Emerson SST1400 User Manual

Electronic Air Cleaner

Model NumberModel Number

Model Number

Model NumberModel Number

SST

SST1000SST1000

SST1000

SST1000SST1000

SST1400SST1400

SST1400

SST1400SST1400

SST1600SST1600

SST1600

SST1600SST1600

SST2000SST2000

SST2000

SST2000SST2000

OFF

OPERATING

LIGHT

ON

OO

WNER’S MANUWNER’S MANU

O

WNER’S MANU

OO

WNER’S MANUWNER’S MANU

••

InstallationInstallation

•

Installation

••

InstallationInstallation

••

OperationOperation

•

Operation

••

OperationOperation

••

Basic SST Service GuideBasic SST Service Guide

•

Basic SST Service Guide

••

Basic SST Service GuideBasic SST Service Guide

••

Technical Repair GuideTechnical Repair Guide

•

Technical Repair Guide

••

Technical Repair GuideTechnical Repair Guide

••

Repair PartsRepair Parts

•

Repair Parts

••

Repair PartsRepair Parts

Please read and familiarize yourself with the contents of this manual beforePlease read and familiarize yourself with the contents of this manual before

Please read and familiarize yourself with the contents of this manual before

Please read and familiarize yourself with the contents of this manual beforePlease read and familiarize yourself with the contents of this manual before

installing, operating or performing maintenance on the unit.installing, operating or performing maintenance on the unit.

installing, operating or performing maintenance on the unit.

installing, operating or performing maintenance on the unit.installing, operating or performing maintenance on the unit.

White-Rodgers is a division

of Emerson Electric Co.

www.white-rodgers.com

ALAL

AL

ALAL

PART NO. 37-6373FPART NO. 37-6373F

PART NO. 37-6373F

PART NO. 37-6373FPART NO. 37-6373F

Replaces 37-6373E

0631

RR

ULES FOR SAFEULES FOR SAFE

R

ULES FOR SAFE

RR

ULES FOR SAFEULES FOR SAFE

INSTINST

INST

INSTINST

Please read instructions before installing and using the Electronic Air Cleaner. This will help you obtain the full benefit from

the Electronic Air Cleaner you have selected.

ALLAALLA

ALLA

ALLAALLA

TION TION

TION

TION TION

ELECTROCUTION HAZARDELECTROCUTION HAZARD

ELECTROCUTION HAZARD

ELECTROCUTION HAZARDELECTROCUTION HAZARD

Shut off power at fuse panel beforeShut off power at fuse panel before

Shut off power at fuse panel before

Shut off power at fuse panel beforeShut off power at fuse panel before

servicing. Failure to do so could result inservicing. Failure to do so could result in

servicing. Failure to do so could result in

servicing. Failure to do so could result inservicing. Failure to do so could result in

serious personal injury or death.serious personal injury or death.

serious personal injury or death.

serious personal injury or death.serious personal injury or death.

AND OPERAAND OPERA

AND OPERA

AND OPERAAND OPERA

WW

ARNINGARNING

!

W

ARNING

WW

ARNINGARNING

▲

TIONTION

TION

TIONTION

If this unit has an electrical cord, the cord has a grounding type

plug with a third (grounding) pin. This plug will fit only into a

grounding type power outlet. If the proper type of outlet is not

available, contact qualified personnel to install a proper outlet.

Do not alter the plug in any way.

WW

ARNINGARNING

!

W

ARNING

WW

ARNINGARNING

▲

To reuce the risk of electric shock, The power cordTo reuce the risk of electric shock, The power cord

To reuce the risk of electric shock, The power cord

To reuce the risk of electric shock, The power cordTo reuce the risk of electric shock, The power cord

must be connected to an appropriate outlet. Do notmust be connected to an appropriate outlet. Do not

must be connected to an appropriate outlet. Do not

must be connected to an appropriate outlet. Do notmust be connected to an appropriate outlet. Do not

alter the plug in any way.alter the plug in any way.

alter the plug in any way.

alter the plug in any way.alter the plug in any way.

WW

ARNINGARNING

!

W

ARNING

WW

ARNINGARNING

▲

Do not attempt installation of this unit unless you areDo not attempt installation of this unit unless you are

Do not attempt installation of this unit unless you are

Do not attempt installation of this unit unless you areDo not attempt installation of this unit unless you are

familiar with the necessary tools, equipment, utilityfamiliar with the necessary tools, equipment, utility

familiar with the necessary tools, equipment, utility

familiar with the necessary tools, equipment, utilityfamiliar with the necessary tools, equipment, utility

connections and potential hazards.connections and potential hazards.

connections and potential hazards.

connections and potential hazards.connections and potential hazards.

Installation should be performed only by a qualifiedInstallation should be performed only by a qualified

Installation should be performed only by a qualified

Installation should be performed only by a qualifiedInstallation should be performed only by a qualified

service provider.service provider.

service provider.

service provider.service provider.

Failure to do so could result in reduced performanceFailure to do so could result in reduced performance

Failure to do so could result in reduced performance

Failure to do so could result in reduced performanceFailure to do so could result in reduced performance

of the unit, serious personal injury or death.of the unit, serious personal injury or death.

of the unit, serious personal injury or death.

of the unit, serious personal injury or death.of the unit, serious personal injury or death.

WW

ARNINGARNING

!

W

ARNING

WW

ARNINGARNING

▲

Installation of this unit must comply with local electricInstallation of this unit must comply with local electric

Installation of this unit must comply with local electric

Installation of this unit must comply with local electricInstallation of this unit must comply with local electric

codes or other applicable codes.codes or other applicable codes.

codes or other applicable codes.

codes or other applicable codes.codes or other applicable codes.

Review and understand local codes prior to installation.Review and understand local codes prior to installation.

Review and understand local codes prior to installation.

Review and understand local codes prior to installation.Review and understand local codes prior to installation.

Do not use this apparatus in an explosive atmosphere.Do not use this apparatus in an explosive atmosphere.

Do not use this apparatus in an explosive atmosphere.

Do not use this apparatus in an explosive atmosphere.Do not use this apparatus in an explosive atmosphere.

Failure to do so could result in serious personalFailure to do so could result in serious personal

Failure to do so could result in serious personal

Failure to do so could result in serious personalFailure to do so could result in serious personal

injury or death.injury or death.

injury or death.

injury or death.injury or death.

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

Rules for Safe Installation and Operation .............2

How the Air Cleaner Works ..................................3

Construction of the Air Cleaner ............................ 3

Preinstallation .......................................................4

Installation ............................................................6

Wiring Instructions................................................7

Operation .............................................................8

Maintenance and Washing ...................................8

Specifications .......................................................9

Basic SST Service Guide ...................................10

Technical Repair Guide ......................................11

Air Cleaner Retrofit (Upgrade) Kit Installation ....13

Repair Parts ....................................................... 14

Wash Reminder.................................................. 16

1. Read the Owners Manual and the Rules for Safe

Operation carefully. Failure to follow these rules and

instructions could cause a malfunction of filter or

unsatisfactory service.

2. Follow a regular service and maintenance schedule

for efficient operation.

3. Unit must run for one full hour after installation. This

will allow the collecting cells to reach peak efficiency.

4. If Air Flow Monitor is required, order F859-0381 kit.

CACA

UTIONUTION

!

CA

UTION

CACA

UTIONUTION

▲

CABINET AND CELLS MAY CONTAINCABINET AND CELLS MAY CONTAIN

CABINET AND CELLS MAY CONTAIN

CABINET AND CELLS MAY CONTAINCABINET AND CELLS MAY CONTAIN

SHARP EDGES.SHARP EDGES.

SHARP EDGES.

SHARP EDGES.SHARP EDGES.

Use care when servicing unit or handlingUse care when servicing unit or handling

Use care when servicing unit or handling

Use care when servicing unit or handlingUse care when servicing unit or handling

cells. Failure to do so could result incells. Failure to do so could result in

cells. Failure to do so could result in

cells. Failure to do so could result incells. Failure to do so could result in

minor personal injury.minor personal injury.

minor personal injury.

minor personal injury.minor personal injury.

DID YOU GET THE RIGHT SIZEDID YOU GET THE RIGHT SIZE

DID YOU GET THE RIGHT SIZE

DID YOU GET THE RIGHT SIZEDID YOU GET THE RIGHT SIZE

AIR CLEANERAIR CLEANER

AIR CLEANER

AIR CLEANERAIR CLEANER

Model SST1000 Model SST1000

Model SST1000 is designed for heating or cooling blow-

Model SST1000 Model SST1000

ers delivering 600 to 1200 cubic feet of air per minute

(cfm.)

Model SST1400 Model SST1400

Model SST1400 is designed for heating or cooling blow-

Model SST1400 Model SST1400

ers delivering 1000 to 1600 cfm.

Model SST1600 Model SST1600

Model SST1600 is designed for heating or cooling blow-

Model SST1600 Model SST1600

ers delivering 1000 to 2000 cfm.

Model SST2000 Model SST2000

Model SST2000 is designed for heating or cooling blow-

Model SST2000 Model SST2000

ers delivering 1600 to 2200 cfm.

See specifications on page 9.

BASIC TOOLS REQUIREDBASIC TOOLS REQUIRED

BASIC TOOLS REQUIRED

BASIC TOOLS REQUIREDBASIC TOOLS REQUIRED

Tin Snip

Screwdriver

Rule or Tape Measure

Drill

2

ABC

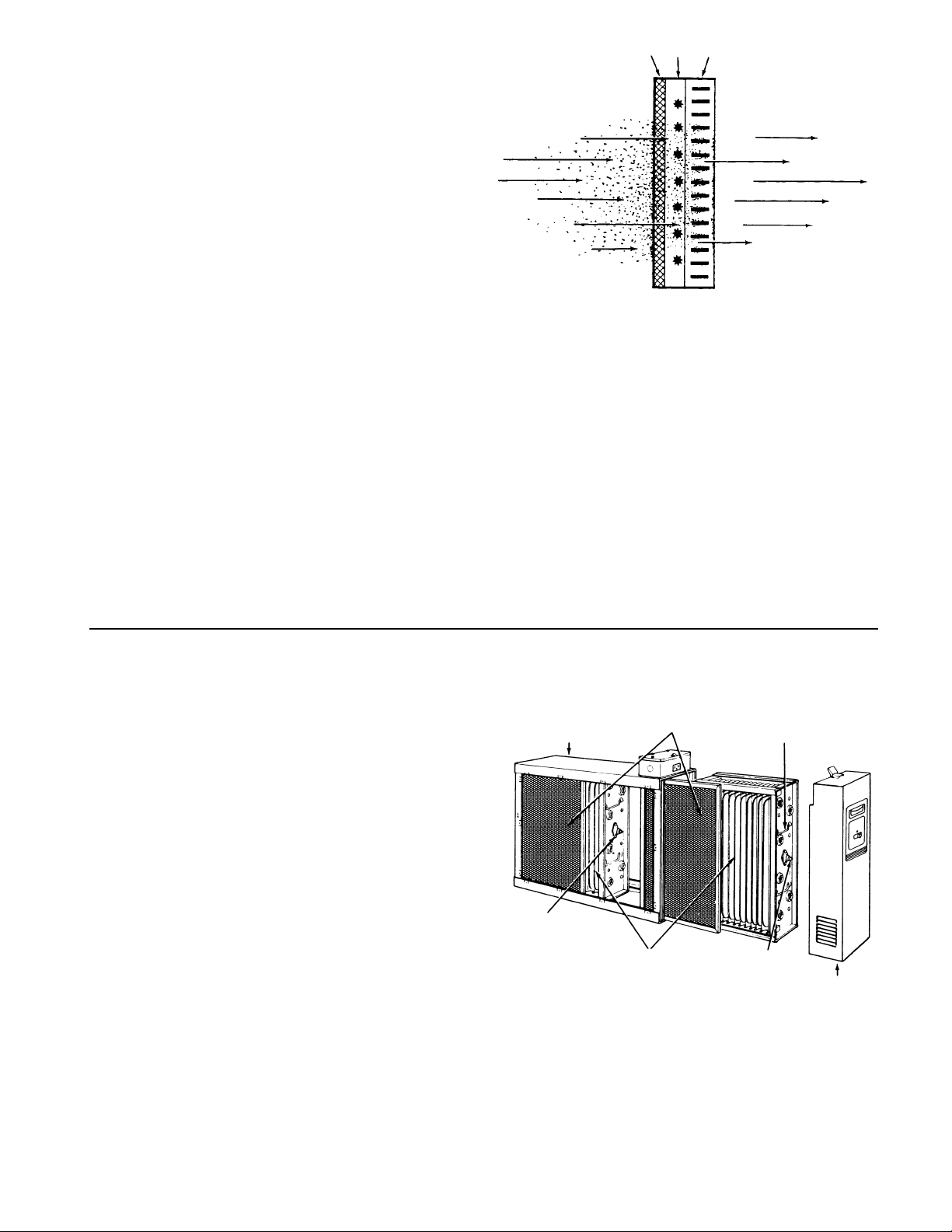

Dirty Air In Clean Air Out

Cabinet

Pre-Filters

Handle

Contact

Button

Contact

Button

Collecting Cells

Power Pack

HOHO

W W

W

W W

THE THE

THE

THE THE

HO

HOHO

Dirt particles flowing through the ducts (Figure 1) first enters

the pre-filters (A) where large particles (hair, lint, etc.) are

trapped. Smaller particles (smoke, dust, pollen, etc.) pass

through these pre-filters and enter the ionizing section (B).

Here each tiny particle receives a positive electrical charge.

These charged particles then enter the collecting section

(C). This section consists of a series of aluminum plates

which are alternately charged negative and positive.

The positive charge of the particles cause them to be

repelled by the positive plates and attracted to the negative

plates where they are collected . . . just as a magnet attracts

iron filings.

Clean-filtered air re-enters the supply duct system.

White Dust (Lint)White Dust (Lint)

White Dust (Lint)

White Dust (Lint)White Dust (Lint)

An Electronic Air Cleaner is designed to collect two major

types of contaminants: ➀ Irritants (Pollens, Spores, Molds,

Bacteria, etc.) and ➁ Black Soiling Contaminants (Dirt and

Smoke particles).

The residue on the collecting plates of an electronic air

cleaner is black, indicating it is removing dirt from the air

stream. After installing an air cleaner you may notice white

dust (typically, long linty particles or fibers – from carpets,

cotton materials or drapery fabrics). This material is not

collected by the air cleaner because it does not contain the

irritants or soiling contaminants listed above or settles out of

the air before reaching the air cleaner. The presence of

white dust does not indicate an air cleaner requires service.

AIR CLEANER AIR CLEANER

AIR CLEANER

AIR CLEANER AIR CLEANER

WW

ORKSORKS

W

ORKS

WW

ORKSORKS

Figure 1Figure 1

Figure 1

Figure 1Figure 1

Carbon (Charcoal) FiltersCarbon (Charcoal) Filters

Carbon (Charcoal) Filters

Carbon (Charcoal) FiltersCarbon (Charcoal) Filters

Odors are gas molecules, not particles. They cannot be

removed by an Electronic Air Cleaner or by any other

filtration media designed to remove airborne particles.

However, some gases can be absorbed by an activated

carbon filter or diluted with fresh outdoor air. When odors

are present, the addition of charcoal filters will neutralize

odors, such as cooking odors, pet odors, cigar and cigarette

odors, ozone, etc. Optional charcoal filters are available for

your Air Cleaner. Refer to the parts list for the charcoal filter

part number for your Air Cleaner. Charcoal filters require

replacement. They cannot be washed. While there is no rule

of thumb for how often they should be changed, you can

use your best judgement based on the odors you perceive

in your environment.

CONSTRCONSTR

CONSTR

CONSTRCONSTR

Not only is your air cleaner easy to install, it is also easy to

operate and maintain. Its basic components, and their

functions, are as follows: (See Figure 2)

Cabinet Cabinet

Cabinet - mounts to existing duct work and houses the

Cabinet Cabinet

Collecting Cells Collecting Cells

Collecting Cells - are made in two sections and perform the

Collecting Cells Collecting Cells

Pre-filters Pre-filters

Pre-filters - are in two sections which are interchangeable.

Pre-filters Pre-filters

Power Pack- Power Pack-

Power Pack- contains operating and power on lights as well

Power Pack- Power Pack-

UCTION OF UCTION OF

UCTION OF

UCTION OF UCTION OF

collecting cells and pre-filters.

actual collecting of dust, dirt, and other impurities

from the air. They contain the ionizing and collection sections described above.

Each cell must be installed with the ionizing wires

on the air entering side. Each cell must be oriented

with the handles and contact button (Figure 2)

toward the operator.

They serve as a pre-filter to trap large particles

such as hair and lint before they can enter the cell

sections.

as the solid state components that convert the 120

volt power supply to the high-voltage, direct current

required for the collecting cell.

THE THE

THE

THE THE

AIR CLEANERAIR CLEANER

AIR CLEANER

AIR CLEANERAIR CLEANER

Figure 2Figure 2

Figure 2

Figure 2Figure 2

3

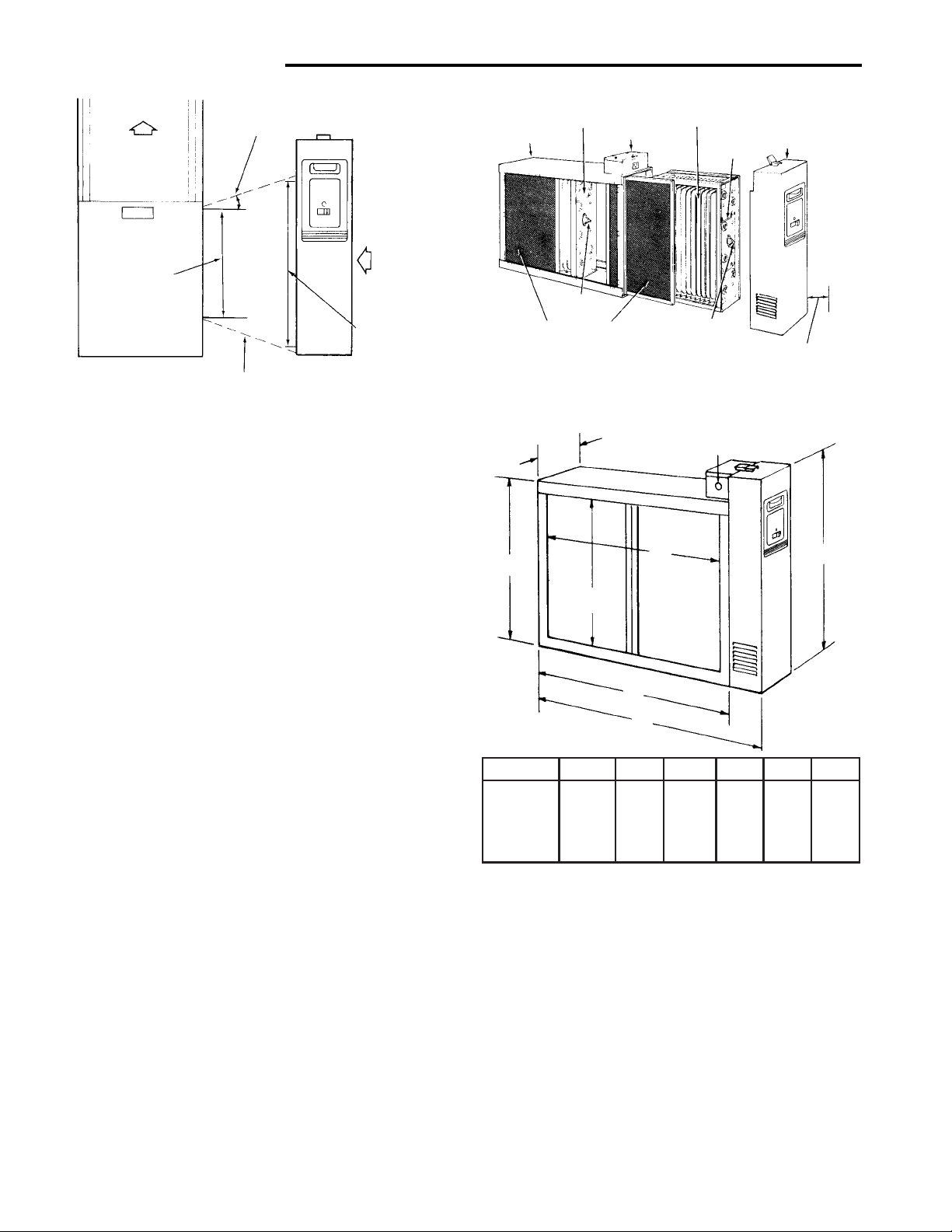

SST1000 24 3/4 21 5/16 18 5/8 13 9/16 16 7/16 19 1/16

SST1400 29 11/16 26 1/4 23 5/8 13 9/16 16 7/16 19 1/16

SST1600 25 1/2 21 5/16 18 5/8 17 3/4 20 5/8 23 3/8

SST2000 29 11/16 26 1/4 23 5/8 17 3/4 20 5/8 23 3/8

MODEL NO. A B C D E F

PREINSTPREINST

PREINST

PREINSTPREINST

ALLAALLA

ALLA

ALLAALLA

TIONTION

TION

TIONTION

Not to Exceed 20

Air Flow

Furnace

Opening

Electronic

Air Cleaner

Opening

Furnace

Your air filter must be mounted in the return air duct of a

central forced-air system, on the air entering side of your

furnace. (See Figure 3 for example.)

Select a location that meets the following:

1. The face of the cell will be at a right angle to the air

stream.

2. Allow the following clearances to permit removal of

cells and pre-filters: (See Figures 4 and 5)

Model SST1000 - 14 inches

Model SST1400 - 15 inches

Model SST1600 - 14 inches

Model SST2000 - 15 inches

For complete dimension data refer to Figure 5.

3. The air filter is not to be placed in the discharge of

either the heating or cooling unit.

IMPORTANT: IMPORTANT:

4.

IMPORTANT: If atomizing spray type humidifier is

IMPORTANT: IMPORTANT:

used, it must be installed downstream from the air

filter.

5. If the air cleaner has a power cord installed, unit must

be located close enought to the outlet so connection

can be made without the use of an extension cord.

If your furnace duct system has a pre-installed boot,

discard front cover of boot and slide the air cleaner

component inside the boot. For installation of Air Cleaner

Retrofit (ACR) kits, see page 13.

If furnace opening cannot be enlarged to required size, a

transition sheet metal section must be used. Transition

must be planned for each job. Reduction should not be

more than 4 inches per linear foot, approximately 20

angular degrees (Figure 3).

Transition Section

(if Needed)

Figure 3

LOCATING THE AIR FILTERLOCATING THE AIR FILTER

LOCATING THE AIR FILTER

LOCATING THE AIR FILTERLOCATING THE AIR FILTER

Electronic

Air Cleaner

Air Flow

(Interchangeable)

Collecting Cell

Cabinet

Pre-Filters

(Interchangeable)

E

DIRECTION OF AIR FLOW THROUGHDIRECTION OF AIR FLOW THROUGH

DIRECTION OF AIR FLOW THROUGH

DIRECTION OF AIR FLOW THROUGHDIRECTION OF AIR FLOW THROUGH

Your air cleaner is shipped from the factory with air flow

from left-to-right. If this air flow is suitable for the

installation, no further changes need to be made (Figure 4). For right-to-left air flow, remove both pre-filter

and cell sections. Turn cells upside down (with the

same end facing the cabinet opening). This will locate

the ionizing wires at the right, and both contact buttons

and cell handles will be facing the power door. Air flow

direction must agree with arrow embossed on end of

collecting cells.

After installing the cell sections, install pre-filters in cabinet

tracks on the right. This will again place the pre-filters on

the air entering side (on the same side as ionizing wires).

4

Outlet Box

Contact

Button

D

THE AIR CLEANERTHE AIR CLEANER

THE AIR CLEANER

THE AIR CLEANERTHE AIR CLEANER

(Interchangeable)

Figure 4

6 7/8"

B

A

Figure 5

Collecting Cell

Handle

Contact

Button

Knockouts for

3/4" Conduit

(three sides)

C

Power Pack

See text for Cell

Removal Clearance

F

TYPICAL MOUNTING POSITIONSTYPICAL MOUNTING POSITIONS

Air Flow

Figure 8

TYPICAL MOUNTING POSITIONS

TYPICAL MOUNTING POSITIONSTYPICAL MOUNTING POSITIONS

Air Flow

Air Flow

Rear View

Figure 6

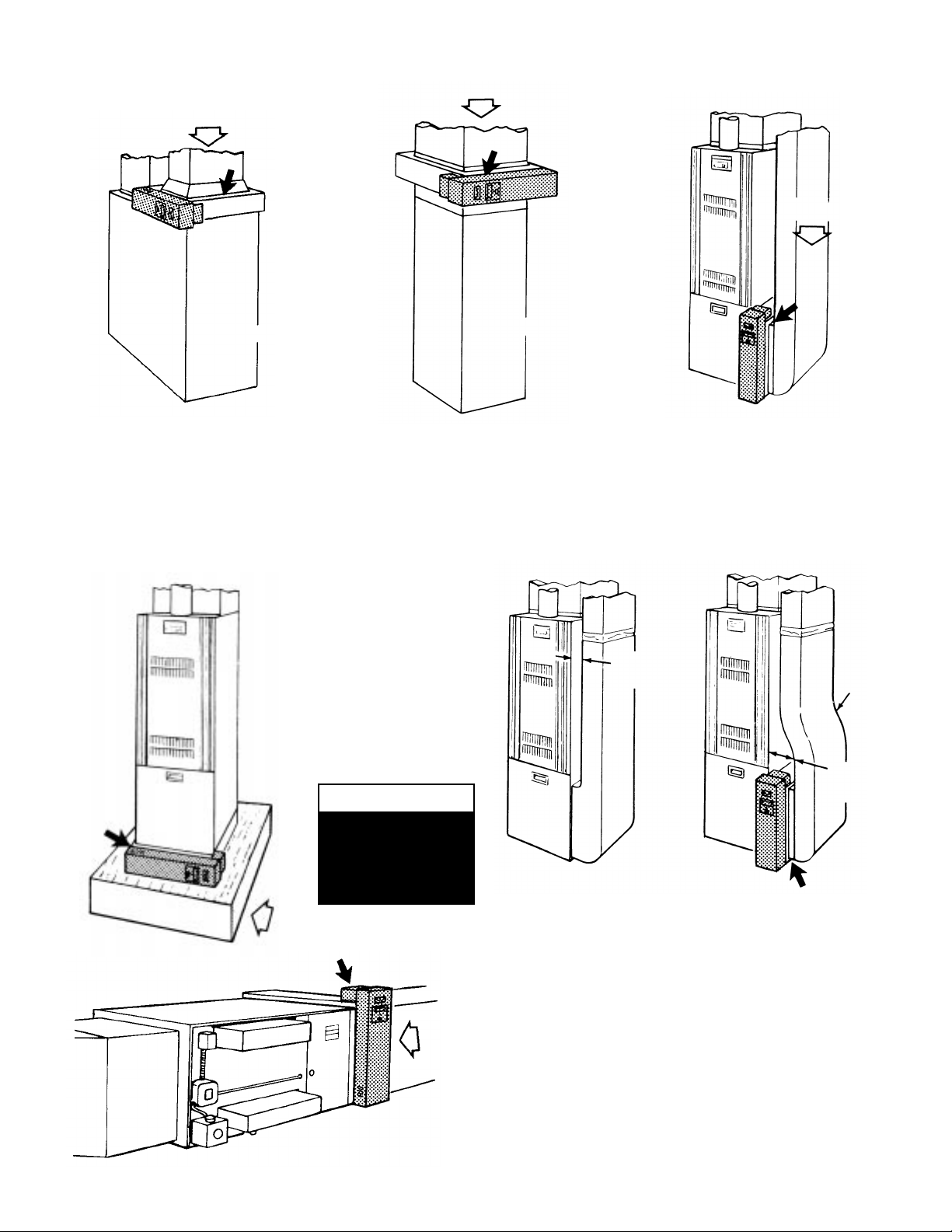

BASEMENT FURNACEBASEMENT FURNACE

BASEMENT FURNACE

BASEMENT FURNACEBASEMENT FURNACE

(LOWBOY) (Figure 6)(LOWBOY) (Figure 6)

(LOWBOY) (Figure 6)

(LOWBOY) (Figure 6)(LOWBOY) (Figure 6)

Cleaner is mounted horizontally in return plenum,

just above furnace.

Figure 9

Figure 7

COUNTERFLOWCOUNTERFLOW

COUNTERFLOW

COUNTERFLOWCOUNTERFLOW

FURNACE (Figure 7)FURNACE (Figure 7)

FURNACE (Figure 7)

FURNACE (Figure 7)FURNACE (Figure 7)

Cleaner is mounted horizontally in re-

turn duct or plenum, just above furnace.

HIGHBOY FURNACEHIGHBOY FURNACE

HIGHBOY FURNACE

HIGHBOY FURNACEHIGHBOY FURNACE

(Figure 9)(Figure 9)

(Figure 9)

(Figure 9)(Figure 9)

Installation beneath furnace.

Cleaner mounts horizontally,

where return air enters from

below. Raise furnace and install beneath base.

After attaching the air cleaner

cabinet to the furnace, carefully

slide or lift and place the furnace into position. Do not “walk”

the furnace into position.

CACA

UTIONUTION

CA

CACA

UTION

UTIONUTION

Air Flow

HORIZONTAL FURNACEHORIZONTAL FURNACE

HORIZONTAL FURNACE

HORIZONTAL FURNACEHORIZONTAL FURNACE

(Figure 11)(Figure 11)

(Figure 11)

(Figure 11)(Figure 11)

Cleaner is mounted vertically

in the return duct near furnace.

Air Flow

!

▲

Walking furnaceWalking furnace

Walking furnace

Walking furnaceWalking furnace

into position couldinto position could

into position could

into position couldinto position could

cause damage tocause damage to

cause damage to

cause damage tocause damage to

the air cleanerthe air cleaner

the air cleaner

the air cleanerthe air cleaner

cabinet.cabinet.

cabinet.

cabinet.cabinet.

Rear View

HIGHBOY FURNACEHIGHBOY FURNACE

HIGHBOY FURNACE

HIGHBOY FURNACEHIGHBOY FURNACE

(Figure 8)(Figure 8)

(Figure 8)

(Figure 8)(Figure 8)

Side installation. Cleaner

is mounted vertically,

where return air enters

side inlet of furnace.

Less than

7 Inches

Figure 10

OFFSET INSTALLATIONOFFSET INSTALLATION

OFFSET INSTALLATION

OFFSET INSTALLATIONOFFSET INSTALLATION

(Figure 10)(Figure 10)

(Figure 10)

(Figure 10)(Figure 10)

Typical use of duct offset to match air filter opening.

If duct connection to furnace allows less than nine

inches for mounting the air cleaner, shorten the

lateral trunk, or attach an offset fitting to the elbow.

Offset

At Least

9 Inches

Figure 11

5

Loading...

Loading...