Page 1

User Manual

GFK-2224Y

August 2019

PACSystems™ RX3i and RSTi-EP TCP/IP

Ethernet Communications User Manual

Page 2

Warnings and Caution Notes as Used in this Publication

WARNING

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or may be

associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a Warning

notice is used.

CAUTION

Caution notices are used where equipment might be damaged if care is not taken.

Note: Notes merely call attention to information that is especially significant to understanding and operating the

equipment.

These instructions do not purport to cover all details or variations in equipment, nor to provide for every

possible contingency to be met during installation, operation, and maintenance. The information is

supplied for informational purposes only, and Emerson makes no warranty as to the accuracy of the

information included herein. Changes, modifications, and/or improvements to equipment and

specifications are made periodically and these changes may or may not be reflected herein. It is

understood that Emerson may make changes, modifications, or improvements to the equipment

referenced herein or to the document itself at any time. This document is intended for trained personnel

familiar with the Emerson products referenced herein.

Emerson may have patents or pending patent applications covering subject matter in this document. The

furnishing of this document does not provide any license whatsoever to any of these patents.

Emerson provides the following document and the information included therein as-is and without

warranty of any kind, expressed or implied, including but not limited to any implied statutory warranty of

merchantability or fitness for particular purpose.

© 2019 Emerson. All rights reserved.

Emerson Terms and Conditions of Sale are available upon request. The Emerson logo is a

trademark and service mark of Emerson Electric Co. All other marks are the property of their

respective owners.

Page 3

Contents i

Table of Contents

Table of Contents ..................................................................................................................................... i

Table of Figures ....................................................................................................................................... ix

Section 1: Introduction......................................................................................................................... 1

1.1 Revisions in this Manual ........................................................................................................ 2

1.2 PACSystems Documentation ................................................................................................ 3

1.2.1 PACSystems Manuals ................................................................................................... 3

1.2.2 RX3i Manuals ............................................................................................................... 3

1.2.3 RSTi-EP Manuals ........................................................................................................... 4

1.3 Ethernet Interfaces for PACSystems Controllers ..................................................................... 5

1.3.1 RX3i Rack-Based Ethernet Interfaces – Features ........................................................... 5

1.3.2 RX3i & RSTi-EP Embedded Ethernet Interface - Features ............................................... 6

1.3.3 Ethernet Interface Specifications .................................................................................. 8

1.3.4 Ethernet interface Ports ............................................................................................. 10

1.3.5 Station Manager ......................................................................................................... 11

1.3.6 Firmware Upgrades .................................................................................................... 12

1.3.7 SRTP Client (Channels) ............................................................................................... 12

1.3.8 Modbus TCP Client (Channels) ................................................................................... 12

1.3.9 Ethernet Global Data (EGD) ........................................................................................ 13

1.3.10 SRTP Inactivity Timeout .............................................................................................. 14

1.4 Ethernet Redundancy Operation ......................................................................................... 14

1.4.1 Hot Standby (HSB) CPU Redundancy .......................................................................... 15

1.4.2 Non-HSB Redundancy ................................................................................................ 16

1.4.3 Effect of Redundancy Role Switching on Ethernet Communications ........................... 16

1.4.4 SRTP Server Operation in a Redundancy System ......................................................... 18

1.4.5 SRTP Client Operation in a Redundancy System .......................................................... 18

1.4.6 Modbus TCP Server Operation in a Redundancy System ............................................. 19

1.4.7 Modbus TCP Client Operation in a Redundancy System .............................................. 19

1.4.8 EGD Class 1 (Production & Consumption) in a Redundancy System ............................ 19

1.4.9 EGD Class 2 Commands in a Redundancy System ....................................................... 19

1.4.10 Web Server Operation in a Redundancy System ......................................................... 20

1.4.11 FTP Operation in a Redundancy System ...................................................................... 20

1.4.12 SNTP Operation in a Redundancy System ................................................................... 20

1.4.13 Remote Station Manager Operation in a Redundancy System..................................... 20

1.4.14 IP Address Configuration in a Redundancy System ...................................................... 21

Page 4

Contents ii

Section 2: Installation and Start-up: RX3i/RSTi-EP Embedded Interface .................................................. 22

2.1 RX3i/RSTi-EP Embedded Ethernet Interface Indicators .......................................................... 22

2.1.1 Ethernet Port LEDs Operation ..................................................................................... 22

2.1.2 Module Installation .................................................................................................... 25

2.2 Ethernet Port Connector ..................................................................................................... 25

2.2.1 Connection to a 10Base-T/100Base-TX Network......................................................... 25

2.2.2 10Base-T/100Base-TX Port Pinouts ............................................................................ 25

2.3 Pinging TCP/IP Ethernet interfaces on the Network ............................................................... 26

2.3.1 Determining if an IP Address is Already Being Used ..................................................... 26

Section 3: Installation and Start-up: Ethernet Module Interfaces ........................................................... 27

3.1 Ethernet Module Interface Characteristics............................................................................ 28

3.1.1 Front Panel Port ......................................................................................................... 29

3.1.2 Ethernet Port Connections ......................................................................................... 29

3.1.3 LEDs on the RX3i Ethernet Interface Module ............................................................... 30

3.1.4 Ethernet LEDs ............................................................................................................. 30

3.1.5 Restart/Reset Pushbutton Operation .......................................................................... 32

3.2 Ethernet Module Installation ............................................................................................... 34

3.2.1 Module Installation .................................................................................................... 34

3.2.2 Module Removal ........................................................................................................ 34

3.3 Ethernet Port Connectors ................................................................................................... 35

3.3.1 Embedded Switch ...................................................................................................... 35

3.3.2 Connection to a 10Base-T/100Base-TX/1000Base-T Network ..................................... 37

3.4 Station Manager Port .......................................................................................................... 39

3.4.1 Port Settings .............................................................................................................. 39

3.5 Verifying Proper Power-Up of the Ethernet Interface After Configuration ............................... 39

3.6 Pinging TCP/IP Ethernet interfaces on the Network ............................................................... 40

3.6.1 Determining if an IP Address is Already Being Use ....................................................... 40

3.7 Ethernet Plug-in Applications .............................................................................................. 41

Section 4: Configuration ..................................................................................................................... 42

4.1 RX3i/RSTi-EP Embedded Ethernet Interfaces ........................................................................ 43

4.1.1 Ethernet Configuration Data ...................................................................................... 43

4.1.2 Initial IP Address Assignment ...................................................................................... 44

Page 5

Contents iii

4.1.3 Configuring the Ethernet Interface Parameters .......................................................... 45

4.2 RX3i Rack-Based Ethernet Interface Modules........................................................................ 57

4.2.1 Ethernet Configuration Data ...................................................................................... 58

4.2.2 Initial IP Address Assignment ...................................................................................... 59

4.2.3 Configuring Ethernet Interface Parameters ................................................................ 64

4.2.4 Configuring Ethernet Global Data ............................................................................... 71

Section 5: Ethernet Global Data .......................................................................................................... 90

5.1 Comparison Model for Ethernet Global Data Support ........................................................... 91

5.2 Ethernet Global Data Operation .......................................................................................... 91

5.2.1 EGD Producer ............................................................................................................. 91

5.2.2 EGD Consumers ......................................................................................................... 92

5.3 EGD Exchanges .................................................................................................................. 92

5.3.1 Content of an Ethernet Global Data Exchange ............................................................ 93

5.3.2 Data Ranges (Variables) in an Ethernet Global Data Exchange .................................... 93

5.3.3 Valid Memory Types for Ethernet Global Data............................................................. 93

5.3.4 Planning Exchanges .................................................................................................... 95

5.3.5 Using Ethernet Global Data in a Redundancy System .................................................. 95

5.4 Sending an Ethernet Global Data Exchange to Multiple Consumers ....................................... 95

5.4.1 Multicasting Ethernet Global Data .............................................................................. 96

5.4.2 Broadcasting Ethernet Global Data ............................................................................. 97

5.4.3 Changing Group ID in Run Mode ................................................................................ 97

5.5 Ethernet Global Data Timing ............................................................................................... 99

5.5.1 EGD Synchronization .................................................................................................. 99

5.5.2 Configurable Producer Period for an EGD Exchange .................................................. 100

5.5.3 Consumer Update Timeout Period ........................................................................... 100

5.6 Effect of PLC Modes and Actions on EGD Operations ........................................................... 102

5.6.1 Run Mode Store of EGD ............................................................................................ 103

5.7 Monitoring Ethernet Global Data Exchange Status .............................................................. 108

5.7.2 Exchange Status Word Error Codes ........................................................................... 108

Page 6

Contents iv

Section 6: Programming EGD Commands ......................................................................................... 110

6.1 General Use of EGD Commands......................................................................................... 111

6.2 Using EGD Commands in a Redundancy System ................................................................. 111

6.3 COMMREQ Format for Programming EGD Commands ........................................................ 111

6.4 COMMREQ Status for the EGD Commands ......................................................................... 112

6.4.1 COMMREQ Status Values ......................................................................................... 113

6.5 Read PLC Memory (4000).................................................................................................. 113

6.5.1 Read PLC Memory Command Block .......................................................................... 114

6.6 Write PLC Memory (4001) ................................................................................................. 117

6.6.1 Write PLC Memory Command Block ......................................................................... 117

6.7 Read EGD Exchange (4002) ............................................................................................... 119

6.7.1 Read EGD Exchange Command Block ....................................................................... 119

6.8 Write EGD Exchange (4003) .............................................................................................. 122

6.8.1 Write EGD Exchange Command Block ...................................................................... 122

6.9 Masked Write to EGD Exchange (4004) .............................................................................. 124

6.9.1 Masked Write EGD Exchange Command Block ......................................................... 124

Section 7: SNTP Operation................................................................................................................ 127

7.1 Normal SNTP Operation .................................................................................................... 127

7.1.1 SNTP Broadcast and Multicast Operation Mode ........................................................ 127

7.1.2 SNTP Unicast Operation Mode.................................................................................. 127

7.2 Multiple SNTP Servers (Applies only to SNTP Broadcast and Multicast Mode) ........................ 128

7.3 Loss or Absence of SNTP Timing Signals ............................................................................. 128

7.4 Time-Stamping of Ethernet Global Data Exchanges ............................................................ 129

7.4.1 Obtaining Timestamps from the Ethernet Interface Clock ........................................ 130

7.4.2 Obtaining Timestamps from the CPU TOD Clock ...................................................... 132

Section 8: Programming SRTP Channel Commands ........................................................................... 143

8.1 Model Comparison for SRTP Server Capabilities .................................................................. 144

8.2 SRTP Channel Commands ................................................................................................. 144

8.2.1 Channel Operations ................................................................................................. 144

8.2.2 Aborting and Re-tasking a Channel ........................................................................... 145

Page 7

Contents v

8.2.3 Monitoring the Channel Status ................................................................................. 145

8.2.4 SRTP Channel Commands in a Redundant System .................................................... 145

8.2.5 Executing a Channel Command ................................................................................ 146

8.3 COMMREQ Format for Programming Channel Commands .................................................. 147

8.3.1 The COMMREQ Command Block: General Description ............................................. 148

8.3.2 Establish Read Channel (2003) ................................................................................. 150

8.3.3 Establish Write Channel (2004) ................................................................................ 154

8.3.4 Send Information Report (2010) ............................................................................... 157

8.3.5 Abort Channel (2001) ............................................................................................... 160

8.3.6 Retrieve Detailed Channel Status (2002) .................................................................. 161

8.4 Programming for Channel Commands ............................................................................... 164

8.4.1 COMMREQ Sample Logic .......................................................................................... 164

8.4.2 Sequencing Communications Requests .................................................................... 167

8.4.3 Managing Channels and TCP Connections ................................................................ 168

8.4.4 Use “Channel Re-Tasking” To Avoid Using Up TCP Connections ................................ 168

8.4.5 Client Channels TCP Resource Management ............................................................. 169

8.4.6 SRTP Application Timeouts....................................................................................... 169

8.5 Monitoring Channel Status ............................................................................................... 170

8.5.1 Format of the COMMREQ Status Word ..................................................................... 170

Section 9: Modbus/TCP Server .......................................................................................................... 172

9.1 Model Comparison for Modbus/TCP Server Capabilities ...................................................... 173

9.2 Modbus Conformance Classes ........................................................................................... 174

9.2.1 Server Protocol Services ........................................................................................... 174

9.2.2 Station Manager Support ......................................................................................... 174

9.3 Reference Mapping .......................................................................................................... 174

9.3.1 Modbus Reference Tables ........................................................................................ 174

9.3.2 Address Configuration ............................................................................................. 176

9.4 Modbus Function Codes ................................................................................................... 177

Section 10: Modbus/TCP Client .............................................................................................. 179

10.1 Model Comparison for Modbus/TCP Client Capabilities ....................................................... 180

10.2 Communications Request ................................................................................................. 180

10.2.1 Structure of the Communications Request ............................................................... 180

10.2.2 COMMREQ Function Block ....................................................................................... 181

10.2.3 COMMREQ Command Block ..................................................................................... 181

Page 8

Contents vi

10.2.4 Modbus/TCP Channel Commands ............................................................................ 181

10.2.5 Status Data .............................................................................................................. 182

10.2.6 Operation of the Communications Request .............................................................. 182

10.3 COMMREQ Function Block and Command Block ................................................................ 184

10.3.1 The COMMREQ Function Block ................................................................................. 184

10.3.2 The COMMREQ Command Block .............................................................................. 185

10.4 Modbus/TCP Channel Commands ..................................................................................... 186

10.4.1 Open a Modbus/TCP Client Connection (3000) ......................................................... 186

10.4.2 Close a Modbus/TCP Client Connection (3001) ......................................................... 189

10.4.3 Read Data from a Modbus/TCP Device (3003) .......................................................... 190

10.4.4 Write Data to a Modbus/TCP Device (3004) .............................................................. 197

10.4.5 Mask Write Register Request to a Modbus Server Device (3009) ............................... 201

10.4.6 Read/Write Multiple Registers to/from a Modbus Server Device (3005) .................... 202

10.5 Status Data ...................................................................................................................... 204

10.5.1 Types of Status Data ................................................................................................. 204

10.6 Controlling Communications in the Ladder Program .......................................................... 205

10.6.1 Essential Elements of the Ladder Program ................................................................ 205

10.6.2 Managing Channels and TCP Connections ................................................................ 206

10.6.3 Client Channels TCP Resource Management ............................................................. 206

10.6.4 COMMREQ Ladder Logic Example ............................................................................. 207

10.6.5 Troubleshooting a Ladder Program .......................................................................... 212

10.6.6 Monitoring the Communications Channel ................................................................ 213

Section 11: OPC UA Server ..................................................................................................... 217

11.1 Model Comparison for OPC UA Server Capabilities .............................................................. 218

11.2 OPC UA Certificate Security ............................................................................................... 218

11.2.1 Controlling the OPC UA Server with PAC Machine Edition ......................................... 218

11.2.2 Application Logic to Control the OPC UA Server ........................................................ 222

11.2.3 Connect OPC UA Client to OPC UA Server ................................................................. 232

Page 9

Contents vii

Section 12: Diagnostics ......................................................................................................... 245

12.1 What to do if You Cannot Solve the Problem ...................................................................... 246

12.2 Diagnostic Tools Available for Troubleshooting .................................................................. 246

12.3 Initialization Example of the RX3i Ethernet ETM001-Jx Module Interface .............................. 248

12.4 ETHERNET OK/OK LED Blink Codes for Hardware Failures (ETM001-Jx) ................................. 250

12.5 Controller Fault Table ....................................................................................................... 251

12.5.1 Controller Fault Table Descriptions ........................................................................... 252

12.6 Monitoring the Ethernet Interface Status Bits ..................................................................... 255

12.6.1 LAN Interface Status (LIS) Bits ................................................................................... 258

12.6.2 Channel Status Bits ................................................................................................... 260

12.7 Monitoring the FT Output of the COMMREQ Function Block. ............................................... 261

12.8 Monitoring the COMMREQ Status Word ............................................................................ 263

12.8.1 Format of the COMMREQ Status Word ..................................................................... 263

12.8.2 Major Error Codes in the COMMREQ Status Word ..................................................... 264

12.8.3 Minor Error Codes for Major Error Codes 05H (at Remote Server PLC) and 85H (at Client

PLC) ......................................................................................................................... 265

12.8.4 Minor Error Codes for Major Error Code 11H (at Remote Server PLC) ......................... 266

12.8.5 Minor Error Codes for Major Error Code 90H (at Client PLC) ...................................... 268

12.8.6 Minor Error Codes for Major Error Code 91H (at Remote Modbus/TCP Server) .......... 271

12.8.7 Minor Error Codes for Major Error Code A0H (at Client PLC) ...................................... 272

12.9 Using the EGD Management Tool (RX3i Ethernet Module) .................................................. 273

12.9.1 Installing the EGD Management Tool ....................................................................... 273

12.9.2 Launching the EGD Management Tool ..................................................................... 273

12.9.3 Monitoring EGD Devices ........................................................................................... 274

12.9.4 Monitoring Status of Ethernet Global Data for a Device ............................................ 275

12.10 Troubleshooting Common Ethernet Difficulties ................................................................. 279

12.10.1 COMMREQ Fault Errors ............................................................................................. 279

12.10.2 PLC Timeout Errors ................................................................................................... 279

12.10.3 Application Timeout Errors ....................................................................................... 281

12.10.4 EGD Configuration Mismatch Errors ......................................................................... 281

12.10.5 Station Manager Lockout under Heavy Load ............................................................. 282

12.10.6 PING Restrictions ..................................................................................................... 282

12.10.7 SRTP and Modbus/TCP Connection Timeout ............................................................ 282

12.10.8 Sluggish Programmer Response after Network Disruption ....................................... 283

Page 10

Contents viii

12.10.9 EGD Command Session Conflicts .............................................................................. 285

12.10.10 SRTP Request Incompatibility with Existing Host Communications Toolkit Devices or

Other SRTP Clients ................................................................................................... 285

12.10.11 COMMREQ Flooding Can Interrupt Normal Operation .............................................. 285

12.10.12 Accelerated EGD Consumption Can Interfere with EGD Production .......................... 285

12.10.13 Channels Operation Depends Upon PLC Input Scanning ........................................... 286

Section 13: Network Administration ....................................................................................... 288

13.1 IP Addressing ................................................................................................................... 288

13.1.1 IP Address Format for Network Classes A, B, C .......................................................... 288

13.1.2 IP Addresses Reserved for Private Networks .............................................................. 289

13.1.3 Multicast IP Addresses .............................................................................................. 289

13.1.4 Loopback IP Addresses ............................................................................................. 289

13.1.5 Overlapping Subnets ................................................................................................ 290

13.2 Gateways ......................................................................................................................... 293

13.2.1 Networks Connected by a Gateway .......................................................................... 293

13.3 Subnets and Supernets ..................................................................................................... 293

13.3.1 Subnet Addressing and Subnet Masks ...................................................................... 294

13.3.2 Example: Network Divided into Two Subnets ............................................................ 294

13.3.3 Example: Two Networks Combined into a Supernet .................................................. 295

SNTP Time Transfer to CPU Parameters (task n) .................................................................................... 303

Page 11

Contents ix

Table of Figures

Figure 1: Ethernet Connection System Diagram ..................................................................................................... 5

Figure 2: Ethernet Operation in Redundancy Mode .............................................................................................. 15

Figure 3: Basic Non-HSB System with Redundant IP.............................................................................................. 16

Figure 4: RJ45 Connector ..................................................................................................................................... 25

Figure 5: Ethernet Cable Routing ......................................................................................................................... 26

Figure 6: ETM001-Jx Faceplate ............................................................................................................................. 28

Figure 7: ETM001-Kxxx Faceplate ........................................................................................................................ 28

Figure 8: Ethernet Port Connectors on IC695ETM001-Kxxx ................................................................................... 29

Figure 9: Install Module into RX3i Backplane ........................................................................................................ 34

Figure 10: Remove Module from RX3i Backplane ................................................................................................. 34

Figure 11: Diagram of Embedded Ethernet Switch ............................................................................................... 35

Figure 12: System Diagram: Ethernet Routing Using Embedded Switch ................................................................ 36

Figure 13: Connection Using Hub/Switch/Repeater .............................................................................................. 38

Figure 14: Direct Connection to the Embedded Ethernet Ports .............................................................................. 38

Figure 15: Expand CPU Slot to Display Ethernet Node ........................................................................................... 44

Figure 16: Expand RX3i CPU Node to Configure Embedded Ethernet interface ....................................................... 47

Figure 17: CPE330/CPE400/CPL410/CPE100/CPE115/ETM001-Kxxx Settings tab .................................................. 49

Figure 18: CPE330 Advanced Ethernet Configuration LAN1 & LAN2 ...................................................................... 50

Figure 19: CPE100/CPE115/CPE400/CPL410 Advanced Ethernet Configuration LAN1 & LAN2 ............................... 51

Figure 20: SNTP PME configuration for the CPE302/CPE305/CPE310/CPE330/CPE400/CPL410 CPU settings .......... 52

Figure 21: SNTP Multicast/Broadcast or Unicast Mode Settings ............................................................................ 52

Figure 22: UTC Time Zone Settings ...................................................................................................................... 53

Figure 23: Terminals Tab Settings in PAC Machine Edition .................................................................................... 53

Figure 24: Adding Ethernet Global Data (EGD) to the Configuration ..................................................................... 54

Figure 25: Defining EGD Produced Data Exchange ............................................................................................... 55

Figure 26: Defining EGD Consumed Data Exchange ............................................................................................. 55

Figure 27: Configuring Multicast & Broadcast EGD on LAN1 ................................................................................. 56

Figure 28: Configuring Multicast & Broadcast EGD on LAN2 ................................................................................. 57

Figure 29: Setting Temporary IP Address .............................................................................................................. 60

Figure 30: Install ETM001-Jx Module in Rack/Slot & Expand to Configure .............................................................. 64

Figure 31: Expand Node to View Ethernet Global Data ......................................................................................... 71

Figure 32: Local Producer ID ................................................................................................................................ 72

Figure 33: Configuring the EGD Configuration Server ........................................................................................... 73

Figure 34: Exchange ID Offset in an Ethernet Redundancy System ........................................................................ 88

Figure 35: Configuring Redundancy for Ethernet Global Data ............................................................................... 89

Figure 36: Configuring Produce in Backup Mode Parameter ................................................................................. 89

Figure 37: Producing & Consuming Ethernet Global Data ..................................................................................... 91

Page 12

Contents x

Figure 38: Adding Symbolic Reference to Ethernet Global Data Exchange ............................................................. 94

Figure 39: Grouping of Devices for Ethernet Global Data Multicasting .................................................................. 96

Figure 40: Memory Sharing between PLC and Ethernet interface .......................................................................... 99

Figure 41: EGB Timing Example #1 .................................................................................................................... 101

Figure 42: EGB Timing Example #2 .................................................................................................................... 101

Figure 43: Sample COMMREQ Ladder Diagram .................................................................................................. 111

Figure 44: Example: Masked Write to EGD Exchange Bit Mask and Data Bits ....................................................... 126

Figure 45: Obtaining Timestamps from the Ethernet interface Clock .................................................................. 130

Figure 46: Obtaining Timestamps from the PLC Time Clock ................................................................................ 131

Figure 47: Obtaining Timestamps from the SNTP Server’s Time Clock................................................................. 132

Figure 48: Synchronizing CPU Time-of-Day Clock to an SNTP Server ................................................................... 133

Figure 49: Operating Sequence for CPU Clock Synchronization ........................................................................... 134

Figure 50 Hardware Configuration Module in PME ............................................................................................. 136

Figure 51: COMMREQ to Control the CPU Time-of-Day Clock .............................................................................. 137

Figure 52: COMMREQ Sequence for Establish Read Channel ............................................................................... 146

Figure 53: COMMREQ for Programming Channel Commands ............................................................................ 147

Figure 54: Interpreting Detailed Channel Status Words ...................................................................................... 163

Figure 55: Sample Ladder Logic for COMMREQ .................................................................................................. 166

Figure 56: Interpreting COMMREQ Status Word ................................................................................................. 170

Figure 57: Calculations for Modbus File and Record %W Memory Address ........................................................... 175

Figure 58: Phases of a COMMREQ Execution ...................................................................................................... 181

Figure 59: Illustration of Phased Operation of a COMMREQ ................................................................................ 183

Figure 60: The COMMREQ Function Block .......................................................................................................... 184

Figure 61: Interpreting the COMMREQ Status Word ........................................................................................... 205

Figure 62: COMMREQ Ladder Logic Segment ..................................................................................................... 207

Figure 63: COMMREQ Ladder Logic Segment (continued) .................................................................................. 208

Figure 64: COMMREQ Ladder Logic Segment (continued) .................................................................................. 209

Figure 65: COMMREQ Ladder Logic Segment (continued) .................................................................................. 210

Figure 66: COMMREQ Ladder Logic Segment (continued) .................................................................................. 211

Figure 67: COMMREQ Ladder Logic Segment (continued) .................................................................................. 211

Figure 68: COMMREQ Ladder Logic Segment (continued) .................................................................................. 212

Figure 69: Example of Start OPC UA Server Service Request ................................................................................ 223

Figure 70: Example of Stop OPC UA Server Service Request ................................................................................. 224

Figure 71: Example of Clear OPC UA Server Service Request ................................................................................ 225

Figure 72: Example of Restart OPC UA Server Request ........................................................................................ 226

Figure 73: SERVER_STATUS Word bit definitions ................................................................................................ 227

Figure 74: Example of Get OPC UA Server Status Service Request ........................................................................ 228

Figure 75: CONFIG_STATUS Word bit definitions ................................................................................................ 229

Figure 76: Server Status Definition ..................................................................................................................... 230

Figure 77: Config Status Definition .................................................................................................................... 230

Page 13

Contents xi

Figure 78: Example of Get Provisioning Mode Status Service Request .................................................................. 231

Figure 79: OPC UA Binary Connection String ...................................................................................................... 232

Figure 80: Project Inspector/Ethernet Config Window ........................................................................................ 233

Figure 81: OPC UA Server Client Connection String ............................................................................................. 234

Figure 82: OPC UA Client Connection Dialog ...................................................................................................... 234

Figure 83: PME Controller Hardware Configuration – Passwords Disabled .......................................................... 235

Figure 84: PME Controller Hardware Configuration – Passwords Enabled ........................................................... 236

Figure 85: PME Online Command to Set Passwords ............................................................................................ 237

Figure 86: Example OPC UA Address Space ........................................................................................................ 238

Figure 87: PME Variable Inspector ...................................................................................................................... 239

Figure 88: Application Variable Address Space ................................................................................................... 240

Figure 89: OPC UA Address Space - Server Node ................................................................................................. 241

Figure 90: Server Specific Address Space ............................................................................................................ 241

Figure 91: BuildInfo Subscription ....................................................................................................................... 242

Figure 92: OPC UA Address Space - Application Information ............................................................................... 242

Figure 93: OPC UA Address Space – Device Information ..................................................................................... 243

Figure 94: States of the Ethernet interface ......................................................................................................... 248

Figure 95: Fault Extra Data Example .................................................................................................................. 251

Figure 96: Monitoring FT Output in COMMREQ Function Block ........................................................................... 261

Figure 97: Decoding the COMMREQ Status Word ............................................................................................... 263

Figure 98: EGD Management Tool Screenshot ................................................................................................... 273

Figure 99: EGD Monitoring Tool Monitoring EGD Network ................................................................................. 274

Figure 100: EGD Management Tool Displaying EGD Exchange Information ........................................................ 275

Figure 101: EGD Management Tool Displaying EGD Statistics ............................................................................ 276

Figure 102: EGD Management Tool Displaying List of Variables for an Exchange ................................................ 277

Figure 103: IP Address Format for Network Classes A, B, C .................................................................................. 288

Figure 104: CPE330 Overlapping Local IP Subnet Example .................................................................................. 290

Figure 105: Expected Response Path .................................................................................................................. 292

Figure 106: Actual Response Path ...................................................................................................................... 292

Figure 107: Gateway Connected to Two Networks ............................................................................................. 293

Figure 108: Class B Network netid and hostid Bit Formats .................................................................................. 294

Figure 109: Use of Subnet Mask ......................................................................................................................... 294

Figure 110: Network 2 Divided into Subnets 2.1 and 2.2 .................................................................................... 295

Figure 111: Subnet Mask Used to Affect a Supernet ............................................................................................ 296

Figure 112: Resulting Supernet .......................................................................................................................... 296

Page 14

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 1

Section 1: Introduction

This chapter includes basic information about Ethernet interfaces for the PACSystems family of controllers. It

describes features of the Ethernet interfaces in both conventional and redundancy systems. The rest of this

manual provides instructions for installing and applying the PACSystems Ethernet interfaces:

Section 2:, Installation and Start-up: RX3i/RSTi-EP Embedded Interface describes user features and basic

installation procedures.

Section 3:, Installation and Start-up: Ethernet Module Interfaces describes user features and basic installation

procedures.

Section 4:, Configuration describes assigning a temporary IP address and configuring the Ethernet interface

parameters. For the RX3i rack-based and embedded interfaces, describes how to configure Ethernet Global

Data (EGD) and set up the RS-232 port for Local Station Manager operation.

Section 5:, Ethernet Global Data describes basic EGD operation for rack-based and embedded interfaces.

Section 6:, Programming EGD Commands describes a set of commands that can be used in the application

program to read and write PLC data or use Ethernet Global Data exchange data over the network.

Section 7:, SNTP Operation describes the benefit of synchronizing SNTP-capable interfaces with an SNTP

server to keep internal clocks up-to-date for accurate timestamp communications.

Section 8:, Programming SRTP Channel Commands explains how to implement PLC to PLC communications

over the Ethernet network using Service Request Transfer Protocol (SRTP) Channel commands.

Chapter 9, Modbus/TCP Server describes the implementation of the Modbus TCP Server feature for the

PACSystems family of products.

Chapter 10, Modbus/TCP Client explains how to program communications over the Ethernet network using

Modbus TCP Channel commands.

Chapter 11, OPC UA Server explains how to program communications for this protocol using the embedded

Ethernet port.

Chapter 12, Diagnostics describes diagnostic techniques for a PACSystems Ethernet interface. This chapter

also lists COMMREQ Status codes.

Chapter 13, Network Administration discusses how devices are identified on the network and how data is

routed among devices.

Appendix A, Configuring Advanced User Parameters describes optional configuration of internal operating

parameters used by the Ethernet interface. For most applications, the default Advanced User Parameters

(AUPs) should not be changed.

Page 15

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 2

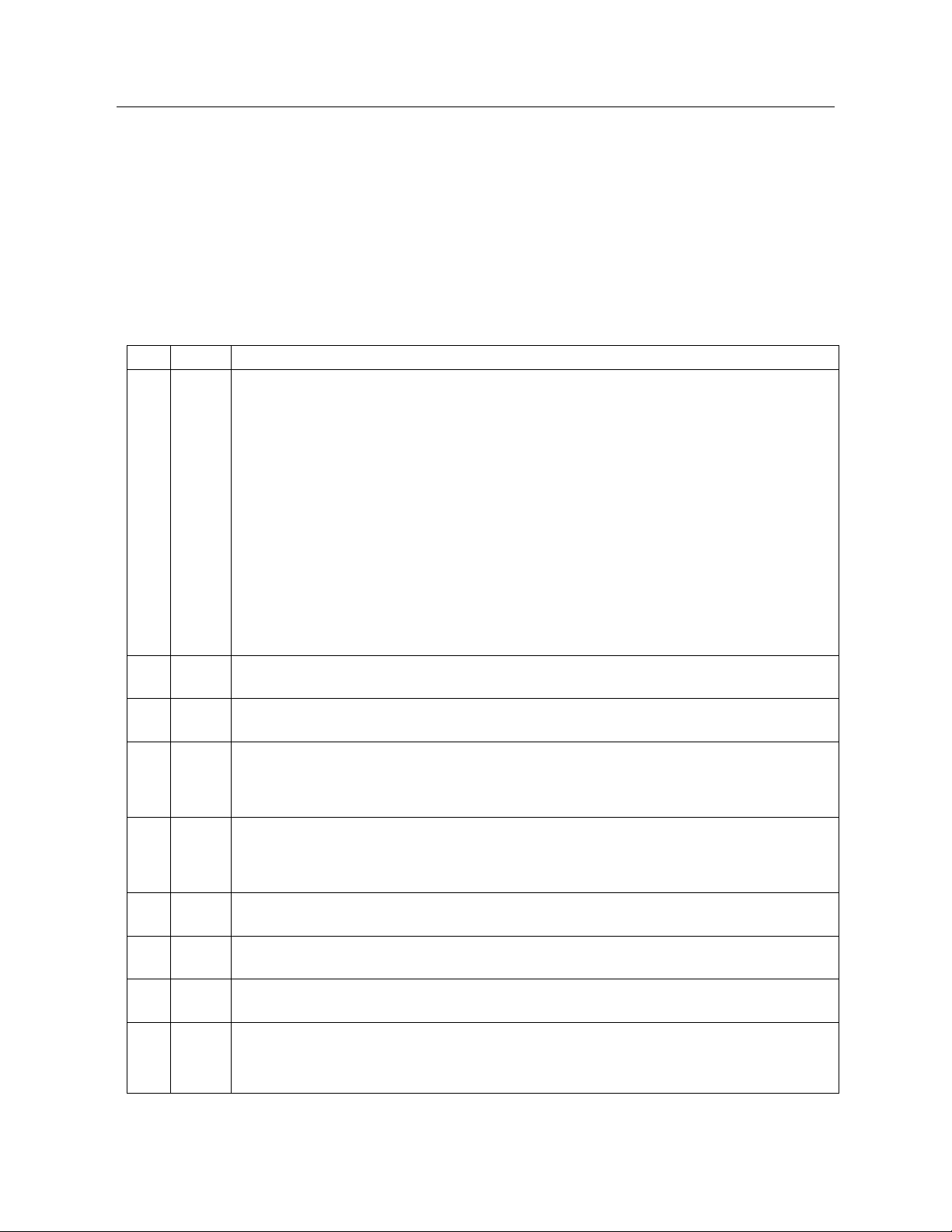

1.1 Revisions in this Manual

A given feature may not be implemented on all PACSystems Ethernet interfaces. To

determine whether a feature is available on a given model and firmware version, please

refer to the Important Product Information (IPI) document provided with the product.

This revision of TCP/IP Ethernet Communications for PACSystems RX3i and RSTi-EP

includes the following changes:

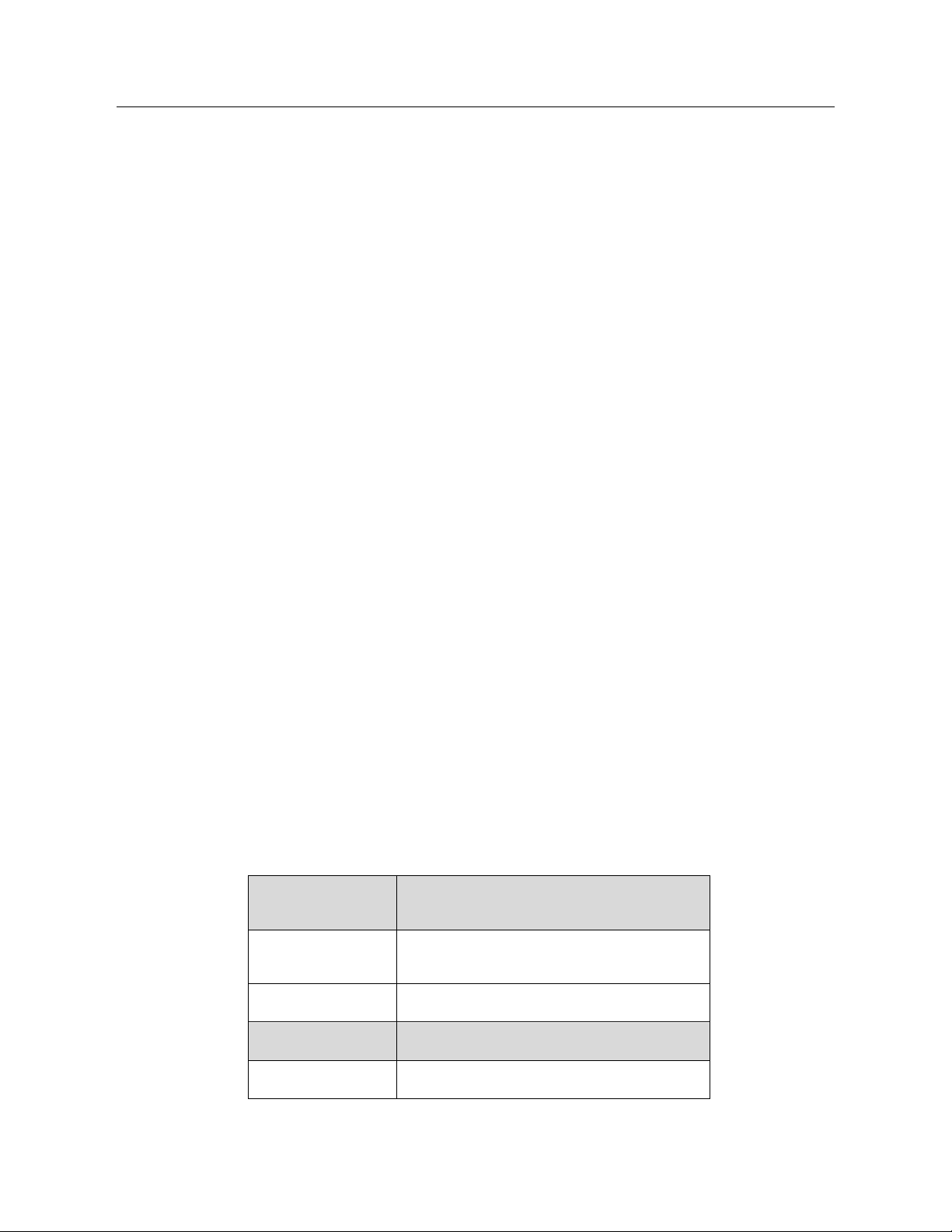

Rev

Date

Description

Y

Aug2019

• RX3i IC695ETM001-Kxxx Available

o Backwards compatible with IC695ETM001

o Station Manager serial port replaced with Ethernet port

o Two Ethernet connectors relocated to the bottom of the module.

o Achilles Level 2 Security cert-tested.

o New option to select user-based parameters into menu systems. AUP

functionalist is partially deprecated.

• Diagnostics information for the RX3i embedded Ethernet interface has been moved

from Chapter 12 to Chapter 11.

W

Jul2018

• Added IC695CPL410 (new CPU w/Linux)

V

Apr2018

• Extended the document to EPSCPE115

U

Feb2018

• Addition of CPE302 throughout.

• Clarification (Section 1.3.4) as to which products support 1000Base-T IEEE 802.3.

T

Oct2017

• Added CPE400 LAN3 (Redundancy-only LAN)

• Clarified support for Redundant IP Addressing in various CPU configurations.

S

Aug2017

• Content added to Ethernet interface Status Bits for RSTi-EP CPE100.

R

May2017

• Content added in support of RSTi-EP CPE100.

Q

Mar2017

• Content added in support of CPE400 and embedded SNTP.

P

Sept2015

• Added section Sessions and Subscriptions for OPC UA.

• Content added in support of CPE330 (new product).

Page 16

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 3

M

Oct2014

• Effective with RX3i CPE305/CPE310 firmware version 8.20, OPC UA Server is

supported using the embedded Ethernet port.

• Effective with RX3i CPE305/CPE310 firmware version 8.30, EGD Class 1 is supported

on the embedded Ethernet interface. Earlier CPU versions do not directly support

EGD. However, EGD was supported on the Ethernet interface Module ETM001.

L

Jun2013

Newly available features:

• TCP/IP communication services using SRTP

• SRTP Client (Channels)

• Modbus/TCP Server, supporting Modbus Conformance classes 0, 1, and 2.

• Modbus/TCP Client, supporting Modbus Conformance classes 0, 1, and Function

Codes 15, 22, 23, and 24 for Conformance class 2.

• Support for Unicast mode, and Daylight Saving and Local Time corrections for SNTP

operation.

Diagnostics information for the RX3i embedded Ethernet interface has been moved from

Chapter 2 Section 2:to 11. Configuration information has been moved to Section 4:.

Information about Channel Status bits has been removed from chapters 2, 7 and 9, and

consolidated in Chapter 11.

1.2 PACSystems Documentation

1.2.1 PACSystems Manuals

PACSystems RX7i, RX3i and RSTi-EP CPU Reference Manual

GFK-2222

PACSystems RX7i, RX3i and RSTi-EP CPU Programmer’s Reference Manual

GFK-2950

PACSystems TCP/IP Ethernet Communications Station Manager User Manual

GFK-2225

PACSystems Hot Standby CPU Redundancy User’s Guide

GFK-2308

PAC Machine Edition Logic Developer Getting Started

GFK-1918

PACSystems RXi, RX7i, RX3i and RSTi-EP Controller Secure Deployment Guide

GFK-2830

PACSystems RX7i Installation Manual

GFK-2223

1.2.2 RX3i Manuals

PACSystems RX3i System Manual

GFK-2314

PACSystems RX3i Ethernet Network Interface Unit (NIU) User’s Manual

GFK-2439

Page 17

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 4

PACSystems RX3i IEC 61850 Ethernet Communication Module User Manual

GFK-2849

PACSystems RX3i Serial Communications Modules User Manual

GFK-2460

PACSystems RX3i IEC 104 Server Module IC695EIS001 User’s Manual

GFK-2949

PACSystems RX3i IC695CPE400 1.2GHz 64MB Rackless CPU w/Field Agent QSG

GFK-3002

PACSystems RX3i IC695CPL410 1.2GHz 64MB Rackless CPU w/Linux QSG

GFK-3053

1.2.3 RSTi-EP Manuals

PACSystems RSTi-EP System Manual

GFK-2958

Page 18

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 5

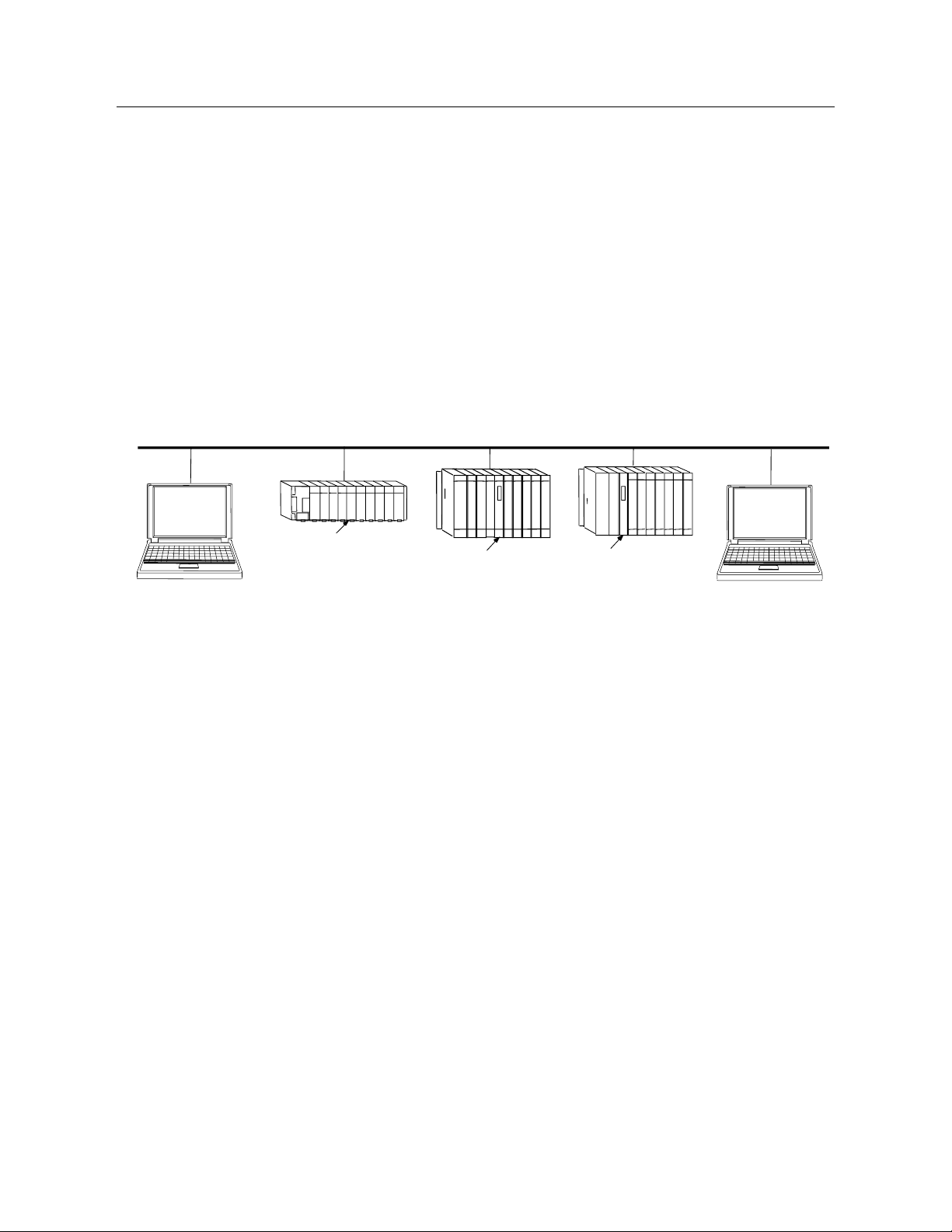

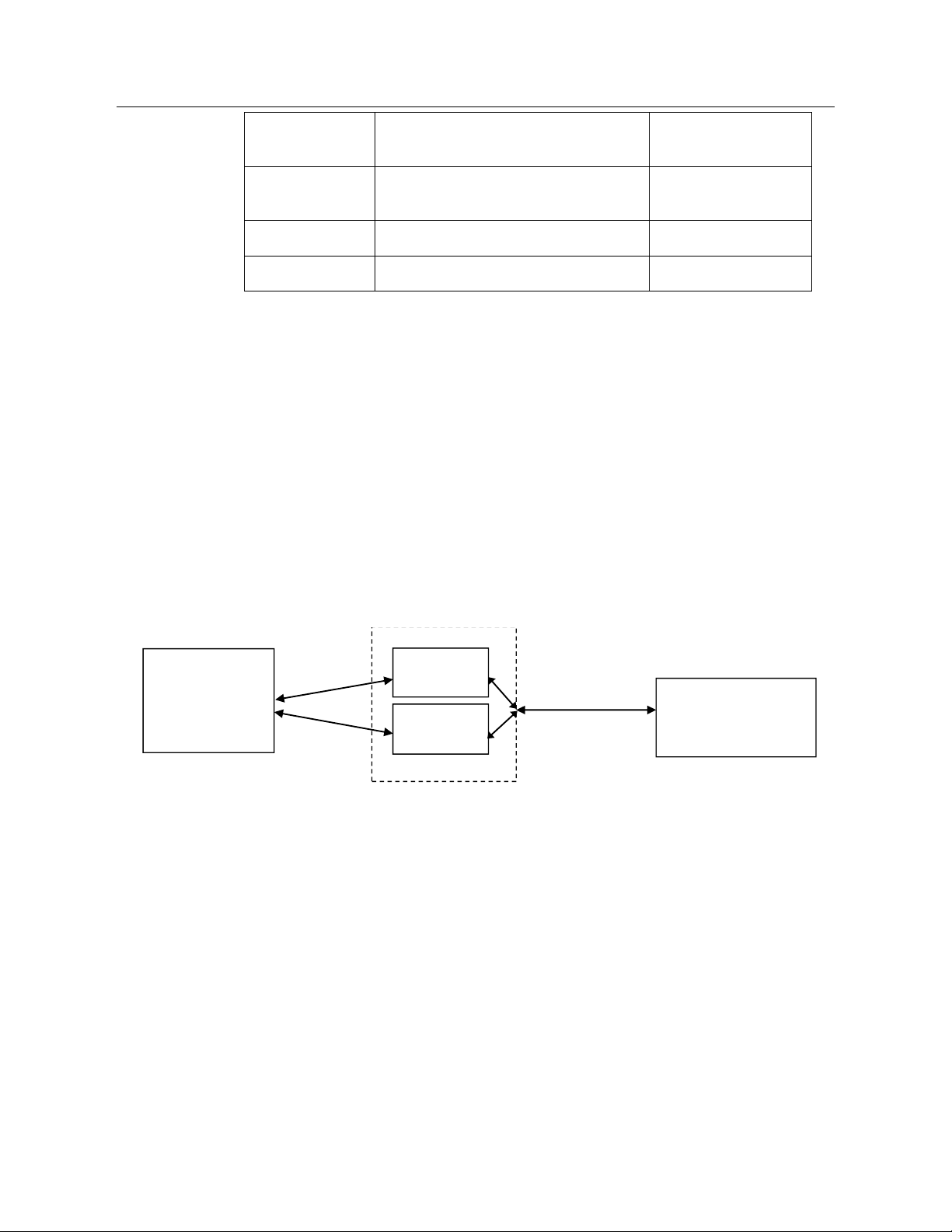

1.3 Ethernet Interfaces for PACSystems Controllers

A PACSystems Ethernet interface enables a PACSystems controller to communicate with

other PACSystems equipment and with Series 90 and VersaMax controllers. The Ethernet

interface provides TCP/IP communications with other PLCs, host computers running the

Host Communications Toolkit or CIMPLICITY software, and computers running the TCP/IP

version of the programming software. These communications use the proprietary SRTP

and Ethernet Global Data (EGD) protocols over a four-layer TCP/IP (Internet) stack.

The Ethernet interface has SRTP client/server capability. As a client, the interface can

initiate communications with other PLCs that contain Ethernet interfaces. This is done

from the PLC ladder program using the COMMREQ function. As a server, the Ethernet

interface responds to requests from devices such as PLC programming software, a Host

computer running an SRTP application, or another PLC acting as a client.

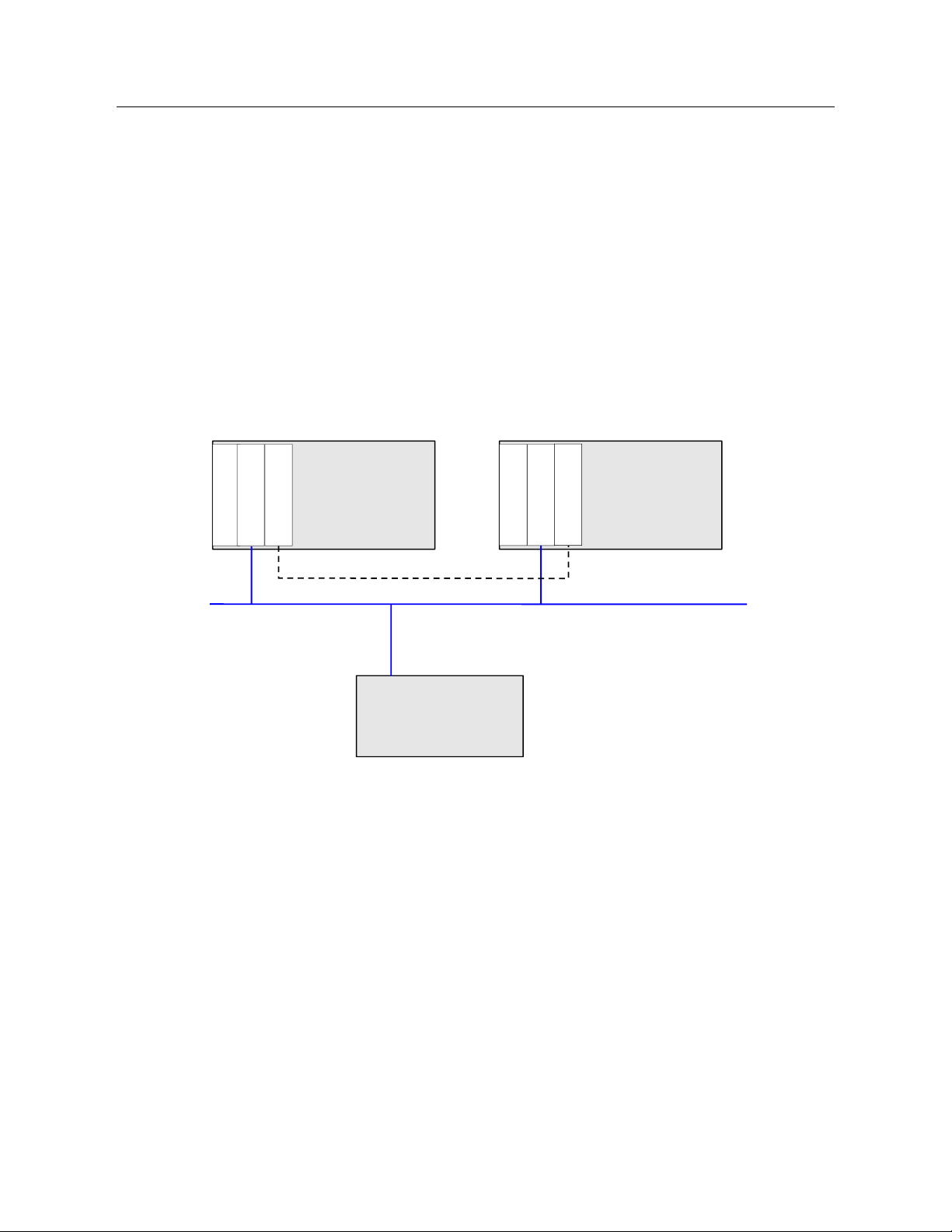

Network

Connection

Ethernet Cable

Host Computer or Control

Device running a Host

Communications Toolkit

Ethernet

Interface

PACSystems and Series 90 PLCs

Computer Running

Programming Software-

TCP/IP Ethernet

Ethernet

Interface

Ethernet

Interface

Network

Connection

Figure 1: Ethernet Connection System Diagram

1.3.1 RX3i Rack-Based Ethernet Interfaces – Features

▪ Full RX3i Controller programming and configuration services with inactivity timeout

▪ Periodic data exchange using Ethernet Global Data (EGD)

▪ EGD Commands to read and write PLC and EGD exchange memory over the network

▪ TCP/IP communication services using SRTP

▪ SRTP Client (Channels)

▪ Modbus TCP Server, supporting Modbus Conformance classes 0, 1, and 2

▪ Modbus TCP Client, supporting Modbus Conformance classes 0, 1, and Function Codes 15, 22, 23,

and 24 for Conformance class 2

▪ Redundant IP Addressing capability

Page 19

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 6

▪ Comprehensive station management and diagnostic tools

▪ Extended controller connectivity via IEEE 802.3 CSMA/CD 10 Mbps, 100M bps and 1000 Mbps

Ethernet LAN port connectors

▪ Network switch that has Auto negotiate, Sense, Speed, and crossover detection

▪ Protocol is stored in flash memory in the Ethernet interface and is easily upgraded through the CPU

serial port.

▪ Communications with remote PLCs and other nodes reachable through routers. The gateway IP

address must be configured.

1.3.2 RX3i & RSTi-EP Embedded Ethernet Interface - Features

▪ Periodic data exchange using Ethernet Global Data (EGD).

▪ Full RX3i controller programming and configuration services with inactivity timeout

▪ TCP/IP communication services using SRTP.

▪ SRTP Client (Channels)

▪ Modbus TCP Server, supporting Modbus Conformance classes 0, 1, and 2.

▪ Modbus TCP Client, supporting Modbus Conformance classes 0, 1, and Function Codes 15, 22, 23,

and 24 for Conformance class 2.

▪ Communications with remote PLCs and other nodes reachable through routers. The Gateway IP

address must be configured.

▪ Comprehensive station management and diagnostic tools. For supported commands, refer to the

PACSystems TCP/IP Ethernet Communications Station Manager User Manual, GFK-2225J or later.

1.3.2.1 CPE302/CPE305/CPE310

▪ Extended controller connectivity via IEEE 802.3 CSMA/CD 10 Mbps and 100 Mbps Ethernet LAN port

connectors.

▪ Network switch that has Auto negotiate, Sense, Speed, and crossover detection.

▪ Direct connection to Base-T (twisted pair) network switch, hub, or repeater without an external

transceiver.

Page 20

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 7

CPE330/CPE400/CPL410

• Two independent 10/100/1000 Ethernet LANs under the control of the embedded RX3i PLC. Port 1

attaches to LAN1 through a dedicated RJ45 connector. Port 2 attaches to LAN2 through a pair of

internally-switched RJ45 connectors. Space is provided to mark in the two corresponding IP

addresses.

• The embedded Ethernet interface permits the CPU to support two LANs.

• CPE400 has a third Ethernet port (located on the underside) which is under the control of Field

Agent.

• CPL410 also has a third Ethernet port (located on the underside) which is under the control of the

Linux OS.

RSTi-EP CPE100/CPE115

• Two independent 10/100 Ethernet LANs. Port 1 attaches to LAN1 through a dedicated RJ45

connector. Port 2 attaches to LAN2 through three internally-switched RJ45 connectors.

• The embedded Ethernet interface permits the CPU to support two LANs.

Refer to the PACSystems RX7i, RX3i and RSTi-EP CPU Reference Manual, GFK-2222,

specifically to the section, RX3i CPU Features and Specifications for RX3i CPUs & RSTi-EP

CPU Features and Specifications for RSTi-EP CPU, for a detailed list of features and

specifications.

Page 21

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 8

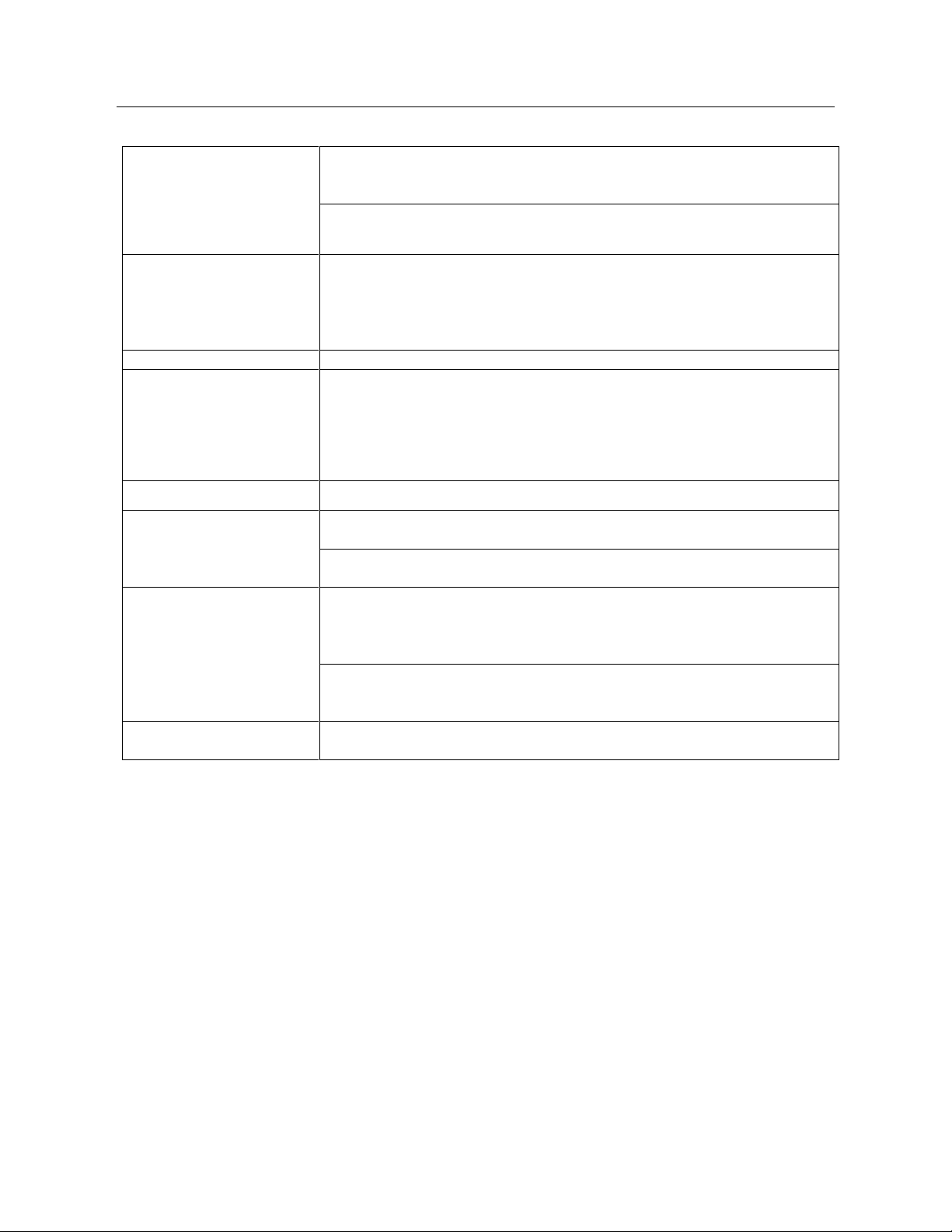

1.3.3 Ethernet Interface Specifications

RX3i Rack-Based Ethernet

Interface Modules

Connectors

IC695ETM001-Jx or earlier

- Two RJ45 connectors

- One 9-pin d-sub male serial connector (Station Manager port)

IC695ETM001-Kxxx

Three autosensing RJ45 ports

LAN

IC695ETM001-Jx or earlier:

IEEE 802.3 CSMA/CD Medium Access Control 10/100 Mbps

IC695ETM001-Kxxx:

IEEE 802.3 CSMA/CD Medium Access Control 10/100/1000 Mbps

Number of IP addresses

One

Maximum number of

simultaneous connections

▪ A maximum of 48 SRTP Server total connections

▪ A maximum of 16 Modbus/TCP Server connections

▪ A maximum of 32 communication channels. (Each channel may be an

SRTP Client or a Modbus/TCP Client. Any given channel can be assigned

to only one protocol at a time.)

Embedded Ethernet Switch

Yes – Allows daisy chaining of Ethernet nodes.

Serial Port

IC695ETM001-Jx

Station Mgr Port: RS-232 DCE, 1200 - 115200 bps.

IC695ETM001-Kxxx

Not applicable.

Station Manager

IC695ETM001-Jx

Access via local serial port or remote UDP. Refer to the PACSystems TCP/IP

Ethernet Communications Station Manager User Manual, GFK-2225J or later,

for supported commands.

IC695ETM001-Kxxx

Station Manager serial port has been replaced by the front panel Ethernet

port

Maximum ETM001 Modules

per CPU rack

Eight positions

Page 22

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 9

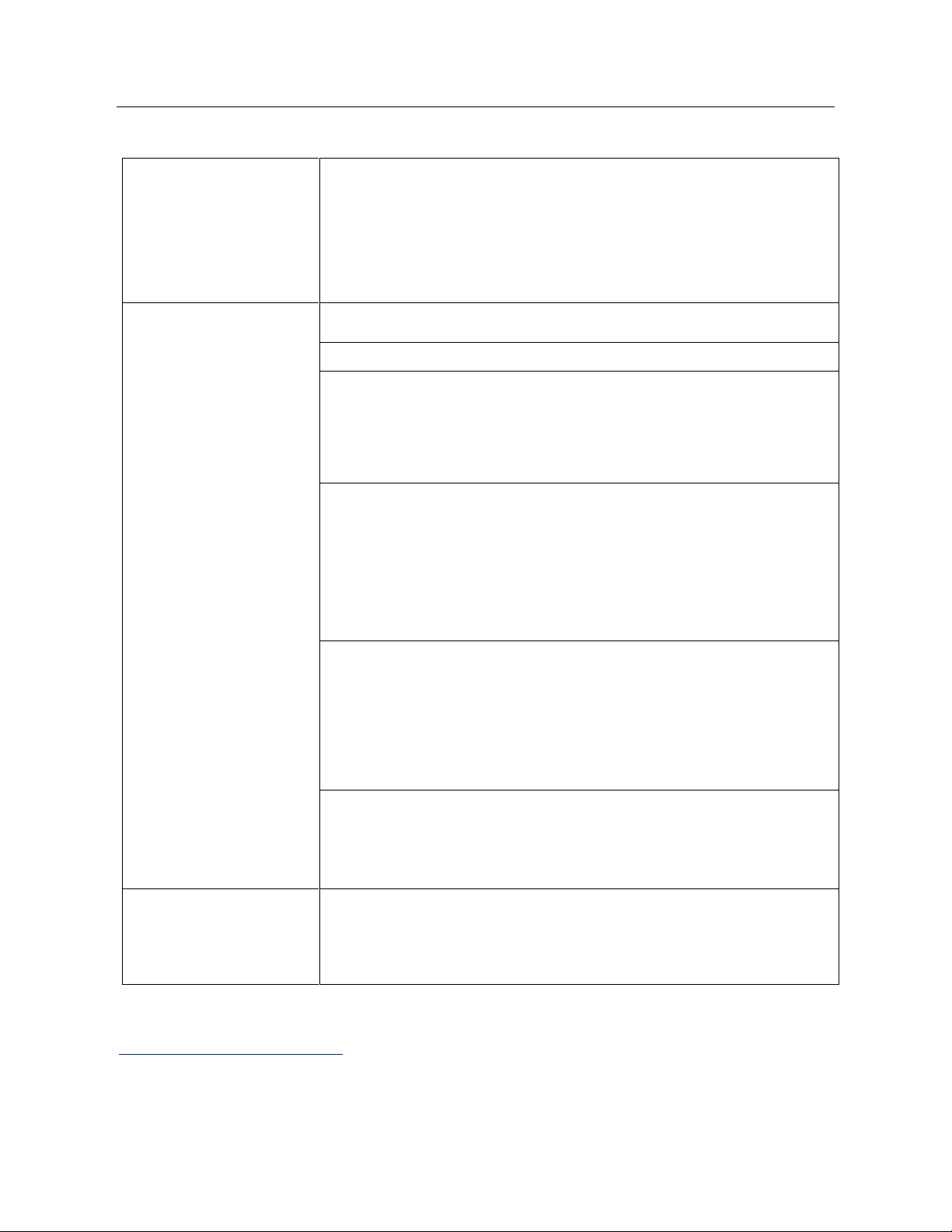

1.3.3.1 RX3i Embedded Interface

Connector

CPE302/CPE305 & CPE310: One RJ45 connector

CPE330: Three RJ45 connectors

CPE400: Six RJ45 connectors: five on front for LAN1, LAN2 & LAN3; one EFA

on underside. (There is also a serial RJ45 on underside, marked COM1.)

CPL410: Six RJ45 connectors: five on front for LAN1, LAN2 & LAN3; one ETH

on underside. (There is also a serial RJ45 on underside, marked COM1.)

CPE100/CPE115: Four RJ45 connectors

LAN

IEEE 802.3 CSMA/CD Medium Access Control 10/100/1000 Mbps

CPE302/CPE305 & CPE310 has one 10Base-T/100Base-TX Port (LAN1)

CPE330 has two independent 10/100 Mbps Ethernet LANs:

▪ The top Ethernet port attaches to LAN1 using a dedicated RJ45

connector

▪ The bottom two Ethernet ports attach to LAN2 using a pair of internally-

switched RJ45 connectors

CPE400 supports four independent 10/100/1000 Ethernet LANs which are

under the control of the embedded RX3i PLC.

▪ LAN1 attaches via the upper, dedicated RJ45 front-panel connector.

▪ LAN2 and LAN3

1

each attach via a pair of internally-switched RJ45 front-

panel connectors.

▪ The fourth LAN, labeled EFA (Embedded Field Agent), is located on the

underside, and is specifically used for Field Agent connectivity.

CPL410 supports four independent 10/100/1000 Ethernet LANs which are

under the control of the embedded RX3i PLC.

▪ LAN1 attaches via the upper, dedicated RJ45 front-panel connector.

▪ LAN2 and LAN3 each attach via a pair of internally-switched RJ45 front-

panel connectors.

The fourth LAN, labeled ETH (Ethernet), is located on the underside, and is

under the control of the embedded Linux Operating System.

CPE100/CPE115 supports two independent 10/100 Ethernet LANs located

on the front panel.

▪ LAN1 attaches via the upper, dedicated RJ45 connector.

▪ LAN2 attach via three internally-switched RJ45 connectors.

Number of IP addresses

CPE302/CPE305 & CPE310: One IP address

CPE330 has two IP addresses

CPE400 has four IP addresses (one for EFA, three for Ethernet LANs)

CPL410 has four IP addresses (one for ETH, three for Ethernet LANs)

CPE100/CPE115 has two IP addresses

1

CPE400 firmware version 9.30 supports Redundancy via LAN3. No LAN components other than the two Redundant

CPUs are permitted on LAN3. All firmware versions of CPL410 support the same feature.

Page 23

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 10

Maximum number of

connections

For CPE302/CPE305 & CPE310 LAN1:

▪ Up to 32 SRTP Server connections, includes:

▪ Up to 16 simultaneous Modbus/TCP Server connections.

▪ Up to 16 Client channels. (Each channel may be an SRTP Client or a

Modbus/TCP Client. Any given channel can be assigned to only one

protocol at a time.)

▪ OPC UA Server with support for up to 5 concurrent sessions with up to

10 concurrent variable subscriptions and up to 12,500 variables.

▪ Up to 255 simultaneous Class 1 Ethernet Global Data (EGD) exchanges.

For CPE330, CPE4001 and CPL410, the embedded Ethernet permits the CPU

to support LAN1 and LAN2 with:

▪ Up to 48 simultaneous SRTP Server connections, and

▪ Up to 16 simultaneous Modbus/TCP Server connections

▪ Up to 32 Clients are permitted; each may be SRTP or Modbus/TCP

▪ OPC UA Server with support for up to 5 concurrent sessions with up to

10 concurrent variable subscriptions and up to 12,500 variables

▪ Up to 255 simultaneous Class 1 Ethernet Global Data (EGD) exchanges.

For CPE100/CPE115, the embedded Ethernet permits the CPU to support

LAN1 and LAN2 with:

▪ Up to 16 simultaneous SRTP Server connections, and

▪ Up to 8 simultaneous Modbus/TCP Server connections

▪ Up to 8 Clients are permitted; each may be SRTP or Modbus/TCP

▪ Up to 8 simultaneous Class 1 Ethernet Global Data (EGD) exchanges.

Station Manager

Access remote UDP Refer to the PACSystems TCP/IP Ethernet Communications

Station Manager User Manual, GFK-2225J or later for supported commands.

1.3.4 Ethernet interface Ports

The PACSystems Ethernet interface use auto-sensing 10Base-T/100Base-TX/1000Base-T

RJ45 shielded twisted pair Ethernet ports for connection to either a 10BaseT, 100BaseTX

or 1000Base-T IEEE 802.3 network.

The RX3i CPE330, CPE400 and CPL410 embedded Ethernet interface additionally

supports 1000Base-T IEEE 802.3 connections.

The RX3i Controllers with embedded Ethernet provide one such port; dedicated Ethernet

interface Modules provide two.

The port automatically senses the speed (10 Mbps, 100 Mbps or 1000Mbps), duplex

mode (half-duplex or full-duplex) and cable configuration (straight-through or crossover)

attached to it with no intervention required.

Page 24

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 11

1.3.4.1 Ethernet Media

The Ethernet interface can operate directly on 10Base-T/100Base-TX/1000Base-T media

via its network ports.

10Base-T: 10Base-T uses a twisted pair cable of up to 100 meters in length between each

node and a switch, hub, or repeater. Typical switches, hubs, or repeaters support

connections in a start topology.

100Base-TX: 100Base-TX uses a cable of up to 100 meters in length between each node

and a switch, hub, or repeater. The cable should be data grade Category 5 unshielded

twisted pair (UTP) or shielded twisted pair (STP) cable. Two pairs of wire are used, one for

transmission, and the other for collision detection and receive. Typical switches, hubs, or

repeaters support 6 to 12 nodes connected in a star wiring topology.

1000Base-T: 1000Base-T uses a cable of up to 100 meters in length between each node

and a switch, hub, or repeater. The cable should be data grade Category 6 unshielded

twisted pair (UTP) or shielded twisted pair (STP) cable or better. Four pairs of wire are

used which are designed to operate over 4-pair UTP cable and supports full-duplex data

transfer at 1000Mbps. Typical switches, hubs, or repeaters support 6 to 12 nodes

connected in a star wiring topology.

1.3.5 Station Manager

The built-in Station Manager function of the Ethernet interface provides on-line

supervisory access to the Ethernet interface, through the Station Manager port or over

the Ethernet cable. Station Manager services include:

▪ An interactive set of commands for interrogating and controlling the station.

▪ Unrestricted access to observe internal statistics, an exception log, and

configuration parameters.

▪ Password security for commands that change station parameters or operation.

For remote Station Manager operation over the Ethernet network, the Ethernet interface

uses IP addressing. A PACSystems Ethernet interface cannot send or receive remote

Station Manager messages sent to a MAC address.

Refer to the PACSystems TCP/IP Ethernet Communications Station Manager User Manual,

GFK-2225 for complete information on the Station Manager.

Page 25

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 12

1.3.6 Firmware Upgrades

PACSystems Ethernet interfaces receive their firmware upgrades indirectly from the RX3i

CPU using the WinLoader software utility. WinLoader is supplied with any updates to the

Ethernet interface software. The user connects WinLoader to the PLC CPU serial port and

specifies the target module by its Rack/Slot location.

For the CPU module, the embedded Ethernet interface firmware is upgraded along with

the rest of the CPU firmware. WinLoader seamlessly upgrades first the CPU firmware and

then the embedded Ethernet firmware without user intervention. Each Ethernet interface

module’s firmware must be explicitly upgraded by specifying the rack and slot location of

the module to the WinLoader utility.

Firmware upgrades for the CPE330, CPE400, CPL410 and CPE100/CPE115 are performed

over Ethernet using a web browser. This method provides enhanced security features.

Instructions for the procedure are included in the corresponding upgrade kit

documentation. The WinLoader utility will not work with the CPE330, CPE400, CPL410 or

CPE100/CPE115 CPUs.

1.3.7 SRTP Client (Channels)

SRTP Client allows the PACSystems PLC to initiate data transfer with other SRTP-capable

devices on the network. SRTP channels can be set up in the PLC application program.

SRTP supports COMMREQ-driven channel commands to establish new channels, abort

existing channels, transfer data on an existing channel, and retrieve the status of an

existing channel.

Any given channel can be assigned to only one protocol at a time. For the number and

combinations of channels supported, refer to Section 1.3.3 Ethernet Interfaces for

PACSystems Controllers.

1.3.8 Modbus TCP Client (Channels)

Modbus TCP Client allows the PACSystems PLC to initiate data transfer with other Modbus

TCP server devices on the network. Modbus TCP channels can be set up in the application

program. The Modbus TCP Client supports COMMREQ-driven channel commands to open

new channels, close existing channels, and transfer data on an existing channel.

Any given channel can be assigned to only one protocol at a time. For the number and

combinations of channels supported, refer to Section 1.3 Ethernet Interfaces for

PACSystems Controllers.

Page 26

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 13

1.3.9 Ethernet Global Data (EGD)

▪ EGD Classes:

• EGD Class 1 is configured exchanges with no logic control of EGD operation.

o Supported in

CPE302/CPE305/CPE310/CPE330/CPE400/CPL410/CPE100/CPE115

• EGD Class 2 is EGD Commands which are logic-driven EGD exchanges using

COMMREQs.

o Supported on IC695ETM001

o Not supported on embedded Ethernet ports of

CPE302/CPE305/CPE310/CPE330/CPE400/CPL410/CPE100/CPE115 at

time of publication

Each PACSystems RX3i CPU supports up to 255 Class 1 simultaneous EGD exchanges and

RSTi-EP CPU CPE100/CPE115 supports up to eight Class 1 simultaneous EGD exchanges.

EGD exchanges are configured using the programmer and stored into the PLC. Both

Produced and Consumed exchanges can be configured. PACSystems Ethernet interfaces

support both selective consumption of EGD exchanges and EGD exchange production

and consumption to the broadcast IP address of the local subnet.

Note: For Broadcast addressing a Subnet value of 0.0.0.0 is NOT supported.

1.3.9.1 Synchronizing EGD Timestamps with SNTP

Both the ETM001-Jx and -Kxxx Ethernet interfaces can be configured to use Simple

Network Time Protocol (SNTP) to synchronize the timestamps of produced EGD

exchanges.

With an appropriate PME Hardware Configuration, the embedded Ethernet interface on

the CPE302, CPE305, CPE310, CPE330, CPE400 and CPL410 will also support SNTP. For

more information on PME Hardware Configuration, please refer to Section 4.1.3,

Configuring the Ethernet Interface Parameters.

Note: The RSTi-EP CPE100/CPE115 does not support SNTP.

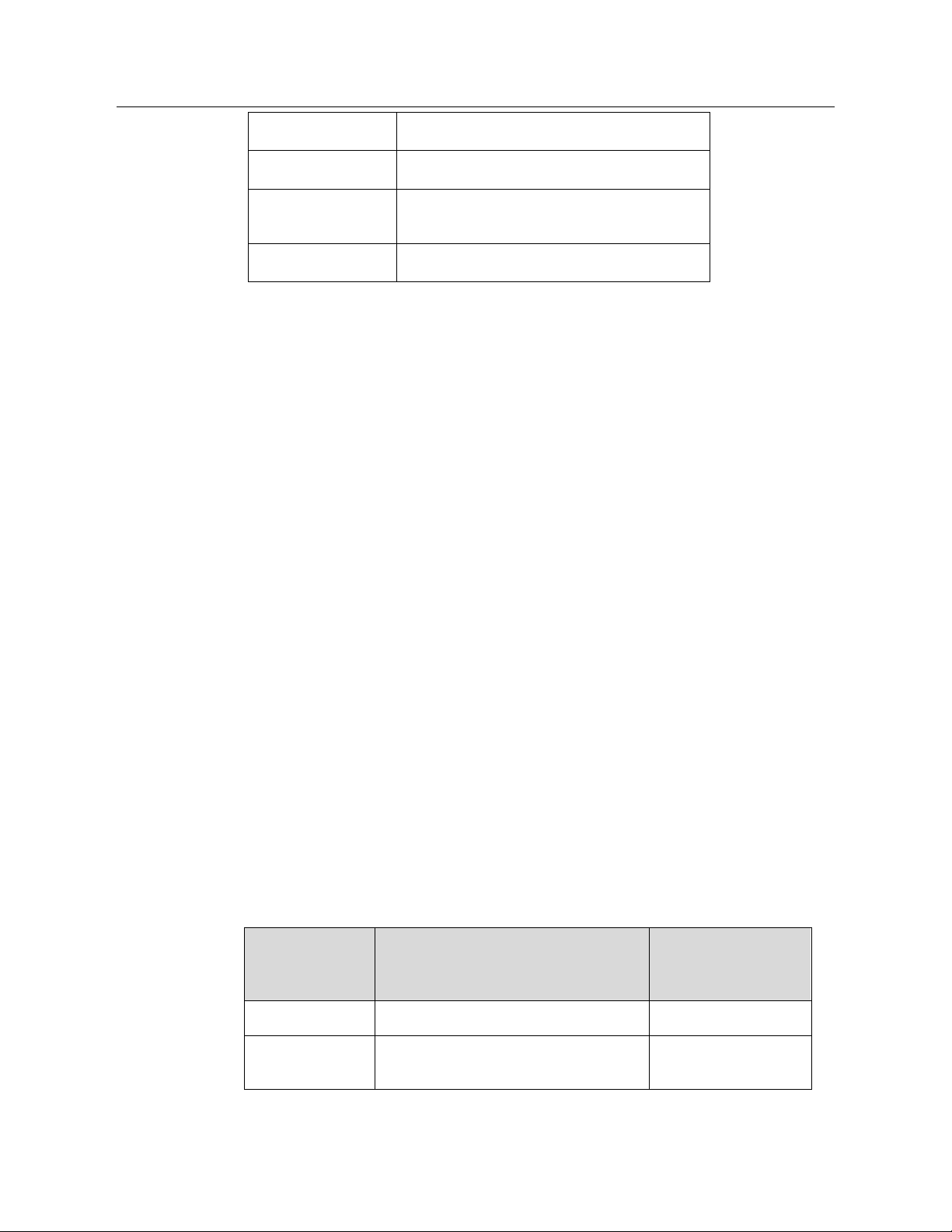

Ethernet interface

module

SNTP Support

ETM001-Jx

Yes, with PME Hardware Configuration

(default configuration without using AUP file)

ETM001-Kxxx

Yes, with PME Hardware Configuration

CPU

SNTP Support

CPL410

Yes, with PME Hardware Configuration

Page 27

PACSystems™ RX3i and RSTi-EP TCP/IP Ethernet Communications User Manual Section 1

GFK-2224Y August 2019

Introduction 14

CPE400

Yes, with PME Hardware Configuration

CPE330

Yes, with PME Hardware Configuration

CPE302/CPE305/

CPE310

Yes, with PME Hardware Configuration

CPE100/CPE115

Not supported

1.3.10 SRTP Inactivity Timeout

Starting with Release 6.00, the PACSystems Ethernet interface supports inactivity

timeout checking on Secure Real-Time Transport Protocol (SRTP) server connections with

any PAC Machine Edition (PME) PLC programmer. Until the server connection is removed,

other programmers cannot switch from Monitor to Programmer mode. With inactivity

timeout checking, the Ethernet interface removes an abandoned SRTP server connection

and all its resources when there is no activity on the connection for the specified timeout

interval. Without the SRTP inactivity timeout, an abandoned SRTP server connection

persists until the underlying TCP connection times out (typically 7 minutes). All network

PME programmer connections initially use an SRTP inactivity timeout value of 30 seconds

(as set by the "vconn_tout" AUP parameter).

PME programmers can override the initial timeout value on a specified server connection.

Typically, the PME programmer sets the SRTP inactivity timeout to 20 seconds. An

inactivity timeout value of zero disables SRTP inactivity timeout checking.

The SRTP server uses an internal inactivity timeout resolution of 5 seconds. This has two

effects. First, any non-zero inactivity timeout value (either set by AUP parameter or

overridden on the programmer connection) is rounded up to the next multiple of 5

seconds. Additionally, the actual SRTP inactivity timeout detection for any individual

connection may vary up to an additional 5 seconds. The actual inactivity detection time

will never be less than the specified value.

Note: The SRTP inactivity timeout applies only to programmer connections over SRTP. It

does not affect HMI or SRTP channels.

1.4 Ethernet Redundancy Operation

The Redundant IP feature allows a single IP address to be assigned to two Ethernet

modules, where the two modules are in two different PLCs configured as a redundant

system. This functionality has been integrated into the product line, as follows:

CPU

Embedded Ethernet Redundancy

Support

Support via Ethernet

Module (ETM001-Jx

or ETM001-Kxxx)

CPL410

All firmware versions

Not supported

CPE400

Embedded Ethernet requires CPU

Firmware Version 9.30

Not supported

Page 28