Page 1

Part Number D301150X412

January 2021

™

FloBoss

S600+ Flow Computer

Instruction Manual

Remote Automation Solutions

Page 2

S600+ Instruction Manual

Device Safety Considerations

Reading these Instructions

Before operating the device, read these instructions carefully and und erstand their safety implications. In some

situations, improperly using t his device may result in damage or injury. Keep this manual in a convenient location

for future reference. Note that these instructions may not cover all details o r variations in equipment or cover every

possible situation regarding installation, operation, or maintenance. Should problems arise that are not covered

sufficiently in the text, immediately contact Customer Support for f urther information.

Protecting Operating Processes

A failure of this device – for whatever reason -- may leave an operating proces s without appropriate protection and

could result in possible damage to property or injury to persons. To protec t against this, you should review the

need for additional backup equipm ent or provide alternate means of protection (such as alarm devices, output

limiting, fail-safe valves, relief valves , emergency shutoffs, emergency switches, etc.). Contact Remote Autom ation

Solutions for additional inform ation.

Returning Equipment

If you need to return any equipment t o Remote Automation Solutions, it is y our responsibility to ensure that the

equipment has been cleaned to safe lev els, as defined and/or determined by applicable federal, state and/or local

law regulations or codes. You als o agree to indemnify Remote Automation Solutions and hold Remote Automation

Solutions harmless from any liability or damage which Remote Automation Sol utions may incur or suffer due to

your failure to ensure device cleanliness.

Grounding Equipment

Ground metal enclosures and exposed metal parts of electrical instruments in accordance with OSHA rules and

regulations as specified in Design Safety Standards for Electrical Systems, 29 CFR, Part 1910, Subpart S, dated:

April 16, 1981 (OSHA rulings are in agr eement with the National Electrical C ode). You must also ground

mechanical or pneumatic instrument s that include electrically operated devices such as lights, switches, relays ,

alarms, or chart drives.

Important: Complying with the codes and regulations of authorities having jurisdiction is e s sential to ensuring

personnel safety. The guidelines and r ecommendations in this manual are i ntended to meet or exceed applicable

codes and regulations. If differences occur between this manual and t he c odes and regulations of authorities

having jurisdiction, those codes and regulations must take precedence.

Protecting from Electrostatic Discharge (ESD)

This device contains sensitive elec tronic components which be damaged by exposure to an ESD voltage.

Depending on the magnitude and durat ion of the ESD, it can result in erratic operation or complete failure of the

equipment. Ensure that you correct ly care for and handle ESD-sensitive components.

System Training

A well-trained workforce is critical t o the success of your operation. Knowing ho w to correctly install, configure,

program, calibrate, and trouble-shoot your Emerson equipment provides y our engineers and technicians with the

skills and confidence to optimize y our investment. Remote Automation Solutions offers a variety of ways for your

personnel to acquire essential system expertise. Our full-time prof es sional instructors can conduct cl as sroom

training at several of our corporate offices, at your site, or even at your re gional Emerson office. You can also

receive the same quality training via our live, interactive Emerson Virtual Classroom and save on travel costs. For

our complete schedule and further i nformation, contact the Remote Autom ation Solutions Training Depar tment at

800-338-8158 or email us at education@emerson.com

.

Ethernet Connectivity

This automation device is intende d to be used in an Ethernet network which does not have public access. The

inclusion of this device in a publicly ac cessible Ethernet-based network is not recommended.

ii Revised January-2021

Page 3

S600+ Instruction Manual

Contents

Chapter 1 – General Information 1-1

1.1 Scope of Manual .............................................................................................................. 1-1

1.2 FloBoss S600+ Flow Computer ....................................................................................... 1-2

1.3 Config600 Configuration Software ................................................................................... 1-5

1.3.1 Config600 Lite ...................................................................................................... 1-6

1.3.2 Config600 Lite Plus .............................................................................................. 1-7

1.3.3 Config600 Pro ...................................................................................................... 1-7

1.4 Additional Technical Information ...................................................................................... 1-9

1.4.1 Open Source Software ......................................................................................... 1-9

Chapter 2 – Installation 2-1

2.1 Preparing for Installation .................................................................................................. 2-1

2.2 Environmental Considerations ......................................................................................... 2-2

2.3 Required Tools for Installation ......................................................................................... 2-2

2.4 Installing the S600+ .......................................................................................................... 2-3

2.4.1 Unpacking the S600+ ........................................................................................... 2-3

2.4.2 Removing the Front Panel ................................................................................... 2-3

2.4.3 Installing the Panel-Mounted Unit ........................................................................ 2-6

2.4.4 Reinstalling the Front Panel ................................................................................. 2-8

2.5 Installing and Removing Modules .................................................................................... 2-8

2.6 Installing EMC Protection ............................................................................................... 2-10

Chapter 3 – CPU Module 3-1

3.1 CPU Module (P152) ......................................................................................................... 3-1

3.2 Power Supply ................................................................................................................... 3-4

3.2.1 Watchdog Relay ................................................................................................... 3-4

3.2.2 On-Board Battery Backup .................................................................................... 3-4

3.3 Communication Ports ....................................................................................................... 3-5

3.3.1 RS-232 Serial Port ............................................................................................... 3-6

3.3.2 RS-422/RS-485 Multi-drop Port ........................................................................... 3-7

3.3.3 Ethernet LAN Ports .............................................................................................. 3-7

3.3.4 Local Operator PC or Remote Display Port ......................................................... 3-8

3.4 CPU Connectors and Jumpers ........................................................................................ 3-9

3.5 USB Port ........................................................................................................................ 3-10

3.6 Additional Technical Information .................................................................................... 3-10

Chapter 4 – Input/Output (I/O) 4-1

4.1 I/O Module (P144) ............................................................................................................ 4-1

4.1.1 Analogue Inputs (ANIN) ....................................................................................... 4-3

4.1.2 Analogue Outputs (DAC) ..................................................................................... 4-5

4.1.3 Digital Inputs (DIGIN) ........................................................................................... 4-6

4.1.4 Digital Outputs (DIGOUT) .................................................................................... 4-8

4.1.5 Turbine Pulse Inputs ............................................................................................ 4-9

4.1.6 Pulse Outputs (PULSEOUT) .............................................................................. 4-10

4.1.7 Raw Pulse Output (RAWOUT) ........................................................................... 4-11

4.1.8 Frequency Inputs ............................................................................................... 4-12

4.1.9 PRT/RTD Inputs ................................................................................................. 4-13

4.1.10 Jumper Settings ................................................................................................. 4-14

4.2 Prover Module (P154) .................................................................................................... 4-16

4.2.1 Digital Inputs (DIGIN) ......................................................................................... 4-18

4.2.2 Digital Outputs (DIGOUT) .................................................................................. 4-20

Revised January-2021 Contents iii

Page 4

S600+ Instruction Manual

4.2.3 Turbine Pulse Inputs .......................................................................................... 4-21

4.2.4 Pulse Outputs (PULSEOUT) .............................................................................. 4-22

4.2.5 Frequency Inputs ............................................................................................... 4-22

4.2.6 Raw Pulse Output (RAWOUT) ........................................................................... 4-23

4.2.7 Jumper Settings ................................................................................................. 4-24

4.3 HART Module (P188) ..................................................................................................... 4-24

4.4 Mezzanine Module (P148) ............................................................................................. 4-27

Chapter 5 – Front Panel 5-1

5.1 Description ........................................................................................................................5-1

5.2 Front Panel Port ................................................................................................................5-2

5.3 Keypad ..............................................................................................................................5-2

5.3.1 Function Keys (F1 - F4) ........................................................................................5-2

5.3.2 Direction and Menu Keys ......................................................................................5-3

5.3.3 Numeric Keys ........................................................................................................5-3

5.3.4 Operation Keys .....................................................................................................5-3

5.3.5 Alarm LED and Alarm Keys ..................................................................................5-4

5.4 LCD Display ......................................................................................................................5-4

5.5 Navigating the Displays .....................................................................................................5-6

5.5.1 DISP Key ...............................................................................................................5-8

5.5.2 Moving Through the Menus ..................................................................................5-8

5.5.3 Menu Hierarchy .....................................................................................................5-9

5.5.4 Security Codes ......................................................................................................5-9

5.6 Changing a Display Option ...............................................................................................5-9

5.7 Changing a Display Value .............................................................................................. 5-10

5.8 Changing a Calculation Mode ........................................................................................ 5-11

5.9 Assigning a Default Page ............................................................................................... 5-11

5.10 Assigning a Page to a Function (F) Key ........................................................................ 5-12

5.11 Using the Exponential (EXPT) Key ................................................................................ 5-12

5.12 Using the Print Key ........................................................................................................ 5-13

5.13 Enabling USB ................................................................................................................. 5-14

5.14 Exporting Reports (USB) ................................................................................................ 5-14

5.15 Selecting a Configuration ............................................................................................... 5-16

Chapter 6 – Webserver Access 6-1

6.1 Defining Webserver Access ..............................................................................................6-1

6.2 Accessing the S600+ ........................................................................................................6-2

6.3 Navigating the Webserver Interface ..................................................................................6-4

Chapter 7 – Startup 7-1

7.1 Starting the S600+ ............................................................................................................7-1

7.2 Warm Start ........................................................................................................................7-1

7.3 Cold Start ..........................................................................................................................7-2

7.3.1 Initiating a Cold Start .............................................................................................7-2

7.4 Startup Menu .....................................................................................................................7-3

7.4.1 Network Setup .......................................................................................................7-4

7.5 Messages ..........................................................................................................................7-7

Chapter 8 – Troubleshooting 8-1

8.1 Guidelines .........................................................................................................................8-1

8.2 Checklists ..........................................................................................................................8-2

8.2.1 Power Issues .........................................................................................................8-2

8.2.2 Startup Menu .........................................................................................................8-2

8.2.3 Front Panel Lighting ..............................................................................................8-2

8.2.4 Front Panel LED ....................................................................................................8-2

8.2.5 I/O LED .................................................................................................................8-3

8.2.6 I/O Fail Messages .................................................................................................8-3

iv Contents Revised January-2021

Page 5

S600+ Instruction Manual

8.2.7 Serial Communications ........................................................................................ 8-3

8.3 Procedures ....................................................................................................................... 8-3

8.3.1 Reflash Firmware ................................................................................................. 8-4

8.3.2 Send and Reflash the Config File ........................................................................ 8-4

8.3.3 Clear SRAM ......................................................................................................... 8-5

8.3.4 Changing the Fuse ............................................................................................... 8-6

Appendix A – Glossary A-1

Appendix B – Front Panel Navigation B-1

B.1 Main Menu ........................................................................................................................ B-2

B.2 Flow Rates Menu ............................................................................................................. B-2

B.3 Totals Menu ...................................................................................................................... B-3

B.4 Operator Menu ................................................................................................................. B-4

B.5 Plant I/O Menu ................................................................................................................. B-5

B.6 System Settings Menu ..................................................................................................... B-5

B.7 Tech/Engineer Menu ........................................................................................................ B-6

B.8 Calculations Menu ............................................................................................................ B-7

Index I-1

Revised January-2021 Contents v

Page 6

S600+ Instruction Manual

[This page is intentionally left blank.]

vi Contents Revised January-2021

Page 7

Chapter 1 – General Information

Chapter

Contents

Chapter 3

Describes the use of the communications and power

In This Chapter

1.1 Scope of Manual ................................................................................... 1-1

1.2 FloBoss S600+ Flow Computer ............................................................ 1-2

1.3 Config600 Configuration Software ........................................................ 1-5

1.3.1 Config600 Lite ........................................................................ 1-6

1.3.2 Config600 Lite Plus ................................................................ 1-7

1.3.3 Config600 Pro ........................................................................ 1-7

1.4 Additional Technical Information .......................................................... 1-9

1.4.1 Open Source Software ........................................................... 1-9

This manual covers the installation and startup procedures (including

basic maintenance, operation, and troubleshooting) for the FloBoss™

S600+ flow computer (the “S600+”). For information about

Config600™, the PC-based configuration software for the S600+, refer

to the Config600 Software User Manual (Part D301220X412).

S600+ Instruction Manual

This manual focuses on the S600+, the enhanced version of the S600

with a new CPU module. Refer to technical specification FloBoss

S600+ Flow Computer (S600+) for technical information.

Note: Use of this equipment in a manner not specified by Remote

This chapter details the structure of this manual and provides an

overview of the S600+ and its components.

1.1 Scope of Manual

This manual contains the following chapters:

Automation Solutions may impair the protections the

equipment provides.

Chapter 1

General Information

Chapter 2

Installation

Provides an overview of the S600+ and its

configuration software (Config 600).

Provides instructions on installing the S600+

housing, as well as installation preparation and

panel mounting procedures. This chapter also

describes the installation and removal of the plug-in

modules.

CPU

Chapter 4

Input/Output (I/O)

Chapter 5

Front Panel

Revised January-2021 General Information 1-1

connector blocks, field wiring configurations, and

jumper settings for the CPU module.

Describes the use of the plug-in connector blocks,

field wiring configurations, and bit link setti ngs f or

the I/O modules.

Describes the front panel keypad, communications

port, and display area. This chapter also shows how

you access the S600+ through the front panel

display, including keypad functions, screen di splays,

display navigation basics, data entry, and report

printing.

Page 8

S600+ Instruction Manual

Chapter 7

Describes how to initiate a warm or cold system

Appendix A

Provides definitions for pertinent terms and

Appendix C

Describes the operation of the gas chromatograph

Chapter Contents

Chapter 6

Webserver Access

Provides instructions on accessing the S600+

through a webserver interface, including

descriptions of screen displays and interface

navigation basics.

Startup

Chapter 8

Troubleshooting

Glossary

Appendix B

Front Panel Display

Navigation

Chromatographs

Index Provides an alphabetic listing of items and topics

1.2 FloBoss S600+ Flow Computer

start.

Provides maintenance and troubleshooting

procedures, including basic board-level test

procedures.

acronyms.

Lists the front panel display screens; provides a

navigation reference.

software application module for the S600+.

contained in this manual.

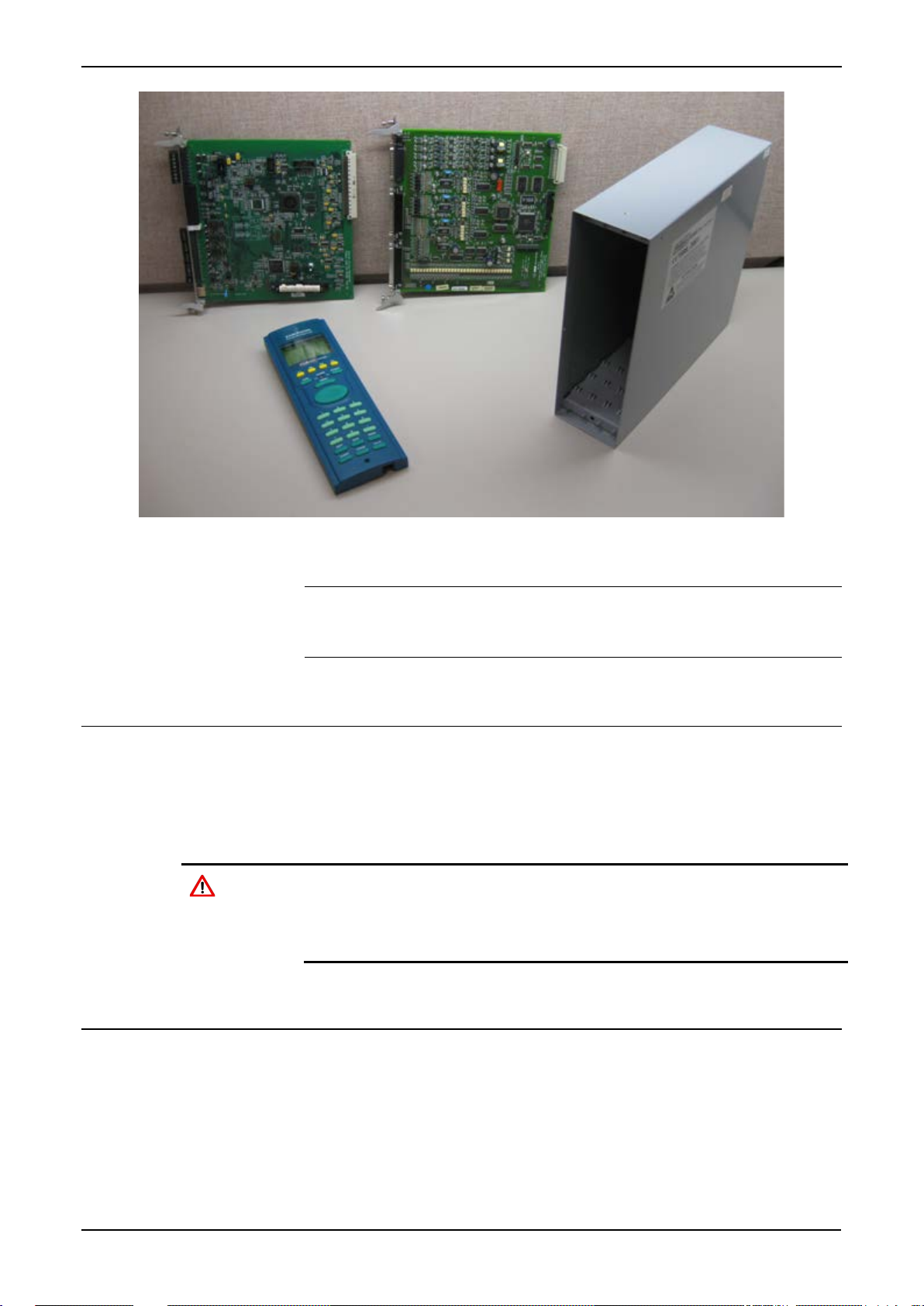

Figure 1-1. The FloBoss S600+ Flow Computer

The FloBoss S600+ Flow Computer is a panel-mounted (for indooruse) flow computer designed specifically to measure hydrocarbon

liquid and gas where versatility and accuracy matter. The standard

features of the S600+ make it ideal for fiscal measurement, custody

transfer, batch loading, and meter proving applications. The S600+

allows you to configure multi-stream, multi-station applications,

enabling you to simultaneously meter liquids and gasses.

The S600+ is designed for use either as a stand-alone flow computer or

as a system component. The intelligent I/O modules fit both gas and

liquid applications and typically support two dual-pulsed streams and a

header. Adding I/O modules (up to a maximum of three) allows you to

configure up to six dual-pulsed streams or up to 10 single-pulsed

streams and two headers. The S600+ supports orifice, ultrasonic,

1-2 General Information Revised January-2021

Page 9

S600+ Instruction Manual

turbine, positive displacement, Coriolis, Annubar, and V-Cone® flow

meter types and master meter, small volume compact, and pipe (both

bi-directional and uni-directional) proving methods.

The S600+ offers a variety of communication interfaces:

Two LAN ports (on the enhanced CPU module) for Ethernet

10Base-T or 100Base-T full-duplex connectivity (using either

Modbus TCP or Modbus over Ethernet protocols).

Note: The Ethernet module (P190), which provided an additional

Ethernet port for previous versions of the S600, is not

compatible with the S600+.

HART® communication using up to two 12-channel HART

modules, each of which supports point-to-point and multi-drop

architectures for up to 50 transmitters.

Note: The FloBoss S600+ is fully compatible with HART 5

devices, and HART 7 devices are backwards compatible

with HART 5 devices.

An embedded webserver allows remote access to the flow

computer. Security is provided using user name and password

protection with a detailed event log for audit purposes (supports

Windows® Internet Explorer® Version 5 or greater).

Two configurable RS-232 serial ports.

Three RS-422/RS-485 serial ports (supporting up to 57,600 bps

baud) and up to four RS-485 2-wire serial ports (supporting up to

57,600 baud rate) for connection to intelligent meters, Modbus

SCADA data networks, DCS supervisory systems, and so on.

One dedicated configuration port (located on the bottom of front

display panel) for connection to the Config 600 configuration

software.

Additional communications interfaces include:

• Serial Q.Sonic®

• Serial printer

• Serial or Modbus TCP Daniel chromatograph via Modbus

• Serial peer-to-peer

• Modbus EFM protocol, Modbus RTU, Modbus ASCII, Modbus

over Ethernet, and Modbus TCP

Miscellaneous interfaces which can operate via serial or Modbus

TCP:

Daniel liquid ultrasonic

Daniel gas ultrasonic

Sick ultrasonic

Daniel chromatograph

Revised January-2021 General Information 1-3

Page 10

S600+ Instruction Manual

Note: All ports can connect to DCS systems, ultrasonic meters,

Coriolis meters, and so on.

The S600+ uses distributed processing to achieve maximum

performance. The CPU module incorporates a hardware floating point

processor. Each additional module also has local processing to convert

inputs and output from engineering units to field values and vice-versa,

as well as running background tests and PID loops.

The firmware uses 64-bit (double) precision floating point numbers for

the highest accuracy when performing all metering calculations.

Cumulative totals are stored in three separate memory locations (Trireg format) for maximum integrity. The user language LogiCalc™ also

allows you to perform logical control and double-precision

mathematical functions on the database objects.

Figure 1-2. CPU Module

1-4 General Information Revised January-2021

Page 11

Figure 1-3. Intelligent I/O Module

Front Display

The S600+’s front panel interface enables you to manage an existing

S600+ Instruction Manual

Panel

configuration or create a configuration using the PC-based Config 600

configuration software.

A communications port on the bottom of the panel provides a way to

directly connect to a PC. The front panel interface consists of a backlit

LCD display, a 29-button keypad, and an alarm status LED (see Figure

1-4).

Figure 1-4. Front Display Panel

1.3 Config600 Configuration Software

Using Config 600, you can both send (upload) new or modified

configurations to the S600+ and receive (download) existing

Revised January-2021 General Information 1-5

Page 12

S600+ Instruction Manual

IPL600

Remote Automation Solutions provides a separate utility program

configurations from the S600+. You can also define the following

functions:

Stream and station totalisation.

Batch totalisation and correction.

Three-term PID control.

Flow balancing.

Flow scheduling.

Automatic proving sequence.

K-factor or meter factor linearisation.

Valve monitor/control.

Sampler control.

Station densitometer.

Station gas chromatograph.

Forward, reverse, and premium error totals.

Comprehensive maintenance mode.

Reporting.

Modbus.

Modify display matrix.

Config600 is a suite of software editors that enables you to monitor,

configure, and calibrate the S600+. The software comes in three

versions – Config600 Lite, Config600 Lite Plus, and Config600 Pro –

with Config600 Pro being the most powerful version.

Note: The S600+ does not operate until you send a configuration to it

from the host PC.

called “Interactive Program Loader 600” (or “IPL600”).

Using IPL600 and an IP or a dedicated serial port connection between

a host PC and an S600+, you can transfer and receive configuration

files (reports, Modbus configurations, customised displays, and

LogiCalc programs). While included as the Config Transfer utility in

Config600, IPL600 has a standalone use for situations when you do not

need the full functionality of Config600. Details on using Config

Transfer/IPL600 are provided in the Config600 Software User Manual

(Part D301220X412).

1.3.1 Config600 Lite

Use the Config 600 Lite software editor suite to modify pre-developed

configurations, transfer existing configurations, edit items on the front

panel display, and customise reports.

Note: You typically use Config600 Lite to custom-configure a new

S600+ during installation.

With Config600 Lite you can:

1-6 General Information Revised January-2021

Page 13

Edit process configuration data, including orifice size, analog input

scaling, alarm limits, and keypad values.

Build and customise Modbus slave maps, Modbus master polling

sequences, front panel displays, and period report formats.

Customise the alarm system, including alarm groups, suppression,

and inhibits.

Configure system security by setting user names and passwords,

and assigning access levels for each data object on the displays.

Specify the engineering units and totalisation rollover value.

Reflash the CPU module firmware with software upgrades and

transfer configurations via the Config Transfer utility (IPL600).

1.3.2 Config600 Lite Plus

The Config600 Lite Plus software editor suite provides all the

functionality of the Config600 Lite suite, but adds the ability to create

a configuration file.

With Config600 Lite Plus you can:

S600+ Instruction Manual

Create a new application from base templates for gas, liquid, and

prover applications.

Edit process configuration data, including orifice size, analog input

scaling, alarm limits, and keypad values.

Build and customise Modbus slave maps, Modbus master polling

sequences, front panel displays, and period report formats.

Customise the alarm system, including alarm groups, suppression,

and inhibits.

Configure system security by setting user names and passwords,

and assigning access levels for each data object on the displays.

Specify the engineering units and totalisation rollover value.

Reflash the CPU module firmware with software upgrades and

transfer configurations via the Config Transfer utility (IPL600).

1.3.3 Config600 Pro

Use the Config600 Pro software editor suite to create new

configurations, modify existing configurations, transfer existing

configurations, edit items on the front panel display, and edit custom

reports.

With Config600 Pro you can:

Create a new application from base templates for gas, liquid, and

prover applications.

Edit process configuration data, including orifice size, analog input

scaling, alarm limits, and keypad values.

Build and customise Modbus slave maps, Modbus master polling

sequences, front panel displays, and period report formats.

Specify the engineering units and totalisation rollover value.

Revised January-2021 General Information 1-7

Page 14

S600+ Instruction Manual

Customise the alarm system, including alarm groups, suppression,

text, and inhibits.

Configure system security by setting user names and passwords,

and assigning access levels for each data object.

Add and remove objects from the database.

Program special features using LogiCalc.

Reflash the CPU module firmware with software upgrades and

transfer configurations via the Config Transfer utility (IPL600).

Note: To obtain a Config600 Pro license you must first attend and

successfully complete a training course.

1-8 General Information Revised January-2021

Page 15

1.4 Additional Technical Information

Name

Form Number

Part Number

FloBoss™ S600+ Flow Computer

S600+

D301151X412

Config600™ Configuration Soft ware

Config600

D301164X012

Config600™ Configuration Software User Manual

A6169

D301220X412

Refer to the following technical documents (available at

www.EmersonProcess.com/Remote) for additional and most-current

information.

Table 1-1. Related Technical Information

1.4.1 Open Source Software

The FloBoss S600+ contains open source software covered by the

GPL, GPL2, GPL3, LGPL, OpenSSL, SSLeay, zlib, libzip2, and

Apache open source software licenses. The specific software being

used is U-Boot, the Linux kernel, glibc, Apache web server, mod_sll,

mod_alias, mod_rewrite, OpenSSL, BusyBox, ntpclient, tar32, and

JFFS2. These licenses are contained on the S600+ Open Source

Software CD (part number S600SRCOPEN). Source code is available

upon request. You may obtain a copy of this source code by contacting

your local Remote Automation Solutions sales office. This product

includes software developed by the OpenSSL Project for use in the

OpenSSL Toolkit (http://www.openssl.org). This product includes

cryptographic software written by Eric Young (eay@cryptsoft.com).

S600+ Instruction Manual

Revised January-2021 General Information 1-9

Page 16

S600+ Instruction Manual

[This page is intentionally left blank.]

1-10 General Information Revised January-2021

Page 17

Chapter 2 – Installation

Failure to exercise proper electrostatic discharge precautions (such as

In This Chapter

2.1 Preparing for Installation ....................................................................... 2-1

2.2 Environmental Considerations .............................................................. 2-2

2.3 Required Tools for Installation .............................................................. 2-2

2.4 Installing the S600+ .............................................................................. 2-3

2.4.1 Unpacking the S600+ ............................................................. 2-3

2.4.2 Removing the Front Panel ..................................................... 2-3

2.4.3 Installing the Panel-Mounted Unit .......................................... 2-6

2.4.4 Reinstalling the Front Panel ................................................... 2-8

2.5 Installing and Removing Modules ......................................................... 2-8

2.6 Installing EMC Protection ................................................................... 2-10

This chapter provides instructions on installing the S600+, including

installation preparation, procedures for panel-mounting, the installation

and removal of plug-in modules, and electromagnetic compatibility

(EMC) considerations.

S600+ Instruction Manual

Caution

wearing a grounded wrist strap) when accessing the back of the unit or

when handling CPU or I/O modules may reset the processor or damage

electronic components, resulting in interrupted operations.

2.1 Preparing for Installation

The S600+ installation must conform to all applicable local codes and

regulations. All installation procedures should be in accordance with

normal practices of good workmanship. Although the S600+ shipped

to you may not include all of the hardware options described in this

manual, the procedure for the basic installation of the unit remains the

same.

Note: We strongly recommend you familiarize yourself with the

procedures described in this chapter before you begin to install

the S600+.

The S600+ uses a modular design that provides maximum flexibility

and ease of installation. The basic panel-mounted version consists of

three major components:

Fabricated metal case, complete with pre-installed PSU/backplane

and four card slots for the modules (a dedicated CPU slot and three

I/O slots).

Removable front panel comprising the LCD display and keypad

assembly.

Plug-in modules. A CPU module and one I/O module are supplied

for a basic configuration; two blank plates are supplied to cover the

unused slots.

Figure 2-1 shows the S600+ system components.

Revised January-2021 Installation 2-1

Page 18

S600+ Instruction Manual

performance.

Figure 2-1. FloBoss S600+ System Components

Note: User-supplied tools to assist in the installation process may

include a Phillips screwdriver, a regular screwdriver, a small

adjustable spanner wrench, and a 2.5mm Allen key.

2.2 Environmental Considerations

The S600+ panel mounted flow computer is designed for use within

the control room. Place it in a position that provides ease of use,

comfort, and safety for operators and maintenance personnel. The

optimum height for viewing and using the display and keypad is at

operator eye level.

Caution

If you install one or more units in a confined space with other heatproducing equipment, give special attention to the combined heating

effect. This combined heat could increase the environmental

temperature beyond its acceptable threshol d, thereby impacting

2.3 Required Tools for Installation

2-2 Installation Revised January-2021

Before you attempt to install the S600+, ensure that you have the

following tools:

Small flat-blade screwdriver suitable for the slot-headed captive

screws on the rear of the case that secure each plug-in board into

the case.

5.5 mm (5 BA) hex or small adjustable wrench for the front panel

bosses.

Page 19

2.5 mm Allen key suitable for the hex cap screw on the front face

of the front panel that secures the front panel molding to the case.

2.4 Installing the S600+

Refer to the following procedures for installing the various S600+

components, including the front panel, panel-mounted unit, and

modules.

2.4.1 Unpacking the S600+

Unpack the S600+ carefully and inspect parts for visual damage.

Note: Do not discard packaging material until after you have

2.4.2 Removing the Front Panel

S600+ Instruction Manual

identified all pieces of the shipment and you are confident that

all parts are working correctly.

To begin the mounting process, remove the front panel from the

S600+:

1. Ensure power has been removed from the S600+.

2. Using a 2.5 mm Allen key, remove the hex cap screw from the

bottom centre of the front panel (refer to Figure 2-2).

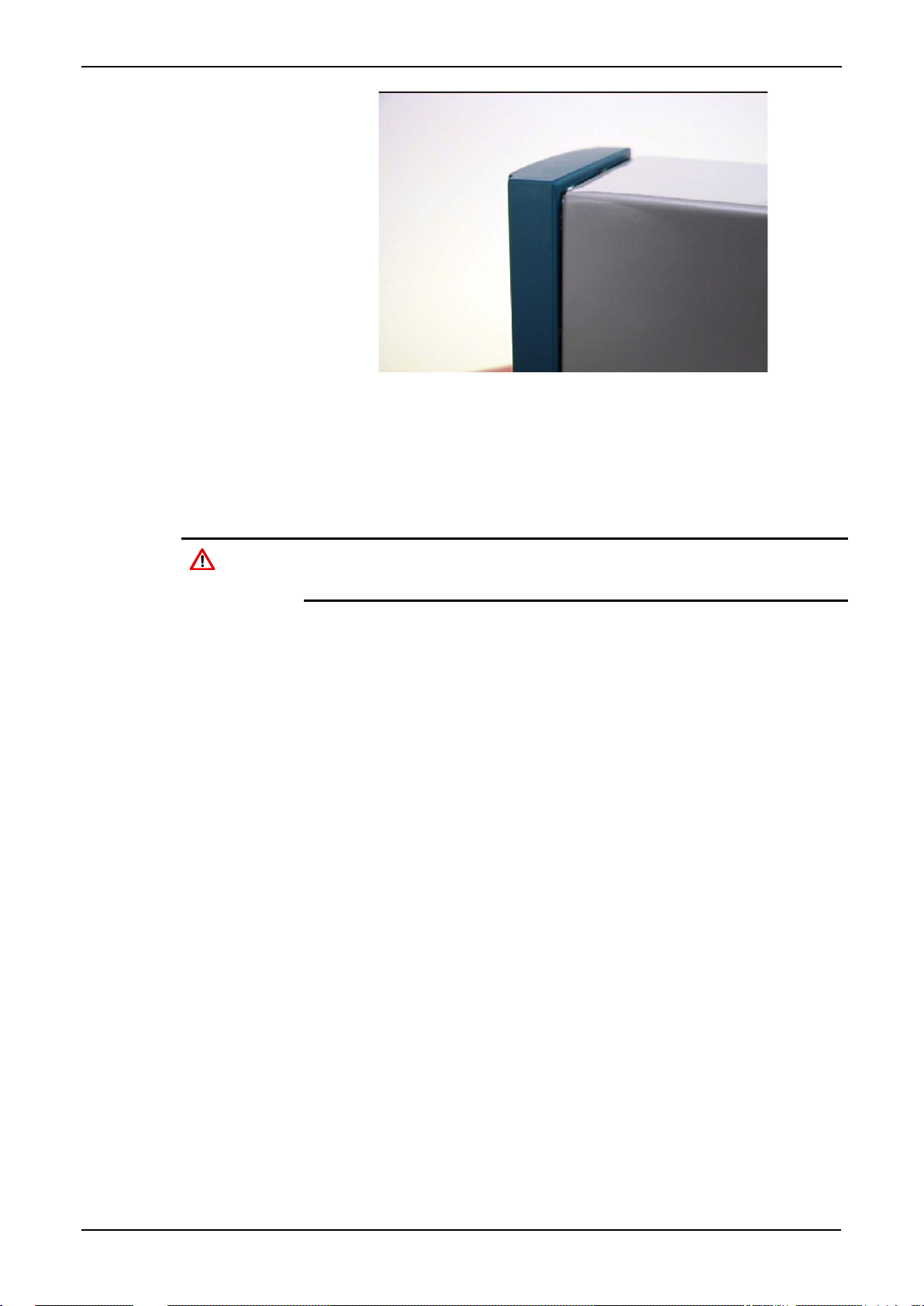

Figure 2-2. Removing the Front Panel

Note: A security cap may cover the hex cap screw.

3. Carefully slide the front panel up 4 mm (0.15 in) to allow it to clear

the retaining groove at the top of the case, and then allow the panel

to come forward to clear the panel case completely (refer to Figure

2-3).

Revised January-2021 Installation 2-3

Page 20

S600+ Instruction Manual

clamp. Be sure to leave it intact without damaging the ribbon cable.

Caution

Figure 2-3. Lifted Front Panel

4. Disconnect the ribbon cable from the back of the front panel at the

blue connector (refer to Figure 2-4). Observe the orientation of the

connector with its mating keyway. You must correctly re-insert the

ribbon cable at the end of the installation process.

Do not remove the ribbon cable from the S600+ housing. This might

damage the S600+. Also, the ribbon cable may also have an EMC

2-4 Installation Revised January-2021

Page 21

S600+ Instruction Manual

Part

Dimensions

Display Keypad Molding

85 mm (3.35") width x 269 mm (10.59") height x 28 mm (1. 10" ) deep

Case

84.5 mm (3.327") width x 270 mm (10.63") height x 303. 8 m m (11.94")

deep

Panel Cutout

66 mm (2.6") width x 150 mm (5.9") height

Pitch Between Cases

110 mm (4.33") giving 25 mm (0.98") air gap

Max Panel Thickness

10 mm (0.39")

Access

Allow 300 mm (11.81") clearance directly behind case for maintenance

Disconnect

Here

Figure 2-4. Remove Connector

5. Remove the top and bottom bosses from the unit housing, using a

5.5 mm (5 BA) hex wrench.

Table 2-1. Mounting Dimensions

Revised January-2021 Installation 2-5

Page 22

S600+ Instruction Manual

2.4.3 Installing the Panel-Mounted Unit

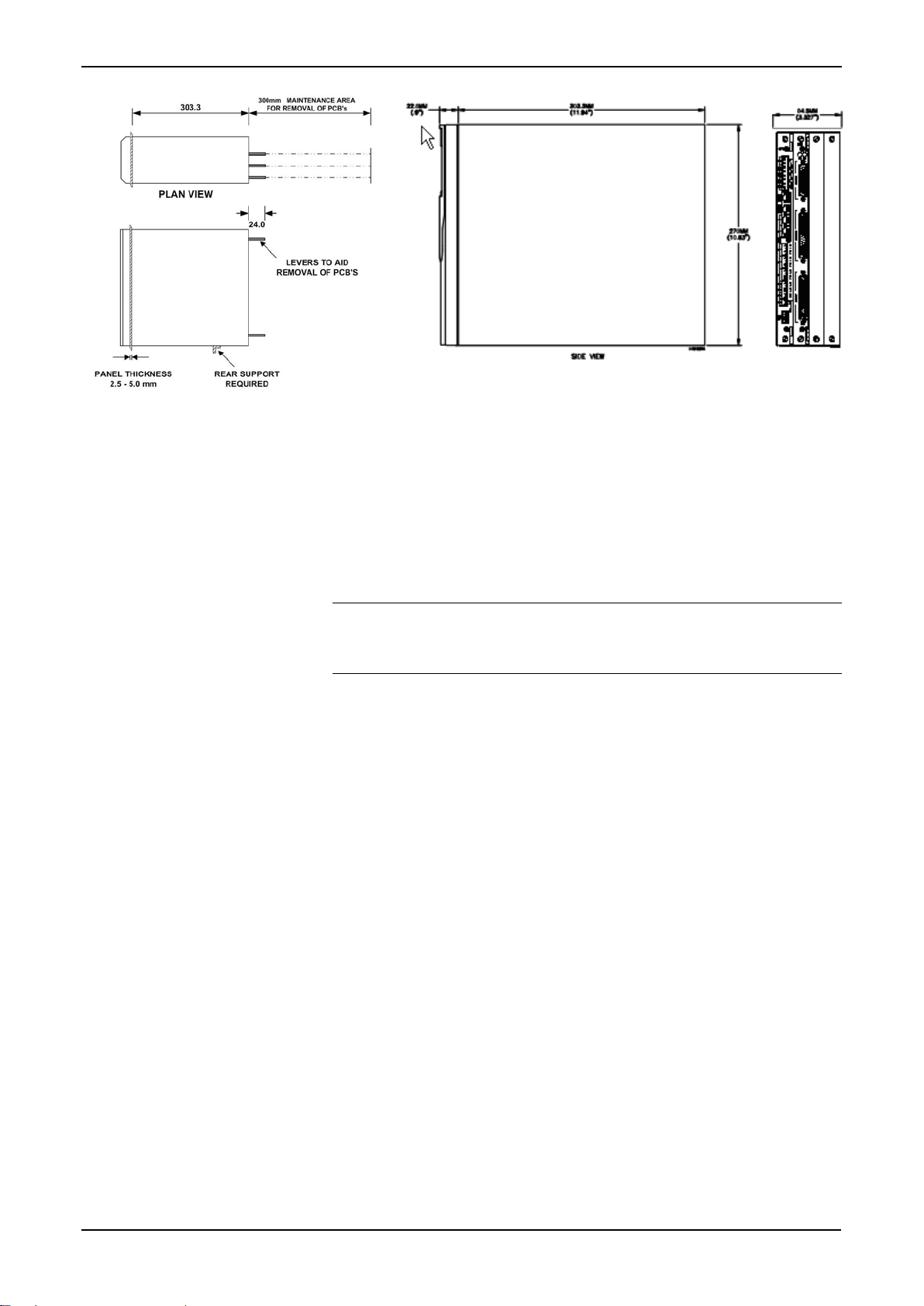

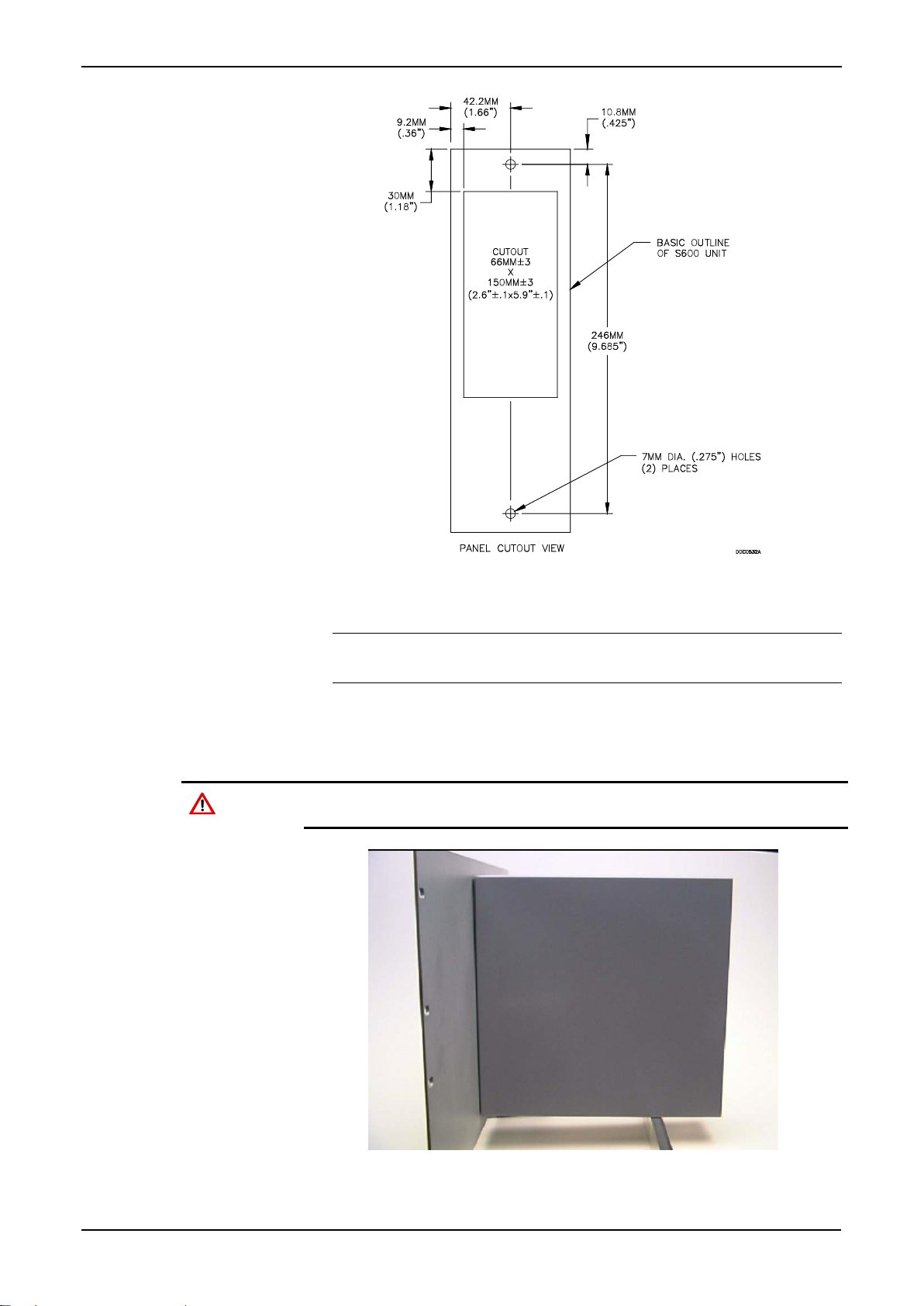

Figure 2-5. Panel Mount Dimensions

After removing the front panel, install the panel-mounted unit:

1. Keeping environmental considerations in mind, construct the

framework of the cubicle to support the operating panel.

Note: A standard 483 mm (19 in) rack that is 311 mm (12.25 in)

high can accommodate up to four S600+s provided you

support the rear of the case.

2. Refer to Figure 2-6 and Table 2-1 for position details for two 7 mm

(0.276 in) holes and a cutout. The panel cutout should be

rectangular for each S600+. Allow a tolerance of ± 3 mm (0.12 in)

on each axis.

2-6 Installation Revised January-2021

Page 23

S600+ Instruction Manual

Caution

Figure 2-6. Panel Cutout Dimensions

Note: The S600+ fits into existing S500 and 869 flow computer

panel cutouts.

3. Ensure a panel thickness of at least 3 mm (0.12 in) to prevent

distortion. If you use a thinner panel, support the rear of the case

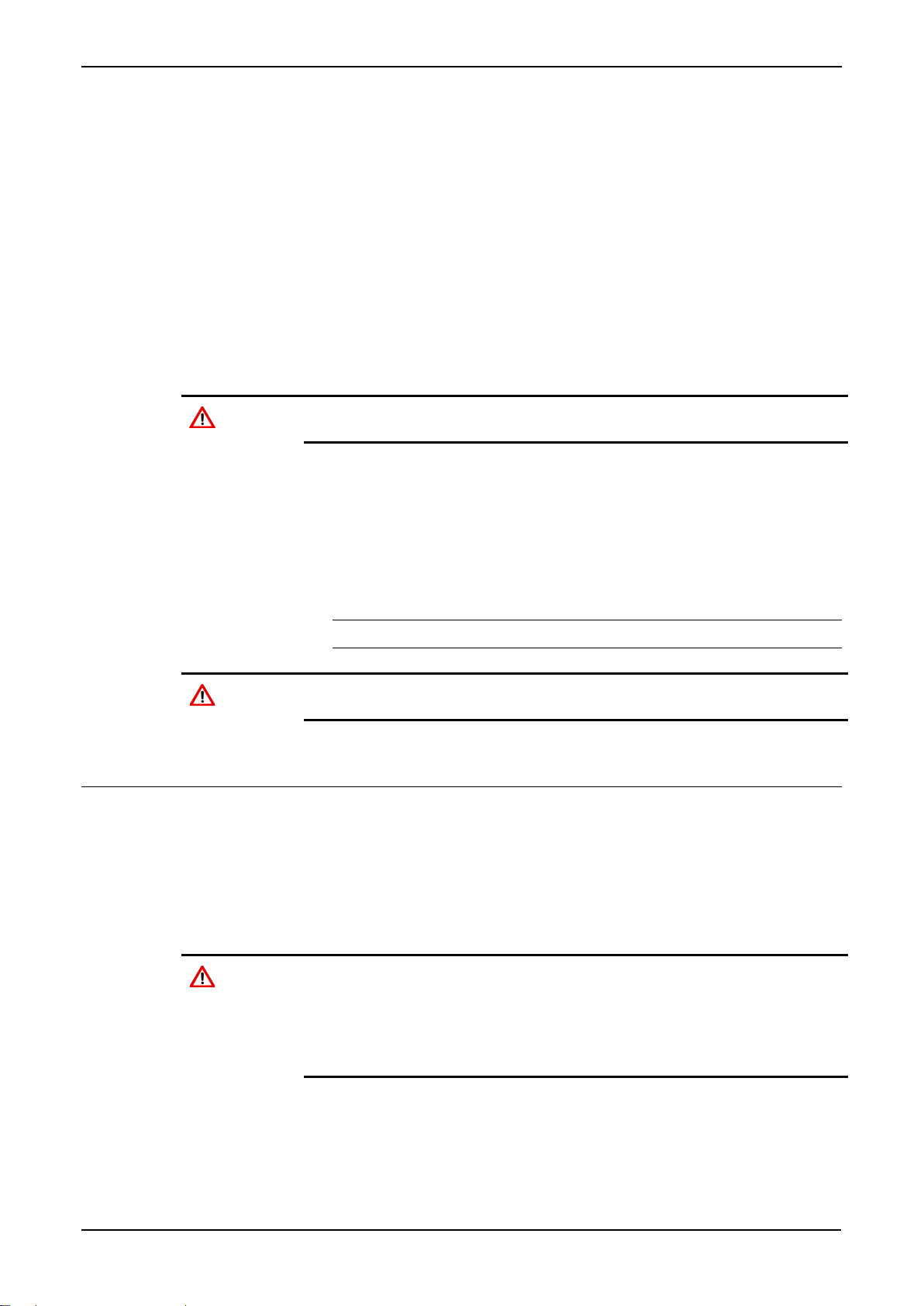

(refer to Figure 2-7).

Always use a rear support or anchor to prevent twisting and other

distortion effects during installation and maintenance.

Figure 2-7. Panel Mount Support

Revised January-2021 Installation 2-7

Page 24

S600+ Instruction Manual

Take suitable electrostatic discharge precautions before you remove

Removal

To remove a module:

2.4.4 Reinstalling the Front Panel

Caution

4. Place the front of the case against the rear of the prepared cutout.

5. Re-install the top and bottom bosses and tighten with a 5.5 mm (5

BA) hex wrench.

6. Once you have fitted the rear support, use a self-tapping screw to

secure the case to the rear support. The maximum depth of the

screw inside the case should be 3 mm (0.12 in).

Re-installing the front panel is the final stage of the installation

process:

1. Connect the ribbon cable to the front panel.

Note how the connector fits into the keyway. You must insert the

ribbon cable correctly. Do not force the connector into the keyway.

2. Place the top of the front panel over the retaining groove on the top

boss and slide the front panel downwards.

3. Secure the front panel by placing the hex cap screw into its recess

in the bottom centre of the front panel.

4. Using a 2.5 mm Allen key, tighten the screw finger-tight. Turn an

additional 180 degrees clockwise to complete the installation.

Note: Replace the security cap if one was originally fitted.

Caution

Do not over-tighten the screw. Over-tightening will damage the panel

face.

2.5 Installing and Removing Modules

The S600+ ships with the CPU and I/O modules already installed.

Follow this procedure if you need to remove the modules for

maintenance or upgrade purposes.

The CPU module is located at the left-most rear slot of the case. You

can insert I/O modules in the remaining slots or leave them empty.

Cover any empty slots with the blank cover plates.

Caution

any of the modules.

The terminals on some modules may be wired to electrical potentials

sufficiently high to cause electrical shock and injury. Turn off and

discharge any power sources for connected devices before you

perform any installation or repair work.

1. Power down the S600+ before you attempt to extract a module.

2. Unscrew the retention screws before you attempt to remove a

2-8 Installation Revised January-2021

module. This avoids damage to the ejectors (refer to Figure 2-8).

Page 25

S600+ Instruction Manual

Ejectors

Figure 2-8. Unscrewing the Retention Screws

3. Unlatch the ejectors for the appropriate module and pull the

module clear of the case. You may need to rock the module slightly

to release it from its connectors (refer to Figures 2-9 and 2-10).

Figure 2-9. Using the Ejectors

Revised January-2021 Installation 2-9

Page 26

S600+ Instruction Manual

Installation

To install a module:

during the installation.

Figure 2-10. Module Ready for Removal or Insertion

1. Carefully align the module with the guides (located at the top and

bottom of the case). Gently slide the module into the case until it

seats fully with the appropriate connector on the backplane.

2. Press each of the two ejectors securely into place once the module

is fully inserted.

Caution

Inserting and seating a module along the guides does not require

excessive force. Take care not to twist or othe r wise distort the module

3. Secure the module with the retention screws (two per board).

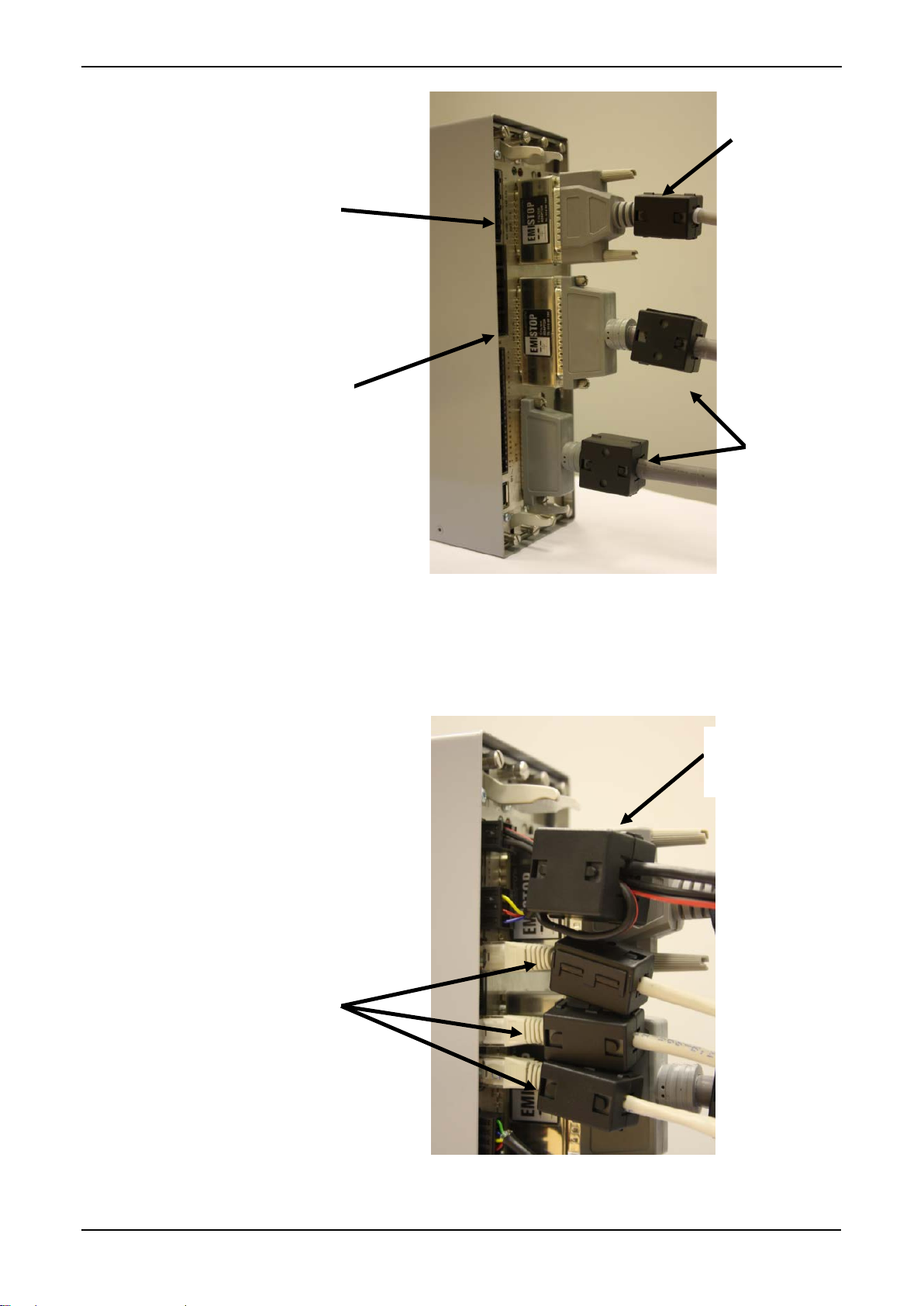

2.6 Installing EMC Protection

Your site may require you to install electromagnetic compatibility

(EMC) shielding on the S600+ to minimize electromagnetic

interference. The S600+ EMC protection kit (which came with your

S600+) typically has the following components:

2-10 Installation Revised January-2021

1 security backplate (place over the installed modules)

1 25-way EMISTOP Inline T Filter Adaptor (attach to the 25-pin

socket A on the I/O module)

1 37-way EMISTOP Inline T Filter Adaptor (attach to the 37-pin

socket B on the I/O module)

3 large (for 13mm cable) ferrite clamps

3 medium (for 10mm cables) ferrite clamps

1 small (for 6.5mm cables) ferrite clamp

Page 27

S600+ Instruction Manual

Remove screws

2 M3 x 6mm screws (which secure the EMC backplate to the sides

of the S600+ housing)

5 TY523 Ty-Rap self-locking cable fasteners (use as necessary to

secure cables)

Note: These are standard components for a standard configuration. If

your S600+ has a different configuration (for example,

additional modules), you may have more components.

Install the EMC kit after you install the S600+ but before you wire the

modules.

To install the EMC components:

1. Unscrew and remove the small Phillips-head screws on the I/O

module (see Figure 2-11).

Revised January-2021 Installation 2-11

Figure 2-11. Screws on I/O Module

2. Place the security backplate over the modules already installed in

the S600+ and secure the backplate to the I/O module using the two

screws you removed in step 1 (see Figure 2-12).

Page 28

S600+ Instruction Manual

Figure 2-12. Security Backplate in Place

Note: In actual operation, the two right-most slots on the S600+

shown in Figure 2-12 would either contain modules or

would be covered by blanking plates.

3. Secure the backplate to the sides of the S600+ housing using the 2

M3 x 6mm screws.

4. Place and secure the 25-way and 37-way EMISTOP adaptors (see

Figure 2-13) onto, respectively, sockets A and B on the I/O module

(see Figure 2-14).

Figure 2-13. EMISTOP Connector

5. Wire the modules according to your site’s requirements.

6. Attach a small ferrite clamp onto the wiring to socket A on the I/O

module. Attach large ferrite clamps onto the cables to sockets B

and C (see Figure 2-14).

2-12 Installation Revised January-2021

Page 29

Large

clamps

Large

Medium

Medium

clamp

25-way

EMISTOP

37-way

EMISTOP

S600+ Instruction Manual

ferrite

ferrite

Figure 2-14. Clamps on I/O Module Wiring

7. Attach a large ferrite clamp onto the wiring to the CPU’s power

connections and one medium clamp to the COM3 and COM 4

connections (see Figure 2-15).

ferrite

clamp

ferrite

clamps

Figure 2-15. Clamps on CPU Module Power & COM Connections

Revised January-2021 Installation 2-13

Page 30

S600+ Instruction Manual

Medium

clamp

Small

8. Attach a medium ferrite clamp onto the wiring for COMs 5, 6, and

7 and a small ferrite clamp onto the Ethernet cable (see Figure 2-

16).

ferrite

clamp

ferrite

Figure 2-16. Clamps on CPU Module COM and Ethernet Connections

This completes the installation process and provides the S600+ with

EMC protection.

2-14 Installation Revised January-2021

Page 31

Chapter 3 – CPU Module

In This Chapter

3.1 CPU Module (P152) ............................................................................ 3-1

3.2 Power Supply ...................................................................................... 3-4

3.2.1 Watchdog Relay .................................................................... 3-4

3.2.2 On-Board Battery Backup ...................................................... 3-4

3.3 Communication Ports ......................................................................... 3-5

3.3.1 RS-232 Serial Port ................................................................. 3-6

3.3.2 RS-422/RS-485 Multi-drop Port ............................................. 3-7

3.3.3 Ethernet LAN Ports ................................................................ 3-7

3.3.4 Local Operator PC or Remote Display Port .......................... 3-8

3.4 CPU Connectors and Jumpers ........................................................... 3-9

3.5 USB Port ........................................................................................... 3-10

3.6 Additional Technical Information ...................................................... 3-10

This chapter provides information on the power and communication

connections for the CPU module.

Caution

Failure to exercise proper electrostatic di sch arge precautions (such as

wearing a grounded wrist strap) when accessing the back of the unit or

when handling CPU or I/O modules may reset the processor or damage

electronic components, resulting in interrupted operations.

S600+ Instruction Manual

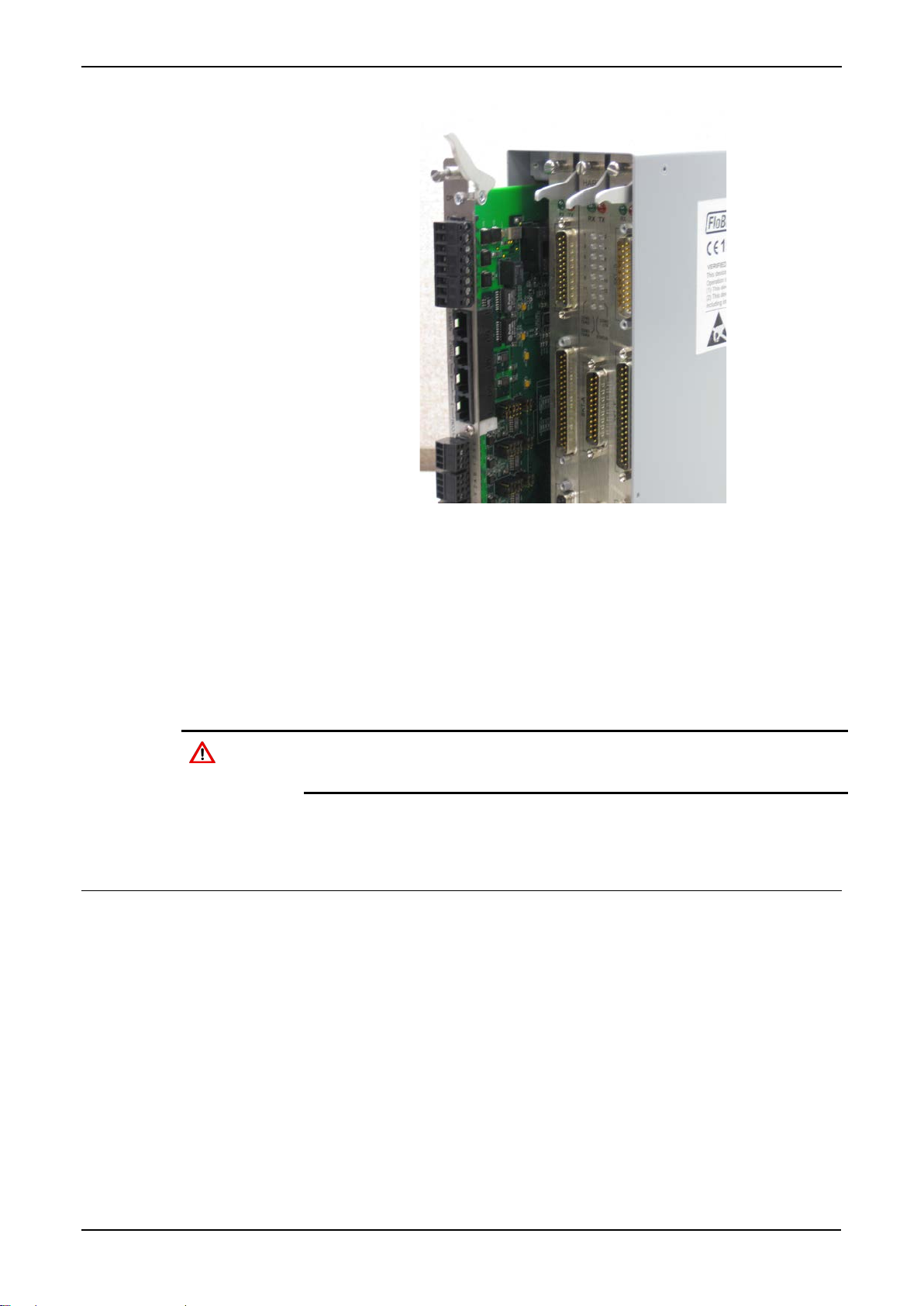

3.1 CPU Module (P152)

The CPU module contains the host processor and associated

peripherals, which form the heart of the S600+ system. Various plug-in

connections are provided on the rear backplate of the CPU module.

Refer to Figure 3-1 for an illustration of the CPU module backplate

and to Figure 3-2 for a schematic of the CPU power terminations.

Figure 3-3 shows the wiring terminations. Additionally, the module

uses connectors and jumpers, which are set at the factory prior to

shipping. See Section 3.5, Jumpers for further information.

It is recommended that all wiring be made with stranded wire that is no

larger than 1.5 mm2 (0.0023 in2) For the communication ports, wiring

of 1.75 mm2 to 1.65 mm2 (0.0027 in2 to 0.0025 in2) is recommended.

Power wiring is recommended to be 1.5 mm2 (0.0023 in2). Observe all

local wiring practices and regulations.

Caution

Do not use a Mega or similar instrument to check for isolation or

continuity between signals on any of the S600+ connectors. These

instruments produce voltages far in excess of design parameters and

may damage the S600+ or its connectors.

Revised January-2021 CPU Module 3-1

Page 32

S600+ Instruction Manual

TB-1 Power

First Ethernet port

COM 3

COM 4

Four additional RS-485

ports (COM 9 through

2)

USB port

Second Ethernet port

COM 5

COM 6

COM 7

Note: You can configure

the A (

12 as a digital input

Backup

battery

Ejector

latches

–) terminal of COM

COM 1

Figure 3-1. CPU Module Backplate

3-2 CPU Module Revised January-2021

Figure 3-2. CPU Module

Page 33

S600+ Instruction Manual

P153 FRONT PANEL

SERVICE

COMM - 1

RJ-12

RTS

TX

GND

GND

RX

CTS

PC SETUP

LCD & SETUP

RESERVED FOR FRONT PANEL

AND CONFIG 600 COMMS

1

2

3

4

5

6

Revised January-2021 CPU Module 3-3

Figure 3-3. CPU Module Terminations

Figure 3-4. Front Panel Terminations

Page 34

S600+ Instruction Manual

Pin

Function

1

+24 V dc INPUT

2

0 V (Return) INPUT

3

+24 V dc OUTPUT (500 mA)

4

+15 V dc OUTPUT (100 mA)

5

0 V (Return) OUTPUT

Pin

Function

6

Normally Closed

7

Common

8

Normally Open

3.2 Power Supply

The power connection is a plug-in, standard 5 mm pitch screw terminal

block on the CPU module. The power supply connector is labeled TB-

1. Refer to Table 3-1 for the TB-1 pin connections.

Power the S600+ using a nominal 30 Volts dc power source capable of

supplying 2 Amps. The S600+ operates between 20 and 32 Volt dc.

The startup in-rush current may draw 6 amps for approximately 100

milliseconds. This in-rush becomes significant when multiple flow

computers are connected to the same power supply.

An on-board anti-surge fuse (2.5 Amp slow blow rating) protects the

supply line should a fault occur within the unit.

Fully regulated 15 and 24 Volts dc supplies are also available for

applications such as powering loops or pre-amplifiers. Resettable

thermal fuses protect these outputs.

Table 3-1. TB-1 Pin Connections (Power)

3.2.1 Watchdog Relay

A single pole, double-throw relay with Normally Open or Normally

Closed terminals provides the watchdog status from pins 6, 7, and 8 of

TB-1. Table 3-2 shows the TB-1 pin connections. Connection is

through plug-in, standard 5 mm pitch screw terminals.

The relay is energized during normal operation. A CPU failure causes

the relay to de-energize.

Note: Contact is rated at 1 Amp, 30 Volts dc and 30 Volts ac, and is a

Form “C” contact.

Table 3-2. TB-1 Pin Connections (Watchdog Relay)

3.2.2 On-Board Battery Backup

The backup battery (see Figure 3-2) retains the contents of the SRAM

on the CPU module, the PC-compatible BIOS CMOS memory area,

and the calendar clock. The battery, a Lithium 3.0 volt 1500

mAmp/hour unit, is user-replaceable. For further battery specifications,

see the technical specification (S600+). To ensure that the battery is

3-4 CPU Module Revised January-2021

Page 35

S600+ Instruction Manual

Replacing the

COM 1-7

Comm ports 1 through 7 are essentially unchanged from previous

fully functional, the S600+ software routinely performs a regular load

test on the unit.

Battery

To replace the backup battery on the CPU module:

Note: Before beginning this process, ensure that any critical processes

the S600+ controls are otherwise managed.

1. Power down the S600+.

2. Disconnect wiring from the CPU module.

Note: Remove the security backplate, if one is installed on the

S600+.

3. Unscrew the retention screws.

4. Unlatch the ejectors (see Figure 3-2) and pull the board clear of the

case.

5. Place the CPU module on a flat anti-static surface so that the

battery faces up (as shown in Figure 3-2).

6. Use a small screwdriver to carefully prise the battery out of its

holder.

Note: The CPU module is designed to hold sufficient charge to

provide time (3-5 minutes) for you to replace the battery.

7. Replace the battery with an exact duplicate (Lithium 3V 1500

mAh, type CR12600SE, part number S600+BATTERY).

8. Slide the CPU module back into the S600+ case, ensuring that it

seats firmly into its connectors.

9. Secure the retention screws.

Note: If appropriate, replace the EMC backplate.

10. Reconnect wiring and apply power to the S600+.

3.3 Communication Ports

The CPU has 12 standard communication ports: nine serial and two

Ethernet (see Figure 3-1). Table 3-3 details the communications ports.

versions of the S600.

Comm ports 1 and 7 contain internal connections to other boards in the

S600+ which are not available for external host or local operator

communications. You can use Comm Port 3 or 4 to route Remote

Display connections. Comm 1 (located at the base of the faceplate) is

reserved for Config Transfer functions.

Revised January-2021 CPU Module 3-5

Page 36

S600+ Instruction Manual

COM 9-12

The S600+ adds four new RS-485 serial ports (COM 9 through COM

Communications Port

Backplate Descriptor

Description

Network 1

NTWK1

Ethernet

Network 2

NTWK2

Ethernet

Comm 4

COM4

RS-232

Comm 3

COM3

RS-232

Comm 5, 6 & 7

TB2, TB3, TB4

RS-422 or RS-485

Comm 9

TB6 Comm 10

TB6 Comm 11

TB6 Comm 12

TB6

USB

Pin

Function

1

GND

2

DTR

3

RTS

4

TX 5 RX 6 CTS

7

DSR

8

DCD

12), located in the lower half of the CPU module (see Figure 3-1).

Table 3-3. Communication Ports

For information on the communications port on the front panel which

can also act as Comm 2, refer to Chapter 5, Front Panel.

3.3.1 RS-232 Serial Port

The CPU module’s backplate provides two RS-232 (RS-232D)

communications ports labeled COM3 and COM4. The ports use FCC68 RJ-45 connectors. The COM3 and COM4 pin connections are

shown in Table 3-4. Figure 3-5 shows a sample pin connection.

Converters are commercially available to configure either 9-way D

type or 25-way D type connection. The ports support baud rates from

2400 to 57600 bps.

Table 3-4. COM3 and COM4 Pin Connections

Figure 3-5. Pin Connections

3-6 CPU Module Revised January-2021

Page 37

The maximum cable length is a function of the baud rate and quality of

Channel

Pin

Function

COM5

1 B 2 A 3 Z 4

Y

COM6

5 B 6 A 7 Z 8

Y

COM7

9 B 10 A 11 Z 12

Y

cable used. For example, a maximum length of 15 m (50 ft) should be

used at 19200 bps when using unscreened cable.

Connect ports to the peripheral devices using multi-conductor, shielded

cable not longer than 8 meters (approx. 25 feet). We recommended

(especially in noisy environments) that you connect the cable screen to

protective earth to keep the signal ground separate.

3.3.2 RS-422/RS-485 Multi-drop Port

The CPU module provides three RS-422 or RS-485 ports, labeled

COM5, COM6, and COM7. These provide high speed/long distance

links of up to 57600 bps and 1200 m (4000 ft). The ports use the

connector labeled TB-2. Table 3-5 shows the COM5, COM6, and

COM7 pin connections.

Note: Jumpers on the enhanced CPU module now provide RS-485

linking, so that wire linking is no longer necessary. If the cable

is already linked (as in an upgrade), you do not need to remove

the linked pairs.

S600+ Instruction Manual

Table 3-5. COM5, COM6, and COM7 Pin Connections

3.3.3 Ethernet LAN Ports

The CPU module provides two Ethernet ports – labeled NTWK1 and

NTWK2 (ENET0 an ENET1 in Config600 software) – for high-speed

communications using an Ethernet Local Area Network (LAN)

architecture. The speed of data transfer is 100Mb full duplex when

using 100BASE-T twisted pair cable.

These ports use a FCC-68 RJ-45 connector. No hardware configuration

or wiring is required for these communications ports.

Note: There is only one gateway, which is available through the

ENET0 port. If the destination IP is outside of the network,

then the packet goes to the gateway for transmission outside of

the network. If the gateway is on the same network as the end

devices, usually one end or the other of the IP address is 0 or

Revised January-2021 CPU Module 3-7

Page 38

S600+ Instruction Manual

Value

Description

Disable Eth

Port (Option 1)

Disables the Ethernet port when the cable is

unplugged and causes the ping command to fail.

Enable Eth Port

(Option 2)

Enables the Ethernet port when the cable is

unplugged. This is the default.

Connecting to

You need a special serial cable to connect the host PC to the S600+. A

255. The gateway address must also have the same subnet

mask as any host devices. Since each host on the network uses

the same gateway, this is also why there is only ever one

gateway, and also why there is no facility to put a subnet mask

into the gateway. The Network I/F settings for the Gateway

address and subnet only appear under ENET0.

Configuring Two

Ethernet Networks

The second generation S600+ CPU module has two Ethernet ports,

NTWK1 and NTWK2. To correctly route messages to each network,

set the third octet of the IP address of the ENET1 port to a different

value than for the ENET0 port. For example, if the IP address for

ENET0 is 129.76.69.74, set the third octet of the second Ethernet port

to a different value, such as 129.76.70.74. This correctly routes

incoming messages to the relevant host port.

Failure to do this may cause the flow computer to mistakenly attempt

to send packages out of the wrong interface causing communication

problems. However if this is required then the following steps can be

taken to ensure that when a network cable is disconnected, the

associated Ethernet port is disabled.

Note: This only works when using binary.app 06.22 or above.

To configure the Ethernet port behaviour when a cable is unpluggled:

1. Cold start the FloBoss S600+.

2. Navigate to the Network Setup menu (Option 3).

3. Select Wire Unplug Cfg (Option 3).

4. Select one of the following options:

5. Return to the cold start menu once the correct option has been

selected and restart the machine.

3.3.4 Local Operator PC or Remote Display Port

You can configure COM3 or COM4 to connect the S600+ to a remote

display or the host PC (COM2).

Use only shielded, multi-conductor cable to connect to the COM3-4

port. It is recommended—particularly in noisy environments—that you

connect the cable shield to earth ground to keep the signal ground

separate.

the S600+

ready-made link cable (part number 3080017) is available for a PC

with a 9-pin serial port.

Alternatively, you may fabricate your own link cable using the wiring

details in Figure 3-6.

3-8 CPU Module Revised January-2021

Page 39

S600+ Instruction Manual

Jumper/Connector

Description

P1

Back plane connector

P2

Cold start forced on power up

P3

Security jumper (Off – Level 1 security enabled)

P4

Debug console (factory use only)

P5

Processor programming header (factory us e only)

P6

CPLD programming header (factory use only)

P7

Termination resistors for COM5 (1-2 side for ON)

P8

Termination resistors for COM6 (1-2 side for ON)

P9

Termination resistors for COM7 (1-2 side for ON)

P10

RS-422/RS-485 selector for COM5.

Jumper 14-15 must always be fitted

P11

RS-422/RS-485 selector for COM6.

Jumper 14-15 must always be fitted

P12

RS-422/RS-485 selector for COM7.

Jumper 14-15 must always be fitted

P13

Termination resistors for COM10 (1-2 ON)

Note: Due to the high baud rate used for the communications between

the host PC and the S600+, restrict the maximum cable length

to 5 m (15 ft).

Figure 3-6. Link Cable

3.4 CPU Connectors and Jumpers

Table 3-6 shows the connectors and jumpers on the CPU module. This

information is for identification purposes only. Do not modify these

settings, unless told to do so by the factory.

Note: The position values shown in boldface are the default

configuration settings, which may not apply to your specific

configuration.

Table 3-6. CPU Jumpers

Revised January-2021 CPU Module 3-9

1-2, 4-5, 7-8, 10-11 side for RS-422

1-2, 4-5, 7-8, 10-11 side for RS-422

1-2, 4-5, 7-8, 10-11 side for RS-422

Page 40

S600+ Instruction Manual

Jumper/Connector

Description

P14

Termination resistors for COM9 (1-2 ON)

P15

Termination resistors for COM12 (1-2 ON)

P16

P17

TB6 serial port or digi tal input mode selecto r

2-3 and 5-6 for digital input

P18

Termination resistors for COM11 (1-2 ON)

P20

Watchdog Jumper on 2-3 must be selected

P26

Flash write protect

P27

Flash boot selection (NAND/NOR)

Name

Form Number

Part Number

FloBoss™ S600+ Flow Computer

S600+

D301151X412

3.5 USB Port

1-2 and 4-5 for serial port

Use the USB 2.0 port on the CPU module to export alarm history,

event history, and report history information to a USB flash drive.

You access the export facility either through the S600+ front panel or

the webserver. Select Tech/Engineer > USB. Using the front panel

you can also enable or disable the USB port.

Note: For detailed instructions, see Chapter 5, Front Panel.

3.6 Additional Technical Information

Refer to the following technical documentation (a vaila b le at

www.EmersonProcess.com/Remote) for additional and most-current

information.

Table 3-7. I/O Module Technical Specifications

3-10 CPU Module Revised January-2021

Page 41

Chapter 4 – Input/Output (I/O)

Failure to exercise proper electrostatic discharge precautions (such as

may damage the S600+.

In This Chapter

4.1 I/O Module (P144) ............................................................................. 4-1

4.1.1 Analogue Inputs (ANI N) ....................................................... 4-3

4.1.2 Analogue Outputs (DAC) ..................................................... 4-5

4.1.3 Digital Inputs (DIGIN) ........................................................... 4-6

4.1.4 Digital Outputs (DIGO UT) .................................................... 4-8

4.1.5 Turbine Pulse Inputs ............................................................ 4-9

4.1.6 Pulse Outputs (PULSEOU T ) .............................................. 4-10

4.1.7 Raw Pulse Output (RAWOUT) ........................................... 4-11

4.1.8 Frequency Inputs ............................................................... 4-12

4.1.9 PRT/RTD Inputs ................................................................. 4-13

4.1.10 Jumper Settings ................................................................. 4-14

4.2 Prover Module (P154) ..................................................................... 4-16

4.2.1 Digital Inputs (DIGIN) ......................................................... 4-18

4.2.2 Digital Outputs (DIGO UT) .................................................. 4-20

4.2.3 Turbine Pulse Inputs .......................................................... 4-21

4.2.4 Pulse Outputs (PULSEOU T ) .............................................. 4-22

4.2.5 Frequency Inputs ............................................................... 4-22

4.2.6 Raw Pulse Output (RAWOUT) ........................................... 4-23

4.2.7 Jumper Settings ................................................................. 4-24

4.3 HART Module (P188) ...................................................................... 4-24

4.4 Mezzanine Module (P148) .............................................................. 4-27

S600+ Instruction Manual

This chapter provides information on plug-in connector blocks and

field wiring (ANIN and PRT signals) for the I/O, Prover, and HART

modules. This chapter also discusses the pulse counting mezzanine

module (P148) which is included as a daughter board on the IO and

Prover boards.

Caution

wearing a grounded wrist strap) when accessing the back of the unit or

when handling CPU or I/O modules may reset the processor or damage

electronic components, resulting in interrupted o perations

Perform all wiring with stranded wire no larger than 1.75mm2. Observe

all local wiring practices and regulations.

Caution

Do not use a Mega or similar instrument to check for isolation or

continuity between signals on any of the S600+ connectors. These

instruments produce voltages far in excess of design parameters and

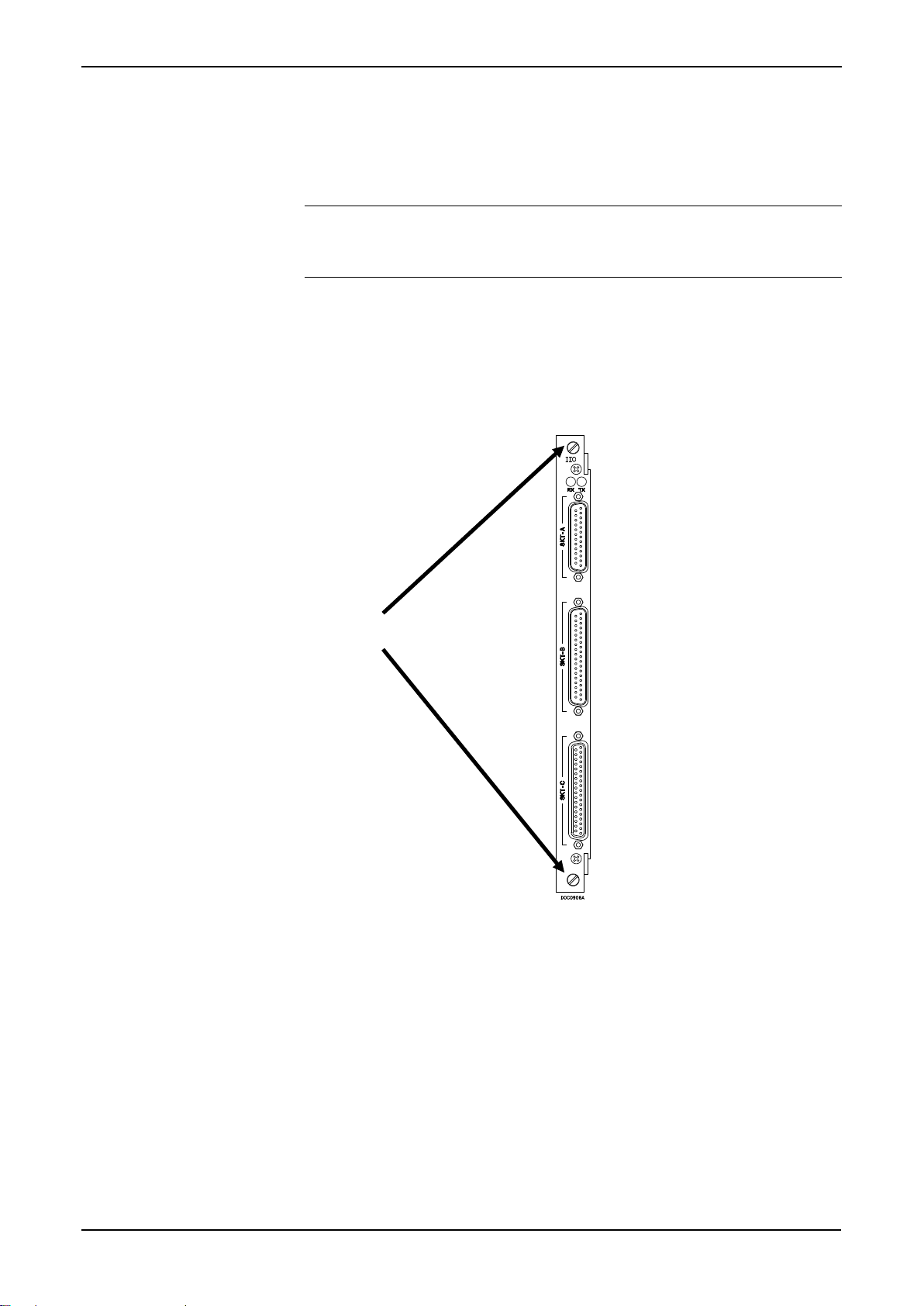

4.1 I/O Module (P144)

The I/O module (P144) measures process signals the CPU uses while

running the flow computer functions. The module provides 12

analogue inputs (AI), 4 analogue outputs (AO), 16 digital inputs (DI) ,

12 digital outputs (DO), 4 pulse inputs (PI), 5 pulse outputs (PO), 3

frequency (density) inputs, and 3 PRT/RTD inputs. Refer to Figure 4-2

for the I/O module terminations.

Revised January-2021 I/O 4-1

Page 42

S600+ Instruction Manual

SKT-A

ANIN 1

ANOUT 1

SKT-C

DIGIN 7

DIGOUT 3

Turbine Inputs

SKT-B

ANIN 11

DI

DIGOUT 1

Freq Inputs

Pulse Outputs

Mezzanine

module (P148)

For field wiring, the module provides three low-density D-type

connectors: SKT-A, SKT-B, and SKT-C (refer to Figure 4-1).

-10

-4

-12

GIN 1-6

-2

Figure 4-1. I/O Module (P144)

-16

-12

4-2 I/O Revised January-2021

Figure 4-2. Example I/O Module (with Mezzanine Module)

Page 43

+15V

+15V

+15V

+15V

+15V

+15V

0-1 V

+12V

1mA

0-1 V

+12V

1mA

0-1 V

+12V

1mA

0-1 V

+12V

1mA

0-1 V

+12V

1mA

0-1 V

+12V

1mA

0-1 V

+12V

1mA

0-1 V

+12V

1mA

0-1 V

+12V

1mA

SKT A

SKT B

SKT C

COMMON + VE

DIG IN 5-

DIG IN 8-

COMMON + VE

DIG IN 9-

DIG IN 10DIG IN 11DIG IN 12-

COMMON + VE

DIG IN 13-

DIG IN 14-

DIG IN 15-

DIG IN 16-

COMMON + VE

RAW PULSE +

OUTPUT -

HIT

HIT

10 K

10 K

10 K

10 K

10 K

10 K

10 K

10 K

10 K

4 - 20 mA

1 - 5 V

1 - 5 V

1 - 5 V

1 - 5 V

SKT A

SKT B

SKT C

ADC 1+

ADC 2+

ADC 3+

ADC 4+

ADC 5+

GND

ADC 6+

ADC 7+

ADC 8+

ADC 9+

ADC 10+

GND

ADC 11+

ADC 12+

GND

PULSE OUT 1+

PULSE OUT 2+

PULSE OUT 3+

PULSE OUT 4+

PULSE 1-4 COM

+ DENSITY

- INPUT 1

+ DENSITY

- INPUT 2

+ DENSITY

- INPUT 3

+ PULSE

- OUTPUT 5

DIG OUT 1+

DIG OUT 2+

DIG OUT 3+

DIG OUT 4+

COMMON GND

DIG OUT 5+

DIG OUT 6+

DIG OUT 7+

DIG OUT 8+

COMMON GND

DIG OUT 9+

DIG OUT 10+

DIG OUT 11+

DIG OUT 12+

COMMON GND

+ DUAL PULSE

- CHANNEL 1

+ DUAL PULSE

- CHANNEL 2

+ DUAL PULSE

- CHANNEL 3

+ DUAL PULSE

- CHANNEL 4

SUPPLY

DAC 4 OUTPUT

GROUND

SUPPLY

DAC 3 OUTPUT

GROUND

SUPPLY

DAC 1 OUTPUT

GROUND

SUPPLY

DAC 2 OUTPUT

GROUND

I+

PRT 1 V+

INPUT V-

I-

I+

PRT 2 V+

INPUT V-

I-

I+

PRT 3 V+

INPUT V-

I-

DIG IN 1-

DIG IN 2-

DIG IN 3-

DIG IN 4-

DIG IN 6-

DIG IN 7-

SERVICE

SERVICE

SERVICE

SERVICE

SERVICE

SERVICE

0v

0v

0v

+24v

+24v

+24v

+24v

LK 29

LK 30

8

21

9

22

10

20

11

24

12

25

13

23

1

14

2

15

3

16

4

5

17

18

6

19

8

7

20

30

31

32

33

35

34

12

9

27

10

28

11

29

36

37

4

1

21

24

5

2

22

25

6

3

23

26

13

14

15

16

17

18

19

37

36

35

34

33

32

31

30

29

28

27

26

25

4

23

3

22

2

21

1

20

19

18

17

16

15

14

13

12

11

10

9

8

7

24

5

I/O MODULE (P144)

S600+ Instruction Manual

4.1.1 Analogue Inputs (ANIN)

Figure 4-3. I/O Module Terminations

Each I/O module has two fully floating A/D converters, each

measuring five single-ended analogue input (ANIN) channels. Each

channel (ANIN 1-10) is configurable within a 0 to 5.25 volt or 0 to 22

mA input range. The module also provides two current-only inputs

(ANIN 11 and 12), for a total of 12 analogue inputs.

Revised January-2021 I/O 4-3

Page 44

S600+ Instruction Manual

Set the channels for each A/D converter to the s ame value to guarantee

settings on the I/O module.

The primary measurement for ANIN 1-10 is voltage, which is

compared to a stable reference source. The channels are configurable

to current using a bit link (jumper) on the module to place a high

accuracy calibrated shunt resistor in parallel with the input. Refer to

Figures 4-4 and 4-5.

Caution

accuracy. Set all channels ANIN 1-5 on the first A/D converter for either

voltage or current. Set all channels ANIN 6-10 on the second A/D

converter for either voltage or current. Refer to Table 4-13 for jumper

Figure 4-4. Analogue Input Schematic (with IS Barrier and using Internal Resistor)

Figure 4-5. Analogue Input Schematic (without IS Barrier and using External Resistor)

The ANIN channels use the connectors labeled SKT-A and SKT-B,

which are located on the backplate of the I/O module. Channels CH1

to CH10 are located on connector SKT-A. Channels CH11 and CH12

are located on connector SKT-B. Refer to Tables 4-1 and 4-2 for the

ANIN pin connectors.

4-4 I/O Revised January-2021

Page 45

Table 4-1. ANIN Pin Connections for SKT-A

Pin

Function

8

ANIN-CH1

21

ANIN-CH2

9

ANIN-CH3

22

ANIN-CH4

10

ANIN-CH5

20

RETURN CH1-5

11

ANIN-CH6

24

ANIN-CH7

12

ANIN-CH8

25

ANIN-CH9

13

ANIN-CH10

23

RETURN CH6-10

Pin

Function

8

ANIN-CH11 (current)

7

ANIN-CH12 (current)

20

GND

Table 4-2. ANIN Pin Connections for SKT-B

S600+ Instruction Manual

4.1.2 Analogue Outputs (DAC)

The S600+ supports four analogue outputs (D/A Converter). Each

D/A Converter channel is fully floating and provides its own floating

supply. Loads of up to a 650-ohm loop impedance can be connected

directly. The unit can be used in either source or sink configuration.

Refer to Figures 4-6, 4-7, and 4-8.

The D/A Converter output channels use the connector labeled SKT-A,