-4 pass/fail

relay state 0

Write uncalibrated status to momory

NO

Is maximum

allowed time

(30s) passed?

YES

Valve closes Valve closes

LED displays

valve is not

fully closed code

7-7 pass/fail

relay state 0

Is device calibrated?

YES

Is button pressed and held

for at least 0.5 seconds?

YES

Is button

released before

10 seceonds?

YES

Begin partial stroke calibration

Writing status value to

memory successful?

YES

Valve opens

NO

NO

LED displays

valve opening

time failure code

5-5 pass/fail

relay state 0

NO

NO

Is partial

stroke position

reached?

YES

Is minimum

allowed time (50ms)

passed?

YES

Is writing

calibrated value

to memory

successful?

YES

writing error code 6-6

pass/fail relay state 0

NO

NO

Is button

released before

15 seceonds?

YES

Set partial stroke time

tolerance range to 20%

NO

range value to

NO

LED displays

LED displays memory error

continuous fast ashing

Pass/fail relay state 0

NO

Is writing

tolerance

memory

successful?

Is button

released before

20 seceonds?

Set partial stroke time

tolerance range to 30%

YES

Is writing

tolerance

range value to

memory

successful?

NO

Is button

released?

YES

Set partial stroke time

tolerance range to 40%

NO

YES YES

LED displays writing

error code 6-6 pass/fail

relay state 0

YES

Is writing

tolerance

range value to

memory

successful?

NO

LED displays

partial stroke test

complete code 2-2

for all tolerance range

pass/fail relay state 1

LED displays

calibrarion

complete code

3-3 pass/fail

relay state 1

LED displays

range set to

20% complete

code 5-1

LED displays

range set to

30% complete

code 5-2

LED displays

range set to

40% complete

code 5-3

Page 16

Message Table for ESD Conventional

LED Status Flash

Code

Solid ON Unit operating correctly No action required

1 - 1 Device not calibrated Need to perform the calibration procedure before the partial stroke test

2 - 2

3 - 3 Calibration completed No action required

4 - 4

5 - 1

5 - 2

5 - 3

5 - 5 Partial stroke test failed

6 - 6 Module memory error Contact factory

7 - 7

Continuous fast

ashing

Diagnostic Relay Message Problem Cause / Solution

Partial stroke test passed within

tolerance range

Valve has not moved during

partial stroke test

Partial stroke time tolerance

range is set to 20%

Partial stroke time tolerance

range is set to 30%

Partial stroke time tolerance

range is set to 40%

Valve is not fully at the required

open or closed position

Hardware failure Contact factory

No action required

Possible causes include:

1) The valve is stuck

2) The shaft is broken

No action required

No action required

No action required

The valve did not reach the partial stroke position within the allotted time. Possible causes include:

1) The valve is stuck or sluggish

2) The GO™ Switch target for the partial stroke position is set incorrectly

3) The shaft is broken

Unit cannot calibrate or run a partial stroke test without the valve starting in the required open or

closed position. Check the following:

1) Air supply to actuator

2) Solenoid is powered

3) Cam setting for fail open or fail closed valves as required

Electrical Ratings

Current/Voltage

Open/Closed Indication 0.25A@24VDC w/5V drop

Dry Contact Rating Minimum Current Through Switch

Module Voltage 18-28VDC

Module Current 50mA (MAX)

Pilot Current (Standard) 20mA

PST Feedback Relays 800mA@24VDC MAX

Solenoid Pilot/SOV

Maximum PowerRating

0.25A@120VAC w/5V drop

Contacts: 5 mA

250mA@125VAC MAX

800mA@24VDC MAX

250mA@125VAC MAX

Diagnostic Relay and Pass/Fail Relay Outputs:

The diagnostic relay outputs the status ash code as shown in the

Message Table Above.

DIAGNOSTIC RELAY

TIMING CHART

EXAMPLE OF A 2-2 RESPONSE

The Pulse Train will repeat 3 times. In order to use this diagnostic

relay output, control logic should count the number of positive

transitions in order to get the message number. Clear the count

register in the logic when you see a logic low (open) for more than

one second. The Pulse Train can be reset anytime by activating the

Calibration Switch or the PST/Calibration Activation Input.

16

Page 17

Pass/Fail Relay:

The Pass/Fail Relay indicates whether the PST passed or failed. In this

example the relay is closed (high) from the last successful Partial

Stroke Test.

PASS / FAIL RELAY

TIMING CHART

PARTIAL STROKE TEST

SWITCH / ACTIVATION

(USER INITIATED)

PASS / FAIL RELAY

(HIGH = CLOSED)

When the Partial stroke test button is pressed for less than 5 seconds

the test begins and the Pass/Fail Relay opens (low). The Pass/Fail

Relay closes again once the unit passes a Partial Stroke Test.

Hardware Fault Tolerance: HFT = 0

Device Type: Type A

Systematic Capability: SC3 - SIL3 Capable

Useful Life: 10 years

The proof test procedure should verify the ESD valve controller allows

the ESD valve to function 100% on command, and that any failures

related to the valve, actuator or partial stroke test function are

revealed. The partial stroke test should be preformed monthly.

Special Conditions of Safe Use (All installations)

Clean only with a damp cloth to prevent possibility of

electrostatic discharge.

For Explosion Proof installations, the internal ground connection shall

be used and the external ground connection, if supplied in addition,

is supplemental bonding allowed where local authorities permit, or is

required.

When installing with a third party listed nipplemount solenoid, it is

the responsibility of the installer to provide ttings, and apparatus,

suitable for the area classication in accordance with the National

Electrical Code.

All cable entry devices or conduit stopping boxes shall be certied

in type of explosion protection ‘d’, suitable for the conditions of use

and correctly installed.

The IIC enclosures are excluded from use in Carbon disulphide

atmospheres.

The air pressure to the valve block, when tted, shall not exceed 7

bar.

Preventative Maintenance

TopWorx™ are designed to operate for one million cycles without

servicing. Call the factory when you are approaching this milestone

for a preventative maintenance kit and instructions.

Personal preforming maintenance and testing on the product shall

be competent to do so.

Page 18

Dimensions and Materials: TopWorx™ DXP

Cast aluminum bracket is recommended for installation with SS 8553 valve in vibrating environment.

Enclosure Cast A360 aluminum with dichromate

Fasteners 304 Stainless Steel standard

Shaft 304 Stainless Steel standard

Shaft Bushing Oilite Bronze

Indicator Dome Polycarbonate, UV F1 rated

Seals O -ring seals available in:

Enclosure Housing Bolts 8 ft.-lbs [10.8 N·m] +/-10%

Indicator Dome Screws 320 in-oz. [2.3 N·m] +/-10%

Bottom Mounting Holes 10 ft.-lbs [13.6 N·m] +/-10%

SHAFT TYPE OPTIONAL

SEE SHAFT DETAIL SECTION

MINIMUM 2.25” (63.5) REQUIRED CLEARANCE

IN ORDER TO DISENGAGE THE SHAFT FROM THE LID BUSHING

AND REMOVE LID WHERE OPTIMUM CONDITIONS APPLY

MATERIALS OF CONSTRUCTION

conversion coating inside & out, epoxy

coated exterior rated for 250 hrs. salt

spray per ASTM B117

316 Stainless Steel optional

316 Stainless Steel optional

Buna, & Silicone

Fastener Torque Specications

18

Page 19

Dimensions and Materials: TopWorx™ DXP - Flameproof Ex d IIC

Cast aluminum bracket is recommended for installation with SS 8553 valve in vibrating environment.

IN ORDER TO DISENGAGE THE SHAFT FROM THE LID BUSHING

AND REMOVE LID WHERE OPTIMUM CONDITIONS APPLY

SHAFT TYPE OPTIONAL

SEE SHAFT DETAIL SECTION

MINIMUM 2.25” (63.5) REQUIRED CLEARANCE

MOUNTING SURFACE

Enclosure Cast A360 aluminum with dichromate

Fasteners 304 Stainless Steel standard

Shaft 304 Stainless Steel standard

Shaft Bushing Oilite Bronze

Indicator Dome Polycarbonate, UV F1 rated

Seals O -ring seals available in:

Enclosure Housing Bolts 8 ft.-lbs [10.8 N·m] +/-10%

Indicator Dome Screws 320 in-oz [2.3 N·m] +/-10%

Bottom Mounting Holes 10 ft-lbs [13.6 N·m] +/-10%

MATERIALS OF CONSTRUCTION

conversion coating inside & out, epoxy

coated exterior rated for 250 hrs. salt

spray per ASTM B117

316 Stainless Steel optional

316 Stainless Steel optional

Buna, & Silicone

Fastener Torque Specications

VALVE TYPE OPTIONAL

SEE INTEGRATED PNEUMATIC

CONTROL VALVES SECTION

Page 20

Dimensions and Materials: TopWorx™ DXS

Cast aluminum bracket is recommended for installation with SS 8553 valve in vibrating environment.

IN ORDER TO DISENGAGE THE SHAFT FROM THE LID BUSHING

AND REMOVE LID WHERE OPTIMUM CONDITIONS APPLY

SHAFT TYPE OPTIONAL

SEE SHAFT DETAIL SECTION

MINIMUM 2.5” (63.5) REQUIRED CLEARANCE

MOUNTING SURFACE

OPTIONAL CONDUIT ENTRIES USED

ONLY WHEN 4 ENTRIES ARE SPECIFIED

OPTIONAL CONDUIT ENTRIES

BOTH SIDES

MATERIALS OF CONSTRUCTION

Enclosure Cast 316 Stainless Steel

Fasteners 304 Stainless Steel standard

316 Stainless Steel optional

Shaft 304 Stainless Steel standard

316 Stainless Steel optional

Shaft Bushing N/A

Indicator Dome Polycarbonate, UV F1 rated

Seals O -ring seals available in:

Buna, & Silicone

Fastener Torque Specications

Enclosure Housing Bolts 8 ft.-lbs [10.8 N·m] +/-10%

Indicator Dome Screws 320 in-oz. [2.3 N·m] +/-10%

Bottom Mounting Holes 10 ft.-lbs [13.6 N·m] +/-10%

20

VALVE TYPE OPTIONAL

SEE INTEGRATED PNEUMATIC

CONTROL VALVES SECTION

Page 21

Interior and Indicator Assemblies

Interior Assembly

24 VDC PILOT

ESD MODULE CONTAINS (2) REED

RELAYS FOR FULL OPEN/CLOSED

INDICATION PLUS TIMER CIRCUIT

TARGET WHEEL

UPPER CAM

LOWER CAM

ENCLOSURE

DXP TROPICALIZED ALUMINUM

DXS 316 STAINLESS STEEL

TARGET MAGNET

CAM TARGET

MODEL 35 GO SWITCH TO SET

PARTIAL STROKE POSITION

VALVE

ANODIZED ALUMINUM

316 STAINLESS STEEL

0.86 Cv 1/4” NPT PORTS

3.7 Cv 1/2” NPT PORTS

PAD LOCK PROVIDED

BY END USER

OPTIONAL EXTERNAL PUSH PIEZO SWITCH

WITH LOCKING SHIELD FOR INITIATING

THE PARTIAL STROKE PROCEDURE

Page 22

Certications & Approvals

PESO

Ex d IIC T* Gb or Ex d IIB+H2 T* Gb; Ex tb IIC T* Db IECEx SIR 07.0093X / Sira 07ATEX1273X USL/CNL Class I,

Div 1, GrCD; Class II, Div 1, GrEFG UL File E125326

EAC RU C-US, M1062.B0027

KOSHA 19-GA4B0-0179X, 19-GA4BO-0180X & 19-GA4BO-0178X

NEPSI GY18.1386X

InMetro UL-BR 18.0096X

PESO P433642

Ex e MB IIC T* Gb; Ex tb IIIC T* Db

IECEx SIR 09.0088X / Sira 09ATEX3209X (DXR)

Ex nA nC IIC T* Gc; Ex tb IIIC T* Dc

USL/CNL Class I, Div 2, GrABCD; Class II, Div 2, GrFG UL

File E125326

USL/CNL General Purpose UL

File E359150

Environmental Ratings: Type 4, 4X; IP 66/67

Conformance to Directives: ATEX 2014/34/EU, EMC 2014/30/EV, LVD 2014/35/EO

*Operating and Ambient temperature ratings vary depending on bus/sensor option(s), reference certicate for specic markings available.

Consult factory for certication questions or to request a custom product.

22

Page 23

Page 24

24

Page 25

Safe Use

User instructions (in compliance with ATEX 2014/34/EU Directive, Annex II, 1.0.6)

Instructions for safe selection, installation, use, maintenance and repair

1. The equipment may be used in zones 1 or 2.

2. The equipment may be used in the presence of ammable gases and vapors with apparatus groups IIC or IIB or IIA and with temperature

classes T3, T4, T5 or T6.

3. The equipment is certied for use in ambient temperatures in the range of -50°C to +60°C and should not be used outside this range.

(NOTE: Ambient temperature range may change according to protection method)

4. The equipment is to be installed by suitably trained personnel in accordance with the applicable code of practice

(typically IEC 60079-14)

5. Under certain extreme circumstances, the plastic cover over the valve position indicator may generate an ignition-capable level of

electrostatic charge. Therefore, particularly in the event of an installation in zone 0, the equipment shall not be installed in a location

where the external conditions are conducive to the build-up of electrostatic charge, e.g. wind-blown dust, etc. Additionally the equipment

shall only be cleaned with a damp cloth.

6. Periodic inspection of the equipment and system should be performed by suitably trained personnel in accordance with the applicable

code of practice (typically IEC 60079-17) to ensure it is maintained in a satisfactory condition.

7. The equipment does not require assembly or dismantling.

8. The equipment is not intended to be repaired by the user. Repair of the equipment is to be carried out by the manufacturer, or their

approved agents, in accordance with the applicable code of practice.

Special Conditions of Safe Use (All installations)

Clean only with a damp cloth to prevent possibility of electrostatic discharge.

For Explosion Proof installations, the internal ground connection shall be used and the external ground connection, if supplied in addition, is

supplemental bonding allowed where local authorities permit, or is required.

When installing with a third party listed nipple-mount solenoid, it is the responsibility of the installer to provide ttings, and apparatus,

suitable for the area classication in accordance with the National Electrical Code.

All cable entry devices or conduit stopping boxes shall be certied according to protection type and suitable for the conditions of use and

correctly installed.

The IIC enclosures are excluded from use in carbon disulphide atmospheres.

The air pressure to the valve block, when tted, shall not exceed 10.0bar.

Special Conditions or Safe Use (Flameproof Installations)

1. The IIC enclosures are excluded from use in carbon disulphide atmospheres.

2. The air pressure to the valve block, when tted, shall not exceed 10.0 bar.

3. For ambient temperatures above 110ºC, the degrees of ingress protection IP66 and IP67 are not endorsed.

4. The slotted hexagonal head cover screws are not of standard form; they shall only be replaced with identical screws sourced from the

equipment manufacturer.

5. The hexagonal head cover screws are to be replaced only with stainless steel 304, grade A2-70 or A4-80 screws to ISO 35061.

6. Periodic inspection of the equipment and system should be performed by suitably trained personnel in accordance with the applicable

code of practice (typically IEC 60079-17) to ensure it is maintained in a satisfactory condition.

7. Cover fasteners are to be tightened to a torque valve of 10.85Nm (8 ft./lbs) minimum.

Page 26

Notes:

26

Page 27

Page 28

GLOBAL SUPPORT OFFICES

North America

3300 Fern Valley Road

Louisville, Kentucky 40213 USA

T. +1 502 969 8000

info.topworx@emerson.com

Asia-Pacific

Asia Pacic Pte Ltd - TopWorx

c/o ASCO ASIA

BLK4008, Ang Mo Kio Avenue

10 #04-17/22, Techplace 1

Singapore 569625

Europe

Horseld Way

Bredbury Industrial Estate

Stockport SK6 2SU UK

T. +44 0161 406 5155

info.topworx@emerson.com

T. +65 6891 7550

info.topworx@Emerson.com

Middle East

P.O. Box 17033

Jebel Ali Free Zone

Dubai 17033

United Arab Emirates

T. +971 4 811 8283

Africa

24 Angus Crescent

Longmeadow Business Estate

East Modderfontein

Gauteng South Africa

T. +27 11 451 3700

info.topworx@emerson.com

For comprehensive information on our company, capabilities, and products –

including model numbers, data sheets, specications, dimensions, and certications:

Visit us: Emerson.com/TOPWORX

Your local contact: Emerson.com/contactus

The Emerson logo is a trademark and service mark of Emerson Electric Co. TopWorx™ and GO™ Switch

are registered trademarks of the Emerson family of companies. All other marks are the property of their

respective owners. © 2020 Emerson Electric Co. All rights reserved.

Information contained herein - including product specications is subject to change without notice.

ES-00936-1 R19-ENUS |06-20

28

Loading...

Loading...