Page 1

Therm-O-Disc

Product Information

INNOVATIVE SOLUTIONS

Page 2

Sensing Solutions

Hermetic Solutions

Putting systems in touch with their

surroundings to enable new levels of

understanding, awareness, and response.

Electro-

Mechanical

Bimetals

Thermal

Fuses

(TCO)

Packaged

Sensors

Temperature

Gasoline

Vapors

Wireless

WiHART

Power

Enabling safe, reliable, and effi cient system control.

Ensuring a robust electrical or signal

connection across adverse

environmental conditions.

Engineered Products

AC/R

Terminals

SH Plates

Power Bolts

Sight Glass

Industrial

Sensor/Power

Feedthroughs

Battery Seals

Defense

Packages

Feedthroughs

Initiator

Assemblies

Laser Lidding

Trustworthy, stable

company with over 75

years of proven reliability

Over 1/2 billion units

produced annually

Leading product

application experts

Broadest range of

product options

Local, direct support,

worldwide

Rapid custom

prototypes

Page 3

Bimetal Disc

Thermostat

Product Information and

Application Notes

Page 4

Table of Contents

Application Notes ...........................................................................................................................................3

10H /10HMR ................................................................................................................................................12

10RS .............................................................................................................................................................16

12S, 14S, 15S ...............................................................................................................................................19

14T ...............................................................................................................................................................26

30M ..............................................................................................................................................................33

36T /36TMR/36F ..........................................................................................................................................38

37T ...............................................................................................................................................................52

39T ...............................................................................................................................................................61

44T, 48T .......................................................................................................................................................65

49T, 49F .......................................................................................................................................................70

58T ...............................................................................................................................................................74

59T, 66T .......................................................................................................................................................79

60T/60TMR ..................................................................................................................................................85

60F, 61F ........................................................................................................................................................95

64T,64F ........................................................................................................................................................98

69T ............................................................................................................................................................ 102

74T ............................................................................................................................................................ 108

75TF .......................................................................................................................................................... 112

HLX ........................................................................................................................................................... 117

Page 5

Bimetal Disc Thermostat

Application Notes

Operating Principles

Bimetal disc thermostats are thermally actuated switches.

When the bimetal disc is exposed to its predetermined calibration

temperature, it snaps and either opens or closes a set of contacts.

This breaks or completes the electrical circuit that has been applied

to the thermostat.

Bimetal Disc Thermostat Therm-O-Disc3

Page 6

There are three basic types of thermostat switch actions:

• Automatic Reset: This type of control can be built to either open or close its electrical contacts as the temperature

increases. Once the temperature of the bimetal disc has returned to the specifi ed reset temperature, the contacts

will automatically return to their original state.

• Manual Reset: This type of control is available only with electrical contacts that open as the temperature increases. The contacts may be reset by manually pushing on the reset button after the control has cooled below the

open temperature calibration.

• Single Operation: This type of control is available only with electrical contacts that open as the temperature

increases. Once the electrical contacts have opened, they will not automatically reclose unless the ambient that

the disc senses drops to a temperature well below room temperature (typically below -31°F).

Temperature Sensing & Response

Many factors can affect how a thermostat senses and responds to temperature changes in an application.

Typical factors include, but are not limited to, the following:

• Mass of the thermostat

• Switch head ambient temperature. The “switch head” is the

plastic or ceramic body and terminal area of the thermostat.

It does not include the sensing area

• Air fl ow across the sensing surface or sensing area.

The “sensing surface” (or area) consists of the bimetal disc and metal

disc housing

• Air fl ow across the switch head of the thermostat

• Internal heating from carrying the application electrical load

• Disc cup or housing type (i.e. enclosed, as on left in picture below, or

exposed, as on right)

• Rate of temperature rise and fall in the application

• Intimacy of contact between the thermostat sensing surface and the surface it is mounted on

• Heat transfer by conduction, convection or radiation

Therm-O-Disc Bimetal Disc Thermostat4

Page 7

It is important to understand that the temperature of the thermostat will typically change more slowly than or lag the

temperature it is trying to sense. The impact of the factors mentioned previously will determine the magnitude of the

thermal lag. Thermal lag will directly affect determination of thermostat calibration to regulate or limit temperature

for a particular application. Reference the “Determining Calibration” section for how to use a thermocouple sample

thermostat to establish thermostat calibration.

Control Location

The location of the thermostat should be carefully selected. Adequate time should be used to determine the

temperatures in the various locations within the product to assure the location of the sensor can best measure

and control the performance of the product. Various methods may be employed to measure these temperatures

such as infrared thermography, multiple thermocouples, etc.

Determining Calibration

A thermocouple sample thermostat is typically used as a key indication of what the calibration temperature of a

thermostat should be for a particular application (see Figure 3). The thermocouple is ideally attached internally to the

control on the bimetal disc for optimum results since the bimetal disc is the component that senses the temperature in

a bimetal thermostat. The sample control has the same thermal response as a functional thermostat but the

contacts will not open.

Once a preliminary calibration temperature has been determined with the thermocouple sample control, a

functional control calibrated at the desired temperature must be tested in the application to verify that the calibration

is appropriate. Therm-O-Disc provides thermocouple samples upon request. Type J, Type K, and Type T

thermocouples are available.

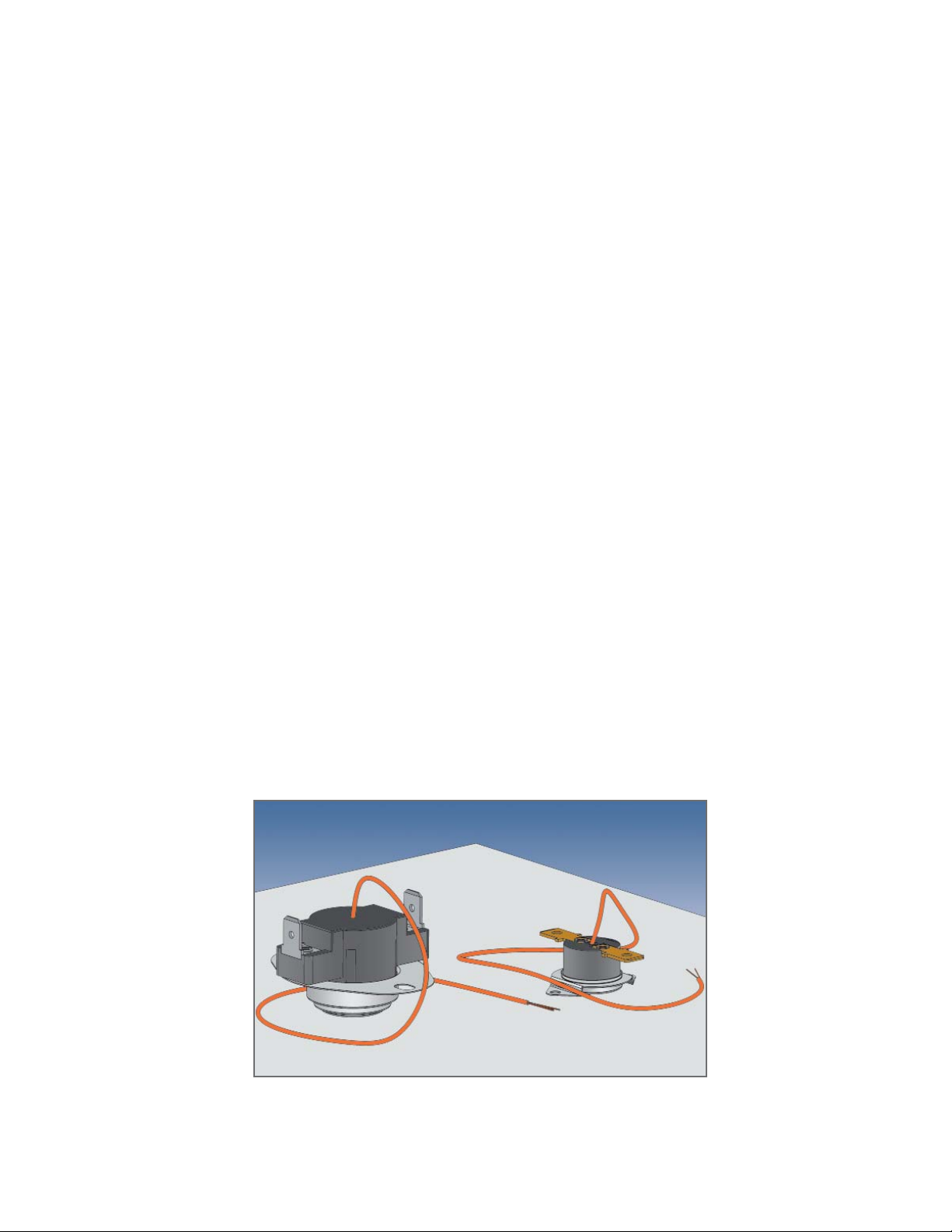

A thermocouple may be placed externally on a thermostat (see Figures 4 and 5). The preferable location would be on

the metal disc “cup” / mounting bracket at a point closest to the sensing surface. The sensing surface is the fl at area of

the “cup” or bimetal housing for thermostats with enclosed bimetal discs. Those with

exposed bimetal discs should have the thermocouple positioned as close to the disc as is practical. Care should be

taken to assure that the thermocouple wires do not contact one another except at the sensing junction.

Figure 3

Thermocouple Sample Controls

Bimetal Disc Thermostat Therm-O-Disc5

Page 8

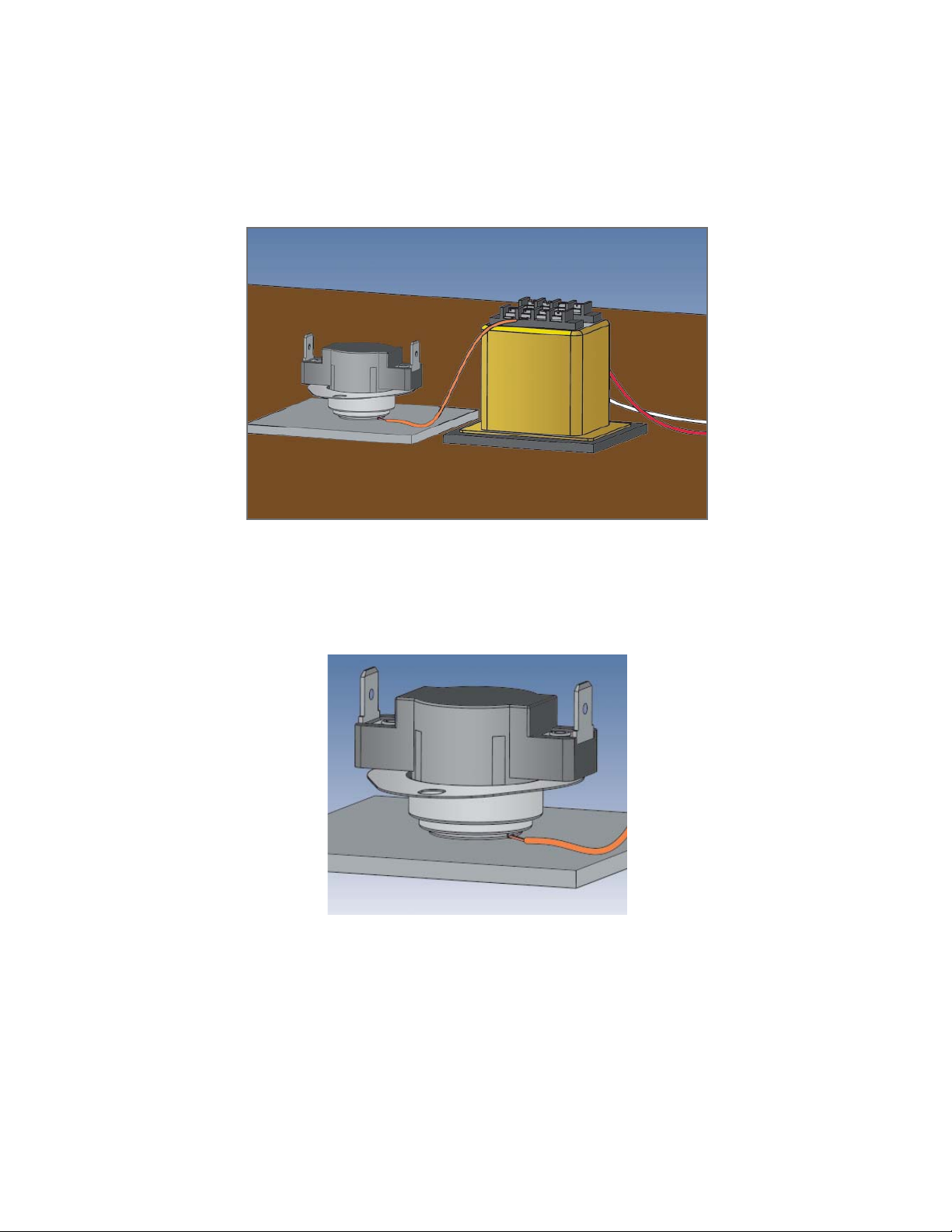

Figure 4

Thermocouple placed externally to thermostat

Figure 5

Thermocouple placed externally to thermostat

Therm-O-Disc Bimetal Disc Thermostat6

Page 9

Thermostats are used to both regulate and to limit temperatures.

A thermostat that regulates temperature is exposed to temperatures

of normal operating conditions of a particular application, plus an

overshoot temperature. A thermostat that limits temperature is exposed

to temperatures of abnormal operating conditions, plus an overshoot

temperature. It is important to determine both the normal and abnormal

operating temperatures as well as the respective temperature overshoots

in each application in order to specify the appropriate thermostat

calibration. Since most applications include both regulating and limiting

thermostats, it is essential to prevent nuisance tripping of the limit by

fully understanding the temperature overshoots. It is important to know

what the maximum exposure temperature is to assure that components

and complete units do not exceed their respective rated temperatures.

The maximum exposure temperature is the combined result of the maximum ambient temperature added to the

temperature increase due to the application plus the overshoot.

Test Guidelines

Install the thermocouple sample thermostat in the appropriate location (see earlier section named “Control Location”)

using both the same mounting and electrical connections as will be used in the application. The thermocouple lead

should be connected to a device that will monitor and record the output from the thermocouple. Only personnel

properly trained in the safe use of electrical equipment should perform testing. Caution must be exercised to assure

that line voltage, if present, must not injure personnel or damage equipment. Use of an isolation transformer is

recommended if there is any chance that the thermocouple wires may see line voltage.

CAUTION To avoid a false reading of the unit under test, thermocouple wires must not make contact with

each other except at the temperature sensing junction.

CAUTION Ensure that the thermocouple wire insulation will provide isolation against short circuiting and

shock hazards.

CAUTION The terminal of the temperature measuring instrument, to which the thermocouple is attached,

will be the same potential as the connecting circuit wire. This instrument must be

electrically isolated and considerable caution must be exercised in its use, since one of the

thermocouple terminals is frequently grounded to the instrument chassis.

It will likely be necessary to conduct several trials with varying ambient temperature, air fl ow rate and/or volume,

rate of temperature rise or fall, etc. to identify normal and abnormal operation. Normal manufacturing and

assembly variation between units and any applicable approval agency requirements or industry standards must

also be considered.

Bimetal Disc Thermostat Therm-O-Disc7

Page 10

Monitor the temperatures under normal operating conditions using the

thermocouple sample thermostat. Repeat using conditions for abnormal

operating conditions. Conduct as many trials as are necessary to understand

all the potential fault conditions and to assure that the rated temperature of

components (including the thermostat) and the test units are not exceeded.

The test may be set up to be able to manually open the electrical circuit

when the thermocouple sample thermostat reaches a particular target

temperature (as determined from testing described above). Continuing to

monitor the temperature of the thermocouple sample after the circuit is

manually opened, and determining the maximum temperature excursion

beyond the “open” temperature can determine the temperature overshoot.

This can be conducted for both regulating and limiting thermostats. Once the preliminary calibration value for the

thermostat has been determined, by taking into account normal and abnormal operating conditions, product and

test variation and overshoots, it is necessary to repeat testing with functional thermostats. It may be necessary to

try thermostats calibrated both higher and lower than the targeted temperature to better optimize the calibration

temperature. This will also provide useful information for specifying the calibration tolerance.

Important Notice

Users must determine the suitability of the control for their application, including the level of reliability required, and

are solely responsible for the function of the end-use product. These controls contain exposed electrical components

and are not intended to withstand exposure to water or other environmental contaminants which can compromise

insulating components. Such exposure may result in insulation breakdown and accompanying localized

electrical heating.

A control may remain permanently closed or open as a result of exposure to excessive mechanical, electrical, thermal

or environmental conditions or at normal end-of-life. If failure of the control to operate could result in personal injury

or property damage, the user should incorporate supplemental system control features to achieve the desired level of

reliability and safety. For example, backup controls have been incorporated in a number of applications for

this reason.

Therm-O-Disc Bimetal Disc Thermostat8

Page 11

Glossary

Ambient – The typical environmental temperature at which a product is exposed.

Approval Agencies – Agencies created to verify the safety and/or functionality of electrical and gas household

products. Therm-O-Disc products are typically recognized at the major global agencies, including UL, CSA, VDE,

CQC, and MITI.

Automatic Reset – A type of thermostat that will reset itself at a specific temperature (set point minus differential =

reset temperature).

Bimetal – Metallic strip material made by bonding two different materials together with different thermal

expansion rates.

Bumper – An actuating pin that transmits motion from the sensing mechanism to an actuating arm.

Contacts – Term for components used in all electrical-type products that physically make and break

electrical circuits.

Comparative Tracking Index (CTI) – A measure of material surface electrical tracking (resistance).

Cycle Rating – The agency-recognized number of operations that a control will function, given a specific temperature

range and electrical load.

Dielectric Strength – A product’s ability to withstand an application of a pre-determined over-voltage for a specified

period of time.

Differential – The temperature difference between the opening and closing points of a control.

Disc Cup – A cup that holds a disc in place on a disc-type control.

Disc – A thin, circular bimetallic component.

DPDT (Double Pole, Double Throw) – An electrical term where “pole” is a leg of an electrical circuit and “throw”

describes the switch action. Therefore, a DPDT will switch two legs and each leg will open a set of contacts, and close

another set (4 contacts).

DPST (Double Pole, Single Throw) – An electrical term where “pole” means a leg of an electrical circuit and “throw”

describes the switch action. Therefore, DPST will switch two legs and each leg is switched open or closed by one

mechanism.

Fan-Type Control – A thermal control designed such that the contacts close on temperature rise. Also referred to as

“close on rise,” or “normally open.”

Fuse-Type Control – A control built to cycle only once.

Limit-Type Control – A thermal control designed such that the contacts open on temperature rise. Also referred to as

“open on rise,” or “normally closed.”

M1 – Refers to manual reset devices. If the reset button is held down, the control can cycle thermally.

M2 – Refers to manual reset devices. If the reset button is held down, the control must stay open and not

reset automatically.

Bimetal Disc Thermostat Therm-O-Disc9

Page 12

Manual Reset (M.R.) – A control that opens automatically, but must be reclosed manually by pressing a button

or lever.

NTC (Negative Temperature Coefficient) – A resistor that reduces resistance (ohms) with a temperature increase.

Pole – The number of completely separate circuits contained in a control.

Prime Differential – The thermal differential between the nominal open temperature and the minimum close

temperature.

PTC (Positive Temperature Coefficient) – A resistor that increases resistance (ohms) with temperature increase.

Reference Dimension – A dimension without tolerance used only for information purposes that does not govern

production or inspection operations.

Reset Temperature – The temperature at which the contacts return to their normal position.

Set Point – Temperature at which normally closed contacts will open, or normally open contacts will close. Also

referred to as operating temperature.

SPDT (Single Pole, Double Throw) – An electrical switch term where “pole” means a leg of an electrical circuit and

“throw” describes the switch action. Therefore, a SPDT will switch one leg that will open a set of contacts, and close

another set.

SPST (Single Pole, Single Throw) – An electrical term describing switch actions. A SPST will switch one leg and open

one set of contacts.

Stenciling – The marking on a product identifying the product type, calibration temperature, part number and plant

of manufacture.

Switchcase – The component that represents the thermostat “body,” made from insulating material that supports

switch mechanisms.

Thermal Cutoff (TCO) – A product that functions as a thermal fuse (one time operation). Various operating

temperatures are achieved by formulating a pellet that melts at very specific temperatures.

Thermistor – A device that exhibits a large change in electrical resistance with a change in temperature.

Tolerance – The allowable range above or below the set point or reset temperature.

Trip-Free – A term associated with manual reset type controls. When the reset button is depressed it cannot restrict

the normal opening of the control.

Therm-O-Disc Bimetal Disc Thermostat10

Page 13

Important Information

Many variables can affect the operational characteristics of a thermostat. It is for this reason that we recommend

that you conduct thorough testing of our products in your specific application. Therm-O-Disc has both functional and

thermocoupled samples readily available for determining the desired performance and the correct response in your

application. To obtain samples please contact your local Therm-O-Disc sales representative directly. To ensure a quick

turnaround, please have the following information ready:

• Application description

• Electrical load

• Operating temperature requirements

• Agency recognition(s) required

• Mounting and terminal confi gurations

• Estimated annual volume

Don’t know what product you need? Do you have a general question about our products? Visit

thermodisc.com or contact your local Therm-O-Disc sales office. Our Applications Engineers are

always available to assist you in answering your questions or in obtaining any samples you may need.

Bimetal Disc Thermostat Therm-O-Disc11

Page 14

10H Linear Limit Series

Special Purpose Controls

Snap-Action Capillary Controls

The 10H series temperature control from Therm-O-Disc was originally developed to sense

hot spots along the length of electric baseboard heaters. It is also used in other applications

where it is necessary to sense temperatures along a continuous length.

The 10H capillary tube is vacuum-charged with selected fl uids to give specifi c calibrations.

When the calibration temperature is reached, a change in fl uid vapor pressure allows the

diaphragm to snap through and operate the contacts. The snap-action design provides

high-speed contact separation and excellent reliability.

Typical applications for the 10H include electric baseboard heaters and other HVAC

applications.

Therm-O-Disc Bimetal Disc Thermostat12

Page 15

Features and Benefits

The 10H features include:

• The ability to sense temperature along a continuous length.

• Excellent sensitivity. Since the capillary tube is charged, the 10H responds to the hottest spot along the capillary tube.

• High-speed contact separation for long contact life.

• Design flexibility provided by a variety of switch actions, capillary tube lengths, mounting brackets and terminations.

Switch Actions

The 10H is available in two switch actions:

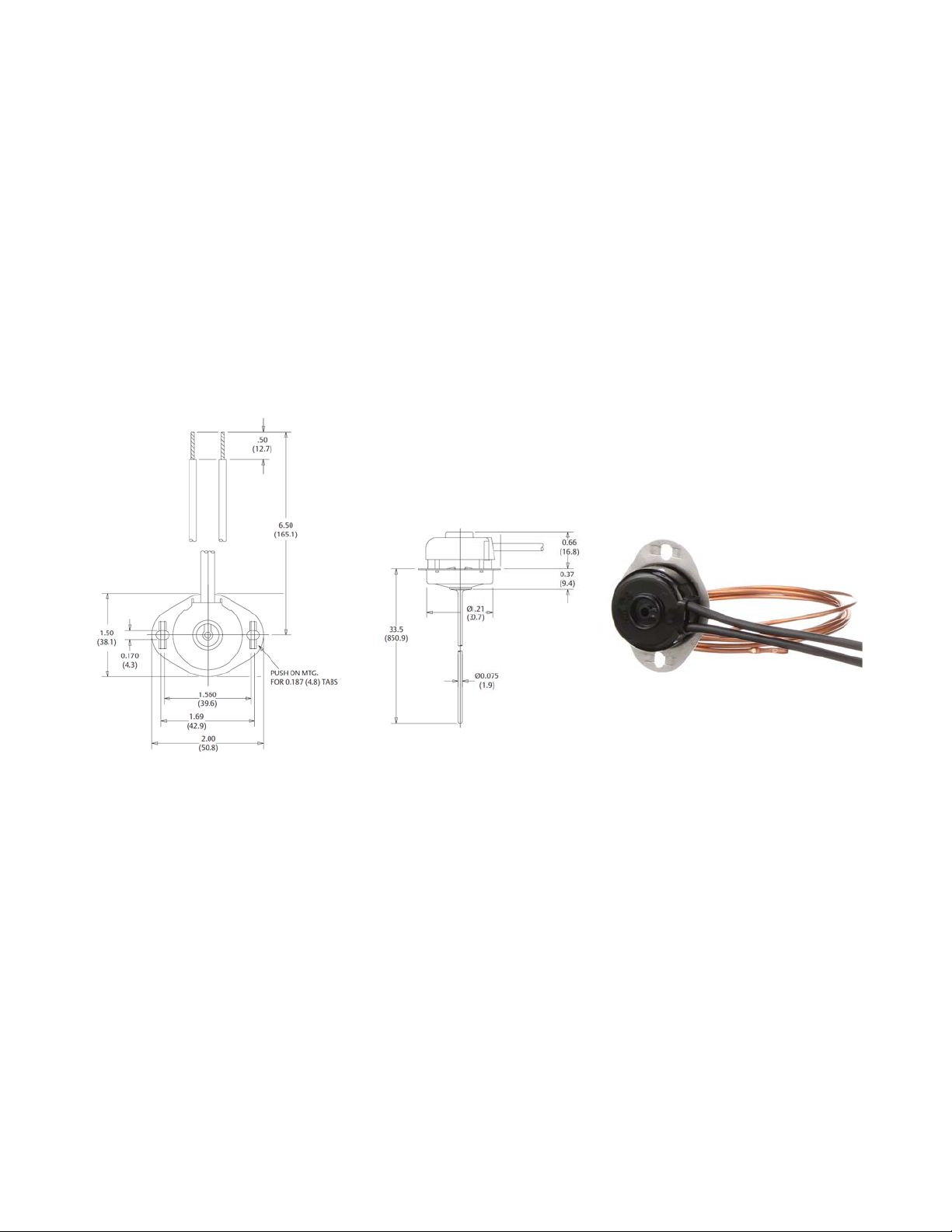

Automatic Reset (Type 10H11) – SPST contacts open on temperature rise and automatically reset on temperature fall

(see figure 1).

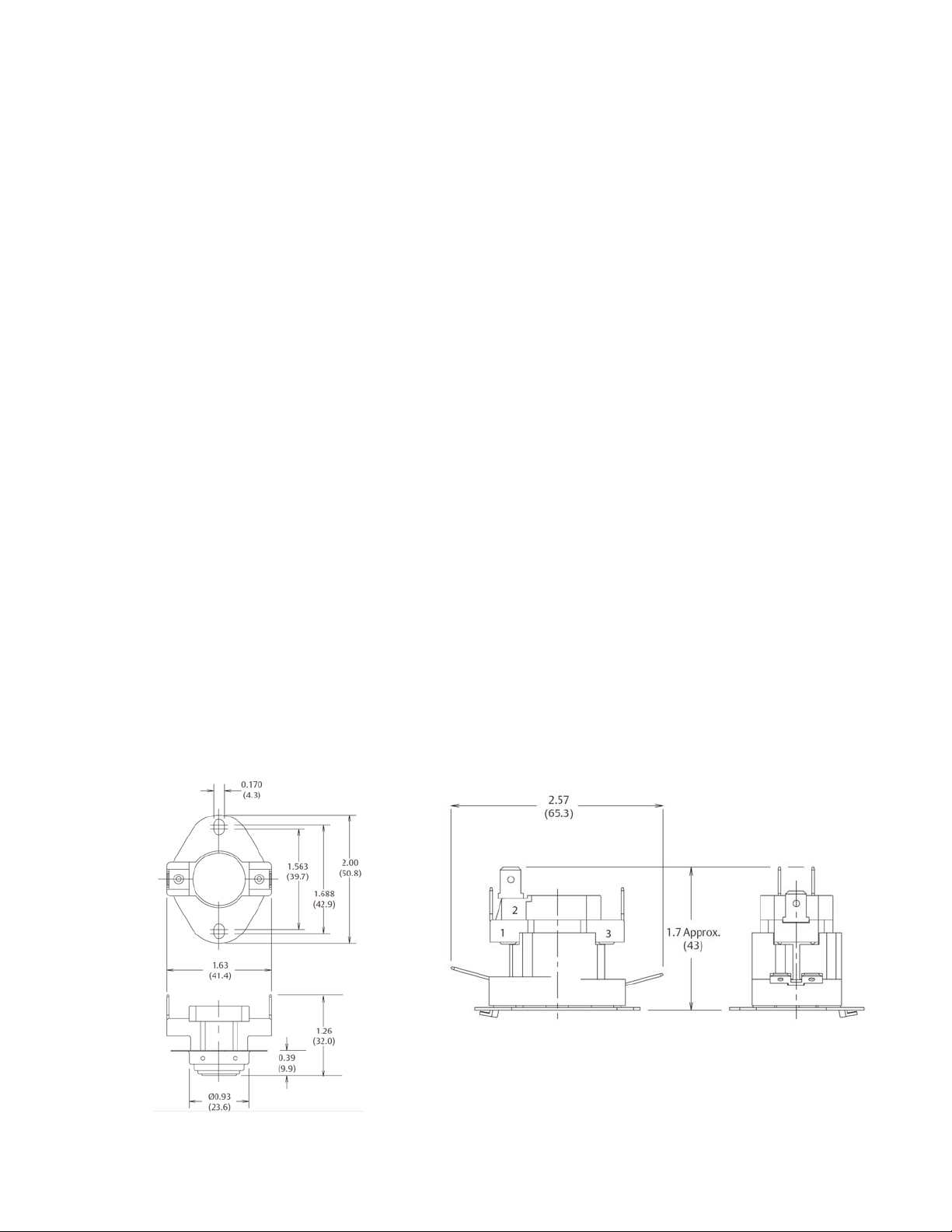

Shown with terminal cover and “push on” mounting bracket.

Figure 1

Dimensions are shown in inches and (millimeters).

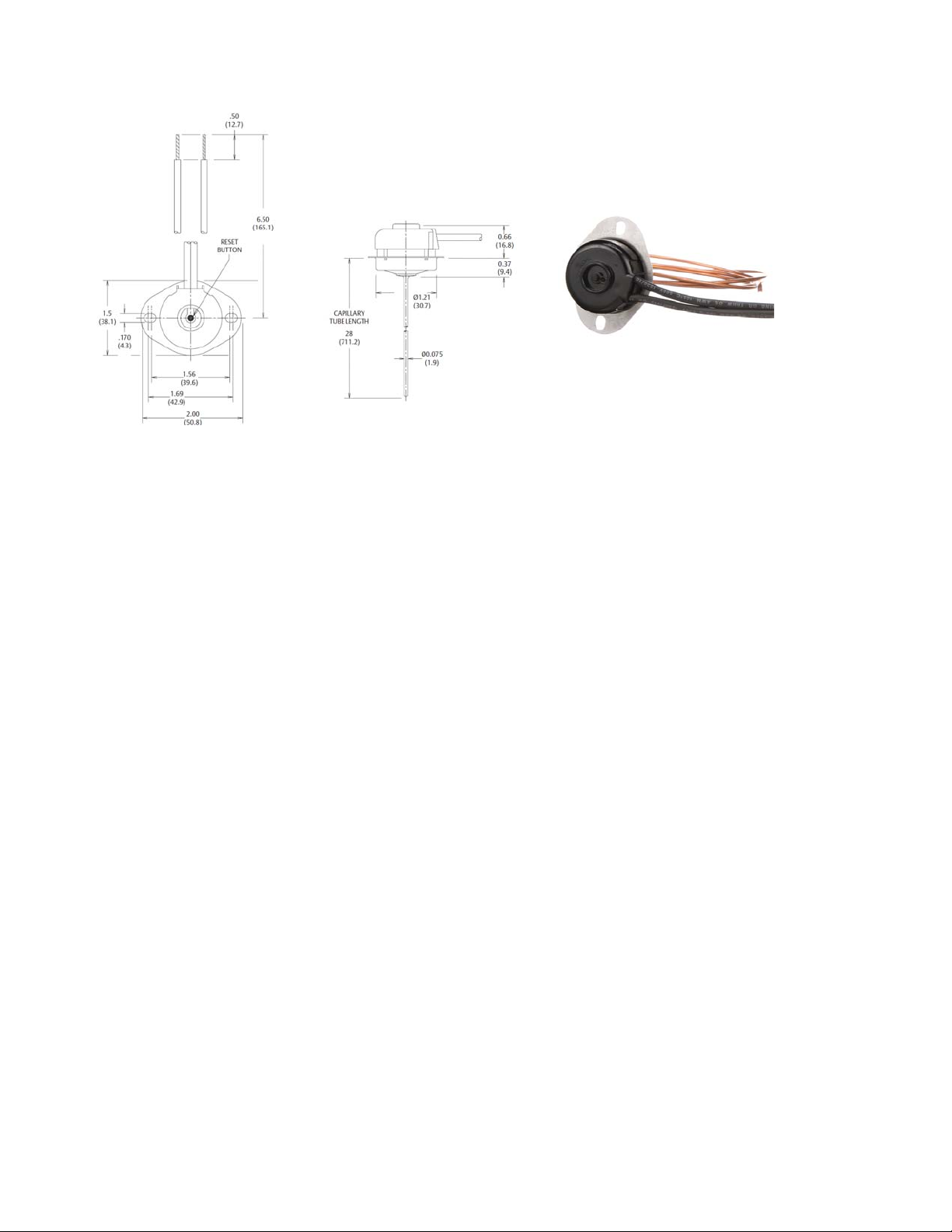

Manual Reset (Type 10H14) – SPST contacts open on temperature rise and can be reset when the control has cooled to

a lower temperature and the reset button has been depressed. The 10H manual reset is agency recognized as an “M1

trip free” construction, which means that if the reset button is held down, the control can cycle thermally

(see figure 2).

Bimetal Disc Thermostat Therm-O-Disc13

Page 16

Shown with required terminal cover and standard mounting bracket

Figure 2

Dimensions are shown in inches and (millimeters).

Terminal Characteristics

The 10H can be calibrated to open on temperature rise between 150°F (65.6°C) and 350°F (177°C), with a standard

tolerance of ±15°F (±8.5°C). The 10H automatic reset will reclose the contacts at approximately 40°F (22°C) below its

open temperature. Manual reset controls may automatically reset when exposed to temperatures below -31°F (-35°C).

Capillary Tube

The 10H is available with the copper capillary tube in preferred lengths from 24” to 144” as measured from the bottom

of the mounting fl ange.

Mounting Brackets

The standard mounting bracket (see fi gure 2) has two slots, each .170” (4.318mm) wide. An alternate “push on”

mounting bracket (see fi gure 1) is also available.

Terminations

Standard leads are two 6 1/2” (165.1mm), #14 AWG, 105°C, 1/32” (10.8mm) thick, black PVC insulation, stripped 1/2”

(12.7mm). Also available (automatic reset only) are 1/4”(6.30mm), 90° angle, .032” (0.8mm) blade terminals. A

snap-on terminal cover is available for controls supplied with lead wires.

Therm-O-Disc Bimetal Disc Thermostat14

Page 17

General Electrical Ratings

The 10H series of controls has been rated UL and CSA. The agency ratings can be used as a guide when evaluating

specifi c applications. However, the mechanical, electrical, thermal and environmental conditions to which a control

may be exposed in an application may differ signifi cantly from agency test conditions. Therefore, the user must not rely

solely on agency ratings, but must perform adequate testing of the product to confi rm that the control

selected will operate as intended in the user’s application.

Thermostat

Typ e

10H11

(Auto Reset)

10H14

(Manual

Reset)

10H11

(Auto Reset)

10H14

(Manual

Reset)

Note: For complete and current ratings, please consult a Therm-O-Disc sales engineer. At thermostat end-of-life, the contacts may remain

permanently open or closed.

Maximum Open

Temperature

350 °F (177 °C) 221 °F (100 °C)

350 °F (177 °C) 221 °F (100 °C)

350 °F (177 °C) 221 °F (100 °C)

350 °F (177 °C) 221 °F (100 °C)

Maximum

Switchcase

Temperature

Volts ACResistive

277

600

277

600

277

600

277

350

600

Amperes

25

25

25

10

25

15

10

-

-

Inductive Amps

FLA LRA

4.8

4.8

28.8

-

-

-

-

-

28.8

-

-

-

Pilot

Duty VA

480

125

480

125

125

-

460

350

400

Cycles

100,000

100,000

6,000

6,000

100,000

100,000

6,000

6,000

6,000

Agency

Recognition

Guide MBPR2,

File MH-5304

CSA File

LR19988

UL

Bimetal Disc Thermostat Therm-O-Disc15

Page 18

10RS Radiant Energy Series

Special Purpose Control

Snap-Action Radiant Controls

The 10RS line of controls from Therm-O-Disc offers reliable sensing of radiant energy

in hot surface ignition applications, such as gas clothes dryers.

The unique snap-action bimetal design not only provides high-speed contact

separation and time-proven reliability, but also enables the 10RS to maintain radiant

sensitivity while compensating for ambient temperature changes.

A glass ‘window’ is used to maximize the effect of radiant energy on the bimetal

element without exposing the entire control to high ignitor temperatures.

These features have made the Therm-O-Disc 10RS an integral component of gas

ignition systems.

Therm-O-Disc Bimetal Disc Thermostat16

Page 19

Features and Benefits

The 10RS features include:

• Glass “window” design maximizes effect of radiant energy without sensor overheating.

• Unique “U”-shaped actuator compensates for ambient temperature conditions.

• High-speed contact switching for exceptional life characteristics.

Switch Actions and Typical Applications

The 10RS is an automatic reset, single pole, single throw (SPST) switch that opens its electrical contacts when exposed

to heat generated by radiant energy. This is accomplished with a “U”-shaped bimetal actuator which has one leg

exposed to radiant energy while the other leg is shielded.

As radiant energy passing through the glass “window” heats the exposed bimetal leg, a temperature differential is

created which causes the bimetal element to snap and open the contacts. As radiant energy dissipates, both actuator

legs return to approximately the same temperature, allowing the contacts to automatically reclose.

Typical Applications

The type 10RS control is utilized in gas-fired appliances in conjunction with a hot surface ignitor. As red hot ignitor

temperatures are achieved, the 10RS opens the circuit which signals the gas valve to open. Upon ignition, radiant

energy from the gas flame keeps the 10RS open until the operating cycle is completed. Once the gas valve closes and

the flame dissipates, the contacts reclose and the ignition cycle is complete.

Calibration

The standard 10RS calibration calls for the contacts to open within 12 to 20 seconds after exposure to a radiant energy

source. Contact reclose occurs within 26 to 40 seconds after the radiant source dissipates.

Note: Calibration timing of the 10RS in the actual application is dependent upon the type of ignition system and

position of the sensor relative to the radiant energy source.

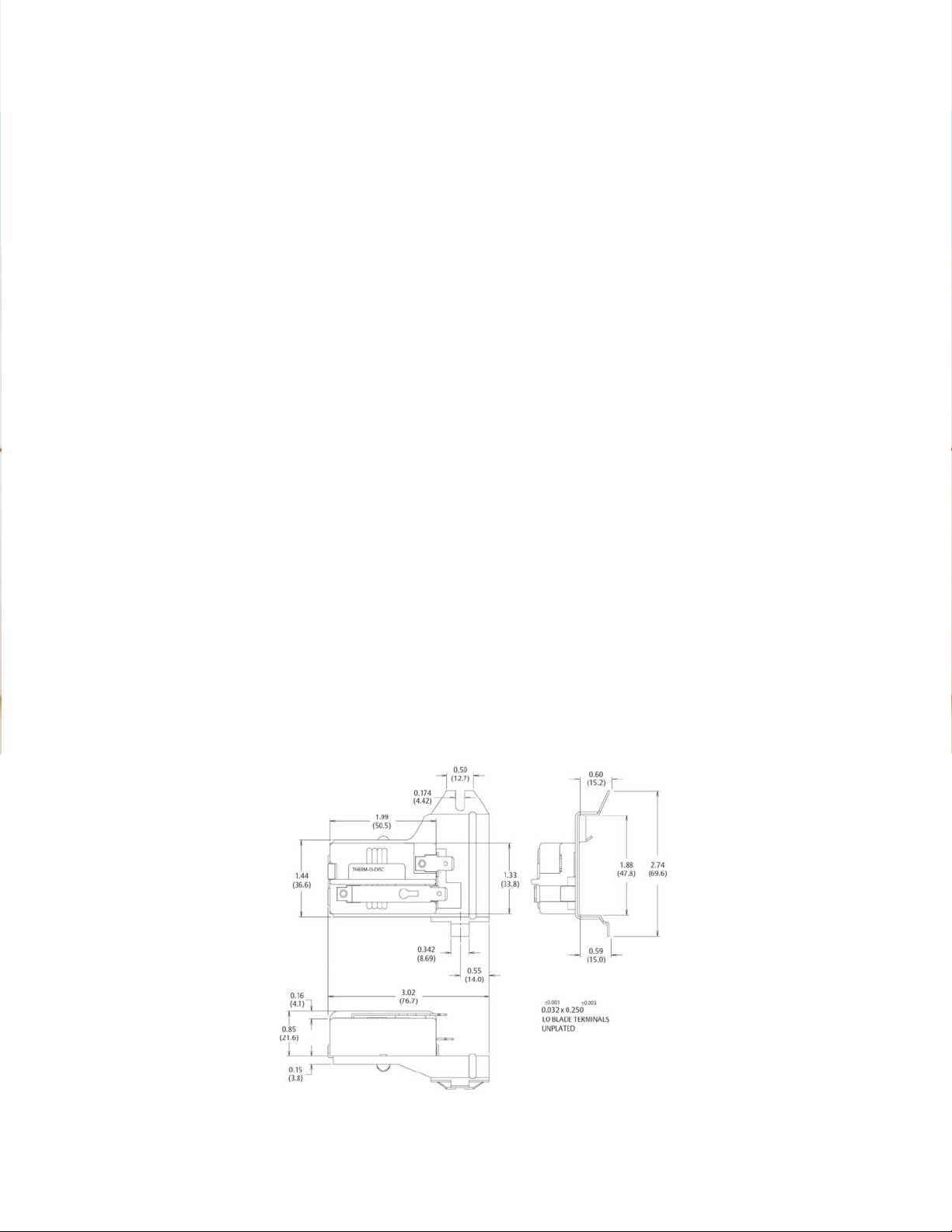

Dimensions are shown in inches and (millimeters).

Bimetal Disc Thermostat Therm-O-Disc17

Page 20

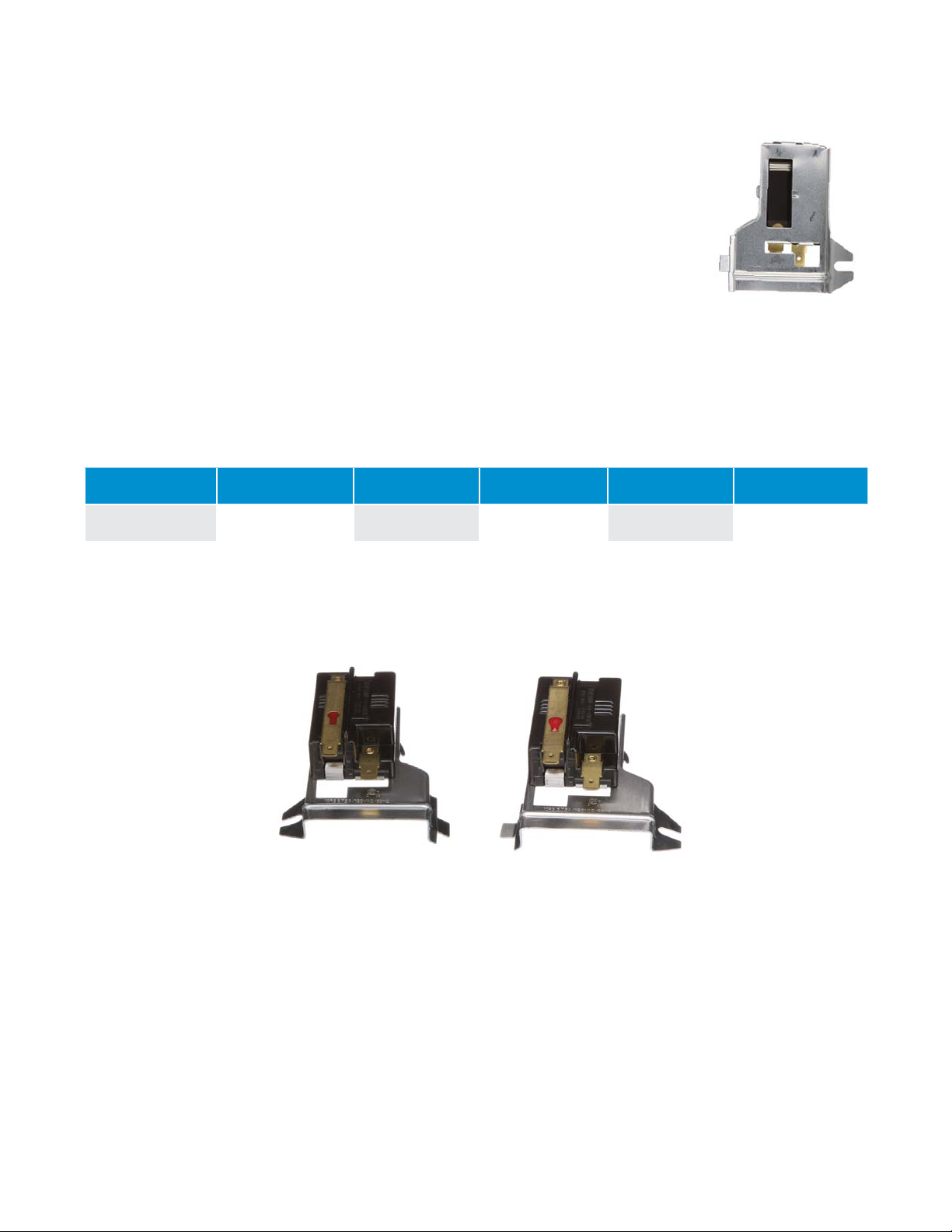

Mounting Bracket

The 10RS is available in two standard tab mounts. The brackets are fabricated from .032”

(.81mm) aluminum and can easily be mounted with a sheet metal screw.

Terminal Configurations

The 10RS is furnished with .032” x .250” (.81mm x 6.35mm) brass quick connects in the

horizontal position.

General Electrical Ratings

The agency ratings can be used as a guide when evaluating specifi c applications. However,

the mechanical, electrical, thermal and environmental conditions to which a control may be

exposed in an application may differ signifi cantly from agency test conditions. Therefore, the user must not rely solely

on agency ratings, but must perform adequate testing of the product to confi rm that the control selected will operate

as intended in the user’s application.

Maximum Bimetal

Temperature (°F)

375 325 100,000 5.75 120

Note: At thermostat end-of-life the contacts may remain permanently closed or open. For complete and current ratings, please contact our Sales

Engineering Department

Maximum Ambient

Temperature (°F)

Cycles Resistive Amperes Volts AC Agency Recognition

CSA

File 112672-0-000

Therm-O-Disc Bimetal Disc Thermostat18

Page 21

12S, 14S, 15S Series

Time Delay Relays and Sequencers

Time Delay Relays and Sequencers

The Therm-O-Disc type 12S, 14S and 15S series time delay relays and sequencers are fi eld-

proven devices for controlling the operation of heating elements and/or fans in electric

furnaces and heat pumps. These controls combine a solid-state positive temperature

coeffi cient (PTC) heater with bimetal actuated contacts to provide time-delayed electrical

switching. A wide variety of bimetal disc and PTC combinations are available to provide a

broad range of timings. The 12S is a single timing device while the 14S uses two bimetal discs

to achieve two independent timings. The 15S consists of one, two or three 12S and/or 14S

controls mounted on a common plate.

Bimetal Disc Thermostat Therm-O-Disc19

Page 22

Features and Benefits

The 12S, 14S and 15S features include:

• Available with auto-reset SPST, DPST and SPDT switch configurations.

• PTC heater for stable operation over a wide range of temperatures and voltages.

• Snap-action bimetal disc for high-speed contact separation.

• Standard operating ambients between -40°F (-40°C) and 150°F (65.6°C).

• Available with a wide variety of terminals and mounting plates.

• Welded construction for integrity of current-carrying components.

• Quiet operation

Switch Actions and Typical Applications

Automatic Reset SPST – Can be built to either open or close a set of contacts within a specified time range.

Automatic Reset DPST – Utilizes one bimetal disc to simultaneously open or close two independent sets of contacts

within a specified time range.

Automatic Reset SPDT – This 12S configuration is the same as the SPST except with the addition of an auxiliary

contact that makes and breaks circuit in opposition to the main contacts.

CAUTION . . . When designing a SPDT circuit, an electrical load must be applied to terminal 2 and/or 3 to avoid a

transient short circuit condition during switching.

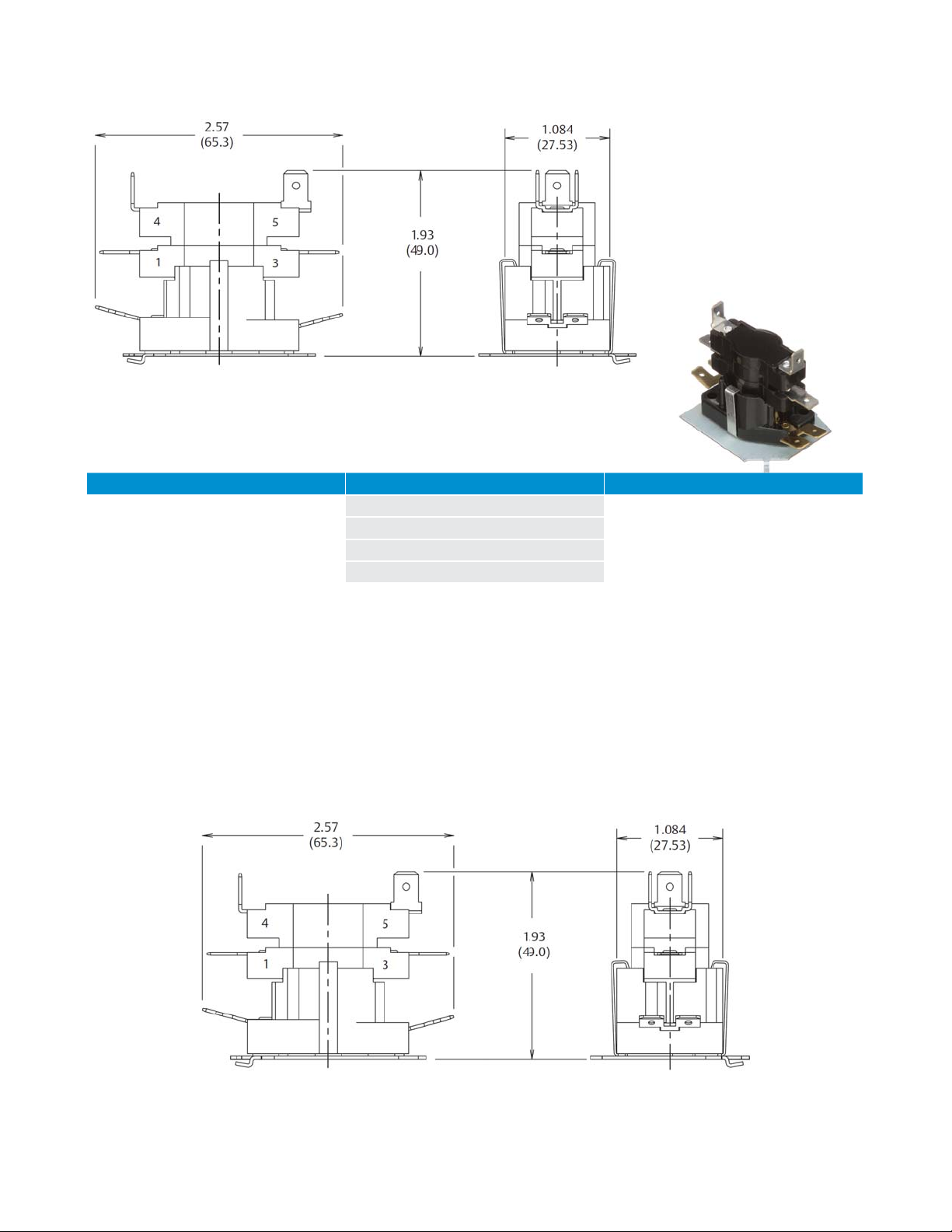

12S Series

The 12S series utilizes one bimetal disc to achieve single-timing operation. The 12S is available in SPST (see figure 1),

SPDT (see figure 2), and DPST (see figure 3) switch actions. A variety of standard timings are available for general time

delay applications.

SPST Switch Action

(12S20)

SPDT Switch Action

(12S50)

Figure 1

Therm-O-Disc Bimetal Disc Thermostat20

Figure 2

Page 23

12S Timings*

PTC ON OFF

24VAC

*Please contact us to discuss specific timings needed.

DPST Switch Action

(12S22)

Figure 3

Dimensions are shown in inches

and (millimeters).

1-30 Sec. 40-80 Sec.

10-40 Sec. 20-60 Sec.

20-55 Sec. 15-55 Sec.

25-110 Sec. 5-45 Sec.

14S Series

The 14S series is available in two possible configurations:

• 2 stages, where each stage is SPST and operated by a disc for each stage. The two stages can

have different on/off times. See figure 4.

• 3 stages, where the two lower stages are DPST operated simulataneously by one disc. The

top stage is SPST and operated by the other disc.

SPST Switch Action (Each Stage)

(14S22)

Figure 4

Dimensions are shown in inches and (millimeters).

Bimetal Disc Thermostat Therm-O-Disc21

Page 24

14S Timings*

PTC ON OFF

24VAC 1-110 Sec. 1-110 Sec.

*Please contact us to discuss specific timings needed.

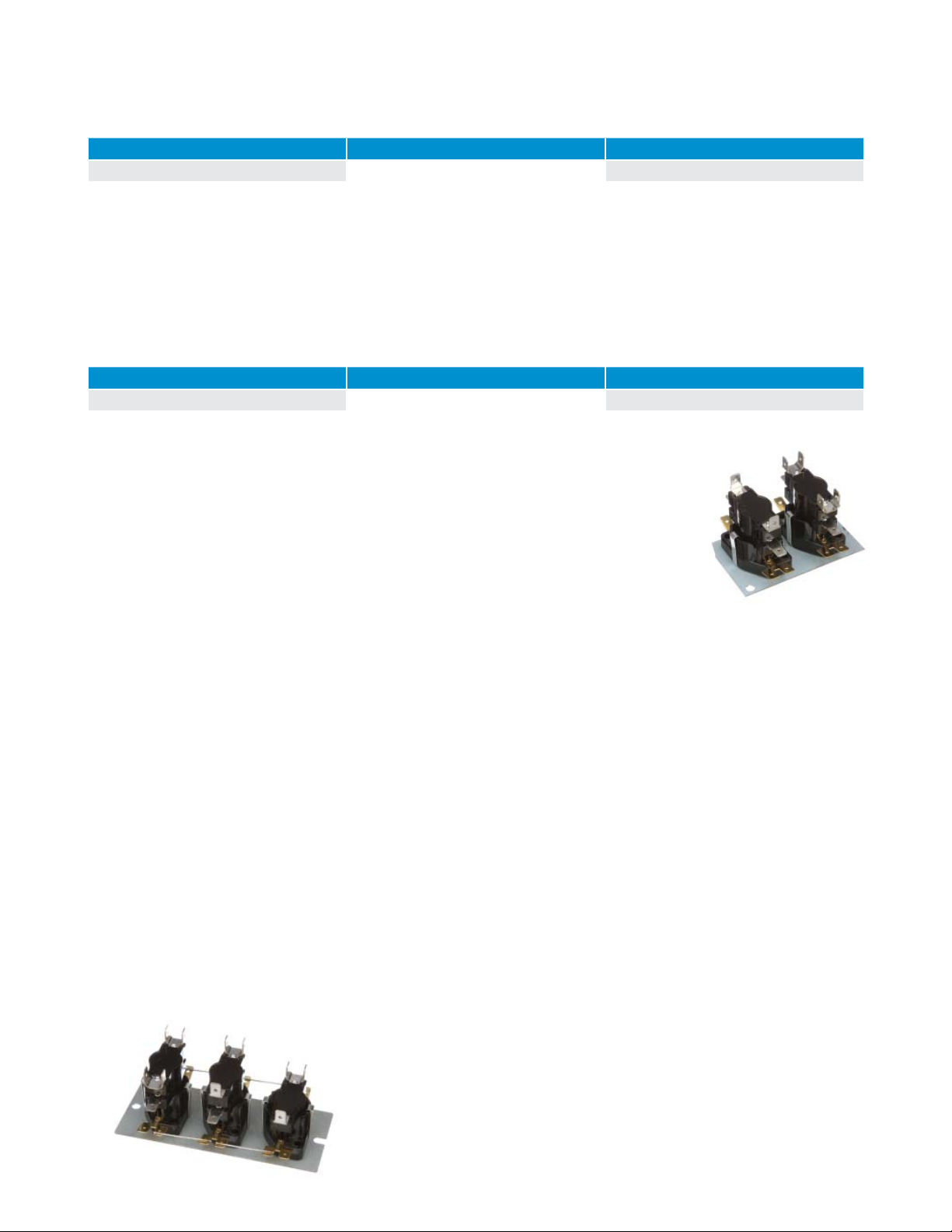

15S Series

The 15S series consists of either two or three 12S and /or 14S controls mounted on a common baseplate. The timing of

the package assures that a set of designated contacts will turn on fi rst and turn off last.

The chart shows the timing range for the 15S package.

15S Timings*

PTC ON OFF

24V 1-110 Sec. 1-110 Sec.

*Please contact us to discuss specific timings needed.

PTC Heater

Solid state PTC (Positive Temperature Coeffi cient) heaters are used to bias the operation of the

contacts. These heaters are self-current limiting for stable switch operation over a range of

temperatures and over-voltages. The standard line of controls uses a 24VAC PTC rated for Class

II circuits. The peak inrush current of the 24VAC PTC heater varies from .35 to 1.0 amps. The

inrush current drops below 1/2 of the peak value within approximately 10 seconds and reaches

a steady state current between 0.10 and 0.18 amps.

Operating Ambients

The standard sequencer line is designed to operate in ambients ranging from -40°F to 150°F (-40°C to 65.6°F). The

actual sequencer ON and OFF times are 100% checked to the required timings at a 75°F (23.9°C) ambient. The OFF

timings are determined after the PTC heater has been energized for a total of five minutes. Timings in an ambient

above or below 75°F (23.9°C) will vary and should be evaluated in the end use application to determine suitability. A

specfic high ambient construction is available at extra cost to allow operation up to 165°F (74°C). This construction

requires an “H” in our type number (example 12SH22).

Standard Terminals and Markings

The standard heater terminals are .032” x .250” (6.3 x .8mm) double 15° brass male quick connects. The stage

terminals are .032 x .250” (6.3 x .8 mm) tin plated brass. See figures 1, 2, 3, 4 for common stage terminals and

terminal numbering

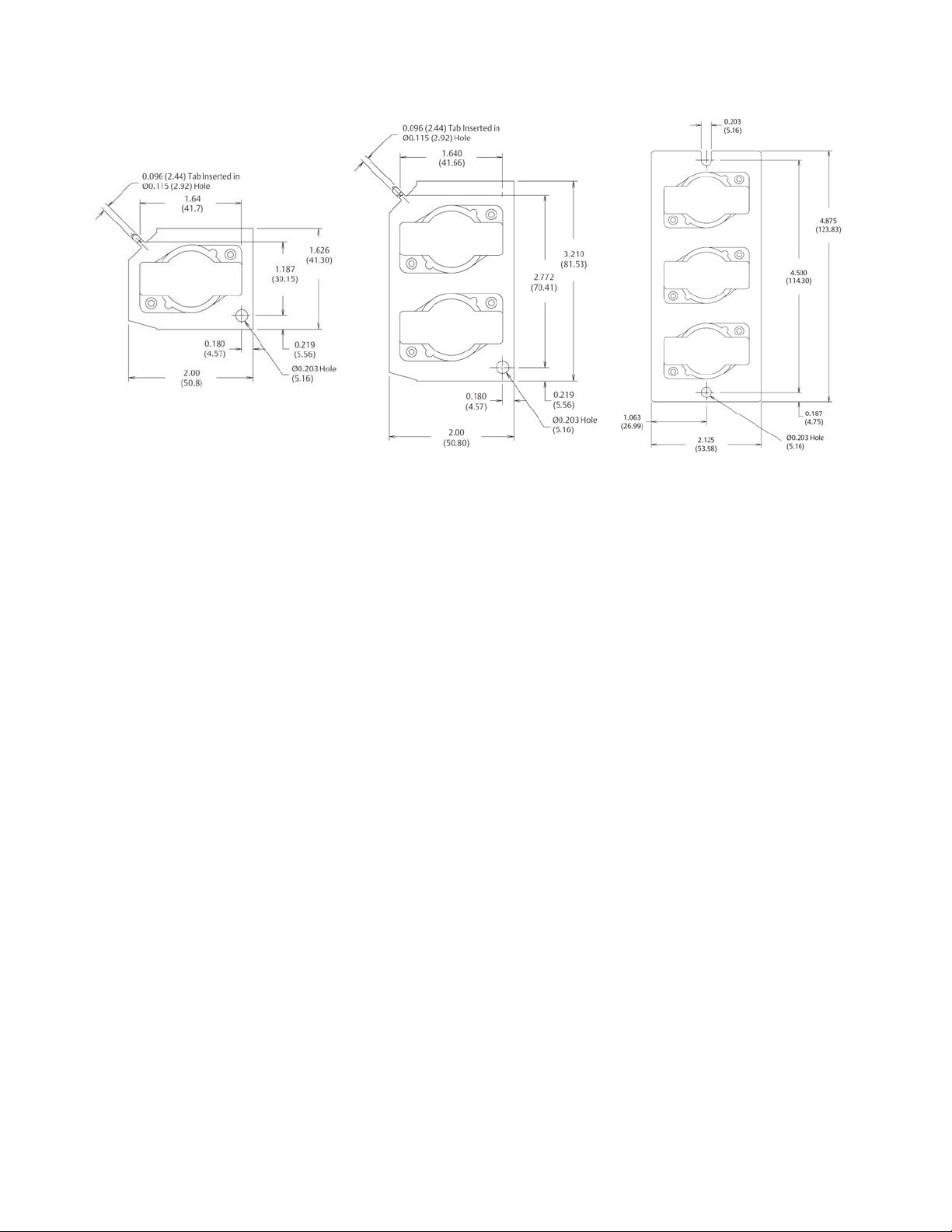

Mounting Plates

The standard mounting plate incorporates a tab and hole arrangement for mounting one (see figure 5) or two (see

figure 6) controls. The standard mounting plate for three controls incorporates a slot and hole arrangement (see figure

7). Optional or custom mounting plates are available to meet specific application requirements.

Therm-O-Disc Bimetal Disc Thermostat22

Page 25

Figure 5

Figure 6

Figure 7

Electrical Spacings

The 12S, 14S, 15S series have electrical spacings of 1/4” (6.35mm) through air and 3/8” (9.52mm) over surface to

ground. With the suffix “X,” increased spacings of 3/8” (9.53mm) through air and 1/2” (12.7mm) over surface to

ground are available.

General Electrical Ratings

The agency ratings can be used as a guide when evaluating specific applications. However, the mechanical, electrical,

thermal and environmental conditions to which a control may be exposed in an application may differ significantly

from agency test conditions. Therefore, the user must not rely solely on agency ratings, but must perform adequate

testing of the product to confirm that the control selected will operate as intended in the user’s application.

Bimetal Disc Thermostat Therm-O-Disc23

Page 26

UL Agency Rating

Type Switching Action Volts AC

240 25 8 48 - 100,000

12S/15S SPST

12S

12S

12S/15S DPST

14S

* Note: For complete ratings information, please contact our Sales Engineering Department. At thermostat end-of-life, the contacts may remain

permanently closed or open. Maximum combination inductive/resistive, where maximum inductive load is 7FLA, 42LRA. Upper Stage Only.

(Auxiliary Contacts 1-2)

SPDT

(Main Contacts 1-3)

SPDT

2 Pole and

3 Pole

240 30* - - - 100,000

277 25 - - - 30,000

480 12.5 5 30 480 100,000

240 25 8 48 - 100,000

277 25 - - - 30,000

480 12.5 5 30 480 100,000

240 - 4.1 8 125 30,000

277 25 - - - 30,000

480 - - - 125 30,000

480 - 3 16 - 100,000

120 - 13.8 82.8 125 30,000

240 25 8 48 125 100,000

240 30* - - - 30,000

277 25 - - - 30,000

480 12.5 5 30 480 100,000

240 25 8 - - 100,000

240 30* - - - 100,000

480 12.5 5 - - 100,000

Resistive

Amps

Inductive amps

FLA LRA

Pilot Duty

VA

Cycles Agency Recognition

UL E19279

CSA Agency Ratings

Type Switching Action Volts AC

120 - 1.0 6.0 - 100,000

12S/15S SPST

12S

12S

12S/15S DPST

14S

* Note: For complete ratings information, please contact our Sales Engineering Department. At thermostat end-of-life, the contacts may remain

permanently closed or open. Maximum combination inductive/resistive, where maximum inductive load is 7FLA, 42LRA. Upper Stage Only.

(Auxiliary Contacts 1-2)

SPDT

(Main Contacts 1-3)

SPDT

2 Pole+

3 Pole

240 - 5.0 30 - 100,000

240 30* - - - 100,000

480 - - - 125 100,000

120 - 10 60 - 100,000

240 - 5 30 - 100,000

480 - - - 125 100,000

120 10 - - 125 100,000

240 5 5 30 - 100,000

480 - - - 125 30,000

120 - 10 60 - 100,000

240 25 5 30 - 100,000

240 30* - - - 100,000

480 - - - 125 100,000

240 25 5 30 - 100,000

240 30* - - - 100,000

480 - - - 12.5 100,000

Resistive

amps

Inductive amps

FLA LRA

Pilot Duty

VA

Cycles Agency Recognition

CSA 062037

Therm-O-Disc Bimetal Disc Thermostat24

Page 27

Part Numbering System

Common Sequencer Type Numbers for 12S and 145

Type Number of Stages Description

12S20 1 Normally Open, SPST

12S22 2 Normally Open, DPST

12S50 1 Normally Open, SPDT

14S22 2 Normally Open, Each Stage SPST

14S222 3 Normally Open –

Lower Two Stages DPST

Upper Stage SPST

15S Type Numbers

1st Suffi x

1st sequencer

on baseplate

2nd Suffi x

2nd sequencer on

baseplate (if provided)

3rd Suffi x

3rd sequencer on

baseplate (if provided)

1 1 1 12S20

2 2 2 12S22

4 4 4 14S22

You can combine any above confi gurations on a common base plate.

Example: 15S221 would contain 12S22-12S22-12S20

Base sequencer type

at each location

Bimetal Disc Thermostat Therm-O-Disc25

Page 28

14T Series

Moisture Resistant Temperature Controls

Heavy-Duty Snap-Action Temperature Controls

The 14T line of heavy-duty sealed bimetal disc controls from Therm-O-Disc meets the higher

electrical requirements of commercial applications. The design provides moisture resistance for

moisture prone environments. The snap-action of the 1” temperature sensing bimetal disc provides

high-speed contact separation resulting in exceptional life characteristics at electrical loads up to

25 amps at 120/240VAC. A variety of mounting confi gurations, lead wires and terminations

give maximum design fl exibility. The heavy-duty construction and long life characteristics

have made the 14T a popular choice for heating, ventilation and air conditioning systems.

Therm-O-Disc Bimetal Disc Thermostat26

Page 29

Features and Benefits

The 14T features include:

• Sealed construction provides moisture resistance for moisture prone environments.

• High-speed contact separation ensures long contact life.

• A wide variety of mounting configurations, lead wires and terminations provide maximum design flexibility.

• Large 25 amp capacity allows direct control of compressors and fans, reducing the need for additional components.

Switch Actions and Typical Applications

The 14T is available in two switch actions:

Automatic Reset SPST – In this configuration, the switch can be built to either open or close its electrical contacts

on temperature rise. Once the temperature in the application has returned to the specified reset temperature,

the contacts will automatically return to their original state. Typical uses of this construction include limiting and

regulating temperatures in air conditioners, heat pumps and fan coil units.

Automatic Reset SPDT – This design is the same as the SPST described above with the addition of an auxiliary contact

which makes circuit upon opening of the main contacts and breaks circuit when the main contacts reset. Refer to

the “General Electrical Ratings” chart for rating limitations on the auxiliary contacts. Typical uses of this construction

include fan speed changeover at a specified temperature and lighting of an indicator lamp when an abnormal

temperature condition has been reached.

Bimetal Disc Thermostat Therm-O-Disc27

Page 30

Mounting Configurations

The 14T is available in a variety of mounting configurations:

Surface Mounting – The surface mounting configuration positions the bimetal disc sensing element firmly against the

mounting surface, thereby sensing the actual mounting surface temperature (see figures 1 and 2).

SPST Surface Mounting

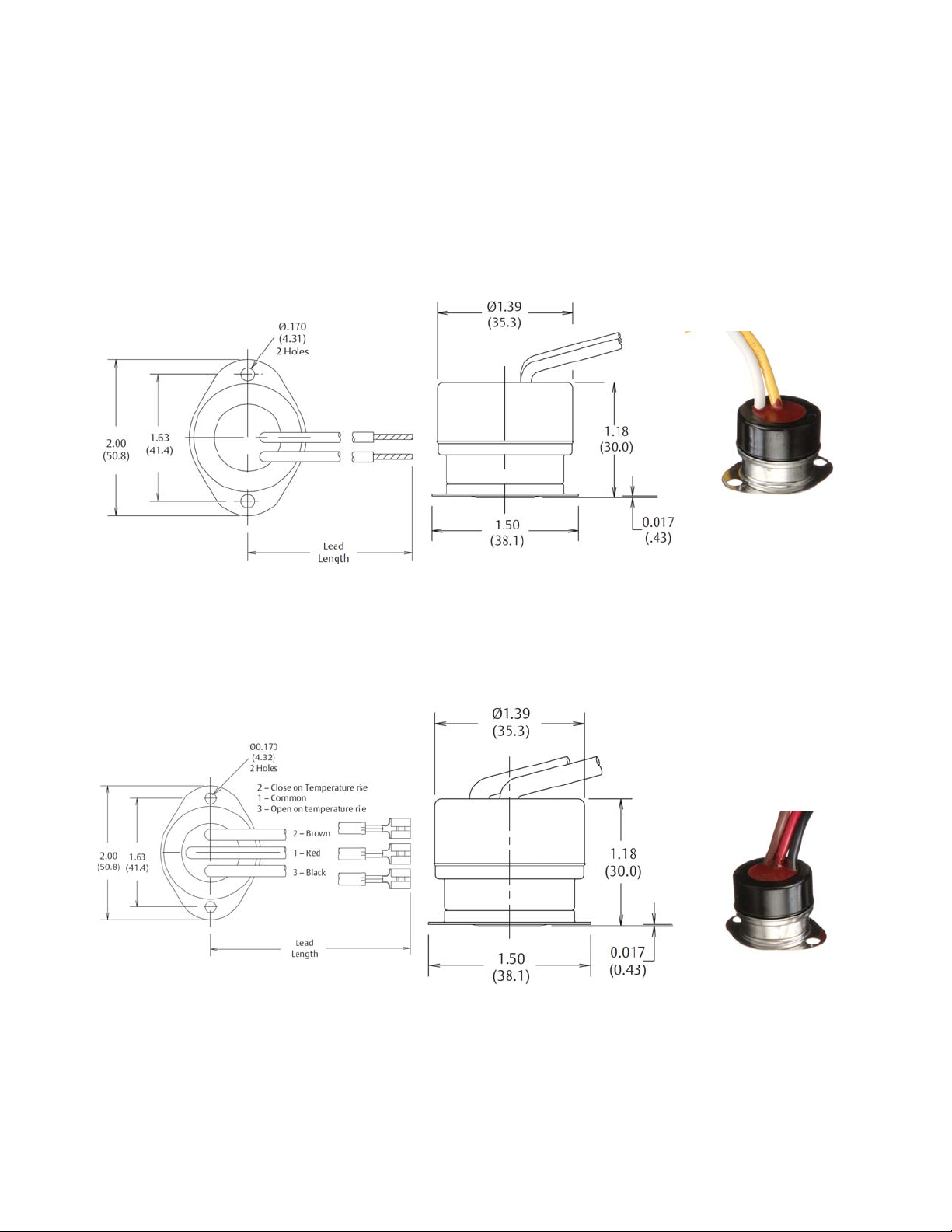

Figure 1

Dimensions are shown in inches and (millimeters).

SPDT Surface Mounting

Figure 2

Dimensions are shown in inches and (millimeters).

Therm-O-Disc Bimetal Disc Thermostat28

Page 31

No Mounting Flange – The 14T is available without a mounting flange for customers who wish to design their own

mounting method. Dimensions as shown in figures 1 and 2, except there is no mounting bracket shown.

Tube Mounting – In this mounting configuration, the 14T is supplied with a saddle-shaped disc cup and a removable

spring clip which holds the control firmly on a tube. This configuration is available for 3/8”, 1/2”, 5/8” O.D. tubes

figure 3).

(see

Figure 3

Dimensions are shown in inches and (millimeters).

Lead Wire and Terminal Configurations

The standard lead wires are #18 AWG stranded copper wire with 1/32” thick 105°C PVC insulation. A variety of other

lead wire size and insulation thickness combinations are available at additional cost. The standard lead wire direction

exits from the top of the control. The lead wire can also be specifi ed to exit perpendicular to the mounting hole center-

line for surface mount and parallel to the tube for tube mounting. This can be varied in 45 angular degree increments,

if required by the application.

Bimetal Disc Thermostat Therm-O-Disc29

Page 32

Conduit Connector – The 14T is also available with a conduit connector designed to enclose the lead wires in a rigid

thin wall or flexible metal conduit. In this configuration, the leads extend from the top of the control instead of the side

(see figure 4).

Figure 4

Dimensions are shown in inches and (millimeters).

The standard insulation colors are red, brown and black. Other colors can be provided, as required by a specifi c

application.

The standard maximum combined lead wire length is 24” for SPST and 36” for SPDT controls. Additional lead wire and

a variety of popular quick connect terminals are available at additional cost.

For more information on optional lead wires, insulation colors and terminations, please consult one of our sales

engineers.

Therm-O-Disc Bimetal Disc Thermostat30

Page 33

Calibration Temperatures, Differentials and Tolerances

To use the calibration chart, locate the range in the left hand column, in which the highest calibration set point (open

or close) falls. Then locate, across the top, the range in which the nominal differential falls. The standard open and

close set point tolerances are shown where the two columns converge. The chart also indicates which differentials are

available in each of the calibration set point ranges. Tighter open and close tolerances are available at additional cost.

For more information on tightened tolerances or availability of differentials not listed in the chart, please consult one of

oursales engineers.

Calibration Temperatures, Differentials and

Standard Tolerance of the 14T Series (SPST and SPDT only)

Highesy

Calibration Set

point Range

(Open or Close)

0°-80°F

-18°-26°C

81°-2221°F

27°-105°C

10-14°F

5.5-8°C

Open Close Open Close Open Close Open Close Open Close

±6

±3.5

±5

±3

Part Numbering System

14T

(Optional suffi x)

C - Conduit connector

±6

±3.5

±5

±3

Nominal Differentials

(nominal open and close set point)

15-19 °F

8.5-10.5 °C

±6

±3.5

±5

±3

±6

±3.5

±5

±3

20-29 °F

11-16 °C

±6

±3.5

±5

±3

1 - No mounting fl ange

2 - Surface mounting fl ange

3 - Tube mount

±6

±3.5

±5

±3

30-39 °F

16.5-21.5 °C

±6

±3.5

±5

±3

±7

±4

±5

±3

40-50 °F

22-33°C

±6

±3.5

±5

±3

1 - Contacts open on

temperature rise (SPST)

2 - Contacts close on

temperature rise (SPST)

3 - Single pole, double

throw (SPDT)

±7

±4

±7

±4

Bimetal Disc Thermostat Therm-O-Disc31

Page 34

General Electrical Ratings

The 14T series of controls has been rated by major agencies throughout the world. The agency ratings can be used as a

guide when evaluating specifi c applications. However, the mechanical, electrical, thermal and environmental condi-

tions to which a control may be exposed in an application may differ signifi cantly from agency test conditions. There-

fore, the user must not rely solely on agency ratings, but must perform adequate testing of the product to confi rm that

the control selected will operate as intended in the user’s application.

Max Temp. Contact Arrangement

SPST or SPDT any load

14T, 14F

221 °F*

105 °C

14T, 14F

150 °F*

65.5°C

265°F

129.5 °C

14T

221 °F*

105 °C

150 °F

65.5 °C

265 °F

129.9 °C

combination execpt

resistive rating on one

contact set only

SPST or SPDT any

combination

SPST or SPDT any load

combination execpt

resistive rating on one

contact set only

SPST or SPDT (125VA pilot

duty only on contacts 1-2

of SPDT)

SPST

SPST

SPDT

(limited to 125VA on one

contac t)

SPST or SPDT

(any load combination)

SPST

Cycles

Rating

6,000 16 72 125 - 120

6,000 10 45 125 - 240

30,000 10 60 125 25 120

30,000 5 30 125 25 240

30,000 16 72 125 15 240

30,000 10 60 125 - 277

100,000 10 60 125 25 120

100,000 5 30 125 25 240

30,000 2.5 15 575

100,000 0.5 600

100,000 0 0 125 25 277

100,000 10 120

30,000 10 60 125 25 120

30,000 5 30 125 25 240

60,000 16 72 125 - 120

60,000 10 45 125 - 240

30,000

30,000

30,000 7.5 45 125 15 120

30,000 3.75 22.5 125 15 240

30,000 16 72 125 - 240

30,000 2.5 15 575

100,000 0.5 600

100,000 10 120

Inductive Amps

FLA LRA

10

5

60

30

Pilot

Duty VA

125

125

Resistive

Amperes

5 240

25

25

5 240

Volts AC

120

240

Agency

Recognition

UL

E29653

CSA

LR10281

Note: This is a consolidated summary of the 14T series rating. For complete and current ratings information, please contact our Sales Engineering

Department. At thermostat end-of-life, the contacts may remain permanently closed or open.

Therm-O-Disc Bimetal Disc Thermostat32

Page 35

30M MOTOR PROTECTION Series

s

Special Purpose Controls

Special Purpose Controls

The Therm-O-Disc line of Motor Protectors offers accurate and reliable protection against hazardous

overheating in single phase/single voltage A/C motors. Available in a variety of product types,

these motor protectors employ a snap-acting, current and temperature responsive bimetal disc

for proven performance over life. An internal resistance heater utilizes the effects of current to

bias the operation of the bimetal disc for added thermal response. A wide range of bimetal

and heater combinations are available to cover specifi c design requirements. This design

fl exibility and proven performance has made Therm-O-Disc Motor Protectors a popular

choice among the leading manufacturers of fractional horsepower motors.

Bimetal Disc Thermostat Therm-O-Disc33

dou

Page 36

Features and Benefits

The Motor Protector features include:

• High-speed contact separation ensures long contact life.

• Current and temperature responsiveness for excellent design flexibility.

• Manual and automatic reset switching actions combined with a wide selection of bimetal discs

and heaters to meet a variety of possible application needs.

• 100% temperature calibration and trip time tests assure high quality levels.

The Operating Principle of Motor Protectors

The operating mechanism inherent to all Therm-O-Disc Motor Protectors is the snap-action bimetal disc. During

abnormal conditions, heat generated by resistance and/or motor ambient causes the bimetal disc to snap at the

specified calibration temperature. This allows the circuit to open within the maximum safe limits of the motor

windings. Once the motor returns to a normal operating temperature, the bimetal disc resets (automatically or

manually). This closes the circuit and re-energizes the motor. This same snap-action principle is utilized in millions of

Therm-O-Disc products applied in the appliance, heating and air conditioning industries.

Side Entry Terminals

Figure 1

Dimensions are shown in inches and (millimeters).

Therm-O-Disc Bimetal Disc Thermostat34

Page 37

End Entry Terminals

Figure 2

Dimensions are shown in inches and (millimeters).

Type 30M – The Therm-O-Disc Type 30M (see figure 4) SPST manual reset protector is a compact device designed for

applications where inadvertent equipment restarts may result in potential hazard. The contacts may be manually reset

after the control has cooled 30°-50°C below the open temperature calibration. The 30M features a “trip free” manual

reset design. UL designates the 30M reset as “M1,” meaning the motor protector shall automatically reset to the

closed position after normal operating conditions have been restored if the reset button is held in the reset position.

Typical uses include disposer and oil burner applications where “tripping” the device should result in the end user

taking corrective action. Standard terminations are weld-type connections. Male quick connect terminals, lead

wire assemblies and bimetal and heater combinations are available to meet specific requirements. This “trip free”

construction means that processing the reset button will not reclose the contacts until the control has cooled.

Figure 3

Dimensions are shown in inches and (millimeters).

Bimetal Disc Thermostat Therm-O-Disc35

Page 38

Lead Wire and Terminal Configurations

All Therm-O-Disc Motor Protectors can be furnished with a variety of terminal and lead wire confi gurations. Custom

packages or special assemblies may be specifi ed to meet unique application needs. By taking advantage of our high

volume production methods, Therm-O-Disc may be able to provide signifi cant savings. Our sales engineers can assist

in selecting a package that is tailored to specifi c requirements.

Mounting Configurations

Due to the variation of terminal and switch configurations, Therm-O-Disc Motor Protectors may be mounted in

a number of positions. For maximum performance, we recommend locating the protector as close to the motor

windings as possible. Customers typically provide their own mounting methods.

Product Quality

Therm-O-Disc Motor Protectors are assembled, calibrated and tested automatically, using the latest manufacturing

technologies and quality methods. Each motor protector is 100% temperature calibrated and tested to ensure high

quality levels. Our goal of providing motor protectors of the highest uniform quality is reinforced by the training of

our operators in modern statistical techniques. Therm-O-Disc is committed to continuously improving our quality

and manufacturing capabilities. This objective, in turn, allows our products to meet the escalating standards of our

customers.

Protector Selection

To determine which Therm-O-Disc Motor Protector is right for a specifi c application, simply use the following steps:

• Select the appropriate switch action (manual or automatic) and product type.

• Verify that electrical load does not exceed the recommended rating of the device.

• Determine calibration based on test data.

• Determine the specifi c bimetal and heater resistance required for the application. (Consult factory for trip curves.)

• Test the protector to verify compliance with specifi c requirements.

• Choose from a variety of optional components to complete a package.

Calibration Range, Differentials, and Standard Tolerances

Protector Type 30M

Open Range (°C) 80-150

Open Tolerance (°C) ±5

Close Range (°C) 45-110

Close Tolerance (°C) ±10

Minimum Differential (°C) 30

Maximum Differential (°C) 50

NOTE: For additional information on calibrations, tolerances or differentials not listed in this chart, please contact our Sales Engineering Department.

Therm-O-Disc Bimetal Disc Thermostat36

Page 39

General Electrical Ratings

The Motor Protector series has been rated by major agencies throughout the world. The agency ratings can be used

as a guide when evaluating specifi c applications. However, the mechanical, electrical, thermal and environmental

conditions to which a control may be exposed in an application may differ signifi cantly from agency test conditions.

Therefore, the user must not rely solely on agency ratings, but must perform adequate testing of the product to

confi rm that the control selected will operate as intended in the user’s application.

Protector

Typ e

30M 150

* Therm-O-Disc Motor Protectors are recognized by Underwriters Laboratory (UL) and certifi ed by the Canadian Standards Association

(CSA). For complete details on European Agencies or the latest rating information, please contact our Sales Engineering Department.

Maximum

Temperature (°C)

Recommended

Contact Ratings*

50 amp L.R. @ 120 V

37 amp L.R. @240V

Limited

Short Circuit

1000 amp Circuit:

40 amp fuse @240V

Group Fusing

Short Circuit

2000 amp Circuit:

80 amp fuse @120V

Recognition

File E52937

File LR80616

Part Numbering System

30M

Bimetal Resistance

A- .0015 Ω

B- .0042 Ω

L- .0075 Ω

Heater Resistance

A- .0320 Ω

B- .0260 Ω

C- .0390 Ω

D- .0620 Ω

E- .0490 Ω

G- .0980 Ω

L- .0200 Ω

M- .0150 Ω

Terminal Type

No. 1 No. 3

5- Stub 1/4” MQC

6- Stub Stub

Open (°C)

A- 86

B- 90

C- 95

D- 100

E- 105

F- 110

G- 115

H- 120

J- 125

K- 130

L- 135

M- 140

N- 145

P- 150

S- 80

Close (°C)

A- 45

B- 50

C- 55

D- 60

E- 65

F- 70

G- 75

H- 80

J- 85

K- 90

L- 95

M- 100

N- 105

P- 110

Agency

UL

CSA

Bimetal Disc Thermostat Therm-O-Disc37

Page 40

36T Series

Snap-Action Temperature Controls

Snap-Action Temperature Control

The 36T Series of 1/2” bimetal temperature controls from Therm-O-Disc offers

proven reliability in a compact, versatile, cost-effective design. The snap

action of the bimetal disc provides high-speed contact separation resulting

in excellent life cycle characteristics at electrical loads up to 15 amps at

120VAC and 10 amps at 250VAC (100,000 cycles) and 16 amps at 250VAC

(30,000 cycles).

A variety of terminal and mounting configurations are available for maximum

design flexibility. The quality, reliability, affordability, versatility and world-wide

agency approvals of the 36T Series make it the thermostat of choice for a wide

variety of temperature control applications.

Therm-O-Disc Bimetal Disc Thermostat38

Page 41

Switch Actions

The 36T is available in three single pole, single throw (SPST) switch actions:

Automatic Reset – Can be built to either open or close its contacts on temperature rise.

Manual Reset – Available with contacts that open on temperature rise. The contacts can be reset by depressing the

button after the control has cooled down.

Single Operation Fuse Disc – Available with contacts that open on temperature rise, and which never reclose unless

the ambient temperature drops below +32°F (0°C) or below -31°F (-35°C).

Typical Applications

The 36T is applied to a wide variety of applications as either a regulating control or a safety limit. Examples of

applications include:

• Coffeemakers • Water heaters

• Sandwich toasters • Furnaces

• Dishwashers • Boilers

• Dryers • Electric heaters

• Washing machines • Offi ce equipment

• Refrigerators • Automotive seat heaters

• Microwave ovens

Mounting Confi gurations

The 36T is available in several mounting configurations:

No Mounting Bracket – The 36T may be specified without a mounting bracket. One popular version (designated

36TM or 36TMH) has a switch body designed to accept the customer’s clamp bracket (see Figure 1).

1.32

(33.5)

Ø0.62

(15.8)

0.26

(6.7)

0.57

(14.4)

0.48

(12.1)

Ref.

0.09

(2.4)

Figure 1

Dimensions are shown in inches and (millimeters).

Bimetal Disc Thermostat Therm-O-Disc39

Page 42

Surface Mount Bracket – The bimetal disc sensing element is positioned firmly against the mounting surface so it

senses the actual mounting surface temperature (see Figure 2). There are many available surface mounting brackets

available – typically in either aluminum or stainless steel.

0.145

(Ø3.70)

2 Holes

1.23

(31.2)

0.94

(23.8)

0.29

(7.4)

1.32

(33.6)

0.47

(11.9)

0.01

0.69

(17.6)

(0.4)

Figure 2

Dimensions are shown in inches and (millimeters).

Surface brackets can be supplied on the 36T either loose or crimped in a fixed position (except for ceramic body 36Ts,

36Ts with stainless steel disc housings, and 36Ts with raised pad disc housings, which must be supplied loose).

Airstream Mount – The bimetal housing extends through a hole in the mounting surface into the airstream (see

Figure 3). There are many available aluminum and stainless steel airstream mount configurations.

Ø0.145

(3.70)

Mounting

Holes

1.18

0.94

(30.0)

(23.8)

0.81

(20.6)

0.63

(16.0)

0.83

(21.1)

Ø0.62

(15.8)

0.18

(4.6)

Figure 3

Dimensions are shown in inches and (millimeters).

Therm-O-Disc Bimetal Disc Thermostat40

Page 43

Terminal to Mounting Hole Crimp Angle

Both surface brackets and air stream housings can be supplied where the customer can specify the angular

orientation (in 15 degree increments) of the terminals with respect to the mounting hole centerline (see figure 4).

45°

90°

90° crimp angle 45° counterclockwise crimp angle

Figure 4

Stud Mount – The 36T can be supplied with an integral threaded stud mount. Figure 5 shows two popular brass stud

mounts with hex shape (brass stud available with plastic switchcases only). Figure 6 shows an aluminum stud mount

available with plastic or ceramic switchcases.

Figure 5

Figure 6

Bimetal Disc Thermostat Therm-O-Disc41

Page 44

36T Board Mount – The 36T is mounted on extension straps, for applications where the thermostat must extend

further into the airstream to sense adequately (see Figure 7). Available strap lengths include 2” (50.4mm), 3”

(75.6mm), 5” (126mm) and 7” (176.4mm). Insulating sleeves can be provided for the extension straps, and various

mounting board configurations are available.

Figure 7

Thermal Response

Most 36Ts are provided with an enclosed disc. The enclosed disc construction provides greater protection against

airborne contaminants entering the control. It also protects the bimetal disc from possible damage during customer

handling. In applications where faster response to radiant heat is required, an exposed bimetal disc can be specified.

36T Mounting Options

The letter “A” means available. Consult a Sales Engineer for other available configurations.

Surface Mount – No Mounting Bracket

Description Aluminum

Enclosed (raised pad) A A Figure 8

Enclosed (fl at) A A Figure 9A

Exposed A A Figure 9B

Ø0.62

(15.8)

(not available with ceramic body)

Ø0.62

(15.8)

Stainless Steel

Ø0.62

(15.8)

Drawing

Figure 8 Figure 9A

Dimensions are shown in inches and (millimeters).

Therm-O-Disc Bimetal Disc Thermostat42

Ø0.47

(11.9)

Figure 9B

Page 45

Surface Mount – With Mounting Bracket

Mounting Hole Aluminum Bracket Stainless Steel Bracket Drawing

0.125” (3.2mm) diameter

0.145” (3.7mm) diameter

0.172” (4.4mm) diameter

1.14

(28.9)

0.94

(23.8)

Figure 10A Figure 10B Figure 11

Airstream Mount

Mounting Hole

A

A

A

A

__ A

Ø0.125

(Ø3.2)

2 Holes

1.14

(28.9)

0.94

(23.8)

Ø0.145

(Ø3.7)

2 Holes

Dimensions are shown in inches and (millimeters).

Aluminum

(enclosed)

Aluminum

(exposed)

Stainless Steel

(enclosed)

(not avaiilable with ceramic body)

1.75

(44.4)

1.18

(30.2)

1.31

(33.4)

Stainless Steel

(exposed)

Figure 10A

Figure 10B

Figure 11

0.172

(4.40)

Drawing

0.145” (3.7mm) diameter A A A A Figure 12

0.188” (4.74mm) wide slot A A A A Figure 13

0.170” (4.28mm) wide slot

0.21

(5.2)

0.19

(4.8)

0.94

(23.8)

1.18

(30.0)

Figure 12

Enclosed Disc

Exposed Disc

0.145

(Ø3.7)

__ A

0.21

(5.2)

0.19

(4.8)

0.188

(4.74))

1.70

(43.1)

1.25

(31.8)

Figure 13

A A Figure 14

0.21

(5.2)

Enclosed Disc

Exposed Disc

0.94

(23.8)

0.18

(4.5)

0.170

(4.28)

2.00

(50.8)

1.56

(39.7)

1.69

(42.9)

Figure 14

Enclosed Disc

Exposed Disc

1.50

(38.1)

Dimensions are shown in inches and (millimeters).

Bimetal Disc Thermostat Therm-O-Disc43

Page 46

Stud Mount

Thread Stud length Material Drawing

M4 x 0.7mm 0.24” (6mm)

M4 x 0.7mm 0.190” (4.7mm) Aluminum Figure 16

36T Terminals

(not available with ceramic body)

0.24

[6.0]

M4 X 0.7 mm

0.62

[15.9]

Brass

0.19

[4.7]

Figure 15

Dimensions are shown in inches and (millimeters).

ÿ

0.62

[15.8]

Figure 16

Figure 15

M4 X 0.7 mm

Most 36Ts are supplied with 1/4” x .032” (6.3mm x .8mm) quick connect blade terminals that are available in

unplated brass, tin plated brass and nickel plated steel. We also have 3/16” (4.8mm) blade terminals available in both

.020” (0.5mm) and .032” (0.8mm) thicknesses. Most of these blade terminals are available in 0, 45 and 90 degree

angles. The 36T can also be supplied with various weld tab and crimp/solder terminals. Please see the 36T

Standard Terminals chart that shows our most frequently used terminals. Note that other configurations/platings

may be available if our standard offerings do not satisfy your application. Please contact a Sales Engineer to

discuss requirements.

Therm-O-Disc Bimetal Disc Thermostat44

Page 47

36T Standard Terminals

Dimensions are shown in inches and (millimeters). “A” designates available.

Mounting Hole Terminal Angle

3/16 x .020 (4.8 x 0.5 blade)

3/16 x .032 (4.8 x 0.8 blade)

1/4 x .032 (6.3 x 0.8 blade without stops)

1/4 x .032 (6.3 x 0.8 blade)

.020 (0.5) weld tab 90

.020 (0.5) crimp/solder 90

.020 (0.5) solder low -- A -- Figure 23

.020 (0.5) PCB solder 90

low

45

90

low

45

90

low

45

90

low

45

90

O

O

O

O

O

O

O

O

O

O

O

Unplated

Brass

A

-A

A

A

A

A

A

A

-A

A

-- -- A Figure 21

-- A -- Figure 22

-- A -- Figure 24

Tin Plated

Brass

A

A

A

A

A

A

A

A

A

A

A

A

Tin Plated

Brass Steel

A

A

A

A

-A

A

A

A

A

-A

Drawing

Figure 17

Figure 18

Figure 19

Figure 20

3/16 (4.8) x 0.020 (.5) Blade

90

Available

Angles

45

Low

3/16 (4.8) x 0.032 (.8) Blade

90

45

Low

Available

Angles

1/4 (6.3) x 0.032 (.8) Blade Without Stops

90

45

Low

Available

Angles

Figure 17 Figure 18 Figure 19

1/4 (6.3) x 0.032 (.8) Blade

90

45

0.020 (.5) Weld Tab

Low

Available

Angles

Figure 20 Figure 21

0.020 (.5) Crimp / Solder

18 - 20 Ga. Wire

0.020 (.5) Solder

0.11

(Ø2.8)

0.020 (.5) PCB Solder

Figure 22 Figure 23 Figure 24

Dimensions are shown in inches and (millimeters).

Bimetal Disc Thermostat Therm-O-Disc45

Page 48

36T Switchcases

There are many available switchcases (or switchbodies) available for the 36T. When choosing a particular switchcase,

there are several key items to consider:

Electrical Spacing – This is the minimum distance required to prevent electrical “arcing” from a live part (terminal)

to a dead part (disc housing). The required electrical spacing is determined by the customer’s agency spacing

requirements. There are 36T switchcases with two different spacings available:

• 1/8” (3.2mm) by 1/4” (6.3mm) air/surface – designated by an ‘X’ in the nomenclature (see Figure 25). (Preferred)

• 1/16” (1.6mm) by 1/16” (1.6mm) air/surface (see Figures 26, 27).

The greater spacings are achieved by an increased switchcase height.

Mounting – All of the available switchcases can be provided in both surface (with or without brackets) or airstream

mount configurations. There are several switchcases designed to accept a customer clamp bracket (over the top of

the switchcase). These are designated by an ‘M’ in the nomenclature. (See Figure 27)

0.58

(14.6)

0.58

(14.7)

0.47

(11.9)

0.58

(14.7)

0.37

(9.5)

0.26

(6.7)

0.47

(12.1)

0.57

(14.4)

1/8 (3.2) X 1/4 (6.3) Spacing

TX, TXE, TXH

Figure 25

1/16 (1.6) X 1/16 (1.6) Spacing

T, TE, TH

Figure 26

Dimensions are shown in inches and (millimeters).

1/16 (1.6) X 1/16 (1.6) Spacing

TM, TMH, TME

Figure 27

Switchcase Material – For calibrations up to 350°F (177°C), plastic can be specified; for calibrations above 350°F

(177°C), ceramic is available. Ceramic switchcases are designated by ‘H’ in the nomenclature.

Manual Reset – Manual reset switchcases are basically similar to those used on automatic reset and fuse disc

configurations except for a hole in the top of the case (for the reset pin) and a pad on the top of the case to prevent

overtravel of the reset pin. Please refer to the manual reset portion of the catalog for more information.

Therm-O-Disc Bimetal Disc Thermostat46

Page 49

Calibration Temperatures, Differentials and Tolerances

36Ts (automatic reset) are supplied to customer specified open and close calibration set points with a tolerance on

both set points.

Please refer to the chart below. To use this chart, start by finding the higher of your open/close calibration set points in

the far left hand column. Then look across the top (left to right) to locate your desired nominal differential. Differential

is the difference between your nominal open and close calibration set points. The available open and close set point

tolerances are shown where the two columns converge. Please note that this chart is applicable to either normally

closed contacts (contacts open on temperature rise) or normally open contacts (contacts close on temperature rise).

Example 1:

If you require a nominal open temperature of 250°F (121°C) and a nominal close temperature of 210°F (99°C), then

the nominal differential = 40°F (22°C), so the tolerance on the open temperature is ±7°F (±4°C), and the tolerance on

the close temperature is ±11°F (±6°C). (Refer to the yellow shaded area in the chart.)

Example 2:

If you require a nominal close temperature of 160°F (71°C) and a nominal open temperature of 140°F (60°C), then the

nominal differential = 20°F (11°C), so the tolerance on the open temperature is ± 5°F (±3°C), and the tolerance on the

close temperature is ±7°F (±4°C). (Refer to the gray shaded area in the chart.)

Calibration Temperatures, Differentials and

Standard Tolerance for the 36T Series

Highest

Calibration

Set Point

(Open or

(Close)

35°F-79°F

2°C-26°C

80°F-180°F

27°C-82°C

181°F-230°F

83°C-110°C

231°F-300°F

111°C-149°C

301°F-350°F

150°C-177°C

351°F-428°F

178°C-220°C

*F15-19

*C8.5-10.5

11-13.5

Open Close Open Close Open Close Open Close Open Close Open Close Open Close Open Close

±5

±3±6±3.5±5±3±6±3.5±5±3

±5

±3±6±3.5±5±3

±5

±7

±3

-

-

-

-

-

-

±5

±4

±3

-

-

-

-

-

-

-

-

-

-

-

-

(temperature difference between nominal open and close set point)

20-24

25-29

14-16

±7

±4

±7

±5

±4

±7

±4

-

-

±3.5

-

-

-

-

±7

±3

±4

±5

±3±8±4.5±5±3±8±4.5±6±3.5±9±5

±6

±9±5±6

-

-

-

-

NOTES: 1. We can supply tolerances that are tighter than those shown at extra cost. Please contact a Sales Engineer.

2. Wider tolerances required for conical contact constuction. Please contact a Sales Engineer.

3. Requires ceramic construction for temperatures above 350°F (177°C)

4. Lowest nominal open or close calibration is -6°F (-21°C).

NOMINAL DIFFERENTIAL

30-39

16.5-21.5

±5

±3±8±4.5±6±3.5±8±4.5±7±4±9±5

±5

±3±8±4.5±5±3±8±4.5±6±3.5

±10

±3.5

±5.5±7±4

-

-

-

-

-

-

-

-

-

-

-

-

40-49

22-27

-

-

-

-

±11±6±8

-

-±8±4.5

-

-

50-60

27.5-33.5

±10

±5.5±7±4

±7±4±11±6±8

±11±6±9±5±14

±4.5

±12

±6.5

-

-

-

-

61-80

34-44.5

-

-

±11±6±

±12

±4.5

±6.5

±10

±15

±5.5

±8.5

±16±9±23

±13

-

-

±8

81-100

45-55.5

-

-

9±5±13

±10

±14

±5.5

±11±6±17

±9.5

±12

±20

±6.5

±11

±18

±25

±10

±14

-

-

±7

±8

Bimetal Disc Thermostat Therm-O-Disc47

Page 50

36T Manual Reset

The 36T manual reset is available with normally closed contacts that open on temperature rise and is a non-trip free

design. The 36T manual reset is normally supplied so that it does not automatically reset unless the ambient

temperature drops below -31°F (-35°C).

Once the 36T manual reset has opened at its calibration temperature, the ambient temperature must drop before it

can be reset. To determine the manually resettable temperature for a specific open temperature – refer to the refer

to the graph in Figure 28. The manually resettable temperature is the temperature at which (or below which) the 36T

can be reset. To use this chart, first find the point on the vertical axis that designates the nominal open temperature

minus the tolerance. Then, move across to the curve and find the manually resettable temperature on the horizontal

axis. There are two lines shown: one without a compressible washer, and one with a compressible washer. The

compressible washer (located under the reset button) can be specified (at extra cost) when the customer desires a

higher manually resettable temperature.

Example:

For an open temp/tolerance of 210°F (99°C) ±10°F (±5.5°C), the manually resettable temperature is 100°F (38°C)

without the compressible washer, which means that the 36T can be reset when the temperature is at or below

100°F (38°C).

360 (182)

350 (177)

340 (171)

330 (166)

320 (160)

310 (154)

300 (149)

290 (143)

280 (138)

270 (132)

260 (127)

250 (121)

240 (116)

230 (110)

220 (104)

210 (99)

200 (93)

190 (88)

180 (82)

170 (77)

160 (71)

150 (66)

140 (60)

Minimum Open Temperature – °F (°C)

130 (54)

120 (49)

110 (43)

100 (38)

90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280 290 300 310 320 330 340

(32) (38) (43) (49) (54) (60) (66) (71) (77) (82) (88) (93) (99) (104) (110) (116) (121) (127)(132) (138) (143) (149) (154)(160) (166) (171)

Manually Resettable Temperature - °F (°C)

Figure 28

Therm-O-Disc Bimetal Disc Thermostat48

-31°F (-35°C) MAX. AUTO

-31°F (-35°C) MAX. AUTO

RESET