Emerson SAPAG 8400 Series, SAPAG 8500 Series, SAPAG 8490 Series, SAPAG 8590 Series Installation And Maintenance Instruction

SAPAG

Attention

The safety of

depends on the proper operation of the

pressure relief valves. Consequently, the

valves should be kept clean and should be

periodically tested and reconditioned to

make sure they function properly.

Suitability of the material and product for

the use contemplated by the buyer is the

sole responsibility of the buyer. Also storage,

installation and proper use and application are

the sole responsibility of the purchaser.

Emerson disclaims any and all liability arising

out of same.

Any installation, maintenance, adjustment,

repair and testing performed on pressure relief

valves should be done in accordance with

the requirements of all applicable Codes and

Standards under which those performing such

work should maintain proper authorization

through appropriate governing authorities.

No repair, assembly and test work done by

other than Emerson shall

be covered by the warranty extended by

Emerson to its customers. You assume full

responsibility for your work. In maintaining

and repairing

Emerson products you should use only parts

manufactured by Emerson. Call your nearest

Emerson regional sales

office or representative for a Emerson service

engineer should you wish assistance with your

field needs.

lives and property often

WARNING

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

Table of Contents

1. Introduction

2. Storage and Handling

3. Installation

Care in Handling

Inspection

Inlet Piping

Outlet Piping

4. Hydrostatic Pressure Tests

Hydrostatic Test of Vessel or System

Hydrostatic Test of Outlet System

5. Setting, Testing and Adjustments

New Valves

Reconditioned Valves

Valves Removed from Service

The Test Bench

Test Fluids

Valve Operation

Set Pressure Changes

Set Pressure Adjustment

Nozzle Ring Settings

• Style 8500/8590

Cold Differential Test Pressure Adjustments

• Temperature Correction

• Back Pressure Correction

Seat Leakage Tests

• Metal-to-Metal Seated Valves

• Soft Seated Valves

6. Valve Maintenance

Visual Inspection and Neutralizing

Disassembly

Cleaning

Inspection

Reconditioning of Valve Seats

Lapping Procedures

• Lapping Blocks

• Lapping Compounds

• Machining of Nozzle Seats

• Machining of Disc Insert Seats

Assembly

Assembly of Cap and Lifting Lever Devices

Soft Seat Construction

7. Style Variations

8. Service Records

9. Spare Parts

10. Trouble Shooting Pressure Relief Valves

Seat Leakage

• Seats Damaged by Foreign Matter

• Distortion From Piping Strains

• Operating Pressure too close to Set Pressure

• Chatter

• Incorrectly Adjusting Lifting Gear

• Other Causes of Seat Leakage

• Corrosion

11. Emerson Valves & Controls’ Field Services and Repair Programs

Ordering Information

Emerson.com/FinalControl © 2017 Emerson. All rights reserved.

without notice SAPDR-0060-EN-1308

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

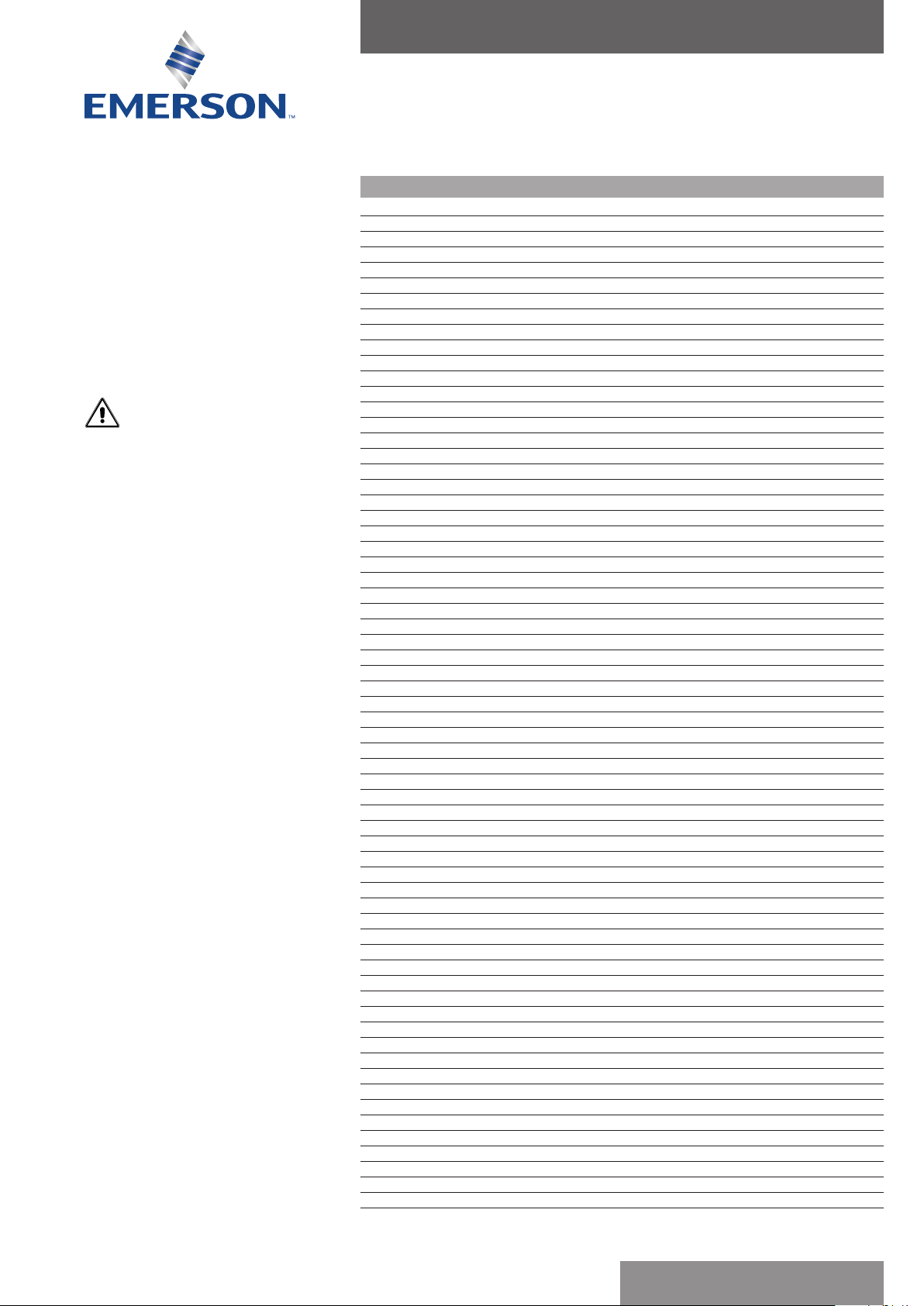

Figure 1

Set Screw

8400/8500

only

Nozzle ring

Note:

This vent must

remain open on

8490/8590

construction

Style 8400 Style 8490 Soft Seat

Parts list

No. Part Name Notes No. Part Name Notes

1 Body

2 Nozzle

3 Nozzle Ring 3

4 Set screw 3, except P-T Orifice 8500/8590

4A Set Screw 3, (M-T Orifice)

4B Set Screw Rod 3, (M-T Orifice)

4C Set Screw Pin 3, (M-T Orifice)

5 Disc Holder 2

6A Bellows Tailpiece 2

6B Bellows 2

6C Bellows Flange 2

8 Disc Insert 1

9 Retention Clip 1

10 O-Ring 1

11 O-Ring Retainer 2

12 Retainer Screw(s) 2

13 Nozzle Ring Lockscrew P-T Orifice 8500/8590

14 Set Screw Plug P-T Orifice 8500/8590 (not shown)

15 Guide 3

16 Spindle 3

17 Spindle Cotter Pin 1 (L-T orifice)

18 Spring 3

19 Spring Washers 3

20 Bonnet

21 Bonnet Stud

22 Bonnet Stud Nut

24 Adjusting Bolt

25 Adjusting Bolt Nut

26 Pipe Plug

27 Set Screw Gasket 1

28 Guide Gasket 2

29 Tailpiece Gasket 1

34 Seal & Wire

35 Seal Clip

36 Nameplate

40 Screwed Cap

41 Cap Gasket 1

Gasket Kit 1,4

42 Test Gag/Plug ( Plug only shown)

43 Test Gag plug gasket 1

(P-T Orifice

have lockscrews)

Style 8500

D-N Orifice

construction

Notes

1. Consumable Spare Parts: Valve parts which should be replaced as part of any disassembly, and

discs and disc inserts which must be replaced if seats are damaged.

2. Repair Spare Parts: Valve parts exposed to wear and/or corrosion during normal operation. They

are in fluid flow paths and may require replacement as part of any repair.

3. Insurance Spare Parts: Valve parts exposed to process or environmental wear and/or corrosion

and may require replacement as part of a major repair.

Emerson Valves & Controls recommends that sufficient inventory of spare parts be maintained to

support process requirements.

Always be sure to use genuine Emerson parts to ensure continued product performance and

warranty.

4. Contains complete set of gaskets for all style of valves

Emerson reserves the right to change the contents without notice page 2

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

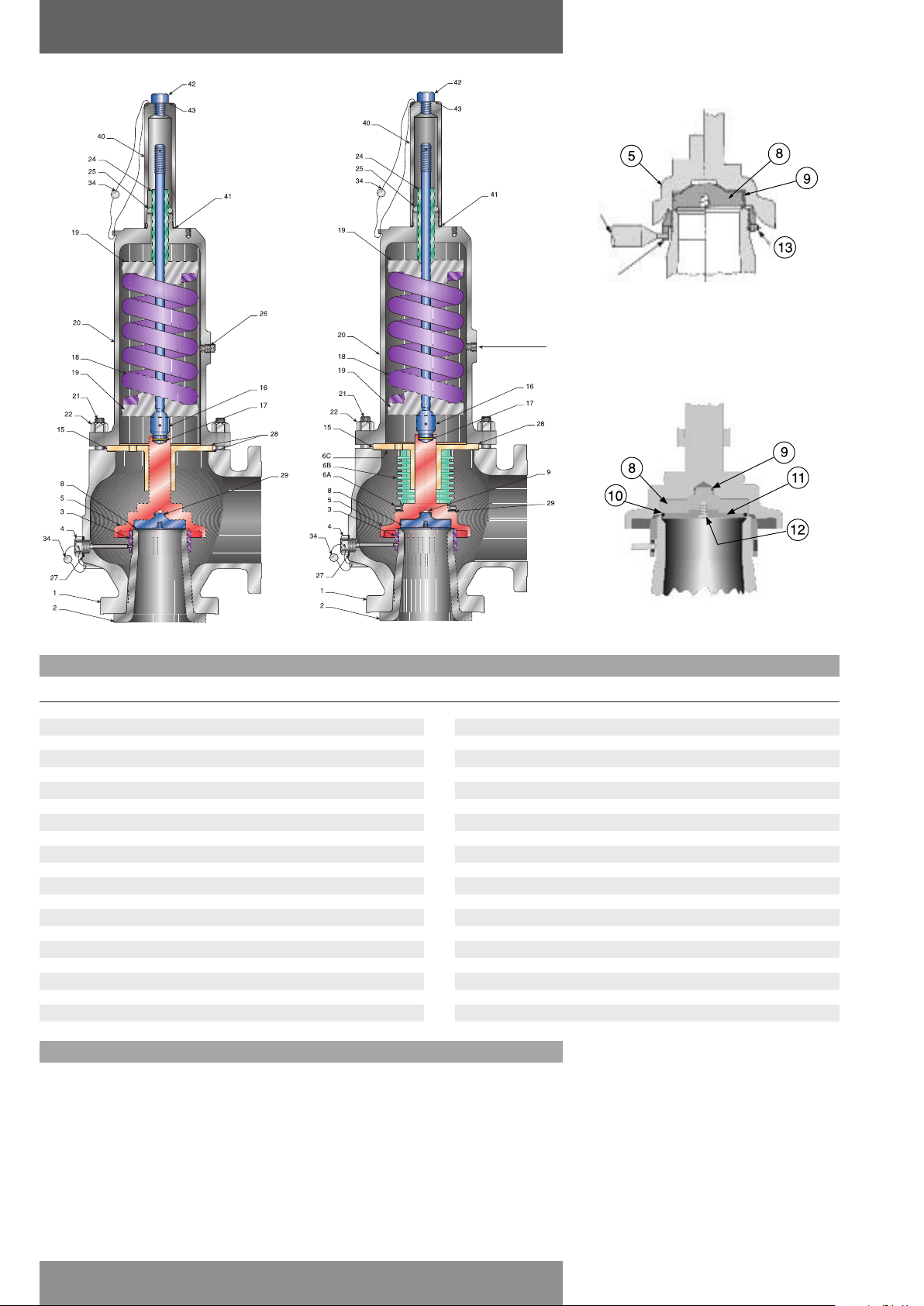

Ordering Spare Parts

When ordering spare parts, the valve size, style and assembly number and/or serial number should

be given together with set pressure, part name and reference number from page 2. The valve

serial number is shown on the valve nameplate. Spare parts may be ordered from any Emerson

Valves & Controls Regional Sales Office or Representative.

Figure 2

Sample nameplate

Safety Precautions

Proper handling, storage, installation, maintenance and operation is essential to the safe and

reliable functioning of any pressure relief product.

Precautionary statements in the form of warnings, cautions and notes are used throughout this

instruction to emphasize important and critical factors where applicable.

Examples:

WARNING: An operating procedure or practice which if not strictly observed may

result in injury to personnel or loss of life.

CAUTION: An operating procedure or practice which if not strictly observed may

result in damage to or destruction of equipment.

These precautionary statements are by no means exhaustive.

Emerson Valves & Controls cannot be expected to know, evaluate, and advise customers

of all the possible applications and operating conditions for its products or of the possible

hazardous consequences which may result from the misapplication or misuse of such products.

Consequently, the improper handling, storage, installation, use or maintenance of any Emerson

Valves & Controls Product by a non Emerson Valves & Controls employee may void any Emerson

Valves & Controls guarantees or warranties with respect to such Product.

All personnel working with Emerson Valves & Controls products should be adequately trained and

thoroughly familiar with the contents of the appropriate instruction manual(s).

Emerson Valves & Controls cannot evaluate all conditions in which the products may be used.

However, Emerson Valves & Controls offers the following general safety suggestions:

• Never subject valves to sharp impact loads.

Rough handling (striking, bumping, dropping, etc.) may alter the pressure setting, deform valve

parts and adversely affect seat tightness and valve performance. Striking a valve which is under

pressure can cause premature actuation.

• Always lower the system pressure to the pressure level specified in the instruction before

making any adjustment to the valve. Furthermore, always install a proper test rod to gag an

installed valve before making any ring adjustments on the valve.

• Ear and eye protection should be used when working on a valve which has pressure.

• Never stand in front of the discharge outlet of a pressure relief valve which is under pressure.

• Always stand to the side of and at a safe distance from the valve discharge and use extreme

care when observing a valve for leakage.

The

above precautions and suggestions are by no means exhaustive and the user should always

approach and use any pressure relief valve with great care.

Operation, Installation and Safety Instructions are available at www.valves.emerson.com or

from your local Emerson regional sales office or representative.

Emerson reserves the right to change the contents without notice page 3

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

1. Introduction

Sapag Series 8000 pressure relief valves have been selected for installation because of their

performance features, reliability and ease of maintenance.

Adherence to the installation and maintenance procedures specified herein will provide the utmost

in safety, a minimum of maintenance, and a long service life. Sapag type 8400/8500/8490/8590

Valves are manufactured in accordance with the requirements of Section VIII Pressure Vessels,

ASME Boiler and Pressure Vessel Code. Type 8400 is a conventional closed bonnet valve. Type

8490 has a balanced bellows for minimizing the effect of back pressure.

Style 8500 is a high performance valve designed specifically for liquid service. The 8500 features

patented contoured liquid trim in a standard 8400/8490 envelope.

2. Storage and Handling

Valves are often on hand at the job site months before they are installed. Unless properly stored

and protected, valve performance may be adversely affected.

Rough handling and dirt may damage or cause misalignment of the valve parts. It is recommended

that the valves be left in their original shipping containers and that they be stored in a warehouse

or at a minimum on a dry surface with a protective covering until they are used.

3. Installation

Care in Handling

Pressure relief valves must be handled carefully and never subjected to sharp impact loads. They

should not be struck, bumped or dropped. Rough handling may alter the pressure setting, deform

valve parts and adversely affect seat tightness and valve performance.

When it is necessary to use a hoist, the chain or sling should be placed around the valve body and

bonnet in a manner that will ensure that the valve is in a vertical position to facilitate installation.

The valve should never be lifted or handled using the lifting lever.

Inlet and outlet protectors should remain in place until the valve is ready to be installed on the

system.

Inspection

Pressure relief valves should be visually inspected before they are installed to ensure that no

damage has occurred during shipment or while in storage.

All protective material, sealing plugs and any extraneous material inside the valve body or nozzle

must be removed.

The valve nameplate and other identifying tags should be checked to ensure that the particular

valve is being installed at the location for which it was intended.

The valve seals protecting the spring setting and ring adjustments should be intact. If seals are not

intact, the valve should be inspected, tested and seals properly installed before use.

Inlet Piping

Pressure relief valves should be mounted vertically in an upright position either directly on

a nozzle from the pressure vessel or on a short connecting fitting that provides direct and

unobstructed flow between the vessel and the valve. Installing a pressure relief valve in other

than this recommended position might adversely affect its operation. Where rounded or beveled

approaches cannot be provided ahead of the valve it is recommended that one size larger nozzle

or fitting be used. A valve should never be installed on a fitting having a smaller inside diameter

than the inlet connection of the valve.

Inlet piping (nozzles) must be designed to withstand the total resultant forces due to the

valve discharging at the maximum accumulated pressure and the expected piping loads. The

magnitudes of the bending moment exerted on the inlet piping will depend on the configuration

and method of supporting the outlet piping.

Many valves are damaged when first placed in service because of failure to clean the connections

properly when installed. Both the valve inlet and the vessel and/or line on which the valve is

mounted must be thoroughly cleaned of all foreign material. The inlet connection bolts or studs

should be drawn down evenly to avoid straining the valve body with possible distortion of the

nozzle flange or base.

Emerson reserves the right to change the contents without notice page 4

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

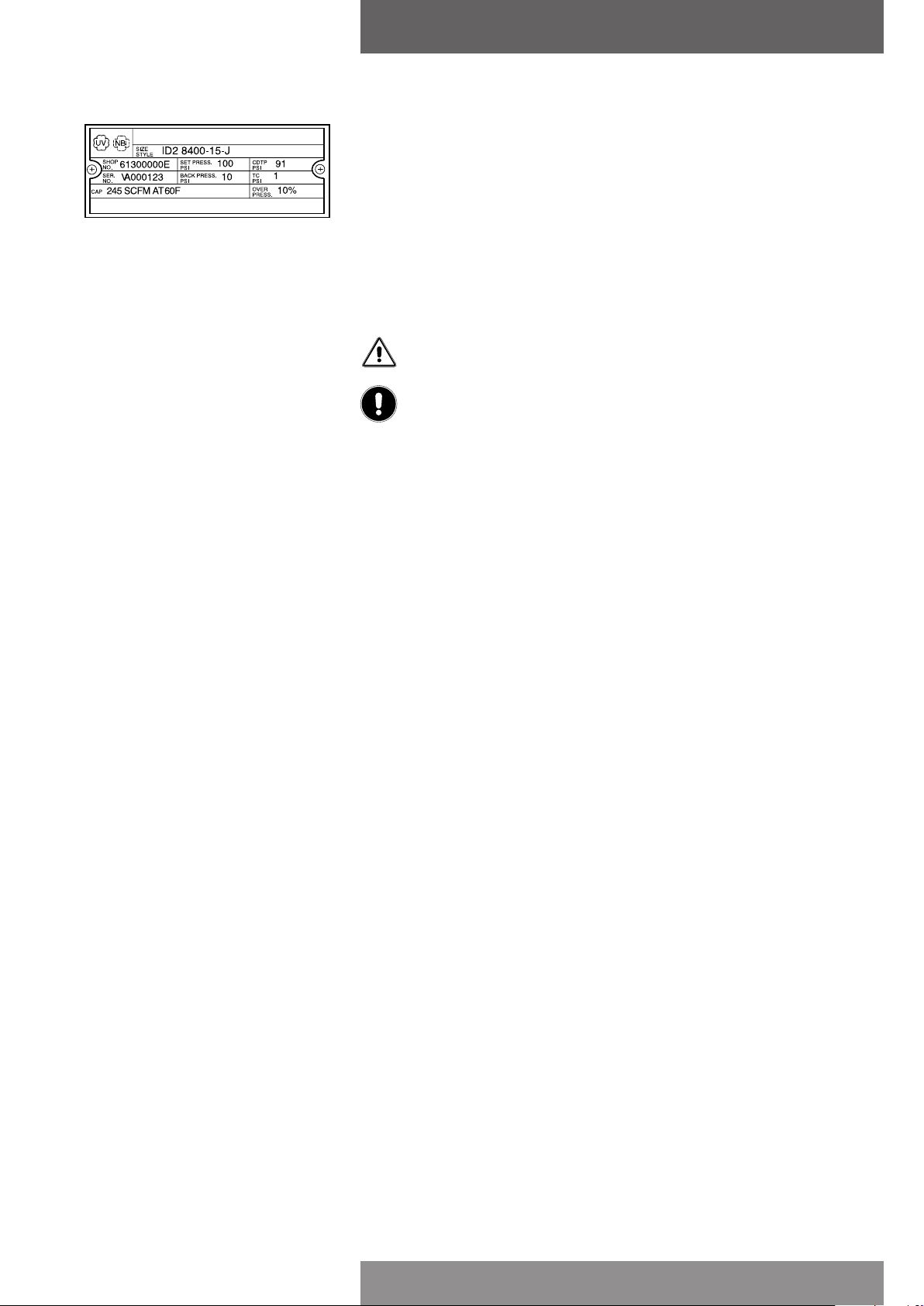

Discharge pipe

Short as

possible

Rounded

approach

Free

support

Top of vessel

Figure 3

Recommended installationdischarging to atmosphere

Lid

Long radius

elbow

Low point

drain

Outlet Piping

Outlet piping should be simple and direct. Where possible, for non-hazardous fluids, a short

discharge pipe or vertical riser connected through a long radius elbow venting directly to

atmosphere is recommended. Such discharge piping should be at least the same size as the valve

outlet.

All discharge piping should be run as direct as is practicable to the point of final release for

disposal. Valve effluent must discharge to a safe disposal area.

Where discharge piping is long, due consideration shall be given to the use of long radius elbows,

and the reduction of excessive line strains through the use of expansion joints and proper means

of support to minimize line sway and vibration under operating conditions. Adequate drainage

is required to prevent corrosive media from collecting in the discharge side of the pressure relief

valve. When required, low point drains shall be provided in the discharge pipe. Particular care

must be observed to ensure that the drains are directed or piped to a safe disposal area.

In installations where the pressure relief valve discharges into a closed system, care must be taken

to ensure that built up and superimposed back pressure has been properly calculated, specified,

and accounted for when sizing and selecting the valve.

Where built up back pressure is expected to exceed 10% of set pressure or if superimposed back

pressure is variable, a bellows valve is required.

4. Hydrostatic Pressure Tests

Hydrostatic Test of Vessel or System

When a pressure vessel or system is to be hydrostatically tested, it is recommended that the

pressure relief valve be removed and a blank flange be installed in its place. This practice

precludes the possibility of any damage to the pressure relief valve. Bent spindles and damaged

valve seats are problems that can be caused by improper hydrostatic test procedures.

Blank flanges must be removed and the pressure relief valve reinstalled before the vessel is placed

in service.

When the hydrostatic test must be performed with the valve in place, a test gag may be used.

Sapag Series 8000 are provided with test gags as standard. In the case of the Type C cap with

lifting lever, the lifting lever assembly must be replaced with a hydrostatic test cap and test

rod prior to hydrostatic testing. When test rods are used, care must be exercised to prevent

overtightening that could damage the valve spindle and valve seats. A test rod which is hand tight

will generally provide sufficient force to hold the valve closed.

After the hydrostatic test, the test rod (gag) must be removed and replaced by either a cap plug or

a cap not fitted with a test rod.

CAUTION: Improper testing may

cause valve damage and seat

leakage.

Hydrostatic Test of Outlet System

When a hydrostatic test must be conducted on the outlet piping system, with the valve in place,

special consideration must be given not to exceed the design pressure limits of the downstream

side of the pressure relief valve. The outlet side of a pressure relief valve is known as the

secondary pressure zone. This zone is normally designed to a lower pressure rating than the

inlet and frequently is designed to a lower pressure rating than the outlet flange. This is

particularly true in the case of balanced bellows designs and in the larger valve sizes.

Consult Sapag products specifications for the back pressure design limits of the Series 8000

valves.

5. Setting, Testing and Adjustments

New Valves

Each Sapag pressure relief valve is carefully set and tested at the factory prior to shipment.

However, it is good practice to inspect the valve prior to installation.

This inspection determines any damage which may have occurred due to rough handling in transit

or storage and initiates appropriate service records.

Reconditioned Valves

Valves which have not been in service for extended periods due to plant shutdown or long term

storage, or valves which have been repaired or reconditioned, should also be tested before being

put into operation.

Valves Removed From Service

Valves being removed from service should be tested on a shop test bench before being

disassembled to determine the set pressure and seat tightness. This is an important phase of

the maintenance routine and the test results should be recorded for review and determination of

necessary corrective action.

The “as received from service” condition of a pressure relief valve is a most useful tool in

establishing the proper time interval between inspections.

Emerson reserves the right to change the contents without notice page 5

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

The Test Bench

The quality and condition of the shop test bench is paramount to obtaining proper test results. The

test bench must be free of leaks and the test fluid must be clean. Solids or other foreign material

in the test medium will damage the seating surfaces of the pressure relief valve being tested.

The test pressure gage must be calibrated and have a range proper to the pressure level of the

valve setting. Set pressure should fall within the middle third of the dial range of the test gage.

The test bench provides an accurate and convenient facility for determining valve set pressure

and seat tightness. It does not duplicate all of the field conditions to which a pressure relief valve

will be exposed while in service. It is not practical to attempt to measure relieving capacity or

blowdown using a test bench.

Test Fluids - Set Pressure Test

The Test Fluid should be air or nitrogen for valves used on gas and vapor service and water for

valves used on liquid service. Valves for steam service should be tested on steam. It may be

necessary to make a correction to the adjusted set pressure to compensate for the difference in

temperature of the test fluids(see appropriate instruction).

Valve Operation

Sapag Series 8000 valves intended for compressible fluid service and tested with air or steam will

open with a sharp clear popping action at the set point. Valves for liquid service tested with water

are considered open when there is a continuous unbroken stream of liquid flowing from the valve.

Set Pressure Changes

Set pressure changes beyond the Sapag specified spring range will necessitate a change in the

valve spring assembly consisting of the spring and two fitted spring washers. The new spring and

washers must be obtained from Sapag and the valve must be reset and the nameplate restamped

by an authorized valve repair facility.

Set Pressure Adjustment

Before making any adjustments reduce the pressure under the valve seat to at least 10% below

the stamped opening pressure. This will prevent seat damage due to turning of the disc on the

nozzle seat and minimize the chance of an inadvertent valve opening. A strong (high) ring position

is necessary to obtain a good clean popping action of the valve on air or gas with the limited

volume available on the test bench.

a. (Not required for testing on liquid.) Remove the nozzle ring set screw and raise the nozzle ring

until it touches the disc holder, then back it down two (2) notches. Exercise care in counting

the number of notches moved so that the ring can be returned to its proper position following

testing.

Moving the notches on the nozzle ring to the left will lower the nozzle ring.

Replace the nozzle ring set screw before each set pressure test. The set screw must engage one

of the ring notches, being careful that it does not bear on the top of a tooth.

b. Remove the cap or lifting lever following the instruction for valve disassembly. (See paragraph

6)

c. Loosen the adjusting bolt nut and turn the adjusting bolt clockwise to increase set pressure or

counterclockwise to reduce set pressure.

d. Retighten the adjusting bolt nut following each adjustment.

e. Two or three consecutive valve openings at the same pressure are necessary to accurately verify

the opening pressure.

f. Once the set pressure has been established, lower the nozzle ring to the installed ring position

as indicated in Table 1 and replace the nozzle ring set screw as described above. Seal wire the

adjusting bolt and adjusting ring set screw with identifying seals.

Nozzle Ring Settings

The nozzle ring adjustment is made at the factory and resetting in service is seldom necessary.

Should it be necessary to change blowdown or reduce valve simmer, the nozzle ring may be

adjusted as follows: (See the next paragraph for P, Q, R and T OrificeType 8500/8590)

a) Remove the nozzle ring set screw and insert a screwdriver to engage the ring notches.

b) Turning the ring to the right raises the ring, thereby increasing blowdown. Turning the ring to

the left lowers the ring, thereby decreasing the blowdown.

c) Do not lower the nozzle ring to the point where the valve begins to have excessive simmer.

Raising of the ring will reduce simmer.

d) The nozzle ring should not be moved more than two notches before retesting. When making

adjustments, always keep count of the number of notches and the direction in which the nozzle

ring is moved. This will permit returning to the original setting in case of error.

Emerson reserves the right to change the contents without notice page 6

CAUTION: Should any adjustments

be made while the valve is

installed on a pressurized system,

the valve should be gagged while

ring adjustments are made.

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

• Type 8500/8590

The Type 8500/8590 in the P, Q, R and T Orifice sizes is preset at the factory and cannot be

externally adjusted in the field, since the special contoured skirt on the disc holder prevents

engagement of the set screw with the nozzle ring. As a result the nozzle ring is not slotted and

is held in place by three set screws. The position of the nozzle ring must be set prior to valve

assembly as follows:

a. Screw the nozzle ring (3) on to the nozzle. The top of the nozzle ring should be below the nozzle

seating surface.

b. Install the disc insert retention clip (9) onto the disc insert. Assemble the disc insert (8) and disc

holder (5). The disc insert should snap into place using hand force only.

c. Lower the disc holder and disc insert carefully onto the nozzle.

d. Reach through the valve body outlet and turn the nozzle ring until it lightly touches the disc

holder. This is the highest lock position.

e. Carefully remove the disc holder and disc insert from the valve.

f. Lower the nozzle ring (turn to the left) the total number of revolutions shown in Table 2.

g. Carefully tighten each of the set screws on the nozzle ring to hold the ring in position.

Table 2

8500/8590 Nozzle Ring Setting

Orifice Size Total revolutions below

highest lock position

P and Q 3/4 Revolution

R and T 1 Revolution

Table 3

Operating

Temperature % Excess Pressure

0-150°F None

151-600°F 1%

601-800°F 2%

801-1000°F 3%

Table 4 - (8400 Style Only)

Orifice Size Saturated Steam Set

Pressure (max)

D, E, F, G, H, J, K, L 1500 psig

M 1100 psig

N, P 1000 psig

Q 600 psig

R, T, T2 300 psig

Table 1

Service Orifice size Nozzle ring setting

(Below Highest Lock Position)

Styles 8400/8490 Pressure Relief Valve Recommended Nozzle Ring Settings

Vapor & Gases D through J -5

K through N -10

P through T -15

Liquids D through G -5

H through K -10

L through N -20

P through T -30

Styles 8500/8590 Pressure Relief Valve Recommended Nozzle Ring Settings

Liquids & Gases D, E, and F -3

G, H, and J -5

K and L -10

M and N -15

P and Q (See table 2)

R and T (See table 2)

Minus sign: indicates number of ring notches below starting position of nozzle ring which is the

highest position with the valve closed (contact with disc holder)

Cold Differential Test Pressure Adjustments

When a pressure relief valve is on a test bench at room temperature and atmospheric pressure,

and is to be installed on a system operating at a higher temperature and/or a higher back pressure,

a compensating adjustment is necessary. The test pressure required to have the valve open at the

desired set pressure under actual service conditions is known as the cold differential test pressure.

• Temperature Correction

When a Sapag Series 8000 valve is set on air or water at room temperature and then used at a

higher service temperature, the test pressure shall be corrected to exceed the set pressure using

the temperature correction shown in Table 3.

Note: this table is not applicable to steam service valves.

• Back Pressure Correction

Conventional valves without balancing bellows set with atmospheric pressure at the outlet and

intended for use under elevated constant back pressure conditions shall be adjusted so that the

test pressure is equal to the set pressure minus the expected back pressure. See example below:

Set Pressure 100 PSI

Constant Back Pressure 10 PSI

Cold Differential Test Pressure 90 PSI

Table 5 - Saturated Steam Service

Air Set Pressure Correction Factors at

Ambient Temperature

Set Pressure % Increase in Spring

(psig) Set Pressure

15-400 3%

401-1000 4%

1001-1500 5%

In all instances, the spring should be selected based on the cold differential test pressure; in the

example above, 90 PSI. See sample nameplate on page 3 which shows how temperature and back

pressure is indicated.

Saturated Steam Correction Factors

Sapag Style 8400 pressure relief valves that are used for saturated steam service and are within

the set pressure limits established in Table 4 may be set on air at ambient temperature, provided

the correction factors in Table 5 are applied to the valve set pressure.

Emerson reserves the right to change the contents without notice page 7

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

Seat Leakage Tests

Ambiguous terms such as “bubble tight”, “drop tight”, “zero leakage” and “commercial tightness” are

sometimes used to describe seat tightness. These terms, however, lack uniform definition and true practical

meaning.

• Test Procedure

API Standard 527 provides a standard for “commercial” tightness and has been adopted by industry and

users in order to clarify testing methods and tightness criteria. This standard applies to flanged inlet nozzle

type pressure relief valves.

• Test Apparatus

A typical test arrangement for determining seat tightness for pressure relief valves per API Standard 527 is

shown in Figure 4. Leakage is measured using a 5/16 in. OD tube with 0.035 in. wall. The tube end is cut

square and smooth, is parallel to and 1/2 inch below the surface of the water. A snap-on type test clamp

shown in Figure 5 is available .

• Procedure

With the valve mounted vertically, the leakage rate in bubbles per minute shall be determined with pressure at the

pressure relief valve inlet raised up to and held at 90 percent of the set pressure (or cold differential test pressure CDTP) immediately after popping. This applies except for valves set at 50 psig or below, in which case the pressure

shall be held at 5 psig below the set pressure immediately after popping. The test pressure shall be applied for a

minimum of one minute for valves of inlet sizes through 2”; two minutes for sizes 21/2”, 3” and 4”; five minutes for

sizes 6” and 8”. Air (or nitrogen) at approximately ambient temperature shall be used as the pressure medium.

• Tightness Standard

a. Metal-to-Metal Seated Valves. The leakage rate in bubbles per minute shall be observed for at least one minute

and shall not exceed the values indicated in table 6 below.

b. Soft Seated Valves. For soft seated valves there shall be no leakage for one minute (zero bubbles for one minute).

Table 6 - Maximum seat leakage rate - Metal seated pressure relief valves

Set Effective Orifice Sizes 0.307 In2 and Smaller Effective Orifice Sizes Larger than 0.307 In

Pressure Max. Bubbles Approximate Leakage Rate Max. Bubbles Approximate Leakage Rate

PSIG per Minute Per 24 Hours per Minute Per 24 Hours

(BarG) Standard Standard Standard Standard

Cubic Feet Cubic Meters Cubic Feet Cubic Meters

15-1000 (1.03-68.9) 40 0,6 0,017 20 0,3 0,0085

1500 (103.4) 60 0,9 0,026 30 0,45 0,013

2000 (137.9) 80 1,2 0,034 40 0,6 0,017

2500 (172.4) 100 1,5 0,043 50 0,75 0,021

3000 (206.8) 100 1,5 0,043 60 0,9 0,026

4000 (275.8) 100 1,5 0,043 80 1,2 0,034

5000 (344.8) 100 1,5 0,043 100 1,5 0,043

6000 (413.7) 100 1,5 0,043 100 1,5 0,043

2

Figure 4 - Typical test arrangement

• Sapag Seat Tightness Standard-Liquid Service Valves (Style 8500/8590)

Sapag liquid service pressure relief valves are checked for seat tightness by a quantitative seat

leakage test.

All of the test fluid passing through an assembled valve is collected and measured per the

following test procedure:

1. The inlet pressure is adjusted to a test pressure which is 90% of the Cold Differential Test

Pressure.

Valves set below 50 psig are tested at 5 psig below the cold differential test pressure.

2. The test pressure is maintained for a period of not less than ten minutes.

• Allowable Leak Rate

The maximum allowable leakage rate should not exceed 10 cubic centimeters per hour per inch of

diameter of nominal valve inlet size. For nominal valve sizes of 1 inch or less, the leakage rate shall

not exceed 10 cubic centimeters per hour. For soft seated valves there shall be no leakage for one

minute.

Note: the cover plate should be

fitted with a suitabble device to

releive body pressure in case of

accidental popping of valve

Air receiver

Tube 5/16” O.D. x 0.0035” Wall

7.92 mm O.D. x .88 mm Wall

Cover plate

• Soft Seated Valves

For exceptional seat tightness, Sapag offers an O-ring soft seat design. Refer to Figure 13 on page

15.

The Sapag soft seat design will provide a valve that has no visible leakage at a test pressure of 90

percent of the set pressure or cold differential test pressure. Soft seated valves are tested using

the same test procedure used for metal-to-metal seated valves.

Emerson reserves the right to change the contents without notice page 8

Note: the tube must

be bent so that reservoir runs

parallel to face of coverplate

Figure 5 - Seat leak apparatus for 150

& 300 lb. outlets 1 inch through 10

inch sices

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

CAUTION: Valves in hazardous

fluid service and any other

materials classified as dangerous

must be neutralized immediately

after removal from service.

Table 7 - Series 8000 disc insert

threaded hole sizes

Orifice Size Thread Size

D & E # 10-24 UNC

F, G H 1/4 - 20 UNC

J, K, L 1/4 - 20 UNC

M, N, P, Q, R, T 3/8 - 16 UNC

Bolt

Remove disc insert by pulling on bolt

6. Valve Maintenance

Visual Inspection and Neutralizing

A visual inspection shall be made when valves are first removed from service. The presence of

deposits or corrosion products in the valve and in the piping should be recorded and valves should

be cleaned to the extent possible prior to disassembly. Check the condition of external surfaces for

any indication of corrosive atmospheric attack or evidence of mechanical damage.

Disassembly

Sapag Series 8000 valves should be disassembled as described below. Parts identification may be

found in Figure 1 on page 2. The parts from each valve should be properly marked and segregated

to keep them separate from parts used in other valves.

a. Remove the cap (40) and cap gasket (41). If the valve has a lifting lever device follow the

instructions on pages 15.

b. Remove the nozzle ring set screw (4) and set screw gasket (27).

Record the position of the nozzle ring (3) with respect to the disc holder (5) by counting

the number of notches required to raise the ring until it just touches the disc holder. This

information will be needed again when reassembling the valve. (Measure the revolutions for P,

Q, R and T Orifice Style 8500/8590. See Table 2)

c. Loosen the adjusting bolt nut (25). Before releasing the spring load, make note of the depth of

the adjusting bolt in the bonnet and count the number of turns required to remove the spring

load. This information will help when reassembling the valve to its approximate original setting.

d. Release all of the spring load by rotating the adjusting bolt (24) in a counterclockwise direction.

e. Remove the bonnet stud nuts (22).

f. Lift the bonnet (20) straight up to clear the spindle (16) and valve spring (18). Exercise care when

lifting the bonnet as the spring and spindle will then be free to fall aside.

g. The spring and spring washers (19) can now be lifted off the spindle (16). The spring and spring

washers are fitted together and must be kept together as a subassembly. Spring washers are

not interchangeable between ends of the spring.

h. Remove the spindle, guide (15), disc holder and disc insert (8). For balanced bellows valves

(Style 8490/8590) special care must be taken not to damage the bellows subassembly (6).

If parts are difficult to remove, due to the presence of corrosive or foreign materials, soaking in

a suitable solvent may be required.

i. Remove the spindle from the disc holder.

j. Lift the guide off the disc holder.

k. Disc Insert Removal

Remove disc insert by turning nut

with wrench

Figure 6

Nut

BoltRectangular bar

Washer

• Orifice Sizes D through M (Metal Seats)

Screw a standard bolt into the tapped hole (see table 7) in the face of the disc insert. Using

hand force pull the bolt straight out. The disc insert with the retention clip (9) should come out

with moderate force.

If the valve has been in dirty service it may be necessary to use a suitable solvent to aid in

removal. If additional pullout force is required, a bolt with a T handle may be used. The method

described below for Orifice sizes N through T may be used if necessary.

• Orifice Sizes N through T (Metal Seats)

Safety precautions should be followed whenever heavy parts are being lifted or transported.

Dropping disc holder assembly may dislodge the insert.

The removal of the insert is accomplished by the use of a tool as shown in Figure 6. This tool

consists of a rectangular steel bar which spans the outside diameter of the disc holder with

a center hole through which the standard bolt can be inserted before screwing into the disc

insert. A nut and washer is also required as shown. Tightening the nut with a wrench will exert

a pulling force on the disc insert and cause it to be removed from the disc holder.

• Orifice Sizes D through K (O-Ring Seats)

The O-Ring seat design for Orifice sizes D through K has a retaining screw in the center of the

disc insert. A drilled and tapped hole (4-40 UNC) is provided in the center of the retaining screw

for removal of the disc insert (Figure 7). Screw a standard bolt into the hole in the retaining

screw. Using hand force pull the bolt straight out. The disc insert with the retention spring

should come out with moderate force.

• Orifice Sizes L through T (O-Ring Seats)

Safety precautions should be followed whenever heavy parts are being lifted or transported.

Dropping the disc holder may dislodge the insert.

Remove the three retaining screws from the insert. Remove the retainer and O-ring seat. A

tapped hole (refer to table 7) is provided in the disc insert for insertion of a removal bolt. Follow

instructions for metal seated insert removal.

Bolt

Figure 7

Remove disc insert by pulling on bolt

Emerson reserves the right to change the contents without notice page 9

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

l. For bellows valves only, place the disc holder in a vise (the larger sizes may require a 3-jaw

vise) as shown in Figure 8. Using a suitable wrench unscrew the tailpiece and bellows from the

disc holder.

m. Remove the nozzle ring (3) from the nozzle (2).

n. Remove the nozzle (2) from the valve body (1) if necessary. Unless the valve seat on the nozzle

has been mechanically damaged or shows signs of corrosive attack, it will not be necessary to

remove the nozzle. In most cases the nozzle can be reconditioned without removal from the

valve body.

To remove the nozzle, turn the valve body over taking care not to damage the bonnet studs

(21).

Turn the nozzle counterclockwise by using the wrench flats on the nozzle flange or a nozzle

wrench designed to clamp onto the nozzle flange.

Cleaning

External parts such as the valve body, bonnet and cap should be cleaned by immersion in a bath

such as hot Oakite solution or equivalent. These external parts may be cleaned by wire brushing,

provided the brushes used do not damage nor contaminate the base metals. Only clean stainless

steel brushes should be used on stainless steel components.

The internal parts such as the guide, disc holder, disc insert, nozzle ring and spindle should be

cleaned by immersion in a commercial high alkaline detergent.

Guiding surfaces on the disc holder and guide may be polished using a fine emery cloth. The

bellows and other metal parts may be cleaned using acetone or alcohol, then rinsed with clean tap

water and dried.

Disc

holder

Figure 8

Bellows

Tailpiece

Tailpiece

gasket

Vise

jaws

Inspection

Check all valve parts for wear and corrosion. The valve seats on both the nozzle and disc insert

must be examined to determine if they have been damaged. Most often, lapping the valve seats is

all that is necessary to restore them to their original condition.

If the inspection shows that the valve seats are badly damaged, remachining will be necessary

or it may be advisable to replace these parts. When the time element is a factor, it may be

advantageous to replace damaged parts from spare parts stock, thereby permitting the replaced

part to be checked and reworked at leisure. (See Figure 10 and Table 8 for critical dimensions.)

The valve spring (18) should be inspected for evidence of cracking, pitting or deformation.

The bellows (6B) in a Style 8490/8590 valve should be inspected for evidence of cracking, pitting

or deformation that might develop into a leak.

The bearing surfaces on the guide and disc holder should be checked for residual product build up

and any evidence of scoring. Inspection of valve components is important to ensure proper valve

performance. Damaged valve parts must be repaired or replaced.

Reconditioning of Valve Seats

The tightness of a valve and its proper operation depend directly on the condition of the seats.

Many pressure relief valve problems are due to eroded or damaged seats.

The standard Sapag Series 8000 valve is constructed with a flat metal-to-metal seat. It is important

that seating surfaces be properly refurbished by lapping with a flat cast iron lap coated with the

correct lapping compound.

• Lapping Procedures

Unless the seats have been badly damaged by dirt or scale, lapping the seating surfaces should

restore them to their original condition. Never lap the disc insert against the nozzle. Lap each

part separately against a cast-iron lapping block of the proper size. These blocks hold the lapping

compound in their surface pores and must be recharged frequently.

Lap the block against the seat. Never rotate the block continuously, but use an oscillating motion.

Extreme care should be taken throughout to make certain that the seats are kept perfectly flat.

If considerable lapping is required, spread a thin coat of medium coarse lapping compound on

the block. After lapping with the medium coarse compound, lap again with a medium-grade

compound. Unless much lapping is called for, the first step can be omitted. Next, lap again using

a fine grade compound. When all nicks and marks have disappeared remove all the compound

from the block and seat. Apply polish compound to another block and lap the seat.

As the lapping nears completion only the compound left in the pores of the block should be

present. This should give a very smooth finish. If scratches appear the cause is probably dirty

lapping compound. These scratches should be removed by using compound free from foreign

material.

Disc inserts should be lapped in the same way as nozzles. The disc insert must be removed from

the holder before lapping. Before the disc insert is placed back in the holder all foreign material

should be removed from both parts. The insert must be free when in the holder. If the disc insert

is damaged too badly to be reconditioned by lapping, it should be replaced.

Remachining the insert will change critical dimensions, affect the action of the valve and is not

recommended.

Top lapping

surface

Motion shown

by dotted

lines

Bottom

rough surface

do not use

Lapping block resurfacing plate

Lapping block

Figure 9

Lapping block

to be squared

up

Emerson reserves the right to change the contents without notice page 10

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

Raised seal face

Minimum face

to seat dim,

refer to Table 8

Seat .004 after lapping

Figure 10 - Nozzle seat critical

dimensions

related

surfaces

.010-.014

machined

.008 min

after

lapping

• Lapping Blocks

Lapping blocks are made of a special grade of annealed cast iron. There is a block for each orifice

size. Each block has two perfectly flat working sides and it is essential that they retain this high

degree of flatness to produce a truly flat seating surface on either the disc insert or the nozzle.

Before a lapping block is used, it should be checked for flatness and reconditioned after use on

a lapping plate. The block should be lapped in a figure eight motion, applying uniform pressure

while rotating the lapping block against the plate as shown in Figure 9.

• Lapping Compounds

Experience has proven that medium coarse, medium fine, and polish lapping compounds will

properly condition any damaged pressure relief valve seat except where the damage requires

remachining. The following lapping compounds, or their commercial equivalents are suggested:

Grit Compound No. Description

320 Medium Coarse

400 Medium

600 Fine

900 Polish

• Machining of Nozzle Seats

If machining of the nozzle seat or other major repairs are necessary it is recommended that the

valve be returned to a Emerson Valves & Controls facility for repair. All parts must be accurately

machined per Sapag specifications. No pressure relief valve will be tight, nor will it operate

properly unless all parts are correctly machined. The most satisfactory way to machine a nozzle is

to remove it from the valve body. However, it may also be machined while assembled within the

valve body.

In any event it is vitally important that the seating surfaces run absolutely true before machining.

Machining dimensions for Sapag Series 8000 valves with metal-to-metal nozzle seats are shown in

Figure 10 and Table 8. Remove only enough metal to restore the surface to its original condition.

Turning to the smoothest possible finish will facilitate lapping.

The nozzle must be replaced when minimum face to seat dimension is reached. This critical

dimension is shown in Table 8.

• Machining of Disc Insert Seats

When the damage to the disc insert seat is too severe to be removed by lapping, the disc insert

may be machined and lapped provided that minimum seat height is maintained (Figure 11 and

table 9).

Table 8 - Minimum nozzle face to seat dimensions (See Figure 10)

Valve Type

Orifice 12, 13, 14, 15,16 22, 23, 24, 25, 26 32, 33, 34, 35, 36, 37 47 42, 43, 44, 45, 46 57 55, 56 65, 66, 67 75, 76, 77

D 3,465 3,465 3,465 3,465 3,465 3,687 3,687 3,687 4,808

E 3,465 3,465 3,465 3,465 3,465 3,687 3,687 3,687 4,808

F 4,027 4,027 4,027 4,027 4,027 4,027 4,027 4,027 4,647

G 3,777 3,777 3,777 3,777 3,777 3,777 3,777 4,777 4,777

H 3,903 3,903 3,903 3,903 4,840 4,840 4,840 4,840 J 4,340 4,340 4,340 4,340 5,121 5,121 6,455 6,455 K 4,715 4,715 4,715 4,715 5,840 5,840 7,027 7,027 L 5.059 5.059 5,277 5,277 5,277 6,250 6,250 6,250 M 5,59 5,59 5,59 5,59 5,59 6,403 6,403 - N 6,121 6,121 6,121 6,121 6,121 - - - P 5,871 5,871 7,621 7,621 7,621 - - - Q 7,746 7,746 7,746 7,746 7,746 - - - R 8,121 8,121 8,121 8,121 8,121 - - - T 9,59 9,59 9,59 - 9.590 (*) - - - -

* Type 42,43,44 not available

Table 9 - Disc insert minimum seat heights

Orifice D & E F G H J K L M N P Q R T

“A” 0,332 0,370 0,369 0,398 0,429 0,531 0,546 0,605 0,632 0,692 0,783 0,781 0,839

“B” 0.021 0.025 0.030 0.036 0.044 0.051 0.063 0.070 0.076 0.091 0.118 0.139 0.176

0.023 0.027 0.032 0.038 0.046 0.053 0.065 0.072 0.078 0.093 0.120 0.141 0.178

Emerson reserves the right to change the contents without notice page 11

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

Assembly

All components should be clean. Before assembling the following parts, lubricate with pure nickel

“Never-Seez”.

• Nozzle and body threads

• Nozzle and body sealing surface

• All studs and nut threads

• Spindle and threads

• Set screw threads

• Spring washer bevels

• Adjusting bolt and bonnet threads

• Bonnet pipe plug

• Cap threads

• Dog shaft bearing threads

• Disc holder threads (bellows valves only)

Lubricate the spindle point thrust bearing and disc insert bearing with pure nickel “Never-Seez”.

Special attention should be given to the guiding surfaces, bearing surfaces and gasket surfaces to

ensure that they are clean, undamaged and ready for assembly. (Figure 12)

For parts identification, refer to Figure 1.

a. Before installing the nozzle (2) apply lubricant to the flange surface in contact with the valve

body (1) and on the body to nozzle threads. Screw the nozzle (2) into the valve body (1) and

tighten with a nozzle wrench.

b. Screw the nozzle ring (3) onto the nozzle (2).

Note: The top of the nozzle ring should be above the nozzle seating surface. For P, Q, R and T

Orifice Style 8500/8590, position the nozzle ring per table 2.

c. For bellows valves only, place the disc holder in a vise (larger sizes may require a 3 jaw vise) as

shown in Figure 8. Install the tailpiece gasket (29).

Screw the bellows assembly onto the disc holder. Tighten with a suitable wrench.

d. Assemble the disc insert (8) and the disc holder (5).

(See page 15 for O-ring soft seat assembly)

Install the disc insert retention clip (9) onto the disc insert.

Install the disc insert into the disc holder. The disc insert should snap into place using hand

force only.

Safety precautions should be followed whenever heavy parts are being lifted or transported.

Dropping disc holder assembly may dislodge the insert.

e. Assemble the disc holder (5) and guide (15) by sliding the guide over the disc holder.

Note: The guide for D and E orifice valves protrudes up into the valve bonnet.

f. Install the two guide gaskets (28), one above and one below the guide.

Note: When assembling bellows valves, the bellows flange eliminates the need for a bottom

guide gasket.

g. While holding the top of the disc holder, install the guide into the body. Align the hole of the

guide with the body outlet. Once the guide is seated, the disc holder and disc insert can be

lowered onto the nozzle.

Note: Lower the nozzle ring below the seats so that it moves freely.

h. Place the spring (18) and washers (19) onto the spindle (16) and assemble the spindle to the disc

holder (5) with the spindle cotter pins.

Note: No cotter pins are required in D through K orifice sizes all other orifice sizes use two

cotter pins.

i. Lower the bonnet (20) over the spindle and spring assembly onto the bonnet studs (21) in the

body. Position the bonnet counter bore on the O.D. of the guide and lower the bonnet onto the

guide.

j. Screw the bonnet nuts (22) onto the bonnet studs and tighten down evenly to prevent

unnecessary strain and possible misalignment.

k. Screw the adjusting bolt (24) and nut (25) into the top of the bonnet to apply force on the

spring. (The original set pressure can be approximated by screwing the adjusting bolt down to

the predetermined measurement.)

l. Move the nozzle ring up until it touches the disc holder, then lower it two notches. This is a test

stand setting only.

m. Place the set screw gasket (27) onto the set screw (4) and screw the set screw into the body

engaging the nozzle ring. The nozzle ring should move back and forth slightly after the set

screw is tightened.

n. The valve is now ready for testing.

“A” min.

after lapping

“B” mach.

Figure 11 - Disc Insert Minimum Seat

Height (Table 9)

Figure 12 - Recommended lubrication

points

After testing, the following measures should be taken:

• Be sure that adjusting bolt nut (25) is locked.

• Return the nozzle ring to either the original recorded position or to the recommended position

shown in Table 1.

• Install the cap or lifting device. See Figure 13 for lifting lever assembly.

• Seal the cap or lifting lever device and nozzle ring set screw to prevent tampering.

Emerson reserves the right to change the contents without notice page 12

Cap plug gasket

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

Test rodCap plug

Cap or cap top

Spindle

Cap test rod

Type B - Threaded cap (Low profile)

Type E - Packed lifting lever

Type H - Bolted cap (Low profile)

Type K - Threaded cap (standard)

Type M - Bolted cap (standard)

Spindle nut

Cap stud

Cap stud nut

Spindle nut

Cap plug

Cap top

Cap

Packed lifting lever

with test rod

Type E

Test rod

Cotter pin

Cap top

gasket

Dog

Dog

shaft

Spindle

Adjusting

bolt

Adjusting

bolt nut

Seal and wire

Cap

Lever nut

Lockwasher

Dog shaft bearing

Gasket

Packed lifting lever

Lever

Dog

shaft

O-ring

Cap

Dog

Valve

spindle

Type E

(Top view)

Forked lever

Cotter pin

Pin

Lever

Regular lifting lever

Cotter pin

Pin

Cap set

screw

Type C

Emerson reserves the right to change the contents without notice page 13

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

Assembly of Cap and Lifting Lever Devices

Series 8000 pressure relief valves are furnished with several different caps and lifting lever

devices. The following describes assembly of the available types of cap construction. (Disassembly

is the reverse of assembly). For part identification refer to Figure 13.

• Type B and K

Install the cap gasket and screw the cap onto the top of the bonnet. Tighten the cap with a strap

wrench. Install the cap plug gasket and screw cap plug into the cap. The test rod is installed only

during system hydrostatic testing. Never install the test rod unless performing system hydrostatic

testing.

• Type C

Screw the spindle nut onto the spindle.

Place the cap on the bonnet. Install the forked lever and forked lever pin. Attach the lever to the

cap using the lever pin and secure with the lever pin cotter.

Adjust the spindle nut until the forked lever rests on the lever and there is a 1/16 inch minimum of

play between the forked lever and the spindle nut. The spindle nut may be adjusted by removing

the forked lever pin, forked lever and cap. When the spindle nut is in proper adjustment, install the

spindle nut cotter pin. Replace the cap and forked lever and install the forked lever pin and forked

lever pin cotter.

Position the lever opposite the valve outlet and install the four (4) cap set screws and tighten them

against the groove in the top of the bonnet.

• Type D

Install the cap gasket on the bonnet. Screw the spindle nut onto the spindle. Place the dog in the

cap and install the dog shaft so that the dog is horizontal and the square on the end of the dog

shaft has a corner on top. With the dog shaft in the position above, scribe a horizontal line on the

end of the dog shaft. This line must be horizontal when the lifting gear is finally installed on the

valve. Install the dog shaft O-ring in the dog shaft bearing and place the dog shaft bearing gasket

on the dog shaft bearing.

Screw the dog shaft bearing into the cap. Rotate the dog shaft so that the dog is pointing down

and install the cap assembly onto the bonnet. Rotate the dog shaft so that the dog contacts the

spindle nut. With the scribed line horizontal, remove the assembly and adjust the position of the

spindle nut. Repeat the operation until the scribed line is horizontal when the dog contacts the

spindle. Remove the assembly and install the spindle nut cotter pin.

Install the lifting gear assembly onto the bonnet and secure it with cap studs and nuts.

For Type D lifting levers that have two part caps (cap and cap top) the above procedure is more

easily accomplished. After the cap is screwed to the bonnet, the positioning of the dog shaft is the

same as above except that the positioning of the spindle nut is performed last through the open

end of the cap.

With the dog in the horizontal position, screw the spindle nut onto the spindle until it contacts the

dog. Install the spindle nut cotter, cap top gasket and screw the cap top into the cap.

• Type E

Assembly of Type E lifting lever is identical to Type D with the addition of the cap plug gasket and

cap plug. The test rod is installed only during system hydrostatic testing. Never install the test rod

unless performing system hydrostatic test.

• Type H and M

Assembly of Type H and M is identical to Type G and L with the addition of the cap plug gasket

and cap plug. The test rod is installed only during system hydrostatic testing. Never install the test

rod unless performing system hydrostatic test.

Soft Seat Construction

Coat O-ring with Parker Super O-Lube and place a small amount of Loctite 242 (or equivalent

removable thread lock) onto retainer screw before assembly. Securely tighten retainer screw(s).

• O-Ring Soft Seats

Sapag Series 8000 metal-to-metal seated pressure relief valves may be converted to an O-ring

soft seat by replacing the standard disc insert and nozzle with those parts designed to house the

O-ring soft seat or vice versa.

Figure 14

8500 O-ring 8400/8490

Soft seat O-ring

Soft seat

Table 10 - soft seat o-ring sizes

Orifice O-ring size

D & E 2-013

2-014

F 2-113

G 2-116

H 2-120

J 2-125

K 2-130

L 2-226

M 2-228

N 2-230

P 2-337

Q 2-346

R 2-352

T 2-438

All Elastomers

Teflon Only

Emerson reserves the right to change the contents without notice page 14

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

7. Style Variations

The Sapag Style 8400 pressure relief valve was designed with flexibility and interchangeability

in mind. Retrofitting from conventional to balanced bellows high performance liquid trim or soft

seat design is accomplished with a minimum number of new parts. These style retrofits can be

accomplished at lowest possible cost.

• Balanced Bellows

A Sapag 8400 conventional non-bellows pressure relief valve may be converted to a Style 8490

balanced bellows valve simply by adding the bellows assembly and tailpiece gasket.

• 8500/8590 Liquid Trim

Sapag Style 8400/8490 pressure relief valves in D to N orifice sizes may be converted to high

performance 8500/8590 liquid service design simply by replacing the standard disc holder with a

8500/8590 disc holder, or vice versa. For P to T orifice sizes a new nozzle ring is also required.

• O-Ring Soft Seat Design

Sapag Series 8000 pressure relief valves in all orifice sizes may be converted from the standard

metal-to-metal seats to an exceptionally tight soft seat design. This style conversion can be

accomplished by replacing the standard disc insert and nozzle with parts adapted to accommodate

the soft seat design.

The Sapag soft seat design uses standard size O-rings and is capable of handling pressures to

1480 PSIG. Standard O-ring materials include Buna N, EPR, Viton, Kalrez, Silicone and Teflon. (See

Figure 14 and Table 10).

8. Service Records

Service records should be completed before a valve is returned to service. These records are

important and will provide guidance on establishing time intervals between repairs as well as

providing the historical record of repairs and service conditions. Well kept records will be useful

in predicting when to retire a valve and which spare parts should be maintained in inventory to

ensure uninterrupted plant operation.

9. Spare Parts

When ordering spare parts, the valve serial number should be given together with set pressure,

part name and item number, valve size and style. On the valve nameplate the valve serial number

is shown.

Spare parts may be ordered from any Emerson Valves & Controls Regional Sales Office or

Representative.

10. Trouble Shooting Pressure Relief Valves

Troubles encountered with pressure relief valves can vitally affect the life and performance of the

valve and must be corrected at the first possible opportunity.

Failure of a pressure relief valve to function properly could result in the rupture of a line or vessel

jeopardizing the safety of personnel and causing damage to property and equipment. Some of the

most common troubles and the recommended correction measures are discussed in the following

paragraphs.

Seat Leakage

Of all the problems encountered with pressure relief valves, seat leakage is the most common and

the most detrimental. A leaking valve allows fluids to circulate into the secondary pressure zone of

the valve where it can cause corrosion of the guide and valve spring.

When a leaking valve problem is not immediately addressed, the leakage itself will further

contribute to seat damage through erosion (wire-drawing).

• Seats Damaged by Foreign Matter

Seating surfaces may be damaged when hard foreign particles such as mill scale, welding spatter,

coke and dirt are trapped between the seats. While this type of damage usually occurs while the

valve is in service, it may also happen in the maintenance shop.

Every precaution should be taken to clean the process system before installing a pressure relief

valve and to test the valve using only clean fluids.

Damaged seating surfaces are generally reconditioned by lapping. Most often small pits and

scratches may be removed by lapping alone. More extensive damage will also require remachining

prior to lapping.

In some instances valve construction can be changed to reduce the effects of seat leakage. The

use of an O-ring soft seat when applicable will minimize leakage and thus eliminate the associated

corrosion and erosion problems. If it is not possible to use a soft seated valve, or if the corrosive

media is present in the exhaust system, conversion to a Style 8490/8590 bellows seated valve will

isolate and protect the guides and valve spring from any corrosive fluids.

Emerson reserves the right to change the contents without notice page 15

Sapag Safety Valves Series 8400/8500/8490/8590

Installation and Maintenance Instructions

• Distortion from Piping Strains

Valve bodies can be distorted by excessive piping loads causing seat leakage. Both inlet and

discharge piping must be properly supported and anchored so that high bending loads are not

transmitted to the valve body.

• Operating Pressure Too Close to Set Pressure

A carefully lapped metal-to-metal seated valve will be commercially tight at a pressure

approximately ten percent under the set pressure or 5 PSI, whichever is greater. Consequently,

this minimum pressure differential should be maintained between set and operating pressure to

avoid seat leakage problems.

• Chatter

Oversized valves, excessive pressure drop in the inlet lines, restrictions in the inlet line, too great

a build up of back pressure or pulsating inlet pressure will cause instability to the pressure relief

valve. In such installations, the pressure under the valve disc may be great enough to cause

the valve to open, but as soon as flow is established, the pressure drops allowing the valve to

immediately close. This cycle of opening and closing sometimes occurs at very high frequency

causing severe seat damage, sometimes beyond repair.

Proper valve selection and installation techniques are paramount to reliable valve performance.

• Incorrectly Adjusting Lifting Gear

A space of 1/16 inch minimum should always be provided between the lifting device and the

spindle lift nut. Failure to provide sufficient clearance may result in inadvertent contact causing a

slight shift in the opening pressure.

• Other Causes of Seat Leakage

Improper alignment of the spindle, too much clearance between the valve spring and the spring

washers, or improper bearing contact between the adjusting bolt and the spring washers, spindle

and disc holder or spindle and lower spring washer may cause seat leakage problems. Spindles

should be checked for straightness and springs and spring washers should be properly fitted and

kept together as a spring assembly.

• Corrosion

Corrosion may result in pitting of valve parts, failure of various valve parts, build up of corrosive

products and general deterioration of the valve materials.

Corrosive attack is generally controlled through selection of suitable materials or by employing

a bellows seal to isolate the valve spring, adjusting bolt, spindle and guiding surfaces from the

corrosive attack of the process fluid.

Environmental corrosion attacks all exposed surfaces, including studs and nuts. In general, the

materials required for a particular service are dictated by the temperature, pressure and the degree

of corrosion resistance required.

11. Emerson Valves & Controls field service and repair programs field service

Emerson Valves & Controls Field Service provides on-site, in line testing and repair capability for all

types of pressure relief devices.

• Parts

Emerson Valves & Controls will help you establish the right mix of on-site spares with Emerson Valves

& Controls’ own distribution and manufacturing support.

• Training

Emerson offers intensive factory or on-site seminars to improve maintenance and application skills.

• Testing

Emerson Valves & Controls has the capability to evaluate pressure relief valve operability either in

the field or at various Emerson Valves & Controls facilities. Special qualifications programs may also

be conducted in our laboratories.

• Contract Management

Emerson Valves & Controls will combine a group of services to satisfy your special maintenance

needs.

WARNING

Product is a safety related component intended for use in critical applications. The improper

The

application, installation or maintenance of the Product or the use of parts or components not

manufactured by Emerson may result in failure of the Product. The advice of a qualified engineer

should be sought prior to any use of the Product.

Any installation, maintenance, adjustment, repair or test performed on the Product must be done

in accordance with the requirements of all applicable Codes and Standards.

The information, specifications and technical data (the “Specifications”) contained in this

document are subject to change without notice. Emerson does not warrant that the

Specifications are current and assumes no responsibility for the use or misuse thereof.

The Purchaser should verify that there have been no changes to the Specifications prior to use.

Emerson reserves the right to change the contents without notice page 16

Loading...

Loading...