SAM1411

Installation and Use

P/N: 6806800M91A

October 2011

Embedded Computing for

Business-Critical Continuity

TM

©

2011 Emerson

All rights reserved.

Trademarks

Emerson, Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are trademarks and service

marks of Emerson Electric Co.

owners.

®

Intel

is a trademark or registered trademark of Intel Corporation or its subsidiaries in the United States and other countries.

™

and all other Java-based marks are trademarks or registered trademarks of Sun Microsystems, Inc. in the U.S. and other

Java

countries.

Microsoft

Microsoft Corporation.

PICMG

Industrial Computer Manufacturers Group.

UNIX

®

, Windows® and Windows Me® are registered trademarks of Microsoft Corporation; and Windows XP™ is a trademark of

®

, CompactPCI®, AdvancedTCA™ and the PICMG, CompactPCI and AdvancedTCA logos are registered trademarks of the PCI

®

is a registered trademark of The Open Group in the United States and other countries.

©

2011 Emerson Electric Co. All other product or service names are the property of their respective

Notice

While reasonable efforts have been made to assure the accuracy of this document, Emerson assumes no liability resulting from any

omissions in this document, or from the use of the information obtained therein. Emerson reserves the right to revise this document

and to make changes from time to time in the content hereof without obligation of Emerson to notify any person of such revision or

changes.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another document as a URL to

a Emerson website. The text itself may not be published commercially in print or electronic form, edited, translated, or otherwise

altered without the permission of Emerson,

It is possible that this publication may contain reference to or information about Emerson products (machines and programs),

programming, or services that are not available in your country. Such references or information must not be construed to mean that

Emerson intends to announce such Emerson products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following notice shall apply

unless otherwise agreed to in writing by Emerson.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in

Technical Data clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and

Documentation clause at DFARS 252.227-7014 (Jun. 1995).

Contact Address

Emerson Network Power - Embedded Computing

Lilienthalstr. 15

85579 Neubiberg/Munich

Germany

Contents

Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Sicherheitshinweise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1.2 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

1.3 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2 Shelf Manager Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.2 Payload Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.2.1 Ethernet Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.2.2 Redundancy Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.2.3 Block Transfer Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2.2.4 Console Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3 Shelf Management Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3.1 IPMB0 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.3.2 IPMC Standard Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.4 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.4.1 Onboard and External Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.4.2 Power Supply Holdup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.5 Frame Ground and ESD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3 Controls, Indicators, and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.1 Face Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.2 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.3 Ethernet Connector (Out-of-Band) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.4 Alarm Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

SAM1411 Installation and Use (6806800M91A)

3

Contents

Contents

Contents

4 SAM1411 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.2 Unpacking and Inspecting the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.3 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3.1 Environmental Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3.2 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.3.3 Rotary Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.4 Installing and Removing the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.4.1 Installing the Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.4.2 Removing the Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5 Shelf Manager File System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1.1 Persistent File Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1.2 Use Cases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.1.2.1 How to Make a File on the RAM Disk File System Persistent . . . . . . . . . . . . . . . 53

5.1.2.2 How to Remove a File from the Persistent File System . . . . . . . . . . . . . . . . . . . 54

5.1.2.3 How to Rollback Factory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.1.2.4 Persistent Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.2 Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6 Firmware Upgrade Facility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.2 Firmware Recovery Image Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.3 Backup Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.4 fcu–Firmware Upgrade Command-Line Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.5 Upgrading Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.5.1 Upgrading CPU Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.5.2 Upgrading the Device-Tree Blob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.5.3 Upgrading the Kernel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.5.4 Upgrading the Ramdisk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.5.5 Activating the Backup Boot Bank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.5.6 Upgrading IPMC Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

SAM1411 Installation and Use (6806800M91A)

4

6.5.7 Example Upgrade Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Contents

7 U-Boot Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7.2 Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

A Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

A.1 Emerson Network Power - Embedded Computing Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

A.2 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

SAM1411 Installation and Use (6806800M91A)

5

Contents

Contents

Contents

6

SAM1411 Installation and Use (6806800M91A)

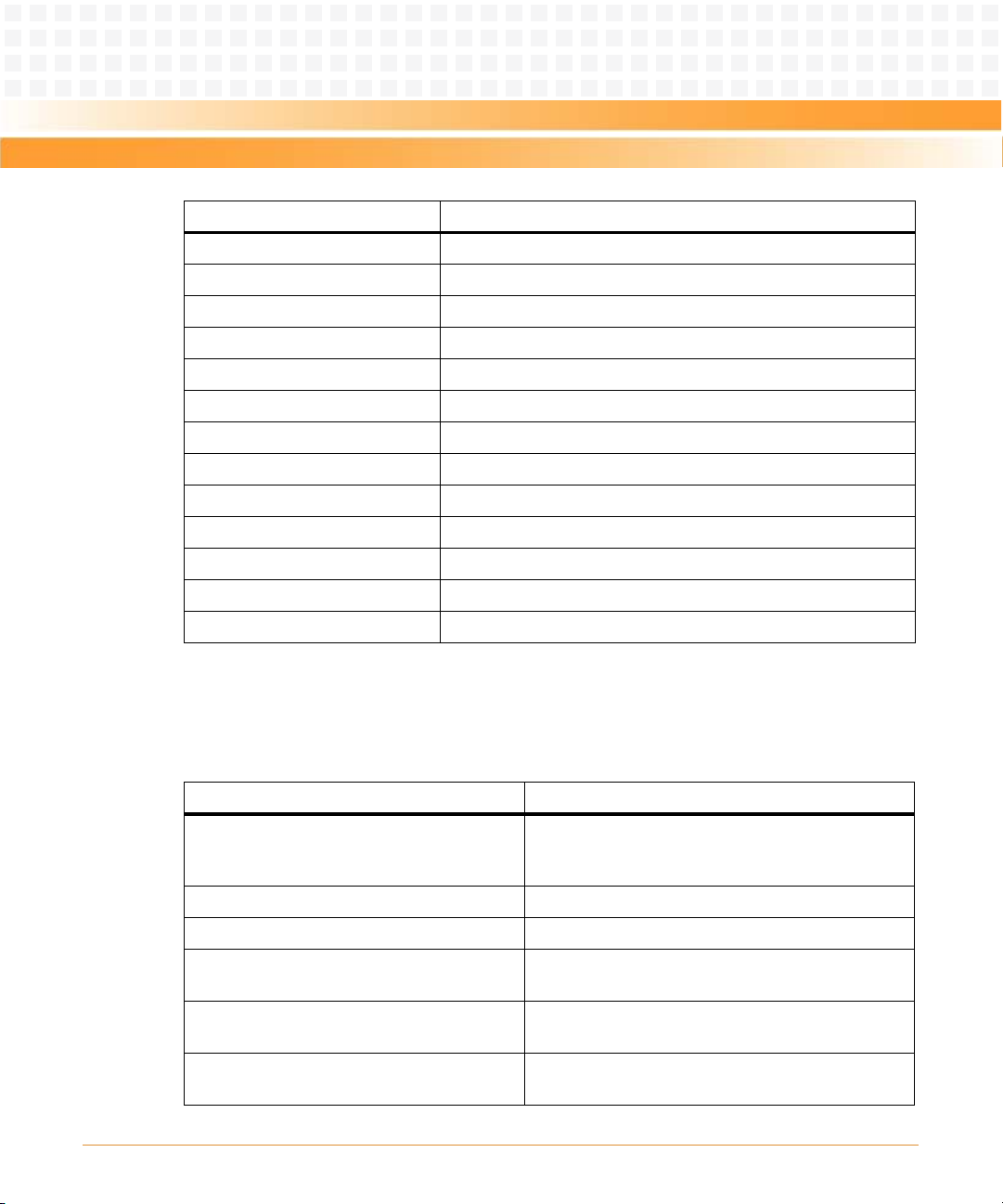

List of Tables

Table 1-1 Standard Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 1-2 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 3-1 Face Plate LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 3-2 Alarm Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 4-1 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 4-2 DC Board Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 7-1 U-Boot Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table A-1 Emerson Network Power - Embedded Computing Publications . . . . . . . . . . . . . . . . . . . 79

Table A-2 Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

SAM1411 Installation and Use (6806800M91A)

7

List of Tables

8

SAM1411 Installation and Use (6806800M91A)

List of Figures

Figure 1-1 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 2-1 SAM1411 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 3-1 Face Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 3-2 Alarm I/O Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 4-1 Rotary Switch Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

SAM1411 Installation and Use (6806800M91A)

9

List of Figures

10

SAM1411 Installation and Use (6806800M91A)

About this Manual

Overview of Contents

This manual is intended for users qualified in electronics or electrical engineering. Users must

have a working understanding of AdvancedTCA and telecommunications. This Installation and

Use provides the information you need to install, access, and operate the shelf manager

SAM1411.

This manual contains the following chapters and appendix:

z About this Manual on page 11, lists all conventions and abbreviations used in this manual

and outlines the revision history.

z Safety Notes on page 17, describes the safety information.

z Sicherheitshinweise on page 21, provides a German translation of the chapter "Safety

Notes".

z Introduction on page 27, gives an overview of the product.

z Shelf Manager Hardware on page 33, provides detailed hardware information of the

product.

z Controls, Indicators, and Connectors on page 39, describes external interfaces of the

product, this includes connectors and LEDs.

z SAM1411 Installation on page 43, describes the installation prerequisites and procedures.

z Shelf Manager File System on page 49, provides information on persistent file support and

use cases.

z Firmware Upgrade Facility on page 59, provides information on the software upgrade tools

swupgrade.sh and fw_tool.

z U-Boot Commands on page 73, lists the U-Boot Commands.

z Related Documentation on page 79, lists related documentation and specifications.

SAM1411 Installation and Use (6806800M91A)

11

About this Manual

About this Manual

Abbreviations

This document uses the following abbreviations:

Abbreviation Definition

AdvancedTCA Advanced Telecommunications Computing Architecture

AMC Advanced Mezzanine Card

ATCA Advanced Telecommunications Computing Architecture

BT Block Transfer

CPU Central Processing Unit

EMC Electromagnetic Compatibility

EMI Electromagnetic Immunity

EN European Norm

ESD Electrostatic Sensitive Device

FCC Federal Communications Commission

FPGA Field-Programmable Gate Array

FRU Field Replacable Unit

GND Ground

HPI Hardware Platform Interface

IEC International Electric Code

IP Internet Protocol

IPM Intelligent Platform Management

IPMB Intelligent Platform Management Bus

IPMC Intelligent Platform Management Controller

IPMI Intelligent Platform Management Interface

LED Light Emitting Diode

MMC Mezzanine Management Controller

NEBS Network Equipment Building System

OOS Out-Of-Service

PCB Printed Circuit Board

12

SAM1411 Installation and Use (6806800M91A)

About this Manual

Abbreviation Definition

PEM Power Entry Module

PICMG PCI Industrial Computer Manufacturers Group

PMC PCI Mezzanine Card

PMC Peripheral Management Controller

RAM Random Access Memory

RoHS Restriction of the use of Certain Hazardous Substances

RTM Rear Transition Module

SAF Software Availability Forum

SDRAM Synchronous Dynamic Random Access Memory

SELV Safety Extra Low Voltages

ShM Shelf Manager

ShMC Shelf Management Controller

TPE Twisted Pair Ethernet

Conventions

The following table describes the conventions used throughout this manual.

Notation Description

0x00000000 Typical notation for hexadecimal numbers (digits are

0b0000 Same for binary numbers (digits are 0 and 1)

bold Used to emphasize a word

Screen Used for on-screen output and code related elements

Courier + Bold Used to characterize user input and to separate it

Reference Used for references and for table and figure

SAM1411 Installation and Use (6806800M91A)

0 through F), for example used for addresses and

offsets

or commands in body text

from system output

descriptions

13

About this Manual

About this Manual

Notation Description

File > Exit Notation for selecting a submenu

<text> Notation for variables and keys

[text] Notation for software buttons to click on the screen

... Repeated item for example node 1, node 2, ..., node

and parameter description

12

.

.

.

.. Ranges, for example: 0..4 means one of the integers

|Logical OR

Omission of information from example/command

that is not necessary at the time being

0,1,2,3, and 4 (used in registers)

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury

Indicates a property damage message

No danger encountered. Pay attention to important

information

14

SAM1411 Installation and Use (6806800M91A)

About this Manual

Summary of Changes

Part Number Date Description

6806800M91A October 2011 Initial version

SAM1411 Installation and Use (6806800M91A)

15

About this Manual

About this Manual

16

SAM1411 Installation and Use (6806800M91A)

Safety Notes

This section provides warnings that precede potentially dangerous procedures throughout

this manual. Instructions contained in the warnings must be followed during all phases of

operation, service, and repair of this equipment. You should also employ all other safety

precautions necessary for the operation of the equipment in your operating environment.

Failure to comply with these precautions or with specific warnings elsewhere in this manual

could result in personal injury or damage to the equipment.

Emerson intends to provide all necessary information to install and handle the product in this

manual. Because of the complexity of this product and its various uses, we do not guarantee

that the given information is complete. If you need additional information, ask your Emerson

representative.

The product has been designed to meet the standard industrial safety requirements. It must

not be used except in its specific area of office telecommunication industry and industrial

control.

Only personnel trained by Emerson or persons qualified in electronics or electrical engineering

are authorized to install, remove or maintain the product.

The information given in this manual is meant to complete the knowledge of a specialist and

must not be used as replacement for qualified personnel.

Keep away from live circuits inside the equipment. Operating personnel must not remove

equipment covers. Only factory authorized service personnel or other qualified service

personnel may remove equipment covers for internal subassembly or component replacement

or any internal adjustment.

Do not install substitute parts or perform any unauthorized modification of the equipment or

the warranty may be voided. Contact your local Emerson representative for service and repair

to make sure that all safety features are maintained.

EMC

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications.

SAM1411 Installation and Use (6806800M91A)

17

Safety Notes

Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense. Changes or

modifications not expressly approved by Emerson could void the user's authority to operate

the equipment. Board products are tested in a representative system to show compliance with

the above mentioned requirements. A proper installation in a compliant system will maintain

the required performance. Use only shielded cables when connecting peripherals to assure

that appropriate radio frequency emissions compliance is maintained.

Installation

Before installing the board make sure the requirements listed in section "Board Exchange" are

met.

Restricted access area - This board is only to be installed in a restricted access area.

Data Loss

Removing the board with the blue LED still blinking causes data loss.

Wait until the blue LED is permanently illuminated, before removing the board.

Damage of Circuits

Electrostatic discharge and incorrect board installation and removal can damage circuits or

shorten their life.

Before touching the board or electronic components, make sure that you are working in an

ESD-safe environment or wear ESD wrist straps.

Board Malfunctioning

Incorrect board installation and removal can result in board malfunctioning.

Make sure that the board is connected to the system backplane via all assembled connectors

and that power is available on all zone 1 power pins.

Damage of the Product

Incorrect installation of the product can cause damage of the product,

Only use handles when installing/removing the product to avoid damage/deformation to the

face plate and/or PCB.

18

SAM1411 Installation and Use (6806800M91A)

Damage of the Product and Additional Devices and Modules

Incorrect installation or removal of additional devices or modules may damage the product or

the additional devices or modules.

Before installing or removing additional devices or modules, read the respective

documentation.

Operation

Board Damage

Board surface

High humidity and condensation on the board surface causes short circuits.

Do not operate the board outside the specified environmental limits. Make sure the board is

completely dry and there is no moisture on any surface before applying power.

Safety Notes

Board Overheating and Board Damage

Operating the board without forced air cooling may lead to board overheating and thus board

damage.

When operating the board, make sure that forced air cooling is available in the shelf.

Injuries or Short Circuits

Board or power supply

In case the ORing diodes of the board fail, the board may trigger a short circuit between input

line A and input line B so that line A remains powered even if it is disconnected from the power

supply circuit (and vice versa).

To avoid damage or injuries, always check that there is no more voltage on the line that has

been disconnected before continuing your work.

Hot Swap

Installing the board into or removing it from a powered system not supporting hot swap or

high availability causes board damage and data loss. Therefore, only install it in or remove it

from a powered system if the system itself supports hot swap or high availability and if the

system documentation explicitly includes guidelines.

SAM1411 Installation and Use (6806800M91A)

19

Safety Notes

RJ-45 Connector

The RJ-45 connector on the face plate must only be used for twisted-pair Ethernet (TPE)

connections. Connecting a telephone to such a connector may destroy your telephone as well

as your board. Therefore:

z Clearly mark TPE connectors near your working area as network connectors.

z Only connect TPE bushing of the system to safety extra low voltage (SELV) circuits.

z Make sure that the length of the electric cable connected to a TPE bushing does not

exceed 100 m.

If you have further questions, ask your system administrator.

Replacement/Expansion

Only replace or expand components or system parts with those recommended by Emerson.

Otherwise, you are fully responsible for the impact on EMC or any possible malfunction of the

product.

Check the total power consumption of all components installed (see the technical

specification of the respective components). Ensure that any individual output current of any

source stays within its acceptable limits (see the technical specification of the respective

source).

Environment

Always dispose of used products according to your country’s legislation and manufacturer’s

instructions.

20

SAM1411 Installation and Use (6806800M91A)

Sicherheitshinweise

Dieses Kapitel enthält Hinweise, die potentiell gefährlichen Prozeduren innerhalb dieses

Handbuchs vorrangestellt sind. Beachten Sie unbedingt in allen Phasen des Betriebs, der

Wartung und der Reparatur des Systems die Anweisungen, die diesen Hinweisen enthalten

sind. Sie sollten außerdem alle anderen Vorsichtsmaßnahmen treffen, die für den Betrieb des

Produktes innerhalb Ihrer Betriebsumgebung notwendig sind. Wenn Sie diese

Vorsichtsmaßnahmen oder Sicherheitshinweise, die an anderer Stelle diese Handbuchs

enthalten sind, nicht beachten, kann das Verletzungen oder Schäden am Produkt zur Folge

haben.

Emerson ist darauf bedacht, alle notwendigen Informationen zum Einbau und zum Umgang

mit dem Produkt in diesem Handbuch bereit zu stellen. Da es sich jedoch um ein komplexes

Produkt mit vielfältigen Einsatzmöglichkeiten handelt, können wir die Vollständigkeit der im

Handbuch enthaltenen Informationen nicht garantieren. Falls Sie weitere Informationen

benötigen sollten, wenden Sie sich bitte an die für Sie zuständige Geschäftsstelle von Emerson.

Das System erfüllt die für die Industrie geforderten Sicherheitsvorschriften und darf

ausschließlich für Anwendungen in der Telekommunikationsindustrie und im Zusammenhang

mit Industriesteuerungen verwendet werden.

Einbau, Wartung und Betrieb dürfen nur von durch Emerson ausgebildetem oder im Bereich

Elektronik oder Elektrotechnik qualifiziertem Personal durchgeführt werden. Die in diesem

Handbuch enthaltenen Informationen dienen ausschließlich dazu, das Wissen von

Fachpersonal zu ergänzen, können dieses jedoch nicht ersetzen.

Halten Sie sich von stromführenden Leitungen innerhalb des Produktes fern. Entfernen Sie auf

keinen Fall Abdeckungen am Produkt. Nur werksseitig zugelassenes Wartungspersonal oder

anderweitig qualifiziertes Wartungspersonal darf Abdeckungen entfernen, um Komponenten

zu ersetzen oder andere Anpassungen vorzunehmen.

Installieren Sie keine Ersatzteile oder führen Sie keine unerlaubten Veränderungen am Produkt

durch, sonst verfällt die Garantie. Wenden Sie sich für Wartung oder Reparatur bitte an die für

Sie zuständige Geschäftsstelle von Emerson. So stellen Sie sicher, dass alle

sicherheitsrelevanten Aspekte beachtet werden.

SAM1411 Installation and Use (6806800M91A)

21

Sicherheitshinweise

EMV

Das Produkt wurde in einem Emerson Standardsystem getestet. Es erfüllt die für digitale

Geräte der Klasse A gültigen Grenzwerte in einem solchen System gemäß den FCC-Richtlinien

Abschnitt 15 bzw. EN 55022 Klasse A. Diese Grenzwerte sollen einen angemessenen Schutz

vor Störstrahlung beim Betrieb des Produktes in Gewerbe- sowie Industriegebieten

gewährleisten.

Das Produkt arbeitet im Hochfrequenzbereich und erzeugt Störstrahlung. Bei

unsachgemäßem Einbau und anderem als in diesem Handbuch beschriebenen Betrieb können

Störungen im Hochfrequenzbereich auftreten.

Wird das Produkt in einem Wohngebiet betrieben, so kann dies mit großer Wahrscheinlichkeit

zu starken Störungen führen, welche dann auf Kosten des Produktanwenders beseitigt werden

müssen. Änderungen oder Modifikationen am Produkt, welche ohne ausdrückliche

Genehmigung von Emerson durchgeführt werden, können dazu führen, dass der Anwender

die Genehmigung zum Betrieb des Produktes verliert. Boardprodukte werden in einem

repräsentativen System getestet, um zu zeigen, dass das Board den oben aufgeführten EMVRichtlinien entspricht. Eine ordnungsgemäße Installation in einem System, welches die EMVRichtlinien erfüllt, stellt sicher, dass das Produkt gemäß den EMV-Richtlinien betrieben wird.

Verwenden Sie nur abgeschirmte Kabel zum Anschluss von Zusatzmodulen. So ist

sichergestellt, dass sich die Aussendung von Hochfrequenzstrahlung im Rahmen der erlaubten

Grenzwerte bewegt.

Warnung! Dies ist eine Einrichtung der Klasse A. Diese Einrichtung kann im Wohnbereich

Funkstörungen verursachen. In diesem Fall kann vom Betreiber verlangt werden,

angemessene Maßnahmen durchzuführen.

Board Installation

Bevor Sie das Board in einem System installieren, überprüfen Sie, ob die im Kapitel "Board

Exchange" aufgeführten Anforderungen erfüllt werden.

Bereich mit eingeschränktem Zugang - Installieren Sie das Board in ein System nur in Bereichen

mit eingeschränktem Zugang.

22

SAM1411 Installation and Use (6806800M91A)

Datenverlust

Ziehen Sie das Board im laufenden Betrieb heraus, obwohl die Hot-Swap LED noch nicht

leuchtet, führt das zu Datenverlust.

Warten Sie deshalb bis die Hot-Swap LED blau leuchtet, bevor Sie das Board herausziehen.

Beschädigung von Schaltkreisen

Elektrostatische Entladung und unsachgemäßer Ein- und Ausbau des Produktes kann

Schaltkreise beschädigen oder ihre Lebensdauer verkürzen.

Bevor Sie das Produkt oder elektronische Komponenten berühren, vergewissern Sie sich, daß

Sie in einem ESD-geschützten Bereich arbeiten.

Fehlfunktion des Produktes

Fehlerhafter Ein- und Ausbau des Produktes kann zur Beschädigung des Produktes führen.

Stellen Sie deshalb sicher, dass das Produkt mit allen Steckern mit der Systembackplane

verbunden ist und über alle Zone 1 Anschlüsse mit Spannung versorgt wird.

Sicherheitshinweise

Beschädigung des Produktes

Fehlerhafte Installation des Produktes kann zu einer Beschädigung des Produktes führen.

Verwenden Sie die Handles, um das Produkt zu installieren/deinstallieren. Auf diese Weise

vermeiden Sie, dass das Face Plate oder die Platine deformiert oder zerstört wird.

Beschädigung des Produktes und von Zusatzmodulen

Fehlerhafte Installation von Zusatzmodulen, kann zur Beschädigung des Produktes und der

Zusatzmodule führen.

Lesen Sie daher vor der Installation von Zusatzmodulen die zugehörige Dokumentation.

Betrieb

Beschädigung des Boards

Hohe Luftfeuchtigkeit und Kondensat auf der Oberfläche des Boards können zu Kurzschlüssen

führen.

Betreiben Sie das Board nur innerhalb der angegebenen Grenzwerte für die relative

Luftfeuchtigkeit und Temperatur. Stellen Sie vor dem Einschalten des Stroms sicher, dass sich

auf dem Board kein Kondensat befindet.

SAM1411 Installation and Use (6806800M91A)

23

Sicherheitshinweise

Überhitzung und Beschädigung des Boards

Betreiben Sie das Board ohne Zwangsbelüftung, kann das Board überhitzt und schließlich

beschädigt werden.

Bevor Sie das Board betreiben, müssen Sie sicher stellen, dass das Shelf über eine

Zwangskühlung verfügt.

Verletzungen oder Kurzschlüsse

Board oder Stromversorgung

Falls die ORing Dioden des Boards durchbrennen, kann das Board einen Kurzschluss zwischen

den Eingangsleitungen A und B verursachen. In diesem Fall ist Leitung A immer noch unter

Spannung, auch wenn sie vom Versorgungskreislauf getrennt ist (und umgekehrt).

Prüfen Sie deshalb immer, ob die Leitung spannungsfrei ist, bevor Sie Ihre Arbeit fortsetzen,

um Schäden oder Verletzungen zu vermeiden.

Hot Swap

Wenn Sie das Board im laufenden Betrieb in ein System, das weder Hot Swap noch High

Availability unterstützt, installieren bzw. herausziehen, wird das Board beschädigt und es

gehen Daten verloren. Installieren/entfernen Sie das Board nur im laufenden Betrieb, wenn das

System Hot Swap oder High-Availability unterstützt und wenn die Systembeschreibung dies

ausdrücklich erlaubt.

RJ-45 Stecker

Der RJ-45 Stecker auf der Frontblende darf nur für Twisted-Pair-Ethernet (TPE) Verbindungen

verwendet werden. Beachten Sie, dass ein versehentliches Anschließen einer Telefonleitung an

einen solchen TPE Stecker sowohl das Telefon als auch das Board zerstören kann. Beachten Sie

deshalb die folgenden Hinweise:

z Kennzeichnen Sie TPE-Anschlüsse in der Nähe Ihres Arbeitsplatzes deutlich als

Netzwerkanschlüsse.

z Schließen Sie an TPE-Buchsen ausschließlich SELV-Kreise

(Sicherheitskleinspannungsstromkreise) an.

z Die Länge des mit dem Board verbundenen Twisted-Pair Ethernet-Kabels darf 100 m nicht

überschreiten.

24

SAM1411 Installation and Use (6806800M91A)

Falls Sie Fragen haben, wenden Sie sich bitte an Ihren Systemadministrator.

Austausch/Erweiterung

Verwenden Sie bei Austausch oder Erweiterung nur von Emerson empfohlene Komponenten

und Systemteile. Andernfalls sind Sie für mögliche Auswirkungen auf EMV oder Fehlfunktionen

des Produktes voll verantwortlich.

Überprüfen Sie die gesamte aufgenomme Leistung aller eingebauten Komponenten (siehe die

technischen Daten der entsprechenden Komponente). Stellen Sie sicher, dass die

Stromaufnahme jedes Verbrauchers innerhalb der zulässigen Grenzwerte liegt (siehe die

technischen Daten des entsprechenden Verbrauchers).

Umweltschutz

Entsorgen Sie alte Batterien und/oder Produkte stets gemäß der in Ihrem Land gültigen

Gesetzgebung und den Empfehlungen des Herstellers.

Sicherheitshinweise

SAM1411 Installation and Use (6806800M91A)

25

Sicherheitshinweise

26

SAM1411 Installation and Use (6806800M91A)

Introduction

1.1 Overview

The SAM1411 is a shelf manager board to be used in the AdvancedTCA systems. It plugs into a

dedicated shelf management slot of an AdvancedTCA system. The SAM1411 performs the

system monitoring, control, and management functions of the entire shelf. It provides

management for up to 16 AdvancedTCA front blades, fans, power entry modules (PEMs), alarm

modules, and shelf FRU info modules that are present in an AdvancedTCA system. It is

designed for redundant operation in AdvancedTCA shelves. Two SAM1411 are deployed in one

shelf. One takes over the role of active shelf manager and the other one acts as standby shelf

manager, which is ready to take over in case of a failure of the active one. Redundant channels

for heart beating and check pointing between the two SAM1411 are provided to support

failover.

The shelf manager consists of hardware (payload and shelf management controller) and

software.

Chapter 1

For information of the software, refer to the System Management Interface Based on HPI-B

(Centellis 31kX/4100/2000/4410) User’s Guide.

The SAM1411 provides the following interfaces:

z Motorola MPC8306S PowerQUICC processor with embedded PowerPC core

z Atmel ATmega2560 (master) and ATmega168 (slave) micro-controllers

z 64/128 MB SDRAM memory

z 64 MB boot and user flash

z Dual redundant IPMB interface

z Two 10/100 Mbps Ethernet ports to the rear connector

z One 10/100 Mbps Ethernet port to the face plate

z Two serial ports to the rear connector for heartbeat with the redundant SAM1411

z One serial port to the rear connector, for configuration and diagnostic purposes (routed to

the Alarm Display Panel)

z 64 MB redundant boot and user flash for recovery

z SPI bus to MicroSD memory module for storage

z I2C to 512K EEPROM for OS environment variable data

SAM1411 Installation and Use (6806800M91A)

27

Introduction

z Telco Alarm connector to the faceplate

z Telco Alarm signals to the ADP LEDs

z Local Temperature Sensor

28

SAM1411 Installation and Use (6806800M91A)

Introduction

1.2 Standard Compliances

The SAM1411, when installed in a compliant chassis, meets the following standards:

Table 1-1 Standard Compliances

Standard Description

UL 60950-1,

EN 60950-1,

IEC 60950-1

CAN/CSA C22.2 No 60950-1

CISPR 22

CISPR 24

EN 55022

EN 55024

FCC Part 15

Industry Canada ICES-003

VCCI Japan

AS/NZS CISPR 22

EN 300 386

NEBS Standard GR-1089

CORE

ANSI/IPC-A610 Rev.C Class 2

ANSI/IPC-7711

ANSI/IPC-7721

ANSI-J-001...003

NEBS Standard GR-63-CORE

ETSI EN 300 019 series

PICMG 3.0 R3.0 Defines mechanics, blade dimensions, power distribution, power and

Defines legal safety requirements

Define s legal EMC requirements on system l evel (predefi ned Emerso n

system)

Defines manufacturing requirements

Defines environmental requirements

data connectors, and system management

SAM1411 Installation and Use (6806800M91A)

29

Introduction

z The product has been designed to meet the directive on the restriction of the use of

certain hazardous substances in electrical and electronic equipment (RoHS) Directive

2002/95/EC.

z The shelf manager board SAM1411 can be operated from -5ºC up to +55ºC without

forced cooling.

30

SAM1411 Installation and Use (6806800M91A)

Introduction

Figure 1-1 Declaration of Conformity

SAM1411 Installation and Use (6806800M91A)

31

Introduction

1.3 Ordering Information

Table 1-2 shows the ordering information of the board.

For further details, contact the local Emerson representative.

Table 1-2 Ordering Information

Order No. Description

SAM1411 Shelf manager board used in AXP1411 systems

32

SAM1411 Installation and Use (6806800M91A)

Shelf Manager Hardware

2.1 Overview

The SAM1411 is compliant to PICMG 3.0 R3.0 (AdvancedTCA). It is equipped with a backplane

connector and is plugged into a 2U slot.

Figure 2-1 SAM1411 Block Diagram

Chapter 2

SAM1411 Installation and Use (6806800M91A)

33

Shelf Manager Hardware

The alignment pin offers a guiderail to the slot and a coding mechanism to ensure the

installation of the board in the matching slot. It also prevents bent pins which may occur during

installation.

The hardware consists of:

z Payload hardware section with

— Ethernet interfaces to the backplane and to the face plate

— Redundant connection between two shelf managers via backplane

— Block transfer interface to the ShMC

z Shelf management controller section with

— IPMB0-A and IPMB0-B interface to the backplane

— Handle switch and status LED interface to the face plate

z Support logic for testing and debugging, as well as local and remote programming of all

programmable devices on the board

z Power supply

2.2 Payload Hardware

The payload hardware on the shelf manager board is always powered when power supply is

present. During power-on, the ShMC keeps the payload in a reset state.

The following interfaces are available:

z Three Ethernet interfaces

z Two redundancy interfaces (serial)

z Block transfer interface

z One diagnostic console interface (serial)

2.2.1 Ethernet Interfaces

The shelf manager board has three Ethernet ports which are available concurrently.

34

SAM1411 Installation and Use (6806800M91A)

Shelf Manager Hardware

One 10/100 BaseT out-of-band interface is accessible via RJ45 connector at the face plate

marked with "ETH". Link and activity status LEDs are integrated into the connector.

Two 10/100 BaseT interfaces are connected to the backplane connector at the pins Eth1-Hub

Tx/Rx and Eth2-Hub Tx/Rx.

These interfaces are compliant with the PICMG 3.0 R3.0 specification (AdvancedTCA) for the

base interface. These ports connect to the base interface of up to two AdvancedTCA switch

boards in the hub slots of an AdvancedTCA shelf.

2.2.2 Redundancy Interfaces

The SAM1411 uses a private, redundant, high-speed, full duplex serial connection for

heartbeating and data replication between the two shelf manager boards.

The redundancy interface is routed to the backplane via differential line LVDS transceivers. The

physical interface of both channels are compliant with the PICMG 3.0 R3.0 (AdvancedTCA)

specification for the update interface.

Each of the serial inputs of the redundancy interface triggers an interrupt to the PowerQUICC

when the other shelf manager board:

z initiates a break-in condition on the serial line

z experiences a power failure

z goes in the reset state

z is extracted

2.2.3 Block Transfer Interface

The payload CPU is connected to the ShMC via a parallel interface with interrupt support called

block transfer interface, implemented in an FPGA.

The block transfer (BT) interface is compliant with IPMI specification v1.5.

SAM1411 Installation and Use (6806800M91A)

35

Shelf Manager Hardware

2.2.4 Console Interface

The SAM1411 provides one EIA-232 serial interface to the backplane, which is routed to the

Alarm Display Panel (ADP) in the AXP1411 shelf. This interface can be used for configuration

and diagnostic purposes. This interface is normally the console of the Payload Processor, but

under software control, can provide access to the ShMC console.

2.3 Shelf Management Controller

The ShMC part is derived from Emerson's IPMC building block and consists of two coupled

microcontrollers:

z IPMC Master Controller (IMC), based on ATmega2560

z IPMC Slave Controller (ISC), based on ATmega168

2.3.1 IPMB0 Interface

IPMB0-A is connected to the I2C controller of the IMC and IPMB0-B is connected to the I2C

controller of the ISC of the ShMC. Both microcontrollers have their own I

handle message transmission and reception independently, including bus error handling and

bus arbitration.

Received messages sent from both the IMC and the ISC channels are collected by the IMC. The

IMC dispatches messages, which have to be sent, either to its own I

transmission.

2.3.2 IPMC Standard Functions

The standard functionality of the Emerson IPMC is available on the IPMC of the SAM1411. For

more information, refer SAM1411 Control via IPMI Programmer’s Reference Guide.

2.4 Power Supply

The SAM1411 is powered by dual redundant +12 VDC feeds, one from each of the PEMs. This

+12 VDC is derived from the -48 VDC feed to each PEM. Each of the two +12 V feeds are

separately fused with a 2 A fuse.

36

2

C controller and

2

C interface or to the ISC for

SAM1411 Installation and Use (6806800M91A)

Shelf Manager Hardware

The power supply is compliant with the requirements of the PICMG3.0 R3.0 (AdvancedTCA)

specification. Each of the four power connections is separately fused. Fuse rating is 1A.

An EMI filter at the power input ensures conducted emission levels below EN 55022 class B.

2.4.1 Onboard and External Supply

The SAM1411 has no provisions to switch off the power input. The board is powered when the

power input to either PEM is in the operating range of -40.5 V to -72 V.

An on-board DC/DC-converter supplies all onboard circuitry, and provides 3.3 V power supply

to external circuits with a consumption of not more than 4.2 W.

The board satisfies the standby power limit of 10 W for AdvancedTCA FRUs, even when

supplying 4 W to external loads. Typical power consumption of the SAM1411 board is 2 .3W.

2.4.2 Power Supply Holdup

The SAM1411 complies with the requirements for board level voltage transients as described

in chapter 4.1.4.3. of PICMG 3.0 (AdvancedTCA) specification.

It satisfies the requirement of uninterrupted operation during a power failure of 5ms, while

supplying 4W to external circuits.

2.5 Frame Ground and ESD

Frame ground connection is provided by the backplane connector FrameGND.

The face plate mounting holes of the board are connected to frame ground.

An ESD strip according to the AdvancedTCA specification PICMG 3.0 R3.0 for rear transition

modules (RTMs) is provided at one edge of the PCB.

SAM1411 Installation and Use (6806800M91A)

37

Shelf Manager Hardware

38

SAM1411 Installation and Use (6806800M91A)

Controls, Indicators, and Connectors

3.1 Face Plate

Figure 3-1 shows the position of connectors and LEDs on the face plate of the board. The

following are the faceplate connectors and indicators on the board:

z One 15-pin D-shell connector for the Telco Alarm cable

z One RJ45 connector for the faceplate Ethernet connector (with integrated Link and

Activity LEDs)

z OOS/IS/ACT/HS LED status indicators

Figure 3-1 Face Plate

Chapter 3

SAM1411 Installation and Use (6806800M91A)

39

Controls, Indicators, and Connectors

3.2 LEDs

Table 3-1 describes the LEDs that can be found on the face plate of the board. The OOS, I/S,

ACT, and H/S LEDs can be controlled via IPMI. For more information, refer SAM1411 Control via

IPMI Programmer’s Reference Guide.

Table 3-1 Face Plate LEDs

LED Color Description

Failure (OOS) LED Red Red: The shelf manager board is out-of-service.

Active (ACT) LED Amber Amber: The shelf manager board is active.

Hot Swap (H/S) Blue Blue (steady): The shelf manager board is ready to be extracted.

Off: The shelf manager board is working properly.

Off: The shelf manager board is in standby mode.

Blue (long blink): The board has been inserted or powered on and

is beginning the integration process. The eject handle switch is

closed.

Blue (short blink): The eject handle switch is open or an

extraction has been requested. The board is shutting down and

transferring control of the shelf to the other shelf manager board.

Off: The shelf manager board is not ready to be extracted. Do not

remove the board during this state.

In Service (I/S) LED Green Green: The shelf manager board is working properly.

Off: The shelf manager is not working properly or is initializing

after power-up.

Link Status /Activity Green ON — Data link is active between the PHY and an external

connection

FLASHING — Data is being transferred

Speed Amber ON — 100Mb/s mode is selected

OFF — 10Mb/s mode is selected

3.3 Ethernet Connector (Out-of-Band)

One 10/100 Mbps Ethernet port is provided via the Ethernet connector on the face plate. It

allows external system managers to access the shelf manager.

40

SAM1411 Installation and Use (6806800M91A)

Controls, Indicators, and Connectors

3.4 Alarm Connector

The DB15 connector provides a means to report system alarm conditions to a higher level such

as a system operator console. Figure 3-2 displays the pinout for the alarm I/O connector:

Figure 3-2 Alarm I/O Connector Pinout

The following table shows the description of the pins:

Table 3-2 Alarm Pin Description

Pin Description

1Minor Alarm Reset +

2Minor Alarm Reset -

3Major Alarm Reset +

4Major Alarm Reset -

5 Critical Alarm - NO (Normally Open)

6 Critical Alarm - NC (Normally Closed)

7 Critical Alarm - COM (Common)

8 Minor Alarm - NO (Normally Open)

9 Minor Alarm - NC (Normally Closed)

10 Minor Alarm - COM (Common)

11 Major Alarm - NO (Normally Open)

12 Major Alarm - NC (Normally Closed)

13 Major Alarm - COM (Common)

14 Pwr Alarm - NO (Normally Open)

SAM1411 Installation and Use (6806800M91A)

41

Controls, Indicators, and Connectors

Table 3-2 Alarm Pin Description

Pin Description

15 Pwr Alarm - COM (Common)

42

SAM1411 Installation and Use (6806800M91A)

SAM1411 Installation

4.1 Overview

To install the SAM1411 into the AdvancedTCA system, follow these steps:

1. Unpack and inspect the board, see Unpacking and Inspecting the Board on page 43.

2. Make sure environmental and power requirements are met, see Requirements on page 44.

3. Install the blade, see Installing and Removing the Board on page 48.

4.2 Unpacking and Inspecting the Board

Chapter 4

Board Damage

Touching the board or electronic components in a non-ESD protected environment causes

component and board damage.

Before touching boards or electronic components, make sure that you are working in an

ESD-safe environment or wear ESD wrist straps.

Shipment Inspection

To inspect the shipment, perform the following steps:

1. Verify that you have received all items of your shipment:

z SAM1411

z Desiccant bag

SAM1411 Installation and Use (6806800M91A)

43

SAM1411 Installation

2. Check for damage and report any damage or differences to the customer service.

3. Remove the desiccant bag delivered along with the board and dispose of it

according to your country’s legislation.

The board is thoroughly inspected before shipment. If any damage has occurred during

transportation or any items are missing, then contact our customer's service immediately.

4.3 Requirements

Before you power up the board, calculate the power needed according to your system

configuration.

4.3.1 Environmental Requirements

Make sure that the board, when operated in your particular system configuration, meets the

environmental requirements specified in Table 4-1.

Operating temperatures refer to the temperature of the air circulating around the board and

not to the component temperature.

Board Damage

High humidity and condensation on the board surface causes short circuits.

Do not operate the board outside the specified environmental limits. Make sure the board

is completely dry and there is no moisture on any surface before applying power.

44

SAM1411 Installation and Use (6806800M91A)

SAM1411 Installation

Table 4-1 Environmental Requirements

Feature Operating Non-Operating (packed state)

Temperature +5ºC (+41°F) to +40ºC (+104°F) (normal

operation) according to NEBS Standard

GR-63-CORE

-5°C (+23°F) to + 55°C (+131°F)

(exceptional operation) according to

NEBS Standard GR-63-CORE

Temp. change +/- 0.25ºC/min according to NEBS

Standard GR-63-CORE

Relative humidity 5% to 90% non-condensing according to

Emerson-internal environmental

requirements

Vibration (tested

in target platform)

Shock Half-sine, 11 mSec, 30 m/Sec

Free fall - 1.0 m (packaged) per ETSI 300 019-2-

0.1 g from 5 to 100 Hz and back to 5 Hz

at a rate of 0.1 octave/minute.

2

-40ºC (-40°F) to +85ºC (+185°F)

+/- 0.25ºC/min

5% to 95% non-condensing according

to Emerson-internal environmental

requirements

2

5-20 Hz at 0.01 g

20-200 Hz at -3.0 dB/octave

Random 5-20 Hz at 1 m

Random 20-200 Hz at -3 dB/octave

Blade level packaging

Half-sine, 6 mSec at 180 m/Sec

2

(Blade level packaging)

100 mm (unpackaged) per GR-63-

CORE

/Hz

2

/Sec

3

2

4.3.2 Power Requirements

Make sure that the board is used in an AdvancedTCA shelf connected to -48VDC up to -60VDC

(rated voltage), according to Telecommunication Network Voltage (TNV-2).

A TNV-2 circuit is a circuit whose normal operating voltages exceed the limits for a safety-extralow-voltage (SELV) under normal operating conditions, and which is not subject to

overvoltages from telecommunication networks.

SAM1411 Installation and Use (6806800M91A)

45

SAM1411 Installation

On board voltages are 12 VDC, 3.3 VDC, 2.5 VDC, 1.0 VDC, and 1.8 VDC:

z 12 VDC voltage is generated by the PEMs from the -48 VDC AdvancedTCA power by a

DC/DC converter with galvanic isolation suitable for TNV-2 circuits.

z 3.3 V, 2.5 V, 1.0V, and 1.8V voltages are derived from the 12 V input power.

Table 4-2 DC Board Power Requirements

Feature Value

Rated Voltage -48 VDC to -60 VDC

US and Canada: -48 VDC

Operating Voltage -40.5 VDC to -72 VDC

US and Canada: -40.5 to -60 VDC

Input current 0.2 A

SAM1411 power dissipation 10 W (max.) including external load of 4 W maximum

The board provides two independent power inputs according to the AdvancedTCA

specification. Each input has to be equipped with an additional fuse of max 90 A located either

in the shelf where the board is installed or in the power entry module (PEM).

4.3.3 Rotary Switch Settings

The two rotary switches on the SAM1411 are used to set the SGA. The first byte of the shelf

address of the shelf FRU information is automatically set to the SGA value.

46

SAM1411 Installation and Use (6806800M91A)

SAM1411 Installation

S1 sets the lower nibble and S2 sets the upper nibble. Use a screwdriver to set the switches by

turning them. A little arrow on the switch shows you the value to which the switch is set.

Figure 4-1 Rotary Switch Location

SAM1411 Installation and Use (6806800M91A)

47

SAM1411 Installation

Two SAM1411 in the same shelf must always be set to the same SGA. Otherwise, the software

detects that the FRU information in the two SAM1411s is different and stops the power-up

process. The red LED blinks and the boards are not powered.

Two SAM1411 in different shelves must always be set to different SGAs. When set to the same

address, both SAM1411 starts and network problems might occur.

4.4 Installing and Removing the Board

Board Damage

Touching the board or electronic components in a non-ESD protected environment causes

component and board damage.

Before touching boards or electronic components, make sure that you are working in an

ESD-safe environment or wear ESD wrist straps.

Since the backplane has no possibility to store the information (part number, serial number,

and so on.) on the shelf, this information is stored on the board itself. The software on the

board always updates this information on a newly inserted board.

z Never exchange more than one of these FRUs (boards) at the same time to guarantee

that the shelf information stays consistent and up to date.

z The board must only be operated in a shelf that is properly grounded.

48

SAM1411 Installation and Use (6806800M91A)

SAM1411 Installation

4.4.1 Installing the Board

Installation Procedure

The following procedure describes the installation of the board. It assumes that your system is

powered. If your system is unpowered, you can disregard the blue LED and thus skip the

respective step.

1. Put on an ESD wrist strap.

2. Connect the strap to the shelf by attaching the front or rear ESD jack.

3. Set the rotary switches according to your needs (see Rotary Switch Settings on page

46).

4. Insert the module into the shelf by placing the top and bottom edges of the board

in the card guides of the shelf. Ensure that the guiding module of shelf and board

are aligned properly. The alignment pin facilitates the insertion and prevents bent

pins.

5. Slide the module into the shelf.

6. Rotate the ejector handle upward until it snaps into place.

7. Wait until the blue LED is on.

8. Screw in the captive screw hand tight.

The blue LED blinks.

9. Wait until the blue LED is OFF.

This indicates that the board is activated.

SAM1411 Installation and Use (6806800M91A)

49

SAM1411 Installation

4.4.2 Removing the Board

Removal Procedure

The following procedure describes how to remove the board from a system. It assumes that

the system is powered. If the system is unpowered, you can disregard the blue LED and thus

skip the respective step.

1. Put on an ESD wrist strap.

2. Connect the strap to the shelf by attaching the front or rear ESD jack.

3. Unlatch the ejector handle by lifting up the center sliding portion of the handle,

then rotate the handle slightly (about 15 degrees).

The blue LED blinks indicating that the module power down process is ongoing.

4. Wait until the blue LED is illuminated permanently.

Data Loss

Removing the board with the blue LED still blinking causes data loss.

Wait until the blue LED is permanently illuminated, before removing the board.

5. Press the handle down to its fully-open position (about 90 degrees).

The board should start to move out of the chassis. Do not force it. If the SAM does

not move, it means the captive screw is not fully unscrewed. Unscrew until loose

and rotate the ejector handle down.

6. Remove the module from the shelf.

50

SAM1411 Installation and Use (6806800M91A)

Shelf Manager File System

5.1 Overview

The root-file system includes all payload applications and configurations. It is stored as a

compressed RAM disk on the flash and extracted into the RAM after the kernel has booted. All

changes in the disk file system are lost after the shelf manager powers down.

To enable persistent file support, a separate journaling flash file system of type ext2 exists. This

ext2 file system is mounted at startup on the /usr/local mount point. Any files stored in

this directory are persistent.

5.1.1 Persistent File Support

To make files persistent that are usually located under the RAM disk root-file system, Emerson

has implemented a persistent file mechanism. All files that are to be stored under the

persistent file system instead of the RAM disk file system are listed in a persistent file map. The

file map is stored with the following file path:

Chapter 5

/etc/persistentmap

For each file that should be persistent, a separate line in the persistent map exists.

The following example shows the default persistent map of the shelf manager.

#

# Map of persistent files.

# This file is sourced during system startup.

# A file specified in the first row is replaced by a symbolic link that

# points to the file in the second row. If the file in the second row

# does not exist it is copied first.

#

# Copyright (c) 2011 Emerson Network Power - Embedded Computing, Inc.

#

#

SAM1411 Installation and Use (6806800M91A)

51

Shelf Manager File System

# SYNTAX

# ------

# <source file on volatile media> <destination file on persistent media>

#

/etc/network.conf /usr/local/etc/network.conf

/etc/rc.d/network.local /usr/local/etc/rc.d/network.local

/etc/appl.conf /usr/local/etc/appl.conf

/opt/bladeservices/etc/bbs-hpib/bbs-hpib.conf /usr/local/etc/bbshpib/bbs-hpib.conf

/var/lib/bbs-hpib/uid_map /usr/local/var/lib/bbs-hpib/uid_map

/etc/ntpd.conf /usr/local/etc/ntpd.conf

/var/lib/dhcp/dhcpd.leases /usr/local/var/lib/dhcp/dhcpd.leases

/etc/dhcpd.conf /usr/local/etc/dhcpd.conf

Each line consists of two columns. The first column specifies the source file which is the file on

the RAM disk file system. The second column specifies the destination file which is the file on

the persistent file system.

At system startup, the shelf manager reads the persistent map and replaces each source file

with a symbolic link to the destination file. If the destination file does not exist, then it is copied

from the RAM disk file system to the persistent file system. The persistent map itself is also

symlinked at startup from the RAM disk file system to the persistent file system. A default map

is copied if it does not exists.

52

SAM1411 Installation and Use (6806800M91A)

Shelf Manager File System

Using this approach, any file in the RAM disk file system, with the exception of

/etc/rc.d/rc.boot, can be made persistent.

Replacing a regular file by a symbolic link is transparent to the applications on the shelf

manager.

5.1.2 Use Cases

The following use cases are described in this section:

z How to make a file on the RAM disk file system persistent

z How to remove a file from the persistent file system

z How to rollback to the factory configuration

5.1.2.1 How to Make a File on the RAM Disk File System Persistent

1. Prepare for editing the persistent map.

Either connect to the shelf manager via telnet and start "vi" to edit the persistent map on

site or download the persistent map using ftp to your local workstation and load the file in

your editor.

2. Add a new line at the end of the persistent map.

The first entry of the line specifies a file on the RAM disk file system and the second line

entry specifies the file on the persistent file system.

3. Save the changes.

If you edit on site, exit the "vi" editor or otherwise, upload your modified file to the shelf

manager using ftp.

4. Create the file on the persistent file system (Optional).

This step allows you to install your own file on the persistent file system. If this step is

omitted, the existing file on the RAM disk file system is copied automatically during system

startup.

5. Reboot the system

After system reboot the file on the persistent media is used instead of the file on the RAM

disk.

SAM1411 Installation and Use (6806800M91A)

53

Shelf Manager File System

5.1.2.2 How to Remove a File from the Persistent File System

1. Prepare for editing the persistent map.

Either connect to the shelf manager via telnet and start "vi" to edit the persistent map on

site or download the persistent map with ftp to your local workstation and load the file in

your editor.

2. Remove the line containing the desired file.

3. Save the changes.

If you edit on site, exit the "vi" editor or otherwise upload the modified file to the shelf

manager using ftp.

4. Remove the file on the persistent file system (optional).

This step is optional because the shelf manager does not use the file on persistent media

any longer.

5. Reboot the system.

After system reboot, the file on the RAM disk is used.

5.1.2.3 How to Rollback Factory Configuration

1. Type the following command to delete all data on the persistent media:

# cd /usr/local && rm -rf *

2. Reboot the system.

5.1.2.4 Persistent Log Files

All log files in /var/log directory are saved in the persistent file area. The /var/log

directory is a symbolic link to /usr/local/var/log. On rebooting the Shelf Manager, all

files stored in /usr/local/var/log are moved to /usr/local/var/log.PREVIOUS.

This allows two separate set of log files to be saved - the current logs in

/usr/local/var/log and the logs from the previous boot in

/usr/local/var/log.PREVIOUS.

54

SAM1411 Installation and Use (6806800M91A)

Shelf Manager File System

5.2 Log Files

There are three types of log files:

1. Linux log files

2. HPI log file (see System Management Interface Based on HPI-B (Centellis CO 31kX/4100/2000)

User’s Guide, chapter HPI Logging Support)

3. Supervisor log file

By default, the log file for supervisor logging is located at /var/log/supervisor.log.

You have the possibility to configure the supervisor logging by changing the configuration file

located at /usr/etc/supervisor/config/sv_config.xml. This XML file allows you to

change the following elements:

Element Description Possible Values

LogSeverity mask Defines what information

will be logged

LogSink mask Defines where the

information will be

logged

LogFile name Location of the logfile Default: /var/log/supervisor.log

LogFile size Maximum logfile size Default: 500 KB

Silent|Trace|Info|Notice|Warning|Error|Critical

|Alert|Emergency|Everything

Stdout|Stderr|Logfile|Syslog

The IP addresses in the log file are dynamic. Only change the elements listed in the table

above.

SAM1411 Installation and Use (6806800M91A)

55

Shelf Manager File System

Example of the configuration file:

<SupervisorConfiguration>

<Logging>

<!-- possible severity values:

Silent|Trace|Debug|Info|Notice|Warning|Error|Critical|Alert|Emergency|Eve

rything -->

<LogSeverity

mask="Info|Notice|Warning|Error|Critical|Alert|Emergency" />

<!-- possible sink values: Stdout|Stderr|Logfile|SysLog -->

<LogSink mask="Logfile"/>

<LogFile name="/var/log/supervisor.log" size="500"/>

</Logging>

<Supervisor msgPort="5566" queueLen="100" filePort="5568"

sendChunkSize="500"

startWaitTime="100" restartWaitTime="1000" transitionMaxTime="20000"

switchWaitTime="30000"

switchIgnoreTime="5000" tieBreak="8" localConnectOnly="0"

fileInterface="0.0.0.0"/>

<!-- for file transfer using ppp interface fileInterface="@srcIpAddr1@"

-->

<HeartBeater id="1" port="5567" type="UDP">

<HeartBeaterGroup name="shmgr" id="1" >

<HeartBeaterNode id="1" ipAddr="192.168.101.9" port="5567"

interval="400" warning="3" inaccessible="5" />

56

SAM1411 Installation and Use (6806800M91A)

Shelf Manager File System

<HeartBeaterNode id="2" ipAddr="192.168.102.9" port="5567"

interval="400" warning="3" inaccessible="5" />

</HeartBeaterGroup>

</HeartBeater>

</SupervisorConfiguration>

SAM1411 Installation and Use (6806800M91A)

57

Shelf Manager File System

58

SAM1411 Installation and Use (6806800M91A)

Firmware Upgrade Facility

6.1 Overview

The Firmware Upgrade Facility (FUF) provides a uniform way to upgrade firmware on Emerson

hub blades, node blades, and AMC modules. It consists of a Firmware Upgrade Command-line

Utility (FCU), flash device drivers, and specially prepared firmware recovery image files.

The ATCA-SAM1411 ramdisk is upgraded using the flashcp utility instead of fcu.

6.2 Firmware Recovery Image Files

Chapter 6

FCU supports specially prepared firmware recovery image (FRI) files as well as firmware images

in the HPM.1 format. HPM.1 is a PICMG standard to upgrade IPMCs.

By default, the image files for the current hardware configurations are stored in

/opt/bladeservices/rom.

The following image files are currently supported:

Filename Description

sam1411-kernel.fri Kernel image for ATCA-SAM1411

sam1411-cpu.fri U-boot firmware image for ATCA-SAM1411

sam1411-dtb.fri Device Tree Binary for ATCA-SAM1411

6.3 Backup Concept

When upgrading the U-Boot firmware, or Device Tree Binary image, or Linux kernel, FCU only

writes into the current stand-by bank. After the upgrade, the stand-by bank must be marked

for next use; this means it is executed after the next reboot.

SAM1411 Installation and Use (6806800M91A)

59

Firmware Upgrade Facility

6.4 fcu–Firmware Upgrade Command-Line Utility

Description

The Firmware Upgrade Command-line Utility (FCU) allows you to:

z Query the current versions of the firmware installed on the Shelf Manager and determine

which firmware devices are active.

z Verify that a specified upgrade image is sound and compatible with the current hardware.

z Upgrade a firmware image.

z Mark a device to be used as the boot source on the next reset.

By default, the FCU binary executable is installed in /opt/bladeservices/bin. This

directory has been added to the PATH environment variable.

The FCU verify and upgrade operations require specially prepared FRI files or HPM files (see

Firmware Recovery Image Files on page 59).

Synopsis

fcu --help [-t<slave address>]

fcu --version

fcu -q [-d <device-id>] [-t<slave address>]

fcu -v -f <filename> [-t<slave address>]

fcu -u -f <filename> [-t<slave address>]

fcu -a -f <filename>

fcu -m -b <bank-letter> -d <device-id> [-t<slave address>]

fcu -s -f <filename>

fcu --activate -b <bank-letter> -d <device-id>

Parameters

-a

--full-upgrade

60

SAM1411 Installation and Use (6806800M91A)

Firmware Upgrade Facility

This option is a shortcut for performing the verify, upgrade, and mark operations. The file

option -f is required. This option should not be combined with other operations.

-r

--activate

This command is available for IPMC devices and images which conform to the HPM.1 standard.

HPM.1 compliant IPMCs store a redundant set of firmware images which may have the states

operational, rollback, or deferred. Using the --activate option, you can set the state of the

addressed firmware bank to "operational". Unlike the --mark option, the --activate

command does not affect the payload operation, this means you can set a previously "rollback"

firmware bank to "operational" without rebooting or resetting the payload. The target IPMC is

immediately functional after switching to the new firmware.

You can obtain the current states of the firmware banks by using the -q command. The state

appears as part of the bank name, for example: "B - Rollback".

-b <bank-letter>

--bank=<bank-letter>

Specifies a flash bank (for example, A or B), where <bank-letter> is the letter designating a

specific bank. This option can be used with the mark or activate operation. Use the query

option -q to list available banks.

-d <device-id>

--device=<device-id>

Specifies a target firmware device, where <device-id> is the name of the device. This option

is used with the mark or query operations. Device ID values vary by hardware. You can display

supported devices on a given blade by using fcu --help. Currently supported values are

listed in the following table:

Device ID Description

atca-sam1411-cpu U-Boot firmware device for ATCA-SAM1411

atca-sam1411-dtb Device Tree Binary device for ATCA-SAM1411

atca-sam1411-kernel Kernel device of ATCA-SAM1411

atca-sam1411-rootfs Root filesystem (ramdisk) device for ATCA-SAM1411

atca-sam1411-hpm.1-ipmc IPMC firmware device

SAM1411 Installation and Use (6806800M91A)

61

Firmware Upgrade Facility

-f <filename>

--file=<filename>

Specifies the FRI file, where <filename> is the complete path and filename of the image file.

This option is used with the verify and upgrade operations.

--force

This option allows the installation of images with non-matching part-number and part-revision

FRU data fields. This option should be used with extreme caution because installing an

incompatible image on a device may render it inoperable.

--help

Displays a brief message describing command usage. It also displays a list of the devices

supported on the blade. This option is exclusive and should not be used with other options.

-m

--mark

Informs FCU to set the boot select so that on the next boot the specified firmware bank will be

ac tive. When mark is com bined wi th the upgra de operation, there is no need to specify a bank;

the bank just upgraded will be marked. Otherwise, you must specify a bank and a device.

Note that on the ATCA-SAM1411 the U-Boot, DTB, Kernel, and Ramdisk are coupled, this

means when you mark a U-Boot image for the nex t reboot, the other corresponding images are

automatically marked as well.

-q

--query

Informs FCU to return firmware information for a specific device (if used with -d) or

information about all firmware devices. The query operation is exclusive and is not intended to

be combined with other operations.

-s

--show

Shows detailed information about a specified file. The information shown includes, for

example image type, version, manufacturer name, and so on. This command may be useful

before a firmware upgrade to determine the version of a new image file.

62

SAM1411 Installation and Use (6806800M91A)

Firmware Upgrade Facility

-t

--target

This option is needed to specify the IPMC address if the operation is to be done on a remote

IPMC. If you do not specify this option, the software tries to access the local IPMC. The -t

option provides a possibility to perform the firmware upgrade on a different blade.

-u

--upgrade

Informs FCU to upgrade the currently inactive bank of the device specified by the target FRI file.

The file option -f is required. The upgrade operation may be combined with the verify and

mark operations.

-v

--verify

Informs FCU to verify the image file specified by the required -f option. This operation verifies

that the specified file is sound and compatible with the current hardware. The verify operation

may be combined with the upgrade and mark operations.

--version

Displays version information for the utility. This option is exclusive and should not be used with

other options.

Usage

Some FCU options can be combined. Some options are exclusive. The following list describes

the valid option combinations:

z --full-upgrade --file=<filename>

z --full-upgrade --file=<filename> --target=xxxxxx

z --help

z --mark --bank=<bank-letter> --device=<device-id>

z --query

z --query --device=<device-id>

z --show --file=<filename>

SAM1411 Installation and Use (6806800M91A)

63

Firmware Upgrade Facility

z --upgrade --file=<filename>

z --upgrade --mark --file=<filename>