Page 1

Instruction Manual

Form 5319

March 2009

Type S402Y

Type S402Y Pressure Reducing Regulator

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion,

re and/or chemical contamination

causing property damage and personal

injury or death.

Fisher® regulators must be installed,

operated, and maintained in accordance

with federal, state, and local codes,

rules and regulations, and

manufacturer’s instructions.

If the regulator vents gas or a leak

develops in the system, service to

the unit may be required. Failure

to correct trouble could result in a

hazardous condition.

Call a gas service person to service

the unit. Only a qualied person must

install or service the regulator.

Introduction

This installation manual covers the installation and

startup procedures for Type S402Y pressure

reducing regulators.

Figure 1. Type S402Y Pressure Reducing Regulator Assembly

Scope of the Manual

This instruction manual provides information on

installation, maintenance, and replacement parts for

Type S402Y pressure-reduction regulators.

Product Description

The Type S402Y is generally employed in residential

or small commercial applications in order to reduce

gas distribution pressures to a specied pressure

range from 4.5-inches w.c. to 2.5 psig (11,0 mbar to

0,17 bar). The Type S402Y has an integral high

capacity internal relief valve.

The Type S402Y is typically used in residential

or small commercial applications to reduce gas

distribution pressures down to a reduced pressure

range from 4.5-inches w.c. to 2.5 psig (11,0 mbar

to 0,17 bar). The Type S402Y has an integral high

capacity internal relief valve.

www.emersonprocess.com/regulators

Specications

Specications for Type S402Y construction are found

on page 2. The following information is stamped on

the regulator at the factory: Type number, orice size,

spring range, and date of manufacture.

D101838X012

Page 2

Type S402Y

Specications

Body Size and End Connection Styles

(1)

NPS 3/4 or 1, NPT

Maximum Operating Inlet Pressure

(2)

125 psig (8,6 bar)

Maximum Allowable Emergency Inlet Pressure

175 psig (12,1 bar)

Allowable Outlet Pressures (Casing)

(2)

Emergency: 10 psig (0,69 bar)

Maximum Operating to Avoid Internal Part

Damage: 5 psig (0,35 bar)

Outlet Pressure Ranges

(2)

See Table 2

Orice Sizes

Temperature Capabilities

-20° to 160°F (-29° to 71°C)

Pressure Registration

Internal

(2)

Spring Case Vent Connection

1 NPT with removable screen (standard)

3/4 NPT with removable screen (optional)

Spring Case Vent and Body Mounting Positions

See Figure 5

External Dimensions

See Figure 6

Approximate Weight

4 pounds (2 kg)

(2)

See Table 1

1. End connections threaded to other than ASME standards can usually be supplied.

2. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

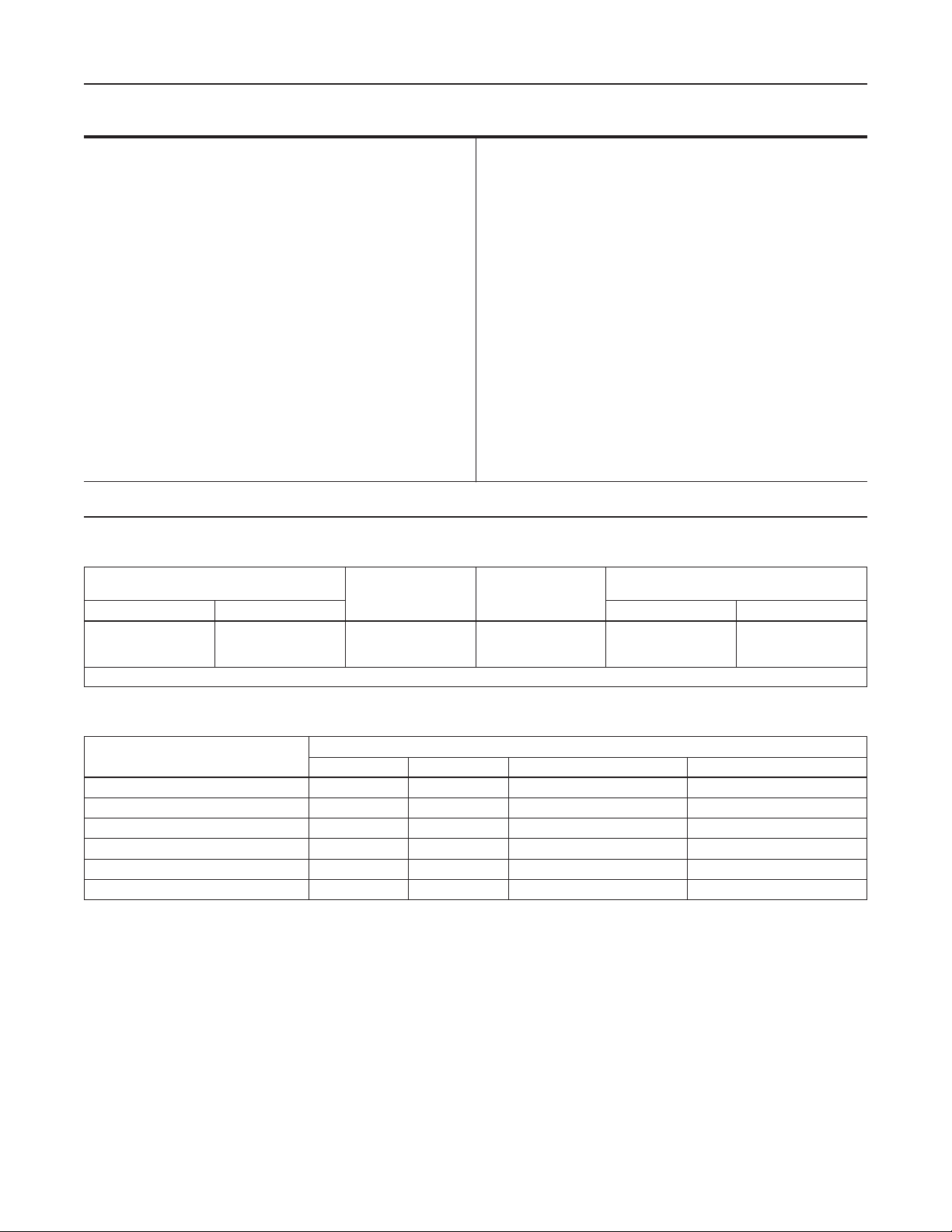

Table 1. Orice Sizes and Cg Coecients

ORIFICE SIZE

Inches mm Psig bar

1/8

3/16

1/4

1. Maximum operating inlet pressure is 125 psig (8,6 bar) for all orice sizes. The optimum performance is based on 2-inches w.c (5 mbar) boost or 1-inch w.c. (2 mbar) droop.

3,2

4,8

6,4

ORIFICE

COLOR CODE

Blue

Green

Brown

WIDE-OPEN C

RELIEF SIZING

12.5

28.2

50.0

FOR

g

MAXIMUM OPERATING PRESSURE FOR

OPTIMUM PERFORMANCE

125

80

60

(1)

8,6

5,5

4,1

Table 2. Outlet Pressure Ranges and Control Spring Data

OUTLET PRESSURE RANGES

4.5 to 6-inches w.c. (11 to 15 mbar) T13539T0012 Red 0.070 (1,78) 2.50 (63,5)

5.5 to 8-inches w.c. (14 to 20 mbar) T13527T0012 Yellow 0.067 (1,70) 2.59 (65,8)

7.5 to 9.5-inches w.c. (19 to 24 mbar) T13563T0012 Olive drab 0.067 (1,70) 3.24 (82,3)

9.5 to 13-inches w.c. (24 to 32 mbar) T13529T0012 Green 0.075 (1,91) 3.00 (76,2)

13-inches w.c. to 1.5 psig (32 mbar to 0,10 bar) T13564T0012 Unpainted 0.120 (3,05) 1.93 (49,0)

1.5 to 2.5 psig (0,10 to 0,17 bar) T13536T0012 Blue 0.120 (3,05) 2.60 (66,0)

Part Number Color Wire Diameter, Inches (mm) Free length, Inches (mm)

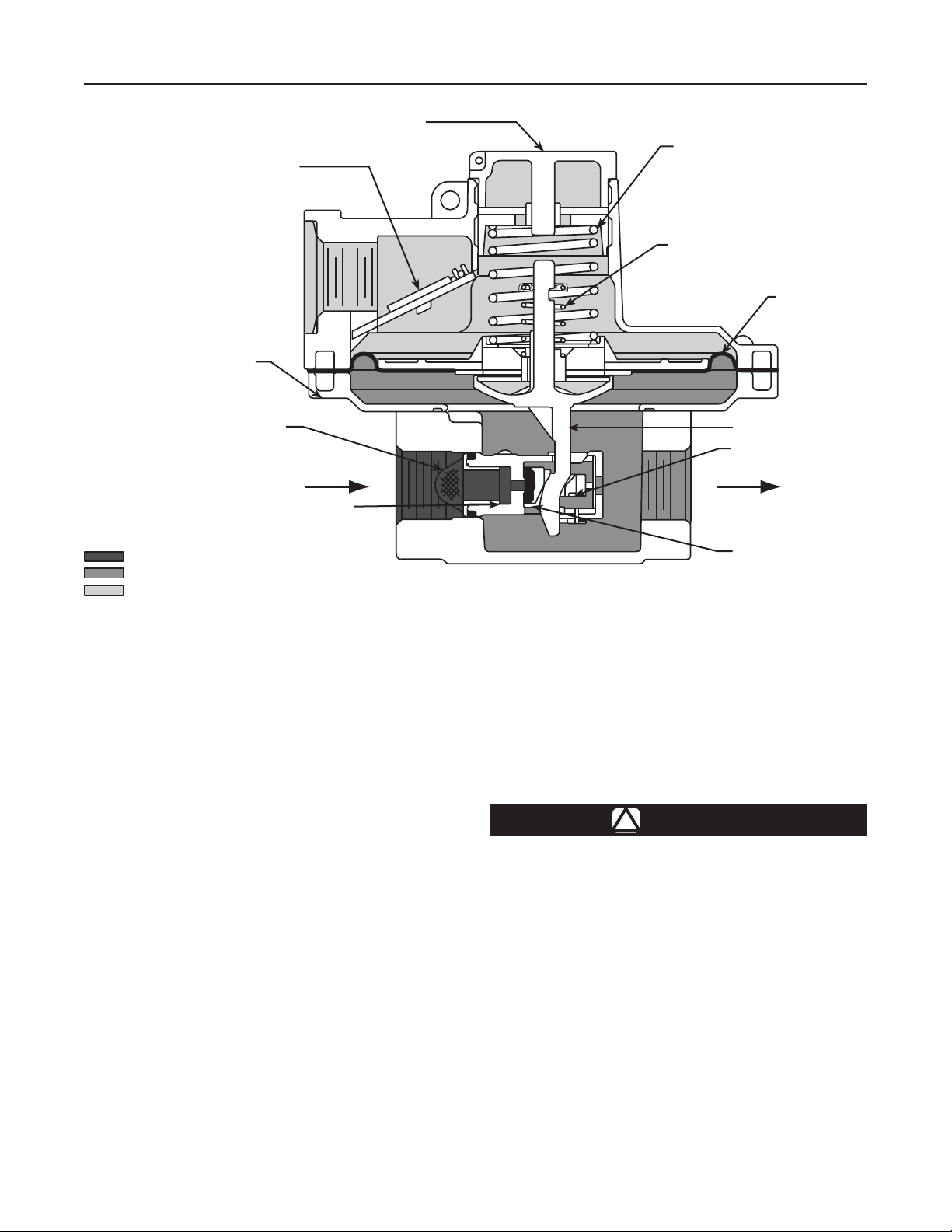

Principle of Operation

CONTROL SPRING DATA

assembly. When downstream demand is reduced, the

pressure under the diaphragm increases. This pressure

Inlet pressure ows through the open orice around

the valve disk and disk holder, around the cam stem

down the remaining length of the orice tube and into

the outlet of the regulator body. However, not all of the

pressure passes directly from the inlet to the outlet of

overcomes the regulator setting (which is set by a

spring) and moves the diaphragm assembly upwards.

This upward motion is transferred to the cam stem which

in turn bears against the sliding contact point on the

back side of the disk holder.

the regulator. Pressure is channelled through openings

in the orice tube and pressurizes the cavity formed by

the body and diaphragm/diaphragm head/cam stem

The inclined surface of the cam then forces the disk

holder toward the orice and reduces gas ow. If a higher

2

Page 3

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

DRILLED CLOSING CAP WITH TRAVEL STOP

TO OPEN RELIEF VALVE

FLAPPER

LOWER CASING

Type S402Y

MAIN SPRING

RELIEF VALVE SPRING

DIAPHRAGM

INLET SCREEN

ORIFICE TUBE ASSEMBLY

M1162

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 2. Type S402Y Operational Schematic

volume ow rate is demanded downstream, the pressure

under the diaphragm decreases. The control spring

force pushes the diaphragm/diaphragm head/cam stem

assembly downward and the valve disk moves away

from the orice.

At the lockup (complete shutoff) position the ratio of

the diaphragm travel to disk travel is 4 to 1 giving the

regulator an effective 4 to 1 lever ratio for positive lockup.

The cam stem is characterized for higher downstream

demand to produce a mechanical boost effect.

Type S402Y regulator includes an internal relief valve

for overpressure protection. If the downstream pressure

exceeds the regulator setting and the regulator is not

able to achieve complete shutoff (lockup) due to foreign

matter lodged between the orice and the valve disk

or a failure in the valve disk, the regulator diaphragm

assembly moves upwards trying to push the valve

disk against the orice. The valve disk and disk holder

being pressed against the orice will prevent the cam

stem from being able to travel any further upward in

conjunction with the diaphragm assembly. The continued

leakage of the inlet pressure into the regulator cavity

will then force the diaphragm and diaphragm head up

off of the seating area of the relief valve overcoming

CAM STEM

DISK HOLDER ASSEMBLY

VALVE DISK

the relief valve spring which was pressing them

together. The resulting gap will allow pressure to exit the

regulator cavity and exhaust through the openings in the

diaphragm head and out the spring case vent

to atmosphere.

Installation

WARNING

!

Personal injury, equipment damage, or

leakage due to escaping accumulated

gas or bursting of pressure-containing

parts may result if this regulator is

overpressured or is installed where

service conditions could exceed the

limits given in Specication Section.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices (as required by Title 49, Part 192,

of the U.S. Code of Federal Regulations,

by the National Fuel Gas Code Title 54 of

the National Fire Codes of the National

Fire Protection Association, or by other

3

Page 4

Type S402Y

applicable codes) to prevent service

conditions from exceeding those limits.

Additionally, physical damage to the

regulator could result in personal

injury or property damage due to

escaping gas.

To avoid such injury and damage, install

the regulator in a safe location.

1. Only personnel qualied through training and

experience should install, operate, and maintain a

regulator. Before installing a Type S402Y

regulator, check for damage which have might

ocurred in shipment. Also check for dirt or foreign

materials which may have accumulated in the

regulator body or in the pipeline.

2. The Type S402Y may be installed in any position

(vertical or horizontal). Apply a good grade of

pipe compound to the male threads (being

sure not to apply pipe compound to ow path

of the pipe) of the pipe and install the regulator

so the ows is in the direction of the arrow cast

on the body. Use approved piping procedures

when installing the regulator. The spring case can

be rotated to any position relative to the body.

require additional vent protection from the

elements. Such protection may be with separate

hood, shields, or the Fisher

4. Regulator operation within the ratings does not

preclude the possibility of damage from the debris

in the lines or from external sources. A regulator

should be inspected for damage periodically and

after any overpressure condition.

5. With proper installation completed, slowly open

the upstream and downstream shutoff valves.

Check all connections for leaks. Check the

downstream equipment for proper operation.

6. If outlet pressure adjustment is necessary, monitor

downstream pressure with a gauge during the

adjustment procedure. To increase the outlet

pressure, the adjusting screw (key 12, Figure 1)

must be turned clockwise. This requires removal of

the closing cap (key 11, Figure 1). To reduce the

outlet pressure setting, turn the adjusting screw

counter-clockwise. Do not adjust the spring to

procedure an outlet pressure setting above the limit

stamped on the regulator.

®

Y602 Series vents.

Overpressure Protection

WARNING

!

A regulator may vent some gas to

the atmosphere. In hazardous or

ammable gas service, vented gas

may accumulate, and cause personal

injury, death, or property damage due

to re or explosion. Vent a regulator

in hazardous gas service to a remote,

safe location away from air intakes or

any hazardous location. The vent line

or stack opening must be protected

against condensation or clogging.

Under enclosed conditions or indoors,

escaping gas may accumulate and be

an explosion hazard. In these cases,

the Type S402Y vent should be piped

away from the regulator to a safe

location outdoors.

3. On outdoors installations, regulators installed with

vents in positions other than vertically down

The wide-open Cg for relief sizing along with the

capacity information should be used in choosing

appropriate overpressure protection devices to

ensure that none of the limits in the Specications

section, Table 1, or Table 2 are exceeded.

Overpressuring any portion of a regulator or

associated equipment may cause leakage,

parts damage, or personal injury due to bursting

of pressure-containing parts or explosion of

accumulated gas. Regulator operation within ratings

does not prevent the possibility of damage from

external sources or from debris in the pipeline. A

regulator should be inspected for damage after any

overpressure condition.

Startup

WARNING

!

In order to avoid an overpressure

condition and possible equipment

damage, pressure gauges should

always be used to monitor pressures

during startup.

4

Page 5

Type S402Y

1. Check to see that all downstream equipment is

turned off.

2. Slowly open the upstream shutoff valve.

3. Slowly open the downstream shutoff valve.

4. Check all connections for leaks.

5. Light the downstream equipment pilot lights

if applicable.

Adjustment

If set pressure adjustment is necessary, monitor

downstream pressure with a gauge during the

adjustment procedure. To increase the outlet

pressure, the adjusting screw (key 12) must be turned

clockwise. This requires removal of the closing cap

(key 11). To reduce the outlet pressure setting, turn

the adjusting screw counterclockwise. Do not adjust

the spring to produce an outlet pressure setting above

the limit stamped on the regulator.

The range of allowable pressure settings is stamped

on the regulator. If a pressure setting beyond this

range is necessary, substitute the appropriate

regulator control spring. When changing the spring,

also change the range stamped on the regulator to

indicate the actual pressure range of the spring in use.

Before increasing the setting, refer to Table 1. Review

the pressure limits for the control spring range being

used and be certain that the new pressure setting

will not result in an overpressure condition. After the

spring adjustment has been completed, replace the

closing cap.

Maintenance

WARNING

!

To avoid personal injury or equipment

damage from sudden release of pressure

or uncontrolled gas, do not attempt any

maintenance or disassembly without

rst isolating the regulator from

system pressure and relieving all

internal pressure as described in the

shutdown procedure.

Regulators that have been diassembled

for repair must be tested for proper

operation before being returned to

service. Due to the care Fisher takes in

meeting all manufacturing requirements

(heat treating, dimensional tolerances,

etc.), use only replacement parts

manufactured or furnished by Fisher to

repair Fisher® regulators. Relight

pilot lights according to normal

startup procedures.

Due to normal wear or damage that

may occur from external sources, this

regulator should be inspected and

maintained periodically. The frequency

of inspection and replacement of parts

depends upon the severity of service

conditions or the requirements of local,

state, and federal rules and regulations.

A program of periodic regulator inspection should be

established. Visually inspect the regulator for:

Shutdown

Installation arrangements may vary, but in any

installation it is important that the shutoff valves be

opened or closed slowly and that the outlet pressure

be vented before venting inlet pressure to prevent

damage caused by reverse pressurization of the

regulator. The steps below apply to the typical

installation as indicated.

1. Slowly close the upstream shutoff valve.

2. Release downstream pressure and be sure the

upstream pressure has been exhausted.

1. Improper installation.

2. Plugged or frozen vent.

3. Wrong regulator in the system.

4. Internal or external corrosion.

5. Age of the regulator.

6. Any other condition that could cause the

uncontrolled escape of gas.

Failure to establish an inspection program, as

outlined above, could result in personal injury or

property damage.

5

Page 6

Type S402Y

Make sure the regulator vent, vent assembly, or vent

pipe does not become plugged by mud, insects, ice,

snow, paint, or etc. The vent screen aids in keeping

the vent from becoming plugged, and the screen

should be clean and properly installed.

Replace any regulators that have had water in their

spring case and/or show evidence of external or

internal corrosion. Checking for internal corrosion may

require complete removal of the adjusting screw and

shutdown of the gas system.

Older regulators are more likely to fail because

of worn, damaged or corroded parts. Periodic

repair of the diaphragm assembly, orice tube

assembly, and other parts subject to wear and/

or corrosion; or a systematic replacement program

should be based on the regulator’s performance,

the service area’s environment, installation practices,

and historical experience.

The following procedures are for complete regulator

disassembly and assembly. All pressure must be

released from the regulator before the following steps

can be performed. While using the maintenance

procedures, refer to Figure 3 for key number locations.

Note

The regulator may remain in the pipeline

during maintenance procedures unless

the body (key 1) is replaced or removed

for repairs.

5. Reassemble in the reverse order of the above

procedures. Place the diaphragm assembly into

position in the lower casing, being sure the

cam stem (key 10) is properly inserted into the

orice tube assembly (key 7). Note that the

diaphragm plate is marked with “Inlet” and

“Outlet”. Install the spring case assembly (key 3)

and using a crisscross pattern, tighten the spring

case screws (key 13).

Orice Tube Assembly Replacement

1. Remove the spring case screws (key 13) which

hold the lower casing to the body (key 1).

Note

When the actuator assembly is

separated from the body, do not rotate

the diaphragm/relief valve assembly

without removing the spring case

screws (key 13). The assembly

incorporates an anti-rotation design,

any rotational movement will damage

the cam stem/diaphragm assembly.

2. Remove the diaphragm/relief valve assembly

(key 10) by tilting it toward the outlet so that the

cam stem slides up and out of the orice tube

assembly (key 7).

3. Remove the orice tube screws (key 9) and then

the orice tube assembly (key 7).

Control Spring or Diaphragm

Assembly Replacement

1. Remove the closing cap (key 11) and turn the

adjusting screw (key 12) counterclockwise until

all compression is removed from the control

spring (key 6).

2. If changing the control spring (key 6) is the only

maintenance required, remove and replace the

control spring.

3. To replace or reposition the spring case, remove

the spring case screws (key 13) and lift off the

spring case assembly (key 3).

4. For diaphragm maintenance, remove the

diaphragm assembly by tilting it toward

the outlet so that the cam stem may be

pulled up and out of the orice tube

assembly (key 7).

4. Reassemble in the reverse order of the above

procedure. Be sure to use a new orice tube

O-ring (key 8), body with O-ring lubricant.

5. Tighten the spring case screws (key 13) to

80-inch-pounds (9.0 N•m) of torque.

6. If necessary, refer to the installation and/or the

startup and adjustment procedures.

Parts Ordering

When corresponding with your local Sales Ofce about

this equipment, always reference the Type number that

can be found stamped on the regulator.

When ordering replacement parts, reference the key

number of each needed part as found in the following

parts list. Separate kits containing all recommended

spare parts are available. If construction changes

are made in the eld, be sure that the information

on the regulator is also changed to reect the most

recent construction.

6

Page 7

Type S402Y

3

11

12 6

10

9

1

22

- Apply Lub / Sealant

4

5

16

8

7

13

T80288

Figure 3. Type S402Y Pressure Reducing Regulator Assembly

7

Page 8

Type S402Y

Parts List

Key Description Part Number

1 Body, Cast Iron

No Gauge Tap

NPS 3/4, NPT T80281T0012

NPS 1, NPT T80282T0012

Outlet Gauge Tap

NPS 3/4, NPT T13649T0012

NPS 1, NPT T13649T0022

3 Spring Case Assembly

For 1 NPT vent T20932T0012

For 3/4 NPT vent T20932T0032

4 Screen-Vent, 18-8 Stainless Steel T1121338982

5 Retaining Ring, Zinc-plated Steel T1120925072

6 Control spring

4.5 to 6-inches w.c. (11 to 15 mbar), 302 SST T13539T0012

5.5 to 8-inches w.c. (14 to 20 mbar),

Zinc-plated steel T13527T0012

7.5 to 9.5-inches w.c. (19 to 24 mbar),

Zinc-plated steel T13563T0012

9.5 to 13-inches w.c. (24 to 32 mbar),

Zinc-plated steel T13529T0012

13-inches w.c. to 1.5 psig (0,03 to 0,10 bar),

302 SST T13564T0012

1.5 to 2.5 psig (0,10 to 0,17 bar), Steel T13536T0012

Key Description Part Number

7 Orice Tube Assembly T13651T0012

1/8-inch T13651T0012

3/16-inch T13651T0112

1/4-inch T13651T0032

8* Orice Tube, O-Ring, Nitrile (NBR) 18B3438X012

9 Orice Tube Screw, Steel T13526T0012

10 Diaphragm/Relief Valve Assembly

Relief Valve Spring Color

Blue T20930T0012

Orange T20930T0022

Green T20930T0032

Red T20930T0042

Brown T20930T0052

11 Closing Cap, ASA 309, Gray T13524T0062

12 Adjusting Screw

4.5 to 6-inches w.c. (11 to 15 mbar), Delrin

5.5 to 8-inches w.c. (14 to 20 mbar), Delrin T13523T0012

7.5 to 9.5-inches w.c. (19 to 24 mbar), Delrin T13523T0012

9.5 to 13-inches w.c. (24 to 32 mbar), Delrin T13523T0012

13-inches w.c. to 1.5 psig (32 mbar to 0,10 bar),

Zinc 1B537944012

1.5 to 2.5 psig (0,10 to 0,17 bar), Zinc 1B537944012

13 Machiine Screw, Steel (4 required) T13646T0012

16 Pipe Plug, 304 Stainless Steel 1E823135042

22 Screen, 18-8 Stainless steel

For 3/4 NPT vent T13643T0012

For 1 NPT vent T13644T0012

23* Gasket, Neoprene (CR) (not shown) 1P753306992

®

T13523T0012

*Recommended spare part.

Delrin® is a mark owned by E. I. du Pont de Nemours and Co.

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every eort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

©Emerson Process Management Regulator Technologies, Inc., 1992, 2009; All Rights Reserved

Loading...

Loading...