Page 1

FloBoss S600+ Modbus Specification Manual

D301904X012

January 2021

FloBoss S600+ Modbus Specification Manual

Remote Automation Solutions

Page 2

FloBoss S600+ Modbus Specification Manual

D301904X012

January 2021

System Training

A well-trained workforce is critical to the success of your operation. Knowing how to correctly install, configure,

program, calibrate, and trouble-shoot your Emerson equipment provides your engineers and technicians with the

skills and confidence to optimize your investment. Remote Automation Solutions offers a variety of ways for your

personnel to acquire essential system expertise. Our full-time professional instructors can conduct classroom

training at several of our corporate offices, at your site, or even at your regional Emerson office. You can also receive

the same quality training via our live, interactive Emerson Virtual Classroom and save on travel costs. For our

complete schedule and further information, contact the Remote Automation Solutions Training Department at

800-338-8158 or email us at education@emerson.com.

ii

Page 3

FloBoss S600+ Flow Computer Modbus Specification Manual

D301904X012

January 2021

Contents

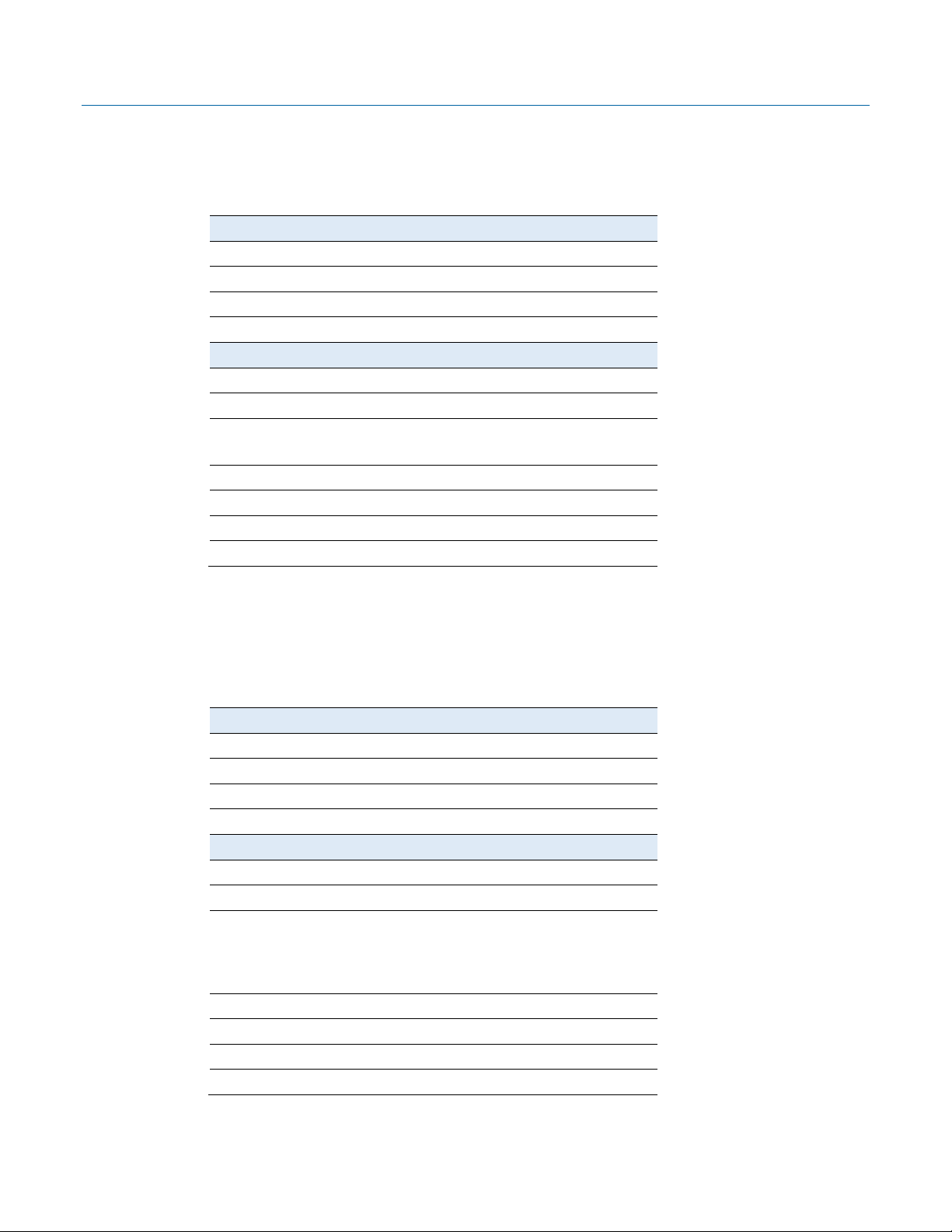

1. Introduction 1

2. Physical Transport of Data 1

2.1 TCP Socket ............................................................................................................................................ 1

2.2 Modbus TCP .......................................................................................................................................... 1

2.3 Serial ..................................................................................................................................................... 1

2.4 Types and Capabilities of Serial Ports ..................................................................................................... 2

3. Network Interface 2

4. Modbus 3

4.1 Configuration........................................................................................................................................ 3

4.2 Master .................................................................................................................................................. 3

4.3 Slave ..................................................................................................................................................... 3

5. RTU/ASCII Protocol 4

6. Implemented Modbus Functions 5

6.1 Function 1: Read Output Status ............................................................................................................. 5

6.2 Function 2: Read Input Status ................................................................................................................ 6

6.3 Function 3: Read Output Registers ........................................................................................................ 6

6.4 Function 4: Read Input Registers ........................................................................................................... 7

6.5 Function 5: Write Single Coil ................................................................................................................. 7

6.6 Function 6: Write Single Register ........................................................................................................... 8

6.7 Function 8: Loopback ............................................................................................................................ 8

6.8 Function 15: Write Multiple Coils ........................................................................................................... 9

6.9 Function 16: Write Multiple Registers .................................................................................................... 9

6.10 Function Codes 65, 66, 67, and 68 ...................................................................................................... 10

7. Message Length Mode 11

8. Register Formats 12

8.1 Register: Float ..................................................................................................................................... 12

8.2 Register: Rosemount ........................................................................................................................... 12

8.3 Register: Double ................................................................................................................................. 13

8.4 Register: Phillips Float ......................................................................................................................... 13

8.5 Register: Phillips Double ...................................................................................................................... 13

8.6 Register: INT ....................................................................................................................................... 13

8.7 Register: LONG_INT ............................................................................................................................ 13

8.8 Register: SCALE 0 nnnn ....................................................................................................................... 13

Contents iii

Page 4

FloBoss S600+ Flow Computer Modbus Specification Manual

D301904X012

January 2021

8.9 Register: Modicon ............................................................................................................................... 14

9. Enron Functions 15

9.1 Enron Modbus Map ............................................................................................................................. 15

9.2 Special Enron Functions for Events ...................................................................................................... 15

Clear/Acknowledge Modbus Event Log ................................................................................. 15

9.2.1

9.2.2 Event Count Register ............................................................................................................ 15

9.2.3 Alarm Count Register ........................................................................................................... 16

9.2.4 Read Modbus Alarm/Event Log Functions ............................................................................. 16

9.3 Special Enron Functions for Data Log Collection .................................................................................. 18

9.4 Read Report Log Configuration ........................................................................................................... 19

9.5 Read Report Log Data ......................................................................................................................... 20

10. S600+ Modbus Configuration Files 21

10.1 Config File Title ................................................................................................................................... 21

10.1.1 Config File Header ................................................................................................................ 22

10.2 Config File Master Section ................................................................................................................... 23

10.3 Config File Slave N Section .................................................................................................................. 24

10.4 Config File Data ................................................................................................................................... 24

10.5 Config File Data Coil ............................................................................................................................ 25

10.6 Config File Data Input .......................................................................................................................... 25

10.7 Config File Data Registers .................................................................................................................... 25

10.8 Discrete Data Point Format ................................................................................................................. 26

Numeric Data Point Format ................................................................................................................. 27

10.9

iv Contents

Page 5

FloBoss S600+ Flow Computer Modbus Specification Manual

D301904X012

January 2021

Contents v

Page 6

FloBoss S600+ Flow Computer Modbus Specification Manual

1. Introduction

This document describes the Modbus communications protocol on the FloBoss S600+ flow

computer. The flow computer has 20 user definable communication tasks. Each of the links may be

individually configured.

2. Physical Transport of Data

2.1 TCP Socket

The TCP/IP stream socket supports both master and slave links.

If the unit is the slave on the link it creates a server socket and listens for clients to connect. The

TCP/IP address of the slave link is the TCP/IP address of the flow computer.

If the unit is the master on the link it acts as a client and attempts to connect to a remote server

machine. When you configure the data link, you specify the TCP/IP address of the slave with which

the master must communicate.

D301904X012

January 2021

The S600+ supports communication between networks using a gateway.

Other communication parameters are independent of the mode of data transfer. ASCII and RTU are

supported over stream sockets and the Modbus map is independent of the transport mechanism.

2.2 Modbus TCP

This protocol is based on the Modbus/TCP Specification. The connection mechanism is TCP/IP

which secures data transfer between any machines connected on a network. The Modbus protocol

is encapsulated into the TCP/IP frame.

The data transfer within the Modbus part of the protocol is standard Modbus. The only significant

difference is that the Modbus CRC is not use; . Instead the CRC used with the TCP/IP protocol is

used.

2.3 Serial

In serial mode the data links communicate over standard serial lines with these specifications:

Baud rates: 2400, 4800, 9600, 19200, 38400, and 57600

Data bits: 7 (ASCII, required for Modbus ASCII) and 8 (RTU, required for Modbus RTU).

Stop bits: 1, 2

Parity: None, Even, Odd

1

Page 7

FloBoss S600+ Flow Computer Modbus Specification Manual

D301904X012

January 2021

2.4 Types and Capabilities of Serial Ports

The S600+ supports the following serial ports:

Com. Port 1: Reserved for the front panel display and keypad.

Com. Port 2: Reserved for the Config600 interface (actually a Modbus slave link)

Com. Ports 3 and Port 4: Dedicated RS-232 with RTS-CST handshaking capabilities

Com. Ports 5, 6, and 7: RS-485/RS-232 capability. RTS line is controlled automatically by the

P152 module’s UART and rapid turnaround is possible on the 485 links.

Com. Port 8: Reserved for I/O board communications.

Com. Ports 9, 10, 11, and 12: Dedicated RS-485.

3. Network Interface

The S600+ includes two 10 or 100 MB/s, full-duplex Ethernet interfaces. The system firmware

provides a full TCP/IP stack implementation on this interface.

Standard supported features include:

Telnet

FTP

Socket-based Modbus communications

The S600+ supports two gateways, which are configured on NWTK1. The IP addresses of the two

network ports

Supported: 193.195.232.1 / 193.195.230.1

Not supported: 193.195.232.1 / 193.195.232.2

must differ in the third octet:

2

Page 8

4. Modbus

Modbus is the standard interface to the S600+. The protocol is based on Gould/Modicon Modbus.

The Config600 configuration software interfaces to the S600+ using Modbus. The link uses the

special function code 65, with specially defined S600+ sub-functions to provide file transfer,

system edit commands, and other specialized functionality. The S600+ is the slave on this link.

4.1 Configuration

The system firmware supports up to 20 communications links. Links can have individual

configurations or can share common parameters or configuration.

Configuration has two parts:

Link Configuration

This step defines the data link’s port or socket, its master or slave status, and whether it uses

RTU or ASCII. You enter this information using Config600 when the link is initially assigned,

but the link configuration can be modified later if required.

FloBoss S600+ Flow Computer Modbus Specification Manual

D301904X012

January 2021

Map Configuration

This step assigns database points and fields to Modbus coils, inputs, and registers using a

text file created using Config600’s map builder utilities. You can modify this map later if

required.

4.2 Master

In master mode, the device communicates with up to 10 slaves on a single-drop link. You can

configure several masters if necessary.

4.3 Slave

In slave mode, the device waits for polls from an external master and responds to polls are

requested. You can define several slaves if necessary. The slave address is configurable per link, so a

single S600+ can have several slave addresses if required.

3

Page 9

FloBoss S600+ Flow Computer Modbus Specification Manual

D301904X012

January 2021

5. RTU/ASCII Protocol

The S600+ fully supports both RTU Modbus and ACSII Modbus. A single configuration switch

enables you to select one or the other. Other communication parameters exist independently of

the ASCII/RTU switch.

RTU Mode

In RTU mode, you must configure the link for 8 data bits. No message header or trailers are

included. The checksum is the 16-bit CRC specified in the -Modbus specification.

ASCII Mode

In ASCII mode, you would normally configure the link for 7 data bits, although the S600+ also

supports 8 data bits. The message starts with the ASCII Modbus start character (the colon, or

“:”). The checksum is the 8-bit LRC defined in the Modbus specification. The message

terminates with the ASCII Modbus trailer characters CR followed by LF.

4

Page 10

FloBoss S600+ Flow Computer Modbus Specification Manual

Poll Format

Response Format

Note

6. Implemented Modbus Functions

Implemented Modbus functions include:

Function 1: Read Output Status

Function 2: Read Input Status

Function 3: Read Output Registers

Function 4: Read Input Registers

Function 5: Write Single Coil

Function 6: Write Single Register

Function 8: Loopback

Function 15: Write Multiple Coils

Function 16: Write Multiple Registers

D301904X012

January 2021

Function Codes 65, 66, 67, and 68

Each of these functions is described in this section.

Note

These message formats exclude the message header (ASCII only), the CRC/LRC, and message trailer

(ASCII only), since these are specific to the data transfer mode.

6.1 Function 1: Read Output Status

Function Code 01 reads the output coils (00001–09999), reading up to 2040 coils per poll in nonextended mode.

Address 1 byte

Function 1 byte

Start Coil 2 bytes

Num Coils 2 bytes

Address 1 byte

Function 1 byte

Byte Count 1 or 2 bytes

: Byte count may be 8-bit or 16-bit

Data byte 1 1 byte (coils 0–7)

Data byte 2 1 byte (coils8–15)

…

Data byte N 1 byte (coils…)

5

Page 11

FloBoss S600+ Flow Computer Modbus Specification Manual

Poll Format

Response Format

Note

Poll Format

Response Format

Note

D301904X012

January 2021

6.2 Function 2: Read Input Status

Function Code 02 reads the input coils (10001–19999), reading up to 2040 coils per poll in nonextended mode.

Address 1 byte

Function 1 byte

Start Input 2 bytes

Num Inputs 2 bytes

Address 1 byte

Function 1 byte

Byte Count 1 or 2 bytes

: Byte count may be 8-bit or 16-bit

Data byte 1 1 byte (inputs 0–7)

Data byte 2 1 byte (inputs 8–15)

…

Data byte N 1 byte (inputs…)

6.3 Function 3: Read Output Registers

Function Code 03 reads the output registers (40001–49999); data can be configured at every

address.

Address 1 byte

Function 1 byte

Start Item 2 bytes

Num Items 2 bytes

Address 1 byte

Function 1 byte

Length 1 or 2 bytes

: Length can be 8-bit byte count, 8-bit

item count; 16-bit byte count, or 16-bit item

count.

Data item 1 2, 4, or 8 bytes

Data item 2 2, 4, or 8 bytes

…

Data item N 2, 4, or 8 bytes

6

Page 12

FloBoss S600+ Flow Computer Modbus Specification Manual

Poll Format

Response Format

Note

Poll Format

Response Format

6.4 Function 4: Read Input Registers

Function Code 04 reads the input registers (30001–39999); data can be configured at every

address.

Address 1 byte

Function 1 byte

Start Item 2 bytes

Num Items 2 bytes

Address 1 byte

Function 1 byte

Length 1 or 2 bytes

: Length can be 8-bit byte count, 8-bit

item count; 16-bit byte count, or 16-bit item

count. t

Data item 1 2, 4, or 8 bytes

Data item 2 2, 4, or 8 bytes

…

Data item N 2, 4, or 8 bytes

D301904X012

January 2021

6.5 Function 5: Write Single Coil

Function Code 05 writes a single coil, either on (1) or off (0), to any valid coil address (00001–

09999).

Address 1 byte

Function 1 byte

Coil Number 2 bytes

Coil Value 2 bytes

Address 1 byte

Function 1 byte

Coil Number 2 bytes

Coil Value 2 bytes

7

Page 13

FloBoss S600+ Flow Computer Modbus Specification Manual

Poll Format

Response Format

Poll Format

Response Format

D301904X012

January 2021

6.6 Function 6: Write Single Register

Function Code 06 (Modicon) writes a value to a single holding register in standard Modbus format

to any valid holding register address (40001–49999).

Address 1 byte

Function 1 byte

Item Number 2 bytes

Value 2 bytes

Address 1 byte

Function 1 byte

Item Number 2 bytes

Value 2 bytes

Note

The write single register function applies only to simple 16-bit registers. The float and double

formats are

not supported.

6.7 Function 8: Loopback

Function Code 08 performs a loopback test. If successful a loopback test returns the poll received.

There are no variable parameters available on this function code.

Address 1 byte

Function 1 byte

Value 1 2 bytes

Value 2 2 bytes

Address 1 byte

Function 1 byte

Value 1 2 bytes

Value 2 2 bytes

8

Page 14

FloBoss S600+ Flow Computer Modbus Specification Manual

Poll Format

Note

Response Format

Poll Format

Note

Response Format

6.8 Function 15: Write Multiple Coils

Function Code 15 writes multiple coils on (1) or off (2). Enter data as a string of up to 8 digits (0s

and 1s). The RHS entry represents the LSB. Data is written to any valid coil address (00001–09999).

Address 1 byte

Function 1 byte

Start Coil 2 bytes

Num Coils 2 bytes

Byte Count 1 or 2 bytes

: Byte count may be 8-bit byte count or

16-bit byte count.

Data byte 1 1 byte (coils 0–7)

Data byte 2 1 byte (coils 8–15)

…

Data byte N 1 byte (coils….)

D301904X012

January 2021

Address 1 byte

Function 1 byte

Coil Number 2 bytes

Coil Value 2 bytes

6.9 Function 16: Write Multiple Registers

Function Code 16 writes to multiple registers.

Address 1 byte

Function 1 byte

Start Item 2 bytes

Num Items 2 bytes

Byte Count 1 or 2 bytes

: Byte count may be 8-bit byte count or

16-bit byte count.

Data item 1 2, 4, or 8 bytes

Data item 2 2, 4, or 8 bytes

…

Data item N 2, 4, or 8 bytes

9

Address 1 byte

Function 1 byte

Page 15

FloBoss S600+ Flow Computer Modbus Specification Manual

D301904X012

January 2021

Item Number 2 bytes

Num Items 2 bytes

6.10 Function Codes 65, 66, 67, and 68

These are Daniel user-defined function codes, used to read or write multiple holding registers in

IEEE single-precision format. The valid address range is 0–65535; data can be configured at every

address.

Note

The Config600 interface to the S600+ is through Modbus. In this case the link uses the special

function codes 65, 66, 67, and 68, with specially defined (S600+-specific) sub-functions to provide

file transfer, system edit commands and other specialized functionality. The S600+ is the slave on

this link.

10

Page 16

FloBoss S600+ Flow Computer Modbus Specification Manual

7. Message Length Mode

Using standard Modbus, all variable length messages include an 8-bit byte count field which allows

the receiver to determine the amount of data in the message. In some applications, the use of this

field is not the actual byte count but the number of data items in the message. This variation only

applies to register messages.

Emerson has added a further extension to this (primarily for communication with the Daniel DMS

supervisory) which extends this field to a 16-bit value. This simply allows more data to be

transferred on the link.

Note

This functionality does not adhere to strict Modbus functionality.

Available message length modes are:

8-bit byte count

The message contains a single byte, which determines the number of data bytes in the

message.

D301904X012

January 2021

8-bit item count

The message contains a single byte, which determines the number of data items in the

message.

16-bit byte count

The message contains a pair of bytes, which determines the number of data bytes in the

message.

16-bit item count

The message contains a pair of bytes, which determines the number of data items in the

message.

11

Page 17

FloBoss S600+ Flow Computer Modbus Specification Manual

D301904X012

January 2021

8. Register Formats

The Modicon Modbus Protocol Reference Guide (publication PI-MBUS-300, from Modicon, Inc.) does

not specify how numbers greater than 16 bits (that is, 32-bit integers and single- and doubleprecision real numbers) should be transferred.

The Modbus protocol has 16-bit elements (“registers”) that are only suitable for transferring 16-bit

integer data. Since no standard exists, Emerson has developed that following formats to transfers

numerical data to third parties and offers these as a standard solution.

Register – Float

Register – Rosemount

Register – Double

Register – Phillips Float

Register – Phillips Double

Register – Int

Register – Long_Int

Register – Scale 0 NNNN

Register – Modicon

Addresses per item (1, 2, or 4)

Each of these registers is described in this section.

8.1 Register: Float

[FORMAT FLOAT]

[FORMAT ENRON FLOAT]

Holds registers as IEEE format single-precision floating point numbers, MSB first. For each point

required, one address is requested in the Modbus message, 4 bytes are returned, and data is

configurable at every address (40001–49999)

8.2 Register: Rosemount

[FORMAT ROSEMOUNT]

Holds registers as IEEE format single-precision floating point numbers, LSB first (used on

Rosemount DCS system). For each point required, two addresses are requested in the Modbus

message, 4 bytes are returned, and data is configurable at every other address (4000

5,…, 49999).

4000

1, 40003,

12

Page 18

FloBoss S600+ Flow Computer Modbus Specification Manual

8.3 Register: Double

[FORMAT DOUBLE]

Holds registers as IEEE format double precision floating point numbers. For each point required,

one address is requested in the Modbus message, 8 bytes are returned, and data is configurable at

every address (40001 - 49999).

8.4 Register: Phillips Float

[FORMAT PHILLIPS FLOAT]

Holds registers as IEEE format single-precision numbers, MSB first. For each point required, two

addresses are requested in the Modbus message, 4 bytes are returned, and data is configurable at

alternate addresses (40001, 40003 ..... 49999).

8.5 Register: Phillips Double

[FORMAT PHILLIPS DOUBLE]

D301904X012

January 2021

Holds registers as IEEE format double-precision numbers, MSB first. For each point required, four

addresses are requested in the Modbus message, 8 bytes are returned, and data is configurable at

every fourth addresses (40001, 40005, 40009,…, 49997)

8.6 Register: INT

[FORMAT ENRON 16-BIT]

Holds registers as 16-bit SIGNED integers, ranging from 32767 (Hex 8001) to 32767 (Hex 7FFF),

and data can be configured at every address (40001–49999)

8.7 Register: LONG_INT

[FORMAT ENRON 32-BIT]

Holds registers as SIGNED long integers. For each point required one is requested and two registers

(4 bytes) are returned in the Modbus message, and data can be configured at every address (40001,

40002,…, 49999).

8.8 Register: SCALE 0 nnnn

[FORMAT SCALE 0 999]

[FORMAT SCALE 0 4096]

[FORMAT SCALE 0 9999]

Holds registers as integers, scaled between 0 and nnnn. In master mode the value returned is

displayed in terms of the selected scaling (where

9999 scaling), and data can be configured at every address (40001–49999).

13

500 would represent 50% on 999 scaling or 5% on

Page 19

FloBoss S600+ Flow Computer Modbus Specification Manual

+

=

Scale Zero- scale Full

0.5 Range x scale) Zero- value(Actual

Trunc ValueInteger Scaled

[ ]

0003 Integer Scaled

5.07.2999 Trunc

Integer Scaled

1000

0.5 9999 x

0)

-

(300

Trunc Integer Scaled

=

+=

+

=

D301904X012

January 2021

Scaled 16-bit integer between 0…9999 (or any other integer combination), where each real is

scaled within this range based upon preconfigured zero and full scales, such that:

For example, a flow rate of 300 m

The supervisory system would then send 3000 to represent the flow rate of 300 m3/hr if the

integer range was 0–999.

3

/hr has a zero scale of 0 m3/hr and a full scale of 1000 m3/hr:

8.9 Register: Modicon

[FORMAT ENRON 16-BIT]

Holds registers as integers (16-bit, valid data 0 - 65535) using Modbus formatting and writes to any

valid holding register (40001–49999)

14

Page 20

FloBoss S600+ Flow Computer Modbus Specification Manual

Address Descriptions

9. Enron Functions

The Enron Modbus protocol has been implemented as part of the Modbus slave application and is

based on the Specifications and Requirements for an Electronic Flow Measurement Remote Terminal

Unit (07-18-1990, Revised 12-05-1994, Enron Corp.)

9.1 Enron Modbus Map

Detailed below are the data areas defined in the Modbus specification. The S600+ Modbus map

builder generates a map which corresponds to this format. Although not recommended, you can

change these settings when you generate the map or by editing the Modbus configuration file.

Coil data (accessed using Modbus function 1, 5 and 15)

0032 Event log Clear command

1000 Boolean variables

Input data: accessed using Modbus function 2

1000 Boolean variables

Input data: accessed using Modbus functions 3, 4, and 16

0032 Event/Alarm log register (see following sections)

0701…0720 Report log configuration registers (see following sections)

0721…0740 Report log data registers (see following sections)

3000 Short integer variable

5000 Long integer variables (not used on S600+)

7000 Floating point variables

D301904X012

January 2021

9.2 Special Enron Functions for Events

9.2.1 Clear/Acknowledge Modbus Event Log

9.2.2 Event Count Register

15

The Enron implementation provides a special set of registers and coils that allow transfer of alarm

and event log data to a supervisory computer.

The normal base address for this data is 32. A coil write with the data value set to this address clears

the event log. A coil write to this address with the data value clear acknowledges the event log.

The normal base address for this value is 7001. It returns as a floating point value. A register read

from this address returns the number of events available for collection.

Page 21

FloBoss S600+ Flow Computer Modbus Specification Manual

Poll Format

Response Format

Bitmap

Unsigned Short

# Bytes

D301904X012

January 2021

9.2.3 Alarm Count Register

The normal base address for this value is 7002. It returns as a floating point value. A register read

from this address returns the number of alarms available for collection.

9.2.4 Read Modbus Alarm/Event Log Functions

The normal base address for this value is 32. Data returns as a series of registers as described

below.

Address 1 to 2551 byte

Function 31 bytes

Start Item 00322 bytes

Num Items Ignored 2 bytes

Address As poll 1 byte

Function 31 bytes

Length <N x 20> 1 byte

where N is a value up to 12, depending on the

number of events available in the buffer

Num Items 2 bytes

Byte Count 1 or 2 bytes

where N is up to 12, depend: Byte count may

be 8-bit byte count or 16-bit byte count.

Alarm/event 1 See below; 20 bytes

Alarm/event 2 See below; 20 bytes

…

Alarm/event N See below; 20 bytes

16

Each alarm or event consists of:

Data Point ID Unsigned Short 2 bytes

Time Stamp Float 4 bytes

Date Stamp Float 4 bytes

Value 1 Float 4 bytes

Value 2 Float 4 bytes

18 bytes total

Bitmap

Bit 9 of this register determines whether the data is an alarm or an event.

Page 22

FloBoss S600+ Flow Computer Modbus Specification Manual

Bit

Name

Description

1

Bit

Name

Description

D301904X012

January 2021

Event/Change Type Bitmap

0 Fixed value Sets when the keypad (override) value changes

1 Zero scale Sets when the low-scale value of an analog changes

2 Full scale Sets when the full-scale value of an analog changes

3 Operator Entry Work Value Not used

4 Boolean Fixed Bit Not used

5 Fixed/Variable Flag

6 Table Entry Change Not used

7 System Command Change Not used

8 Spare

9 Change/Alarm Flag Sets for event/change; clears for alarm

10 Lolo Limit Sets when the LL limit changes

11 Lo Limit Sets when the L limit changes

12 Hi Limit Sets when the H limit changes

13 Hihi Limit Sets when the HH limit changes

14 Rate of Change limit Sets when the ROC limit changes

15 Spare

if item is in keypad/override mode; 0 if the item is

in live mode

Alarm Type Bitmap

0–8 Not used

9 Change/Alarm Flag Sets for event/change, clears for alarm

10 Lolo Limit Sets when the LL alarm sets or clears

11 Lo Limit Sets when the L alarm sets or clears

12 Hi Limit Sets when the H alarm sets or clears

13 Hihi Limit Sets when the HH alarm sets or clears

14 Rate of Change Limit Sets when the ROC alarm sets or clears

15 Set Reset Alarm 1 for alarm set; 0 for alarm clear

Data Point ID

This is a unique ID number which identifies the data point in the S600+ database.

Time Stamp

This floating point number represents the time associated the alarm or event, valued as:

(1000 x HH) + (100 x mm) + (ss)

Data Stamp

This floating point number represents the date associated the alarm or event, valued as:

(10000 x yy) + (100 x mm) + (dd)

17

Page 23

FloBoss S600+ Flow Computer Modbus Specification Manual

Index

Report

Period

Period

Report Description

D301904X012

January 2021

Value 1 and Value 2

For event/change messages these are old and new values (that is, from/to). For alarm messages,

the current value is in item five and the alarm limit is in item six. Both are floating-point formats.

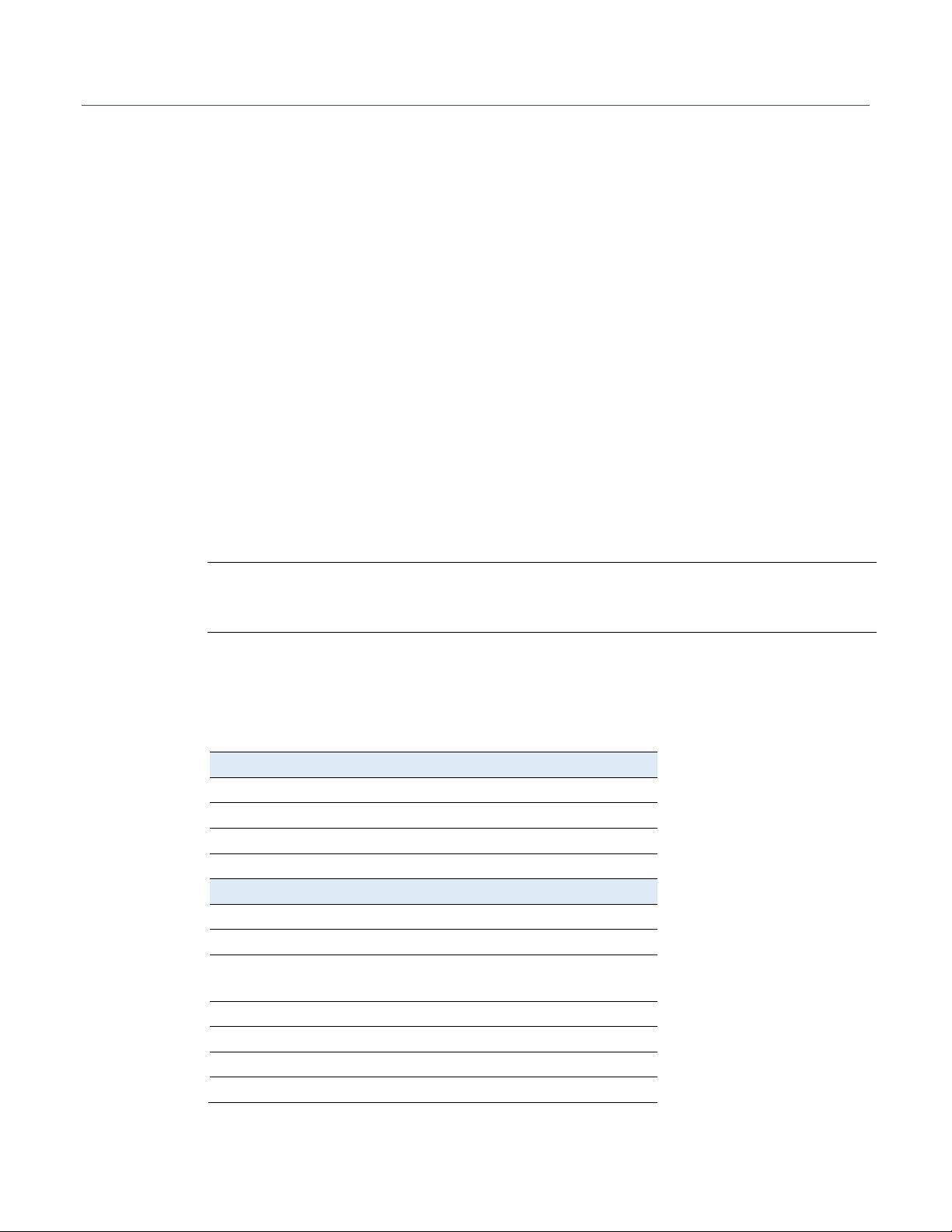

9.3 Special Enron Functions for Data Log Collection

Enron defines a part of registers for reading a pair of report logs from the flow computer. The

S600+ supports this functionality with the following enhancements:

More than two logs are available

The report format can be queried

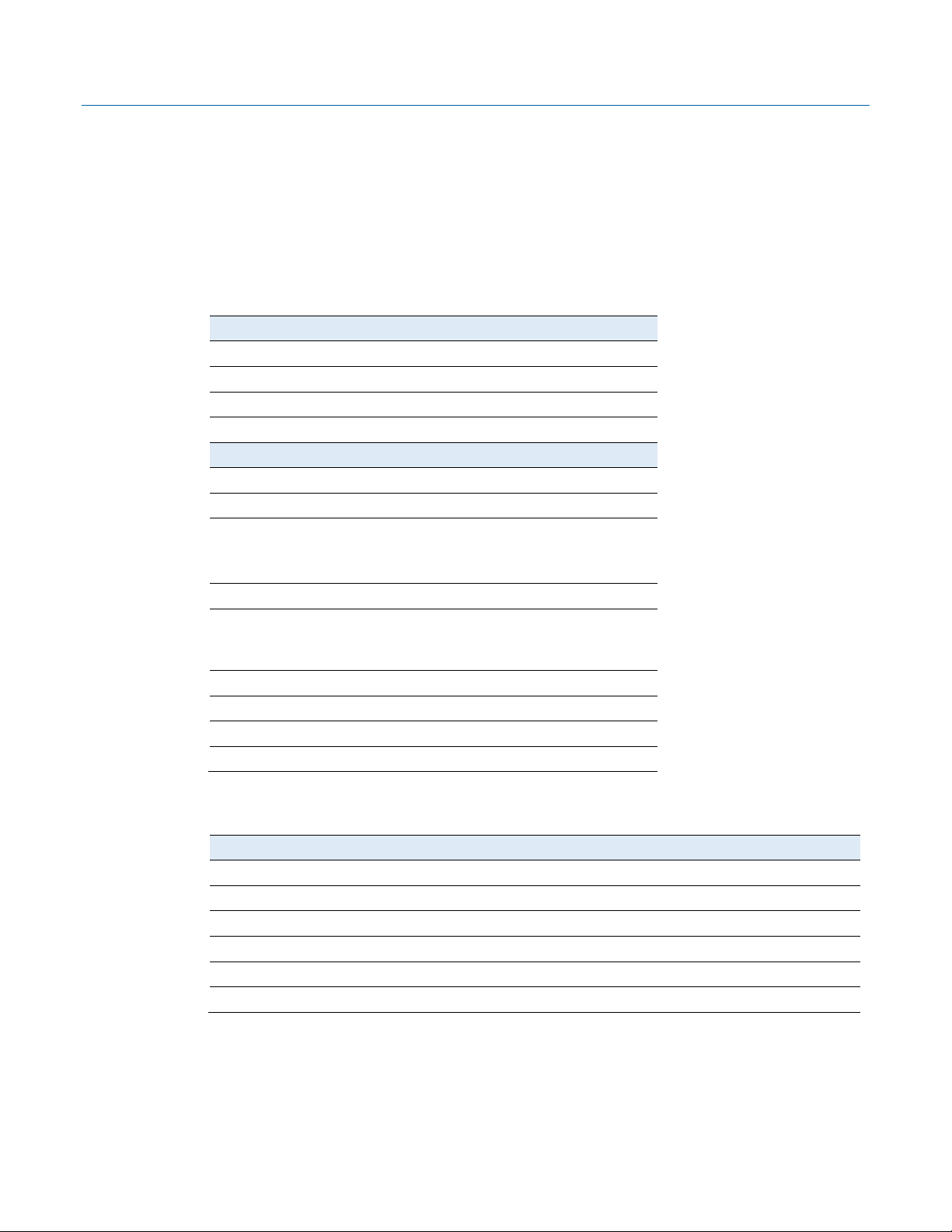

The S600+ supports the following log periods:

1 Fixed Hourly Hourly

2 Maint On demand

3 Batch On demand

4 Basetime 1 period 1 Configurable

5 Basetime 1 period 2 Configurable

6 Basetime 1 period 3 Configurable

7 Basetime 1 period 4 Configurable

8 Basetime 2 period 1 Configurable

9 Basetime 2 period 2 Configurable

10 Basetime 2 period 3 Configurable

11 Basetime 2 period 4 Configurable

12 Basetime 3 period 1 Configurable

13 Basetime 3 period 2 Configurable

14 Basetime 3 period 3 Configurable

15 Basetime 3 period 4 Configurable

16 Proof Report On demand

18

Supported configurable report periods are:

Hourly Shows throughput for the previous hour

2 Hourly Shows throughput for the previous 2 hours

3 Hourly Shows throughput for the previous 3 hours

4 Hourly Shows throughput for the previous 4 hours

6 Hourly Shows throughput for the previous 6 hours

8 Hourly Shows throughput for the previous eight hours

12 Hourly Shows throughput for the previous 12 hours

Daily Shows throughput for the previous day

Page 24

FloBoss S600+ Flow Computer Modbus Specification Manual

Period

Report Description

Poll Format

Response Format

Weekly Shows throughput for the previous week

Monthly Shows throughput for the previous month

Any combination of reports may be active in the S600+ but even if gaps are present, the indices

remain the same.

The Enron specification states that all data is presented in float format. The S600+ uses an

improved method with is a pair of polls for each log. One poll (read configuration) returns the

format of the data in the log, the other poll (read data) return the data in the log, and the items

may be float or long int format.

9.4 Read Report Log Configuration

To read the report log configuration data, you must poll for Modbus registers at one of the

addresses in the Modbus log configuration area of the map. This data is normally placed at register

addresses 701 to 720. Each address corresponds to a particular report period, and the response

defines the format of the report.

D301904X012

January 2021

Address 1 to 2551 byte

Function 31 bytes

Start Item 0701–0720 bytes

Num Items 12 bytes

Address As poll 1 byte

Function 31 bytes

Byte Count <4 x N x 8> 1 byte

where N is a value up to 12, depending on the

number of events available in the buffer

Report Interval Minutes2 bytes

Number of

points

Point 1 data N x 8 bytes (see below)

Point 2 data N x 8 bytes (see below)

…

Point N data N x 8 bytes (see below)

Each data point consists of:

N2 bytes

19

Action Snapshot, Average, or totalize 2 bytes

Data Point ID FloBoss S600+ database

Point id2 bytes

Type 0=long, 1=float2 bytes

Unit Unit index2 bytes

Page 25

FloBoss S600+ Flow Computer Modbus Specification Manual

Poll Format

Note

Response Format

Addr

Function

Addr

Function

D301904X012

January 2021

9.5 Read Report Log Data

To read the actual report log data you must poll for Modbus registers in at one of the addresses

which corresponds to a report log. This data is normally placed at register addresses 721–740. Each

address corresponds to a particular report period, and the response contains the data from the

report.

Address 1 to 2551 byte

Function 31 byte

Start Item 0721–0740 bytes

Num Items Record number2 bytes

: The record number defines which

report to extract from the archive.

Address As poll1 byte

Function 31 byte

Byte Count <4 x N x 8> 1 byte

where N is a value up to 12, depending on the

number of events available in the buffer

Date 10000 x m + 100 x d + y4 bytes float

Time 10000 x h + 100 x m + s4 bytes float

Value 1 First point4 bytes float/long

Value 2 Second point4 bytes float/long

…

Value N Nth point4 bytes float/long

20

Summary of Default Report Config and Data Modbus Addresses

701 Fixed Hourly config 721 Fixed Hourly data

702 Maintenance config 722 Maintenance data

703 Batch config 723 Batch data

704 Base 1 period 1 config 724 Base 1 period 1 data

705 Base 1 period 2 config 725 Base 1 period 2 data

706 Base 1 period 3 config 726 Base 1 period 3 data

707 Base 1 period 4config 727 Base 1 period 1 data

708 Base 2 period 1 config 728 Base 2 period 1 data

709 Base 2 period 2 config 729 Base 2 period 2 data

710 Base 2 period 3 config 730 Base 2 period 3 data

711 Base 2 period 4 config 731 Base 2 period 4 data

Page 26

FloBoss S600+ Flow Computer Modbus Specification Manual

712 Base 3 period 1 config 732 Base 3 period 1 data

713 Base 3 period 2 config 733 Base 3 period 2 data

714 Base 3 period 3 config 734 Base 3 period 3 data

715 Base 3 period 4 config 735 Base 3 period 4 data

716 Proof config 736 Proof data

717 Spare 737 Spare

718 Spare 738 Spare

719 Spare 739 Spare

720 Spare 740 Spare

10. S600+ Modbus Configuration Files

Whenever a Modbus communication task starts, it receives the name of a configuration file. This

file defines the map that links Modbus addresses to S600+ database points.

D301904X012

January 2021

All configuration files are ASCII text files which may be created manually if required. However,

Config600 software program includes Modbus configuration file generators for most common

applications. Always use these file generators. You can then edit the generated files manually.

There are two basic file types, master and slave. Both share many common features, since the slave

configuration file is a subset of the master configuration file. The # symbol is used to indicate a

comment. When a line is read, any characters following a # symbol are ignored. The overall layout

of the configuration files depends on whether the file is for master or slave use:

Format of Master Configuration File

Title

Header Section

Master Section

Slave 1 Data

Slave 2 Data

…

Slave N Data

Format of Slave Configuration File:

Title

Header Section

Slave 1 Data

10.1 Config File Title

This is simply a comment at the start of the file describing its function, version history, etc. The

S600+ ignores this comment.

21

Page 27

FloBoss S600+ Flow Computer Modbus Specification Manual

D301904X012

January 2021

10.1.1 Config File Header

This block, used by both master and slave links, is mandatory. Four commands are supported, all of

which are enclosed in brackets ([]):

[TX BUFF SIZE <NNNN>]

[RX BUFF SIZE <NNNN>]

These lines determine the size in bytes of the message transmit (TX) and receive (RX)

buffers. For normal Modbus operation set them both to

message size Modbus supports. The valid range is 256–65535.

[MSG LENGTH MODE <mode>]

This field determines how the message length part of the Modbus message is handled. The

basic Modbus specification defines this field as a single byte which defines the number of

bytes of data in the message. However, many implementations change this field to be an

item count, i.e. the number of data items in the message.

Additionally, in order to increase the amount of data which may be transferred, the S600+

supports a 16-bit value for this field. This is

only when communicating with the DMS.

not compatible with standard Modbus and is used

256, which is the maximum

The available values for <mode> are:

BYTE_8

•

BYTE_16

•

ITEM_8

•

ITEM_16

•

Note that if either of the 16-bit formats is used, the messages may be longer than 256 bytes

and the tx and rx buffer sizes should be adjusted accordingly.

[CHECKSUM <status>]

This field is used to enable or disable checksum checking on received data. It is intended for

test purposes only. The available values for <status> are

TRUE

•

FALSE

•

Example Header:

[TX BUFF SIZE 256]

[RX BUFF SIZE 256]

[MSG LENGTH MODE BYTE_8]

[CHECKSUM TRUE]

22

Page 28

FloBoss S600+ Flow Computer Modbus Specification Manual

Value

Description

10.2 Config File Master Section

This section is required only for the master task. It defines the master’s poll loop settings, the list of

slave machines with which the master communicates, and a series of polls to perform. Six

commands are supported, all of which are enclosed by brackets ([]):

[POLL DELAY <NNN>]

This specifies the delay between messages (polls). The value is in system ticks (a tick

is 1/60 of a second)

[LOOP DELAY <NNN>]

This specifies the delay at the end of the poll loop (i.e. the time between the last

message and starting the first message again). The value is in system ticks (a tick is

1/60 of a second)

[RETRY LIMIT <NNN>]

This specifies the number of retries the master should perform for a single message

before classing it as failed.

[TIMEOUT <NNN>]

D301904X012

January 2021

This specified the amount of time the master will wait for a response from the slave.

The value is in seconds

[SLAVES <A> <B> <C> <D>]

This command specifies a list of up to 10 slave addresses which the master task will

communicate with.

[SLAVE STATUS OBJ <kp int array number>]

This command is used only by the prover master link and specifies the KPINT_ARRAY

used to indicate the status of the link to each stream. For each stream, the Modbus

master task updates the KPINT_ARRAY with:

0 Link OK

1 Link disabled

2 Telemetry failed

[MESSAGE ADDR:<addr> FUNC:<func> START:<start> NUM:<num> TRIGGER:KPINT <n>]

The message command defines a single message which the master task performs.

Any number of messages may be included. The master task performs the messages

according to their order in the file.

The trigger field is optional. If it is not present, the poll is always performed. If it is

present, the field defines a KPINT object in the database which controls the poll. If

the KPINT object is non-zero, the poll occurs. If the object is zero, the poll does not

occur. The object is set back to zero at the end of the poll loop.

<addr> is the Modbus slave address (0...255)

•

<func> is the Modbus function code code for the message

•

<start> is the data start address for the message

•

<num> is the number of data items in the message

•

23

Page 29

FloBoss S600+ Flow Computer Modbus Specification Manual

D301904X012

January 2021

<n> is the database index for the KPINT object used to control the poll

•

Example Master Section

# MASTER SECTION

[POLL DELAY 5]

[LOOP DELAY 5]

[RETRY LIMIT 3]

[TIMEOUT 5]

# LIST OF SLAVES

[SLAVES 1]

# SLAVE STATUS OBJECT

[SLAVE STATUS OBJ 22]

# NORMAL POLLS

[MESSAGE ADDR:1 FUNC:03 START:9000 NUM:9]

[MESSAGE ADDR:1 FUNC:03 START:9020 NUM:7]

[MESSAGE ADDR:1 FUNC:16 START:9009 NUM:2]

[MESSAGE ADDR:1 FUNC:16 START:9027 NUM:3]

# END OF MASTER SETTINGS

10.3 Config File Slave N Section

Each slave to which the master talked requires a slave data block. The block starts with the

command:

[SLAVE ADDRESS <N>]

<N> can be any valid Modbus slave address value (from1 to 255).

Following this statement is the data map for the slave.

10.4 Config File Data

This section applies to both master and slave links. It defines the relationship between Modbus

addresses and S600+ database points.

The slave has a single map section, while the master can have up to 10 slave sections, each of which

is preceded by the [SLAVE ADDRESS N] command. The map is sub-divided into coil, input, and

register sections, each of which forms independent blocks of data. Within each of these blocks

there may be any number of further sub-blocks.

The map section has these major blocks:

[SECTION COILS]

Indicate the start of the Modbus coil data.

24

[SECTION INPUTS]

Indicate the start of the Modbus input data.

[SECTION REGISTERS]

Indicate the start of the Modbus register data.

Page 30

FloBoss S600+ Flow Computer Modbus Specification Manual

10.5 Config File Data Coil

The coil section can contain any number of blocks of coil data. Each block starts with the

command:

[BASE ADDRESS <NNNN>]

This command determines the base address of the block of data. <NNNN> must be in the

range 0–65535. The base address command is followed by a list of data points each of which

must occupy successive coil addresses. Each of these commands is a discrete data base point

identifier.

10.6 Config File Data Input

The input section can contain any number of blocks of coil data. Each block starts with the

command:

[BASE ADDRESS <NNNN>]

This command determines the base address of the block of data. <NNNN> must be in the

range 0–65535. The base address command is followed by a list of data points, each of

which must occupy successive input addresses.

D301904X012

January 2021

Each of these commands is a discrete data base point identifier.

10.7 Config File Data Registers

The register section can contain any number of blocks of register data. The way in which data is

packed into registers is controlled by three commands:

[BASE ADDRESS <NNNN>]

This command determines the base address of the block of data. It is followed by a list of

data points each of which must occupy successive registers.

0–65535.

[FORMAT <format>]

Each block of register data can represent numeric data in a different format.

Register addressing is probably the most confusing aspect of configuring a Modbus link. The

original Modbus specification defines a register as a 16-bit integer value. Strictly speaking,

this is the only supported register data format. However, most users map a value over

several registers so that a single data item occupies 1, 2, or 4 registers (respectively 2, 4, or 8

bytes). Using this mechanism, you can pack longer integers, floats, or doubles into the

Modbus message.

<NNNN> must be in the range

Supported formats are:

SCALE

•

SCALE 0 999

•

SCALE 0 4096

•

SCALE 0 9999

•

25

Page 31

FloBoss S600+ Flow Computer Modbus Specification Manual

D301904X012

January 2021

FLOAT

•

DOUBLE

•

ENRON 16 BIT

•

ENRON 32 BIT

•

ENRON FLOAT

•

ROSEMOUNT

•

PHILLIPS FLOAT

•

PHILLIPS DOUBLE

•

[ADDRESSES PER ITEM <N>]

This command determines the number of Modbus addresses which each data item

corresponds to. For 16-bit (2 byte) data it is

data it controls the way Modbus register addressing is performed. It is closely related to the

FORMAT command (or more accurately the number of bytes per data item) and the number

of addresses field contained in the poll.

If the data is 32-bit, the number of addresses per item must be set to either 1 or 2. If the

value is set to

(that is, the number of 32-bit entities)

number of addresses per item is

number of Modbus registers

1, the number of addresses contained in the poll is the number of data items

2, the number of addresses contained in the poll is the

always 1. For 32-bit (4 byte) and 64-bit (8 byte)

rather than the number of Modbus registers. If the

If the data is 64-bit, the number of addresses per item must be set to either 1 or 4. If the

value is set to

(that is, the number of 64-bit entities) rather than the number of Modbus registers. If the

number of addresses per item is

number of Modbus registers.

ADDRESSES PER ITEM may be set to –1 for some special data formats. This informs the

Modbus message building code to ignore the number of registers requested. It is typically

used for Enron report data (where the number of registers is used to define the report

number, but the number of registers to be transmitted is actually determined by the report

layout).

Combinations of FORMAT and ADDRESSES PER ITEM commands should support the most

commonly used register formats. The ADDRESSES PER ITEM command must be followed by a list of

data points, each of which must occupy successive register addresses.

Each of these commands is a numeric data base point identifier.

1, the number of addresses contained in the poll is the number of data items

4, the number of addresses contained in the poll is the

10.8 Discrete Data Point Format

All the data that makes up a block is defined using a series of consecutive lines in the configuration

file which refer to objects in the S600+ database. Each line represents a point in the database. You

can add any number of lines to a block. Each block refers to successive coils or inputs.

26

The format of the line is:

<OBJECT_TYPE> <OBJECT_INDEX> <OBJECT_FIELD> < OBJECT_BITNO>

for example:

Page 32

FloBoss S600+ Flow Computer Modbus Specification Manual

ADC 3 MEASURED 0

<OBJECT_TYPE>, <OBJECT_INDEX>, and <OBJECT_FIELD> define a unique point in the database

using the object naming format used by the reports, display and communication configuration

files. <OBJECT_BITNO> is the bit within the specified database point which is mapped to the coil or

input.

See the example slave configuration file for many examples of the format used.

10.9 Numeric Data Point Format

The data which makes up a block is defined using a series of consecutive lines in the configuration

file which refer to objects in the S600+ database. Each line represents a point in the database. You

can add any number of lines to a block. Each block refers to successive registers.

The format of the line is:

<OBJECT_TYPE> <OBJECT_INDEX> <OBJECT_FIELD>

for example:

D301904X012

January 2021

CALCALMITEM 26 INUSE # [MASS-FR)

<OBJECT_TYPE>, <OBJECT_INDEX>, and <OBJECT_FIELD> define a unique point in the database

using the object naming format used by the reports, display and communication configuration

files.

See the example slave configuration file for many examples of the format used.

27

Page 33

FloBoss S600+ Flow Computer Modbus Specification Manual

D301904X012

January 2021

28

Page 34

FloBoss S600+ Flow Computer Modbus Specification Manual

For customer service and technical support,

Global Headquarters,

North America, and Latin America:

products at any time without notice. All sales are governed

RAS accepts no responsibility

Europe:

Middle East/Africa:

Asia-Pacific:

D301904X012

January 2021

visit www.Emerson.com/SupportNet.

Emerson Automation Solutions

Remote Automation Solutions

6005 Rogerdale Road

Houston, TX 77072 U.S.A.

T +1 281 879 2699 | F +1 281 988 4445

www.Emerson.com/RemoteAutomation

Emerson Automation Solutions

Remote Automation Solutions

Unit 1, Waterfront Business Park

Dudley Road, Brierley Hill

Dudley DY5 1LX UK

T +44 1384 487200 | F +44 1384 487258

Emerson Automation Solutions

Remote Automation Solutions

Emerson FZE

P.O. Box 17033

Jebel Ali Free Zone – South 2

Dubai U.A.E.

T +971 4 8118100 | F +971 4 8865465

Emerson Automation Solutions

Remote Automation Solutions

1 Pandan Crescent

Singapore 128461

T +65 6777 8211| F +65 6777 0947

© 2021 Remote Automation Solutions, a business unit of Emerson Automation Solutions.

All rights reserved.

This publication is for informational purposes only. While every effort has been made to

ensure accuracy, this publication shall not be read to include any warranty or guarantee,

express or implied, including as regards the products or services described or their use or

applicability. Remote Automation Solutions (RAS) reserves the right to modify or improve

the designs or specifications of its

by RAS terms and conditions which are available upon request.

for proper selection, use or maintenance of any product, which remains solely with the

purchaser and/or end-user.

Remote Automation Solutions

Loading...

Loading...