Page 1

T205B

Balanced Tank Blanketing Regulator

Best in Class Flow Capacity

12000

10000

Flow Capacity (SCFH)

8000

6000

4000

2000

T205B

0

2

5

10

20

Other Regulators

80

60

40

100

125

150

Inlet Pressure, psig

• Patent-pending design for superior fl ow and pressure management

• Specifi cally designed for pressure-sensitive tank blanketing applications

• Self-operated for quick response to tank pressure changes

* Based on published data of leading competitors

Introduction

The Type T205B is a direct-operated, internally balanced

regulator. This balanced design allows for greater

fl uctuations in inlet pressure, as well as much greater

fl ow capacity. Higher fl ow has become increasingly

important as updated tank blanketing sizing guidelines*

often result in greater fl ow requirements.

* Such as API 6th Edition 2009 and ISO 28300 2008

Application

The Type T205B regulator has been specifi cally designed

for tank blanketing applications. In tank blanketing, a

gas such as nitrogen in brought into the tank in order to

inert the vapor space above the liquid. This application

is characterized by low pressure. The TypeT205B is able

to maintain very low pressure setpoints and respond to

very small changes in pressure.

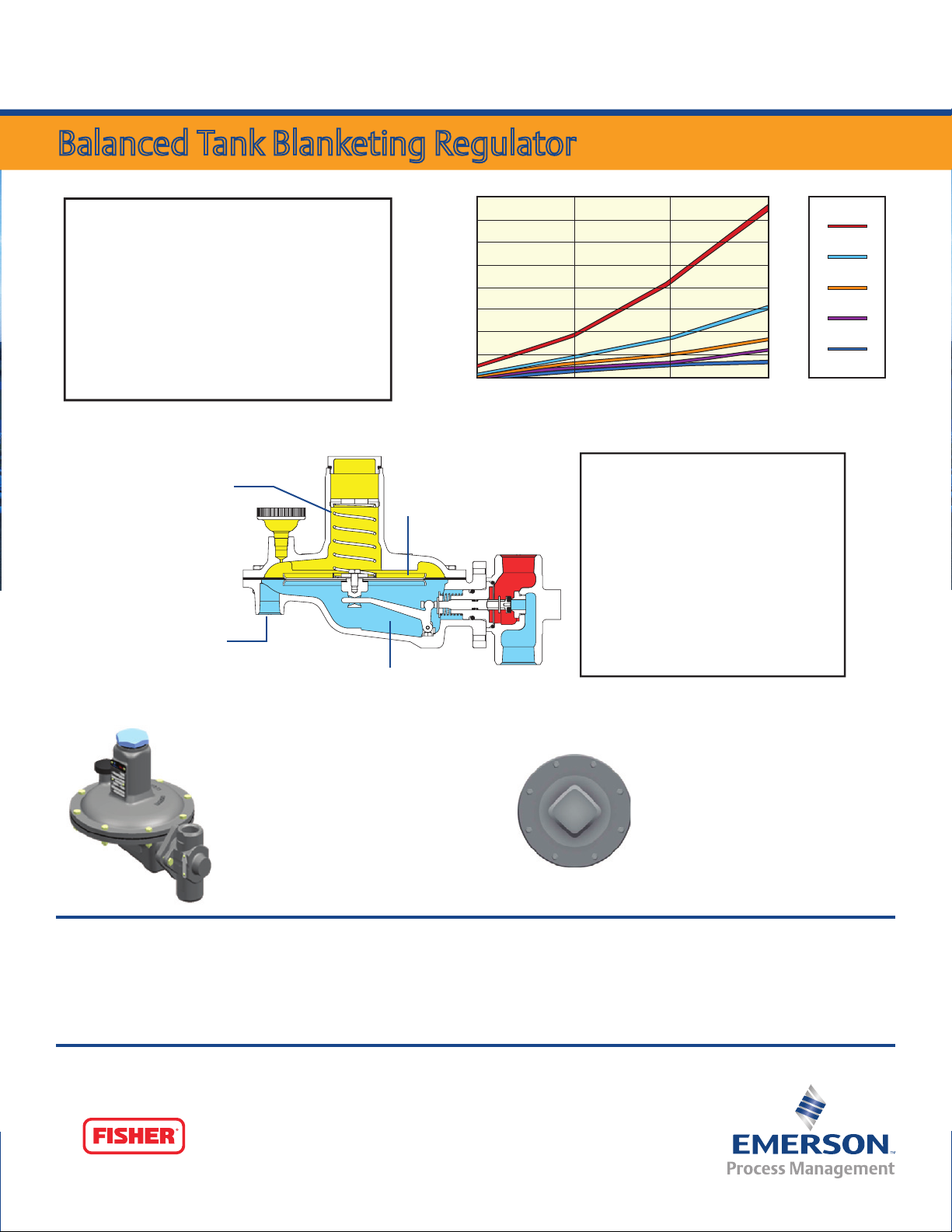

Patent-Pending Balanced Trim Design

www.emersonprocess.com/regulators

The TypeT205B features a patent-pending

balanced trim design. This unique design

allows the regulator to achieve much

higher fl ow capacities than traditional

designs. It is less susceptible to pressure

fl uctuations that can originate from the

blanketing gas supply - thus delivering

more accurate performance.

Page 2

T205B

Balanced Tank Blanketing Regulator

By introducing the least amount of gas

required into a tank, the volume of gas

that escapes through poorly sealed

vents and other paths is reduced. In this

way, signifi cant blanketing gas costs

can be saved. In order to accomplish

this, a regulator that can sense very

low pressures, such as the Type T205B,

is required.

7 different springs

available to

customize pressure

control setting

External sensing

for most accurate

pressure control

Lever design provides increased lockup

force without extra cost and size

1/2-inch

$40,000

$35,000

$30,000

$25,000

$20,000

$15,000

$10,000

$5,000

Nitrogen Cost Per Tank Per Year

$0

1/4-inch 1/2-inch 3/4-inch 1-inch

6.4 mm 12.7 mm 19.1 mm 25.4 mm

Large diaphragm size

to sense very small

pressure changes

New

Airset

Nitrogen Cost vs. Leak Diameter

Nitrogen Escape Path Ð Effective Leak Diameter

• Sizes: 3/4” and 1”

• Body and Casing Materials: Cast

Iron, Steel, Stainless steel (316L)

• End Connections: NPT, CL150 RF,

CL300 RF, PN 16/25/40

• Maximum Inlet Pressure:

200 psig

• Control Pressure Range:

1 inch w.c. to 7 psig

• Trim Materials: FEP, NBR, FKM,

FFKM, EPDM

Blanketing Setpoint

7-inches w.c.

17.5 mbar

2-inches w.c.

5 mbar

1-inches w.c.

2.5 mbar

3/4-inches w.c.

1.9 mbar

1/2-inches w.c.

1.2 mbar

A variety of trim materials are available,

designed to withstand the toughest

tank environments.

Durable casing and body, designed

for many years of service. Available

in 316L stainless steel for greater

chemical resistance.

Industrial Regulators

Emerson Process Management Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

For further information, visit www.fisherregulators.com

Asia-Pacific

Shanghai, China 201206

Tel: +86 21 2892 9000

Our Global Product Brand:

D352027X012 © 2013 Emerson Process Management Regulator Technologies, Inc. All rights reserved.

Printed in the U.S.A. 04/13. Fisher, Emerson Process Management, and the Emerson Process Management

design are marks of one of the Emerson Process Management group of companies. All other marks are the

property of their respective owners.

Quality Assurance

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Distinctive diamond shape cast

into spring case uniquely identifi es

the product as part of the

Fisher® brand and assures you of

the highest-quality engineering,

durability, performance,

and support.

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4 811 8100

Loading...

Loading...